Method of producing photopolymerizable lithographic plate

A lithographic printing plate, photopolymerizable technology, applied in lithographic printing equipment, printing, printing process, etc., can solve the problem of high equipment cost, shortened time for adjusting the moisture content of protective coating, and narrow allowable range of temperature and humidity in the humidity control area, etc. problem, to achieve the effect of stabilizing the sensitivity and controlling the moisture content.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

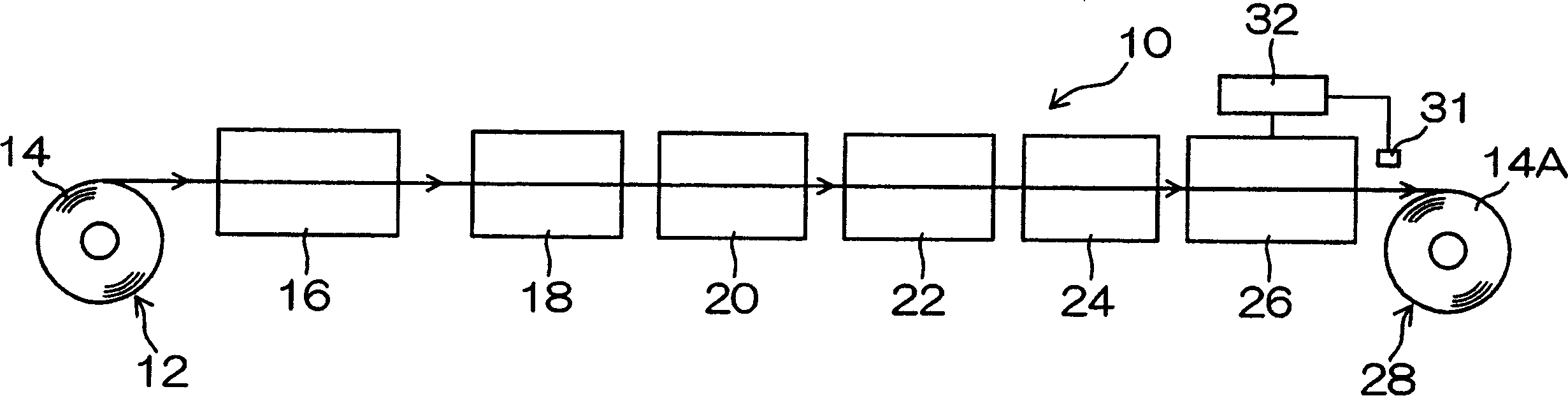

[0187] [Production of photopolymerizable lithographic printing plates]

[0188] A 0.30 mm-thick material 1S mesh-shaped aluminum plate 14 (support) was fixed to a feeder 12 in a coiled (coiled) aluminum coil. In the surface treatment part 16, the aluminum plate 14 continuously sent out from the feeder 12 was immersed in 10% sodium hydroxide at 70° C. for 60 seconds, etched, washed with running water, and rinsed with 20% HNO. 3 Perform neutralization washing and water washing. Under the condition of VA=12.7V, use the alternating waveform current of sine wave, in 1% nitric acid aqueous solution at 300 coulomb / dm 2 The electrolytic surface roughening treatment is carried out on the electric current of the anode. The surface roughness thereof was measured and found to be 0.45 µm (indicated by Ra). followed by immersion in 30% H 2 SO 4 In aqueous solution, after decontamination at 55°C for 2 minutes, at 33°C in 20% H 2 SO 4 In the aqueous solution, the cathode is arranged on t...

Embodiment 2

[0246] In Example 1, a photopolymerizable lithographic printing plate was produced in the same manner as in Example 1, except that the drying air temperature of the overcoat was increased to 200° C. in order to increase the crystallinity of the overcoat to 0.5.

Embodiment 3

[0248] In Example 1, a photopolymerizable lithographic printing plate was produced in the same manner as in Example 1, except that the temperature of the drying air for the overcoat was lowered to 100° C. in order to make the crystallinity of the overcoat 0.2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com