Injection molding method and device

An injection molding device and injection molding technology, applied in the field of injection molding devices, can solve the problems of long molding time, non-uniform coverage of the terminal part of the mold cavity, curing, etc., shorten the molding time, improve transferability, and eliminate deformation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

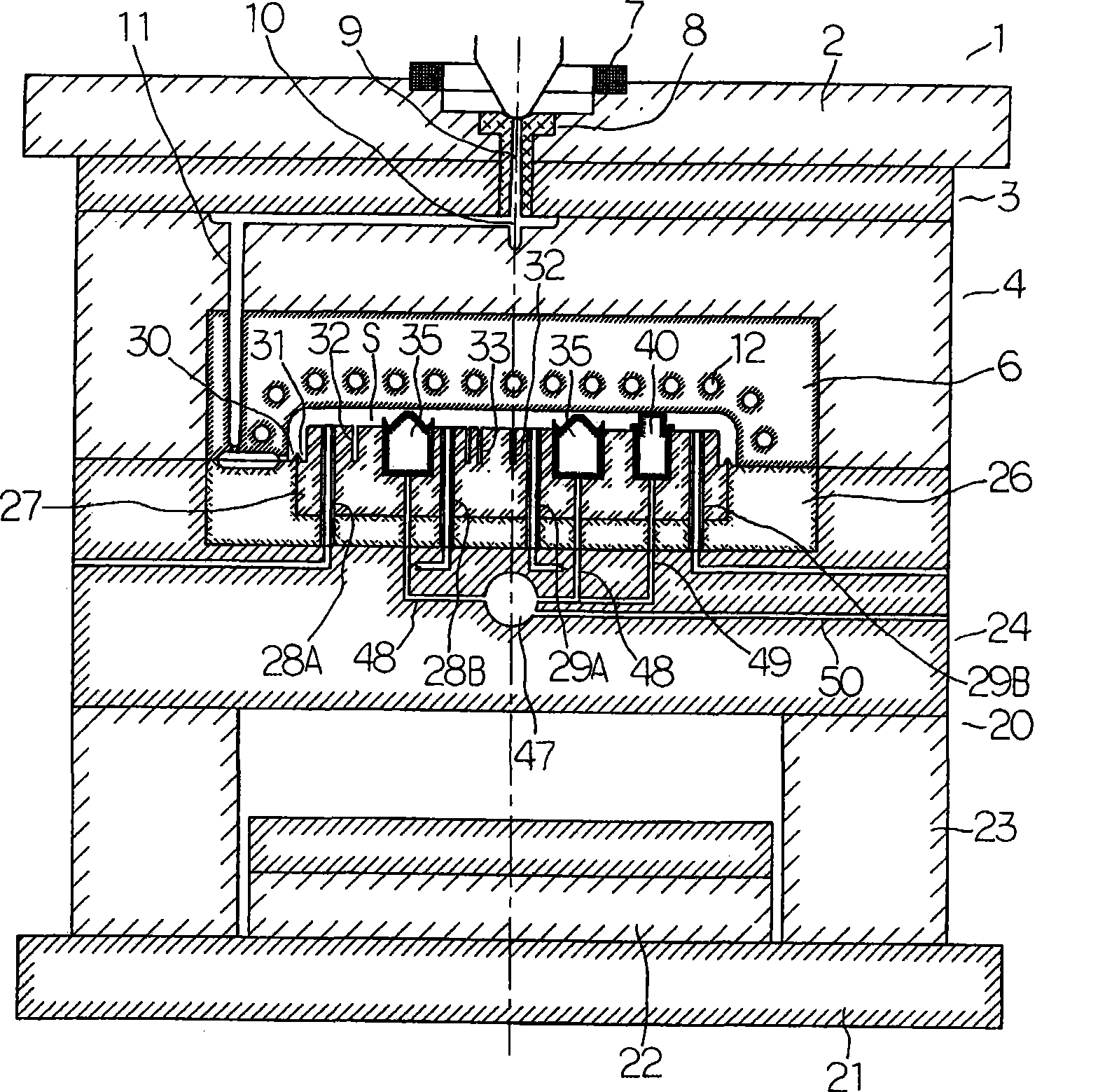

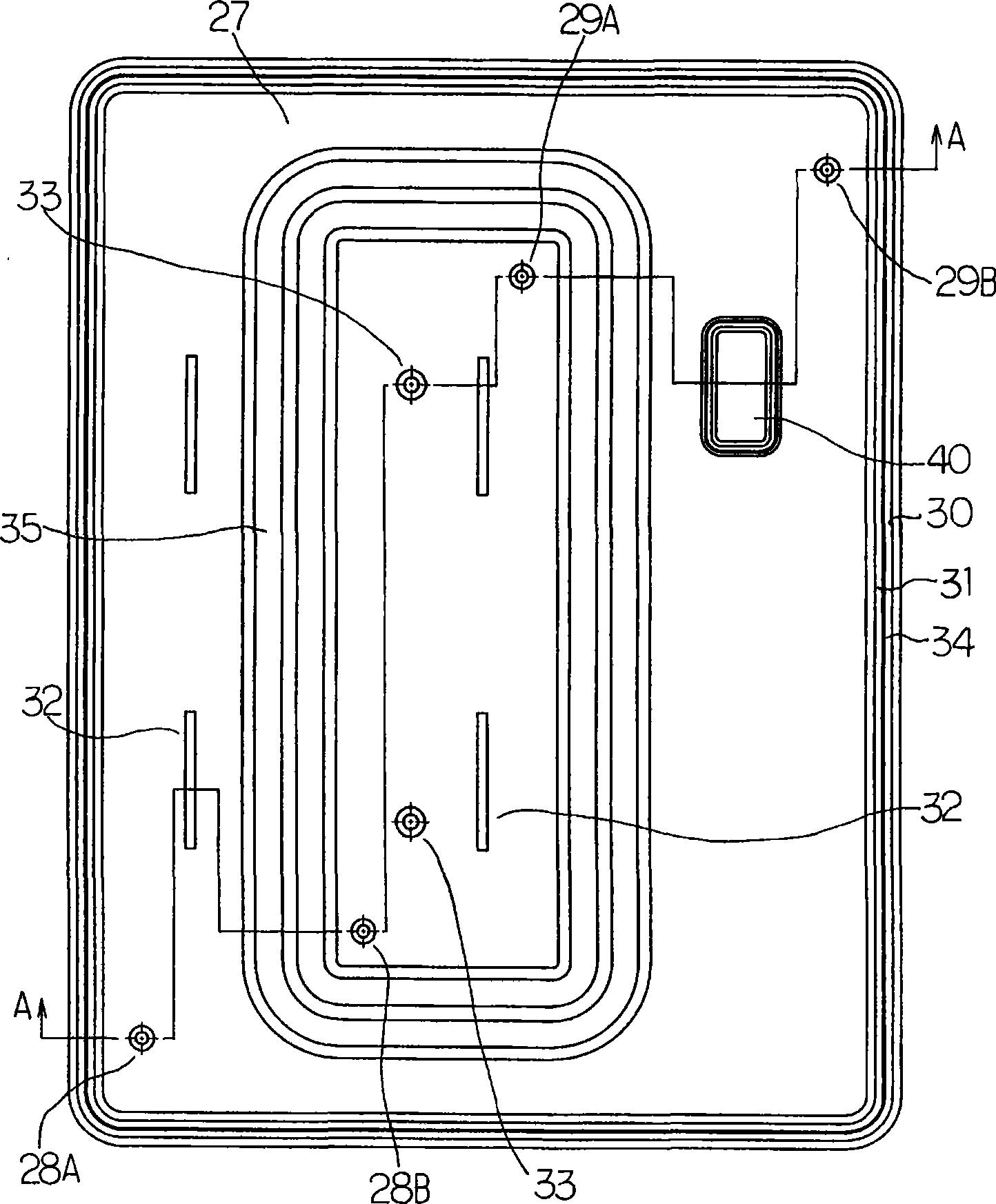

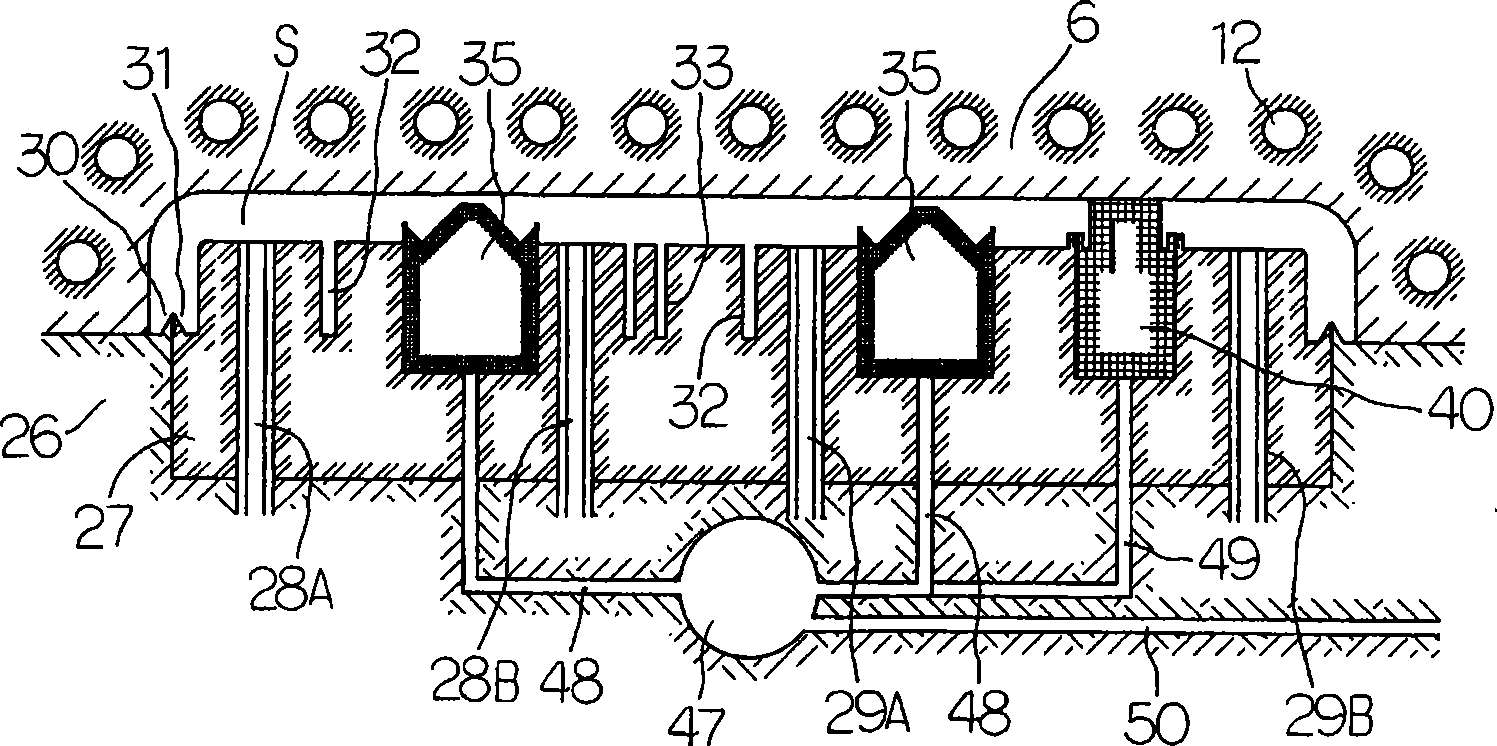

[0138] Embodiments of the present invention will be described below with reference to the drawings. First, according to figure 1 Next, the overall configuration of the injection molding apparatus will be described. 1 is a fixed-side assembly mounted on a fixed platen (not shown) by screws. The fixed-side assembly 1 includes: a first bottom plate 2 on a fixed side; a second bottom plate 3 on a fixed side. fixed on the first bottom plate 2 on the fixed side; the third bottom plate on the fixed side is fixed on the second bottom plate 3 on the fixed side by screws; the female mold part (fixed mold part) 6 is arranged on the fixed side In the recess of the third bottom plate 4 and fixed on the third bottom plate 4 of the fixed side by screws; the positioning ring (locate ring) 7 is arranged on the first bottom plate 2 of the fixed side and leans against the fixed platen. The position is to position the first bottom plate 2 on the fixed side relative to the fixed platen; and a sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com