Device and method for introducing liquids into meat

A liquid injection and injection device technology, applied in the direction of preserving meat/fish with liquid, processing meat through injection, softening meat through injection, etc. It can solve the problems of meat surface damage, salt water accumulation, and the impossibility of uniform distribution of injection liquid, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

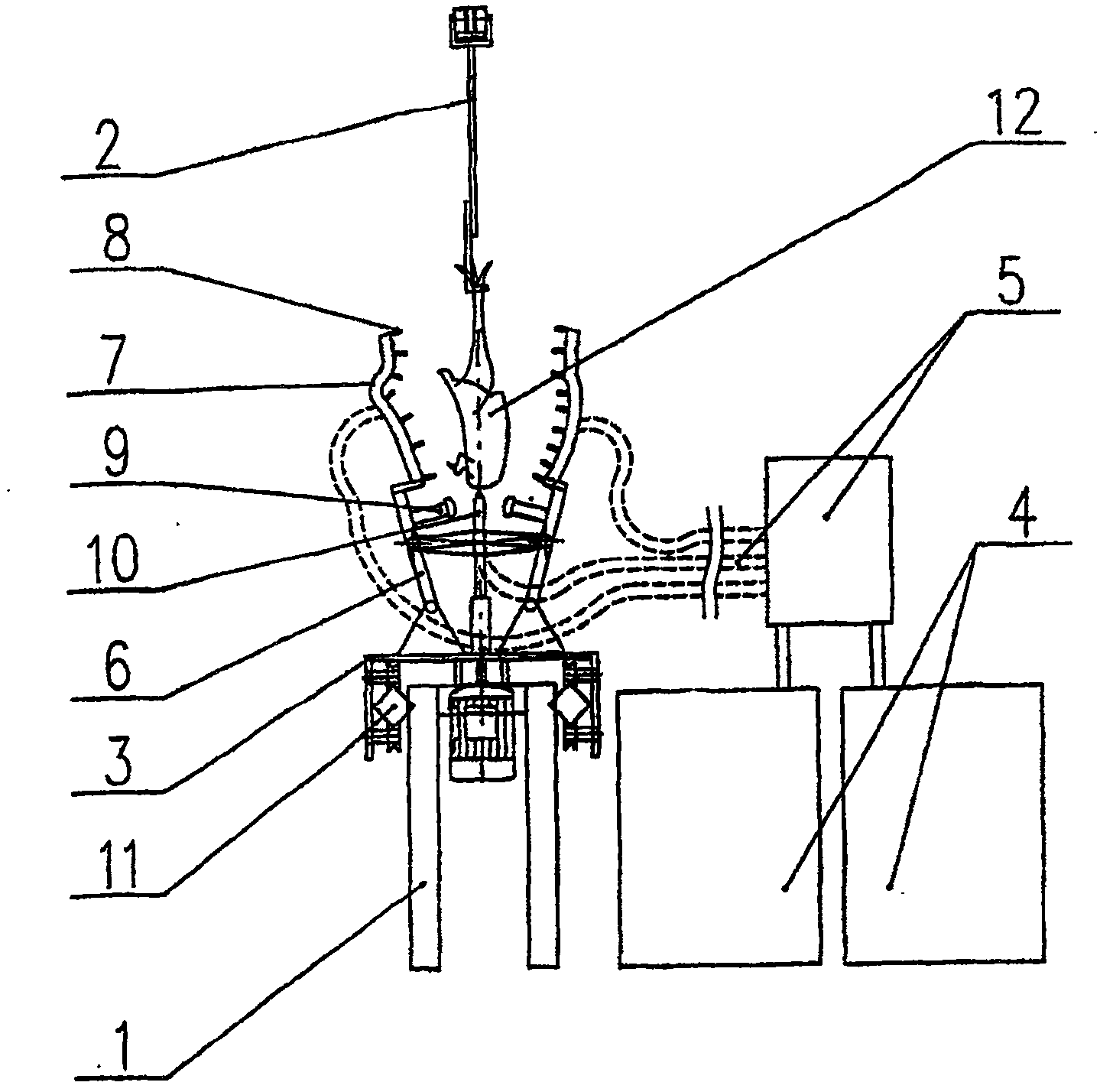

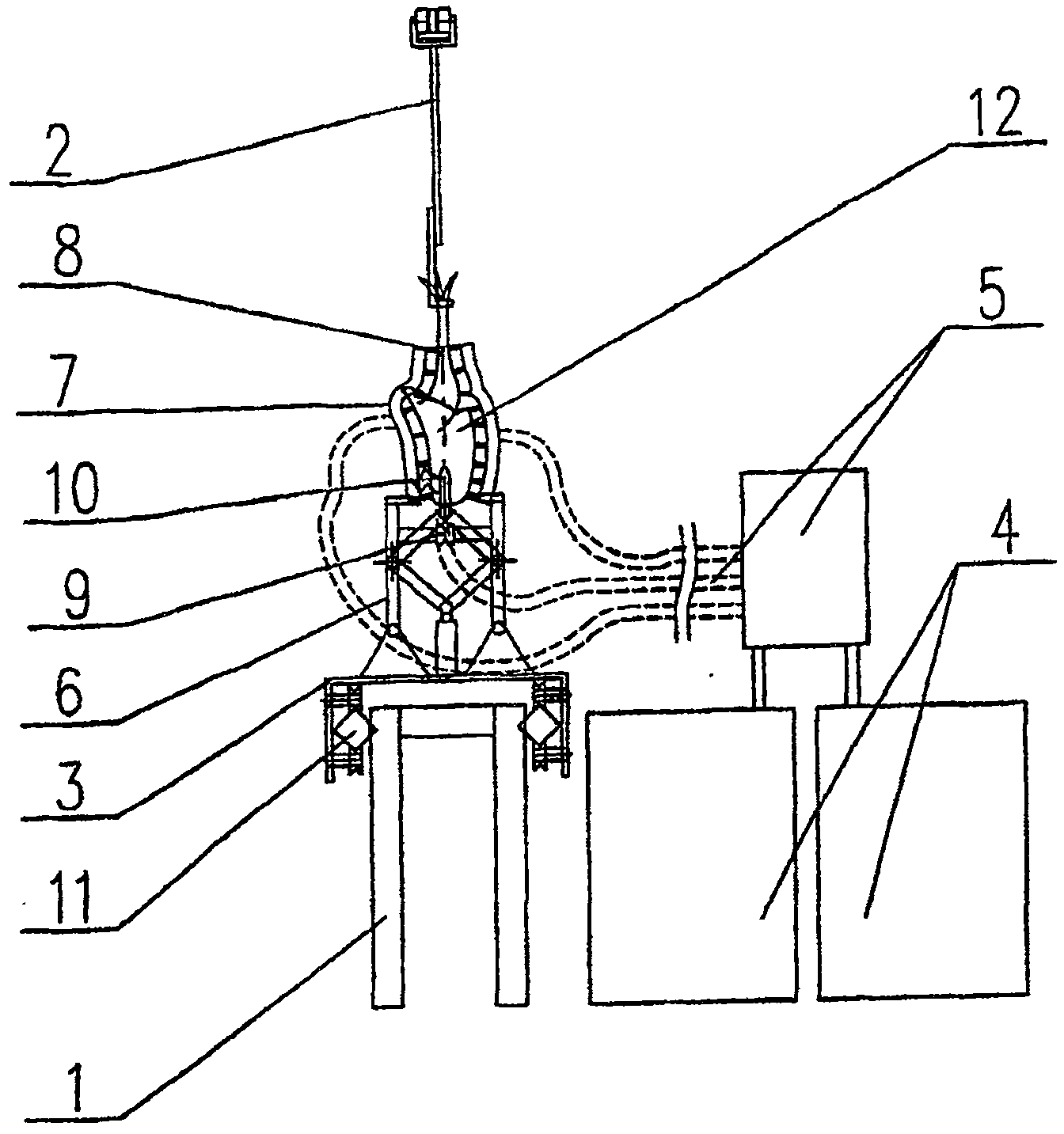

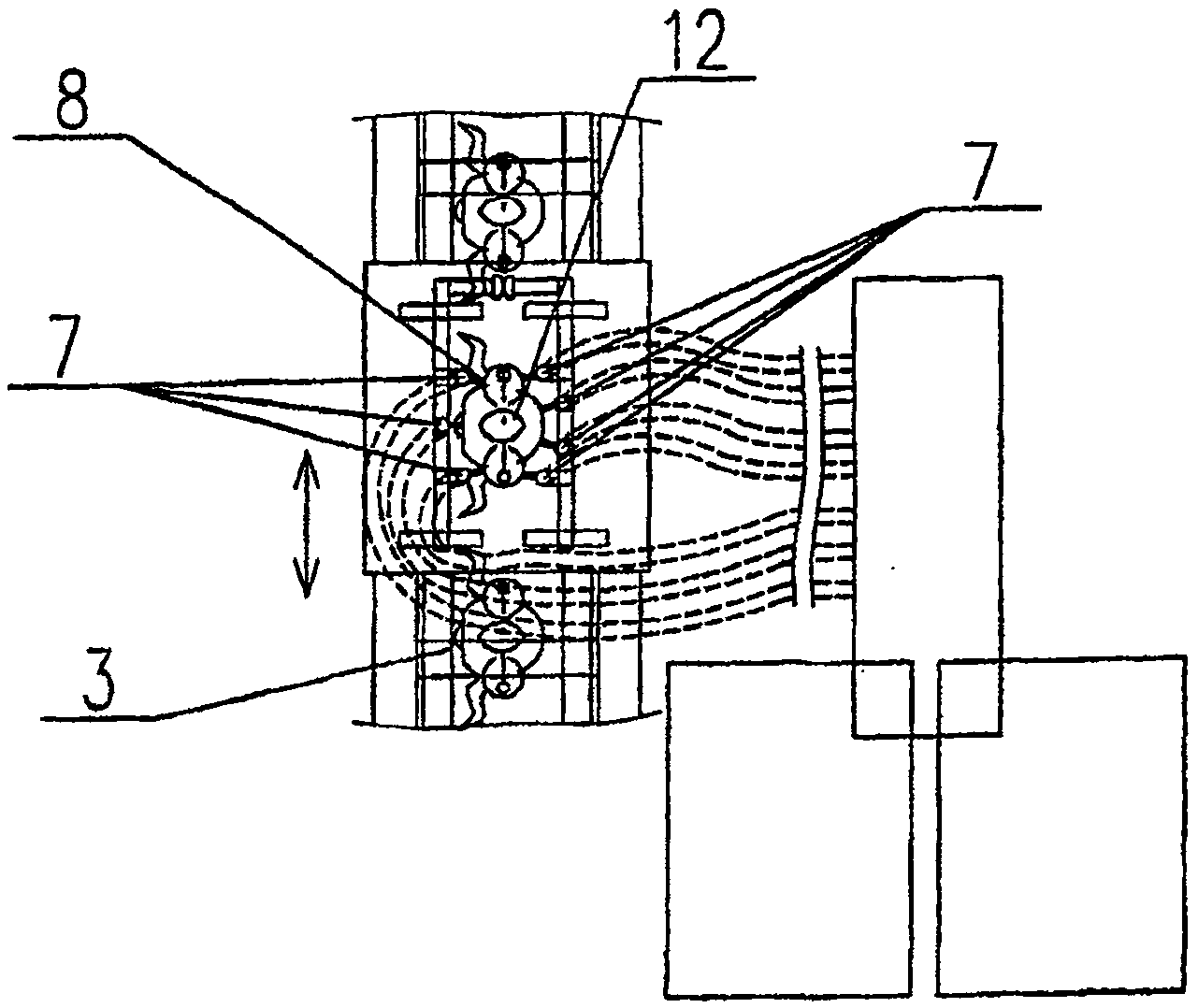

[0070] figure 1 A front view of a possible configuration of the device according to the invention on a slaughter belt with the injection device 6 open is shown. On a conveyor device 2 , in this example a slaughter belt, slaughtered animal bodies 12 , such as bone-in meat of poultry, are arranged. The base of the device according to the invention is located below the slaughter belt. On this base, be provided with two frames 3 that can move on the linear guide 11, as " slide plate ". Two injection devices 6 connected to a plurality of high-pressure devices 4 through a plurality of liquid distribution systems 5 are respectively fixed on each movable frame 3 for needle-free injection.

[0071] Each injection device 6 consists of seven nozzle holders 7 arranged pivotably on the frame 3 , on which nozzle holders a plurality of nozzles 8 are each arranged. The nozzle holder 7 has arranged thereon specifically directed nozzles 8 which are precisely adapted to the anatomy of the pou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com