Patents

Literature

309results about "Meat/fish preservation using liquids" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method and composition for washing poultry during processing

InactiveUS6514556B2Reduce Microbial ContaminationHigh degreeBiocideDough treatmentBiologyMicrobial contamination

The present invention relates to compositions including peroxyacetic acid and peroxyoctanoic acid and methods for reducing microbial contamination on poultry. The methods include the step of applying a mixed peroxycarboxylic acid composition to poultry.

Owner:ECOLAB USA INC

Treatment of meat products

InactiveUS6113963AReduce microbial countPrevent browningBiocideDough treatmentCarboxylic acidNuclear chemistry

Described is a method of sanitizing meat product using aqueous streams having an antimicrobial composition added to the stream. Preferably, the antimicrobial composition includes a mixture of one or more carboxylic acids having up to 18 carbon atoms and one or more peroxycarboxylic acids having up to 12 carbon atoms, preferably a mixture of a C.sub.2-4 peroxycarboxylic acid and a C.sub.8-12 peroxycarboxylic acid.

Owner:ECOLAB USA INC

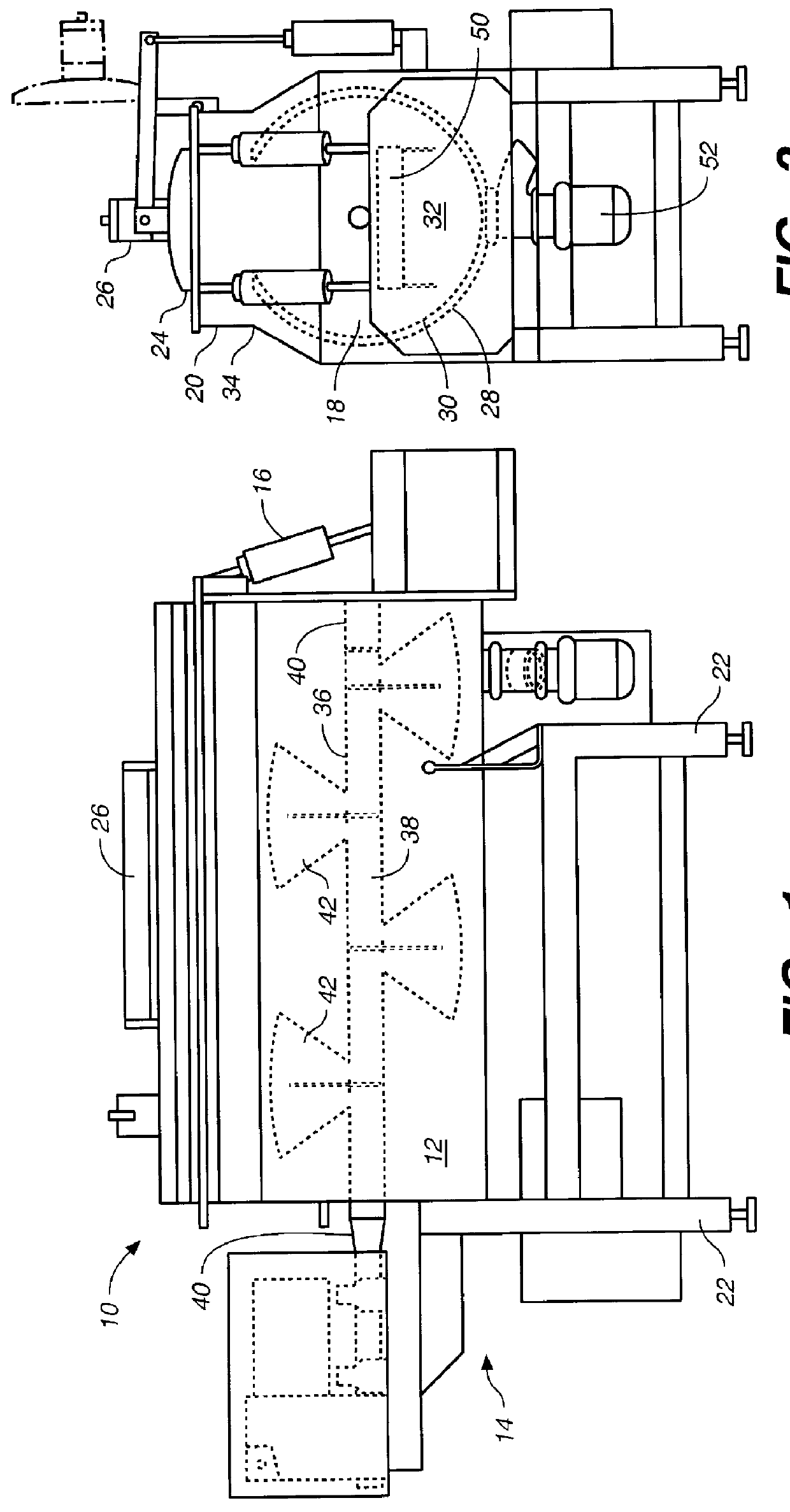

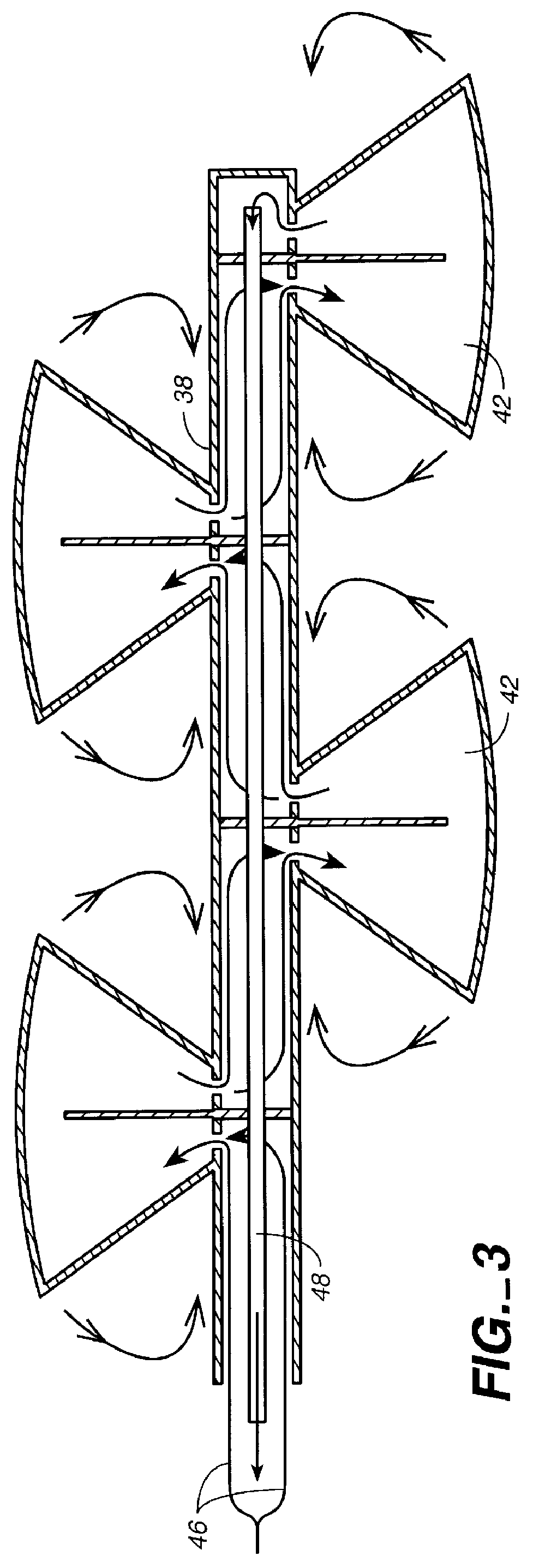

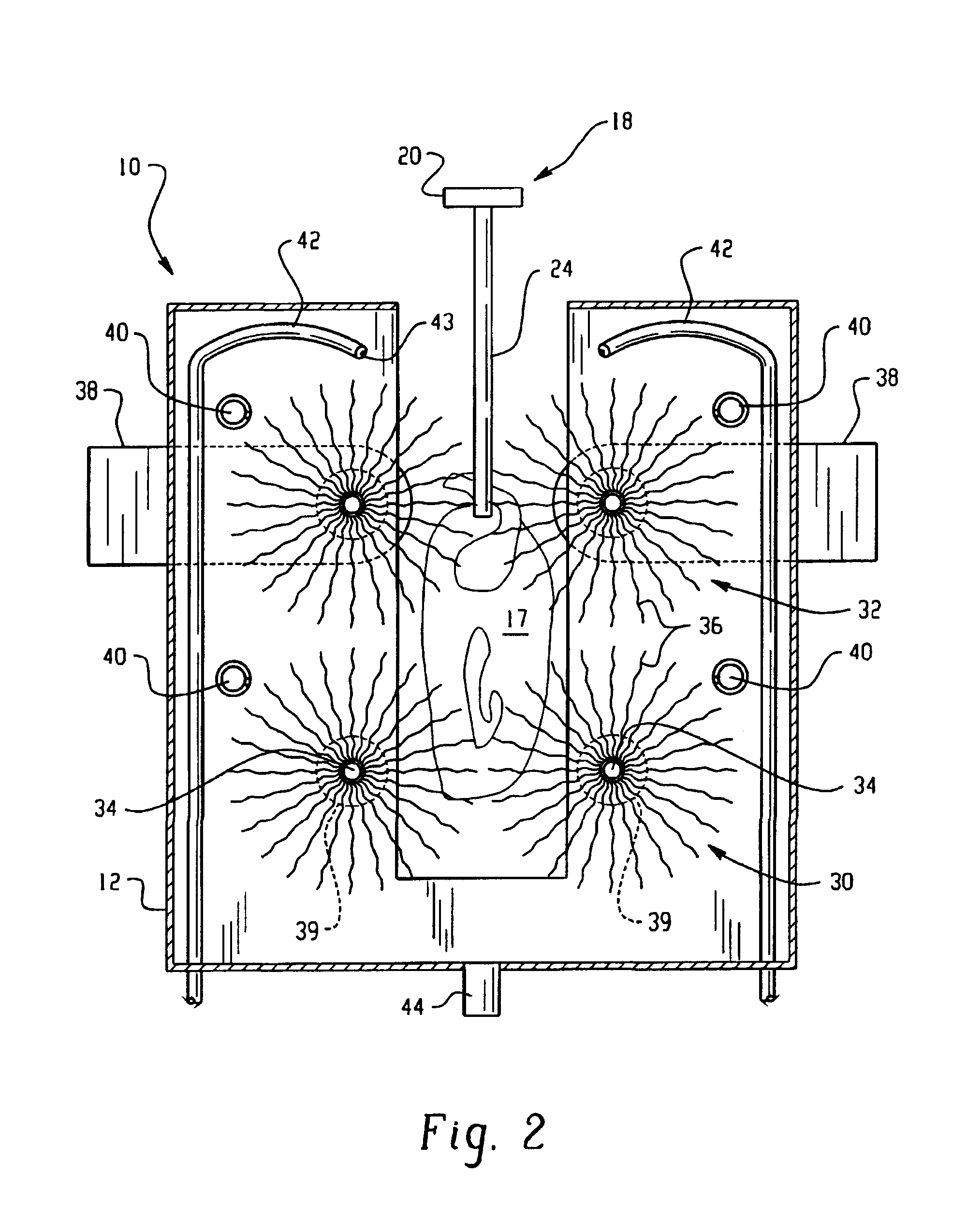

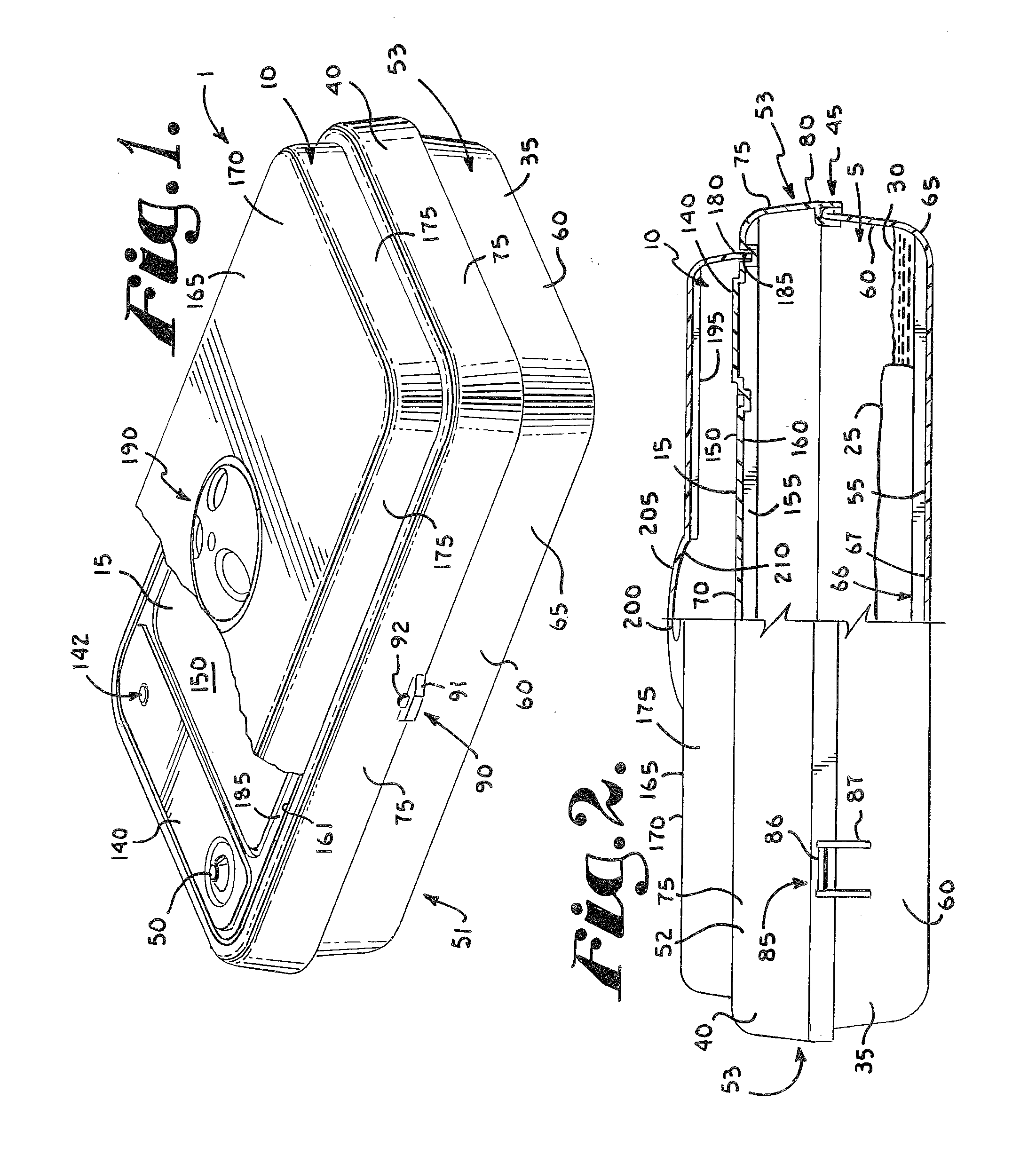

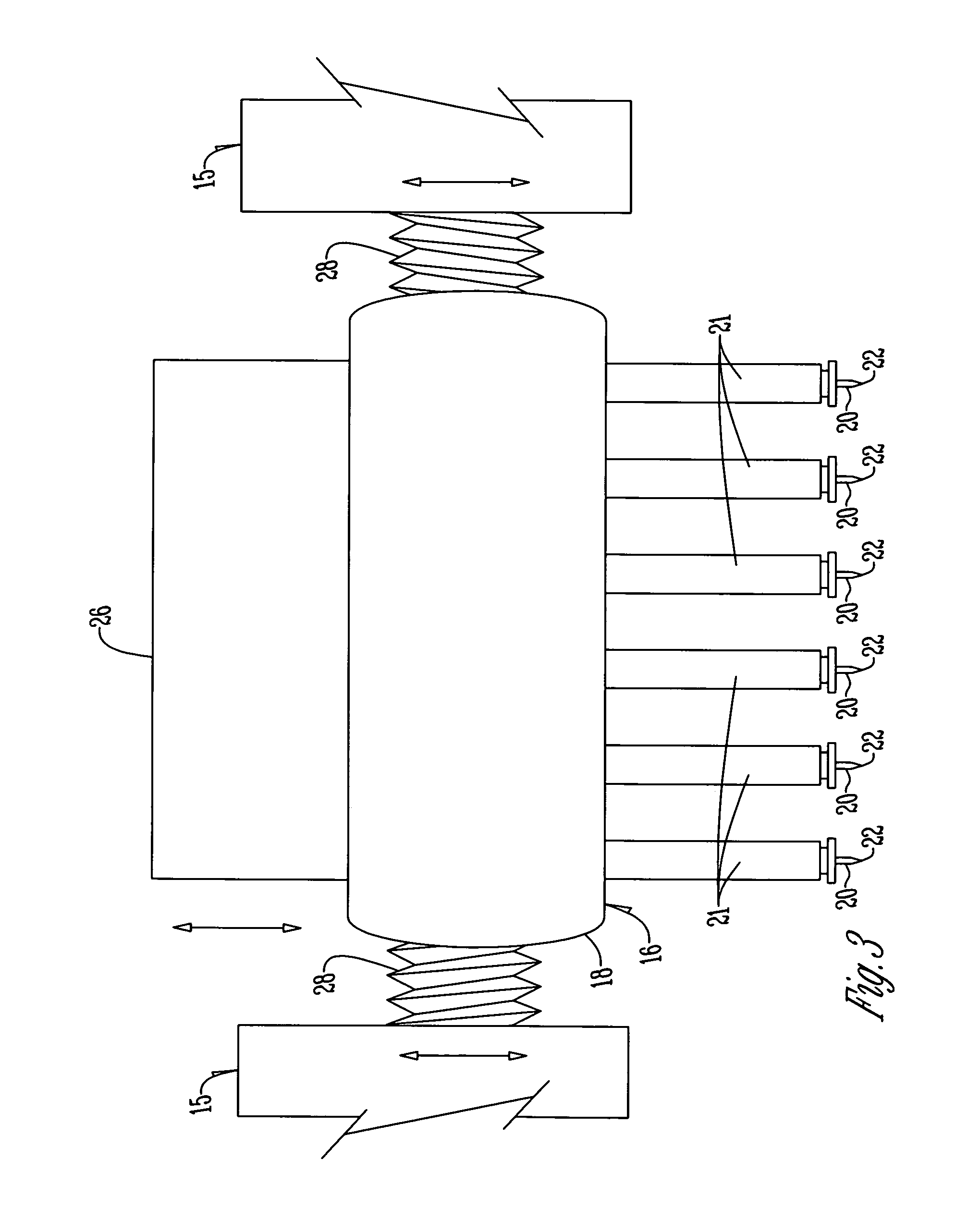

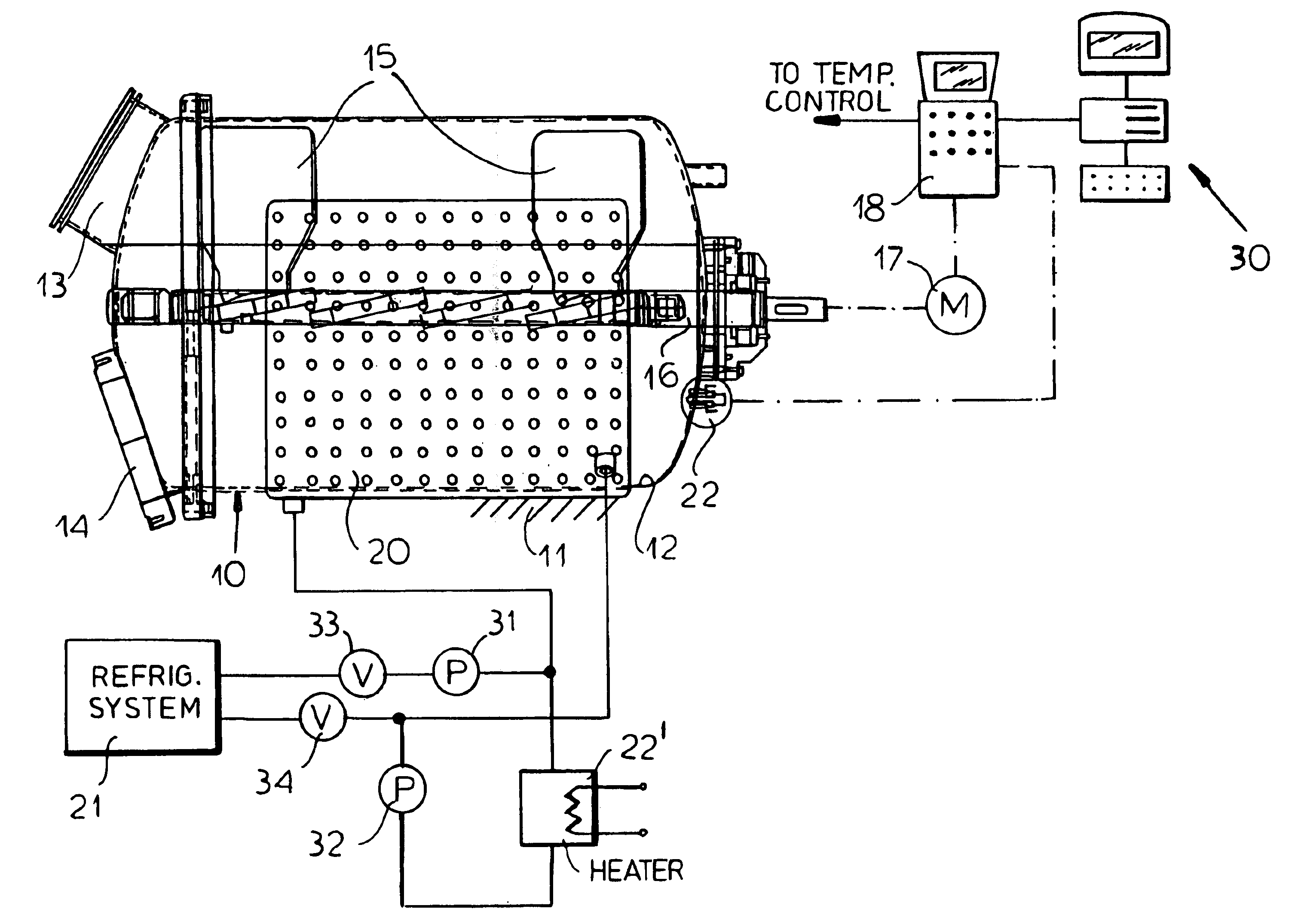

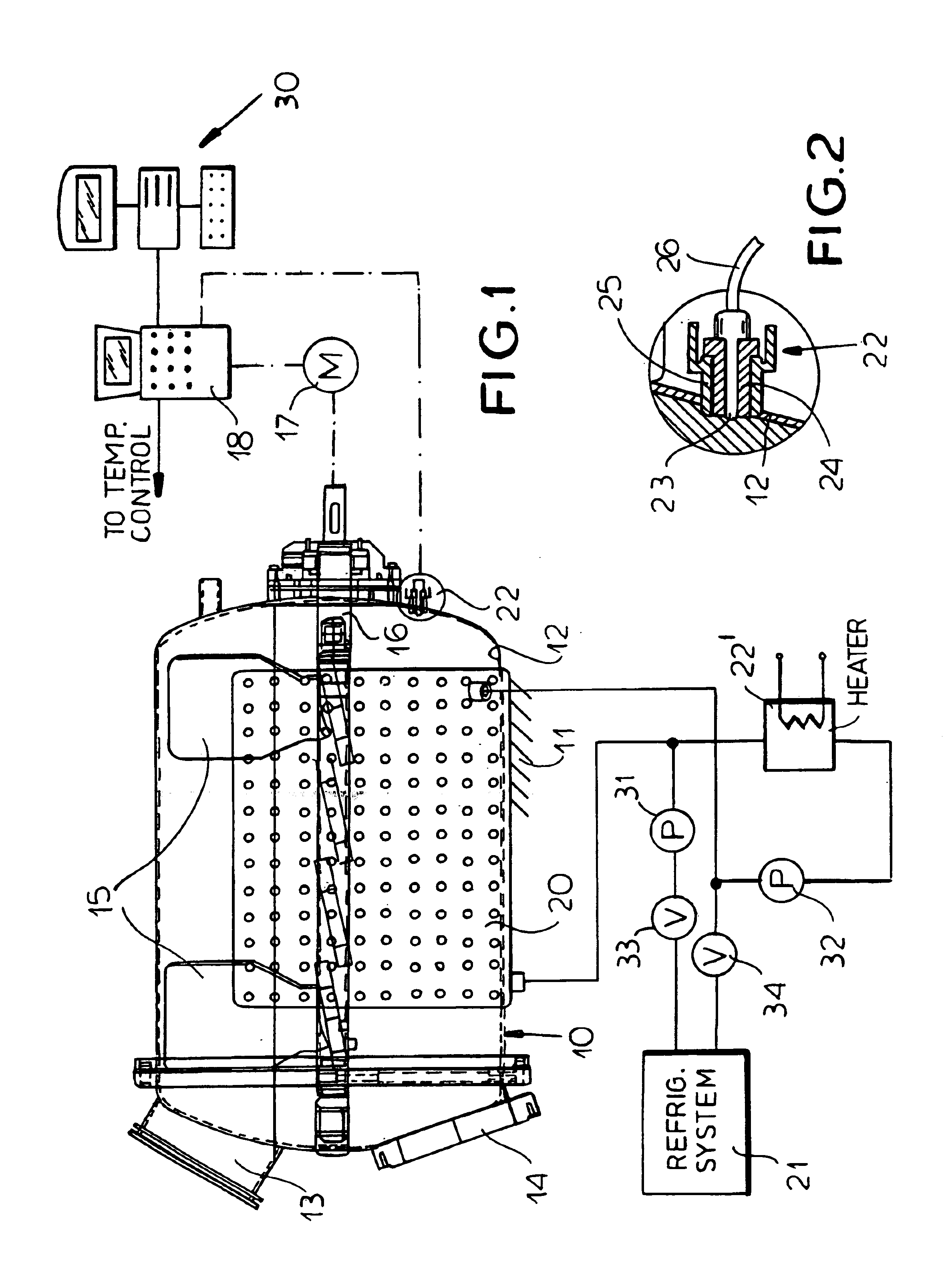

Apparatus for marinating meat products

A vacuum meat marinating machine for products requiring a short vacuum massage cycle, comprising a substantially horizontal cylindrical vessel having a large opening at the top for rapid loading of product, said opening covered by a sealed vacuum cover during operation, and further having a hollow outer wall comprising a jacket for the circulation of liquid refrigerant. A paddle agitator is located within the vessel, having a hollow shaft running longitudinally within the vessel. Affixed at an angle to the shaft are a plurality of hollow triangular-shaped paddles, which paddles push product horizontally during operation. Liquid refrigerant circulates through the hollow wall of the vessel, as well as the hollow agitator shaft and paddles. The agitator shaft is connected to a reversible motor that periodically reverses the direction of rotation, thereby maximizing heat exchange between product and liquid refrigerant.

Owner:HORN DARRELL +1

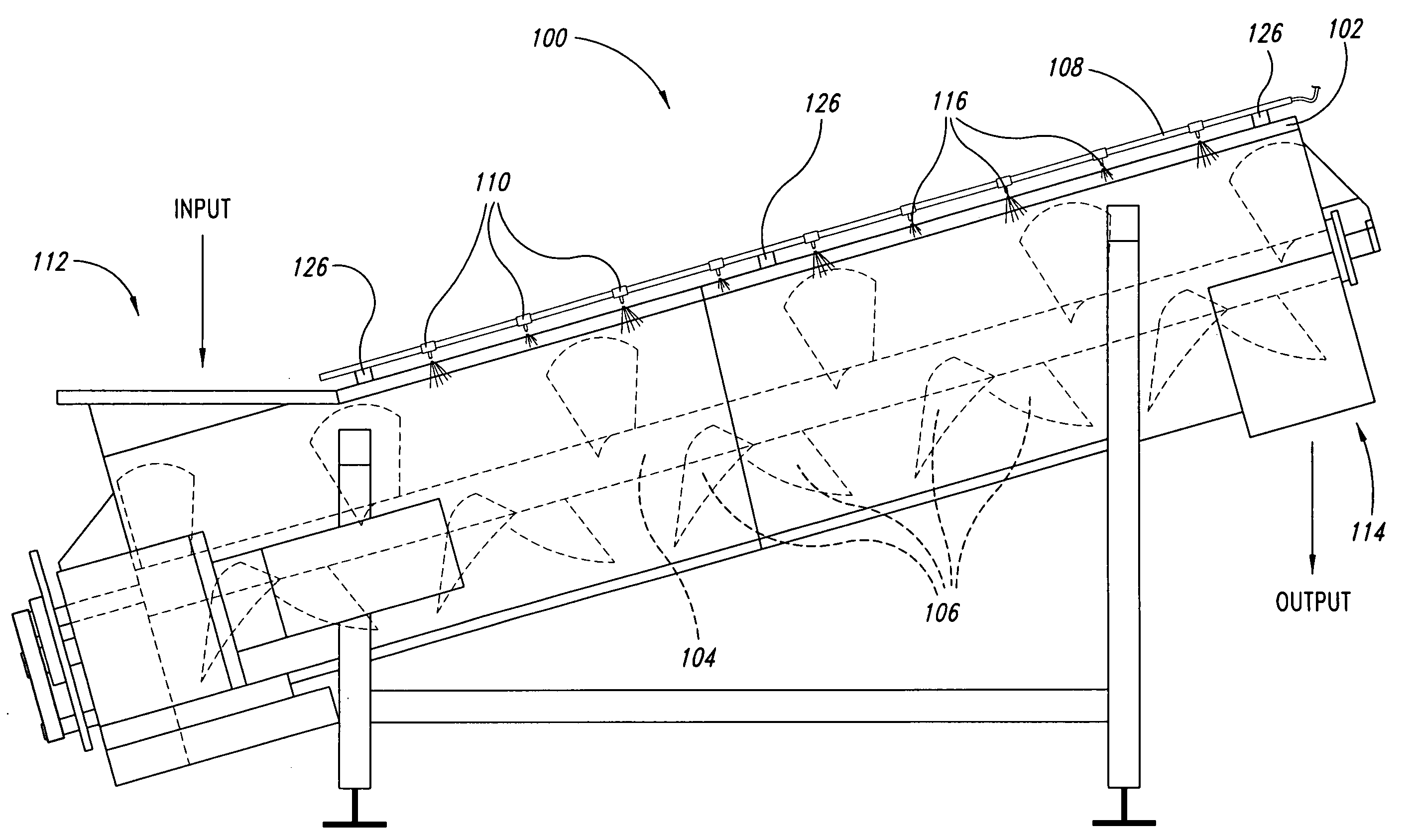

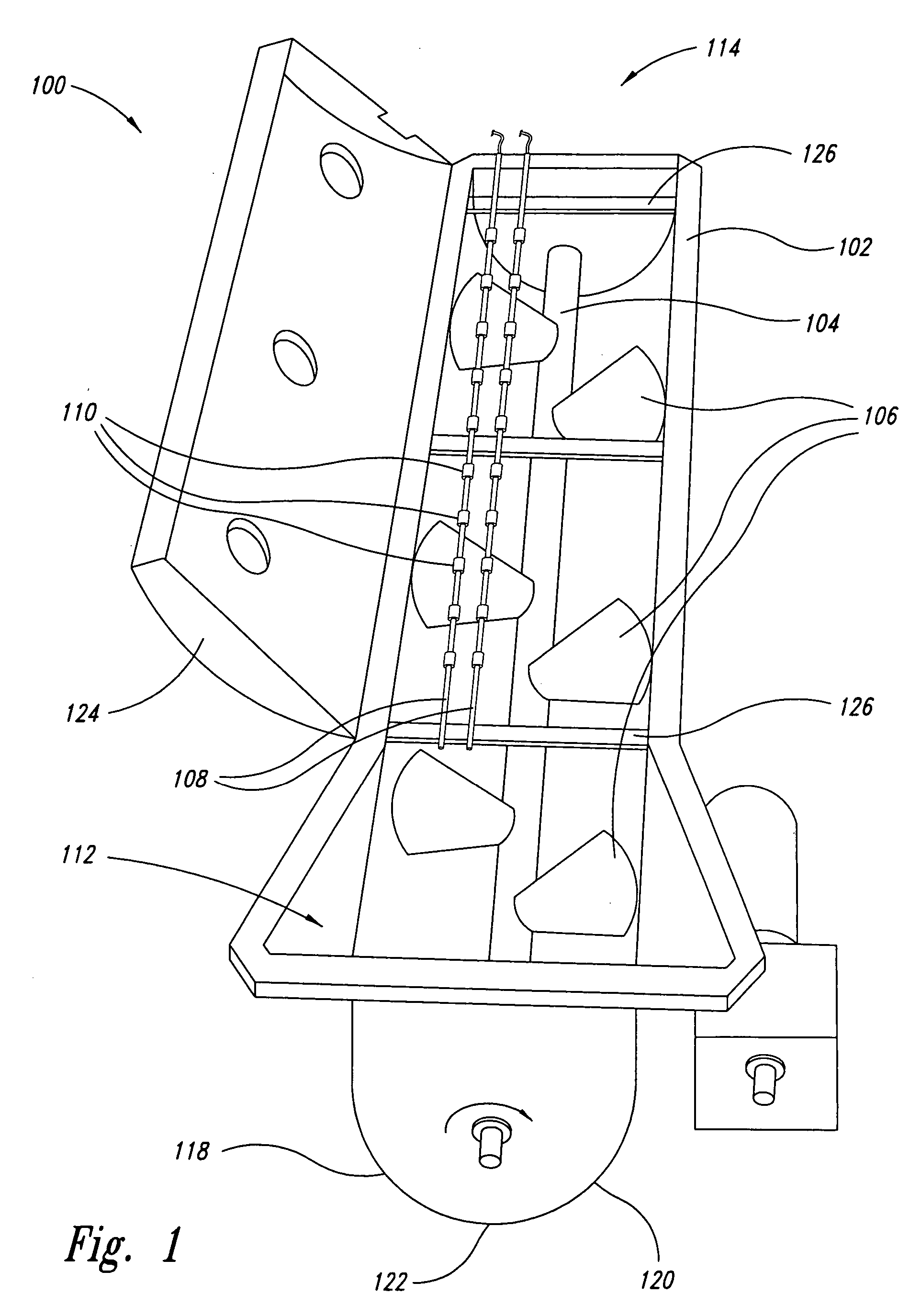

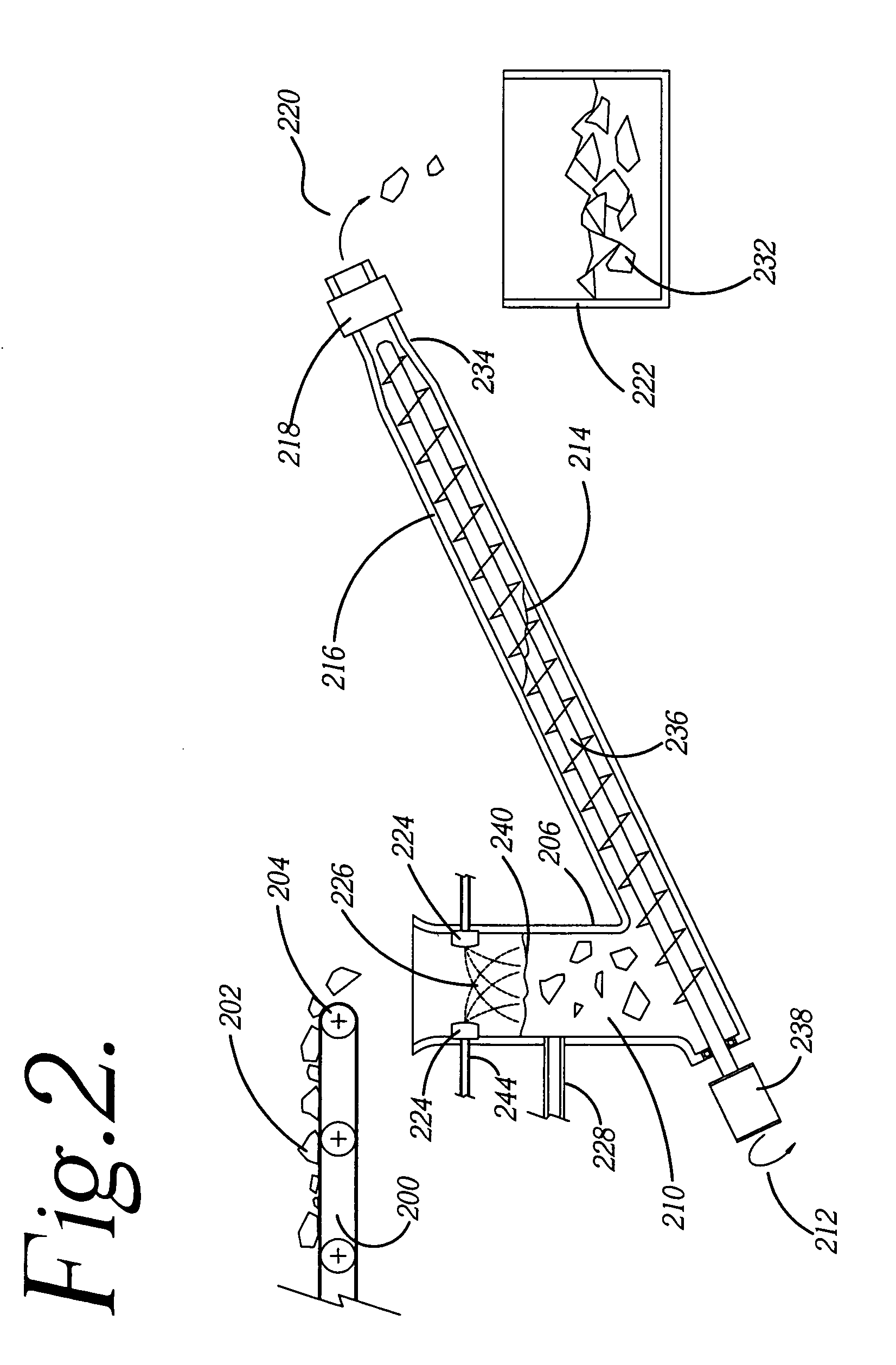

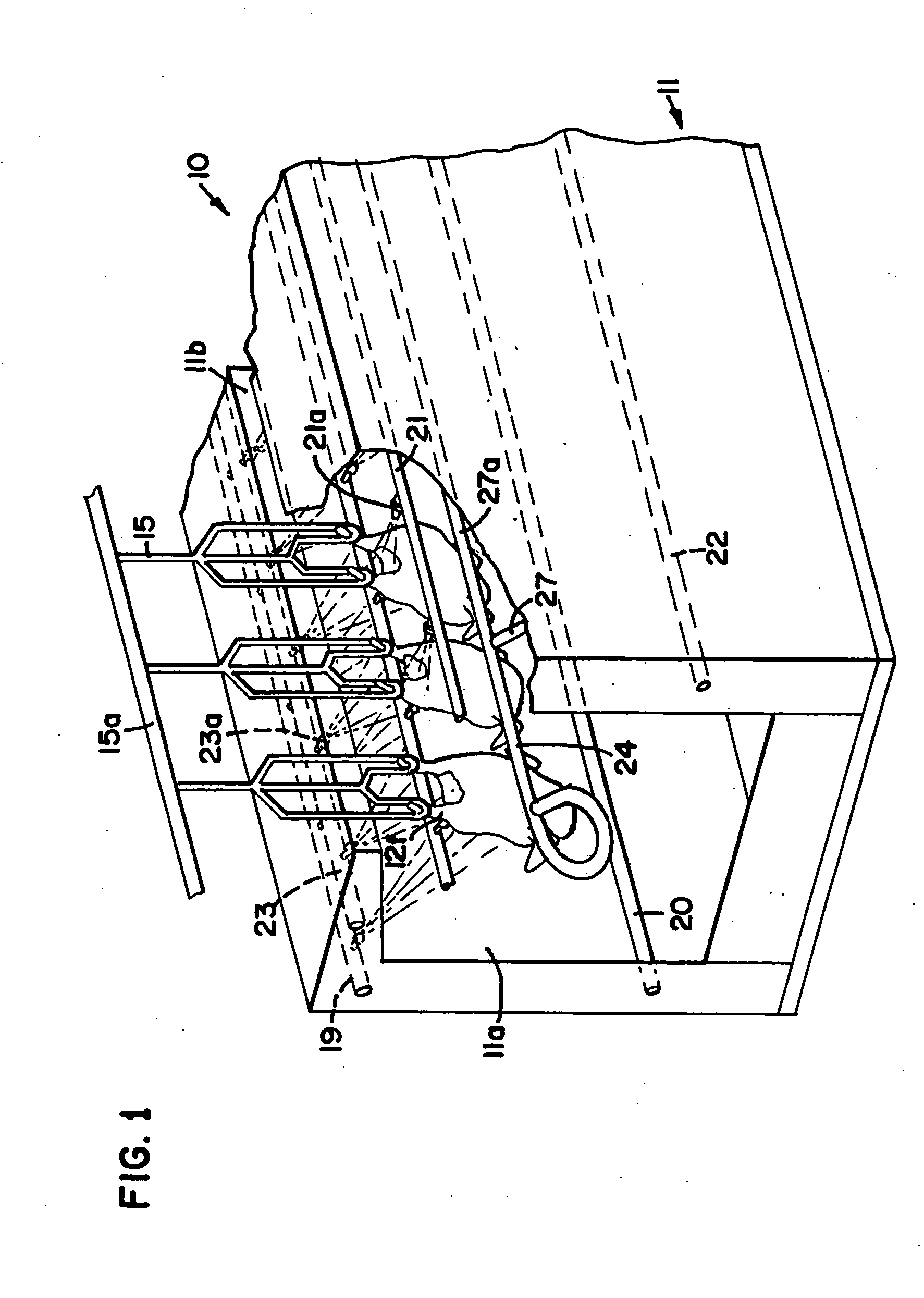

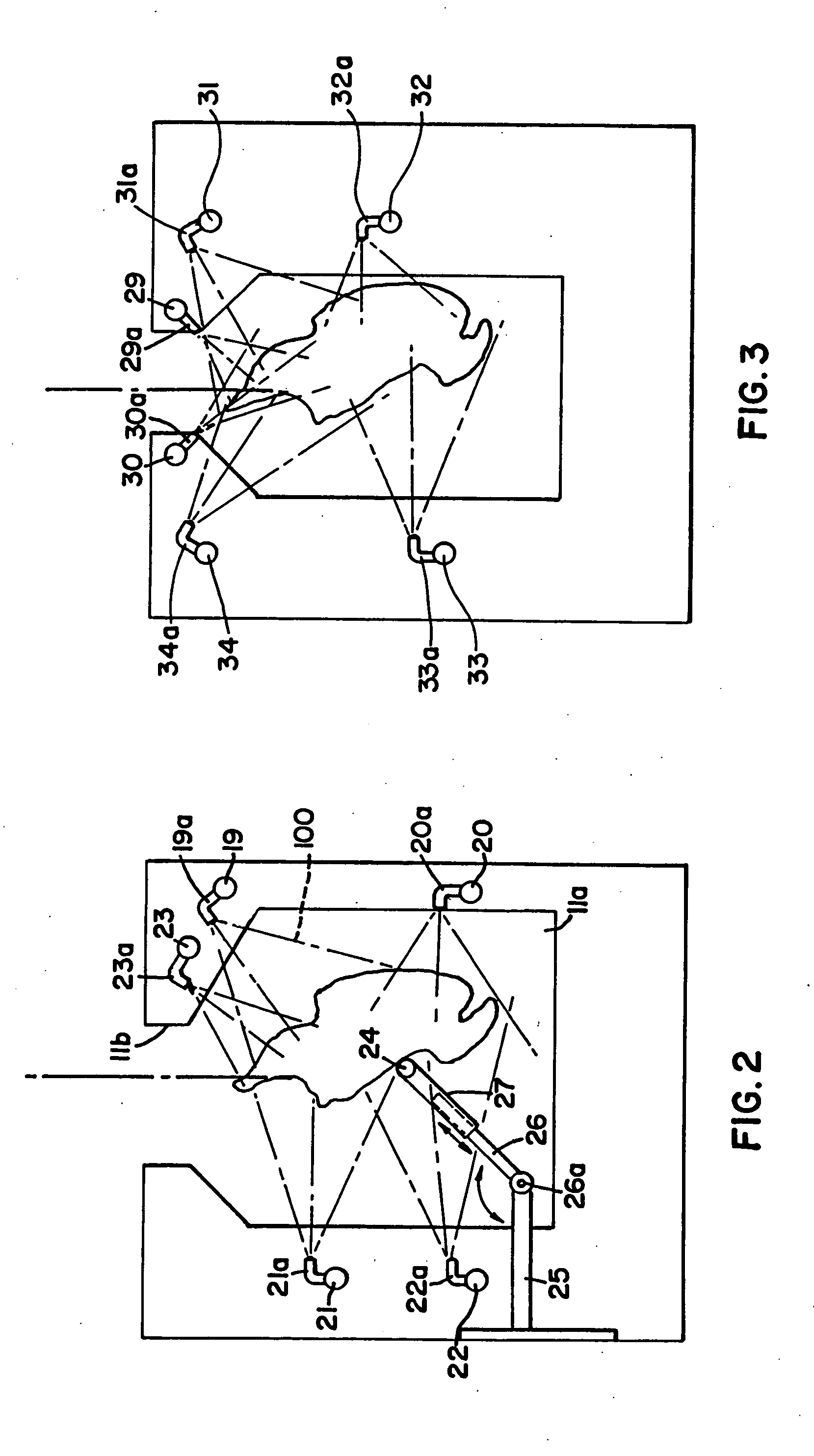

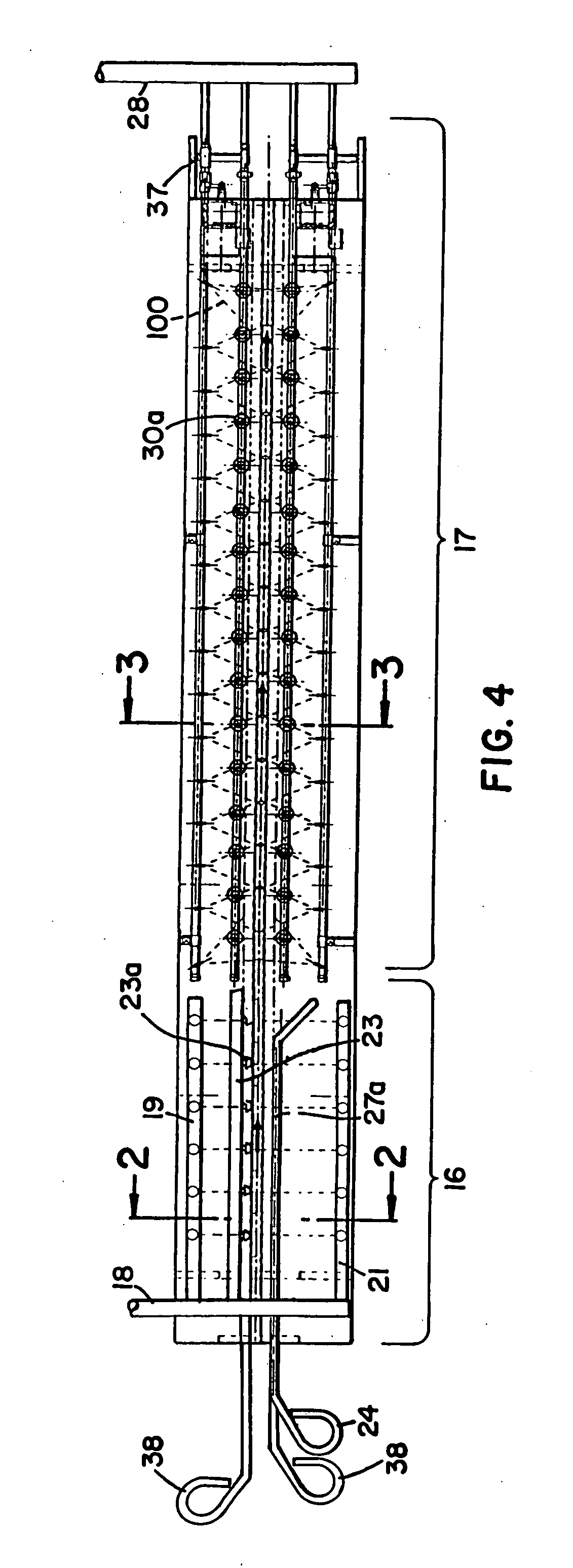

Treatment fluid application apparatus for foodstuffs and methods related thereto

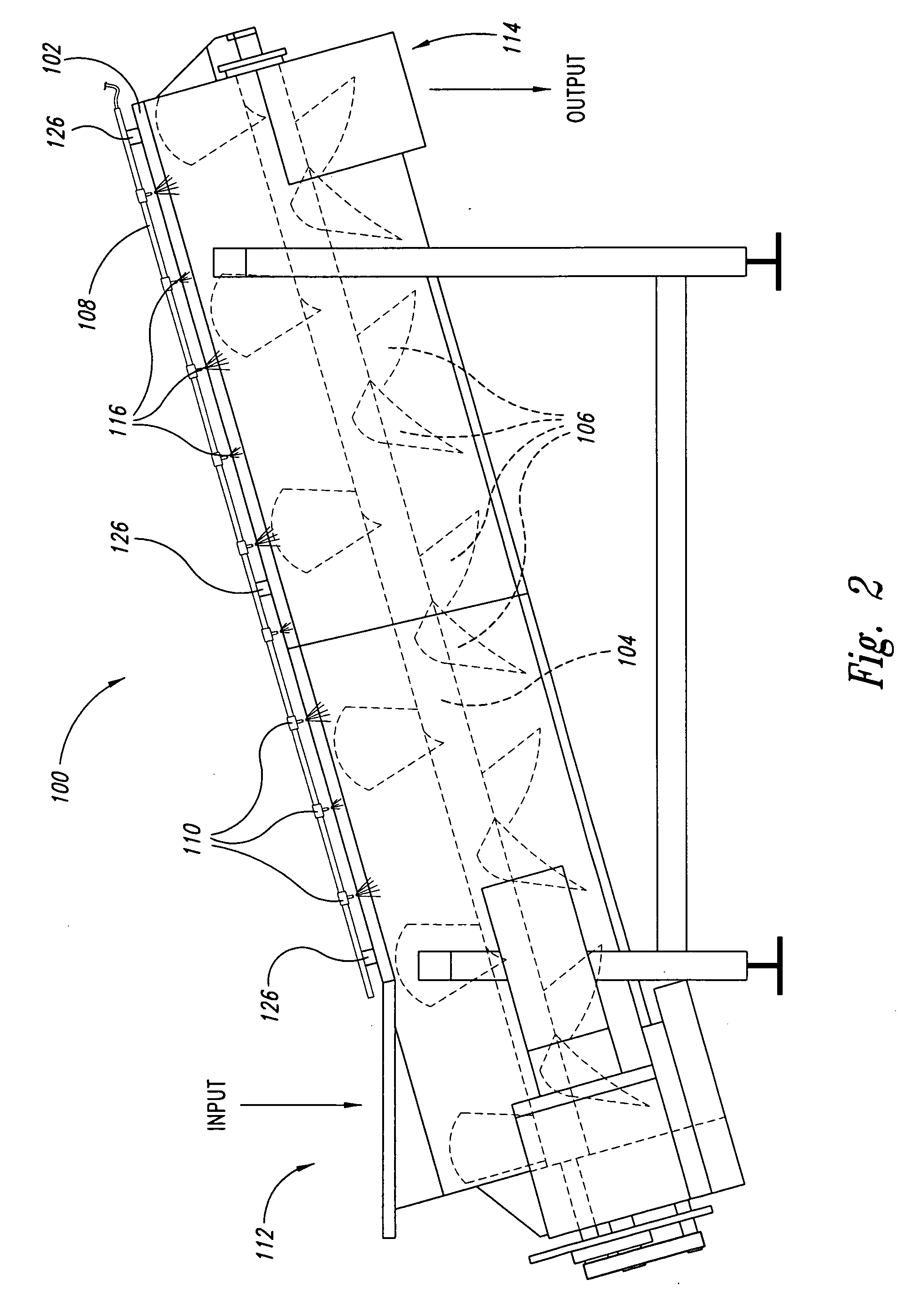

InactiveUS20050058013A1Good lookingImprove EdibilityRotary stirring mixersMeat/fish preservation using liquidsSpiral bladeDisinfectant

Apparatus and methods for applying treatment fluids, such as disinfectants, flavoring agents, and tenderizing agents, to foodstuff surfaces to, for example, reduce populations of microorganisms or fungi, alter taste, or alter texture. In representative embodiments, the apparatus includes a housing, a fluid delivery system, and a shaft with a protruding surface, the latter adapted to rotatably convey, while agitating and tumbling, the foodstuffs from an inlet to an outlet of the housing, as the fluid delivery system applies a treatment fluid to the foodstuffs. In more specific embodiments, the protruding surface may be paddles, or paddles interconnected by a solid web and having angled distal surfaces, or a spiral blade with radial protrusions, or such a spiral blade along a first longitudinal portion of the shaft and paddles along a second longitudinal portion of the shaft.

Owner:ALCIDE CORP

System for handling processed meat and poultry products

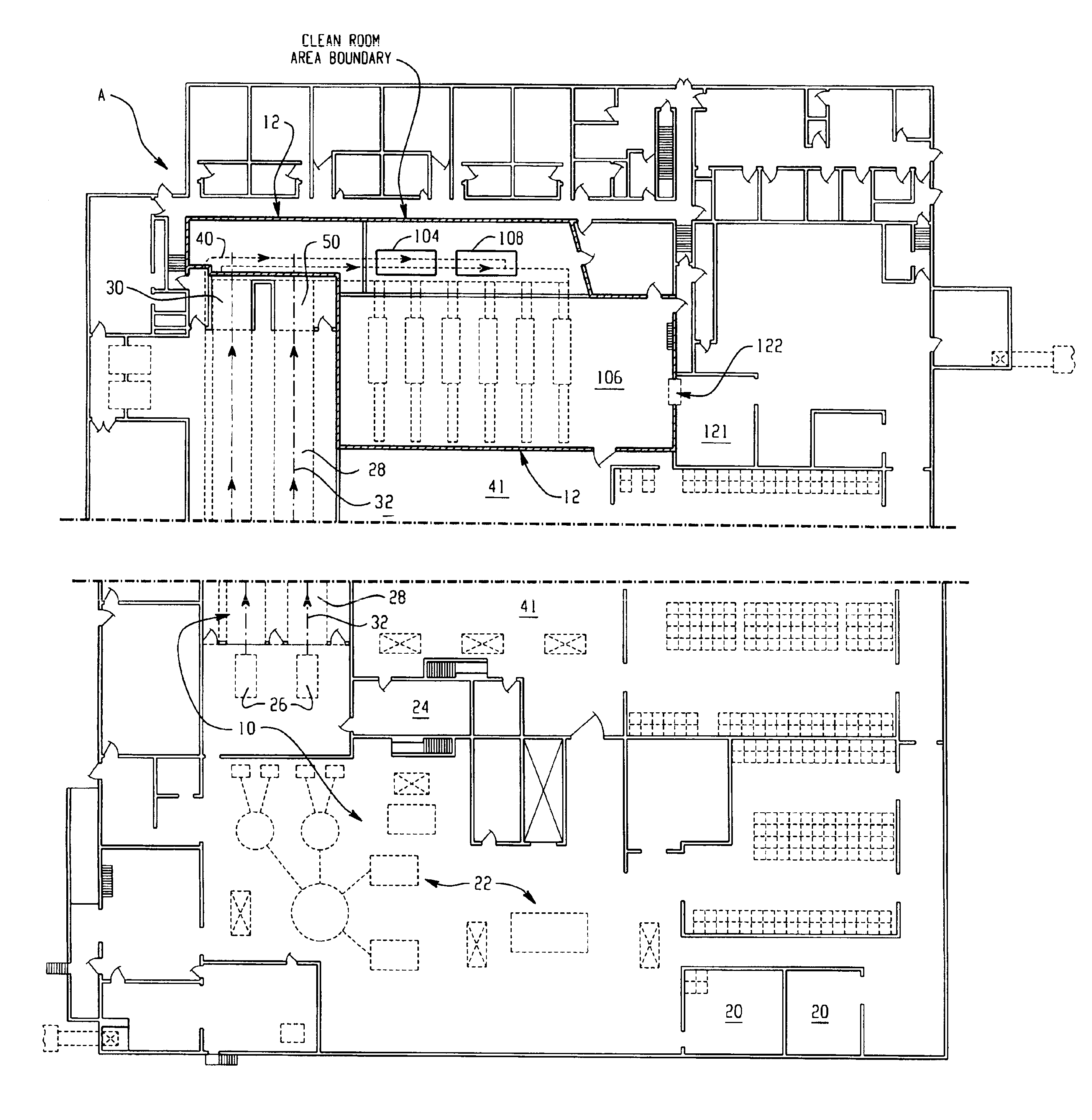

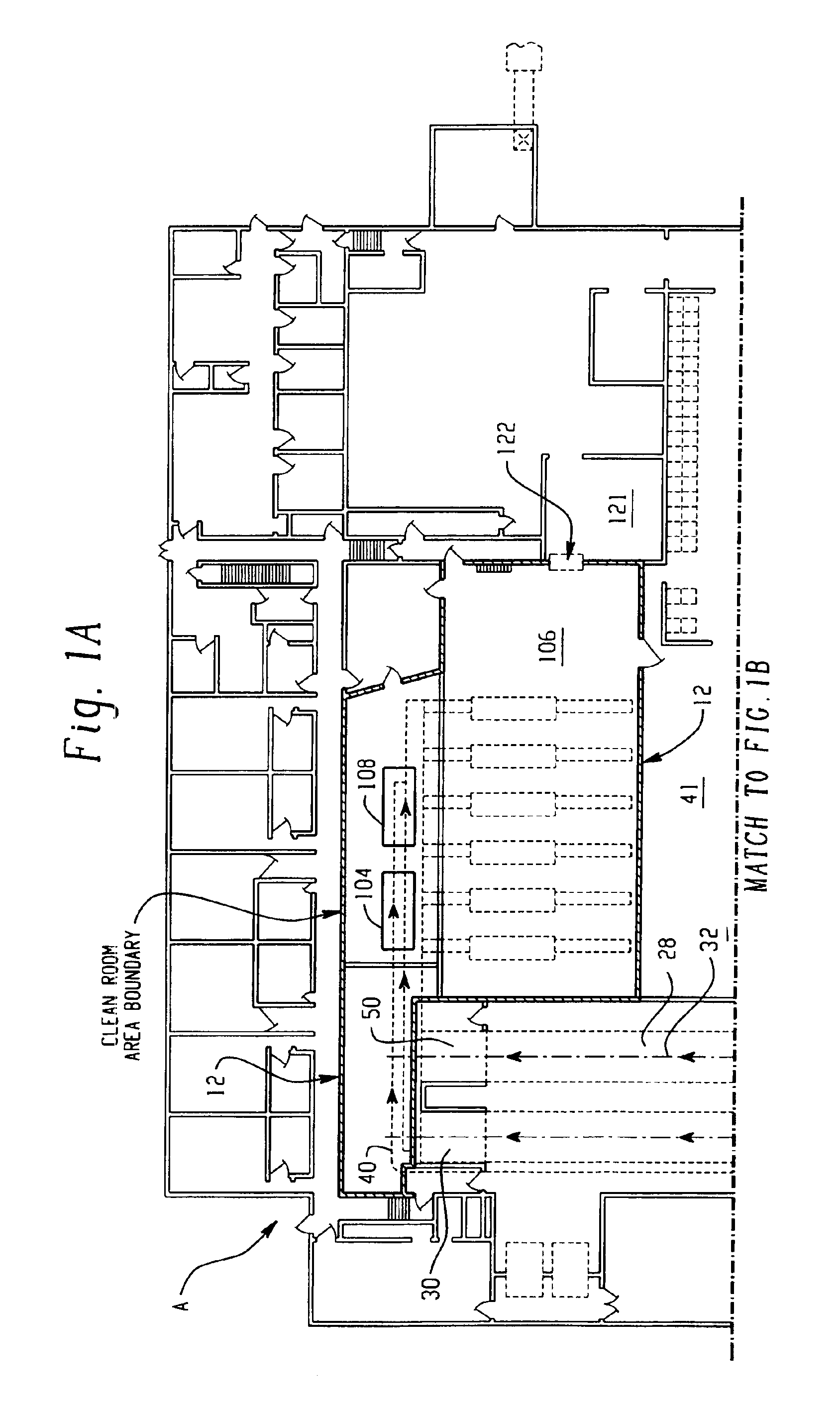

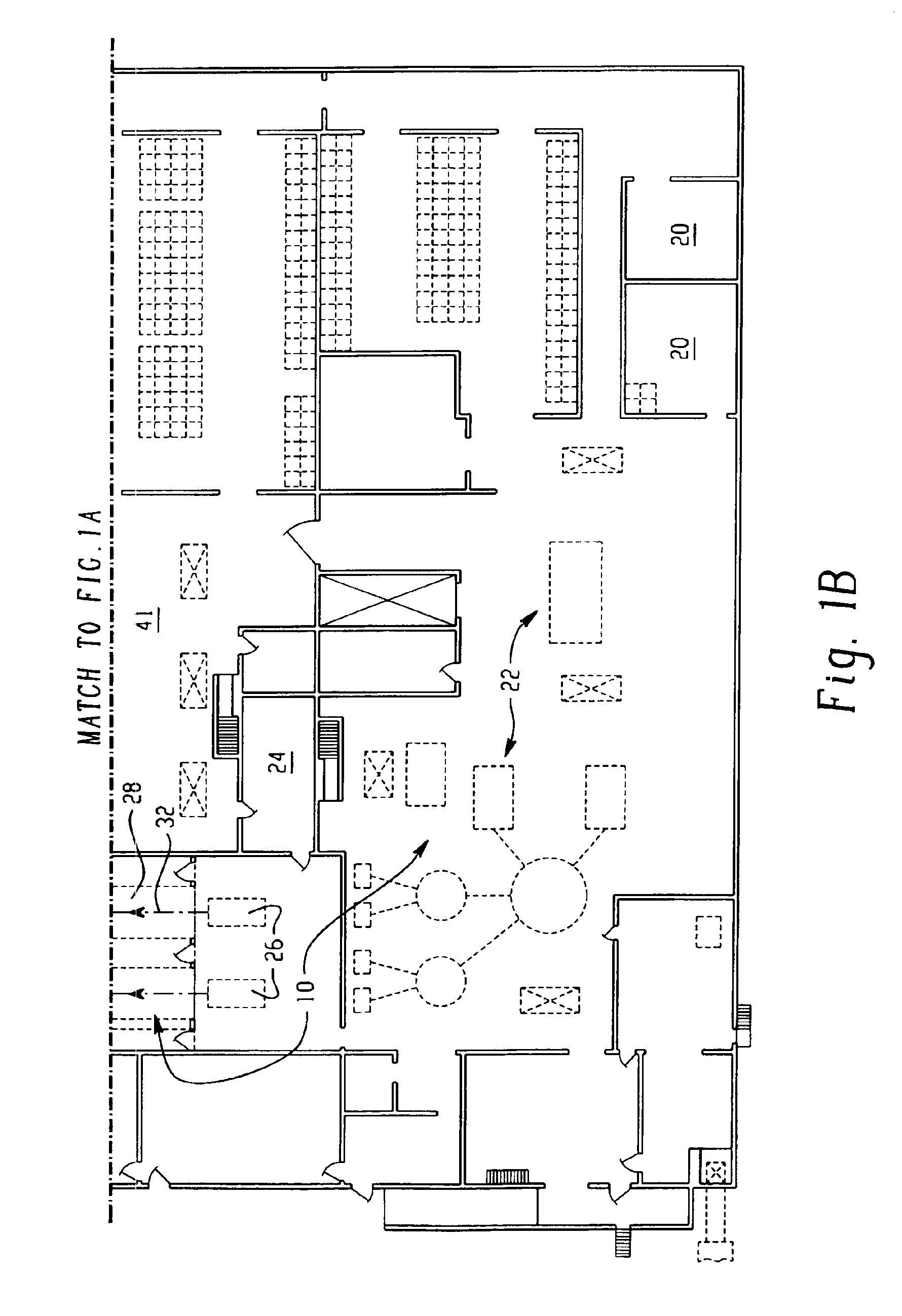

InactiveUS6964788B2Apparent advantageObvious advantagesMeat/fish preservation using liquidsSausage casingsPathogenic microorganismPoultry product

Food products, such as precooked meats, sausages, and the like are microbially decontaminated in their cooking packages to remove surface microorganism contamination from the packages. The cooking packages are removed and the food products optionally subjected to further processing, such as slicing, and then packaged in aseptic packaging. The microbial decontamination step, further processing and packaging are carried out in a clean room which is maintained to a high level of sterilization or disinfection to minimize or eliminate contamination of the food products with pathogenic microorganisms such as Listeria Monocytogenes. The food products thus leave the packaging plant with a much higher assurance of food safety than is found in a conventional packaging plant.

Owner:STERIS CORP

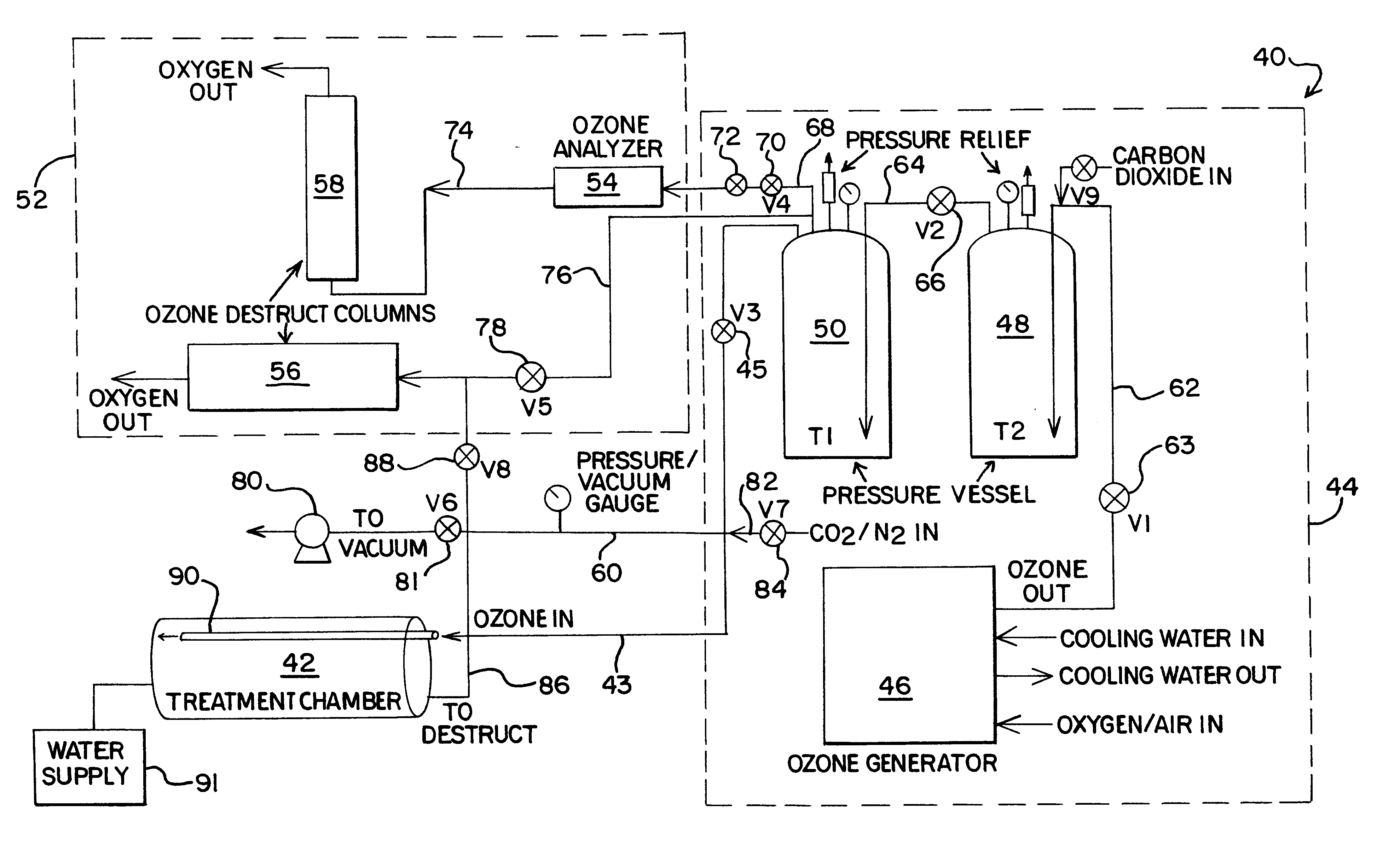

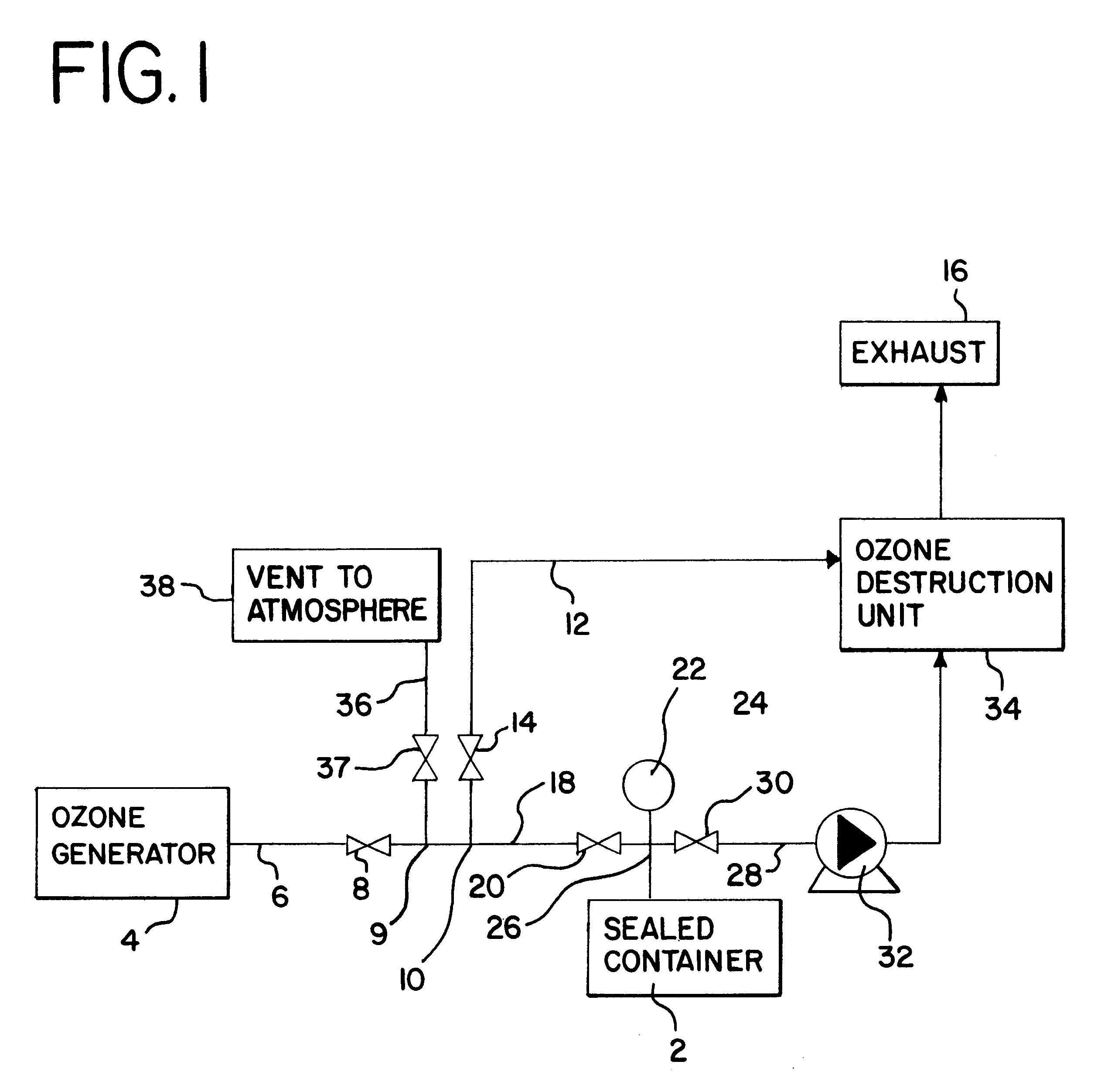

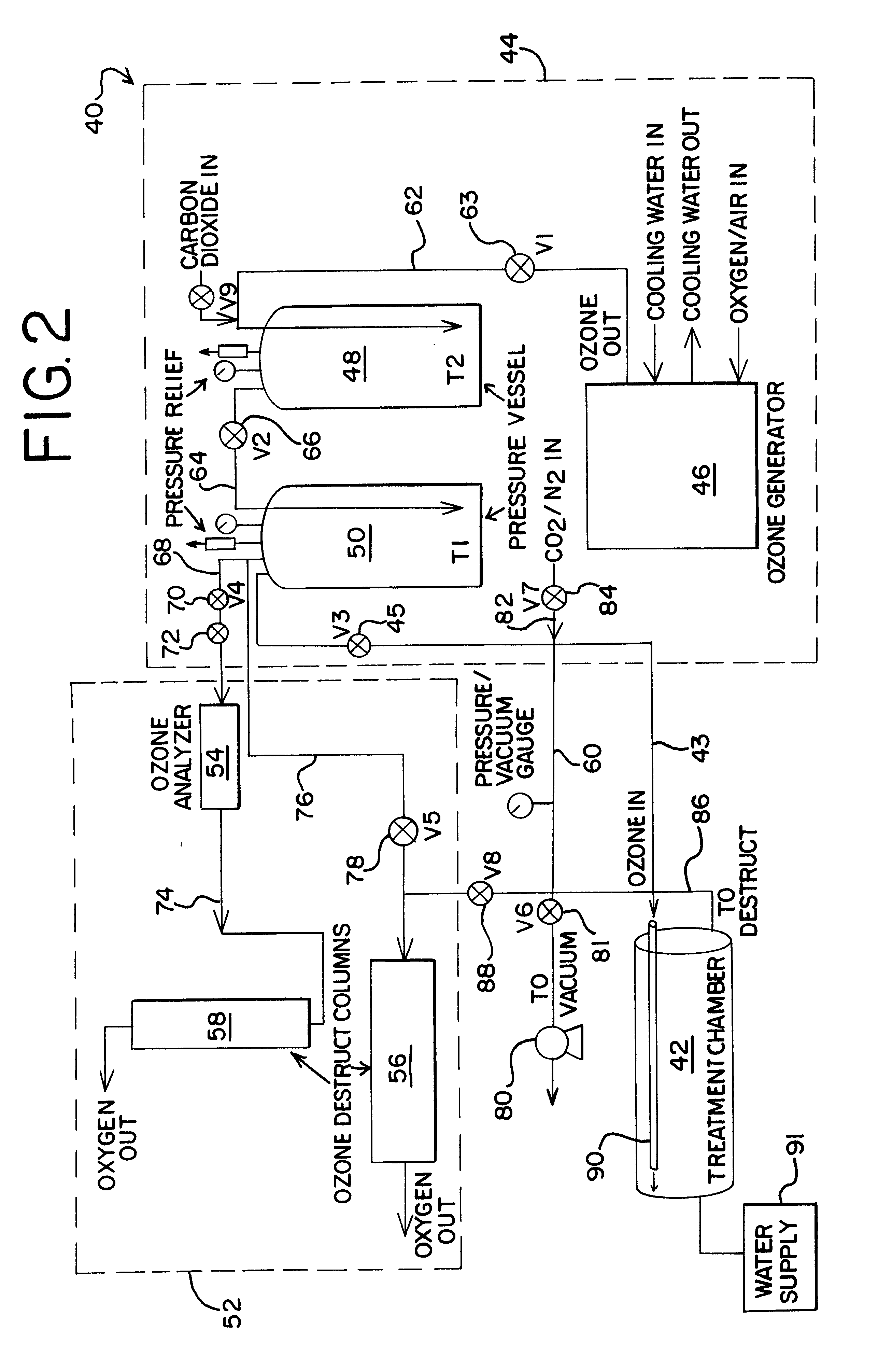

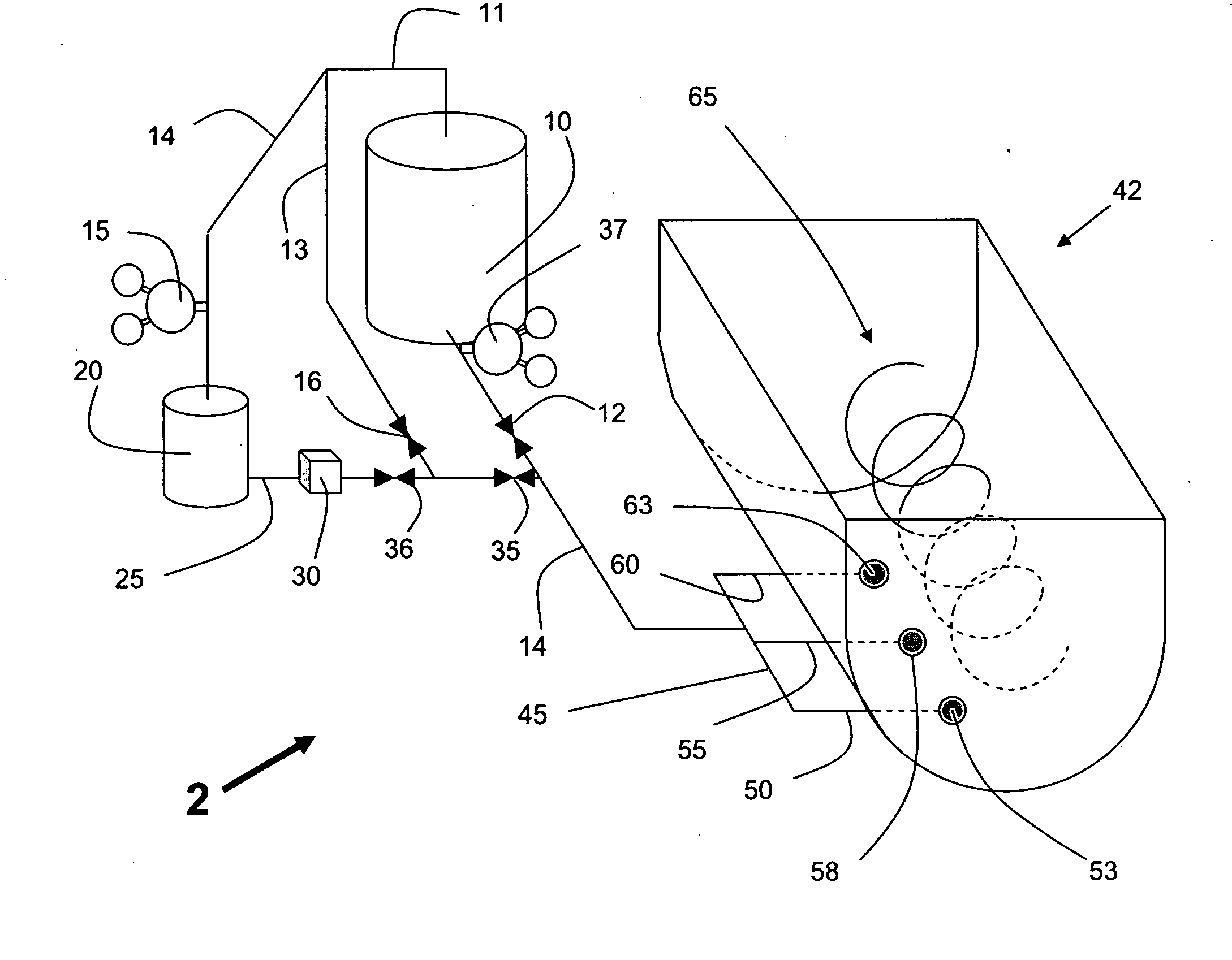

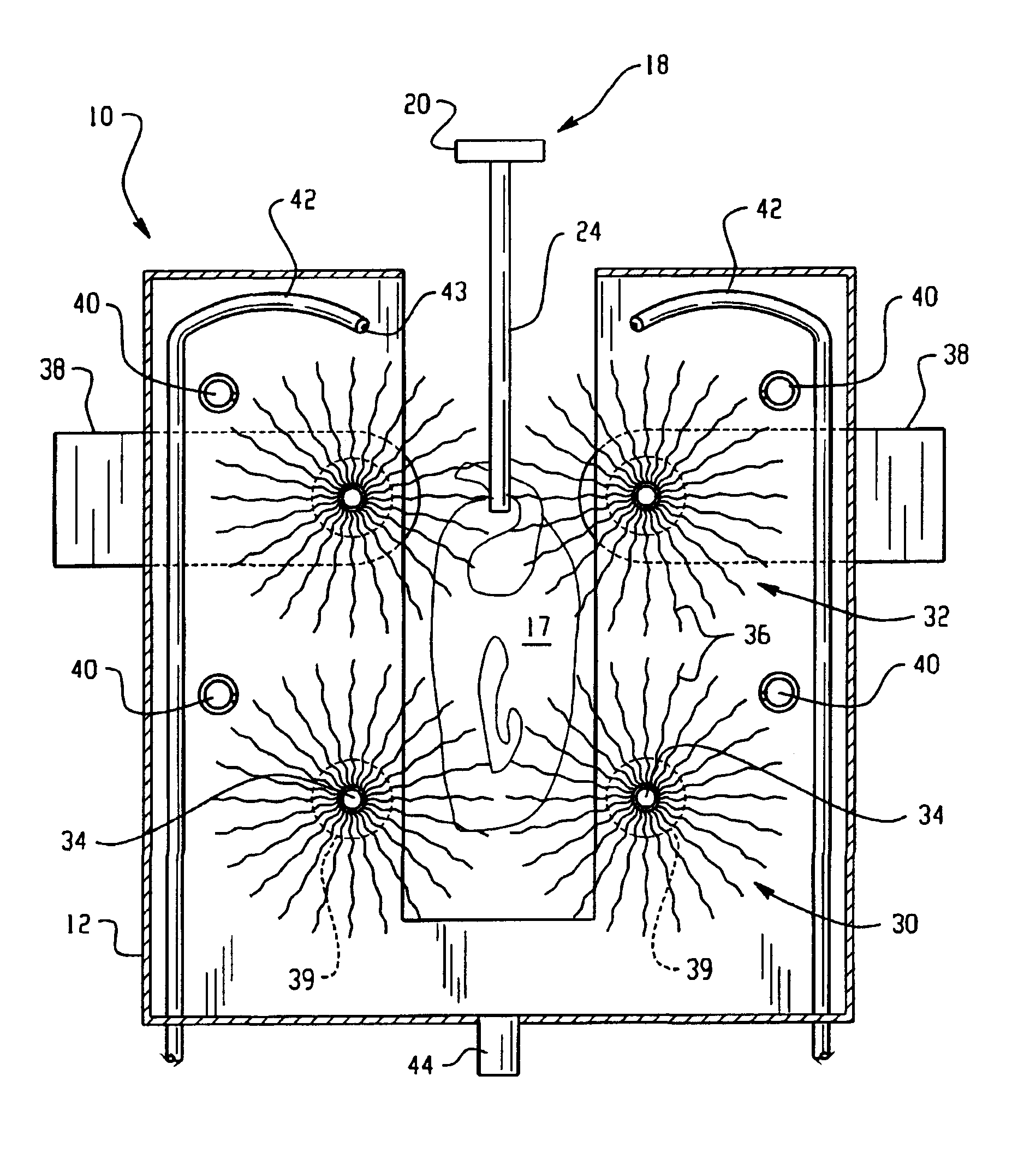

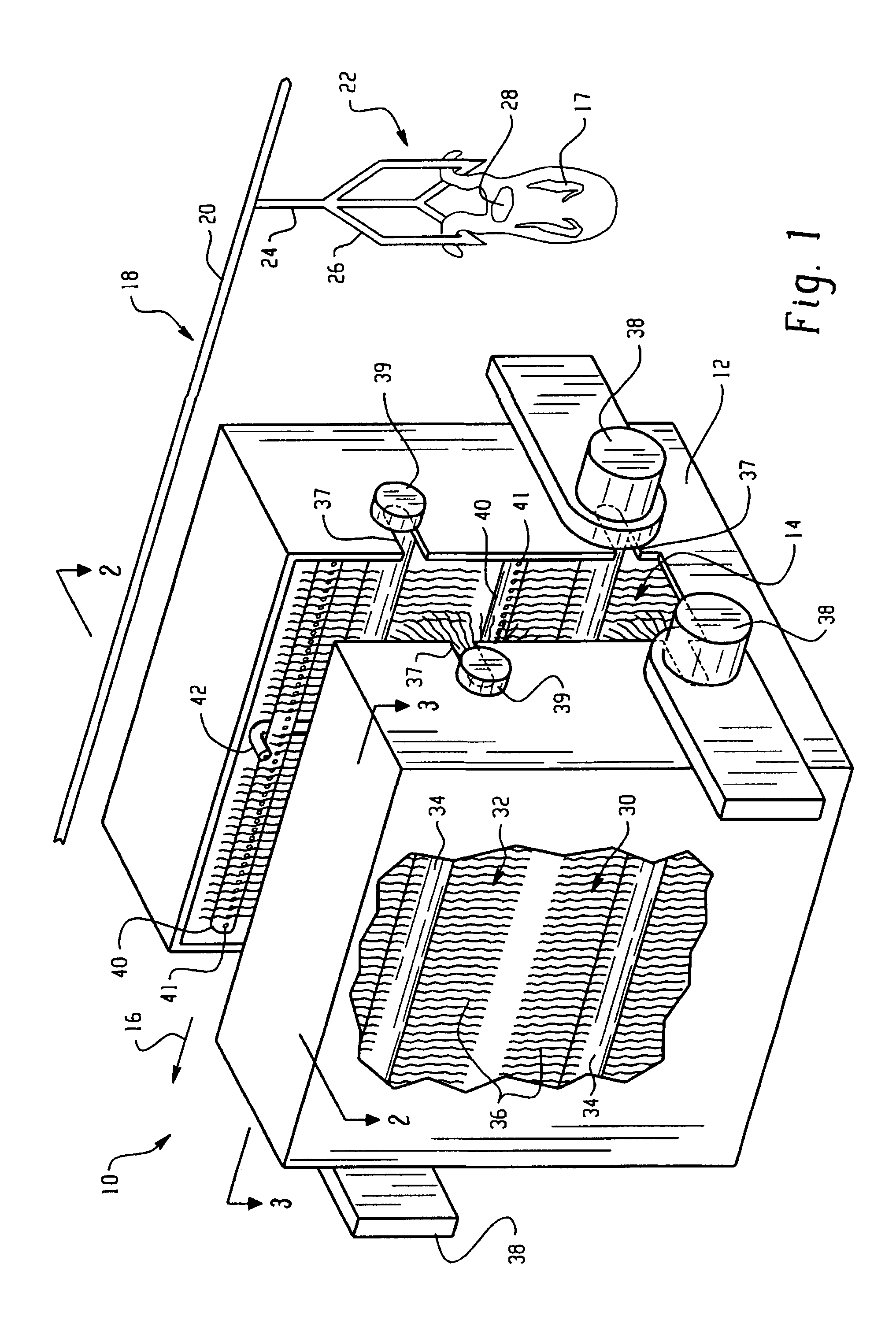

Food disinfection using ozone

Methods and apparatus are provided for decreasing the bacteria count of a food commodity without affecting its overall organoleptic quality (taste, odor, and color). This is accomplished using a treatment fluid comprising ozone, which is injected into a treatment chamber containing the food commodity. Some water is preferably added to obtain better contact of the ozone with the food by forming a thin film of ozonated water on the food surface. Spices and / or other ingredients may preferably be added with the water. The food is placed in a tumbler and the tumbler is set in motion. During treatment good contact between the treatment fluid and the food commodity is obtained by reversibly oscillating the tumbler. A log reduction of 40% or more in bacteria count may be obtained as compared without the ozone.

Owner:AIR LIQUIDE AMERICA INC +2

Method and composition for washing poultry during processing

InactiveUS7381439B2Reduce Microbial ContaminationHigh degreeBiocideAlcoholic beverage preparationMachining processBiology

The present invention relates to compositions including peroxyacetic acid and peroxyoctanoic acid and methods for reducing microbial contamination on poultry. The methods include the step of applying a mixed peroxycarboxylic acid composition to poultry.

Owner:ECOLAB USA INC

Method and system for treating food items with an additive and solid carbon dioxide

ActiveUS20100293969A1Reduce pressureMixing methodsStationary refrigeration devicesLiquid carbonSolid carbon dioxide

Embodiments of the invention generally provide methods and systems that distribute an additive in solid carbon dioxide in an interior of food processing equipment. The additive may be injected into a flow of liquid carbon dioxide upstream of an expander at or adjacent to the interior. Injection of the additive into the interior may be alternated with directing a flow of expanded carbon dioxide into the interior. In some embodiments, the freezing point of the additive with or without a diluent composition and / or additive(s) is lower than a temperature of the liquid carbon dioxide.

Owner:AIR LIQUIDE AMERICA INC +1

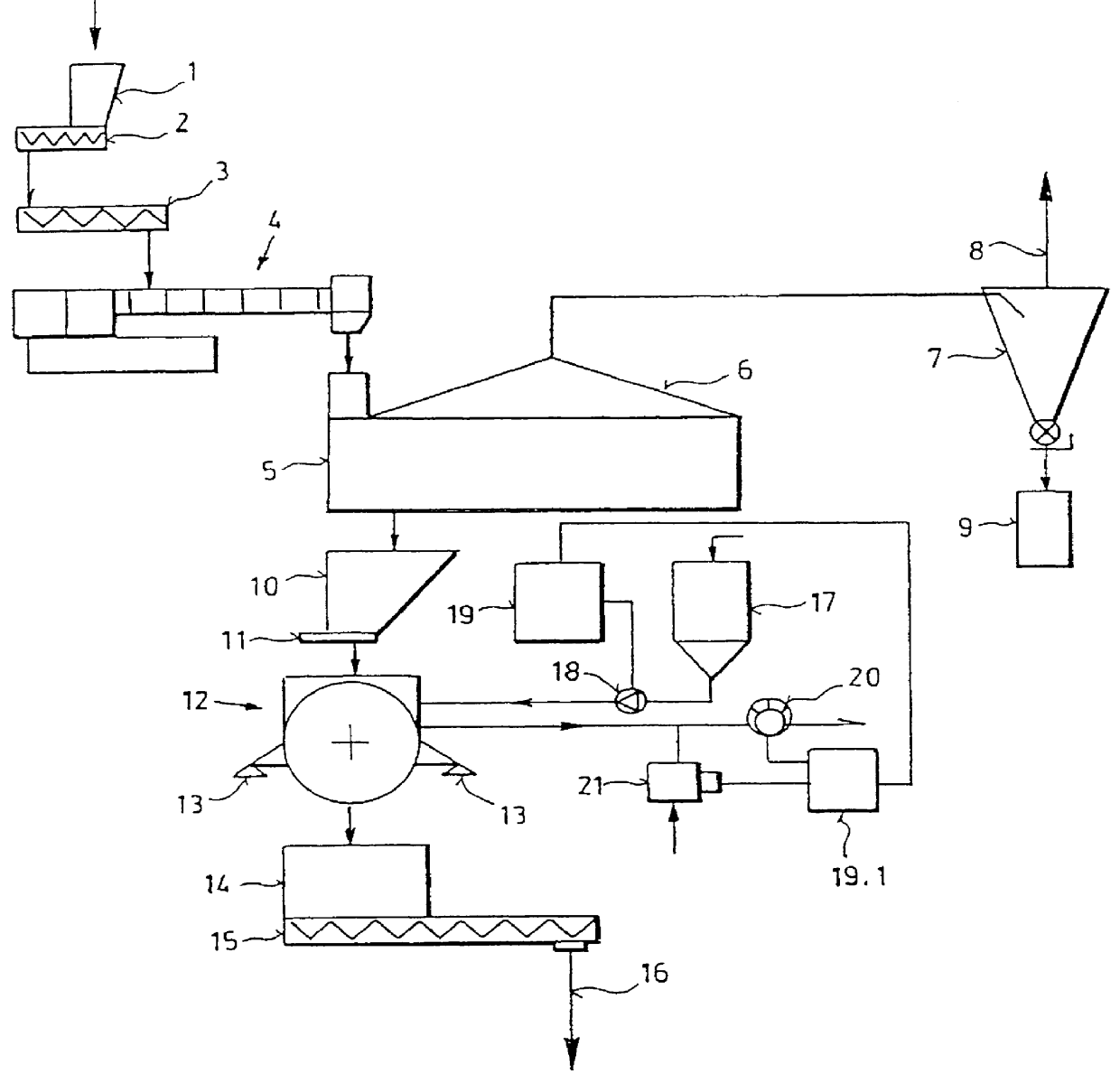

Method of incorporating fatty matter into granulated products

InactiveUS6136353APromote absorptionImprove permeabilityFeeding-stuffAnimal feeding stuffMetering pumpVacuum pump

PCT No. PCT / CH96 / 00265 Sec. 371 Date Dec. 16, 1998 Sec. 102(e) Date Dec. 16, 1998 PCT Filed Jul. 22, 1996 PCT Pub. No. WO98 / 03080 PCT Pub. Date Jan. 29, 1998A method and apparatus for incorporating fatty matter into granulated feed products such as extrudates, pellets and expander pellets with a fat-supplying liquid. Pellets produced in the extruder or expander of press (4) are dried in a dryer (5) and pass through an intermediate container (10) into a mixer (12). Using a metering pump (18) a predetermined amount of fat-supplying liquid is added to the mixer (12) and spread on the surface of product pieces through the mixing process. After a predetermined period of time a vacuum pump (20) generates a negative pressure in the mixer so as to evacuate the air from capillaries or pores of the product pieces. The negative pressure in the mixer is then relieve through an expansion valve (21) so that the air entering into the mixer and into the pores or capillaries of the product pieces transports the fat-supplying liquid on the surface of the product pieces as well as additional fat-supplying liquid into the pores and capillaries, thereby filling them to the extend that a high proportion of approximately 30% fat-supplying liquid is incorporated in the pores of capillaries of the product pieces.

Owner:BUEHLER AG

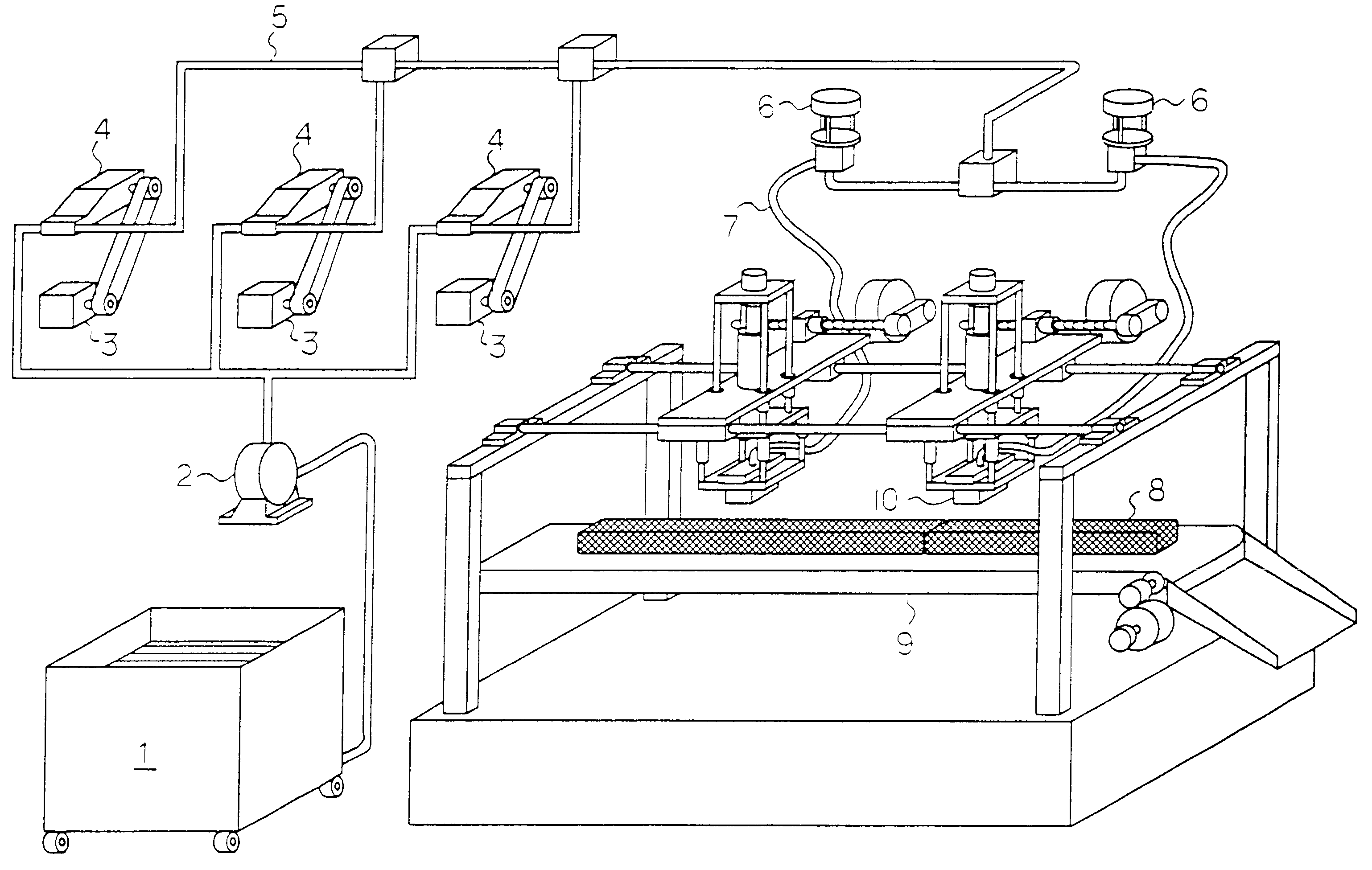

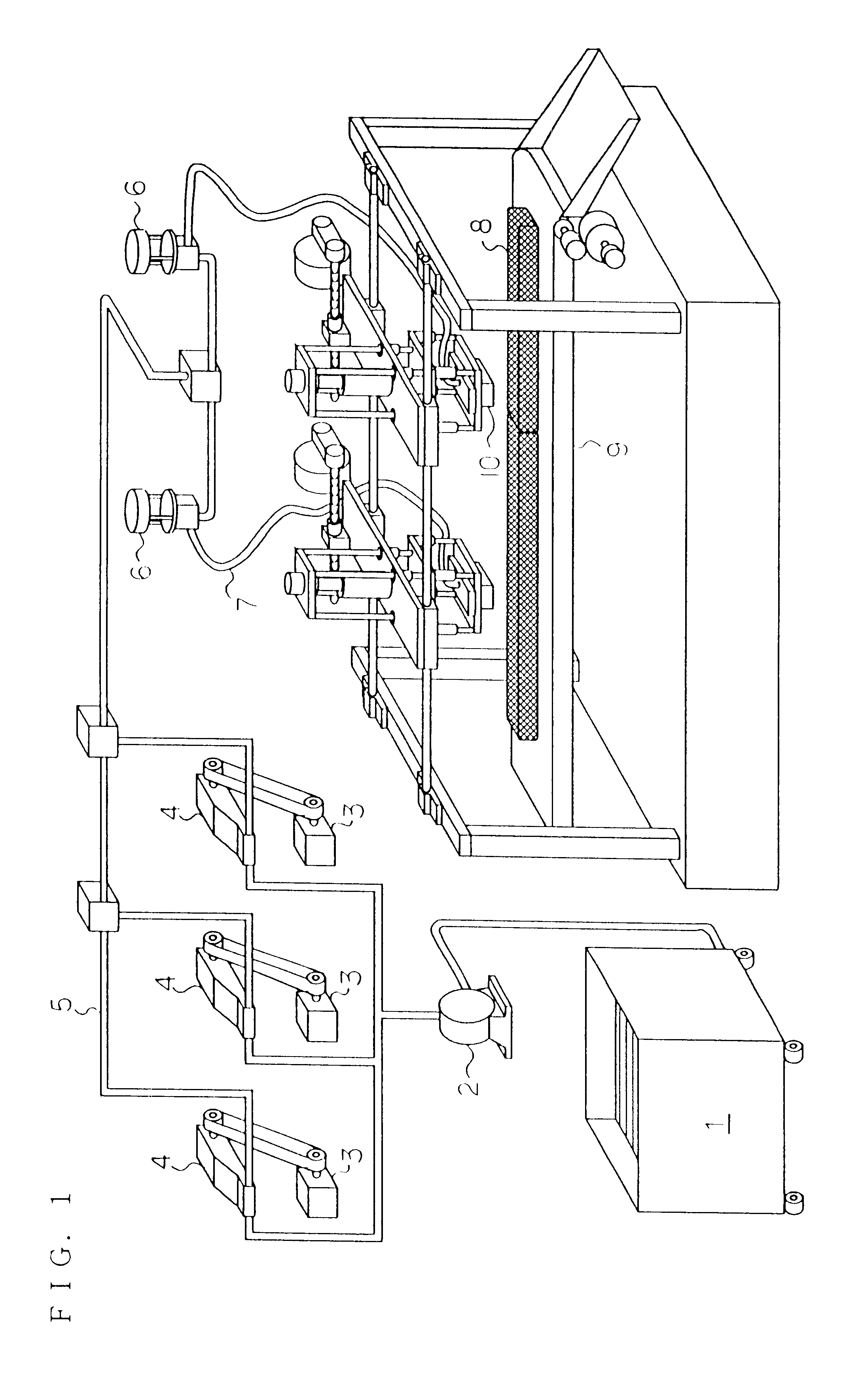

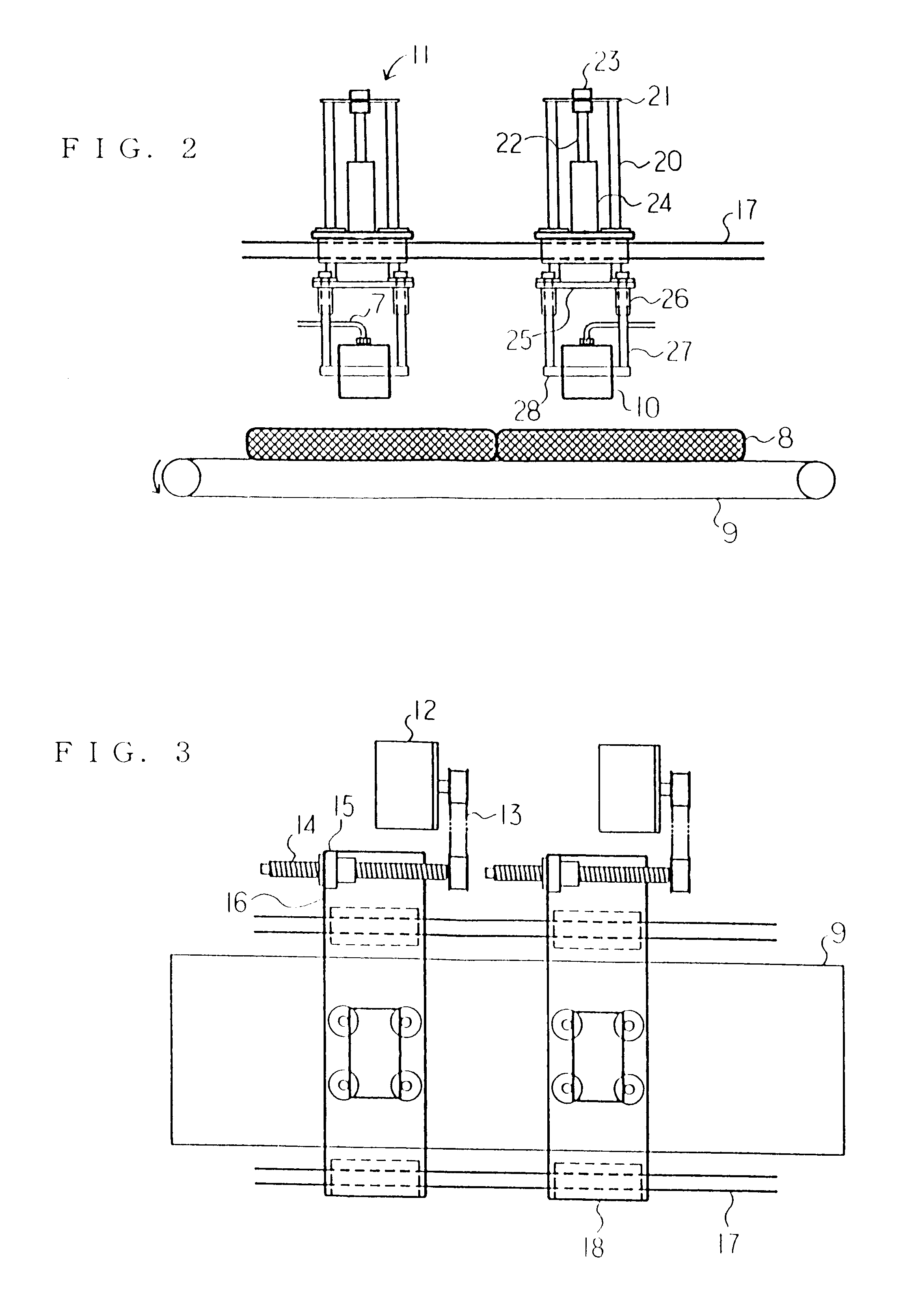

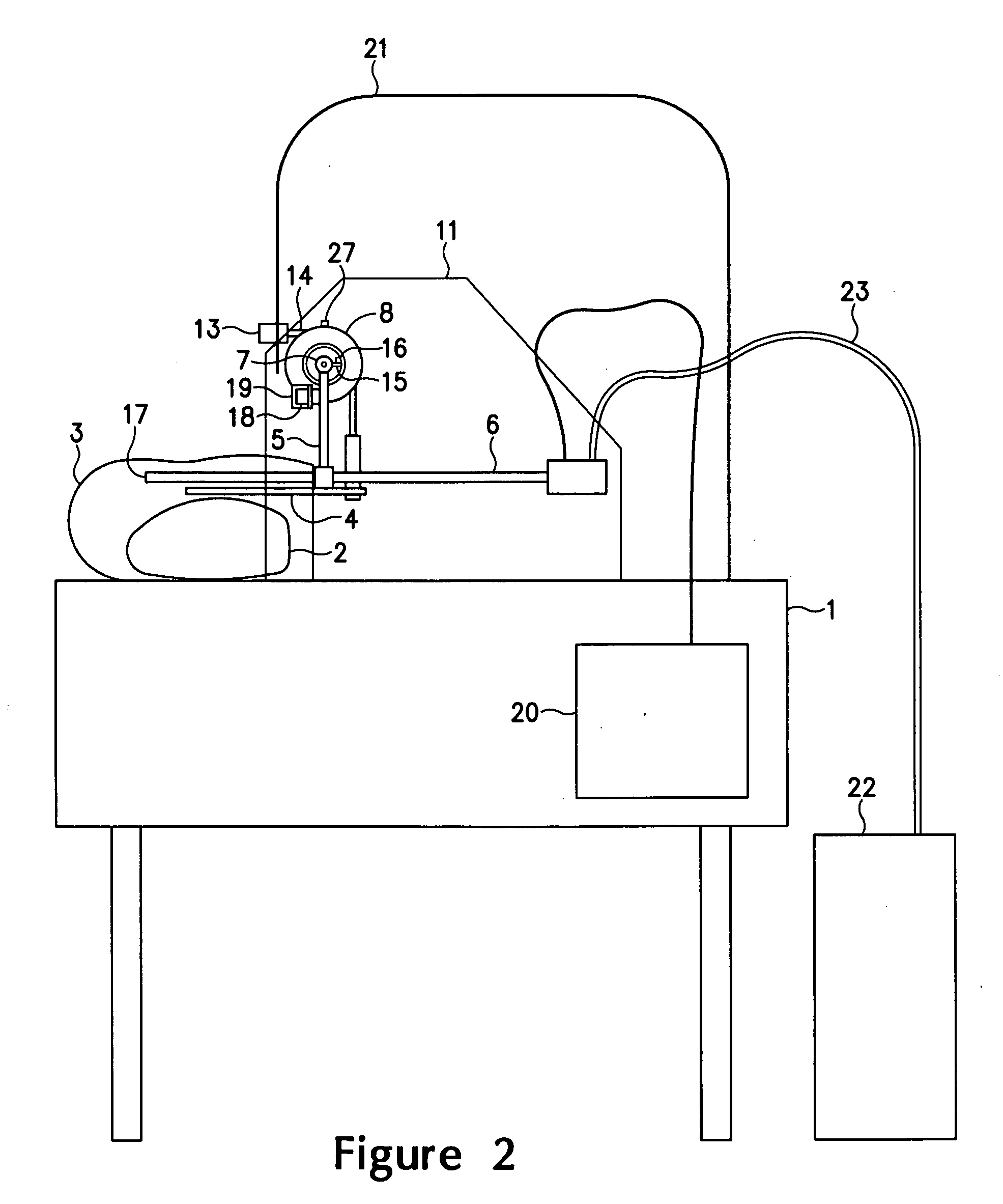

Continuous high-speed pickle injector

InactiveUS6386099B1Improve productivityIncrease speedGrain huskingGrain polishingSaline waterInjection pressure

A continuous high-speed pickle injector is provided with improved productivity that can inject a liquid substance such as brine for curing, seasoning or the like into a block of meat such as pork, beef, livestock meat and the like continuously, and disperse the liquid substance uniformly. A pickle injector which can inject a liquid substance such as brine for curing and the like into a block of meat being conveyed continuously while gradually raising the injection pressure from 0 or a low pressure includes two or more injecting sections being able to repeat an injecting operation, that is, from the start to the completion of the injection of a liquid substance. The two or more injecting sections inject a liquid substance while moving at a speed synchronized with the conveying speed of a block of meat continuously being conveyed during the operation of injection. The timing of the injecting operation for each injecting section is controlled.

Owner:PRIMA MEAT PACKERS LTD

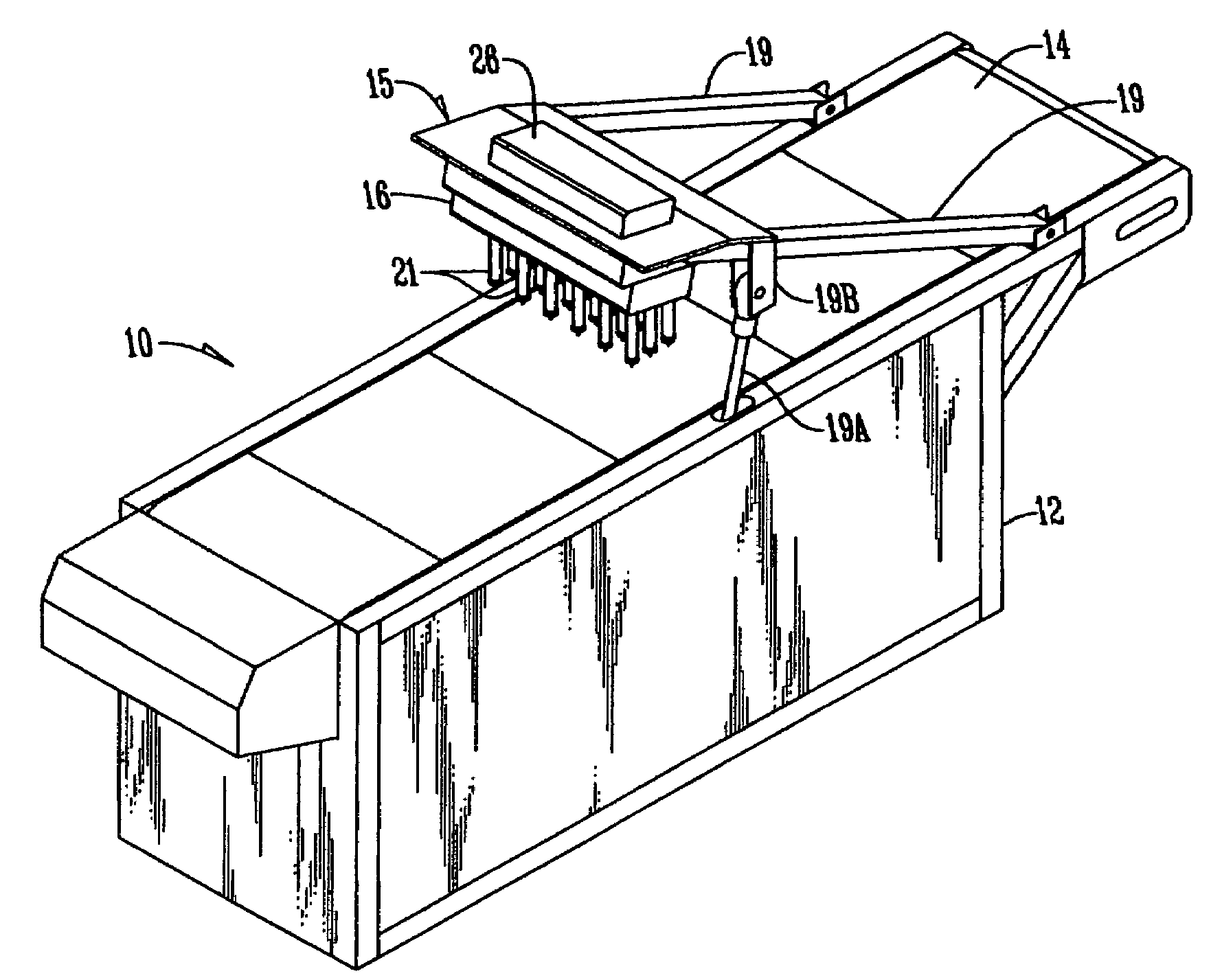

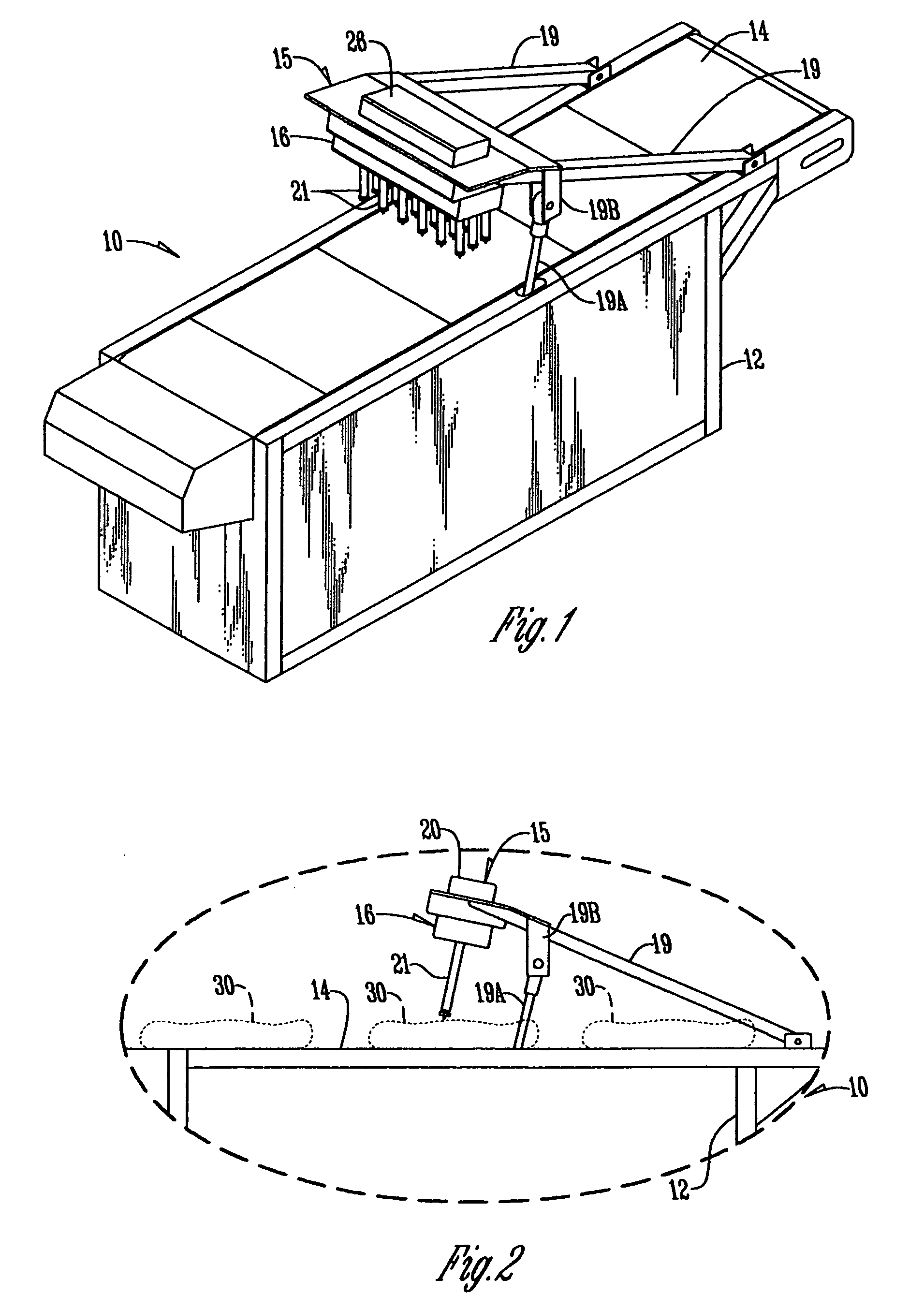

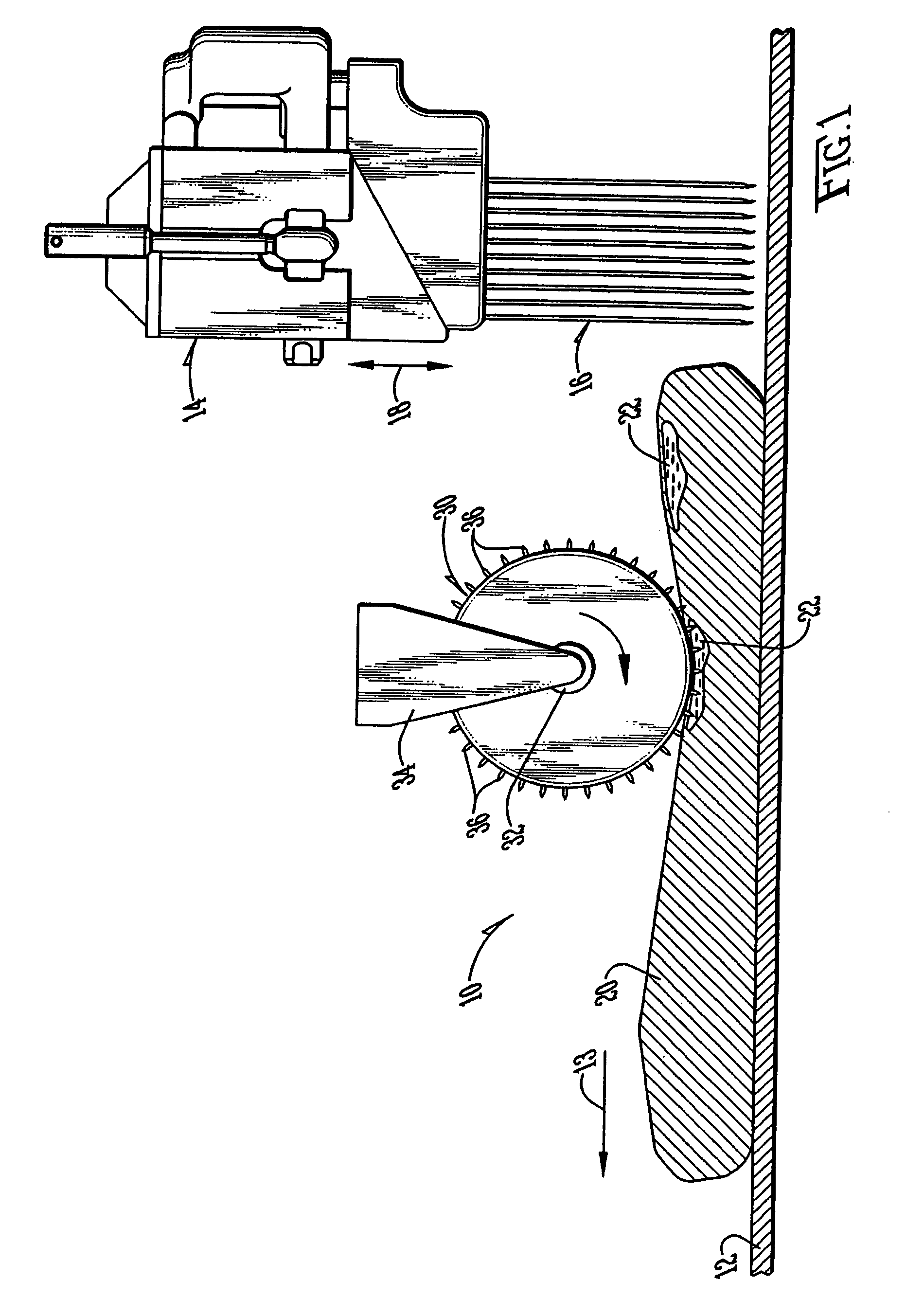

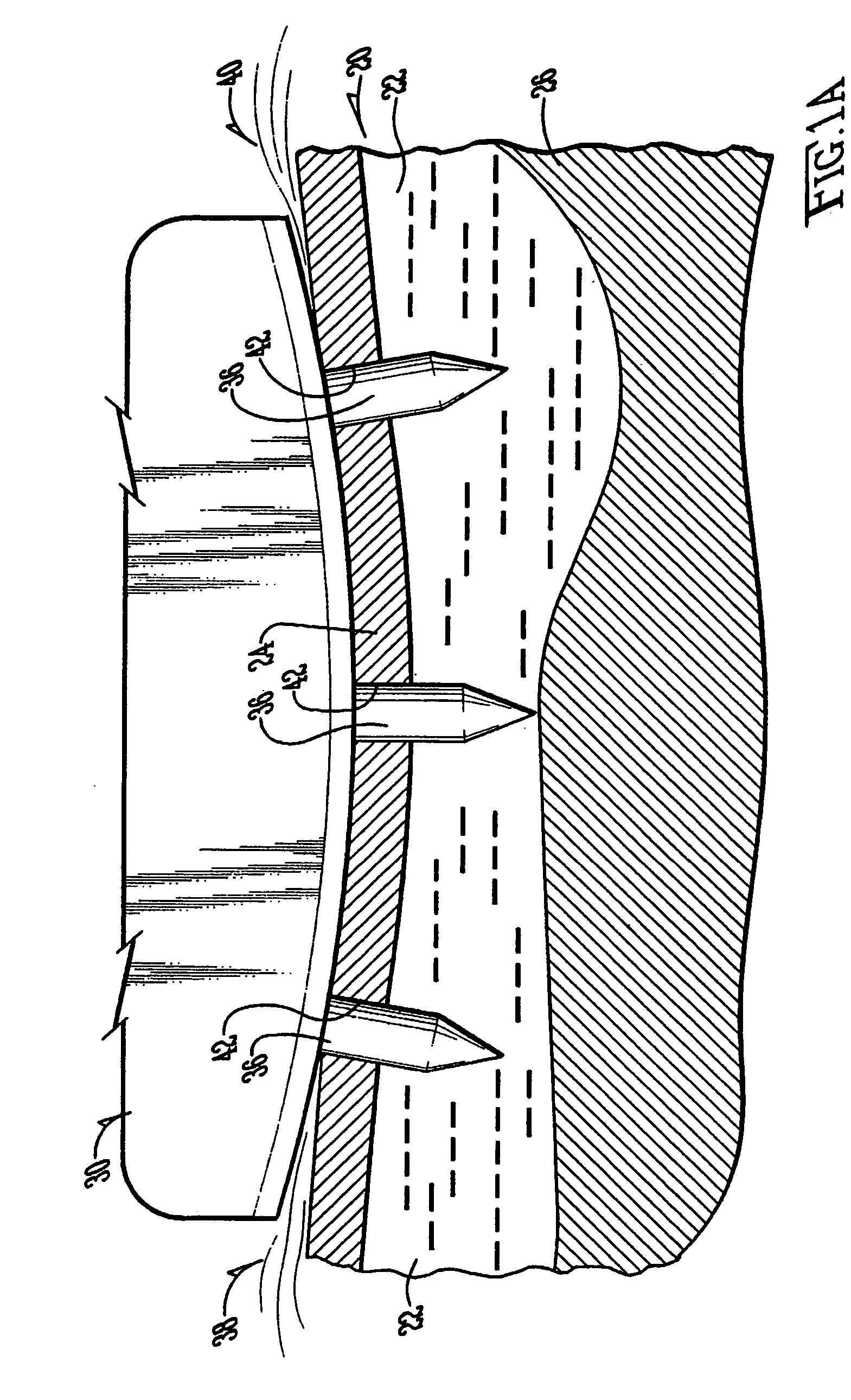

Post-evisceration process and apparatus

InactiveUS6733379B2Preventing line holdupsMinimize cross-contaminationFish washing/descalingPoultry cleaning/disinfectionDead bodyAbdominal evisceration

A process and apparatus for removing or reducing the levels of pathogenic bacteria present on an eviscerated carcass. The process includes introducing the eviscerated carcass to a cleaning apparatus. The cleaning apparatus generally includes a housing structure having an entrance and an exit. Disposed within the housing structure is a rotating brush assembly and a spray assembly. The brushing assembly provides brushing and massaging actions to the surfaces of the carcass whereas the spraying assembly simultaneously directs a cleaning solution onto the surfaces of the carcass.

Owner:RHONDIA INC

Decontamination methods for meat using carbonic acid at high pressures

InactiveUS20050260311A1Avoid separationEfficient separationMeat/fish preservation using liquidsGaseous food ingredientsHigh densityLean meat

A method for separating lean meat from lean meat-containing material, includes combining a particulate material with fluid, subcritical carbon dioxide at a pH of about 7 or less and a pressure of about 600 psig. The material and fluid is introduced into the vessel and is separated into low density and high density fractions. The material from the low density fraction is removed via an outlet and has a higher percentage of fat than the material introduced into the vessel. The material from the high density fraction is removed via an outlet and has a higher percentage of lean meat than the material introduced into the vessel. The vessel can include a centrifuge or a vessel disposed toward the vertical having an upper and lower outlet, wherein the separation is achieved by the respective densities of the material, and the natural or an artificial gravity field, such as in a centrifuge.

Owner:STONE MICHAEL

Apparatus and method for cleaning poultry

Owner:ECOLAB USA INC

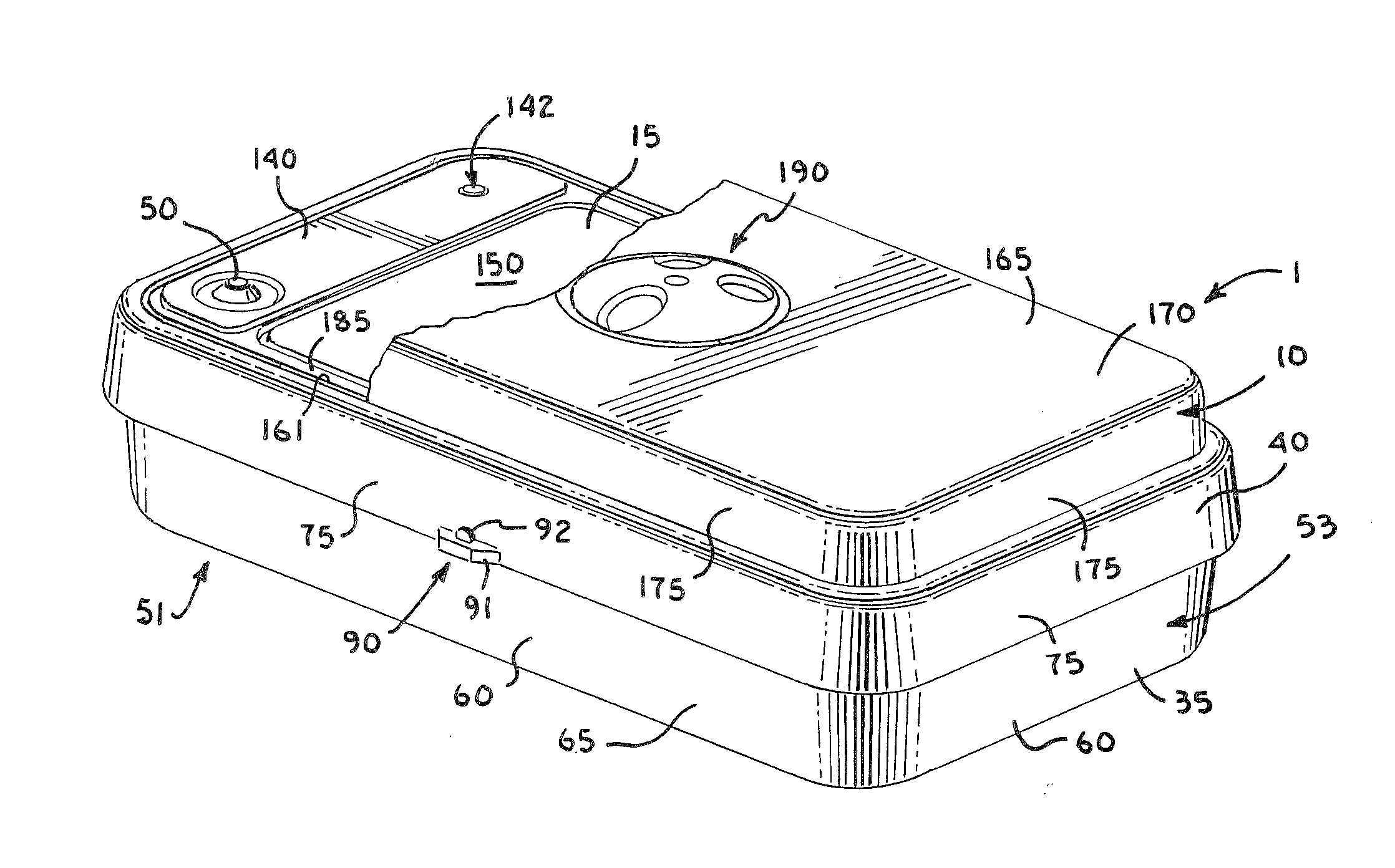

Device for storing, marinating, transporting and serving food including warming cover and cutting board and method therefor

An apparatus for marinating a food in a marinade, storing the food during marination, keeping the food warm after cooking, and supporting the food for cutting is provided, the apparatus including a vacuum-sealable marination chamber; a warming chamber; and a cutting board.

Owner:WANGLER ERIC J

Method and composition for washing poultry during processing

InactiveUS7316824B2Reduce Microbial ContaminationHigh degreeBiocideAlcoholic beverage preparationMachining processNuclear chemistry

The present invention relates to compositions including peroxyacetic acid and peroxyoctanoic acid and methods for reducing microbial contamination on poultry. The methods include the step of applying a mixed peroxycarboxylic acid composition to poultry.

Owner:ECOLAB USA INC

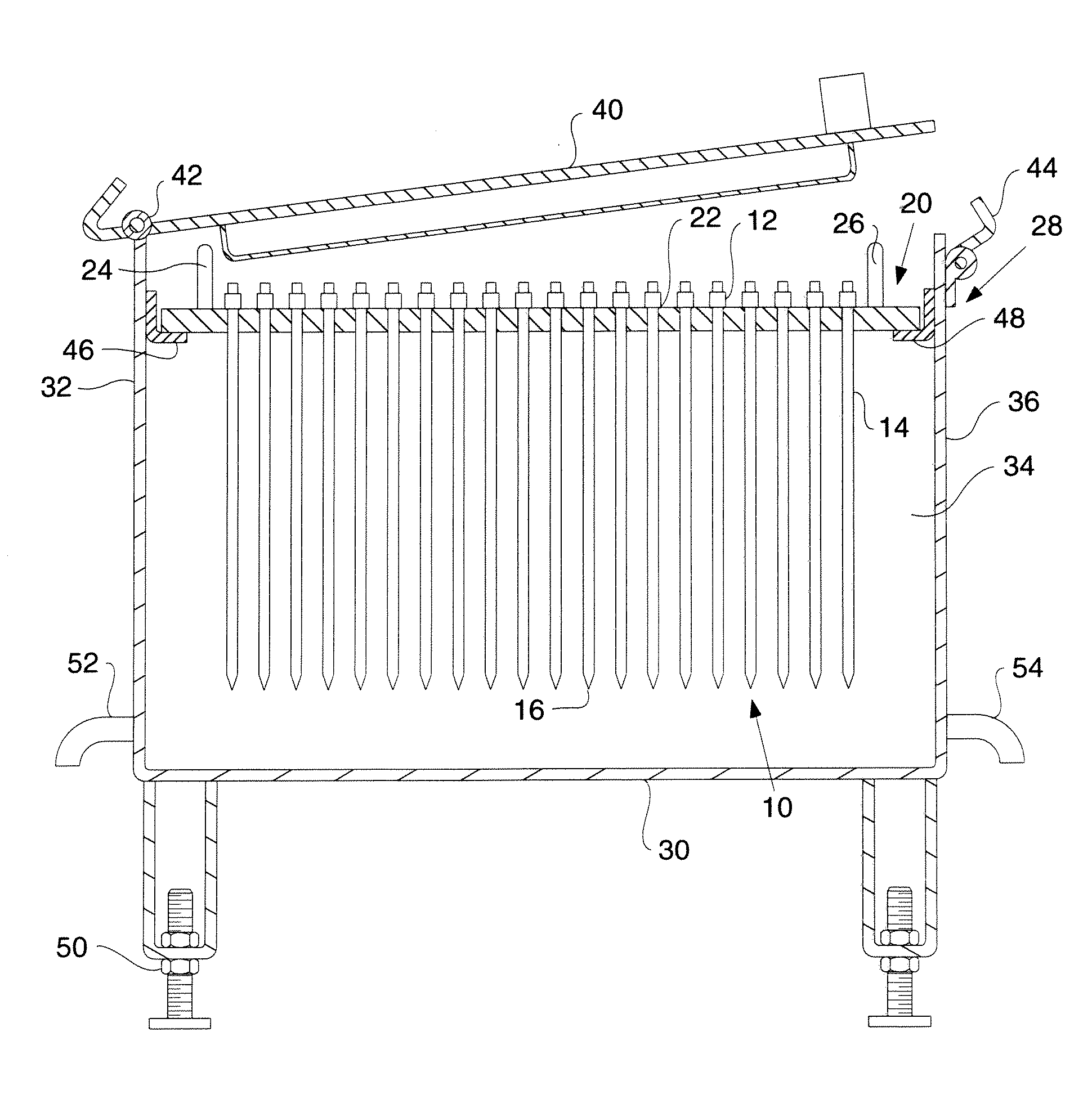

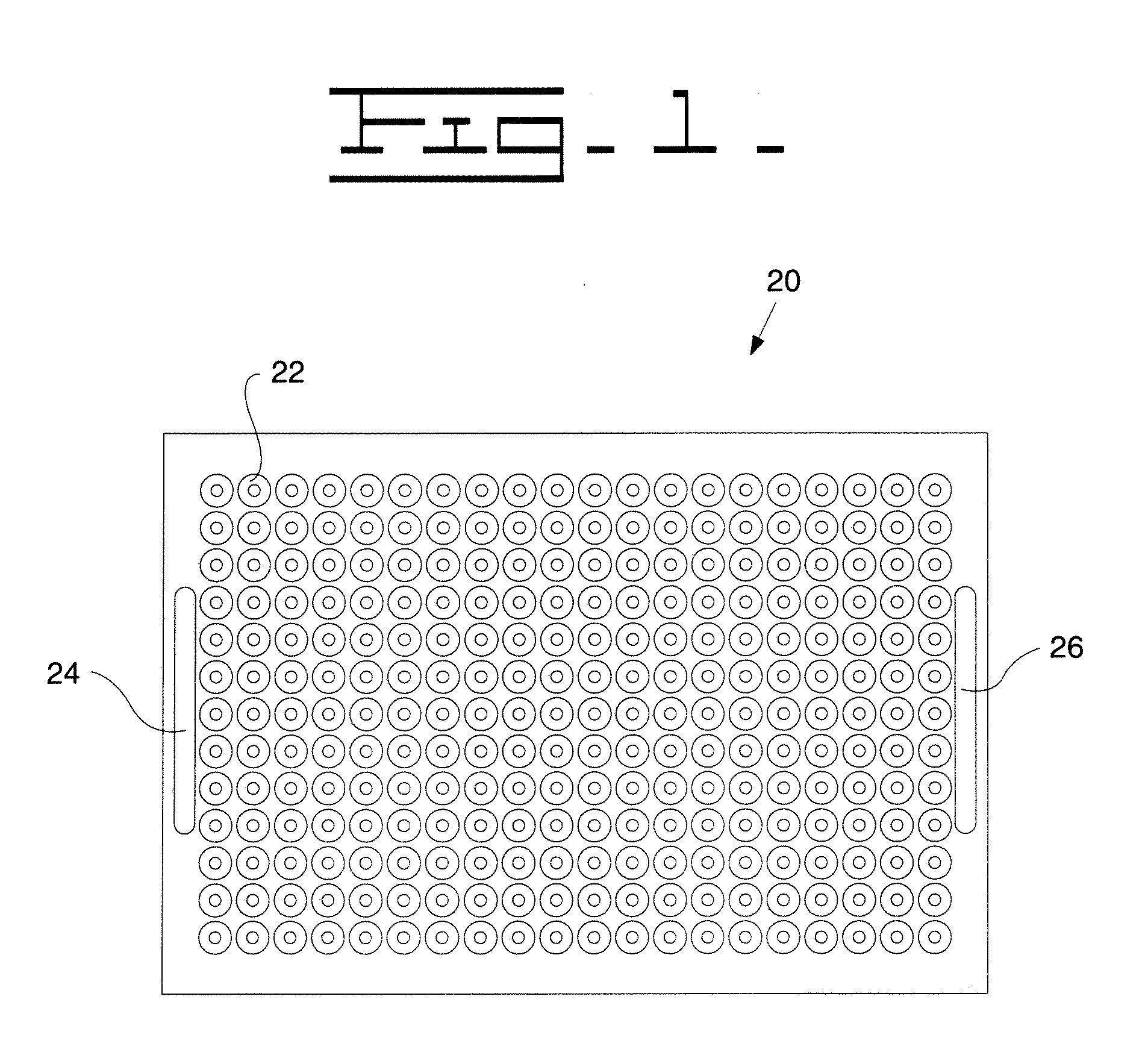

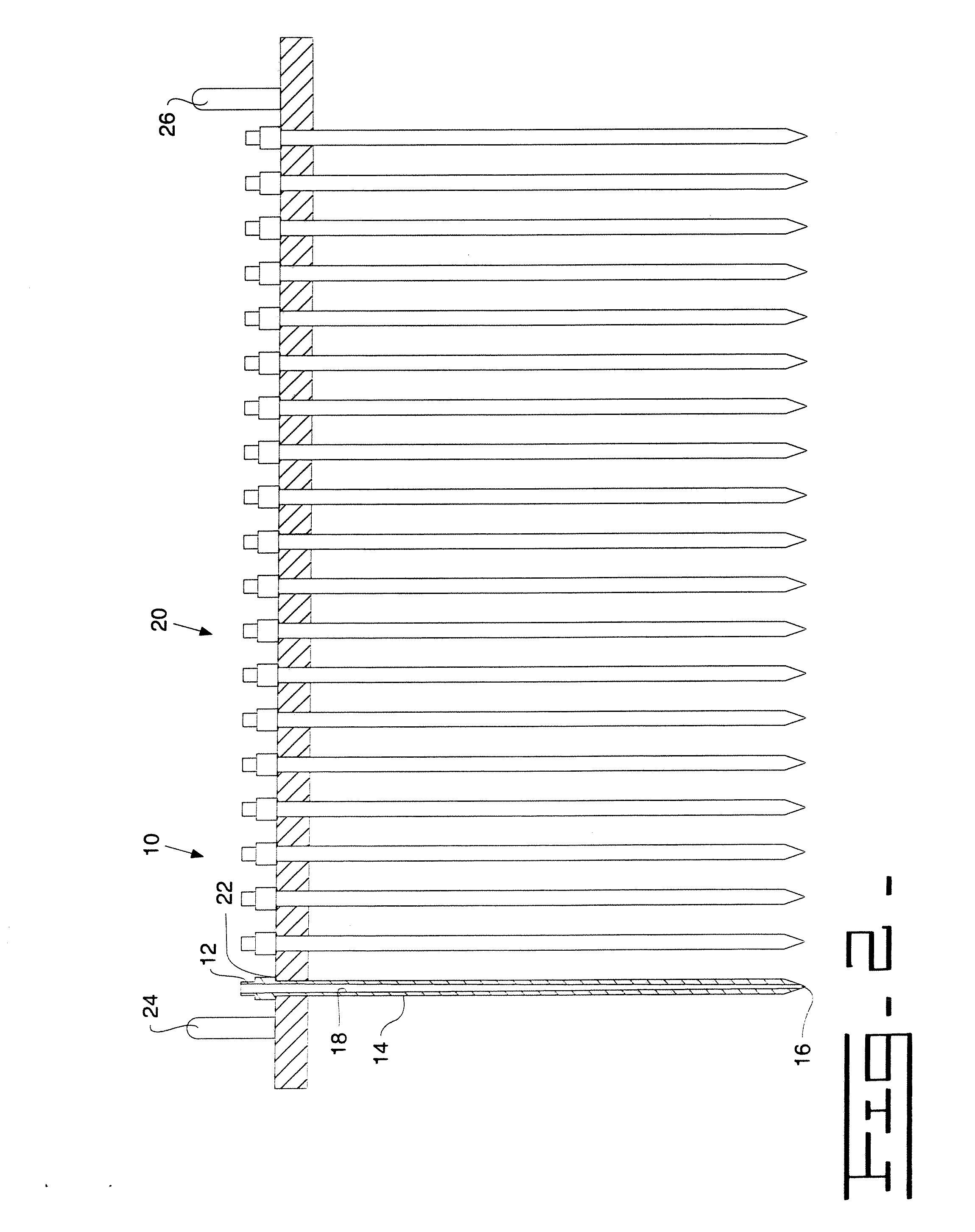

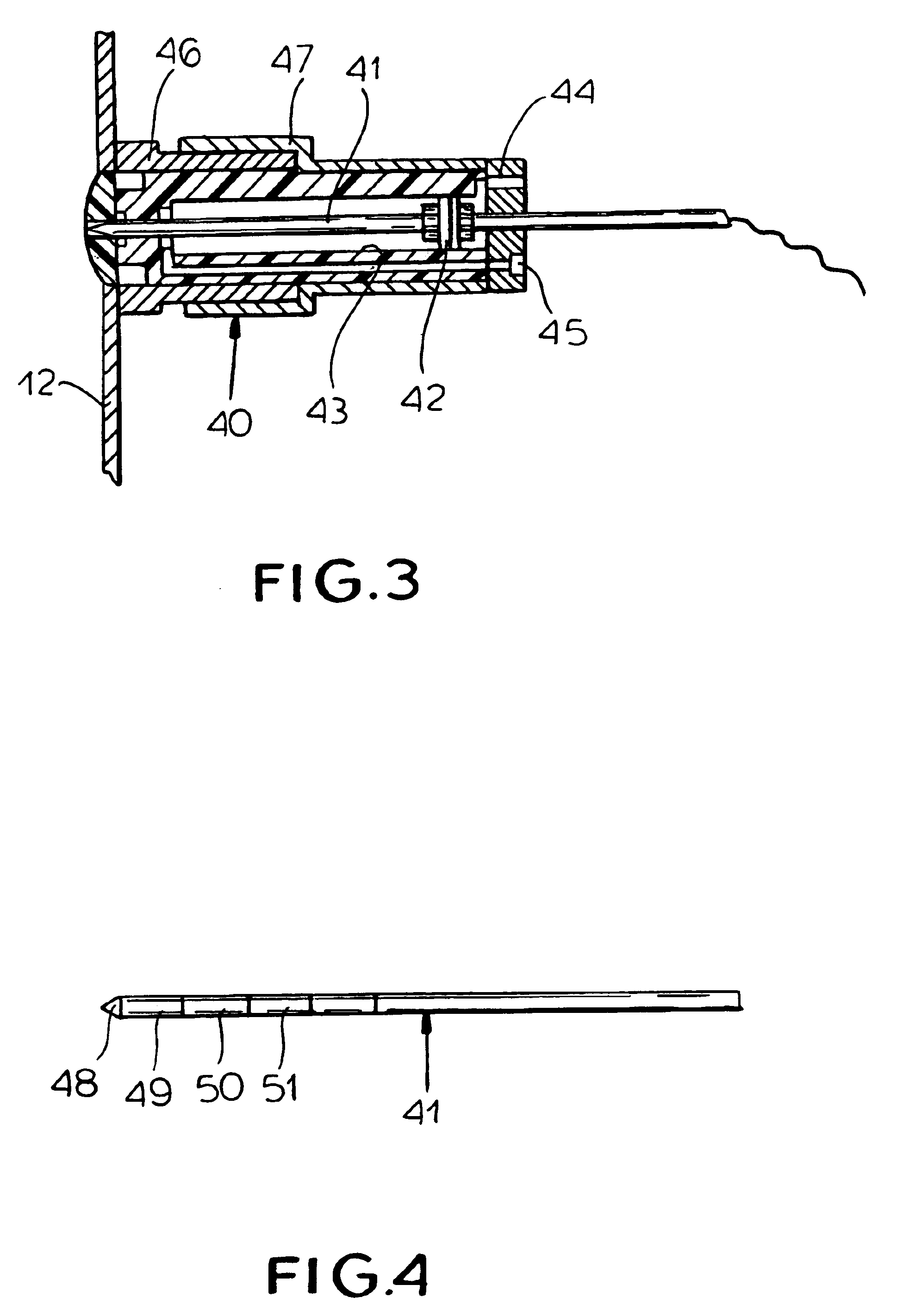

Apparatus for injecting fluid into meat products

InactiveUS7302885B2Easy to disperseIncrease in sizeGrain huskingGrain polishingSyringe needleBiomedical engineering

A method for injecting fluid into meat products comprises taking a plurality of hollow fluid injection needles having sharpened discharge ends, and connecting the needles to a source of pressurized liquid; penetrating the sharpened ends of the needles into the product and thence withdrawing the same while discharging fluid into the product and vibrating the needles for a period of time while they are within the product to enlarge the size of a penetration hole within the product caused by the penetration of the needles to a size greater than the size of the needles to create at least a partial space around the needles to permit fluid from the needles to migrate into the spaces around the needles. The needles have a roughened outside surface.

Owner:STORK TOWNSEND BV

Method for backflushing injector needles

InactiveUS20050000550A1Hollow article cleaningMeat/fish preservation using liquidsMoistureBiomedical engineering

A method for cleaning a plurality of injector needles is disclosed. The method comprises exposing the plurality of injector needles to a cleaning solution, removing the plurality of injector needles from the cleaning solution, and exposing simultaneously the hollow interior shaft of each injector needle to a gaseous stream. The gaseous stream removes any moisture and fine particles that remain in the plurality of injector needles after the injector needles are cleaned. In one embodiment the injector needle's hollow interior shaft is of a lesser diameter at the tip than at the head of the injector needle. The gaseous stream is directed into the injector needle through the tip and exits the needle through the head, thereby simultaneously backflushing the injector needles.

Owner:TYSON FRESH MEATS

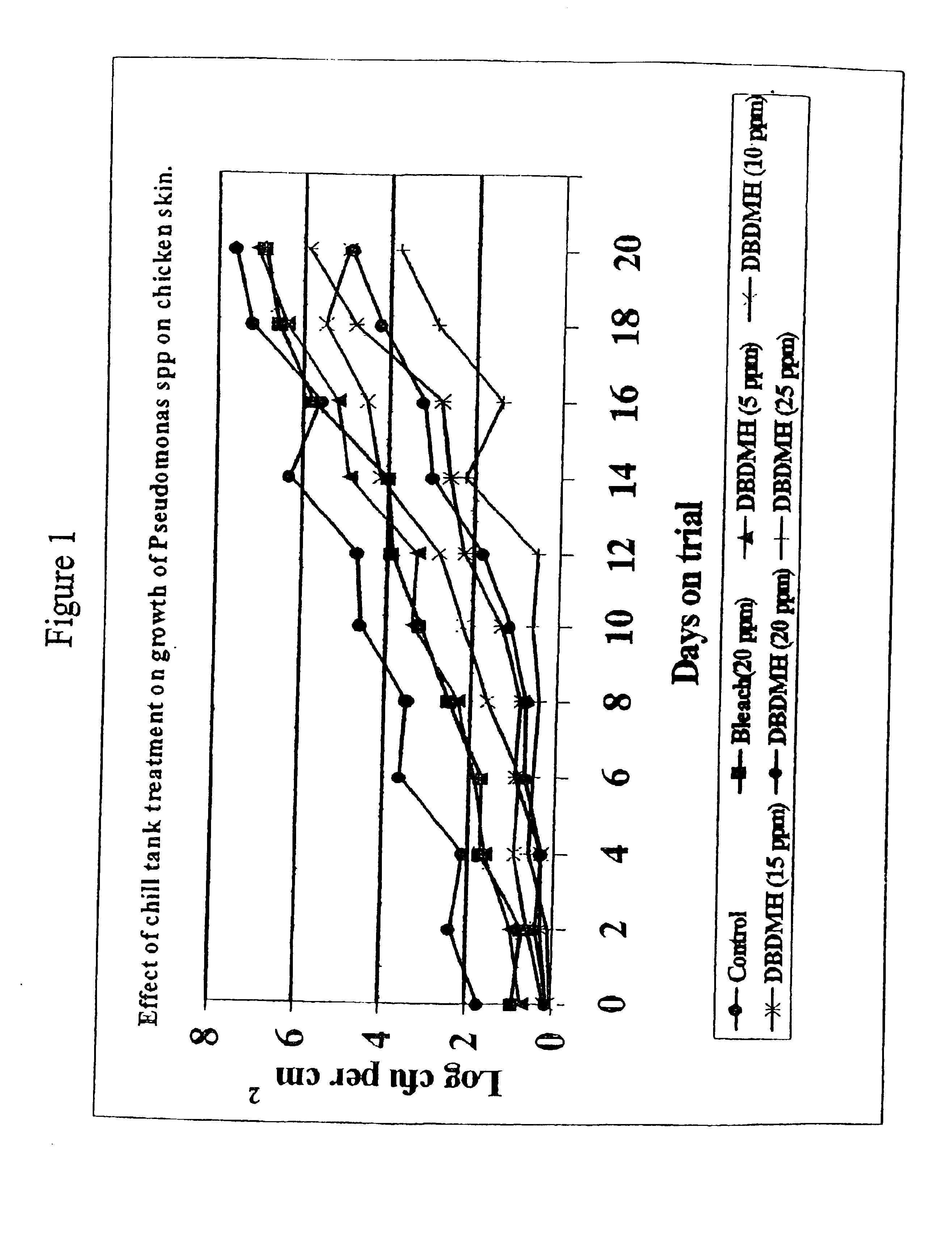

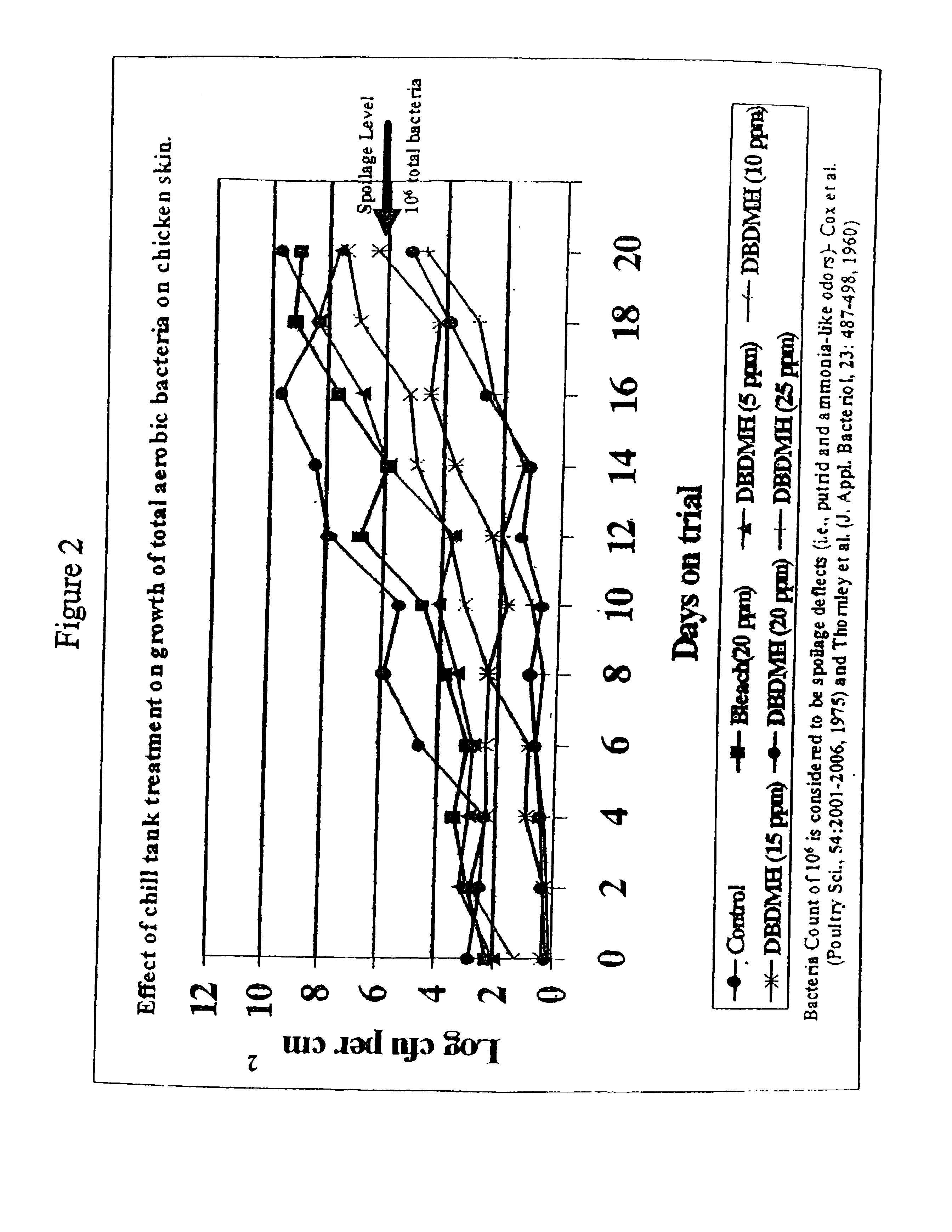

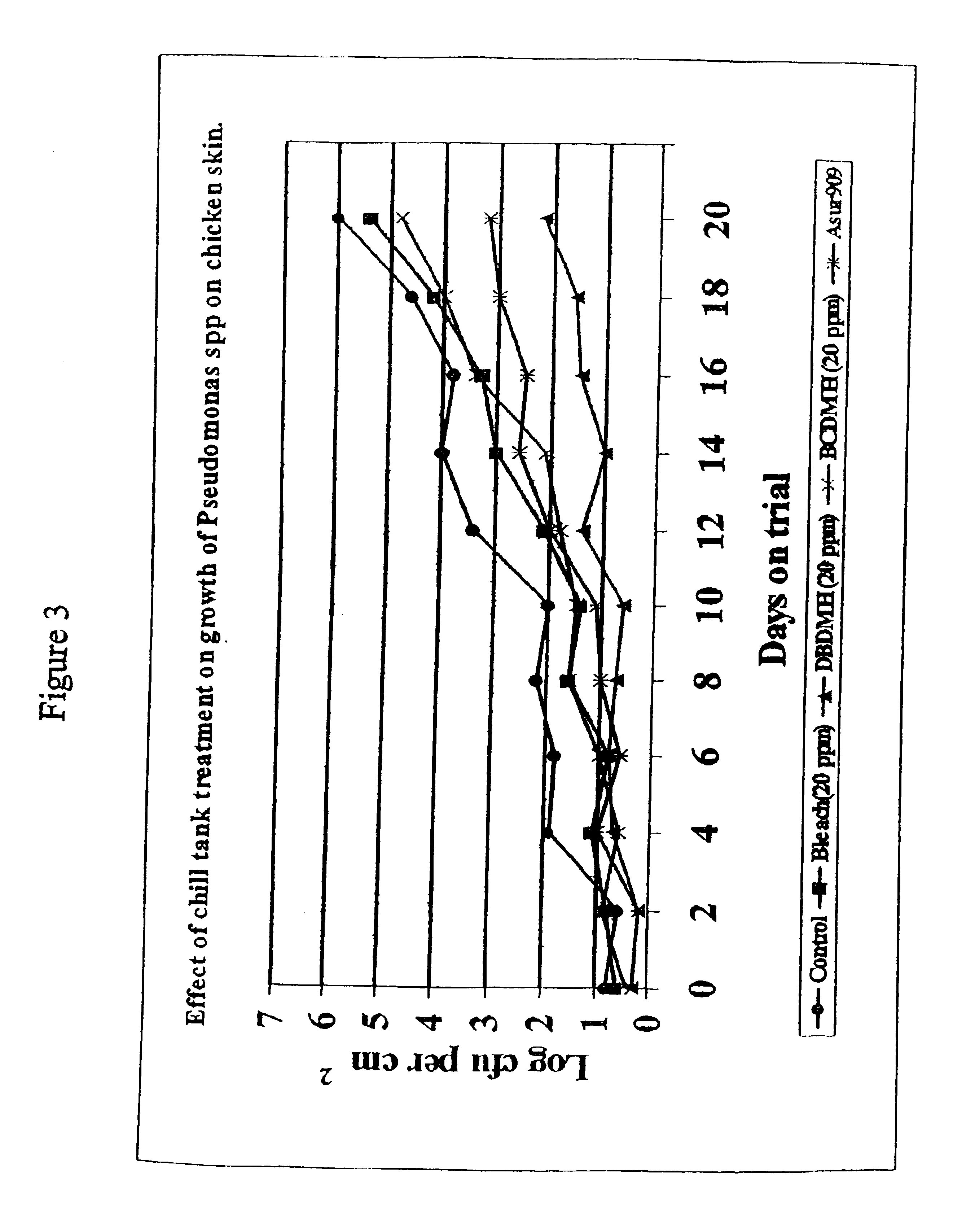

Microbiological control in poultry processing

InactiveUS6986910B2Produced economicallyLow costBiocideDough treatmentBiotechnologyEffective microorganism

Owner:ALBEMARLE CORP

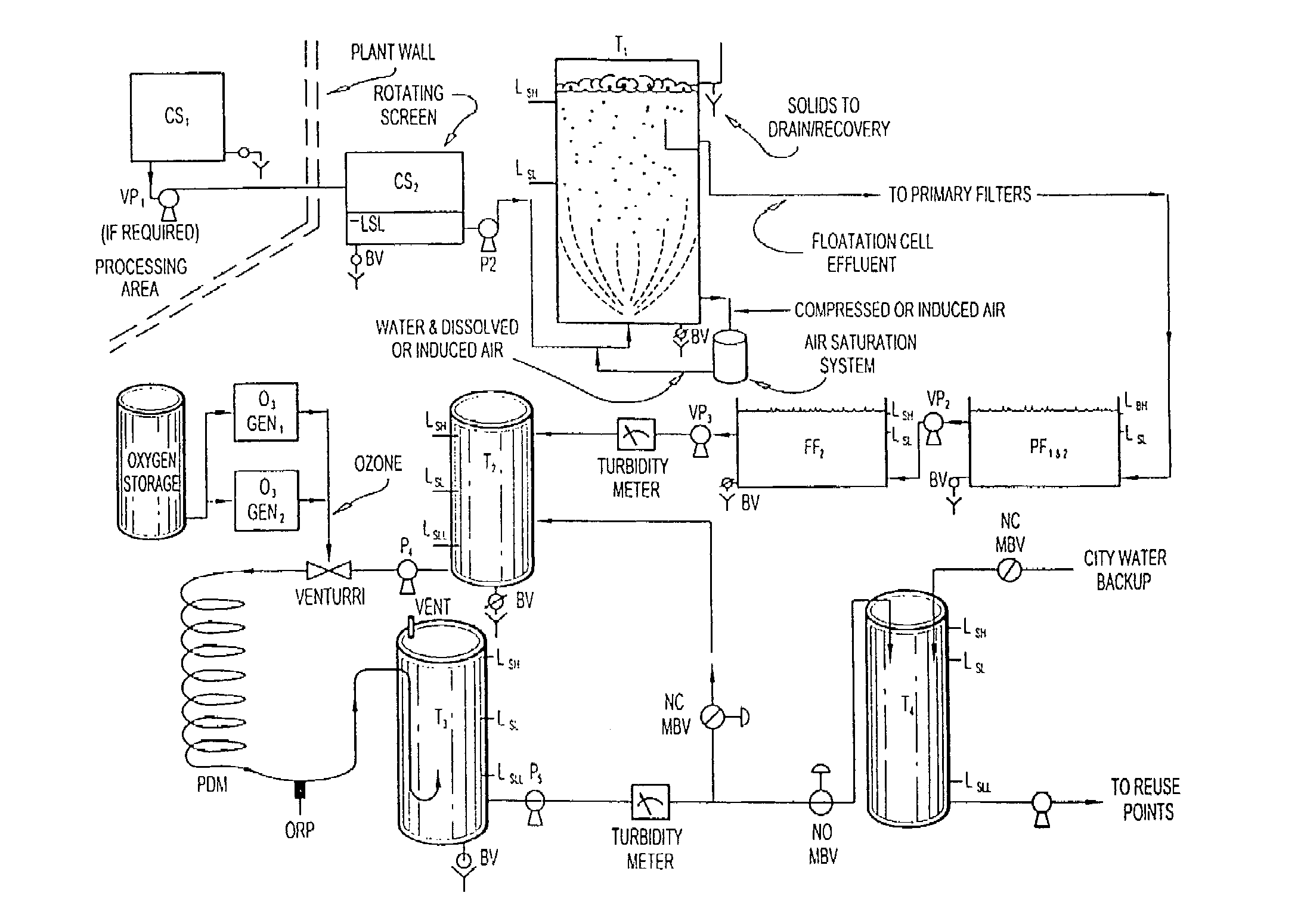

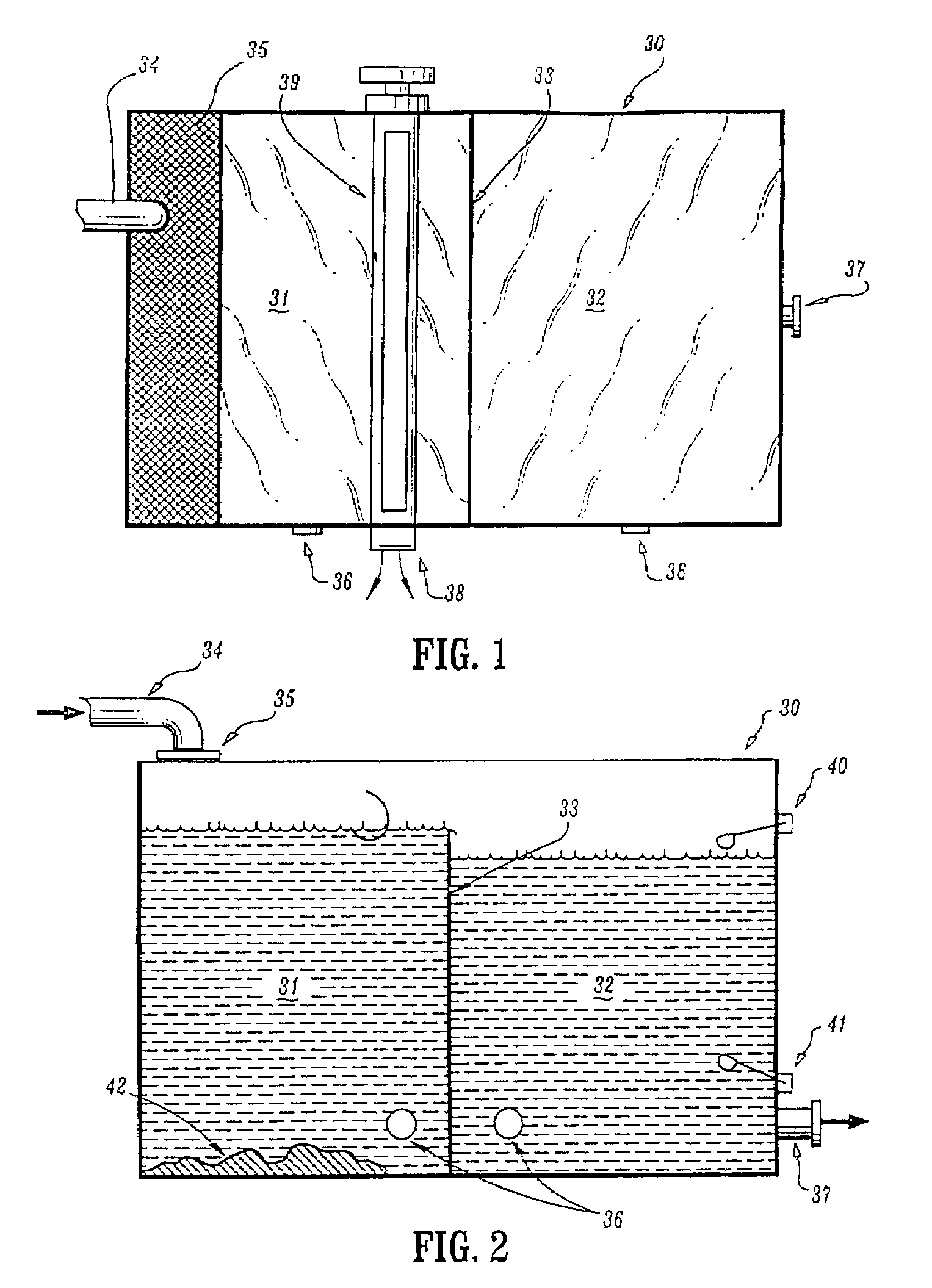

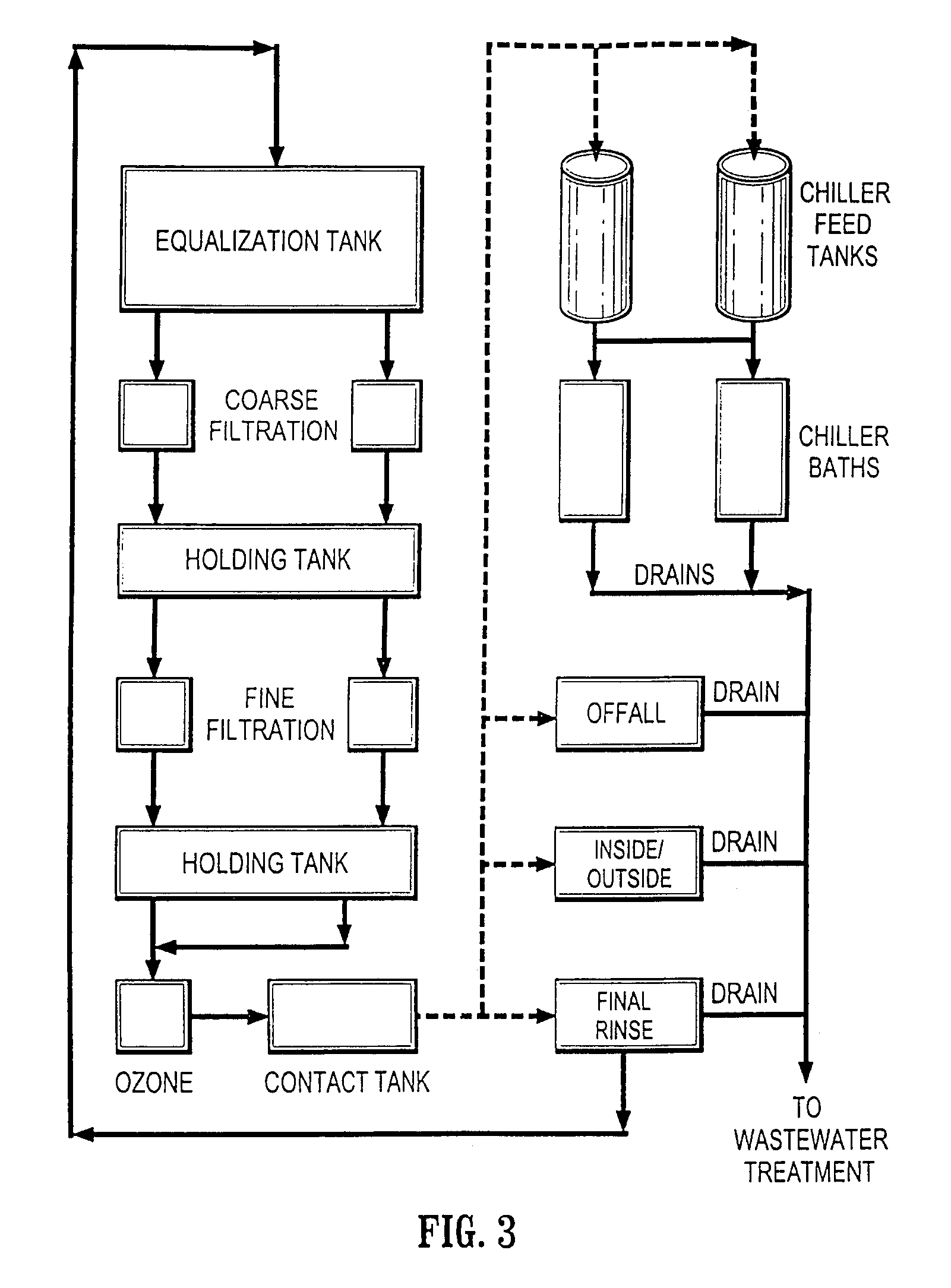

Poultry processing water recovery and re-use process

InactiveUS7077967B2Shorten the counting processImprove food safetyLoose filtering material filtersWater/sewage treatment by neutralisationWater useOil and grease

The inventions of the present disclosure are directed to processes designed to recover water used in certain aspects of the processing of poultry, treat the recovered water to remove solids, fats, oils and greases, animal proteins and pathogenic organisms and to reuse the treated water for poultry processing operations. The processes described herein reduce bacteria and microorganisms associated with the poultry and reuse water. The present disclosure can be employed with an approach that includes unexpected positive results of reacting ozone and chlorine with water being treated for reuse to generate hypochlorous acid and / or other effective biocides. Ozone reacts with fats, oils, and greases, dissolved in the reuse water, to produce specific surface-active agents and surfactants which reduce the surface tension of the water which it is dissolved. The combination of these surface-active agents and surfactants and the biocides cause an extraordinary release and destruction of bacteria from the poultry carcass as well as the reuse water.

Owner:ZENTOX CORP

Method and apparatus for treatment of food products

ActiveUS20070020366A1Reduce inhibitionReduce and inhibit microbial populationWrappers shrinkagePackage sterilisationRest positionEngineering

Method of treating a food product in a container to reduce or inhibit a microbial population on the food product, involving applying to the container an antimicrobial solution (applied in an amount effective to reduce or inhibit the microbial population), and placing the food product in the container. Also a system for treating food products, involving a bagging system, a spray system, and a rotating assembly for returning a spray wand to a resting position.

Owner:UNITED STATES OF AMERICA

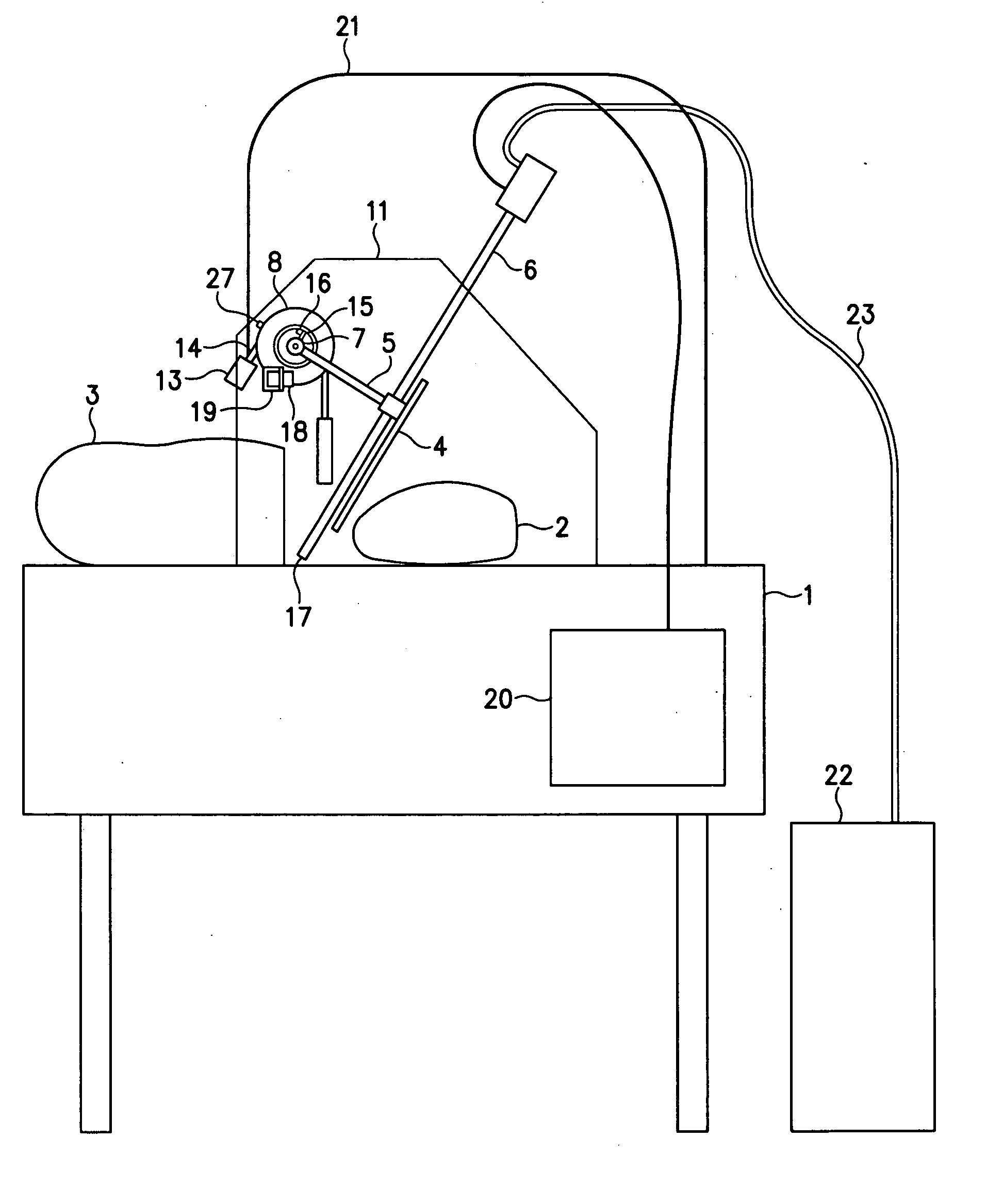

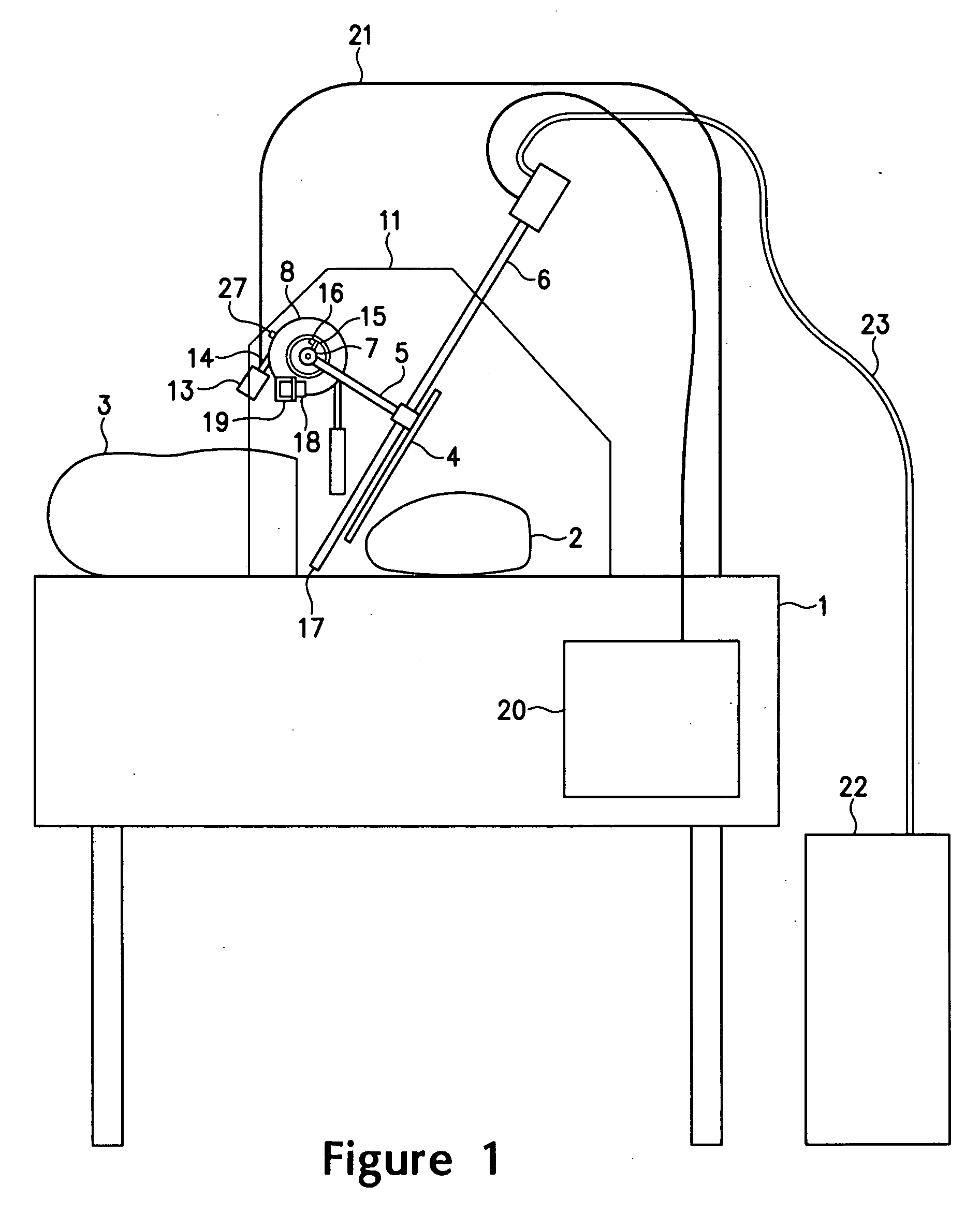

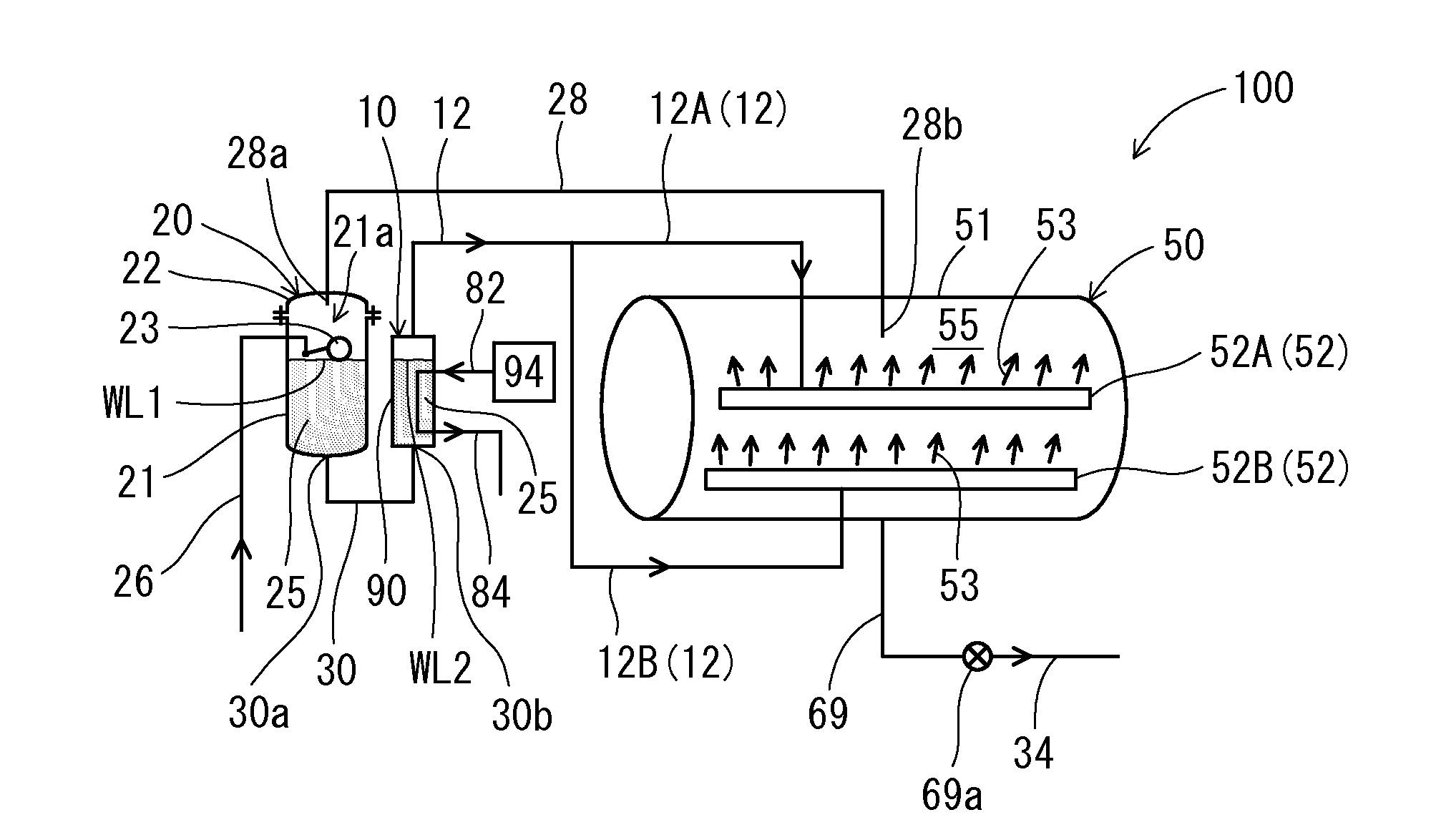

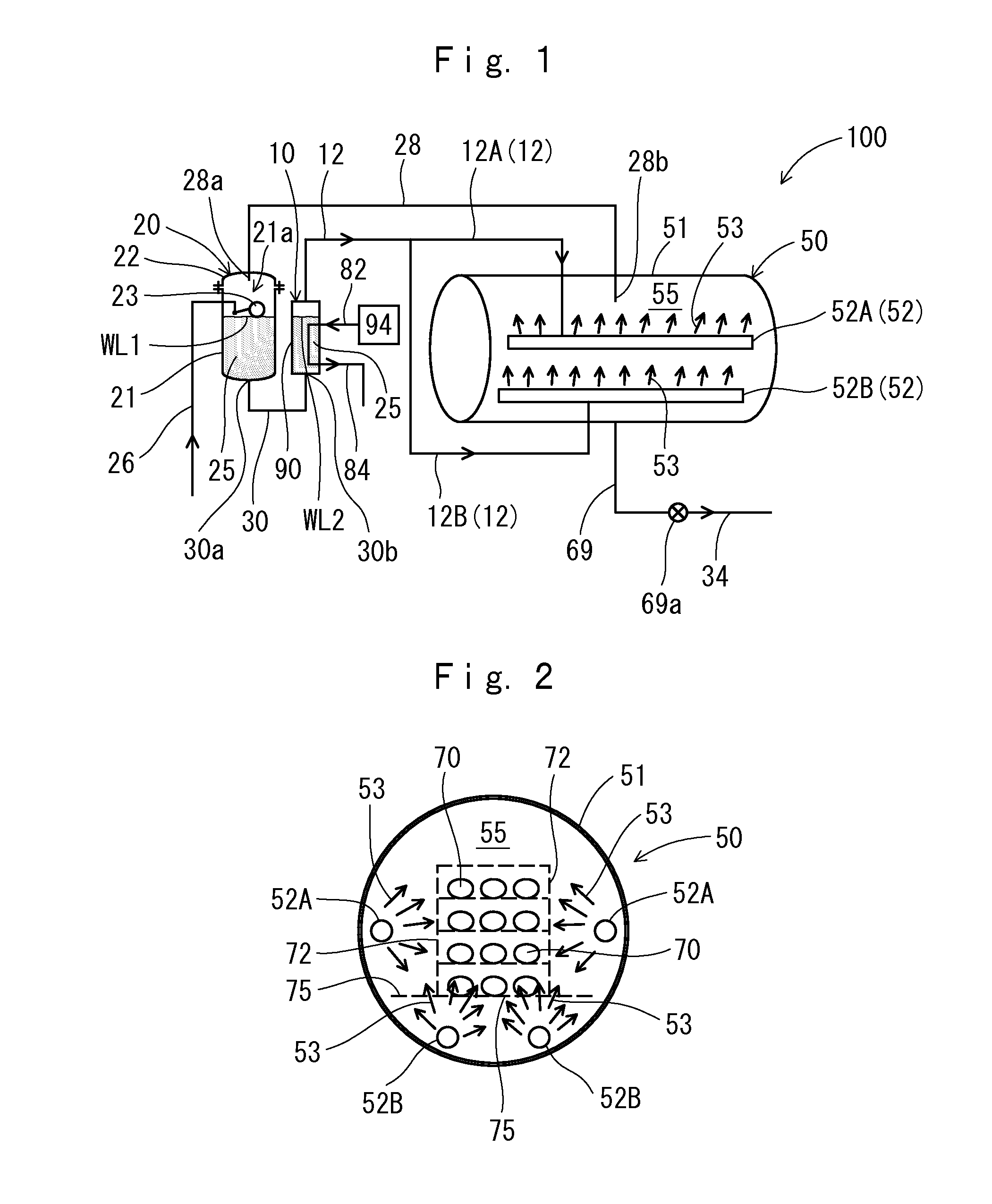

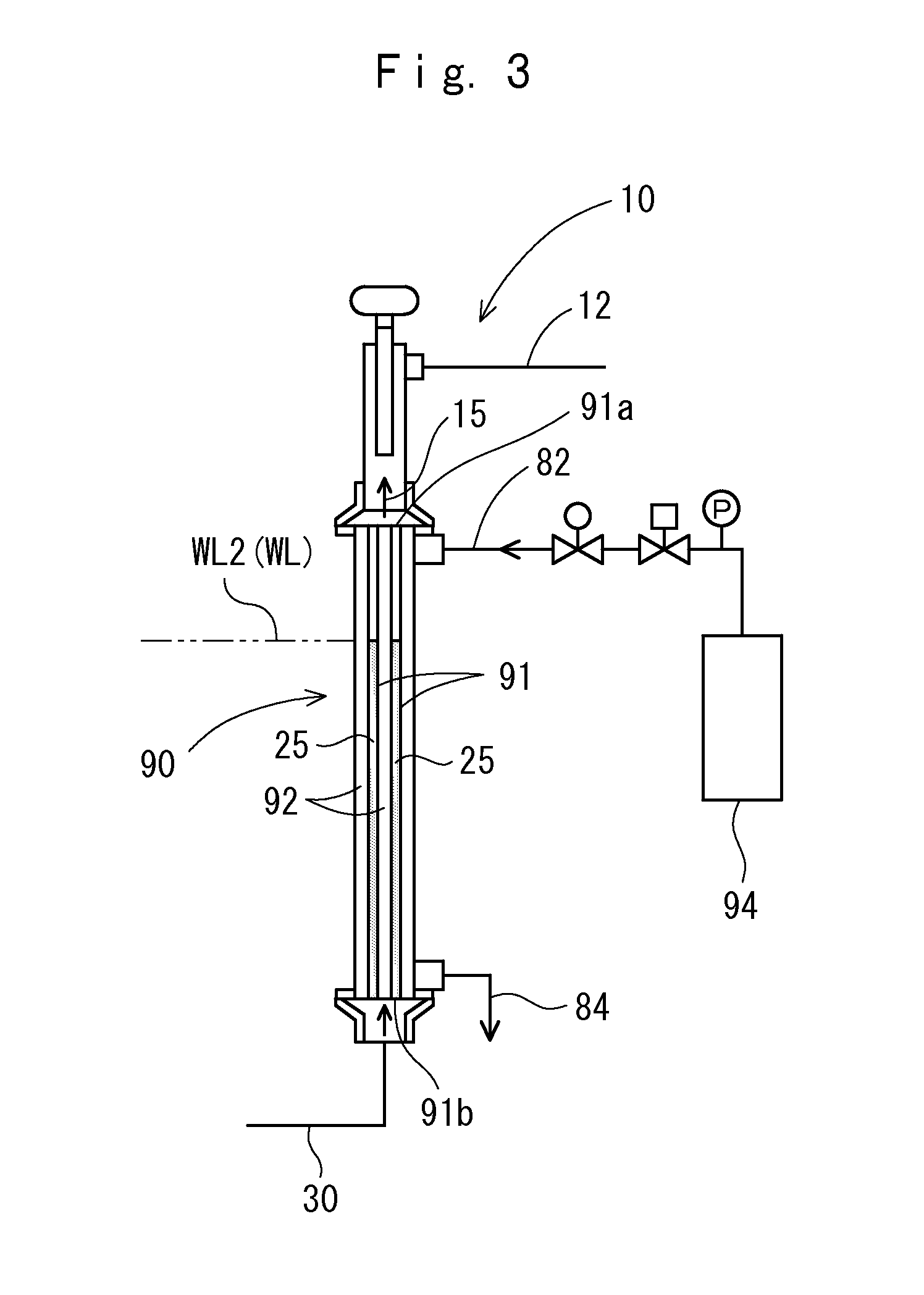

Retort sterilization device, heating device, heat sterilization method, and heat treatment method

ActiveUS20130071546A1Improve energy efficiencySuppress uneven heatingTea extractionTea substituesEngineeringSteam generation

A retort sterilization device includes a water steam generation device for generating water steam and a heating pot, connected to the water steam generation device, for accommodating retort food. The water steam generation device includes a heat exchanger for performing heat exchange between liquid flowing in a liquid path and heating vapor flowing in the vapor path. A top end of the liquid path of the heat exchanger is connected via a water steam supply pipe to a water steam ejection section located in an internal area of the heating pot. The heat exchanger is connected to a liquid container. A bottom end of the liquid path of the heat exchanger is connected to the liquid container via a communicating tube. The liquid container is coupled to the heating pot.

Owner:TOMODA SELLING & SAILING +3

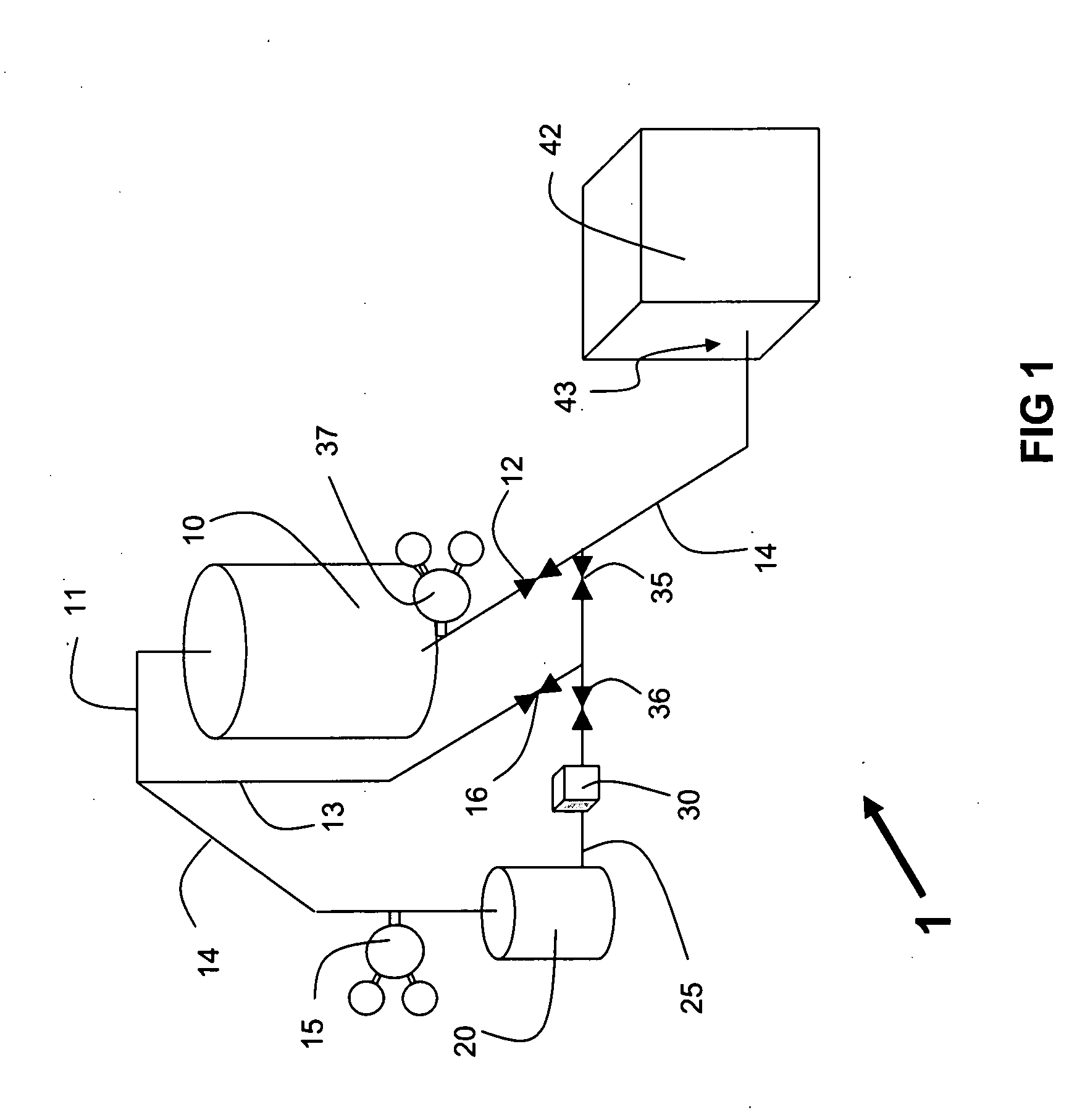

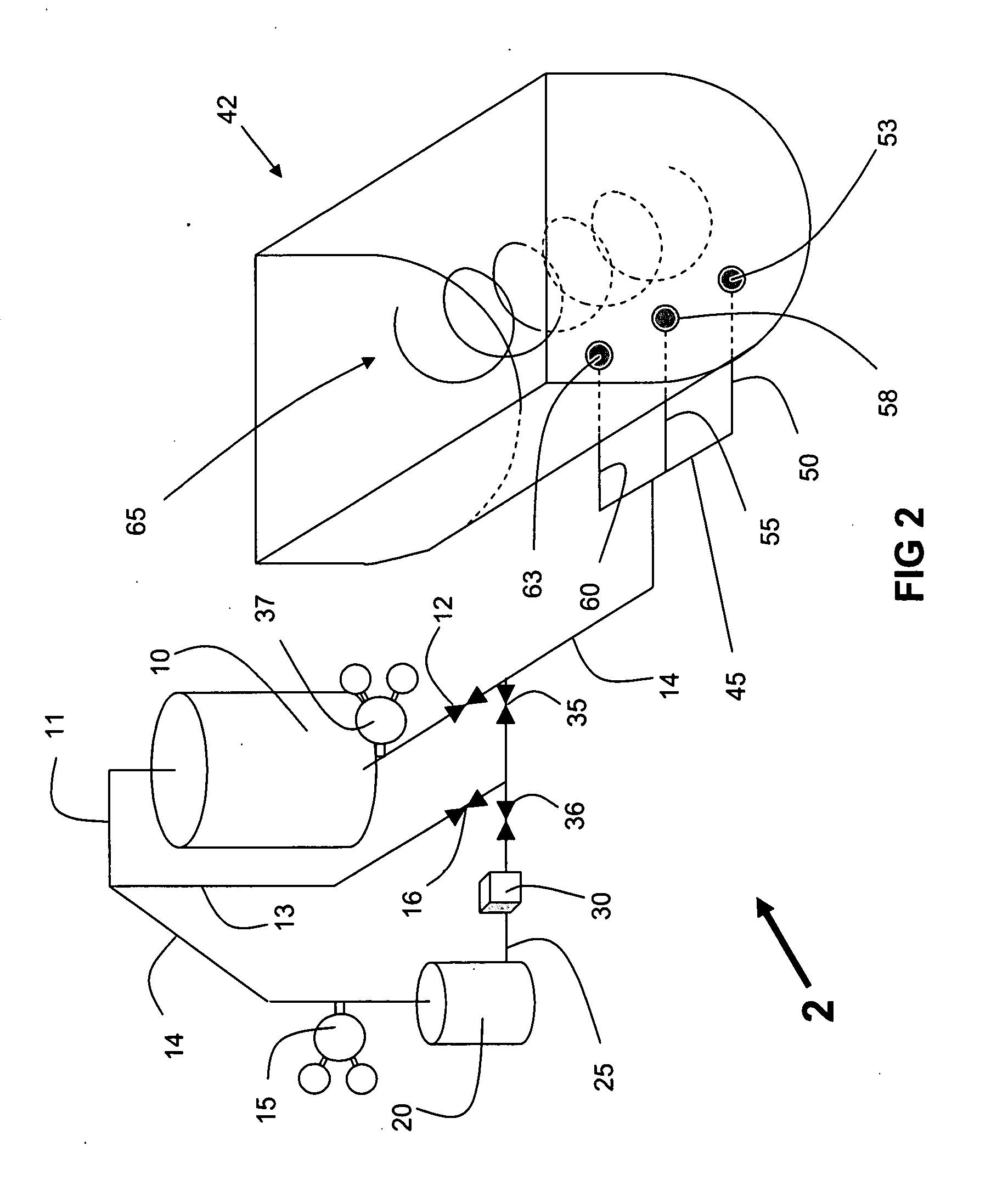

Application System With Recycle and Related Use of Antimicrobial Quaternary Ammonium Compound

ActiveUS20090196967A1Safe and effective and cost efficient recyclingSimple materialWater treatment parameter controlSpecific water treatment objectivesAmmonium compoundsChemical compound

An antimicrobial application system is disclosed, comprising an antimicrobial application unit and a recycle unit. An initial, dilute antimicrobial composition is prepared. The composition is provided to the antimicrobial application unit and applied to workpieces, such as raw poultry. After application to the workpieces, the composition is returned to the recycle tank. The concentration of the antimicrobial in the recycle tank is monitored, and additional antimicrobial is automatically added if the concentration of the antimicrobial in the composition falls below a desired amount. The composition is periodically diverted to a capture tank, and the antimicrobial is selectively removed from the composition. The removed antimicrobial and remaining composition are then disposed of in appropriate manners. The antimicrobial is preferably a quaternary ammonium compound, is more preferably an alkylpyridinium chloride, and is most preferably cetylpyridinium chloride.

Owner:SAFE FOODS CORP

Method and apparatus for evacuating pockets of injected fluid in meat products

Owner:STORK TOWNSEND BV

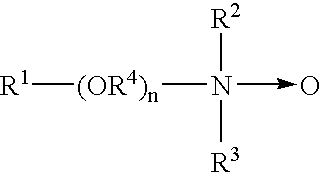

Methods for washing carcasses, meat, or meat products with medium chain peroxycarboxylic acid compositions

ActiveUS20050153031A1Reduce Microbial ContaminationReduce microbial countMilk preservationAnimal feeding stuffCarboxylic acidChemistry

The present invention relates to methods for reducing microbial contamination on carcass, meat, or meat product; or on surfaces used in processing the carcass, meat, or meat product; employing compositions including medium chain peroxycarboxylic acid, and to the compositions. The methods include applying a medium chain peroxycarboxylic acid composition to carcass, meat, meat product or surface.

Owner:ECOLAB USA INC

Method and composition for washing poultry during processing

InactiveUS20050118940A1Reduce Microbial ContaminationHigh degreeBiocideAlcoholic beverage preparationBiologyMicrobial contamination

The present invention relates to compositions including peroxyacetic acid and peroxyoctanoic acid and methods for reducing microbial contamination on poultry. The methods include the step of applying a mixed peroxycarboxylic acid composition to poultry.

Owner:ECOLAB USA INC

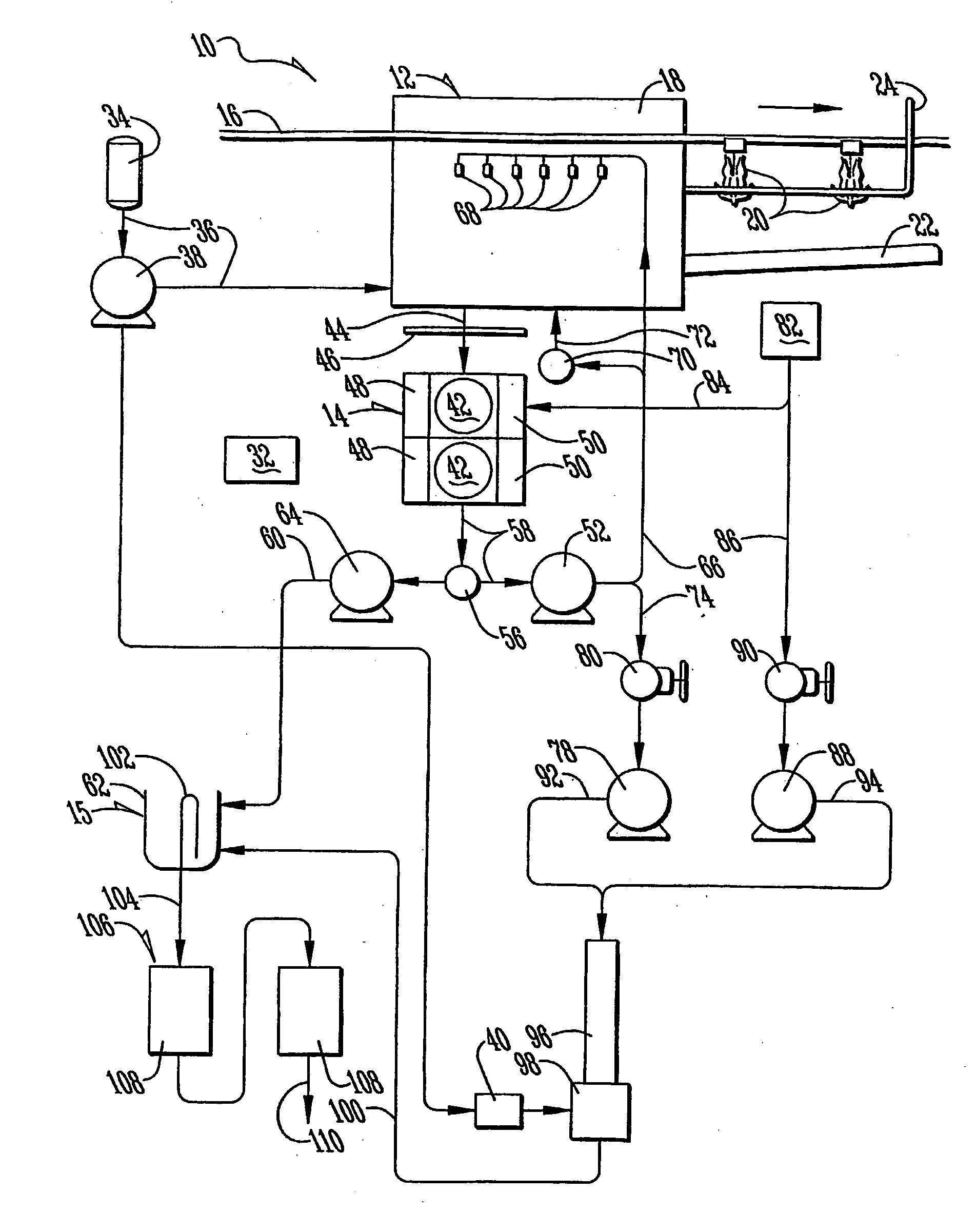

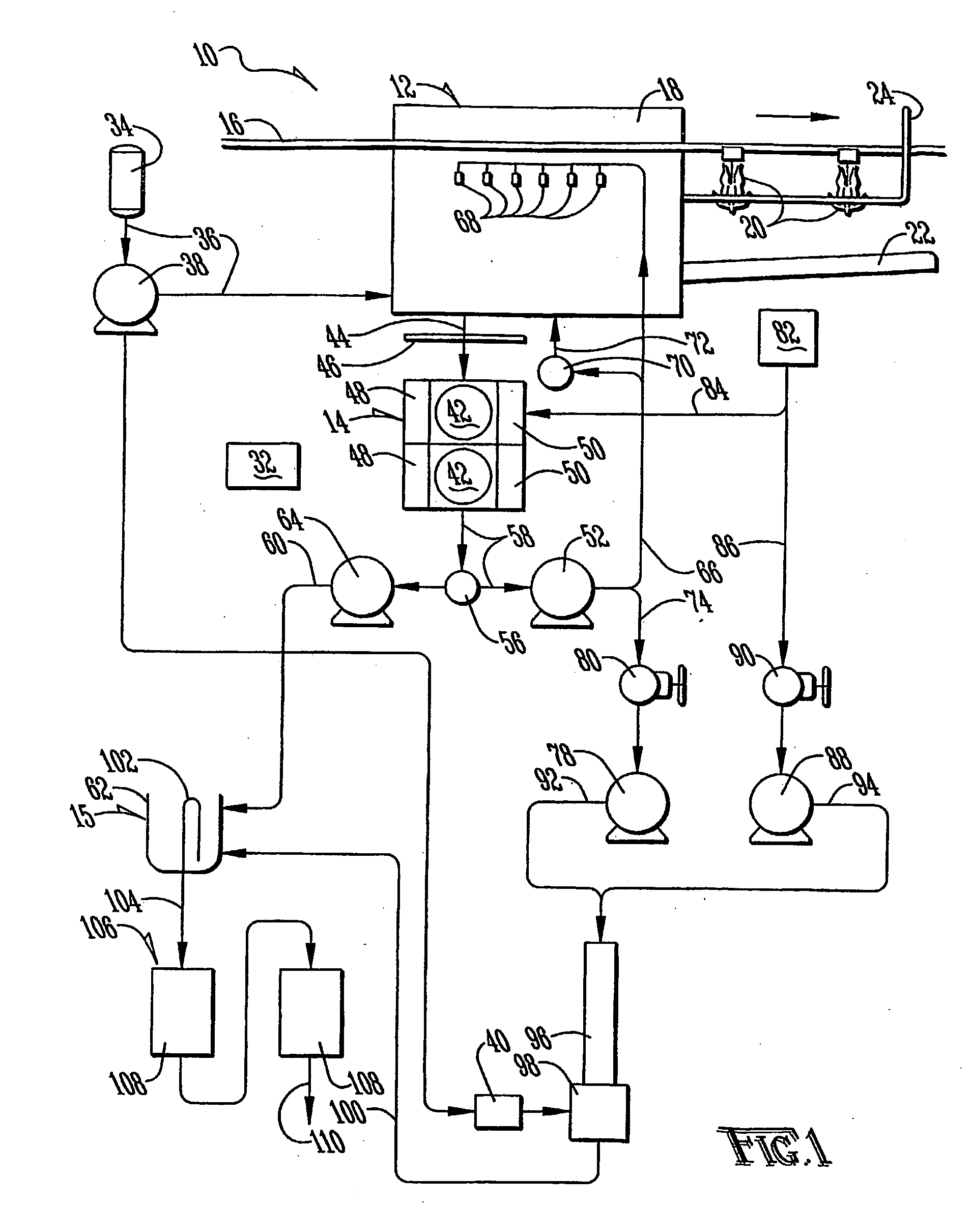

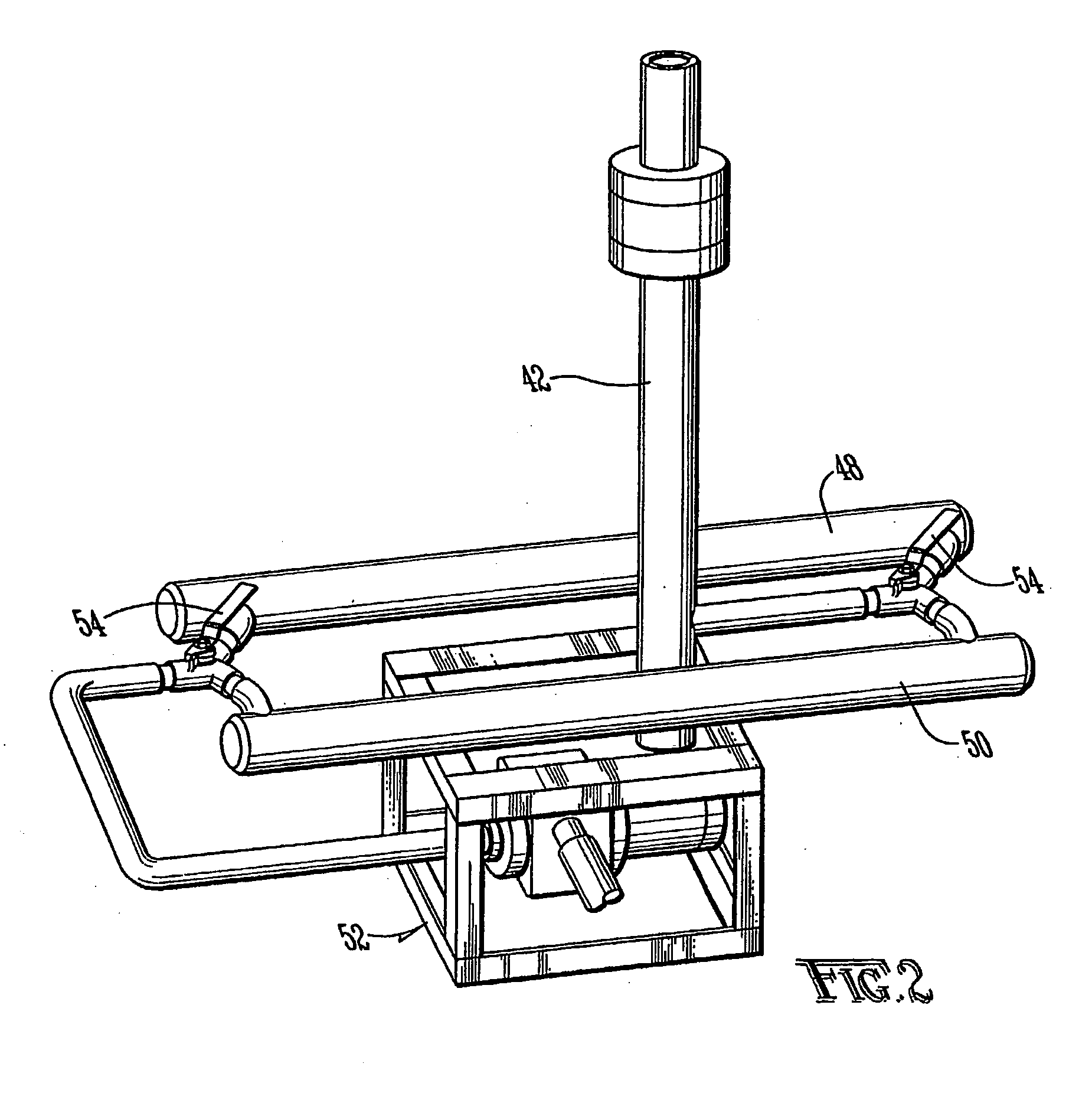

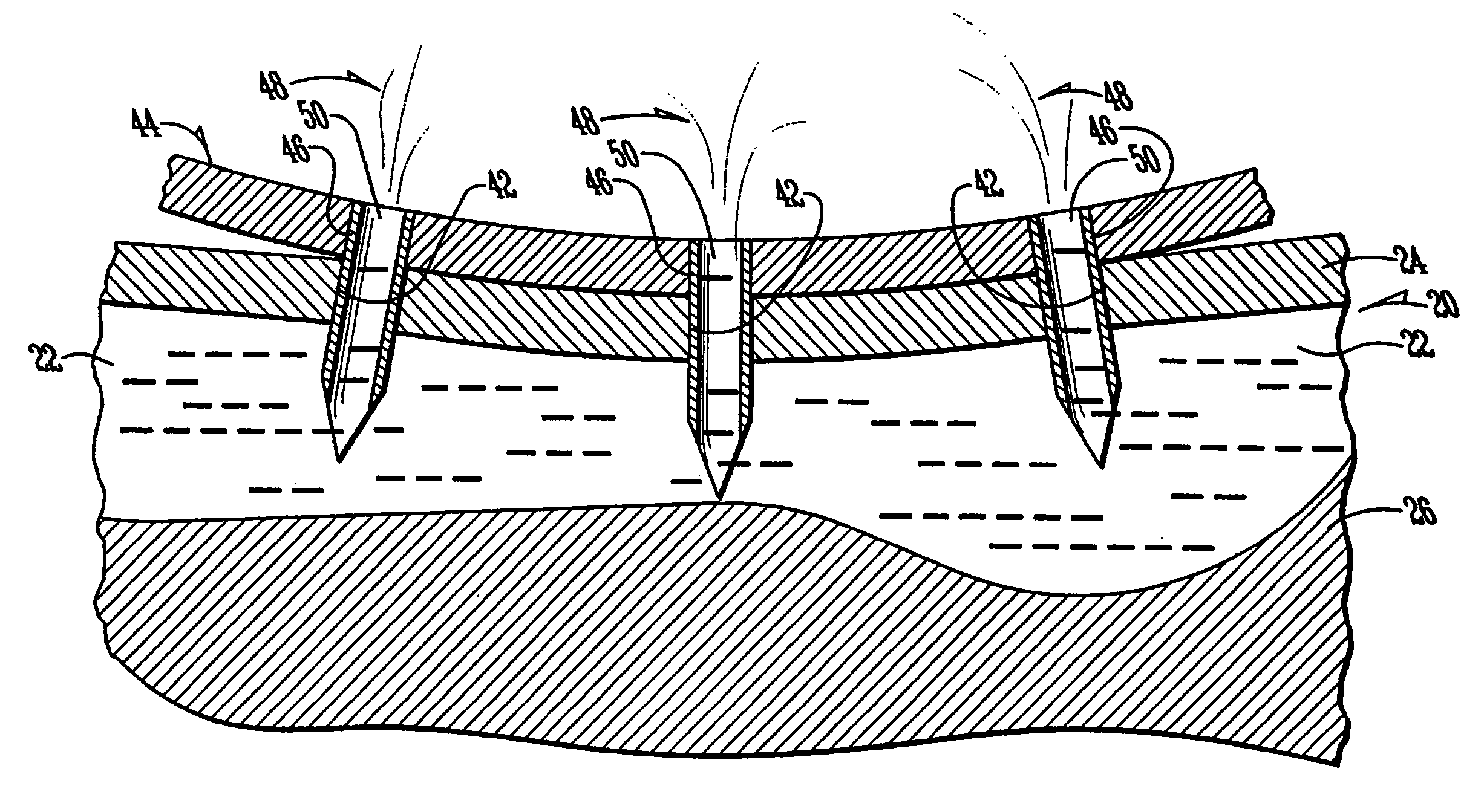

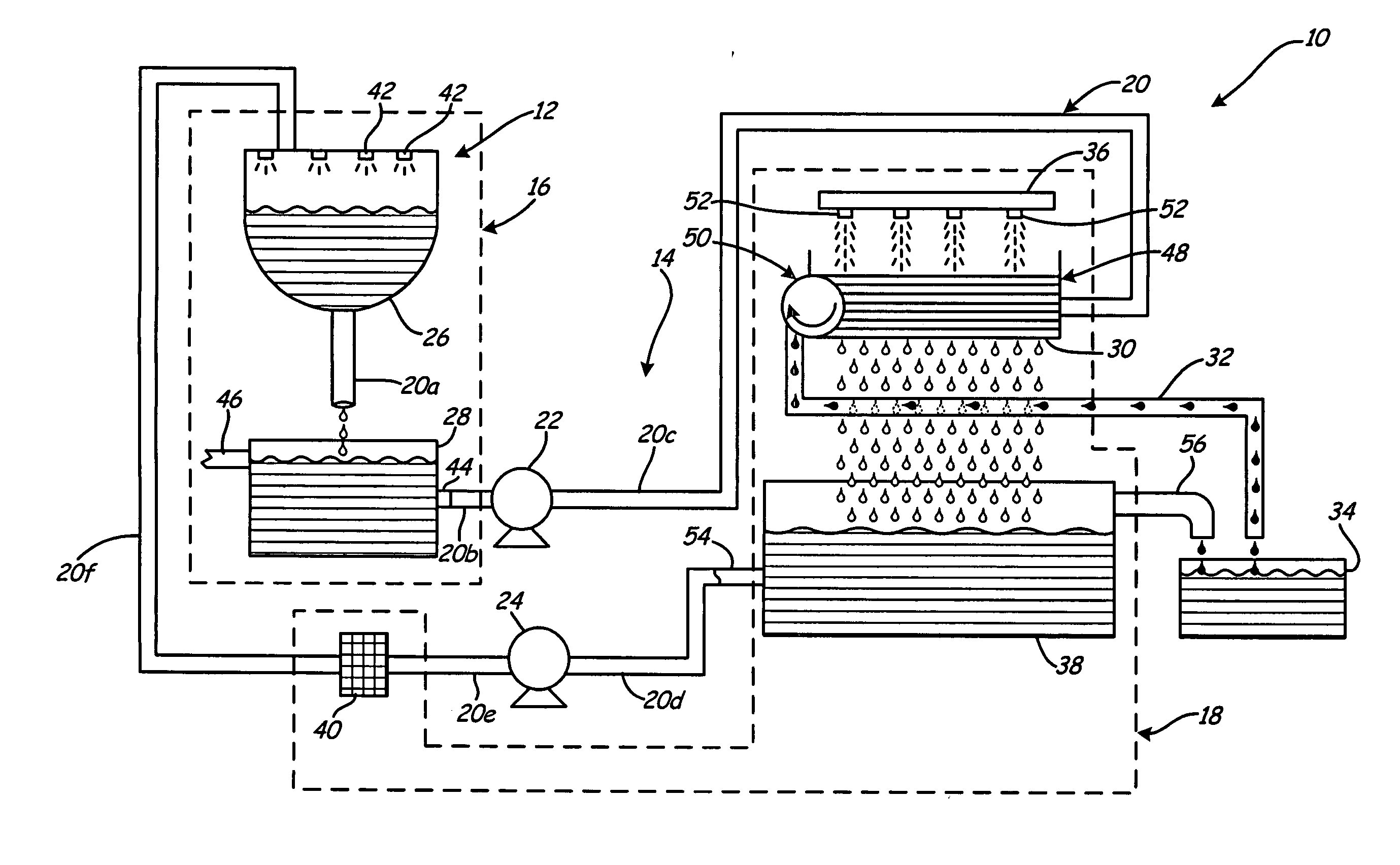

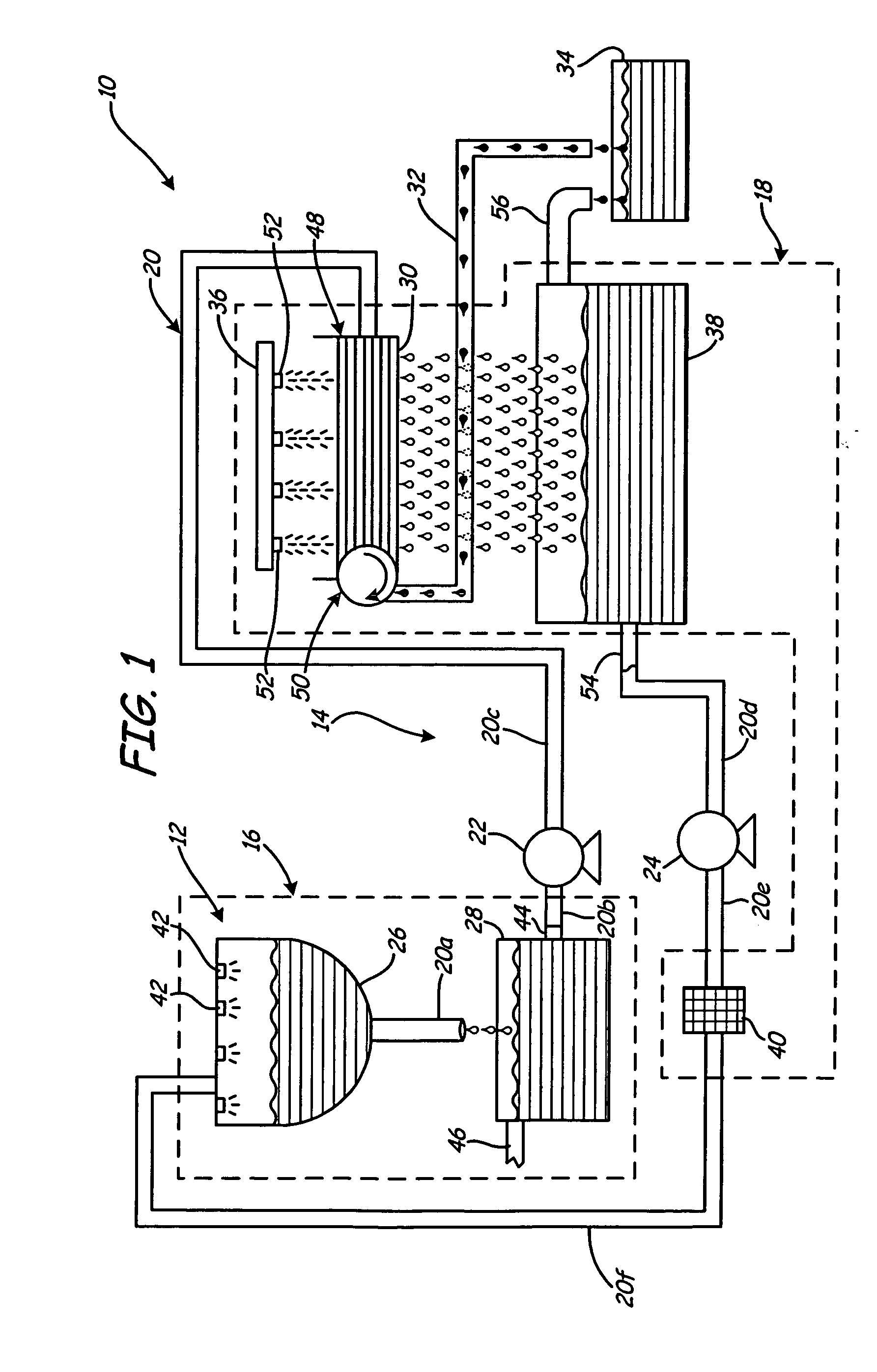

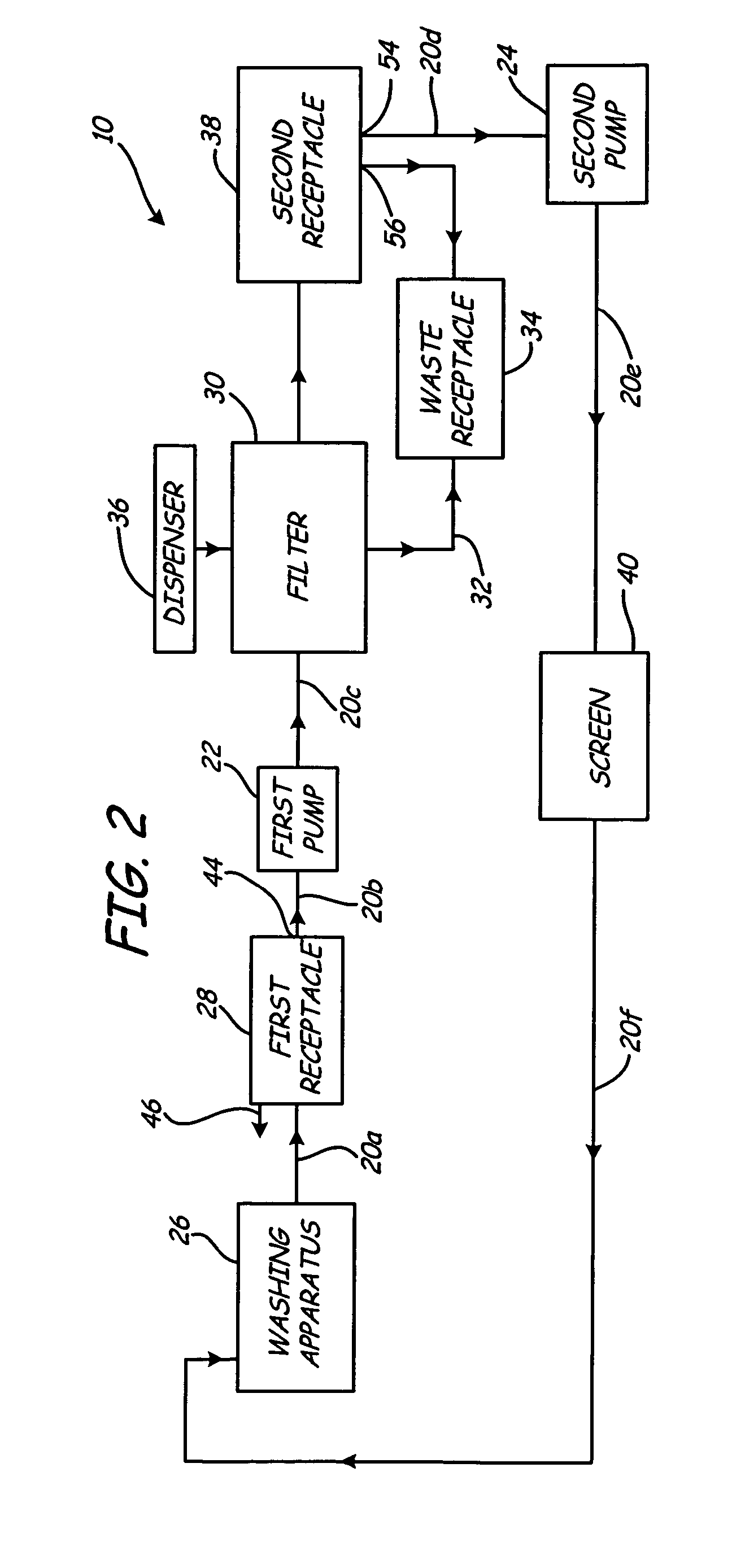

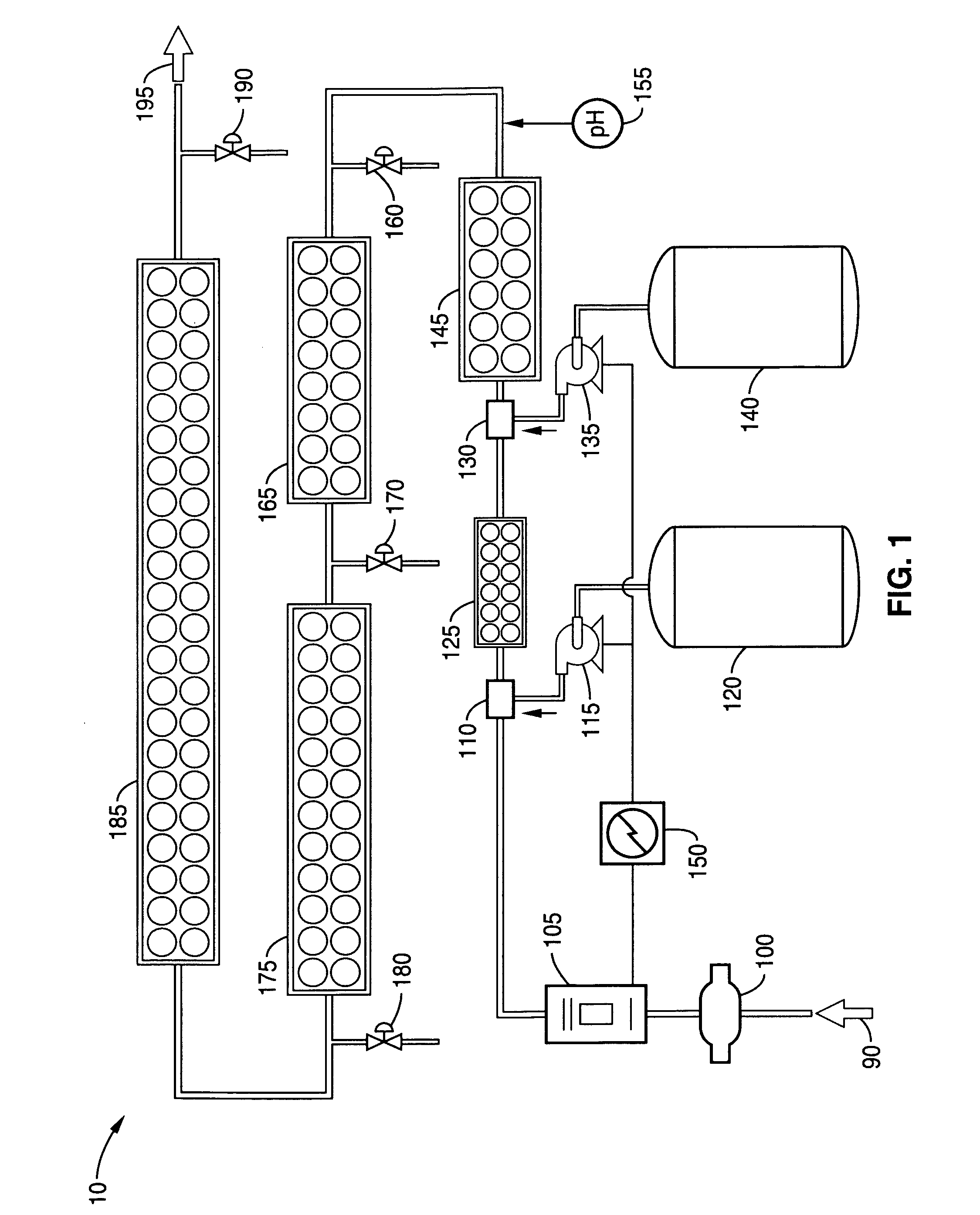

System and method for on-site reclamation, reconditioning, and reapplication of poultry processing water

InactiveUS20070084802A1Fatty/oily/floating substances removal devicesSpecific water treatment objectivesWater cyclingReapplication

A system of the present invention provides on-site reclamation, reconditioning, and re-use of poultry processing water. The system is connectable to a washing apparatus and comprises a first receptacle, a filter, a dispenser, a channel, a second receptacle, piping, and a plurality of pumps for circulating the processing water through the system. The processing water leaving the washing apparatus is collected in the first receptacle and pumped to the filter, where the processing water is filtered. As the processing water is being filtered, the dispenser dispenses an antimicrobial solution and water onto the filter. The debris filtered from the processing water is removed through the channel. The filtered processing water is then collected in the second receptacle prior to re-use.

Owner:ECOLAB USA INC

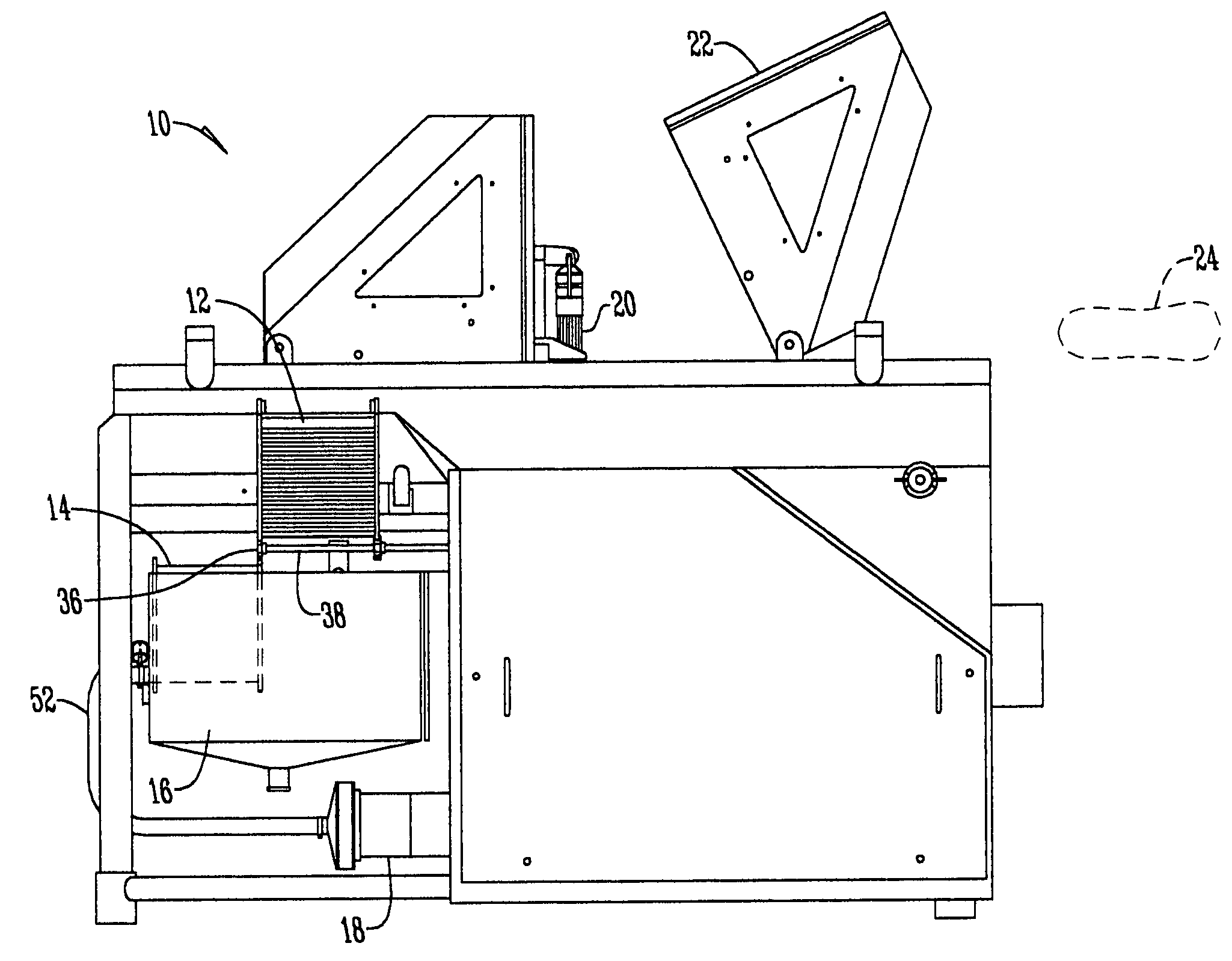

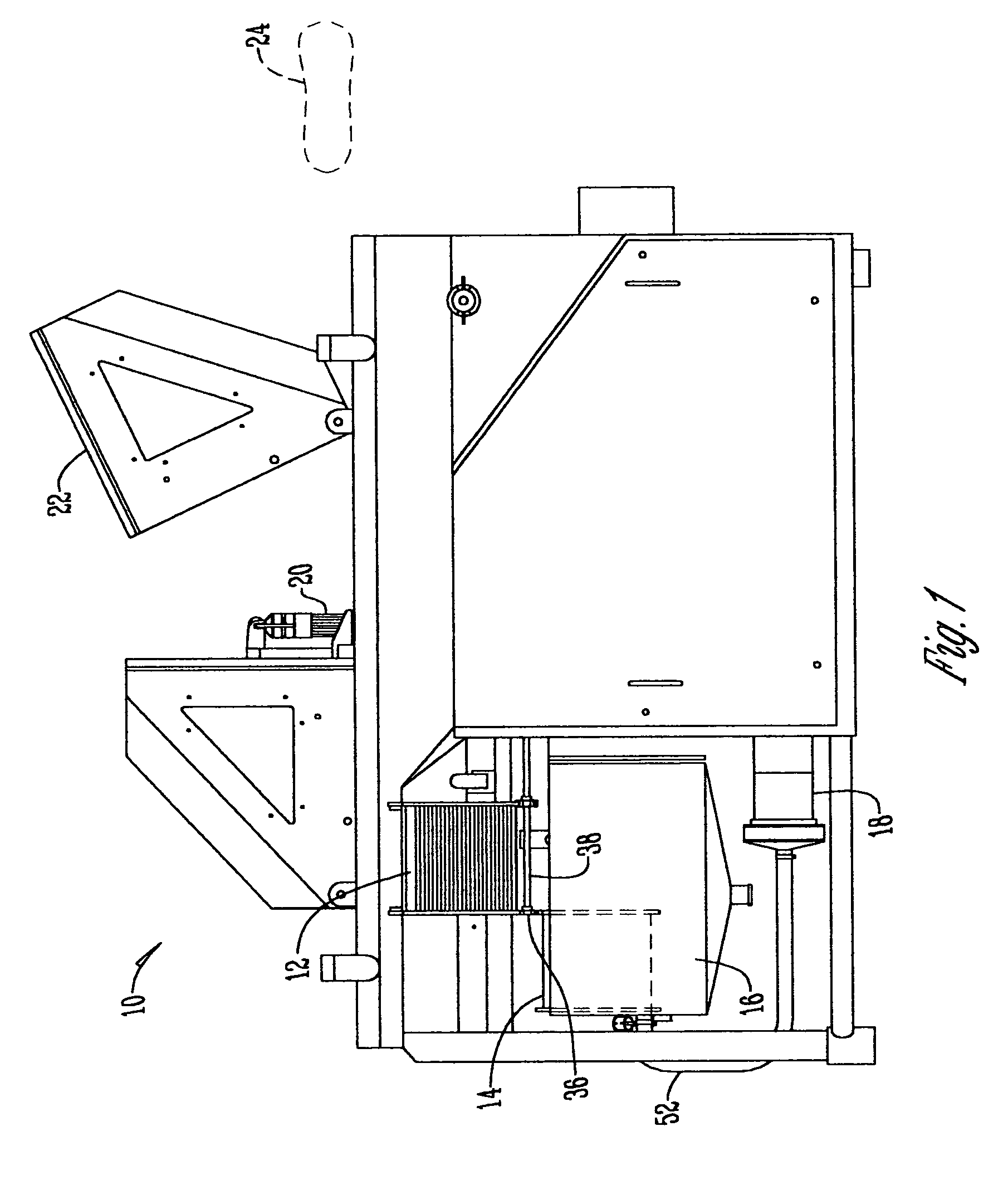

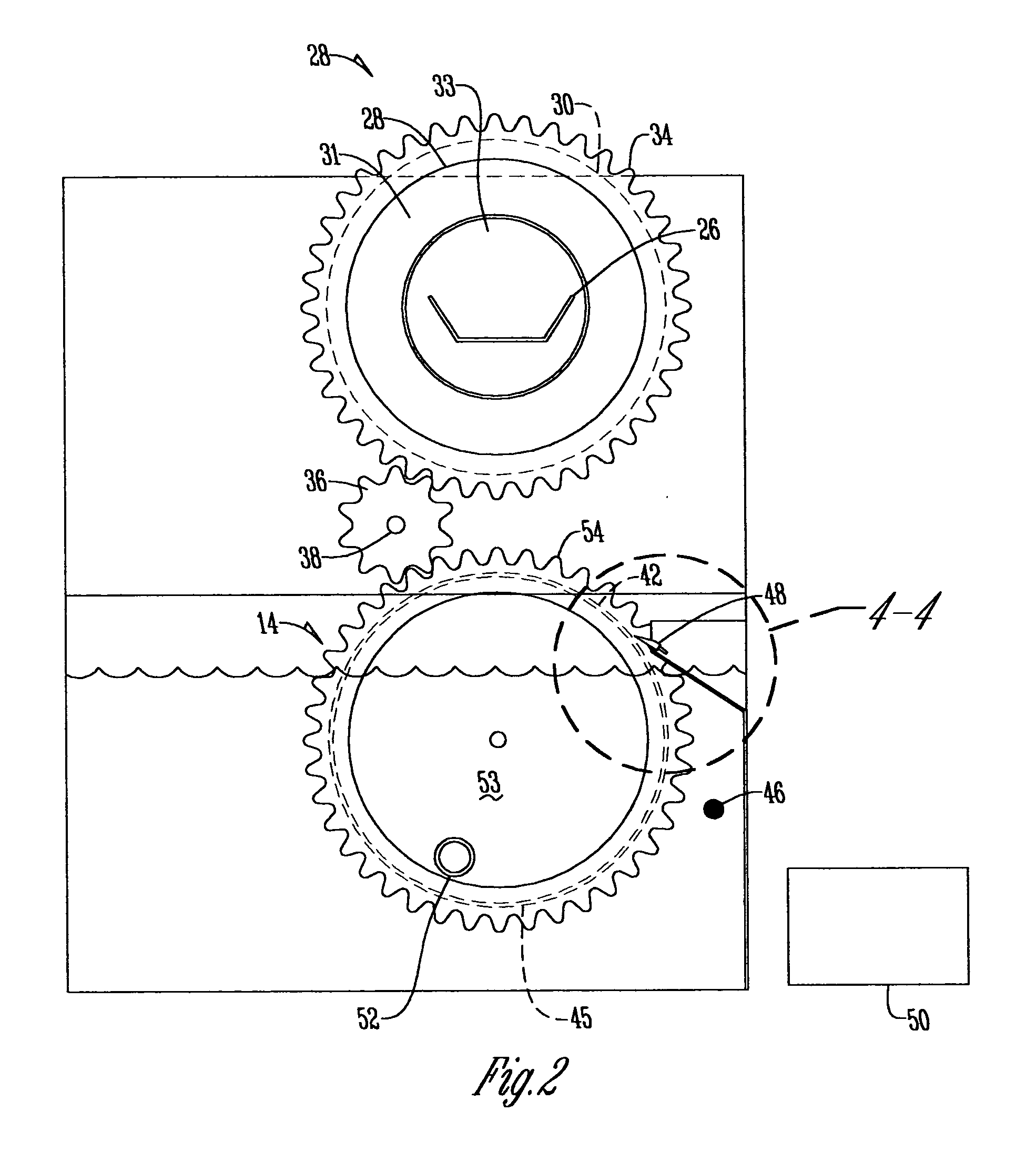

Dual filter system for filtering of injector fluids

A filtering system used on a meat injection machine that injects pickling into meat products. The filter consists of a tank and a first and second rotary filter. The first rotary filter uses a wedge wire wound cylinder and augers having flutes that rotate to catch and push away solid particles toward the second filter. The second filter then uses more wedge wire in a whirlpool effect to ensure all solid materials and foam are in the outside of the filter. Injector fluid is then taken from the center of the inside volume of the second filter to be used in injection needles.

Owner:STORK TOWNSEND BV

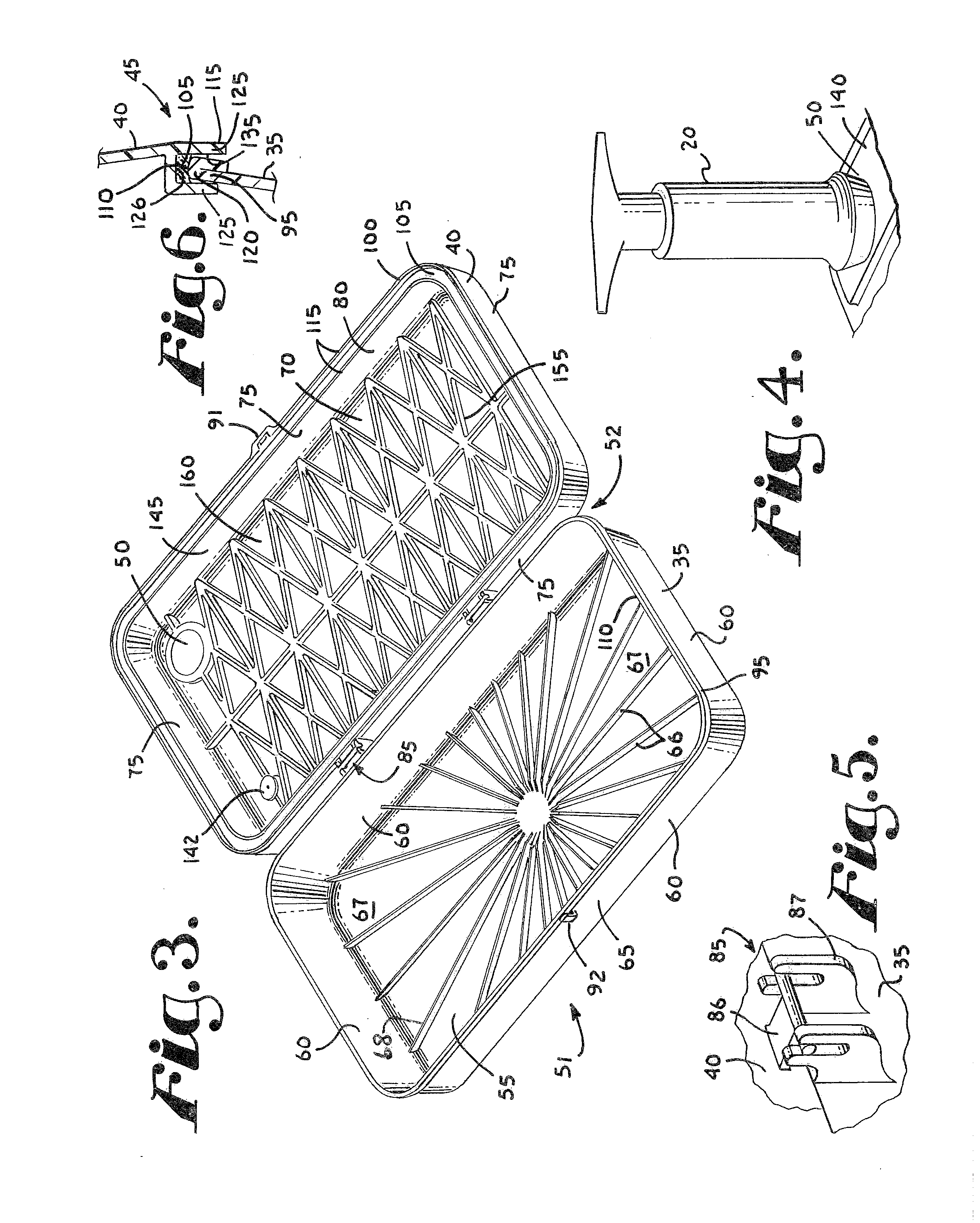

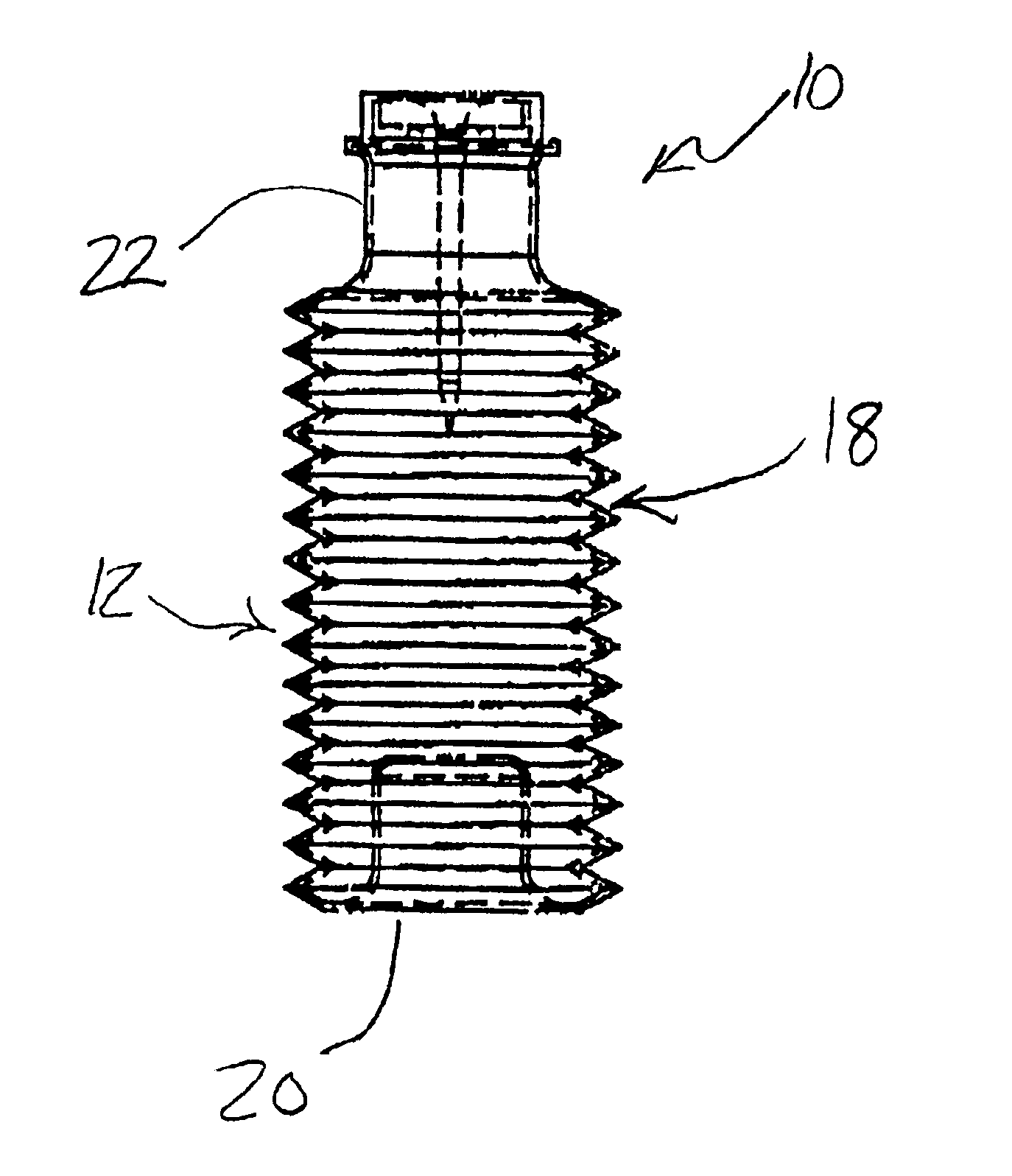

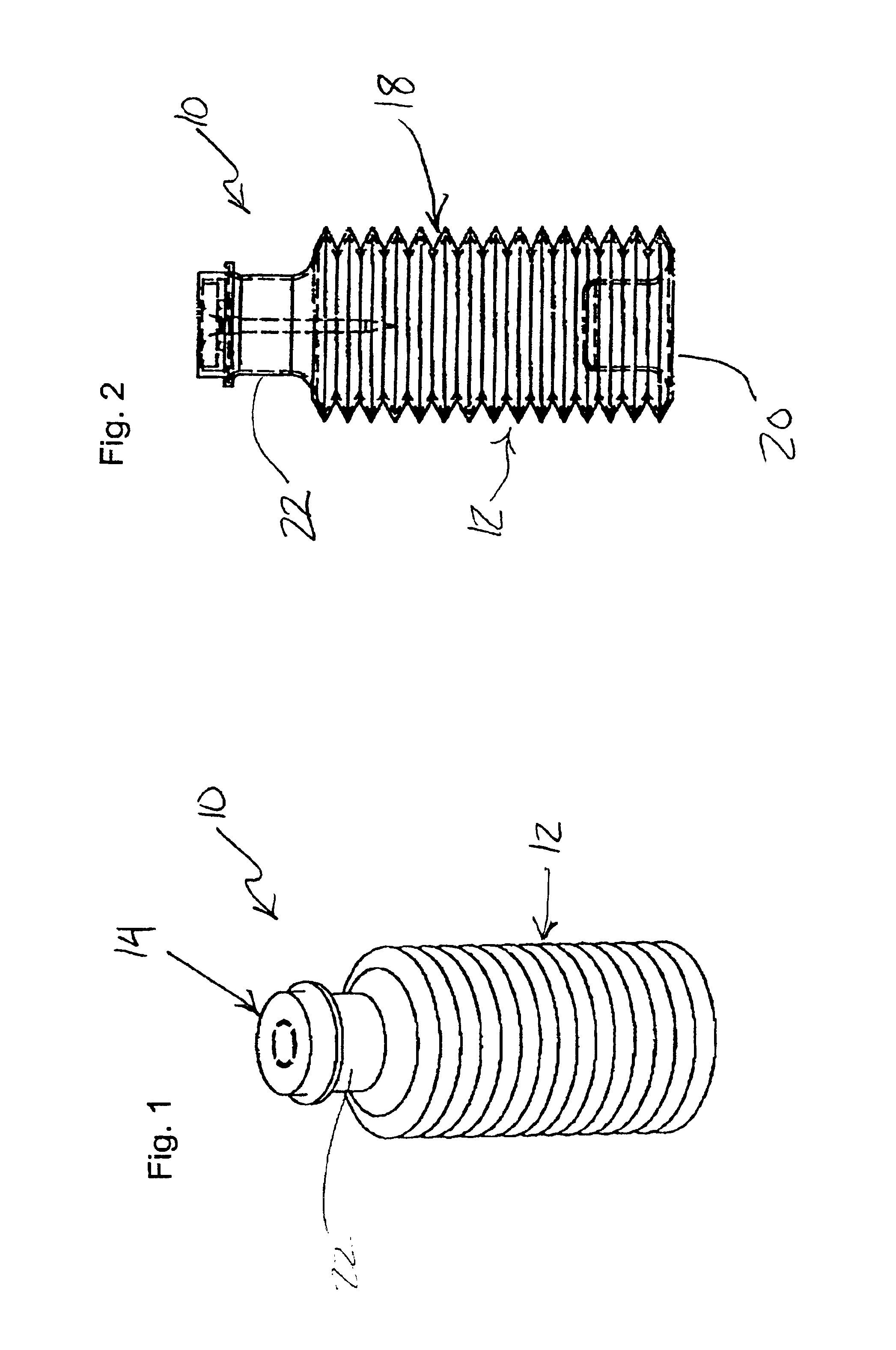

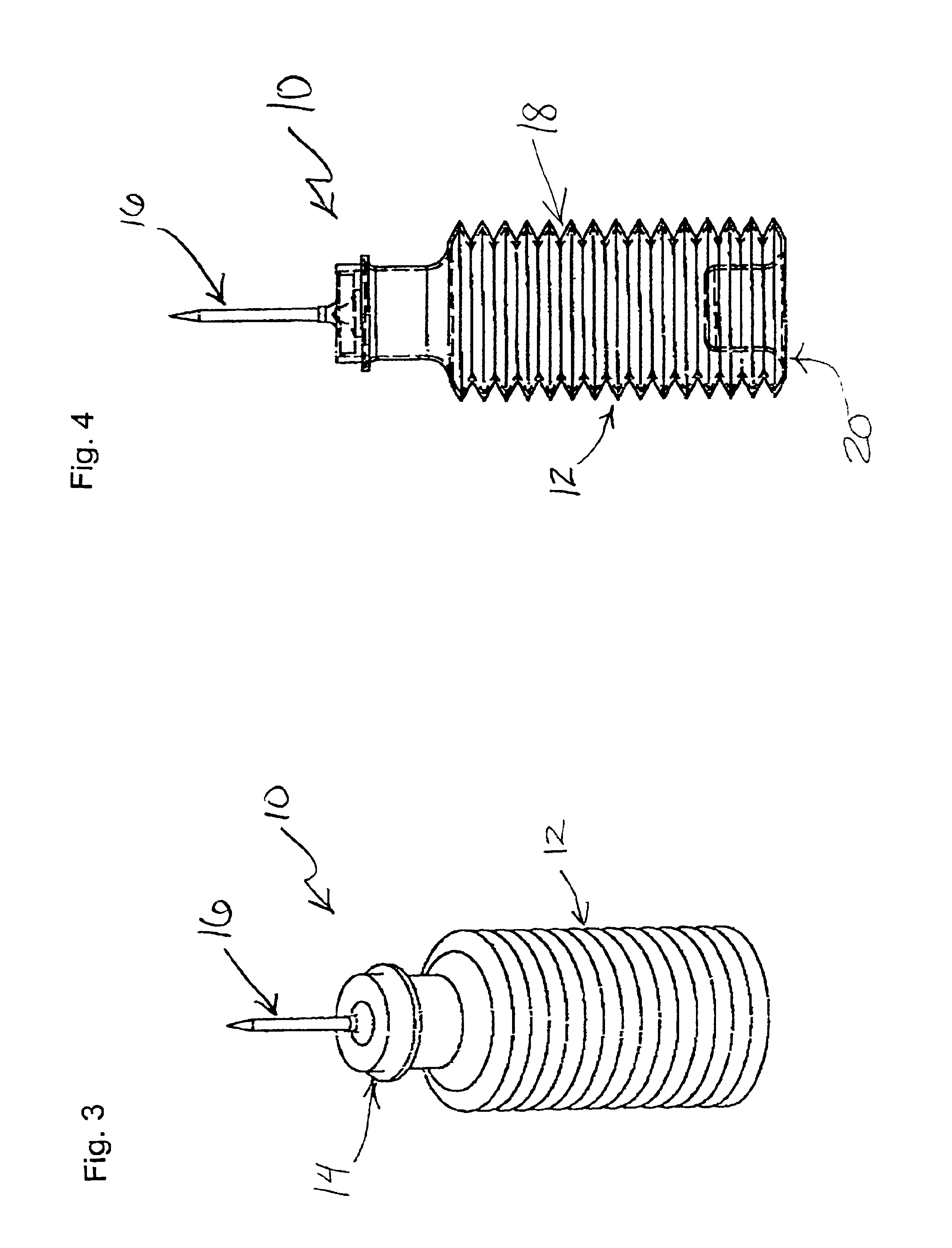

Convertible marinade container/dispenser having a flexibly compressible wall, and method of using same

A container for holding and dispensing a marinade includes a container body, a cap, and a nozzle. The container body includes a compressible accordion-pleated wall. The cap attaches to the container body, and may include a removable central disc. The nozzle is provided for cooperating with the container body to transfer a marinade into a comestible workpiece. A user may break the removable central disc out of the cap to form an opening therein, place the nozzle below the cap and push a nozzle tube upwardly through the cap opening, and may then attach the cap to the container body such that the nozzle tube extends outwardly therefrom. A method of marinating a comestible workpiece includes steps of inserting a container nozzle into an opening formed in the workpiece, and compressing the container to shorten an accordion-pleated wall portion thereof, thereby injecting a marinade into the workpiece.

Owner:EASTMAN OUTDOORS

Method of and apparatus for the processing of meat

InactiveUS6730341B2Simple methodIncrease variabilityGrain huskingGrain polishingProcess engineeringWater holding capacity

The water holding capacity of meat is improved by agitating the meat at an alleged temperature with the processing solution and by maintaining the agitation temperature with precision. A preferred temperature is in the range of 45° to 60° F. and the agitation is preferably a massaging action after injection of the liquid into the meat. The heating or agitation at the elevated temperature can be carried out in one vessel while the subsequent cooling is carried out in at least one second vessel.

Owner:JOHN BEAN TECH CORP

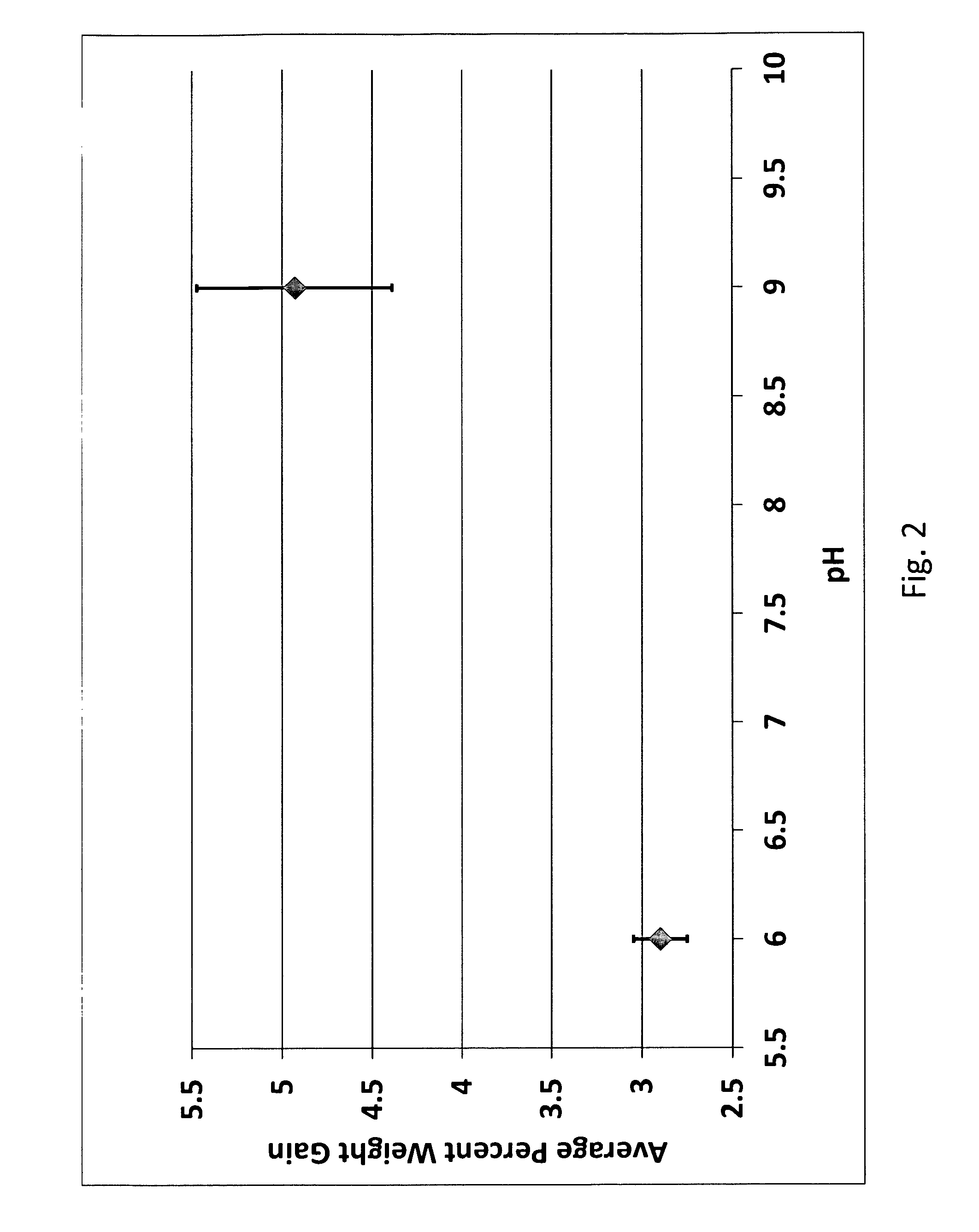

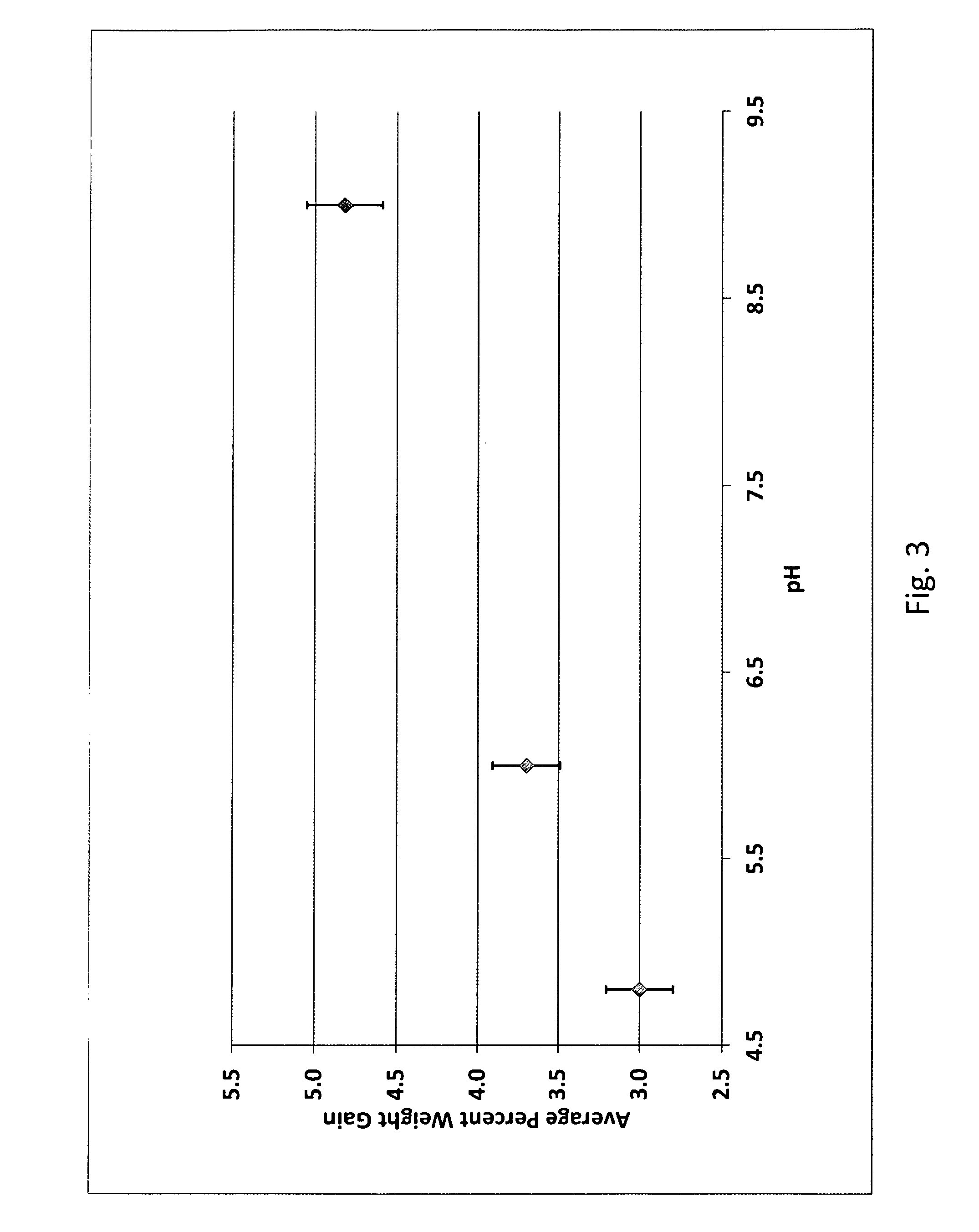

Methods of using peracetic acid to treat poultry in a chill tank during processing to increase weight

ActiveUS20120244261A1Weight increaseSpeed up the processMilk preservationMeat/fish preservation using liquidsAcetic acidProcessing plants

Methods for treating poultry during processing for increasing the weight of the poultry are disclosed. The methods may be performed in a chill tank or other reservoir and utilize either equilibrium peracetic acid or non-equilibrium peracetic acid. The non-equilibrium peracetic acid may be prepared from hydrogen peroxide and a liquid acetyl precursor, such as triacetin. The methods comprise contacting a poultry carcass with peracetic acid-containing water at a pH of about 6 to about 9. The methods result in an increase in the weight of the processed products and an increase in a processing plant's percent yield of the processed products.

Owner:ENVIRO TECH CHEM SERVICES

Popular searches

Dead animal preservation Animal repellants Slaughtering accessories Fruit and vegetables preservation Poultry plucking mechanisms Climate change adaptation Animal fodder preservation Pre-baking dough/flour preservation Meat/fish preservation by freezing/cooling Meat/fish preservation using chemicals

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com