Decontamination methods for meat using carbonic acid at high pressures

a carbonic acid and high pressure technology, applied in meat/fish preservation, food shaping, food preparation and other directions, can solve the problems of lftb presence of bacteria, and achieve the effect of lowering ph and maximizing the effect of microbiocidal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

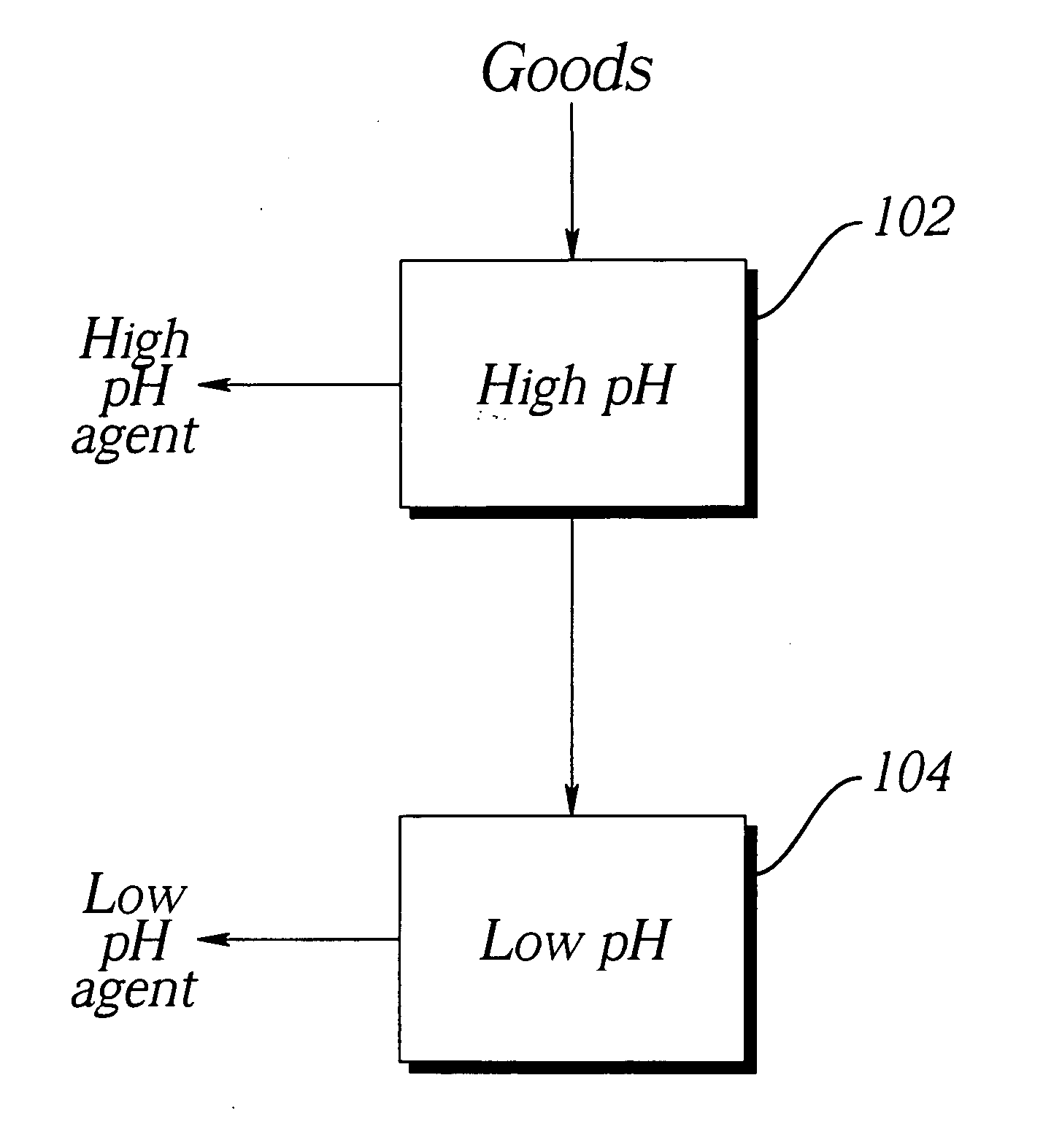

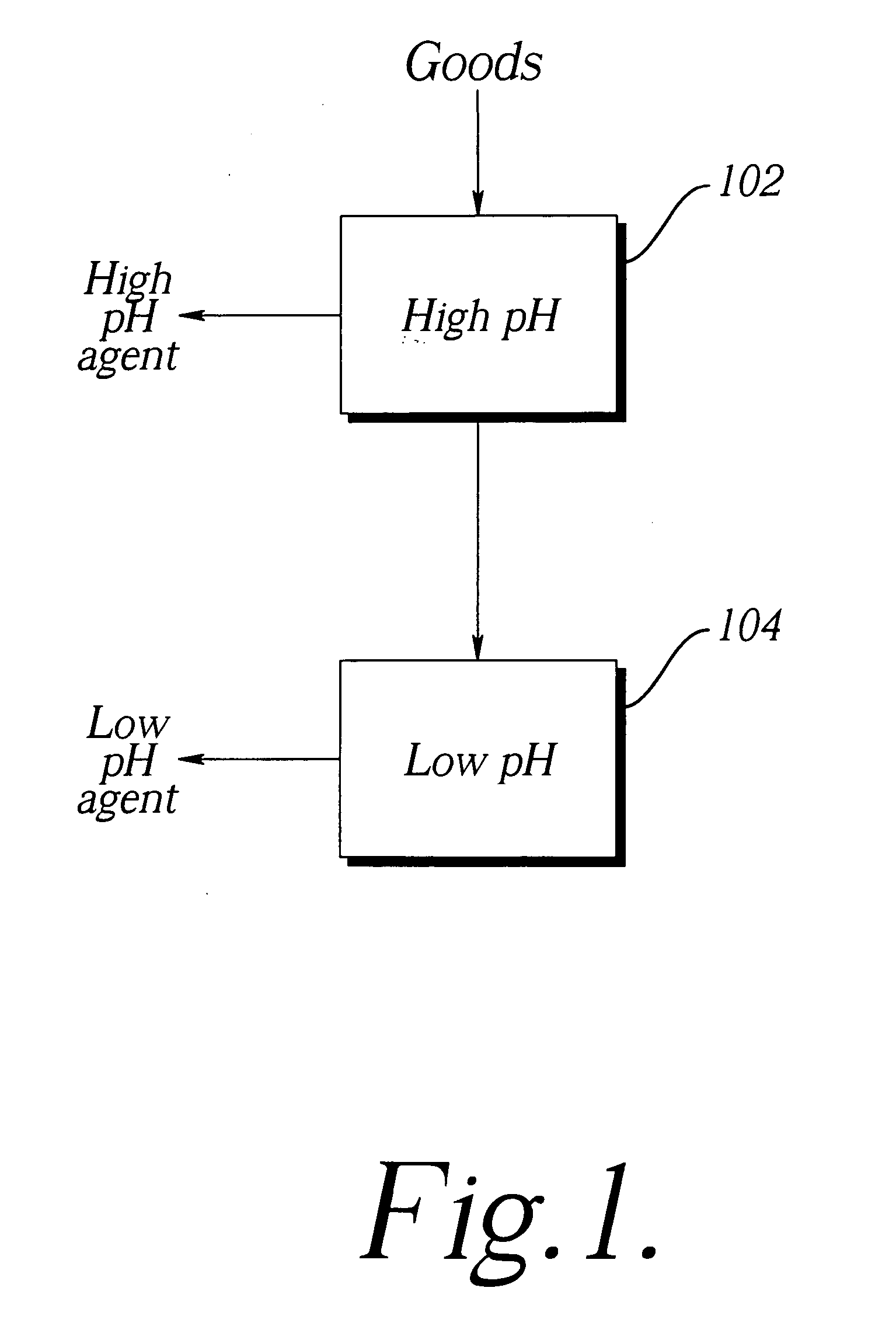

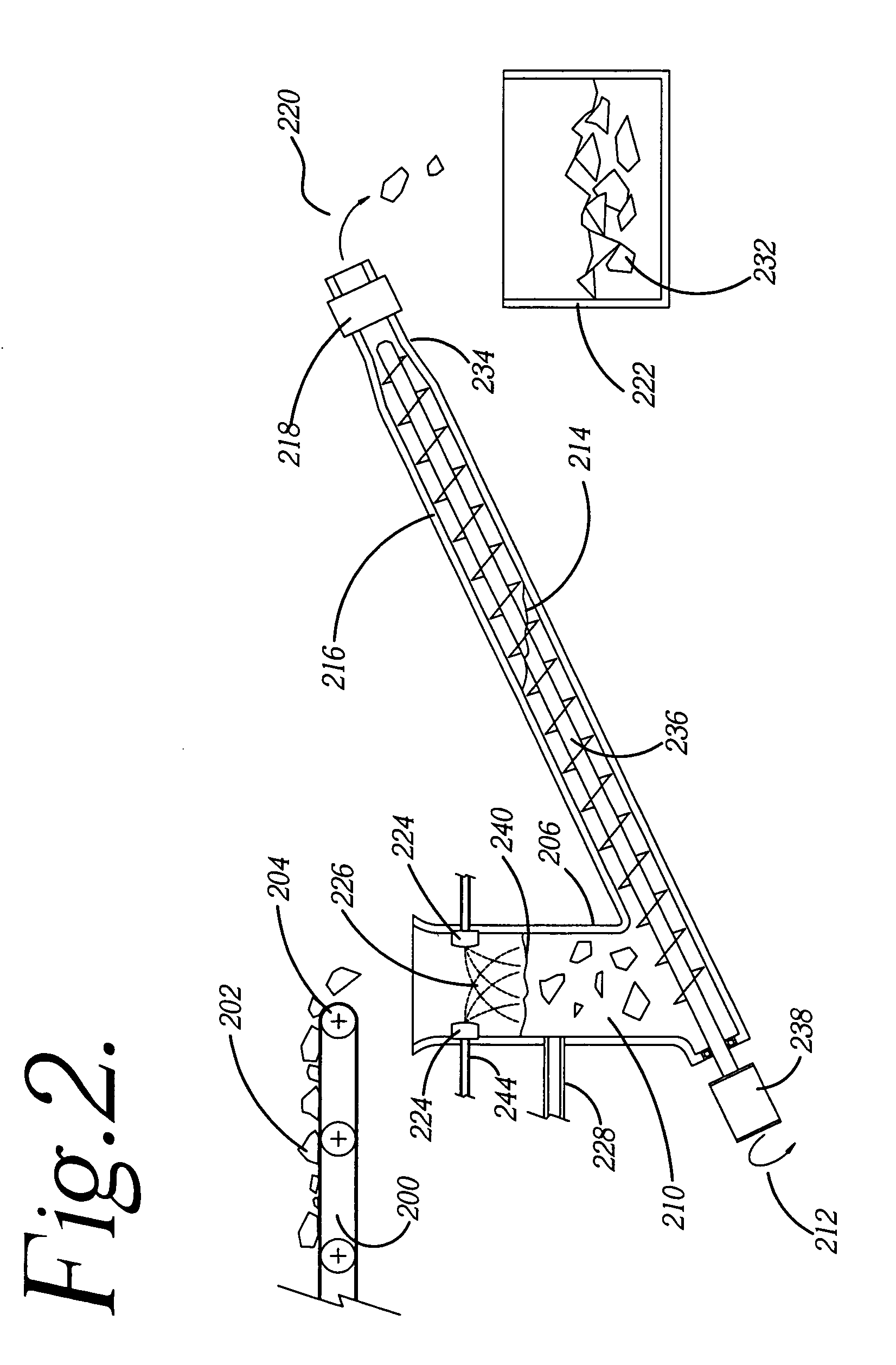

[0061] The decontamination, pasteurization, and processing apparatus and methods described below can be for goods, such as meat, boneless or otherwise, with the optional use of any additional substance(s), liquid(s) and / or gas(es), which use carbon dioxide and water in any selected, relative, and / or measured quantities and at any suitable pressure, combined together in an effective manner so as to produce carbonic acid. Additionally, the water (moisture) content of the goods, such as beef or poultry meats, can be measured and controlled according to the methods disclosed.

[0062] One aspect of the invention provides water content standards for meat. The water content standards can be used to approximate the naturally occurring level of moisture in any meat. The composition of fresh boneless meat, harvested from an animal, can be reduced to substantially two components, lean meat, and fat. Both lean meat and fat can contain a large percentage of water. A more extensive analysis of mea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com