Patents

Literature

82 results about "Reapplication" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The National Institutes of Health will consider only two amendments to the initial grant application. Regardless of the number of amendments, the NIH will not accept a revised (amended) application that is submitted later than two years beyond the date the initial application was received.

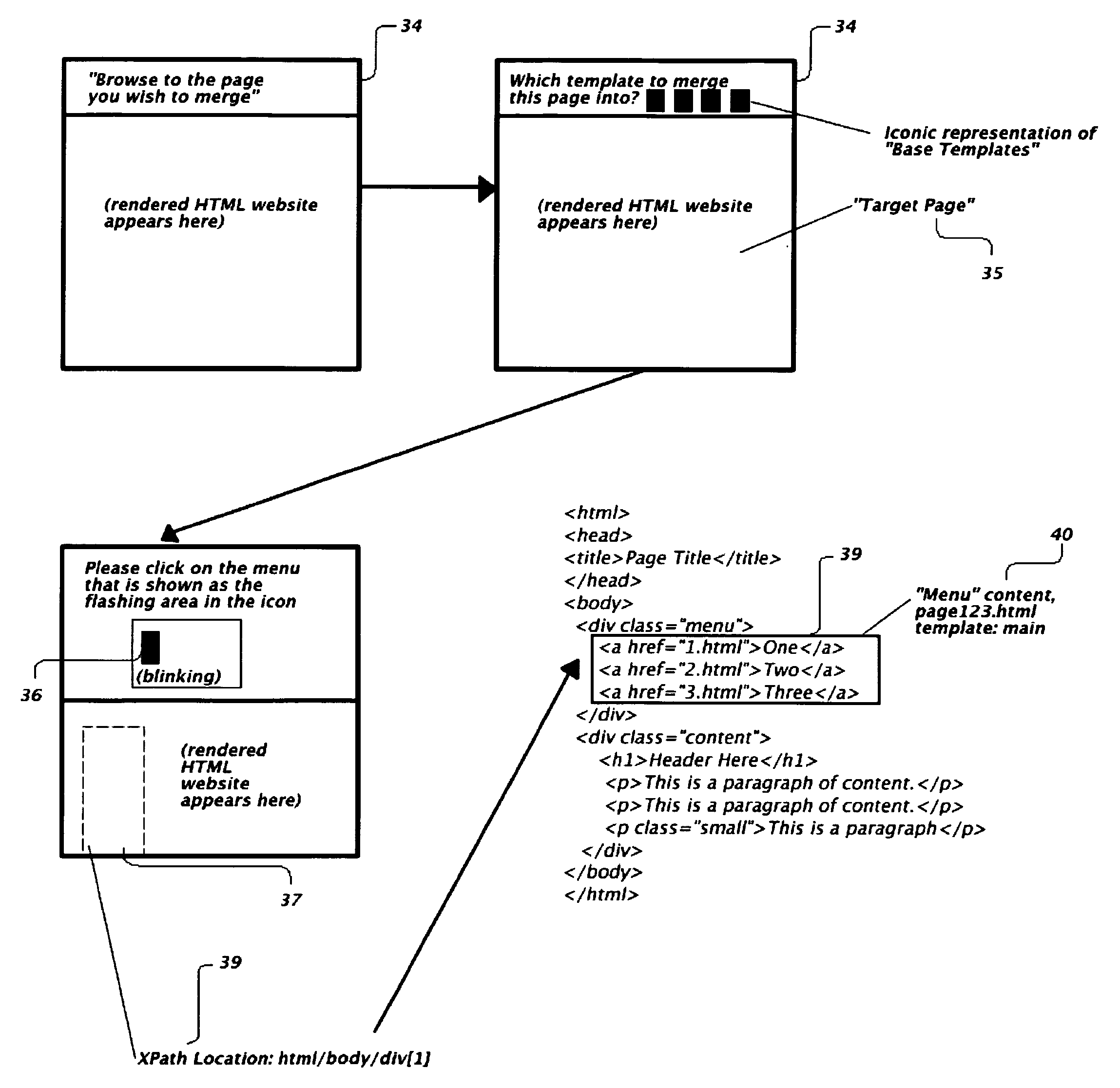

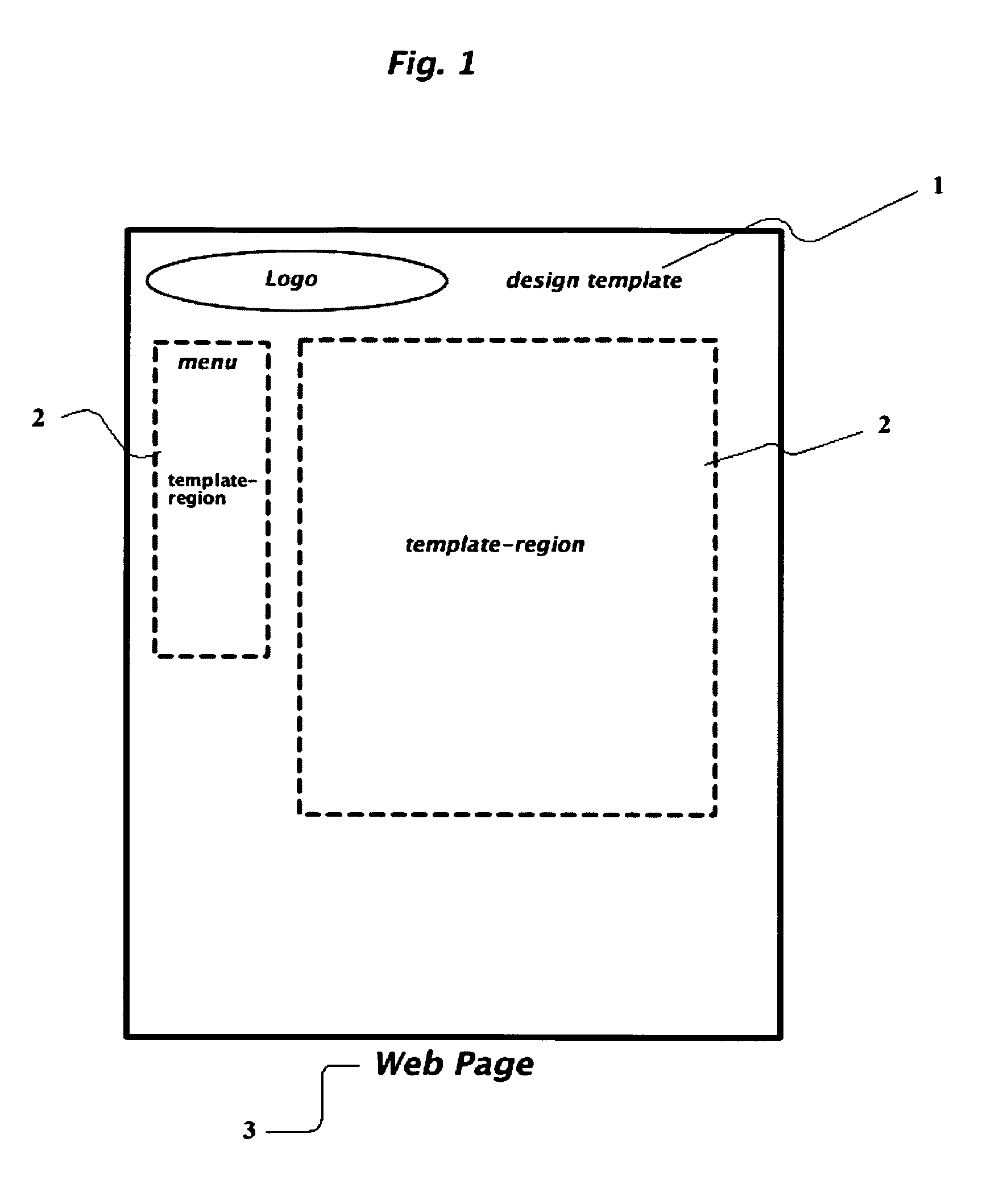

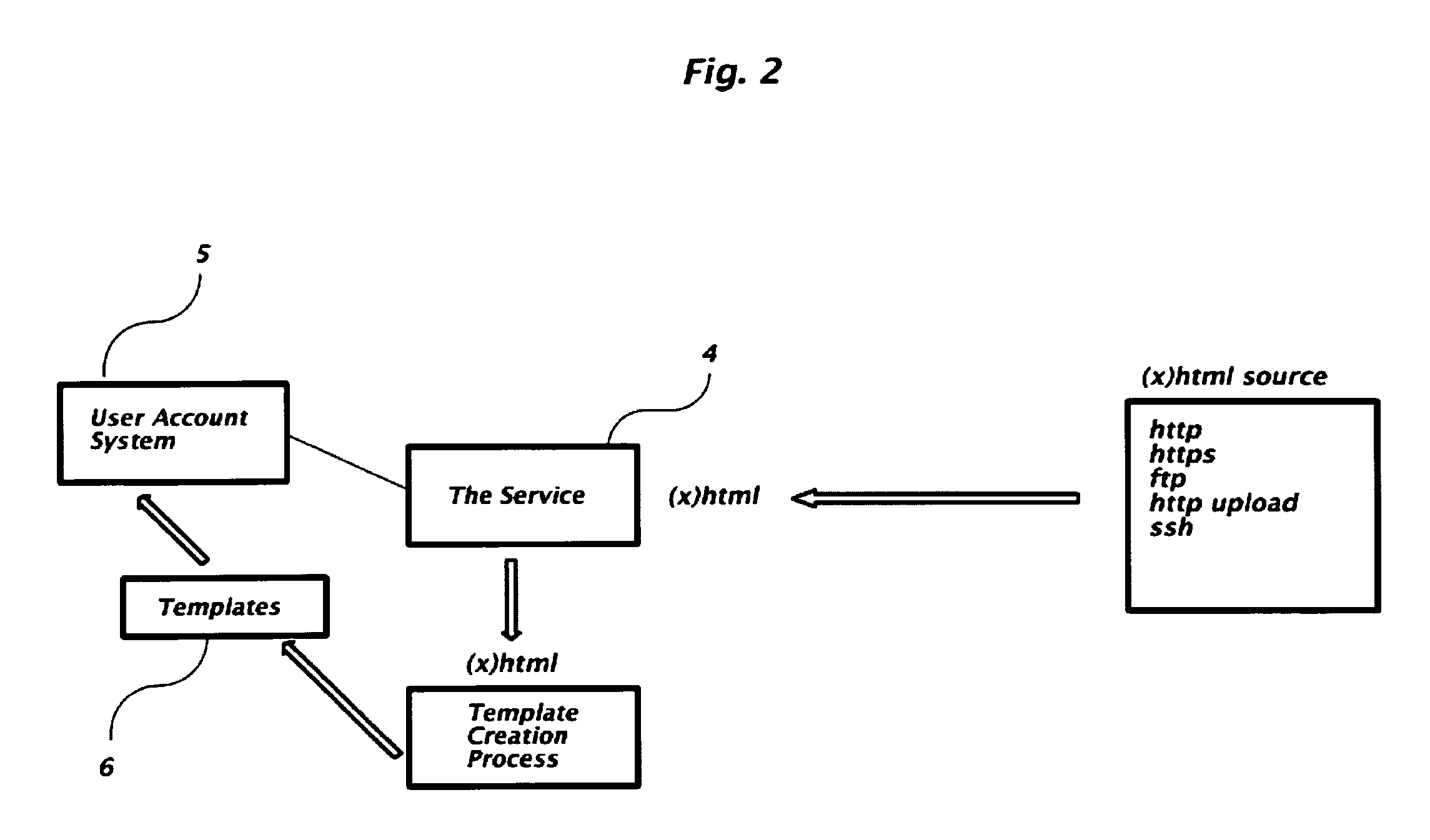

Extraction and reapplication of design information to existing websites

InactiveUS20090019386A1Natural language data processingSpecial data processing applicationsWeb siteComputer graphics (images)

A method and system is provided that allows for the extraction of design templates and other design information from an existing website through a visual point-and-click interface, requiring no programming knowledge; the detection and application of these templates across a plurality of existing web pages; as well as the application of these templates to newly generated content and newly generated or existing software.

Owner:INTERNET SIMPLICITY

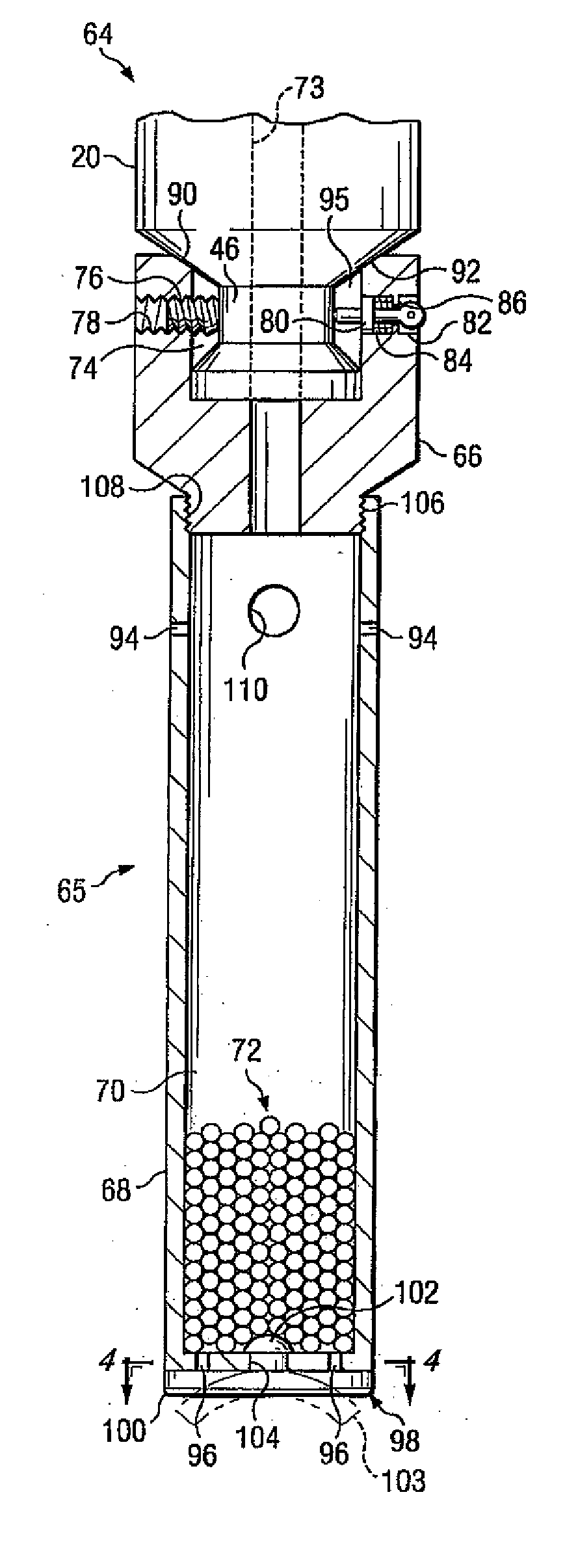

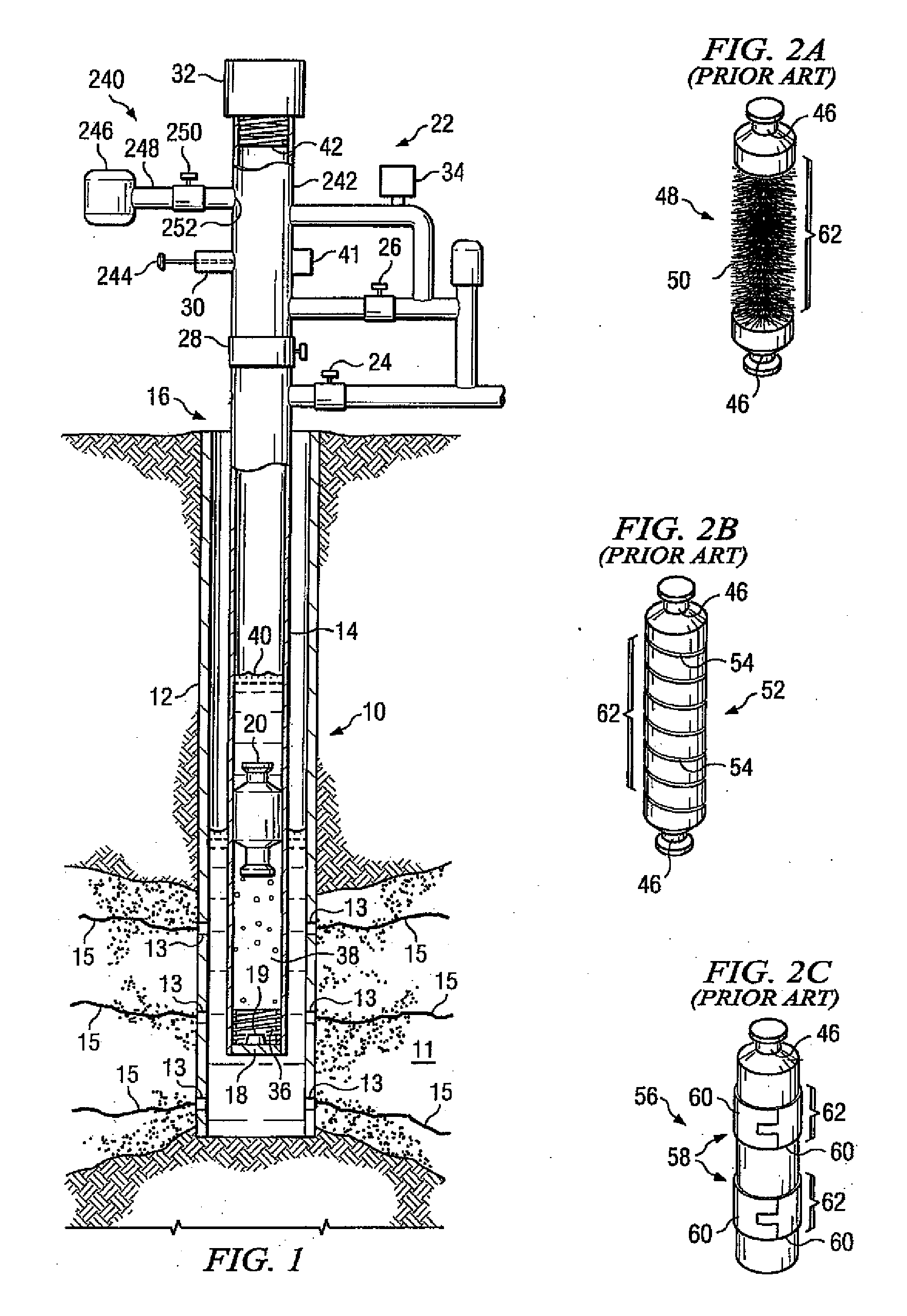

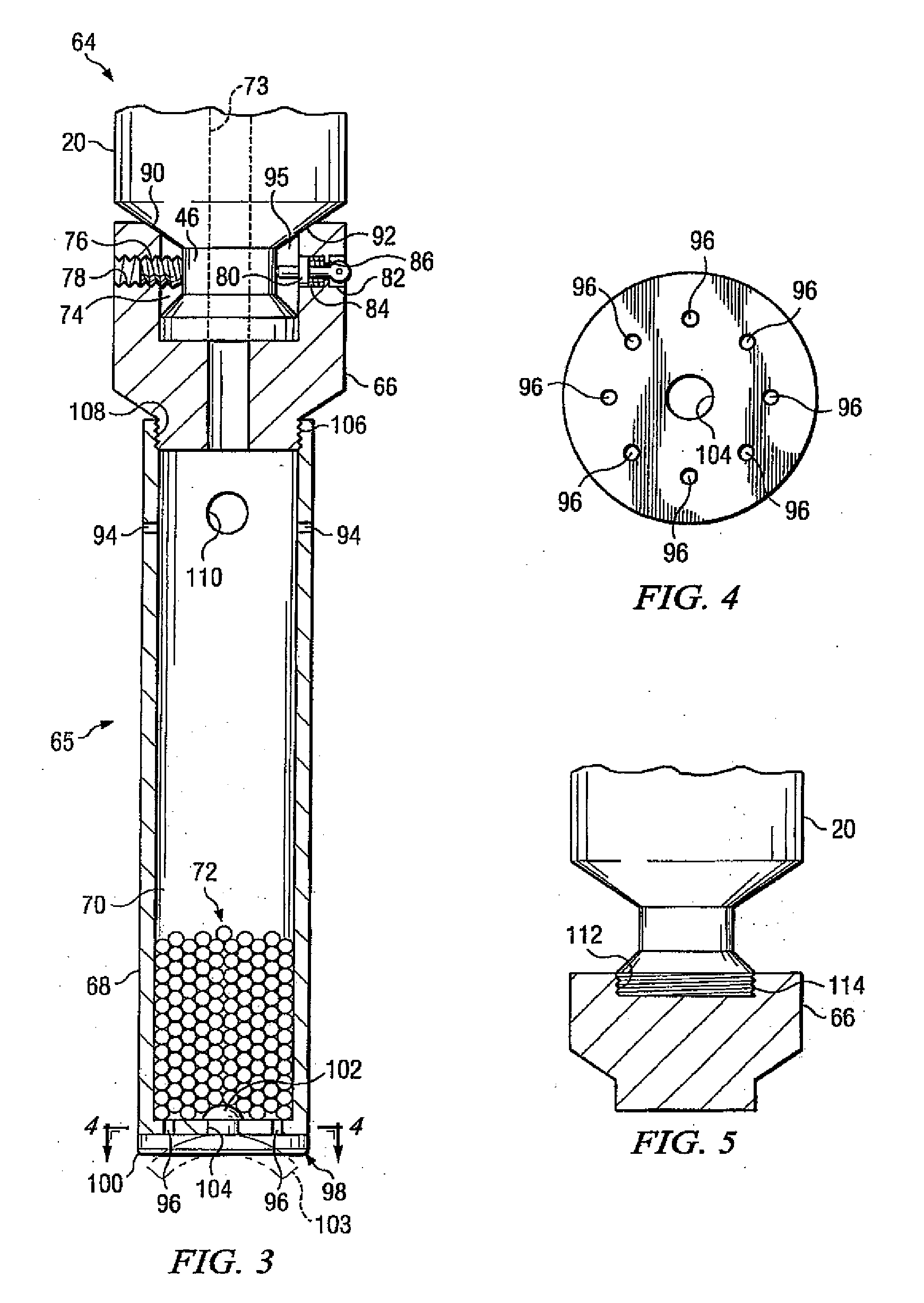

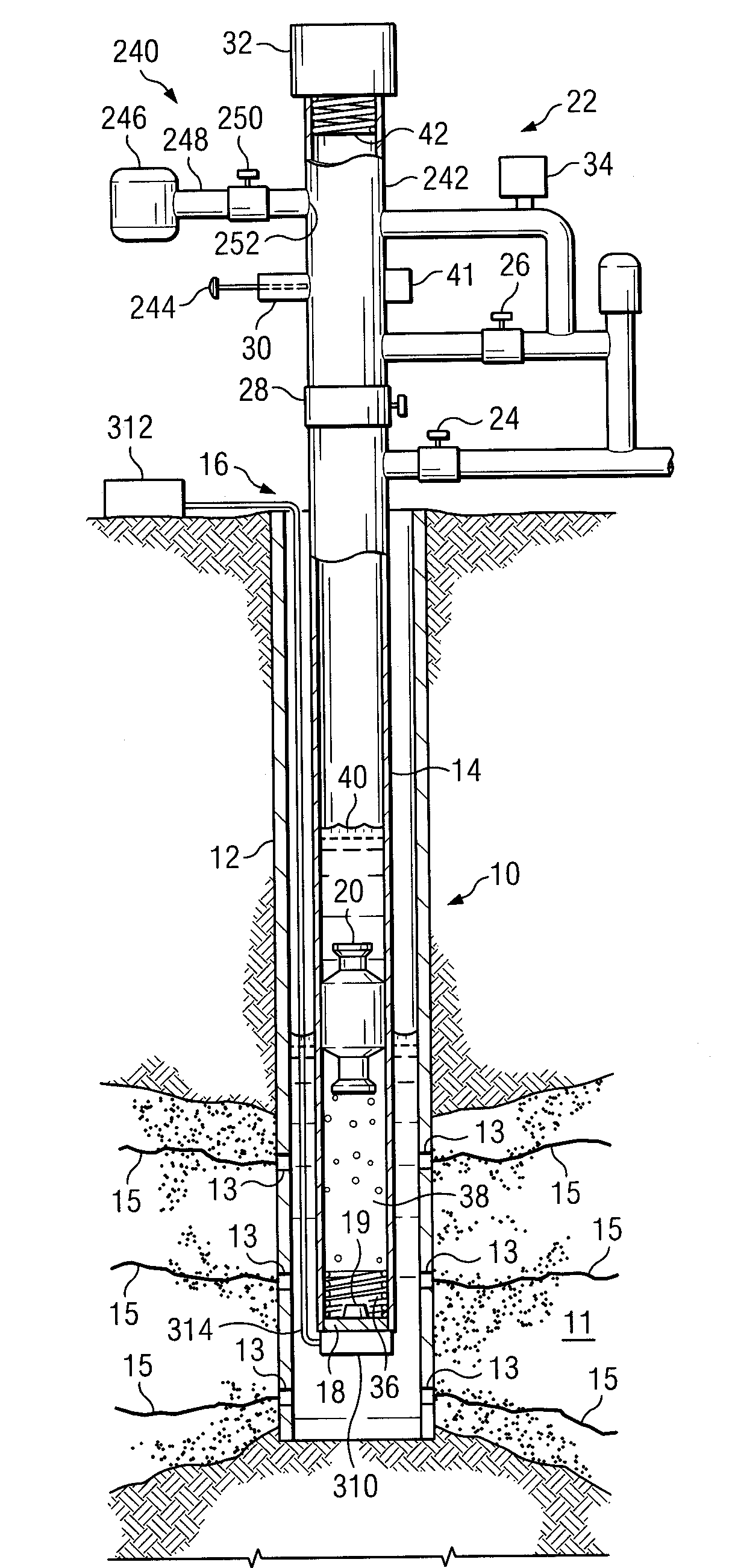

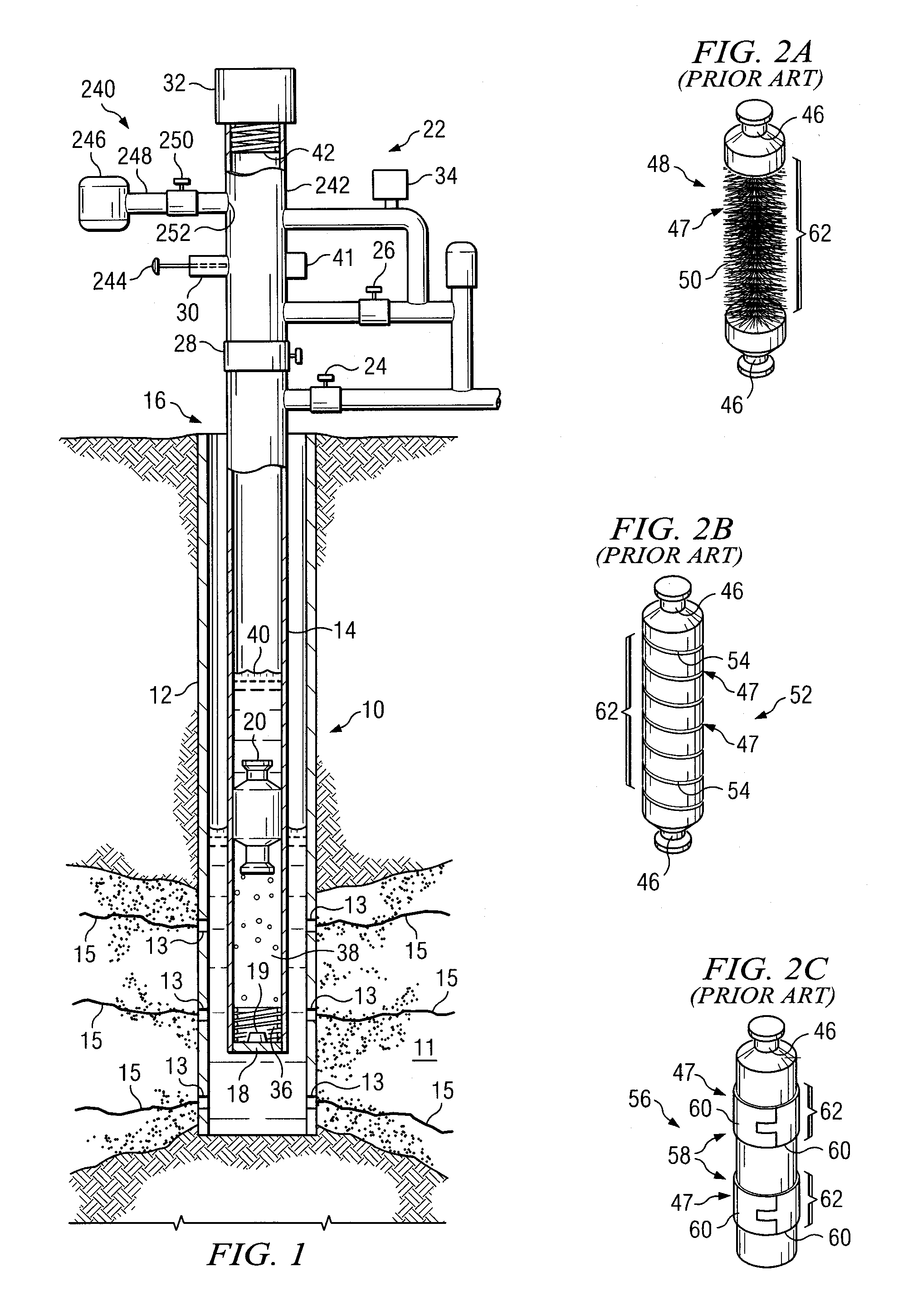

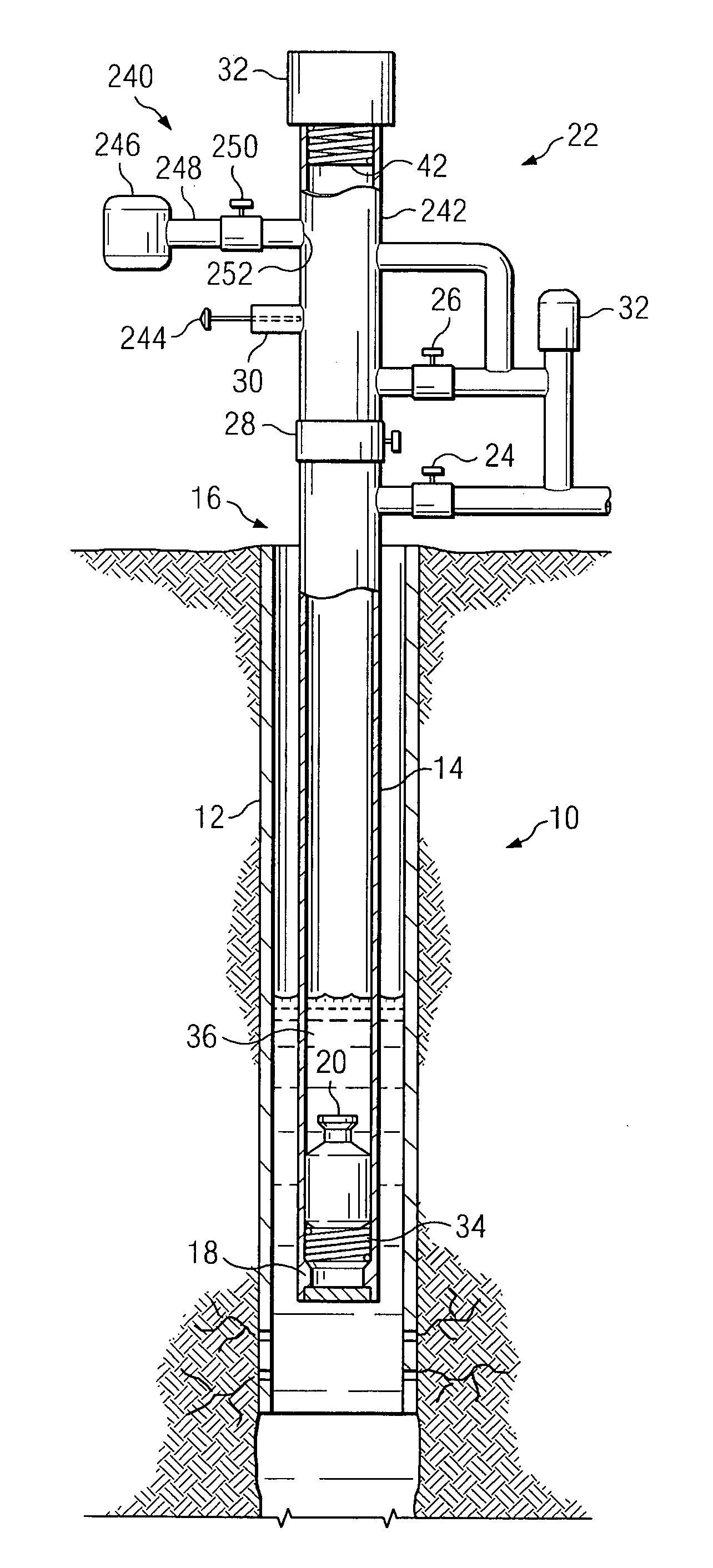

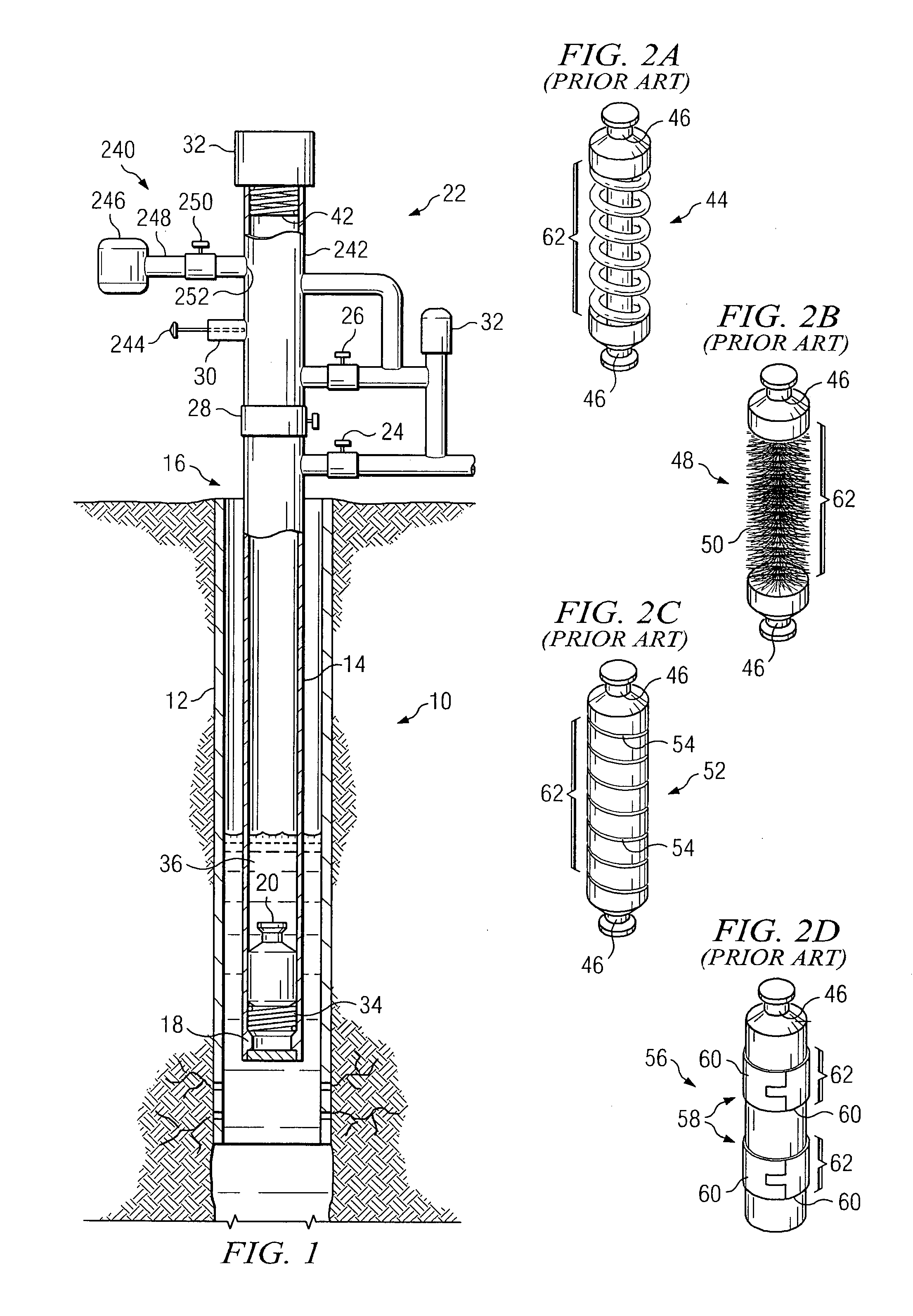

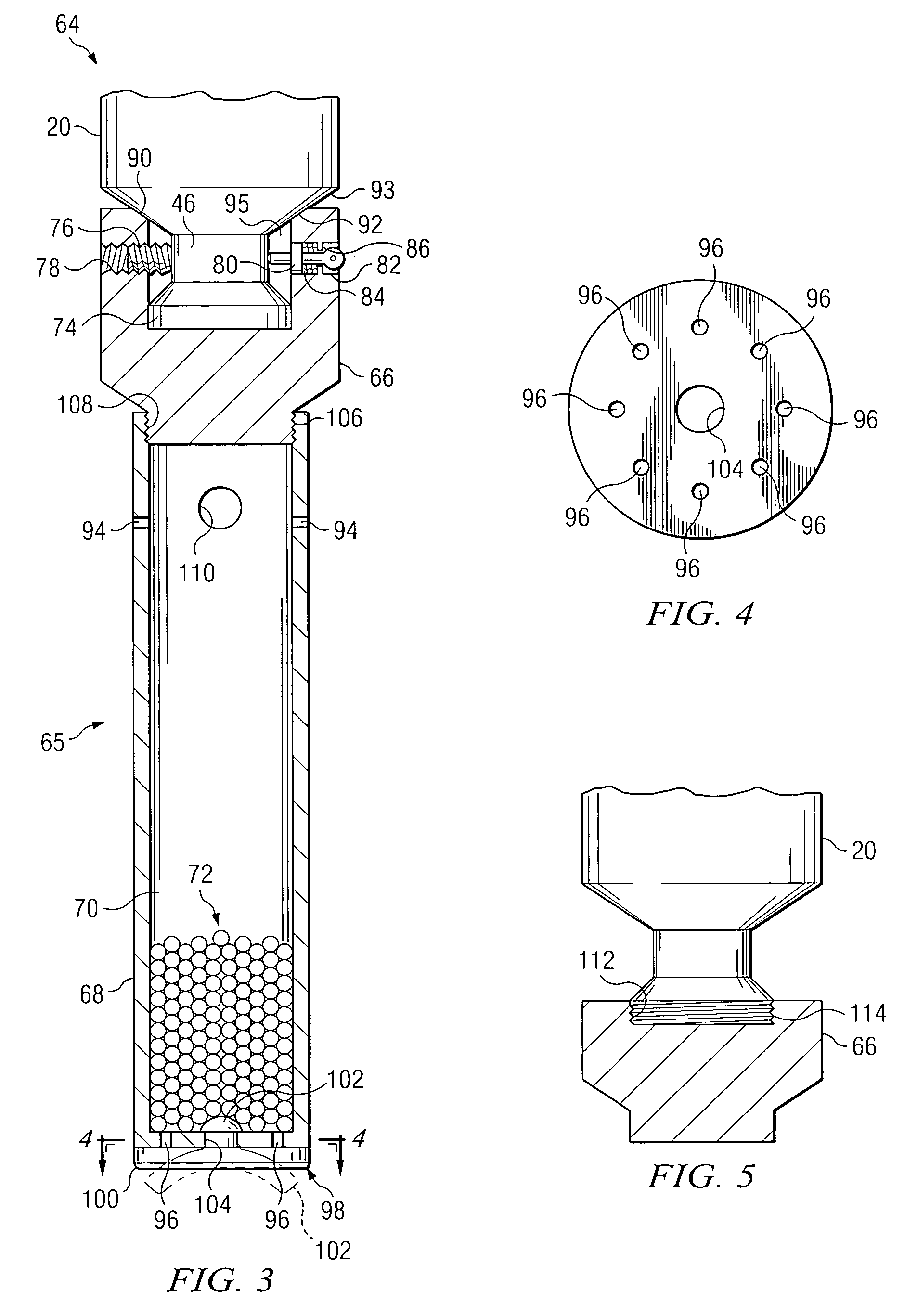

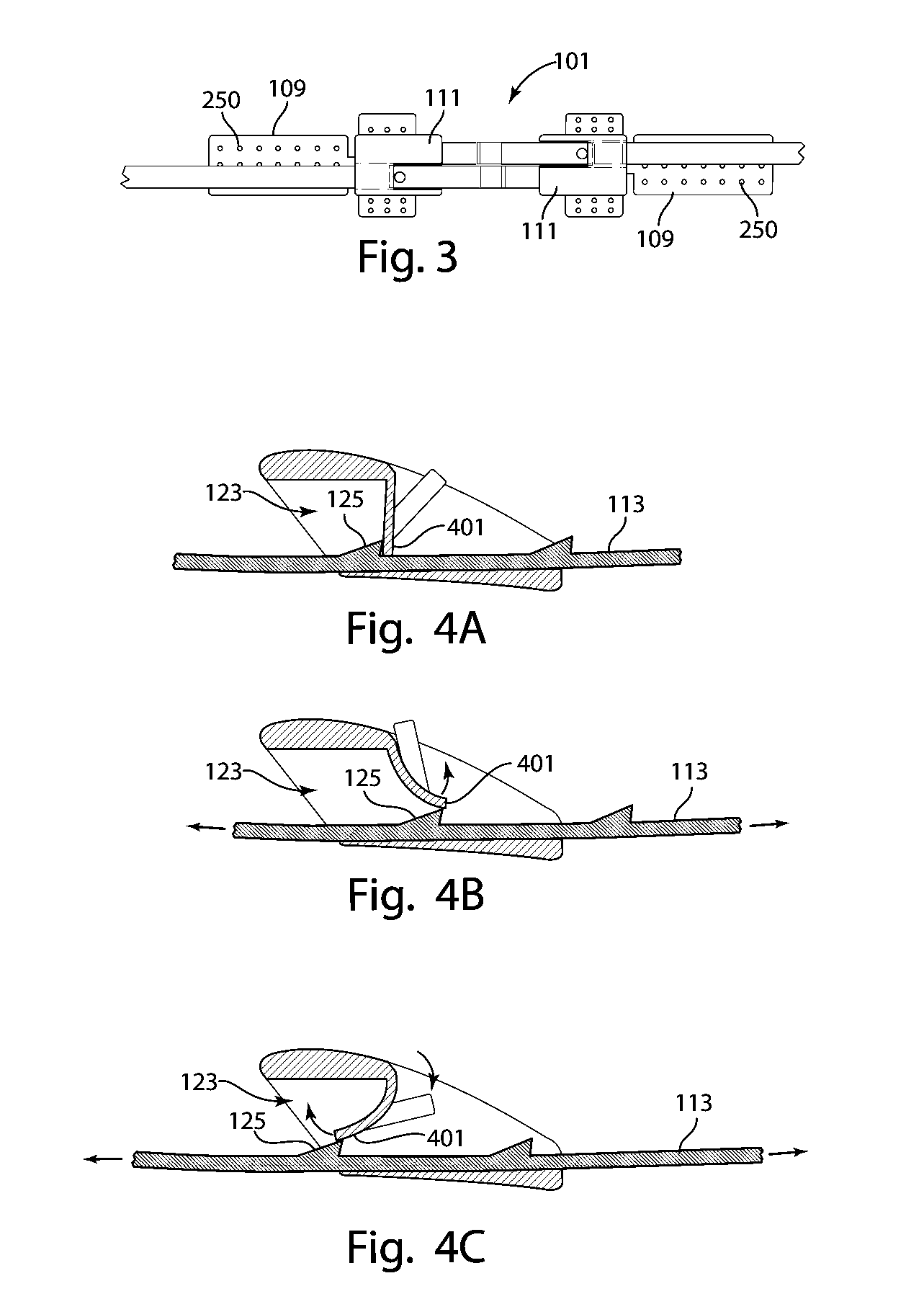

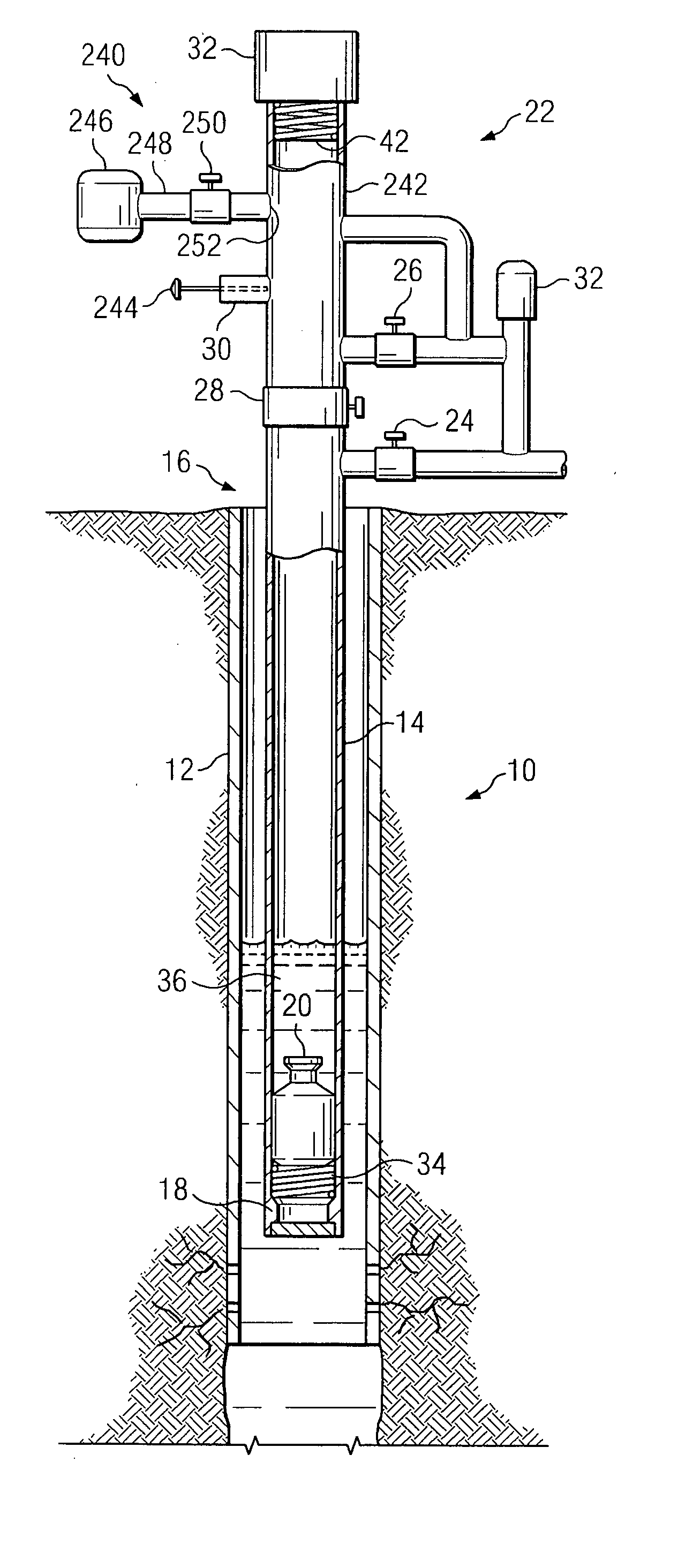

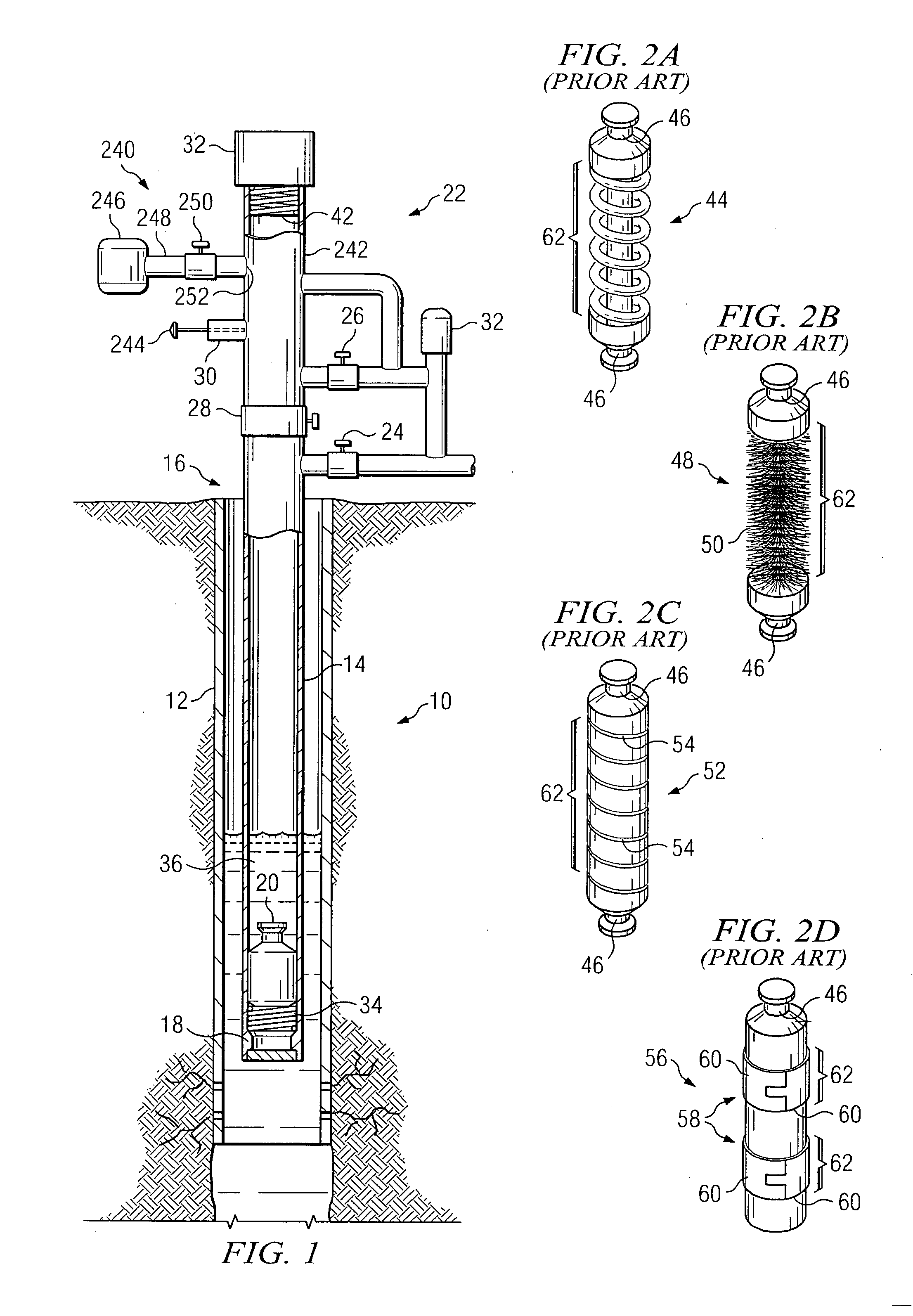

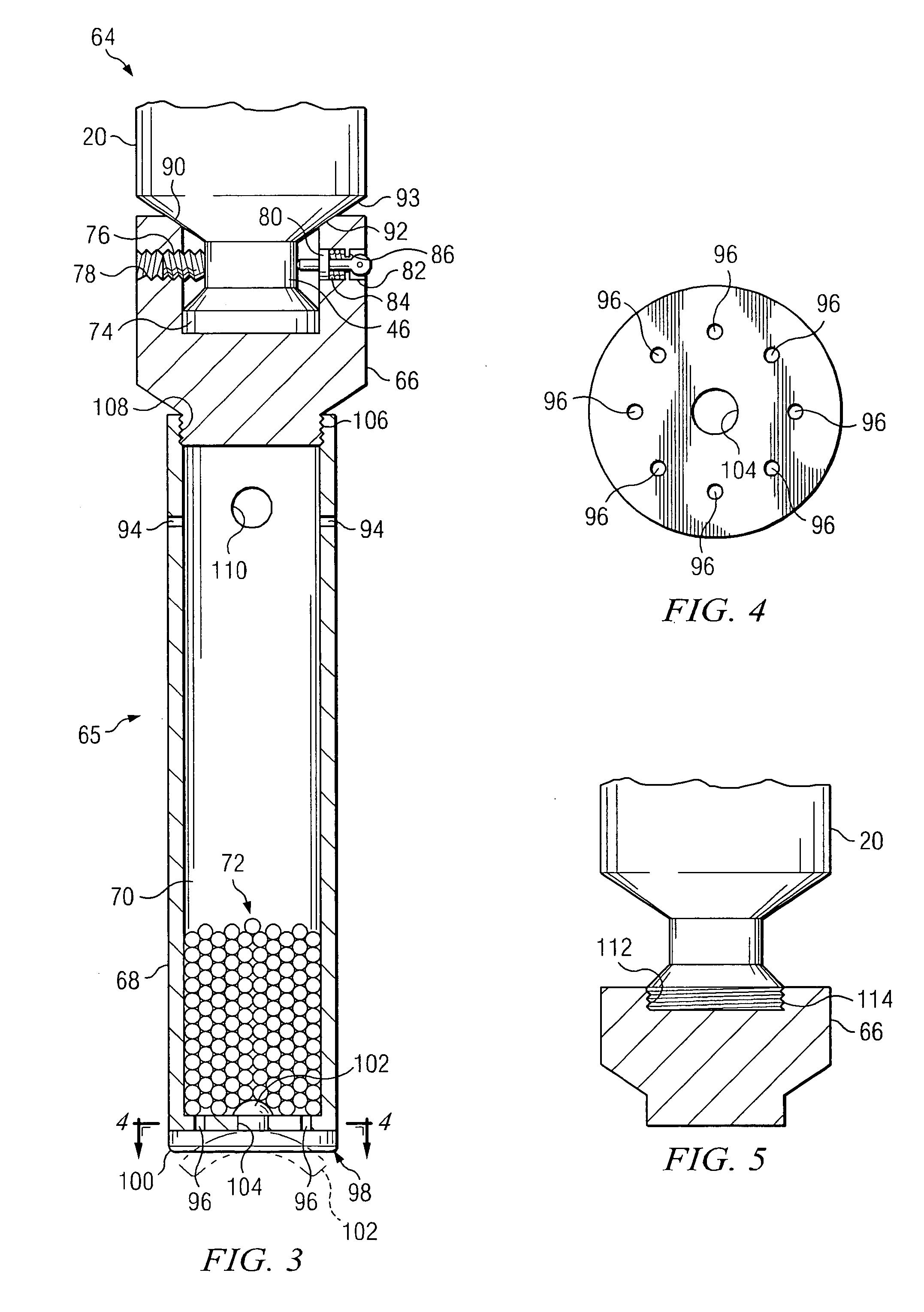

Well chemical treatment utilizing plunger lift delivery system with chemically improved plunger seal

InactiveUS20070039739A1Improve efficiencyOptimize volumeCleaning apparatusFluid removalChemical treatmentFoaming agent

An apparatus incorporating a chemical seal and method for removing fluids from a well is disclosed. The chemical seal is created by a foaming agent which, when in the presence of gas and fluids present in the well, and when agitated by the apparatus, creates foam between the apparatus and the walls of the well in which it operates. The foam improves the seal between the apparatus and the inner wall of the well, improving the efficiency of the apparatus in lifting fluids from the well. Furthermore, the chemical seal improves the distribution of treatment chemicals within the well as it reduces liquid flowback. Automatic recharging or reapplication of the foaming agent and / or treatment chemicals to the apparatus can be accomplished with a chemical application assembly associated with the well.

Owner:CONOCOPHILLIPS CO

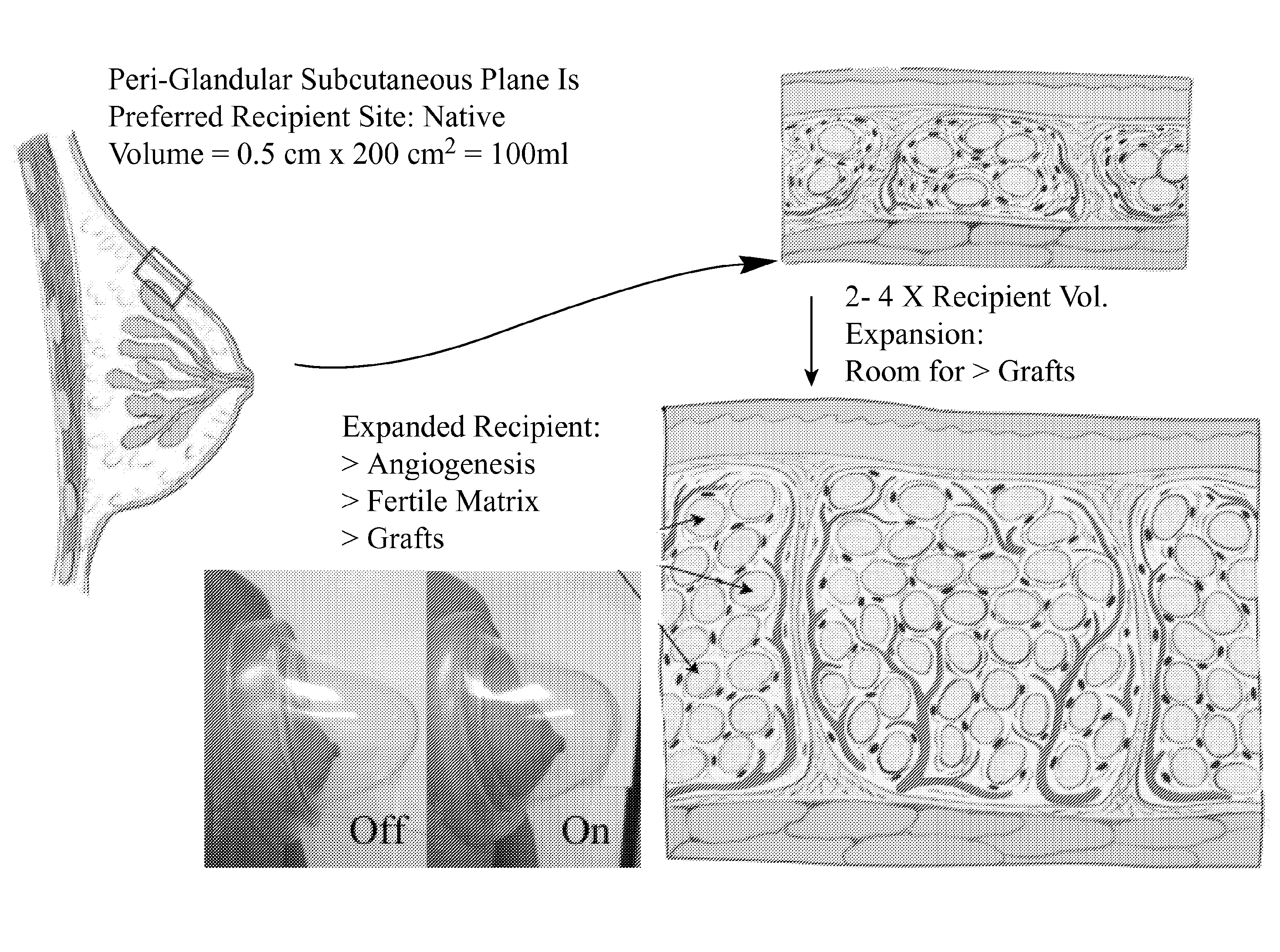

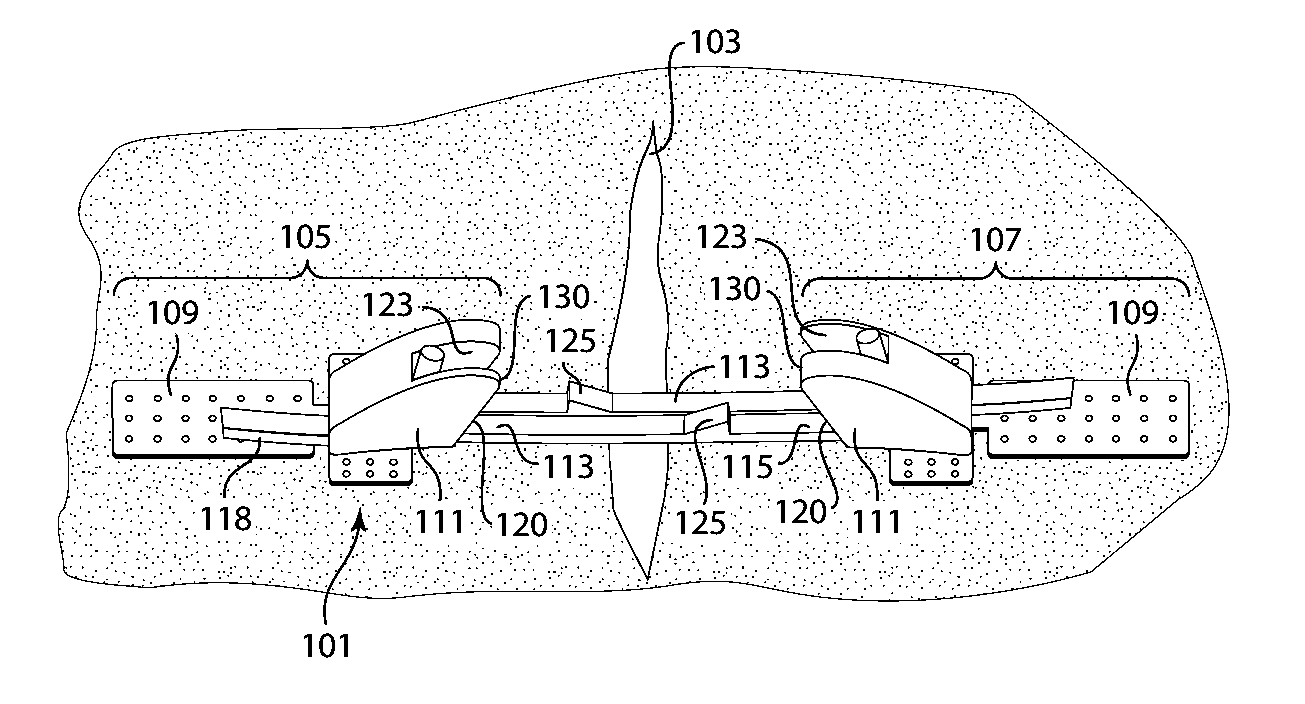

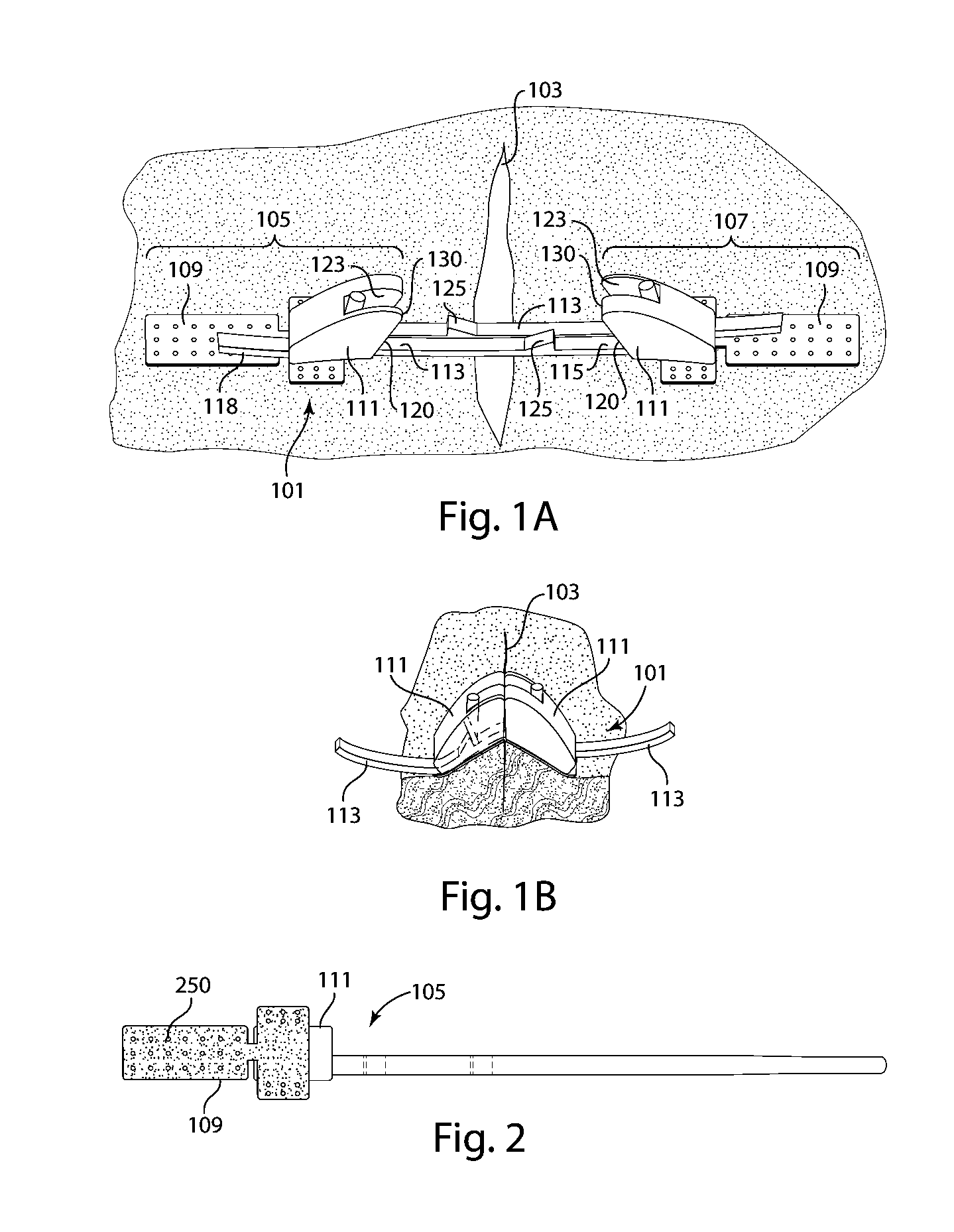

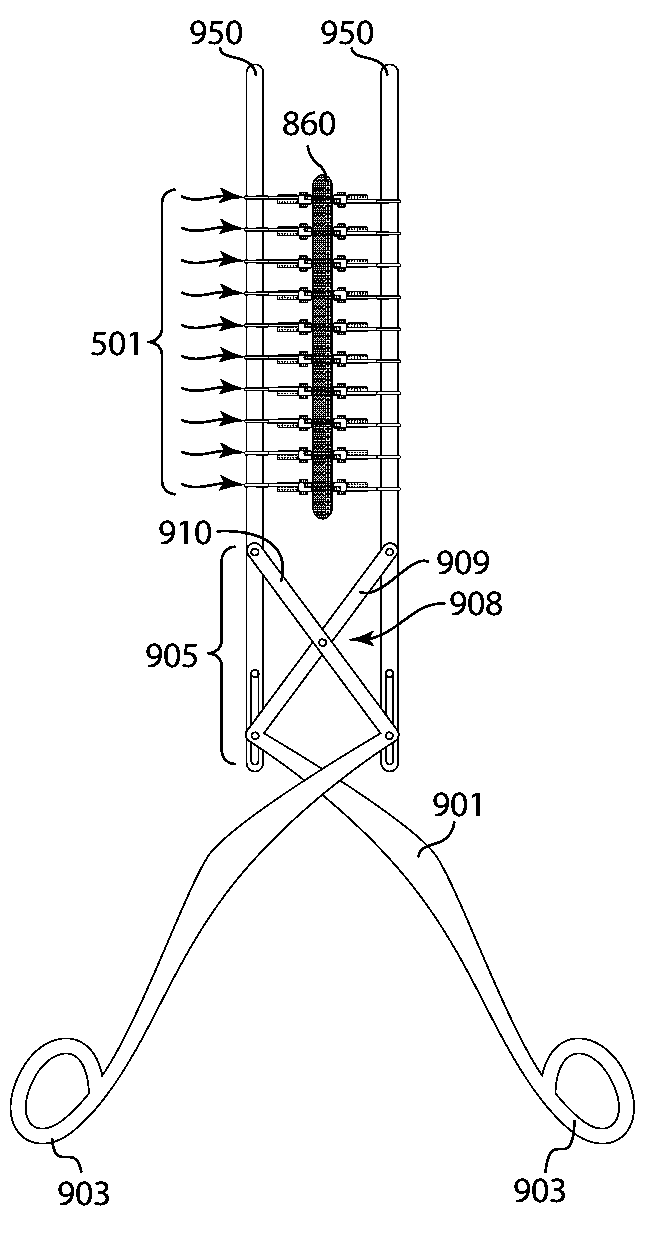

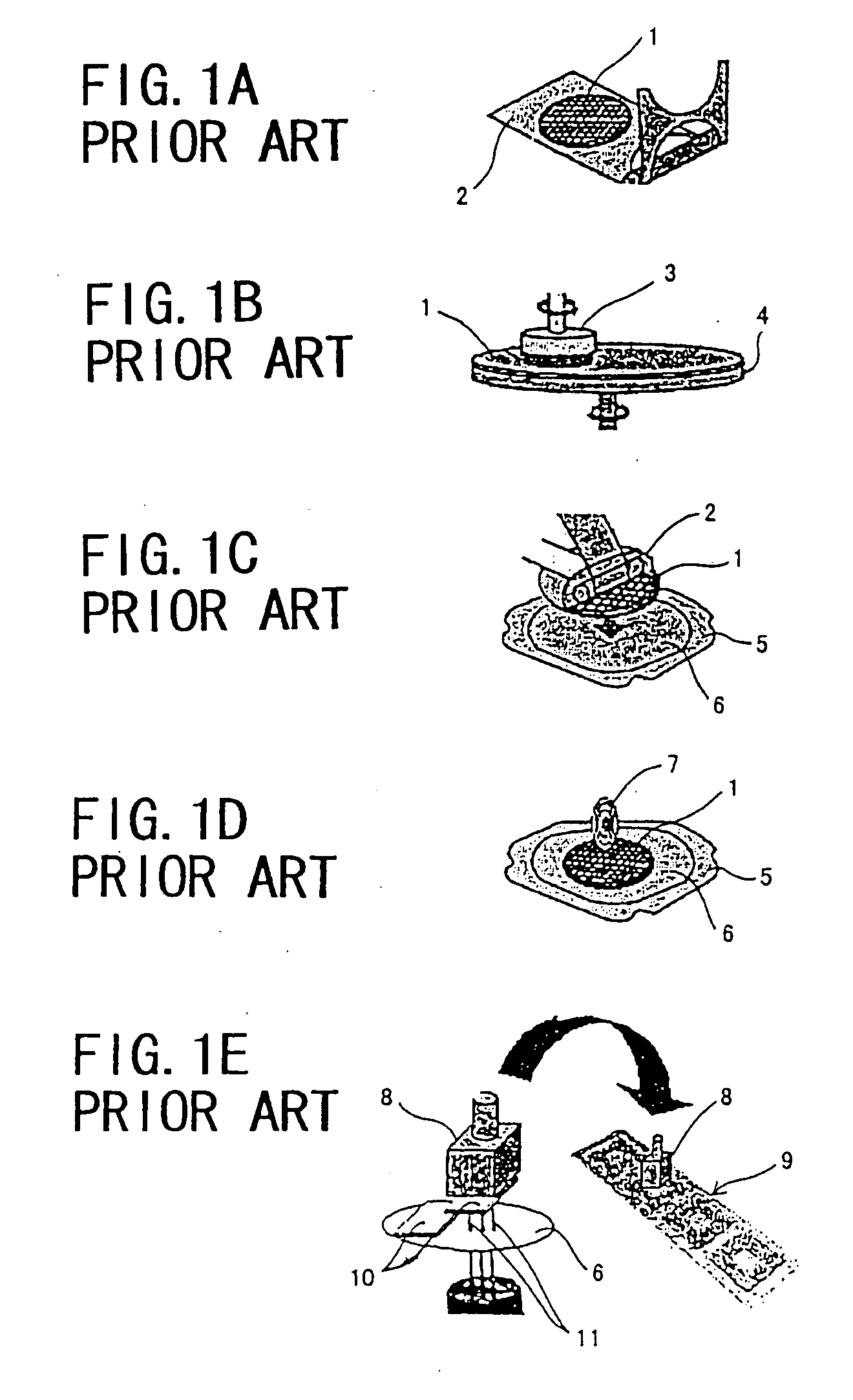

Method and system for preparing soft tissue for grafting, enhancing grafting results, and grafting autologous fat to soft tissue such as the breast

A method is disclosed for preparing a soft tissue site, and augmenting the soft tissue site, such as the breast(s) of a subject through use of devices that exert a distractive force on the breast(s) and grafting of autologous fat tissue such as domes with sealing rims for surrounding each of the breasts and a regulated pump. The method for preparing the soft tissue site, and enhancing fat graft results, entails application of the distracting force to the targeted soft tissue site for several weeks prior to the graft procedure. A related aspect of the invention includes following the preparation steps by transfer of fat from other areas of the subject to the subject's breast(s), and then reapplication of the distractive force to the breast(s) that received the autologous fat graft. Alternatively, fat from genetically related sources may be used, and the fat may be further processed prior to injection. Substantial breast augmentation, high rates of graft survival and negligible graft necrosis (data demonstrating 80% survival and only 20% necrosis is presented) or calcification result from the practice of these methods.

Owner:KHOURI ROGER K

Well chemical treatment utilizing plunger lift delivery system with chemically improved plunger seal

InactiveUS7451823B2Optimize volumeImprove sealingDrilling rodsCleaning apparatusChemical treatmentFoaming agent

Owner:CONOCOPHILLIPS CO

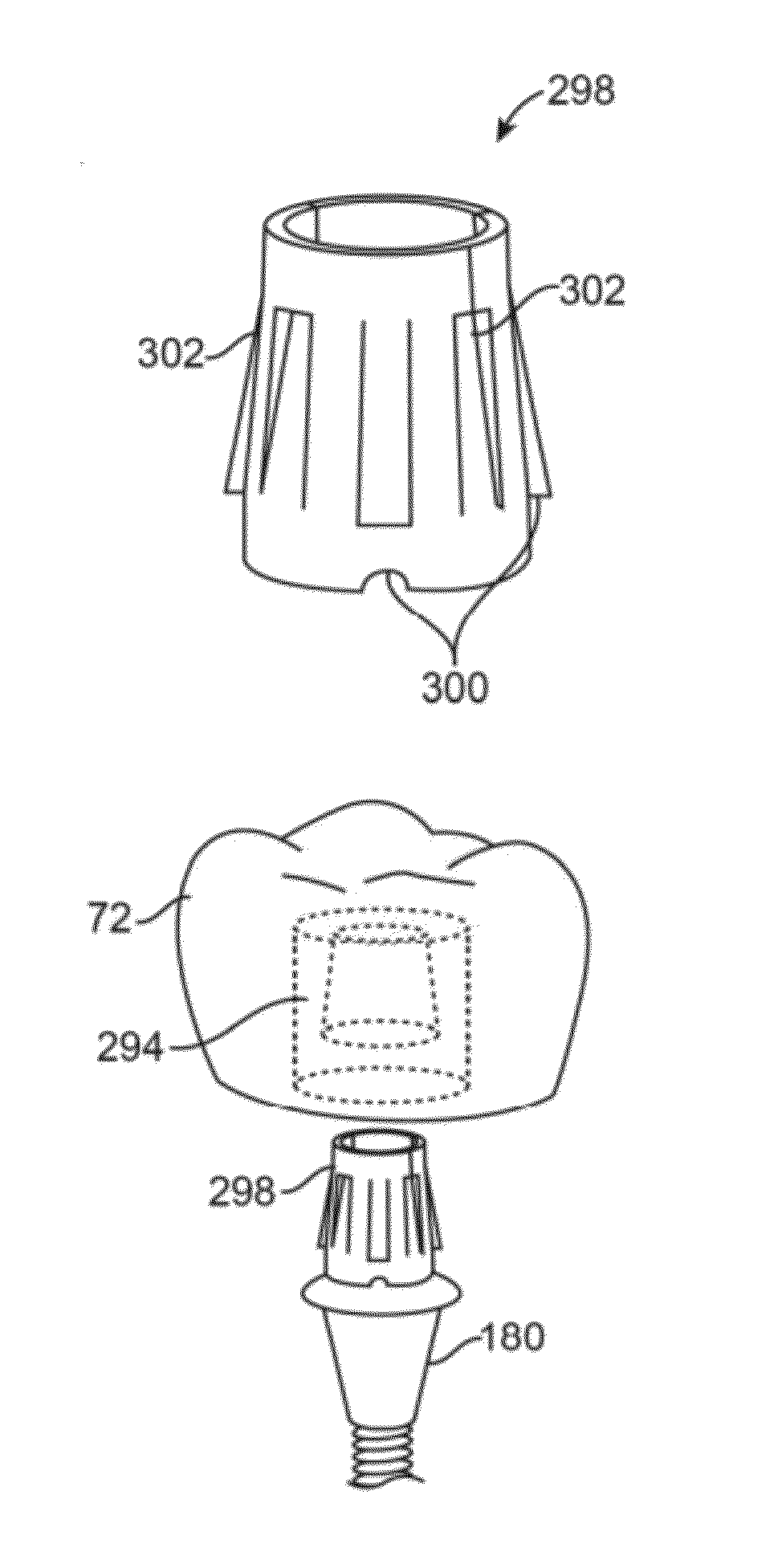

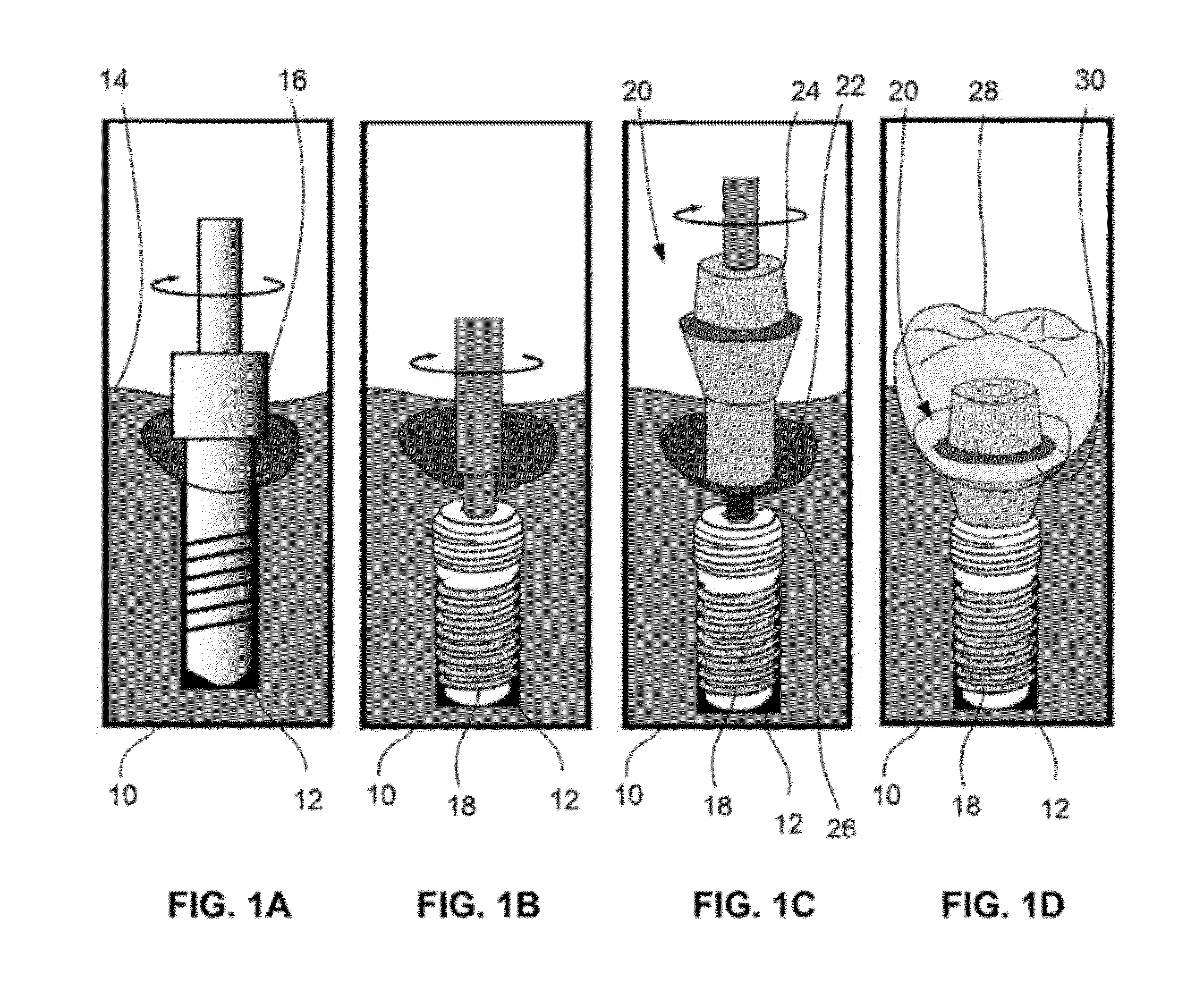

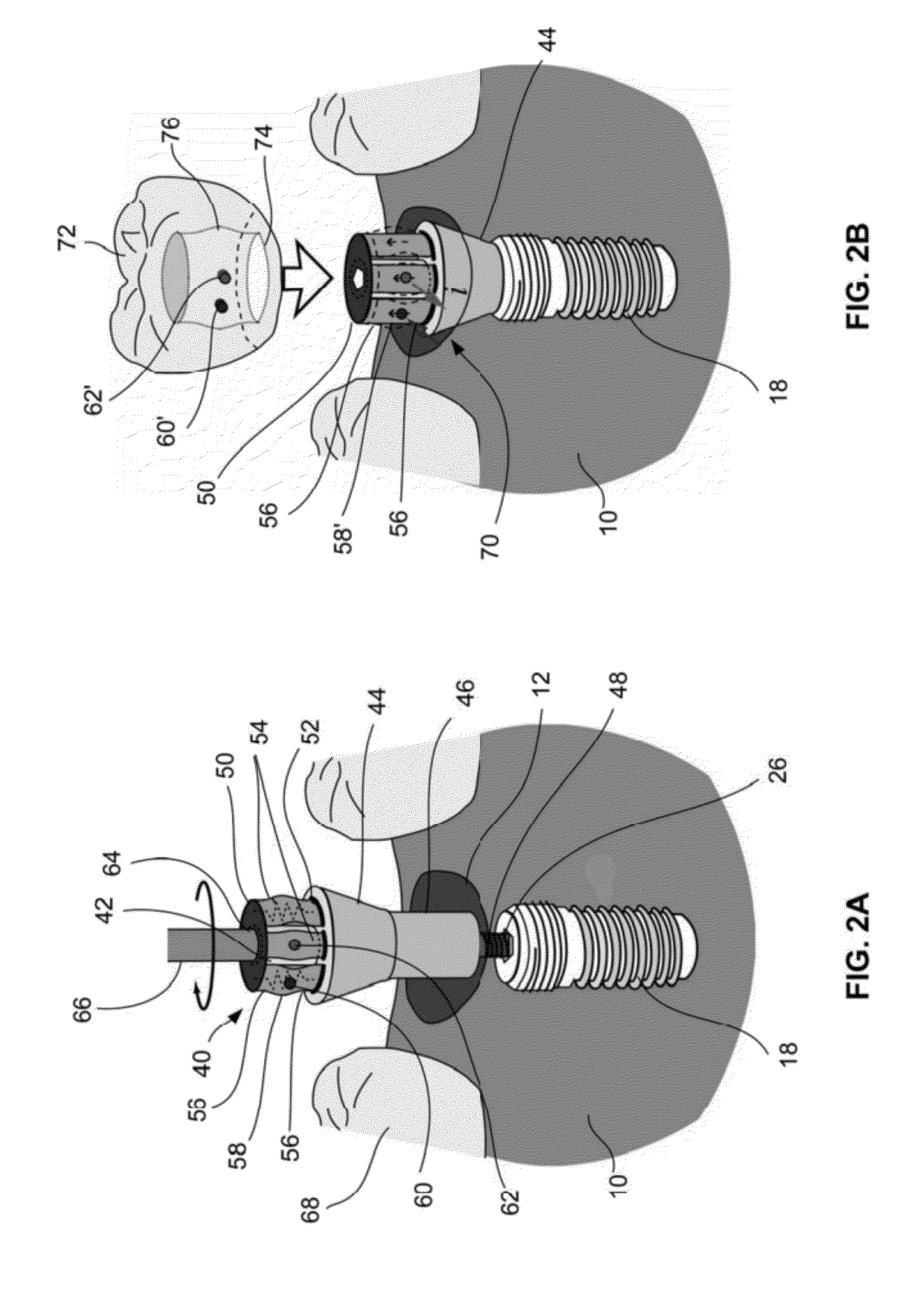

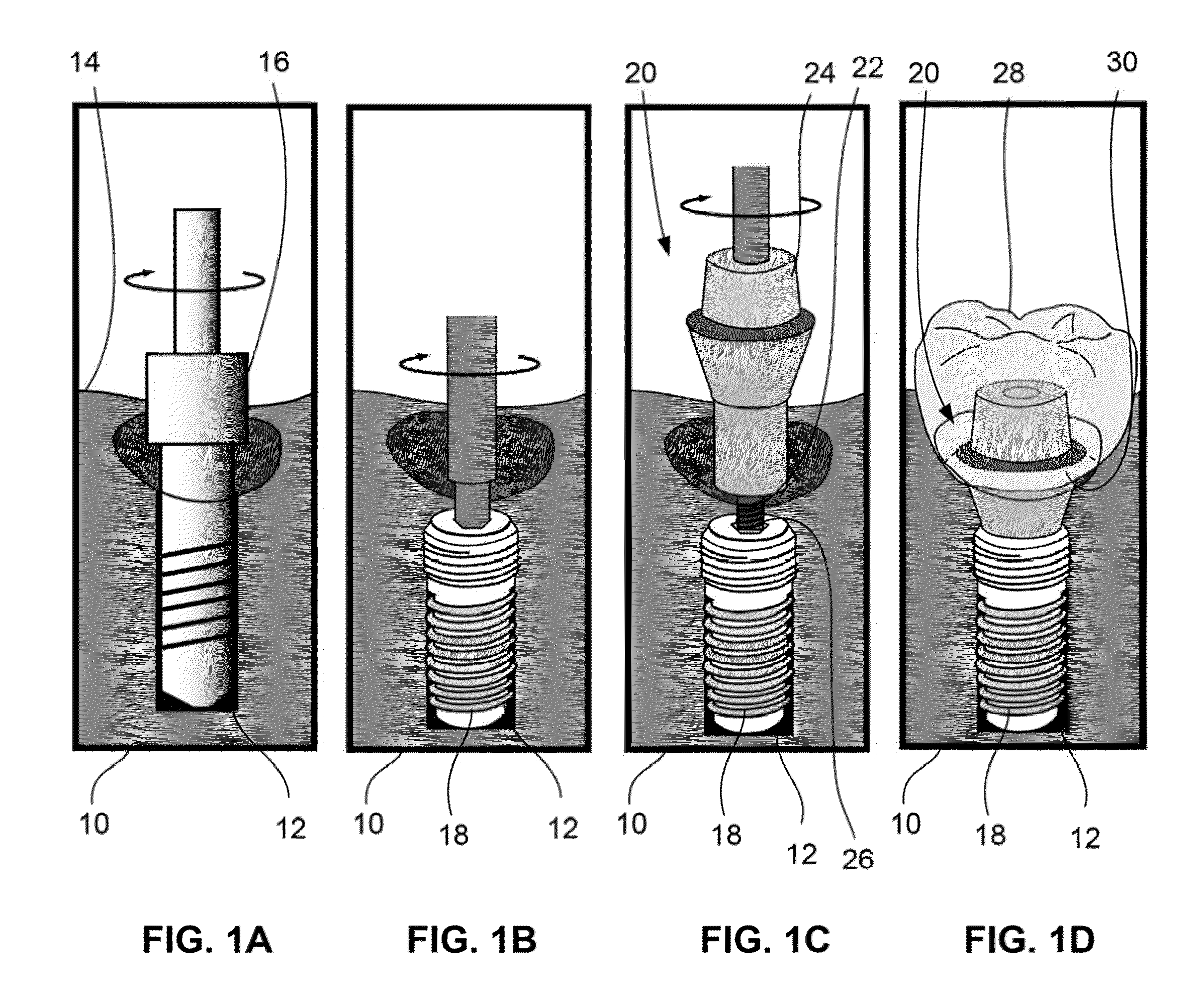

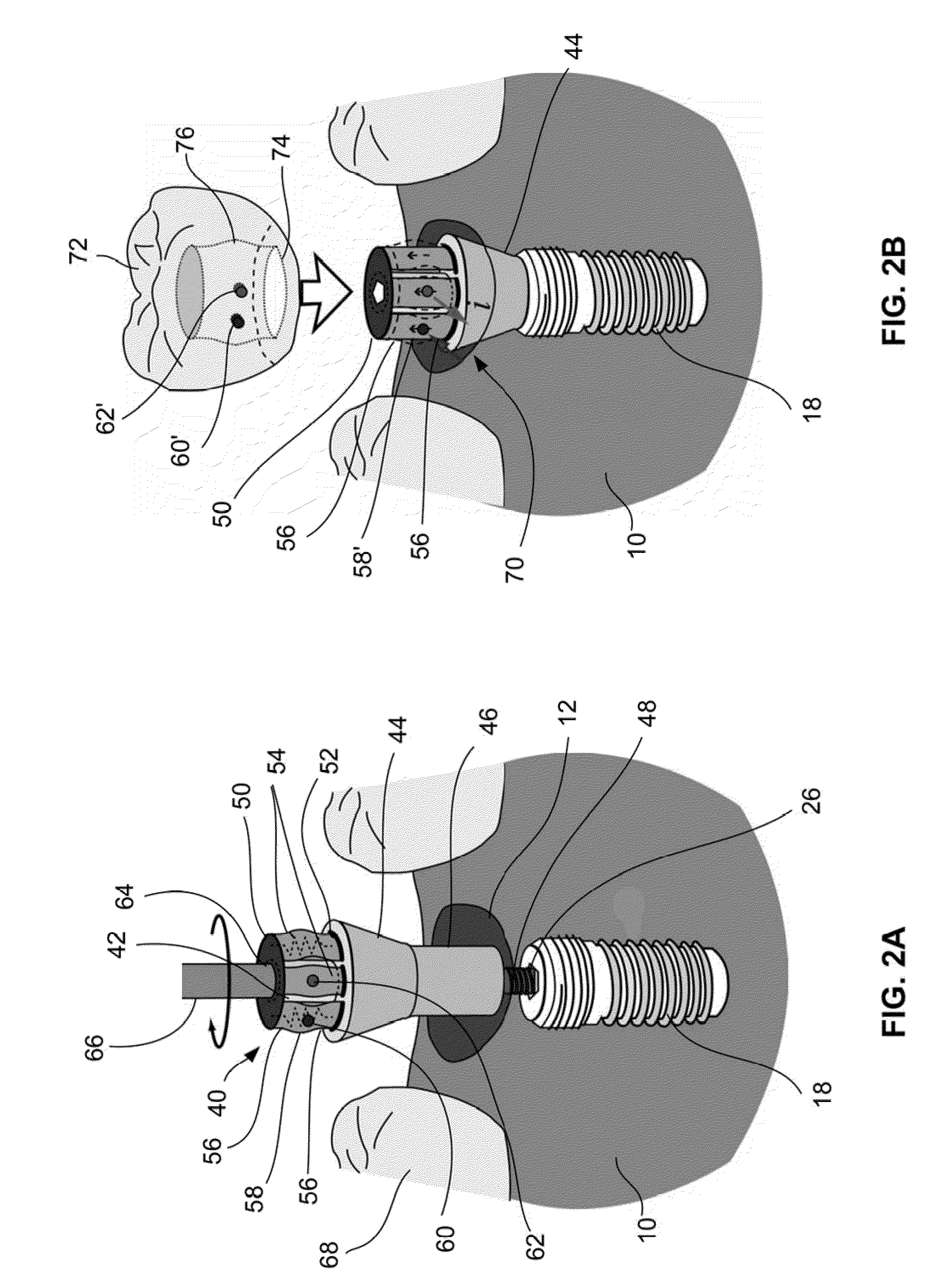

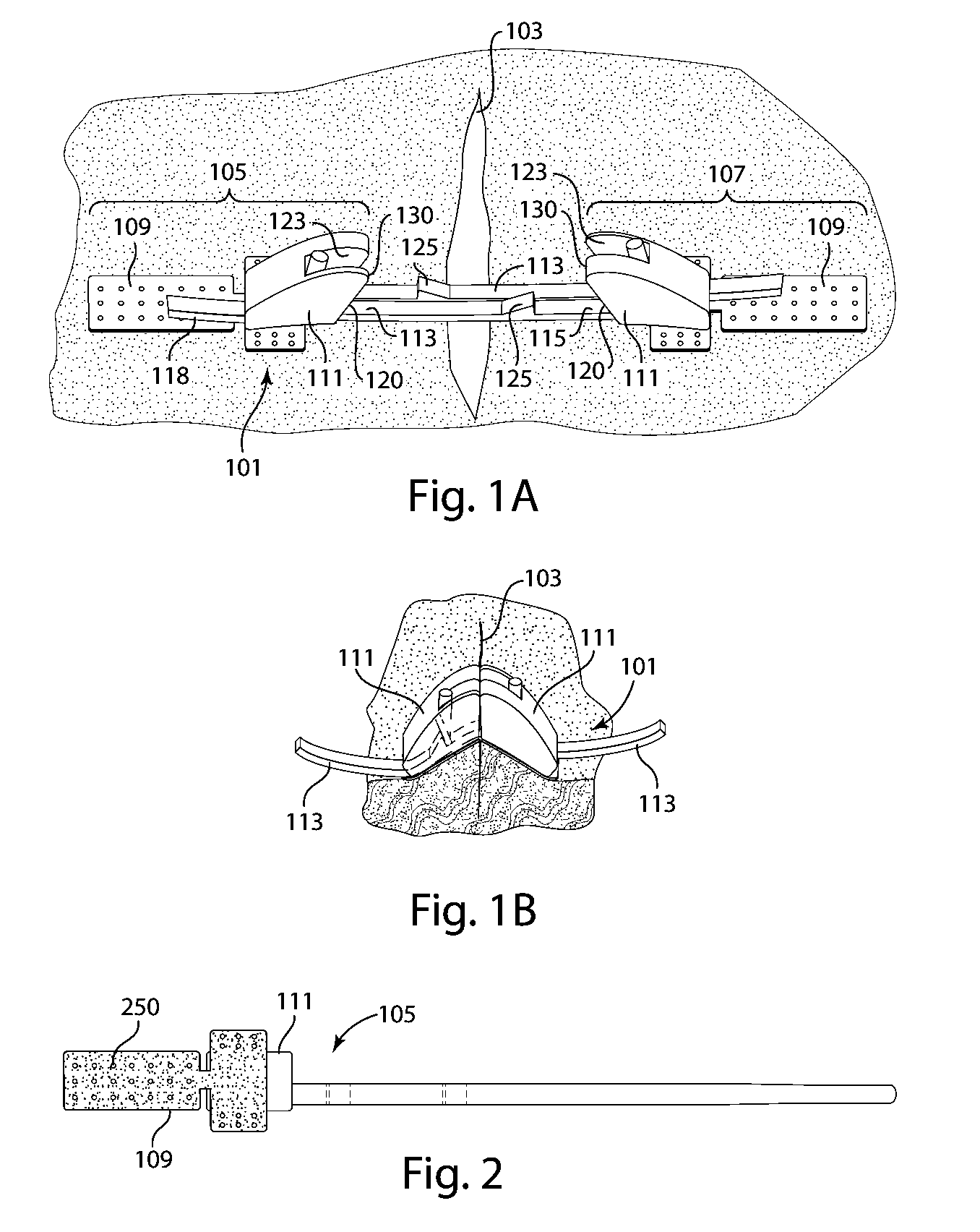

Abutment devices and methods for natural teeth

ActiveUS20120202173A1Prevent movementShorten the lengthDental implantsDentist forcepsNatural toothOral appliance

Root canal abutment devices and methods which facilitate the adjustment or removal of an oral appliance, e.g., a crown or bridge, from a reconfigurable abutment assembly are described. The adjustable abutment assembly may be secured within a pulp chamber of a pre-existing tooth. The abutment assembly has a projecting abutment portion with one or more shape memory alloy sleeves or plates or elements extending along the abutment. Each of the sleeves has a length with at least one curved or arcuate portion. Energy may be applied to the elements such that the arcuate portion flattens to allow for the oral appliance to be placed thereupon while removal of the energy allows the elements to reconfigure into its curved configuration thereby locking the oral appliance to the abutment. Removal of the oral appliance may be effected by reapplication of energy to the elements.

Owner:RODO MEDICAL

Method and system for preparing soft tissue for grafting, enhancing grafting results, and grafting autologous fat and adipocyte derived stem cells to soft tissue such as the breast and other tissue defects

ActiveUS20090312746A1Reduce the possibilityEliminate fatMammary implantsDiagnosticsHigh rateFat grafting

A method is disclosed for preparing a soft tissue site, and augmenting the soft tissue site, such as the breast(s), scar, depression, or other defect, of a subject through use of devices that exert a distractive force on the breast(s) and grafting of autologous fat tissue such as domes with sealing rims for surrounding each of the soft tissue site and a regulated pump. The method for preparing the soft tissue site, and enhancing fat graft results, entails application of the distracting force to the targeted soft tissue site at least intermittently for some period of time and preferably several weeks prior to the graft procedure. A related aspect of the invention includes following the preparation steps by transfer of fat from other areas of the subject to the subject's soft tissue site, and then reapplication of the distractive force to the soft tissue site that received the autologous fat graft. Alternatively, fat from genetically related sources may be used, and the fat may be further processed prior to injection. Substantial soft tissue augmentation, high rates of graft survival and negligible graft necrosis (data demonstrating 80% survival and only 20% necrosis is presented) or calcification result from the practice of these methods.

Owner:KHOURI ROGER

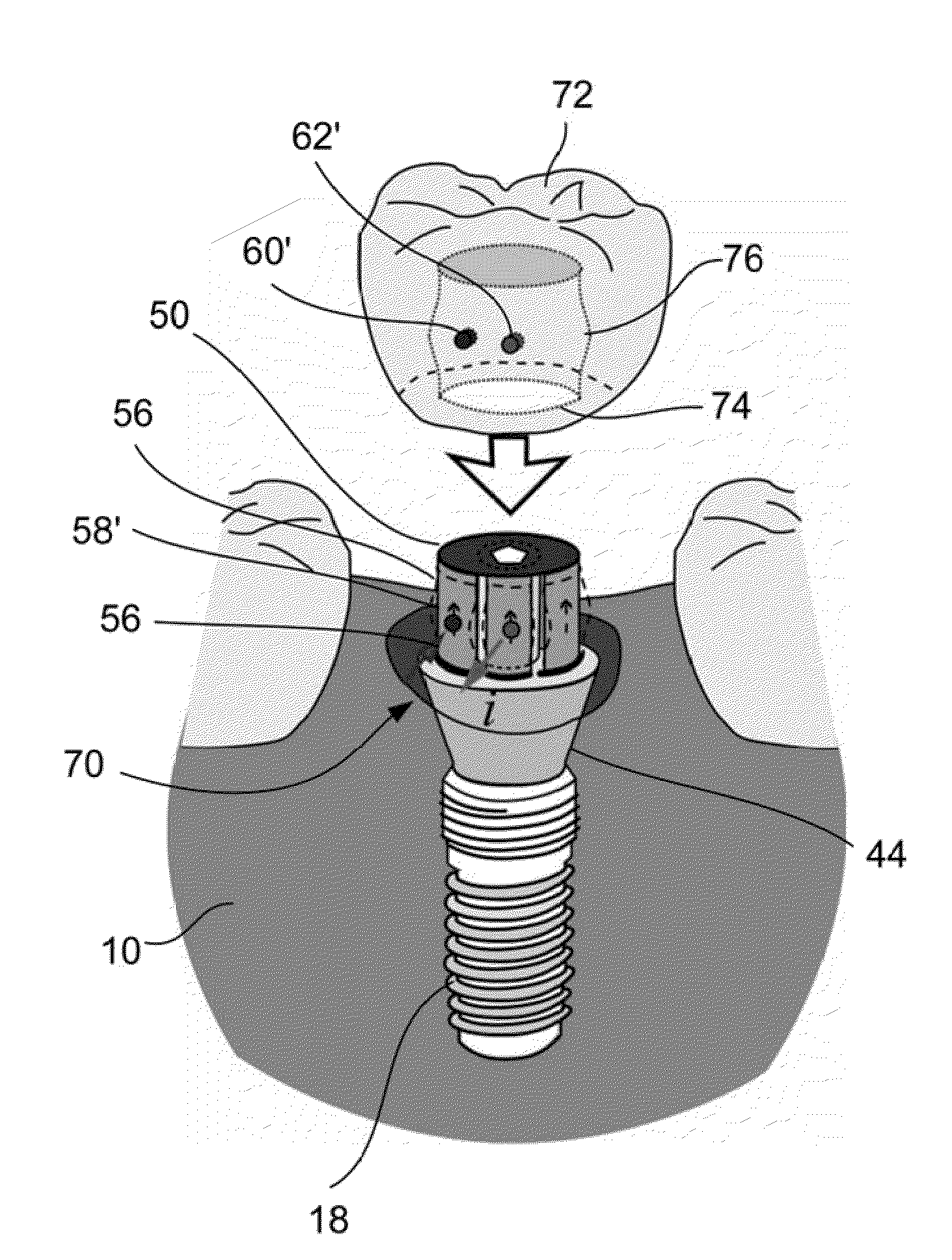

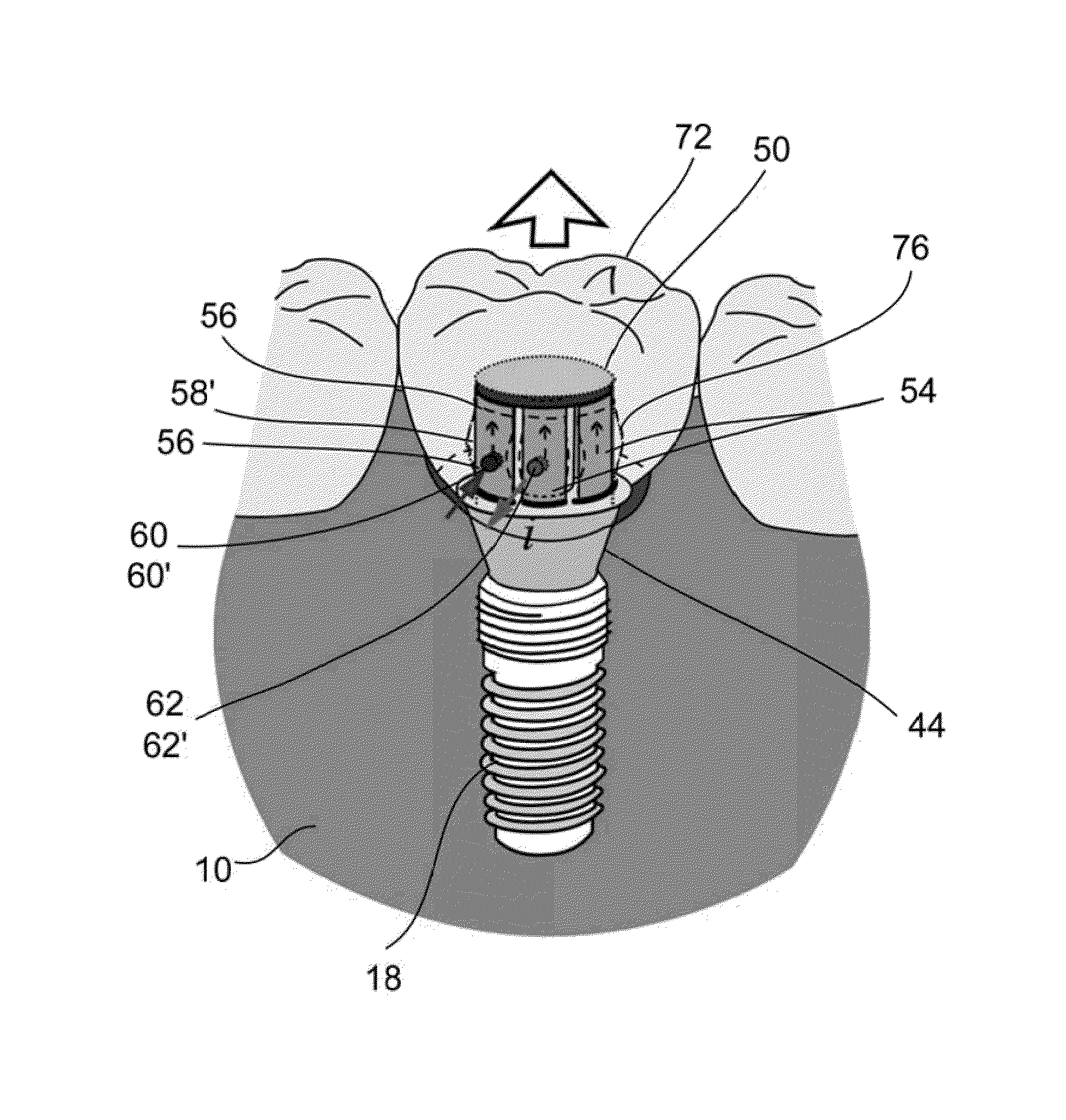

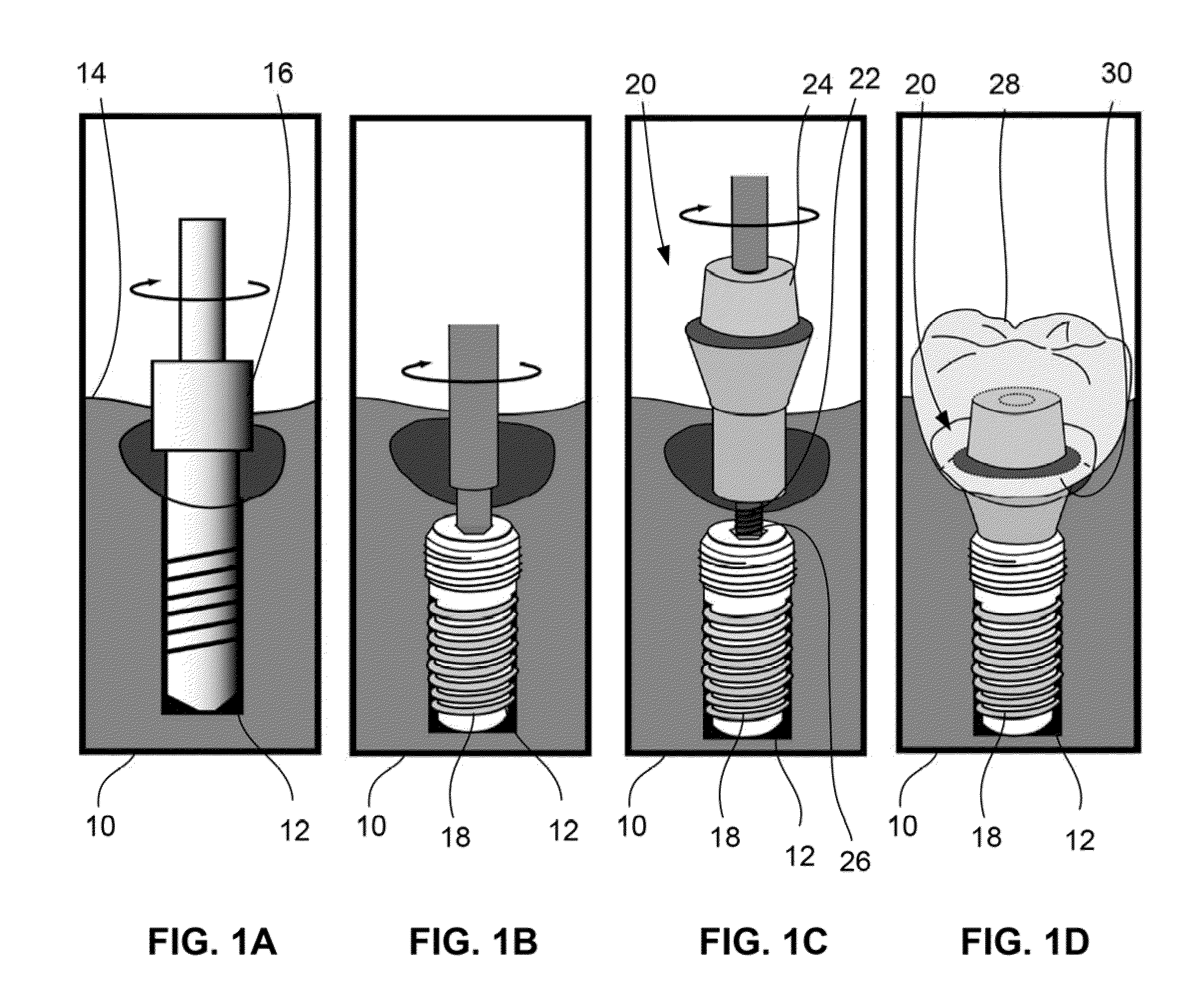

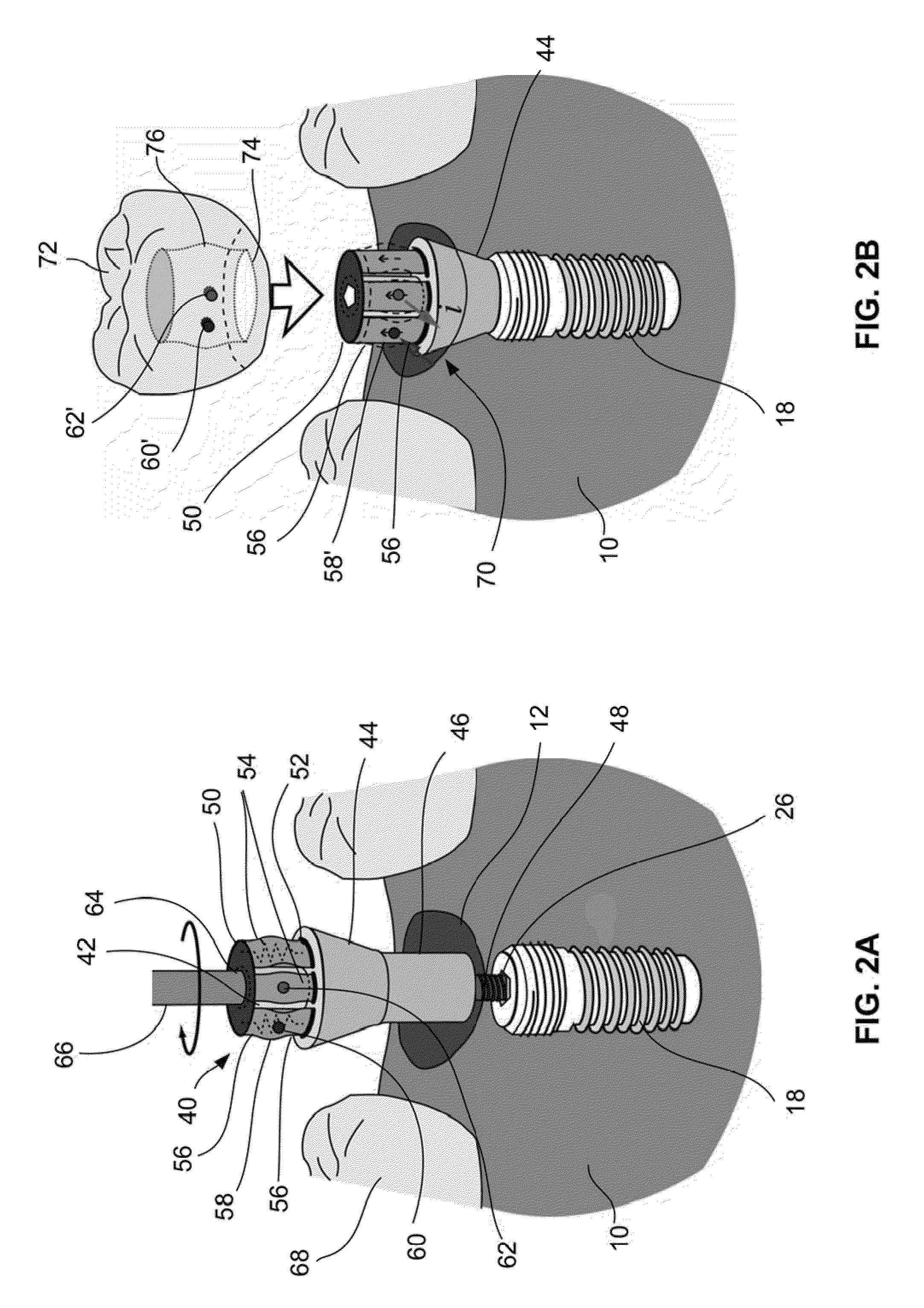

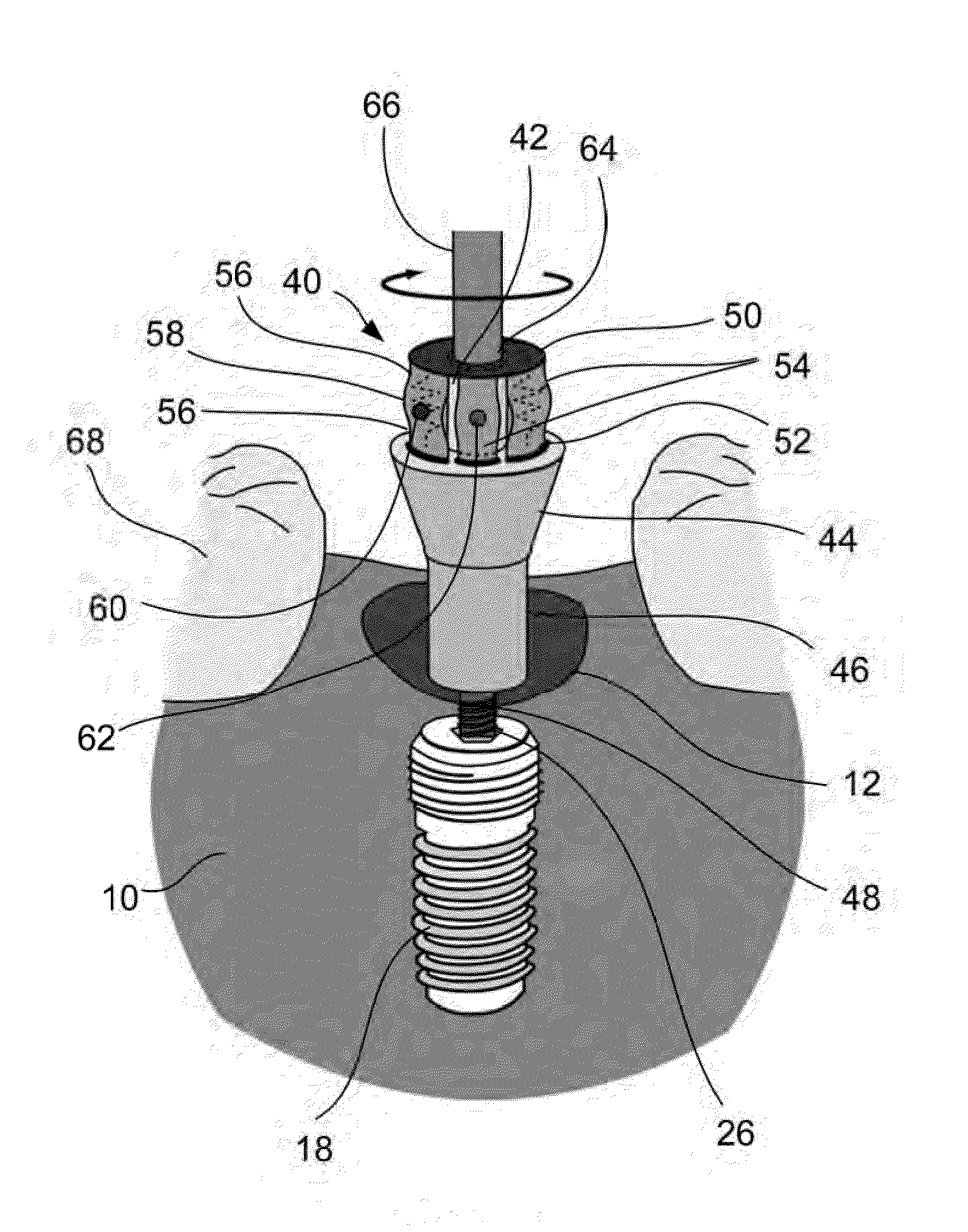

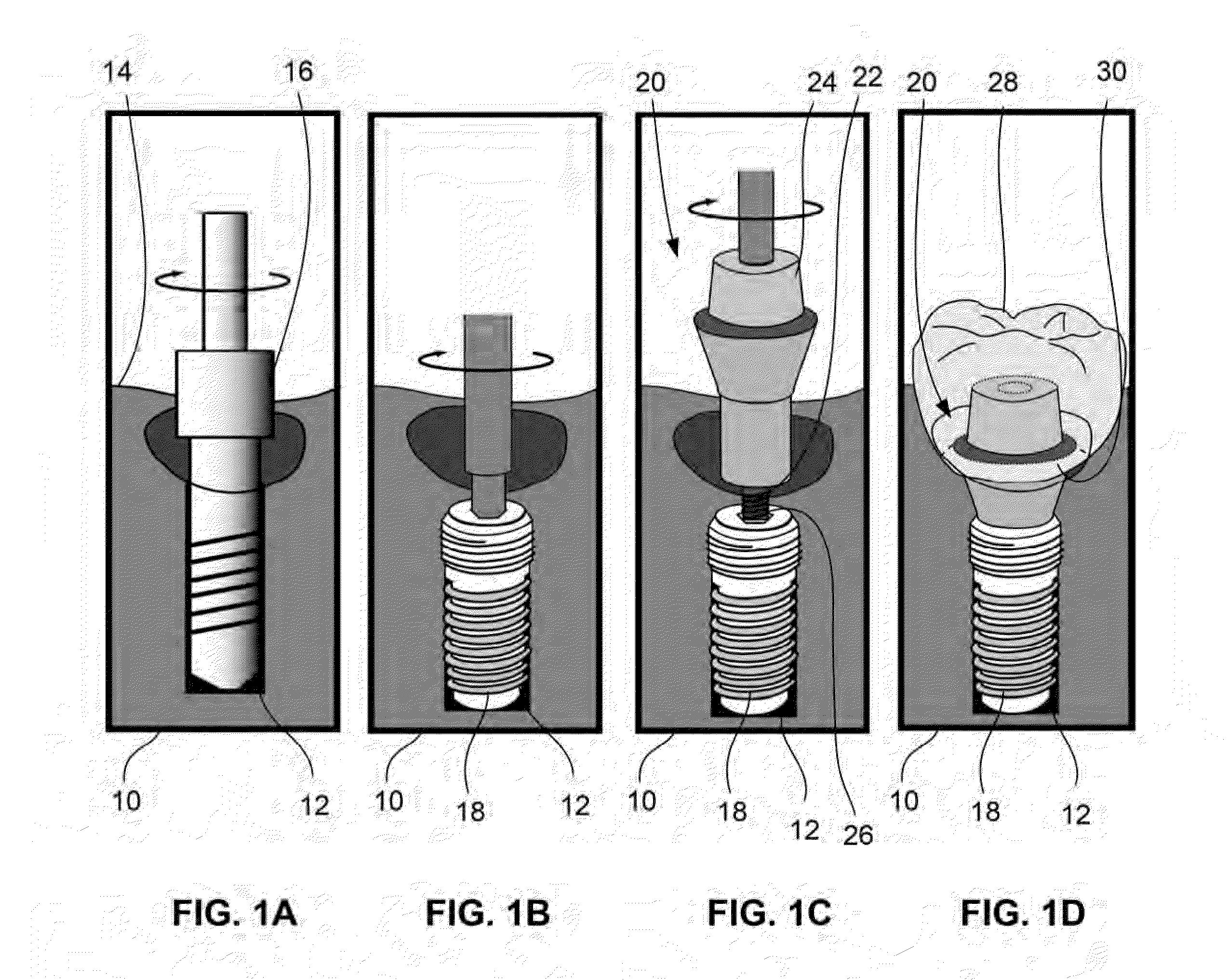

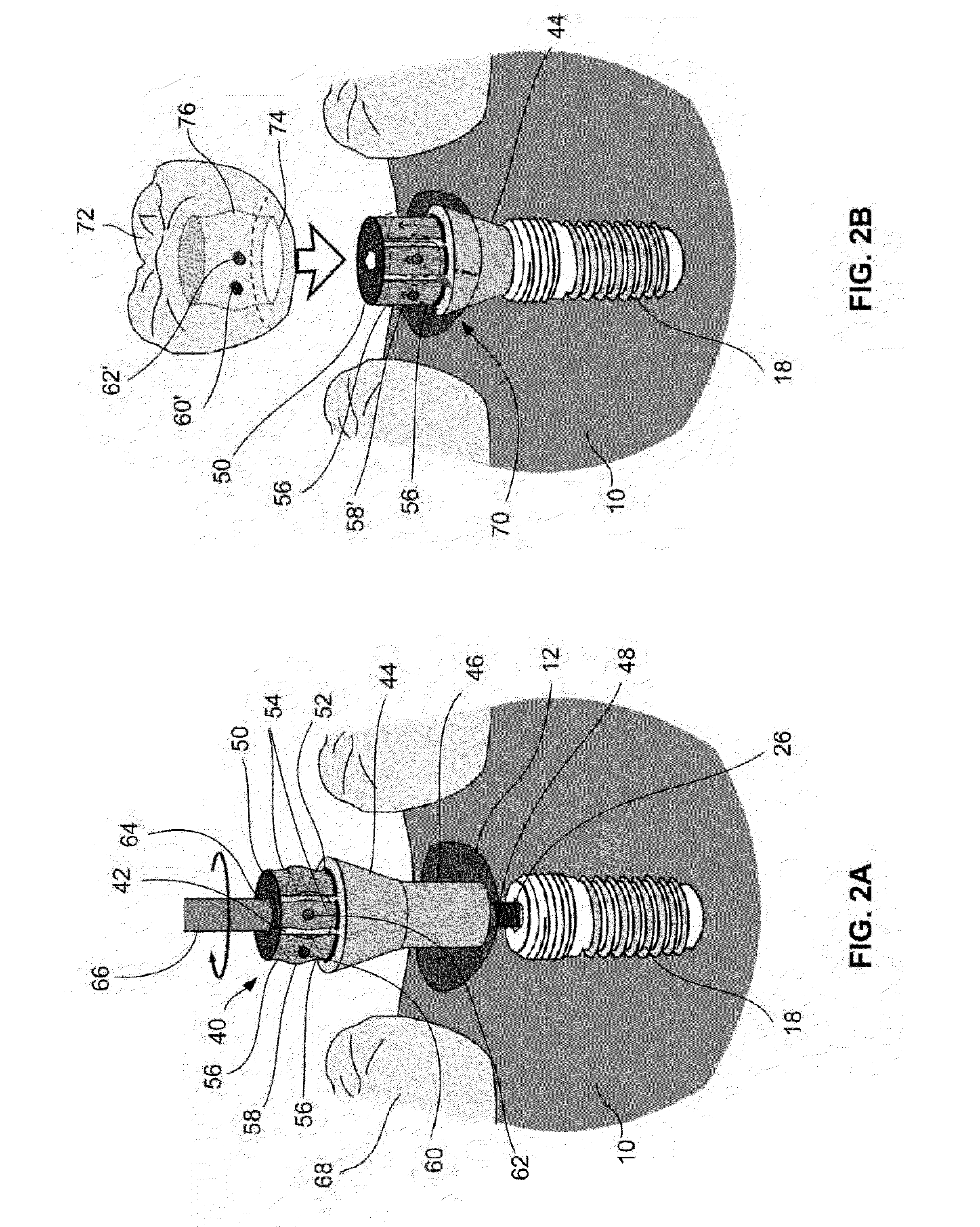

Dental rentention systems

ActiveUS20110014585A1Prevent movementShorten the lengthDental implantsFastening prosthesisOral applianceShape-memory alloy

Dental retention systems which facilitate the adjustment or removal of an oral appliance, e.g., a crown or bridge, from a reconfigurable abutment assembly are described. The adjustable abutment assembly may be secured to an anchoring implant bored into the bones within the mouth. The abutment assembly has a projecting abutment portion with one or more shape memory alloy compression plates or elements extending along the projecting abutment portion. Each of the plates has a length with one or more straightened portions and with at least one curved or arcuate portion. Energy may be applied to the elements such that the arcuate portion self-flattens to allow for the oral appliance to be placed thereupon while removal of the energy allows the elements to reconfigure into its curved configuration thereby locking the oral appliance to the abutment. Removal of the oral appliance may be effected by reapplication of energy to the elements.

Owner:RODO MEDICAL

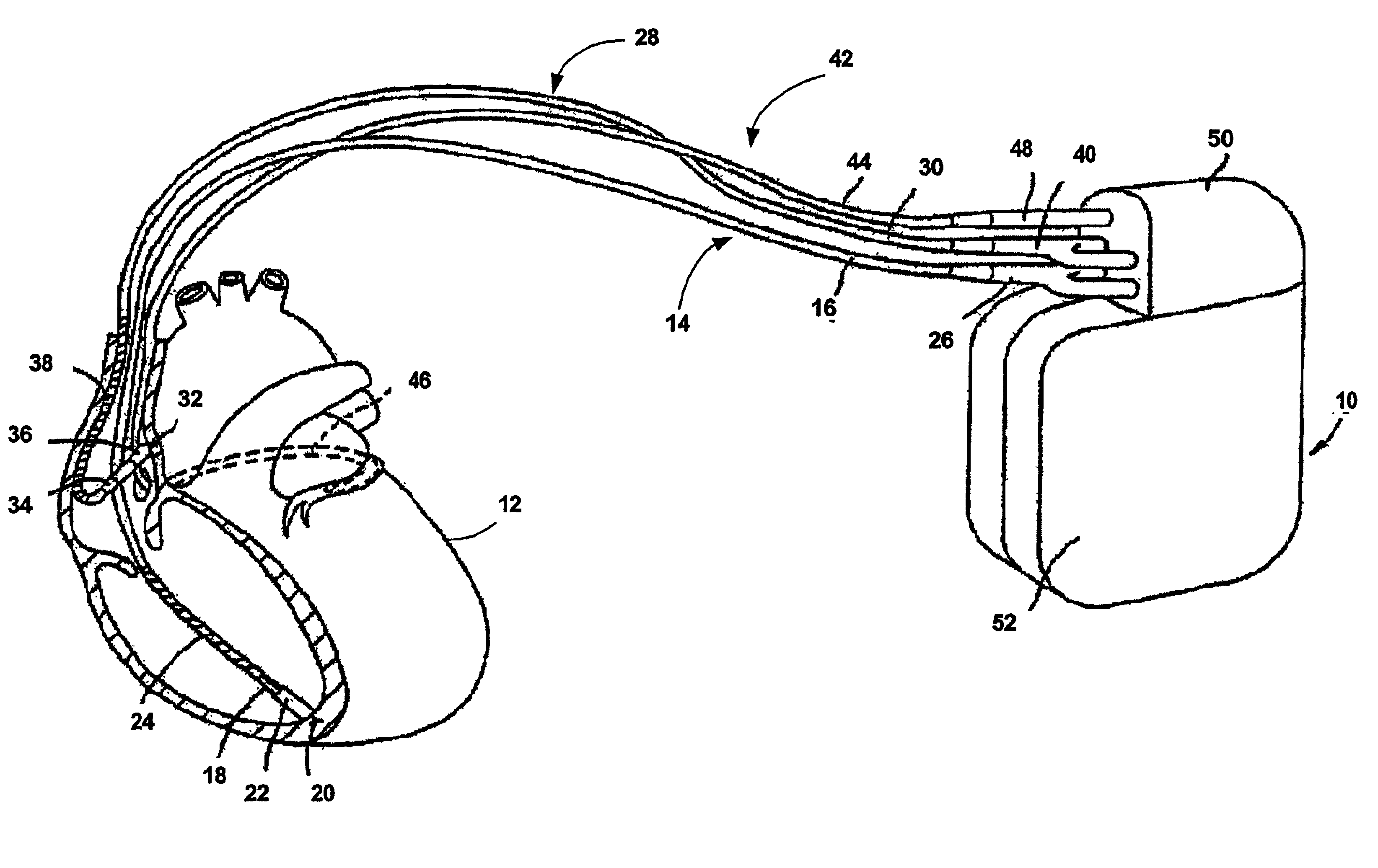

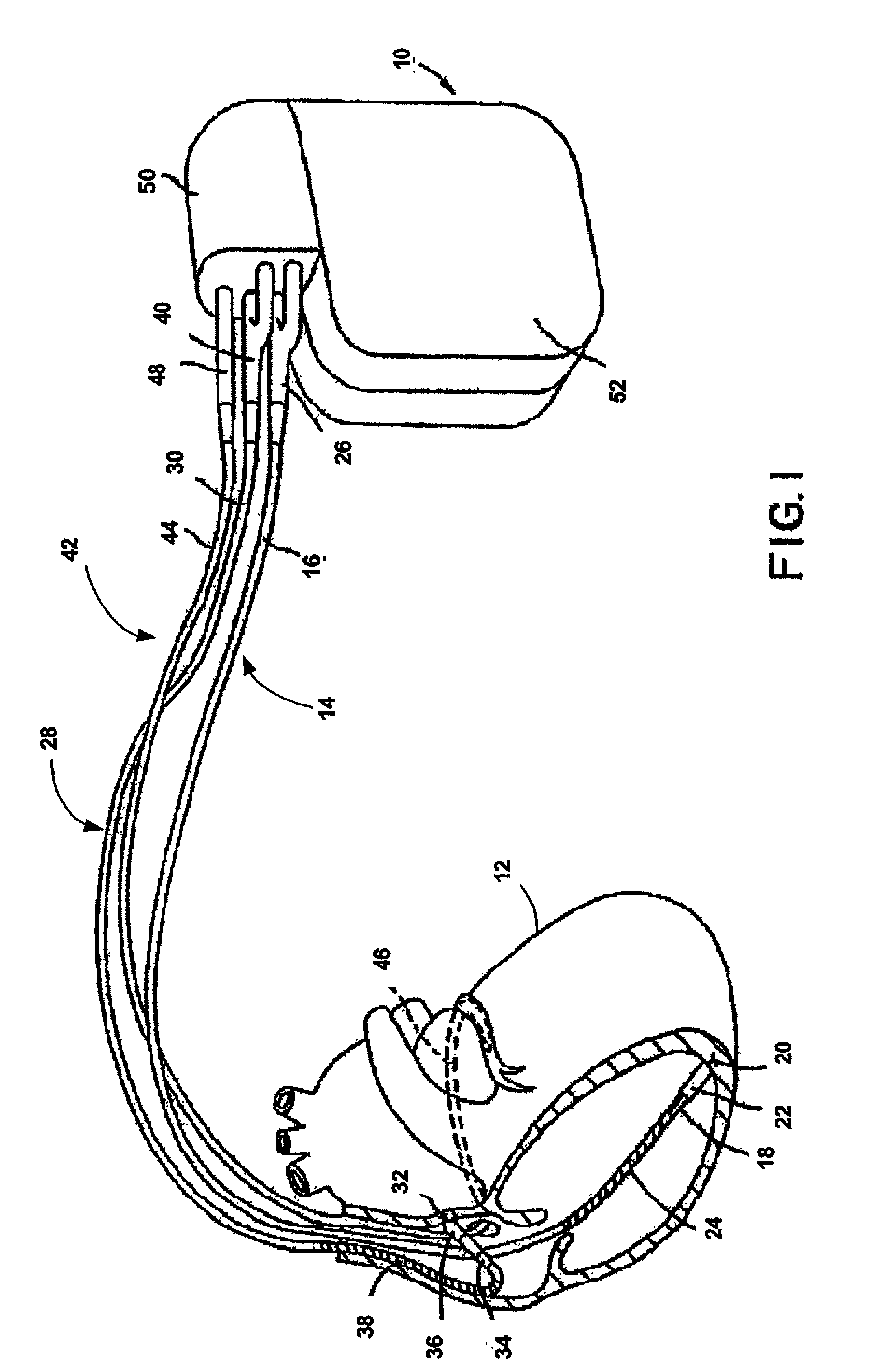

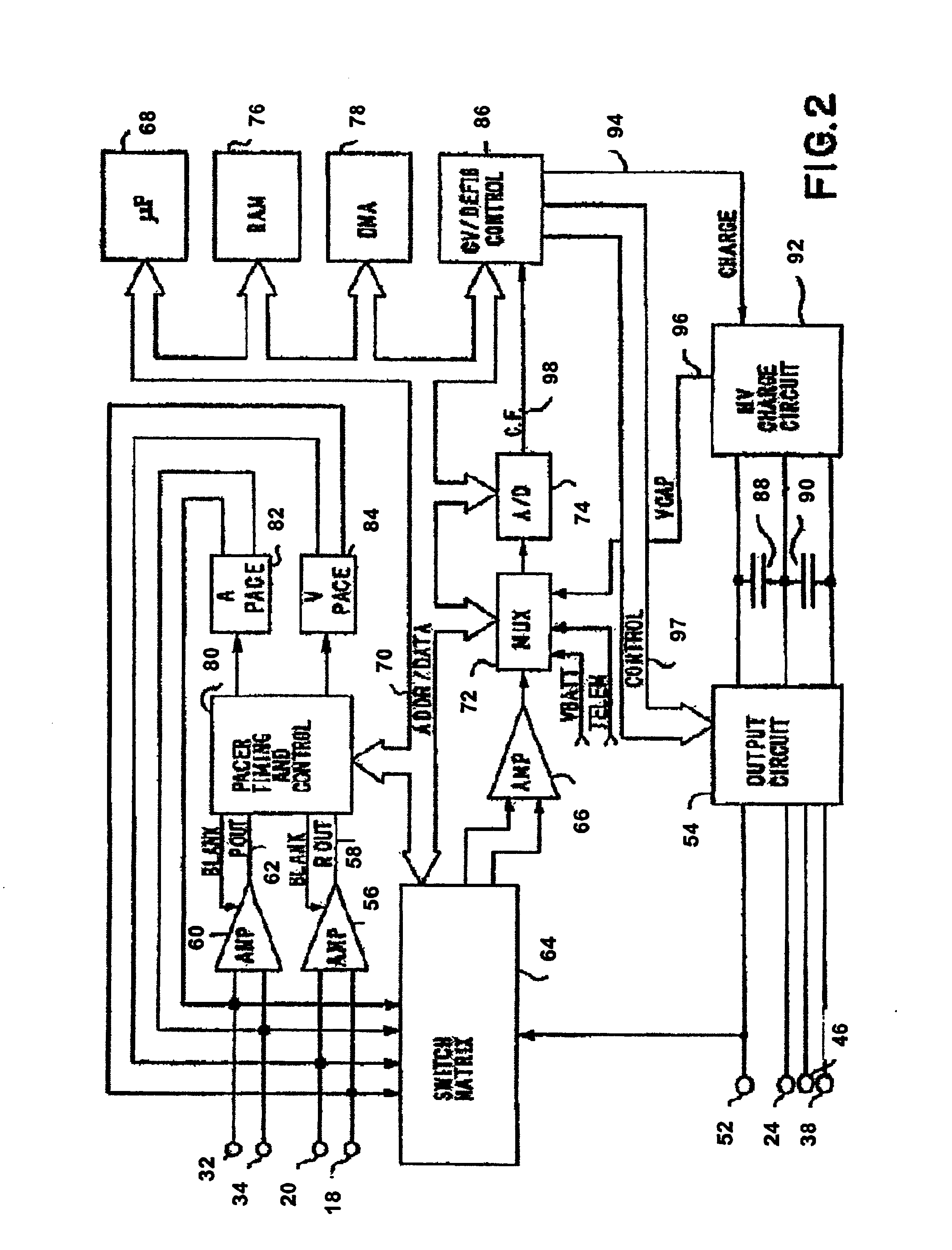

Automated reapplication of atrial pacing therapies

InactiveUS6876880B2Good curative effectReducing atrial tachyarrhythmia burdenHeart defibrillatorsHeart stimulatorsAtrial pacingMedical device

The invention relates to the use of atrial pacing therapies to treat atrial tachycardia (AT). When an AT episode is detected, an implantable medical device applies an ATP therapy. If the AT episode persists, the ATP therapy may be automatically reapplied at a later time during the course of the same AT episode. In particular, previously used ATP therapies are reapplied when episodic conditions, such as cycle length or cycle regularity, change. Although a particular ATP therapy initially may be unsuccessful in terminating the AT, it may prove successful when the cycle length or regularity of the atrial rhythm changes. As the rhythm slows down, the AT may be more responsive to ATP therapies that were previously unsuccessful. As a result, potentially efficacious ATP therapies can be reapplied to terminate AT episodes, and reduce the number of episodes that require more aggressive termination by painful, atrial shocks.

Owner:MEDTRONIC INC

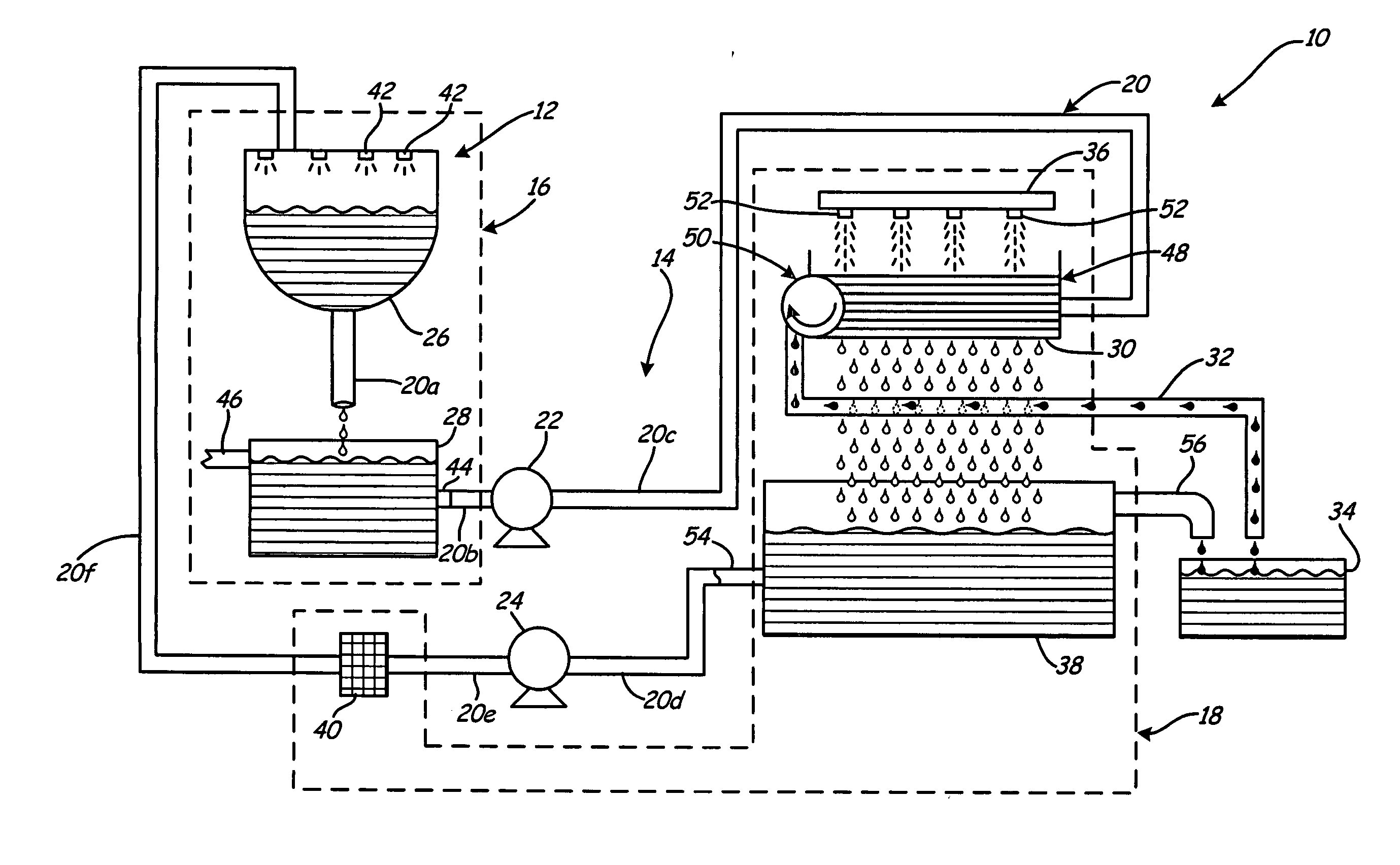

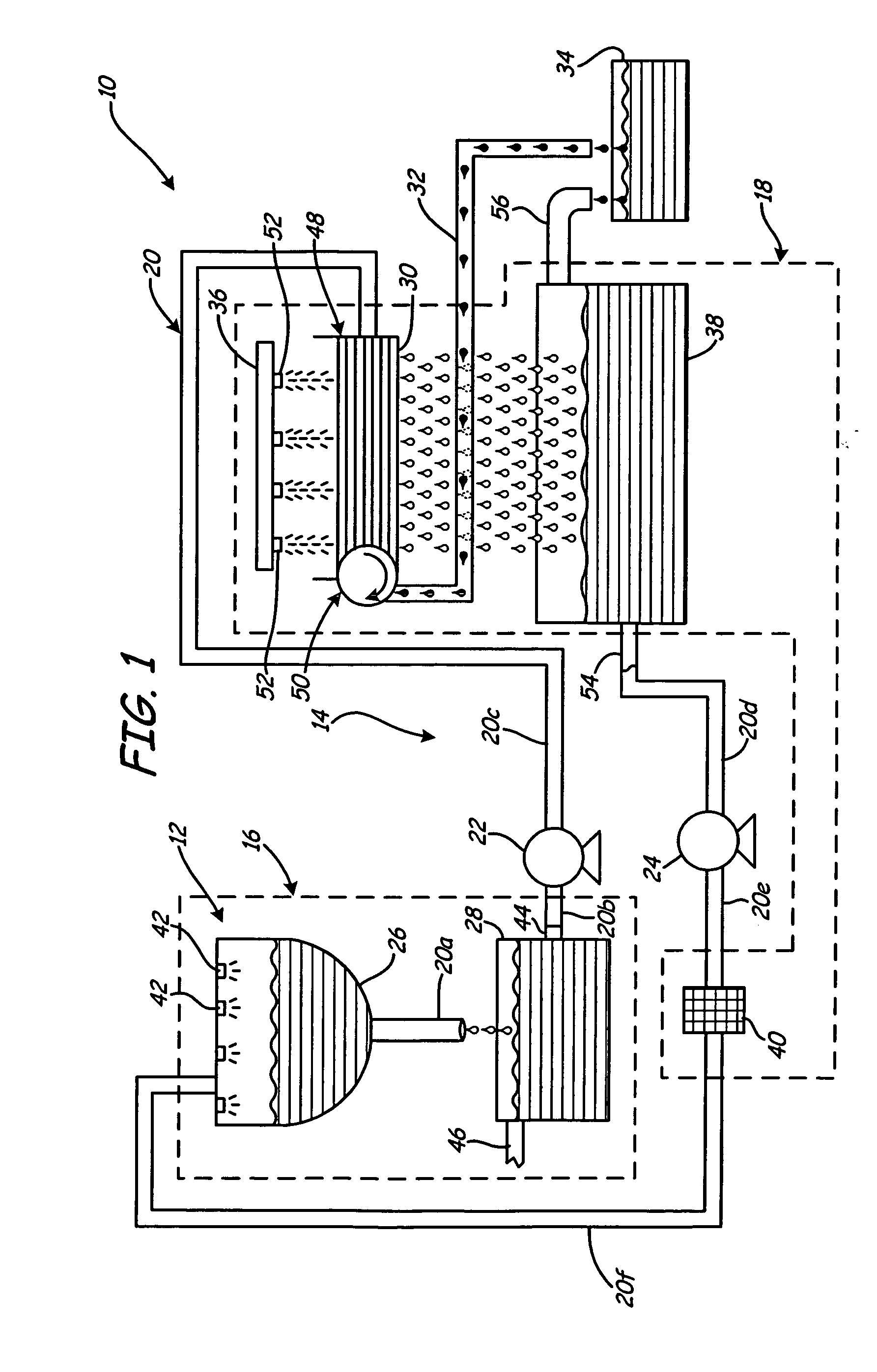

System and method for on-site reclamation, reconditioning, and reapplication of poultry processing water

InactiveUS20070084802A1Fatty/oily/floating substances removal devicesSpecific water treatment objectivesWater cyclingReapplication

A system of the present invention provides on-site reclamation, reconditioning, and re-use of poultry processing water. The system is connectable to a washing apparatus and comprises a first receptacle, a filter, a dispenser, a channel, a second receptacle, piping, and a plurality of pumps for circulating the processing water through the system. The processing water leaving the washing apparatus is collected in the first receptacle and pumped to the filter, where the processing water is filtered. As the processing water is being filtered, the dispenser dispenses an antimicrobial solution and water onto the filter. The debris filtered from the processing water is removed through the channel. The filtered processing water is then collected in the second receptacle prior to re-use.

Owner:ECOLAB USA INC

Well chemical treatment utilizing plunger lift delivery system

InactiveUS7117947B2Improve efficiencyDrilling rodsCleaning apparatusChemical treatmentCompound (substance)

An apparatus and method for delivery of treatment chemicals to the bottom of the wellbore. The delivery system can be a chemical dispenser which can be attached to a plunger used in plunger lift operations, a plunger which has been impregnated with treatment chemicals, a plunger / dispenser apparatus which has an interface section for interfacing with the inside of the tubing and a dispenser section. Automatic recharging or reapplication of chemicals to the chemical delivery system can be accomplished with a chemical application assembly attached to the plunger manifold.

Owner:CONOCOPHILLIPS CO

Devices for Securely Closing Tissue Openings with Minimized Scarring

ActiveUS20140058444A1Improved wound careAvoid insufficient lengthSurgical veterinaryWound clampsMoistureScars

Devices, tools, systems, kits and methods for closing a tissue opening non-invasively are presented. The devices include a tissue closure device that reliably induces eversion of tissue edges that define a tissue opening. The devices may be used in combination with an applicator tool to provide easy and uniform apposition of the tissue closure devices across the tissue opening. Further embodiments provide for releasable locking of the tissue closure devices, allowing for drainage of wound edema and / or treatment of infection, without removal and reapplication of the devices. Still further embodiments allow for the passing of moisture or other substances that may collect under a tissue closure device.

Owner:DERMACLIP US

Light responsive self-tanning products and methods for use

Compositions, methods, and kits for cosmetically producing a tanned appearance in desired areas of skin. The composition includes a self-tanning agent together with intimately admixed naturally-occurring fluorescent materials in a cosmetic carrier. Without prolonged exposure to intense solar or artificial radiation, applying the self-tanning agent imparts a tanned appearance which develops several hours to a day after application. The fluorescent materials absorb at one frequency, and emit at another visible frequency. The admixture of self-tanning agent and fluorescent materials allows application of the self-tanning agent selectively to desired areas of the skin. A light source which emits at the absorbing frequency of the fluorescent materials may be provided together with the compositions in kit form. By illuminating the skin after the composition has been applied and before the self-tanning agent develops its color, any coverage of undesired areas may be easily removed, and any desired areas which were unintentionally untreated may be detected and subject to reapplication.

Owner:SCALES MEDEIROS VIRGINIA A +1

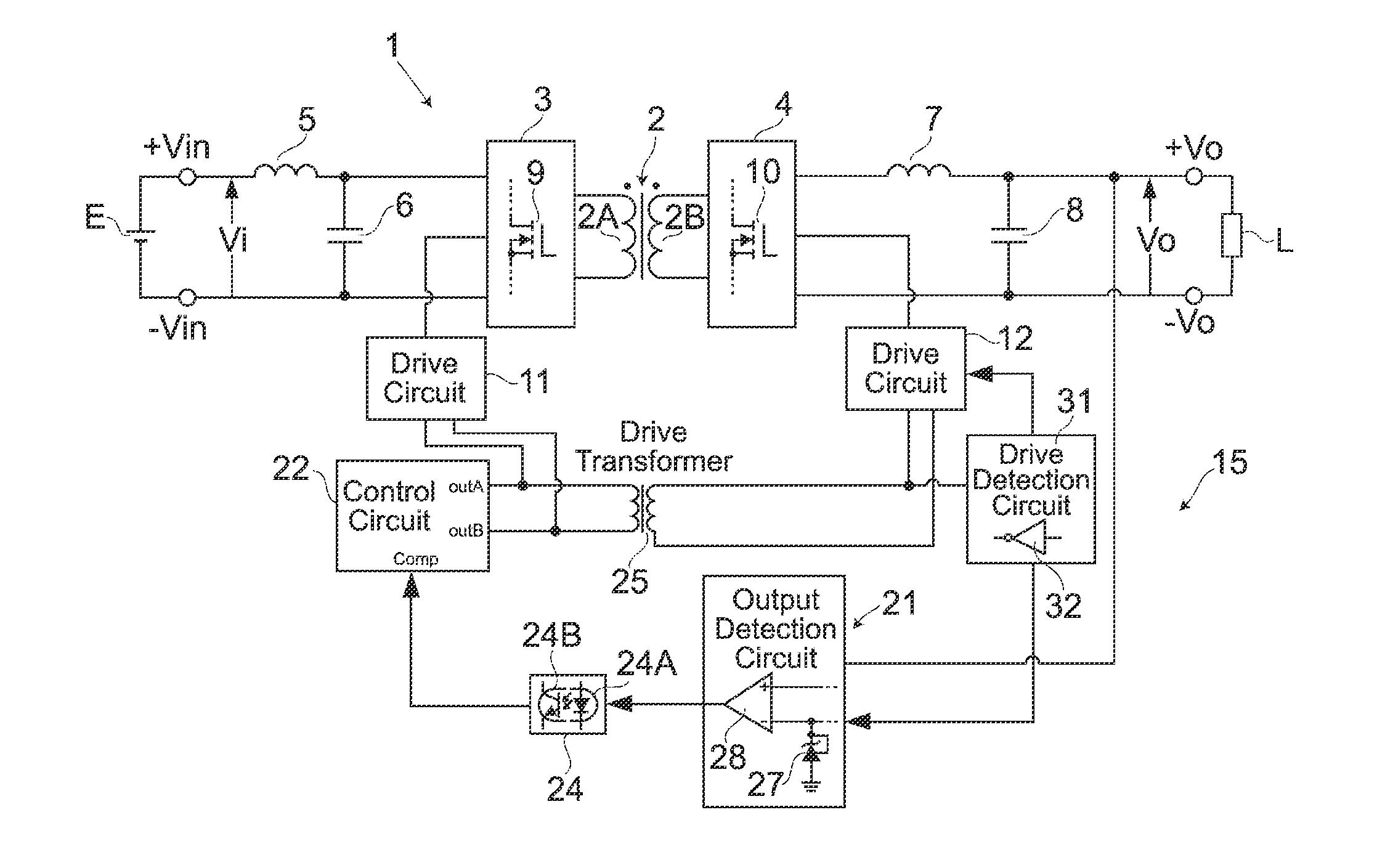

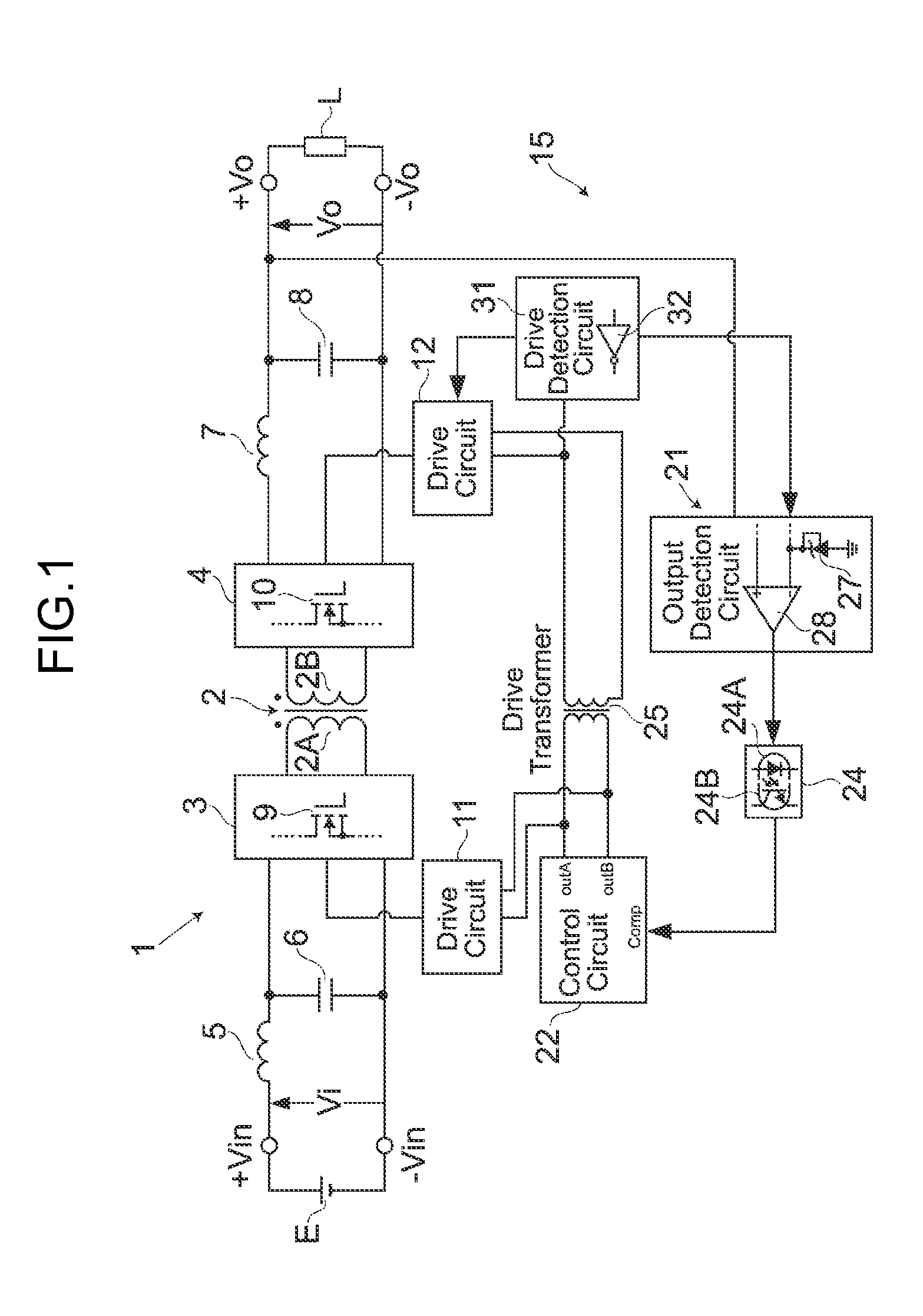

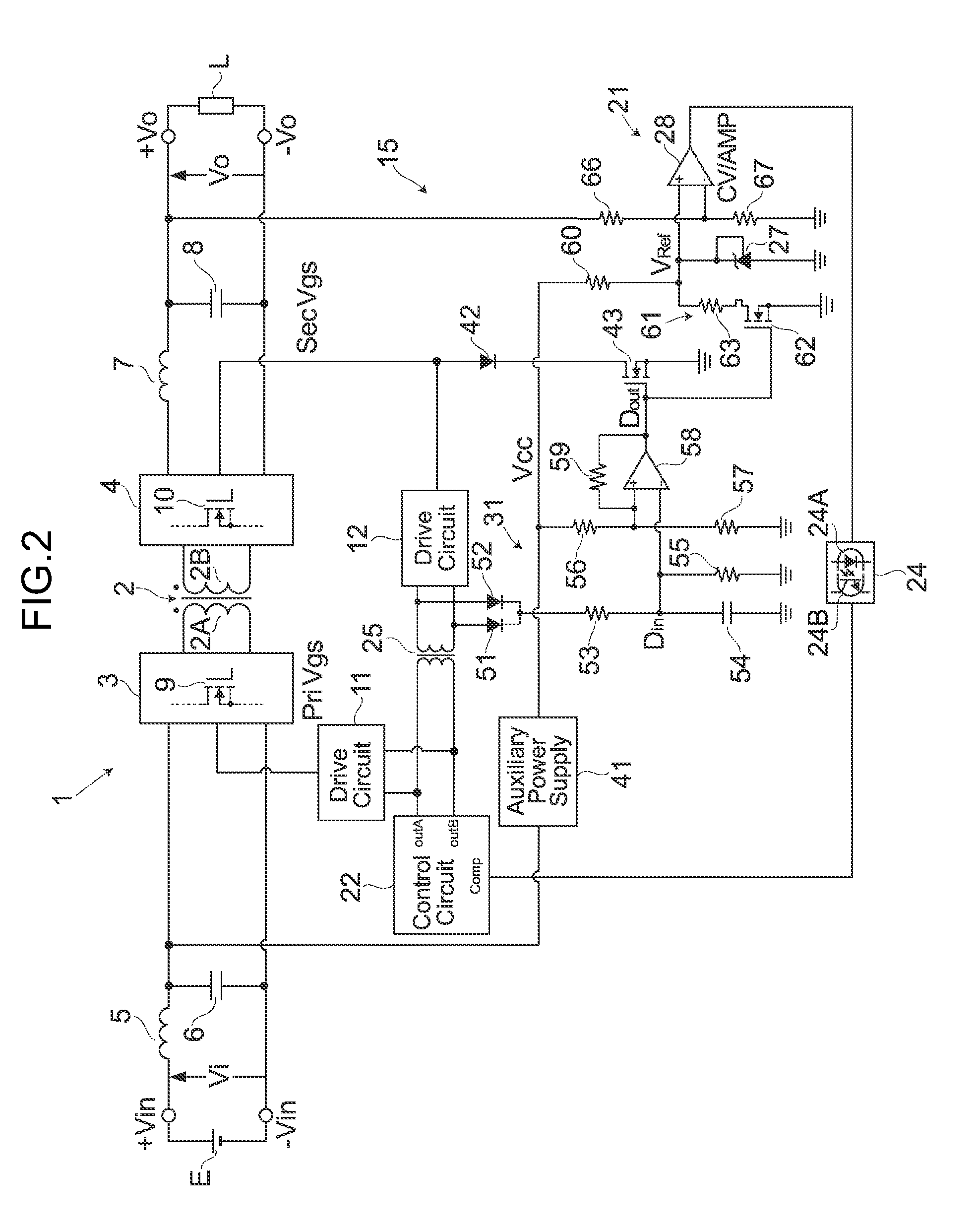

Switching power supply device

A switching power supply device ensuring no voltage dip is caused by a sink current even if started with output voltage accumulated. When input voltage Vi is reapplied with output voltage Vo accumulated, supplying PWM signals to main switching element 9 and rectifying switching elements is stopped by output detection circuit 21 until a voltage produced by dividing output voltage Vo decreases to a first threshold allowable for energy caused by a sink current. Accordingly, inflow of the sink current immediately after reapplication of input voltage and the subsequent voltage dip are inhibited. Afterward, when the voltage produced by dividing the output voltage Vo decreases to the first threshold and then main switching element starts operating by PWM signal from control circuit 22, drive detection circuit 31 detects this condition to permit supplying PWM signal to rectifying switching elements 10, enabling inhibition of the subsequent inflow of the sink current.

Owner:TDK LAMBDA CORP

Well chemical treatment utilizing plunger lift delivery system

InactiveUS20050022994A1Improve efficiencyCleaning apparatusFluid removalChemical treatmentCompound (substance)

An apparatus and method for delivery of treatment chemicals to the bottom of the wellbore. The delivery system can be a chemical dispenser which can be attached to a plunger used in plunger lift operations, a plunger which has been impregnated with treatment chemicals, a plunger / dispenser apparatus which has an interface section for interfacing with the inside of the tubing and a dispenser section. Automatic recharging or reapplication of chemicals to the chemical delivery system can be accomplished with a chemical application assembly attached to the plunger manifold.

Owner:CONOCOPHILLIPS CO

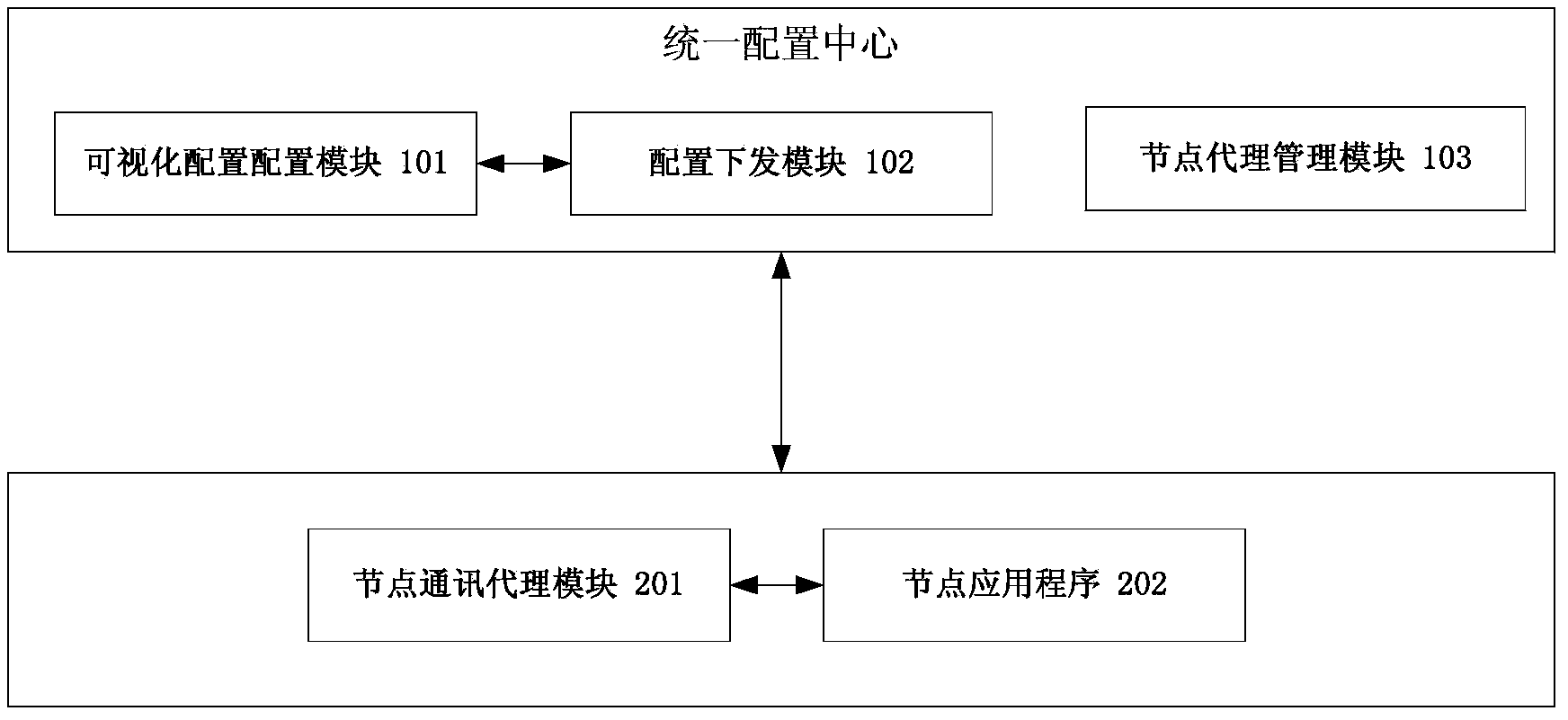

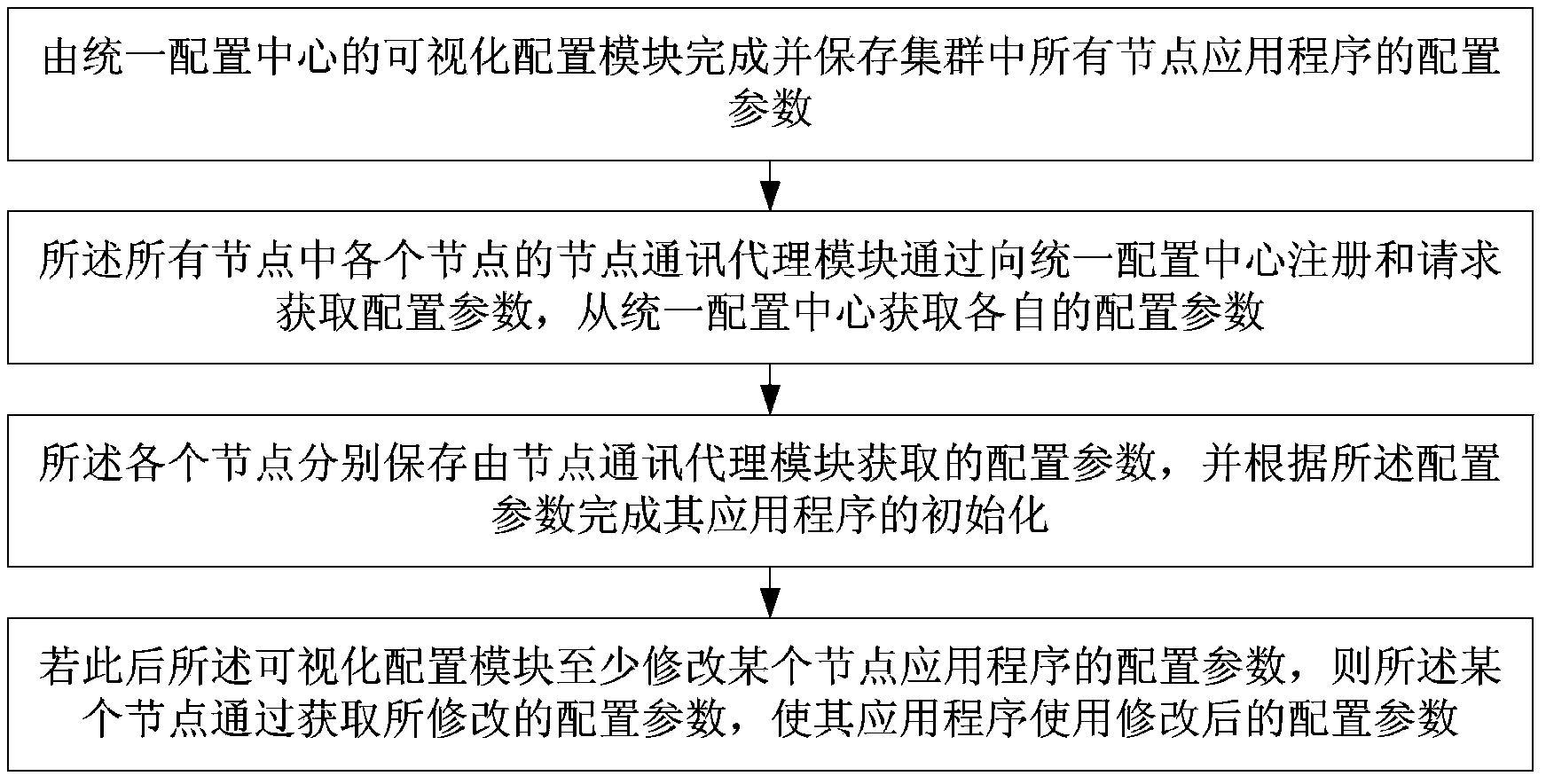

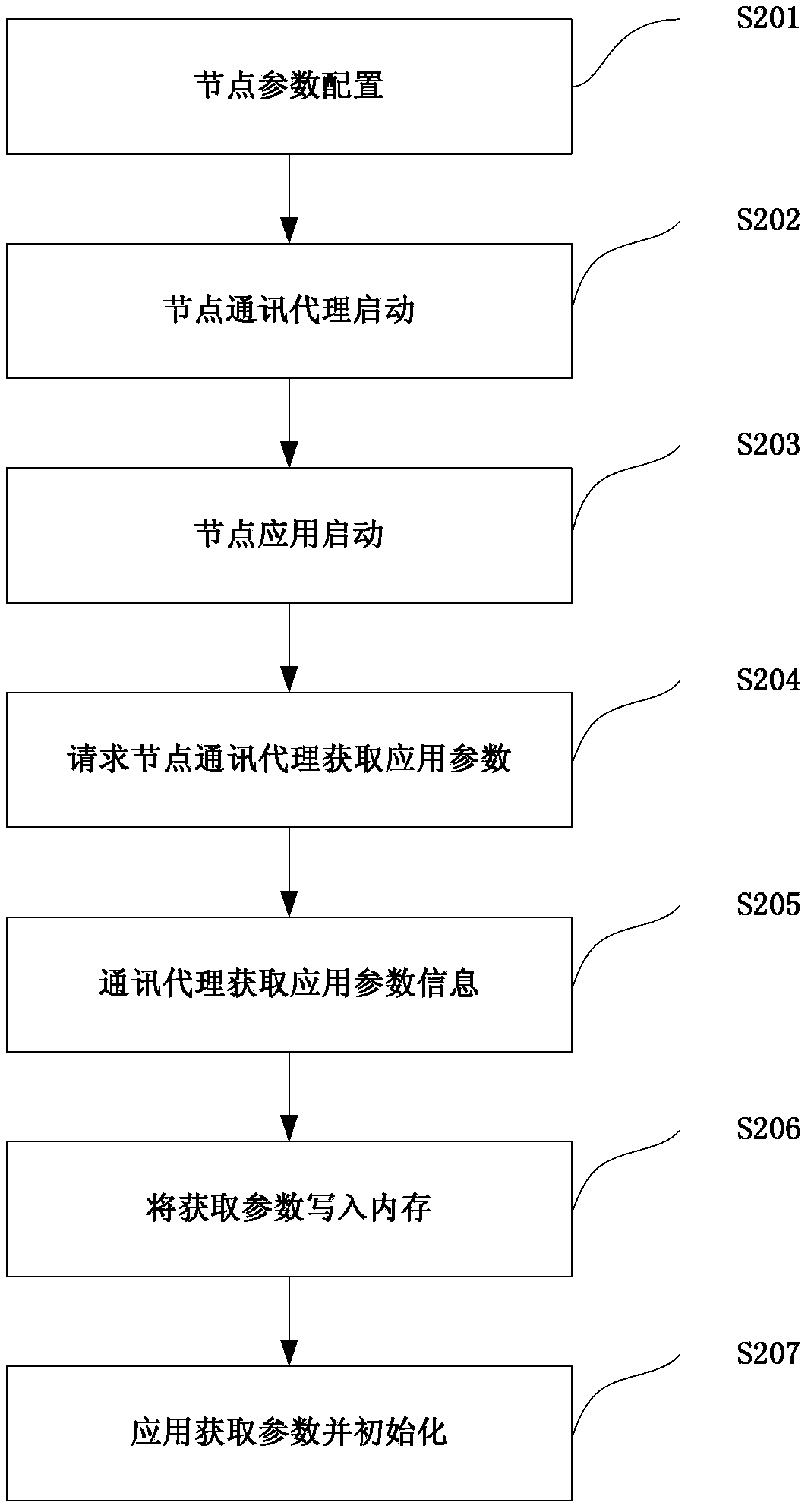

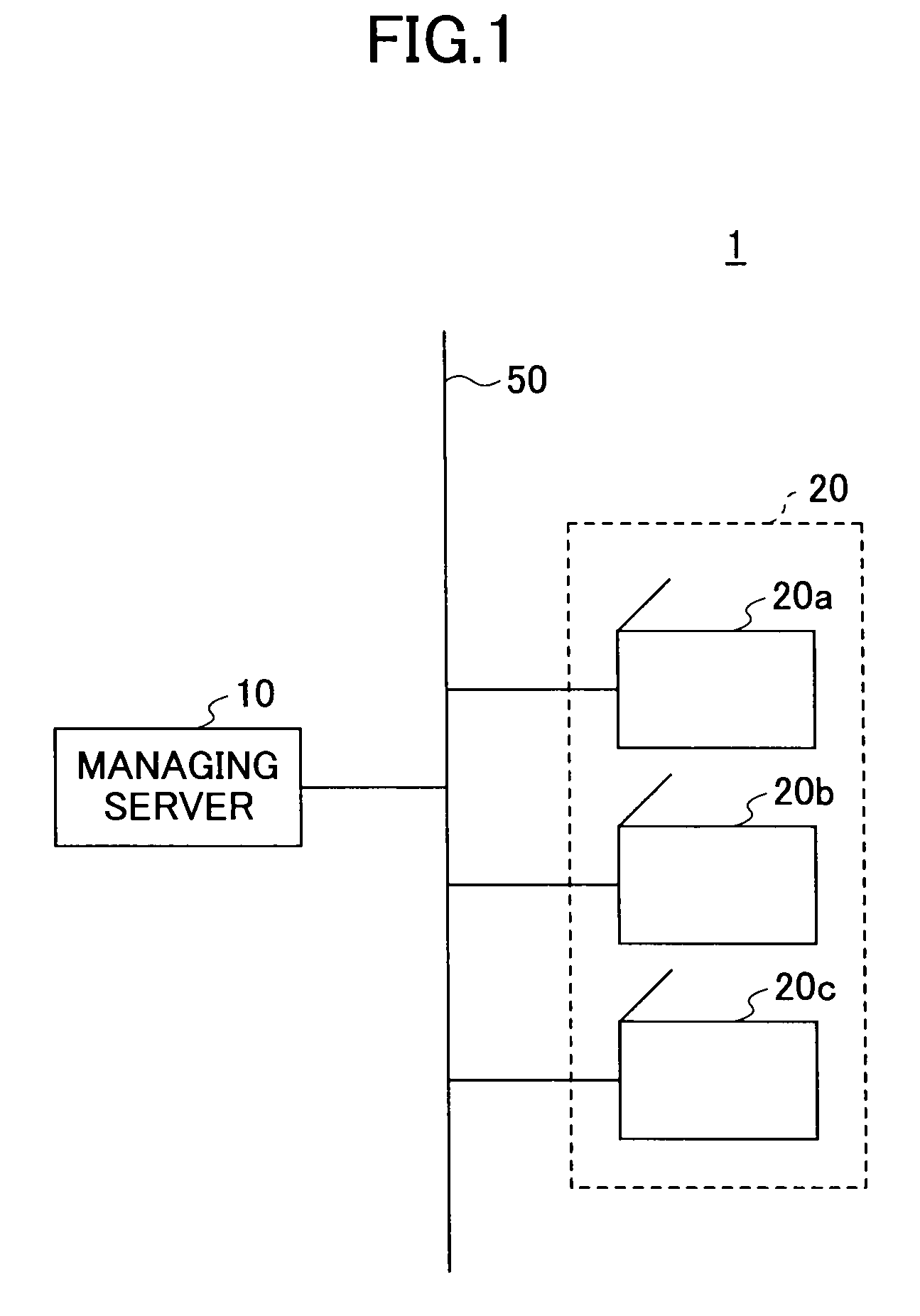

Method and device for uniform configuration of carrier-class clustered applications

InactiveCN103516538AImplement configurationGo documentlessData switching networksReapplicationMultiple node

The invention discloses a method and device for uniform configuration of carrier-class clustered applications. The method comprises the steps that a visualization configuring module of a uniform configuring center is used for completing and storing the configuration parameters of application programs of all nodes in a cluster; a node communication proxy module of each node in all the nodes obtains the configuration parameters through registration and requests to the uniform configuring center and obtains respective configuration parameters from the uniform configuring center; all the nodes store the configuration parameters obtained by the node communication proxy modules respectively and complete the initialization of the application programs of the nodes according to the configuration parameters; if the visualization configuring module modifies the configuration parameters of the application programs of one certain node or multiple nodes, the one certain node or the multiple nodes enable the corresponding application programs to use the modified configuration parameters by obtaining the modified configuration parameters. The method and device for the uniform configuration of the carrier-class clustered applications can carry out real-time online parameter configuration on all the nodes of the cluster, and reapplication is not needed after configuration modification.

Owner:ZTE CORP

Devices for securely closing tissue openings with minimized scarring

Devices, tools, systems, kits and methods for closing a tissue opening non-invasively are presented. The devices include a tissue closure device that reliably induces eversion of tissue edges that define a tissue opening. The devices may be used in combination with an applicator tool to provide easy and uniform apposition of the tissue closure devices across the tissue opening. Further embodiments provide for releasable locking of the tissue closure devices, allowing for drainage of wound edema and / or treatment of infection, without removal and reapplication of the devices. Still further embodiments allow for the passing of moisture or other substances that may collect under a tissue closure device.

Owner:DERMACLIP US

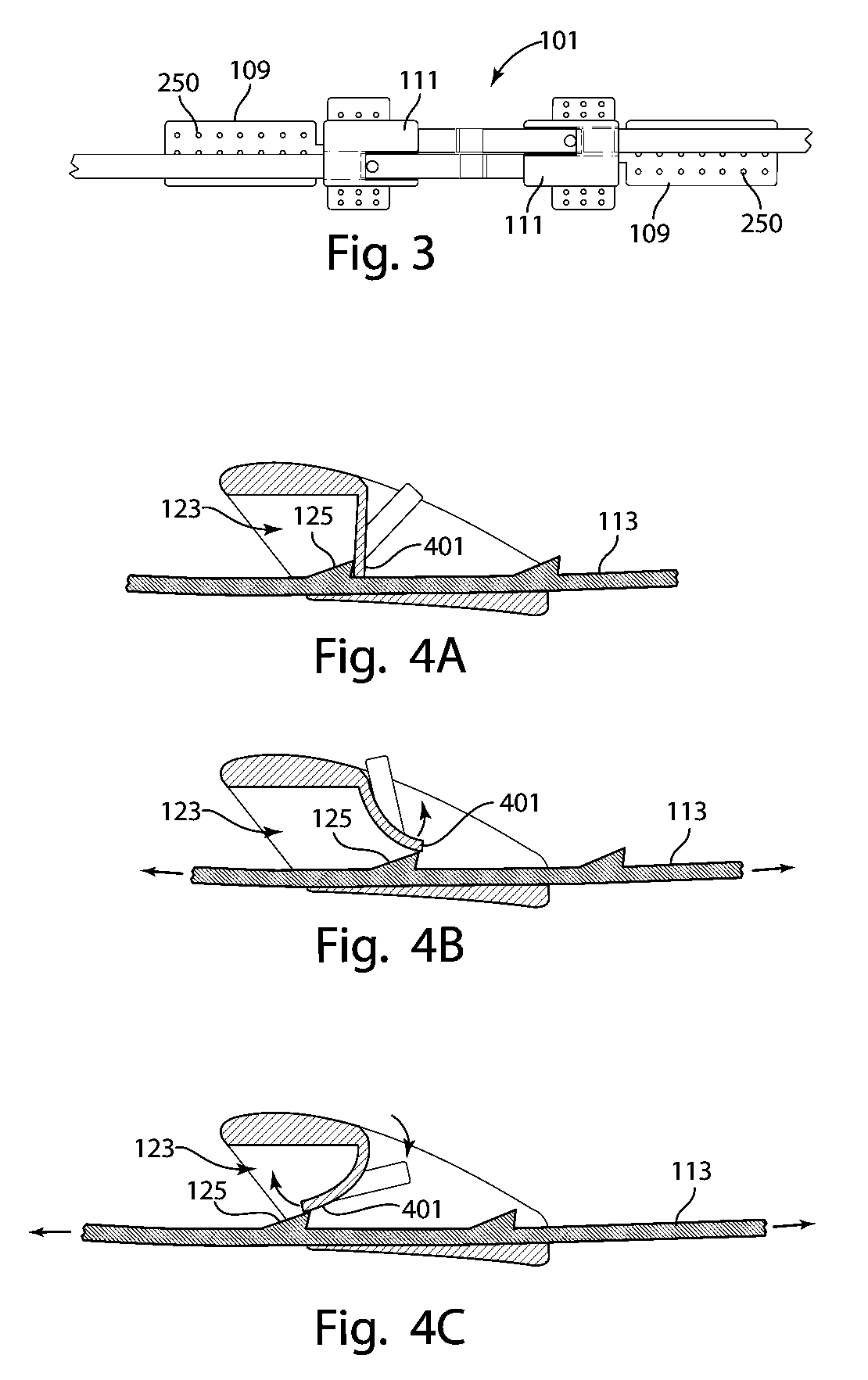

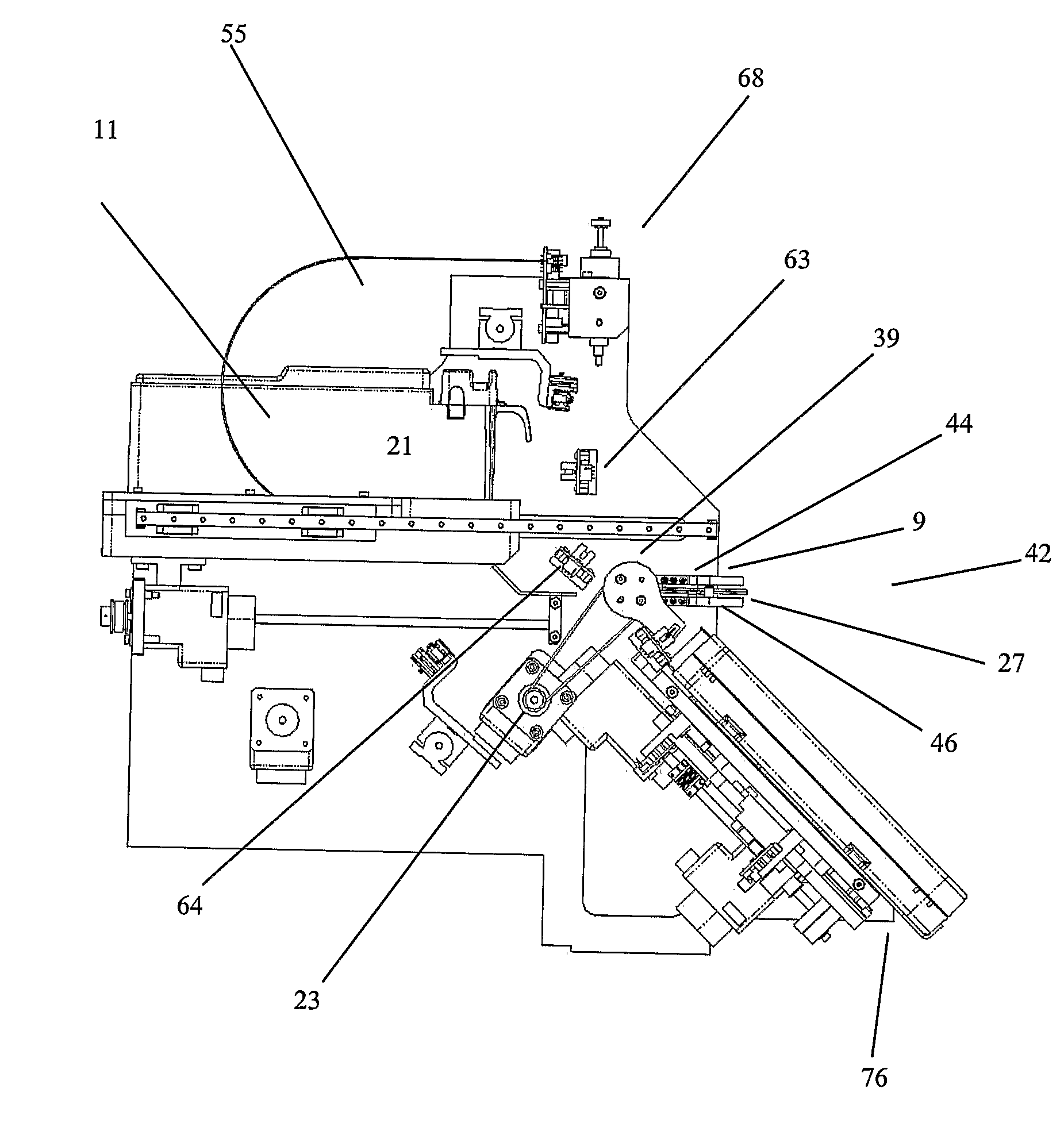

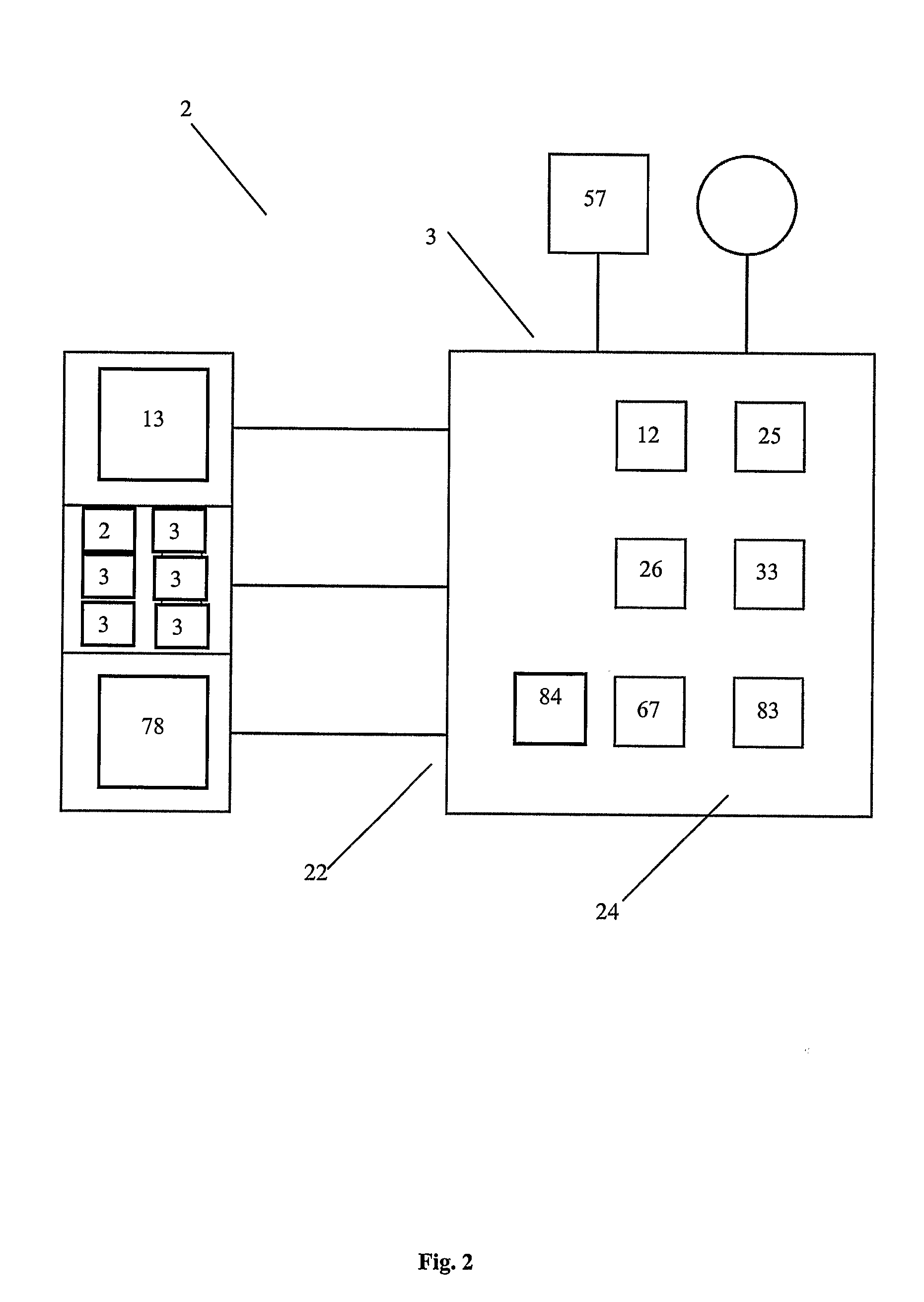

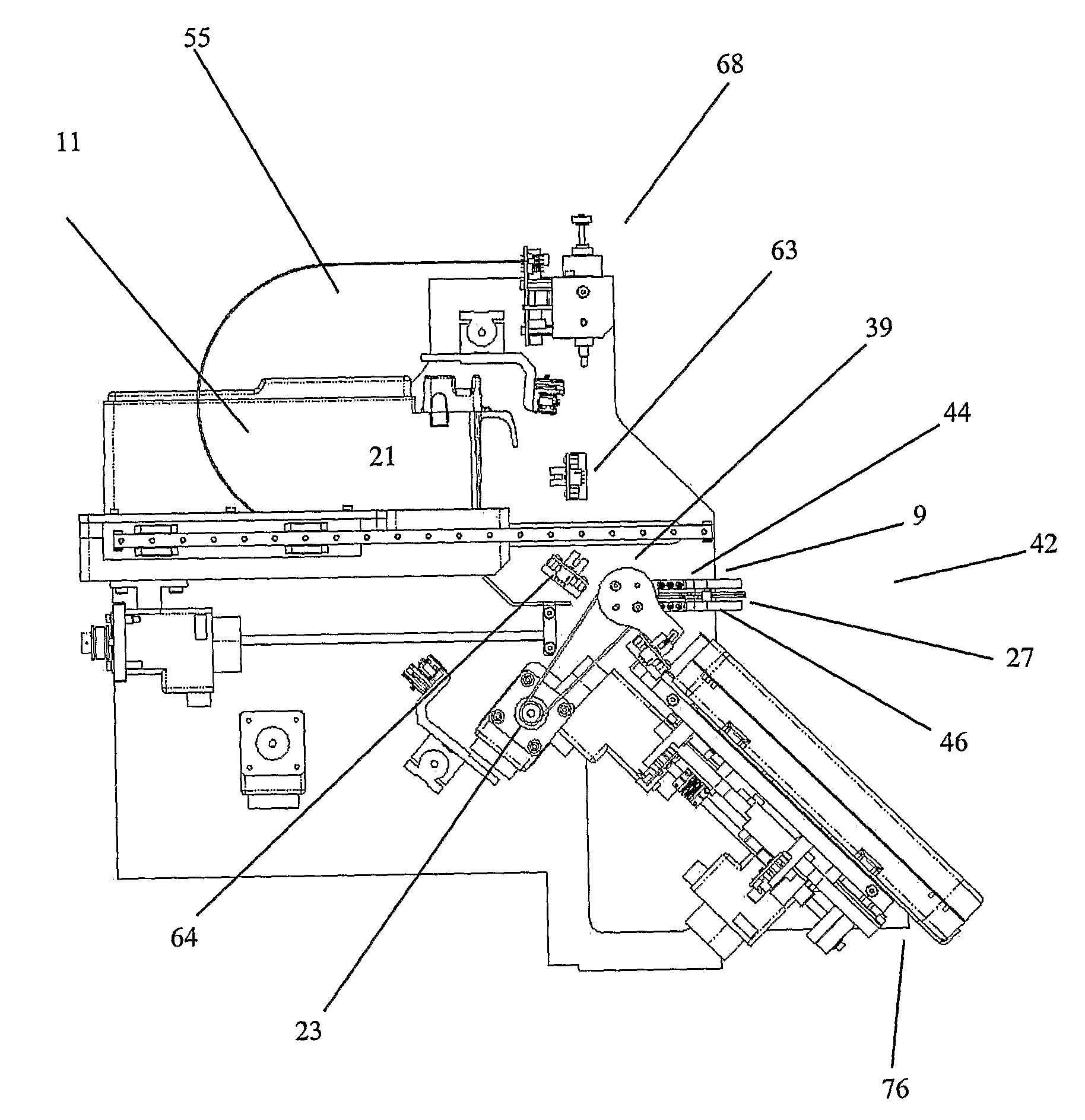

Parallel Processing Fluidic Method and Apparatus for Automated Rapid Immunohistochemistry

InactiveUS20080213804A1Easy to useShorten time for amountBioreactor/fermenter combinationsBiological substance pretreatmentsSurgical operationGuideline

A sample processing system that may be configured to achieve parallel or coincidental sample processing such as histochemical processing may involve a plurality of samples arranged for coincidental movement perhaps by use of angular microscopic slide movements to cause processing activity that may include repeated elimination and reapplication of a fluidic substance perhaps through the action of capillary motion in order to refresh a microenvironment adjacent to a sample such as a biopsy or other such sample. Snap in antibody and other substances may be included to ease operator actions and to permit location specific substance applications perhaps by including single container multiple chamber multiple fluidic substance magazines, linearly disposed multiple substance source, and primary antibody cartridges. Through refreshing of a microenvironment, depletion of the microenvironment is avoided and the time necessary for slide processing may be dramatically shortened from a more common 60 to 120 minutes to perhaps less than 15 minutes so as to permit use of such a system in an intraoperative or surgical environment such as recommended by the College of American Pathologists intraoperative guidelines or the like. Patients may thus avoid a need to be subjected to an additional surgical procedure when lab results become available to see if tumors or the like were fully removed in a prior procedure.

Owner:CELERUS DIAGNOSTICS

Method And Apparatus For Automated Rapid Immunohistochemistry

InactiveUS20080194034A1Reduce manufacturing costEasy to useBioreactor/fermenter combinationsBiological substance pretreatmentsGuidelineMicroscopic scale

A sample processing system that may be configured to achieve parallel or coincidental sample processing such as histochemical processing may involve a plurality of samples arranged for coincidental movement perhaps by use of angular microscopic slide movements to cause processing activity that may include repeated elimination and reapplication of a fluidic substance perhaps through the action of capillary motion in order to refresh a microenvironment adjacent to a sample such as a biopsy or other such sample. Snap in antibody and other substances may be included to ease operator actions and to permit location specific substance applications perhaps by including single container multiple chamber multiple fluidic substance magazines, linearly disposed multiple substance source, and primary antibody cartridges. Through refreshing of a microenvironment, depletion of the microenvironment is avoided and the time necessary for slide processing may be dramatically shortened from a more common 60 to 120 minutes to perhaps less than 15 minutes so as to permit use of such a system in an intraoperative or surgical environment such as recommended by the College of American Pathologists intraoperative guidelines or the like. Patients may thus avoid a need to be subjected to an additional surgical procedure when lab results become available to see if tumors or the like were fully removed in a prior procedure.

Owner:CELERUS DIAGNOSTICS

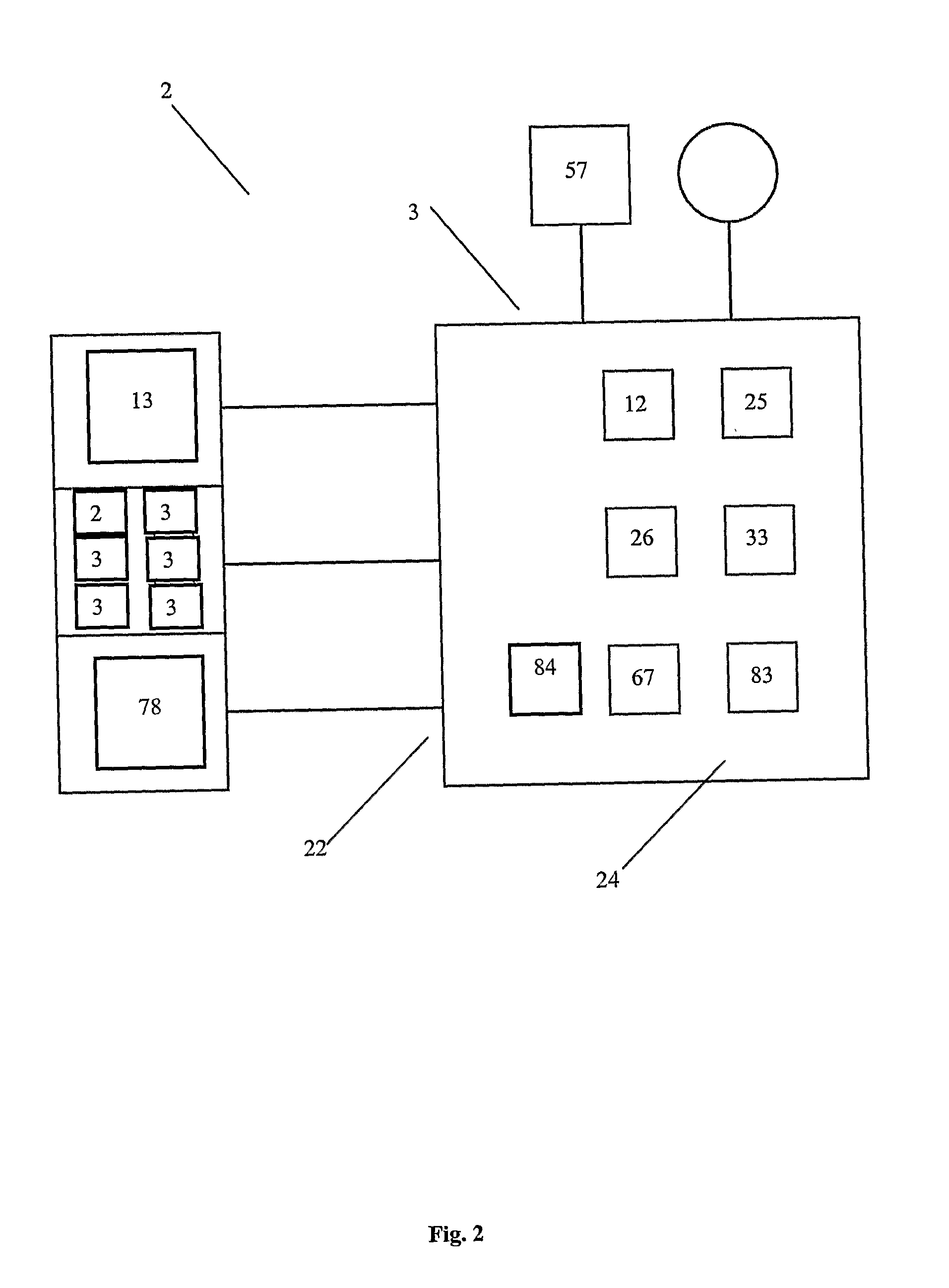

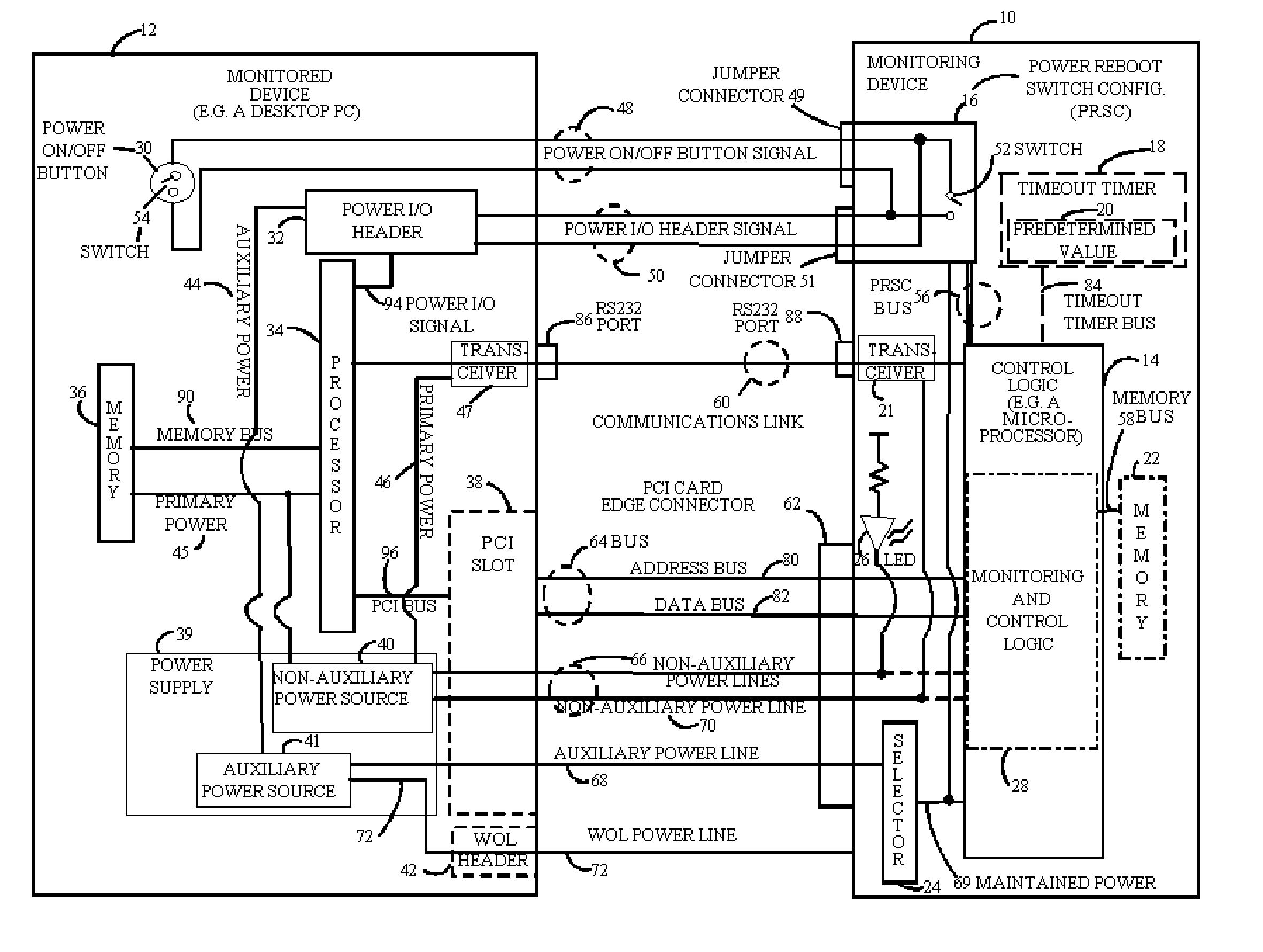

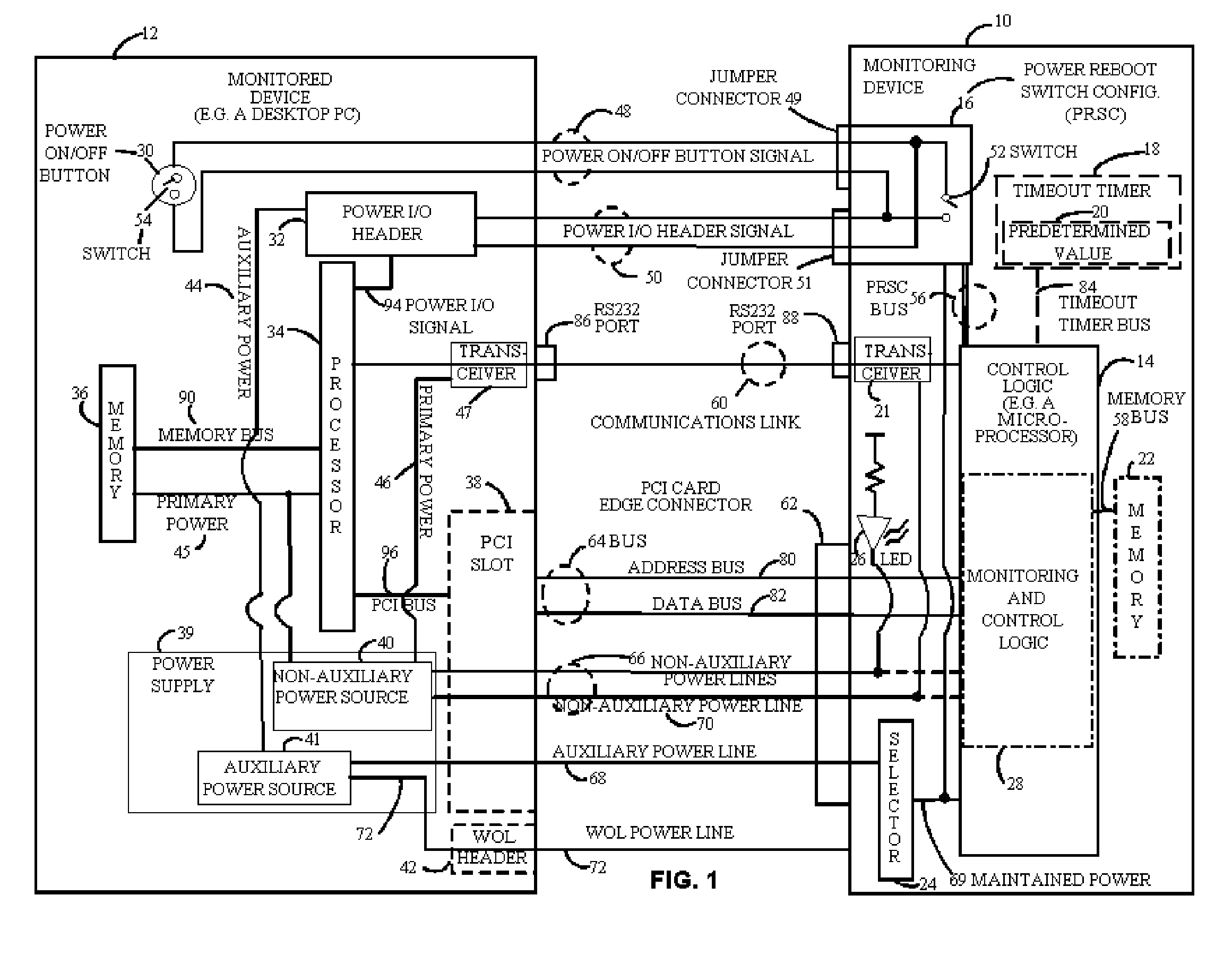

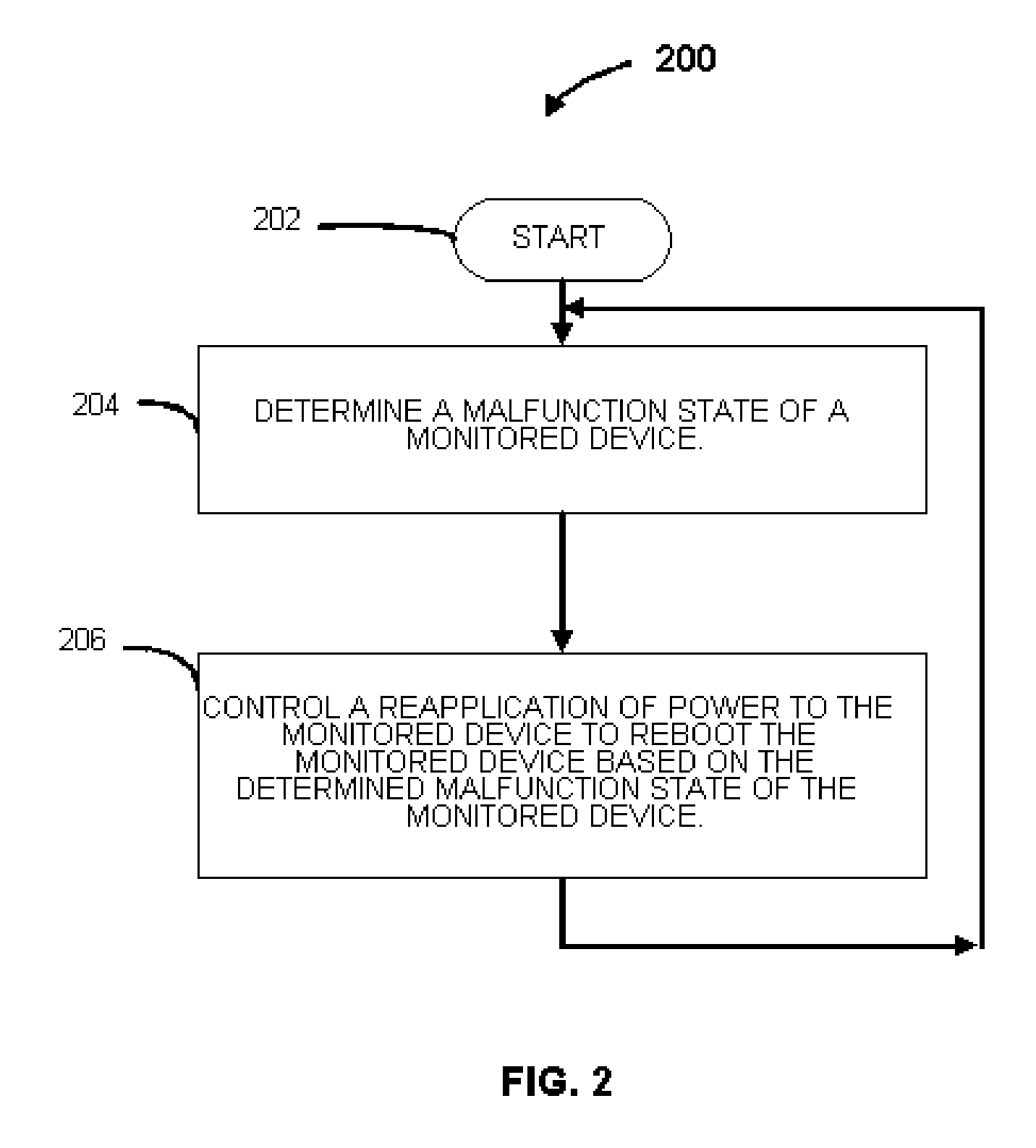

Device and method for malfunction monitoring and control

ActiveUS20070028148A1Digital data processing detailsHardware monitoringStandby powerMonitoring and control

A monitoring device and method are provided to monitor a separate device for malfunctions and to control and restore the malfunctioning monitored device to a normal functioning state. A malfunction state includes the monitored device being powered off or in a standby power state. The monitoring device includes control logic operative to determine a malfunction state of the monitored device and to control a reapplication of power to the monitored device to reboot the monitored device based on the determined malfunction state of the monitored device. The method for monitoring and controlling the monitored device comprises the steps of: determining a malfunction state of the monitored device; and controlling a reapplication of power to the monitored device to reboot the monitored device based on the determined malfunction state of the monitored device.

Owner:ATI TECH INC

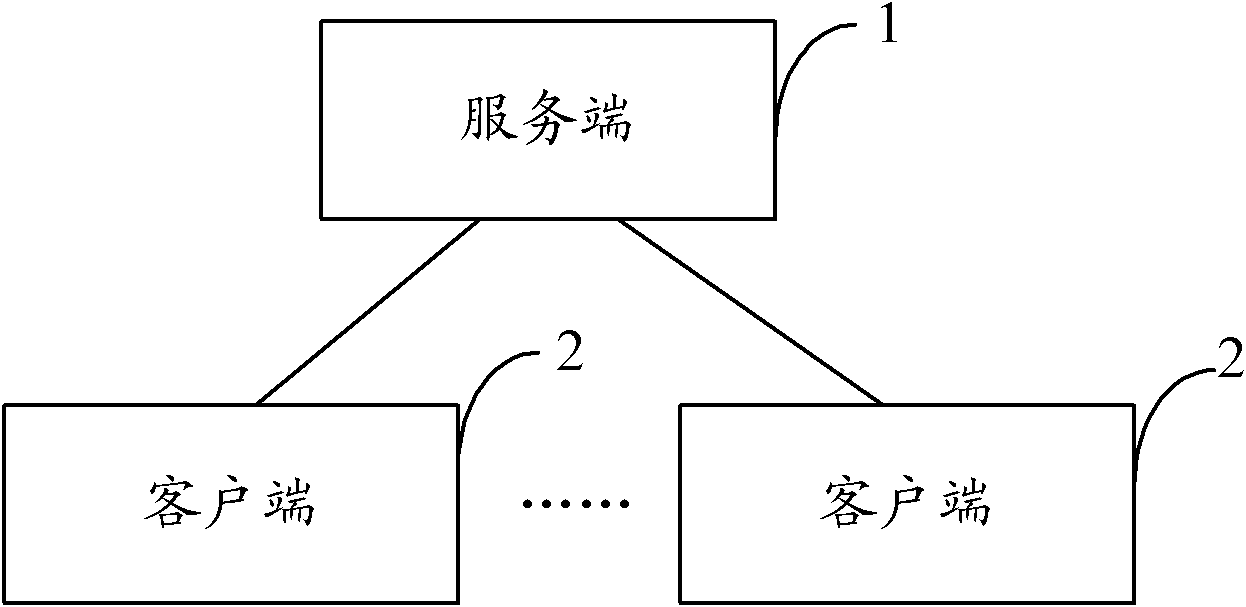

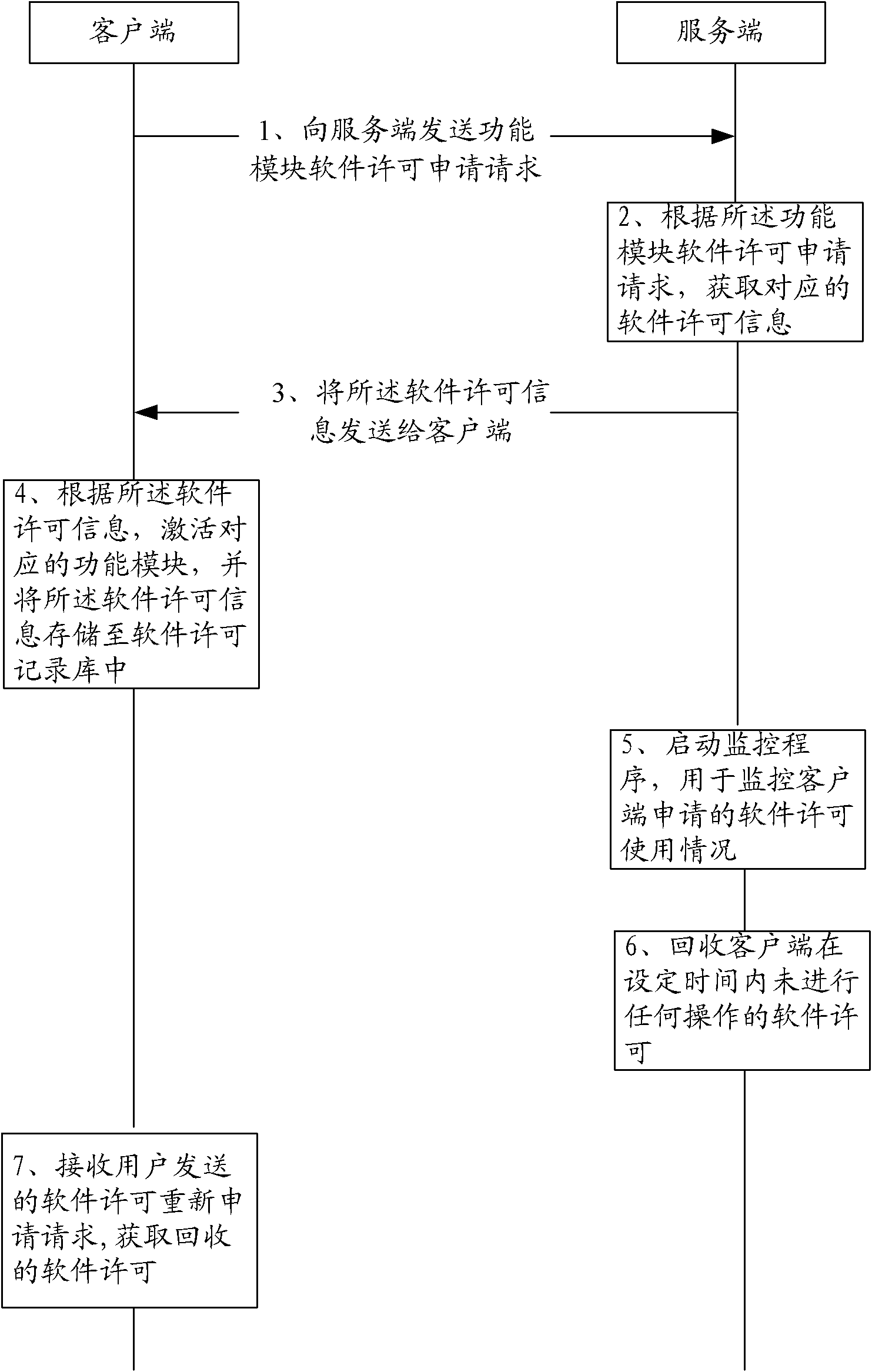

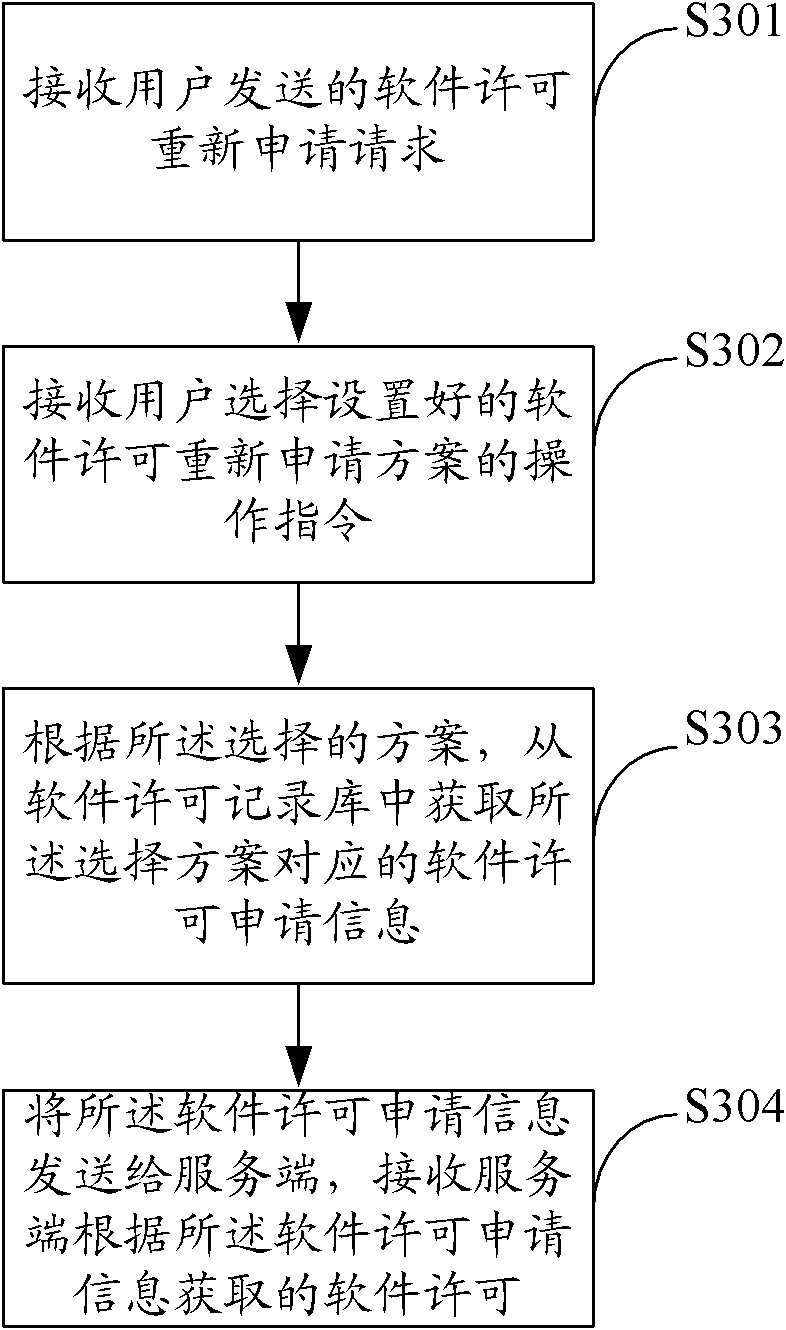

Method and system for software license recovery and automatic reapplication

ActiveCN102467624AImprove efficiencyImprove usabilityProgram/content distribution protectionSoftware licenseSoftware engineering

The invention is applicable to the field of computer software and provides a method and a system for software license recovery and automatic reapplication. The method comprises the following steps that: a client transmits a functional module software license application request to a server; the server acquires corresponding software license information according to the request and transmits the software license information to the client; the client activates a corresponding functional module according to the software license information and stores the software license information in a software license recording library; the server starts a monitoring program to monitor using conditions of a software license applied by the client; the server recovers the software license of the client which is not subjected to any operation in set time; and the client receives a software license reapplication request transmitted by a user and acquires the recovered software license. By an idle software license recovery and automatic reapplication device, the using efficiency of the software license can be effectively improved, and software license reapplication operation of the user is reduced.

Owner:KINGDEE SOFTWARE(CHINA) CO LTD

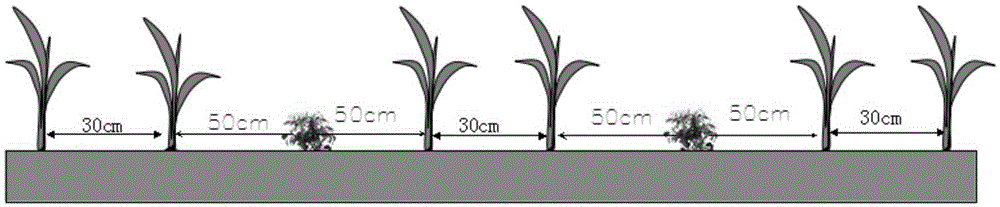

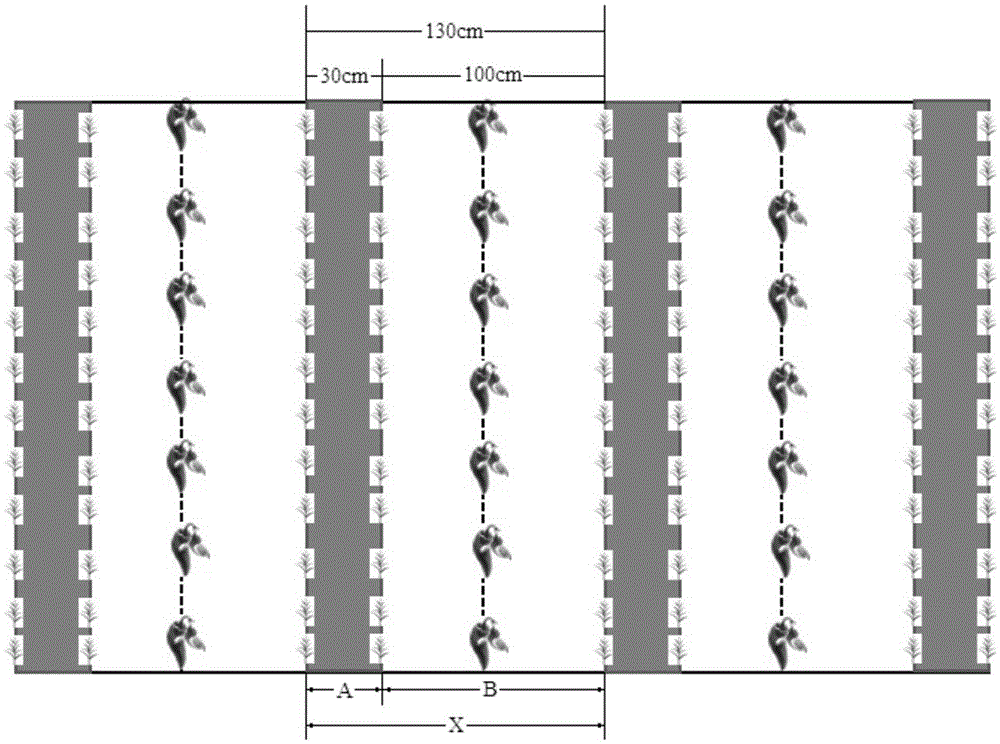

Corn and peanut complex three-dimensional ecological intercropping planting method

ActiveCN105393749AField layout optimizationOptimize layoutPlant cultivationCultivating equipmentsDiseaseContinuous cropping

A corn and peanut complex three-dimensional ecological intercropping planting method relates to a planting method for corns and peanuts. The corn and peanut complex three-dimensional ecological intercropping planting method can solve the problems that in the mode of long continuous cropping of corns and peanuts, straw reapplication is difficult, planting is out-off-balance, physic and chemical properties of soil deteriorate, pests and diseases become serious, the investment is increased but the yield is not increased, row spacing configuration is not reasonable during the conventional intercropping between the corns and the peanuts, and the utilization of light and heat resources is low. The method includes the following steps of: 1) good seed selection; 2) land selection and soil preparation; 3) soil testing and formulated fertilization; 4) field arrangement optimization; 5) seeding and reasonable close planting; 6) fine field management; 7) straw reapplication; and 8) crop rotation, fallowing and land maintaining. Many years of tests show that the yield of the corns can be increased by 2.0% to 8.0% more than that of the conventional planting method; compared with the conventional planting method, the yield of the peanuts can be increased by 1800 to 2200 Kg / hectare in average. The corn and peanut complex three-dimensional ecological intercropping planting method can be applied to the field of crop planting.

Owner:NORTHEAST INST OF GEOGRAPHY & AGRIECOLOGY C A S

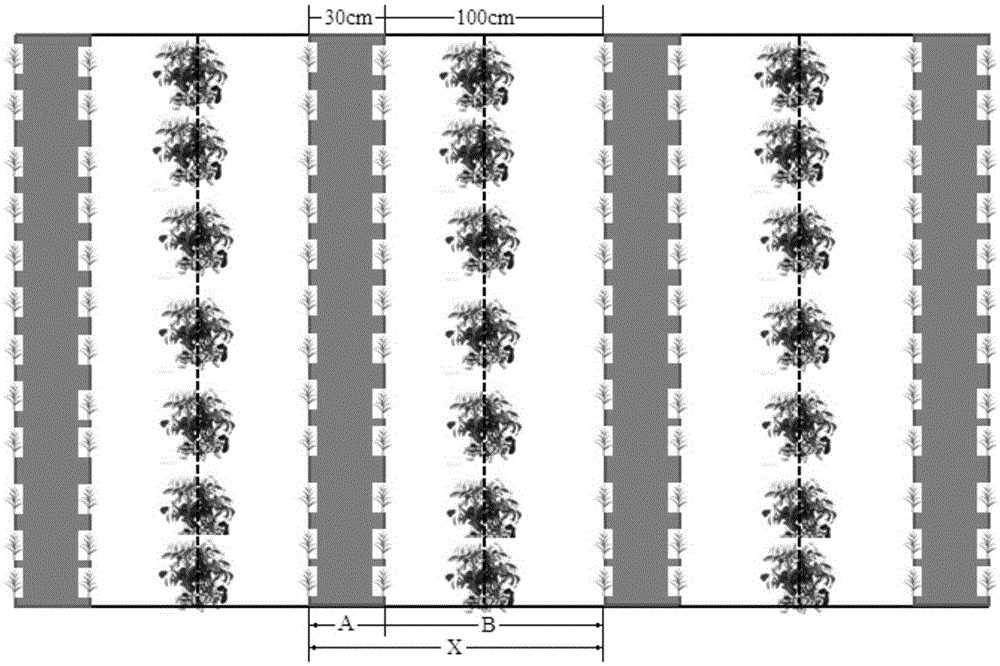

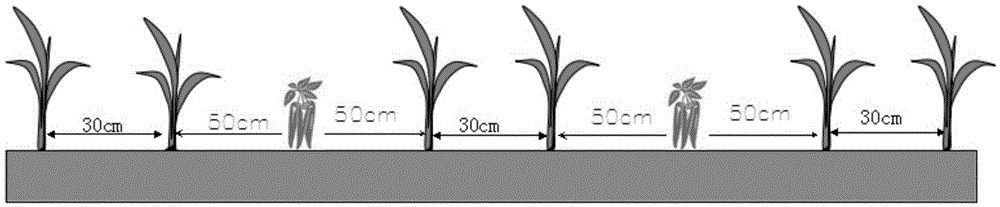

Corn and pepper complex three-dimensional ecological intercropping planting method

ActiveCN105393750AIncrease photosynthetic rateLarge ridge distanceClimate change adaptationCultivating equipmentsThree-dimensional spaceHectare

A corn and pepper complex three-dimensional ecological intercropping planting method relates to a planting method for corns and peppers. The corn and pepper complex three-dimensional ecological intercropping planting method can solve the problems in the prior art that the yields of corns and peppers are low, soil is severely depleted, and the planting benefits are bad. The method includes the following steps of: 1) land selection; 2) field arrangement optimization of crops; 3) good seed selection; 4) reasonable close planting; 5) scientific field management; 6) straw reapplication; and 7) crop rotation and land maintaining. According to the corn and pepper complex three-dimensional ecological intercropping planting method, three-dimensional space can be reasonably utilized, the yield of the corns are increased by 3.5% to 5.5 % more than that of the conventional planting method, and 12000 Kg to 15000 Kg / hectare of the extra peppers can be obtained; and meanwhile, organic matters are increased by 0.2%, and soil structure is improved; like the conventional planting method, the corn and pepper complex three-dimensional ecological intercropping planting method can achieve increased planting benefits of 14000 to 15000 yuan / hectare without special management when the invested cost is constant.

Owner:NORTHEAST INST OF GEOGRAPHY & AGRIECOLOGY C A S

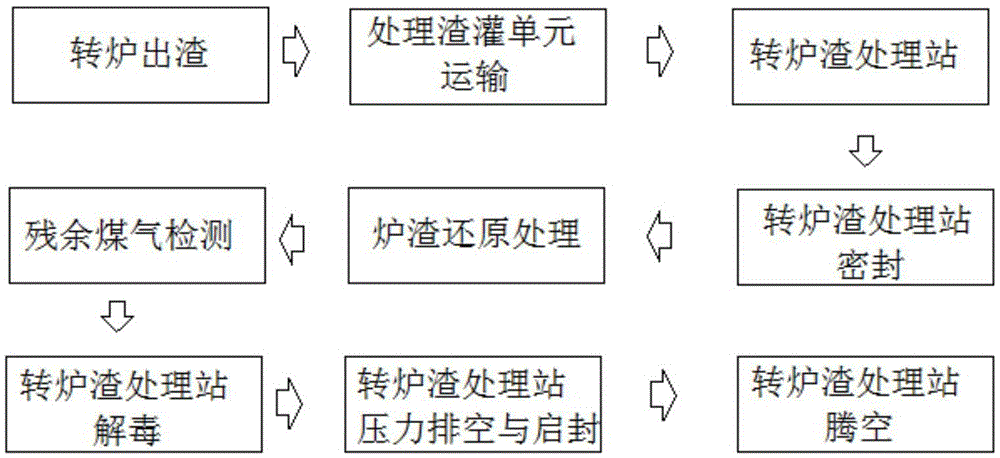

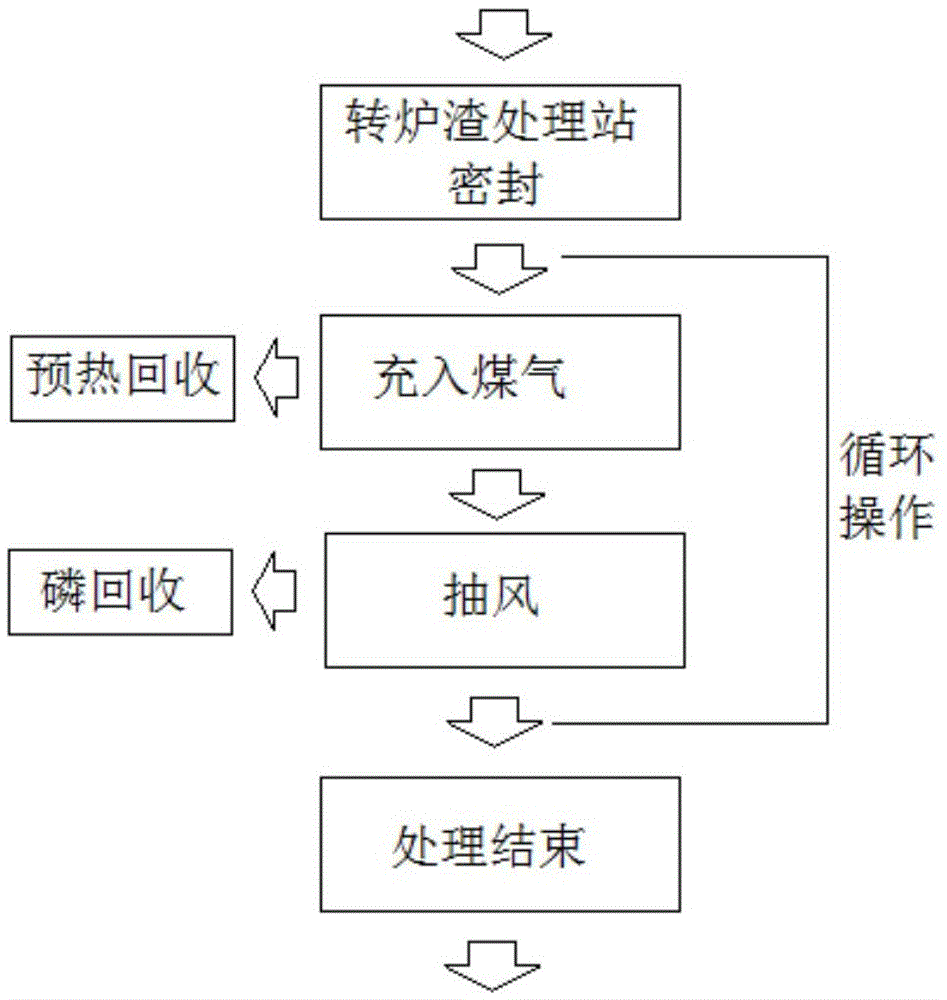

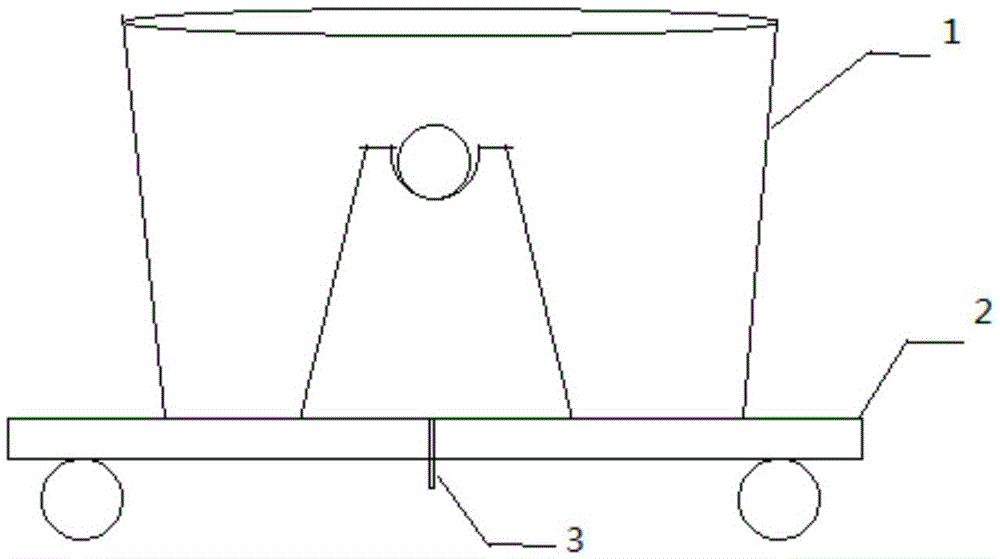

Method for reducing converter slag by utilizing coal gas and recycling furnace slag

ActiveCN105624359AReduce loadReduce consumptionIncreasing energy efficiencyManufacturing convertersSteelmakingThermal state

The invention relates to a method for reducing converter slag by utilizing coal gas and recycling furnace slag. The method comprises the following steps: dividing a converter smelting process into a converter steelmaking process and a converter slag thermal treatment process, wherein in the converter steelmaking process, impurity elements in molten iron enter the converter slag in the form of oxides by virtue of oxidization reaction, thereby forming thermal-state converter slag with high phosphor content; pouring the converter slag into a treated slag filling unit, carrying out the converter slag thermal treatment process, transferring the slag filling unit with the converter slag to a converter slag treatment station, enabling the converter slag to generate thermal-state reduction taking the coal gas as a reducing medium in the converter slag treatment station, wherein a reducing proportion of FeO is greater than 80%, and a reducing proportion of P2O5 is greater than 80%; and while carrying out the thermal-state reduction treatment process, recycling waste heat of the converter slag and recycling gaseous-state phosphor, and taking the treated converter slag as pre-melting slag, and returning the pre-melting slag and an iron-containing cooling material into a converter for reapplication.

Owner:CENT IRON & STEEL RES INST

Shape memory dental retention systems

InactiveUS8317515B2Prevent movementShorten the lengthDental implantsFastening prosthesisOral applianceAbutment

Owner:RODO MEDICAL

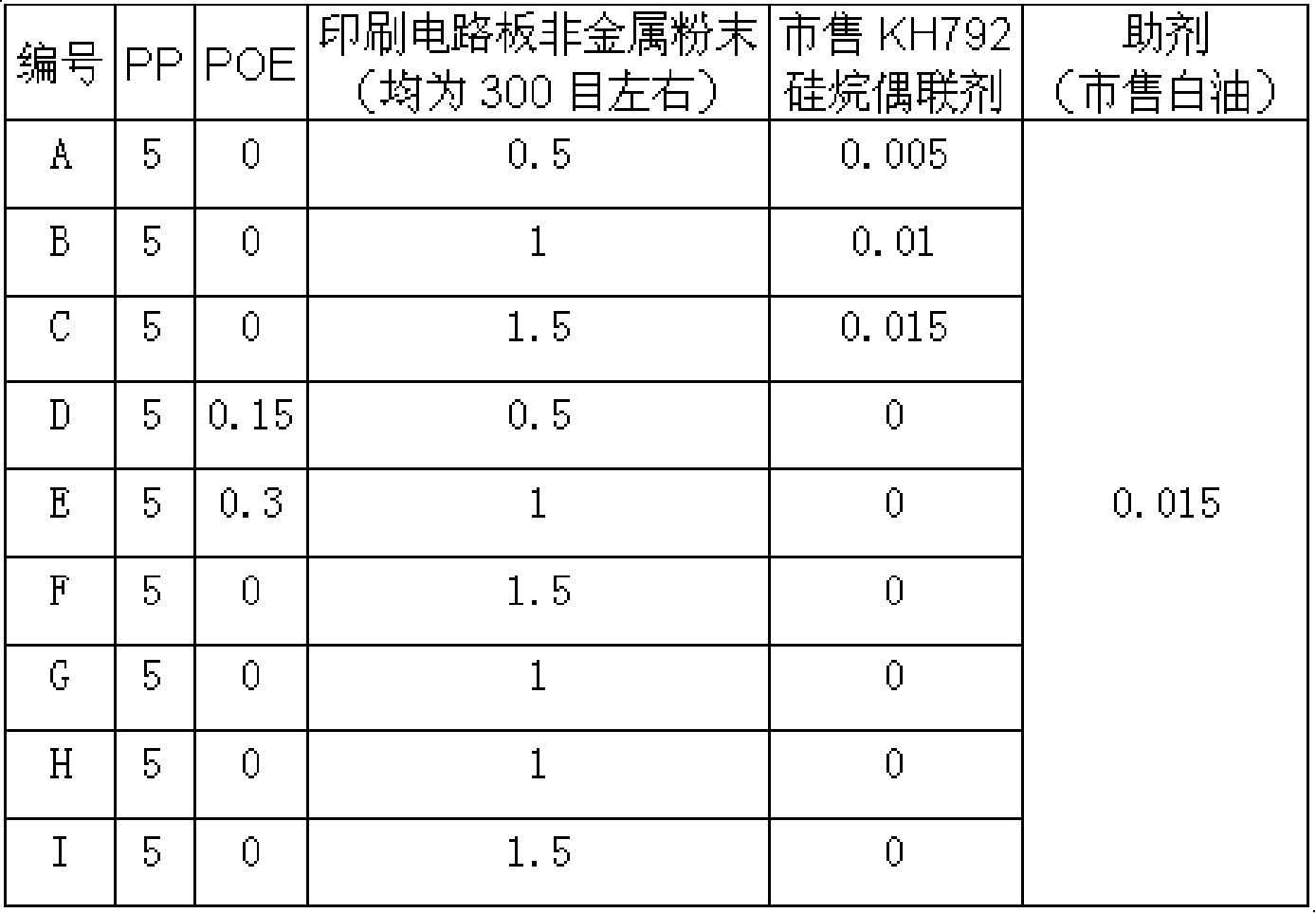

Special-purpose material for automobile bumper and reclaiming utilizing method for waste printed circuit card

ActiveCN101190981AMeet performance requirementsIncrease the value of recyclingBumpersElastomerLinear low-density polyethylene

The invention relates to the reapplication of non-metal material in printed circuit board of electronic waste products, in particular to the special materials of automobile bumper and the preparation method thereof, which belongs to the technological field of resource reproduction of electronic waste products. The special materials of automobile bumper are characterized in that the invention is prepared by the following weight ratio: 50-80 portions of polypropylene, 10-15 portions of non-metal powder of printed circuit board, 10-20 portions of rubber elastomer, 40-60 portions of linear density polyethylene, 0.1-0.5 portions of bismaleimide and 0.1-0.5 portions of coupling agent; the fineness of the non-metal powder of the printed circuit board is less than 400 meshes. The invention has the advantages of simple preparation method of the materials thereof, excellent property and low cost and can fully meet the property requirements of middle and lower grade cars. At the same time, by applying non-metal materials of the waste printed circuit board to the car production industry, the value of resource recycling of the printed circuit board can be raised.

Owner:SICHUAN CHANGHONG ELECTRIC CO LTD

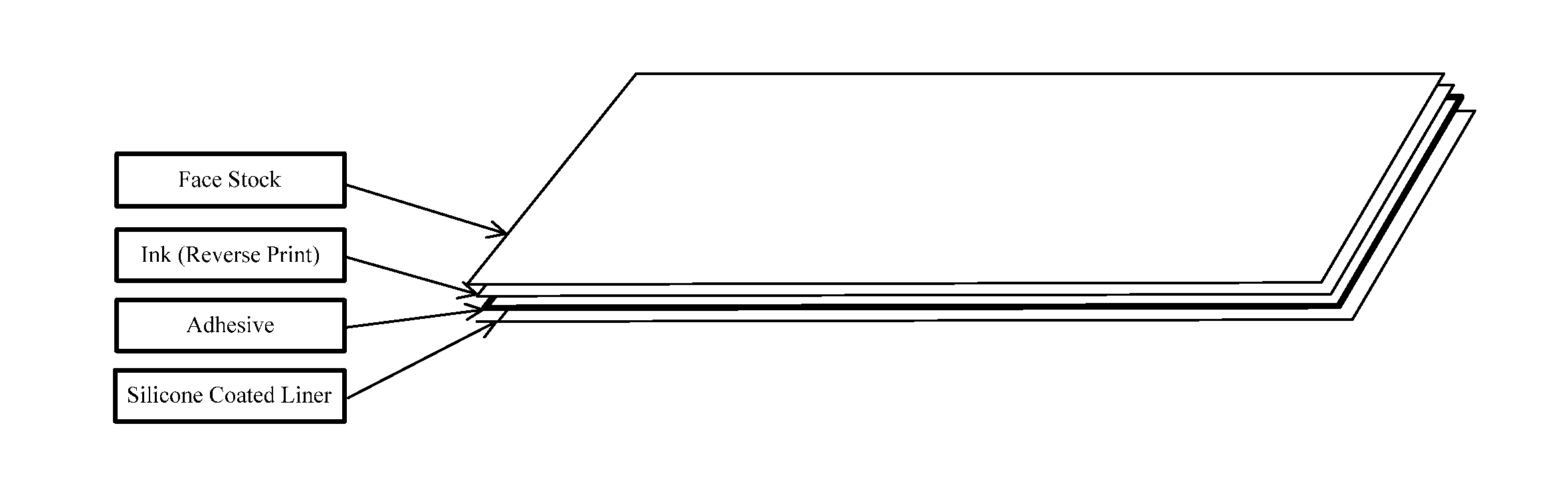

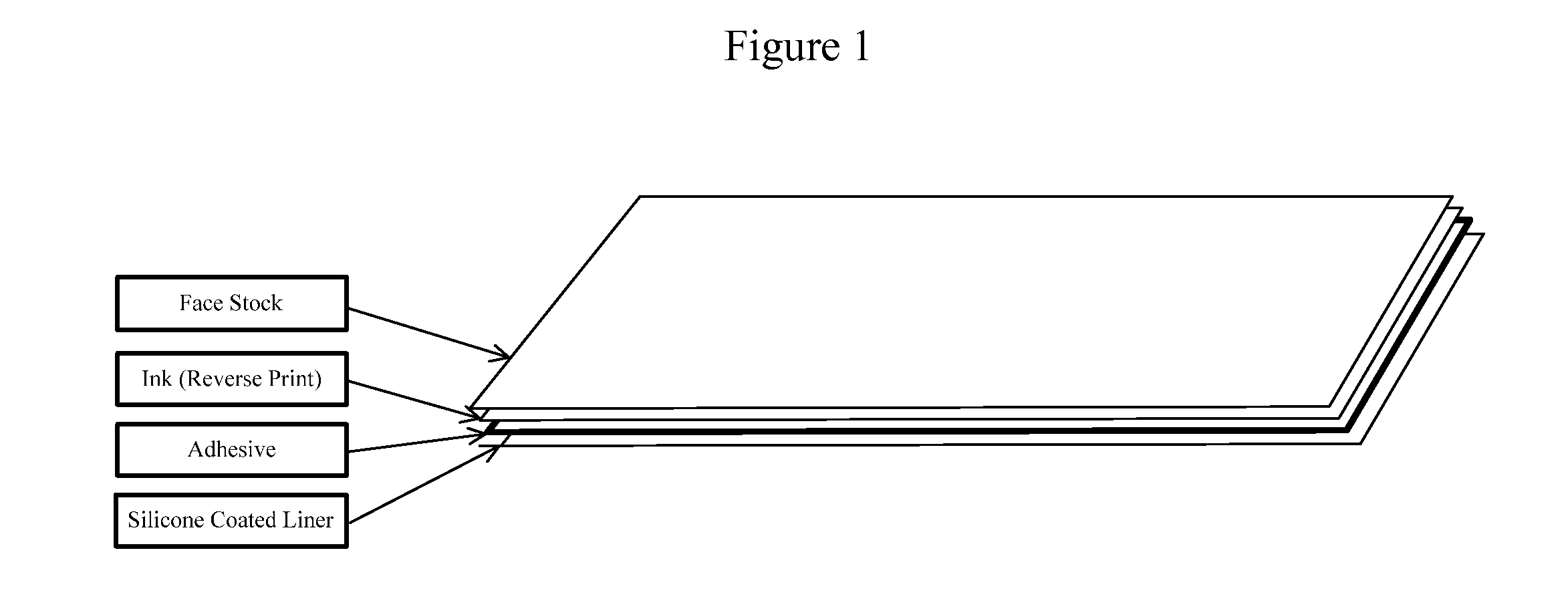

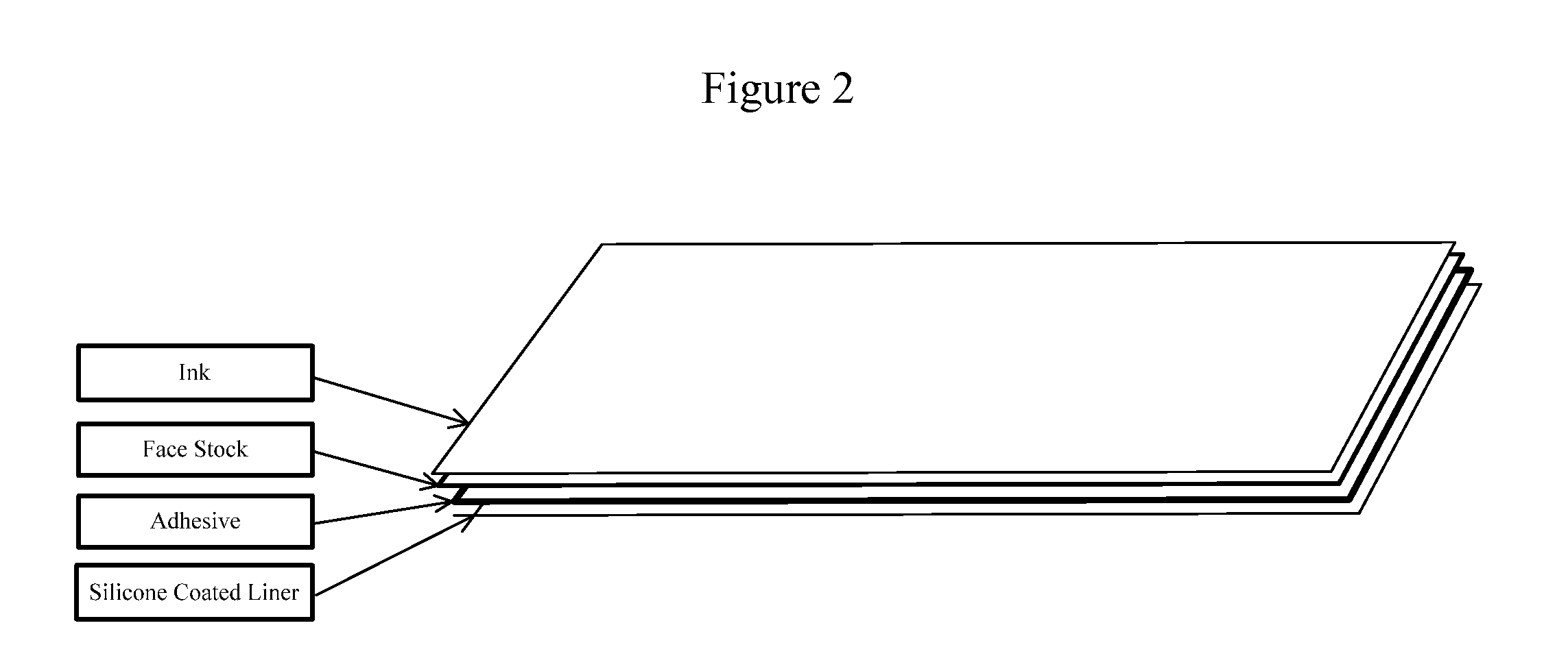

Temporarily removable reverse-printed label assembly

ActiveUS20140259834A1Reduce wasteReduce cross-contaminationStampsIdentification meansEngineeringHot melt

The present invention relates to an adhesive-backed printed pressure sensitive cut label assembly with easy temporary removability, wherein the portion of the label forming the label stock may be printed on the back- or reverse-side of the label face stock and whereby the printed surface is applied with a hot melt or acrylic adhesive that ensures easy short-term removability from a container surface and reapplication thereto. The label stock is laminated to a base stock comprising a paper or polymeric release liner coated with silicone or other adhesive release coating. During manufacturing of the label assembly, the label stock and base stock are simultaneously fed to laminating rollers following a die-cutting process, whereby the two are joined. One feature of the invention is the ease of temporary removability after application to the surface of a container whereby there is no adhesion of the ink printed on the label to the container surface itself. An additional feature is the elimination of the need for an overlamination of the label face stock when using a reverse-printed label face stock over which an appropriate adhesive is applied.

Owner:OUTLOOK GRP LLC

Dental prostheses devices and methods

InactiveUS20150132717A1Prevent movementShorten the lengthDental implantsDentist forcepsShape-memory alloyEngineering

Root canal abutment devices and methods which facilitate the adjustment or removal of an oral appliance, e.g., a crown or bridge, from a reconfigurable abutment assembly are described. The adjustable abutment assembly may be secured within a pulp chamber of a pre-existing tooth. The abutment assembly has a projecting abutment portion with one or more shape memory alloy sleeves or plates or elements extending along the abutment. Each of the sleeves has a length with at least one curved or arcuate portion. Energy may be applied to the elements such that the arcuate portion flattens to allow for the oral appliance to be placed thereupon while removal of the energy allows the elements to reconfigure into its curved configuration thereby locking the oral appliance to the abutment. Removal of the oral appliance may be effected by reapplication of energy to the elements.

Owner:RODO MEDICAL

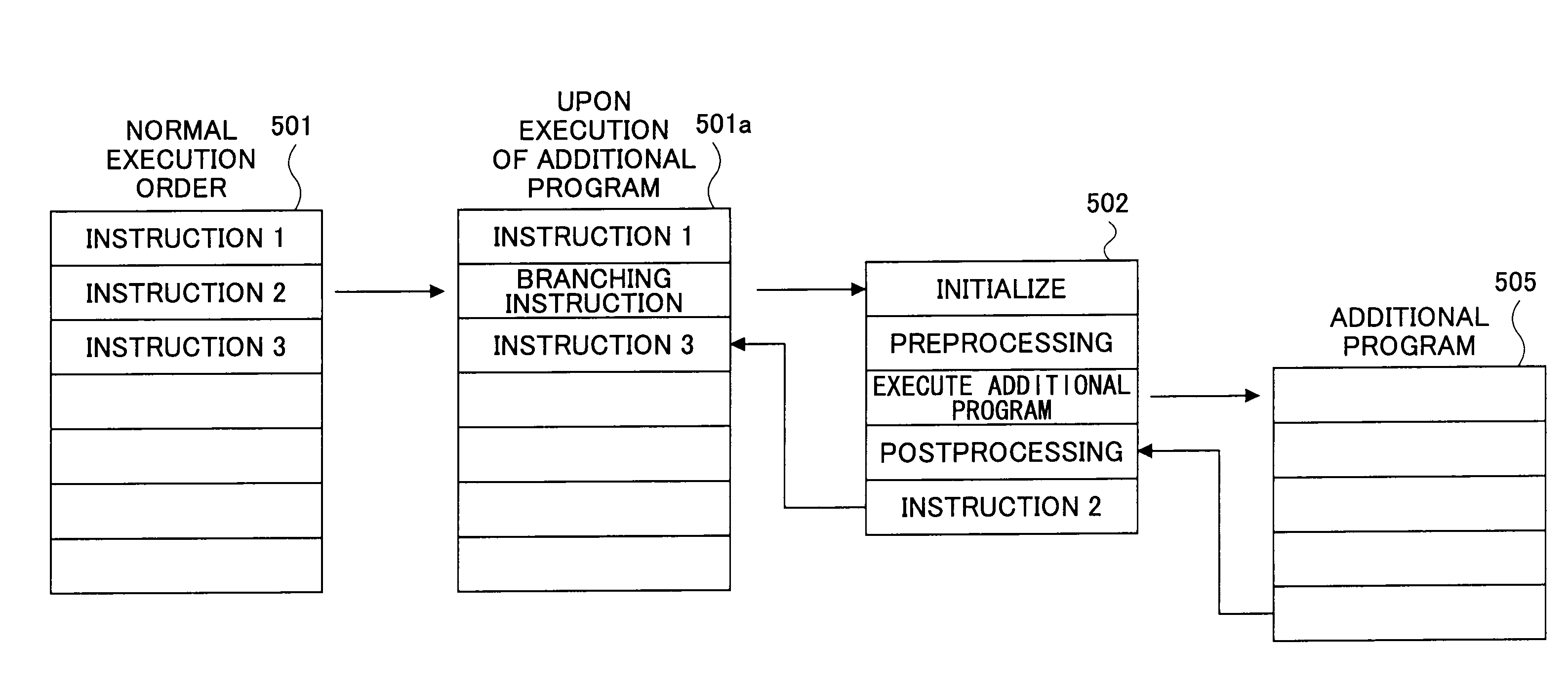

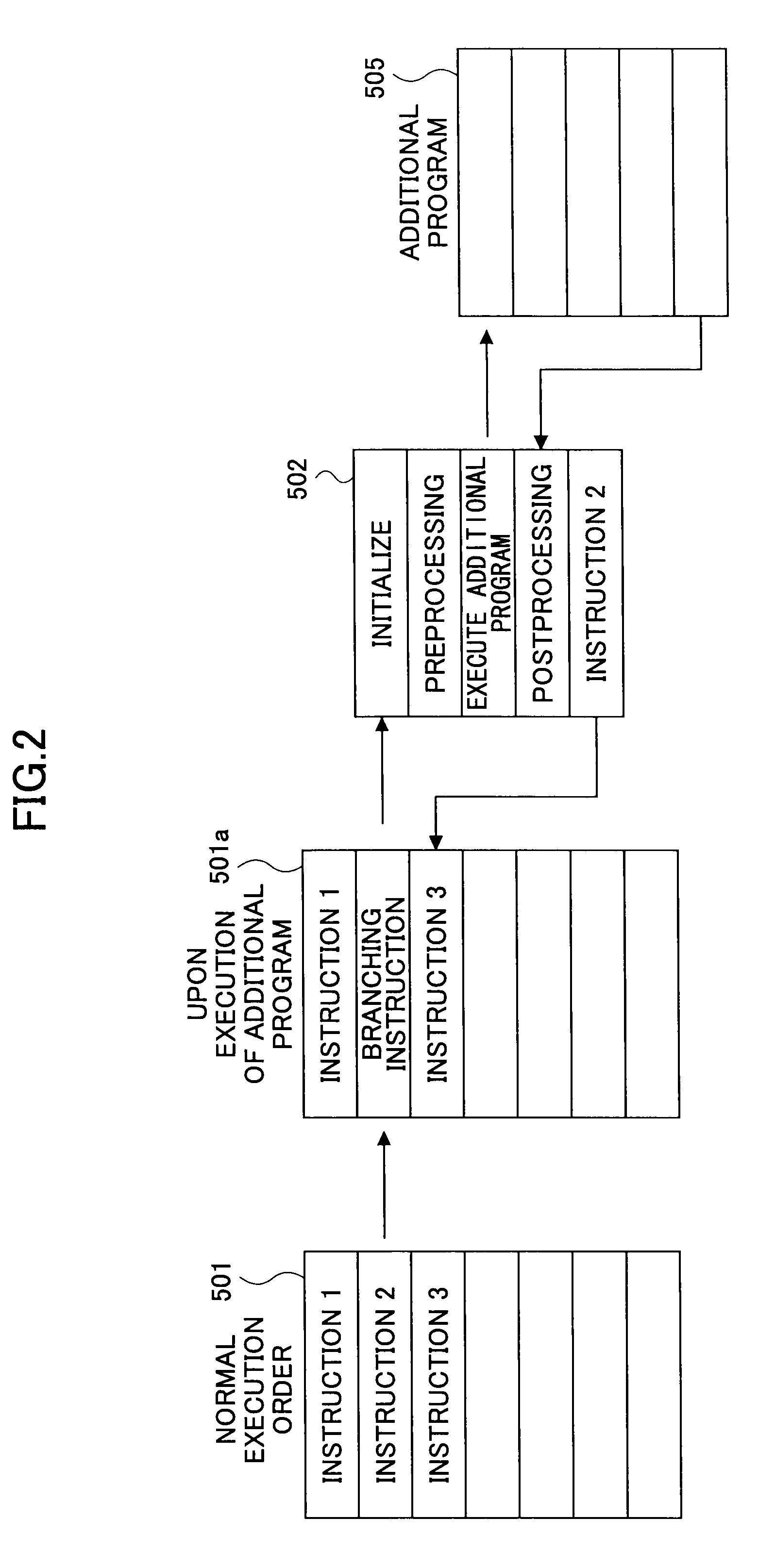

Information processing apparatus, information processing method, and computer-readable program

ActiveUS20090132745A1Improve utilization efficiencyImprove efficiencyEnergy efficient ICTError detection/correctionInformation processingStorage cell

An information processing apparatus improves the efficiency of use of a program capable of dynamically interrupting another program with a process. The program capable of dynamically interrupting another program with a process is received via a network and applied to the other program. A setting is received indicating whether the predetermined program should be applied to the other program when, after the predetermined program is applied, a supply of power to at least a part of the information processing apparatus is terminated and then resumed. Reapplication necessity information indicating the setting is stored in a storage unit. The predetermined program is reapplied to the other program when, after the application of the predetermined program, the supply of power to the at least a portion of the information processing apparatus is terminated and then resumed, based on the reapplication necessity information.

Owner:RICOH KK

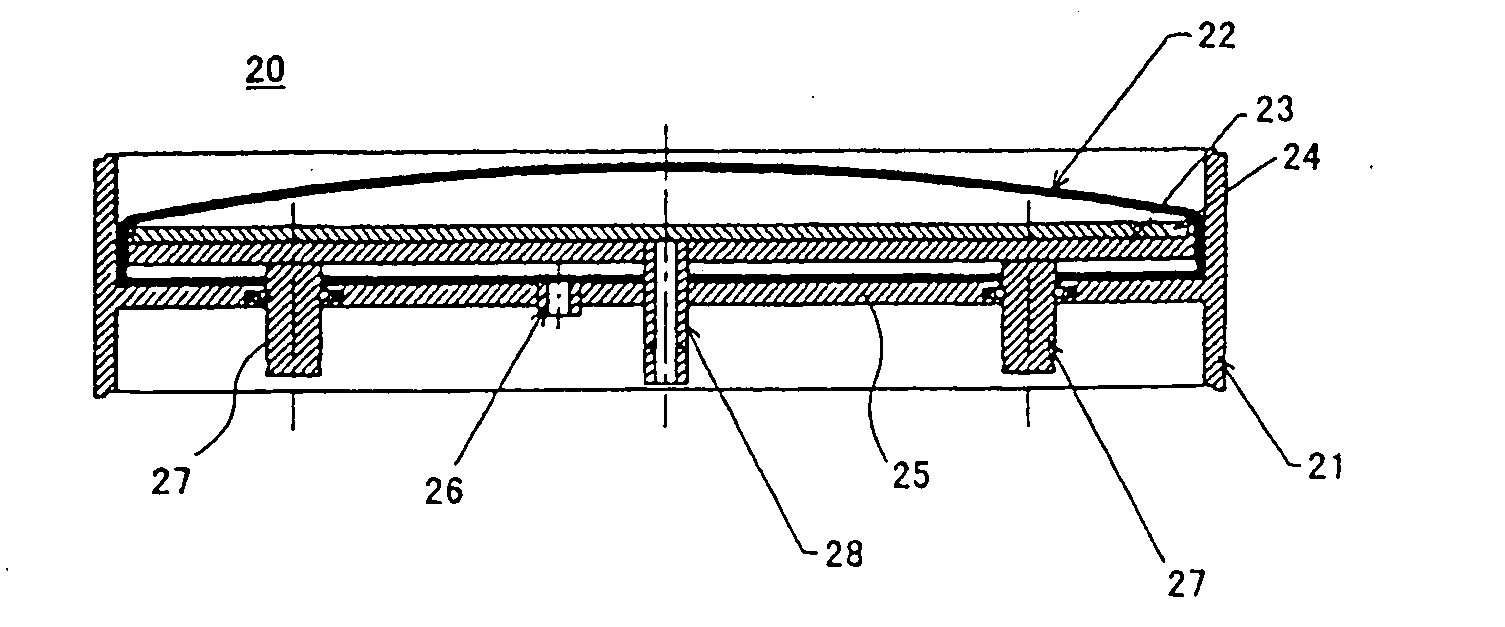

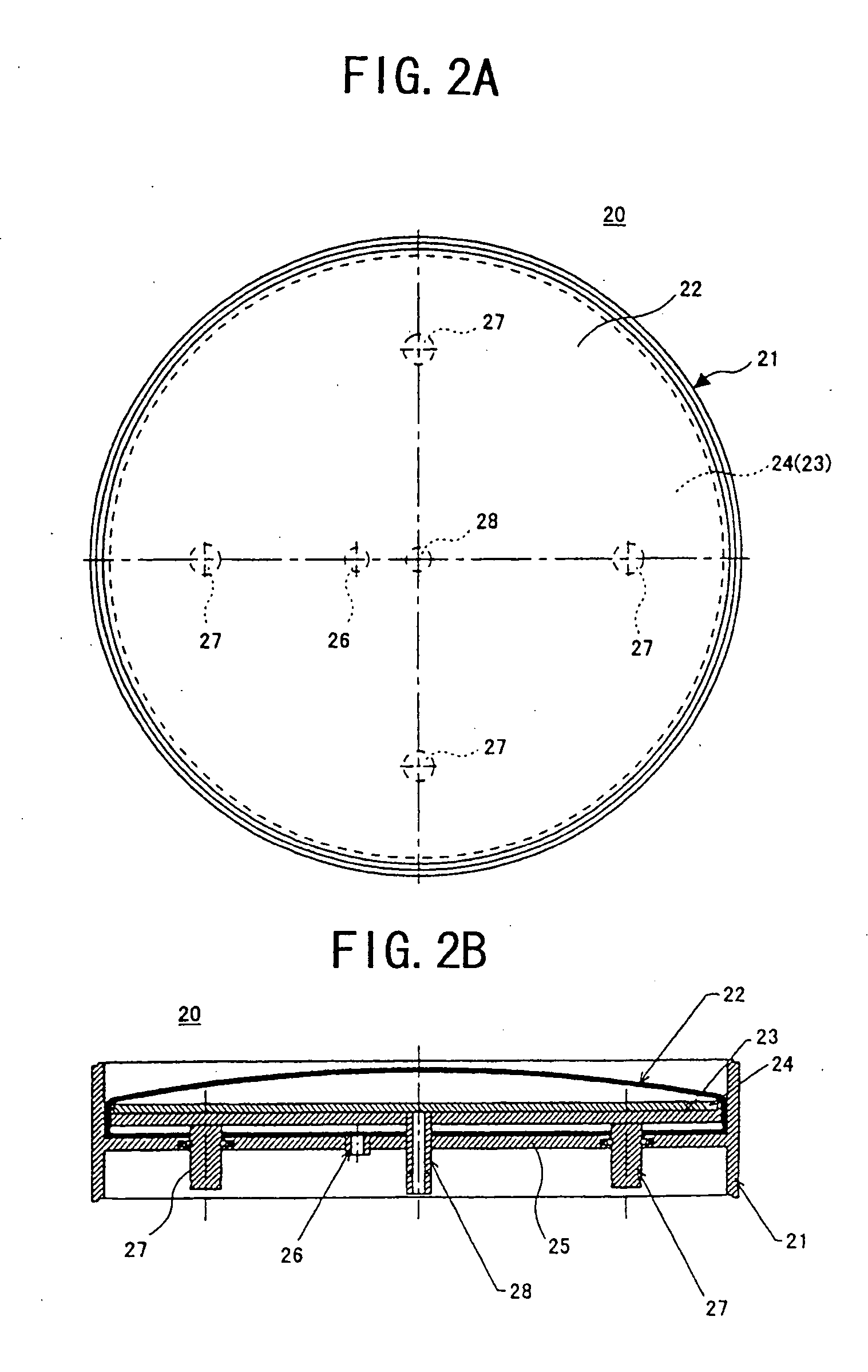

Method of manufacturing a semiconductor device and a method for fixing the semiconductor device using substrate jig

The present invention relates to a method of manufacturing a semiconductor substrate including the back grind step, the dicing step, the pick up step, and the die bonding step of the wafer; and to a semiconductor substrate jig used in such method. The object of the present invention is to mitigate the effect and to prevent damage caused by the lack of strength in thinned semiconductor substrates. A jig with an outer frame 21, and a rubber film 22 arranged within the outer frame 21 and having increasing and decreasing body size while deforming its shape by supplying air therein are provided. As the volume of the rubber film 22 increases, the wafer-fixing jig 20 deforms the rubber film and allows the tapes 2 and 6 arranged between the wafer 1 and the rubber film 22A to be pushed toward the wafer 1 gradually from the center outward. The attachment step, the back grind step, the tape reapplication step, the pick up step and the die bonding step are conducted using such wafer-fixing jig.

Owner:SOCIONEXT INC

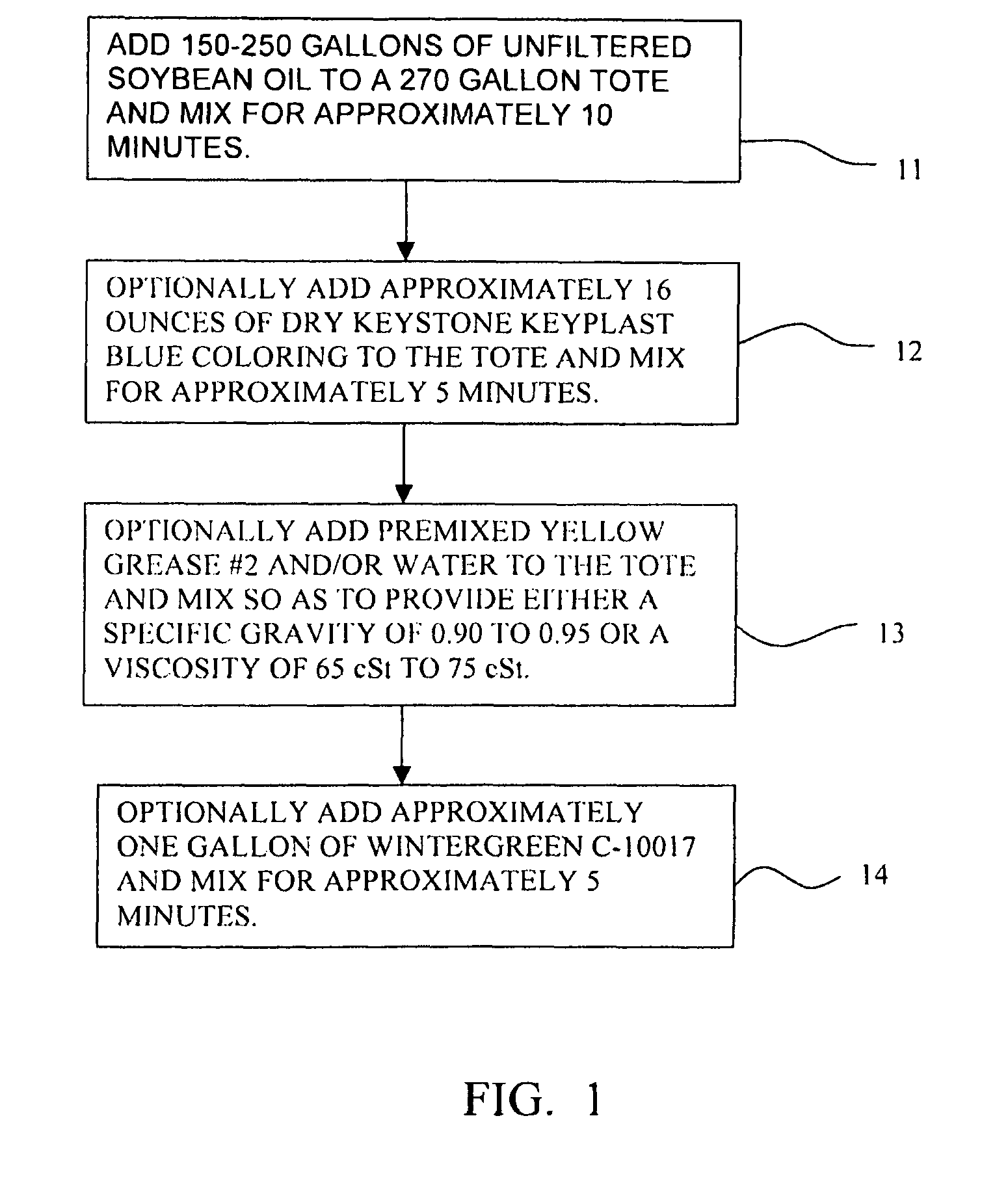

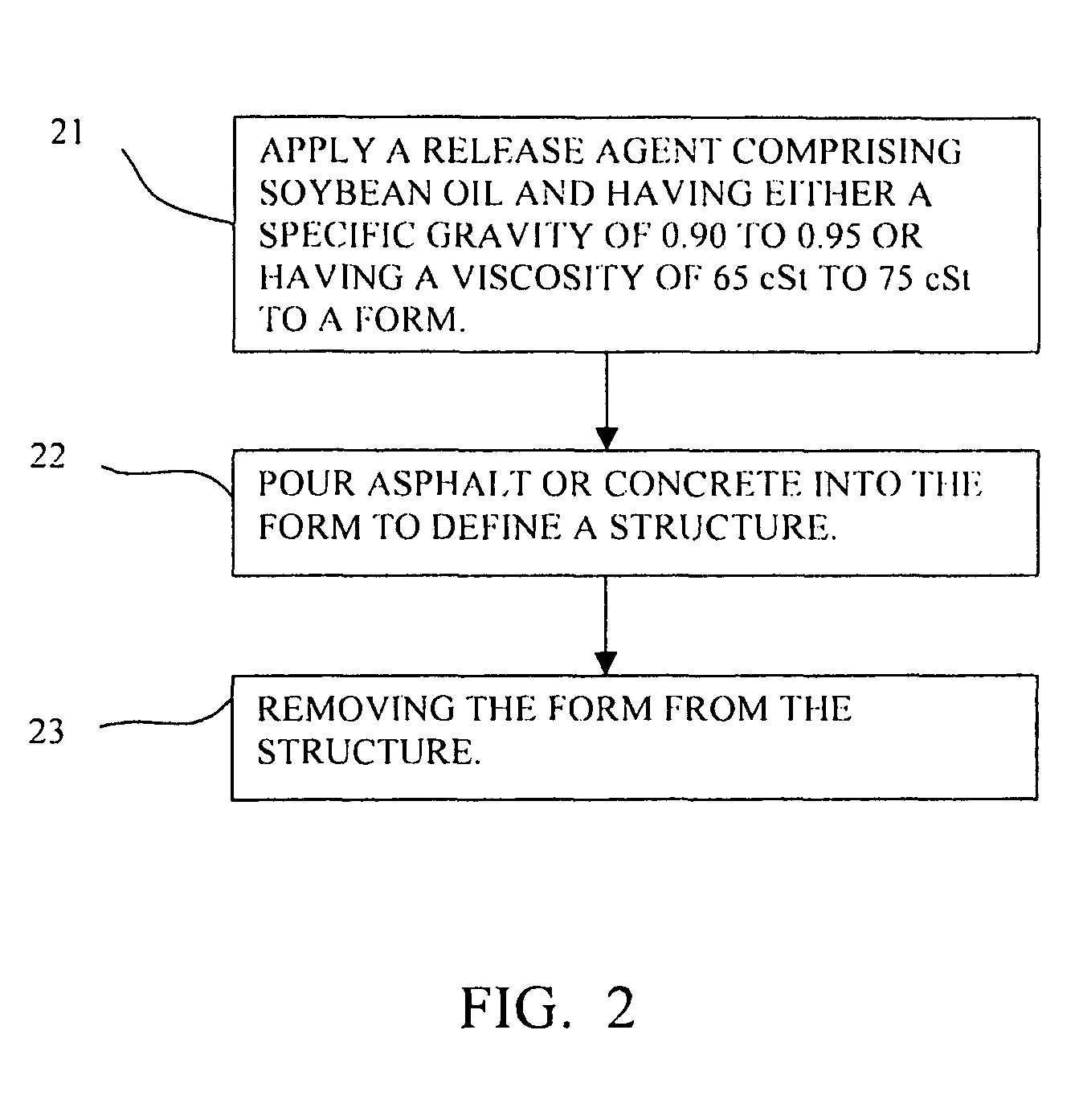

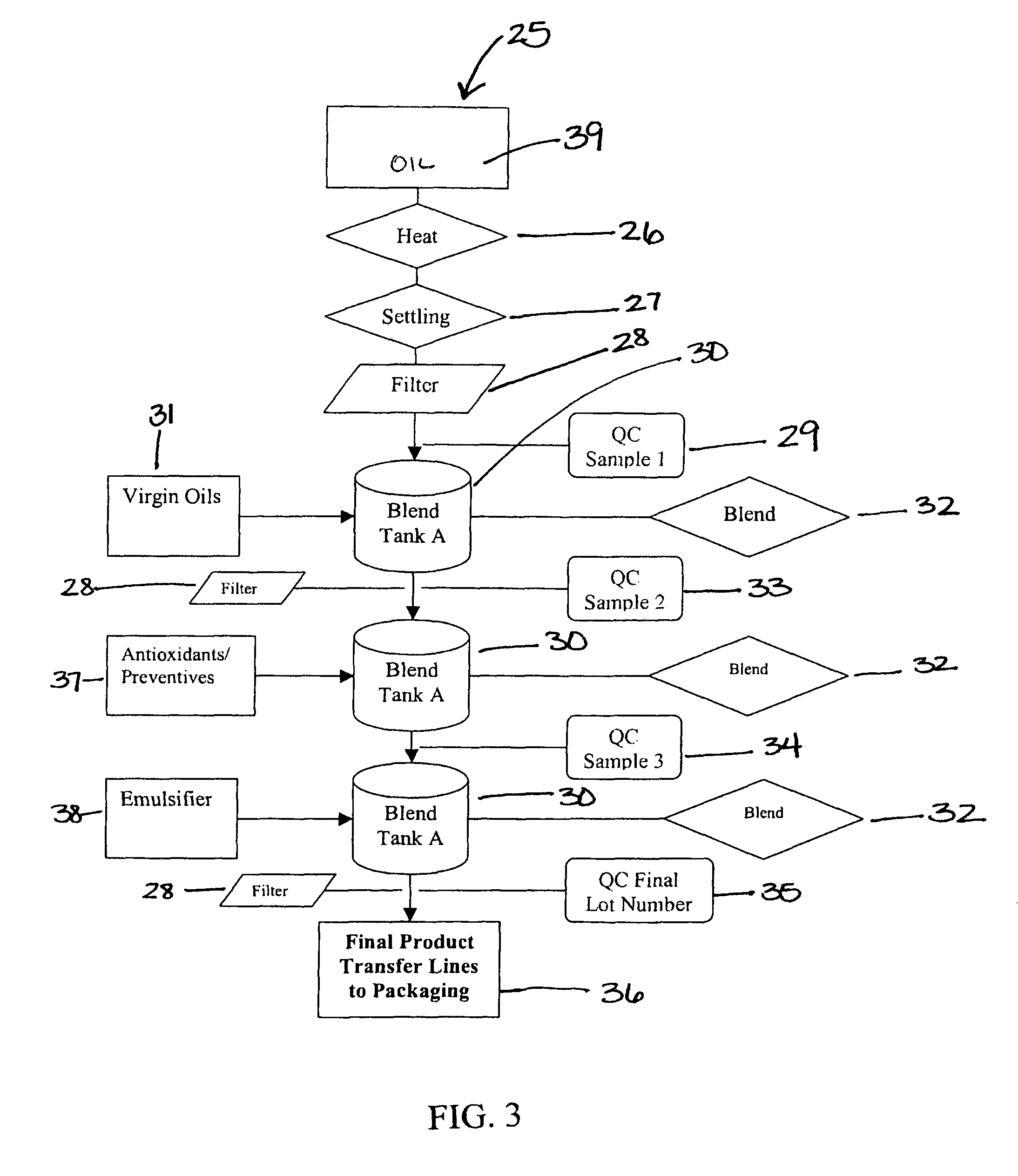

Release agent formulas and methods

InactiveUS8545611B2Increase gravityHigh viscosityOther chemical processesSingle unit pavingsOil and greaseEngineering

A release agent and method for using the same is provided. The release agent may have a high viscosity and gravity measurement and allowing for incorporation of a plurality of alternative oils and greases to be used as coating agent. Additionally, the release agent is adaptable for multiple uses by an end user as a coating agent without the need for reapplication of the release agent after every use. Moreover, the release agent may have additives such as anti-oxidants, preservatives, and emulsifiers that may allow for longer shelf life, easier coating and the like. Still further, the release agent may incorporate coloring and fragrances to make the agent more user friendly and easier to identify for coating purposes by the end user. The release agent may also incorporate freezing point depressants, anti-oxidants, emulsifiers, fragrances and solvent additives to increase shelf life and efficacy of the release agent.

Owner:PALA INVESTMENTS HLDG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com