Patents

Literature

1357results about How to "Prevent browning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Treatment of meat products

InactiveUS6113963AReduce microbial countPrevent browningBiocideDough treatmentCarboxylic acidNuclear chemistry

Described is a method of sanitizing meat product using aqueous streams having an antimicrobial composition added to the stream. Preferably, the antimicrobial composition includes a mixture of one or more carboxylic acids having up to 18 carbon atoms and one or more peroxycarboxylic acids having up to 12 carbon atoms, preferably a mixture of a C.sub.2-4 peroxycarboxylic acid and a C.sub.8-12 peroxycarboxylic acid.

Owner:ECOLAB USA INC

Lactobacillus used for biological preservation and application thereof

ActiveCN101914475APrevent browningReduce morbidityFruit and vegetables preservationBacteriaMoistureBiological organism

The invention discloses lactobacillus used for biological preservation, which is named Lactobacillus plantarum and has been collected in China Center for Type Culture Collection on June 21, 2010 with the collection number of CCTCC M 2010150. The lactobacillus can be used for fruit preservation. The application method comprises the following steps: heating and dissolving an acidizer in water, reducing temperature to normal temperature, adding lactobacillus powder, uniformly mixing, spraying onto fruits in an atomized mode, and storing the fruits at normal temperature or low temperature. Under the condition of normal temperature, the fruits can be preserved for 3 months, and under the condition of low temperature, the fruits can be preserved for 6 months. The Lactobacillus plantarum is obtained by screening a large amount of lactobacillus, can control peel browning and reduce fruit morbidity, and also can properly reduce fruit moisture violation, inhibit the metabolism of the fruits, and prolong the refreshing time.

Owner:山东宝来利来生物工程股份有限公司

Antistaling agent for preventing the browning of the fresh fruit having been cut and the using method thereof

InactiveCN101112208ALower physiological metabolismPrevent browningFruit and vegetables preservationSulfurFilm-coated tablet

The invention relates to an anti-browning and anti-staling agent for fresh cut fruits. The invention is characterized in that the invention contains the following components according to the mass shares: 0.1-0.4 share of cysteine, 0-0.9 share of ascorbic acid, 0-0.20 share of carbohydrate nutritional agents, 0-2.0 shares of calcium preparation, 0.1-0.4 share of esculent acid pH value regulator, 0.001-0.02 share of film-coating agent; the mixture of the components can be used after dissolved in 96.08-99.79 shares of water. The invention relates to a using method of anti-browning and anti-staling agent for fresh cut fruits thereof. The method has the following steps: anti-staling solution is prepared according to a certain proportion of each component; the cut fruits are contacted with the anti-staling solution completely for 3-10 minutes and then packed; the packed fruits are preserved under 2-8 DEG C. The invention is free from nocuity and sulfur, and can be used in instant fresh cut fruits and can effectively prevent browning and have the function of anti-browning and fresh-keeping.

Owner:INST OF AGRI ENG TECH FUJIAN ACAD OF AGRI SCI

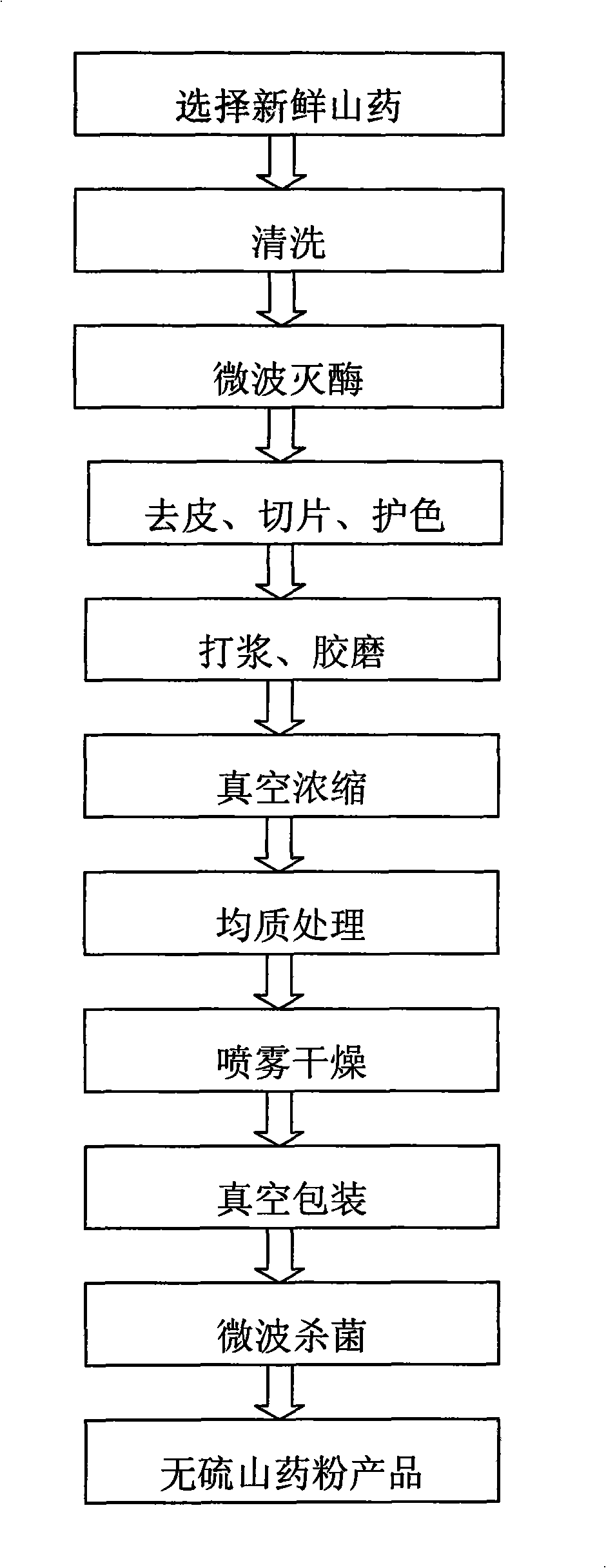

Production method for spray-drying Chinese yam powder without using sulfur to protecting color

InactiveCN101513241AImprove quality and efficiencyIncrease productivityHair cosmeticsDead plant preservationVitamin CAdditive ingredient

The invention relates to a production method for spray-drying Chinese yam powder without using sulfur to protecting color. The Chinese yam is prepared from fresh Chinese yam and is obtained by the steps of microwave enzyme deactivation, shelling, slicing, color protection, pulping, grinding, vacuum condensation, homogenization, spray-drying, vacuum packaging and microwave sterilization. The Chinese yam raw material is deactivated by microwave at temperature of 60 DEG C, cut to slice, and is soaked in sulfur-free color protection liquid containing phytic acid, Ethylenediaminetetraacetic acid disodium, vitamin C and citric acid, the color protection liquid and the Chinese yam slice is pulped together and is milled by a colloid mill, the Chinese yam slurry is concentrated by a vacuum condensation equipment until the content of solid is 15-25% and is homogeneously processed, homogenized liquid material is sprayed and dried by a centrifugal spray-drying machine, the obtained Chinese yam powder is packaged by vacuum and is sterilized by a microwave sterilization equipment to prepare the sulfur-free Chinese yam powder product. The invention has high production efficiency and low cost, the produced Chinese yam product has good color, high safety and complete nutrient composition, and can applied for field such as foodstuff, medicine and cosmetic product.

Owner:袁书林

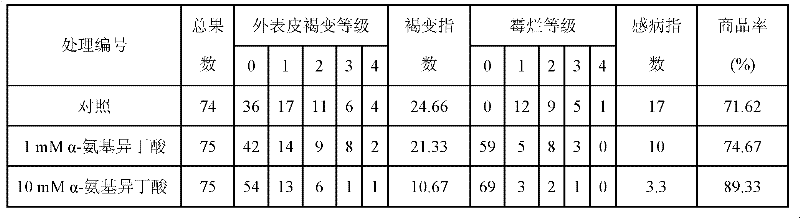

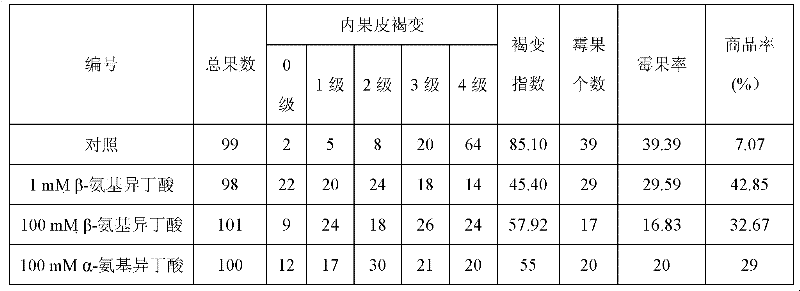

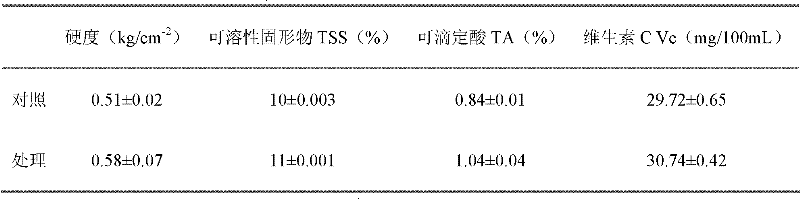

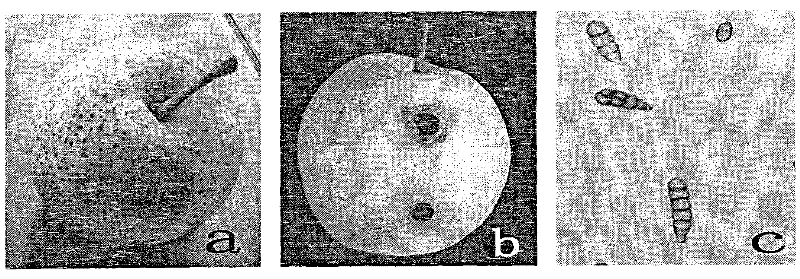

Application of alpha-aminoisobutyric acid or beta-aminoisobutyric acid in preparation of fruit preservative as well as fruit preservative and using method

ActiveCN102224840AReduce decay rateGuaranteed qualityFruit and vegetables preservationAlpha-aminoisobutyric acidPreservative

The invention discloses an application of alpha-aminoisobutyric acid or beta-aminoisobutyric acid in preparation of a fruit preservative as well as the fruit preservative and a using method. Experiments demonstrate that after the fruit is processed by alpha-aminoisobutyric acid or beta-aminoisobutyric acid, the rotting rate of fruit can be effectively reduced, the fruit quality can be maintained,and the preserving time can be prolonged. Thus, the alpha-aminoisobutyric acid or beta-aminoisobutyric acid can be used for preparing the fruit preservative which contains 1-100 mM of alpha-aminoisobutyric acid or beta-aminoisobutyric acid. By processing the fruit such as litchi, longan, yangtao, papaya and mango by use of the fruit preservative and according to the processing method disclosed bythe invention, the rotting rate of fruit can be effectively reduced, the fruit quality can be maintained, the commodity rate of fruit can be improved, and the preserving time can be prolonged. The fruit preservative disclosed by the invention is safe and environmentally-friendly, and the preserving method is simple and convenient.

Owner:SOUTH CHINA BOTANICAL GARDEN CHINESE ACADEMY OF SCI

Preparation method of plant unbleached impregnated specimen

InactiveCN102524245APrevent browningSimplified fixed killing proceduresDead plant preservationBiotechnologyEngineering

The invention provides a preparation method of a plant unbleached impregnated specimen. In the invention, the fixative of the operation process adopts a composite biocidal formula and simplifies the fixing and biocidal procedures, and the operation is simple; and the preservation solution for preserving the plant specimens adopts nontoxic and inexpensive biological extracts, such as garlic extract, ginger extract, carboxylation chitosan and the like, and solves the problem of environmental pollution when preserving and storing the plant specimens. The preparation method of invention can be applied to the impregnation and preservation of monochromatic plants, such as green, yellow, red, white plants and the like, multi-color plants and whole plant specimen, and provides a novel way for preparing the plant unbleached impregnated specimens.

Owner:HENAN UNIV OF SCI & TECH

Method for producing pale disproportionated rosin with high content dehydroabietic acid and P-camphogen simultinuously

InactiveCN1616570APrevent browningPrevent oxidationNatural resin purificationNickel catalystDistillation

The process of producing pale disproportionated rosin with high dehydroabietic acid content and paracymene simultaneously includes the following steps: rinsing turpentine to eliminate impurity, dissolving turpentine in turpentine oil to form turpentine solution, catalytic disproportionating turpentine in solution in the presence of Pd / C catalyst, filtering and decompression distillation to obtain pale disproportionated rosin with high dehydroabietic acid content and disproportionated turpentine oil containing paracymene in 20-60 %, and distilling disproportionated turpentine oil to obtain paracymene and pinane. Or, the rinsed turpentine as material may be re-crystallized to purify and catalytically disproportionated to prepare pale disproportionated rosin containing high dehydroabietic acid in 72-82 %. The Pd / C catalyst may be replaced with skeletal nickel catalyst.

Owner:GUANGXI UNIV

Lactobacillus used for biological preservation and application thereof

ActiveCN101914475BPrevent browningReduce morbidityFruit and vegetables preservationBacteriaMoistureBiological organism

The invention discloses lactobacillus used for biological preservation, which is named Lactobacillus plantarum and has been collected in China Center for Type Culture Collection on June 21, 2010 with the collection number of CCTCC M 2010150. The lactobacillus can be used for fruit preservation. The application method comprises the following steps: heating and dissolving an acidizer in water, reducing temperature to normal temperature, adding lactobacillus powder, uniformly mixing, spraying onto fruits in an atomized mode, and storing the fruits at normal temperature or low temperature. Under the condition of normal temperature, the fruits can be preserved for 3 months, and under the condition of low temperature, the fruits can be preserved for 6 months. The Lactobacillus plantarum is obtained by screening a large amount of lactobacillus, can control peel browning and reduce fruit morbidity, and also can properly reduce fruit moisture violation, inhibit the metabolism of the fruits, and prolong the refreshing time.

Owner:山东宝来利来生物工程股份有限公司

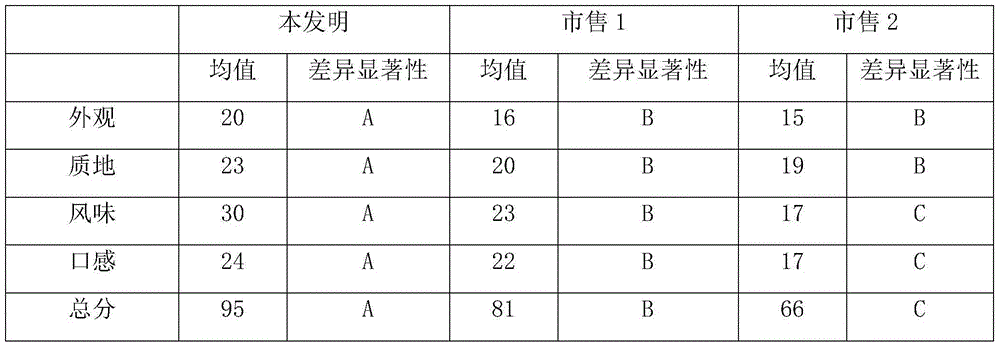

Probiotics troche and preparation method thereof

The invention discloses a probiotics troche and a preparation method thereof. Functional leavening agents and germinated brown rice, Chinese herb medicine extract with anti-cold and hot irritability and a stabilizer capable of effectively enhancing the stability are added into a yoghourt fermenting process; poikilothermal yogurt fermentation enables proliferation of lactic acid bacteria to the maximum extent, so that the anti-cold and hot irritability of lactic acid bacteria is improved. yogurt and fruit and vegetable slurry are pre-treated by using a non-hot-working technology so as to prevent infectious microbe infection in the process, improve the juice yield of the fruit and vegetable slurry, increase the content of soluble cellulose of the fruit and vegetable slurry and prevent the fruit and vegetable slurry from brown stain. Moreover, when the fruit and vegetable slurry and the yogurt are mixed, a scientifically compounded freezing protecting agent which is relatively good in anti-freezing effect is added. Finally, the probiotics troche which is smooth in taste, uniform in texture, stable in state, natural in quality, high in viable count, strong in functionality and long in expiration data is prepared. The viable count is (1.75-2.55)x10<11> CFU / g. At normal temperature, the expiration data is 30-36 months.

Owner:TIANJIN ZHONGTIAN JINGKE SCI & TECH

Processing method for papaya fruitcake

The invention discloses a processing method for a papaya fruitcake. The processing method comprises the following steps: (1) preparation of papaya pulp: pouring papaya into 3-5% of salt water, boiling, mashing and grinding; (2) gelatin melting: mixing 15-25% of cane sugar and 1-3% of edible gelatin, and dissolving by hot water; (3) blending and boiling: adding 15-25% of maltodextrin, 10-20% of coconut milk, 0.5-1.5% of citric acid, 0.1-0.5% of sodium citrate and the melted edible gelatin into the papaya pulp to bend, homogenize, boil and stew until the soluble solid reaches 70-80%; (4) forming and drying: placing the papaya pulp material boiled in the step (3) in a forming die to cool, preparing the formed fruitcake body, then alternating temperature, baking, drying and packaging, so that the papaya fruitcake is obtained. The processing method is simple and feasible, the prepared fruitcake is rich in nutrition, and soft and smooth in taste, has unique papaya fragrance and coconut milk fragrance, can be stored for a long time without particles on the papaya fruitcake, and sugar-flowing, and is suitable for people of all ages.

Owner:廖乐隽

Method for tissue culture and quick propagate technique of reddish blue spider lily

InactiveCN101366357AFast growthPrevent browningHorticulture methodsPlant tissue cultureSaccharumSucrose

The invention discloses a method for the tissue culture of Lycoris haywardii and a rapid propagation technique. The method comprises the following: 1) a step of preparing culture mediums, and components of a basic culture medium and the culture mediums in every stage of tissue culture, as well as the weight of every component contained in each liter are as follows: the basic culture medium comprises MS or 1 / 2MS, wherein the basic culture medium comprises 20 to 40 g / L of sucrose and 8 g / L of agar and has the pH of 5.8; an induction culture medium comprises MS, 0.2 to 1.0 mg / L of TD and 2 g / L of activated carbon; a proliferation culture medium comprises MS, 3 to 7 mg / L of 6-BA and 0.5 to 2.5 mg / L of NAA; a strong seedling culture medium comprises MS, 0.5 to 2.5 mg / L of 6-BA and 0.5 to 1.5 mg / L of NAA; and a rooting culture medium comprises 1 / 2MS, 0.5 to 2.5 mg / L of KT, 0.5 to 2.5 mg / L IBA and 2 g / L of activated carbon; 2) a step of selecting and sterilizing explants; 3) a step of carrying out induction culture, proliferation culture, strong seedling culture and rooting culture; and 4) a step of domesticating and transplanting tissue culture seedlings. The method has the advantages that the induction rate of Lycoris haywardii buds reaches over 90 percent; the proliferation rate of each week is over 500 percent; the growth rate of the Lycoris haywardii buds is accelerated; the browning phenomenon of the explants is effectively prevented; and the rooting of the tissue culture seedlings is promoted at the same time when bulblet browning is prevented.

Owner:HANGZHOU BOTANICAL GARDEN +1

Fresh-keeping method for lichee

InactiveCN1965660AHas antibacterial propertiesImprove ventilation and water permeabilityFruits/vegetable preservation by heatingFruits/vegetable preservation by coatingSulfurEngineering

The invention relates to an antiseptic method of leechee, wherein the invention uses antiseptic polypropylene non-woven cloth, to prepare different fresh-keeping bags, and packs dibutyl fumarate into common non-woven cloth to prepare the non-woven package, while the mass ratio between leechee and fresh agent is 10000:0.1-2; then putts leechee into the fresh-keeping bags, uses lines to tie the bag or uses thermal method to seal the bag, putts into ventilate package box, or putts packed leechee into bamboo frame to be put into fresh-keeping bag. The invention can store leechee at 0-5Deg. C for 30-35days. When the leechee is treated with sulfur, the leechee can be stored at 0-5Deg. C for 90-100day.

Owner:SOUTH CHINA UNIV OF TECH

Boiled lotus root slice processing technology and product thereof

The invention discloses boiled lotus root slice processing technology and a product thereof, and belongs to the technical field of food processing. The technology is characterized by comprising the following steps of: soaking a lotus root in solution consisting of citric acid and kojic acid for 0.5 to 2 hours after washing, selecting and peeling; pickling the lotus root in the solution of salt at 18 to 22 degree Be' for 5 to 10 days; cutting and desalting the lotus root after pickling; boiling the cut lotus root in 0.3 to 0.5 mass percent of calcium lactate solution at the temperature of between 80 and 85 DEG C for 12 to 15 minutes; sorting, packaging and adding decoction which is formed by mixing the citric acid, malic acid, lactic acid, and ascorbic acid and contains 0.3 to 0.5 mass percent of the calcium lactate; and obtaining the product by vacuumizing, sealing, sterilizing and cooling. Boiled lotus root slices prepared by the technology have the characteristics of milky color and luster, tender and crisp texture, safety and sanitation, and convenient eating.

Owner:YANGZHOU HUSN VEGETABLE FOOD

Freezing-inhibiting and sweet potato enzyme-regulating browning promoting method

InactiveCN1672561APrevent browningNo security risksFood preservationFood preparationChipped potatoesEnzyme

The present invention belongs to the field of fruit and vegetable processing technology, and aims at solving the browning problem during producing freeze stored sweet potato chip. The freeze stored sweet potato chip producing process includes the following main steps: 1) sorting sweet potato material, washing and slicing into 4 mm thick chips; 2) scalding the chip at 100 deg.c for 15 sec; and freezing; 3) soaking the frozen chip at 25 deg.c for 30 mm to protect color; 4) amending the chip through vacuum penetration at vacuum of 0.08-0.10 MPa for 30 min, freezing to -18 deg.c fast and packing; and 5) cold storing at low temperature from -28 deg.c to -18 deg.c. Thus produced sweet potato chip has good color, no browning, long storing period and other features.

Owner:NINGBO HAITONG FOOD SCI & TECH CO LTD

Processing method of canned tunas

InactiveCN101779695AGreat tasteImprove antioxidant capacityMeat/fish preservationClimate change adaptationMonosodium glutamateVitamin C

The invention discloses a processing method of canned tunas. Compared with the generally processed canned tunas, the invention has the advantages that cheap tunas such as frigate mackerels and the like are used as raw materials, and aiming at the inherent defects of sour taste, dark color, easy browning and the like of frigate mackerel tunas, the invention provides two solutions correspondingly in the processing method, wherein one solution is color protection treatment, namely a brine soaking method is used for removing partial blood water and soluble protein in tuna bodies by adding citric acid and vitamin C into brine to perform the function of color protection; and the other solution is to add the soup of the invention into the canned tuna meat after the raw materials are processed and cooked to perform the functions of preventing the tuna meat from being oxidized, preventing the tuna meat from browning and improving the taste of the tuna meat, wherein the soup comprises salt, monosodium glutamate, sodium pyrophosphate, sodium tripolyphosphate, citric acid and vitamin C. The invention overcomes the inherent defects of cheap tunas, can be used for processing the cheap tunas used as can raw materials into the canned tunas, and improves the economic benefit and the development prospect of the products.

Owner:H&P FOODS

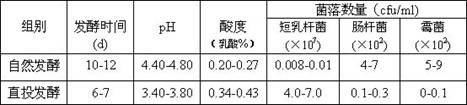

Jerusalem artichoke pickle produced by direct-vat-set lactobacillus brevis leavening agent, and process of same

ActiveCN102613518AIncrease productivityShort fermentation cycleFood preparationNutritionFermentation starter

The utility model relates to jerusalem artichoke pickle produced by direct-vat-set lactobacillus brevis leavening agent and a process of same, and belongs to the technical field of deep processing of vegetable and food bioscience. Lactobacillus brevis is adopted to be developed into high-density lactobacillus brevis leavening agent (the total number of bacterial colonies reaches 109 / ml); and the jerusalem artichoke pickle is produced by utilizing a direct-vat-set leavening process, so that a modern bioprocess technology of producing high-quality jerusalem artichoke pickle quickly is formed and achieved. The invention has a simple technological process and is easy to operate; compared with a conventional leavening process, the direct-vat-set leavening process has the advantages that the operation procedure is simplified, the production cost is reduced, and the nutritional ingredient and flavor substance of the jerusalem artichoke can be kept furthest at the same time; the jerusalem artichoke pickle is crispy, tasty, refreshing, and nourishing, and is a probiotic health product applicable to all ages. The invention is a green natural, safe and healthful production process and technology.

Owner:东台海滨科技创业园管理有限公司

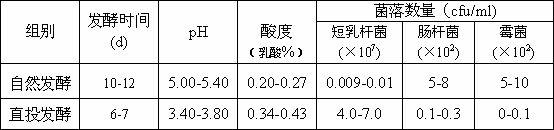

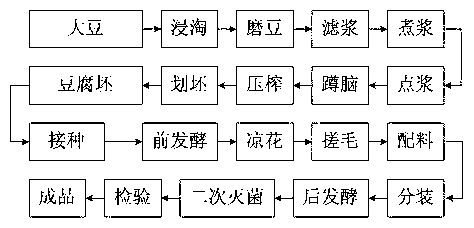

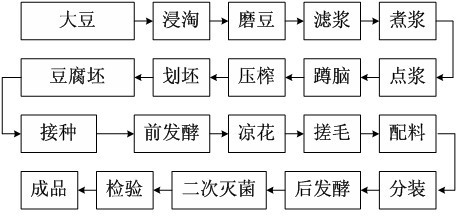

Production process of low-salt oil-free fermented bean curd

InactiveCN102696777APreserve the unique flavorGuarantee quality and safetyCheese manufactureFood scienceAlcoholHot peppers

The invention discloses a production process of low-salt oil-free fermented bean curd. The production process comprises the following steps: after performing the steps of immersing and washing soybean, grinding the soybean, filtering pulp, boiling the pulp, mixing pulp, concentrating, squeezing, dividing, inoculating, performing primary fermentation, cooling and mildewing, adding 8 to 10 percent of salt and 6 to 8 percent of alcohol; adding a proper amount of spice such as hot pepper powder, ginger powder, garlic powder and the like according to the traditional process; subpackaging into small bottles in one step; integrating fermenting, storing and finished product packaging materials; vacuumizing, so that the vacuum degree of the small bottle is 0.8 to 1.0; performing secondary fermentation for 1 to 2 months under the natural condition; performing secondary sterilization on the mature fermented bean curd, wherein the sterilization central temperature is 80 to 85 DEG C and the sterilization time is 25 to 35 minutes; and obtaining the finished products after passing inspection. The production process has the advantages that the unique flavor of the local traditional fermented bean curd is maintained; the characteristics of the times are achieved; the production process is fashionable and novel; the edible range is widened; the low-salt oil-free fermented bean curd has high nutritional value and preference, can realize industrial production and is safe and healthy; and quality safety of the oil-free fermented bean curd is effectively guaranteed.

Owner:WANYUAN LICHUAN FOOD COMPREHENSIVE DEV

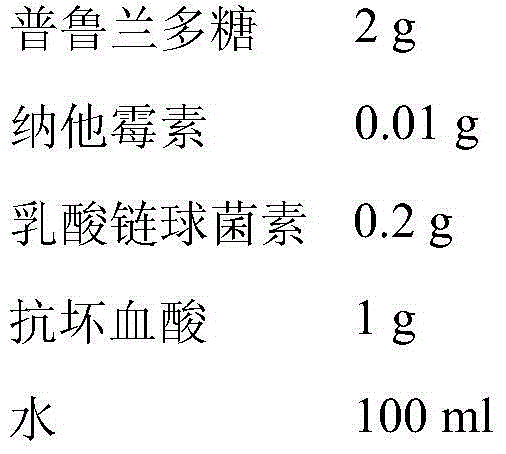

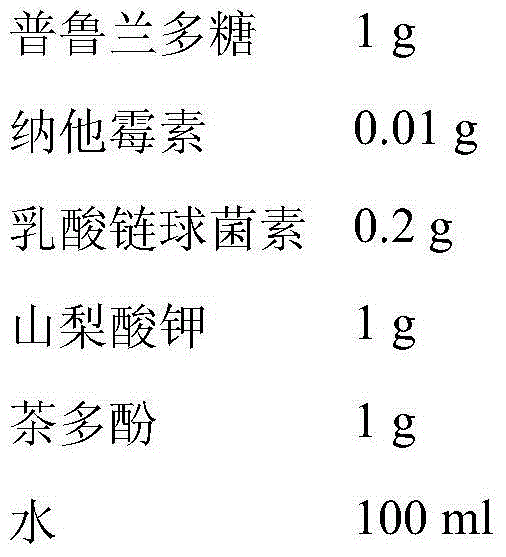

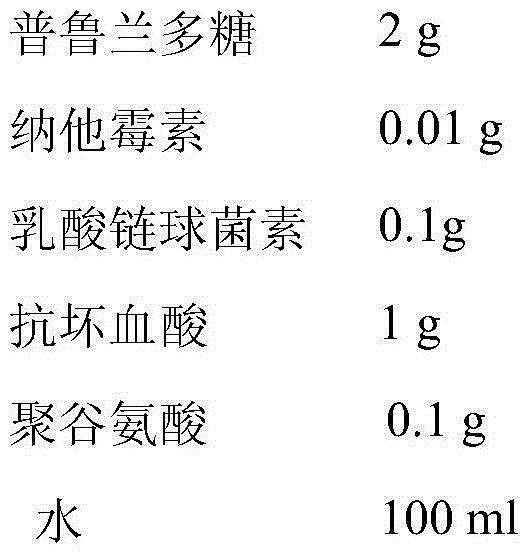

Shrimp preservative containing pulullan polysaccharide

InactiveCN104544472AExtended shelf lifePrevent invasionClimate change adaptationFood preservationShrimpAntioxidant

The invention discloses a shrimp preservative which comprises the following basic components: 0.5-50g / L of pulullan polysaccharide, 0-1g / L of natamycin, 0-5g / L of nisin from streptococcus lactis, 0-20g / L of ascorbic acid, 0-10g / L of polyglutamic acid, 0-20g / L of other antioxidants, 0-30g / L of other antibacterial components, 0-20g / L of other gum components and water as a solvent. When shrimps are soaked, sprayed and / or rubbed with the preservative, the refreshing time of the treated shrimps can be effectively prolonged for 3-4 days. The preservative has the advantages of good filming and preservation property, high security, high antibacterial and anti-oxidation efficiency, long action time and the like.

Owner:SHANDONG ACADEMY OF PHARMACEUTICAL SCIENCES

Preparation method of freeze-dried fruit, vegetable, nut and cereal yoghourt nutritive cubes

The invention provides a preparation method of freeze-dried fruit, vegetable, nut and cereal yoghourt nutritive cubes. The preparation method comprises the following steps of cleaning fruits and vegetables, performing pulping, mixing and blending pulp with yoghourt, performing homogenizing, adding cereals, nuts and fruit granules, performing stirring, performing membrane filling, performing quick-freezing, performing demolding, performing vacuum freeze drying, and performing packaging so as to obtain the freeze-dried fruit, vegetable, nut and cereal yoghourt nutritive cubes. The freeze-dried fruit, vegetable, nut and cereal yoghourt nutritive cubes are produced by a vacuum freeze drying technique, so that original thermal sensitivity components and antioxidation components of products canbe sufficiently guaranteed, the color and the fragrance of fruits and vegetables and the activity of probiotics can also be guaranteed, and transportation and long term storage are facilitated; and besides, the cereals, the nuts and the fruits cooperate, so that the nutrition is more balanced.

Owner:清谷田园食品有限公司

Process of extracting pueraria polysaccharide

The process of extracting pueraria polysaccharide includes the following steps: milling slurry with kudzu vine root, adding cellulase and protease into the slurry for enzymolysis and simultaneous low strength ultrasonic treatment, adding vitamin C and xylose for protecting color, filtering to eliminate fiber, centrifugally separating the filtrate to eliminate starch, vacuum concentrating the centrifugate, adding alcohol before further centrifugally separating to obtain wet pueraria polysaccharide, and drying to obtain pueraria polysaccharide product. The present invention has raised enzyme activity and substrate converting rate, raised extraction rate of polysaccharide and flavone, effective prevention of browning, and natural color of the product.

Owner:宋桃森

Dried persimmon processing method

The invention discloses a dried persimmon processing method. The processing is executed by combining microwave sterilization and baking in a baking room of a heat pump. The method comprises the specific steps of: selecting persimmon fruits, sterilizing the persimmon fruits, baking the persimmon fruits, softening the persimmon fruits, removing bitterness, stacking and covering, shaping, packaging and scattering flour. In the method, the microwave sterilization is used, microorganisms on the surfaces of the persimmon fruits can be quickly killed, so that the persimmon fruits can be prevented from going bad during the processing; furthermore, polyphenol oxidase (PPO) in the persimmon fruits can be killed; the brown stain of the persimmon fruits can be prevented; during the processing of dried persimmon, most working procedures can be executed in the baking room; the continuity is high; the pollution of the dried persimmon is avoided; the dried persimmon production efficiency is improved; the production cost is reduced; the dried persimmon processing method is easy to operate and low in investment; the quality of the dried persimmon is controllable; and the dried persimmon processing method is suitable for large-scale industrial production.

Owner:桂林普兰德生物科技有限公司 +1

Composition for preventing browning of plant tissue culture and using method of composition

InactiveCN103004754AHigh activityPrevent browningDead plant preservationPlant tissue cultureQuinonePlant tissue

The invention discloses a composition for preventing browning of a plant tissue culture. The composition contains a direct antioxidant against phenolic substances and a plant antioxidase system reinforcing agent, and can play the systematic synergic action of two anti-browning mechanisms during the plant tissue culture process, on the one hand, the anti-oxidation action of the anti-oxidant can be realized against the phenolic substances infiltrating into a culture medium so as to reflect the direct reduction action, on the other hand, the plant antioxidase system reinforcing agent can reinforce the activity of antioxidase in strawberry tissues in plant tissues, and the production and the expansion of basic factors of the browning, namely quinone type substances can be reduced; and the combination of the two can effectively prevent the browning phenomenon in primary culture of strawberries and reduce the browning rate from the conventional level of above 30% to below 20%. The composition disclosed by the invention is widely suitable for various plants which are prone to browning in different tissue culture stages. The invention further discloses a using method of the composition.

Owner:SUZHOU HEMEI BIOTECH

Freezing method of fresh shrimp and freeze protective agent of fresh shrimp

InactiveCN105432767AProtect umamiKeep the lookMeat/fish preservation by freezing/coolingMeat/fish preservation using chemicalsBiotechnologyPhenolic content in tea

The invention discloses a freezing method of fresh shrimp and a freeze protective agent of fresh shrimp. The protective agent comprises the first biological preservative and the second biological preservative; the first biological preservative is tea polyphenol solution; and the second biological preservative is a mixture of chitosan, sodium alginate, calcium chloride, lysozyme, propolis, lactoferritin, xylitol and sorbicolan. The protective agent is utilized for freeze preservation of fresh shrimps. The freeze protective agent of fresh shrimp disclosed by the invention is prepared from natural ingredients; the first biological preservative and the second biological preservative are combined, so that the fresh flavor and the original state of appearance of the aquatic products can be better protected; moreover, the freeze protective agent of fresh shrimp reduces nutrient loss, such as protein loss and the like, while inhibits bacteria production; thus, the freeze protective agent of fresh shrimp is capable of greatly prolonging the shelf life and the storage period of the aquatic products.

Owner:高邮市应天水产有限公司

A preparation method for high-fiber recombinant asparagus chips

The present invention discloses a preparation method for high-fiber recombinant asparagus chips, and belongs to the deep processing field of fruits and vegetables. The asparagus chips use discarded scraps of old stems and old roots from asparagus production enterprises as raw materials, and are prepared by the following steps: pre-treating the raw materials, blanching the materials in hot water, preserving color, conducting beating, mixing the materials with adjuvant materials, cooking the mixture for a short time, placing the mixture on plates, drying the mixture under vacuum by two section-type microwave to a moisture content of 10% -15%, drying the mixture by short- and medium-wave infrared method under vacuum to a moisture content below 5%, and packaging the mixture to obtain the end products. The dietary fiber content of the asparagus chips is 8.35% - 10.27%, and every 100g of the chips contains flavonoids 12.73-16.86 mg, polysaccharide 9.34-11.28 mg. The preservation rate of chlorophyll is 70% to 75% after processing, and the chip breaking force is 1123-1443 g. The preparation method provides a novel method for taking full advantage of asparagus scraps, and the microwave vacuum drying and the short- and medium-wave infrared vacuum drying have advantages of quick drying, low temperature and higher nutrient retention rate, etc. The asparagus chips are high in cellulose content, rich in flavonoids, polysaccharide and other active substances, crispy and delicious in taste and high in nutritional value. Therefore, the asparagus chips are leisure crisps for people of all ages.

Owner:JIANGNAN UNIV +1

Processing method for drying litchi pulp and longan pulp

The invention discloses a processing method for drying litchi pulp and longan pulp. The method comprises the following steps of: selecting litchi or longan fruits as a raw material, performing blanching and color protecting treatment on the shelled and denucleated pulp, drying the treated pulp by using hot air to obtain a semi-dry product, and performing microwave vacuum drying till the water content of the product is 10 to 15 percent. The product is golden, thick in flavor, sweet and sour and attractive in appearance; the nutritional components are kept well; and the quality of the product is obviously superior to that of the traditional dehydrated litchi pulp or longan pulp product. The processing method has the characteristics of health, environmental friendliness, short production period, low operating cost and high energy utilization rate, and is favorable for improving the market competitiveness of the dried litchi and longan products.

Owner:FUJIAN AGRI & FORESTRY UNIV

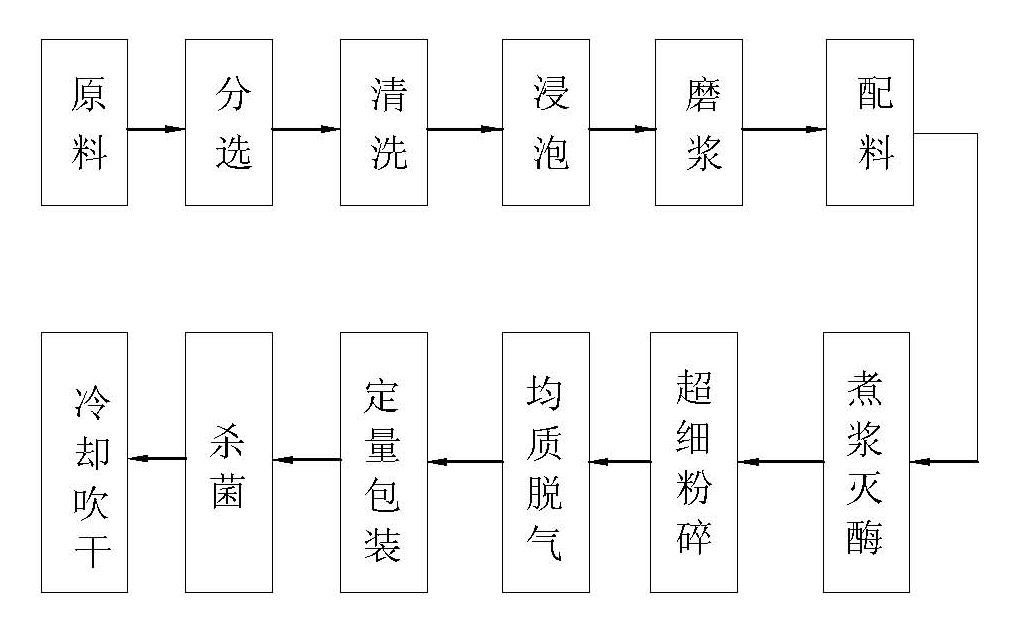

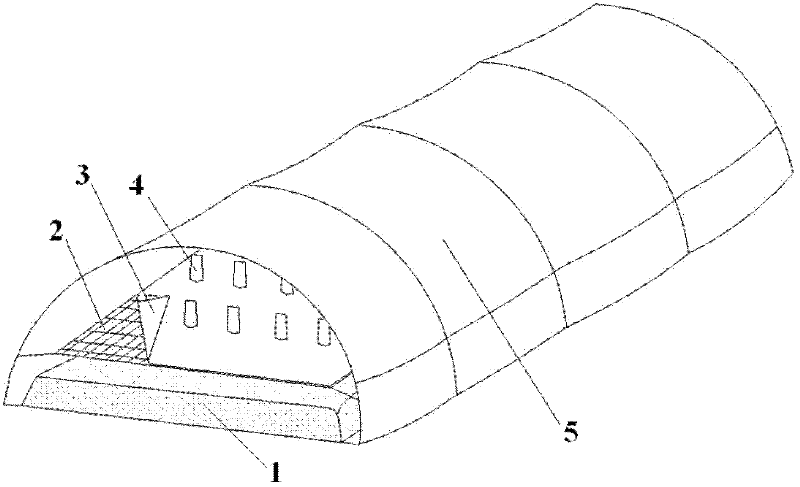

Method for preparing high-concentration soya-bean milk

InactiveCN102138591AWide range of particle sizesRich varietyMilk substitutesFood scienceHigh concentrationDietary fiber

The invention relates to a method for preparing high-concentration soya-bean milk. In the method for preparing the high-concentration soya-bean milk, the high-concentration soya-bean milk is prepared by sorting, cleaning and immersing soybeans, pulping, batching, stewing pulp, deactivating enzyme, performing superfine grinding, homogenizing, degassing, performing quantitative packaging, sterilizing, cooling, and blowing dry sequentially. Compared with the prior art, the method for preparing the high-concentration soya-bean milk has the advantages that: the high-concentration soya-bean milk has high nutritional value by adding abundant edible ingredients, and due to the full utilization of bean dregs, the content of dietary fibers in the soya-bean milk is improved. In addition, in the preparation process, bean immersing water is utilized effectively to realize the zero release of production and protect environment.

Owner:JOYOUNG CO LTD

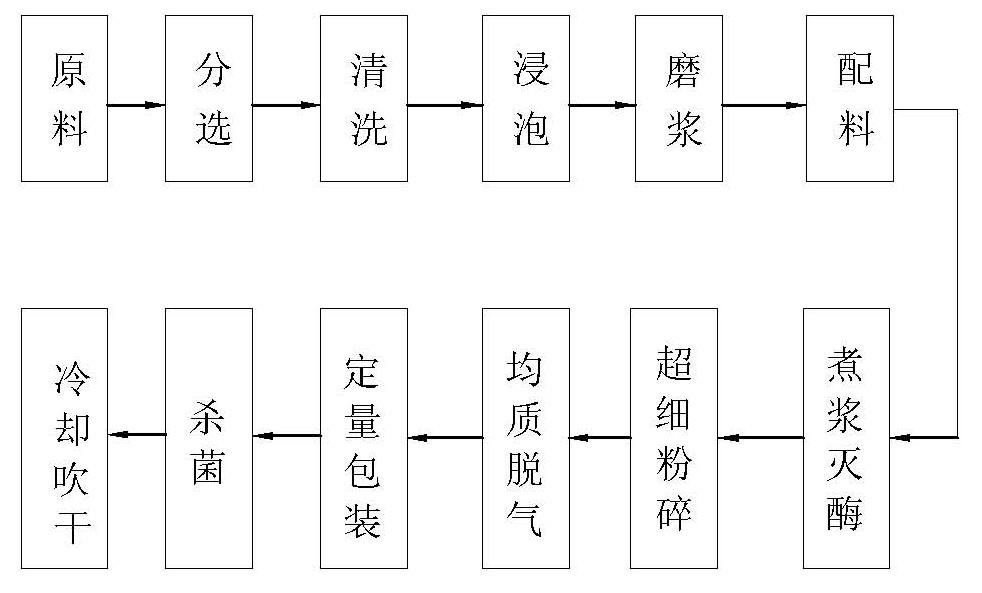

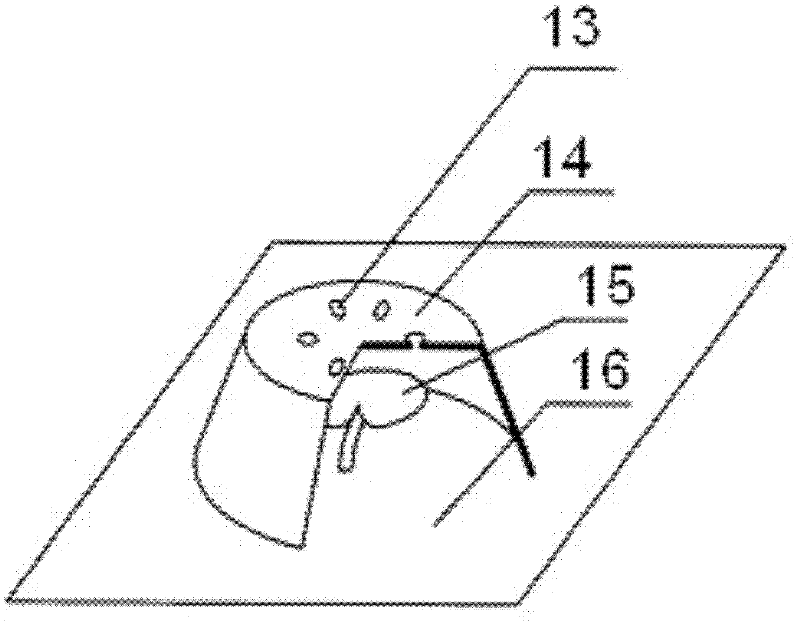

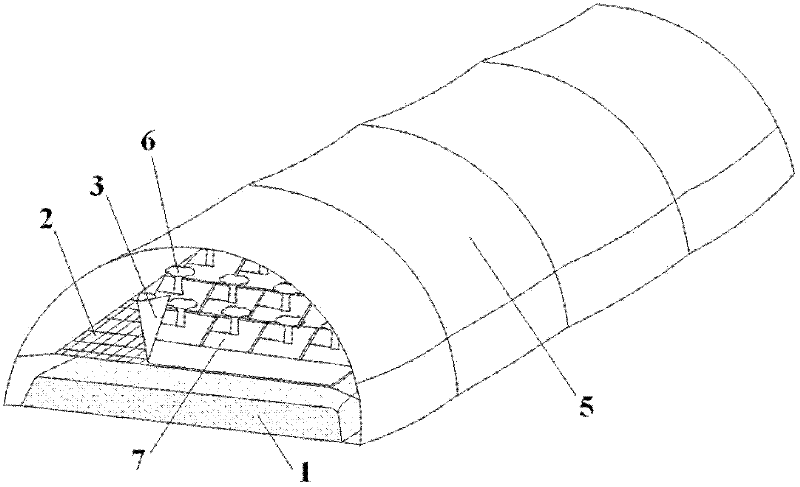

Method for cultivating glossy ganoderma and collecting glossy ganoderma spore powder

InactiveCN102498944AIncrease productionEasy to implementHarvestersHorticultureComing outPlastic materials

The invention discloses a method for cultivating glossy ganoderma and collecting glossy ganoderma spore powder. The method comprises the following steps of: a, cultivating the glossy ganoderma in the conventional method, before the cracking period of fully-ridged glossy ganoderma, arranging a layer of supporting network right above the glossy ganoderma to emergence space of a ridging surface, paving a plastic film on the integral supporting network, and shearing seams on the parts of the supporting network and the plastic film, which are opposite to the glossy ganoderma, so that the glossy ganoderma can come out from the seams; b, when the mature glossy ganoderma sporophores start to produce spore powder, inserting and cushioning a paper cushion on the root of each plant of glossy ganoderma sporophore, and arranging tea filter paper or a non-woven fabric arc shed on the supporting network or the plastic film; and c, harvesting the spore powder when spores of the glossy ganoderma sporophores are produced completely. By the method, the yield of the glossy ganoderma is improved by over 20 percent, the collection rate of the spore powder is maximized to over 98 percent, the glossy ganoderma sporophores are good in growing development, thin in skin and thick in flesh, the incubated spore quantity is maximized, the brown stain rate of the glossy ganoderma is less than 0.2 percent, the spores are robust and full, the content of active ingredients is higher, and the immigration source of the pollution of harmful substances in plastic materials is avoided.

Owner:安徽黄山云乐灵芝有限公司

Litch dry-wine and brewing method

This inventionm discloses a method for brewing dry-type lichee wine including taking lichees as the raw material, squeezing them, fermenting with barm at low temperature, hydrolyzing them with bio-enzymes, metabolic controlling fermentation and clarifying and filtering them to get the raw wine, which is processed for stability including: adding metal ionic complexant to coordinate metallic ions in the spirit to suppress browning of non-biologies, adding silica gel at low temperature to adsorb cold turbid proteins in the spirit and adding bio-antioxidation enzyme resisting against oxidation browning of the lichee wine.

Owner:广东荔枝庄园酒业有限公司

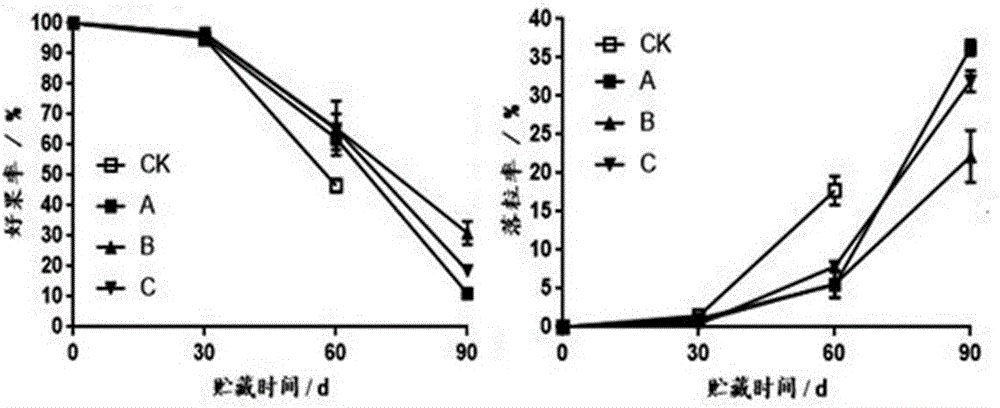

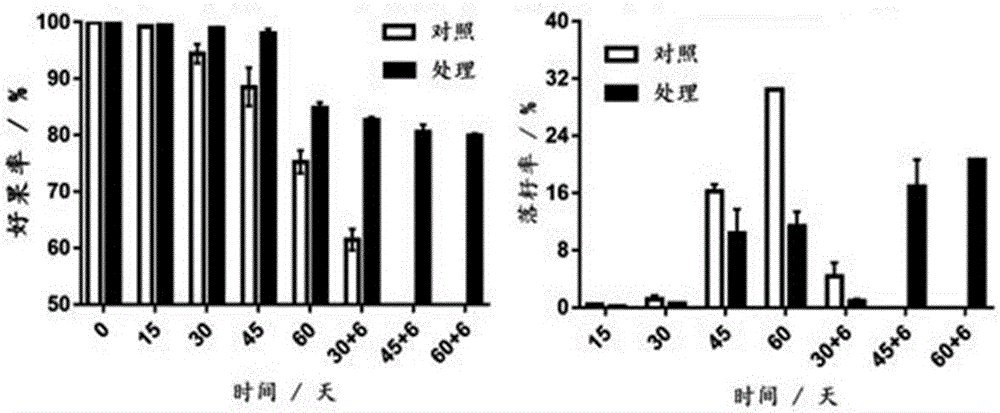

Crystal grape storage and preservation method

InactiveCN106688733AInhibit fruit senescenceImprove disease resistancePlant protectionFruits/vegetable preservation by freezing/coolingWaxBacteriostatic agent

The invention belongs to the technical field of storage and preservation of agricultural products and particularly relates to a crystal grape storage and preservation method, comprising the steps of (1) spraying 1500-2000 times of Trichoderma agent, namely natamycin composite bacteriostatic agent one day before bagging, and picking when reaching 70-80% of maturity; (2) removing bags after picking, picking out rotten fruits, waxing pedicles, subpackaging PE preservation bag lined transfer boxes, healing at normal temperature in the shade for 12-24 h, placing the transfer boxes in a cold store, and sterilizing the cold store and fruits with ozone or ultraviolet; (3) precooling in the cold store at 1.0+ / -0.5 DEG C for 24 h, adding a sterilizing agent and an ethylene blocking agent, tying the bags and storing. Severe biological disease damage, short shelf life, proneness to browning and other problems in existing crystal grape are solved, the shelf life of crystal grape is extended from 7 days to 60 days which leaves 6 days for the sales time, and the crystal grape storage and preservation method is simple to perform, high in efficiency and good in safety.

Owner:GUIYANG UNIV

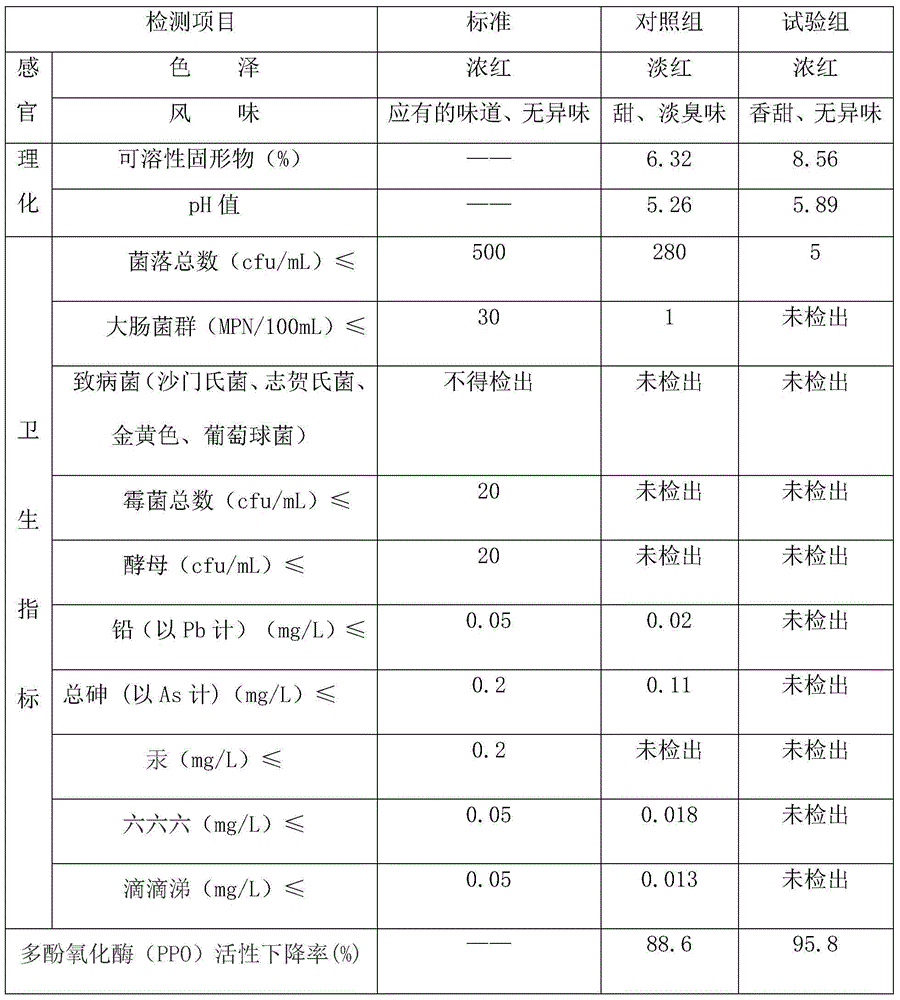

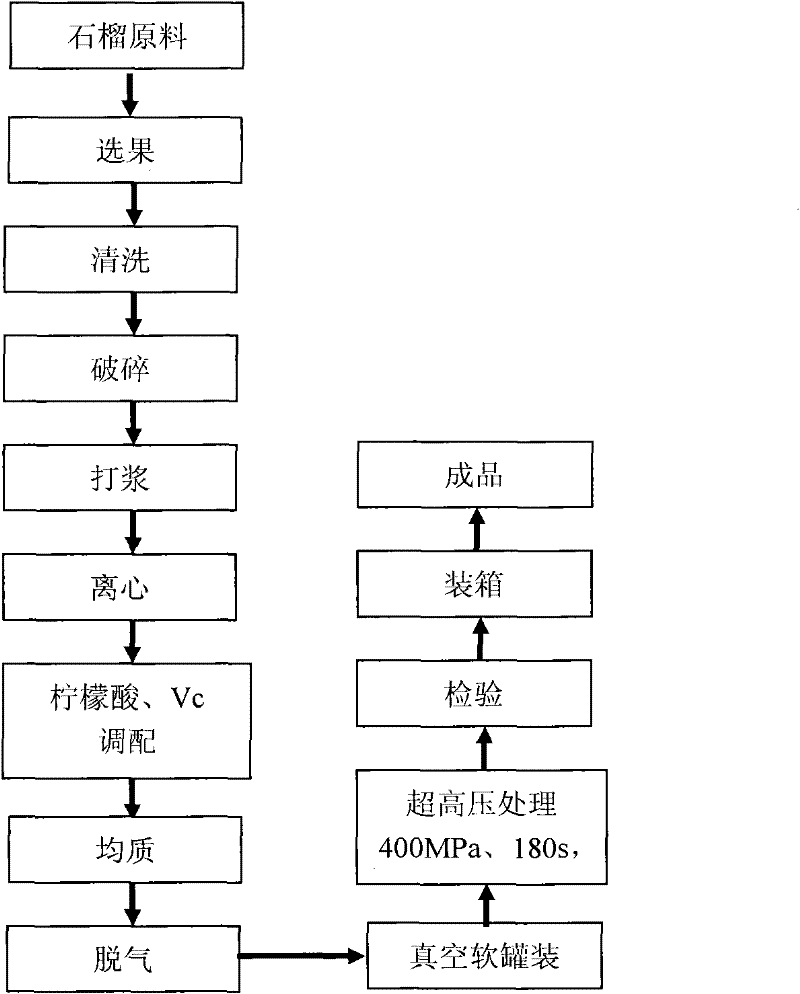

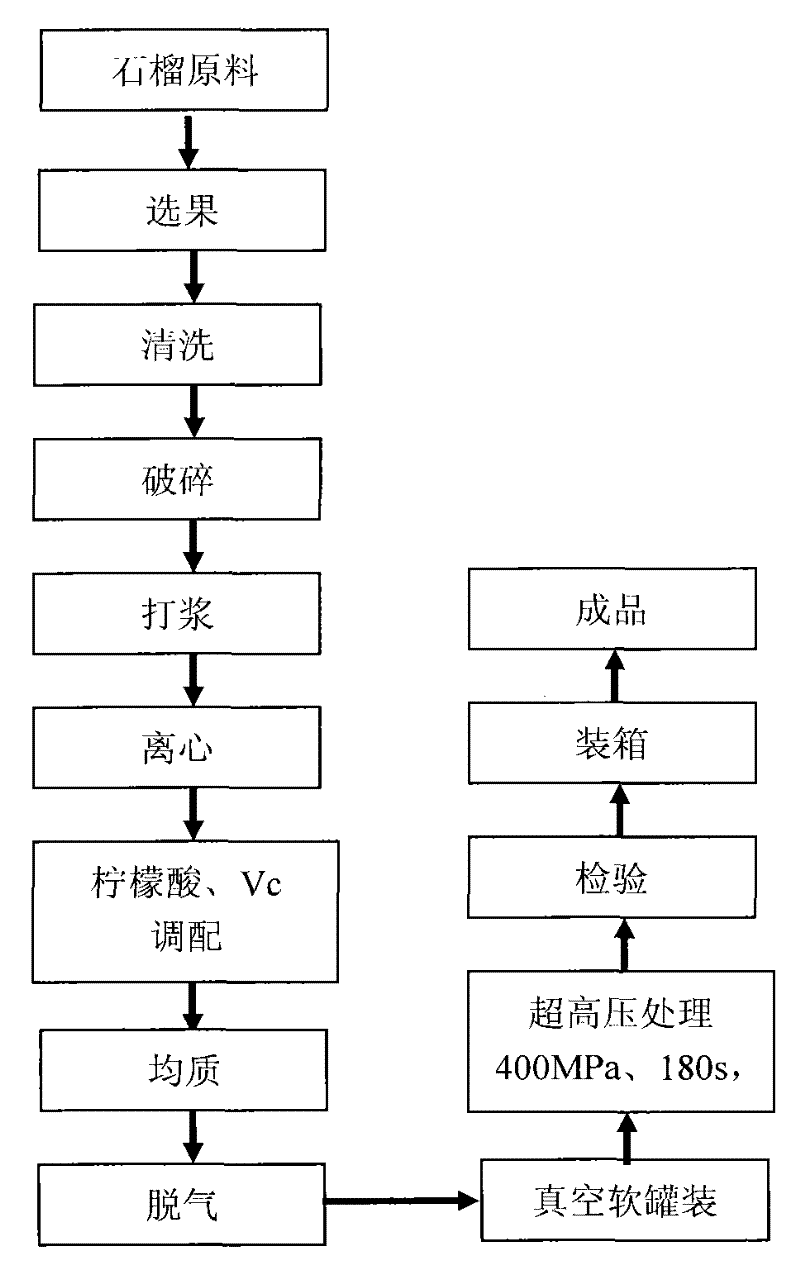

A kind of pomegranate juice and preparation method thereof

The invention discloses grenadine juice and a preparation method thereof, which belongs to the field of fruit juice processing. The grenadine juice is prepared by mixing the following components in mass ratio: 1000 parts of 100 percent of raw grenadine juice, 0.1-0.3 parts of vitamin C and 1-3 parts of citric acid. In the preparation method for the grenadine juice, an ultrahigh-pressure treatmenttechnology is adopted to carry out sterilization and enzyme deactivating, and whole grenadine fruits are pulped, thus, the original flavor and mouth feeling are kept in the processed grenadine juice,and moreover, the effective components in grenadine hulls and seeds are kept to the maximum. The grenadine juice has the effects of promoting the production of body fluid to quench thirst, killing insects, inducing astringency, astringing intestines, relieving diarrhea, stopping bleeding and the like. Through proper blending, certain peculiar smells of the grenadine juice are removed, the grenadine juice is effectively prevented from browning in the storage process, and the shelf life is prolonged.

Owner:新疆玉昆仑天然食品工程有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com