Method for preparing high-concentration soya-bean milk

A technology for soy milk and cooking pulp, applied in dairy products, milk substitutes, applications, etc., can solve the problems of ingredient crushing, poor mixing effect, influence of mixing effect, and limitation of ingredient form, so as to improve taste and nutritional value, and achieve good mixing effect. , the effect of improving liquidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

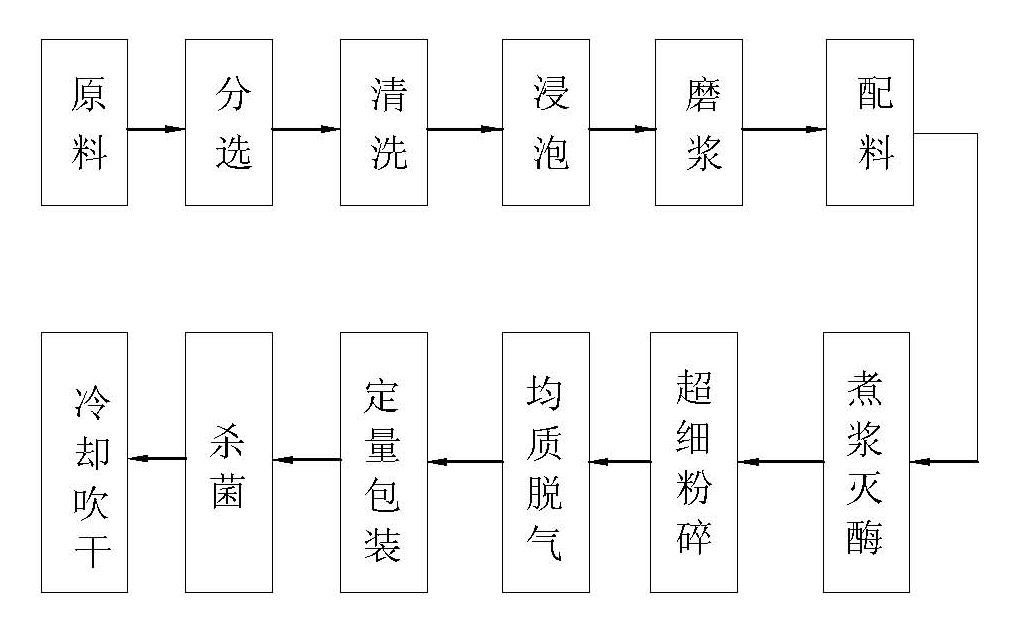

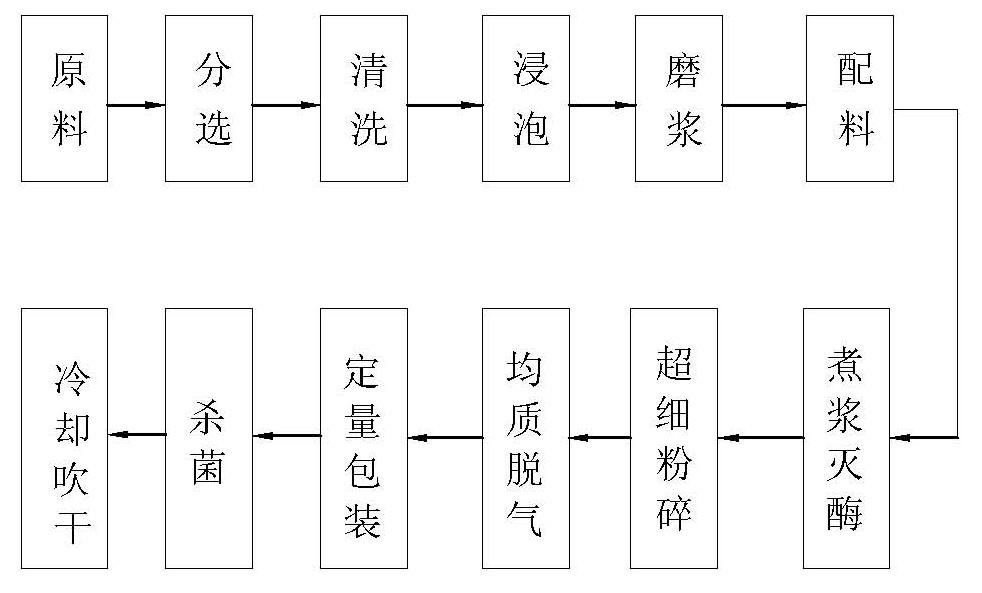

[0031] see figure 1 The flow chart of the preparation method of the high-concentration soybean milk, the present invention sequentially sorts soybeans, washes, soaks, refines pulp, batches, cooks pulp to eliminate enzymes, ultra-fine pulverizes, homogenizes, degasses, quantitatively packs, sterilizes, Cool and dry to make high-concentration soybean milk. The specific preparation process is as follows:

[0032] (1) Sorting and cleaning;

[0033] (2) Soaking;

[0034] (3) Refining;

[0035] (4) ingredients;

[0036] (5) boil pulp and inactivate enzymes;

[0037] (6) ultrafine crushing;

[0038] (7) Homogenization and degassing;

[0039] (8) Quantitative packaging;

[0040] (9) sterilization;

[0041] (10) cooling, drying;

[0042] In step (1), the impurities in soybeans are mainly removed and washed.

[0043] In step (2), the cleaned soybeans ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com