A drying-pyrolysis integrated vertical furnace

A vertical furnace and pyrolysis technology, which is applied in the field of coal chemical industry, can solve the problems of complex design and large investment of pyrolysis furnace equipment, and achieve the effects of easy industrial application, improved heat utilization rate, flexible and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] With reference to the accompanying drawings, the detailed description of the present invention is as follows.

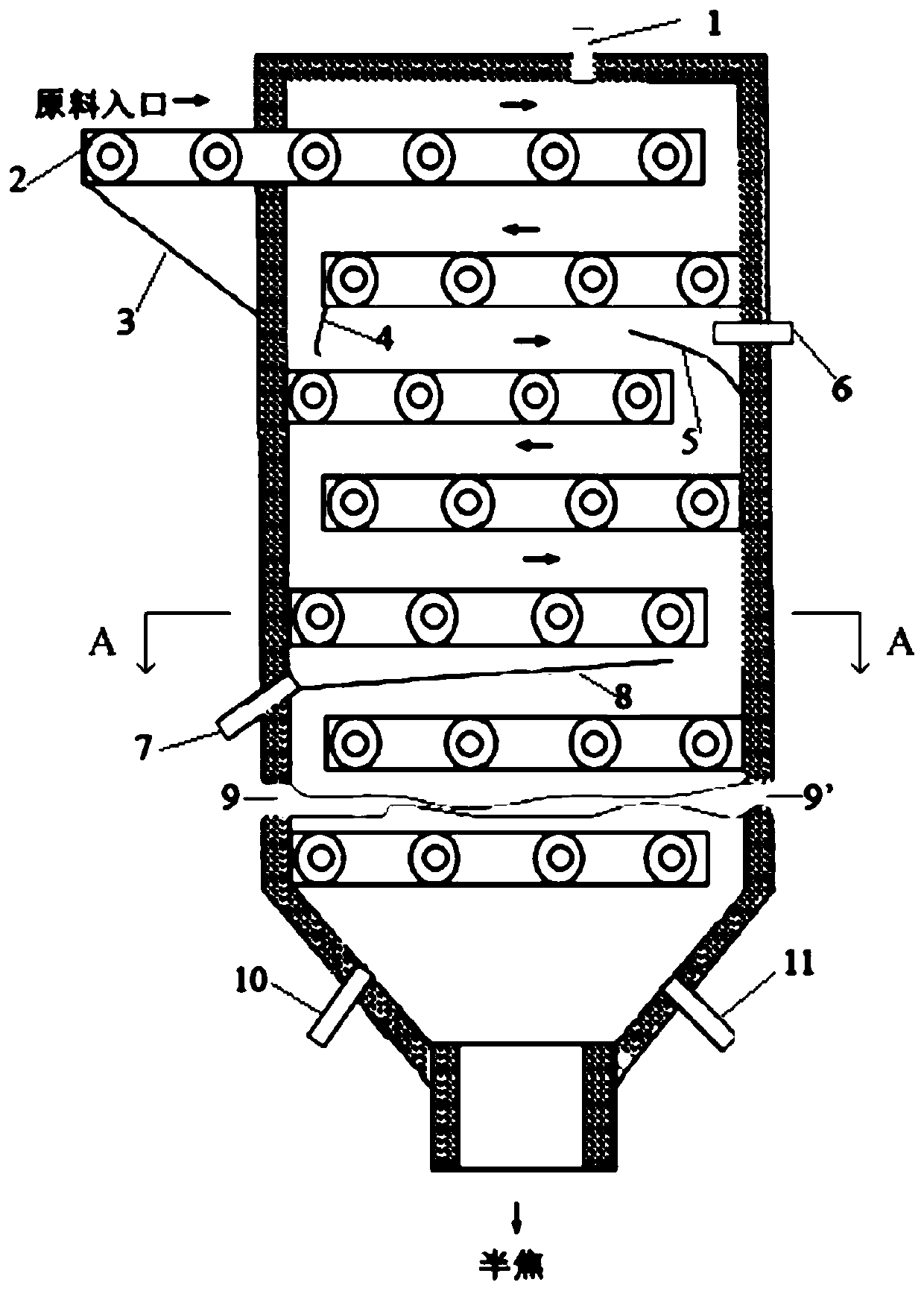

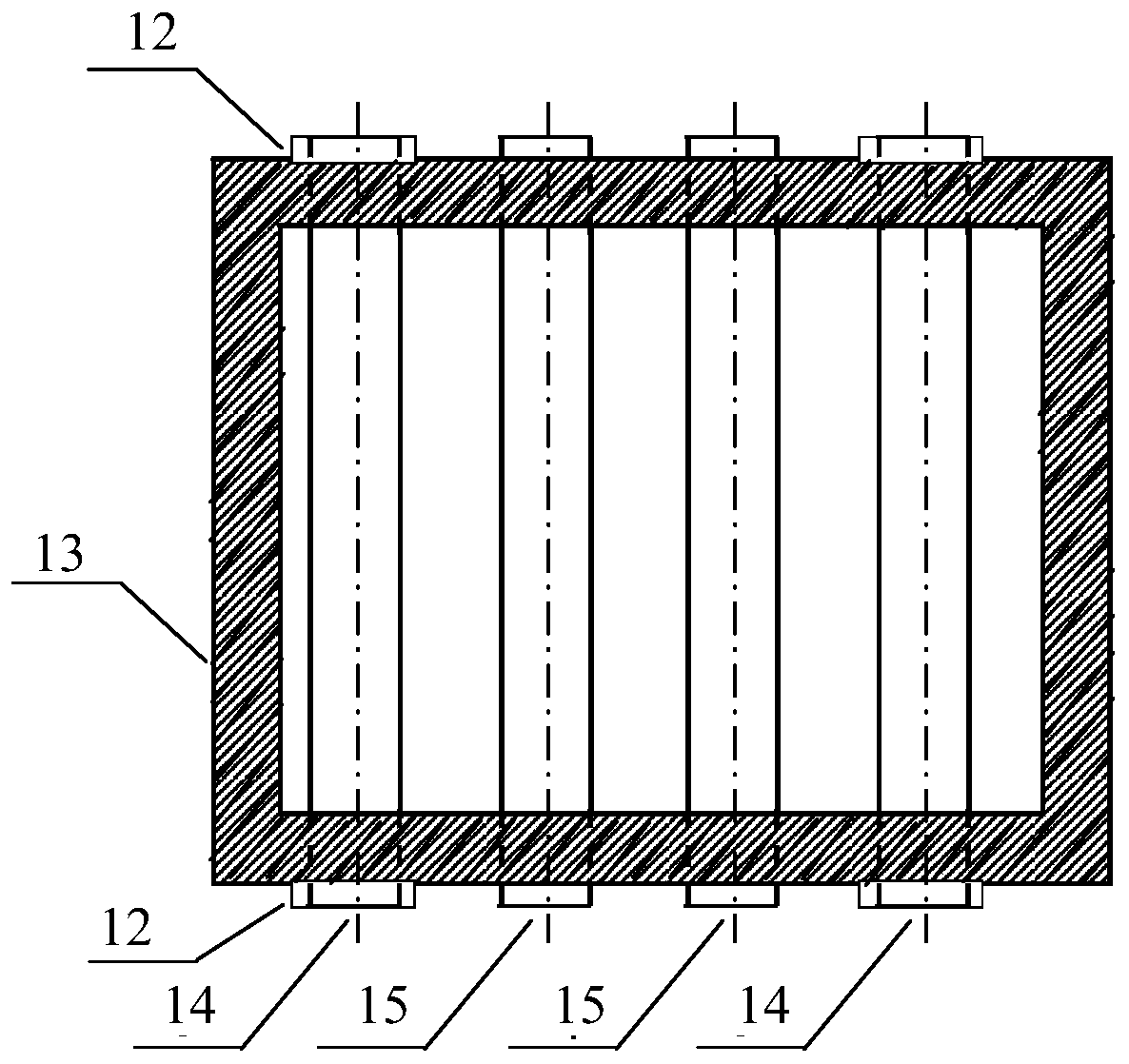

[0031] see figure 1 , The vertical furnace proposed by the present invention includes a material conveying device 2 and a furnace body 13, the furnace body 13 is a cuboid shape, and the bottom of the furnace body 13 is provided with a cone-shaped cavity communicating with the furnace body 13. The top of the furnace body 13 is provided with a pressure balance port 1, which can adjust or balance the pressure according to the pressure change during the actual operation. The upper part of the furnace body 13 is provided with a gas outlet 6, and the bottom of the furnace body 13 is a cone-shaped cavity connected to the furnace body. The middle part of the cone-shaped cavity is evenly provided with four gas heat carrier inlets in the circumferential direction, specifically the first The gas heat carrier inlet 10, the second gas heat carrier inlet 11, the third gas ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com