Energy-saving consumption-reducing electric steamer

A technology of electric steamer and steaming layer, applied in the direction of steam cooking utensils, etc., can solve the problems of low heat energy utilization rate, low steam efficiency, slow steam generation speed, etc., achieve high heat energy utilization rate, increase application range, and high heating efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

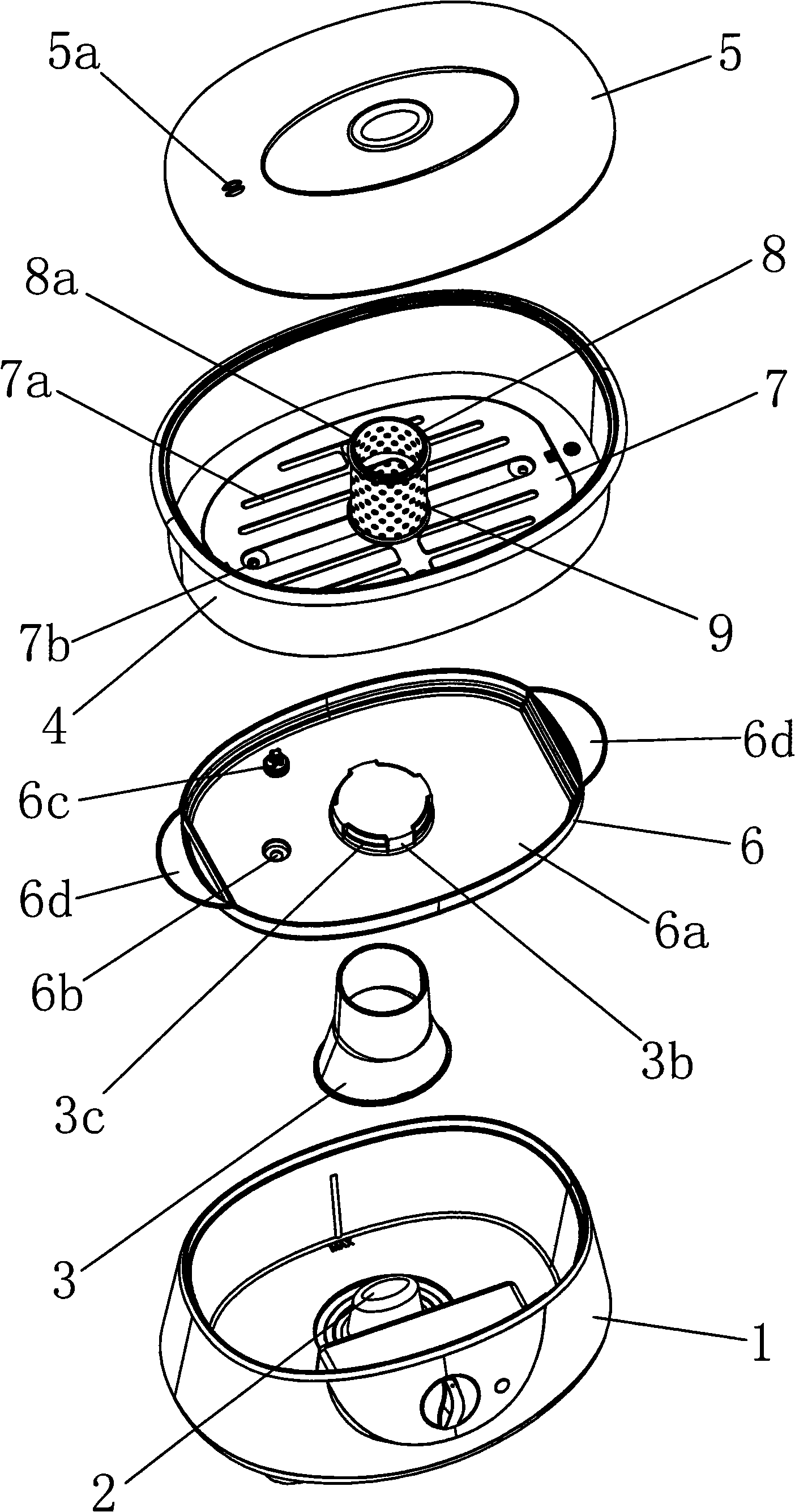

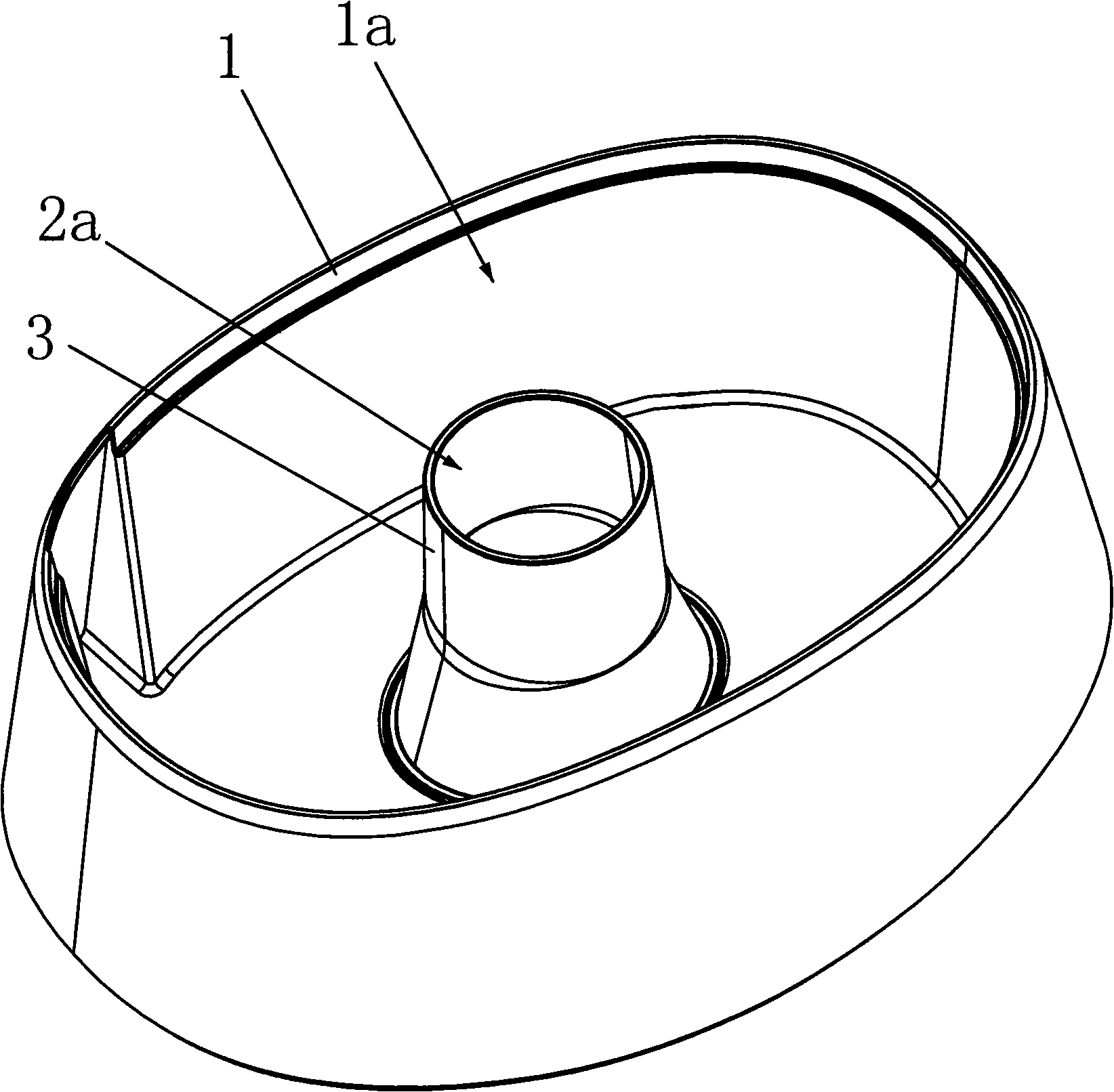

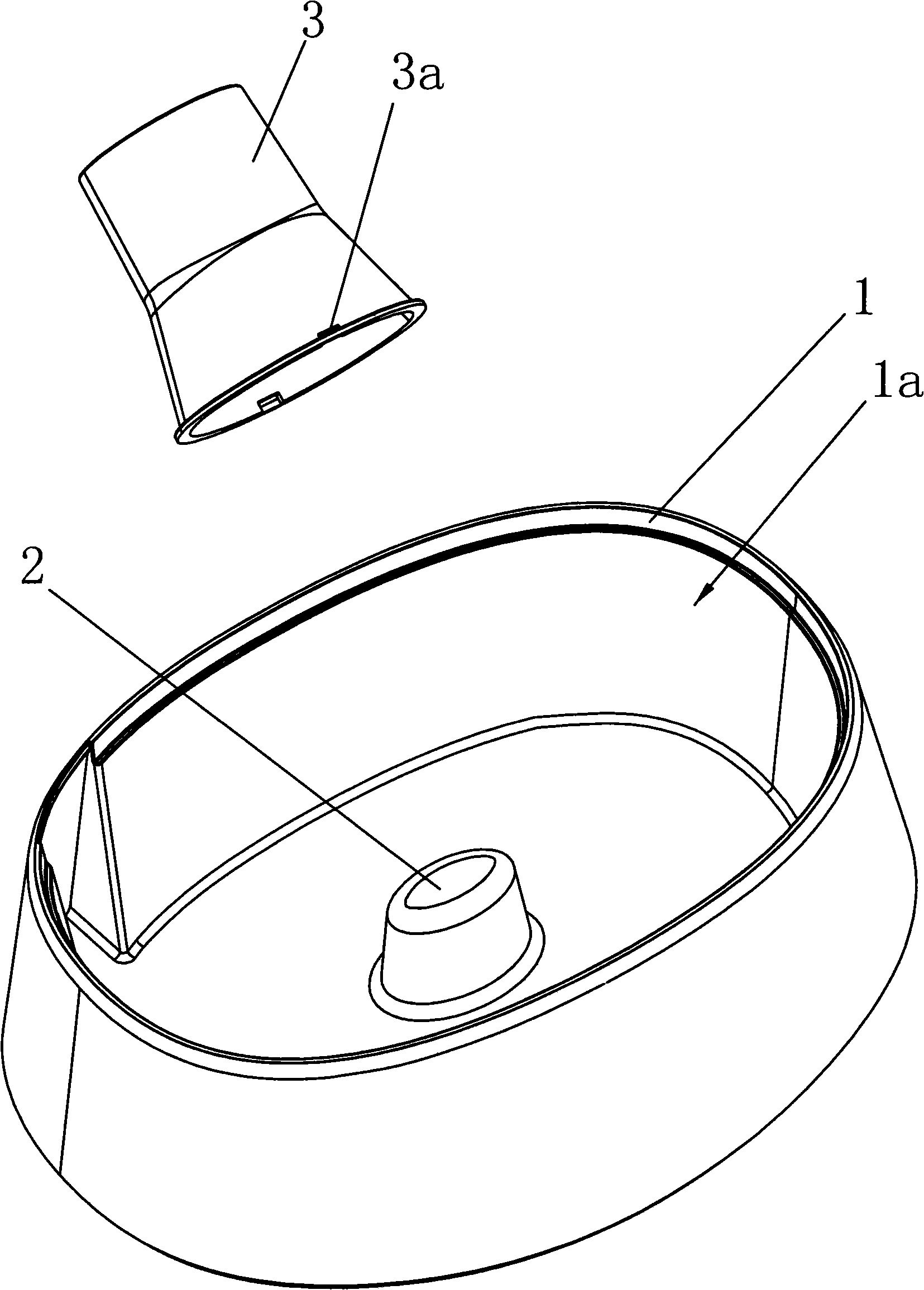

[0023] electric steamer see attached figure 1 To 5, it includes a water container 1 for providing water source, a steaming layer 4 and a top cover 5 for cooking food, and the electric steamer is equipped with a rapid steam generation device, a device for preventing odor, and a water circulation device, and the water container 1 is fixed with a heating element 2 and an isolation cover 3, the heating element 2 is enclosed in the isolation cover 3, and the lower end of the isolation cover 3 is provided with a water inlet tank 3a, image 3 As shown, the water container 1, the heating element 2 and the isolation cover 3 constitute a rapid steam generating device.

[0024] The present invention divides the water container 1 into two regions through the isolation cover 3, figure 2 As shown, one area is a large-area water holding area, that is, the annular area between the isolation cover 3 and the water container 1, which is the water holding chamber 1a, and the other area is the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com