Powder forming mold and preparation method of cold consolidation forming material

A technology for forming molds and powders, which is used in material forming presses, manufacturing tools, presses, etc., and can solve the problems of being unsuitable for laboratory miniaturization, low compressive strength of pellets, and difficulty in demoulding. Wide range, stable pressing, easy demolding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

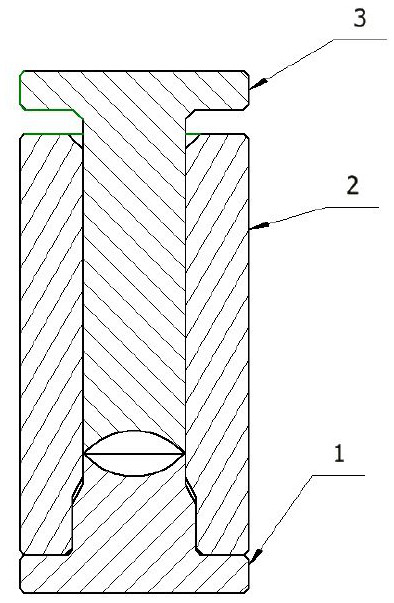

[0028] As shown in Fig. 1, a kind of powder forming mold and cold consolidation profile preparation method described powder forming mold comprises the lower punch 1 that is arranged on the bottom, the cavity 2 of ellipsoid shape, and the upper punch that is arranged on the top 3.

[0029] The ball pressing die includes a T-shaped upper punch 1 and a T-shaped lower punch 3 with a straight through hole in the middle, and T-shaped lower punches 3 whose ends are matched with the vertical through hole. Both the T-shaped upper punch 3 and the T-shaped lower punch 1 are composed of a pressure bearing body with an ellipsoidal bottom and a pressure transmission rod arranged concentrically with the pressure bearing body.

[0030] A kind of powder forming mold and cold consolidation profile preparation method, present embodiment prepares a kind of spherical profile, carries out according to the following steps:

[0031] (1) Lower punch installation: install the lower punch 1 in the vert...

Embodiment 2

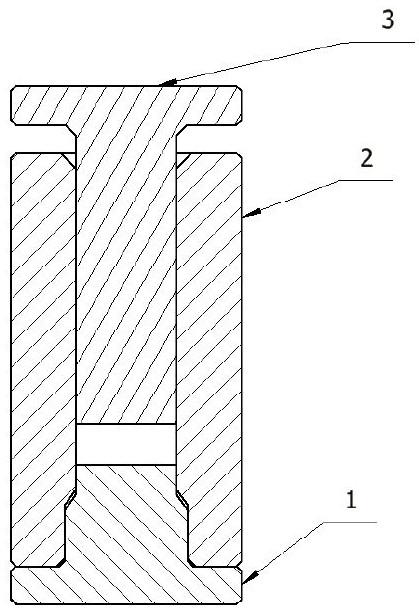

[0043] As shown in Figure 2, a powder forming mold and a method for preparing cold-consolidated molding materials. The powder forming mold includes a lower punch 1 arranged at the bottom, a cylindrical cavity 2 equipped with a tablet pressing assembly, and a cylindrical cavity 2 arranged at the bottom. Upper punch 3.

[0044] The cake pressing mold includes a straight through hole in the middle, and a T-shaped upper punch 1 and a T-shaped lower punch 3 whose ends are matched with the vertical through hole. Both the T-shaped upper punch 3 and the T-shaped lower punch 1 are composed of a pressure bearing body with a flat bottom and a pressure transmission rod arranged concentrically with the pressure bearing body.

[0045] A kind of powder forming mold and cold consolidation profile preparation method, present embodiment prepares a kind of spherical profile, carries out according to the following steps:

[0046] (1) Lower punch installation: install the lower punch 1 in the ver...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com