Patents

Literature

54results about How to "Press down smoothly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

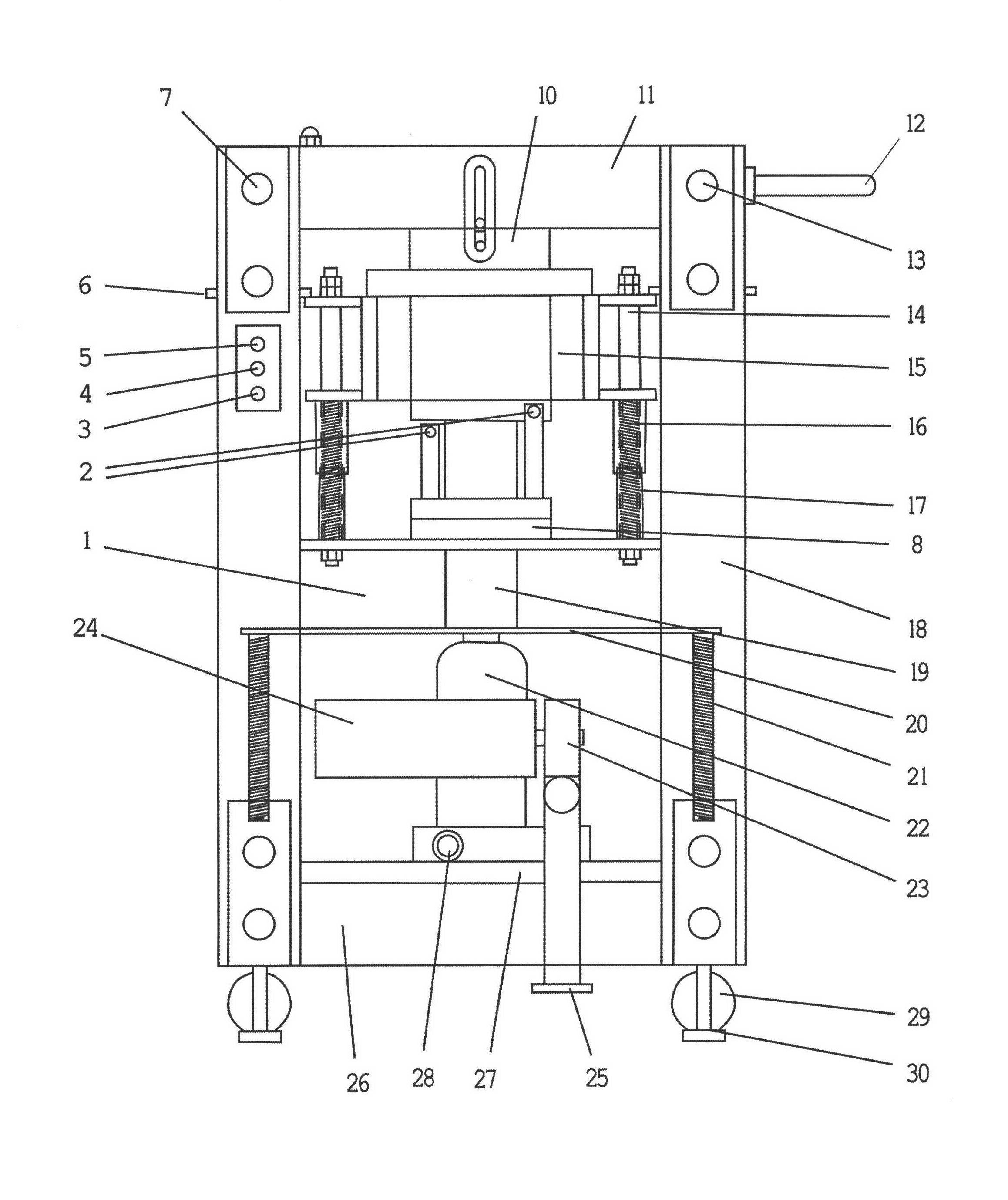

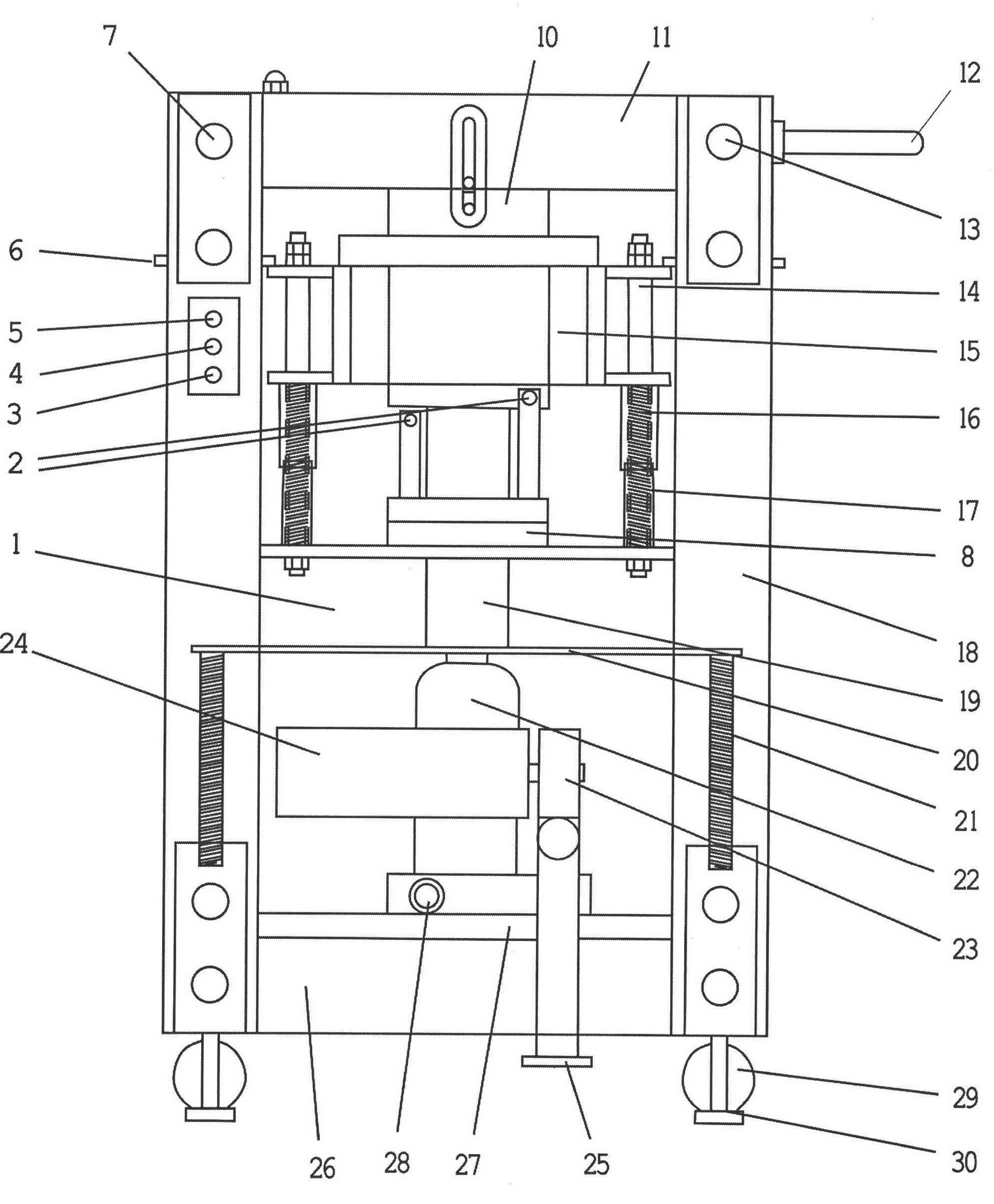

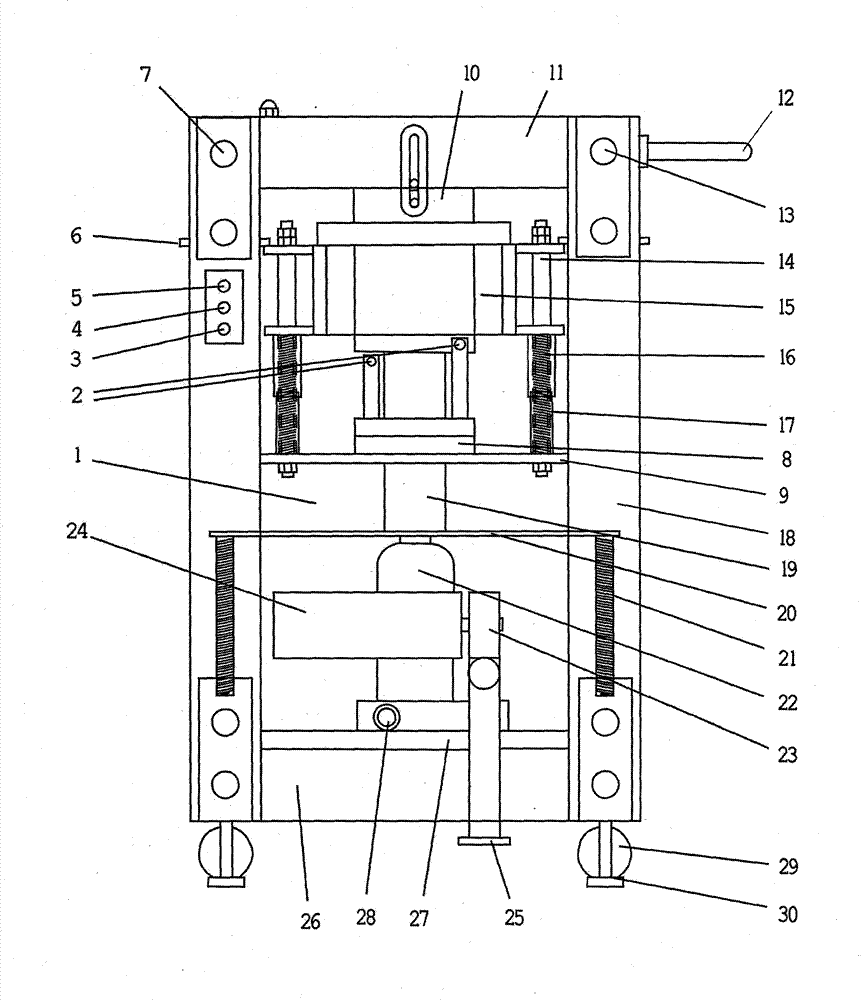

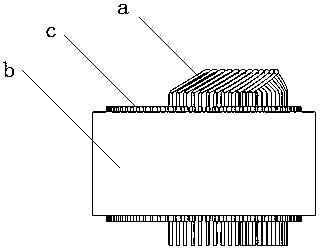

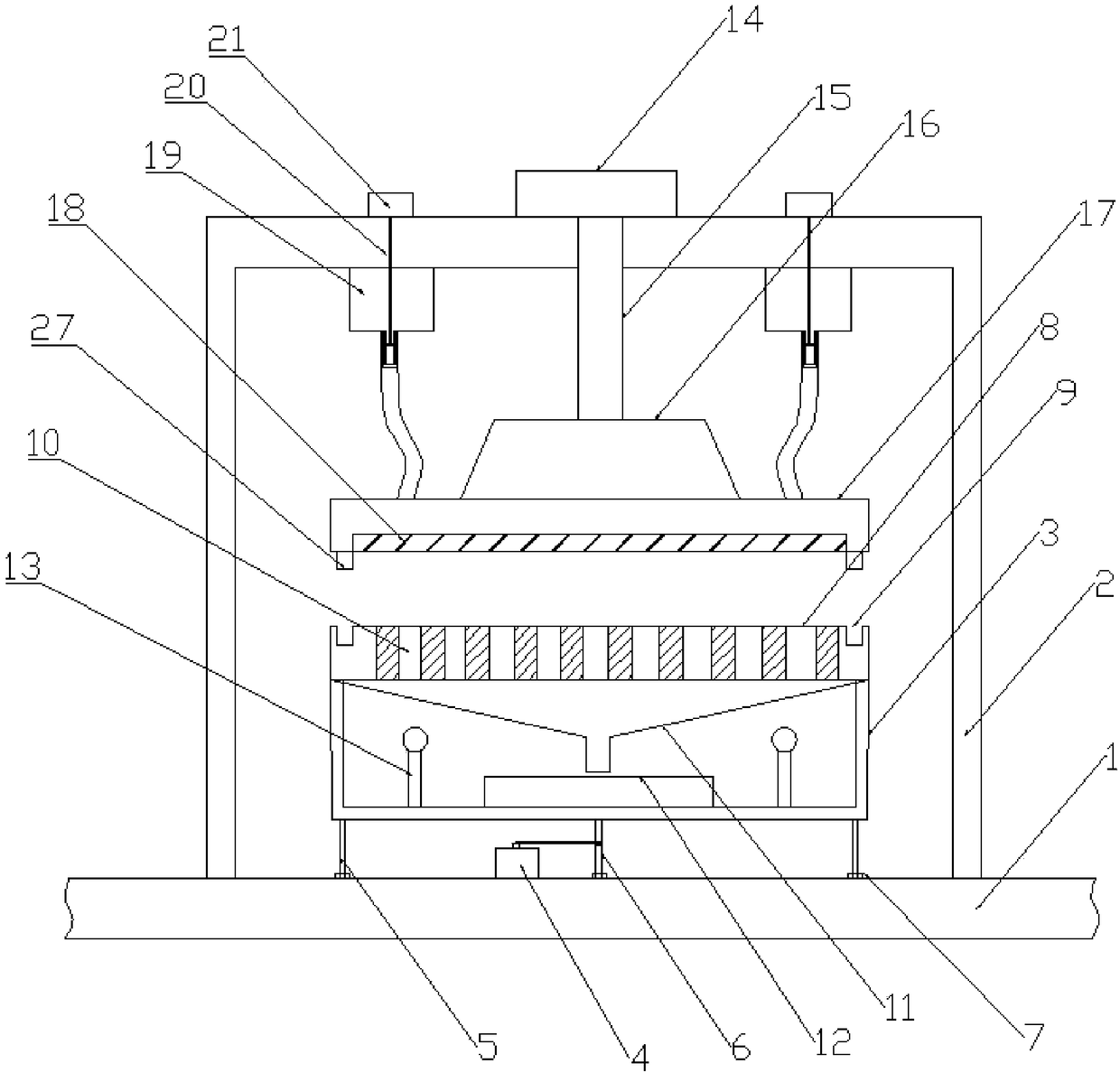

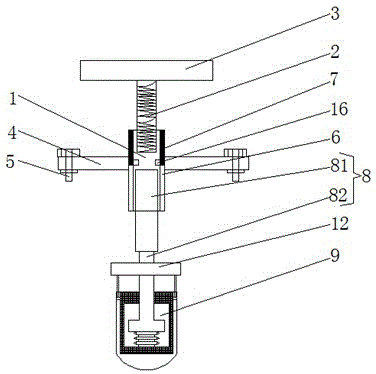

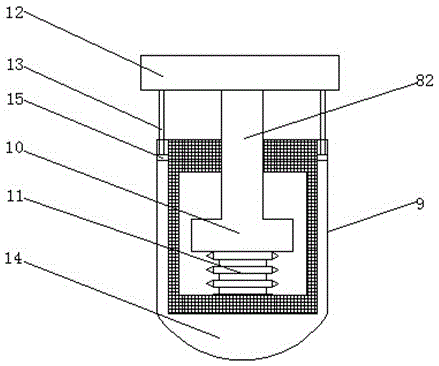

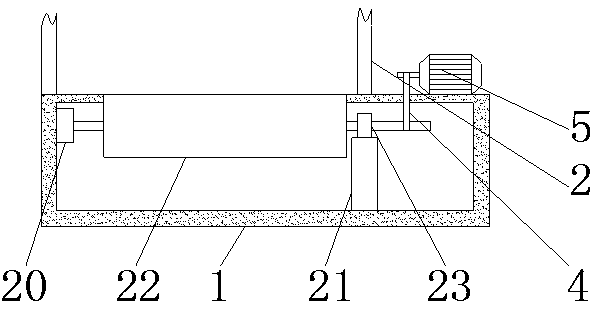

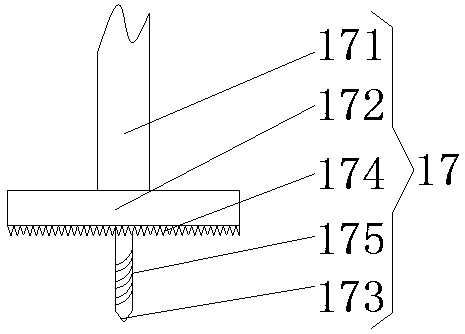

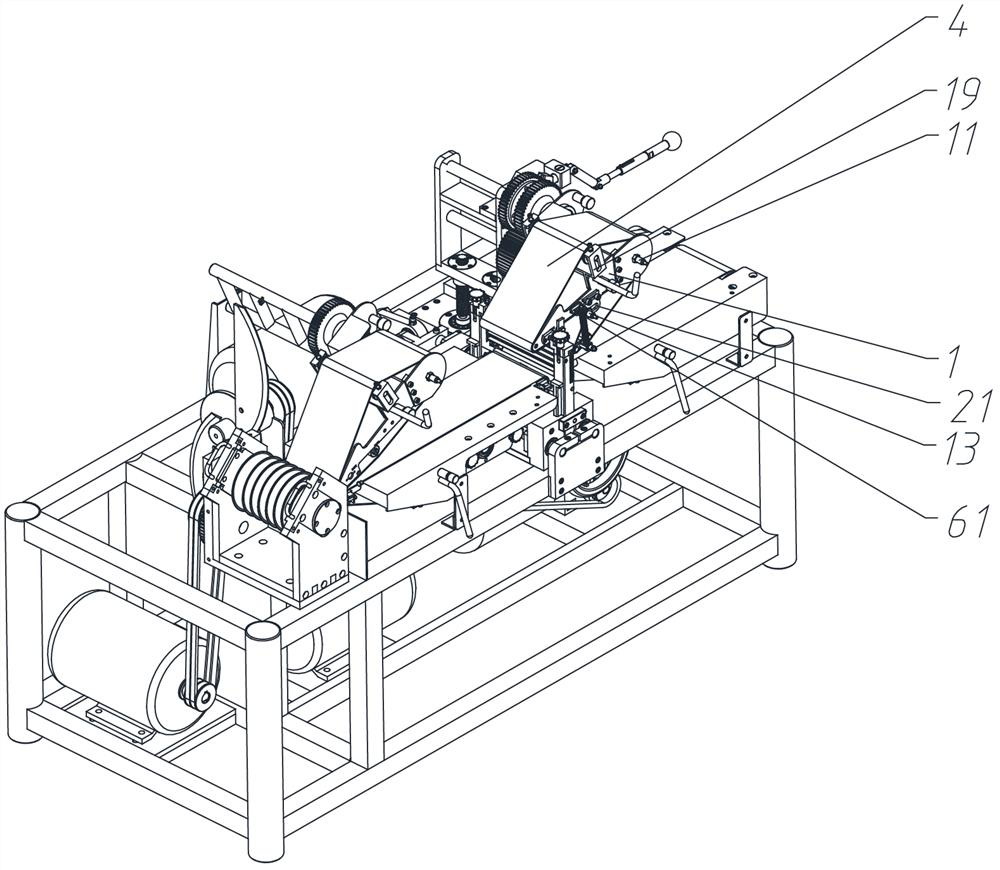

Semi-automatic tea wafer machine and tea wafering process

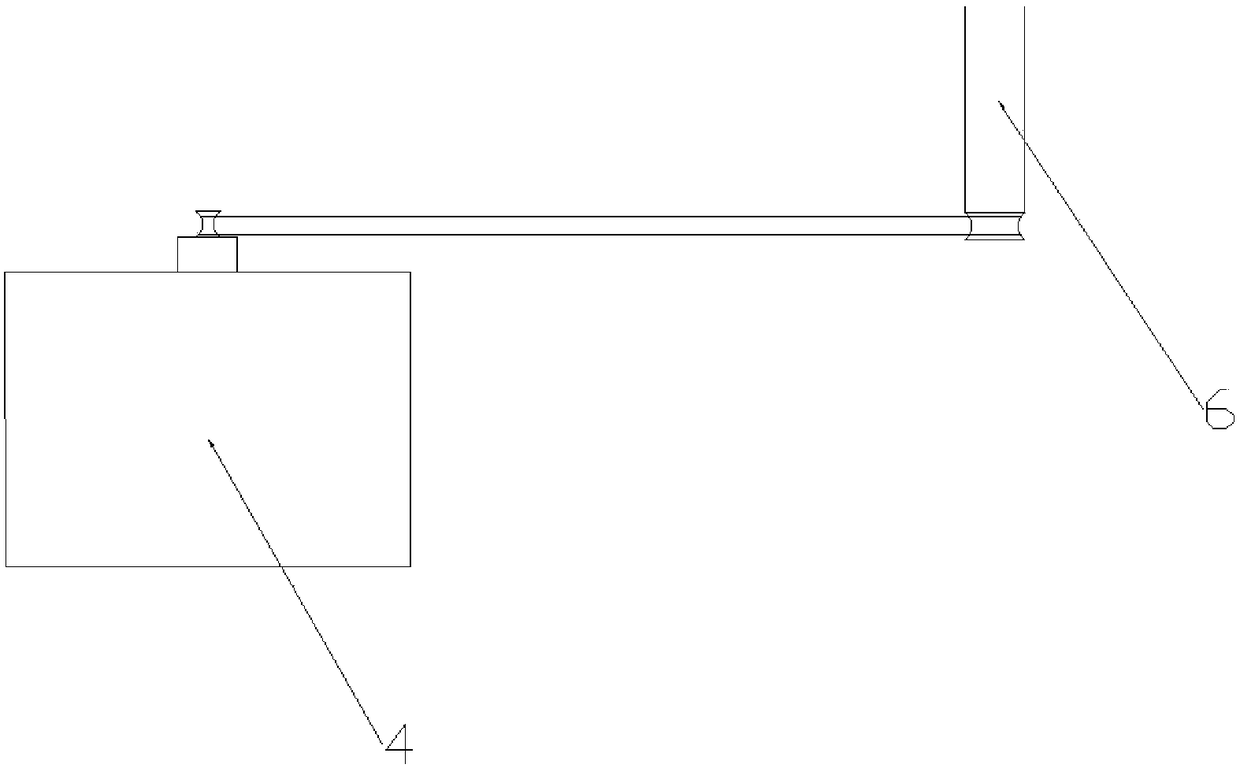

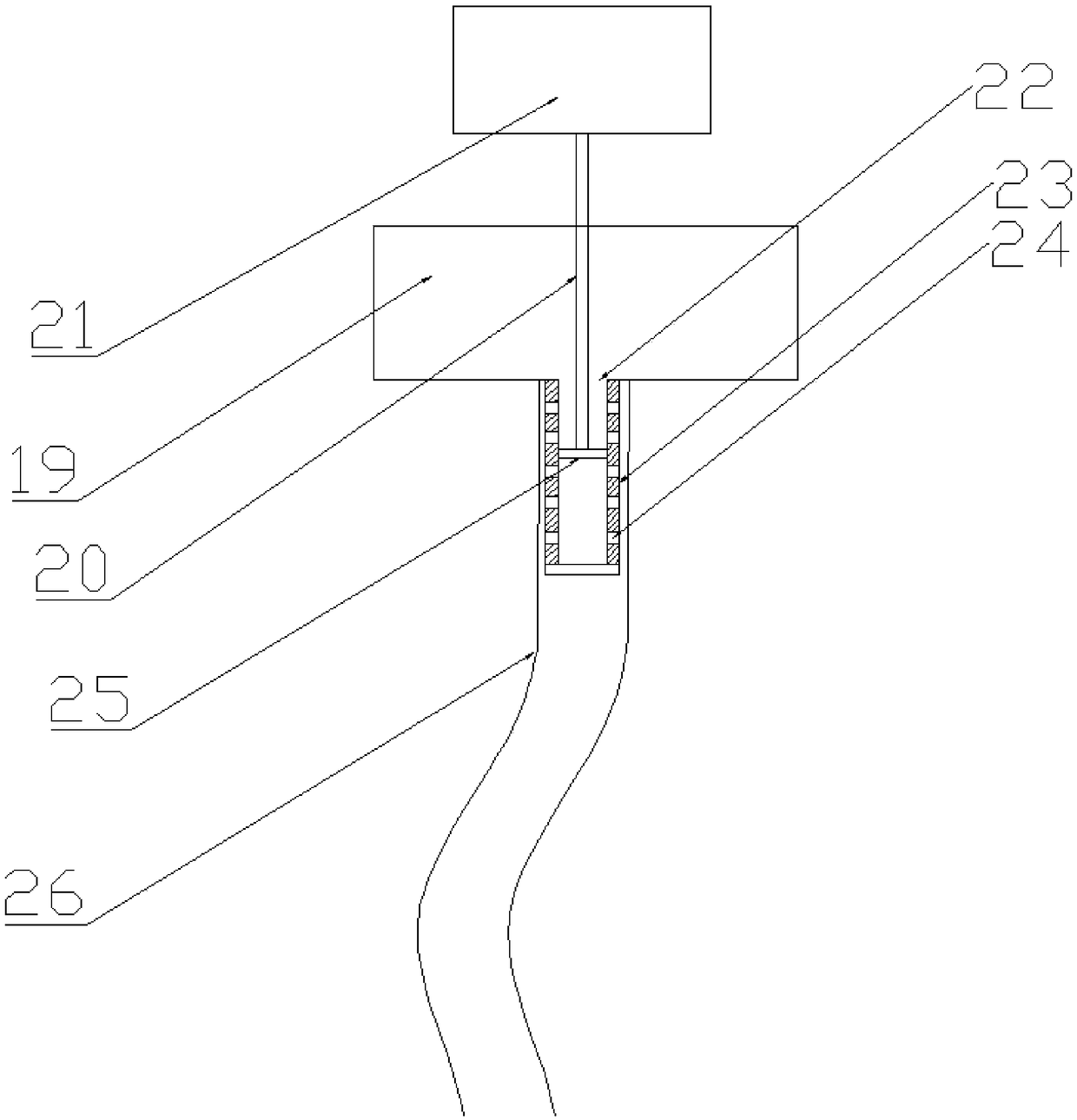

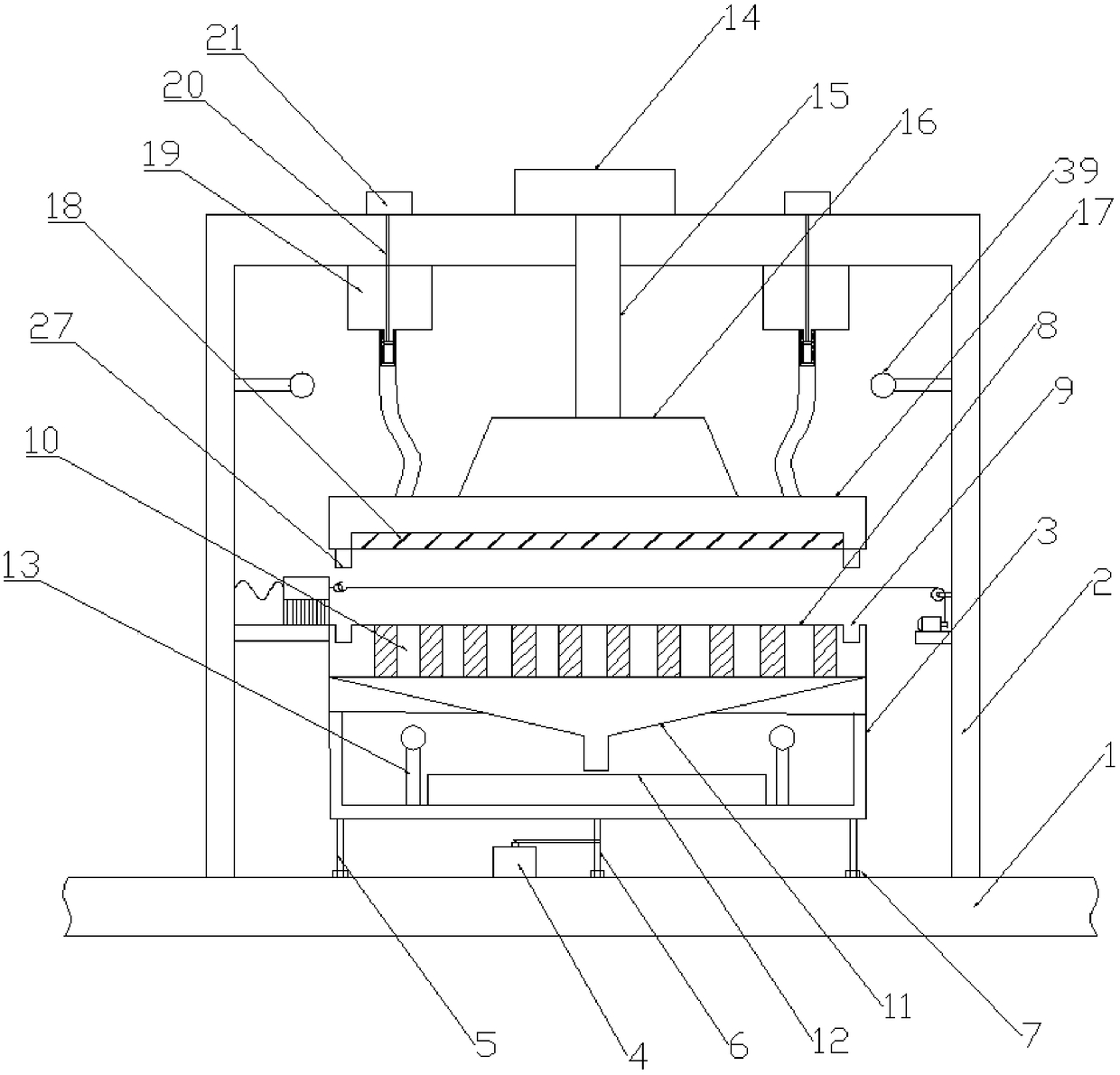

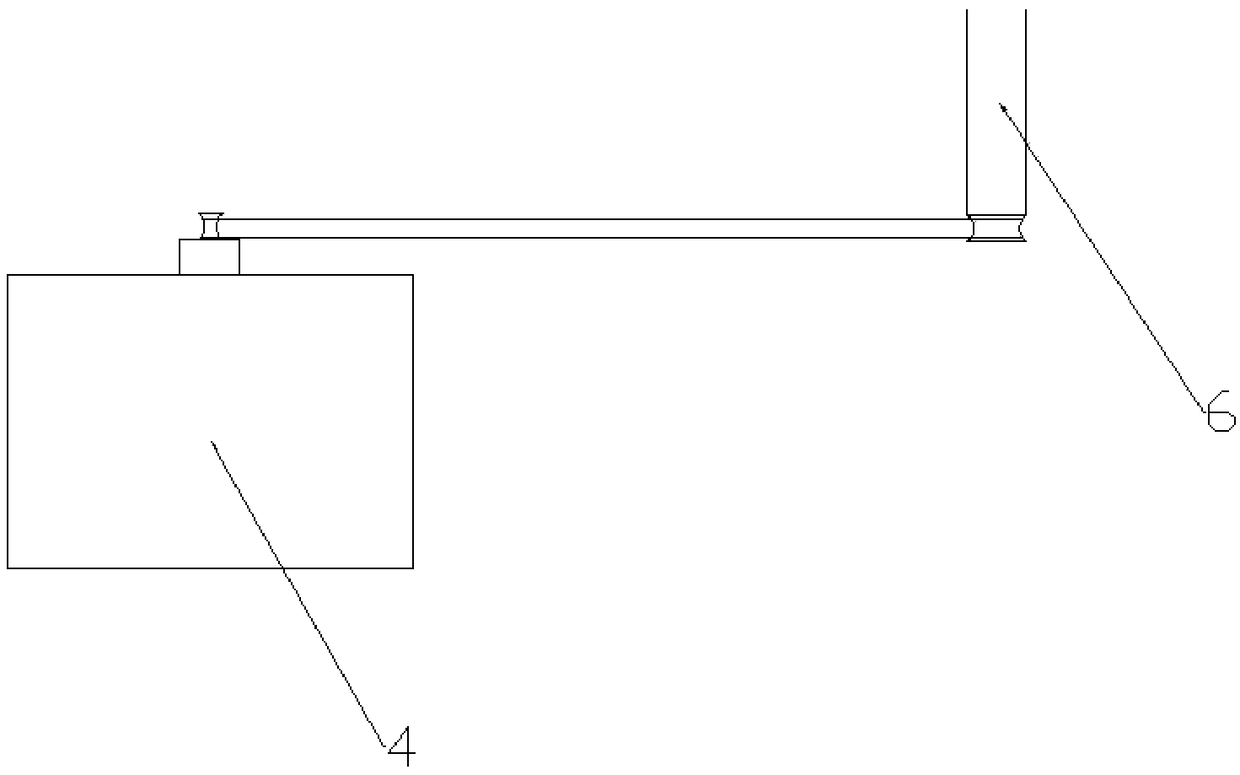

The invention provides a semi-automatic tea wafer machine, comprising a machine body, four columns 18, a lower principal thick bearing plate 26, a supporting plate 27, a jack 22 on the supporting plate, a motor 24 and a transmission cam 23, a pedal 25, a lift sliding panel 20, an oil-way switch 28, a draw spring 21, a lift sliding column 19, a fixed die supporting plate 9, a lift die supporting plate 8, a die slider 14, a spring 17 and a spring sleeve 16 that are arranged on the die slider, two dead levers with different heights and an inductor 2 that are arranged on the fixed die supporting plate 9, a die 15 and a spacer pin 6 that are arranged on the die slider, an upper and principal thick bearing plate 11 and a die cover press plate, etc. A tea wafering process using the semi-automatic tea wafer machine comprises steps of: installing the die; loading teas into the die; wafering a tea cake; and resetting the die. The semi-automatic tea wafer machine of the invention has a simple structure, easy operation, uniform pressure, good wafering effect and high moulding rate and is capable of wafering high-quality tea cakes.

Owner:GUANGXI WUZHOU MAOSHENG TEA IND

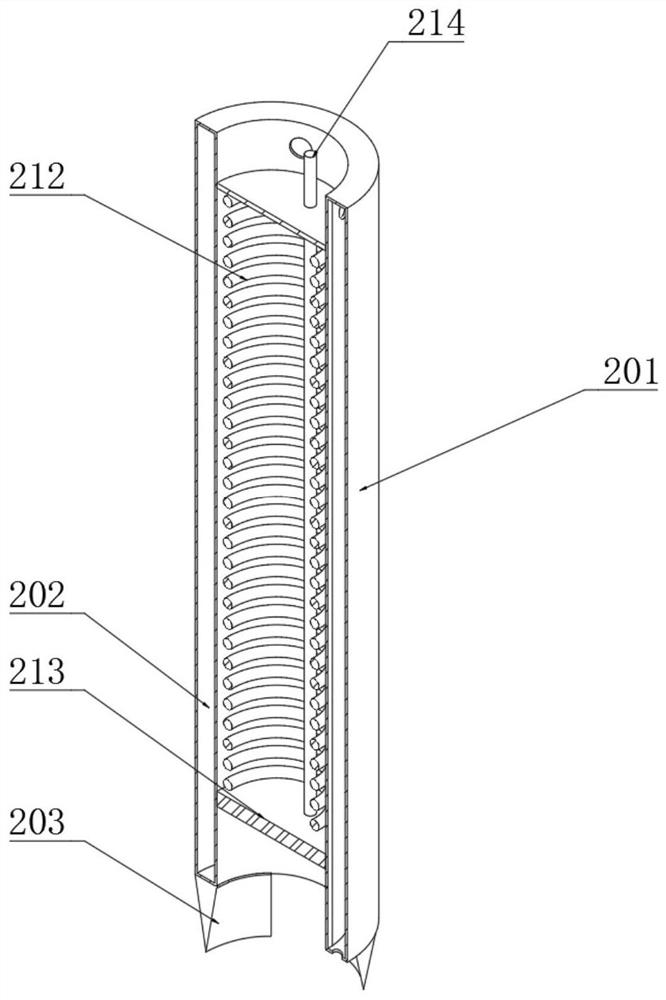

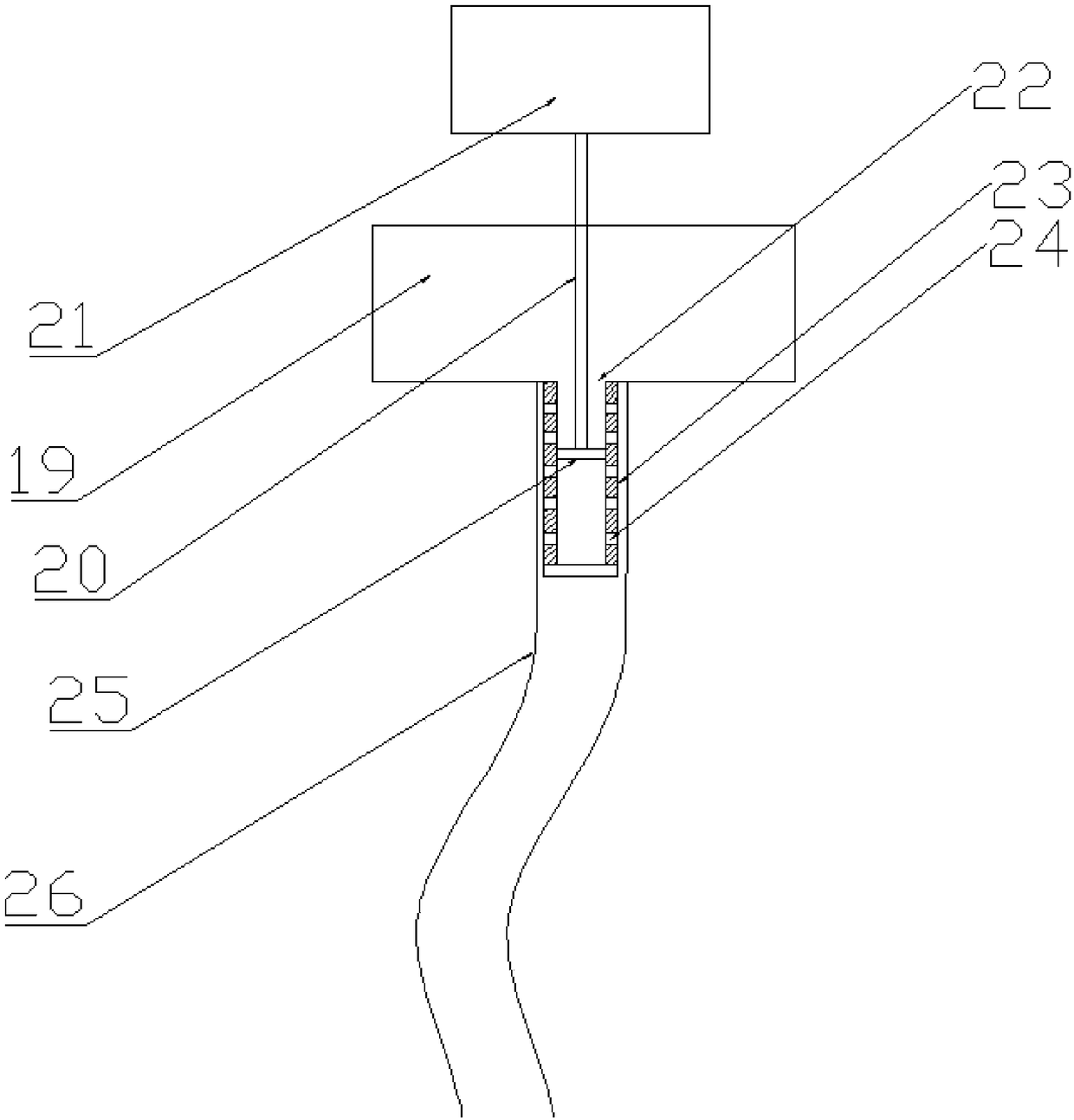

Rock-soil detection device for geological exploration

PendingCN113063623AAvoid Overturning Mixed SituationsAvoid dry conditionsWithdrawing sample devicesPreparing sample for investigationSoil scienceRock core

The invention discloses a rock-soil detection device for geological exploration. A cutting knife is hinged to the bottom end of a rock sampling barrel, a pressing spring is welded to one end of a pulling rope, a transmission motor is installed at the top end of a soil sampling barrel, a sealing limiting plate is clamped to the inner side of a discharging opening, and a soil collecting box is clamped to the side end of an installation connecting frame. Rock is sampled through the rock sampling barrel, the angle of the cutting knife is changed through the pulling rope and the pressing spring, so that the cut rock core can be conveniently and rapidly lifted, personnel can conveniently and visually observe, the soil is sampled through the soil sampling barrel and the auger, and the soil is discharged through the discharging port, the soil at different depths can be rapidly screened when needing to be collected, the situation that the soil is mixed together to influence the detection result is avoided, rock collection and soil collection are separated, mutual interference is avoided, and the situation that the detection result deviates due to mutual influence is avoided.

Owner:李晟

Semi-automatic tea cake press and tea cake pressing process

The invention provides a semi-automatic tea wafer machine, comprising a machine body, four columns 18, a lower principal thick bearing plate 26, a supporting plate 27, a jack 22 on the supporting plate, a motor 24 and a transmission cam 23, a pedal 25, a lift sliding panel 20, an oil-way switch 28, a draw spring 21, a lift sliding column 19, a fixed die supporting plate 9, a lift die supporting plate 8, a die slider 14, a spring 17 and a spring sleeve 16 that are arranged on the die slider, two dead levers with different heights and an inductor 2 that are arranged on the fixed die supporting plate 9, a die 15 and a spacer pin 6 that are arranged on the die slider, an upper and principal thick bearing plate 11 and a die cover press plate, etc. A tea wafering process using the semi-automatic tea wafer machine comprises steps of: installing the die; loading teas into the die; wafering a tea cake; and resetting the die. The semi-automatic tea wafer machine of the invention has a simple structure, easy operation, uniform pressure, good wafering effect and high moulding rate and is capable of wafering high-quality tea cakes.

Owner:GUANGXI WUZHOU MAOSHENG TEA IND

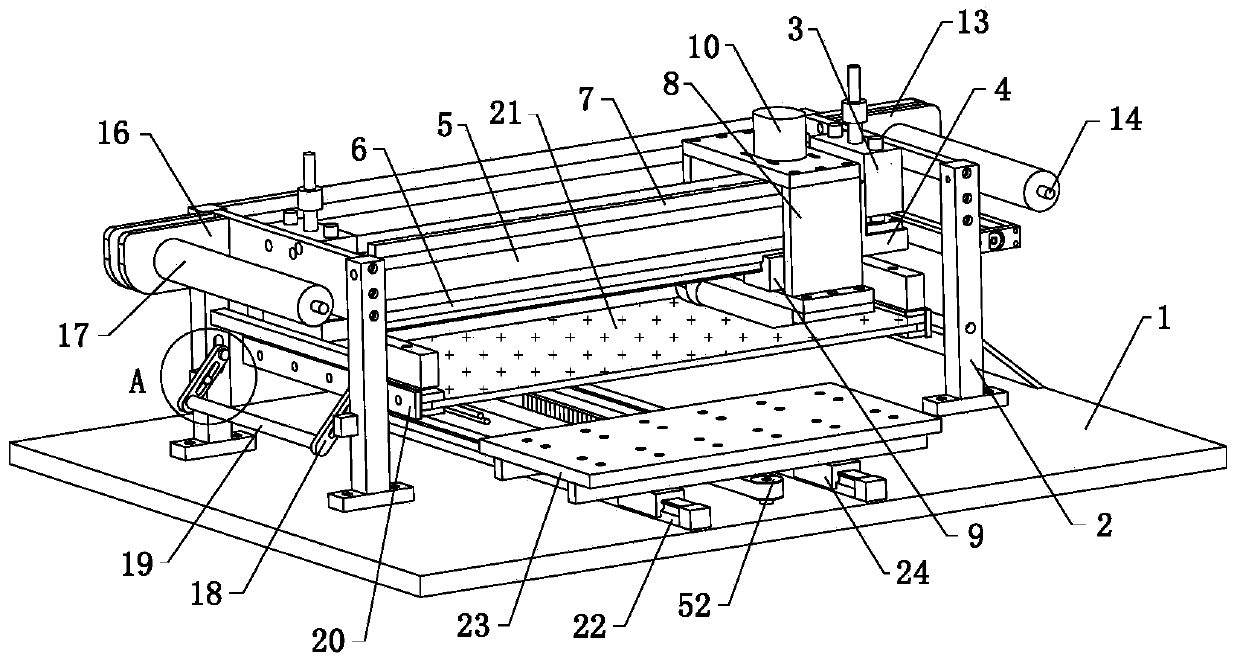

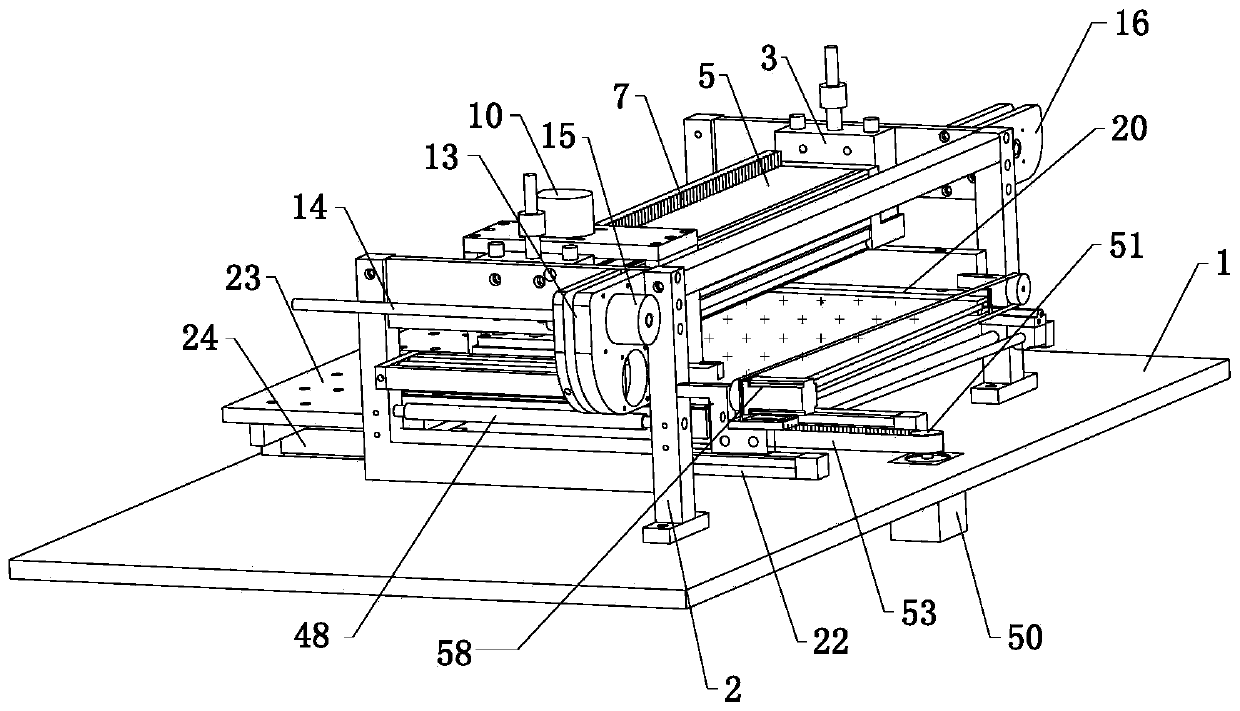

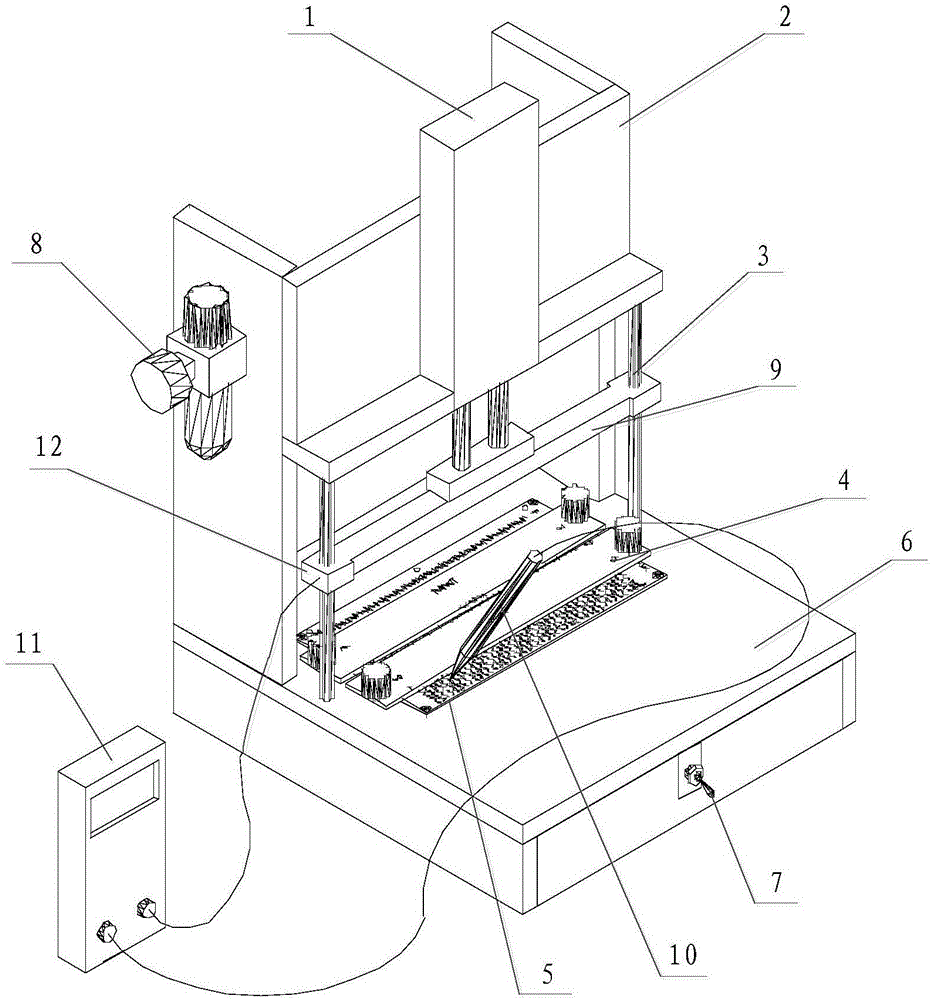

Automatic thermoprinting machine and thermoprinting method thereof

ActiveCN110509663ARealize transmissionSimple structureTransfer printingOther printing apparatusEngineeringSilica gel

The invention discloses an automatic thermoprinting machine and a thermoprinting method thereof. The automatic thermoprinting machine includes a workbench, the top of the workbench is provided with arack, the inner sides at two ends of the rack are symmetrically provided with telescopic driving pieces, the end of each telescopic driving piece is provided with a lifting plate, a cross beam is arranged between the two lifting plates, and a transmission compression roller mechanism is arranged on the cross beam; the bottoms of the two lifting plates are provided with heating sheet frames, and the middles of the heating sheet frames are provided with silica gel heating sheets positioned below the transmission compression roller mechanism; a film transmission mechanism fixed on the rack is arranged below the cross beam; the workbench is provided with a feeding mechanism which is perpendicular to the film transmission mechanism. According to the automatic thermoprinting machine, through thearrangement of the integral structure, the feeding process is simpler and more convenient to control, a film is heated more uniformly, the thermoprinting effect is improved, the operation steps are simplified, and the operation difficulty is reduced.

Owner:浙江智博交通科技有限公司

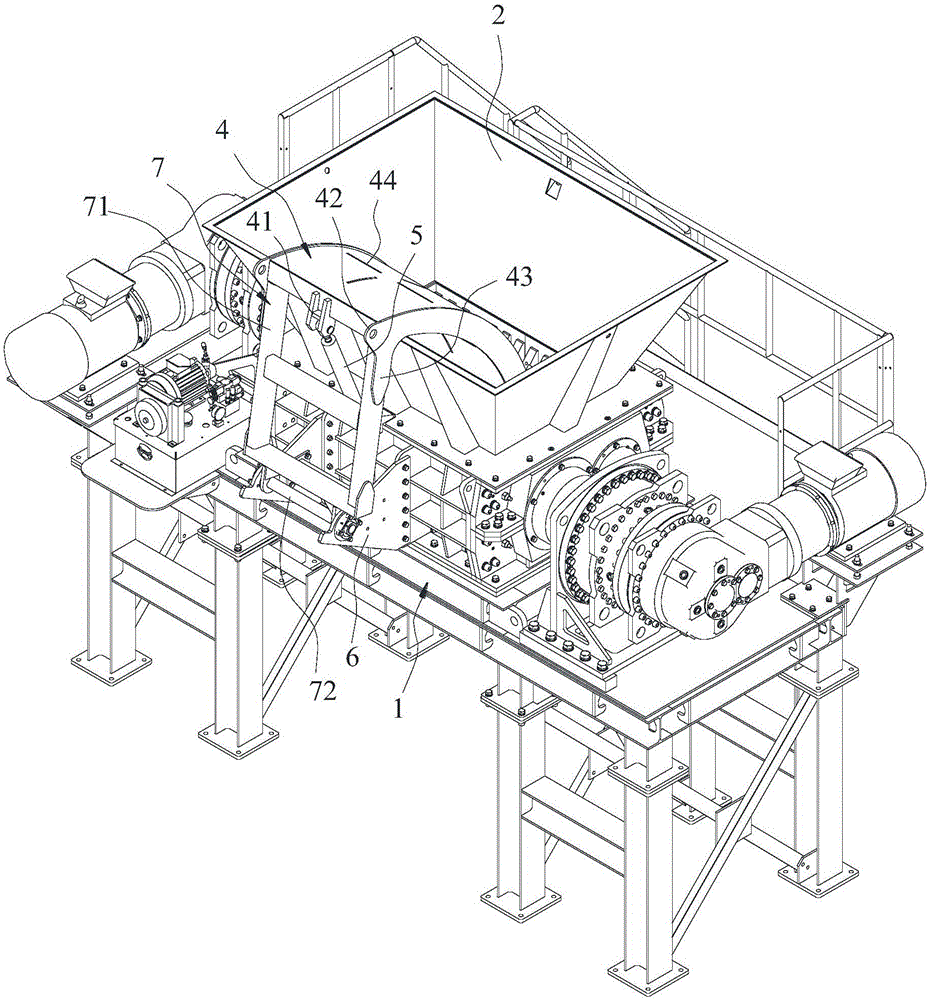

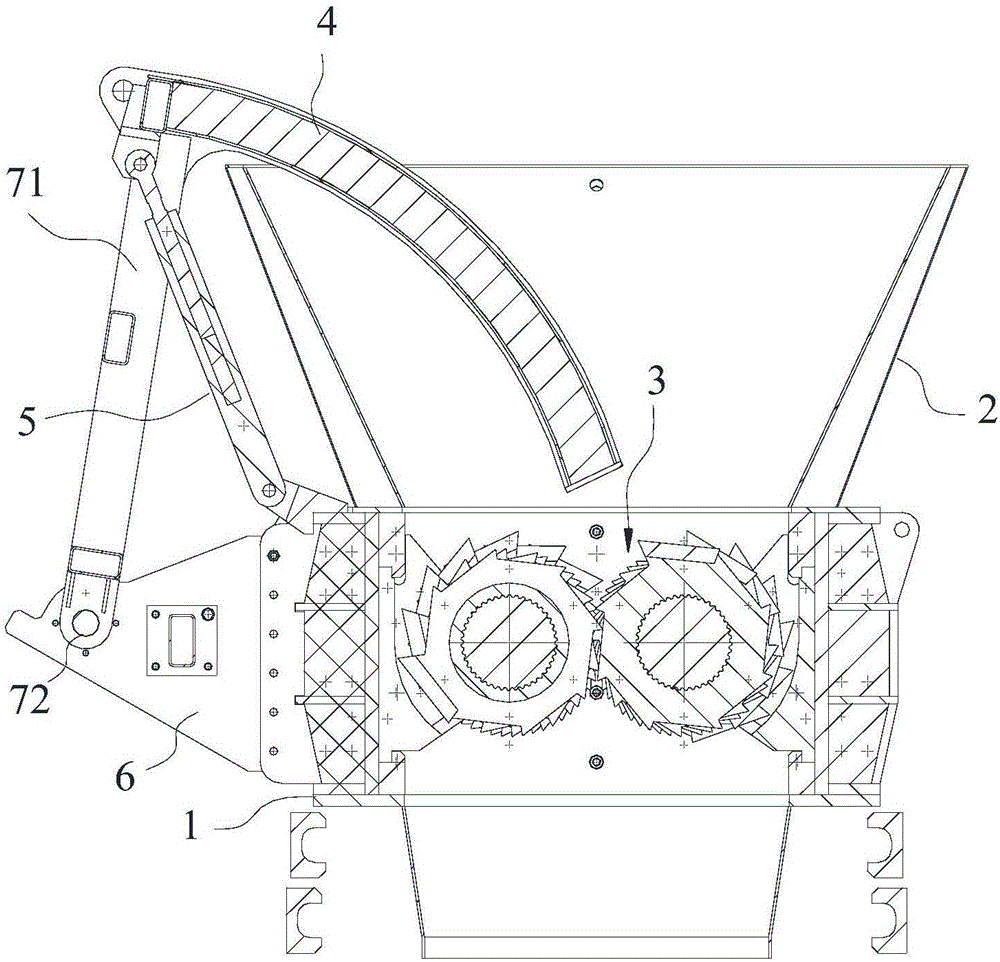

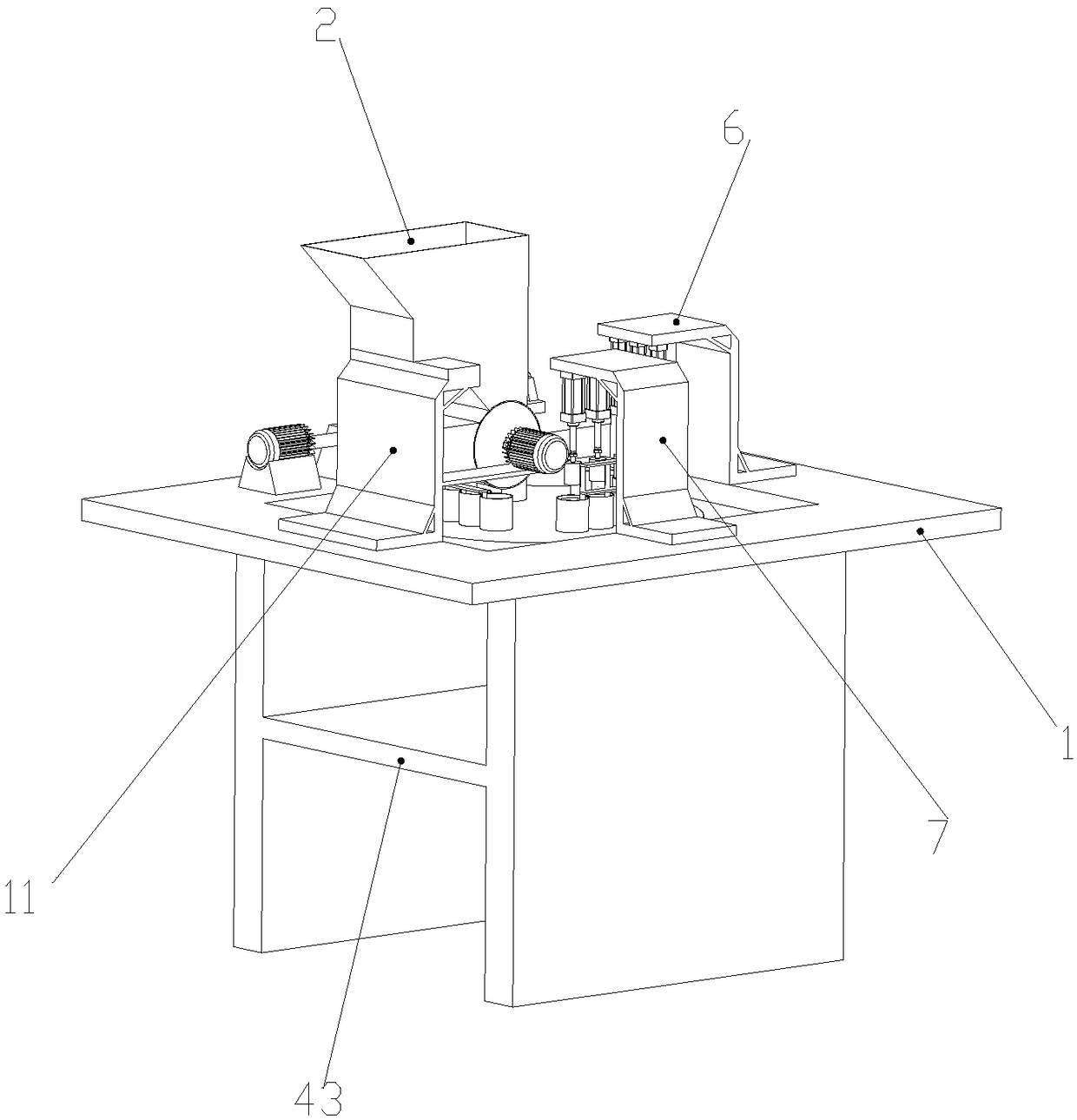

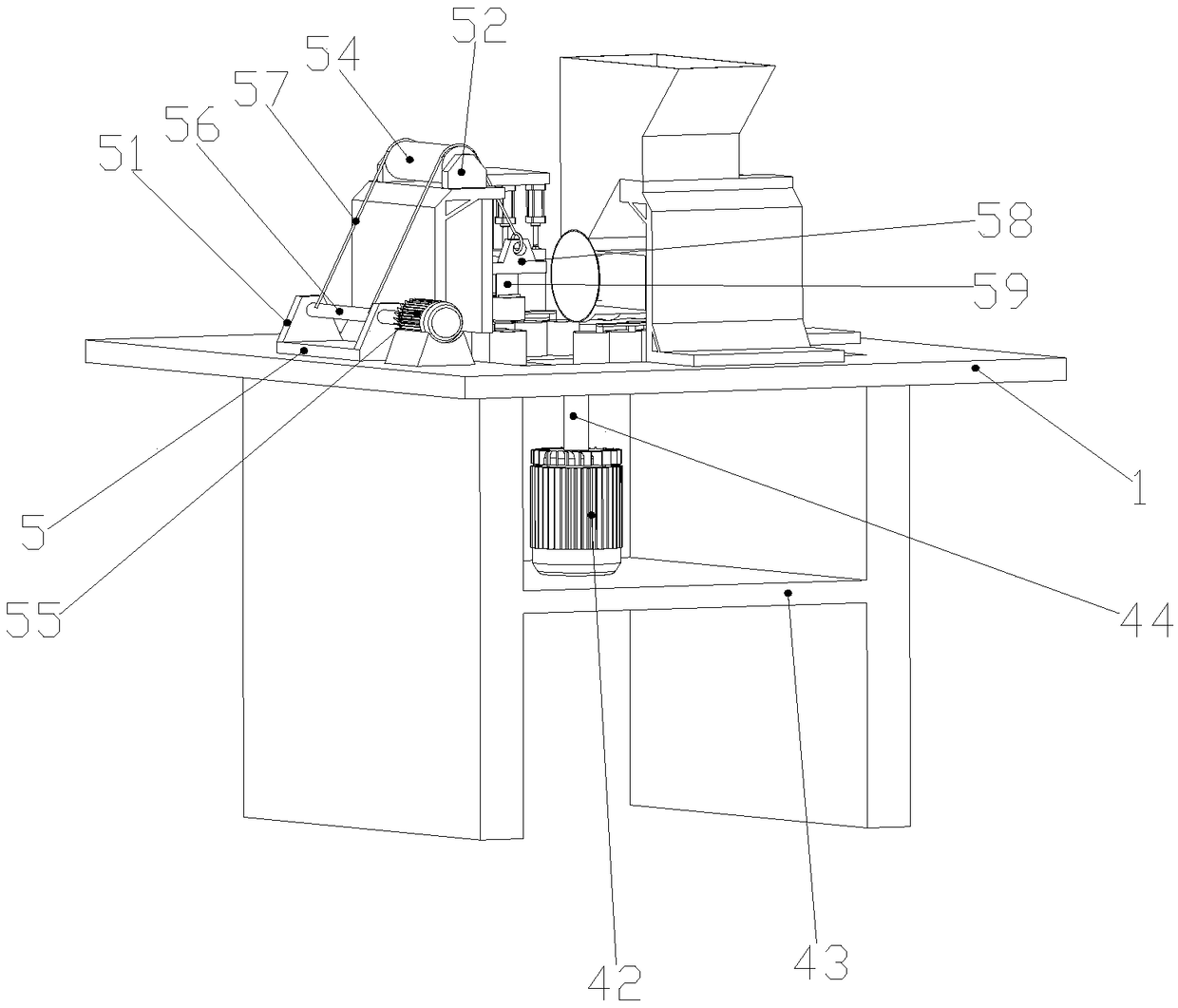

Double-shaft shredding machine with material pressing device

InactiveCN106391250ALarge telescopic resistanceEasy to press downGrain treatmentsHydraulic cylinderEngineering

The invention discloses a double-shaft shredding machine with a material pressing device. The double-shaft shredding machine comprises a rack, a hopper, a cutter roller set, a material pressing plate, a hydraulic cylinder, a supporting frame and a connecting frame; the cutter roller set is mounted on the rack, the hopper is fixed to the rack, a discharging opening of the hopper is vertically opposite to the cutter roller set, one end of the material pressing plate stretches into the hopper and faces the cutter roller set, the other end of the material pressing plate is hinged to a piston rod of the hydraulic cylinder, and a first hinge axis is formed; the end, away from the material pressing plate, of a cylinder body of the hydraulic cylinder is hinged to the rack, one end of the connecting frame is hinged to the other end of the material pressing plate, and a second hinge axis is formed; the first hinge axis and the second hinge axis are separated, the other end of the connecting frame is hinged to the supporting frame, and the supporting frame is fixed to the rack; solid wastes can be conveniently, rapidly and stably pressed, the materials are not easily popped out of the tool shearing range, and the cutter roller set can conveniently and effectively shear and shred the materials.

Owner:GENOX RECYCLING TECH

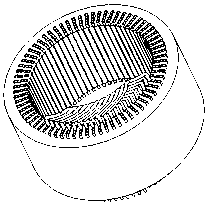

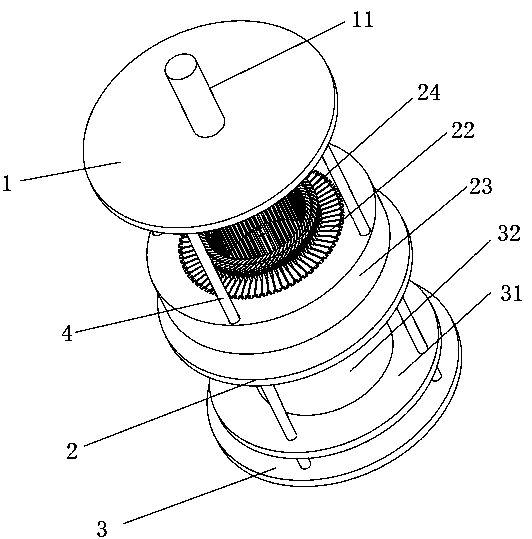

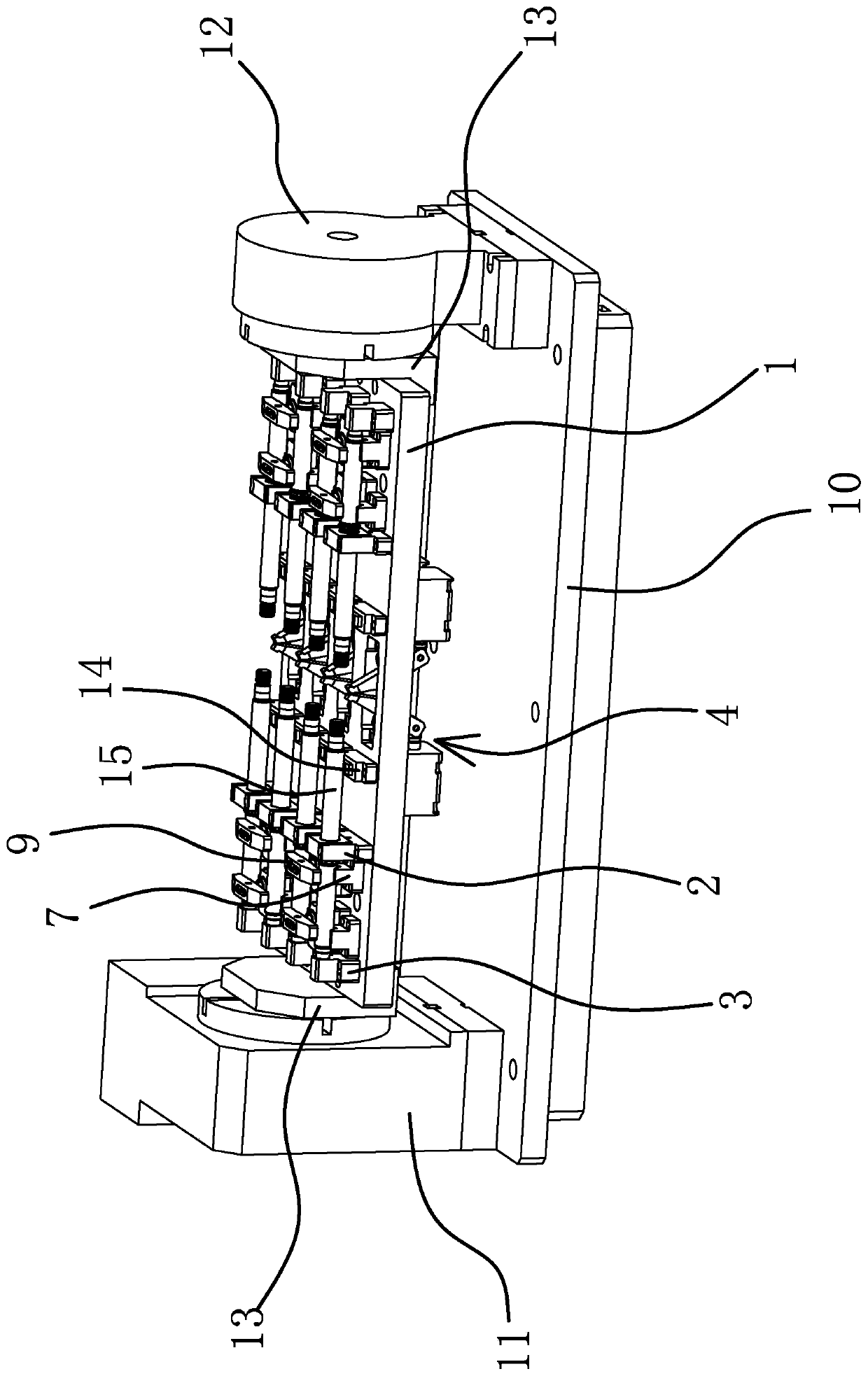

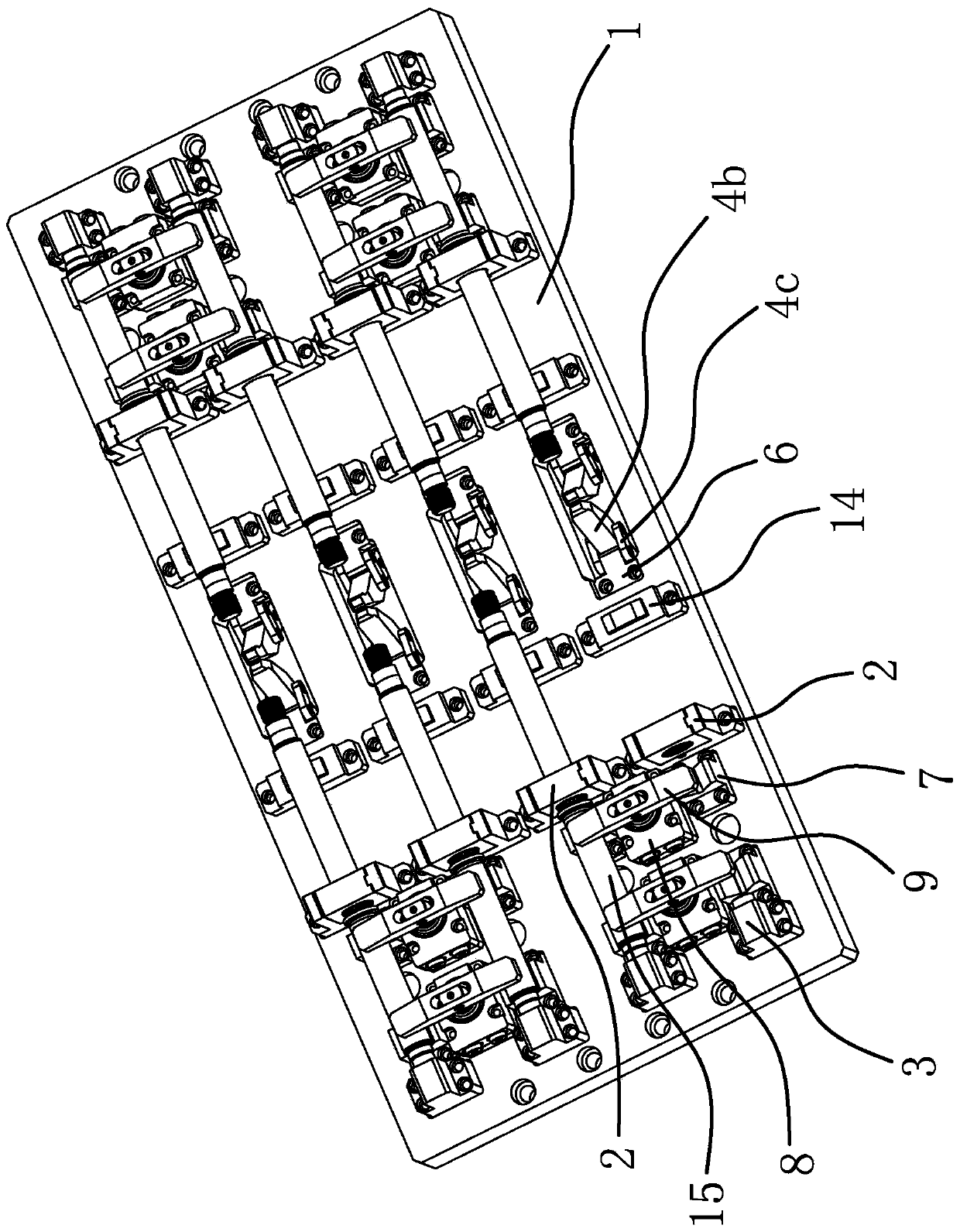

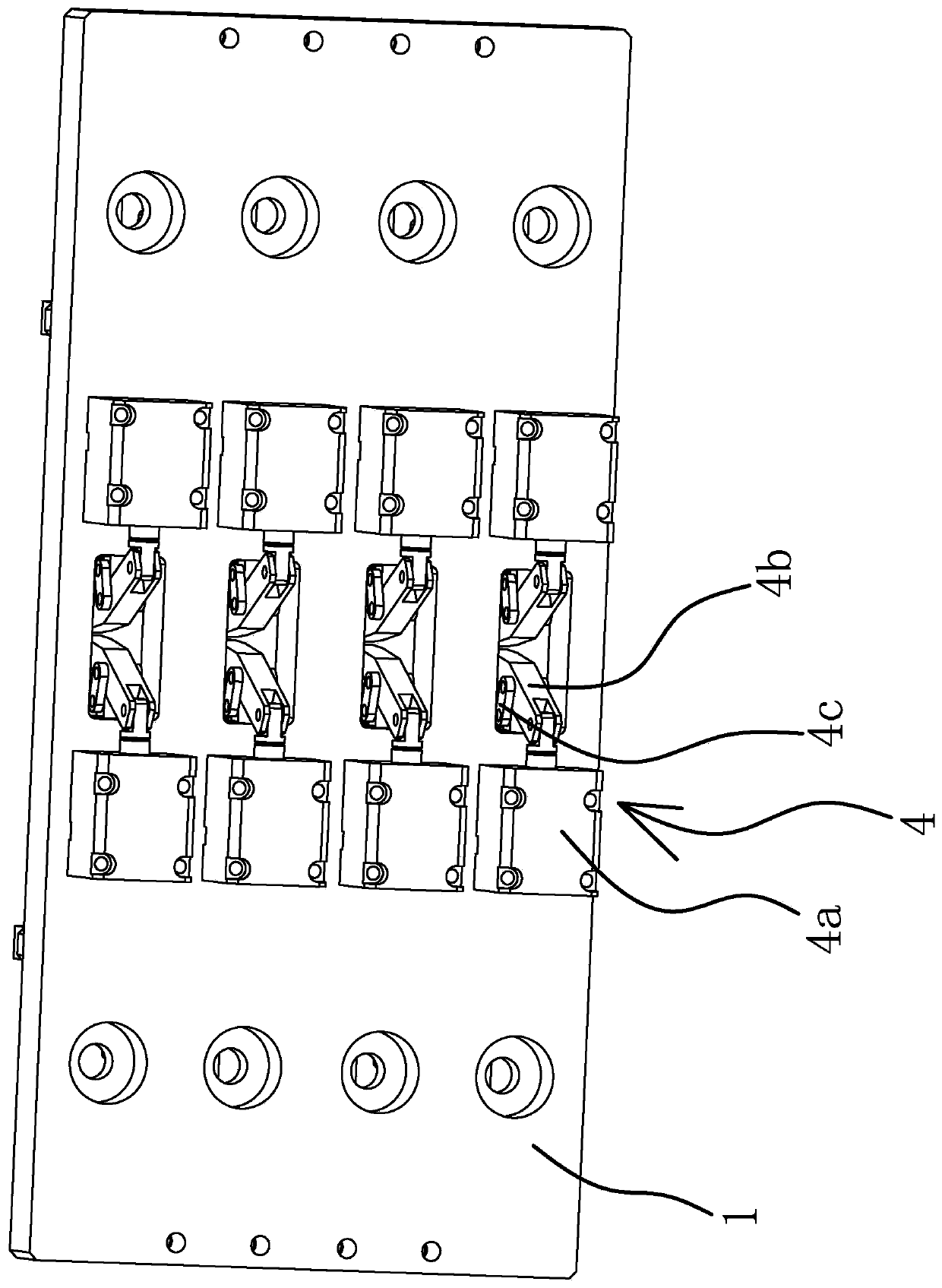

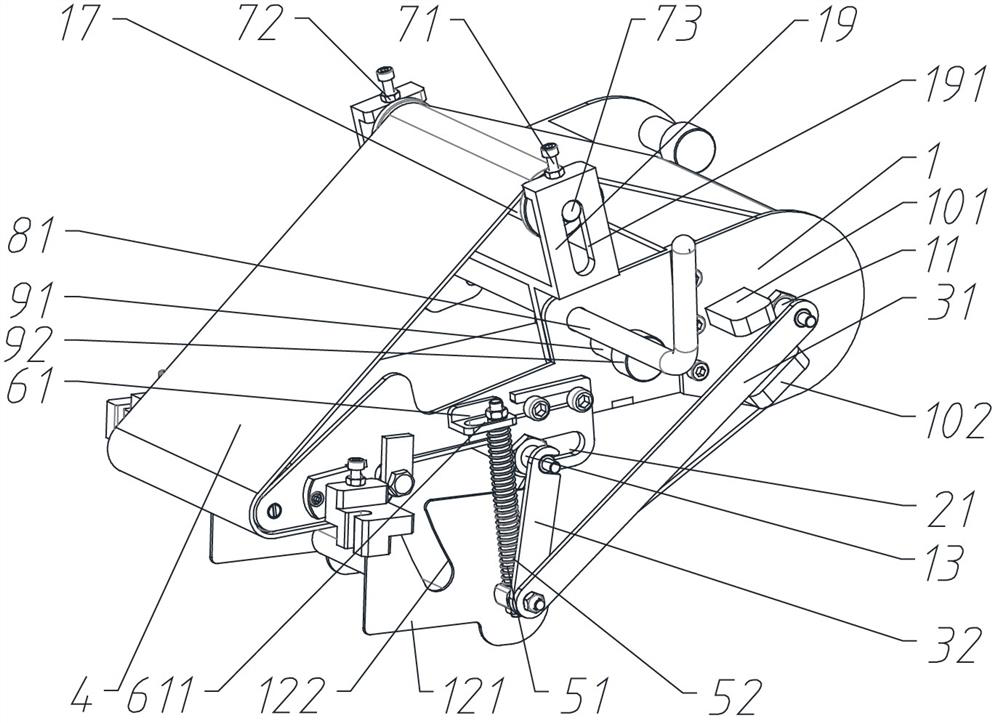

Automatic wire plugging structure of flat-wire motor stator

PendingCN107689719ARealization of automatic insertionPress down smoothlyManufacturing dynamo-electric machinesElectrical and Electronics engineeringStator

The invention discloses an automatic wire plugging structure of a flat-wire motor stator. The automatic wire plugging structure comprises a vertical guide pillar and three support bases sequentially fixed onto the guide pillar from top to bottom, and a slide base bearing a stator core is arranged above the third support base; a slide pin guide is fixed on the second support base, radial slide chutes evenly distributed in a ring are arranged in the upper end of the slide pin guide, and a slide pin capable of sliding radially along each slide chute is placed in the slide chute; a sliding extrusion body is embedded in the outer side of each slide pin; a press component is arranged on the first support base. The automatic wire plugging structure is ingenious in structure and simple and reliable, production efficiency can be improved, the possibility that enameled flat wires are scratched during the course that a winding coil is plugged in the stator core is reduced, insulation reliabilityamong the enameled flat wires is improved, and use of insulation paper among the enameled flat wires in the chutes is favorably avoided.

Owner:HEFEI JUYI POWER SYST CO LTD

Conductive adhesive strip tester

PendingCN106291111AEffectively fixedEasy to detect resistanceResistance/reactance/impedenceAdhesiveEngineering

The invention relates to a conductive adhesive strip tester which comprises a main frame, a base, a testing device and an adjustable pressing device. The main frame is arranged on the base. The adjustable pressing device is vertically arranged on the main frame. A position which corresponds with the adjustable pressing device on the base is provided with a fixing device for fixing the conductive adhesive strip. The lower end of the adjustable pressing device is provided with a pressing transverse rod. One end of the pressing transverse rod is provided with an electrode leading-out end which is connected with one end of the conductive adhesive strip. The base is also provided with a testing circuit board which is arranged below the conductive adhesive strip. One end of the testing device is connected with the electrode leading-out end, and the other end is connected with the testing circuit board. The tester provided by the technical solution of the invention can effectively test uniformity, stability and consistency of resistance of the conductive adhesive strip, thereby finding out whether a fault exists in the conductive adhesive strip.

Owner:深圳市拓普微科技开发有限公司

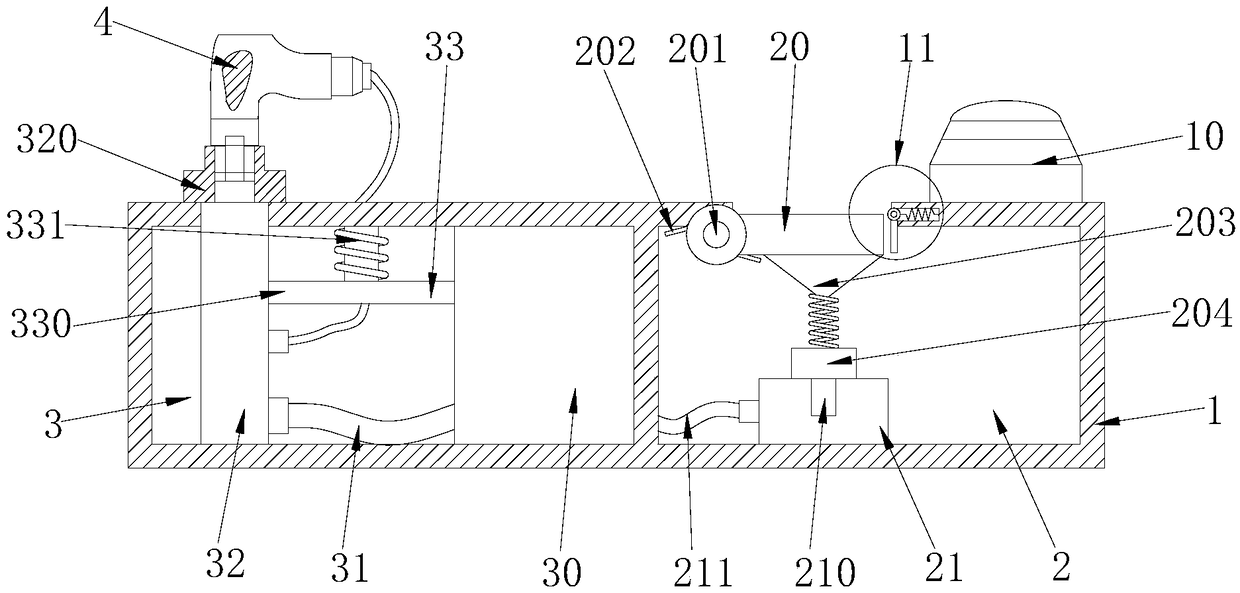

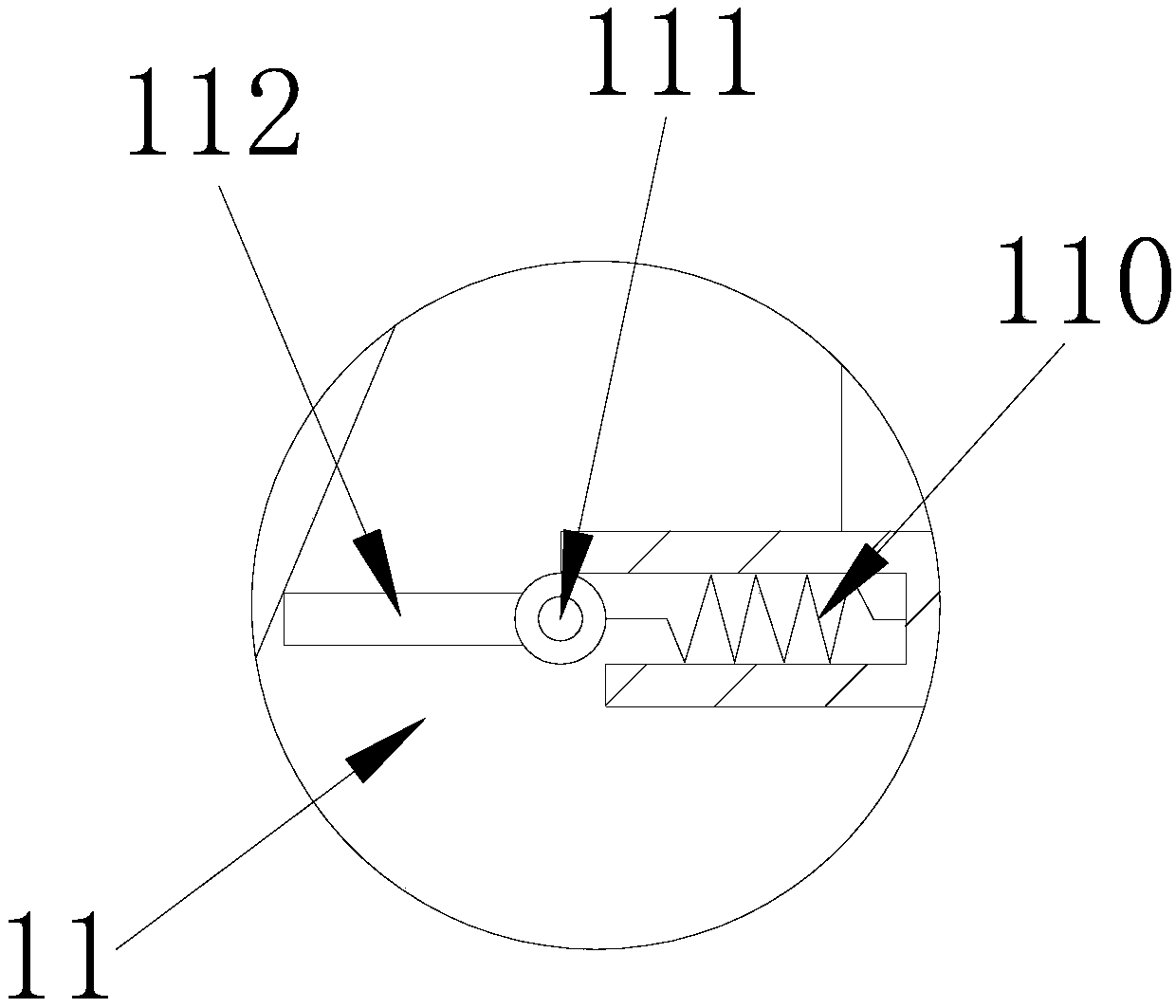

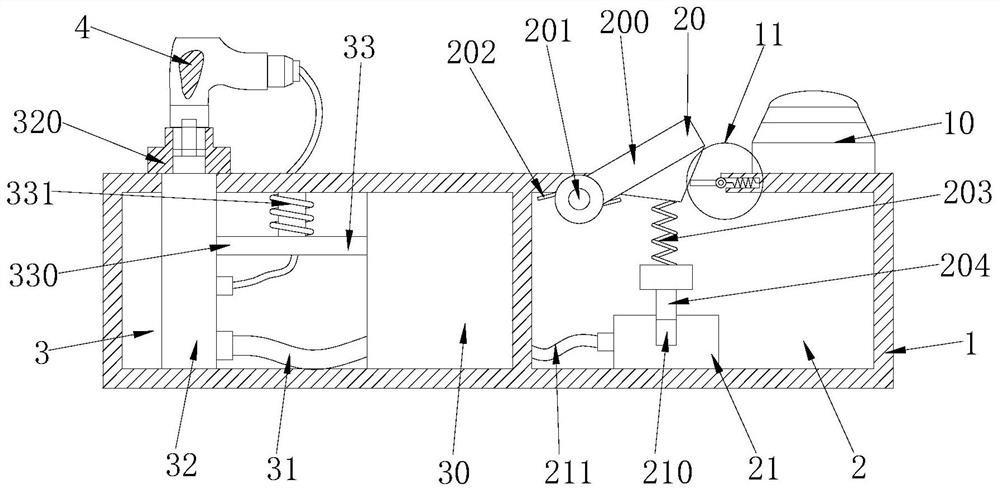

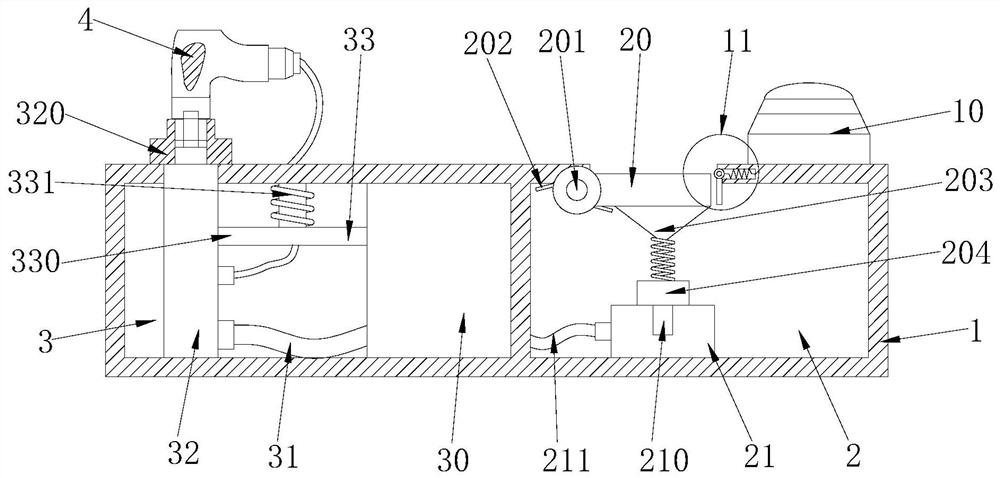

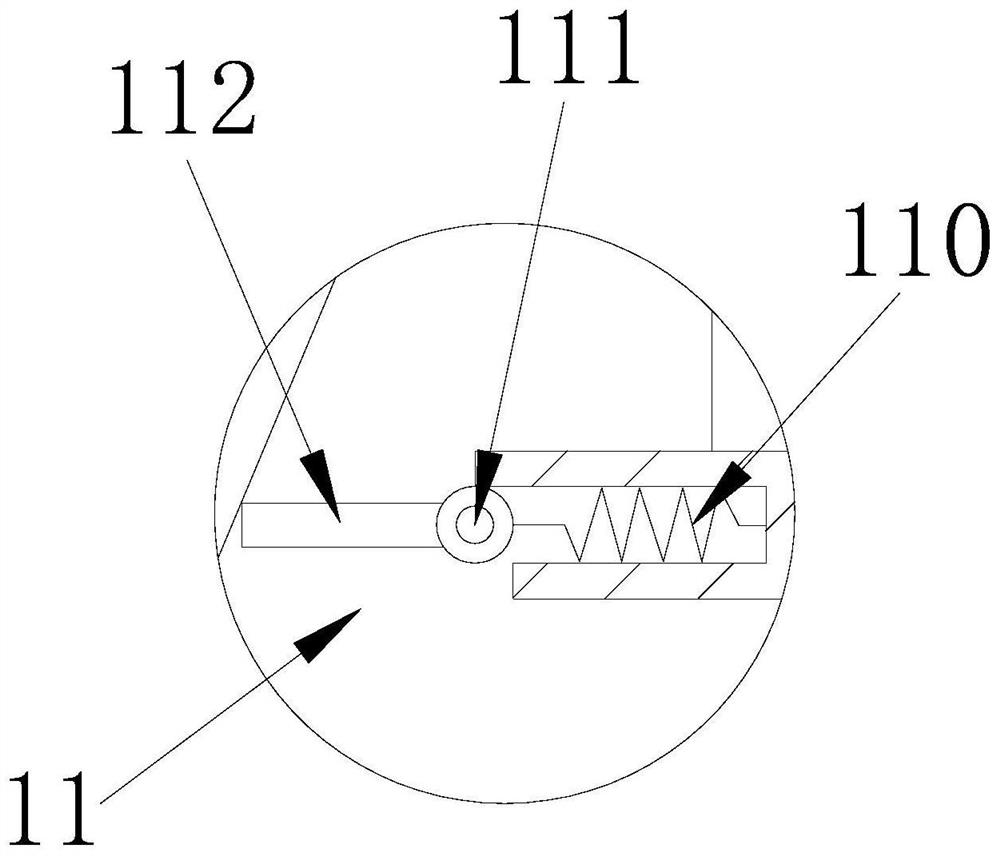

A surface chargingdevice for sharing electric vehicle

ActiveCN109017385AEasy to chargeAvoid occupyingElectric vehicle charging technologyVehicular energy storageParking areaParking space

The invention discloses a surface charging device for shared electric vehicle. The structure comprises a housing protection device, circuit control box, Charger box, charge gun head, the invention hasthe advantages that: sharing the weight of an electric car and the structure of four wheels, the invention avoids other vehicles needing to be charged from occupying the parking space of the shared electric vehicle for charging, At that same time, by separate the charging gun head from the trig device, the charging port of the shared electric vehicle is at the position of the charging gun head aft the electric vehicle is parked, the problem that the charging wire is too long or too short is saved, and the charging wire can be quickly and effectively sorted through the design of the winding column; By embedding the whole equipment under the parking area for the use of the shared electric vehicle parking space, the use function of the parking area can be enhanced, and at the same time, thewater-proof and leakage-proof work can be done well, so that the shared electric vehicle can be charged conveniently, and the charging piles do not need to be searched everywhere, and are convenient to use.

Owner:泰州市扬帆车件有限公司

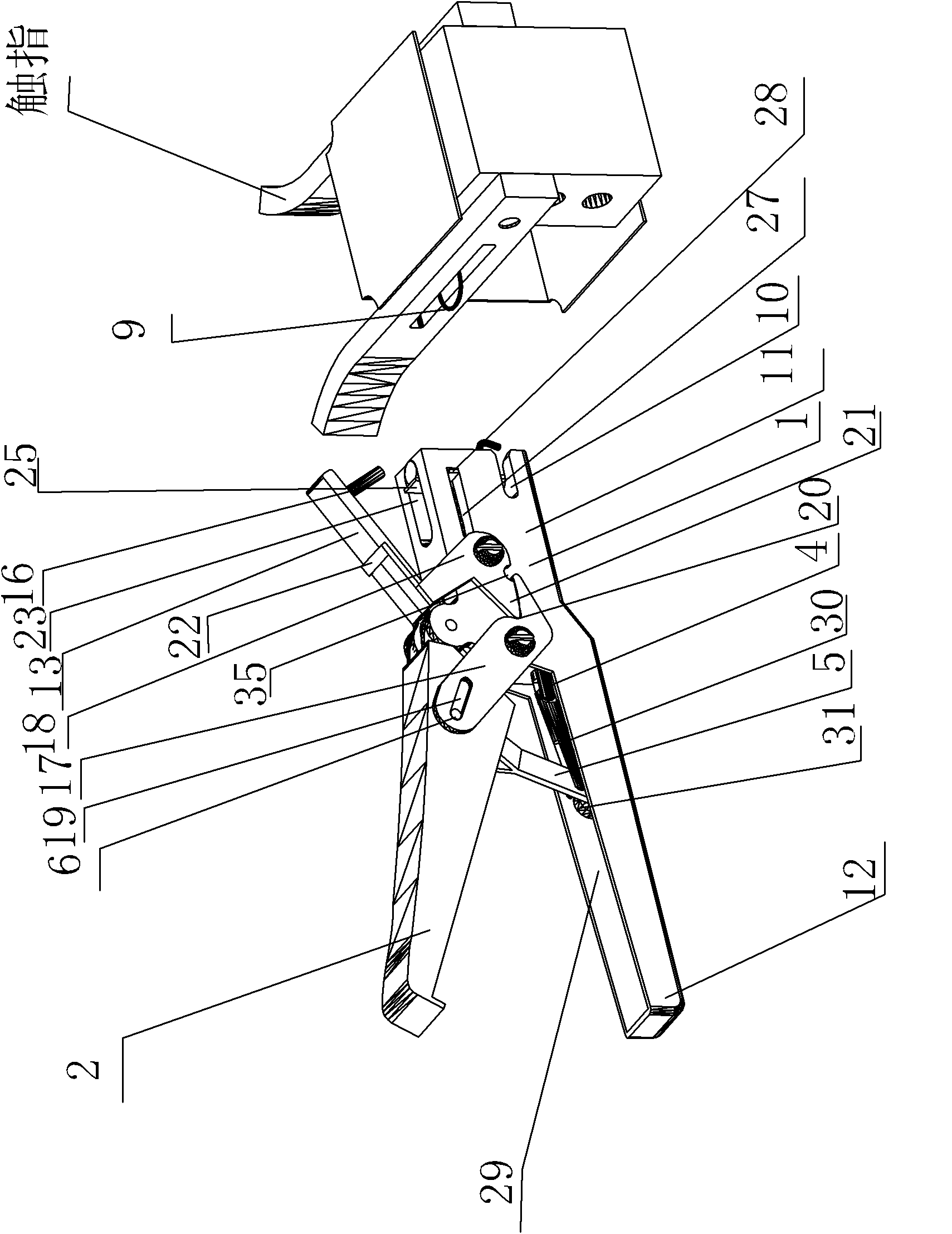

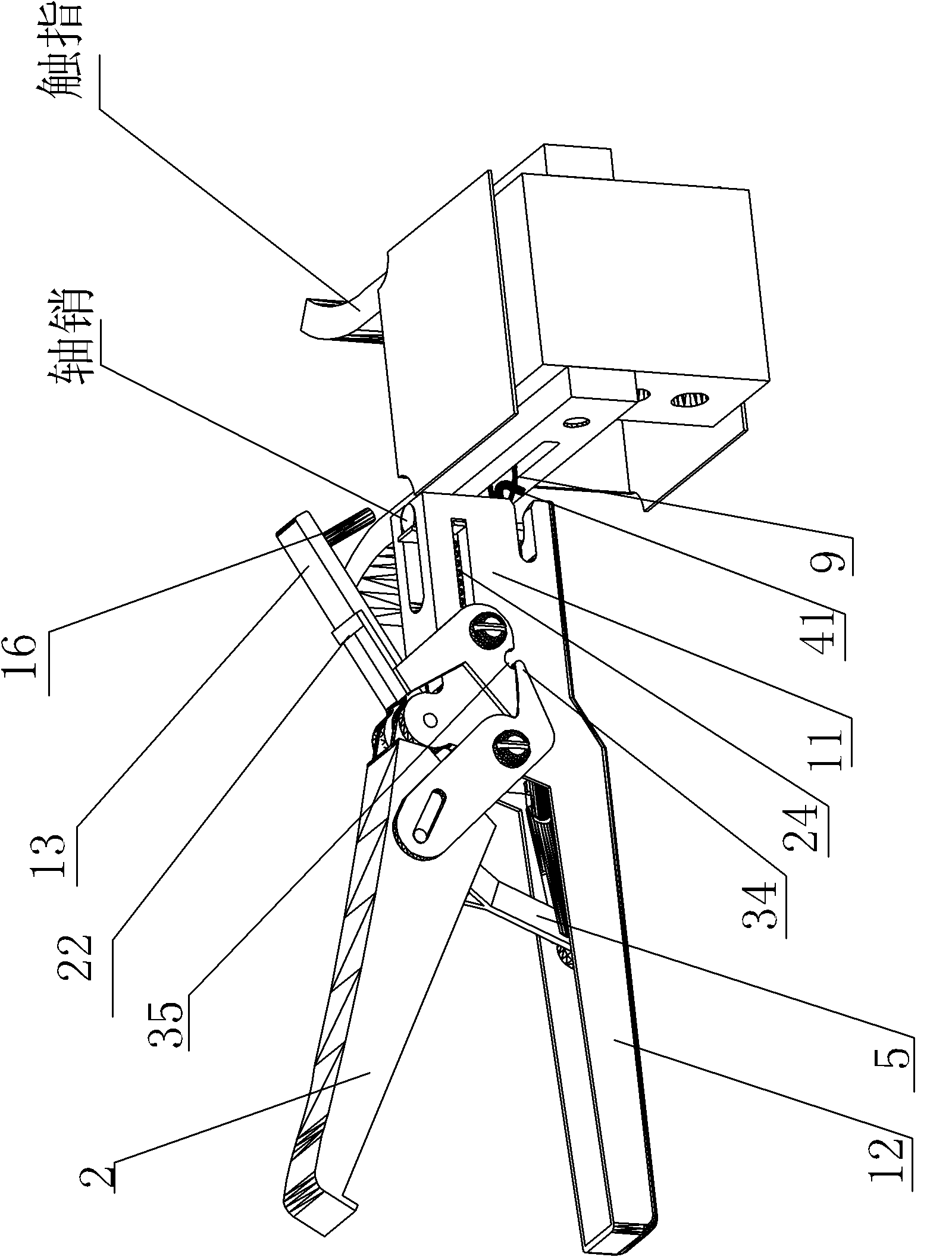

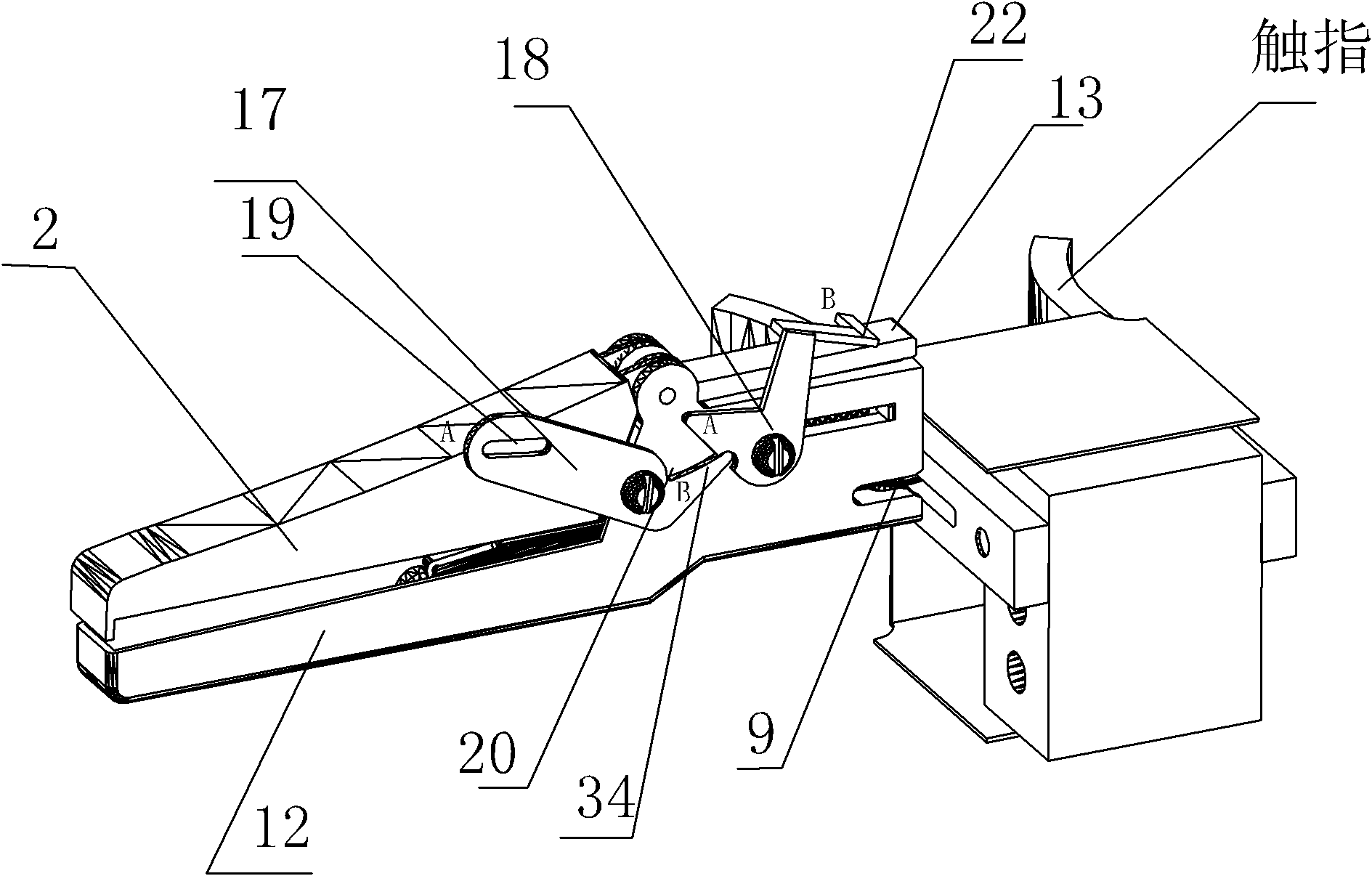

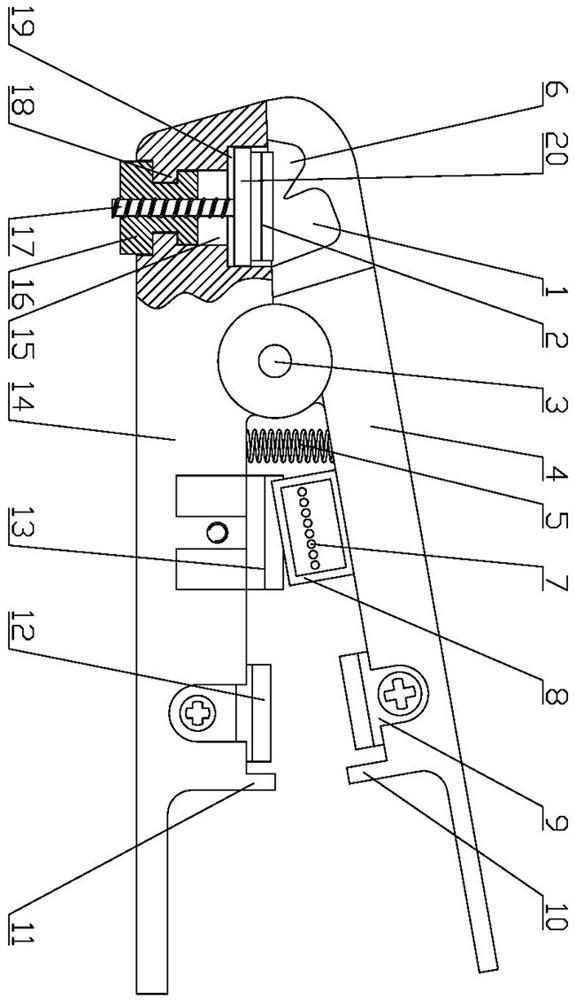

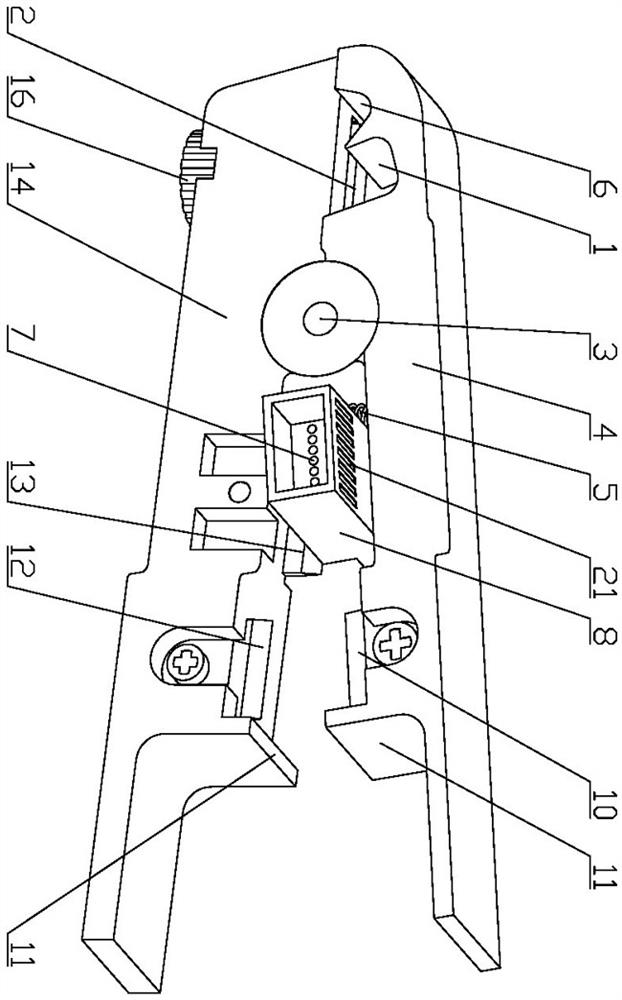

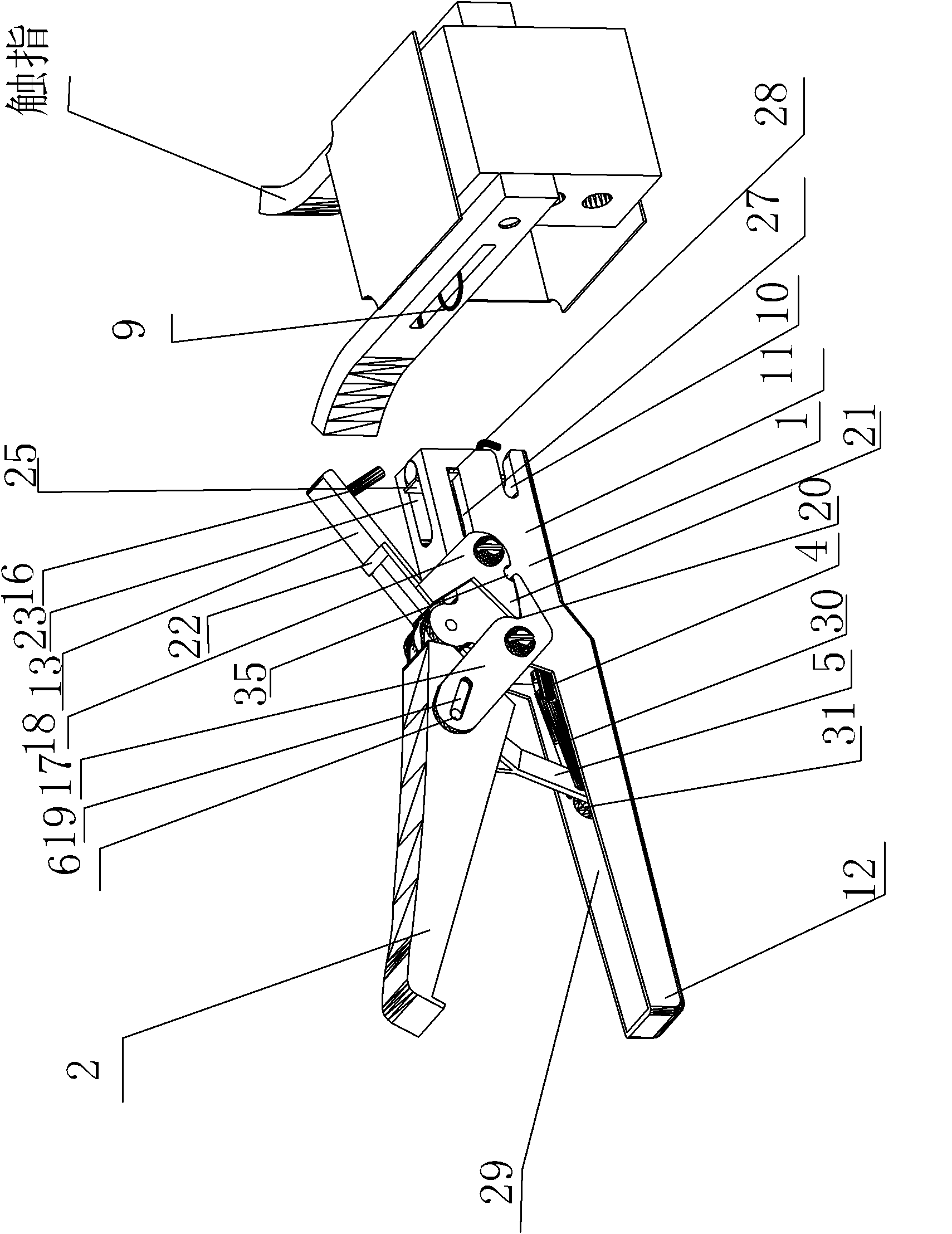

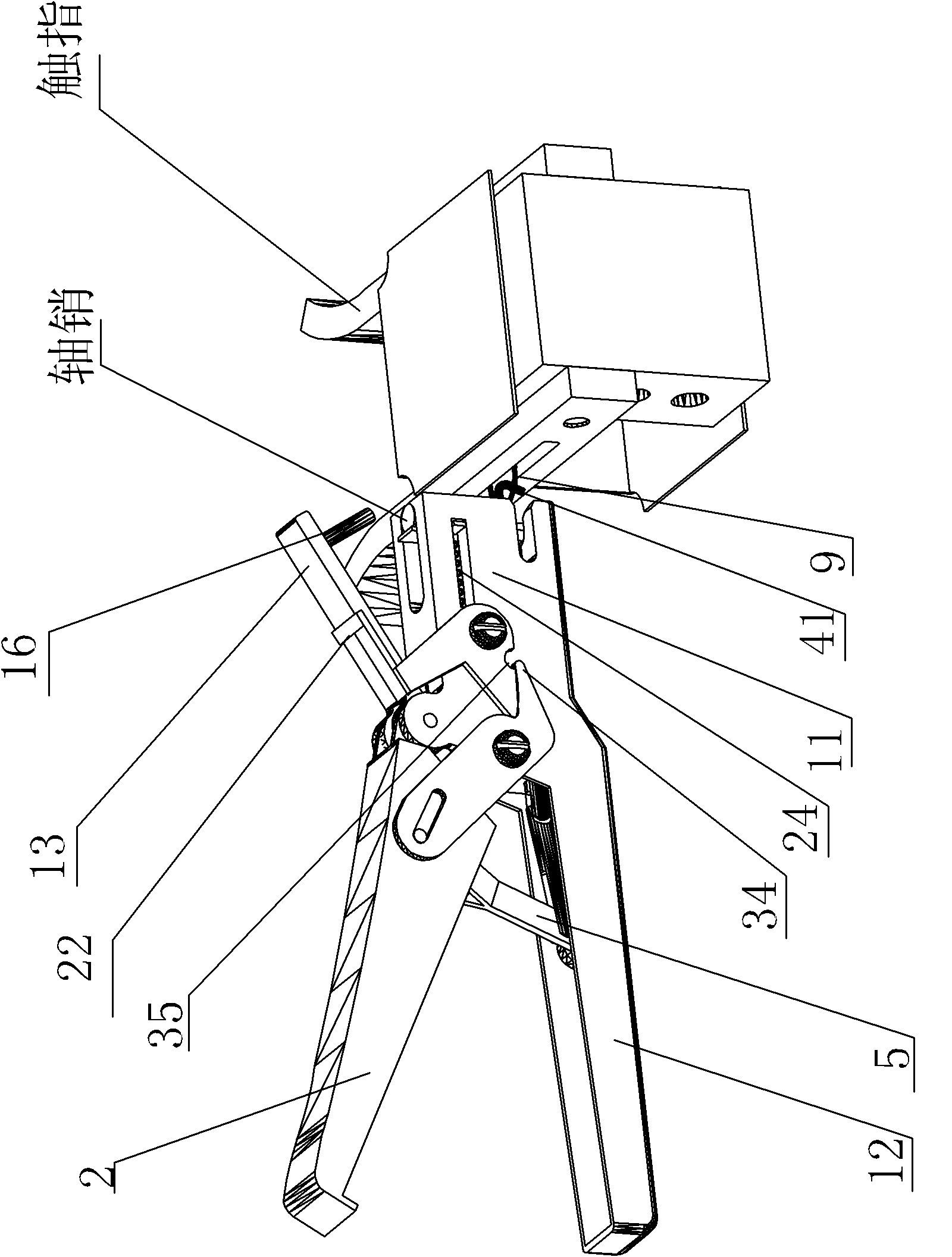

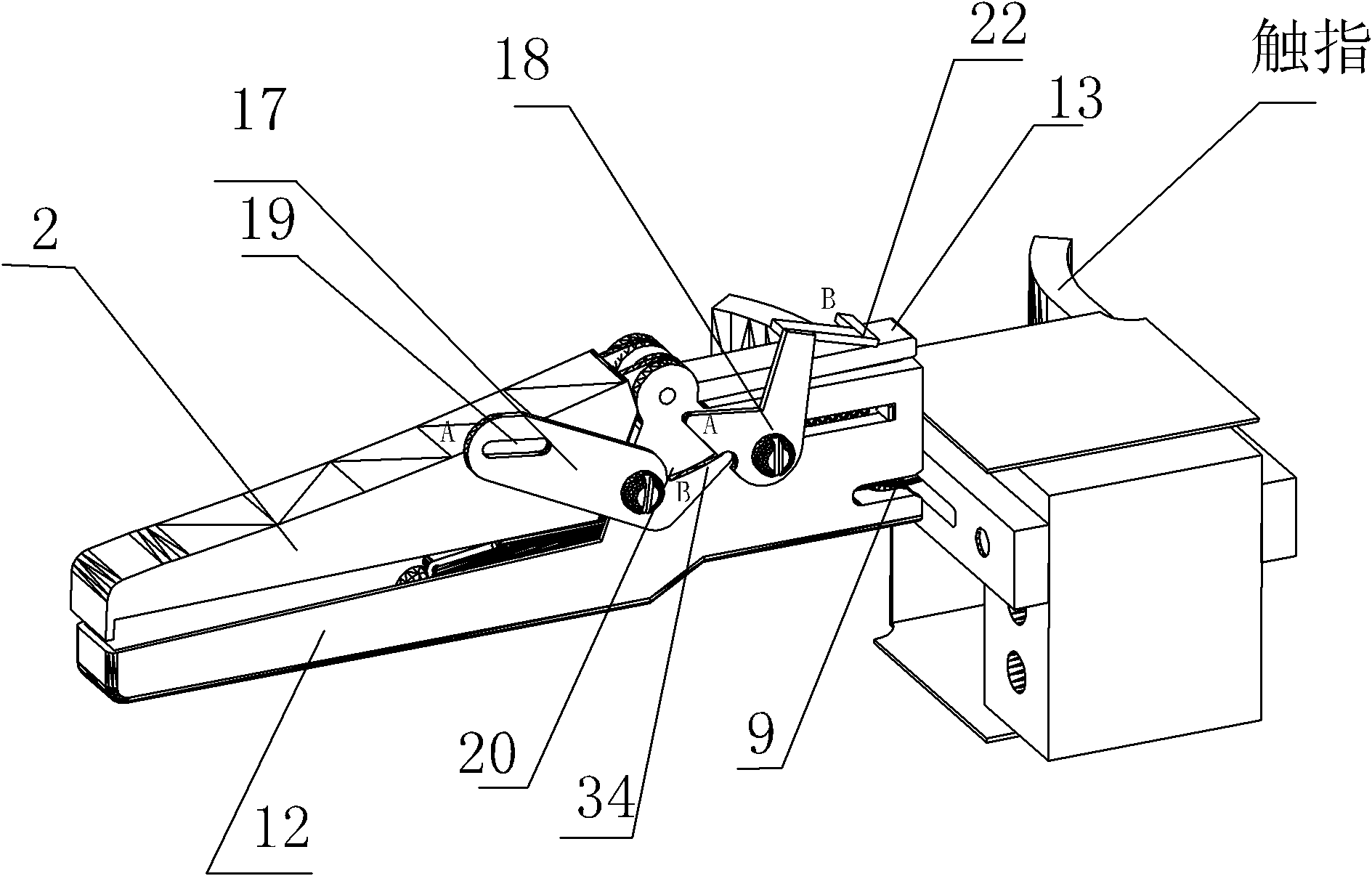

Contact-finger installing tool for high-voltage isolating switch

InactiveCN102074396ADestruction will notEasy to operateElectric switchesEngineeringMechanical engineering

The invention discloses a contact-finger installing tool for a high-voltage isolating switch, wherein a transverse passage is arranged in the lower part of an installing part, a connecting rod is arranged in the transverse passage, a hook is arranged at the front end of the connecting rod, the hook extends out of the front end of the installing part, the rear end of the connecting rod is connected with a hand-pressing handle through an inclined rod, a shaft-pin passage which is vertical to the transverse passage is arranged at the front end of the installing part, a pin outlet is arranged at the lower part at the front end of the installing part, the pin outlet is communicated with the shaft-pin passage, the pin outlet is communicated with the transverse passage, an open slot which can beused for containing the end part of a contact-finger stretched spring is arranged at the front end at the lower part of the installing part, the upper end of the installing part is in shaft connection with a pressure plate, a second reset spring is arranged between the pressure plate and the installing part, a column body for downwards pushing and pressing a shaft pin is arranged at the front endof the pressure plate, and a pushing and pressing mechanism is arranged between the pressure plate and the hand-pressing handle. The invention has the advantages that when the installing tool is operated, the hand-pressing handle only needs to be pressed to pull out the contact-finger stretched spring, meanwhile, the shaft pin is nailed into the end hole of the contact-finger stretched spring, and the installing tool is quite convenient to operate.

Owner:NINGBO ELECTRIC POWER BUREA

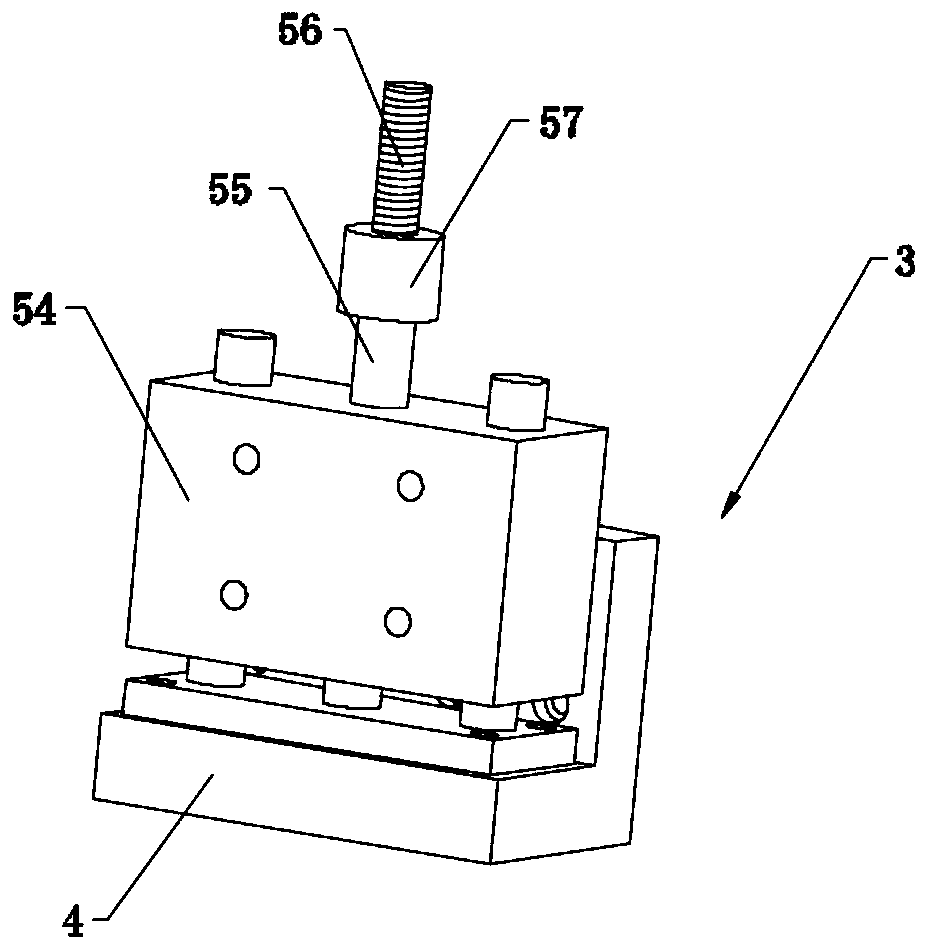

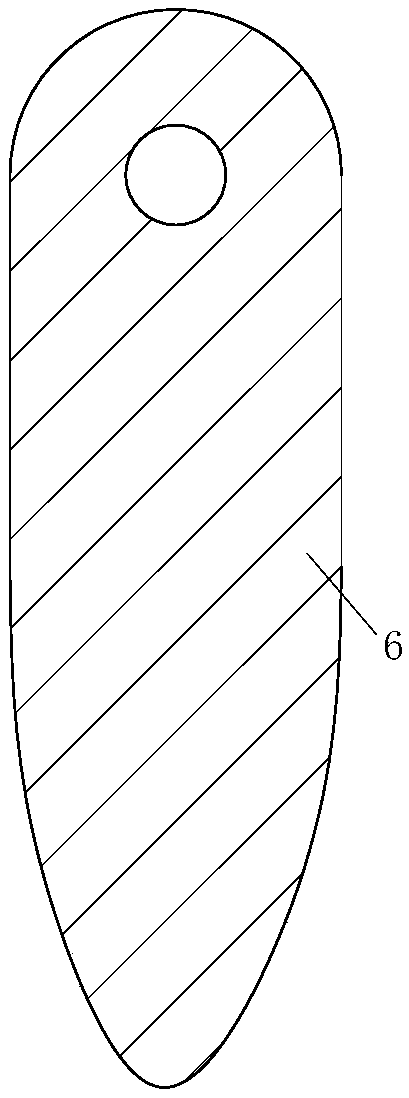

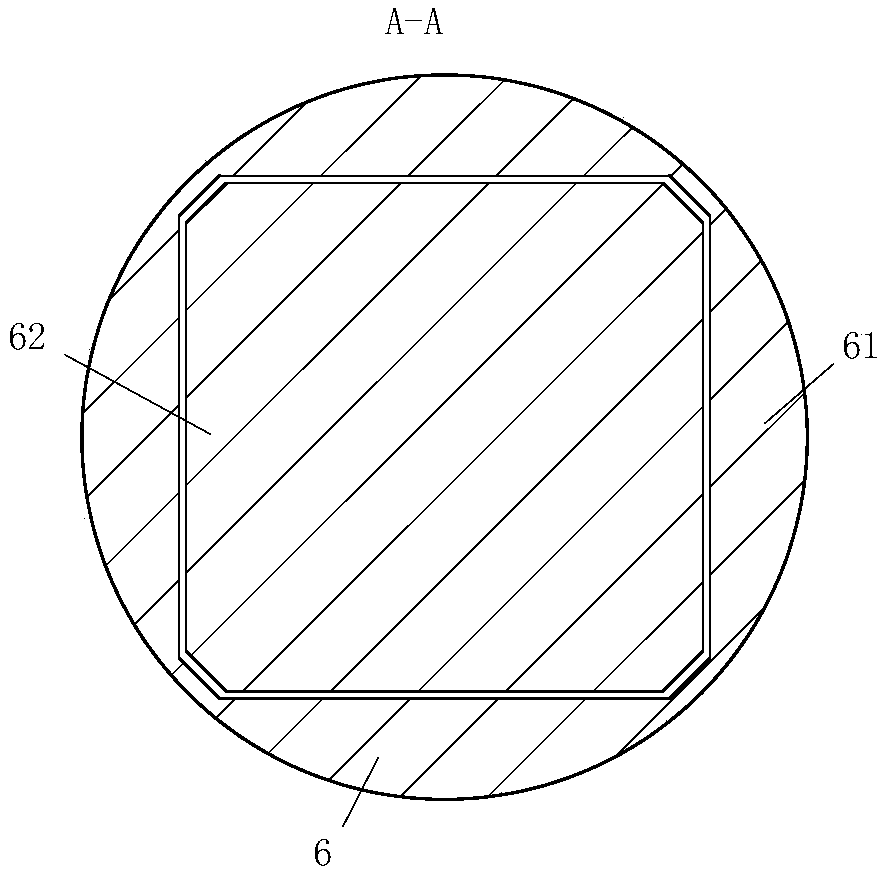

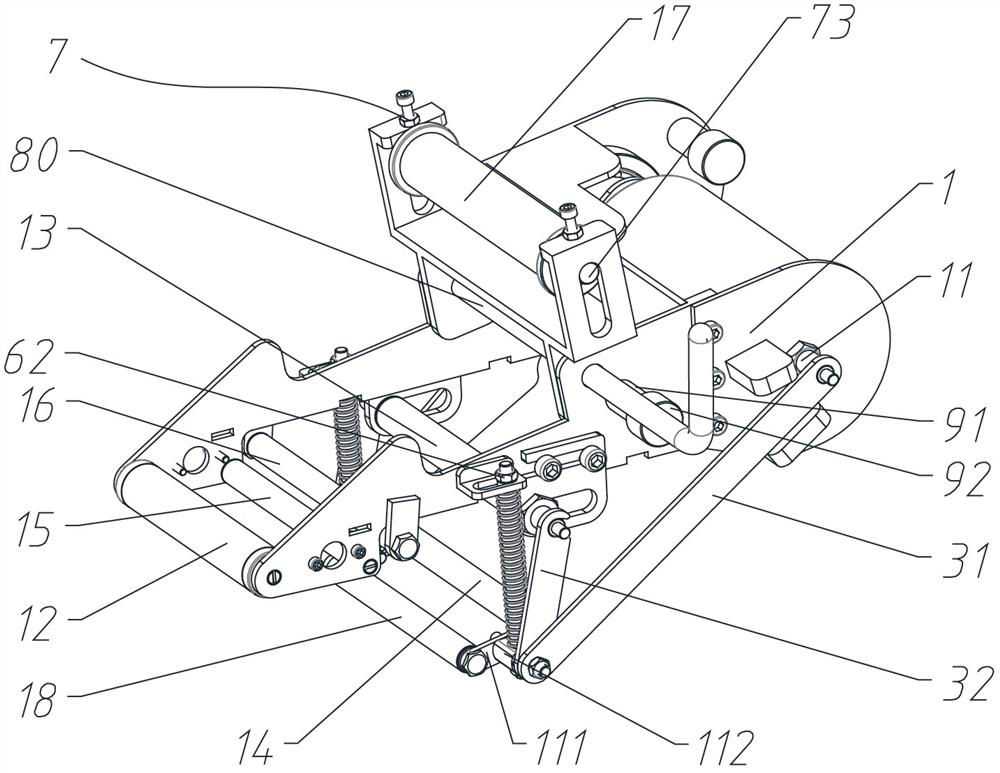

Clamping tool for drilling drive shaft

PendingCN110280802APrevent excessive swingGuaranteed reliabilityPositioning apparatusBoring/drilling componentsDrive shaftEngineering

The invention provides a clamping tool for drilling a drive shaft and belongs to the technical field of clamps. The clamping tool solves the problem how to improve the drilling precision of the drive shaft. The clamping tool comprises a base plate and a support fixed to the base plate. The support is provided with a locating hole for the drive shaft to penetrate through is formed in the support in a penetrating manner. The base plate is further provided with a stop block and an ejecting and pressing mechanism. The stop block and the ejecting and pressing mechanism are located on the two sides of the support in the forming direction of the locating hole. The clamping tool is characterized in that the locating hole is a spline hole, a tooth missing position is arranged on the portion, between the two spline teeth, of the inner side wall of the locating hole, a cavity communicating with the lower portion of the locating hole is formed in the support, an elastic locating assembly is arranged in the cavity, and the elastic locating assembly partially extends into the lower portion of the locating hole under the elastic force effect of the elastic locating assembly. According to the clamping tool for drilling the drive shaft, while accuracy of the drilling position is ensured, the drilling precision is improved, and the production efficiency of enterprises is improved.

Owner:台州市中亚汽车零部件股份有限公司

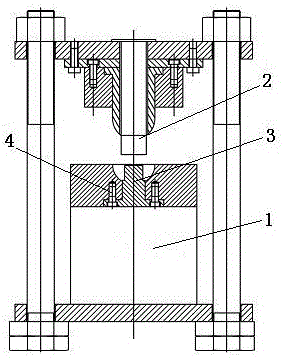

One-time forming hydraulic machine for mine tray

The invention relates to the technical field of punching with hydraulic machines, in particular to a one-time forming hydraulic machine for a mine tray. The one-time forming hydraulic machine for the mine tray is characterized by comprising a hydraulic cylinder, an upper die and a lower die, wherein the lower die is installed on the hydraulic cylinder and internally provided with a punch. The one-time forming hydraulic machine for the mine tray has the characteristics that pressing is stable, operation can be learned easily, and simpleness and safety are achieved.

Owner:安徽碧源环保工程有限公司

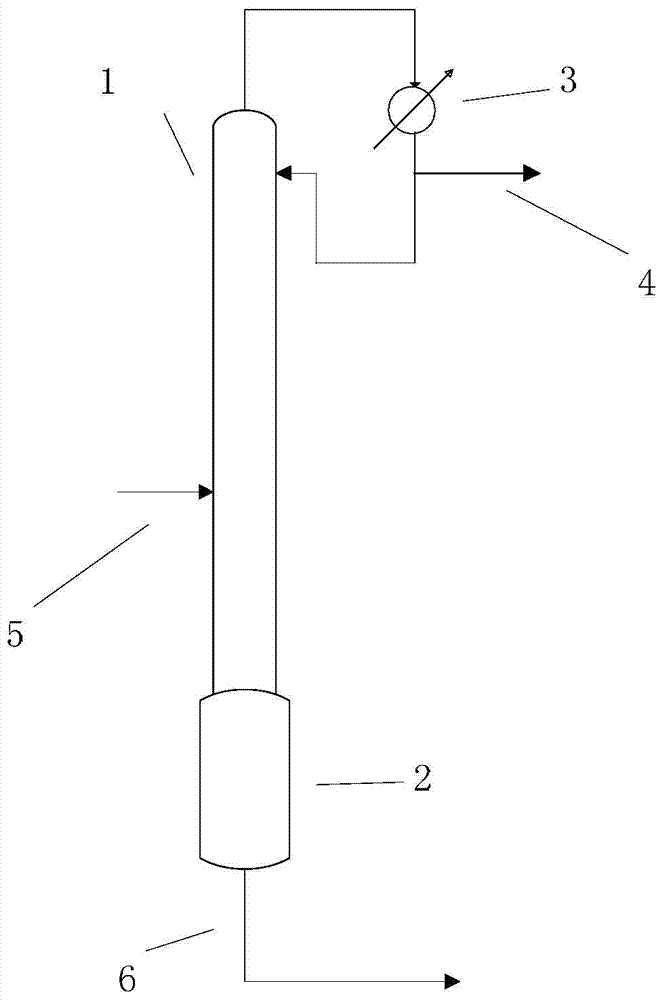

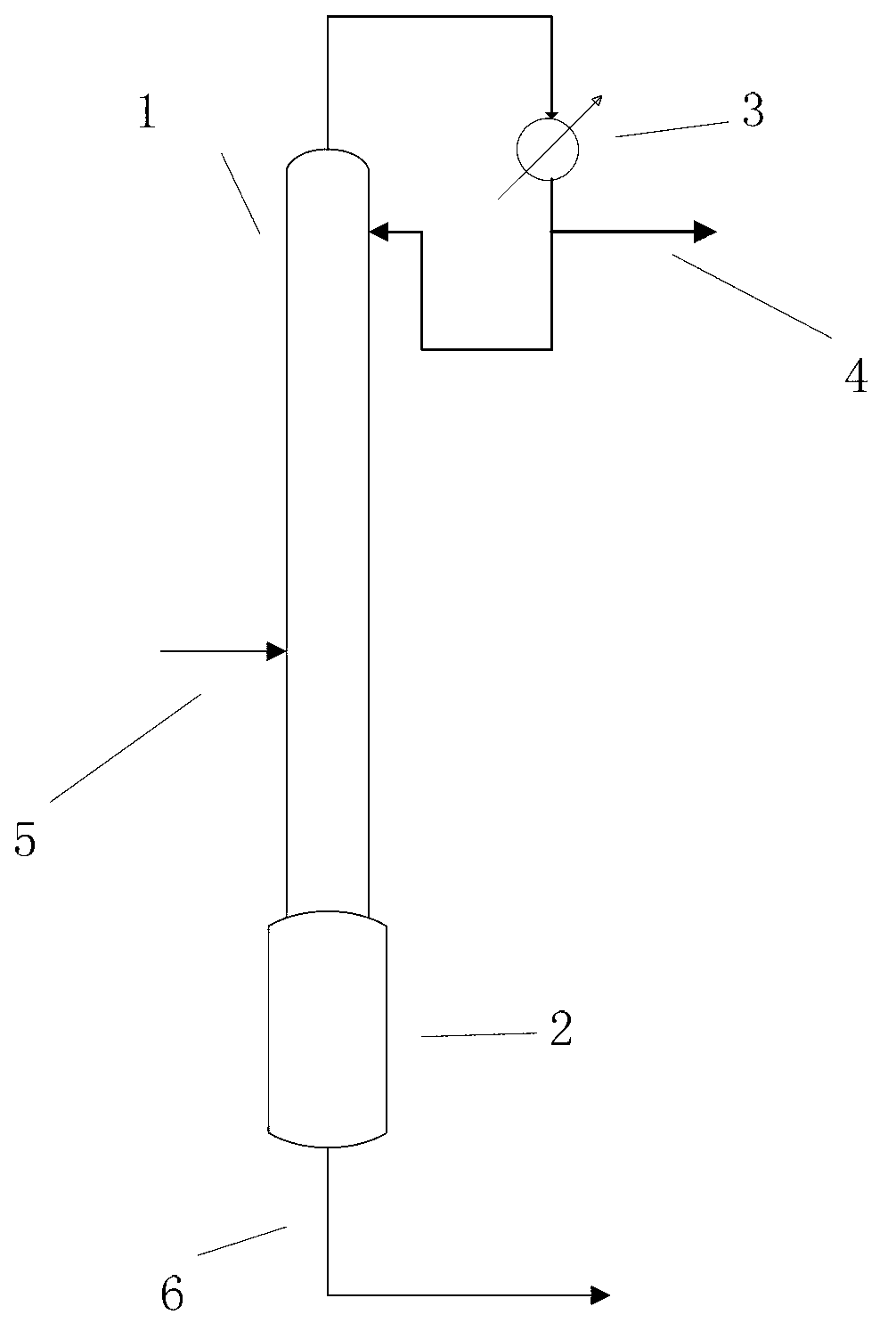

Method for rectifying iodine-containing hydriodic acid feed liquid

ActiveCN103212215BAvoid condensationPress down smoothlyFractional distillationHigh concentrationReflux

The invention provides a method for rectifying an iodine-containing hydriodic acid feed liquid. The method which is adopted for rectifying the iodine-containing hydriodic acid feed liquid comprises steps of: firstly, adding hydriodic acid with high concentration or iodine-containing hydriodic acid with low iodine content and high HI content into a rectifying still, then starting a heating device of the rectifying still and a condensation reflux device on a still top, and operating in a total reflux mode; and when the condensation reflux device on the still top can stably reflux the hydriodic acid, feeding the iodine-containing hydriodic acid feed liquid to be rectified into the rectifying still, and continuously feeding from the still top and a still bottom. When the rectifying method is adopted to rectifying the iodine-containing hydriodic acid feed liquid, I2 in the feed liquid can be effectively prevented from being condensed on a rectifying column top to cause rectifying operation failure.

Owner:TSINGHUA UNIV

Method for rectifying iodine-containing hydriodic acid feed liquid

ActiveCN103212215APreventing failed distillation operationsAvoid condensationFractional distillationChemistryHydroiodic acid

The invention provides a method for rectifying an iodine-containing hydriodic acid feed liquid. The method which is adopted for rectifying the iodine-containing hydriodic acid feed liquid comprises steps of: firstly, adding hydriodic acid with high concentration or iodine-containing hydriodic acid with low iodine content and high HI content into a rectifying still, then starting a heating device of the rectifying still and a condensation reflux device on a still top, and operating in a total reflux mode; and when the condensation reflux device on the still top can stably reflux the hydriodic acid, feeding the iodine-containing hydriodic acid feed liquid to be rectified into the rectifying still, and continuously feeding from the still top and a still bottom. When the rectifying method is adopted to rectifying the iodine-containing hydriodic acid feed liquid, I2 in the feed liquid can be effectively prevented from being condensed on a rectifying column top to cause rectifying operation failure.

Owner:TSINGHUA UNIV

Glue solution saved type pressing device

ActiveCN108437547APress down smoothlyEven by forcePaper-makingBox making operationsWorking environmentEngineering

The invention relates to a glue solution saved type pressing device comprising an operation platform. A fixing frame and a rotating motor are arranged on the operation platform. Four first rotating rods are arranged on the operation platform. The upper ends of the first rotating rods are provided with a supporting frame. A second rotating rod is arranged on the lower side of the supporting frame.A movable round pressing plate is arranged on the top of the supporting frame. Clamping grooves are arranged on the upper surface of the movable round pressing plate. The round movable pressing plateis provided with a plurality of solution discharging holes. A solution discharging funnel is arranged at the bottom end of the movable round pressing plate. A first pneumatic cylinder is arranged on the fixing frame and connected with a fixed round pressing plate. A glue infusing plate is arranged on the lower surface of the round fixed pressing plate. Two glue storage bins are symmetrically arranged inside the fixing frame. The lower ends of the liquid storage bins are provided with first glue outlets. The lower ends of the first glue outlets are provided with fixed glue discharging pipes. The fixed glue discharging pipes are provided with a plurality of second glue outlets. The end, sleeved with a glue discharging hose, of each fixed glue discharging pipe is connected with the fixed round pressing plate. The glue solution saved type pressing device is good in box adhesion effect, free of glue solution waste and high in work environment cleanness degree.

Owner:郑州华美彩印纸品有限公司

Folding and gluing machine pressing device with cleaning assembly

PendingCN108312630ARealize automatic cleaningTo achieve the effect of cleaningPaper-makingBox making operationsWorking environmentEngineering

The invention relates to a folding and gluing machine pressing device with a cleaning assembly. The folding and gluing machine pressing device with the cleaning assembly comprises an operating table,wherein a fixing frame and a first rotary motor are arranged on the operating table; a first fixing block and a second fixing block are arranged on two sides of the fixing frame; a second rotary motoris arranged on the first fixing block; a first rotary rod is arranged on the operating table; a support frame is rotatably connected onto the first rotary rod; a second rotary rod is rotatably connected to the lower part of the middle part of the support frame; a square-shaped fixing groove is formed in the top part of the support frame; a circular movable pressing plate is arranged on the top part of the fixing groove; a discharging funnel is arranged under the circular movable pressing plate; the cleaning assembly is arranged above the circular movable pressing plate, and comprises a cleaning brush; one end of the cleaning brush is fixedly connected with the fixing frame through a spring; the other end of the cleaning brush is connected with the second rotary motor through a steel wirerope; and a glue discharging assembly is arranged on the cleaning assembly. The folding and gluing machine pressing device with the cleaning assembly is good in box gluing effect without causing gluewaste, high in cleanliness of a working environment, and capable of saving time and effort for manually cleaning the pressing plate.

Owner:郑州华美彩印纸品有限公司

Soft-seal valve element of valve

InactiveCN105135049ANot easy to slip offPress down smoothlyOperating means/releasing devices for valvesEngineeringAtmospheric pressure

The invention relates to a soft-seal valve element of a valve. The soft-seal valve element comprises a connecting tube. The top of the connecting tube is sleeved with a threaded column. A handle is integrally formed at the top of the threaded column. Supports are arranged on the two sides of the connecting tube respectively. A bolt is arranged at one end of each support. The interior of the connecting tube is of a hollow structure. Sliding grooves and threaded grooves are formed in the inner wall of the connecting tube. The threaded grooves are formed above the sliding grooves. A stretchable rod is sleeved with the bottom of the connecting tube. The connecting tube is movably connected with a valve element body through the stretchable rod. According to the soft-seal valve element, as the threaded grooves and the sliding grooves are formed in the inner wall of the connecting tube, the effect of converting rotating pressing into sliding pressing is achieved; as a buffering air bag is arranged, the effect of protecting the stretchable rod and the valve element body is achieved; as an air bag layer is arranged, the effect that the valve element body is pressed to achieve better sealing is achieved; and as an air pressure guide rod and a piston are arranged, the effect of pressing the air bag layer is achieved.

Owner:ZHENJIANG KANG DA MACHINERY & ELECTRICAL MFG CO LTD

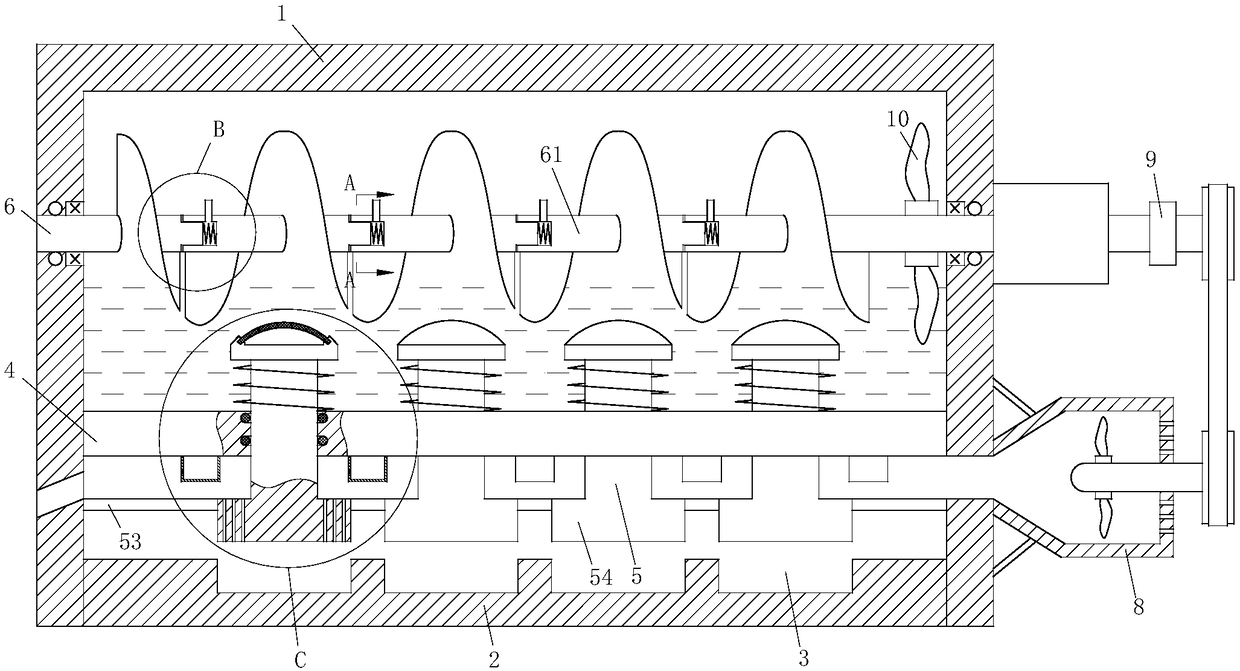

High-efficiency chemical fertilizer granulator

ActiveCN109200948AReduced service lifeAvoid loss of productivityGranulation by material expressionEngineeringRight-to-left

The invention belongs to the technical field of chemical fertilizer granulation equipment, and in particular relates to a high-efficiency chemical fertilizer granulator, which comprises a box body anda discharging board, wherein placing grooves are arranged on the placing board, and the upper side of the placing board is horizontally provided with a fixed plate; the fixed plate is provided with through holes, and a pressing rod is slidably connected into each through hole; pressing blocks are arranged at the lower ends of the pressing rods, and are provided with pressing holes; elastic clothis connected between the pressing blocks; the upper end of each pressing rod is fixedly connected with a pressing head; the upper end of each pressing head is provided with an arc elastic piece, and the upper side of each pressing head is provided with a shaft auger; blades of the shaft augers are in contact with the pressing heads, and the spacing of the blades of the shaft augers gradually increases from right to left. In the high-efficiency chemical fertilizer granulator, the pressing rods stably press down by the shaft augers and first springs in cooperation, and the impact force of pressing is small, thereby avoiding damage to the pressing heads and pressing grooves during the pressing process and reducing maintenance costs.

Owner:陕西科润生物科技有限公司

Packaging bag with moisture-proof effect

InactiveCN109795800AWith moisture-proof effectImprove moisture resistanceContainers preventing decayDesiccantEngineering

The invention relates to the technical field of packaging bags, and discloses a packaging bag with a moisture-proof effect. The packaging bag comprises a packaging bag body, wherein a top cover is fixedly installed at the top of the packaging bag body, and a sealing gasket extending into the packaging bag body is movably installed in the top cover. According to the packaging bag with the moisture-proof effect, through the arrangement of a stabilizing column, a rotating head, a spring and a connecting block, users can place the sealing gasket at the top cover and then rotate the rotating head so as to enable the stabilizing column to drive the sealing gasket to extrude; the spring can provide reverse force, so that the sealing gasket can be pressed down more stably, external moisture is notprone to entering the interior of the packaging bag body, and the moisture-proof effect is better; meanwhile, a protective cover and a desiccant layer are arranged, so that internal air is filtered,moist air is dried and absorbed, and the interior of the packaging bag body is kept dry, so that the moisture-proof effect of the packaging bag body is better, convenience is provided for the users, and the users can use the packaging bag more conveniently.

Owner:XIANGYANG KAIDA PACKAGING & PRINTING CO LTD

Cold press guiding device for wooden door production

InactiveCN110653911AExtrusion works smoothlyPress down smoothlyWood working apparatusFlat articlesPhysicsEngineering

The invention discloses a cold press guiding device for wooden door production. An extrusion structure is connected onto a cold press; a containing structure is arranged right below the extrusion structure; auxiliary structures are arranged on the two sides of the extrusion structure; a lifting pillar is a lifting air cylinder; a containing groove is formed in the middle of the containing structure; a connecting pillar is fixedly connected onto the bottom of the front end of an extension plate through a clamping plate; an inner groove is formed inside the connecting pillar; a baffle is fixedlyconnected with the inner edge of a bottom opening of the inner groove; limiting plates are fixedly connected with two sides of the end, positioned inside the inner groove, of a movable pillar. The guiding device has the following beneficial effects: various guiding and limiting structures are arranged, the operation of cold pressing to extrusion is more stable, so that the technical problems of flaws in a door panel, reworking, lowered production efficiency of a wooden door, and the like, caused by deflection of an extrusion plate, pressure transfer and uneven stress borne by the door panel when a bulge affects the pressure to a pressing plate in case of extrusion, are solved.

Owner:苏州琦少工程科技有限公司

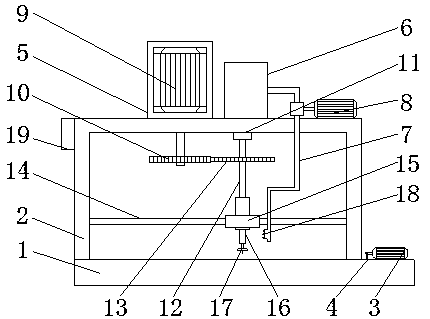

An easy-to-use steel plate drilling device

ActiveCN105880678BEasy to usePromote sportsBoring/drilling componentsMaintainance and safety accessoriesArchitectural engineeringScrew thread

The invention discloses a steel plate drilling device convenient to use. The device comprises a base, the top of the base is provided with a support base and a first motor in sequence from left to right, an output shaft of the first motor is provided with a belt, the belt penetrates through the base and extends into the base, the top of the support base is provided with a motor case, a water tank, a water outlet pipe and a water pump in sequence from left to right, a second motor is fixed into the motor case, and an output shaft of the second motor sequentially penetrates through the bottom of the motor case and the top of the support base and extends into the support base. According to the steel plate drilling device convenient to use, through arrangement of a rotating rod and an automatic extending-and-contracting rod, when the rotating rod rotates, a rotating drum is driven to move downwards in a second sleeve through a thread on the surface of the rotating rod, thus the drilling device can stably press a steel plate and be stressed uniformly, the service life of the drilling device is prolonged, and work efficiency of people is improved.

Owner:上海都宇机械设备制造有限公司

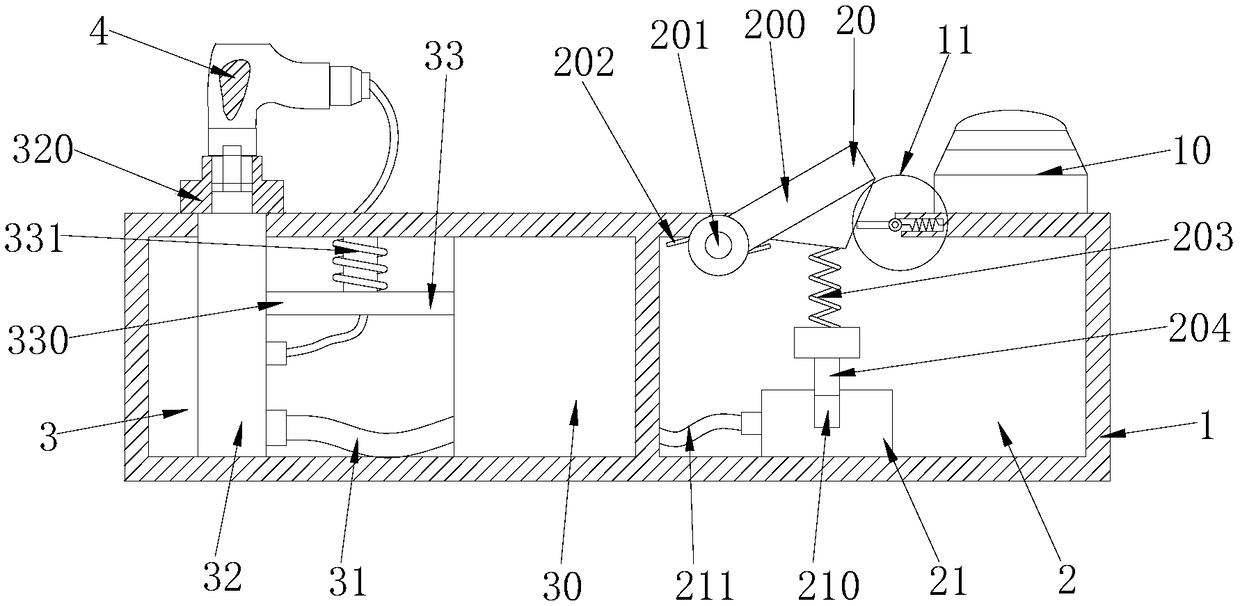

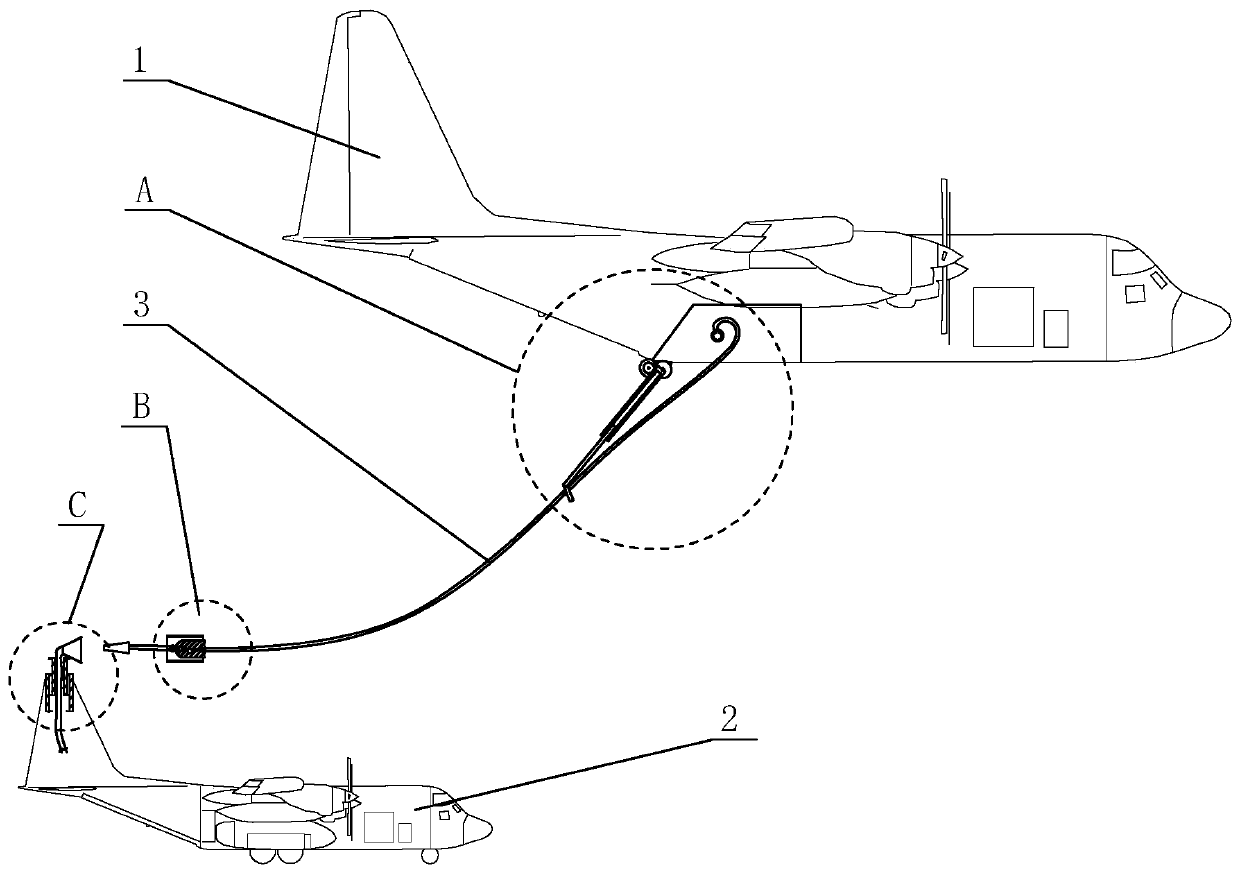

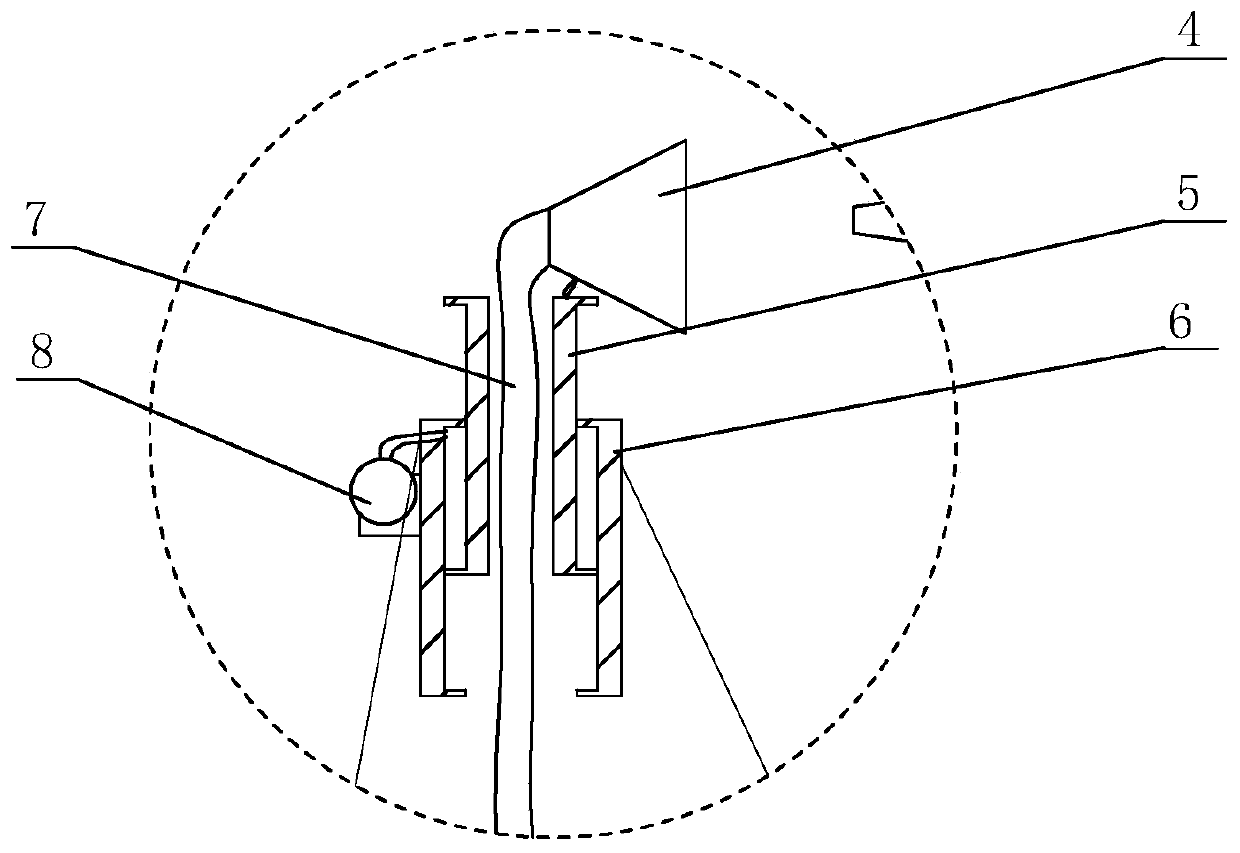

Air refueling device with high safety

ActiveCN110407151AIncrease vertical distancePress down smoothlyLiquid transferring devicesAviationAerospace

The invention relates to an air refueling device with high safety, and belongs to the field of aerospace. The device comprises a refueling pipe, a pipe putting device is arranged on the upper end of the refueling pipe, a refueling opening is formed in the tail end of the refueling pipe, an air flow adjusting device is arranged on the tail of the refueling pipe, and an oil receiving device is arranged on the upper portion of the tail wing of an oil receiving machine. The refueling opening is formed below the rear of the refueling machine, rear-end and scratch accidents are not prone to happening, a wing plate is arranged on the refueling pipe, the wing plate can be adjusted according to the airflow direction and the size, the refueling pipe is stable, meanwhile, the wing plate is adjusted,the end of the refueling pipe is close to the lower portion to the greatest extent, and the vertical distance between the refueling pipe and the refueling can be pulled open.

Owner:丁乃祥

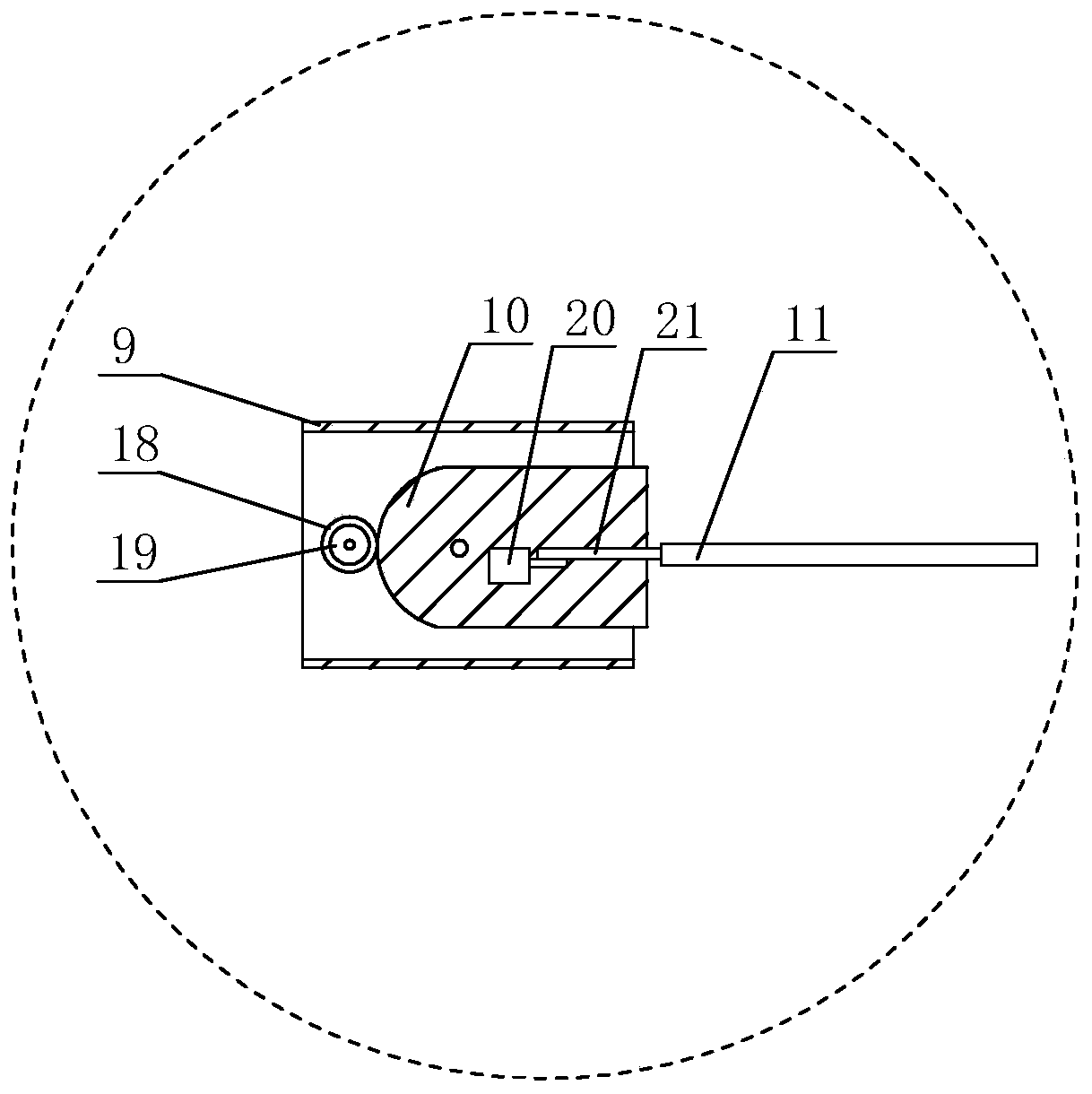

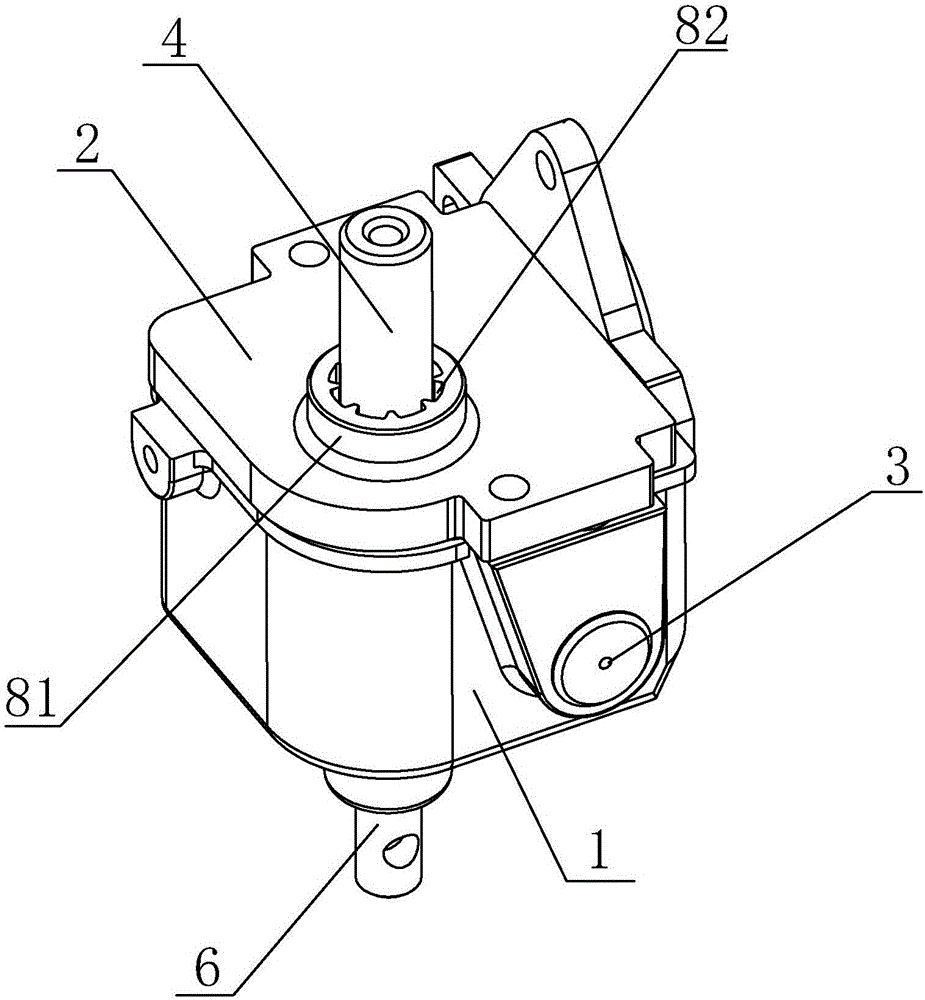

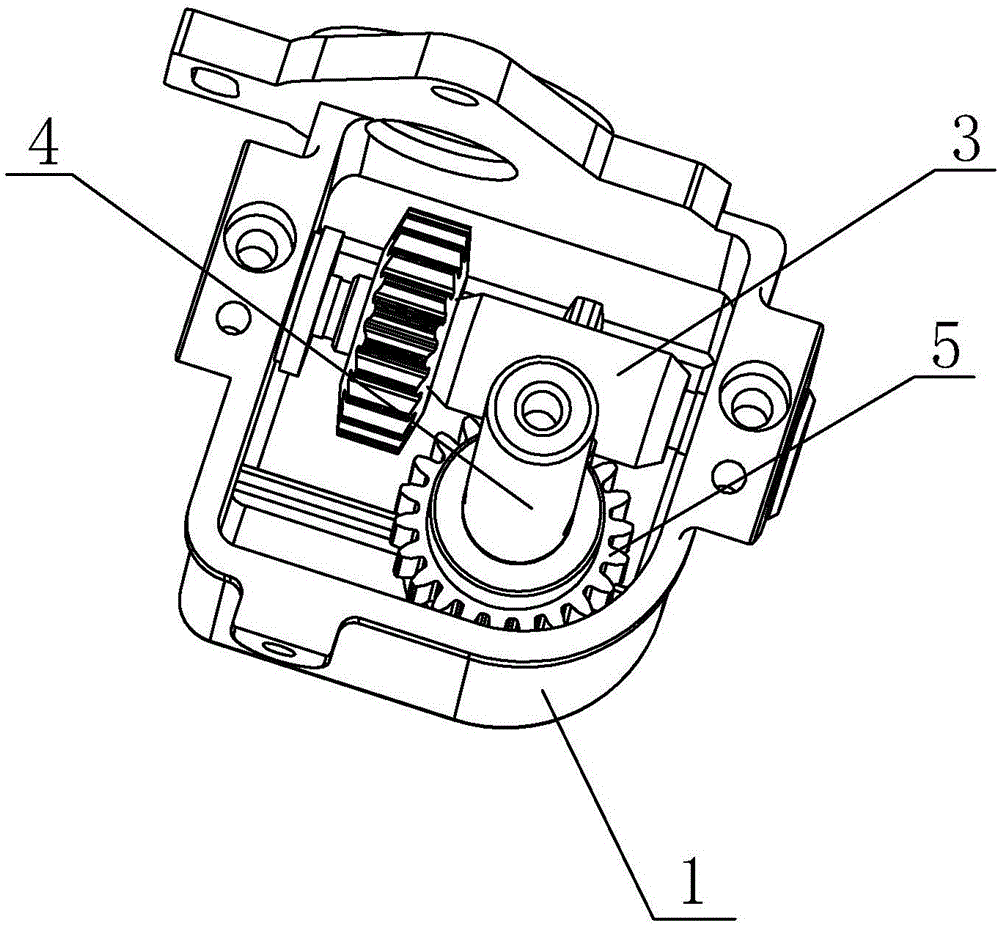

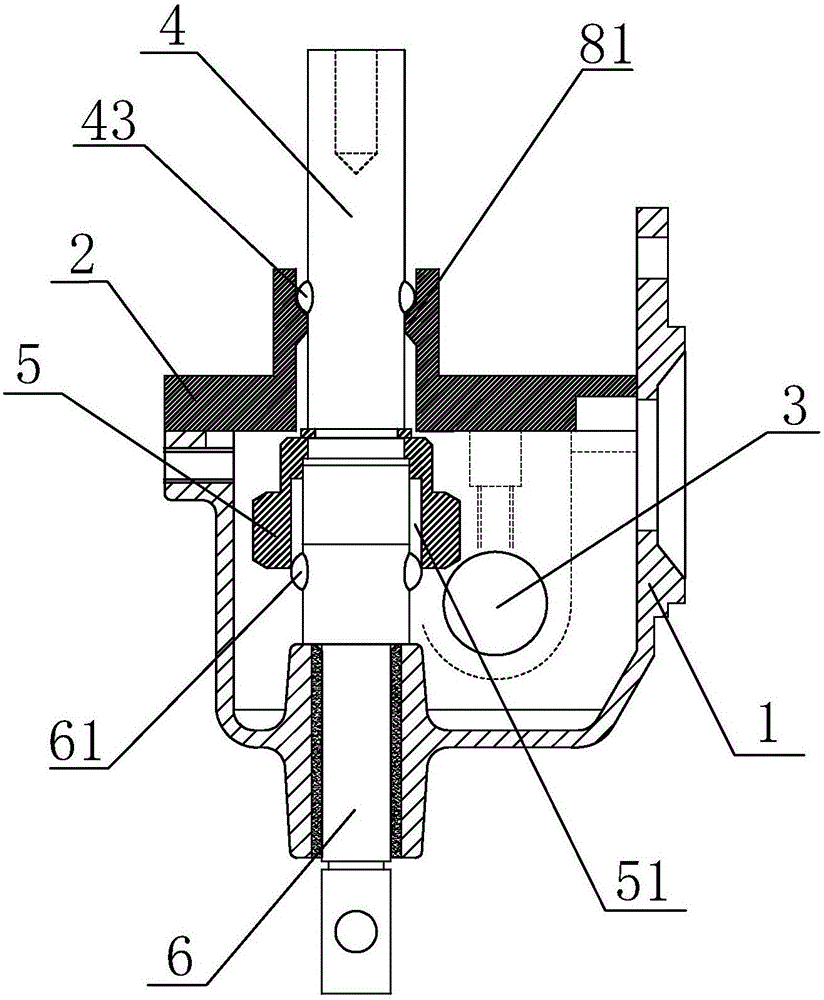

Gear box of fan

ActiveCN106838270AReinforcement of shaking head functionRealization of shaking head functionWind energy generationPump installationsElectric machineryStructural engineering

The invention discloses a gear box of a fan. The gear box comprises a gear box body and a box cover, wherein a motor shaft, a hand-pulling shaft, a worm wheel and a worm-wheel shaft are arranged in the gear box body; the hand-pulling shaft stretches to the exterior of the gear box body through a hand-pulling through hole; the worm-wheel shaft stretches to the exterior of the gear box body through a worm-wheel shaft through hole; the worm wheel is mutually meshed with the motor shaft together; a groove is arranged in the interior of the worm wheel; the worm-wheel shaft is provided with a connecting bulge; the worm wheel is arranged at the bottom of the hand-pulling shaft; the connecting bulge is arranged in the groove; when the hand-pulling shaft is pulled up, the worm wheel upwards moves along the connecting bulge to leave the motor shaft but not to disengage the connecting bulge. When the handle shaft is pulled up, the worm wheel can leave the motor shaft, but the hand-pulling shaft, the worm wheel and the worm-wheel shaft cannot be separated mutually; therefore, the condition that the groove and the connecting bulge generate deflection to cause that the hand-pulling shaft cannot be pressed down cannot occur when the handle shaft is pulled and pressed; therefore, an exception can be guaranteed not to occur to the head shaking function of the fan.

Owner:李力光

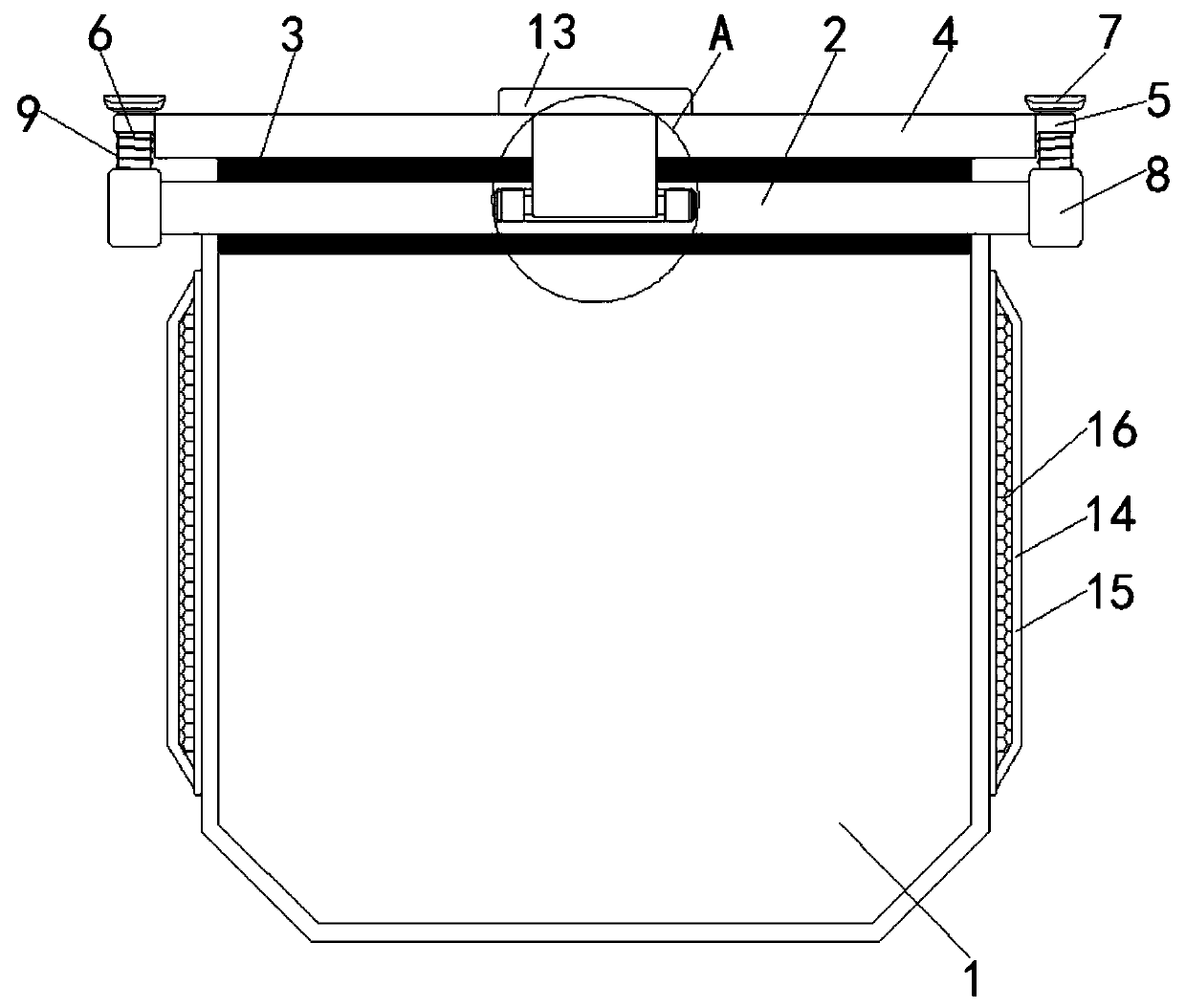

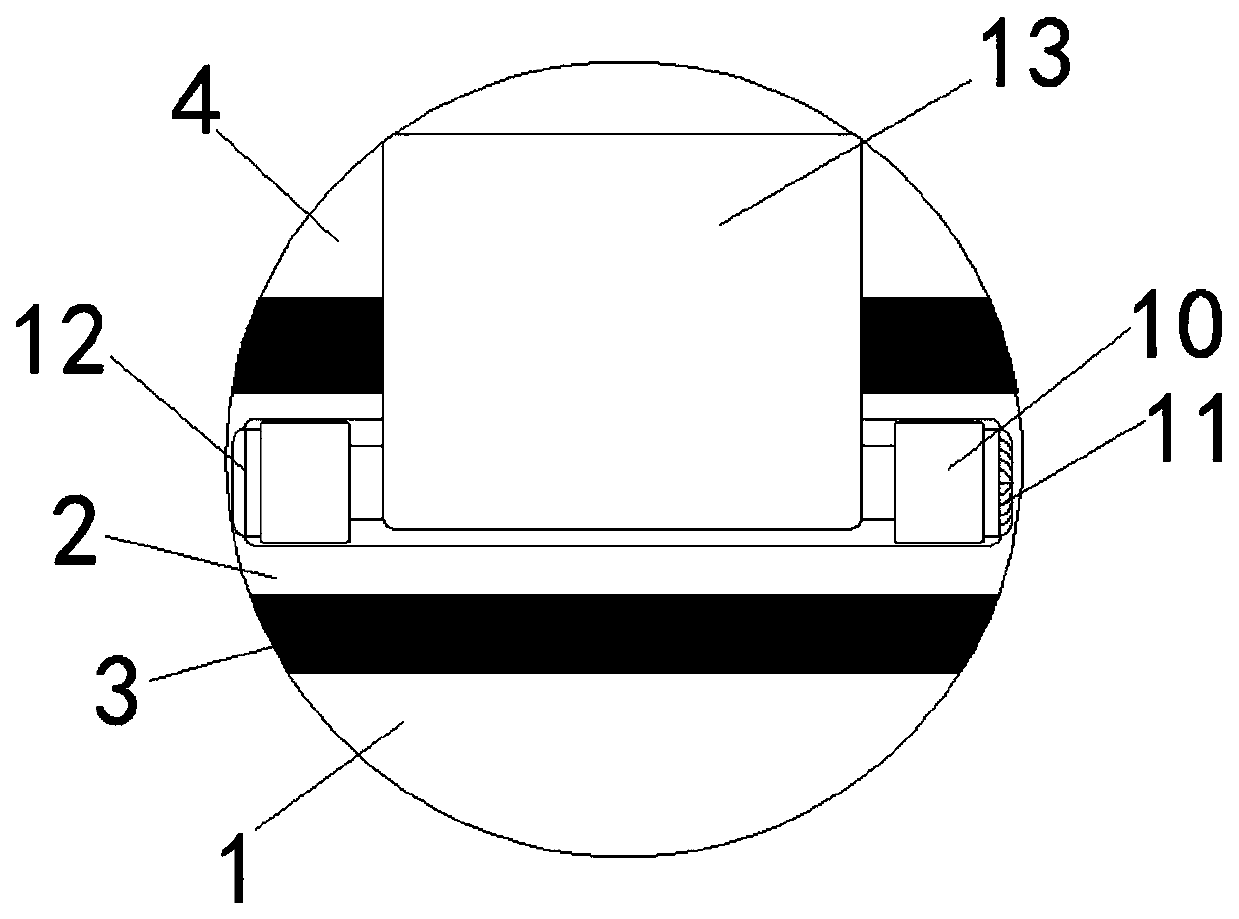

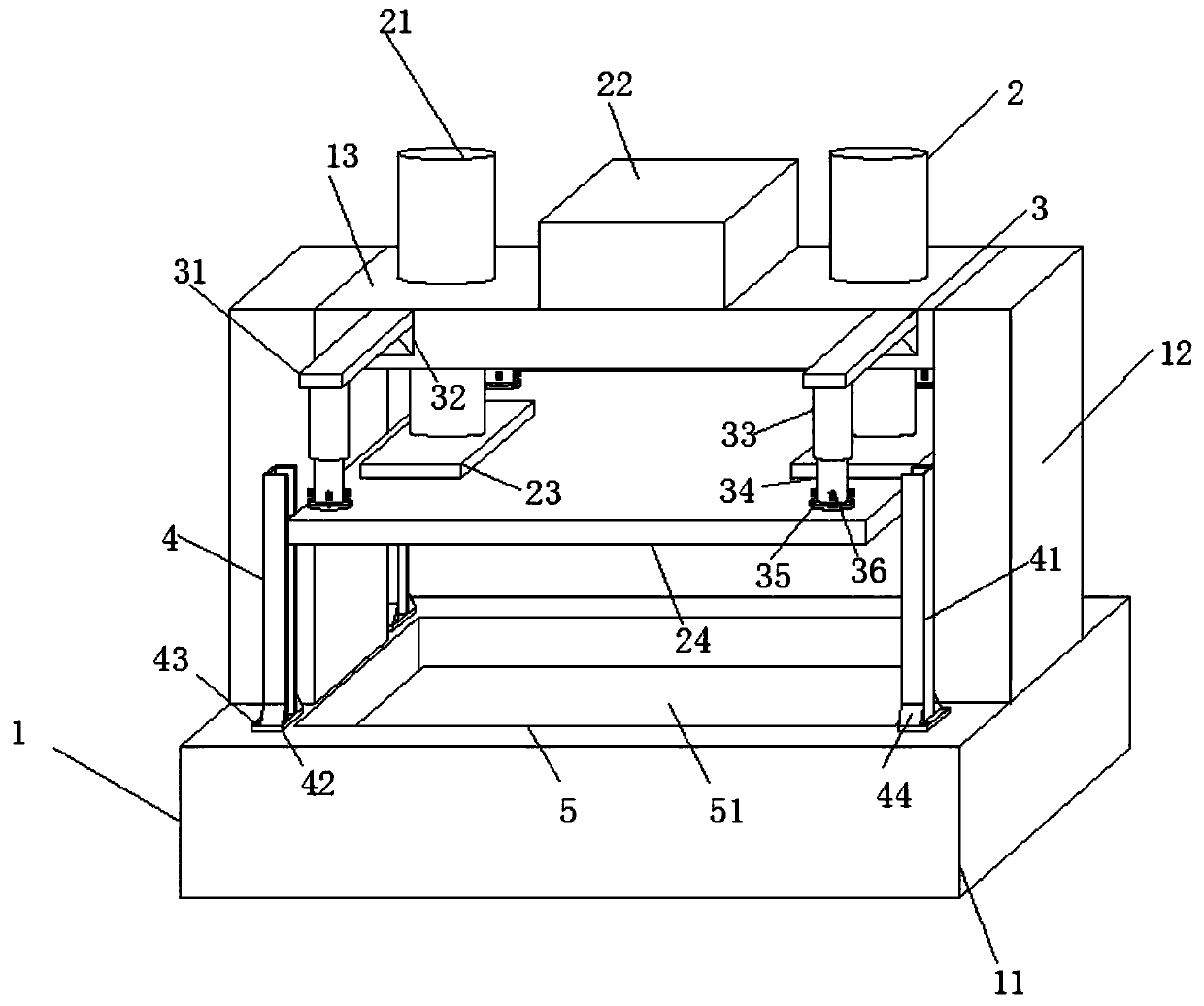

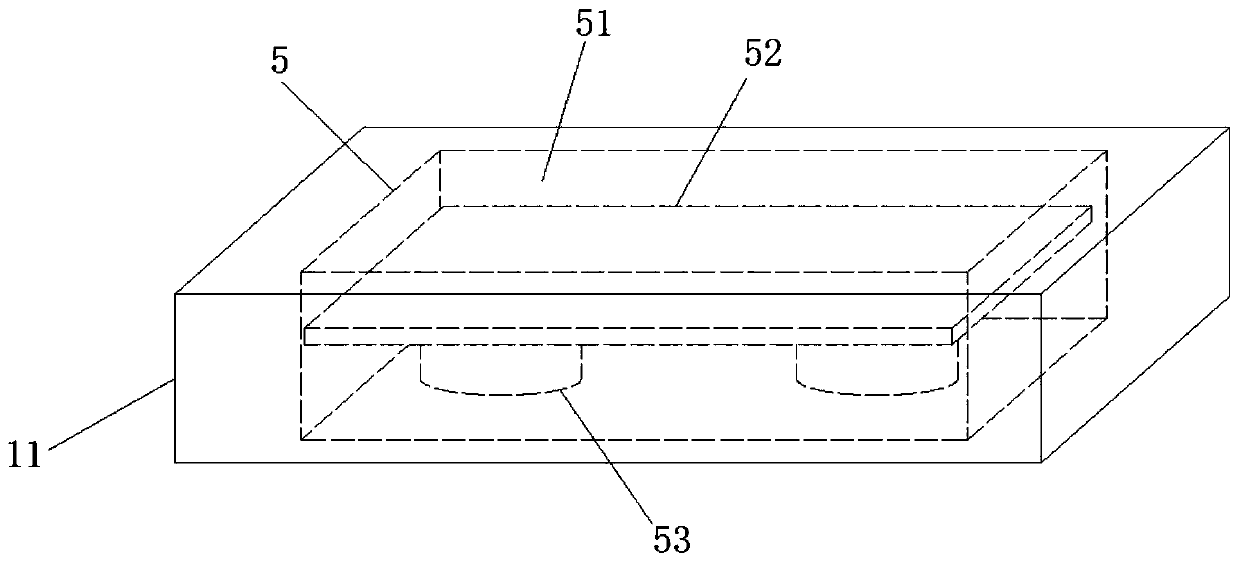

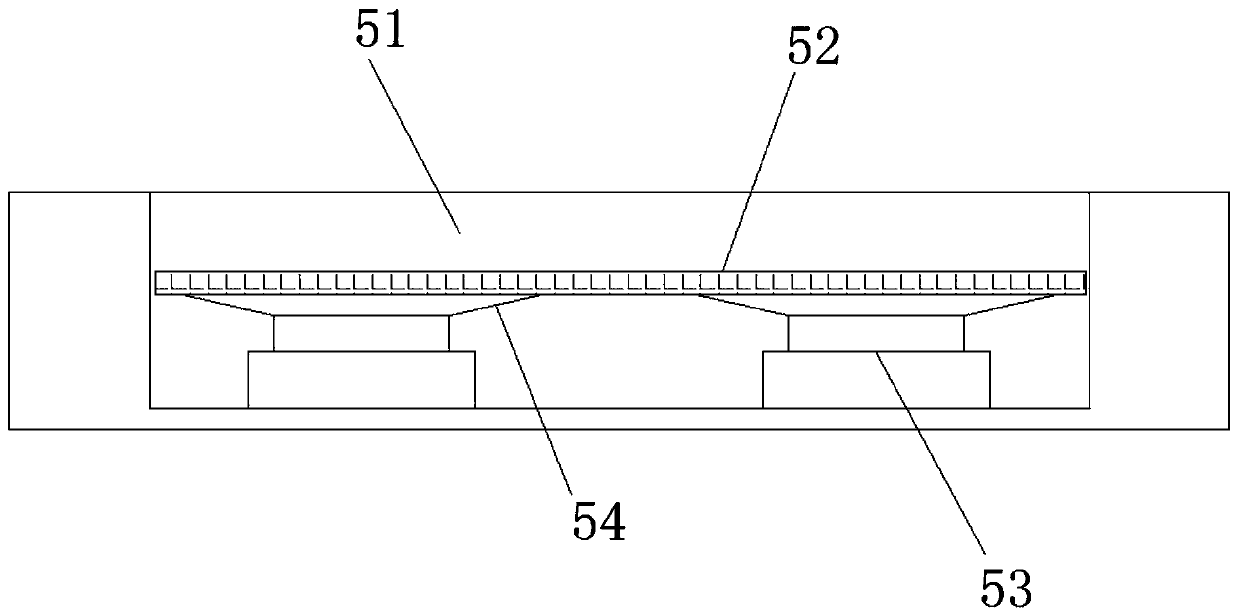

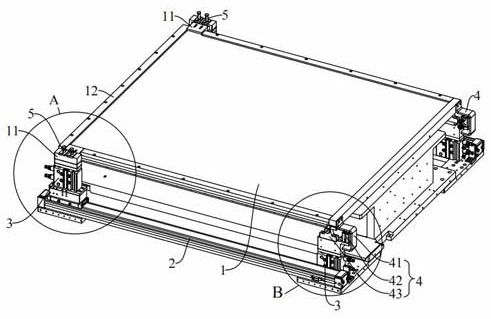

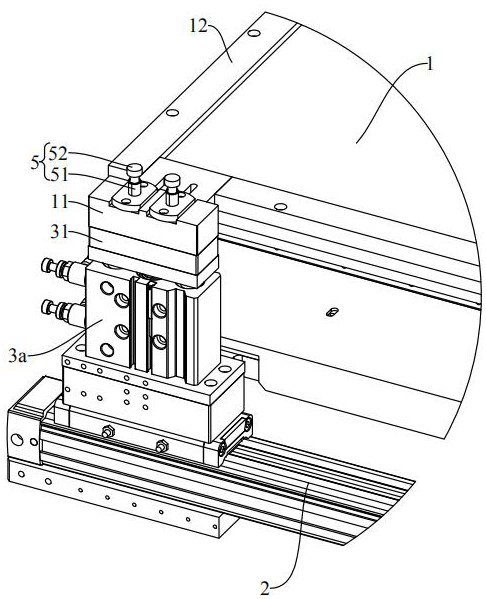

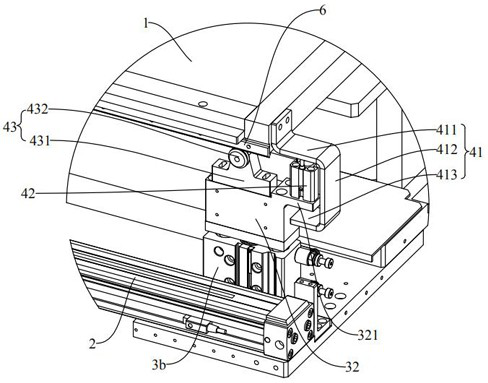

Pressing device and optical detection equipment

ActiveCN112098423AWon't shakeImprove detection accuracyOptically investigating flaws/contaminationStructural engineeringMechanical engineering

Owner:SUZHOU VEGA TECH CO LTD

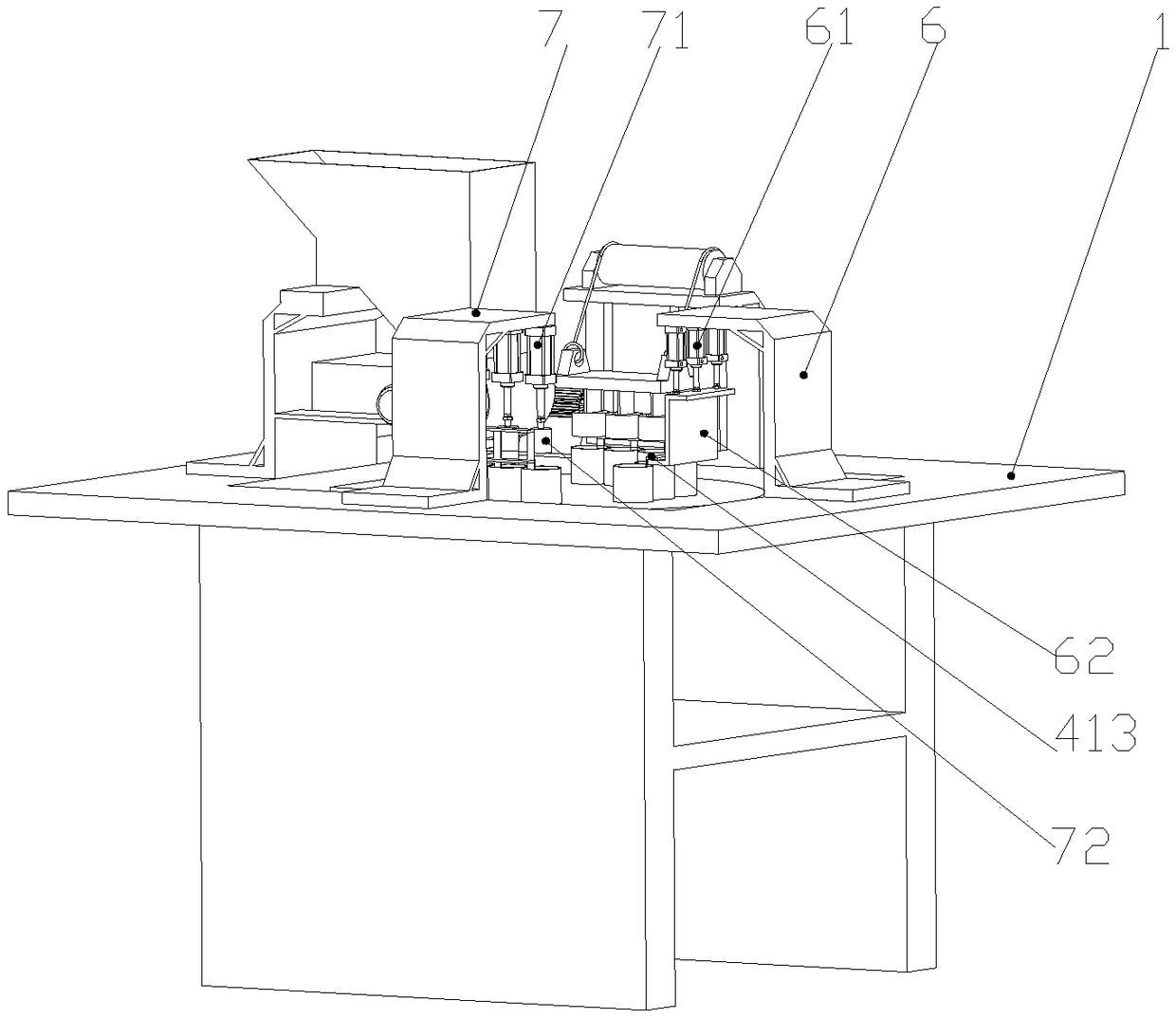

Tea cake pressing machine

The invention discloses a tea cake pressing machine. The machine comprises a working platform, a first supporting seat is arranged at the upper end of the working platform, a feeding hopper is arranged at the upper end of the first supporting seat, an annular sealing block is arranged at the lower end of the feeding hopper, a rotatable rotating roller is attached to the inside of the sealing block, a quantitative groove is formed in the rotating roller, a rotatable rotating disc is arranged in the working platform, a molding-die assembly is arranged on the rotating disc, a third rotating motoris arranged on the working platform, a fourth rotating shaft is arranged at the output end of the third rotating motor, a pull rope rolls around the fourth rotating shaft, a pull plate is arranged atthe lower end of the pull rope, a hook is arranged at the lower end of the pull plate, and a molding die hangs on the hook; tea leaves in the feeding hopper fall into the quantitative groove, the rotating roller continuously rotates, the steam in the steam chamber realizes the softening treatment on the tea leaves in the quantitative groove, the rotating roller continuously rotates, the softenedtea leaves in the quantitative groove fall into a molding-die cavity, when the molding-die cavity with the softened tea leaves on the rotating disc rotates to the lower part of the molding die on thehook, the molding die carries out cake pressing on the softened tea leaves in the molding die cavity.

Owner:THE MOUNT HOLYOKE TANG QING MING TEA

Multifunctional network cable stripping device

PendingCN113809693APress down smoothlyExtended service lifeApparatus for removing/armouring cablesStructural engineeringRegistered jack

The invention relates to the technical field of network installation construction auxiliary equipment, in particular to a multifunctional network cable stripping device, which comprises an upper handle, a lower handle, a hinge shaft, a first cutter blade, a second cutter blade, a cable arranging module, a third cutter blade, a fourth cutter blade, an upper passing stopping table and a lower passing stopping table, wherein the left portions of the upper handle and the lower handle are hinged together through the hinge shaft. According to the invention, the device is reasonable and compact in structure; the first cutter blade and the network cable groove are used for stripping the network cable sheath, and the length of the cable core trimmed by the cable arranging module and the second cutter blade is consistent and tidy and is matched with the length of the cable core mounting position in a crystal head, so that the cable core can be firmly pressed by the crystal head, and poor contact is avoided; the network cable sheath positioned in the crystal head can be clamped by a bayonet in the crystal head, so that the network cable sheath can bear most tensile force, the service life of the network cable is prolonged, and material waste is avoided; and the third cutter blade and the fourth cutter blade are used for stripping the sheath of a telephone line, so that the situation that the telephone line needs to be processed during installation is facilitated.

Owner:国网伊犁伊河供电有限责任公司 +1

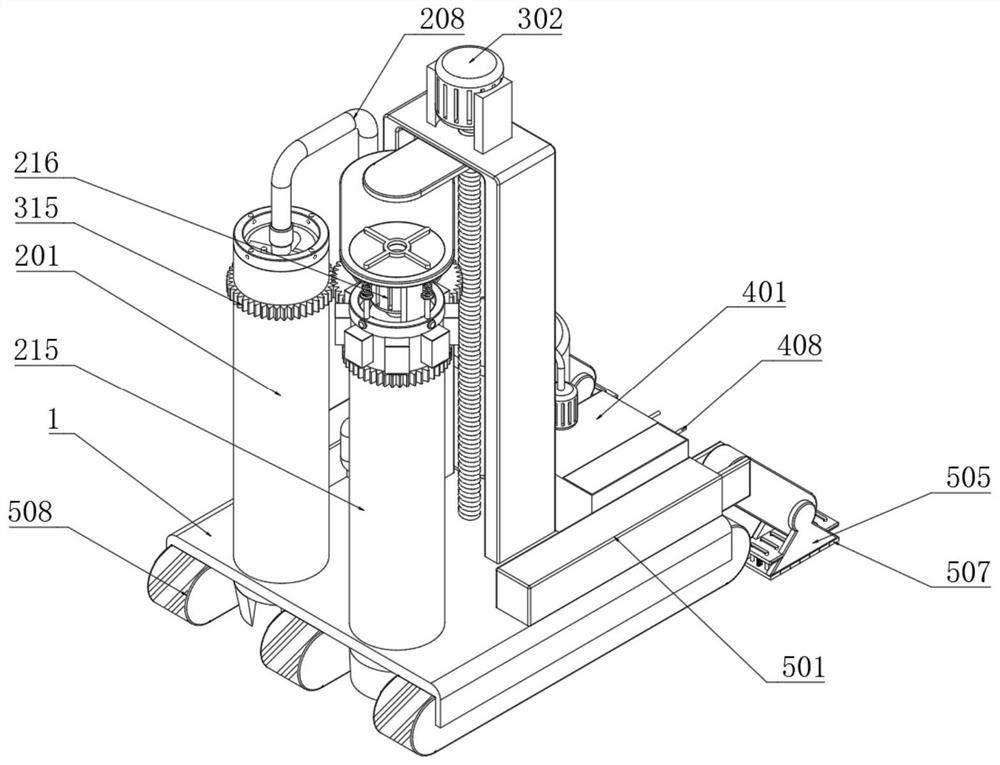

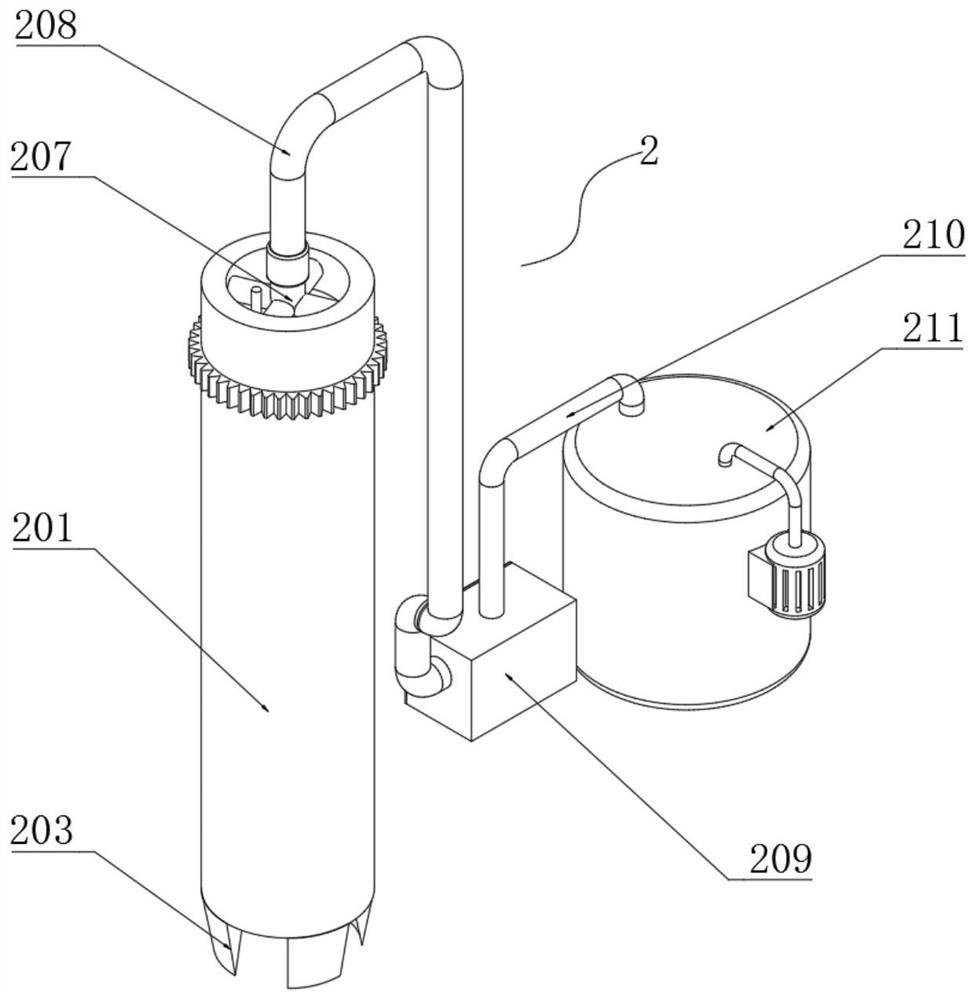

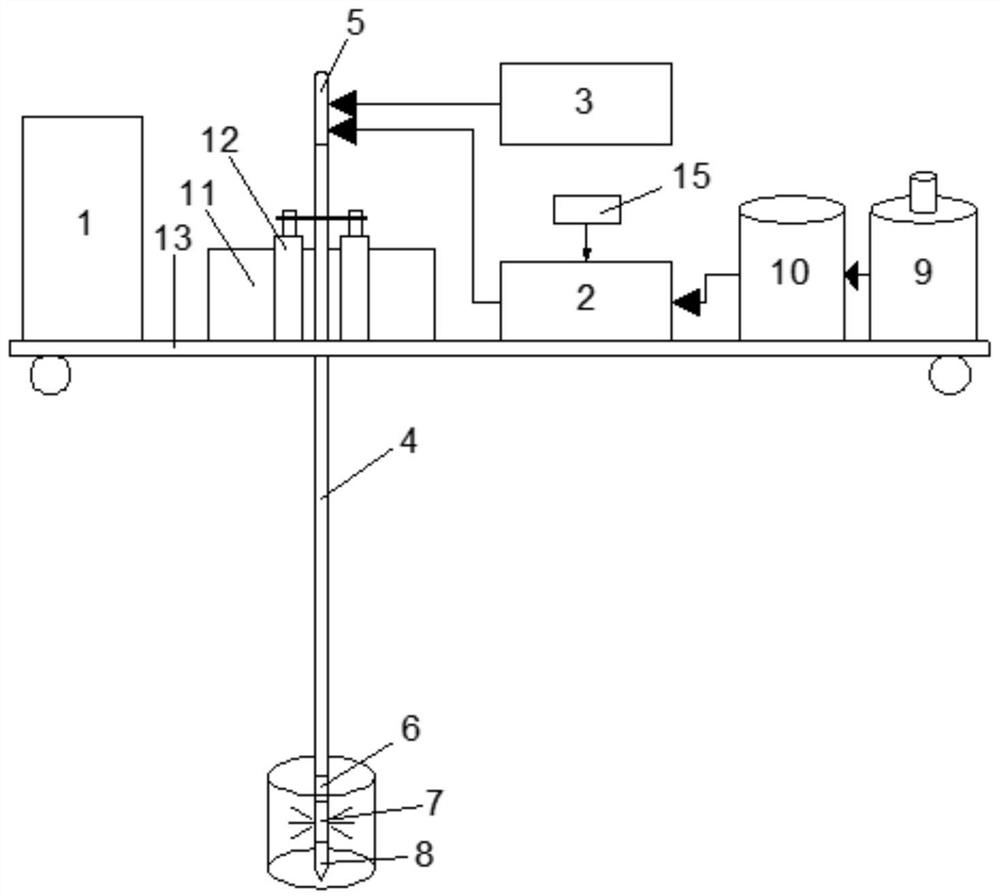

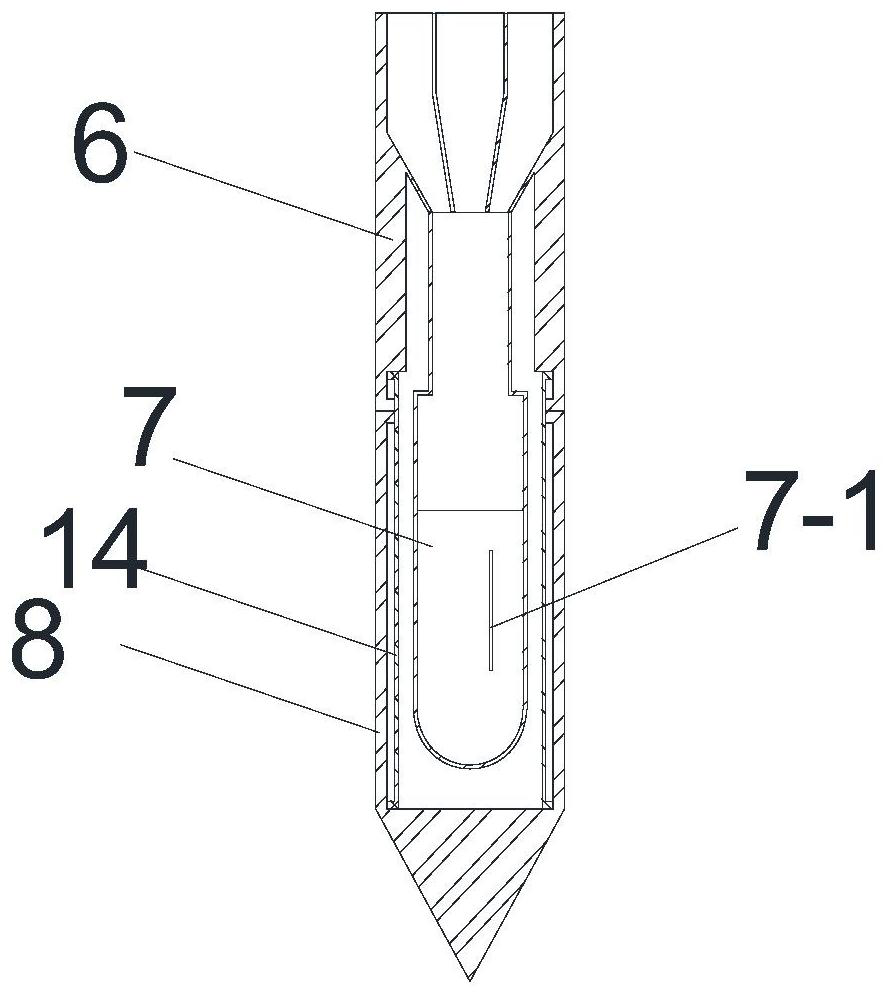

Double-fluid injection integrated system for soil groundwater remediation

PendingCN113290034AReduce labor intensityEasy to liftContaminated soil reclamationGroundwater remediationEnvironmental engineering

The invention discloses a double-fluid injection integrated system for soil groundwater remediation. The double-fluid injection integrated system comprises an injection unit, a dispensing unit and an auxiliary unit, wherein the injection unit comprises an injection pump, an air compressor, an injection rod, an injection ejector rod, a connecting cavity, an injection head, a nozzle shell and an injection control mechanism; the dispensing unit comprises a medicine dispensing groove and a medicine storage groove; the auxiliary unit comprises an electric control cabinet, a rod piece box, a pressing device and a skid-mounted platform; and the injection unit, the dispensing unit and the auxiliary unit are all integrated on the skid-mounted platform. According to the integrated system provided by the invention, in-situ injection remediation of soil and groundwater can be completed, double-fluid simultaneous injection of a liquid medicament and gas is achieved, and the dispersion, diffusion and infiltration capacities of the medicament and the mixing capacity of the medicament and underground pollutants are enhanced, so that the remediation efficiency is improved, and the remediation effect is improved.

Owner:SHANGHAI GREENMENT ENVIRONMENTAL TECH CO L

Self-adaptive press-down device

PendingCN111761640AGuaranteed stabilityImprove stabilityMetal working apparatusStructural engineeringMachine

Owner:石家庄市汉普食品机械有限公司

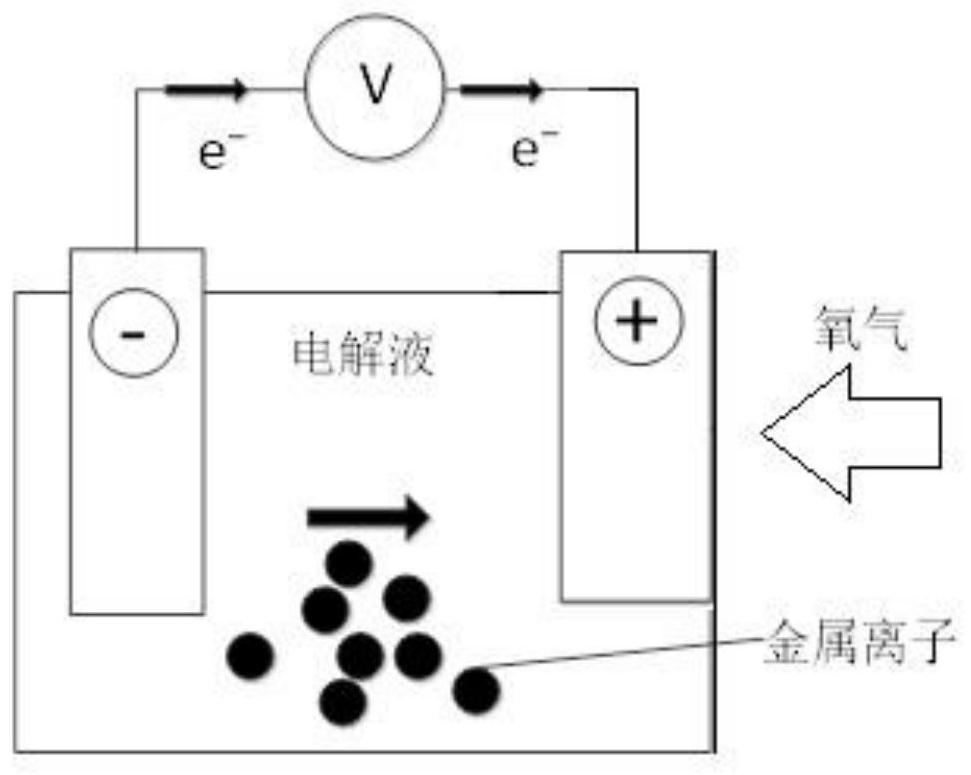

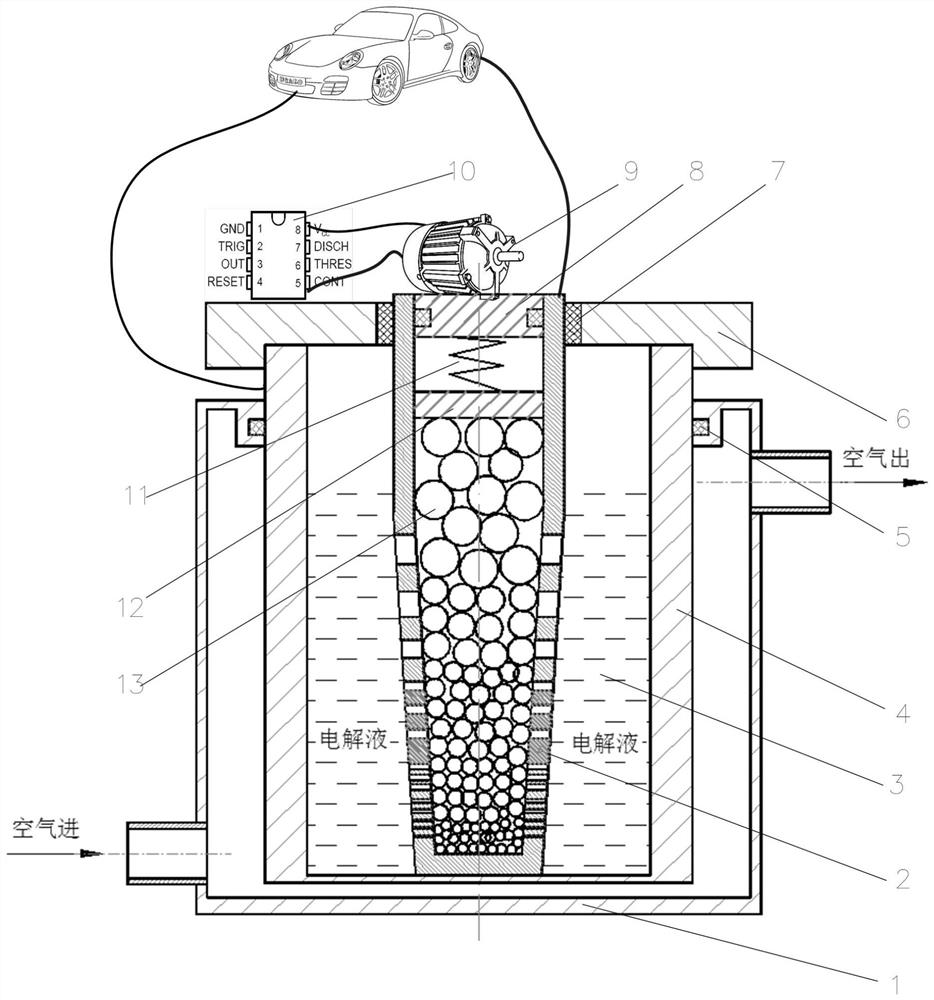

A power metal-air battery

ActiveCN109103550BAdequate responseEvenly distributedFuel and primary cellsElectrical batteryAir cathode

The invention discloses a power metal-air battery. The air battery includes: an air cathode, a metal cylinder, and a metal ball; the air cathode is cylindrical and is sheathed on the periphery of the metal cylinder; an electrolyte is filled between the air cathode and the metal cylinder; the metal ball is filled in the metal cylinder; The side wall of the cylinder is provided with a through hole whose diameter gradually increases from bottom to top; the maximum diameter of the through hole is smaller than the maximum diameter of the metal ball; the electrolyte passes through the through hole and contacts the metal ball; the diameter of the inner surface of the metal cylinder increases from the bottom to the top. increasing sequentially from top to bottom. The air battery of the invention does not need to replace the anode, can fully react the metal oxide, and saves the use cost of the battery.

Owner:CNUS技术公司

A shared electric vehicle ground charging equipment

ActiveCN109017385BPress down smoothlyAvoid enteringCharging stationsElectric vehicle charging technologyParking areaParking space

Owner:泰州市扬帆车件有限公司

Contact-finger installing tool for high-voltage isolating switch

InactiveCN102074396BDestruction will notEasy to operateElectric switchesEngineeringMechanical engineering

The invention discloses a contact-finger installing tool for a high-voltage isolating switch, wherein a transverse passage is arranged in the lower part of an installing part, a connecting rod is arranged in the transverse passage, a hook is arranged at the front end of the connecting rod, the hook extends out of the front end of the installing part, the rear end of the connecting rod is connected with a hand-pressing handle through an inclined rod, a shaft-pin passage which is vertical to the transverse passage is arranged at the front end of the installing part, a pin outlet is arranged at the lower part at the front end of the installing part, the pin outlet is communicated with the shaft-pin passage, the pin outlet is communicated with the transverse passage, an open slot which can be used for containing the end part of a contact-finger stretched spring is arranged at the front end at the lower part of the installing part, the upper end of the installing part is in shaft connection with a pressure plate, a second reset spring is arranged between the pressure plate and the installing part, a column body for downwards pushing and pressing a shaft pin is arranged at the front end of the pressure plate, and a pushing and pressing mechanism is arranged between the pressure plate and the hand-pressing handle. The invention has the advantages that when the installing tool is operated, the hand-pressing handle only needs to be pressed to pull out the contact-finger stretched spring, meanwhile, the shaft pin is nailed into the end hole of the contact-finger stretched spring, and the installing tool is quite convenient to operate.

Owner:NINGBO ELECTRIC POWER BUREA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com