Double-shaft shredding machine with material pressing device

The technology of a dual-shaft shredder and a pressing device is applied in the field of shredders, which can solve the problems of unstable force application, difficult cutting and shredding, low convenience, etc., so as to avoid excessive expansion resistance and avoid stuck. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below, in conjunction with accompanying drawing and specific embodiment, the present invention is described further:

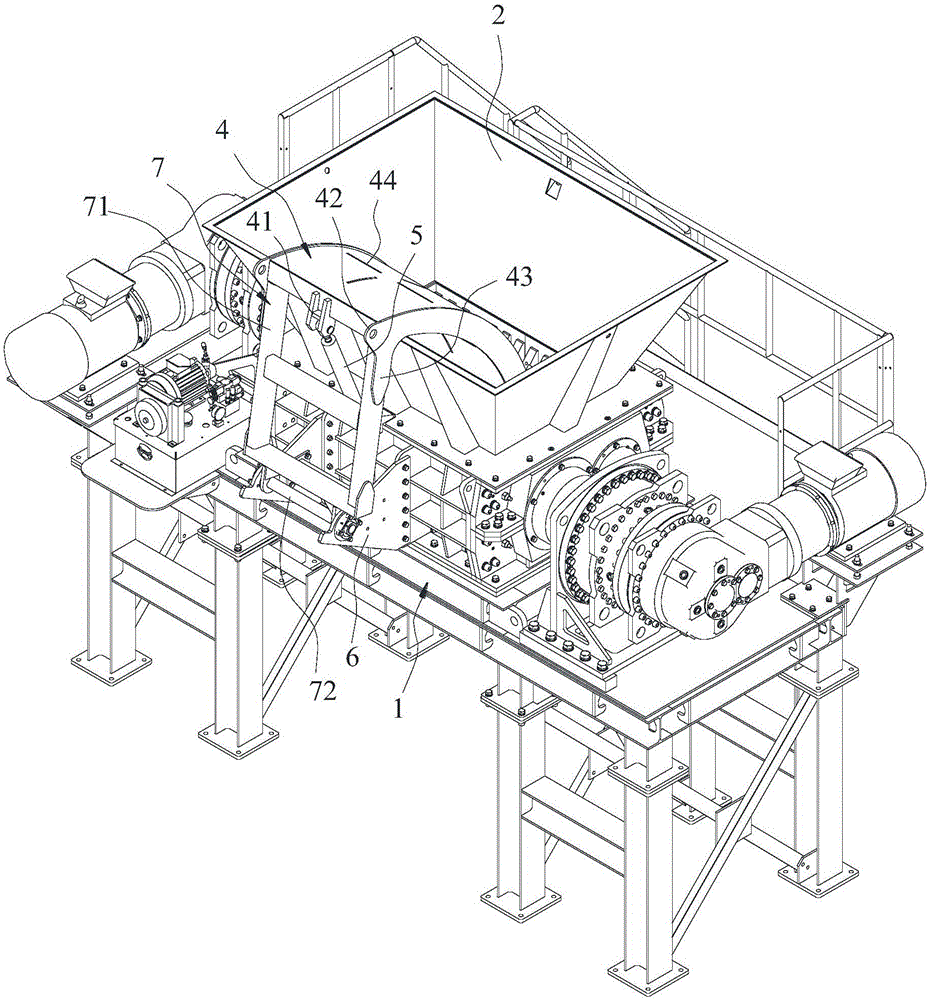

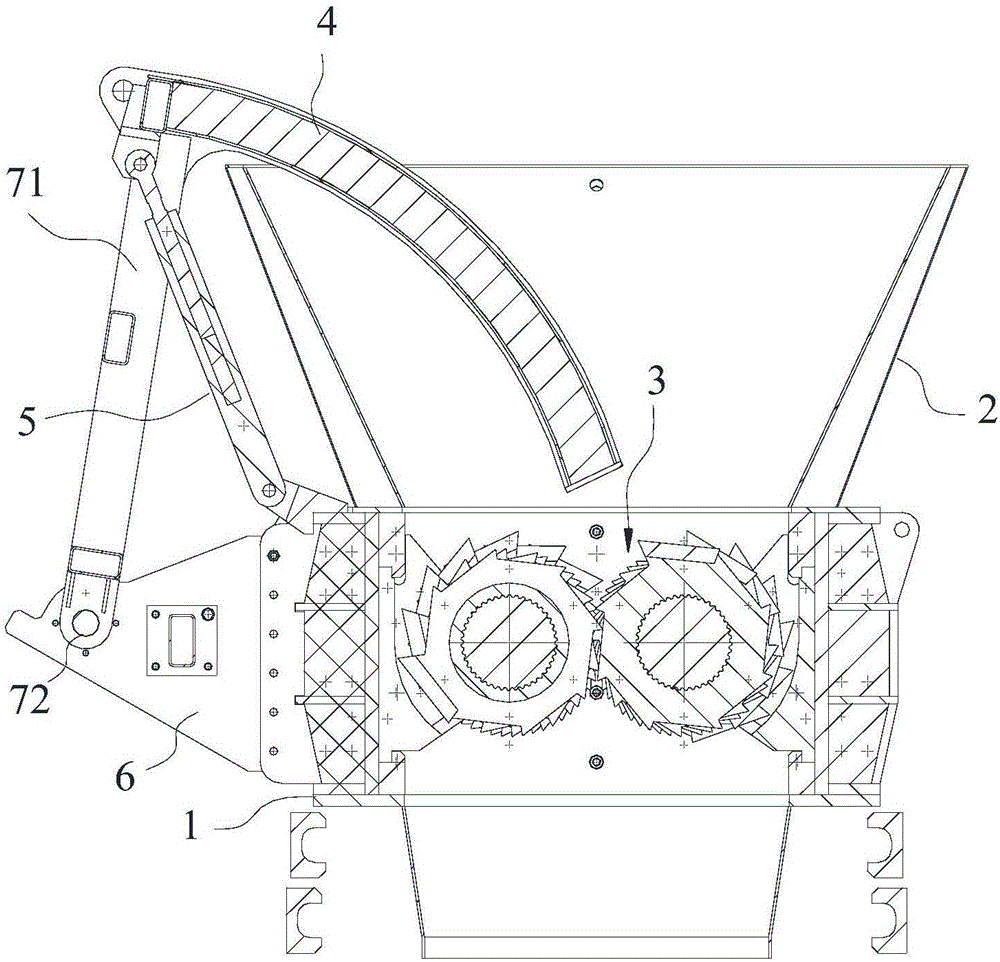

[0017] Such as Figure 1-2 The shown double-shaft shredder with a pressing device includes a frame 1, a hopper 2, a cutter roller group 3, a pressing plate 4, a hydraulic cylinder 5, a support frame 6 and a connecting frame 7, and the cutter roller group 3 is installed on The frame 1 and the hopper 2 are fixed on the frame 1, and the discharge opening of the hopper 2 is vertically opposite to the cutter roller group 3, and one end of the pressing plate 4 extends into the hopper 2 toward the cutter roller group 3, and the other end of the pressing plate 4 One end is hinged with the piston rod of the hydraulic cylinder 5 and forms the first hinged axis, one end of the cylinder body of the hydraulic cylinder 5 away from the binder plate 4 is hinged with the frame 1, and one end of the connecting frame 7 is hinged with the other end of the binder plate 4 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com