Parking lock

A parking lock and lock lever technology, applied in the field of parking locks, can solve the problems of drive unit damage, inconvenient use, complicated operation, etc., and achieve the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

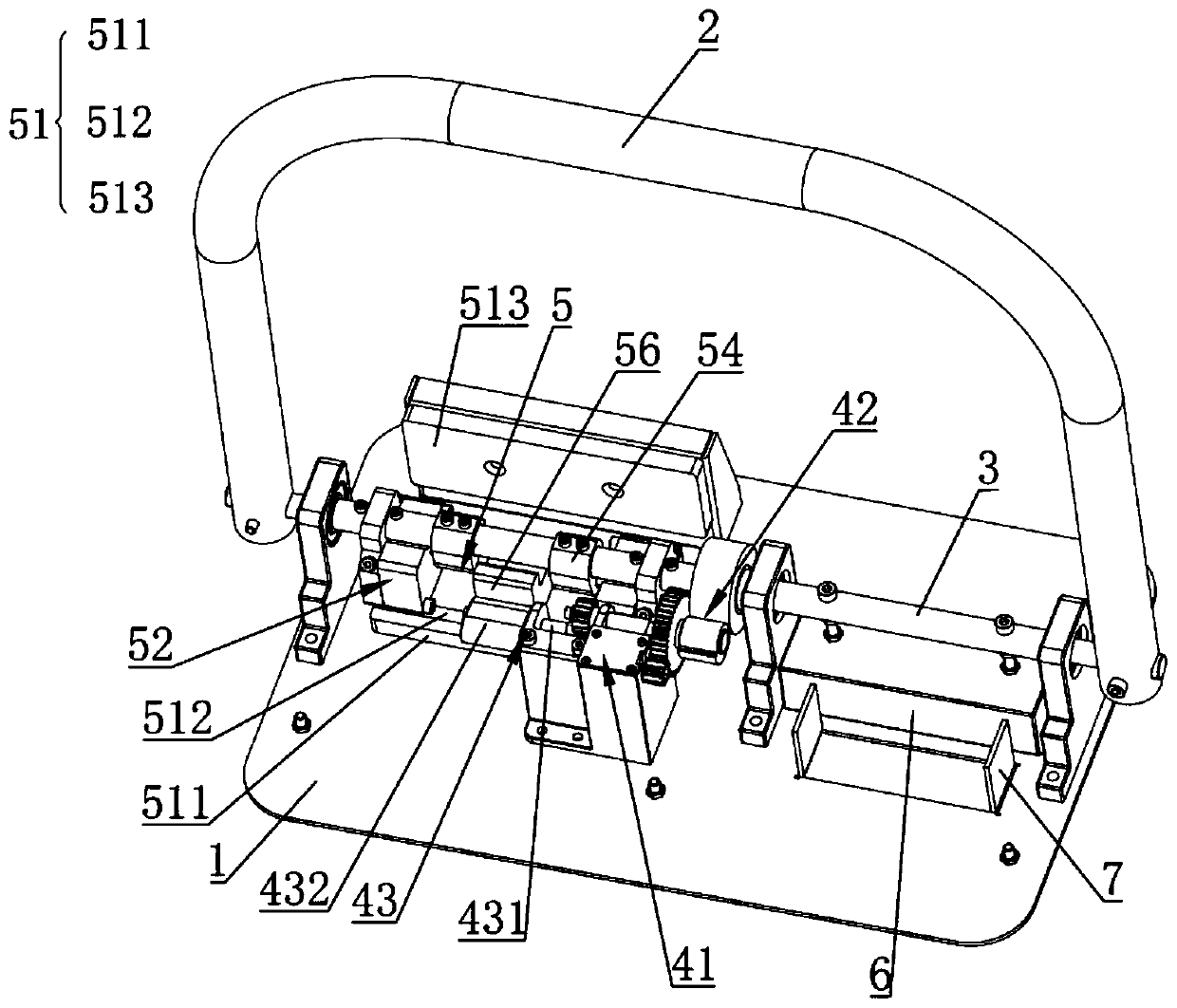

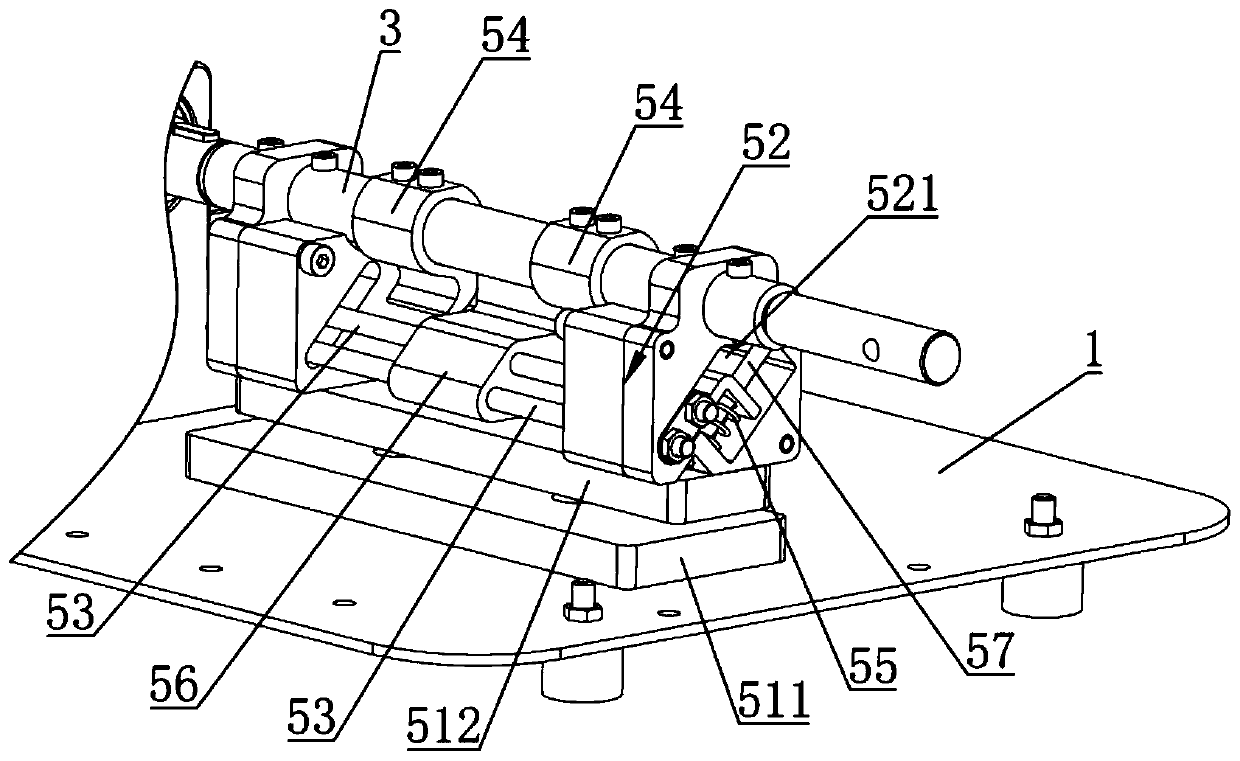

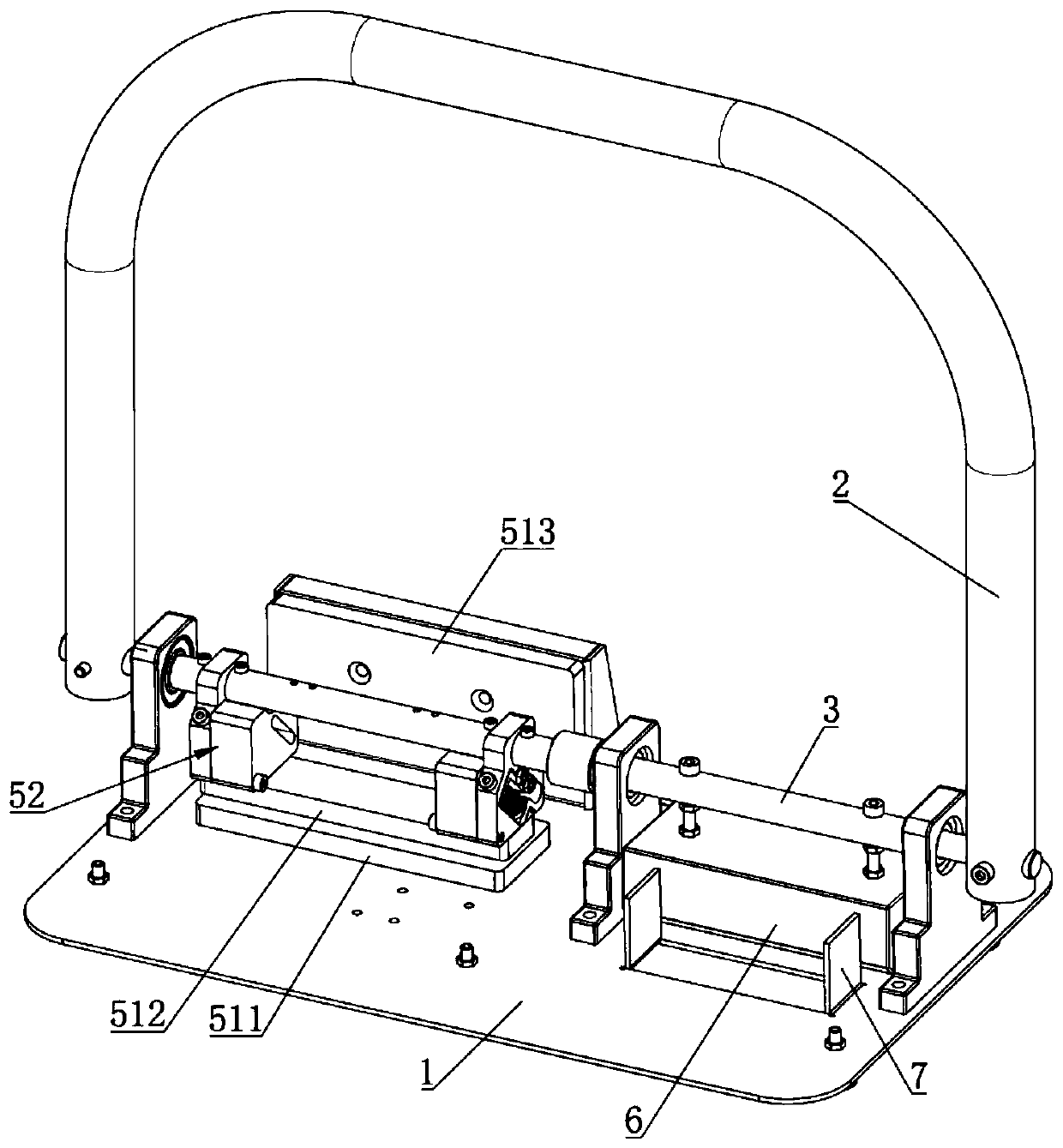

[0036] refer to Figure 1~5 , the present embodiment provides a parking lock, comprising a base 1, a blocking arm 2, a rotating shaft 3, a driving mechanism 4 and a locking mechanism 5 arranged on the base 1, the rotating shaft 3 is rotatably erected on the base 1, the blocking arm 2 and the The rotating shaft 3 is fixedly connected. The driving mechanism 4 includes a driving unit 41 and a clutch assembly 42. The driving unit 41 is connected to the rotating shaft 3 through the clutch assembly 42. The locking mechanism 5 includes a limiting assembly 51, a limiting member 52 and a locking rod 53. The position member 52 is connected to the rotating shaft 3 in rotation, the limit assembly 51 is respectively connected to the limit member 52 and the base 1, the rotating shaft 3 is fixedly connected to the stop member 54, and the locking rod 53 is installed on the limit member 52 and arranged on the rotation path of the stop member 54 In the interference position, the driving unit 41...

Embodiment 2

[0057] refer to Figure 6 ~ Figure 8 The difference between this embodiment and Embodiment 1 is that the locking lever 53 includes a link portion 531 and an interference portion 532, one end of the link portion 531 is connected to the interference portion 532, and the other end is rotatably connected to the stopper 52, and the interference portion 532 Set at the interference position of the rotation path of the stopper 54, the drive unit 41 is connected with the link part 531. In the locked state, the lock lever 53 is set at the interference position of the rotation path of the stopper 54, so that the stopper arm 2 can , the stop arm 2 drives the rotating shaft 3 to rotate, and the stop member 54 drives the lock bar 53 to rotate. Since the lock bar 53 is installed on the limiter 52, its limiter 52 and the limiter assembly 51 are connected with the base 1 in sequence, so that the limiter 52 The activity is limited by the limit assembly 51, so as to achieve the effect of limitin...

Embodiment 3

[0061] refer to Figure 9 ~ Figure 14 The difference between this embodiment and Embodiment 1 is that the eccentric assembly 43 includes a transmission shaft 431, an eccentric wheel 432 and an eccentric rod 433, the transmission shaft 431 is coaxially arranged with the eccentric rod 433, and the eccentric rod 433 is connected to the eccentric wheel 432 and connected to the eccentric The wheel 432 is set eccentrically, the eccentric rod 433 is in contact with the lock rod 53, the transmission shaft 431 is connected to the drive unit 41, and the rotating shaft 3 drives the eccentric wheel 432 to rotate, thereby driving the eccentric rod 433 to rotate, and the eccentric rod 433 moves the guide block 56 to drive The locking bar 53 moves so that the locking bar 53 avoids the interference position where the blocking member 54 rotates.

[0062] In addition, the transmission part 424 is meshed with the driven wheel 421, the transmission efficiency of the meshing transmission is high, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com