Gear box of fan

A technology of fan gear box and gear box, applied in the direction of belt/chain/gear, non-variable-capacity pump, transmission parts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

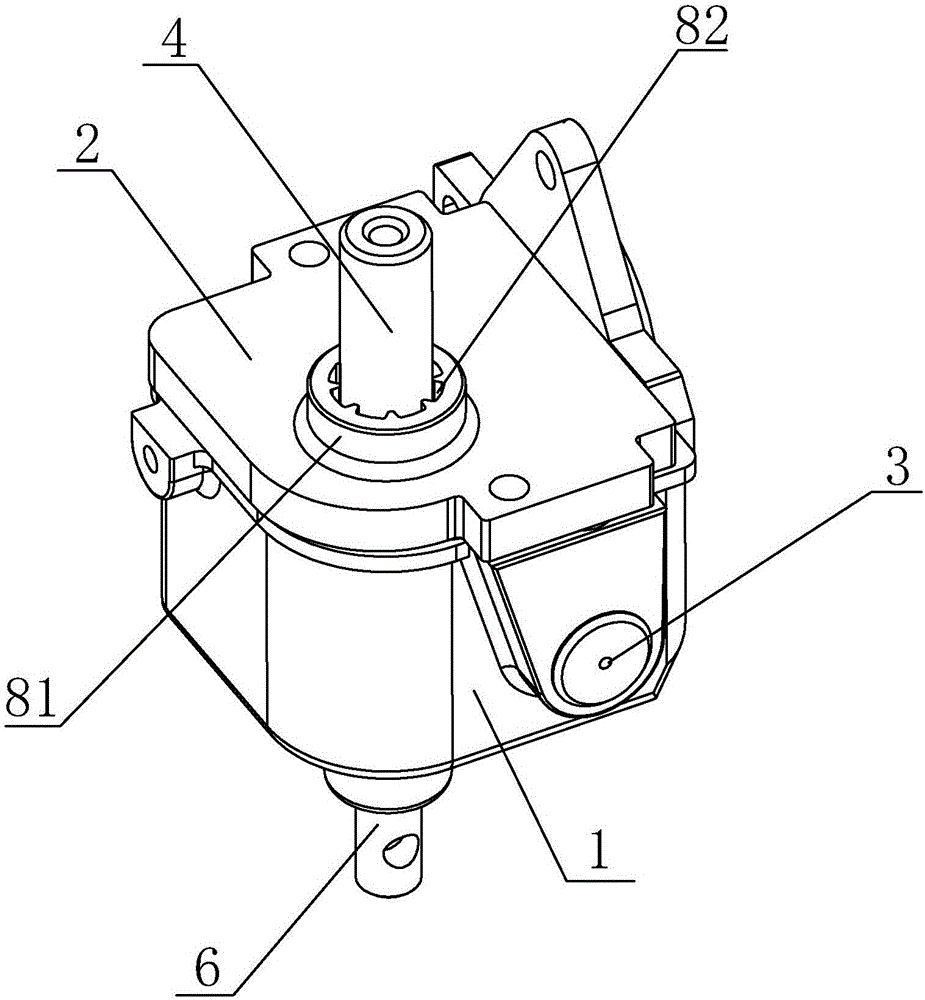

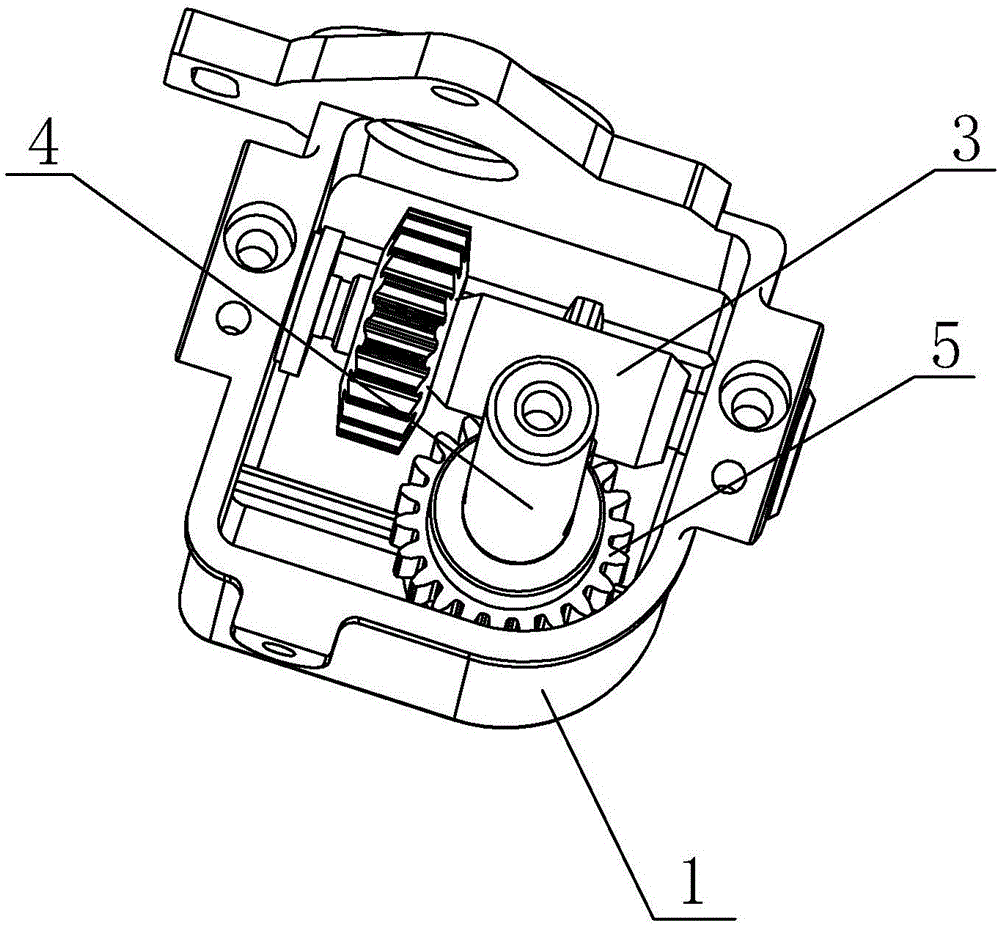

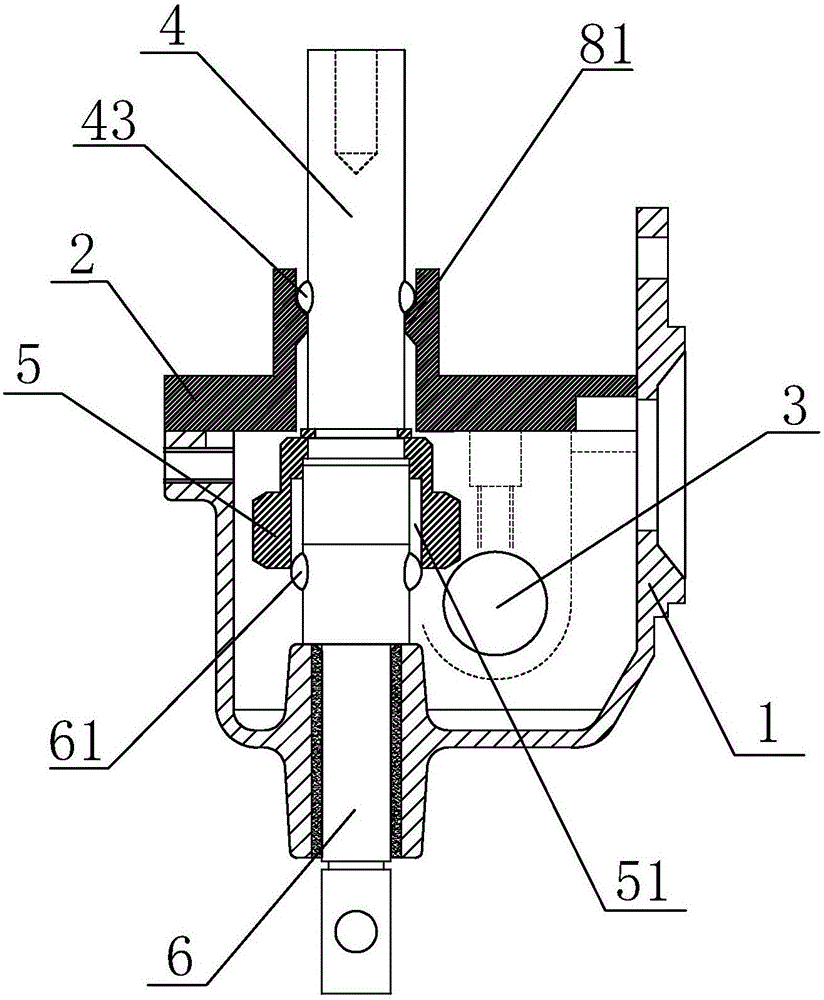

[0022] refer to Figure 1-Figure 8 , a fan gearbox, including a gearbox body 1 and a case cover 2, the gearbox body 1 is provided with a motor shaft 3 inserted into the gearbox body 1 by a fan motor, and a handle for shaking the fan Shaft 4, worm gear 5 for transmission and worm gear shaft 6 for driving the fan to shake the head. The puller shaft 4 extends to the outside of the gearbox body 1 through the puller through hole arranged in the box cover 2. The worm gear shaft 6 extends to the outside of the gearbox body 1 through the through hole of the worm shaft in the gearbox body 1, the worm wheel 5 and the motor shaft 3 are meshed together, the inside of the worm wheel 5 is provided with a groove 51, and the worm wheel shaft 6 is provided There is a connecting protrusion 61 that cooperates with the groove 51. The worm wheel 5 is arranged on the bottom of the handle shaft 4, and the connecting protrusion 61 is arranged in the groove 51. When the handle shaft 4 is pulled out, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com