Semi-automatic tea wafer machine and tea wafering process

A semi-automatic, cake-pressing machine technology, applied in the direction of tea processing before extraction, can solve the problems of difficult operation, high labor intensity, difficult to control hygiene, low molding rate, etc., and achieve good tea-pressing effect, uniform pressure, and high molding rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

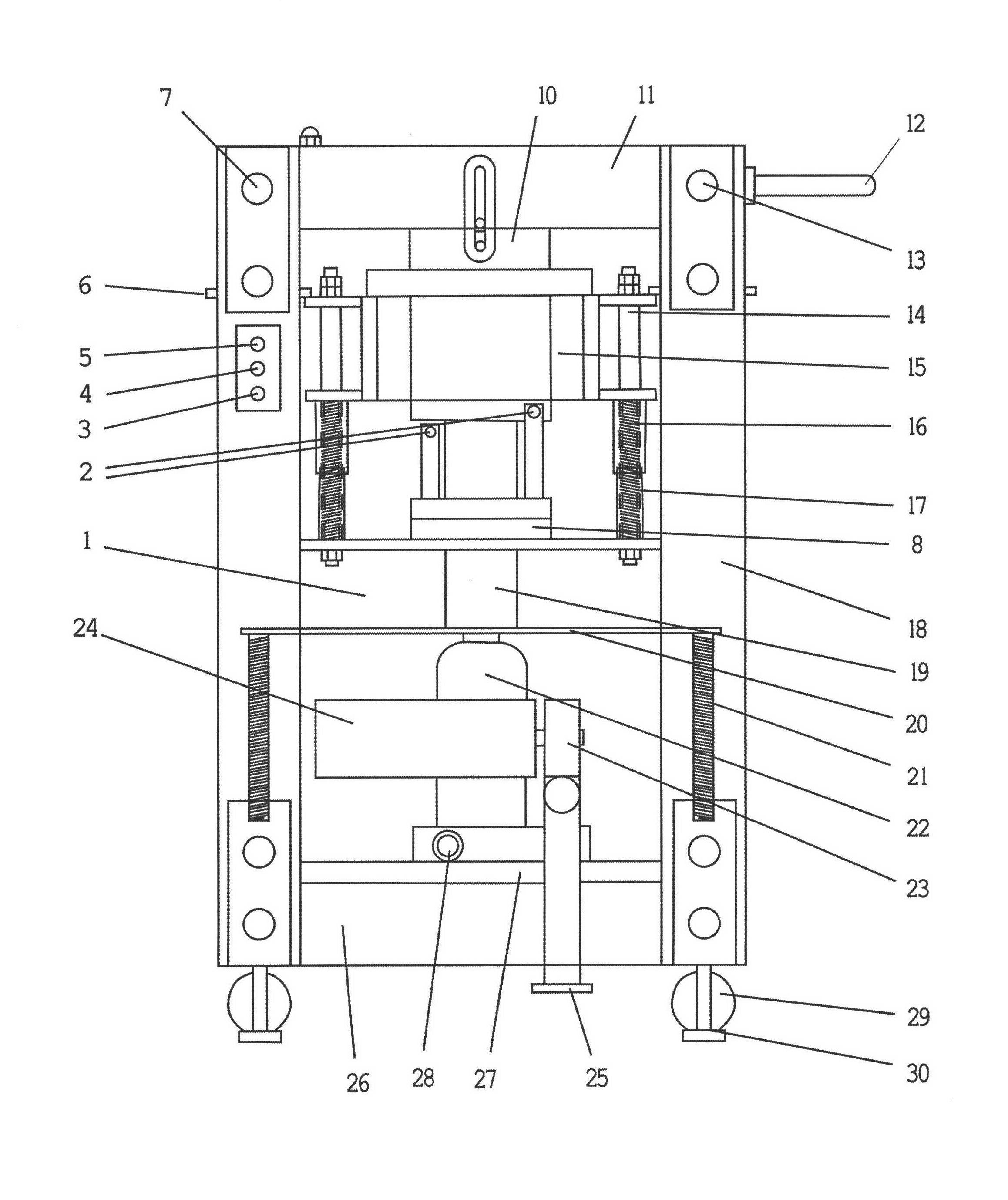

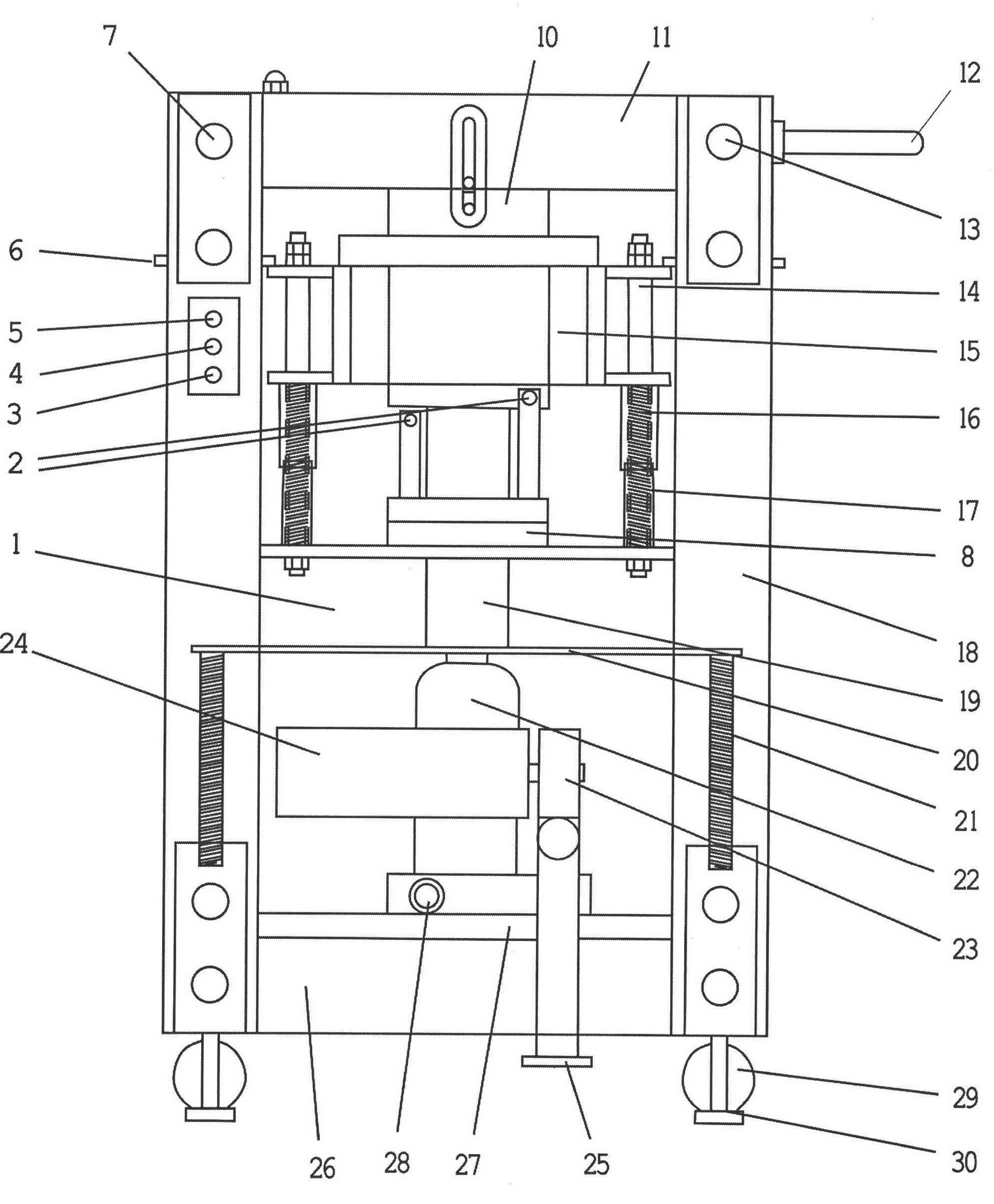

[0017] Referring to the accompanying drawings, the semi-automatic tea cake pressing machine of the present invention includes a body 1, which is characterized in that the body 1 is an upright square body made of high-quality stainless steel, and four columns 18 are connected to each other at the four corners of the body 1; 1 The bottom is equipped with a lower main force support thick plate 26, which is tightly connected with the lower ends of the four columns 18, a supporting plate 27 is installed on the lower main force supporting thick plate 26, and a jack 22 and a jack 22 are fixedly installed on the supporting plate 27. Motor 24, motor 24 one side is equipped with drive cam 23 and driven by motor 24, jack 22 is connected with drive cam 23, and drive cam 23 is connected with pedal 25; The lower end of the jack 22 is provided with an oil circuit switch 28, two sets of extension springs 21 fixed on the column 18 are connected to both sides of the lifting slide plate 20, and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com