Patents

Literature

95results about How to "Avoid loss of productivity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Shared virtualized resource management method and shared virtualized resource management device under shared virtualized resource pool environment

ActiveCN104331375AAvoid loss of productivityEliminate overloadingMemory adressing/allocation/relocationSoftware simulation/interpretation/emulationResource poolVirtualization

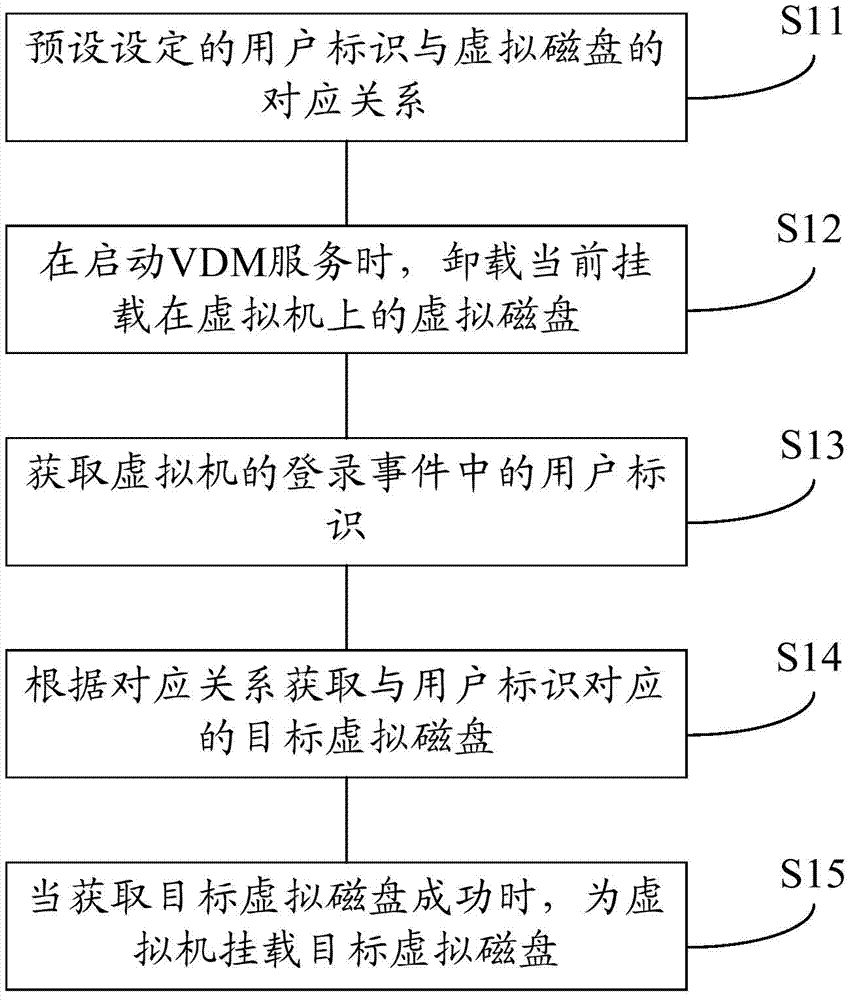

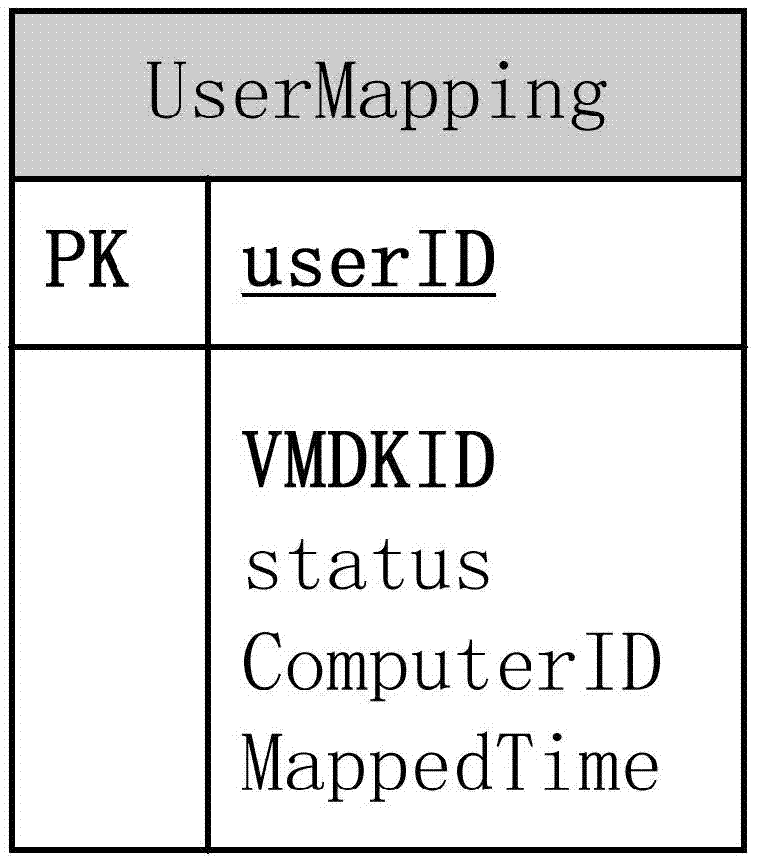

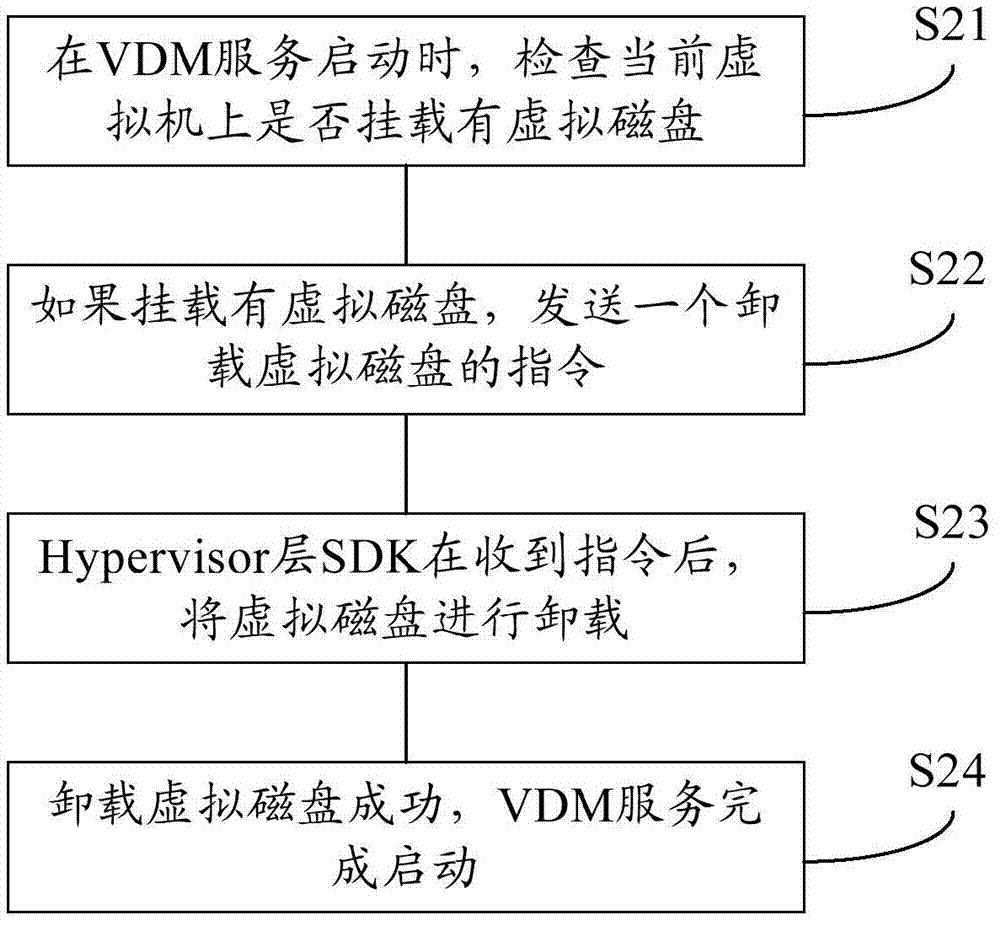

The application discloses a shared virtualized resource management method and a shared virtualized resource management device under a shared virtualized resource pool environment, wherein the method includes the following steps: the corresponding relation between set user identifiers and virtual disks is preset; when virtual disk management (VDM) service is started, a virtual disk currently mounted on a virtual machine is unloaded; the user identifier in the login event of the virtual machine is obtained; according to the corresponding relation, the target virtual disk corresponding to the user identifier is obtained; when being successfully obtained, the target virtual disk is the mounted virtual disk of the virtual machine. Because each user can access specific working data through any virtual machine in the whole shared virtualized resource pool by means of the embodiment of the invention when needing to access the specific working data, the circumstance that a plurality of users need to simultaneously log in the same virtual machine is effectively reduced, and thereby the problem that the load of certain one virtual machine is overhigh as the result of the circumstance is also eliminated; thus the problem that the working efficiency of users is decreased under the circumstance is also prevented.

Owner:CHINA CONSTRUCTION BANK

Grouting and hole-sealing material used for drilling of underground coal mine gas

InactiveCN105016677AAvoid the phenomenon of "air leakage"Accurate pH adjustmentSolid waste managementDrilling compositionPortland cementMetakaolin

The invention provides a grouting and hole-sealing material used for drilling of underground coal mine gas. The material comprises a dry grouting and hole-sealing material and water, wherein a weight ratio of the dry grouting and hole-sealing material to water is 1: 0.8-1.2; the dry grouting and hole-sealing material is composed of the following substances: Portland cement, fly ash, desulphurized gypsum, lime, aluminum powder paste, sodium chloride, metakaolin, and citric acid or sodium carbonate; and the substances composing the dry grouting-and-sealing material are required by weight as follows: 6 to 10 parts of the Portland cement, 0.5 to 3 parts of the fly ash, 0.5 to 3 parts of the desulfurized gypsum, 0.2 to 1 part of the lime, 0.0005 to 0.002 part of the aluminum powder paste, 0.05 to 0.15 part of the sodium chloride, 0.2 to 1.5 part of the metakaolin, and 0.0025 to 0.015 part of the citric acid or 0.005 to 0.03 part of the sodium carbonate. The grouting and hole-sealing material used fo drilling of underground coal mine gas provided by the invention has the advantages of adjustable coagulation time, improved air tightness of hole-sealing, improved hole-sealing efficiency and safety, lowered hole-sealing cost, simplified hole-sealing preparation work, etc.

Owner:HENAN TIANCHENG ENVIRONMENTAL PROTECTION TECH CO LTD

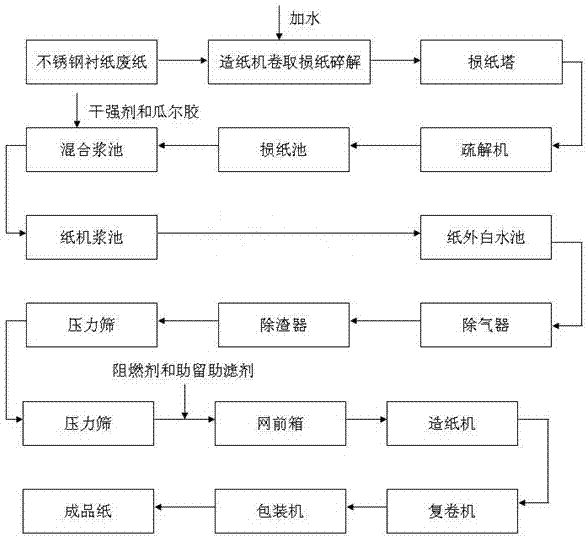

Method for preparing stainless steel interleaving paper by wastepaper

The invention discloses a method for preparing a stainless steel interleaving paper by a wastepaper. The method comprises the following steps of: based on 100% of stainless steel interleaving wastepaper as raw material, disintegrating by a coiling paper-breaking pond, and purifying in a screening way by a papermaking short-recycle system, so that the raw material can be used for the production of a paper machine. Dry strength resin, guar gum and fire retardant are added into sizing agent to replace the pulp sizing and surface sizing (coating). According to the preparation method disclosed by the invention, the environment protection is benefited, the energy can be saved, the process can be simplified, the production efficiency can be improved, and the production cost can be reduced.

Owner:SHANGHAI YINTAI PAPER IND

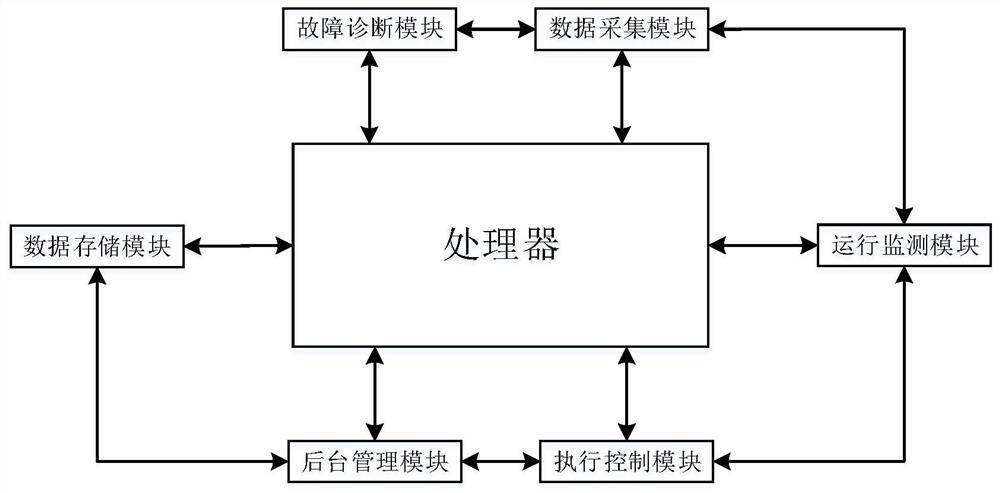

Submersible electric pump monitoring control system

ActiveCN112983844AKnow the fault status in timeImprove maintenance efficiencyPump controlNon-positive displacement fluid enginesControl systemControl engineering

The invention discloses a submersible electric pump monitoring and control system, and relates to the technical field of monitoring and control. The technical problem that a fault of a submersible electric pump cannot be early warned in advance in an existing solution is solved . According to the submersible electric pump monitoring and control system, a fault diagnosis module is arranged, the fault diagnosis module analyzes the fault of the submersible electric pump according to fault data, the fault diagnosis module analyzes a fault state of the submersible electric pump according to the fault data and sets a fault early warning label for the fault state, so that workers and maintenance personnel can know the fault state of the submersible electric pump in time, the maintenance efficiency is improved, an operation monitoring module is arranged and used for analyzing operation data, the operation monitoring module carries out early warning on the operation state of the submersible electric pump in combination with the operation change curve and an early warning model, the fault of the submersible electric pump can be obtained in advance, the early warning capacity is improved, and the situation that the working efficiency is reduced due to sudden fault of the submersible electric pump is avoided.

Owner:HEFEI HENGDAJIANGHAI PUMP IND CO LTD

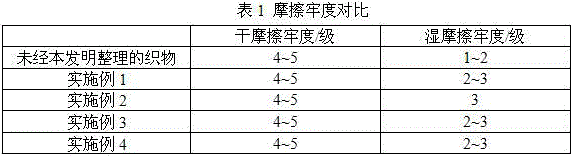

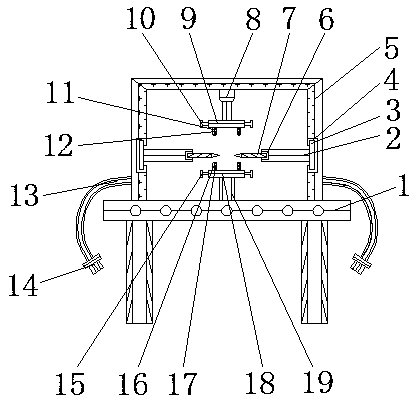

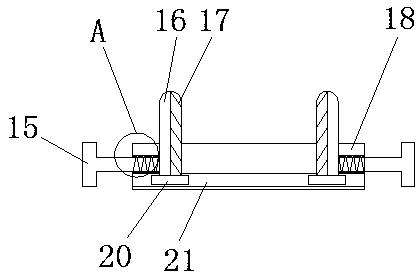

Textile workshop dust removal equipment

InactiveCN107149844ADischarge in timeEfficient dischargeCombination devicesGas treatmentDust explosionWorking environment

The invention discloses textile workshop dust removal equipment, which comprises a dust removal box, wherein dust removal liquid is filled inside the dust removal box; two position limiting plates are fixedly connected with the bottom of the left side of an inner cavity of the dust removal box; a U-shaped block is fixedly connected with the right side of the inner cavity of the dust removal box; the inner cavity of the dust removal box is movably connected with a separation plate; the right side of the separation plate extends to an inner cavity of the U-shaped block; the left side of the separation plate passes through a position between the two position limiting plates and extends to the left side of the dust removal box; a filtering groove is formed in the top of the separation plate; a filtering net is arranged in an inner cavity of the filtering groove. The textile workshop dust removal equipment has the advantages that floccules and dust of a textile workshop can be timely and effectively discharged out; the floccules and the dust can be absorbed to the inside of the dust removal liquid through the dust removal liquid inside the dust removal box; the work environment of the textile workshop is greatly improved; the work environment quality of workers is effectively improved; the dust explosion probability is reduced; the personnel safety of the workers is guaranteed.

Owner:SUZHOU COMFORT TEXTILE NEW MATERIALS TECH CO LTD

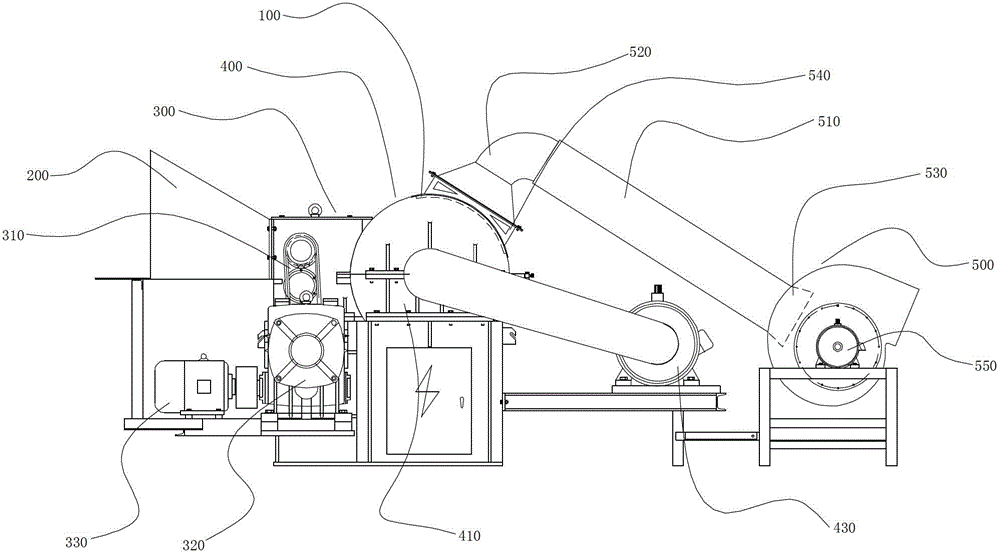

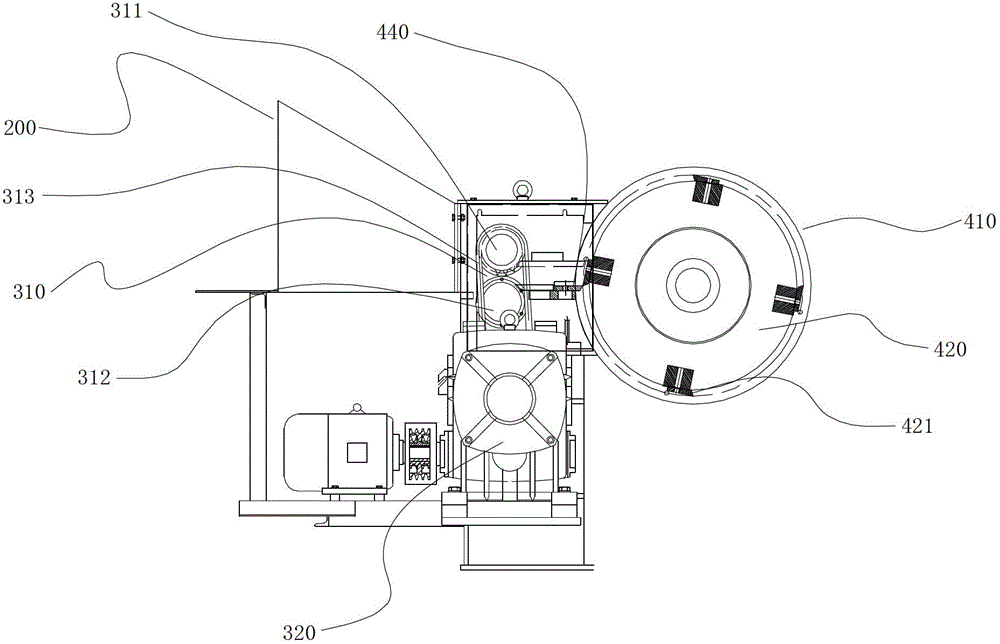

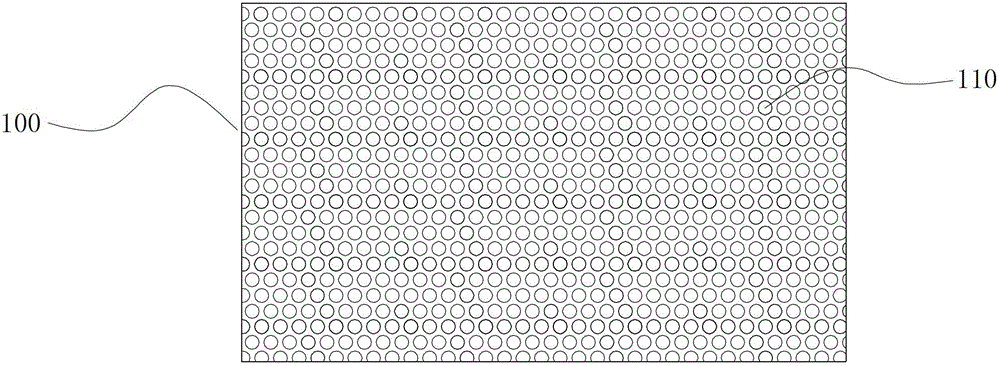

Tree branch pulverizer

The invention discloses a tree branch pulverizer, comprising a feed hopper, a pulverizing unit, a crushing unit and a material suction unit, wherein the feed hopper is communicated with the pulverizing unit, the pulverizing unit is communicated with the crushing unit, the crushing unit is connected with the material suction unit through an air suction pipe, one end of the crushing unit connected to the air suction pipe is provided with a suction ventilator, and one end of the crushing unit connected to the material suction unit is provided with a discharge hopper; the crushing unit comprising a crushing chamber, the crushing chamber is a cylinder and arranged horizontally, the top of the cylinder is provided with a filter screen, the filter screen is fixed on a discharge flange, the discharge flange covers the surface of the filter screen, the meshes of the filter screen is circular, the diameters of the meshes are 15-20mm, and the discharge flange is connected with the suction ventilator. According to the invention, the design is ingenious, by arranging the filter screen on the crushing chamber, high-quality pulverized tree branch particles can be acquired, low working efficiency due to that halfway pulverization of the tree branches blocks the suction ventilator can be avoided, the pulverizer is improved, the cost is low, and the pulverizer disclosed herein can be widely suitable for pulverization of all tree branches.

Owner:环立方园林科技(江苏)有限公司

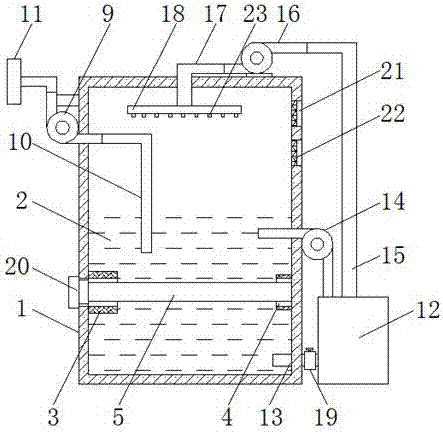

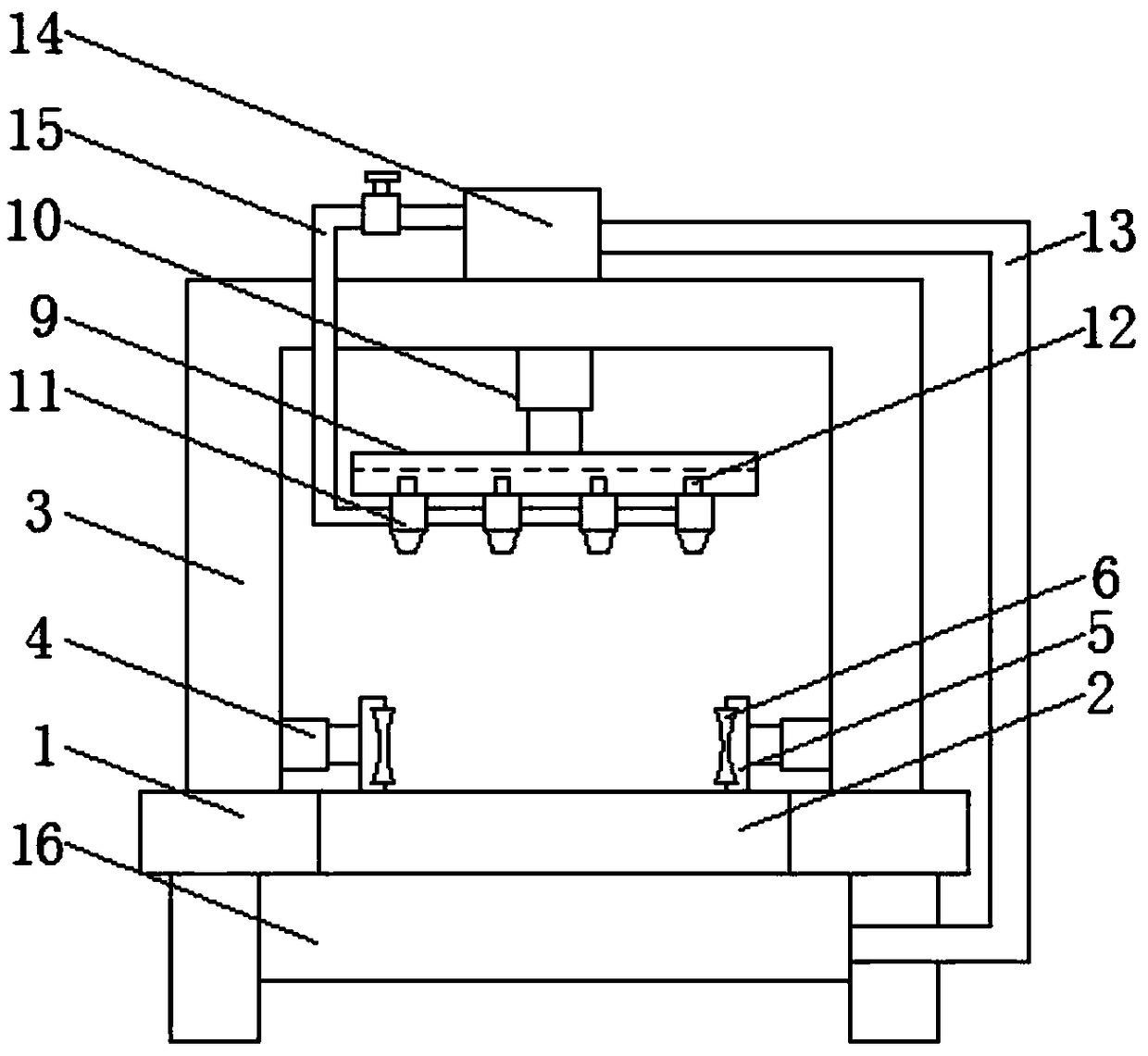

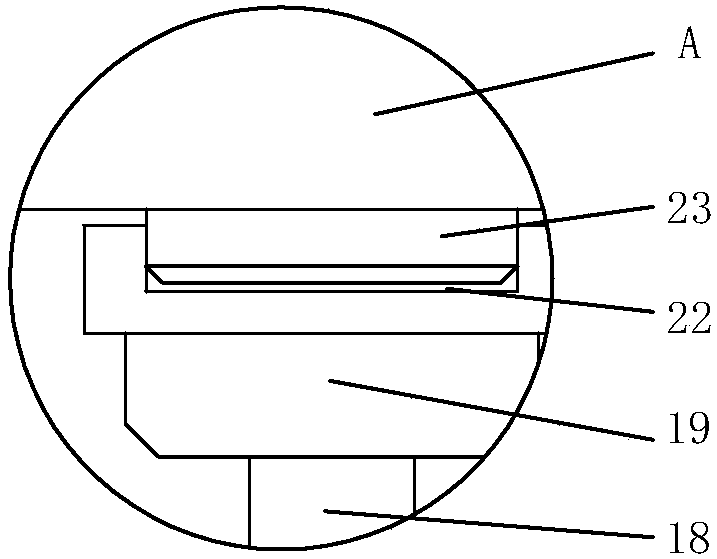

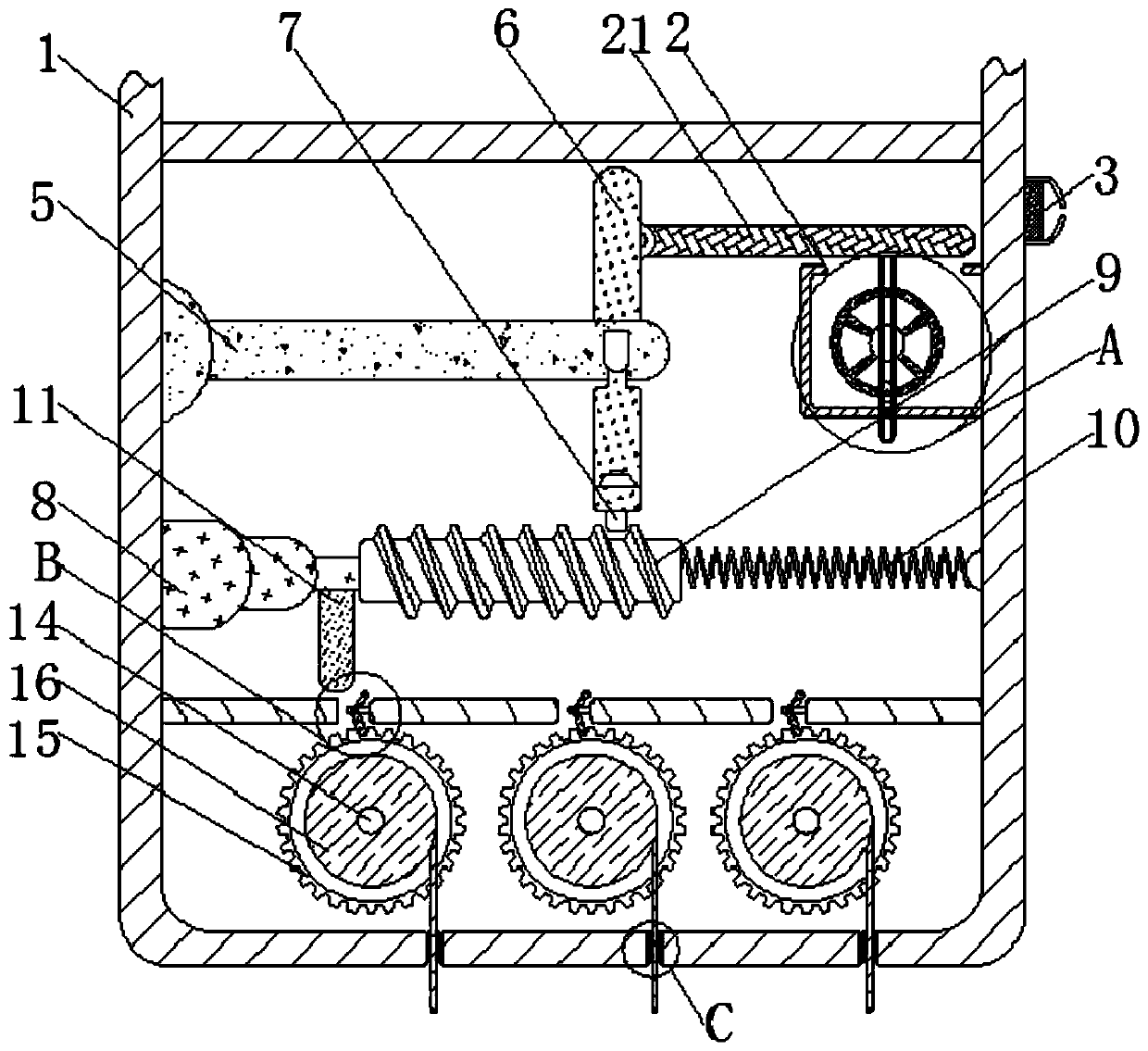

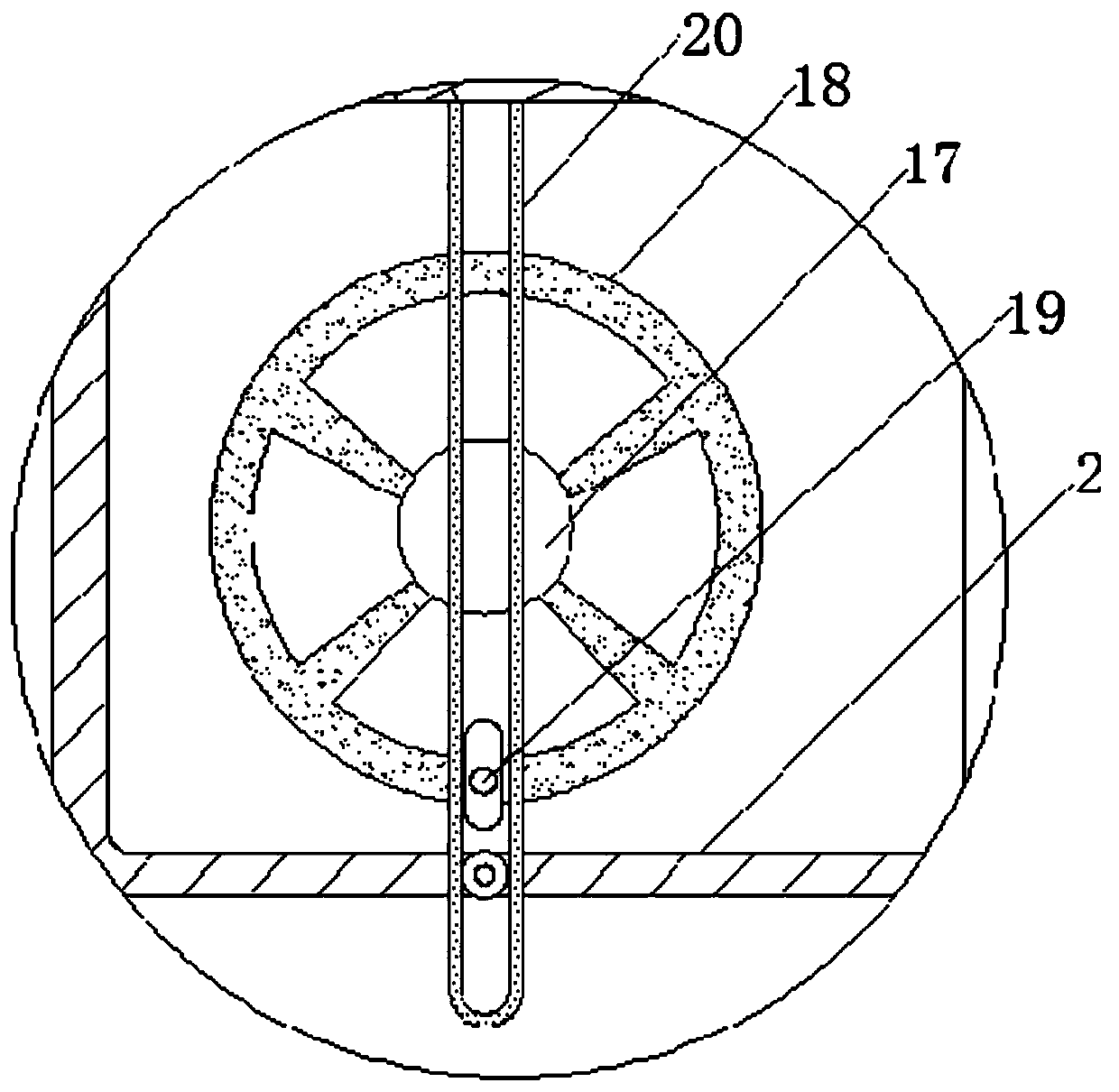

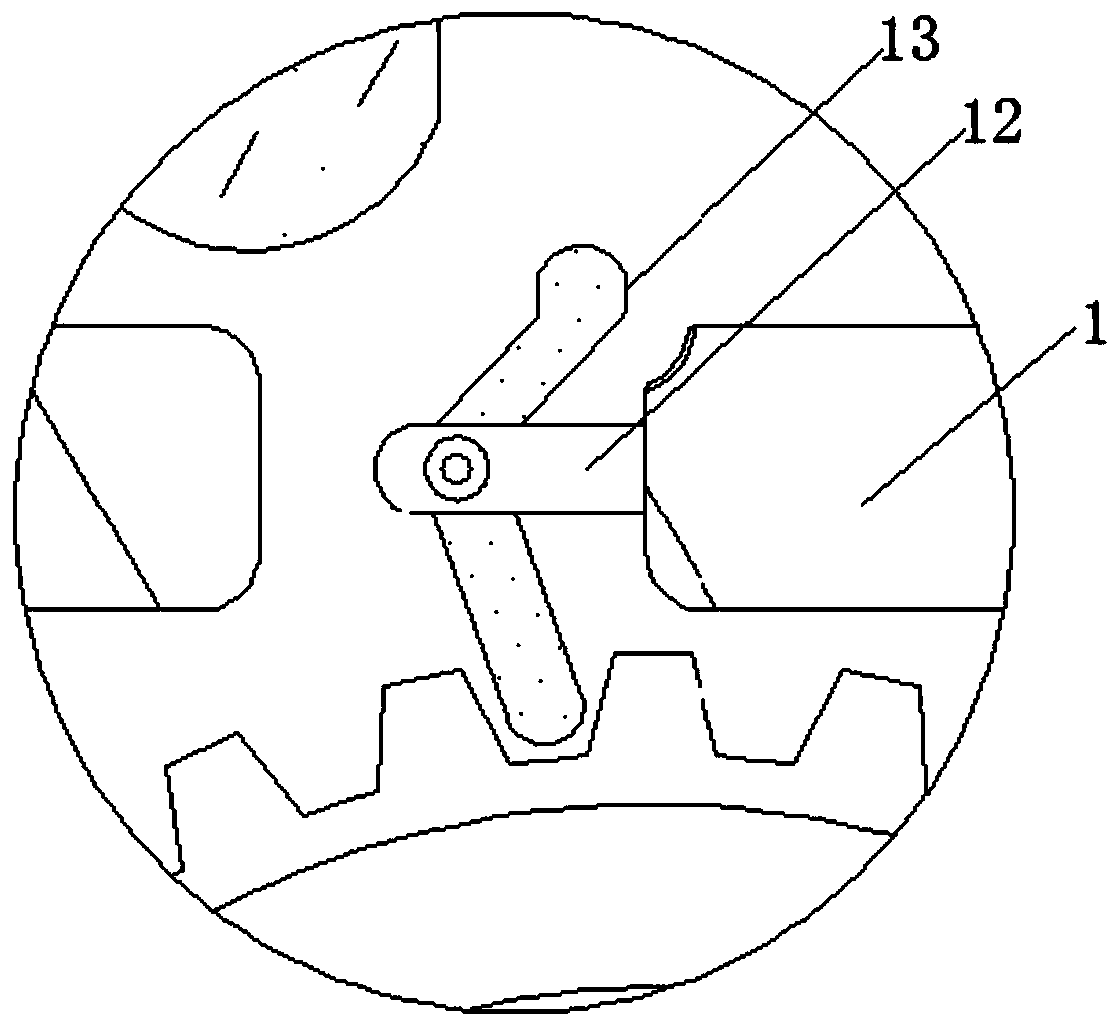

Wood board water cutting device and method having water circulation function

ActiveCN108908523AImpact cleanupReduce cleanupProfiling/shaping machinesStationary filtering element filtersPhysical healthWater storage tank

The invention discloses a wood board water cutting device and method having the water circulation function and belongs to the technical field of wood-working machinery. The wood board water cutting device comprises a working platform. An inner chamber of the working platform is provided with a conveying device. Rotating shafts are arranged in the centers of the outer walls of the left side and theright side of the top of the working platform correspondingly. The front end of each rotating shaft is connected with a guiding plate. A limiting rod is arranged on the outer wall of the top of eachguiding plate. The bottom end of each limiting rod extends to the outer wall of the bottom of the corresponding guiding plate, and the connection position of each guiding rod and the corresponding guiding plate is provided with a groove. By means of the device, chippings generated in the cutting process are flushed into a filter box for centralized treatment through water obtained after cutting, and the problem that the chippings splash everywhere to affect normal work and physical health of people is avoided; the water is separated from the chippings through the filter box, and the chippingscan be treated in a centralized manner conveniently; and meanwhile, the water collected by the filter box is conveyed into a water storage tank for reuse through a water pump, and the water resource is saved.

Owner:浙江博力莫新材料科技有限公司

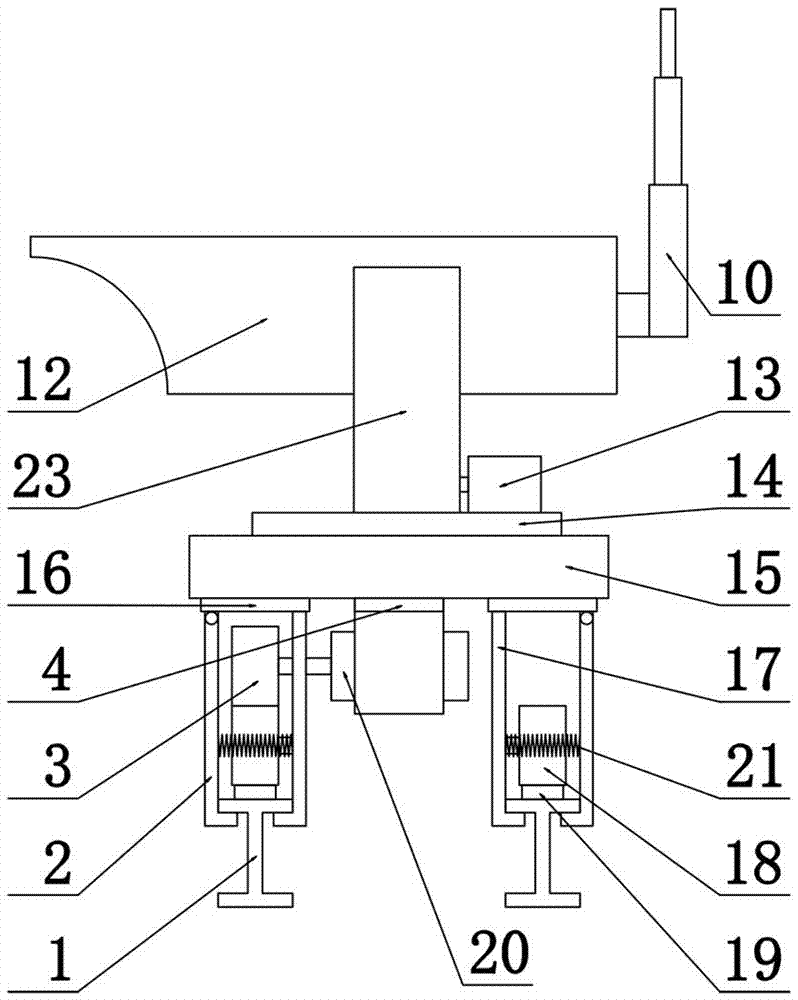

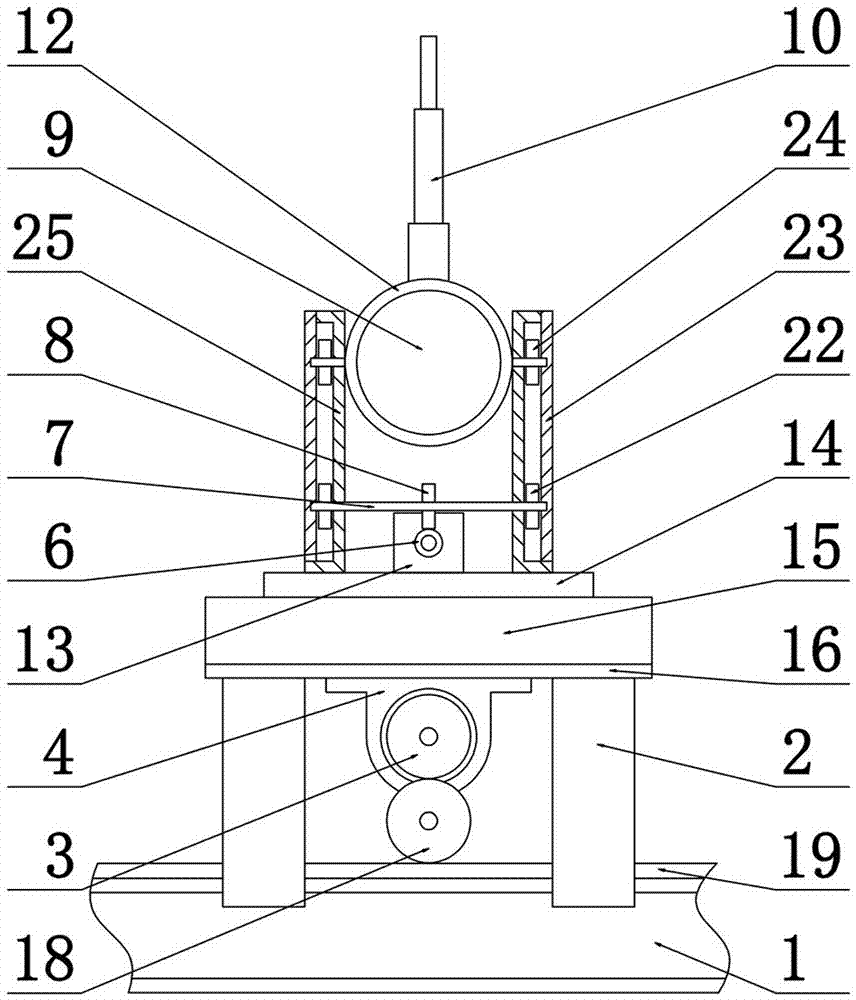

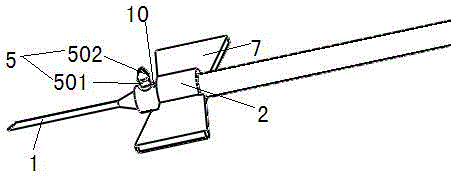

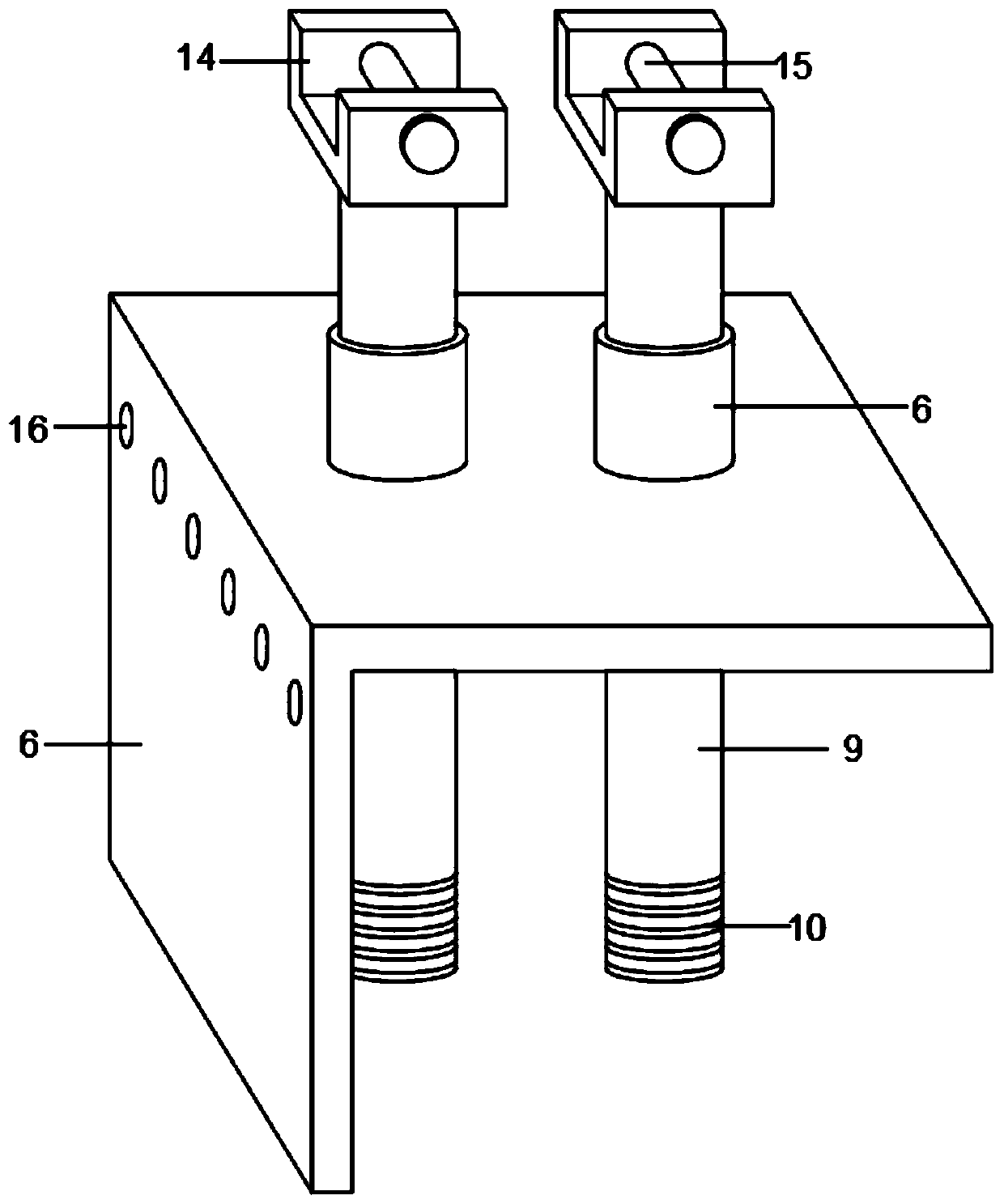

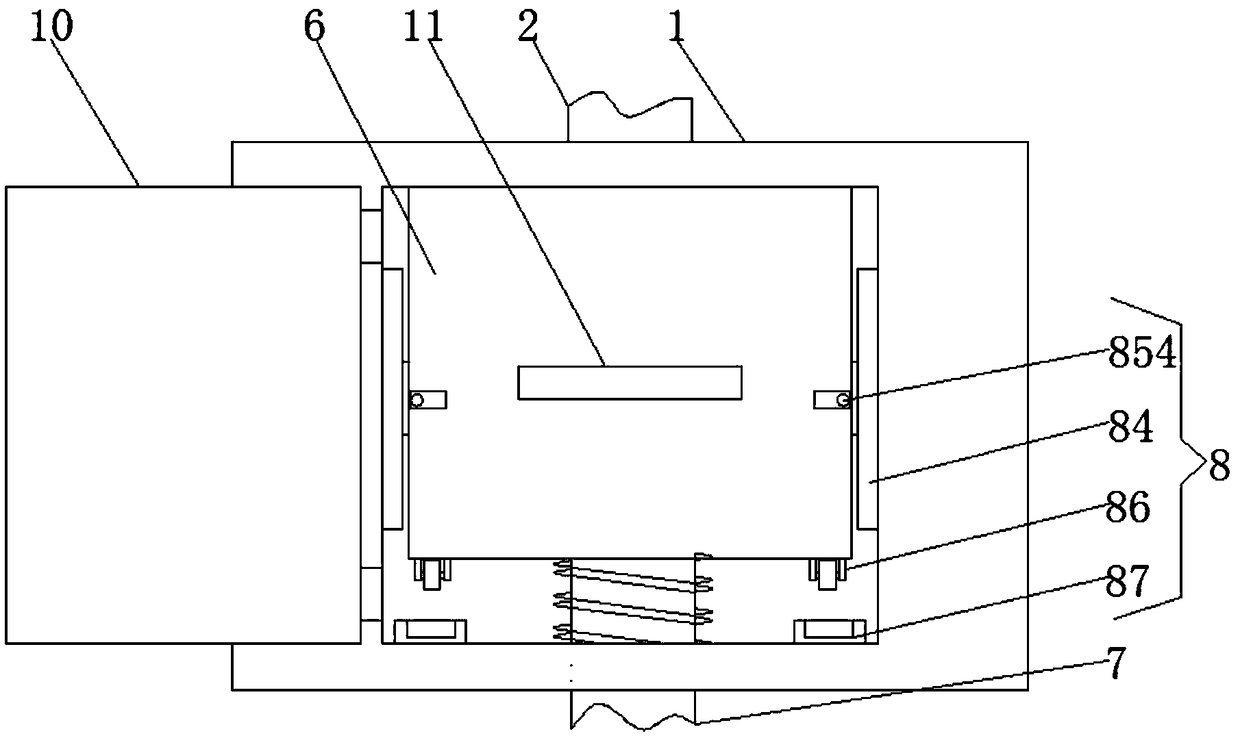

Intelligent desk and digital signal processing method

ActiveCN102411444AHigh positioning accuracyQuick responseInput/output processes for data processingDigital signal processingStructure of Management Information

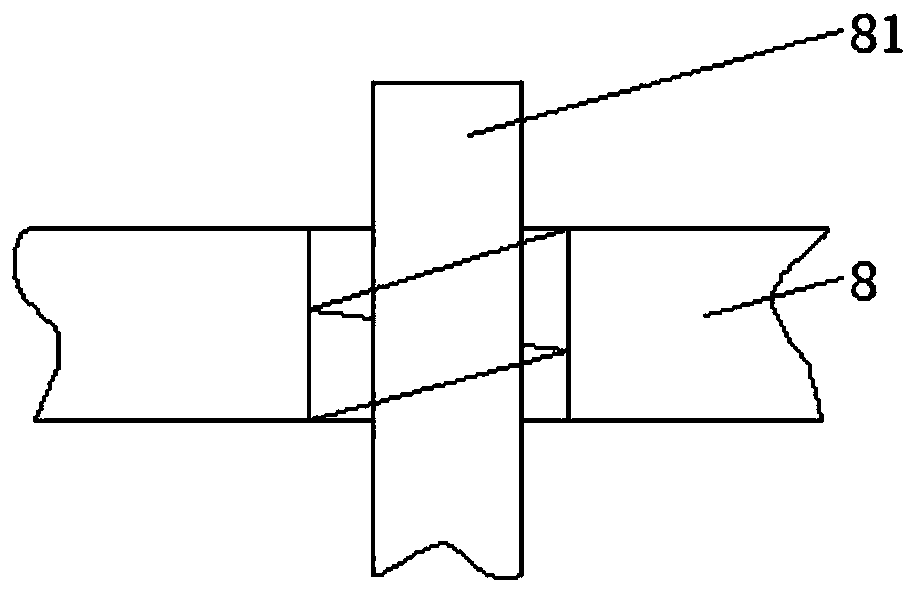

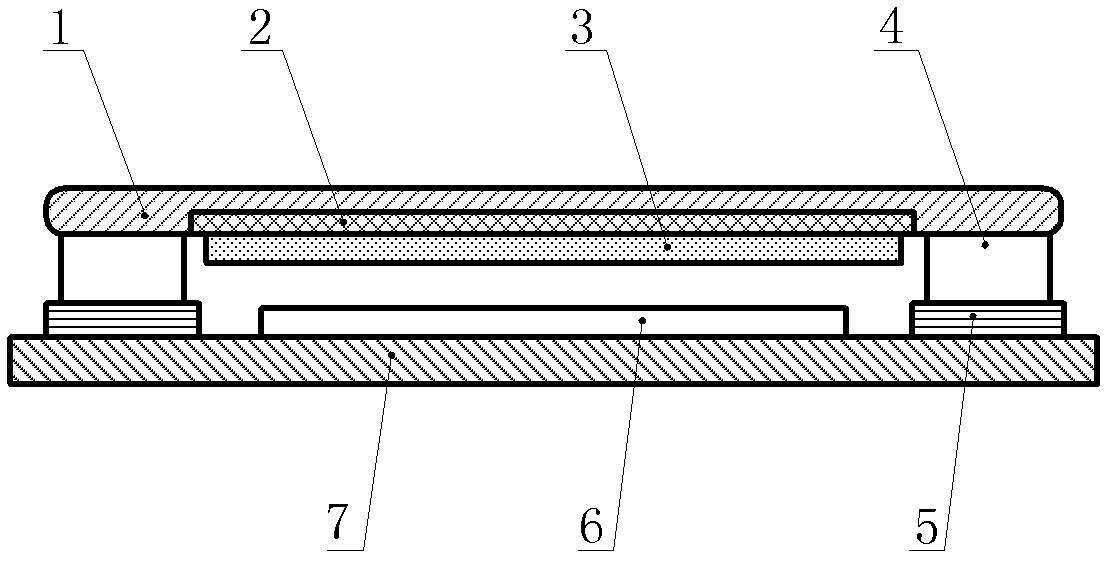

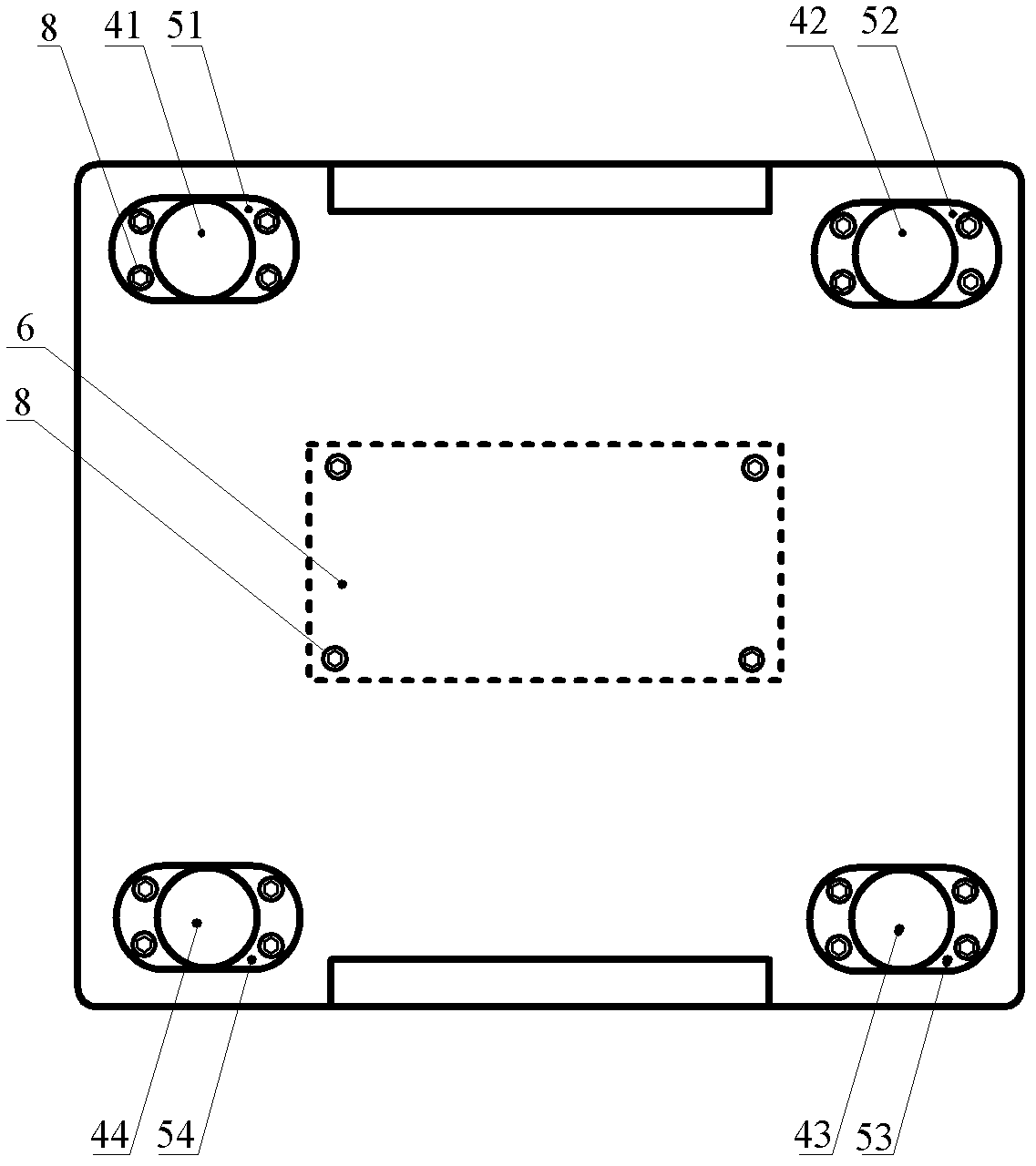

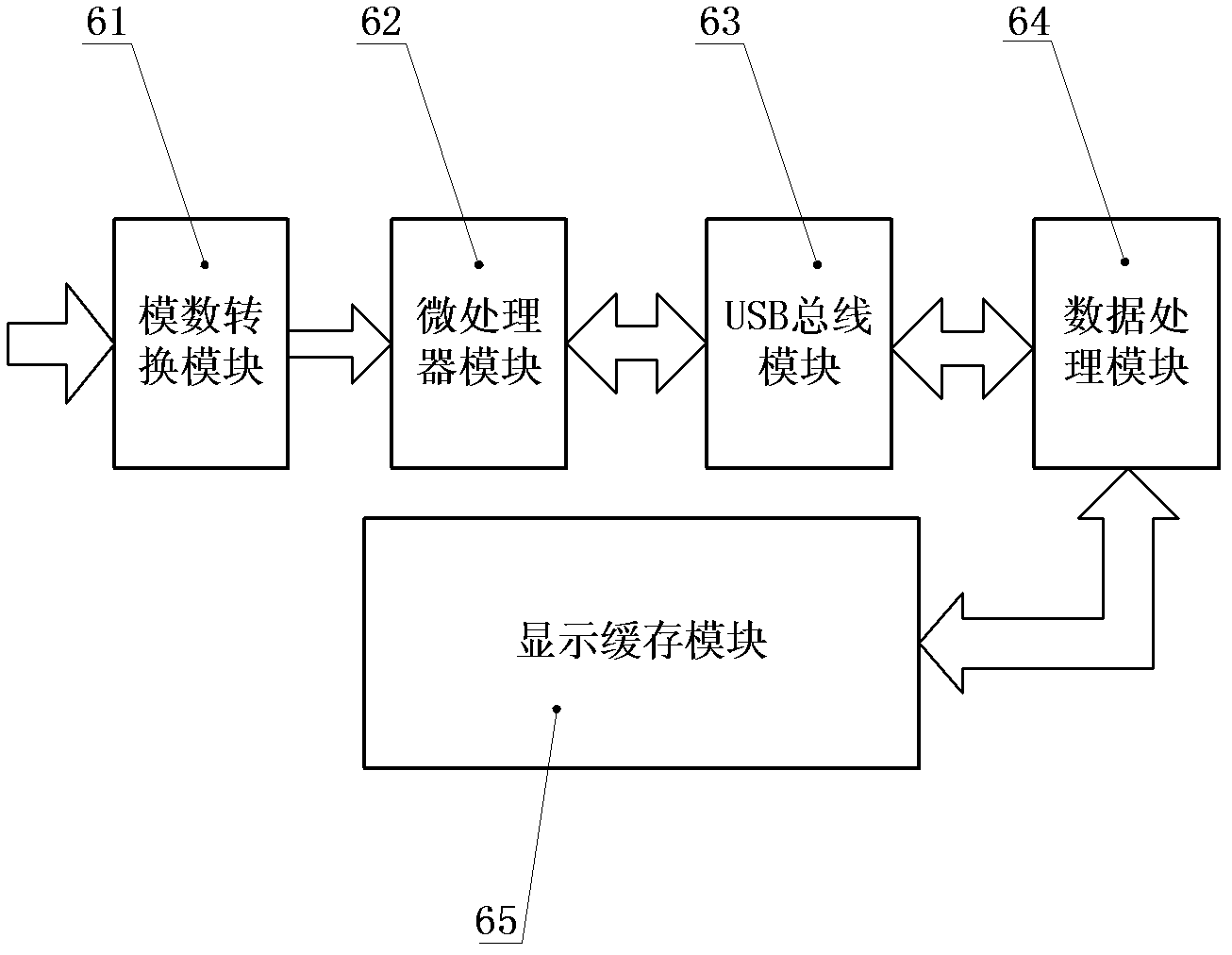

The invention relates to an intelligent desk and a digital signal processing method. The structure of the intelligent desk is that: a signature flat panel (1) is arranged on the intelligent desk; a liquid crystal flat panel display (2) and a liquid crystal display drive board (3) are sequentially arranged below the intelligent desk; four three-dimensional force sensors (4) are fixed at four corners below the signature flat panel (1) through four fixing adapter plates (5); and a digital signal processing plate (6) is fixed above the central position of a base flat panel (7) by internal hexagonal positioning holes (8) on two sides. In the digital signal processing method for the intelligent desk, the digital signal processing plate (6) digitally processes acquired analogue three-dimensional force information, performs digital smooth filtering processing to reduce the influence of interference noises, and performs data fusion processing on data to obtain the three-dimensional force vector information and real-time track coordinates of a contact point of a pen point; and calculated coordinate information is displayed to achieve the real-time visual feedback effects of a writing process.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

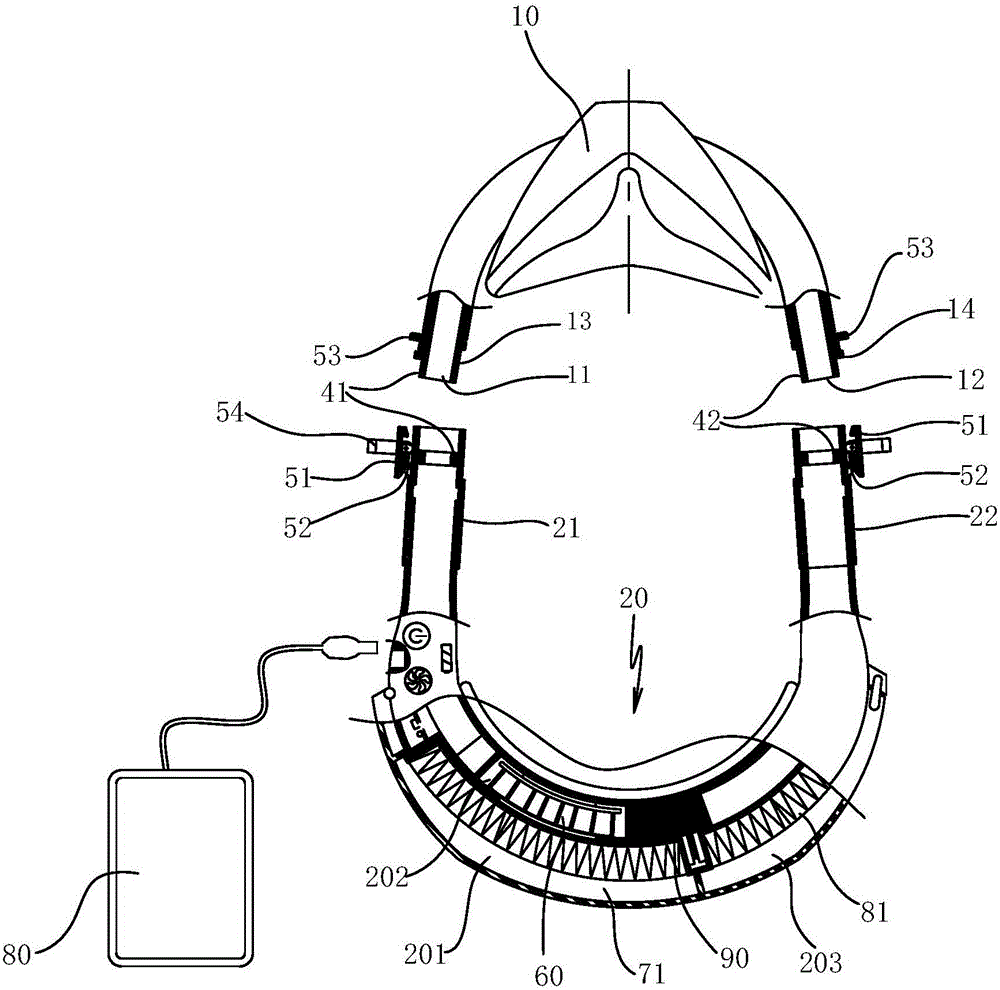

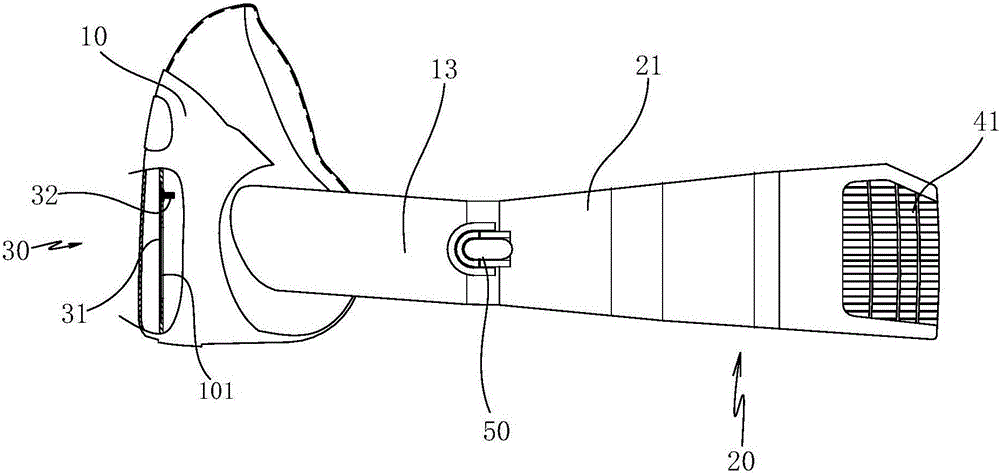

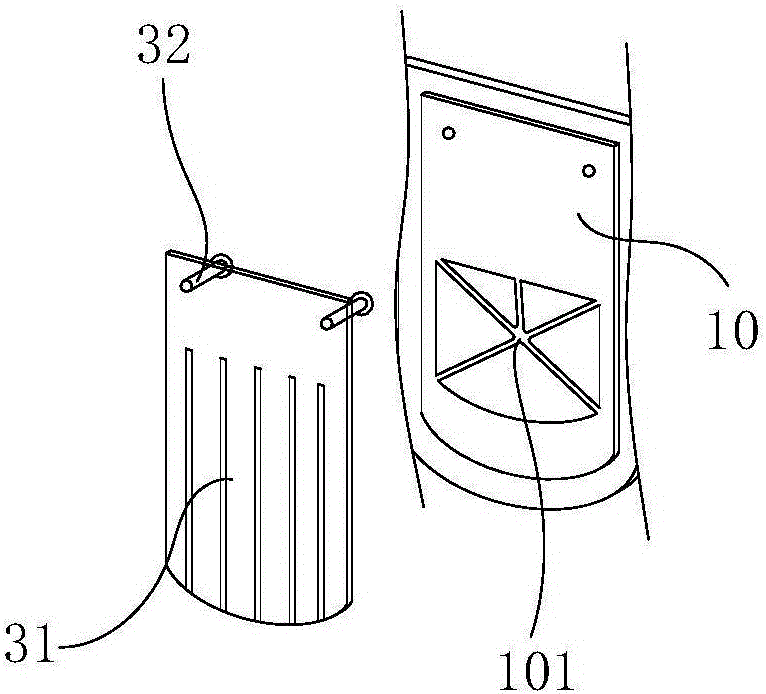

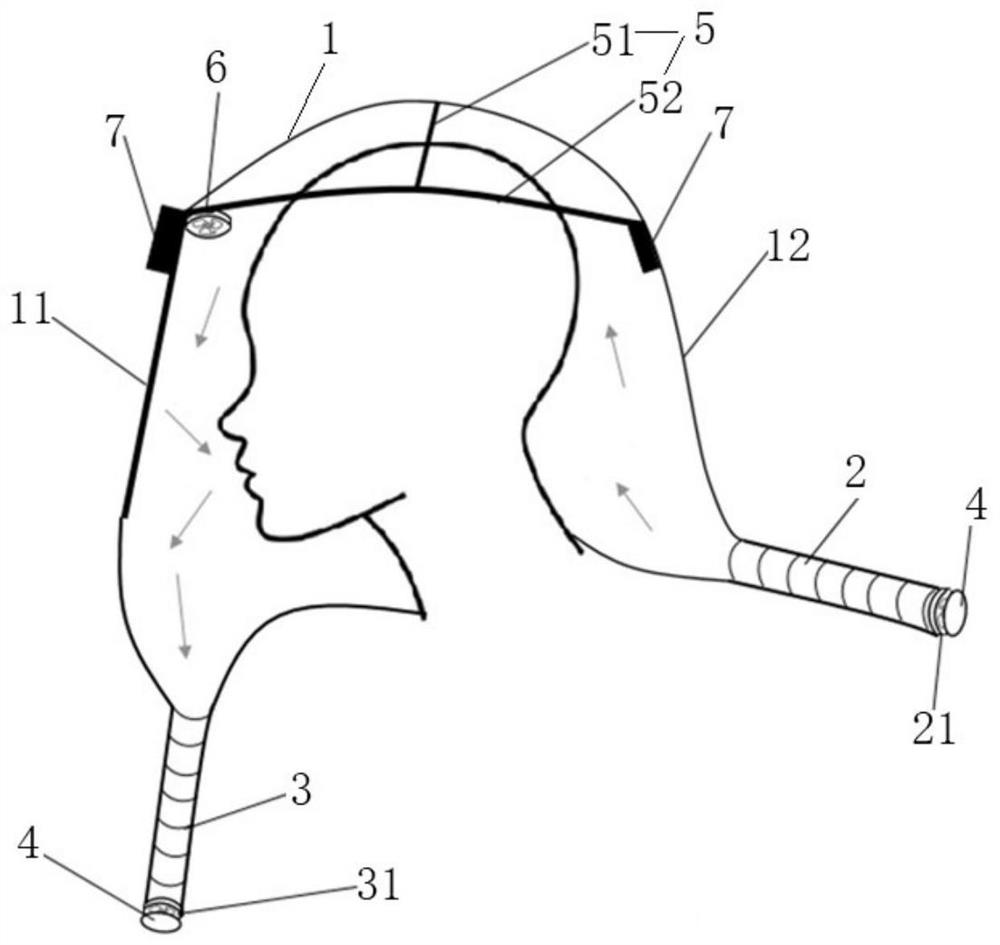

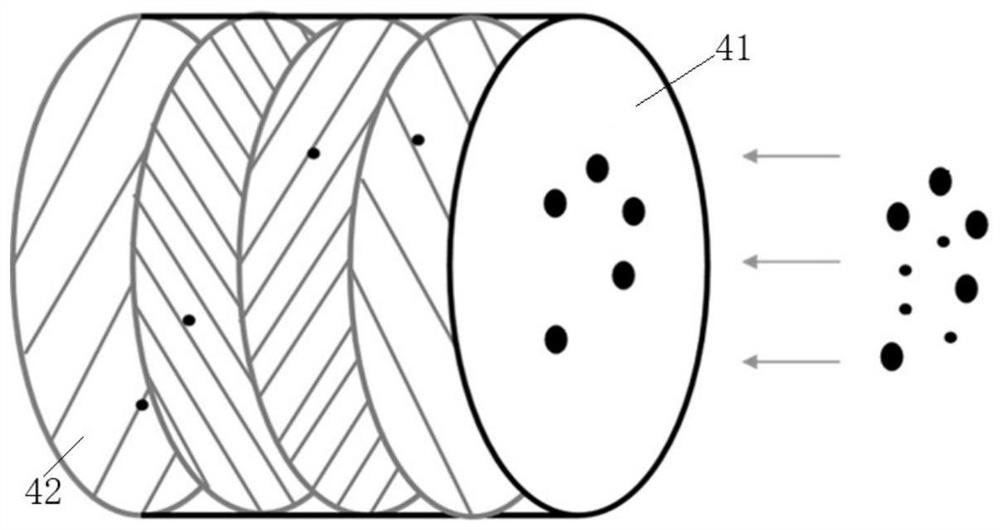

Neck entangled type air purifier

ActiveCN105797290AEasy to wearAvoid reduced productivity or even stop workingBreathing filtersBreathing masksLocal pressureAirflow

The invention relates to a neck entangled type air purifier. The air purifier comprises a mask matched with the face of a worker, the mask is provided with an air inlet, the air inlet is connected with one end of an arch-shaped shell, the bending outline of the arch-shaped shell is matched with the neck outline of the worker, a first filtering unit is arranged in the arch-shaped shell and is communicated with the outside, an induced draft fan is arranged on an air outlet of the first filtering unit, an air outlet of the induced draft fan is communicated with the air inlet of the mask, and an air outlet is formed in the mask and is connected with the other end of the arch-shaped shell; a second filtering unit is further arranged in the arch-shaped shell, and an air inlet of the second filtering unit is communicated with the air outlet of the mask; and an air outlet of the second filtering unit is communicated with the exterior. The worker can conveniently wear the air purifier on the neck, the wearing manner is simple, the induced draft fan guides cleaned air into the mask, then, the cleaned air is guided into the second filtering unit from the mask via the air outlet, the air flow of the whole purifier can form a locally-opened loop system, the problem that the due to breathing of the worker, local pressure of the mask is too large, and the efficiency of the induced draft fan is reduced is solved, and the wear comfort of the mask is improved.

Owner:秦小坤

Method for preparing water-soluble fertilizer by using fish protein hydrolysate

InactiveCN112500224AFully hydrolyzedGood sustained release effectMagnesium fertilisersAnimal corpse fertilisersFertilizerNutrient

The invention provides a method for preparing a water-soluble fertilizer from fish protein hydrolysate. The method comprises the following steps: pretreatment, hydrolysis, concentration, neutralization and compounding. According to the method for preparing the water-soluble fertilizer, hydrolysis is sufficient, nutrient substances in fish materials can be fully utilized, and meanwhile hydrolysis residues can be effectively prevented from being deposited in production equipment; the prepared water-soluble fertilizer is good in slow release effect, the loss of the water-soluble fertilizer in soil is effectively reduced, the utilization rate of the fertilizer is high, the fertilization operation frequency is effectively reduced, and the labor force and the planting cost of planters are effectively reduced; compared with an existing water-soluble fertilizer, the application amount is reduced by 10-13%, balanced nutrient elements can be provided for crops, and the water-soluble fertilizer is easily absorbed by the crops; after the fertilizer is applied for one year, the soil moisture content is increased by about 8-13%, and the soil porosity is increased by about 10-14%.

Owner:安丘市天赐生物肥料有限公司

Movable camera

PendingCN107701876AInnovative designAvoid loss of productivityTelevision system detailsColor television detailsDrive wheelEngineering

Owner:河南力方网络科技有限公司

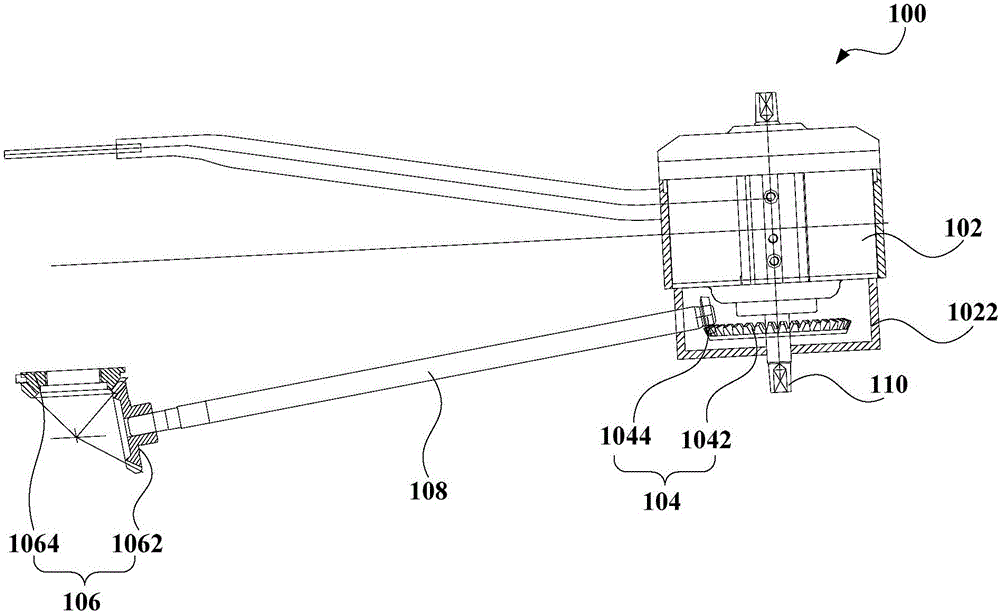

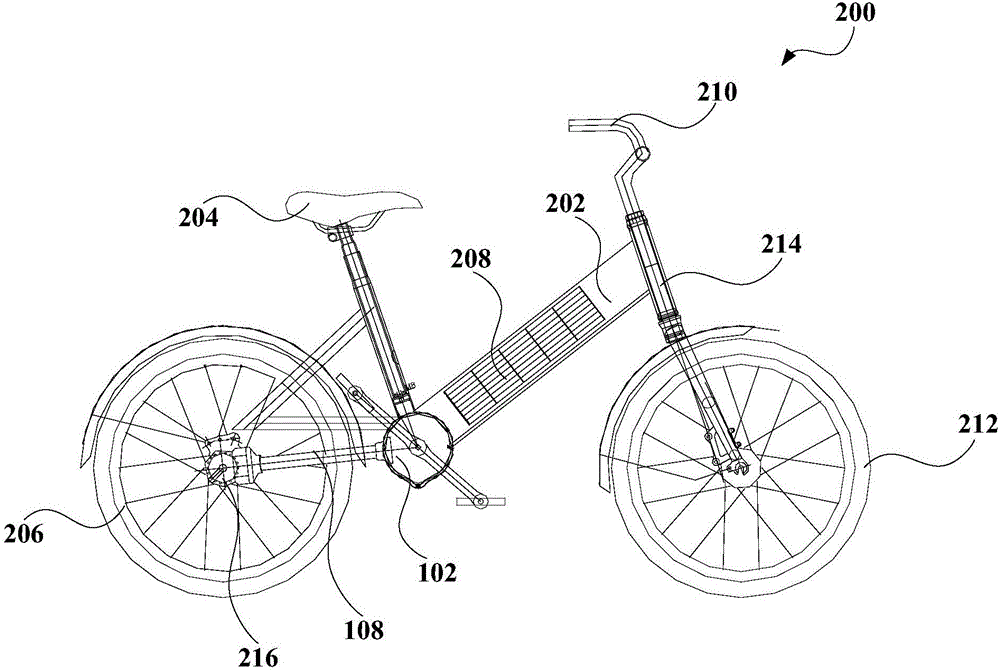

Central motor assembly and electric vehicle

InactiveCN106542039AImprove satisfactionCompact structureRotary transmissionsRider propulsionElectricityVehicle frame

The invention provides a central motor assembly and an electric vehicle. The central motor assembly comprises a central motor, a first gear assembly, a second gear assembly and a first shaft, wherein the central motor is arranged on a frame, and is positioned below a saddle; the first gear assembly is connected with the central motor; the second gear assembly is arranged on a rear wheel shaft, and the second gear assembly and the first gear assembly are positioned at the same side of the frame; the two ends of the first shaft are separately connected with the first gear assembly and the second gear assembly; the central motor rotates to drive the first gear assembly to rotate, and also drives the first shaft to rotate; and the first shaft drives the second gear assembly to rotate, so that the rear wheel is driven to rotate. The central motor assembly provided by the invention avoids the defect that resistance of a rider is increased due to the fact that magnetic retardation is generated without power by taking a hub motor as a power source, facilitates riding of a user, improves product use safety, improves transmission efficiency, increases output torque, saves electric energy of the whole vehicle, and improves use satisfaction degree of the user.

Owner:ZHEJIANG LUYUAN ELECTRIC VEHICLE

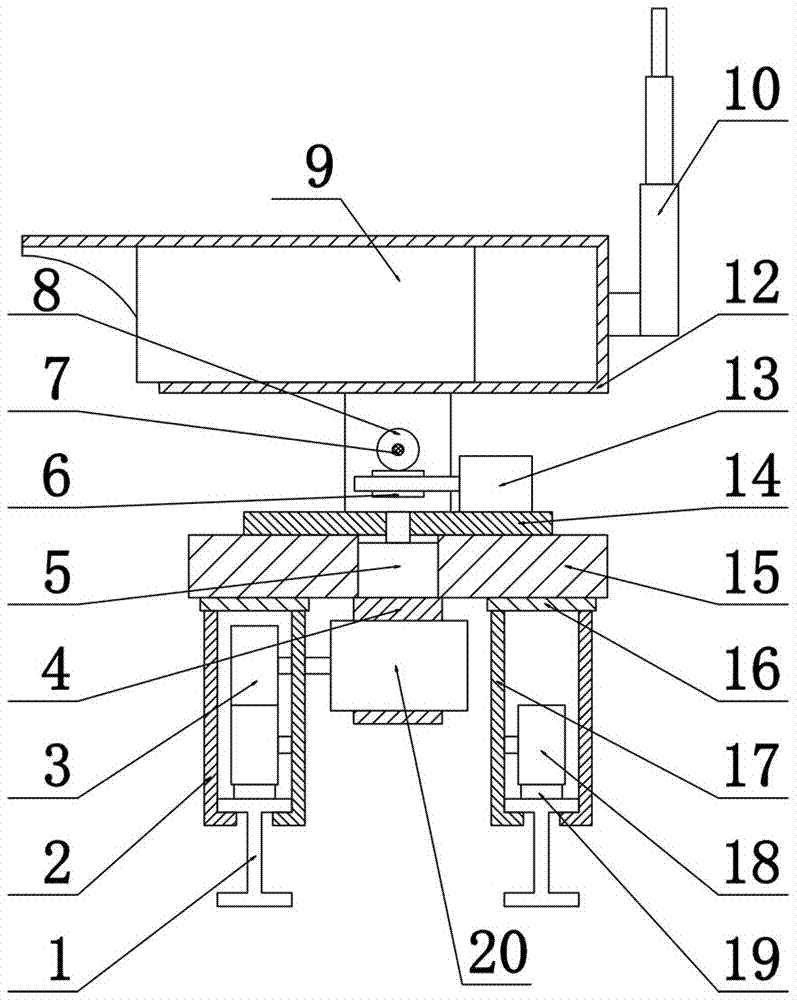

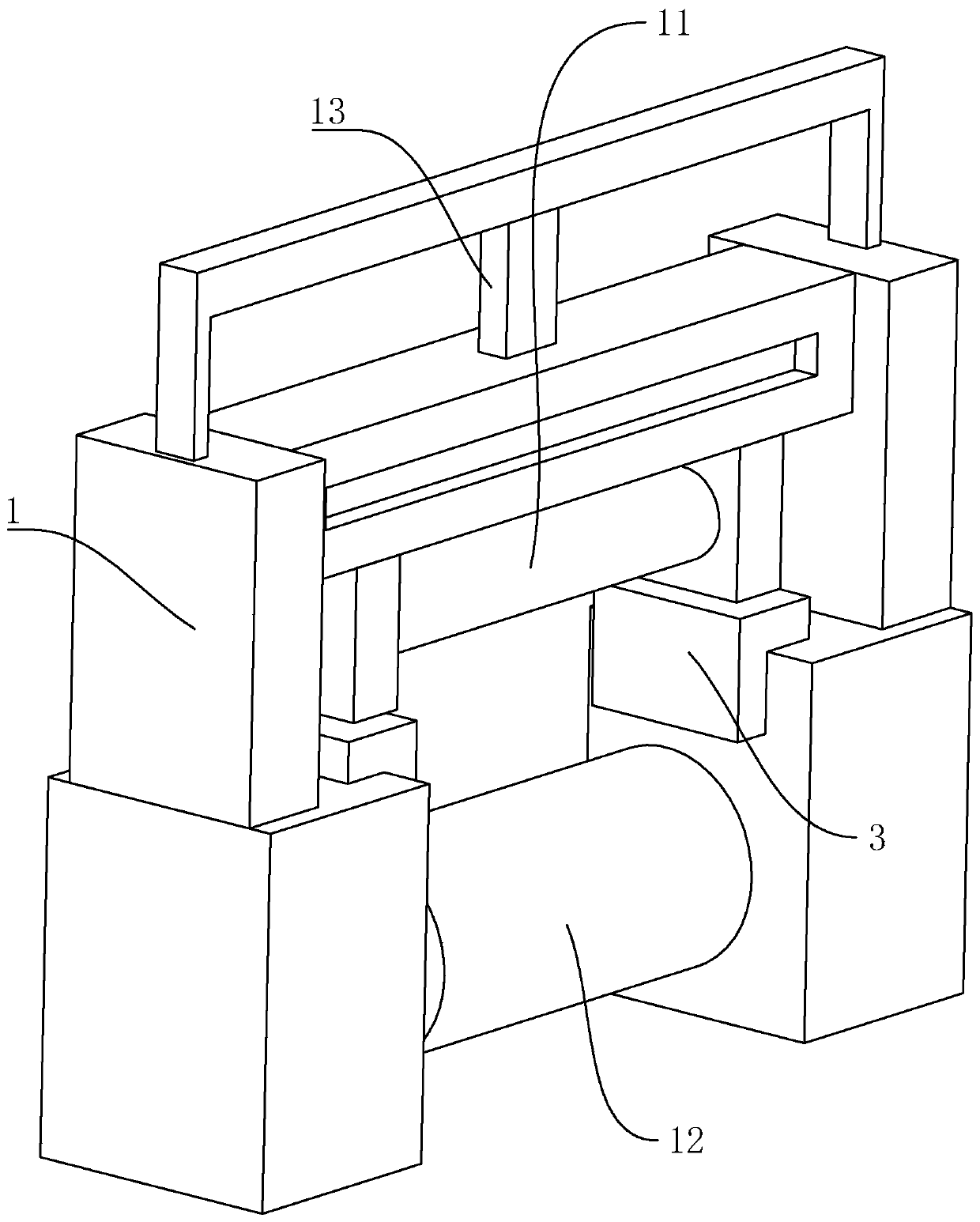

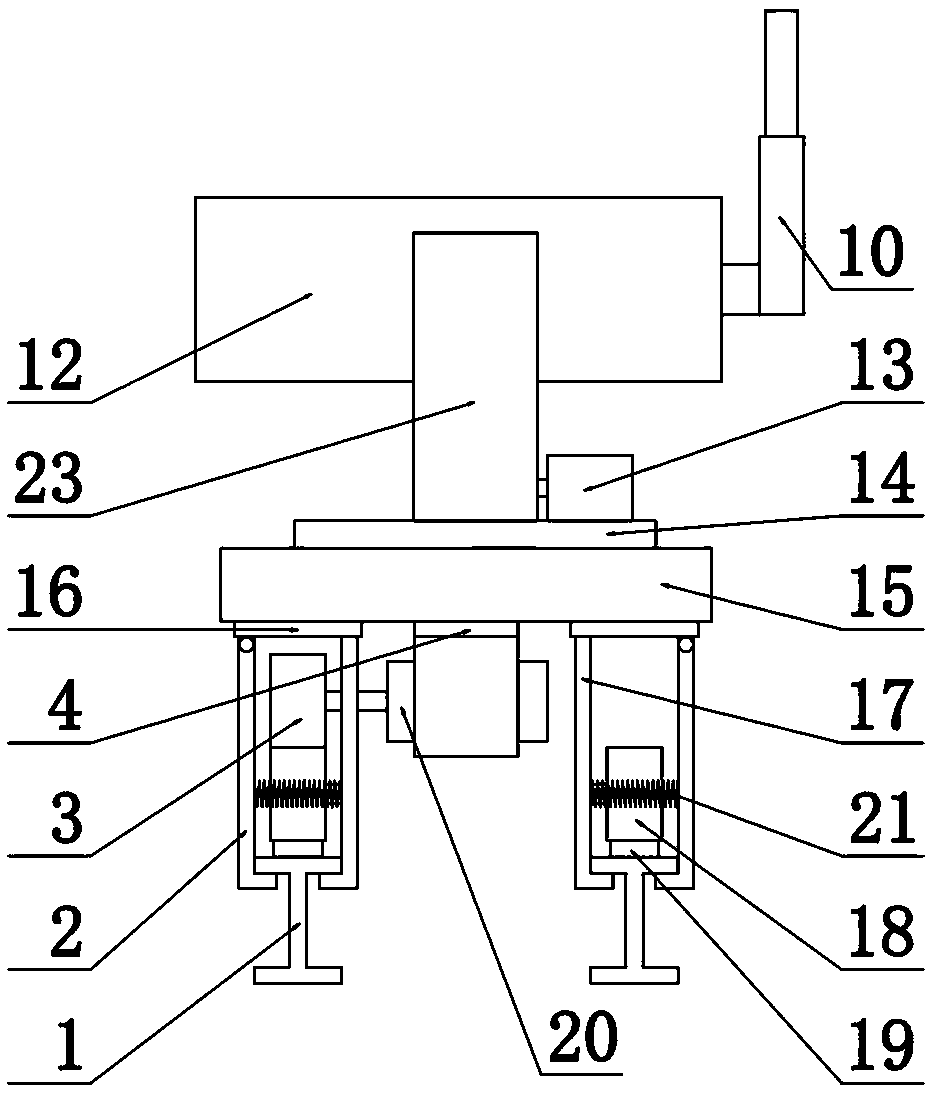

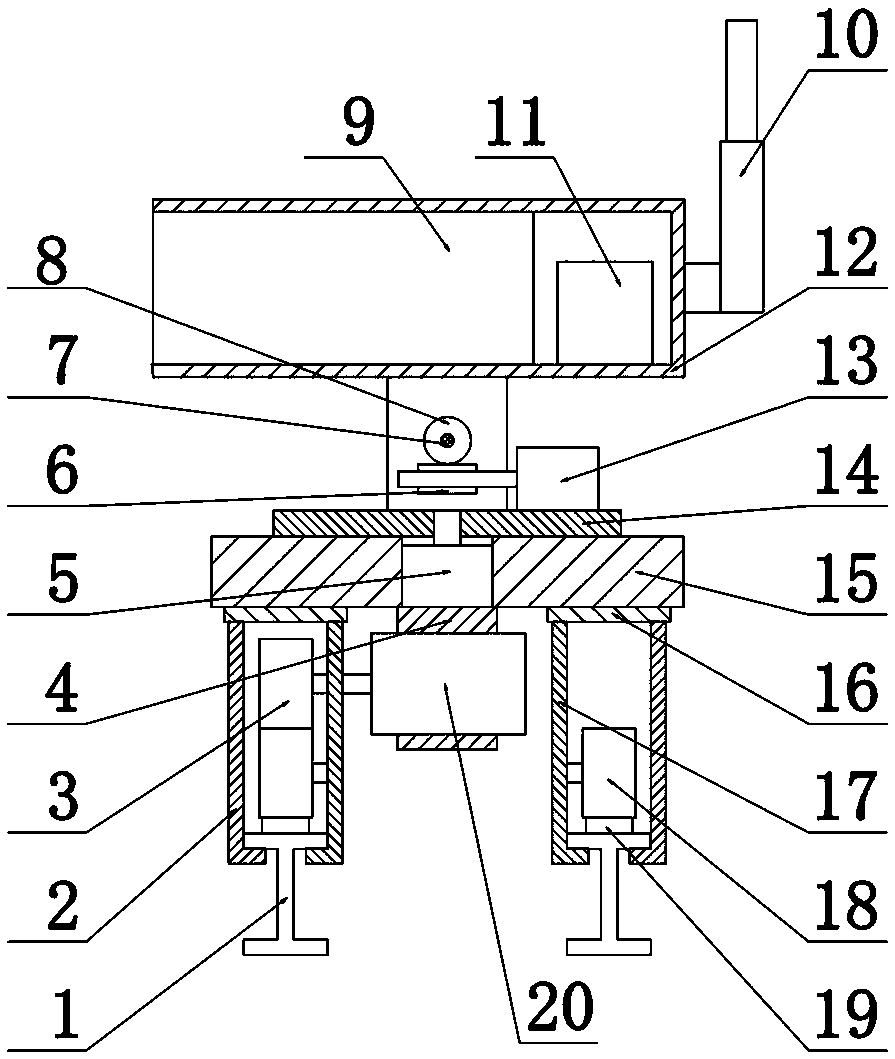

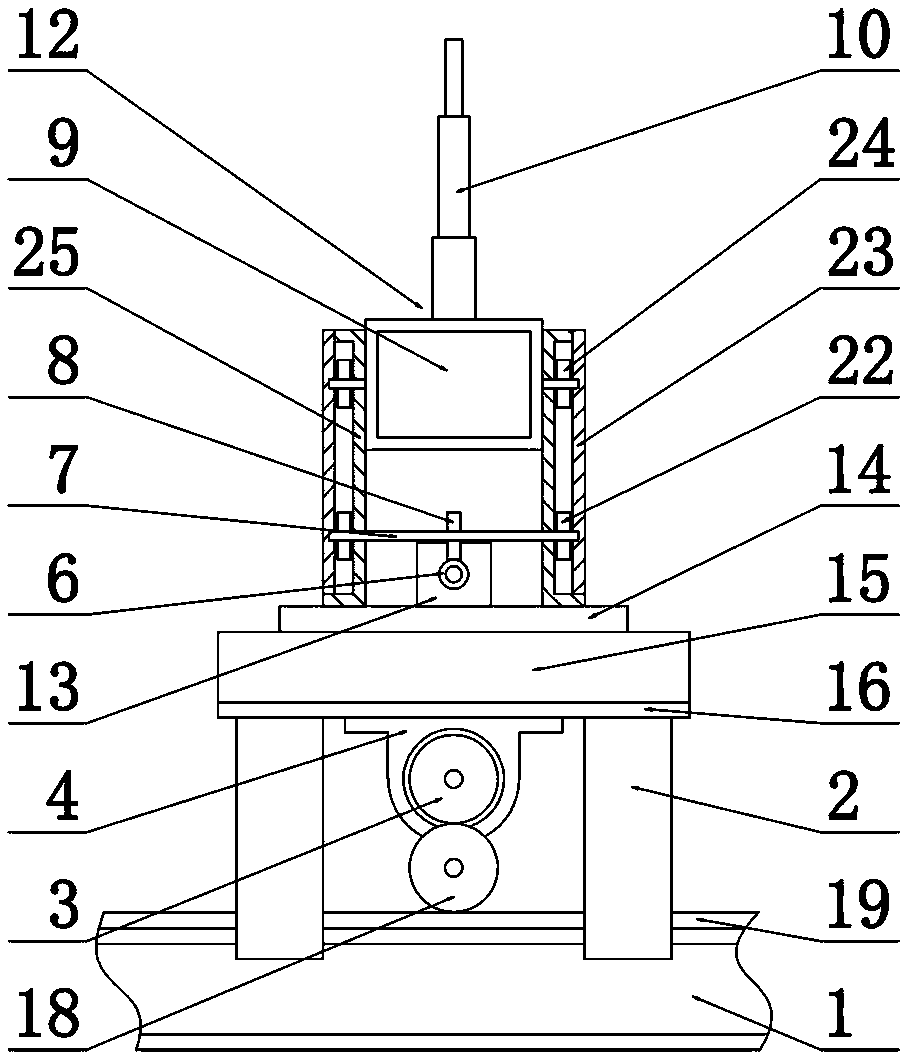

Automatic wall building machine and wall building method thereof

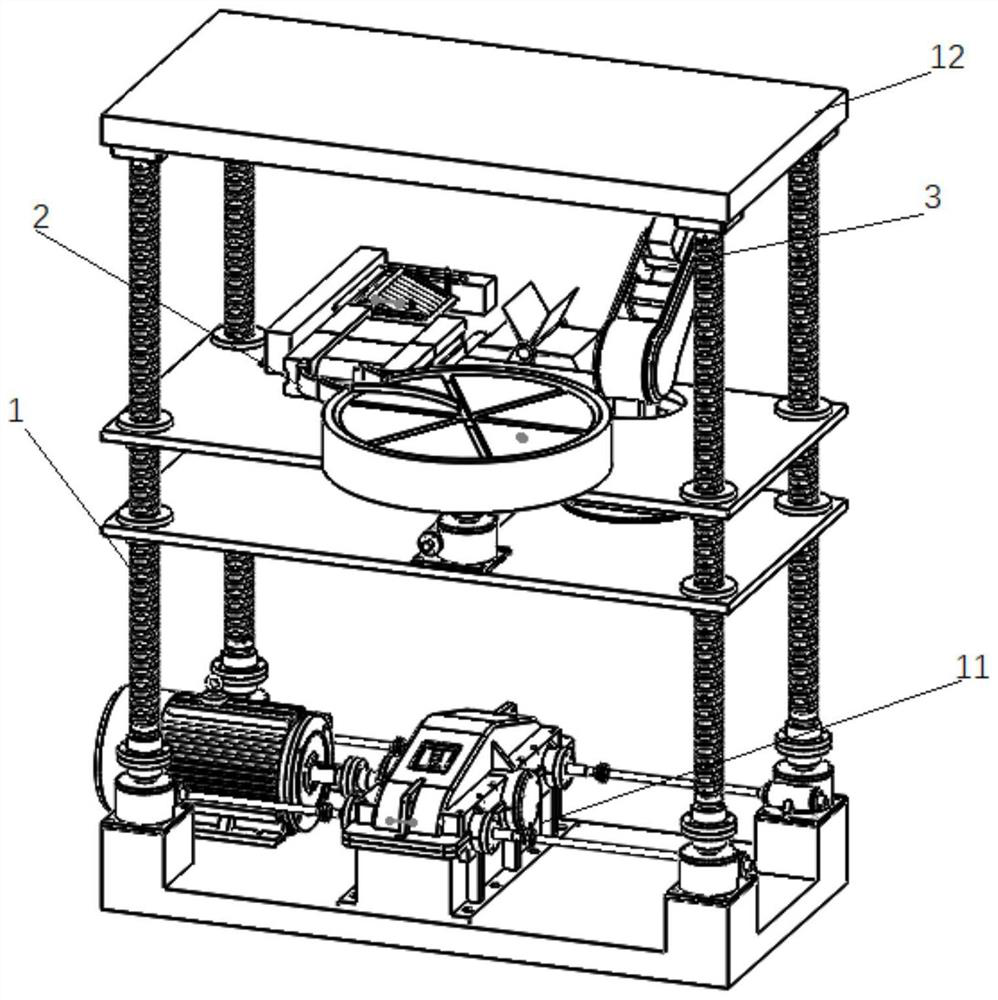

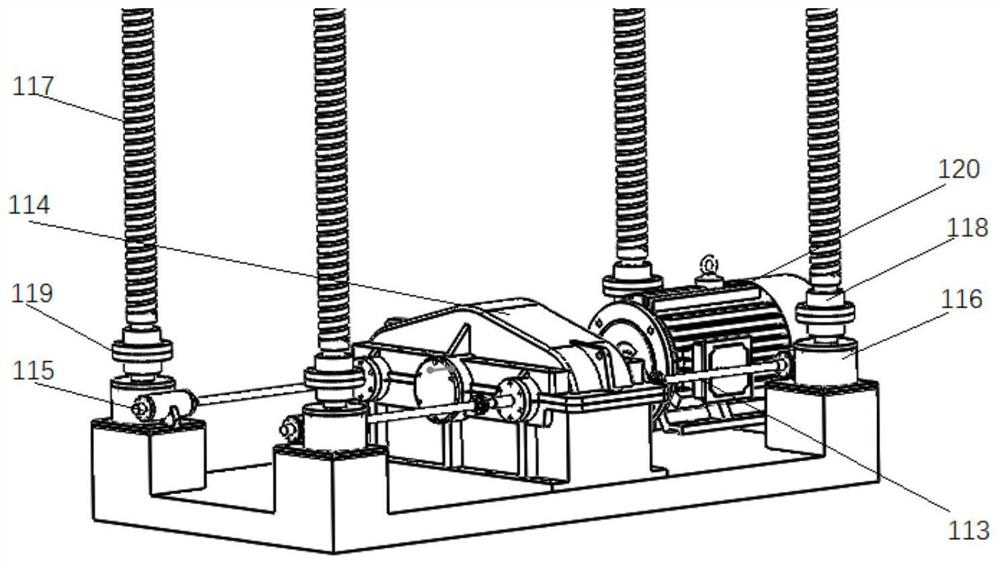

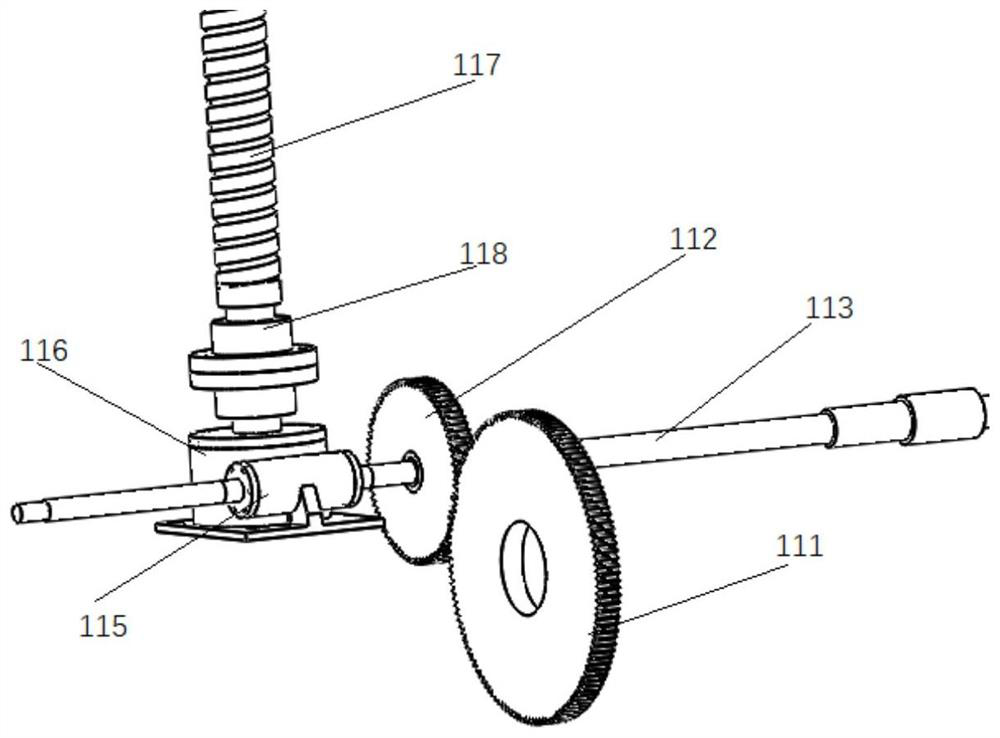

PendingCN112211419ASmooth trafficImprove automation performanceBuilding material handlingBrickTransmission belt

The invention discloses an automatic wall building machine and a wall building method thereof, and belongs to the technical field of constructional engineering automation equipment. Under the drivingof a first motor, a first transmission mechanism drives a lead screw to ascend and descend, so that a top mechanism on a lifting unit automatically ascends and descends; bricks on rotating discs are conveyed to a preset position through the rotating discs, a conveying belt, a bearing disc and a conveyor which are connected in sequence, the bricks are parallel to the wall under the action of fan blades, then cement is sprayed to the outer surfaces of the bricks through a cement spraying fixing unit, and meanwhile a foundation is laid for laying of a next layer of bricks. According to the automatic wall building machine, automatic wall building is completed through mutual cooperation of the lifting unit, a conveying unit and the cement spraying fixing unit, the automation performance is high, labor and effort are not needed in the whole process, the labor cost is greatly saved, the wall building precision is improved through automatic operation, and the construction efficiency is greatlyimproved.

Owner:SHAANXI UNIV OF SCI & TECH

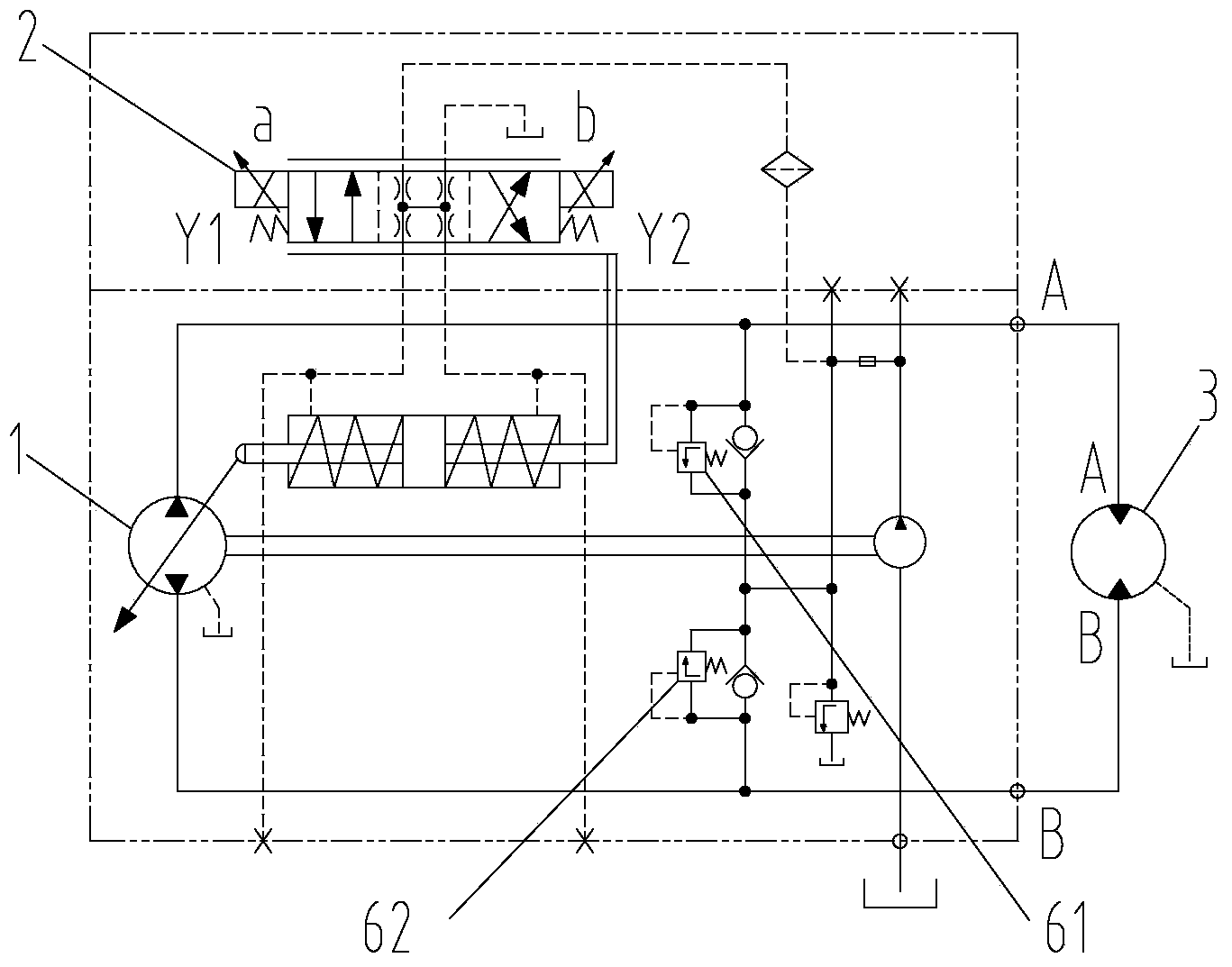

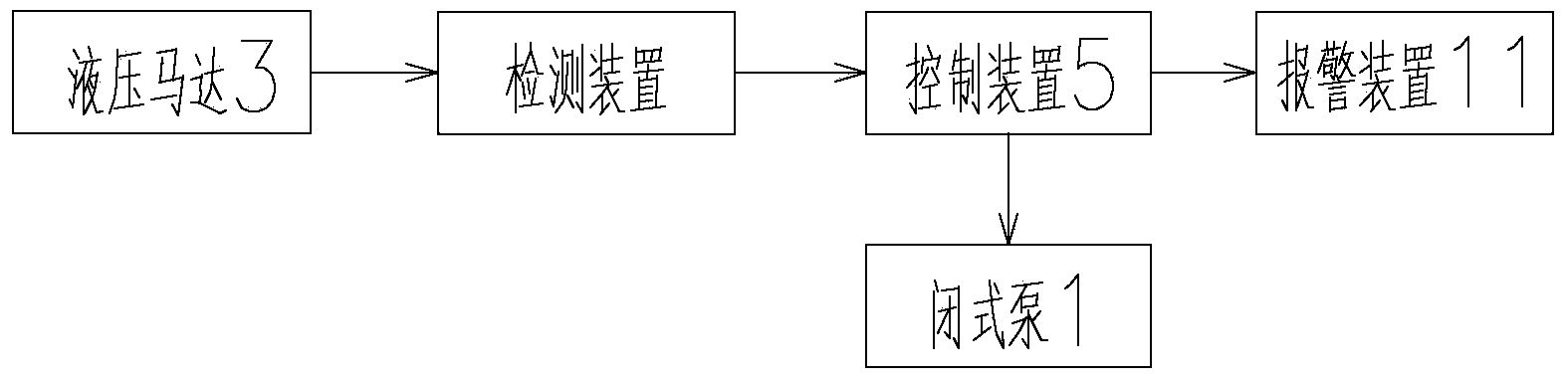

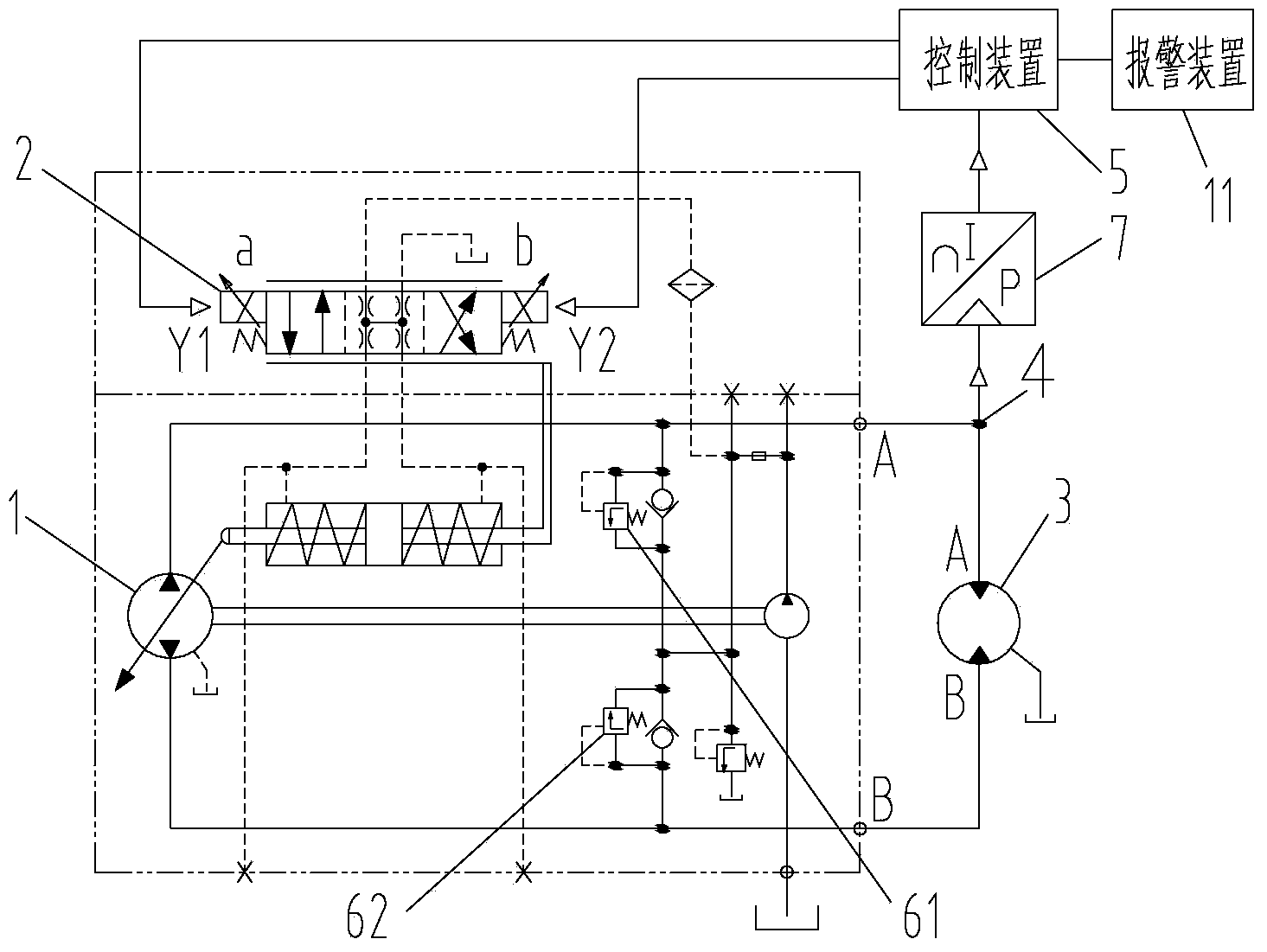

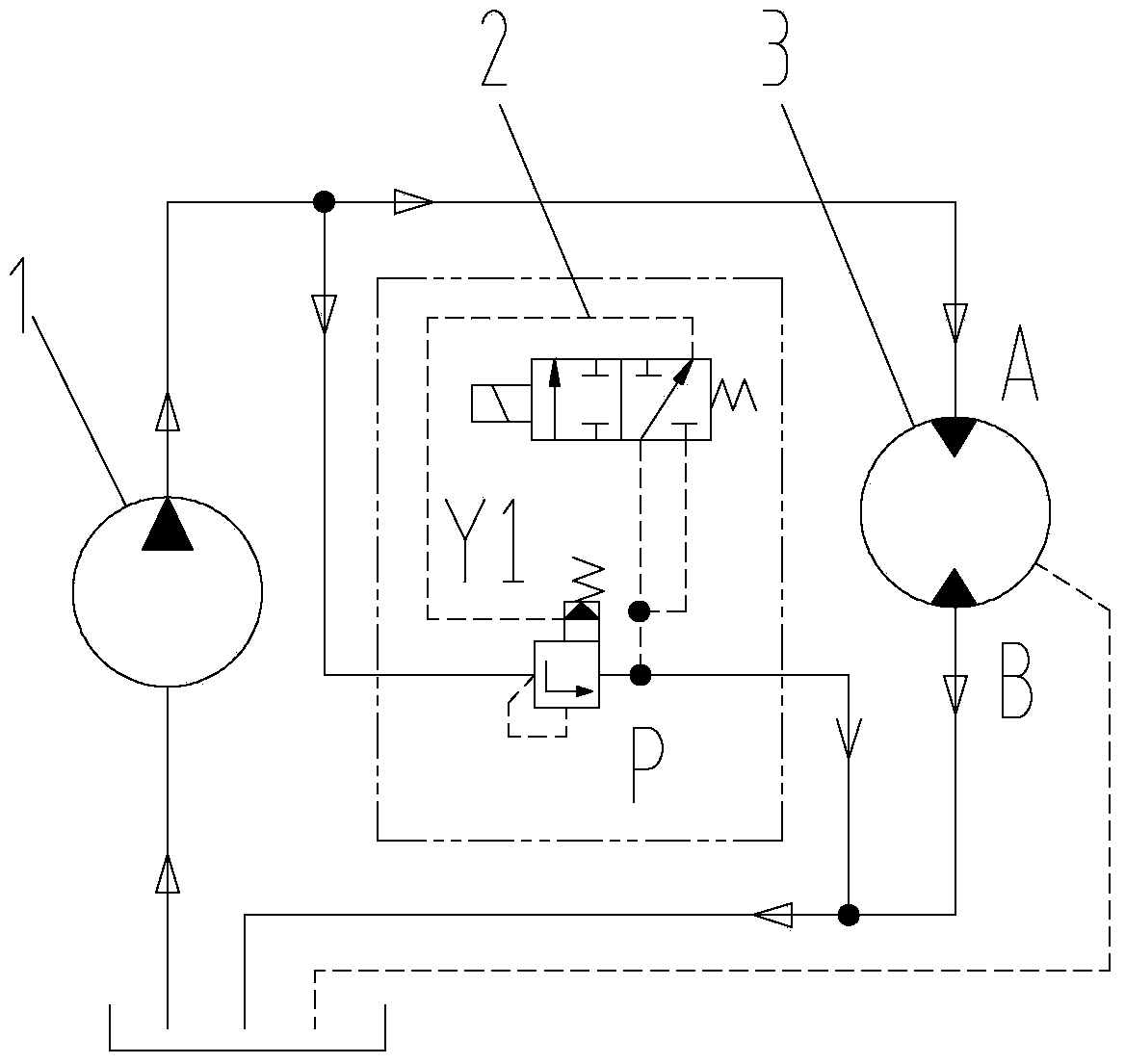

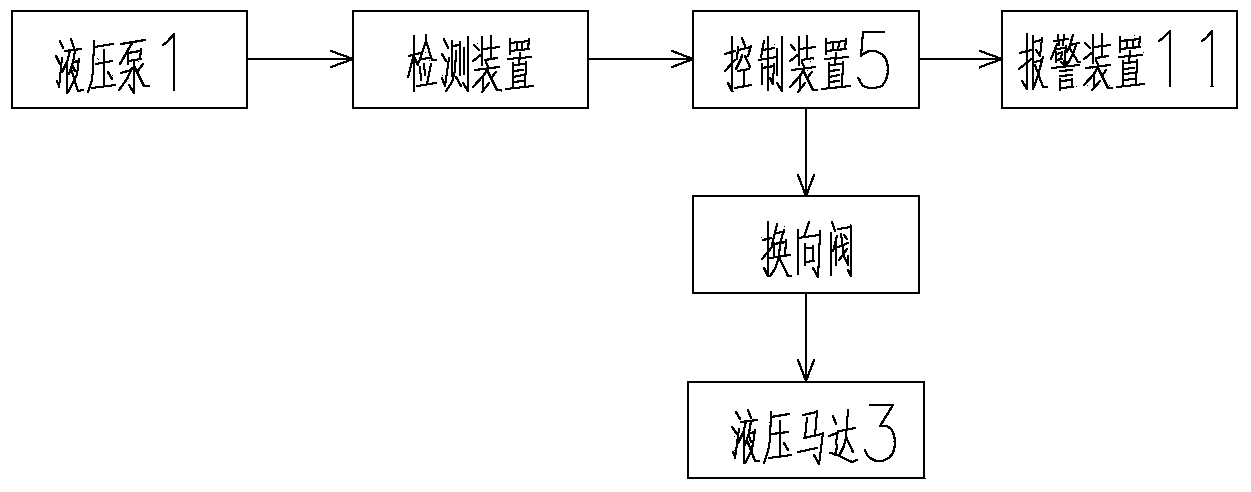

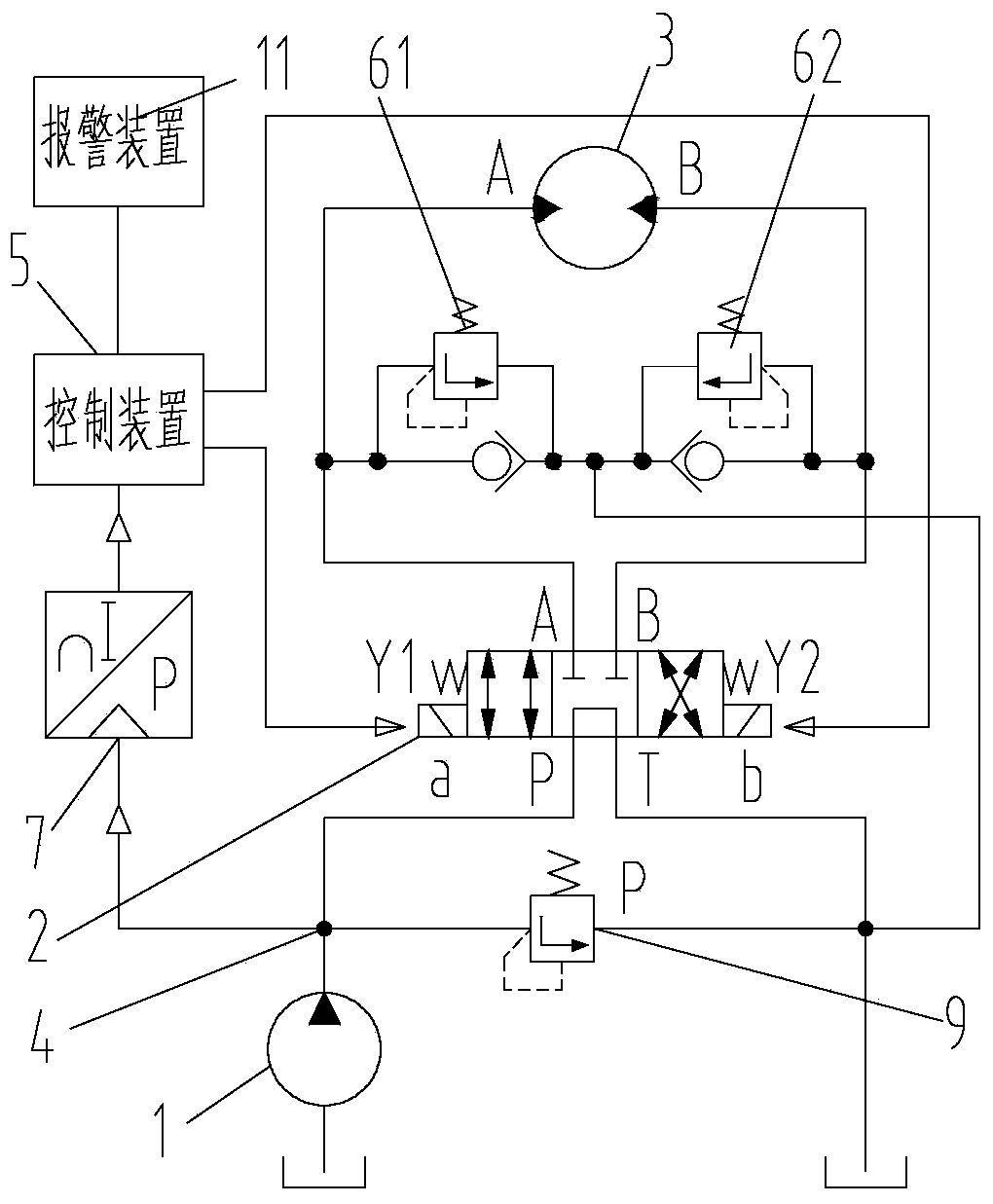

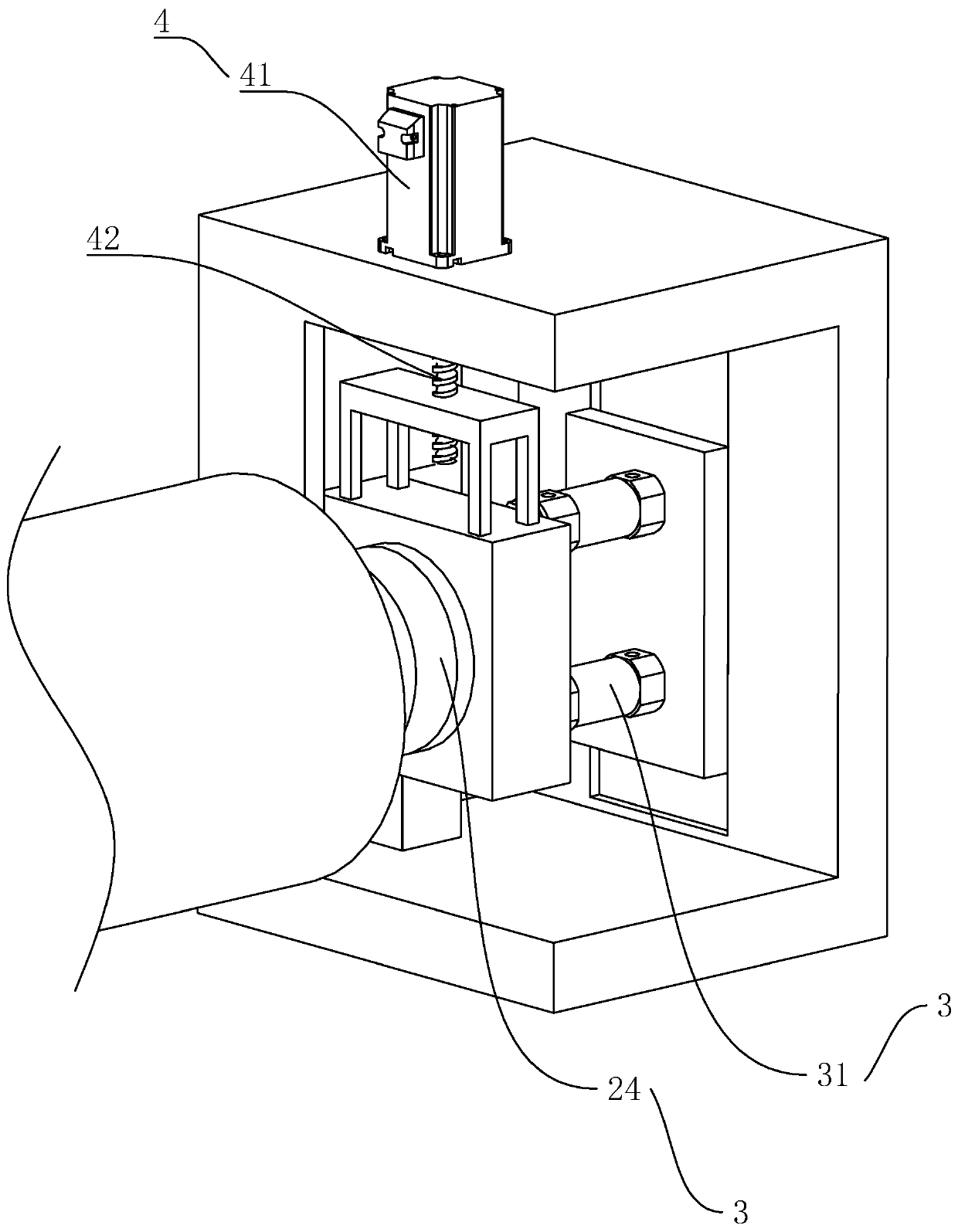

Hydraulic motor locked-rotor prevention control system and method and engineering machine

ActiveCN103644171AGuaranteed to workReduce inversion frequencyFluid-pressure actuator testingServomotorsHydraulic motorControl system

The invention provides a hydraulic motor locked-rotor prevention control system and method and an engineering machine. The hydraulic motor locked-rotor prevention method includes the steps that whether a hydraulic motor (3) is blocked or not is detected; when the hydraulic motor (3) is blocked, the blocking time of the hydraulic motor (3) is calculated; when the locked-rotor time of the hydraulic motor (3) is longer than t1 seconds, it is determined that locked-rotor occurs in the hydraulic motor (3), and the hydraulic motor (3) is controlled to reversely rotate. According to the hydraulic motor locked-rotor prevention method, the problem that in the prior art, working efficiency of a hydraulic system is low due to frequent reverse rotation of the hydraulic motor can be solved.

Owner:ZOOMLION HEAVY IND CO LTD

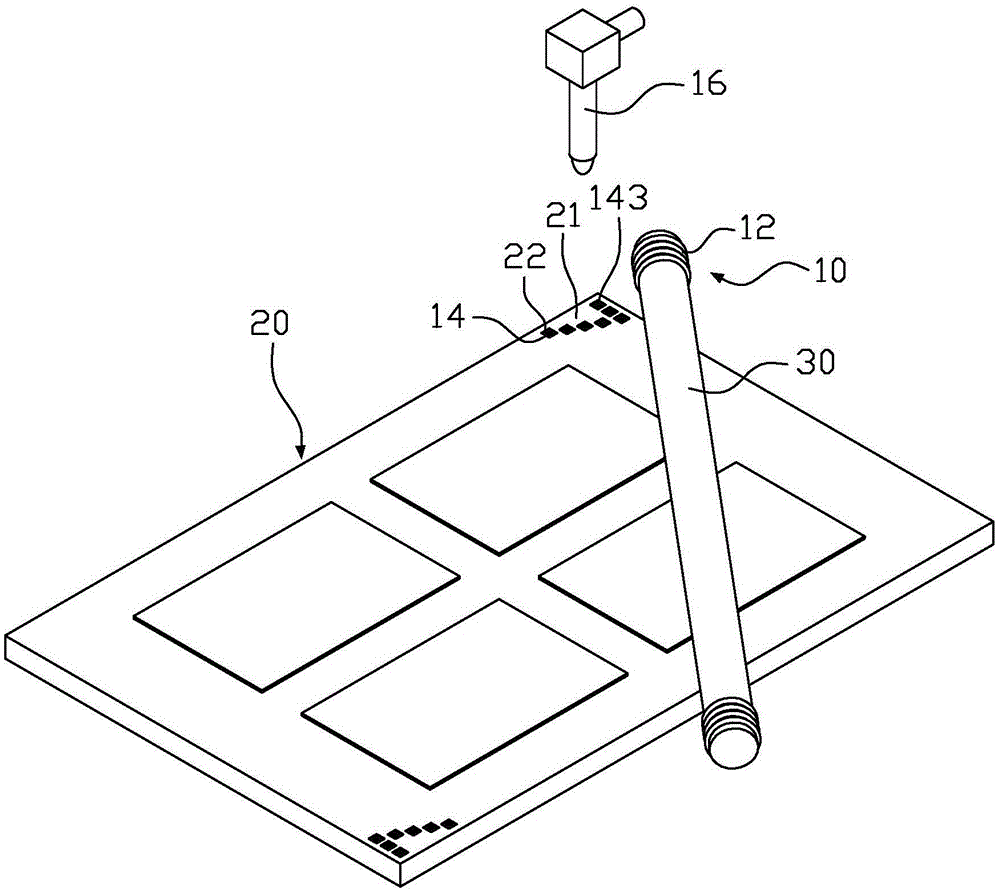

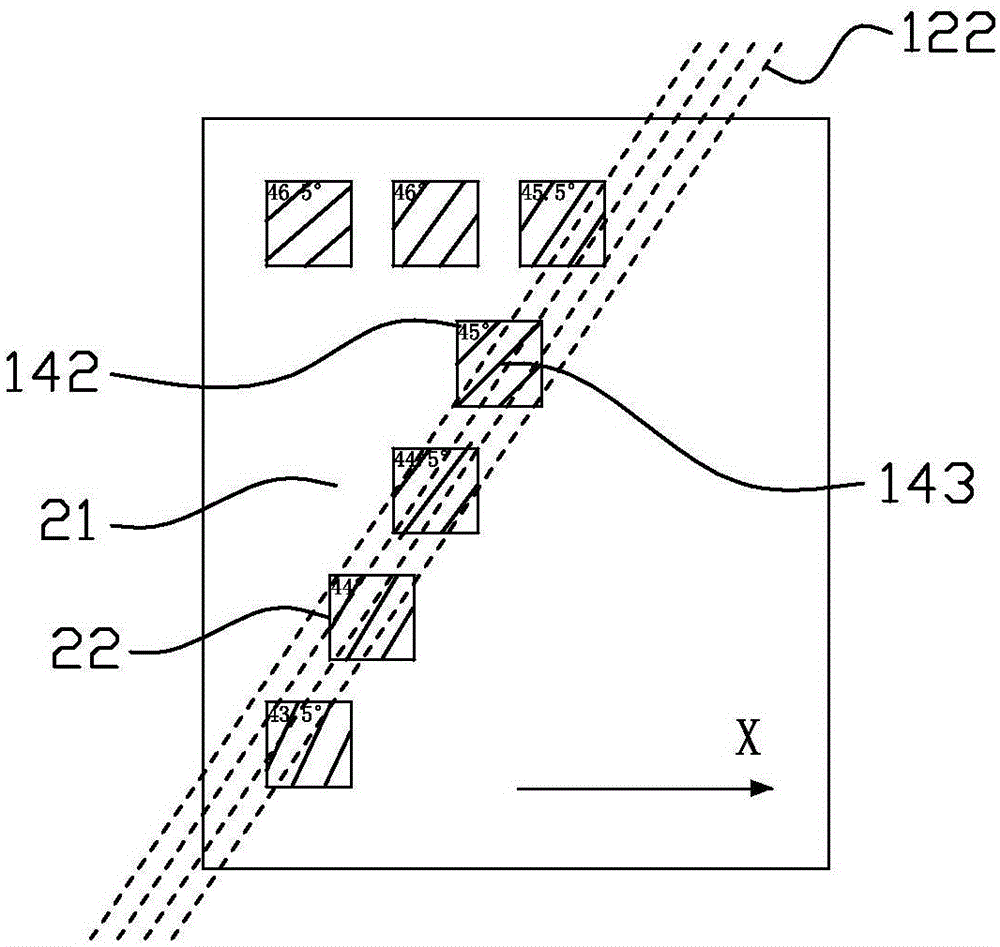

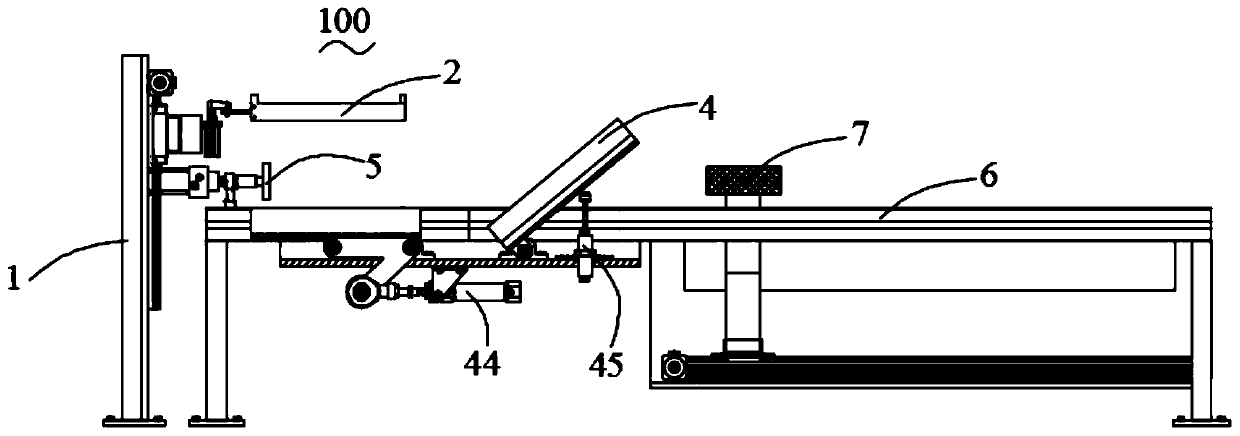

Alignment angle detection apparatus and detection method

ActiveCN105116622AAvoid loss of productivityIncrease productivityUsing optical meansNon-linear opticsEngineeringScratching

The invention provides an alignment angle detection apparatus comprising a marking unit and a standard angle comparison part. The marking unit has an annular protrusion structure, and is coaxially arranged at the end portion of an alignment roll shaft in a sleeving manner. The standard angle comparison part is arranged on the blank zone of a substrate motherboard provided with a PI layer. When the alignment roll shaft rolls for alignment, the marking unit is in contact with the blank zone and draws a trace line in the blank zone through scratching, and the trace line and the standard angle comparison part are compared so as to determine the angle value of the trace line. The invention also provides an alignment angle detection method by the use of the alignment angle detection apparatus.

Owner:KUSN INFOVISION OPTOELECTRONICS

Anti-locking control system and anti-locking method of hydraulic motor and engineering machinery

ActiveCN103629191AGuaranteed to workReduce inversion frequencyFluid-pressure actuator safetyHydraulic motorControl system

The invention provides an anti-locking control system and an anti-locking method of a hydraulic motor and engineering machinery. The anti-locking method of the hydraulic motor comprises the following steps that whether the hydraulic motor (3) is clamped is detected; when the hydraulic motor (3) is clamped, the time when the hydraulic motor (3) is clamped is calculated; when the hydraulic motor (3) is clamped for t1 second, the hydraulic motor (3) is determined to be locked, and a change valve between the oil outlet end of a hydraulic pump (1) and the hydraulic motor (3) is controlled to change, so that the hydraulic motor (3) is reversed. According to the anti-locking method of the hydraulic motor, the problem of lower working efficiency of a hydraulic system due to frequent reversal of the hydraulic motor in the prior art can be solved.

Owner:ZOOMLION HEAVY IND CO LTD

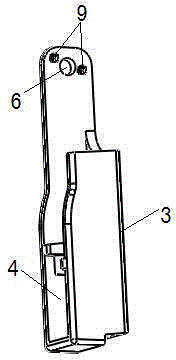

Blood sampling needle protective sleeve and multi-tube blood sampling device

InactiveCN104055528AVersatilityEase of mass productionDiagnostic recording/measuringSensorsBlood samplingSyringe needle

The invention discloses a blood sampling needle protective sleeve which comprises a needle base provided with a needle base and a protective sleeve rotatably connected with the needle base by virtue of a first connecting structure, wherein the first connecting structure comprises a connecting convex column molded at the needle base and a connecting hole formed in the connecting end of the protective sleeve, and the connecting hole is rotatably buckled with the connecting convex column; the blood sampling needle protective sleeve further comprises a locking structure capable of locking the protective sleeve at an initial position; the locking structure comprises a lateral wing and a clamping slot, the lateral ring is molded at the needle base and radially extends, and the clamping slot is formed in the side wall of one side, adjacent to the lateral ring, of the protective sleeve and can be buckled with the lateral ring at the initial position. According to the blood sampling needle protective sleeve, the protective sleeve can be connected with any needle base by virtue of the first connecting structure, so that the protective sleeve has commonality and can be produced in batches; the locking structure can be used for locking the protective sleeve at the initial position, so that the protective sleeve is prevented from rotating randomly, further influencing the visual lines of medical care personnel and reducing the working efficiency in a needle head use process.

Owner:汪贤宗 +2

Metal plate bending machine

The invention discloses a metal plate bending machine, and relates to the technical field of metal plate machining equipment. The metal plate bending machine comprises a rack and an adjusting column,a bending column and an air cylinder which are installed on the rack. The rack is provided with a connecting mechanism used for being connected with the bending column. The connecting mechanism comprises a sliding groove perpendicular to the horizontal plane and a sliding block connected in the sliding groove in a sliding mode. Connecting pieces are arranged on the sliding block; and the connecting pieces are detachably connected to the two ends of the bent column. The bending column comprises a working part in the middle and connecting parts at the two ends. The connecting parts are interconnected with the connecting pieces. Each connecting piece comprises a cylindrical connecting column. According to the metal plate bending machine, the operator can conveniently disassemble, replace andadjust the bending column, the bending column surface treatment convenient for operators, the surface flatness of the bending column is ensured with no requirement for too much time for replacement orlong-time shutdown to cause waste of working time, reduction of the overall working efficiency is avoided and the normal production is ensured.

Owner:无锡银宜华机械有限公司

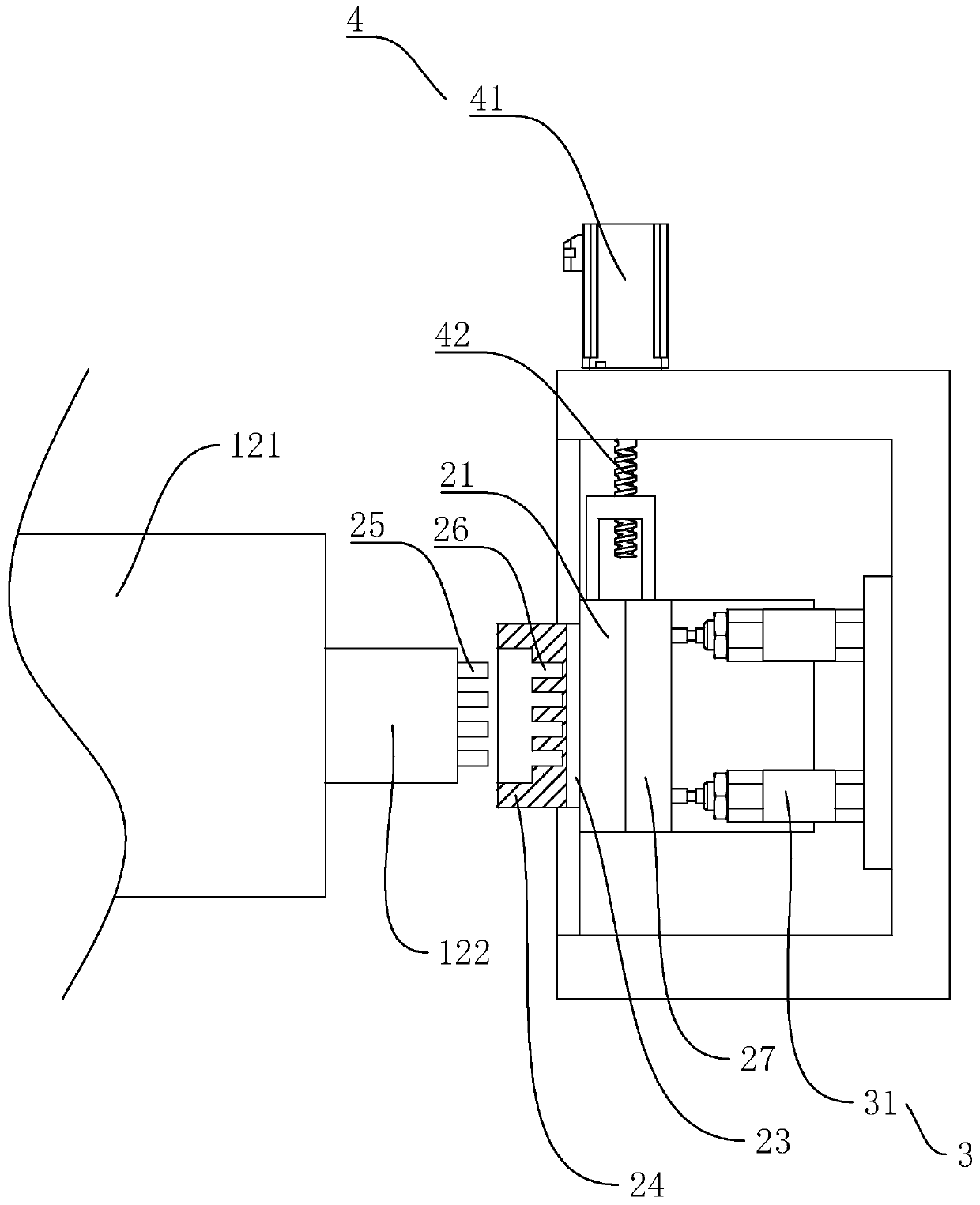

Hard-water-resistant wet rubbing fastness improver and preparation and application methods thereof

ActiveCN106811975AAvoid energy wasteAvoid loss of productivityLiquid/gas/vapor removalDyeing processHard waterDefoaming Agents

The invention discloses a hard-water-resistant wet rubbing fastness improver and preparation and application methods thereof. The hard-water-resistant wet rubbing fastness improver comprises, by weight percentage, 80-94% of weak cation type waterborne polyurethane, 5-15% of cosolvent and 1-5% of defoaming agent. The preparation method includes: accurately weighing the components above, adding the cosolvent and the defoaming agent into the weak cation type waterborne polyurethane while stirring, evenly mixing, and filtering and discharging to obtain the hard-water-resistant wet rubbing fastness improver. The hard-water-resistant wet rubbing fastness improver has the advantages that the hard-water-resistant wet rubbing fastness improver is insensitive to water hardness and salt content, adaptive to production water quality, capable of being used along with post-finishing auxiliaries such as commonly used softening agents, color fixing agents and crosslinking agents, capable of improving the wet rubbing fastness of sueded extra-dark-color active printed or dyed products from 1-2 level to 2-3 level, capable of avoiding energy waste and production efficiency lowering caused by two stentering and capable of solving the problem of oil spot sticky dirt on the surface of cloth at the same time.

Owner:SHANDONG HUANGHE DELTA INST OF TEXTILE SCI & TECH RES INST

Mobile power supply insulating property detection device

InactiveCN108594138AImprove balanceImprove work efficiencyTesting dielectric strengthMeasurement instrument housingEngineeringWorkbench

The invention relates to a mobile power supply insulating property detection device, comprising a workbench, detection probes and a second protective layer. A supporting frame is connected to the topof the workbench, moving slots are fixed on the inner side of the supporting frame, moving discs are respectively mounted in the moving slots, the inner wall, close to the central axis of the supporting frame, of each moving disc is connected with one cross bar, each cross bar is fixedly provided with a clamping slot inside, and each detection probe is arranged on the inner side, close to the central axis of the workbench, of the corresponding clamping slot. A telescopic rod is connected to the inner wall of the top end of the supporting frame, a first fixing plate is arranged at the bottom ofthe telescopic rod, a first bolt is screwed to the outer side of the first fixing plate, and a first limit block is arranged at the bottom end of the first fixing plate. With the arrangement of the detection probes, a second fixing plate, a second limit plate and a second bolt, both sides of the outer wall of mobile power supply can be subjected to insulating property test, and thus, work efficiency of the device is improved.

Owner:DONGGUAN UNIV OF TECH +1

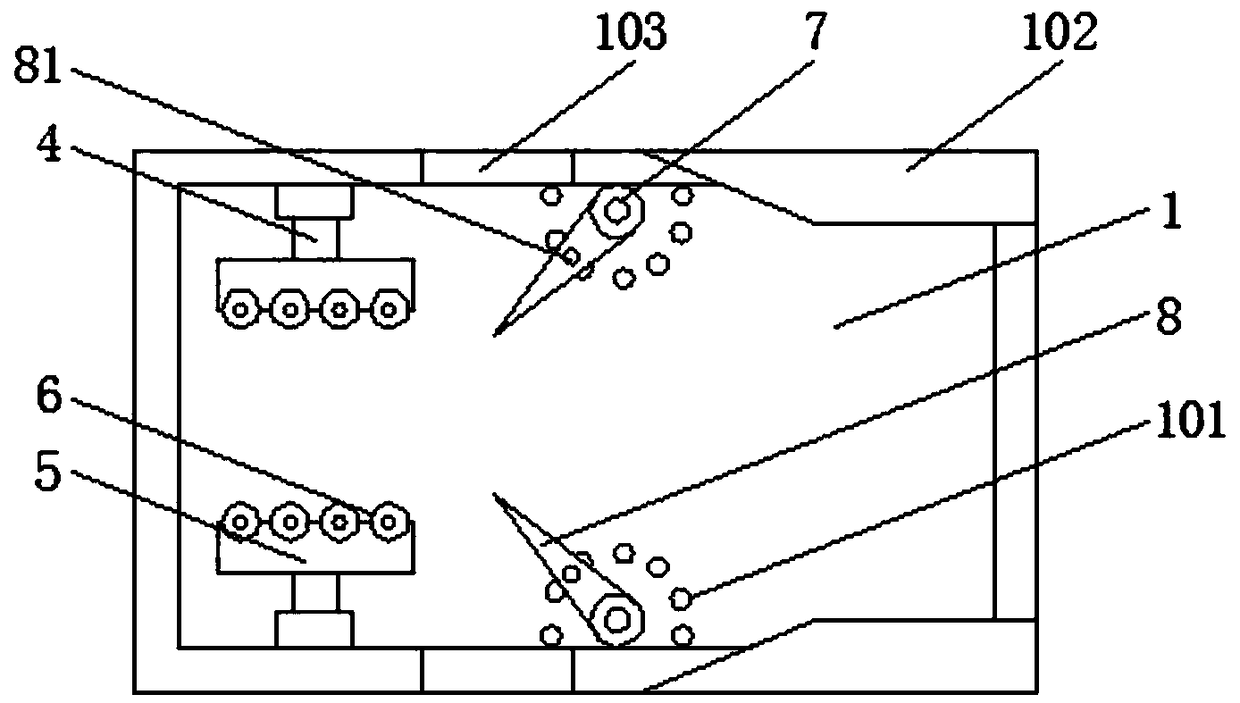

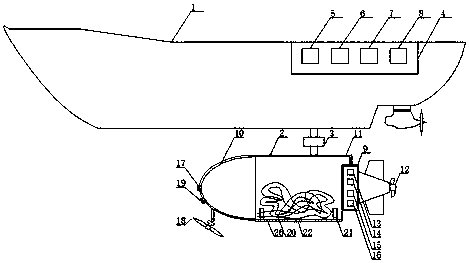

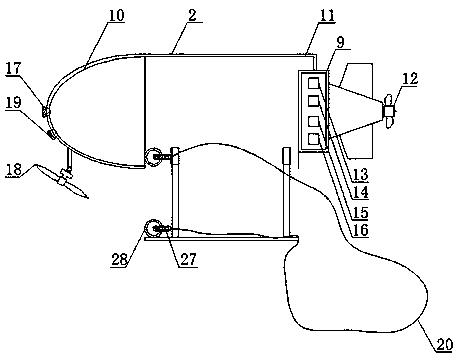

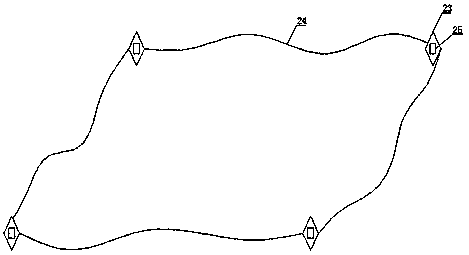

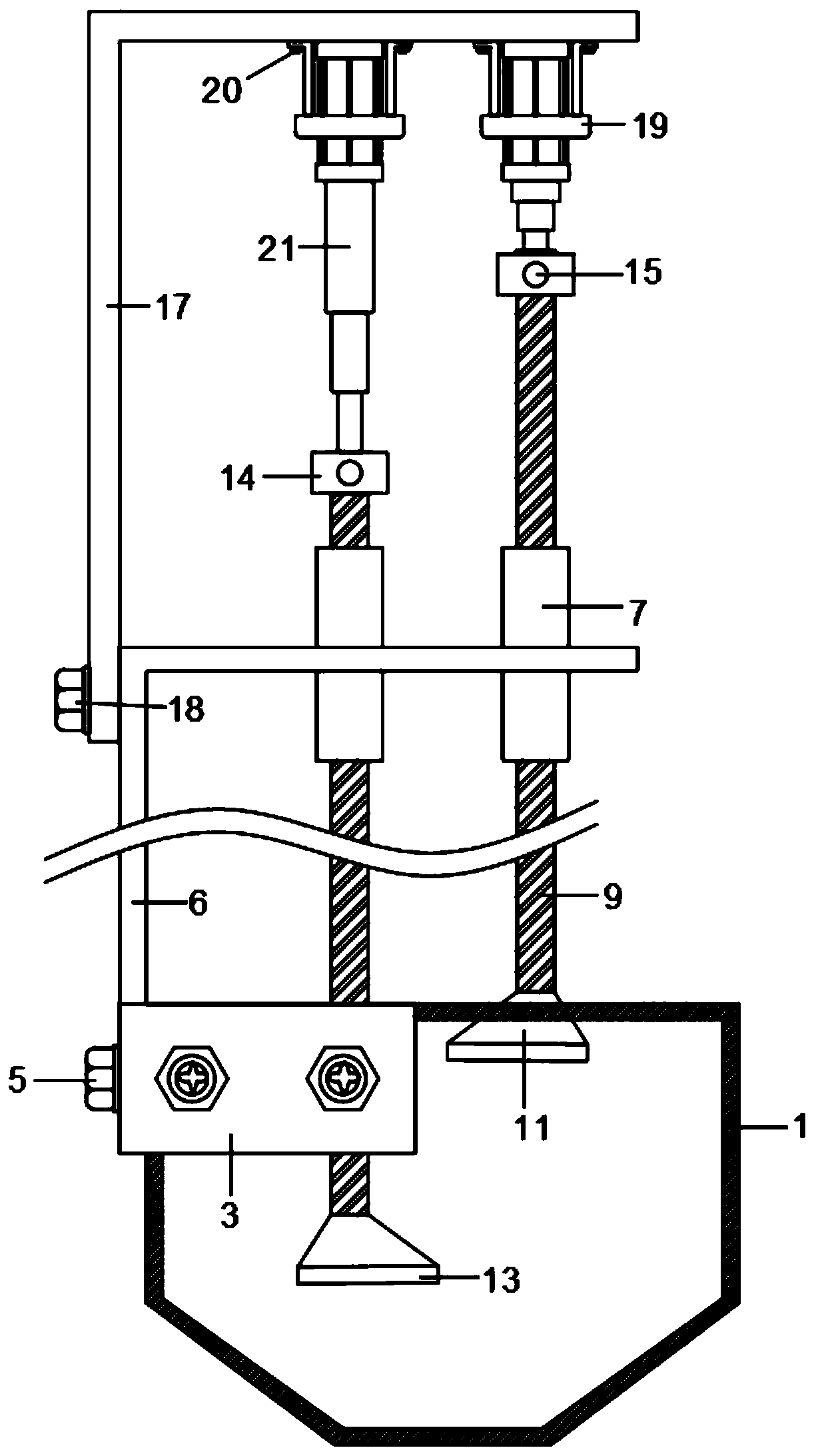

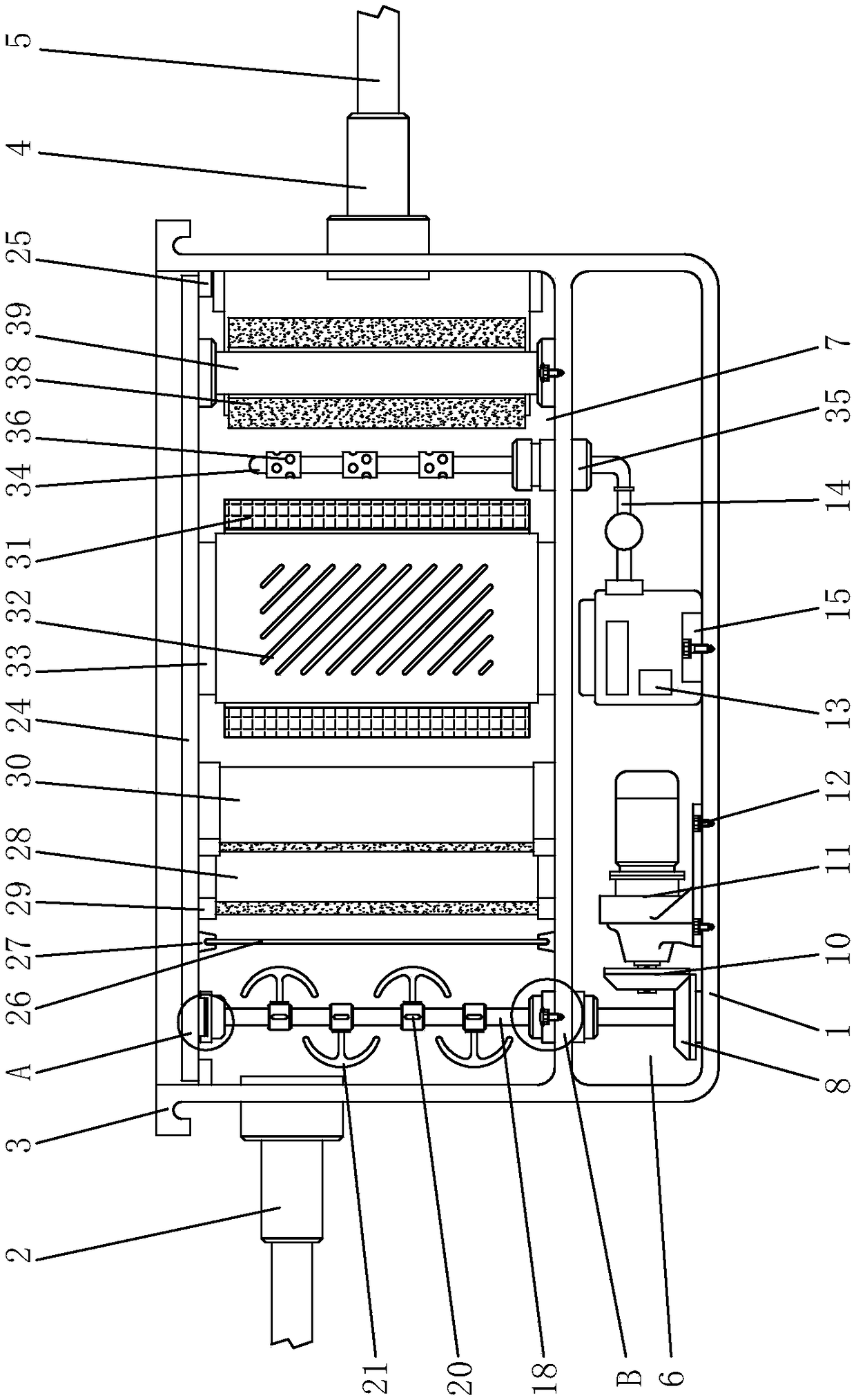

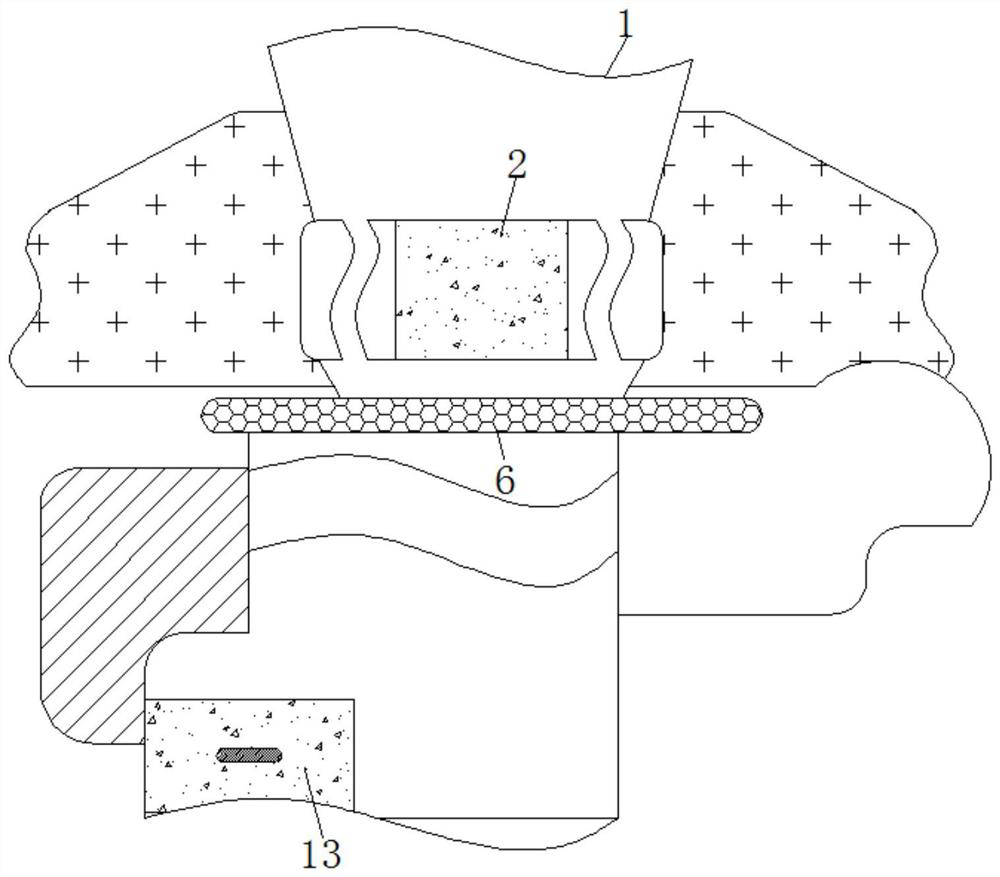

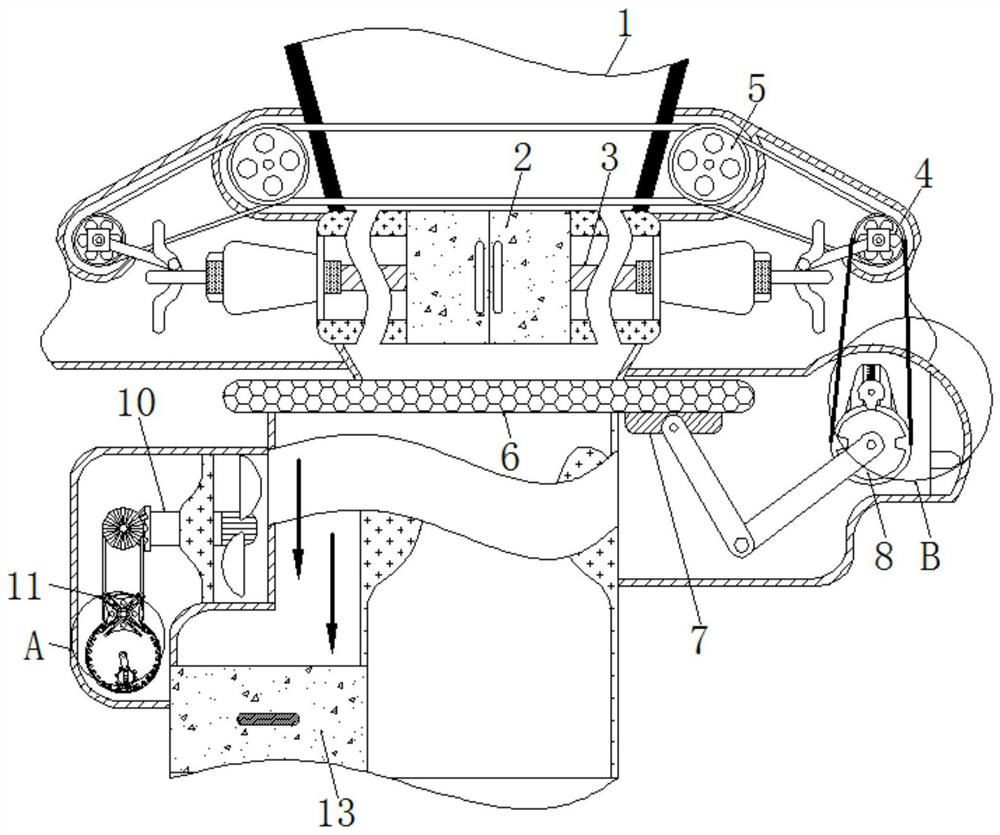

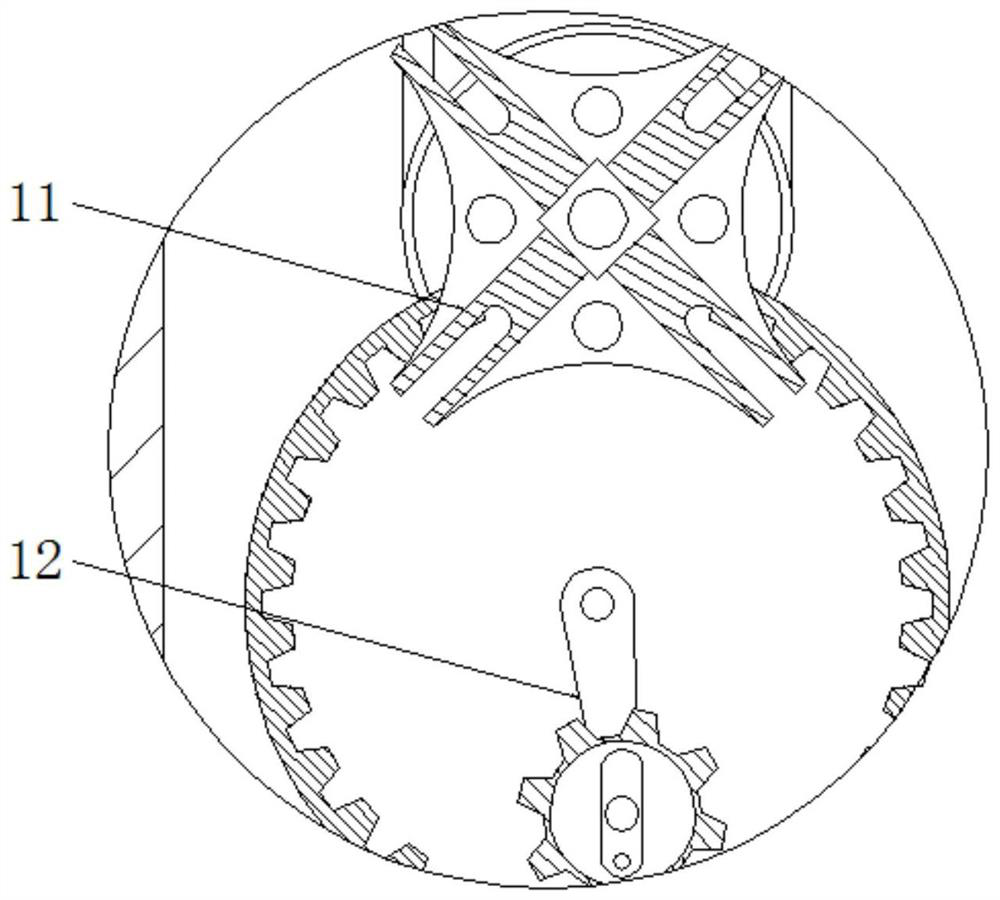

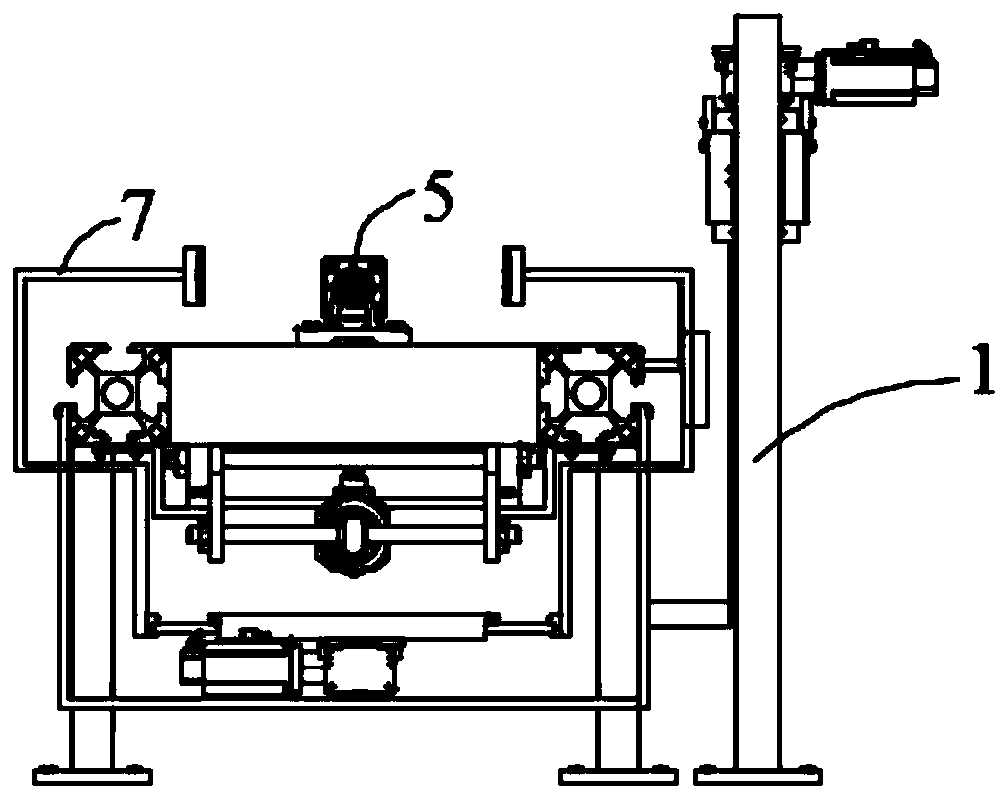

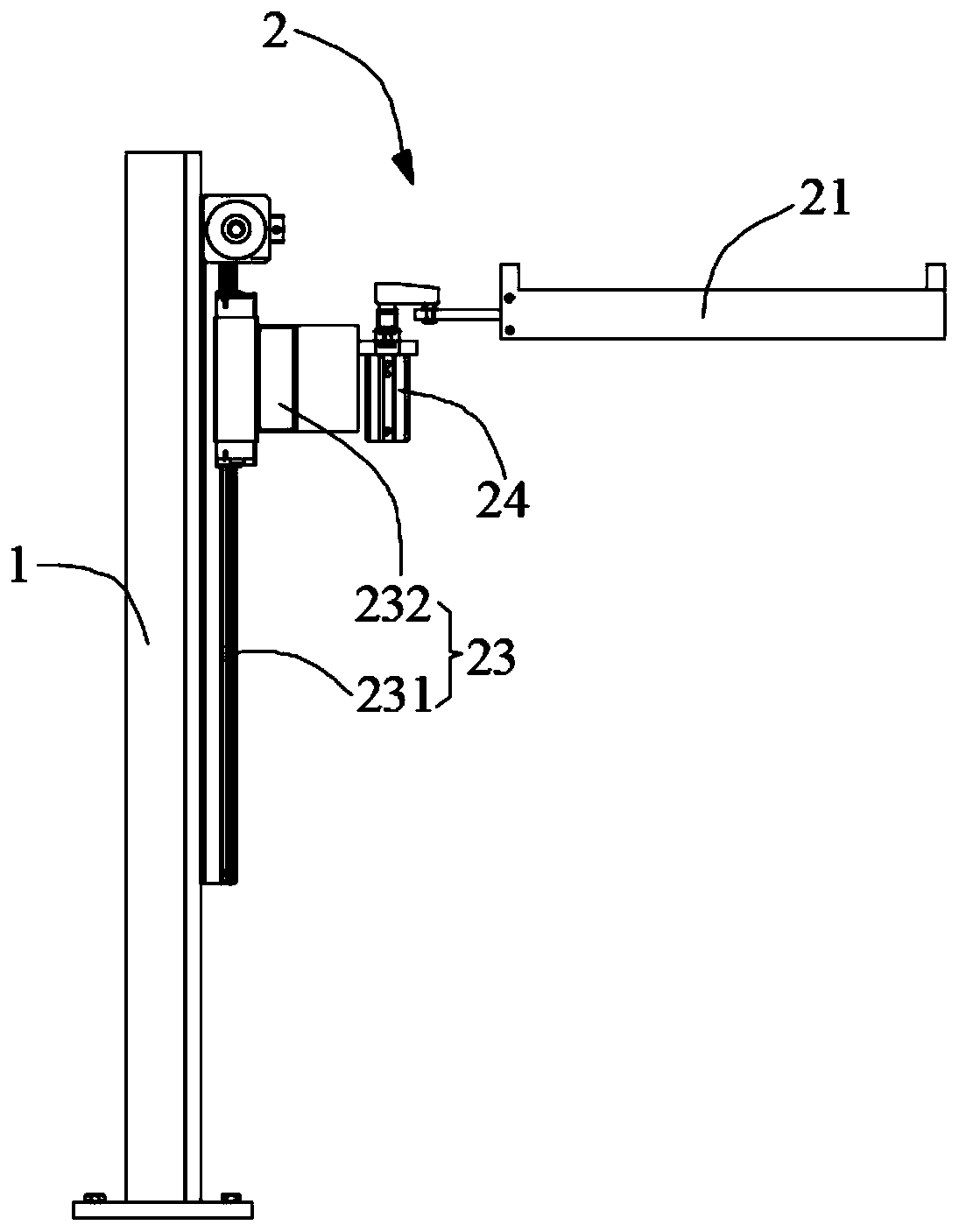

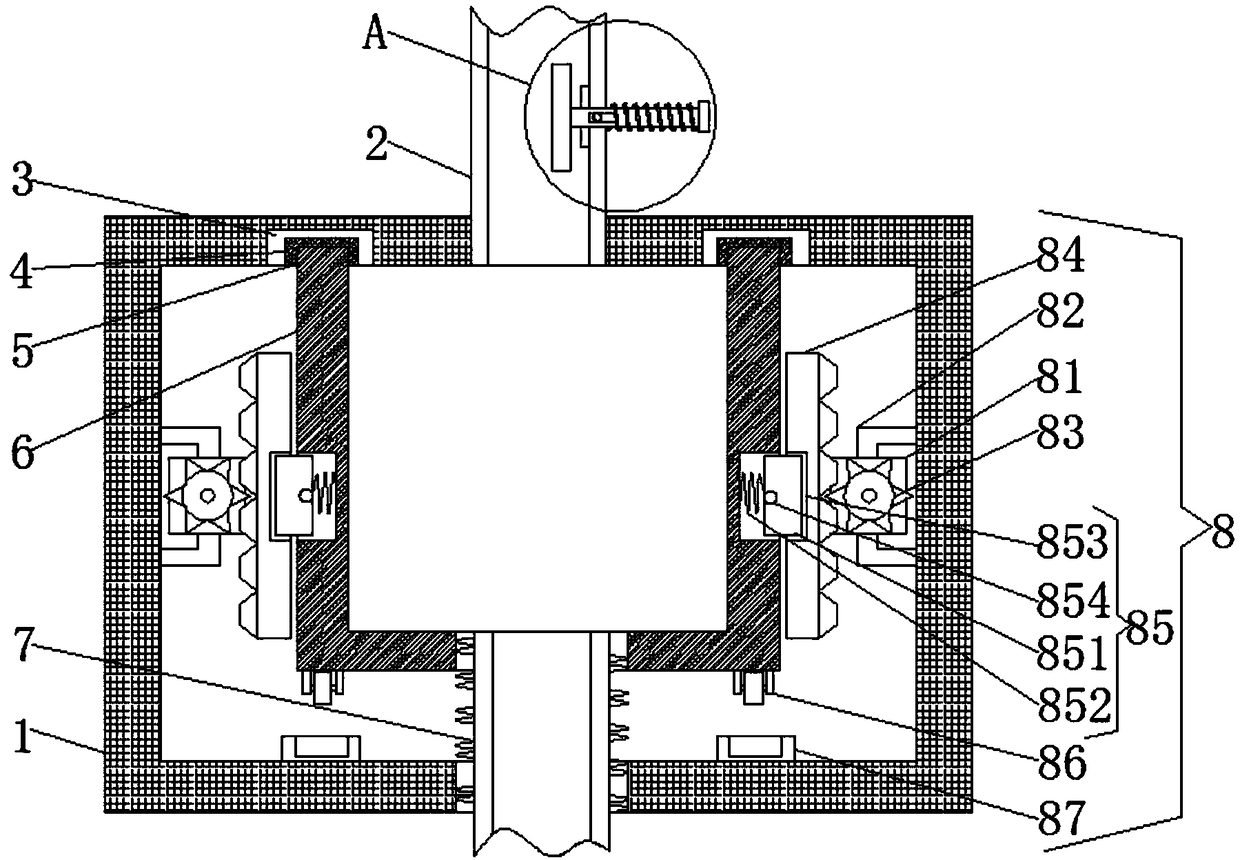

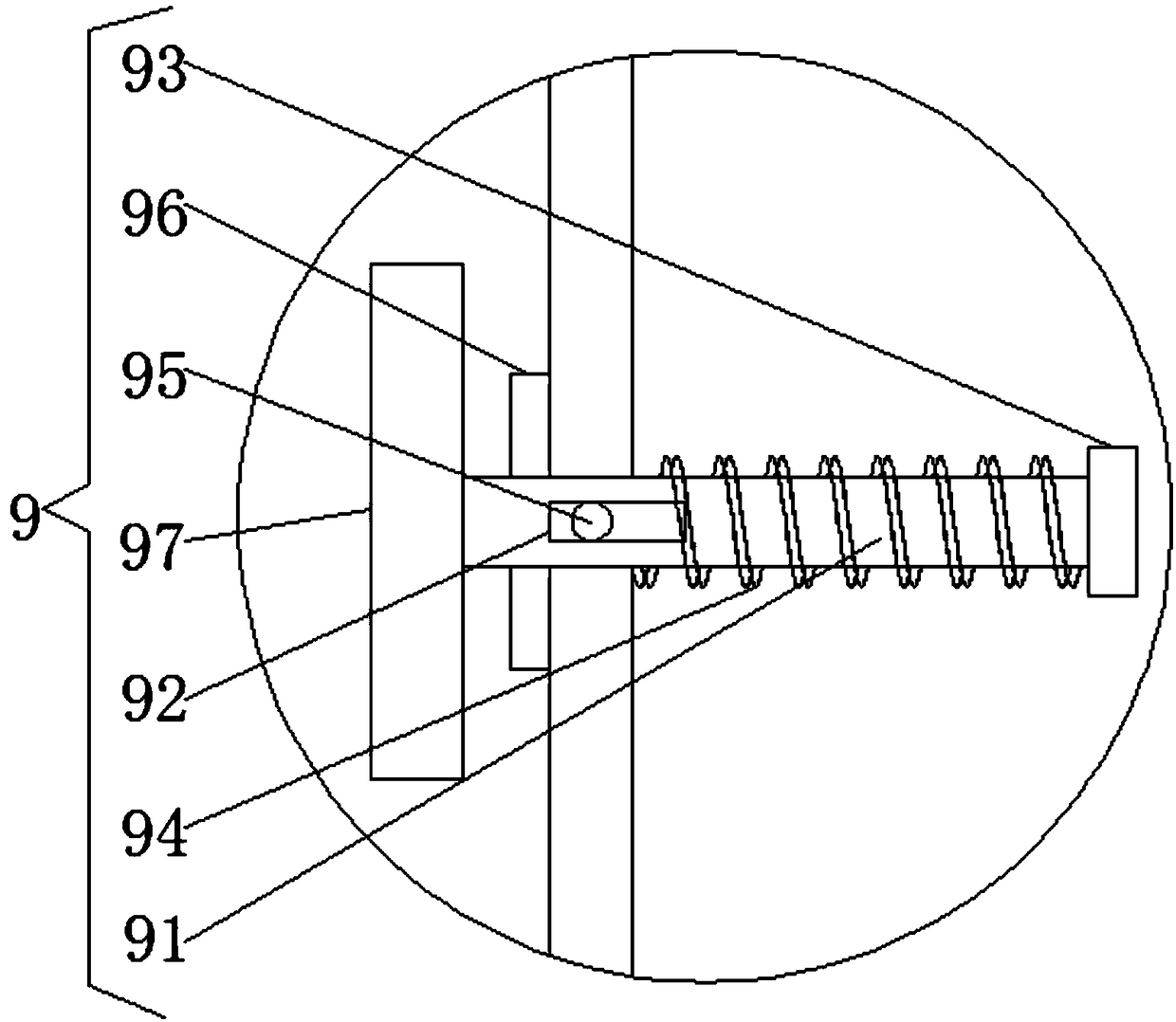

Water plant removing equipment operating in combination with unmanned ship and working method of water plant removing equipment

InactiveCN108166467AAvoid loss of productivityAvoid harmWater cleaningHarvestersMarine engineeringMarine navigation

The invention discloses water plant removing equipment operating in combination with an unmanned ship and a working method of the water plant removing equipment. The water plant removing equipment operating in combination with the unmanned ship comprises the unmanned ship and a removing equipment body; the unmanned ship comprises a first control mechanism; the removing equipment body comprises a second control mechanism, a cutting portion, a storage portion and a screw propulsion mechanism; the second control mechanism comprises a second processor, a second drive device, a second navigation device and a second positioning device; the second navigation device is used for generating the traveling route of the removing equipment body; the second positioning device is used for obtaining secondposition information of the removing equipment body; the cutting portion comprises an underwater camera and a cutting device; the underwater camera is used for shooting the underwater environment; the cutting device is used for removing water plants; the storage portion comprises a containing net bag, an electric-hydraulic pusher and a movable chassis; the movable chassis is connected with the storage portion through the electric-hydraulic pusher; the screw propulsion mechanism is connected with the second drive device; and the screw propulsion mechanism is arranged at the tail end of a shelland used for controlling the underwater course of the removing equipment body.

Owner:苏州亮磊知识产权运营有限公司

Automatic feeding device for mixed plastic color master batches

InactiveCN111590862AImprove stabilityAvoid loss of productivityLarge containersAgricultural engineeringControl theory

Owner:扬州市苏达科技发展有限公司

Movable sensor fixing device

PendingCN107702736AAvoid loss of productivityAvoid reducing the spatial range of monitoring up and downMeasurement apparatus componentsDrive wheelElectric machinery

The invention discloses a movable sensor fixing device which comprises a sensor body and a traveling mechanism. A shell is arranged on the outside of the sensor body. A connecting shaft is horizontally arranged on both sides of the shell. A control unit is arranged on the rear end of the shell. A sensor fixing component is arranged on the lower part of the shell, a partition plate is arranged on the bottom of the sensor fixing component, the traveling mechanism is arranged on the lower part of the partition plate, the traveling mechanism comprises top plates and guide rails, the top plates arearranged at two ends of the partition plate respectively, two ends of the lower part of each top plate are provided with an outer side plate and a fixing side plate in parallel, a traveling driving wheel is arranged at an upper portion and a travelling driven wheel is arranged at a lower portion in a space formed by the outer side plate and the fixing side plate at one end of the lower part of the partition plate, the travelling driving wheel passes through a fixing sealing plate to be rotatably connected to a second motor, and a travelling driven wheel is arranged at a lower portion in a space formed by the outer side plate and the fixing side plate at the other end of the lower part of the partition plate. The movable sensor fixing device increases the detection points and improves thedetection precision.

Owner:河南力方网络科技有限公司

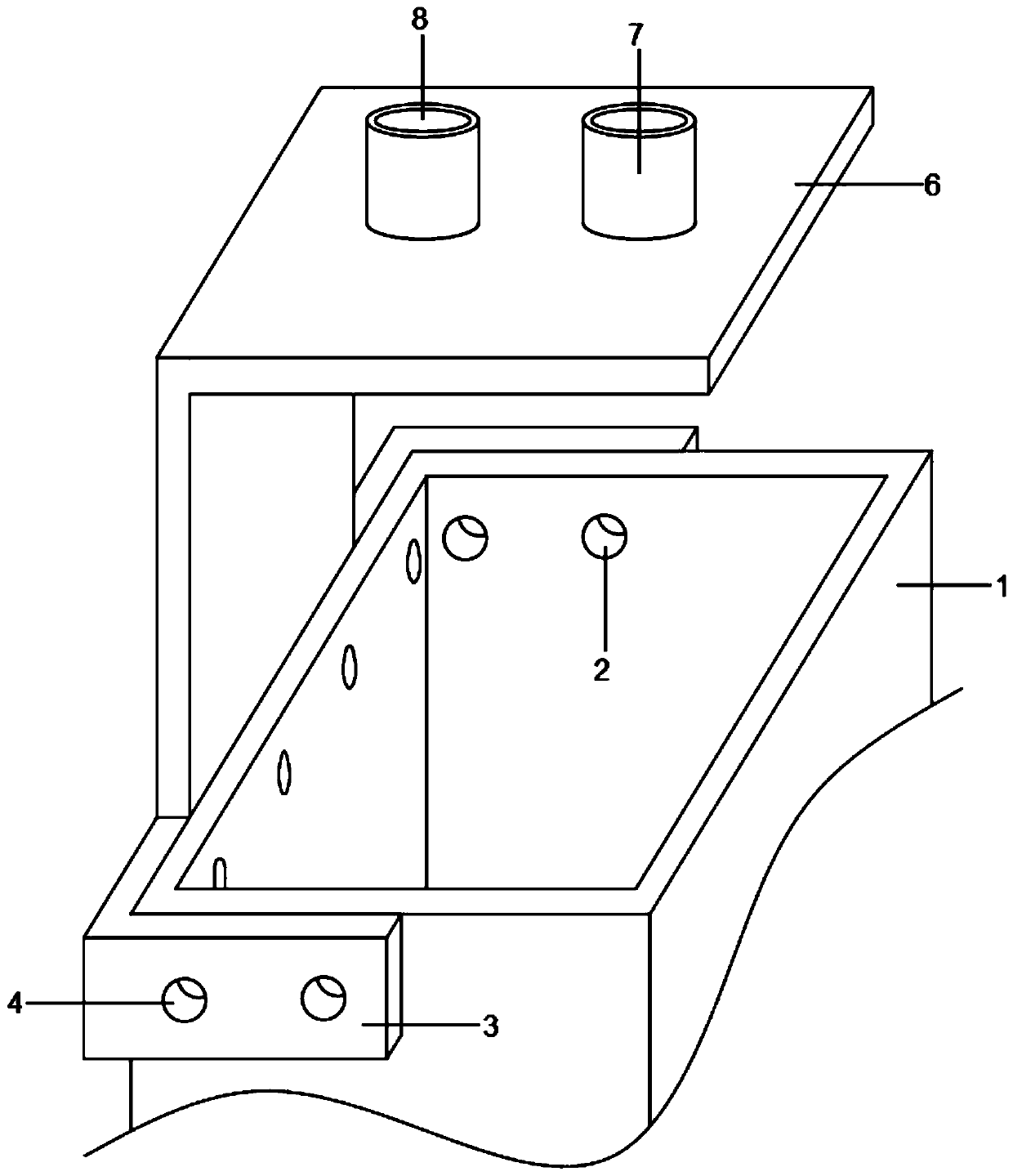

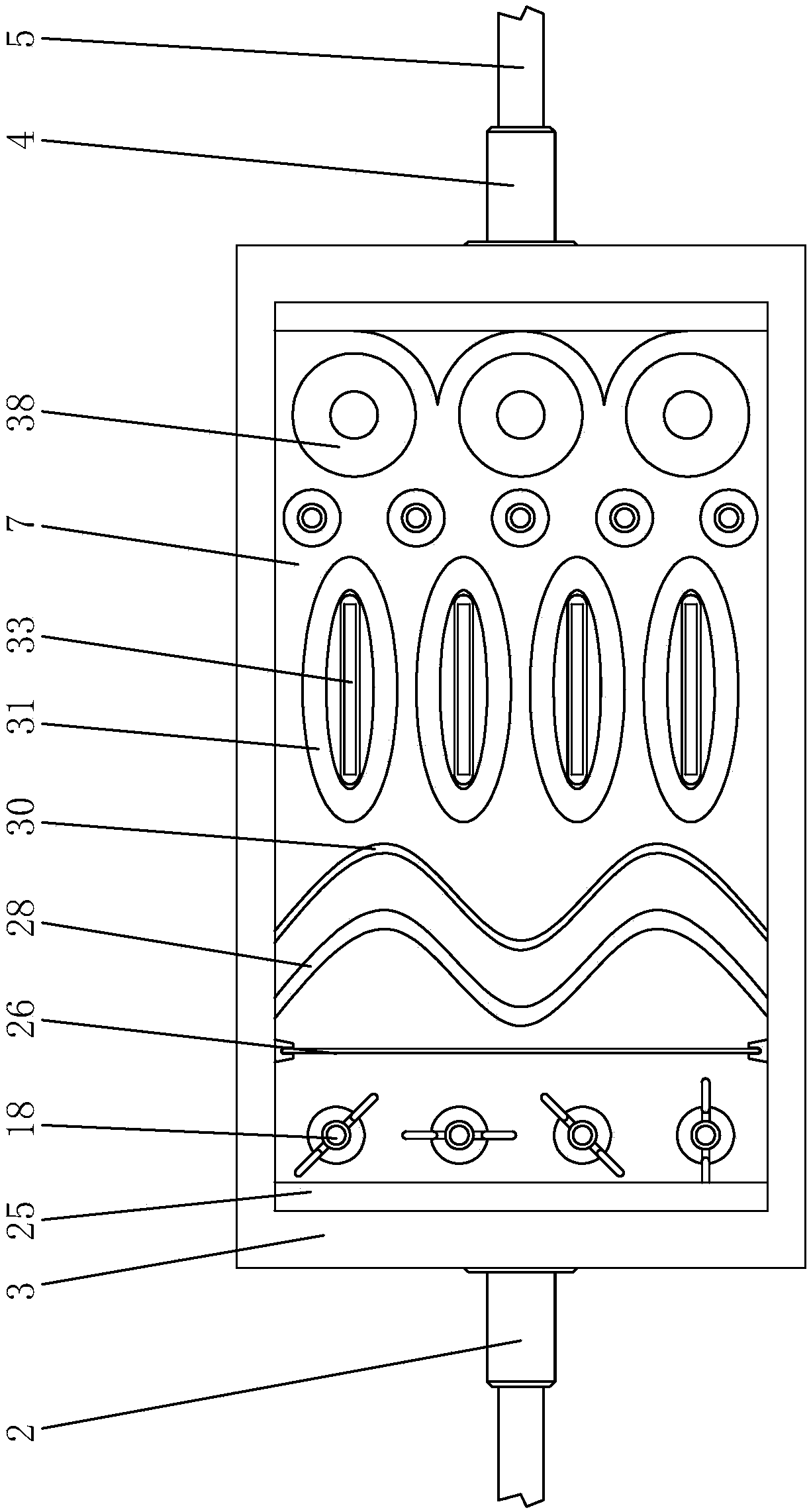

Filter system of fish pond

ActiveCN108575875AIncrease structureImprove performancePisciculture and aquariaEngineeringHigh pressure

The invention discloses a filter system of a fish pond. The filter system comprises a box body shell, a driving gear and a filter screen; the upper part of the left side of the box body shell is connected with a water inlet; an external-turning handle is arranged above the water inlet; a conversion joint is arranged on the right side of the box body shell; the right end of the conversion joint isprovided with a water outlet; a power cabin is arranged at the lower part of the inner part of the box body shell; a filter cabin is arranged above the power cabin; a transmission gear is fixed at theleft end of the inner part of the power cabin; a sealing bearing is arranged above the transmission gear; the right side of the driving gear is connected with a motor; the driving gear is positionedat the right side of the transmission gear; a connecting screw is arranged below the motor; an air compressor is arranged at the right side of the motor; a high-pressure copper pipe is connected to the right side of the air compressor; the lower end of the air compressor is fixed to an internal base; a waterproof screw is arranged in the inner part of the upper end of the sealing bearing; a waterproof cap is arranged on the waterproof screw; and rotating shafts are connected on the sealing bearing. Impurity precipitate is not formed in the filter system, and the blockage of the filter device is avoided.

Owner:日照新睿招商发展有限公司

Curtain device capable of adjusting indoor illumination based on photoresistor

ActiveCN110984830AGood thermal effectAvoid wasting resourcesLight protection screensPhysicsWindow covering

The invention relates to the technical field of furniture, and discloses a curtain device capable of adjusting indoor illumination based on a photoresistor. The device comprises a shell I and a shellII, a photosensitive assembly is fixedly connected to the outside of the shell I, small holes are formed in the surface of the bottom of the shell I, a connecting rod is fixedly connected to the interior of the shell I, a connecting assembly is movably connected to the interior of the shell I, a driving block is fixedly connected to the bottom of the connecting assembly, a telescopic rod is fixedly connected to the interior of the shell I, a threaded rod is fixedly connected to the right side of the telescopic rod, a spring is fixedly connected to the right side of the threaded rod, and a shifting rod is fixedly connected to the bottom of the telescopic rod. Under the interaction between the photosensitive assembly, rotating rods and rotating shafts, when the illumination intensity cannotreach the condition that the curtain continues to be opened, the photoresistor rotates the rotating rods, the curtain cloth is collected into a storage box, and the rotating shafts are driven to rotate, so that gears and blocking rods are clamped, and the function of controlling the curtain to be lifted by light is completed.

Owner:山东华歌建筑设计有限公司

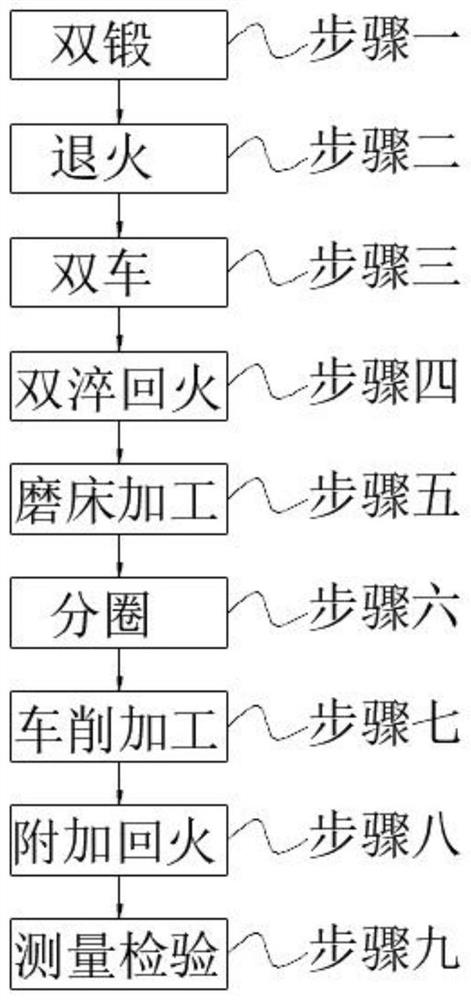

Bearing outer ring machining process

ActiveCN111649071AAvoid deformationAvoid loss of productivityShaftsBearing componentsStress concentrationTempering

The invention discloses a bearing outer ring machining process including the first step of double forging, the second step of annealing, the third step of double turning, the fourth step of double quenching tempering, the fifth step of grinding machine machining, the sixth step of ring separation, the seventh step of turning, the eighth step of additional tempering and the ninth step of measurement and inspection. In the first step, bearing steel is selected as a raw material, then the bearing steel is placed in a heating furnace to be subjected to one-time heating processing, and the bearingsteel is cut into single material sections after heating is completed. By means of the bearing outer ring machining process, a traditional production process of a single bearing outer ring is changed,bearing outer rings which are combined together are machined and produced, stress concentration in the process of conducting forging on the material sections is facilitated, material section deformation caused by uneven stress in the forging process is avoided, and material saving is facilitated; and meanwhile, ellipses and warping of products are eliminated through a grinding machine, the damagerate of the products is decreased, and the situation that due to secondary machining and production, the work efficiency is reduced is avoided.

Owner:河北鑫泰轴承锻造有限公司

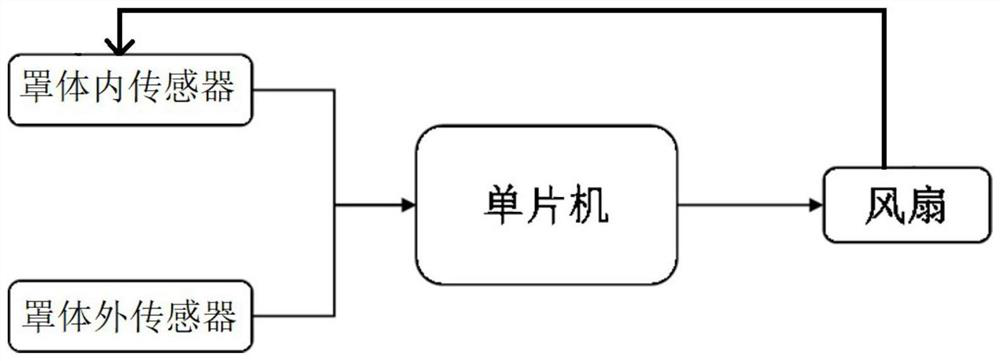

Anti-fog breathing mask for preventing breathing diseases and using method thereof

ActiveCN112806644APrevent foggingAvoid loss of productivityGarment special featuresEfficient regulation technologiesPhysical medicine and rehabilitationAutomatic control

The invention belongs to the technical field of disease prevention and control, and relates to an anti-fog breathing mask for preventing breathing diseases and a using method thereof. The anti-fog breathing mask comprises a mask body wrapping the whole head of a user therein, at least the part, located in front of the user, of the mask body is transparent, the mask body is provided with an air inlet pipeline and an air outlet pipeline, the air inlet pipeline and the air outlet pipeline are each provided with a filtering part, and a temperature adjusting part is arranged above the part, located in front of the user, of the mask body and used for adjusting the temperature in the mask body. The temperature inside and outside the mask is monitored through the automatic control technology, a demisting fan near the mask is controlled through a controller, the temperature inside and outside the mask is intelligently adjusted, water vapor is prevented from being condensed, and therefore an anti-fog effect is achieved.

Owner:RENMIN UNIVERSITY OF CHINA

Device capable of solving problems of non-automatic feeding and easy blockage and inconvenient cleaning of filter screen

The invention relates to the technical field of cables, and discloses a device capable of solving the problems of non-automatic feeding and easy blockage and inconvenient cleaning of a filter screen.The device comprises a feeding box, and feeding is carried out on a cable plastic extruding machine by utilizing the feeding box. The device has the advantages that through cooperative use of the feeding box, baffles, push rods, a first disc and second discs, when the plastic extruding machine is used for manufacturing cable sheaths, automatic quantitative feeding can be realized, on one hand, thephenomenon that the working efficiency is reduced due to the fact that feeding is not carried out in time can be avoided, and on the other hand, the phenomenon that the plastic extruding machine cannot carry out manufacturing in time and is prone to being blocked due to continuous feeding can be avoided; through cooperative use of brush plates, first rotating discs and second rotating discs, an ash layer attached to a sieve plate can be automatically cleared, so that a filter plate does not need to be frequently replaced, and the service life of the filter plate is prolonged. and through cooperative use of special-shaped discs, rotating rods and a collecting box, the cleared ash layer is automatically transferred into the collecting box by utilizing negative pressure, and therefore the ash layer is convenient to collect and the device is more intelligent and convenient to use.

Owner:江南云

Automatic spindle stacking and collecting device

ActiveCN110356925AAutomatic stacking and orderlyIncrease productivityFilament handlingEngineeringMechanical engineering

Owner:武汉裕大华纺织服装集团有限公司

Plastic wire drawing machine

InactiveCN109112653AEasy to disassembleSolve cleanupSpinning solution de-aeratingArtificial thread manufacturing machinesClamp connectionEngineering

The invention discloses a plastic wire drawing machine and relates to the plastic processing technology field. The plastic wire drawing machine comprises a filtering device. The top of the filtering device is fixedly connected to a feeding pipe. The top of the inner wall of the filtering device is fixedly connected to a framework. The bottom of the framework is provided with an annular groove. Theinner wall of the annular groove is fixedly connected to a sealing gasket. The bottom of the framework is provided with a filtering box. The top of the filtering box is tightly connected to the innerwall of the annular groove. The bottom of the filtering box is in threaded connection with a discharging pipe. By using the plastic wire drawing machine, through the structure design of the feeding pipe, the framework, the annular groove, the sealing gasket, the filtering box, the discharging pipe, a moving device, a motor, a support, a gear, a tooth row, a clamp connection device, a clamp connection block, a first spring, a clamp connection groove, a movement rod, a pulley, a slideway plate, a side door and a handle, a problem that the filtering box is not convenient for cleaning so that production efficiency is reduced is solved.

Owner:浙江安尚电气有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com