Hard-water-resistant wet rubbing fastness improver and preparation and application methods thereof

A technology of wet rubbing fastness and enhancer, applied in dyeing, abrasion-resistant fibers, textiles and papermaking, etc., can solve the problems of decreased effect, intolerant of electrolytes, etc., to avoid the decline of production efficiency, avoid energy waste, Solving the effect of unqualified wet rubbing fastness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

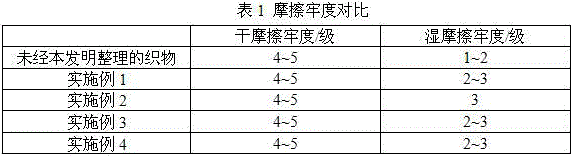

Examples

Embodiment 1

[0025] An agent for improving wet rubbing fastness against hard water comprises the following components by weight: 88% of weak cationic water-based polyurethane, 10% of hydroxyethylene diphosphonic acid, and 2% of defoaming agent. Accurately weigh the above-mentioned components, add hydroxyethylidene diphosphonic acid and defoamer to the weak cationic water-based polyurethane while stirring, mix evenly, filter and discharge the material, and obtain the hard water wet rubbing fastness improving agent.

[0026] Preparation of stenter working solution: sequentially add softener 30g / L, crosslinking agent 20g / L, color fixing agent 30g / L, hard water wet rubbing fastness enhancer 30g / L, pH regulator 1 g / L; , the temperature is 31°C, and the pH value is 4.98.

[0027] Finish the prepared stenter working liquid on the C32*21 133*60 brushed printed fabric by dipping and rolling, the amount of liquid is 65~68%, and then pre-dry with hot air at 105 ℃, and then 160 on the stenter Bake at...

Embodiment 2

[0030] A hard water-resistant wet friction enhancer comprises the following components by weight: 85% of weak cationic water-based polyurethane, 12% of cetyltrimethylammonium chloride, and 3% of defoamer. Accurately weigh the above-mentioned components, add the cosolvent and defoamer into the weak cationic water-based polyurethane while stirring, mix evenly, filter and discharge the material, and obtain the hard water wet rubbing fastness improving agent.

[0031] Preparation of stenter working solution: sequentially add softener 40g / L, crosslinking agent 30g / L, color fixing agent 30g / L, hard water wet rubbing fastness enhancer 40g / L, pH regulator 1.5 g / L; , the temperature is 35°C, and the pH value is 4.53.

[0032] Finish the prepared stenter working liquid on the C32*21 133*60 brushed printed fabric by dipping and rolling, the amount of liquid is 65~68%, and then pre-dry with hot air at 105 ℃, and then 160 on the stenter Bake at ~170°C for 30 s. Test the dry and wet rubbi...

Embodiment 3

[0035] A hard water-resistant wet friction enhancer comprises the following components by weight: 85% of weak cationic water-based polyurethane, 10% of propylene bis(dodecyl dimethyl ammonium bromide), and 5% of defoamer. Accurately weigh the above-mentioned components, add the cosolvent and defoamer into the weak cationic water-based polyurethane while stirring, mix evenly, filter and discharge the material, and obtain the hard water wet rubbing fastness improving agent.

[0036] Preparation of stenter working solution: sequentially add softener 40g / L, crosslinking agent 30g / L, color fixing agent 20g / L, hard water wet rubbing fastness enhancer 40g / L, pH regulator 0.5 g / L; , the temperature is 36°C, and the pH value is 5.67.

[0037] Finish the prepared stenter working liquid on the C32*21 133*60 brushed printed fabric by dipping and rolling, the amount of liquid is 65~68%, then pre-dry with hot air at 105 ℃, and then put it on the stenter at 160 Bake at ~170°C for 30 s. Tes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com