Device and method for treating organic waste gas through synergistic catalysis of plasma

A plasma and organic waste gas technology, applied in chemical instruments and methods, gas treatment, separation methods, etc., can solve problems such as changes in waste gas components, energy waste, and increased operating costs, so as to avoid energy waste and secondary pollution , the effect of shortening the contact time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

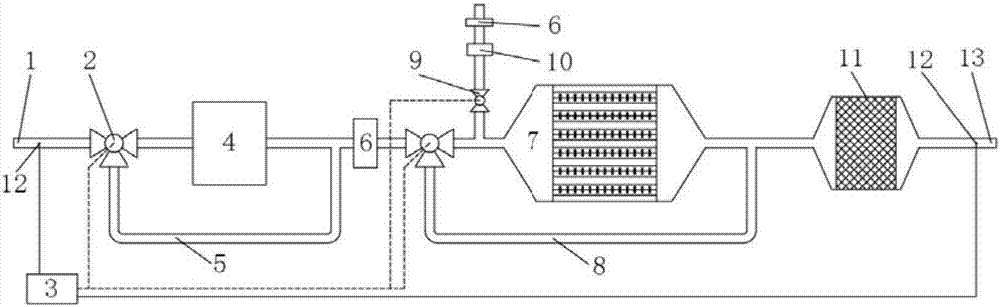

[0038] The exhaust gas enters the exhaust gas inlet 1 and is detected by the gas analyzer 3. The concentration of HCl in the exhaust gas is 100ppm, and the concentration of TVOC is 500ppm. The gas analysis instrument 3 sends a signal to control the electric valve 9 to close, and the opening direction of the electric three-way valve 3 is adjusted to a suitable position.

[0039] The exhaust gas enters the absorption tower 4 through the first electric three-way valve 2. Absorption tower 4 is a spray absorption tower, and the absorption liquid is 2% NaHCO 3 solution. After the waste gas is purified by the absorption tower 4, it enters the filter device 6 to remove solid particles and liquid droplets, and at the same time, the gaseous water content in the waste gas decreases. After that, the exhaust gas enters the plasma reactor 7 through the second electric three-way valve 2, enters the catalytic reactor 11 after being activated and partially oxidized, and finally exits the dev...

Embodiment 2

[0041] The exhaust gas enters the exhaust gas inlet 2 and is detected by the gas analysis instrument 3. The exhaust gas does not contain acidic exhaust gas such as HCl or NH 3For alkaline waste gas, the TVOC concentration is 500ppm. The gas analysis instrument 3 sends a signal to control the electric valve 9 to close, and the opening direction of the electric three-way valve 3 is adjusted to a suitable position. The exhaust gas enters the parallel bypass 5 of the absorption tower through the first electric three-way valve 2, and then enters the plasma reactor 7 through the second electric three-way valve 2 after removing particulate matter through the filter device 6. After being activated and partially oxidized, the waste gas enters the catalytic reactor 11 and finally exits the device through the waste gas outlet 13 . Detected by the gas analyzer 3, the TVOC concentration at the waste gas outlet 13 drops to 45ppm.

Embodiment 3

[0043] The exhaust gas enters the exhaust gas inlet 2 and is detected by the gas analysis instrument 3. The NH in the exhaust gas 3 The concentration is 80ppm, the TVOC concentration is 150ppm, the gas analysis instrument 3 sends a signal to control the opening of the electric valve 9, and the opening direction of the electric three-way valve 3 is adjusted to a suitable position. The exhaust gas enters the absorption tower 4 through the first electric three-way valve 2, and the absorption tower 4 is a spray absorption tower, and the absorption liquid used is 1% H 2 SO 4 solution. After the waste gas is purified by the absorption tower 4, it enters the filter device 6 to remove solid particles and liquid droplets, and the gaseous water content in the waste gas decreases. After that, the exhaust gas enters the parallel bypass 8 of the plasma reactor through the second electric three-way valve 2 . At the same time, the outside air enters the plasma reactor 7 from the air bypas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com