Patents

Literature

1659results about How to "Reduce maintenance frequency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

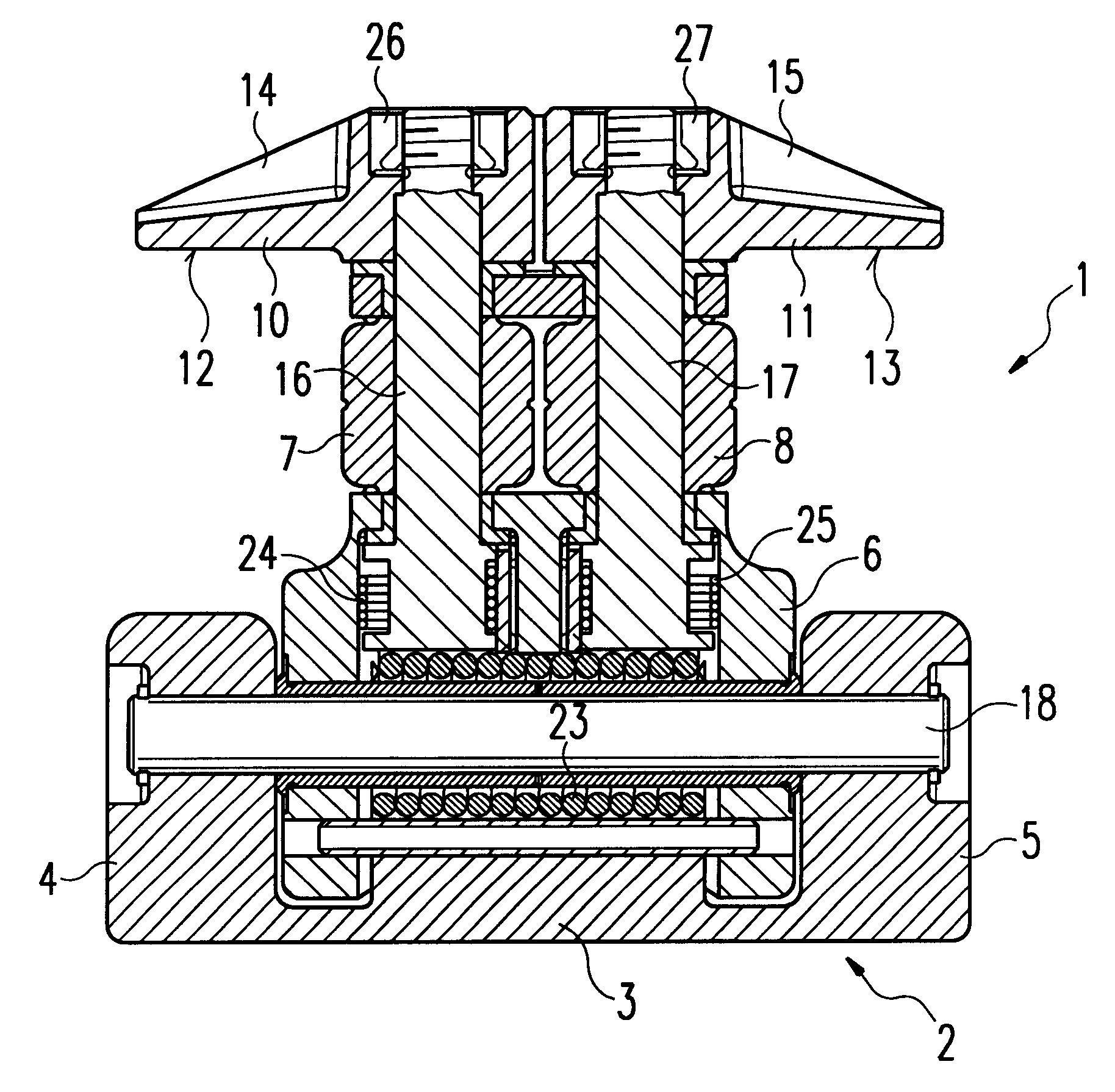

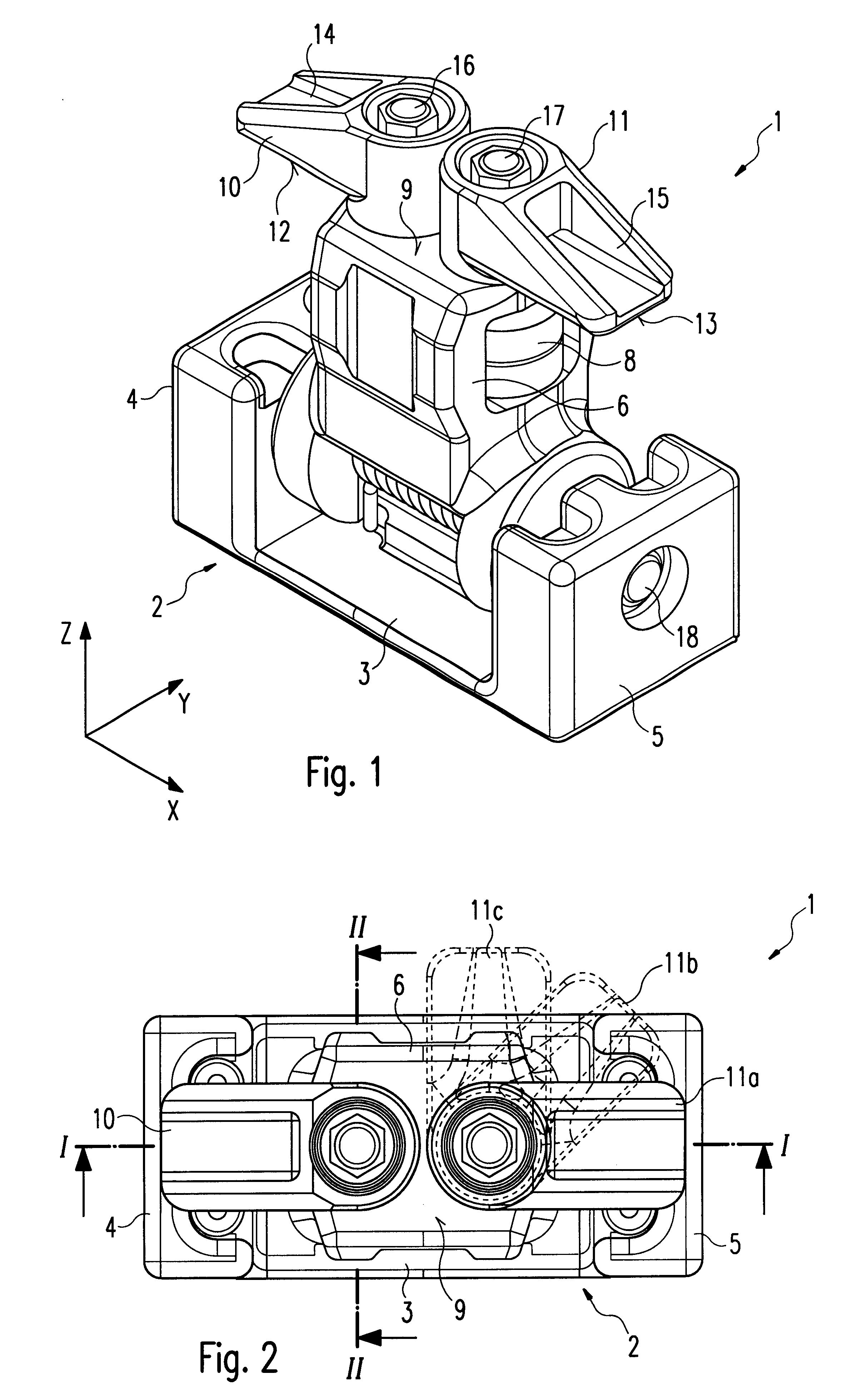

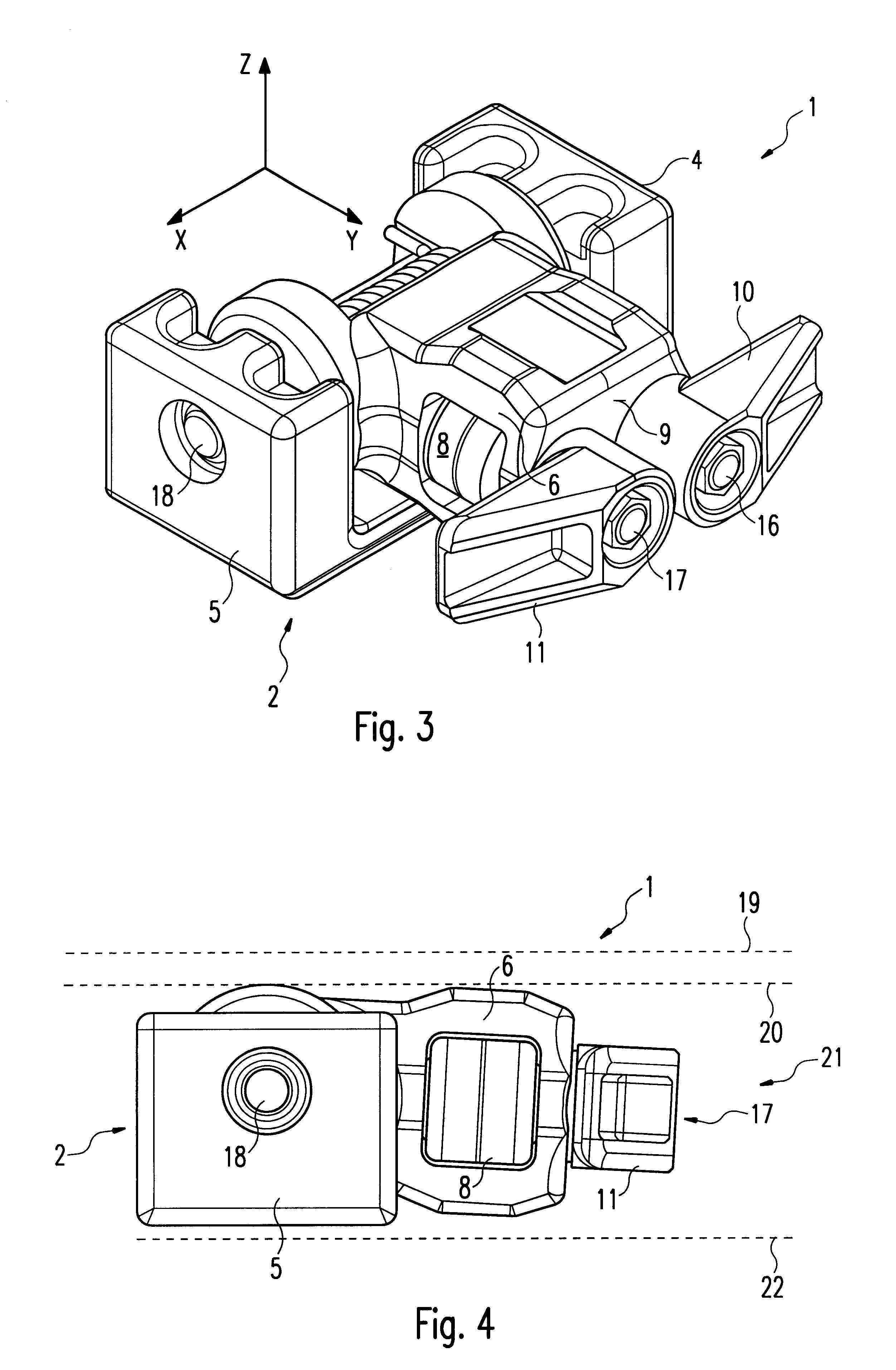

Cargo latch

InactiveUS6270300B1Easy to transportReduce risk of damageVehicle with removable loadingLoad accommodationEngineeringAirplane

Owner:TELAIR INTERNATIONAL GMBH

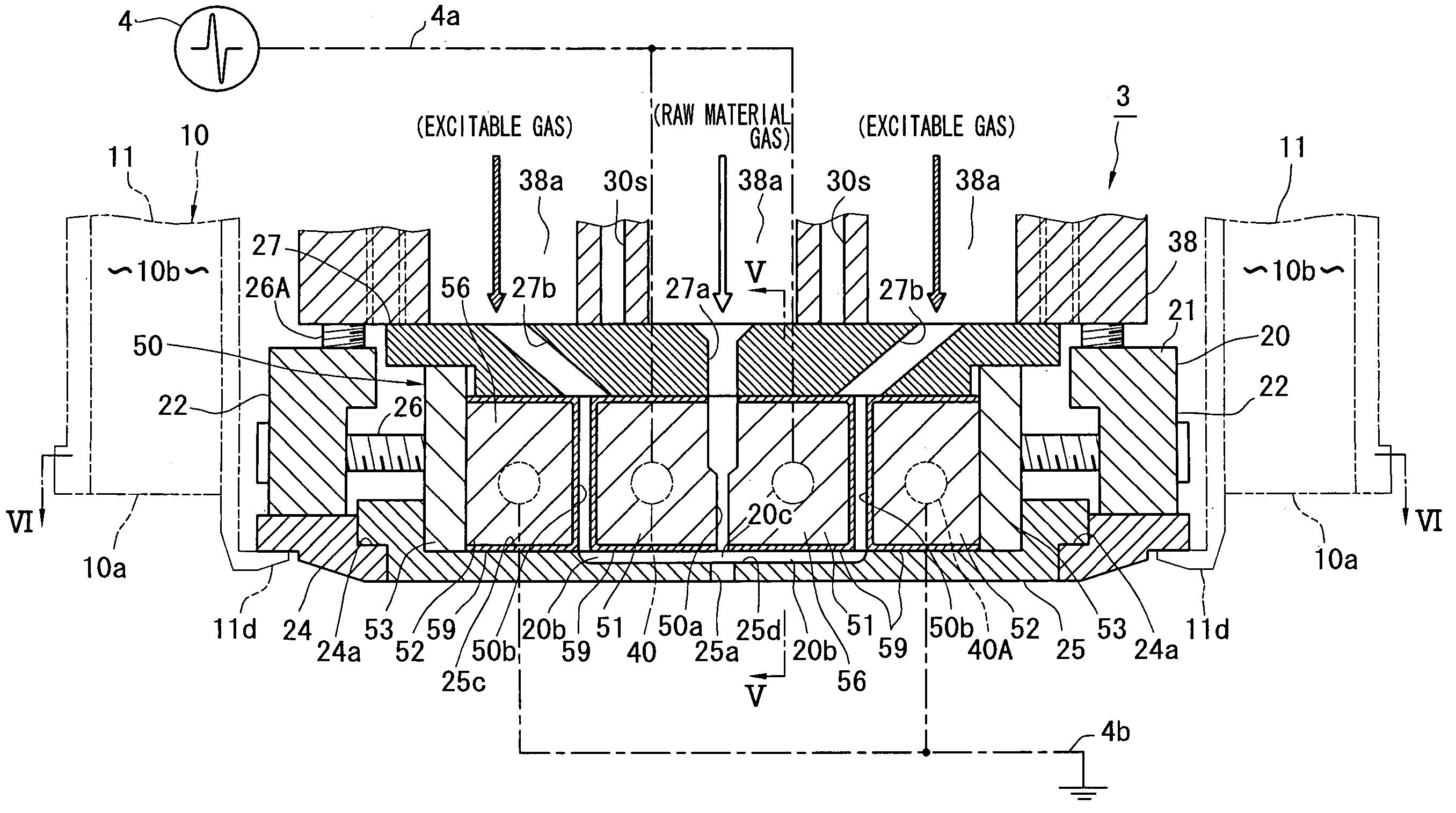

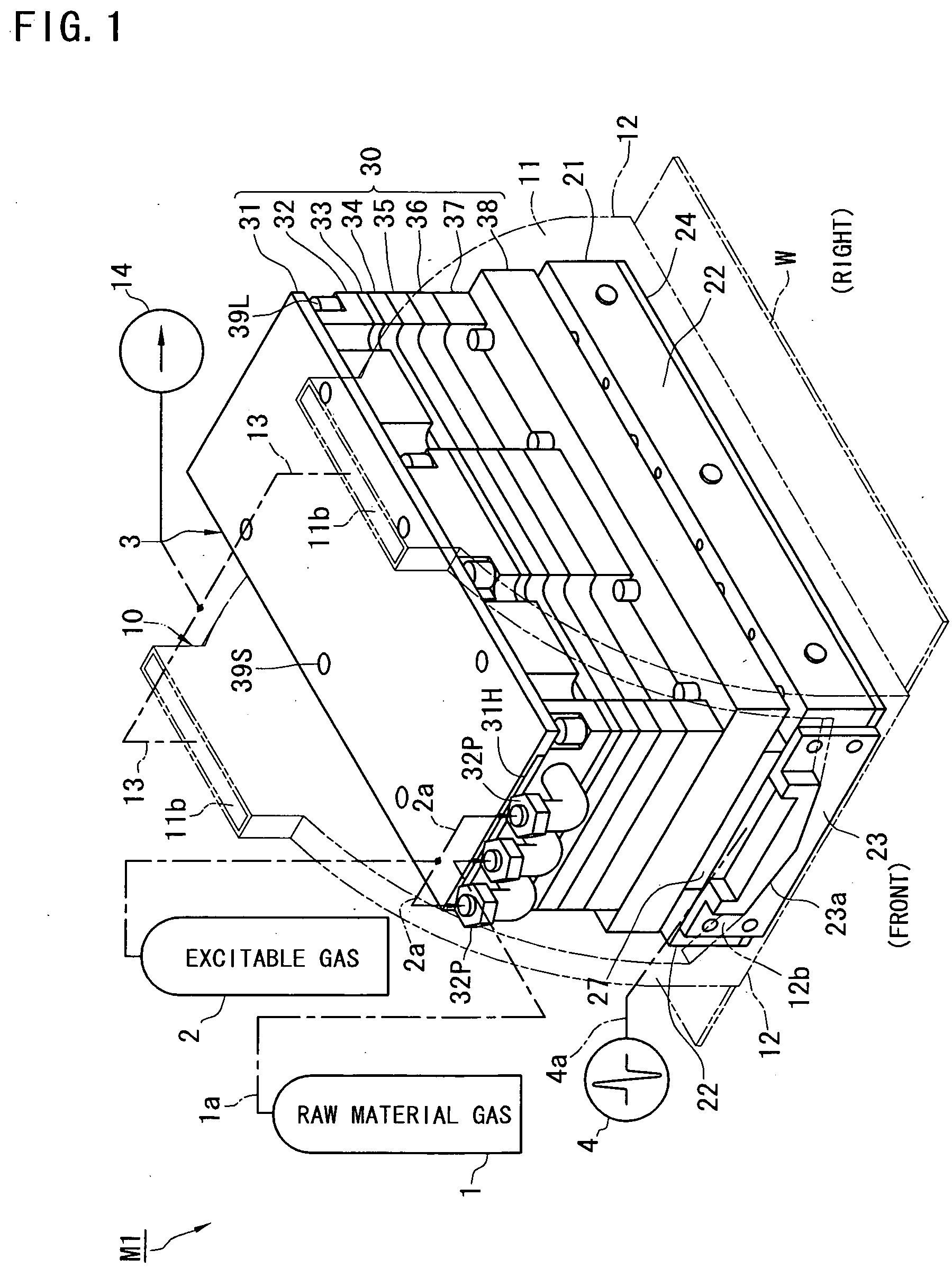

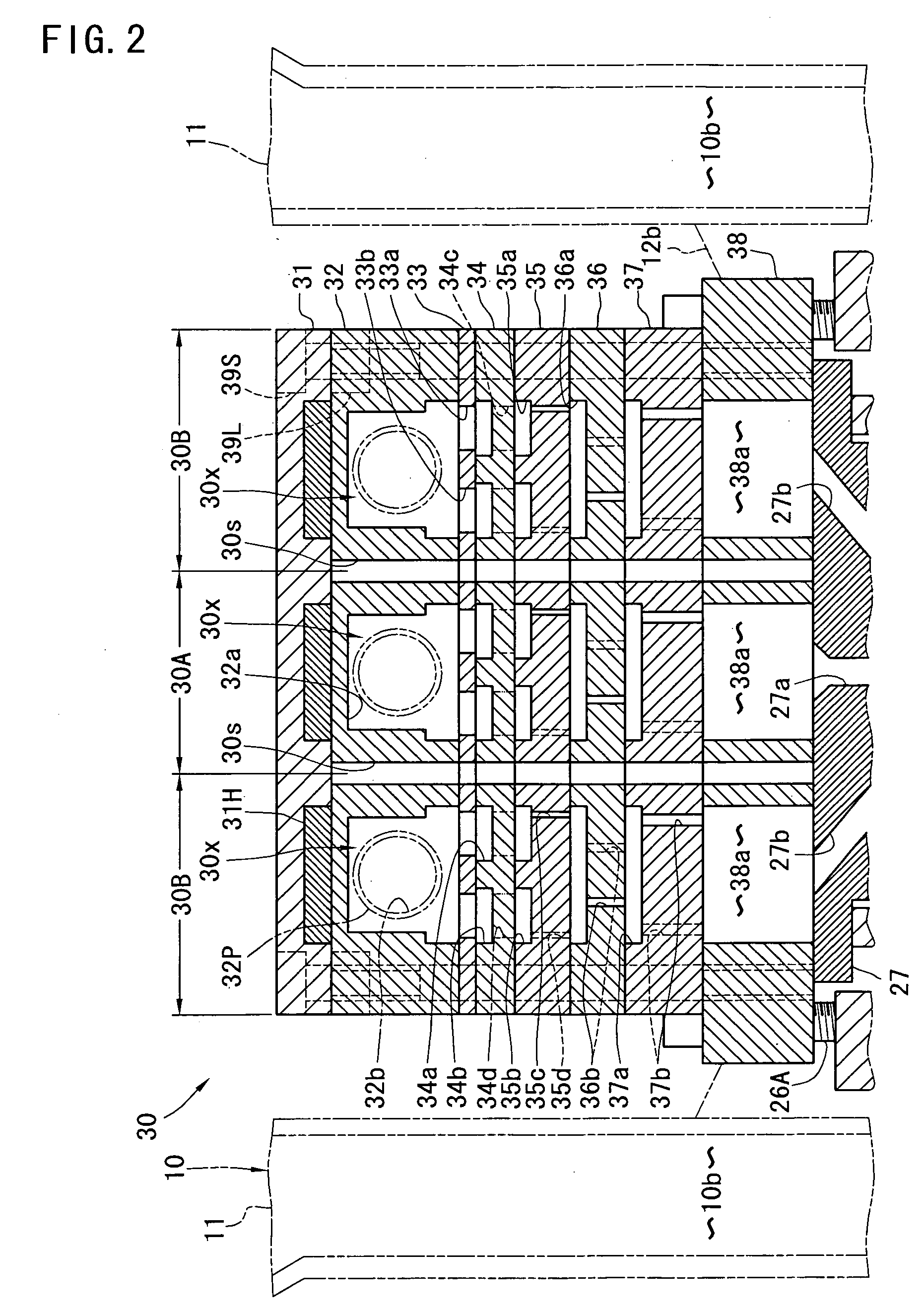

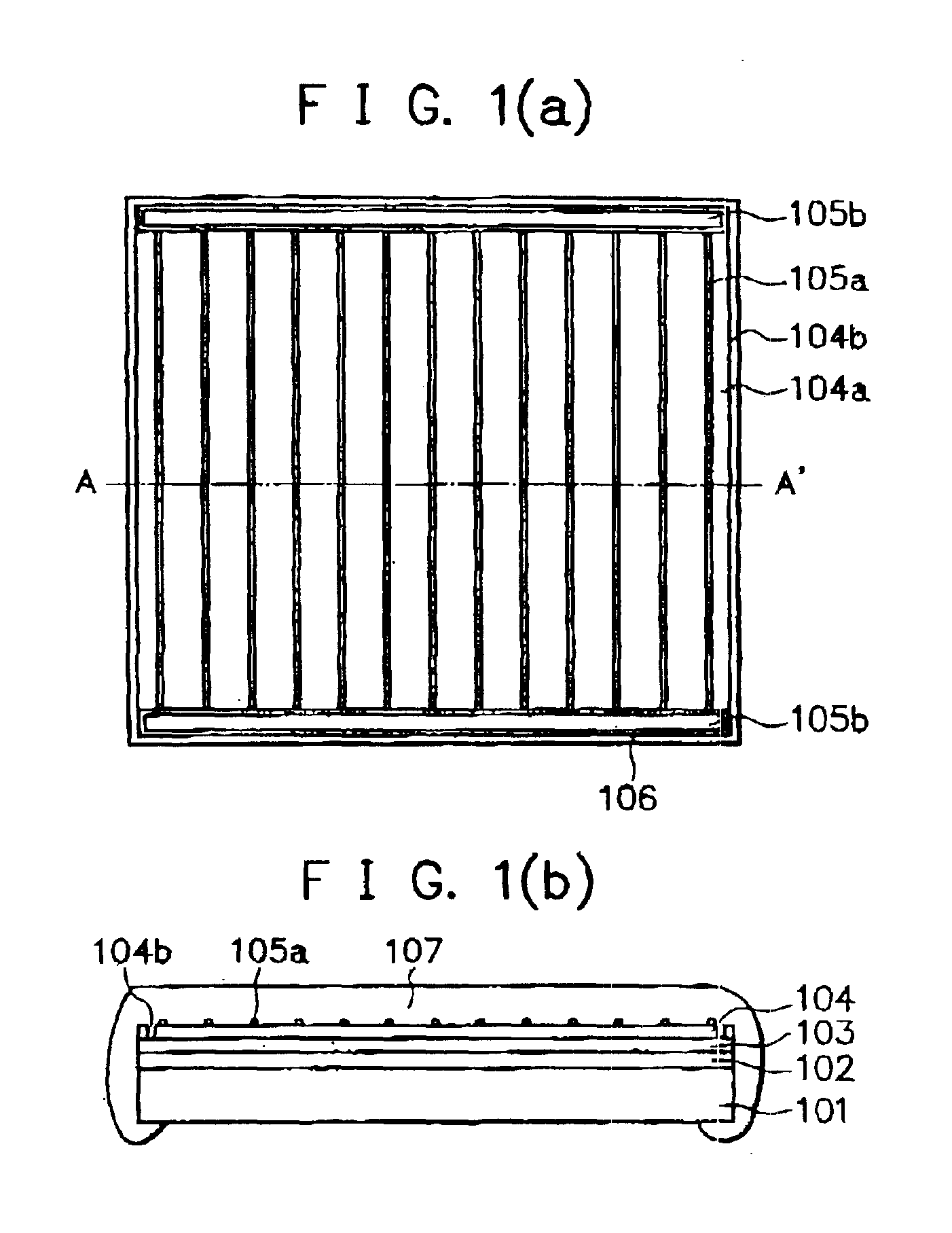

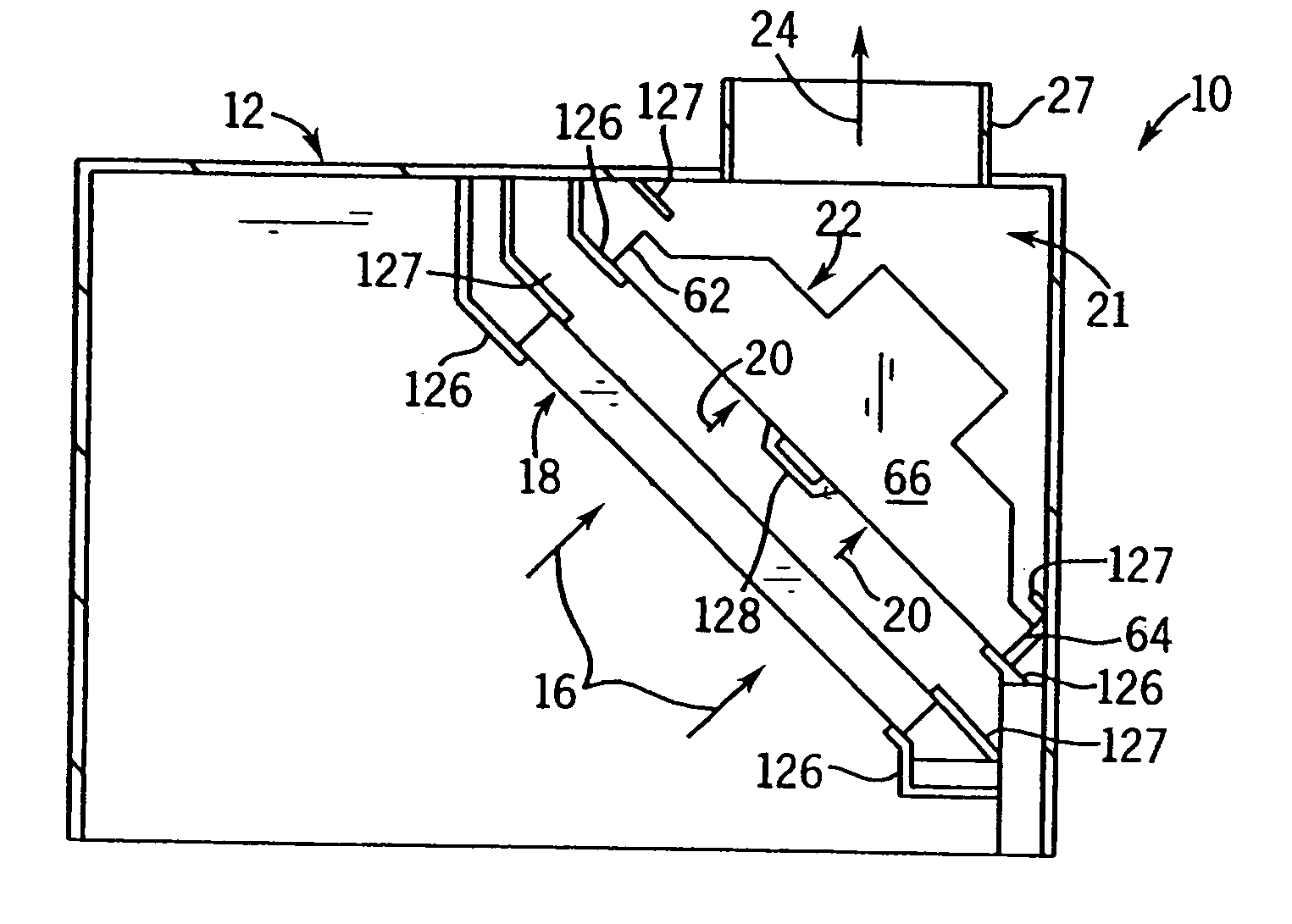

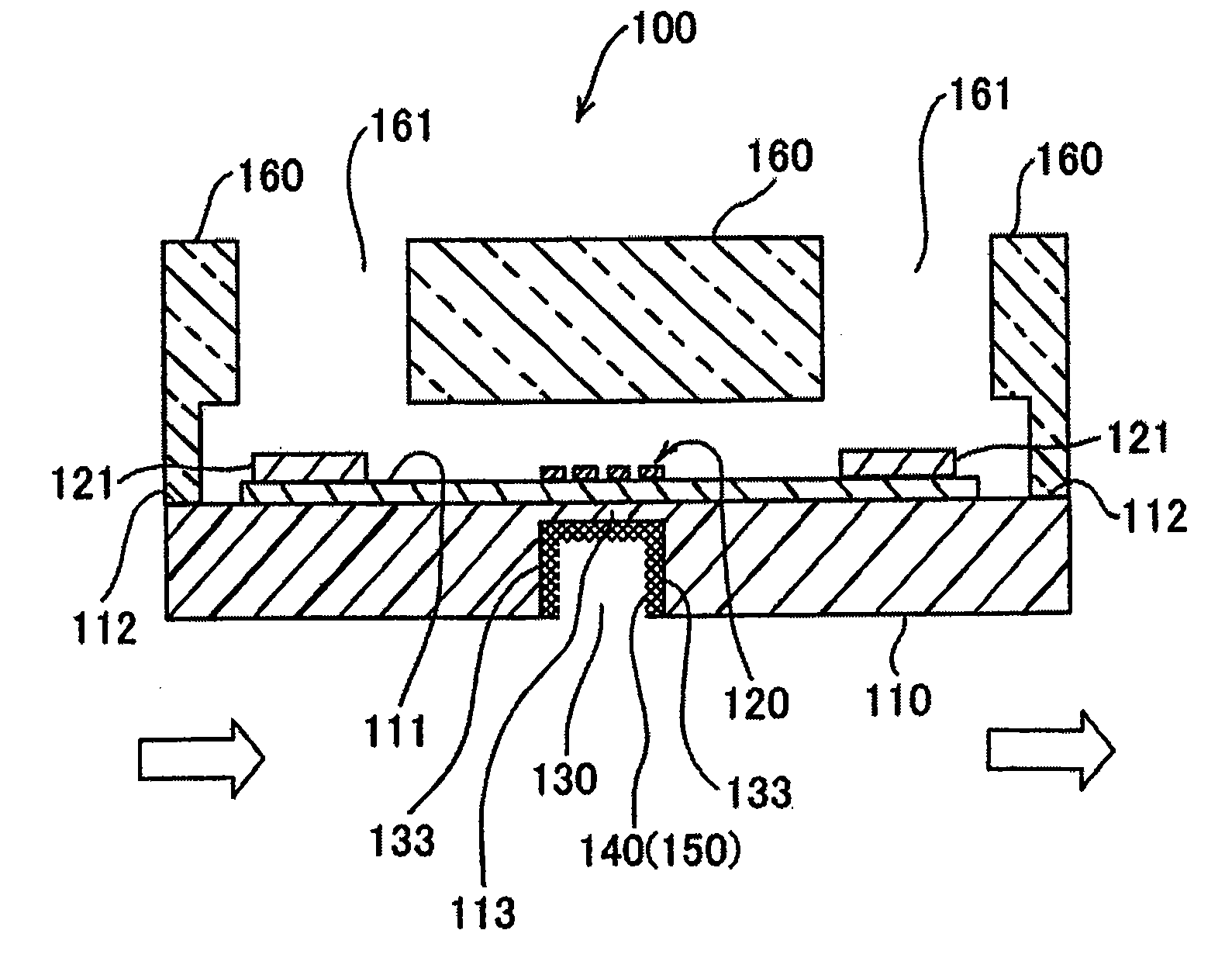

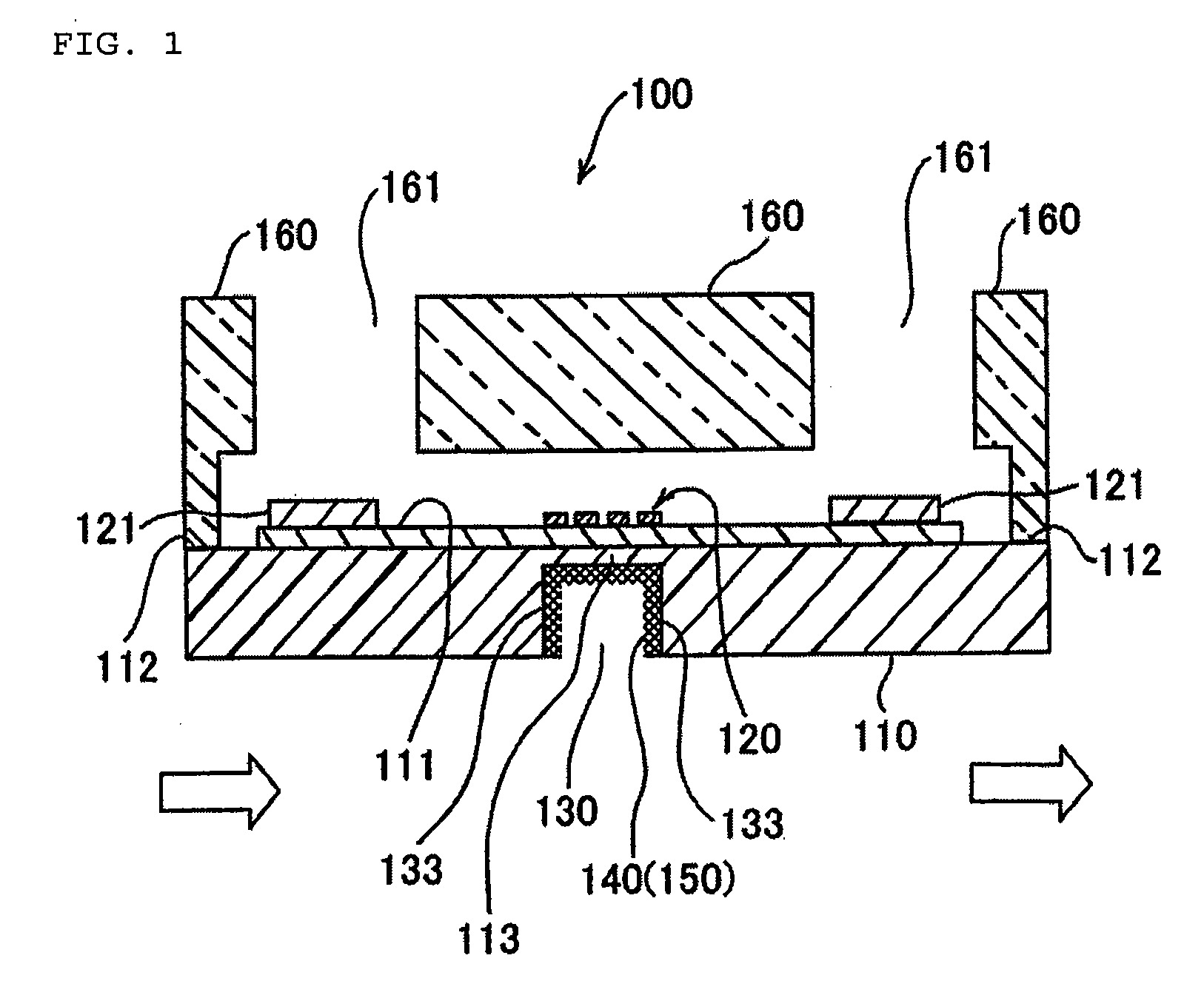

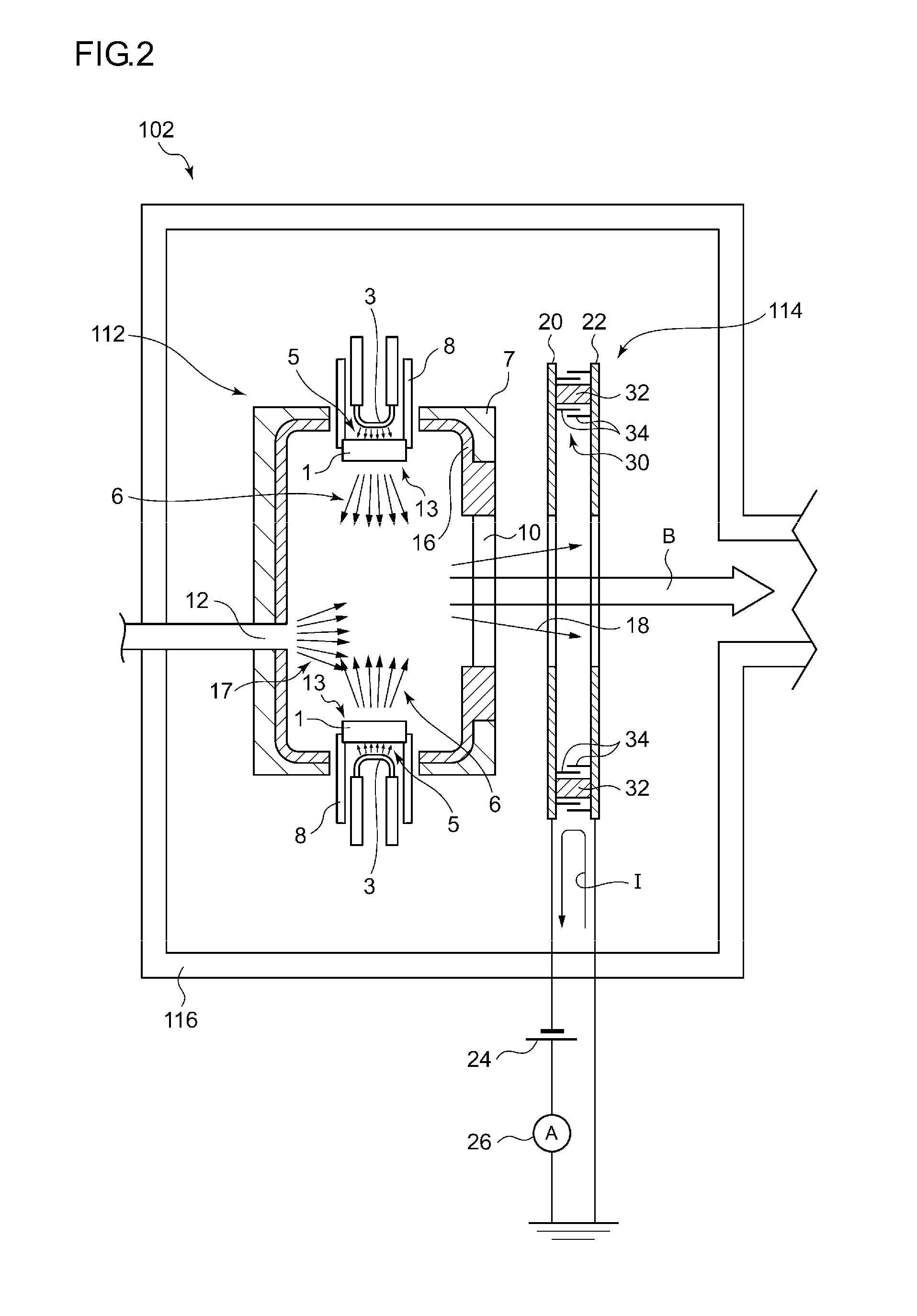

Plasma film forming system

InactiveUS20050016457A1Reduce maintenance frequencyReduce in quantityElectric discharge tubesChemical vapor deposition coatingElectrical and Electronics engineeringRaw material

In a plasma film forming apparatus, two first electrodes 51 connected to a power source 4 and two grounded second electrodes 52 are arranged in the order of the second electrode 52, the first electrode 51, the first electrode 51 and the second electrode 52. A first flow passage 50a formed between the central first electrodes 51 allows a raw material gas (first gas) for being formed into a film to pass therethrough. A plasma discharge space 50b of a second flow passage formed between the first and second electrodes 51, 52 on the both sides allows an excitable gas (second gas) to pass therethrough, which excitable gas is exited by plasma such that the raw material can be formed into a film, but that the excitable gas itself is merely excited but not formed into a film. Those gases are converged at a crossing part 20c between the first and second flow passages and blown off via a common blowoff passage 25a. By this, the apparatus composing members such as electrodes can be prevented from being adhered with a film.

Owner:SEKISUI CHEM CO LTD

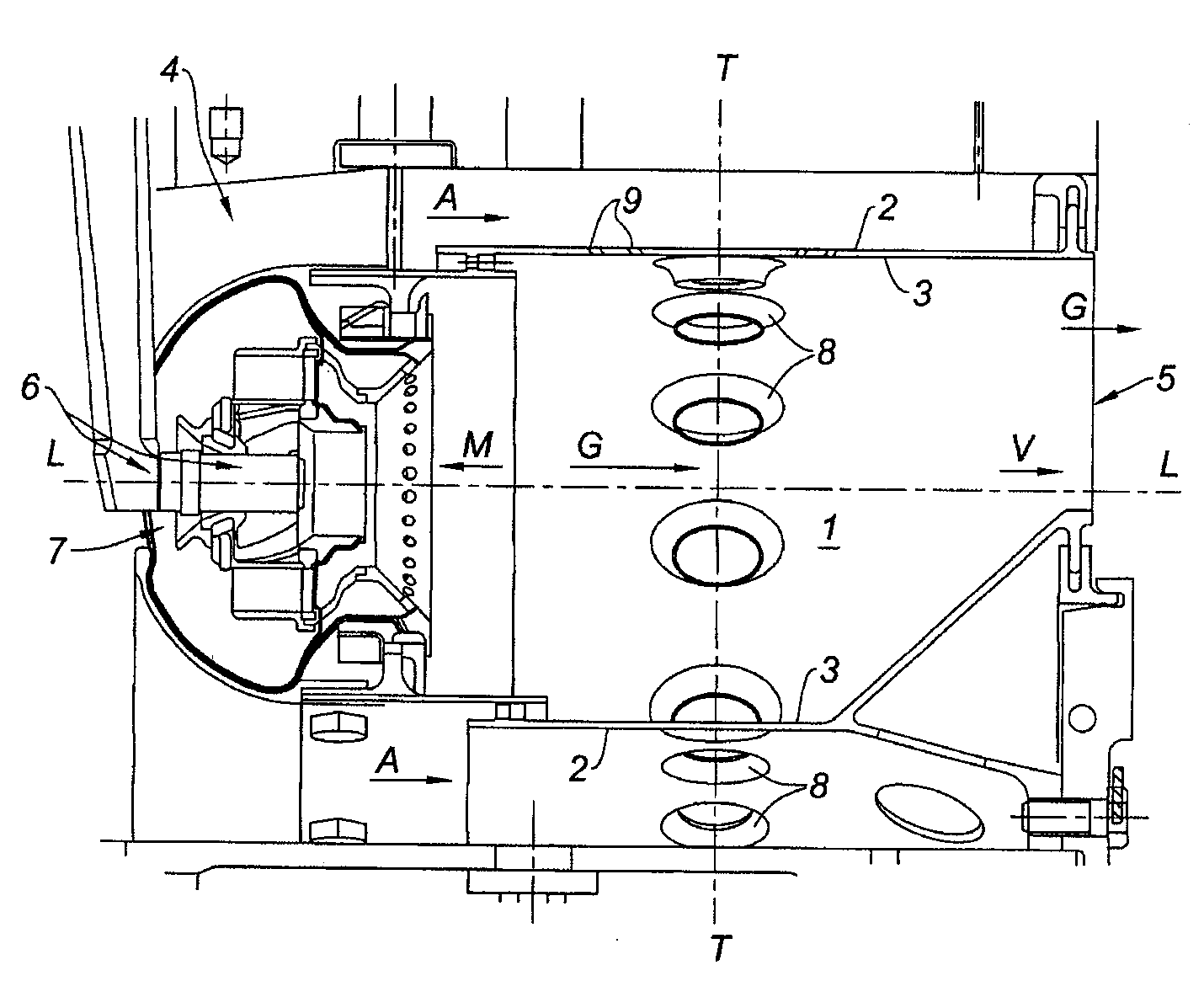

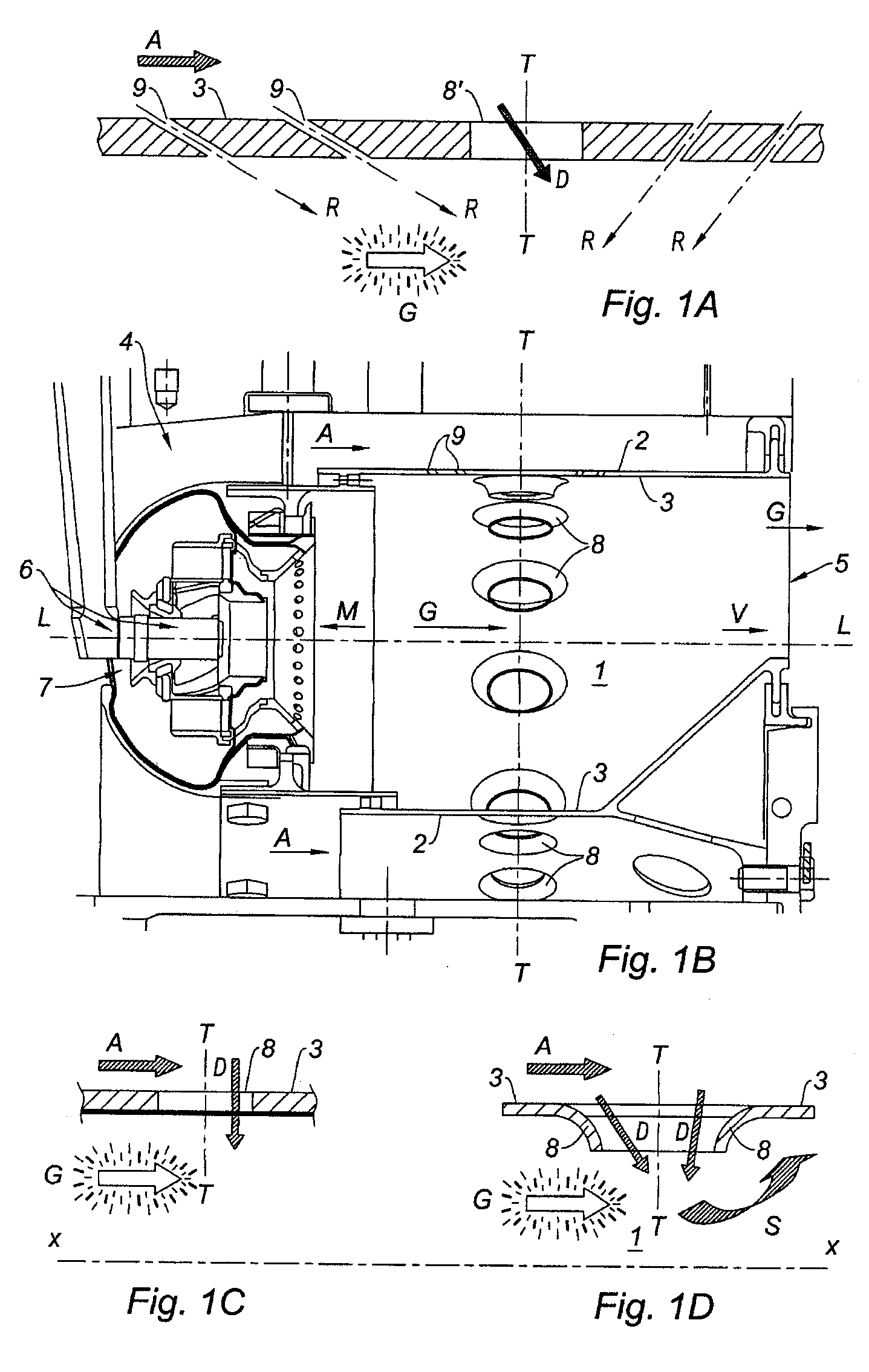

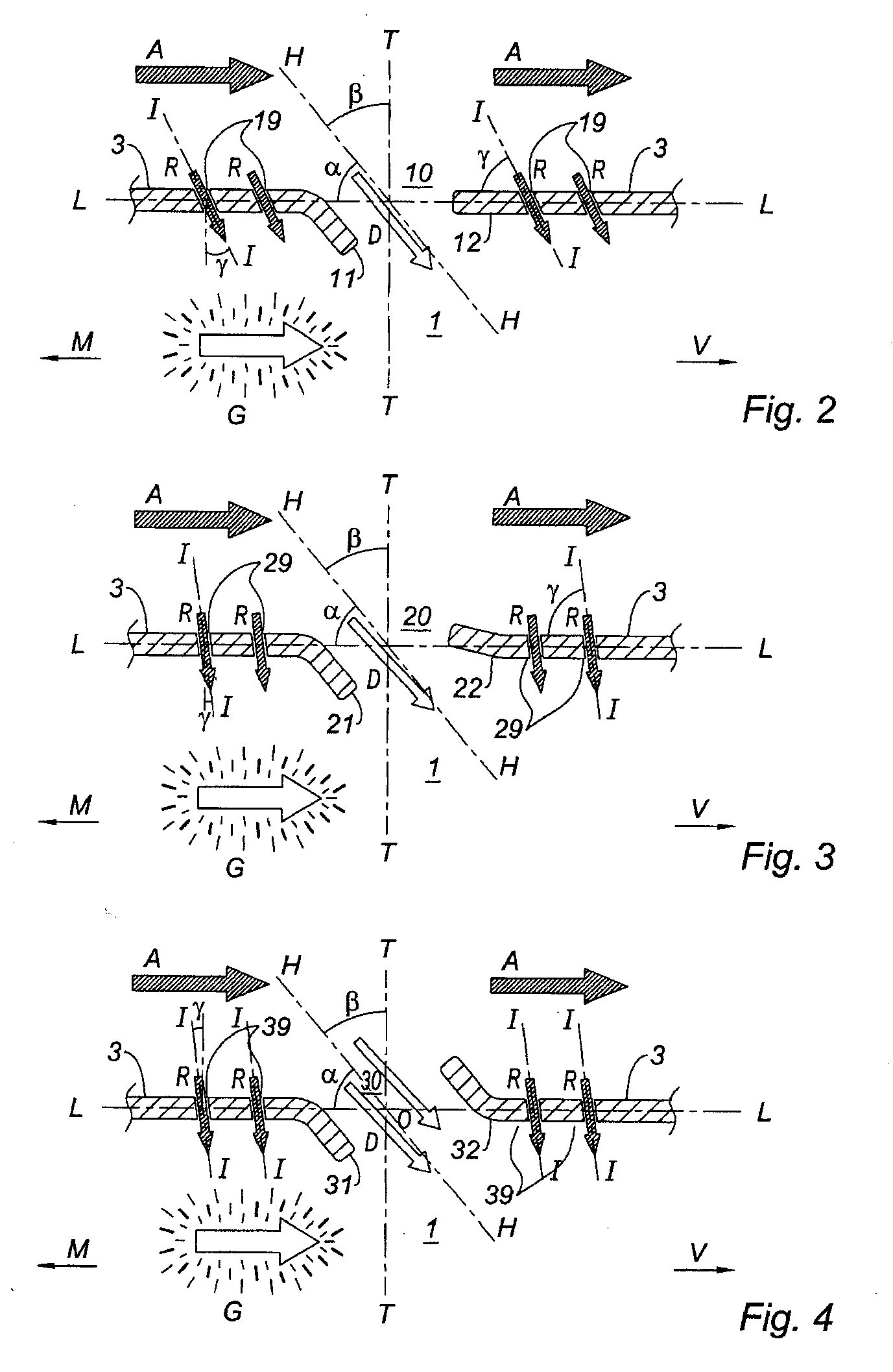

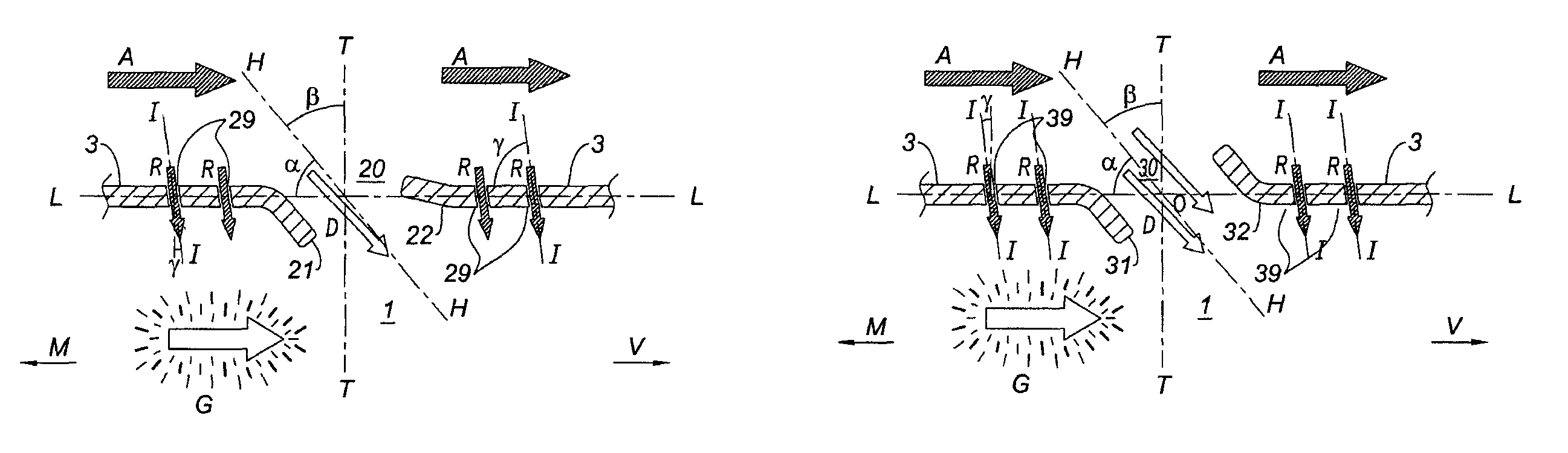

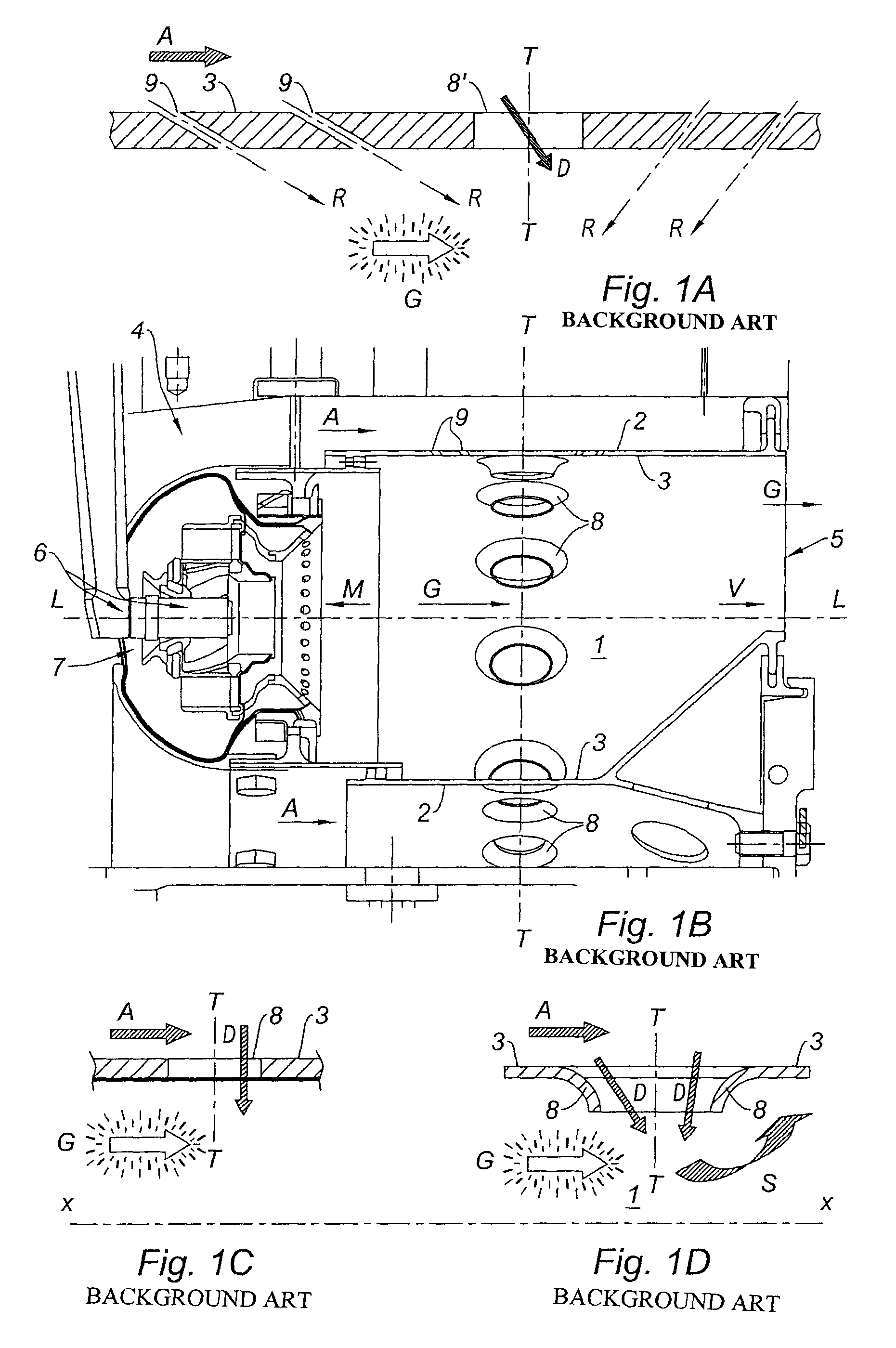

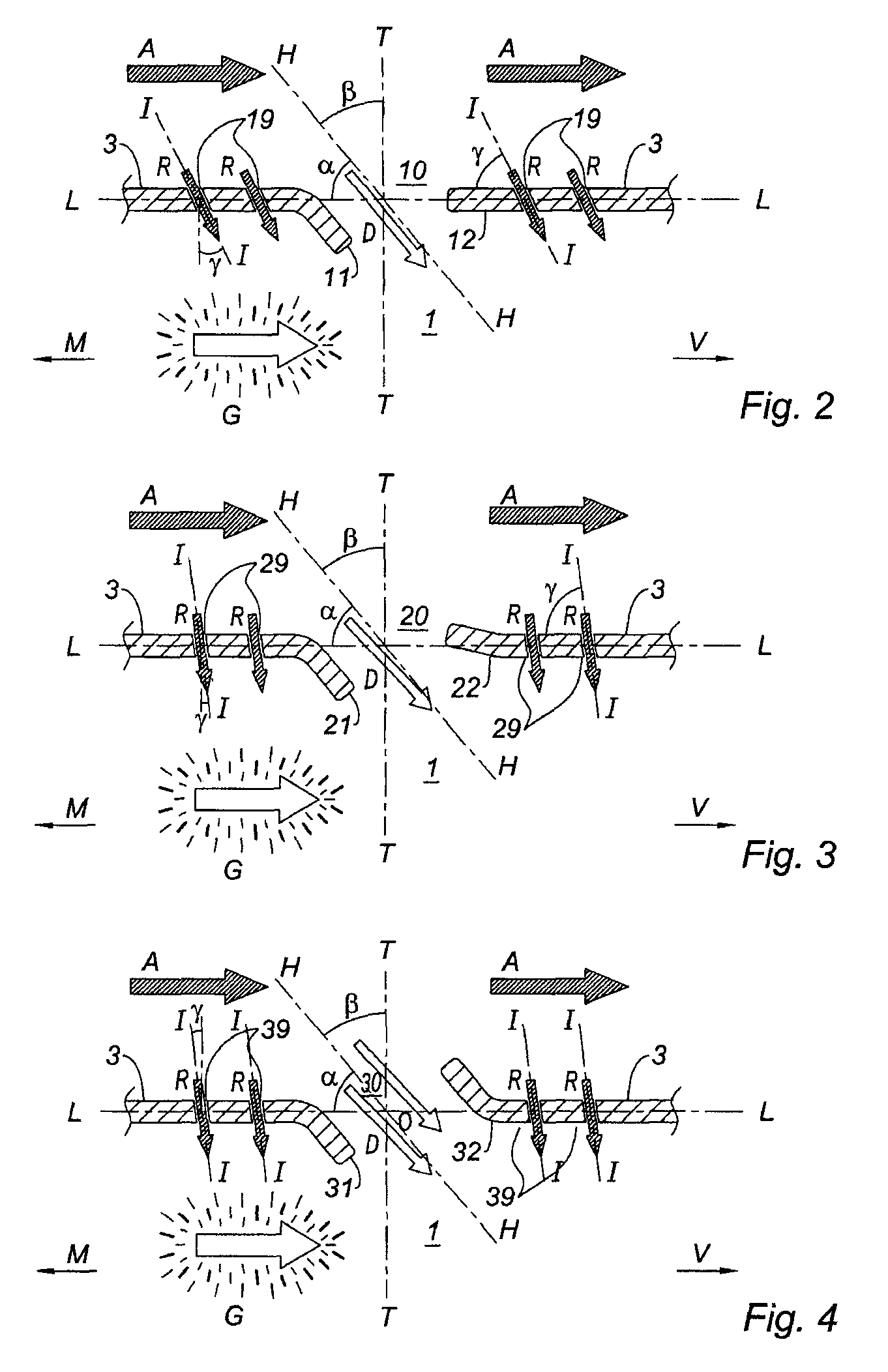

Configuration of dilution openings in a turbomachine combustion chamber wall

ActiveUS20070227149A1Reduce prominenceImprove efficiencyContinuous combustion chamberGas turbine plantsCombustion chamberEngineering

The invention relates to an annular combustion chamber of a turbomachine having an end wall and side walls (3) extending longitudinally from the end wall, situated at the upstream end (M) of the chamber (1), to an orifice for discharging a stream of combustion gases, situated at the downstream end (V) of the chamber (1), the side walls (3) comprising at least one row of openings (30) for the intake of air for diluting the stream of combustion gases.According to the invention, at least one dilution opening (30) has an upstream edge which projects toward the inside of the chamber (1) and a downstream edge which projects toward the outside of the chamber (1) and is asymmetric to the upstream edge with respect to a plane extending transversely to the wall (3), the aperture of the opening (30) having an axis oriented in an oblique direction with respect to the wall (3), this direction being oriented toward the inside (1) and toward the downstream end (V) of the chamber.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

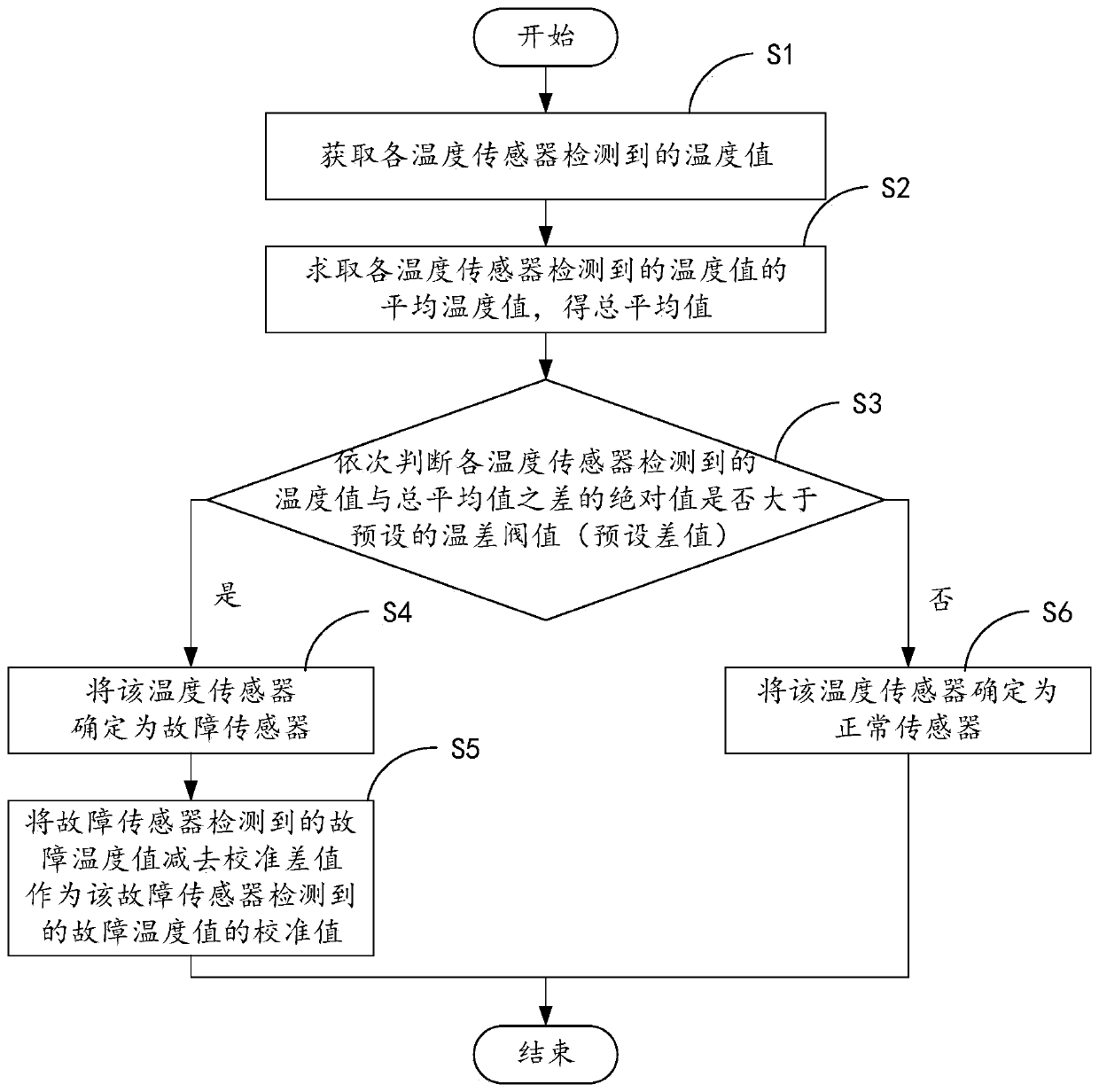

Electric appliance temperature sensor fault detection calibration method, air conditioner and computer readable storage medium

InactiveCN110501094ALow failure rateReduce maintenance frequencyThermometer testing/calibrationTemperature controlEngineering

The invention relates to the air-conditioning field. The electric appliance temperature sensor fault detection calibration method comprises the following steps: obtaining a temperature value detectedby each temperature sensor under the same temperature environment; and judging the temperature sensor, the absolute value of the difference between the detected temperature value of which and an average temperature value detected by each temperature sensor is greater than a preset difference value, as a fault sensor; judging the temperature sensor, the absolute value of the difference between thedetected temperature value of which and the average temperature value detected by each temperature sensor is less than or equal to the preset difference value, as a normal sensor; calibrating the fault temperature value detected by the fault sensor according to the average temperature value detected by each temperature sensor; or calibrating the fault temperature value detected by the fault sensoraccording to the average temperature value detected by the normal sensors. The method can automatically calibrate the fault sensor with accuracy deviation, thereby helping to improve detection accuracy of various temperature sensors in an electrical appliance and improving accuracy of temperature control of the air conditioner.

Owner:GREE ELECTRIC APPLIANCES INC

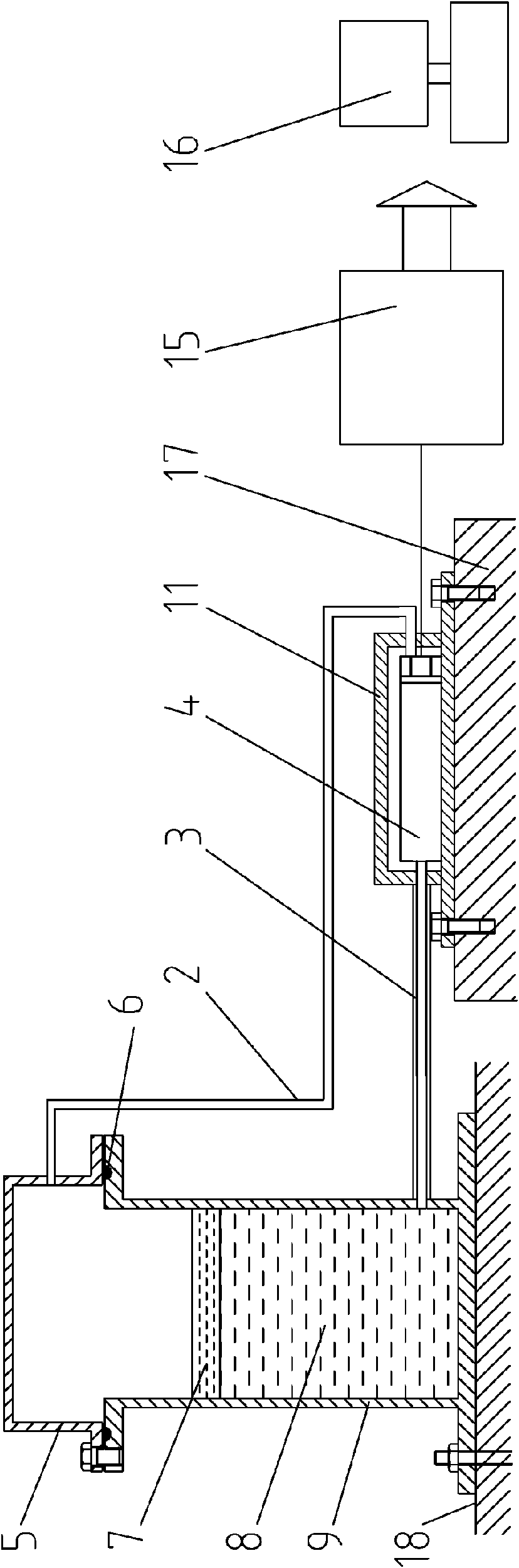

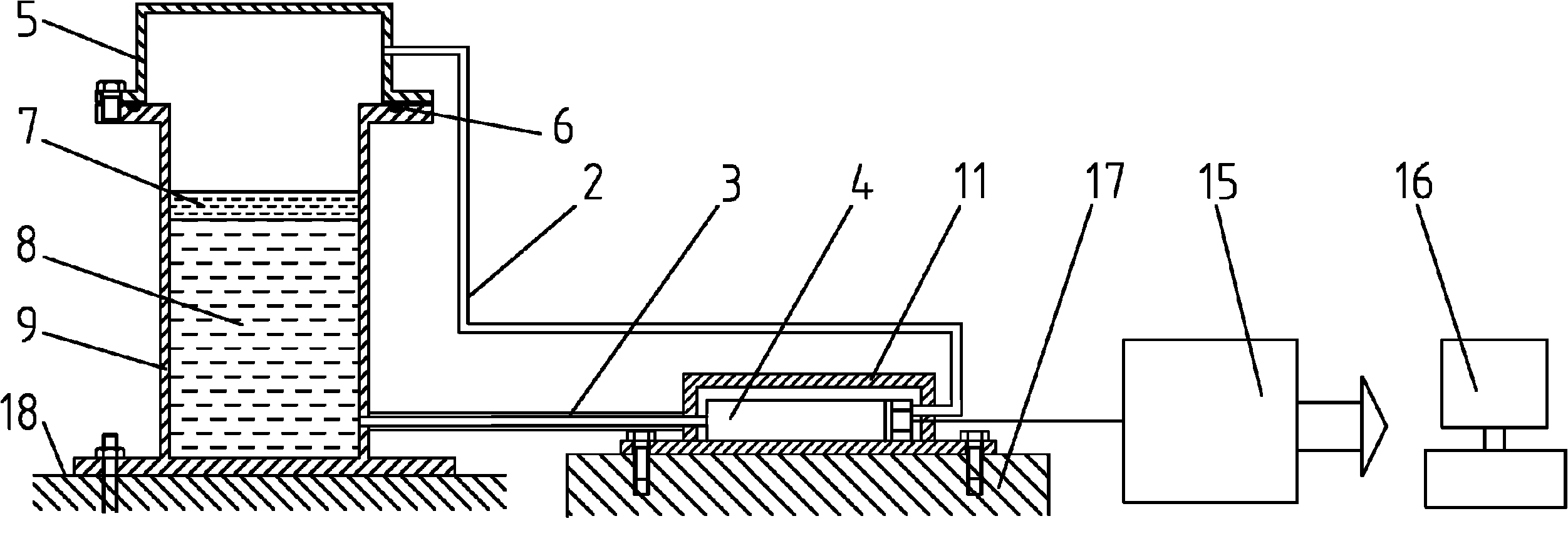

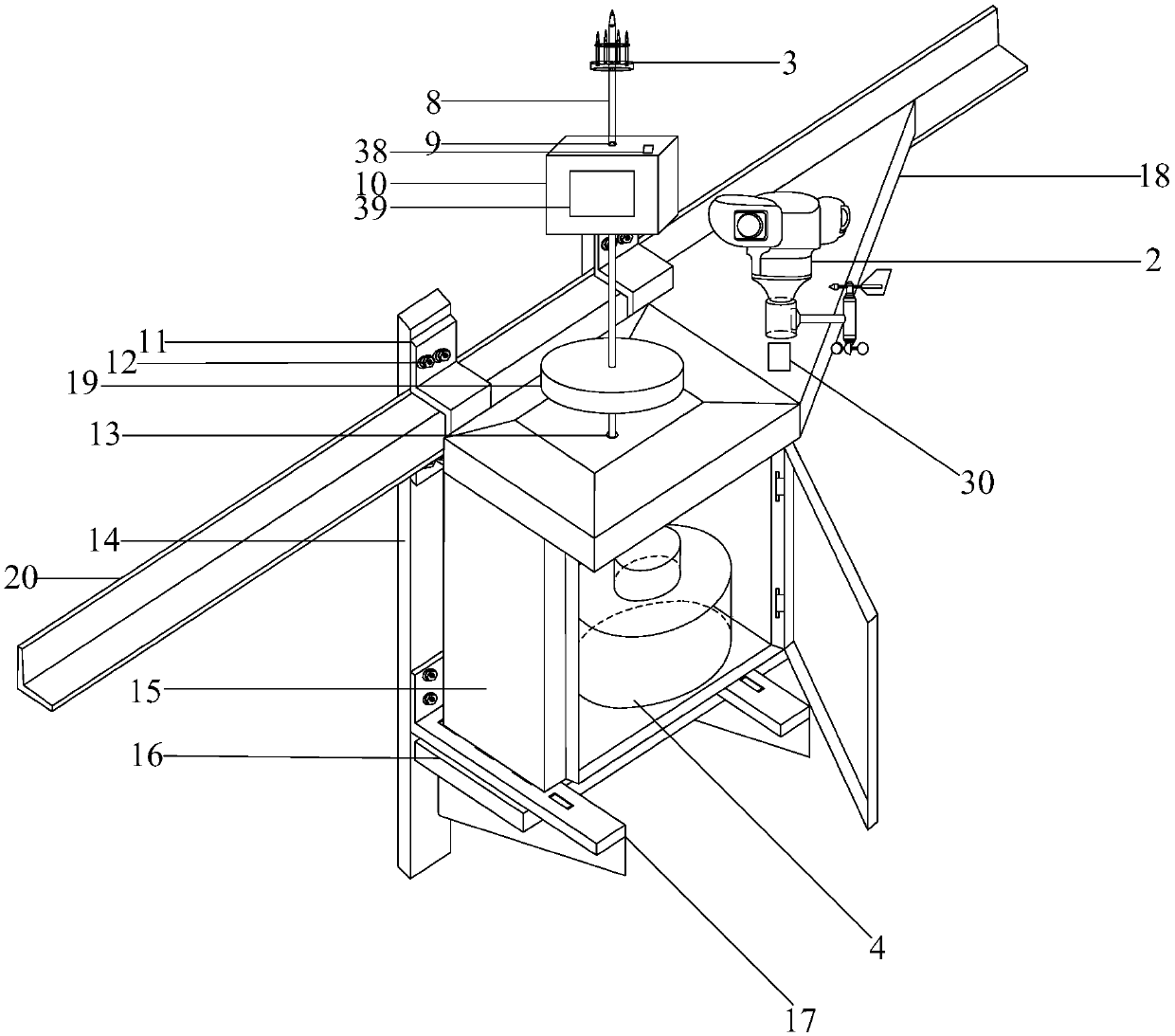

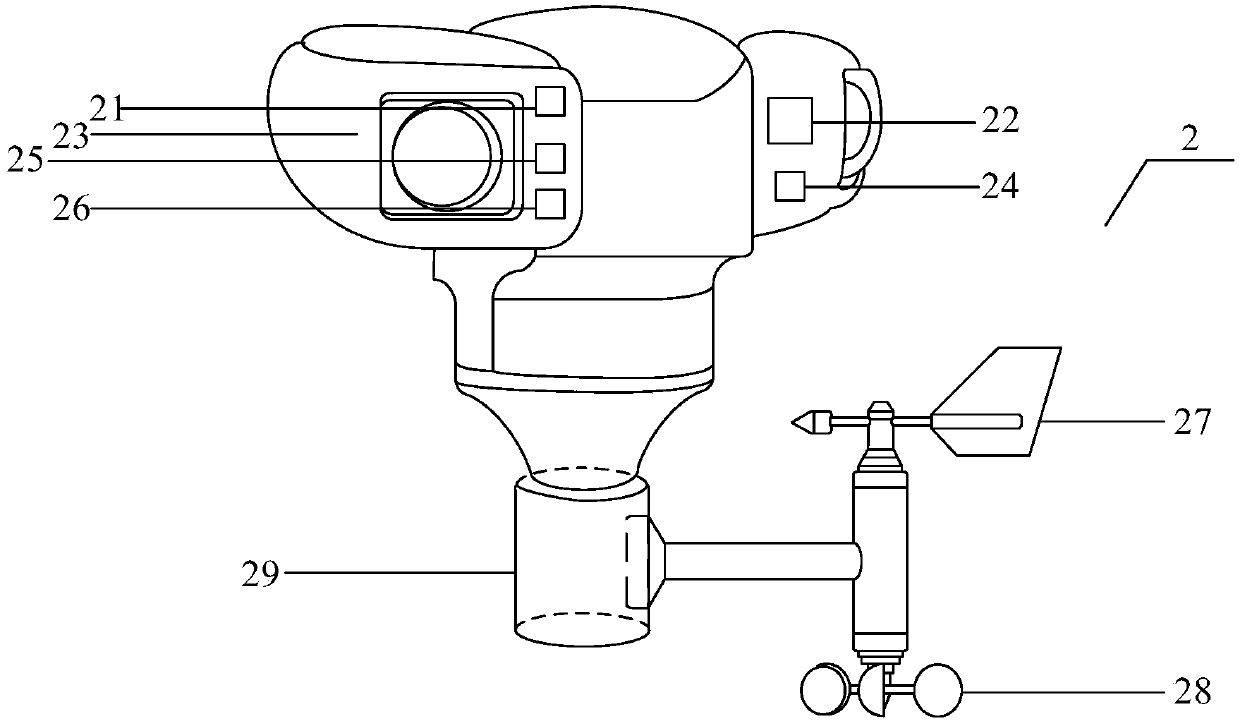

High-speed railway structure settlement monitoring device and monitoring method

ActiveCN102146648ARealize continuous automatic outdoor monitoringReduce the impact of interferenceMeasuring apparatusElectricityPressure transmission

The invention discloses a high-speed railway structure settlement monitoring device and a high-speed railway structure settlement monitoring method. In the device, a seal cover is arranged on the upper part of a liquid storage device; pressure transmission liquid is filled in the lower part of the liquid storage device; the upper part of the liquid storage device is connected with a first pressure leading-in end of a pressure transmitter through an air pipe; the lower part of the liquid storage device is connected with a second pressure leading-in end of the pressure transmitter through a pressure transmission pipe; an electrical signal output end of the pressure transmitter is connected with a data acquisition and transmission system electrically; the data acquisition and transmission system is communicated with a control centre. The device has a simple structure and high precision, is convenient to operate, and can realize long-term automatic monitoring of high-speed railway structure settlement in areas with harsh environment.

Owner:SOUTHWEST JIAOTONG UNIV

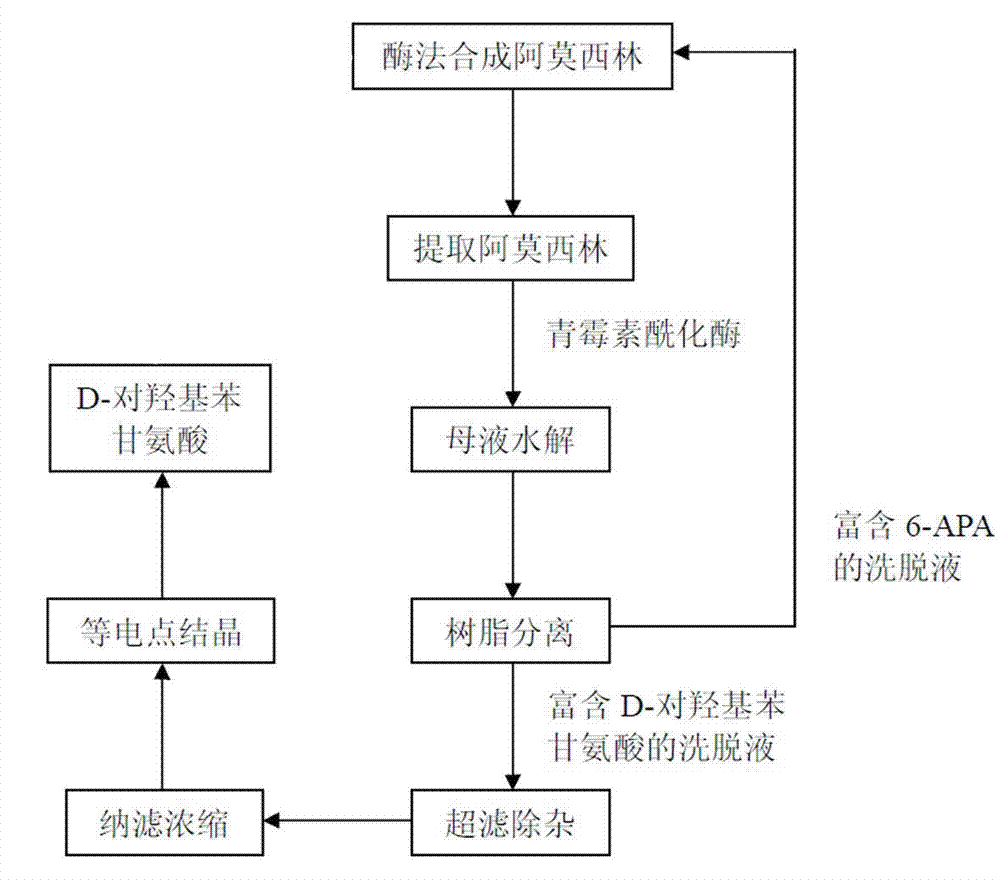

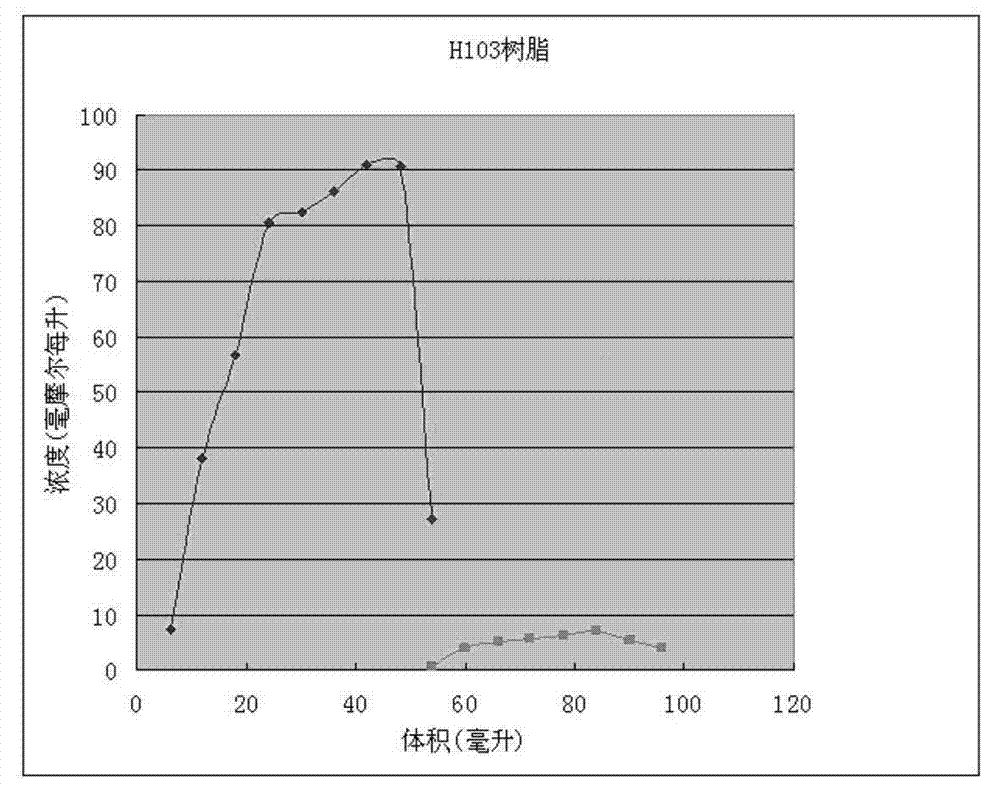

Method for recycling active ingredients in amoxicillin mother liquor synthesized by enzymatic method

ActiveCN102816803AAvoid adverse reactionsRelieve pressureOrganic compound preparationChemical industryBULK ACTIVE INGREDIENTP-hydroxyphenylglycine

The invention discloses a method for recycling active ingredients in the amoxicillin mother liquor synthesized by an enzymatic method. The method includes synthesizing the amoxicillin mother liquor by the enzymatic method; separating the amoxicillin mother liquor through a macro-porous resin column, eluting the separated amoxicillin mother liquor by deionized water, and collecting an eluant rich in D-4-Hydroxyphenylglycine and an eluant rich in 6-amino penicillanic acid (APA) respectively; filtering the eluant rich in D-4-Hydroxyphenylglycine with Daltonian ultrafiltration membranes with a cutoff molecular weight of 150 to 200; performing nanofiltration concentration on the Daltonian ultrafiltration membranes for the filtered liquor with the cutoff molecular weight of 150 to 200, and standing, crystallizing and filtering the concentrated liquor to obtain solids, and drying the solids to obtain the D-4-Hydroxyphenylglycine. According to the method, the technological design is reasonable, the operation is convenient, the recycling effect is good, and energy is saved and the environment is protected.

Owner:NORTH CHINA PHARM GRP SEMISYNTECH CO LTD

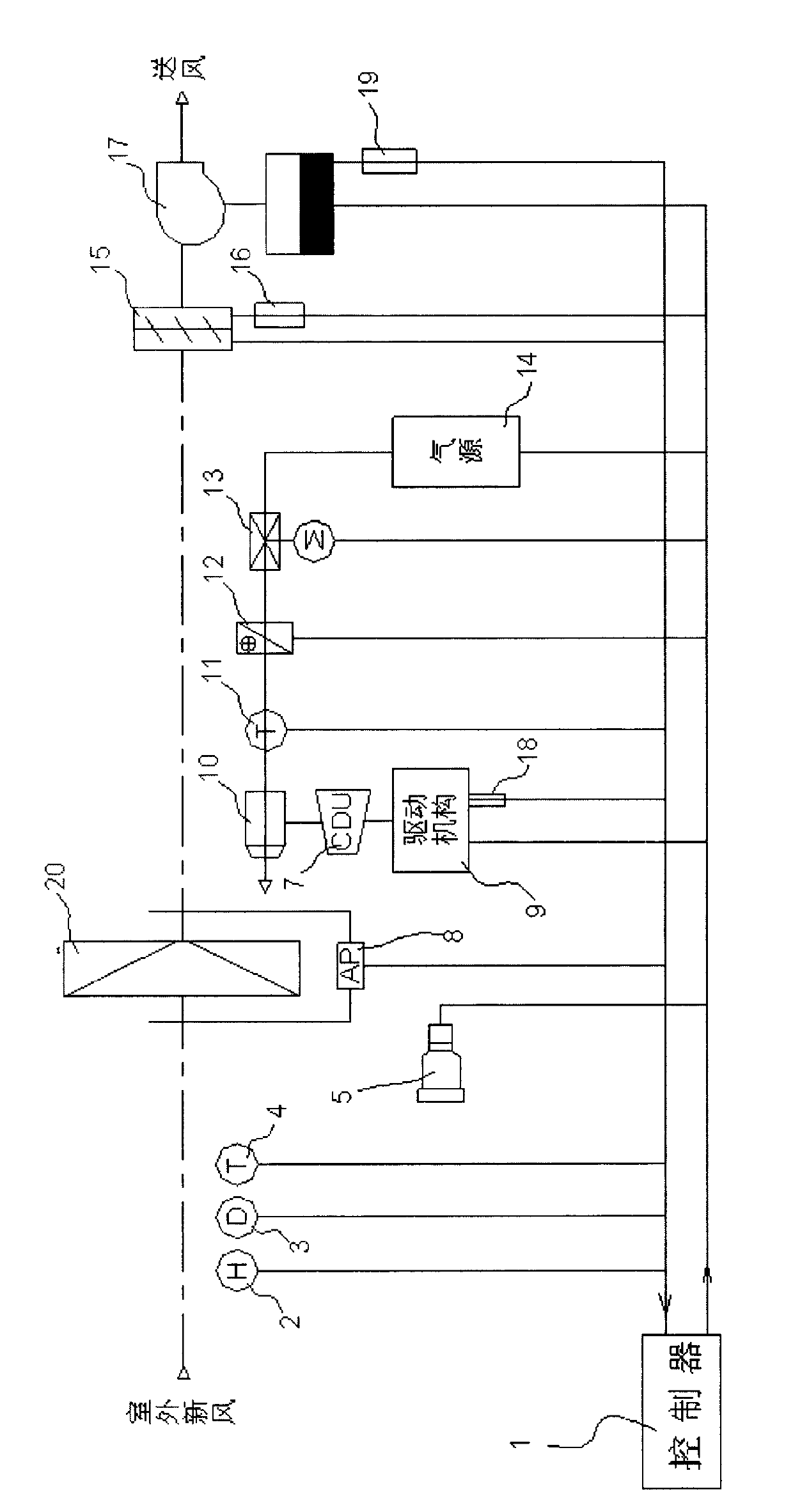

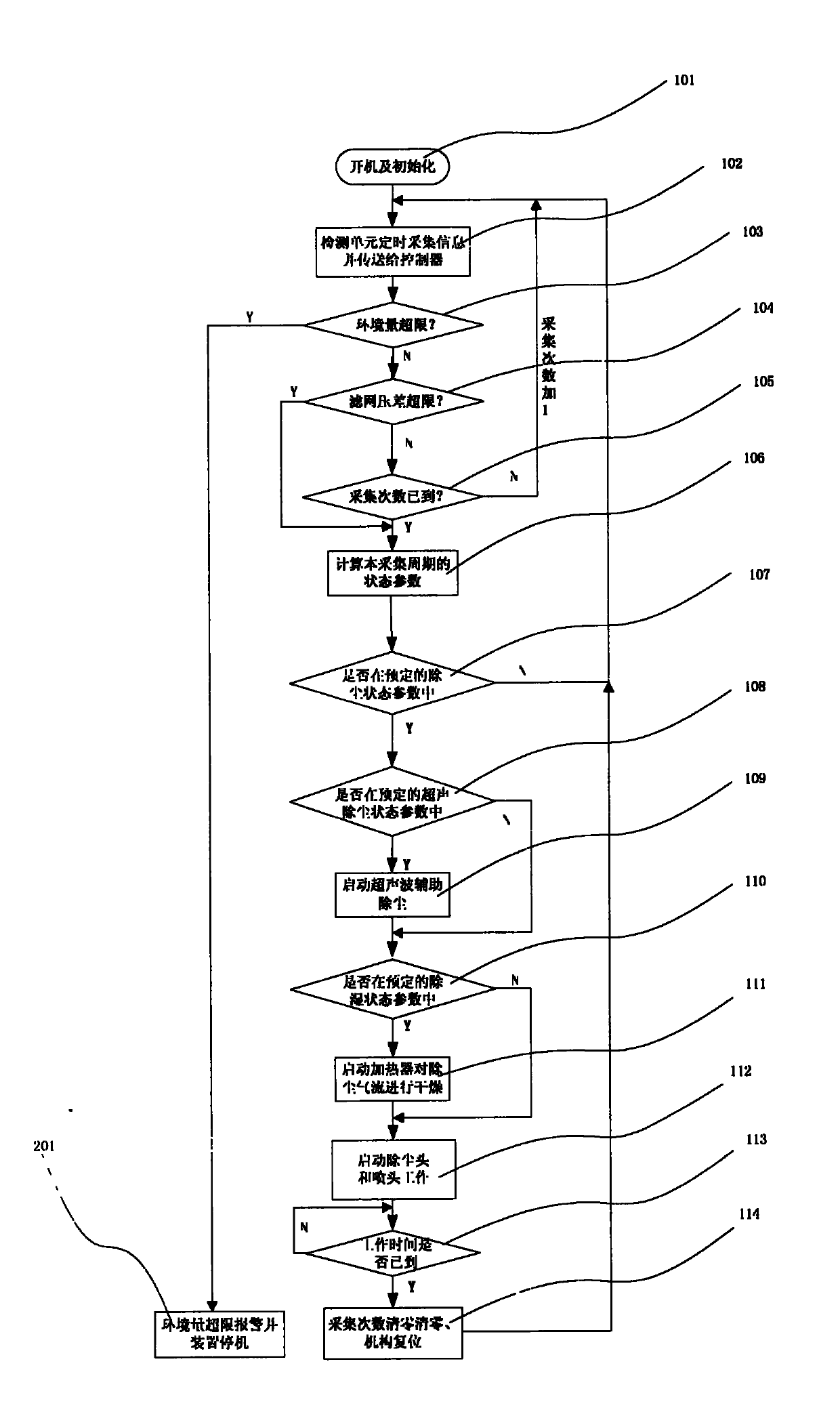

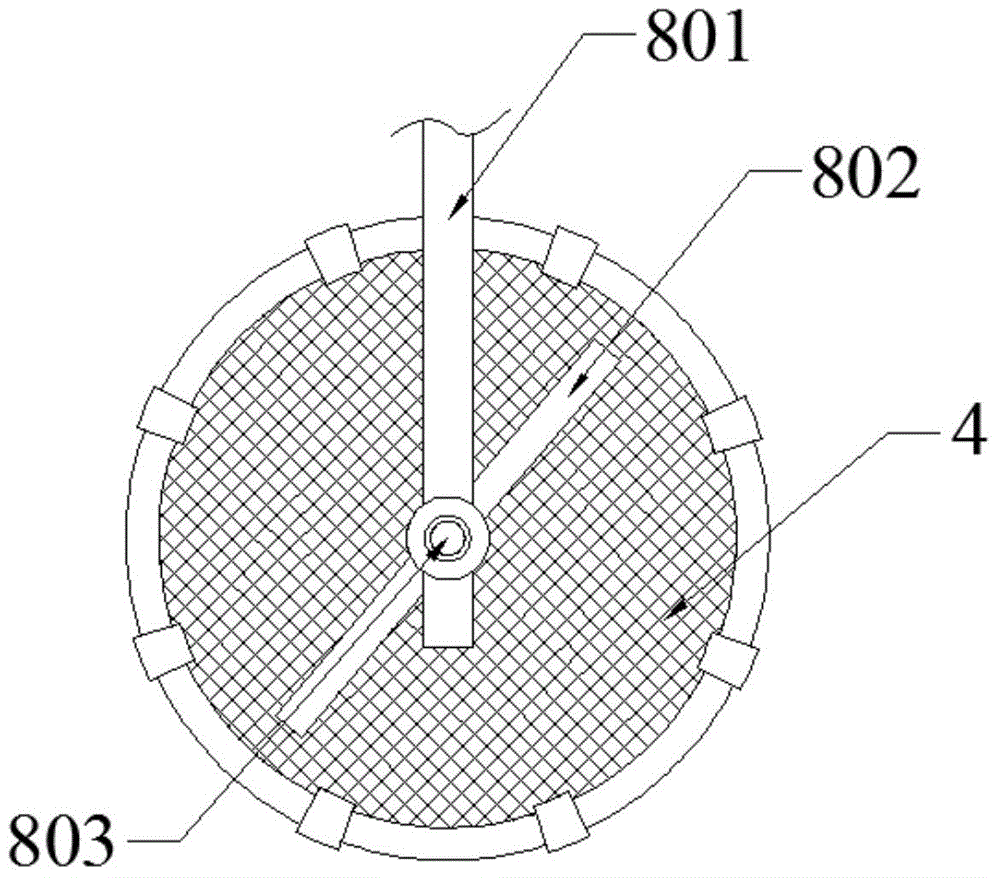

Fresh air ventilating device with self cleaning and dedusting function and dedusting method of fresh air ventilating device

InactiveCN104180465AAvoid accelerated degradationReduce maintenance frequencySpace heating and ventilation safety systemsLighting and heating apparatusFresh airEngineering

The invention relates to the field of ventilation, and discloses a fresh air ventilating device with a self cleaning and dedusting function. The fresh air ventilating device comprises an execution unit, a detection unit, a controller and an air source unit, wherein the detection unit is used for converting the environment quantity related to self cleaning and dedusting and the working state physical quantity of a system component into electric quantity and conditioning the electric quantity into an electric quantity signal which is compatible with the controller for being transmitted to the controller; the execution unit refers to execution components related to the self cleaning and dedusting, a driving circuit and a driving mechanism of the execution components, the execution unit is mainly used for enabling all execution components to work cooperatively according to an operation result of a control strategy under the regulation action of the controller and realizing the self cleaning and dedusting function on a filter screen; the controller is a microprocessor and has the main functions of collecting and processing the environment quantity and the system work state information of the detection unit at regular times, carrying out operation evaluation on a trend and a result of a dust accumulation process of the filter screen according to a dedusting strategy and outputting different dedusting control modes to filter screen dust accumulation situations in different degrees or different types. The invention also discloses a self cleaning and dedusting method using the fresh air ventilating device. The fresh air ventilating device and the self cleaning and dedusting method, disclosed by the invention, have the advantages that in-time and efficient dedusting can be carried out, and the energy source is saved.

Owner:SHENZHEN ZHONGXING SINDI TECH CO LTD

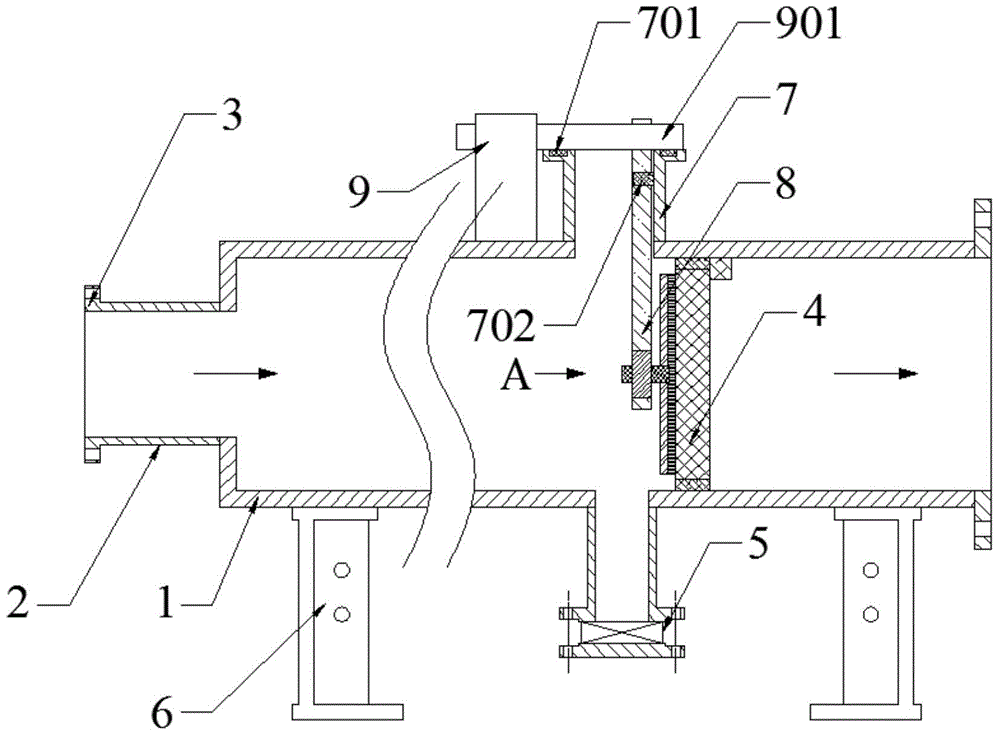

Self-cleaning horizontal type dirt remover

InactiveCN104436822ASimple structureImprove cleaning efficiencyStationary filtering element filtersMotor driveEngineering

The invention provides a self-cleaning horizontal type dirt remover and belongs to the technical field of chemical equipment. The self-cleaning horizontal type dirt remover also comprises a cleaning assembly, wherein the cleaning assembly comprises a cleaning brush, a rotary motor for driving the cleaning brush and a supporting rod for fixing and supporting the rotary motor; the cleaning brush is attached on the side surface of a filtering net towards the inlet end of a body, and is fixedly connected with an output shaft of the rotary motor. The rotary motor drives the cleaning brush to rotate in the vertical surface. The self-cleaning horizontal type dirt remover provided by the invention has the advantages that the structure is simple; due to the arranged cleaning assembly, the filtering net can be cleaned without stoppage, so that the cleaning efficiency is high, no influence on the production process is caused, the frequency of whole maintenance and clearing of the dirt remover is reduced, the production frequency is improved and convenience is brought for use of equipment in the dirt-removing process.

Owner:TIANJIN ZECHANG CHEM EQUIP MFG

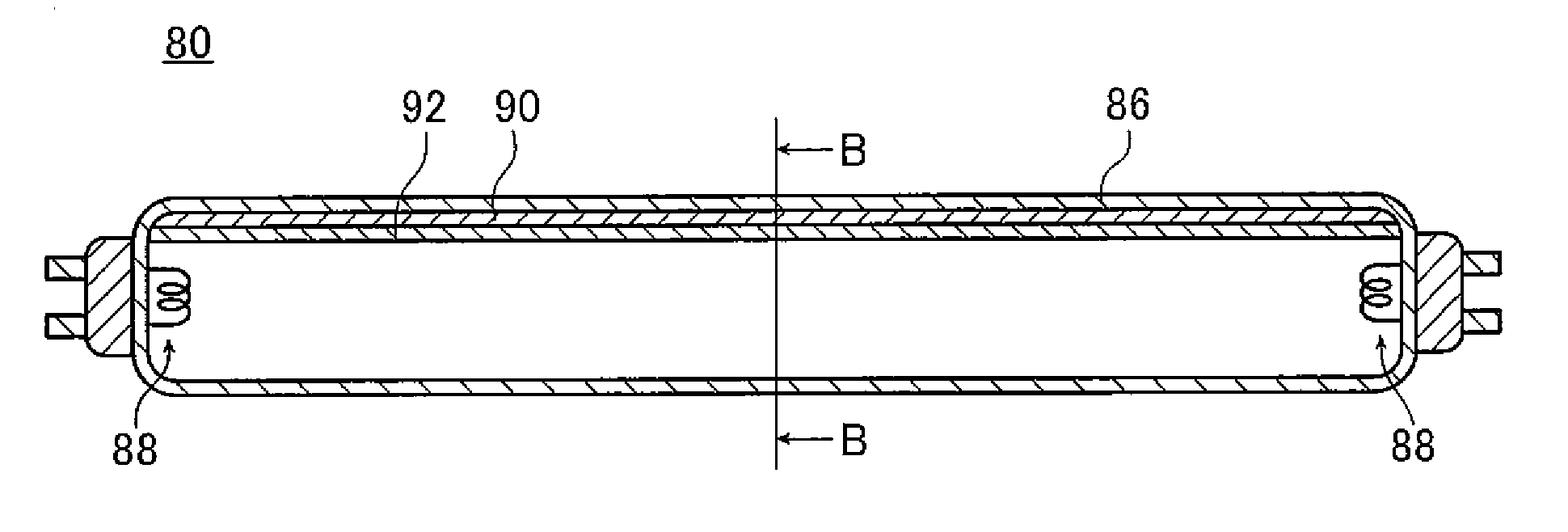

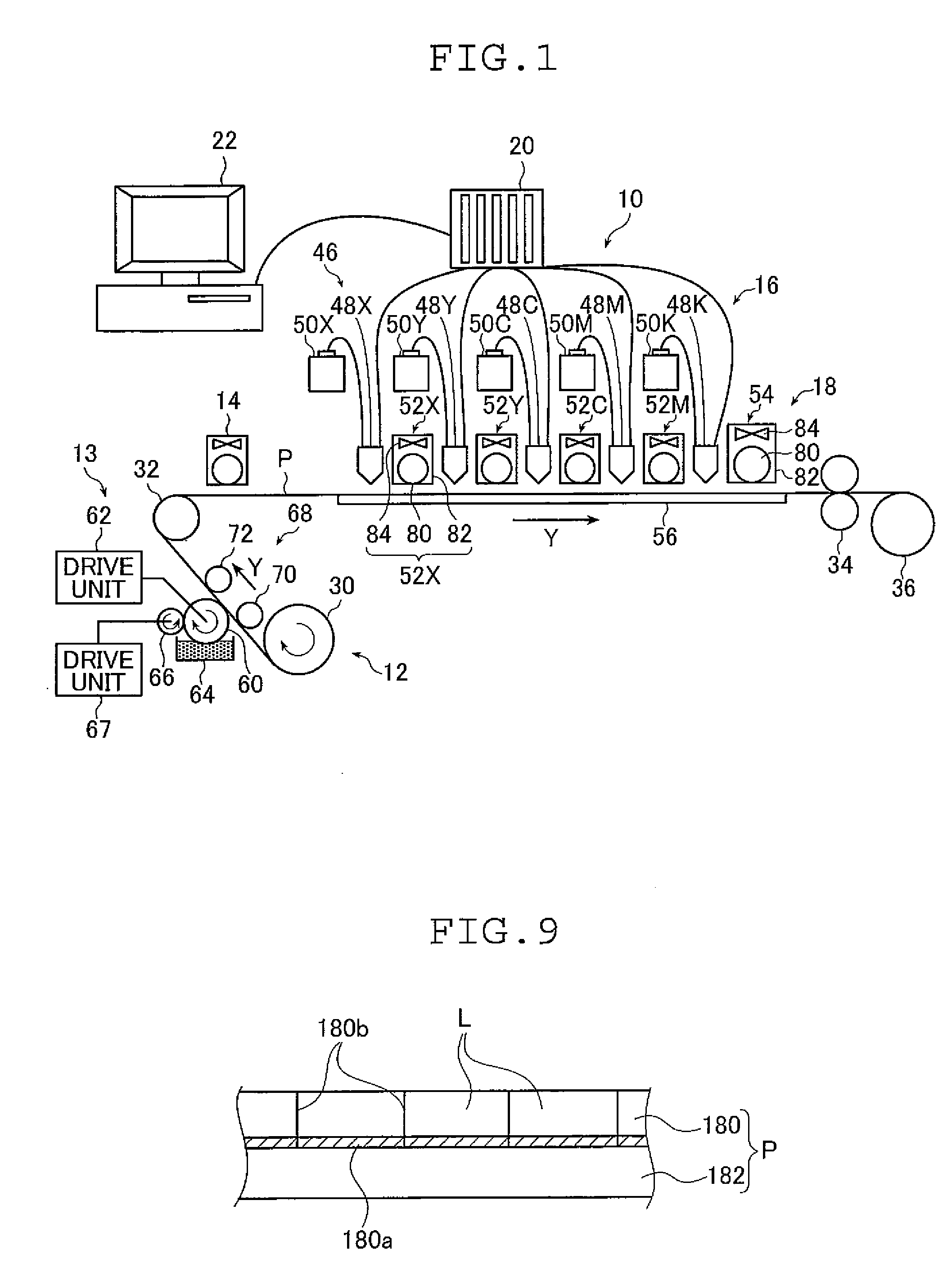

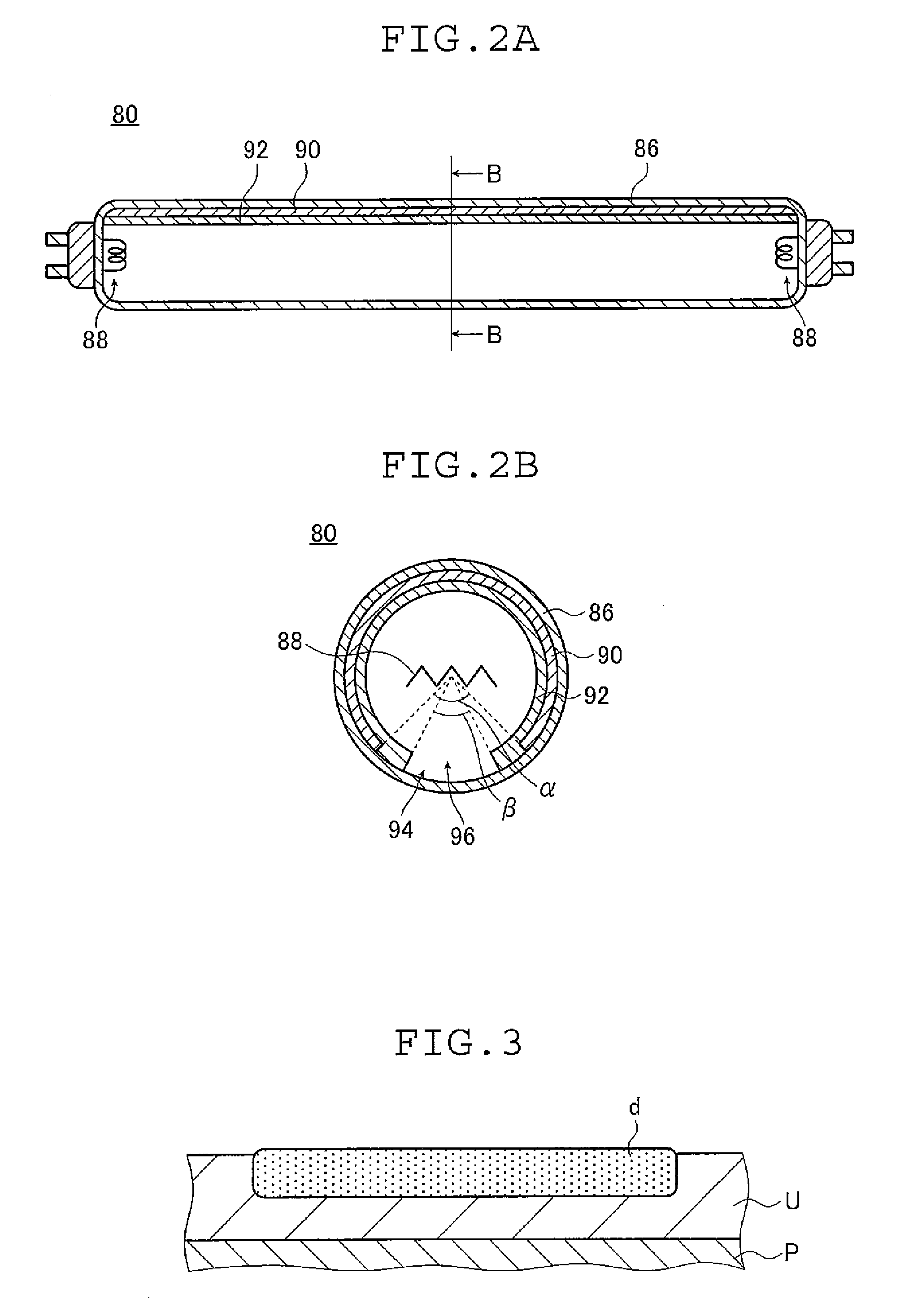

Ink-jet recording device

InactiveUS20090086000A1High strengthReduce intensityOther printing apparatusLight irradiationImage formation

The ink-jet recording device includes an image forming section where an active energy ray-curable ink is ejected onto a recording medium to form an image, and an image curing section which includes at least one light irradiation unit having a fluorescent lamp and which cures the ink on the recording medium upon exposure to active energy rays. The fluorescent lamp has a bulb, a reflective film formed on a bulb inner wall and having a first aperture formed on a recording medium side, and a phosphor film formed on the reflective film and the bulb inner wall and having a second aperture formed on the recording medium side. The formulas: β<α, 60°≦α≦150° and 30°≦β≦90° where α represents a first aperture angle of the first aperture and β represents a second aperture angle of the second aperture are satisfied.

Owner:FUJIFILM CORP

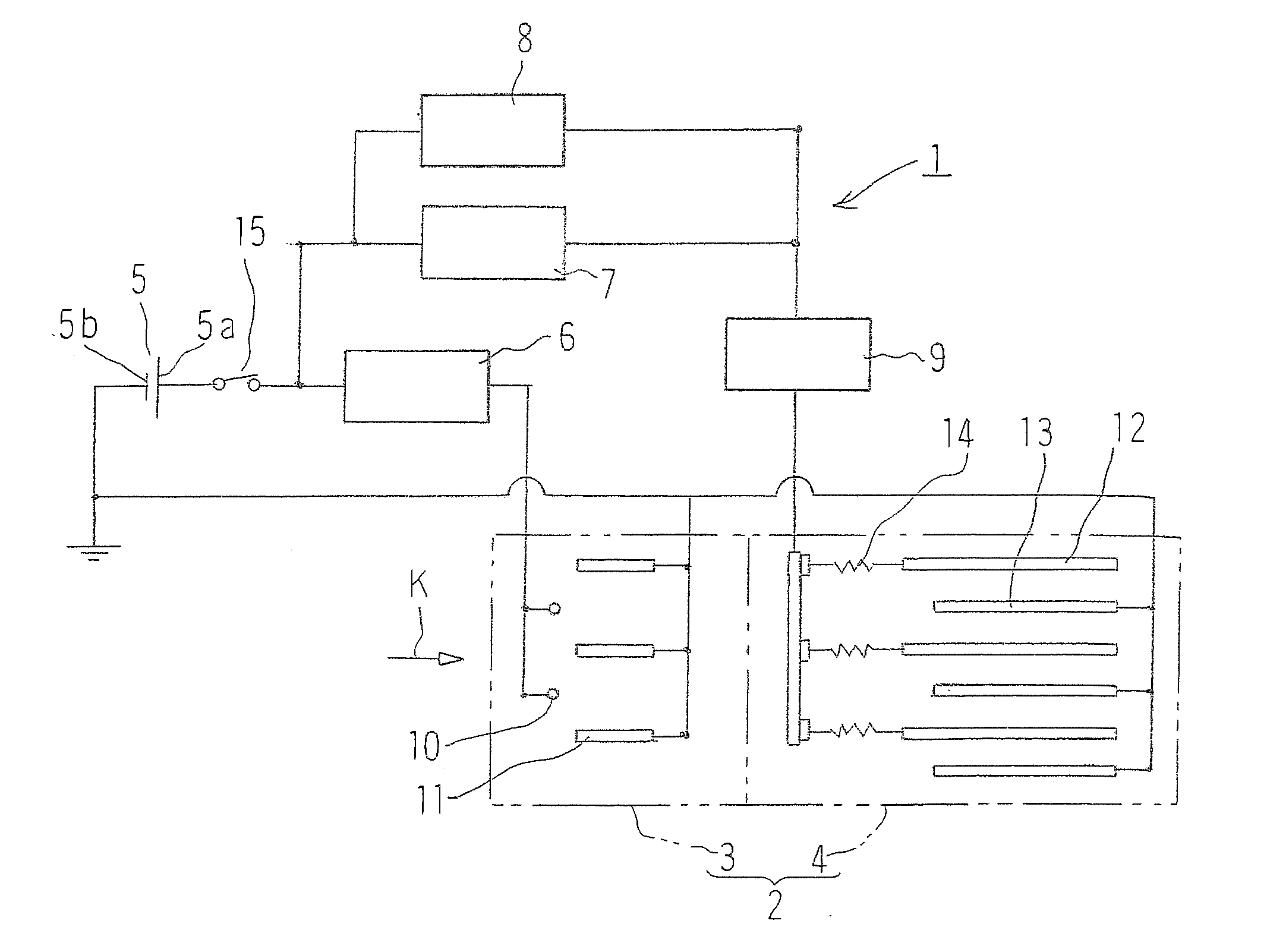

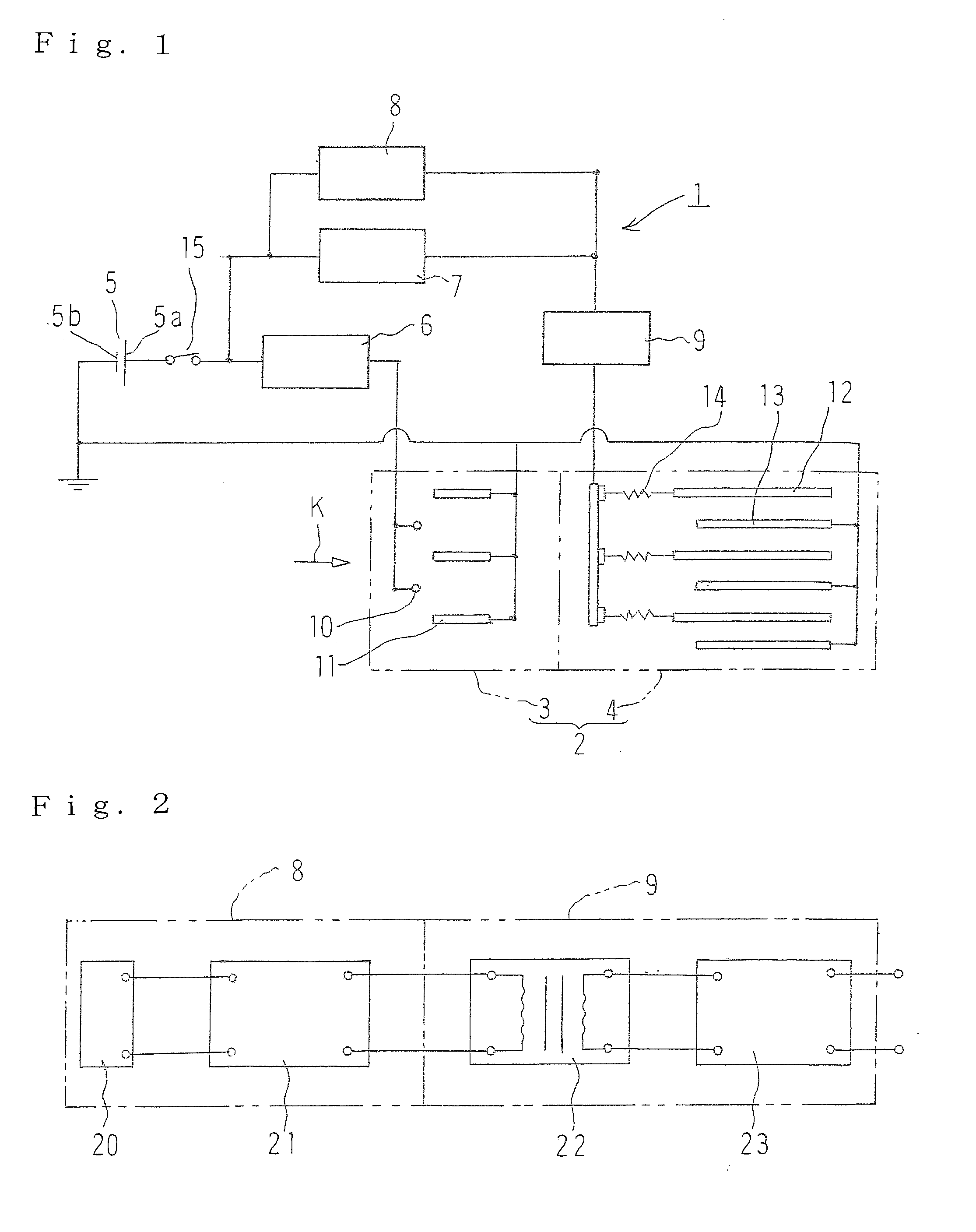

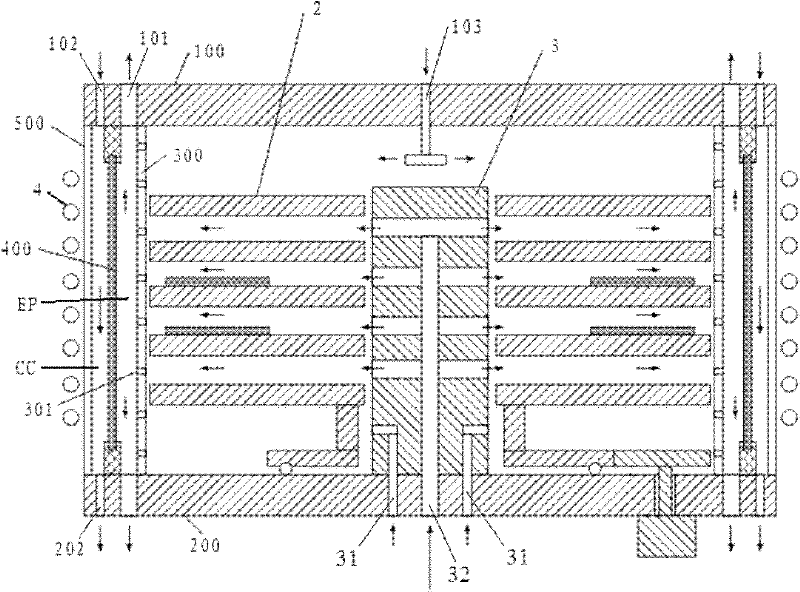

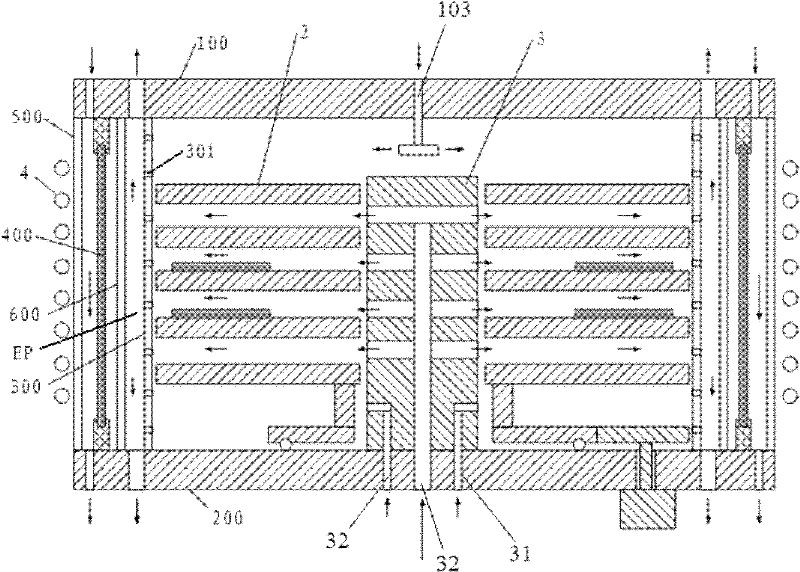

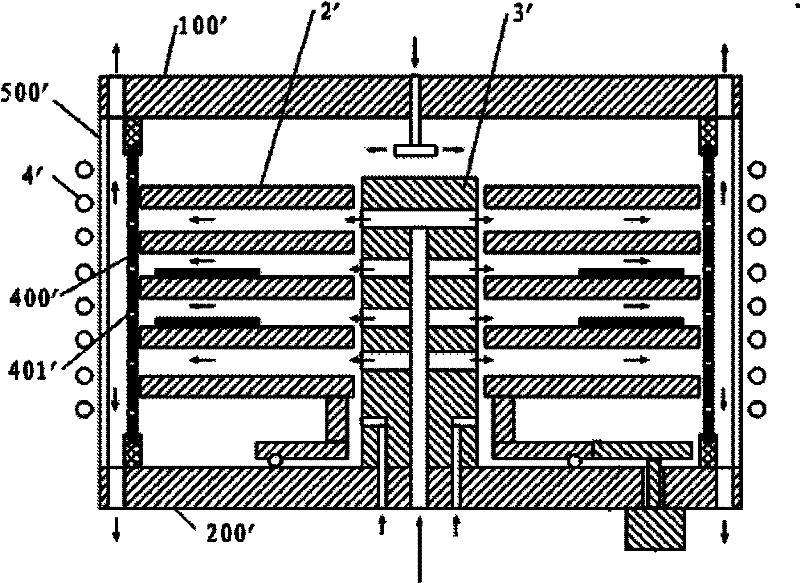

Electrostatic precipitation apparatus for room ventilation and ventilation system incorporating same

InactiveUS20140345463A1Reduce voltageImprove efficiencyMechanical apparatusLighting and heating apparatusControl cellAtmospheric sciences

The exemplary system / apparatus can include an electrostatic precipitation apparatus for room ventilation, which can have a two-stage charging type electrostatic precipitator including an ionization section, a particle collection section and a power supply. The exemplary apparatus can include a constant-current control unit / arrangement interposed between the power supply and the ionization section. A sensing unit / arrangement can be interposed between the power supply and the particle collection section. A voltage step control unit / arrangement can receive the applied voltage value and current value from the sensing unit / arrangement for issuing a command to increase or decrease the predetermined voltage to prevent the particle collection section from anomalously discharging in response to an anomalous discharge. A voltage changing unit / arrangement can change the predetermined voltage in response to a command from the voltage step control unit to control a current and a voltage provided from the power supply to the particle collection section.

Owner:TORNEX

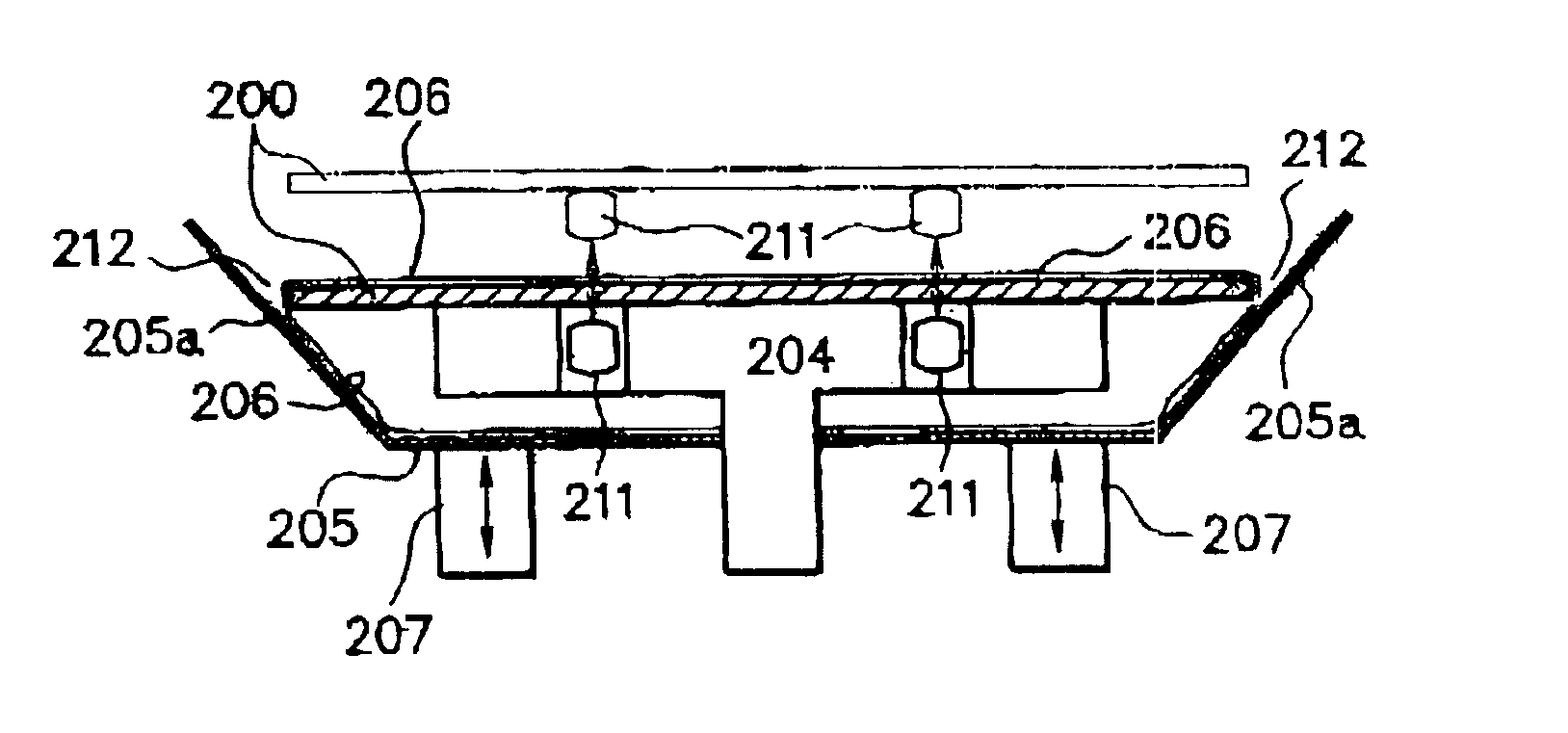

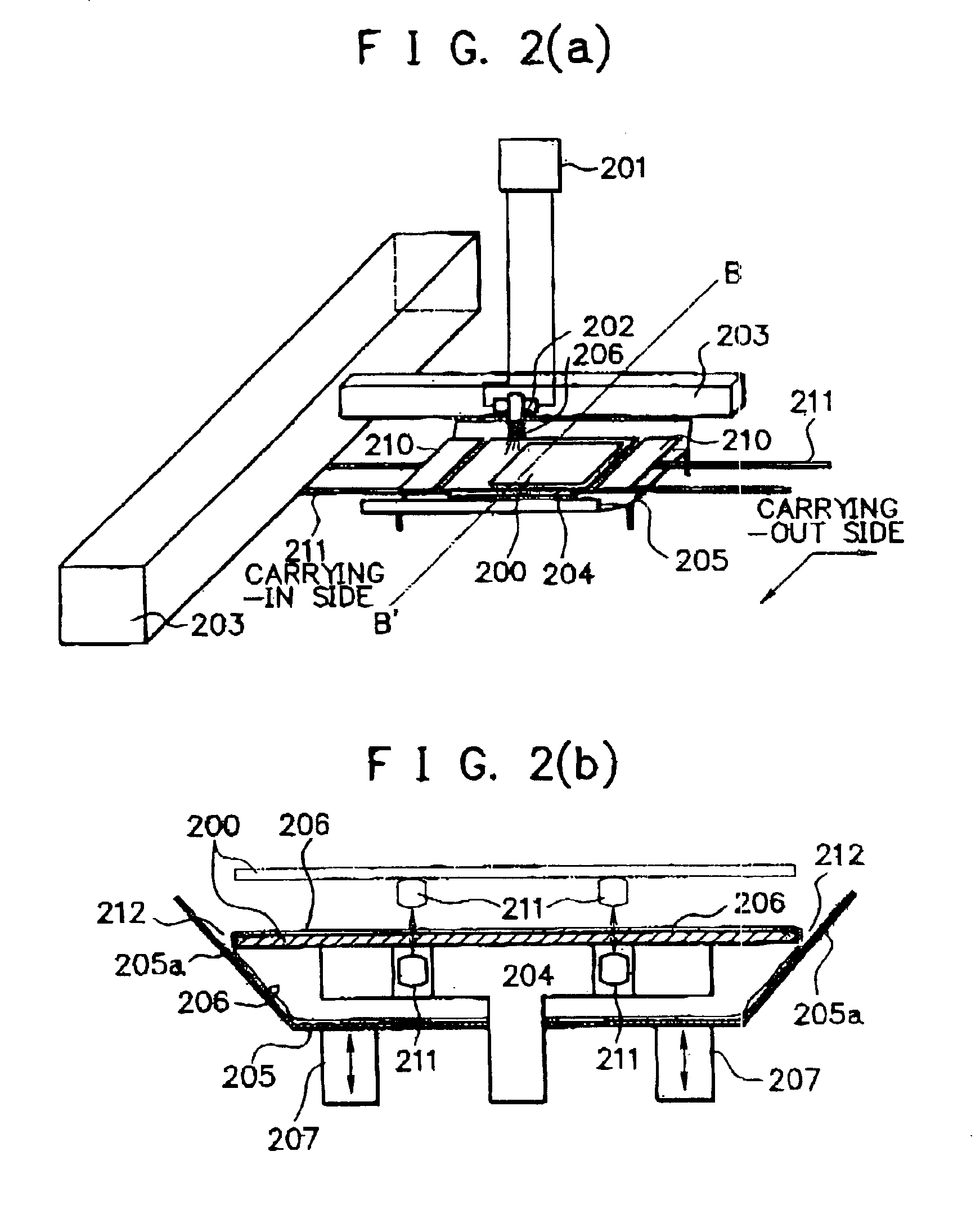

Process and apparatus for producing a substrate having a coating resin layer

InactiveUS6953599B2Maintenance frequency be diminishOperation efficiency be improvePretreated surfacesSpray nozzlesComposite materialCoating

A process for producing a substrate having a coating resin layer includes the steps of carrying in a substrate on a fastening table and fastening the substrate to the table and, while moving a spout for spouting a resin layer precursor or the fastening table in a horizontal direction, spouting the resin layer precursor to apply the resin layer precursor onto the substrate to form a resin layer precursor layer on the substrate. Additional steps include carrying out the substrate having the resin layer precursor layer from the fastening table, and drying and curing the resin layer precursor layer on the substrate to form a coating resin layer on the substrate.

Owner:CANON KK

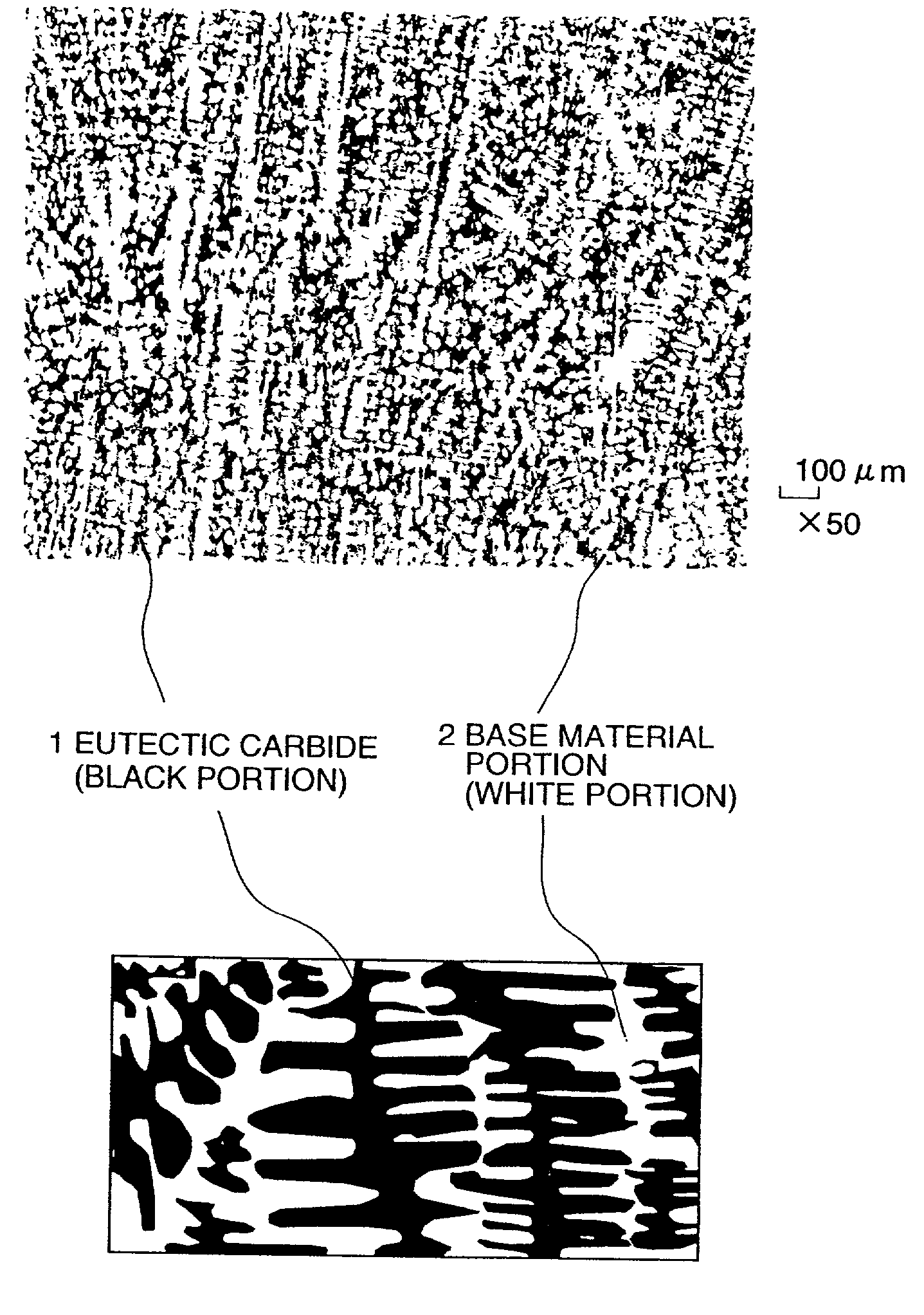

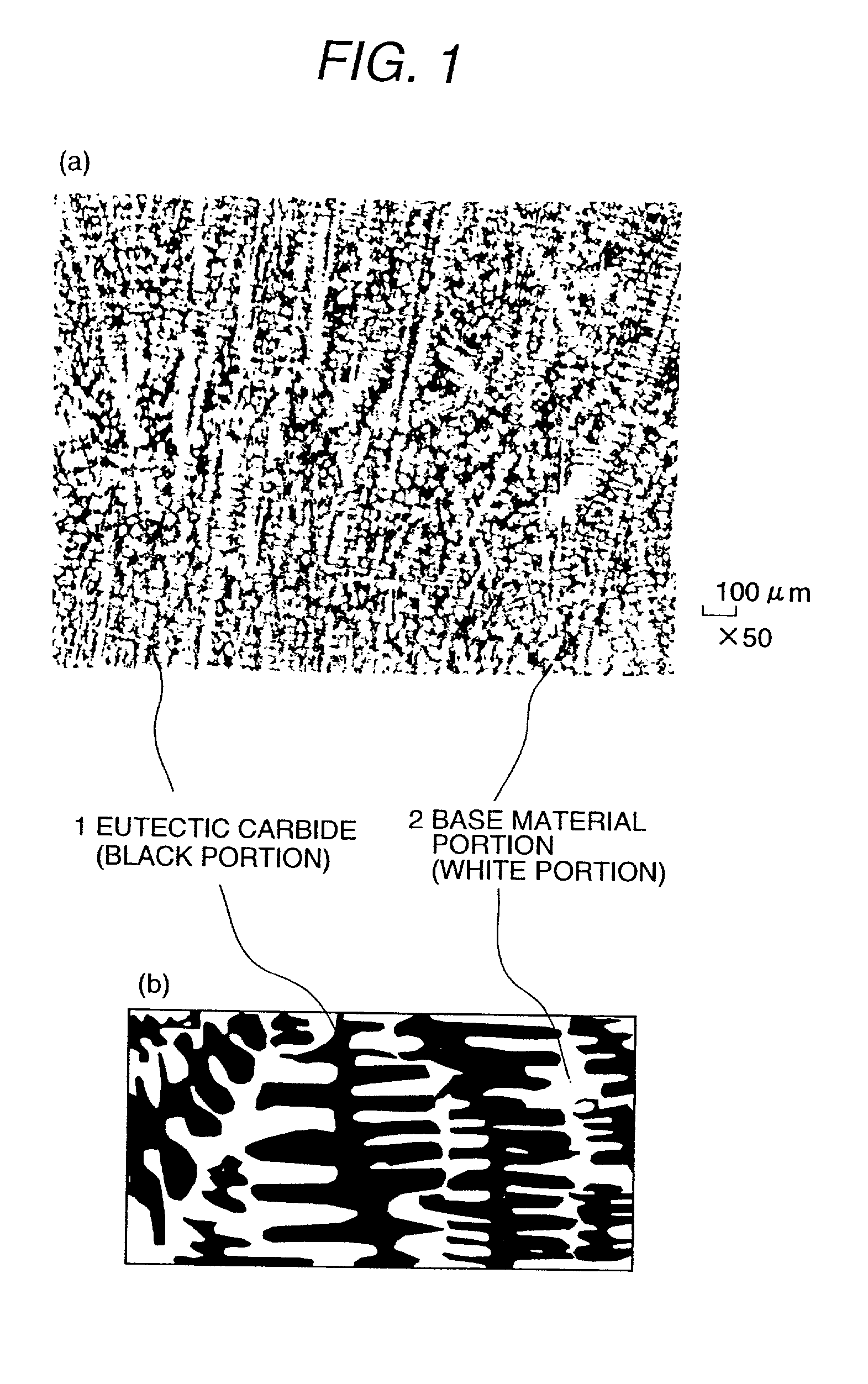

Corrosion-resisting and wear-resisting alloy and device using the same

InactiveUS20020064678A1High hardnessLow ductilityEngine sealsPositive displacement pump componentsOxygenCobalt

To provide a corrosion-resisting and wear resisting alloy including cobalt, nickel or iron as a base used for a sliding part or a valve seat for a machine, and restraining erosion and corrosion caused by eutectic carbide constituting the alloy in an atmosphere with dissolved oxygen. A material is selected from a cobalt base added with Cr and / or W, a nickel base added with Fe and / or Cr, and an iron vase added with Cr and / or Ni. The material is cast into an ingot or a slab to produce an intermediate material. The intermediate material comprises mesh-like eutectic carbide and a base material surrounded by the eutectic carbide. A heat plastic forming is applied to the intermediate material at a temperature 650° C. or more and the solidus temperature or less. The eutectic carbide is formed into multiple grains or clusters as a discontinuous distribution. A resulting corrosion-resisting and wear-resisting alloy has 0.1 to 0.5 of coefficient of friction, and 300 to 600 Hv of Vickers hardness without age-hardening process.

Owner:HITACHI LTD +1

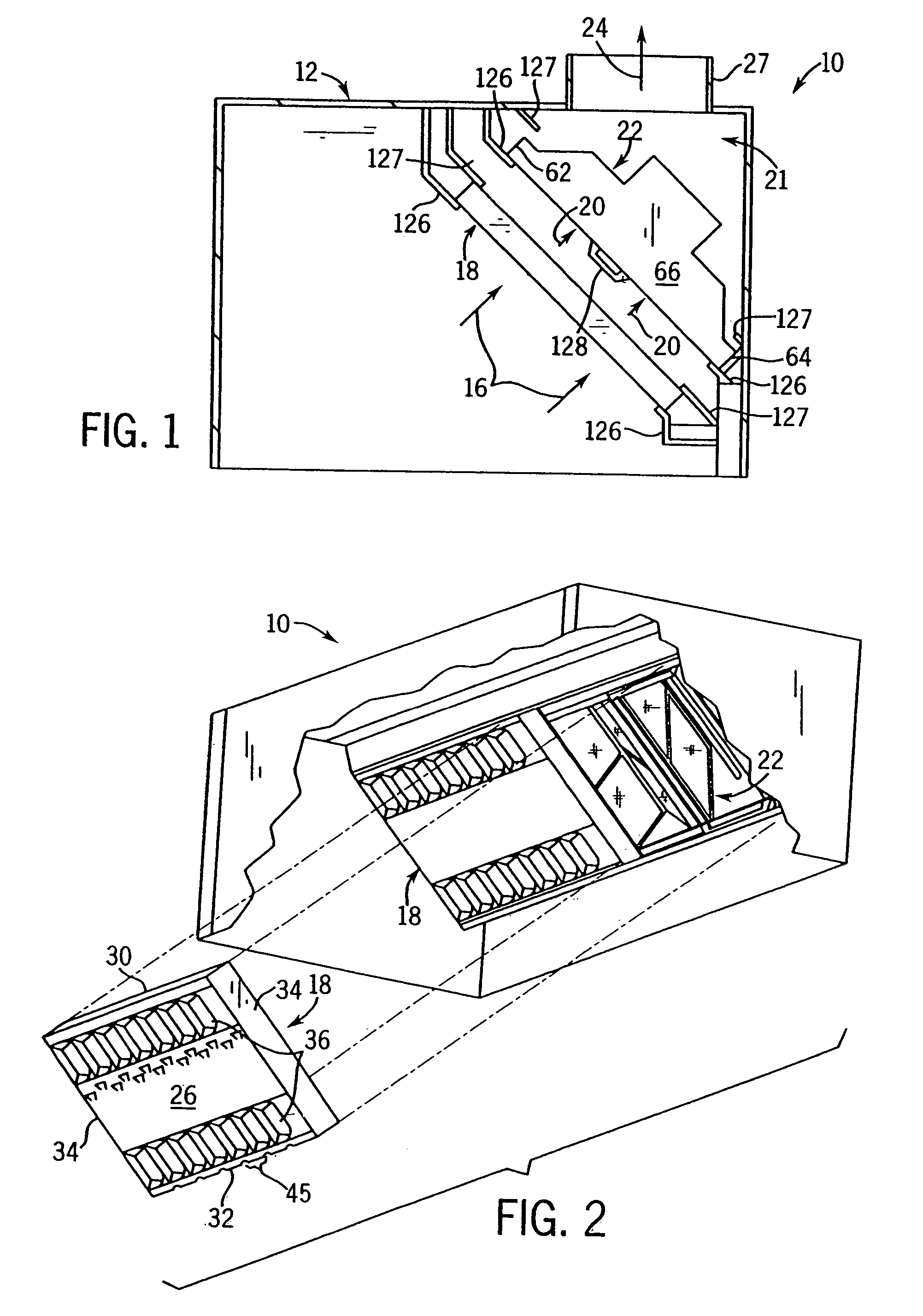

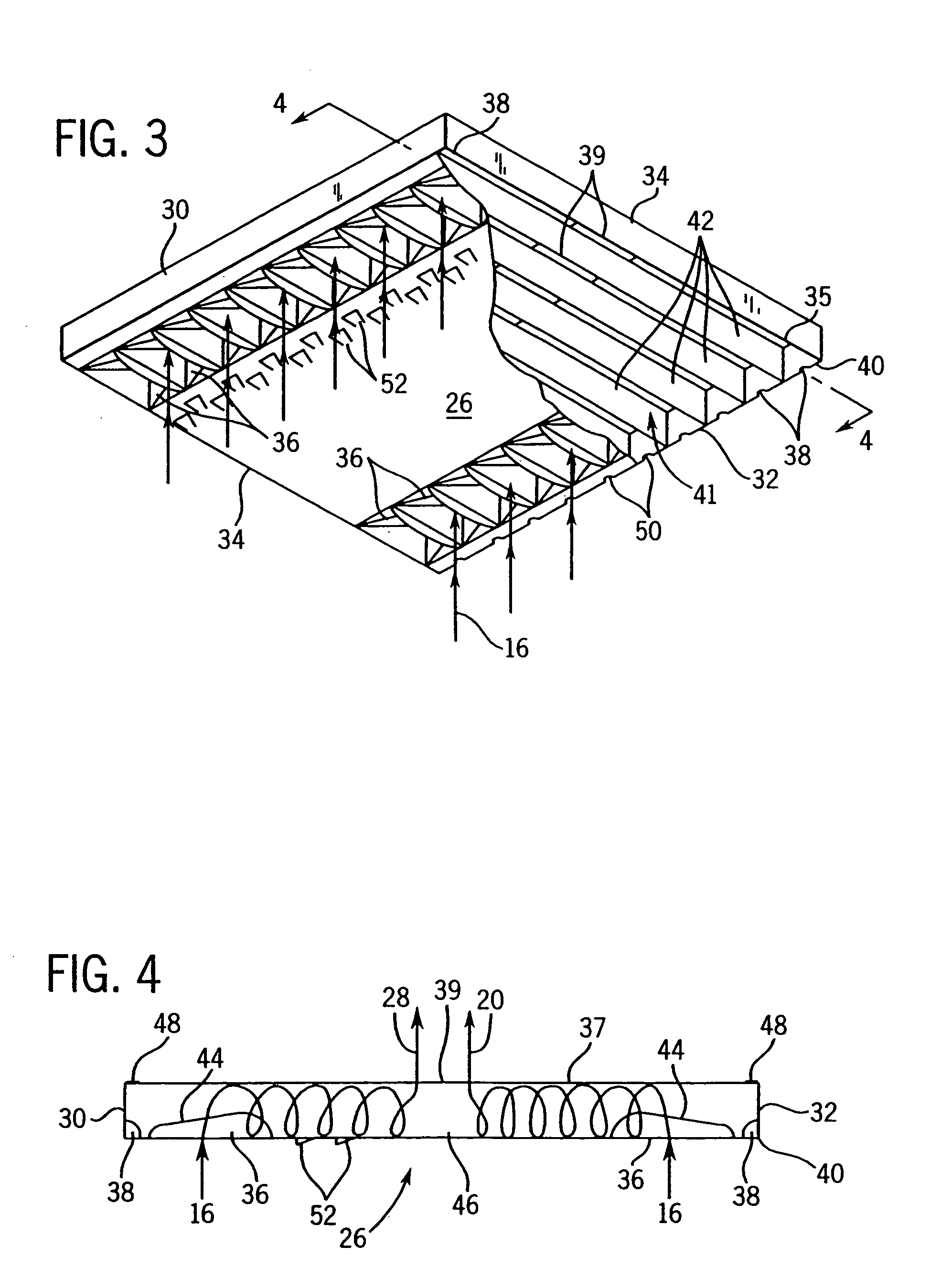

Two stage air filter

InactiveUS6994743B2Remove impuritiesSpeed up the extraction processCombination devicesDomestic stoves or rangesAirflowEngineering

A two stage air purification system is provided for the removal of airborne impurities from an airflow prior to the airflow entering a building's ductwork. In particular, a primary air filter is mounted within the hood of, for example, a cooking area and operable to receive grease-laden air and remove a portion of the impurities. The air is then sent to a secondary filter, also mounted within the hood, that removes additional impurities. The air is then sent through the building's ductwork and eventually out the building.

Owner:GREENHECK FAN

Overhead transmission line on-line monitoring device based on non-contact power-obtaining system

ActiveCN107607832AImprove securityReduce replacement frequencyBatteries circuit arrangementsElectric powerControl systemElectrical battery

The invention provides an overhead transmission line on-line monitoring device based on a non-contact power-obtaining system. The monitoring device is characterized by including a mechanical bearing protection system, an on-line monitoring system, a sensing energy storage adjusting control system, a gap discharge power-obtaining control system, a sensor monitoring analysis system, a master controlsystem and a power supplying protection system, the on-line monitoring system, the sensing energy storage adjusting control system, the gap discharge power-obtaining control system, the sensor monitoring analysis system, the master control system and the power supplying protection system all being arranged on the mechanical bearing protection system. The monitoring device has the advantages of being reasonable in structure and long in service life, being free from extra connection of a power source, needing battery replacement, being convenient to maintain, having a good effect, etc.

Owner:NORTHEAST DIANLI UNIVERSITY

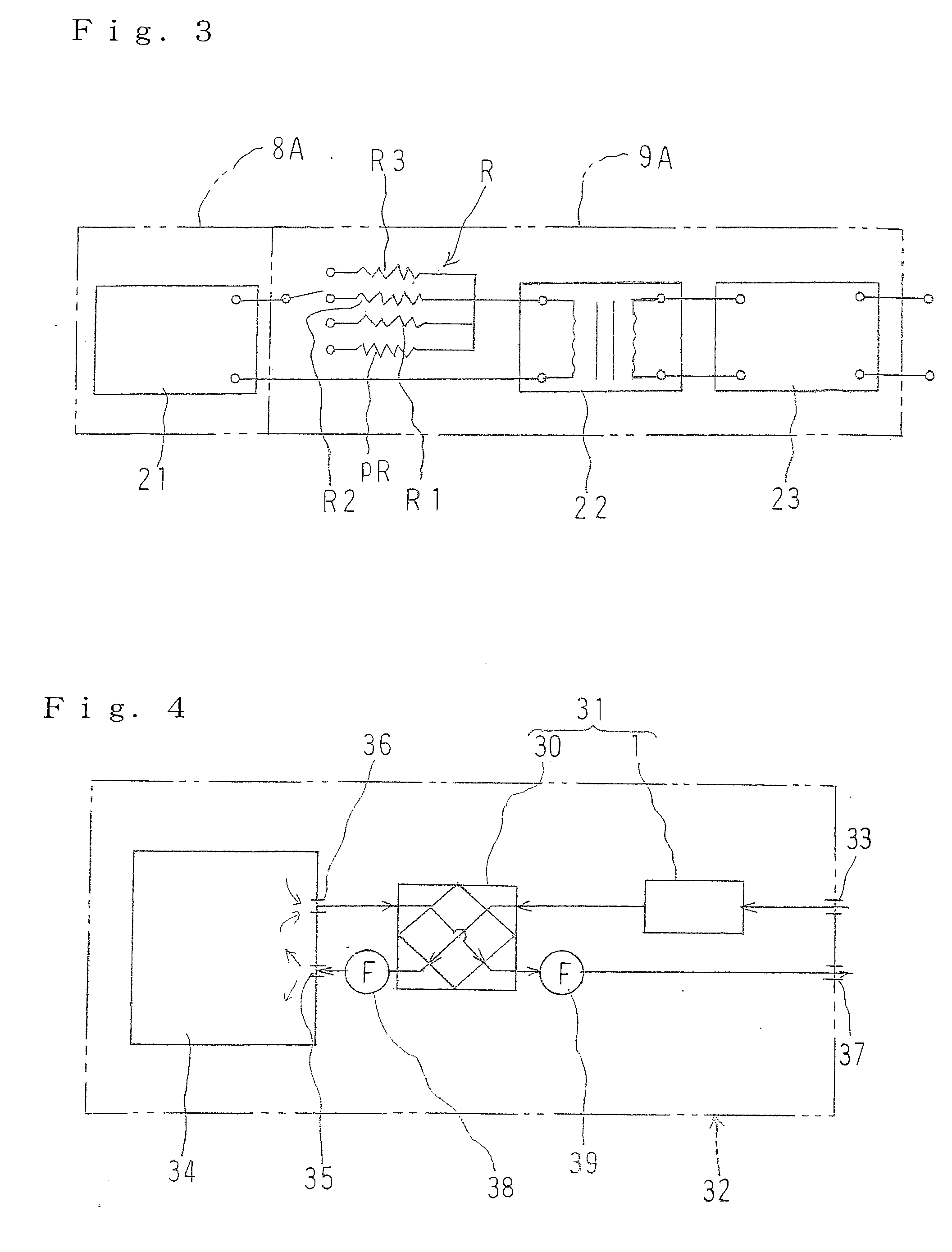

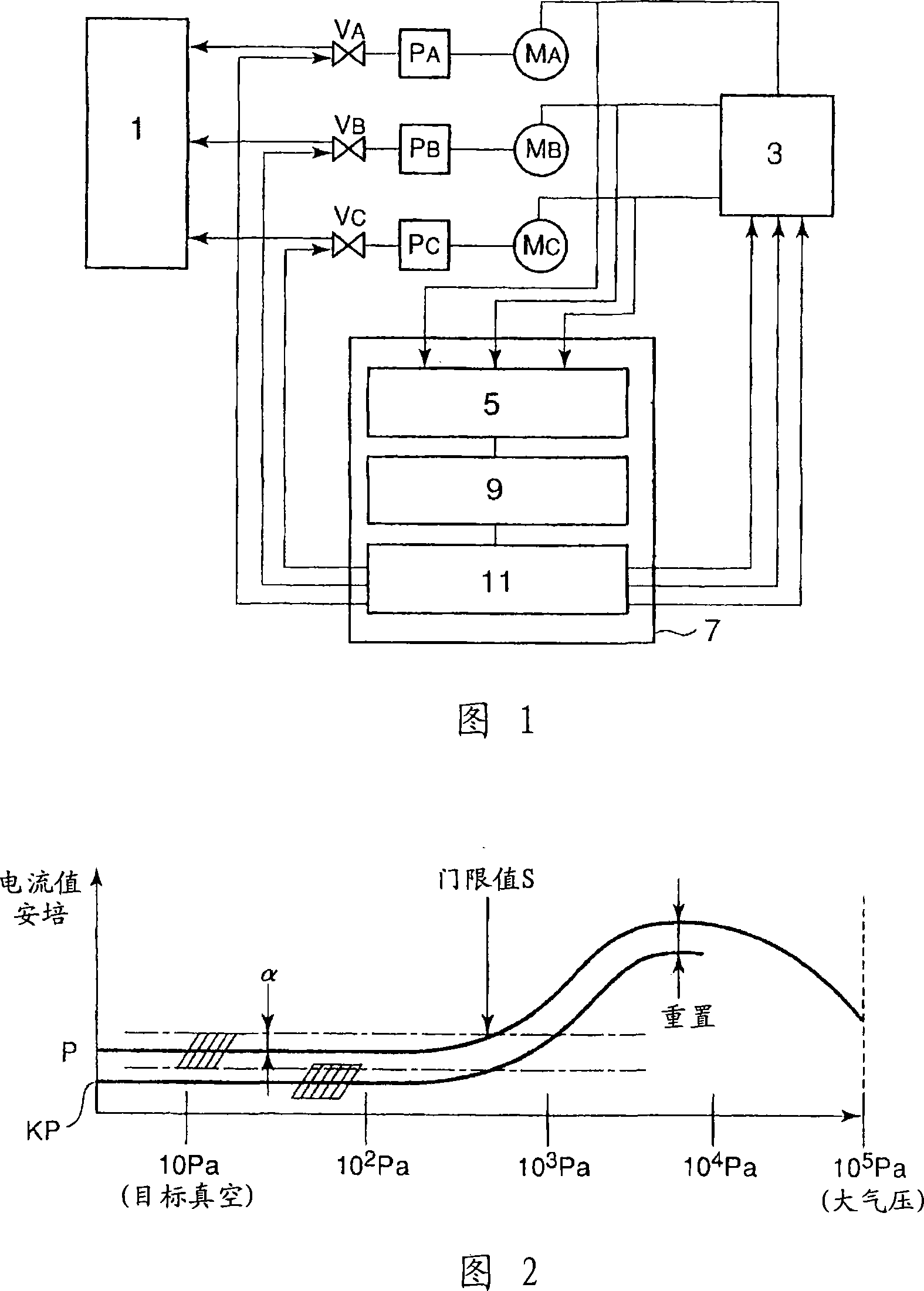

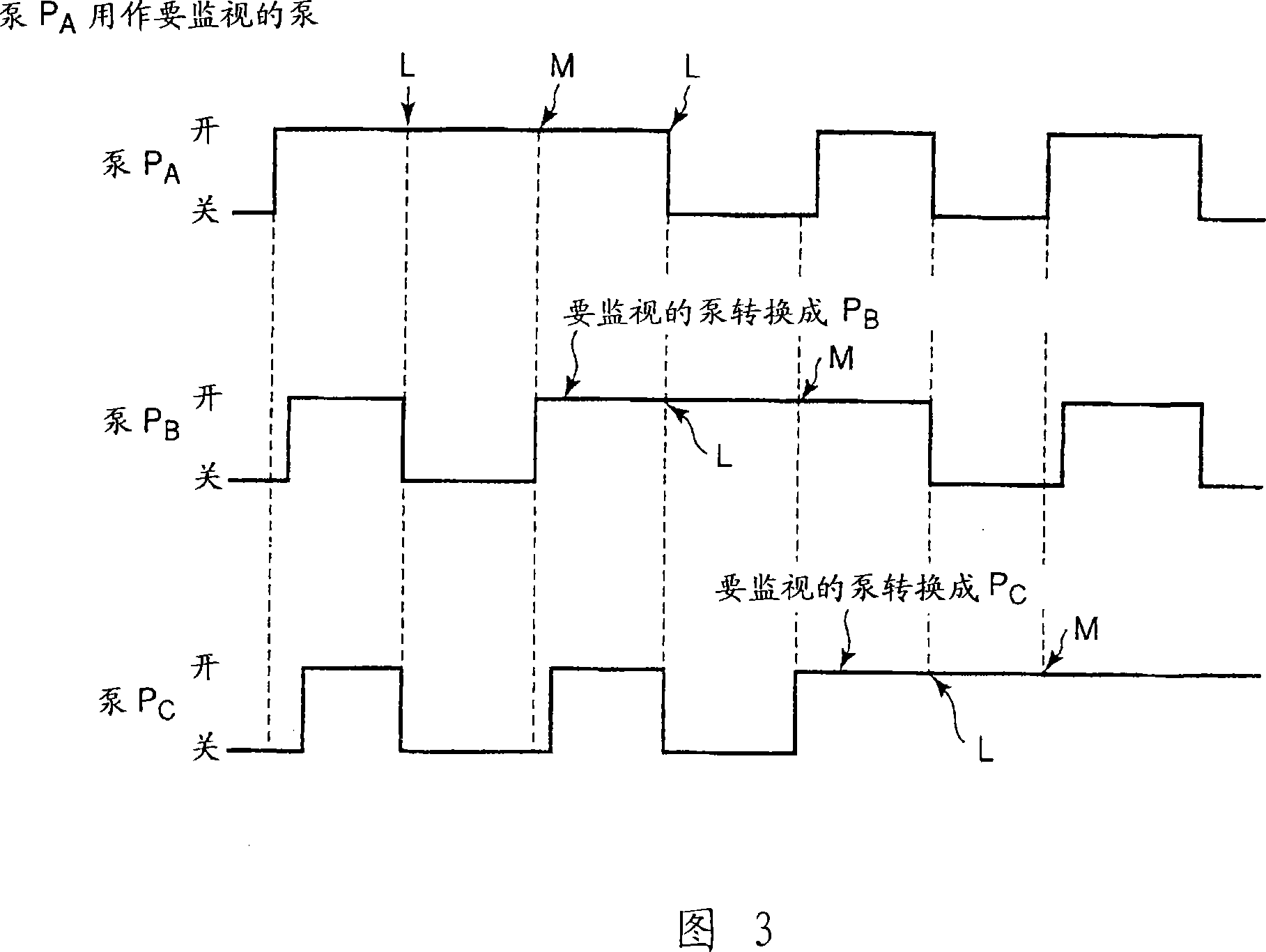

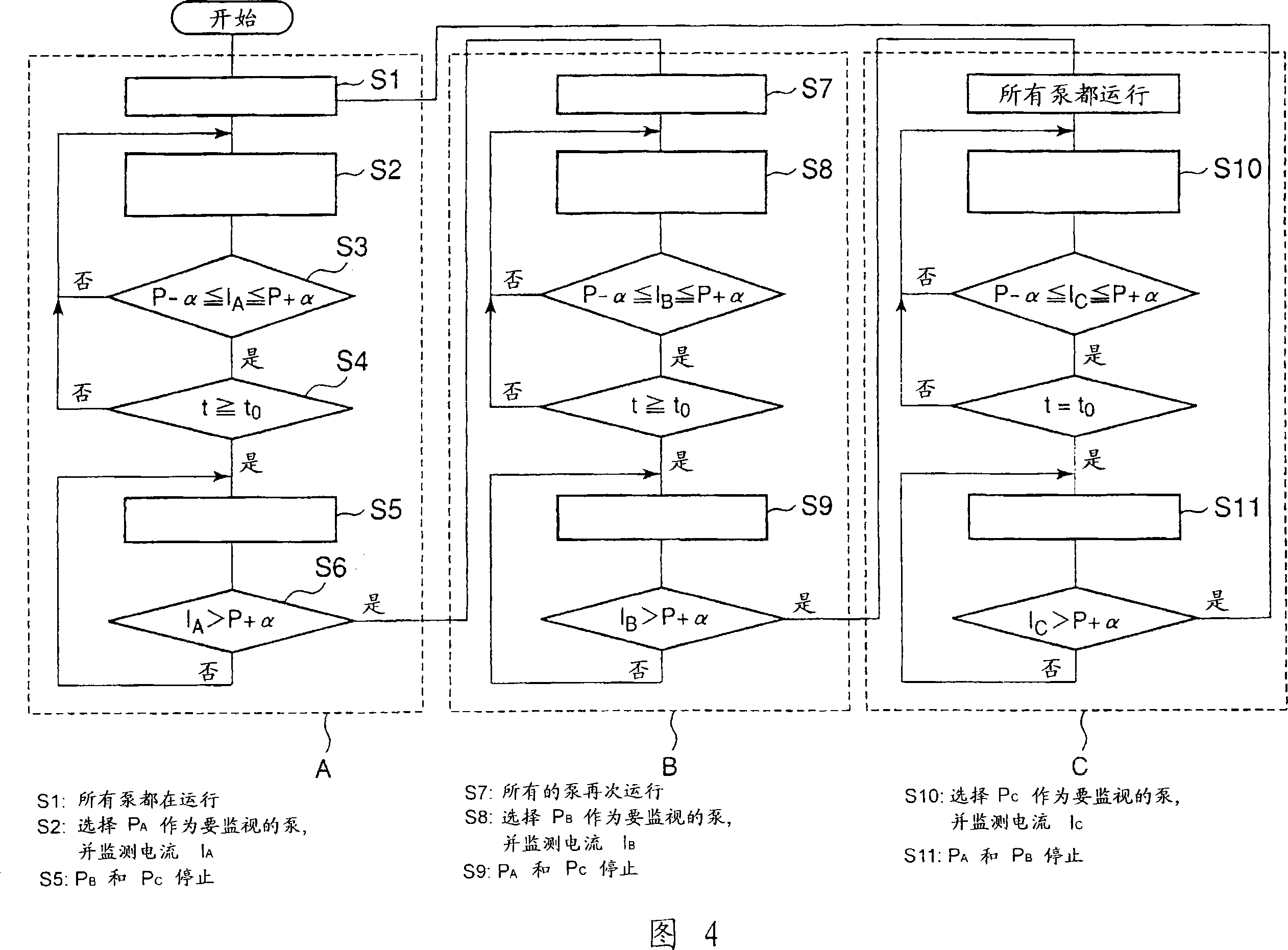

Operation control device and method of vacuum pumps

Owner:ANEST IWATA CORP

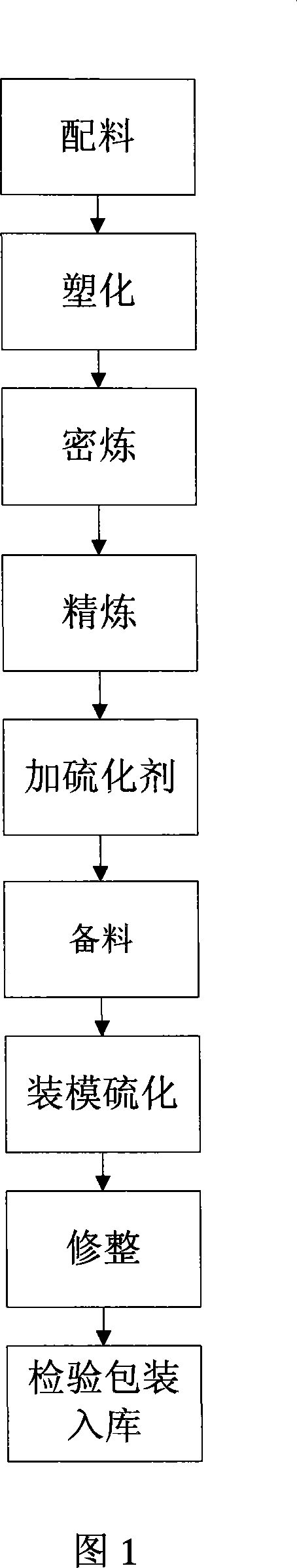

Novel rubber packing plate and production technique thereof

InactiveCN101220184AExtended service lifeGood weather resistanceRail fastenersTetramethylthiuram disulfideElastomer

The invention relates to a novel rubber pad, the parts by weight of components of which are: 80-95 portions of ethylene propylene diene monomer rubber, 5-20 portions of elastomer, 0.6-2.5 portions of sulfur, 0.5-2.0 portions of dicumyl peroxide, 0.5-1.5 portions of 2-Mercaptobenzothiazole, 0.8-1.6 portions of tetramethylthiuram disulfide, 2 portions of p-Phenylenediamine or naphthylamine antioxidant, 60-90 portions of carbon black, 15-45 portions of argil, 15-50 portions of calcium carbonate and 35-45 portions of operation oil. Production technique of the pad is according to the processes of mixing - plasticizing - banburying - refining - adding sulfidizer - preparing material - diefilling and sufidizing - finishing - inspecting packages and putting in storage. The invention has the advantages that: the rigidity, the vibration and the noise of railway are reduced; the service life and compression deforming quality of the pad are enhanced; elasticity loss of the pad and line maintenance expense are reduced; the invention also has the advantages of sufficient raw materials, low cost, innocuity and no pollution.

Owner:四川宏亿复合材料工程技术有限公司

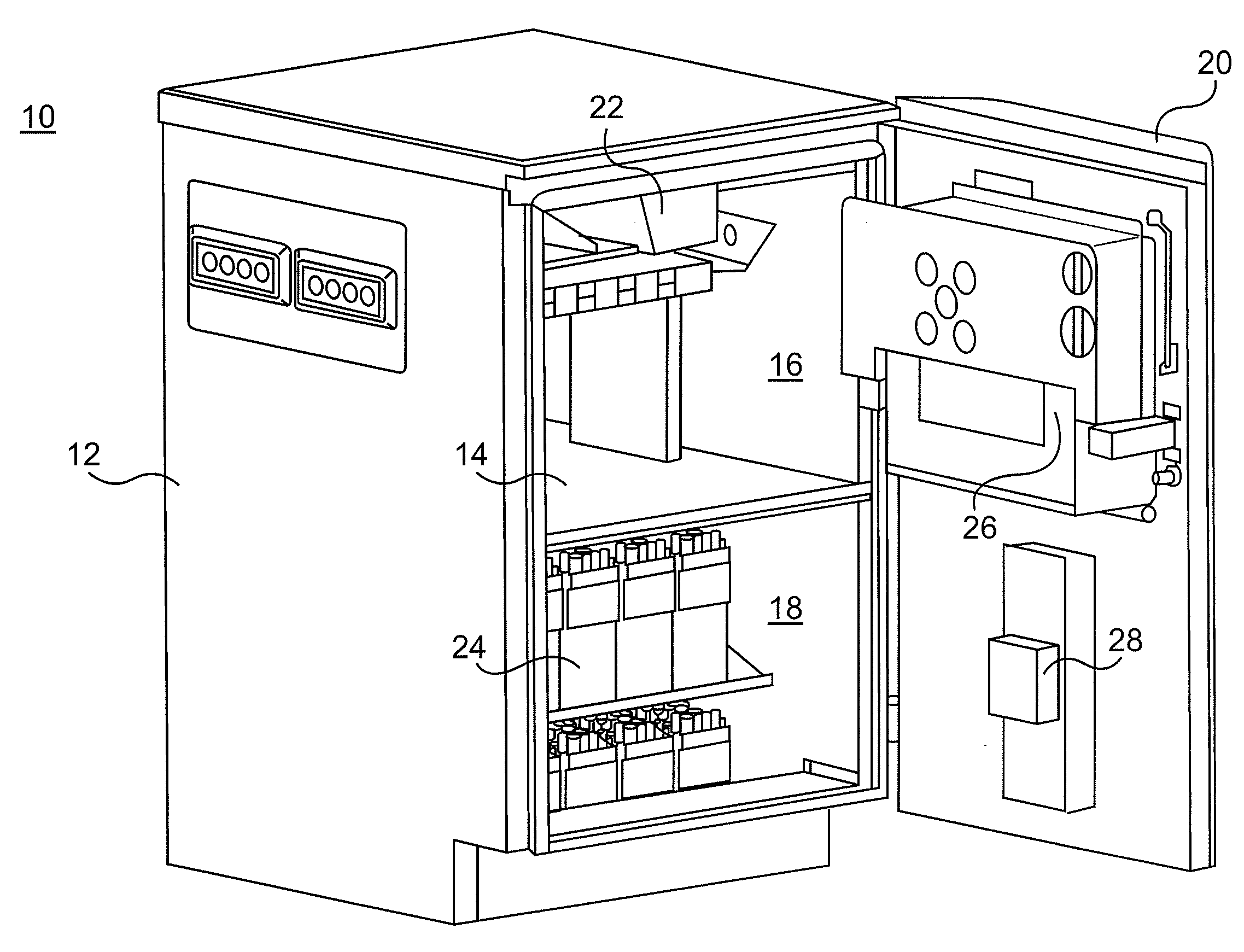

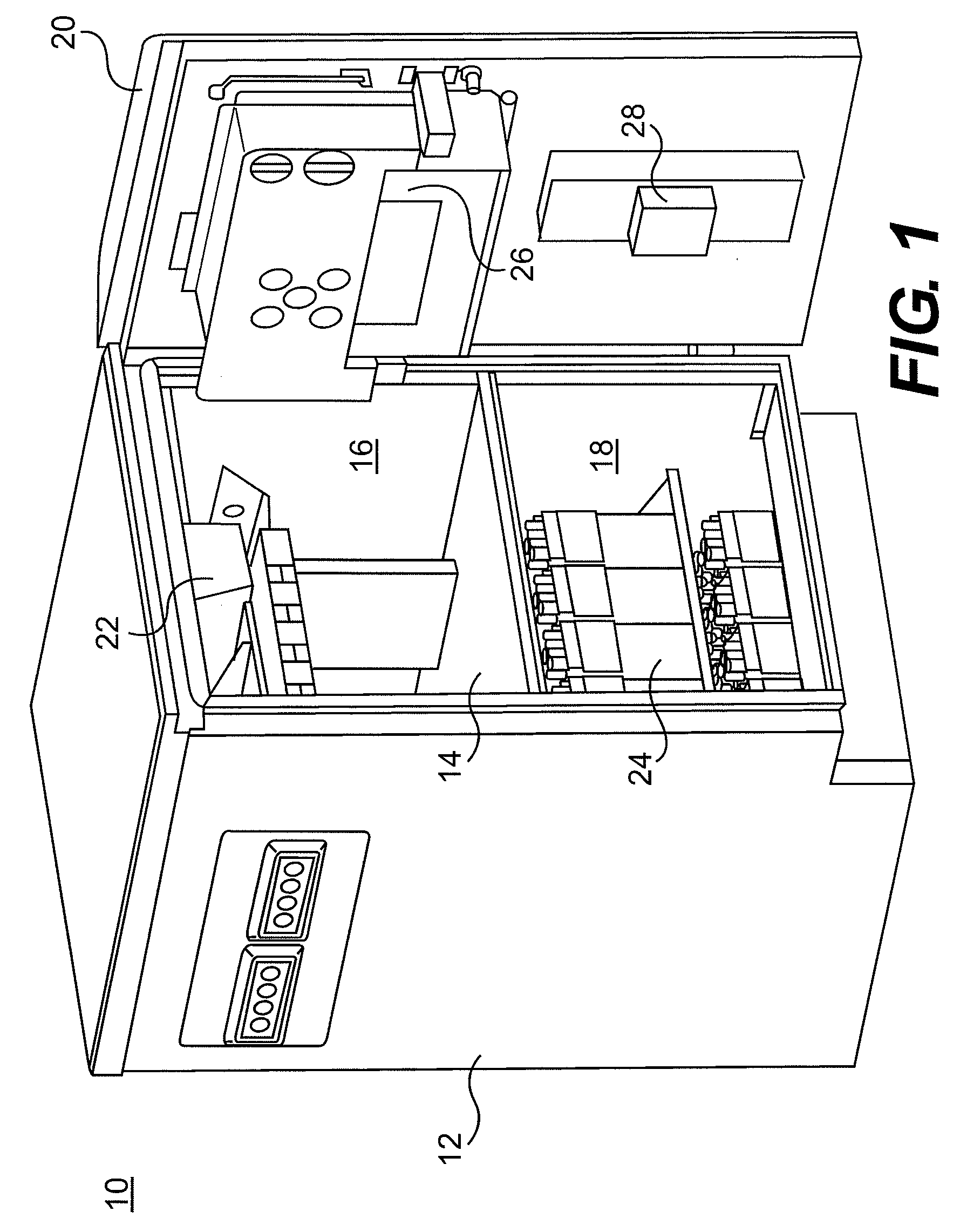

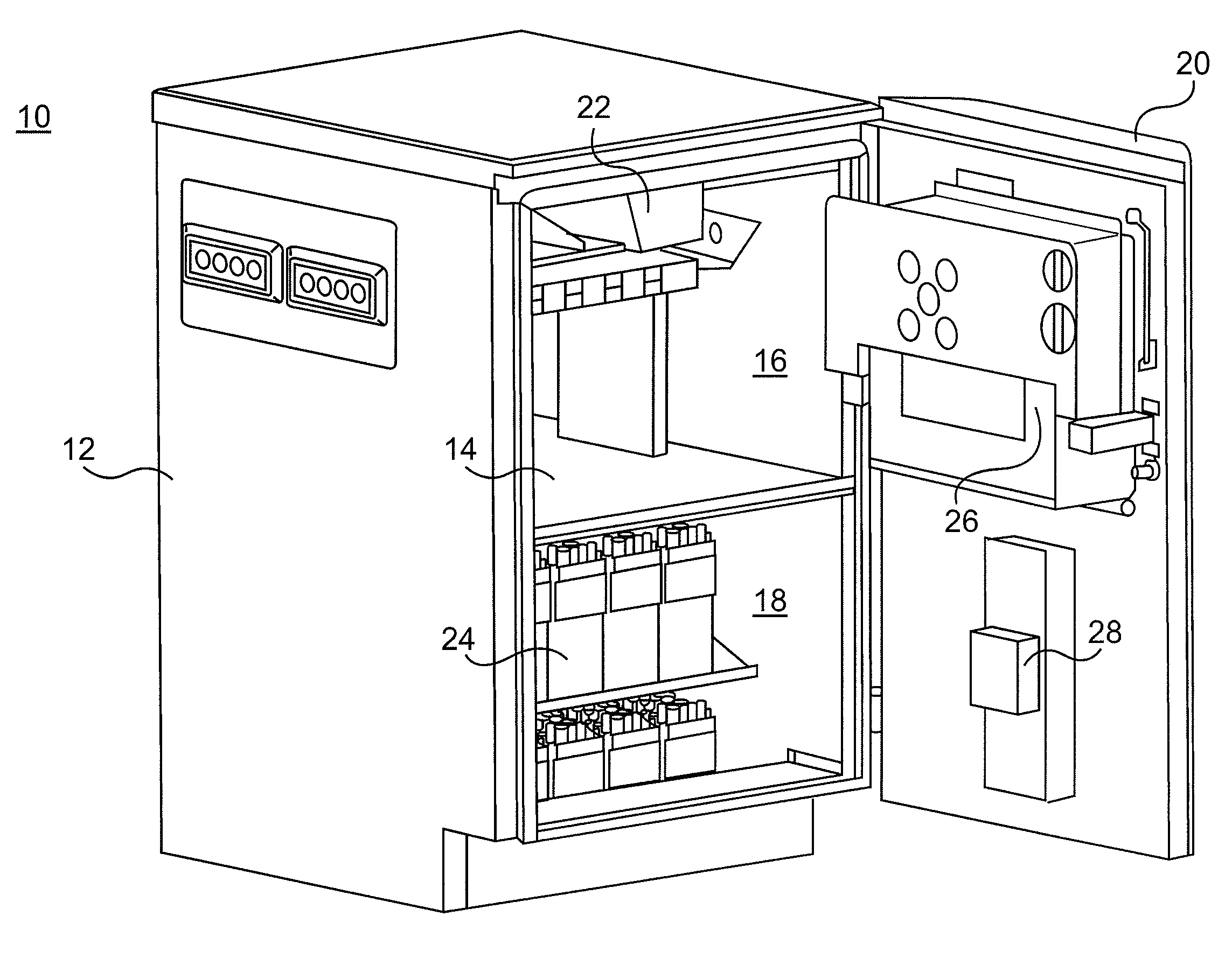

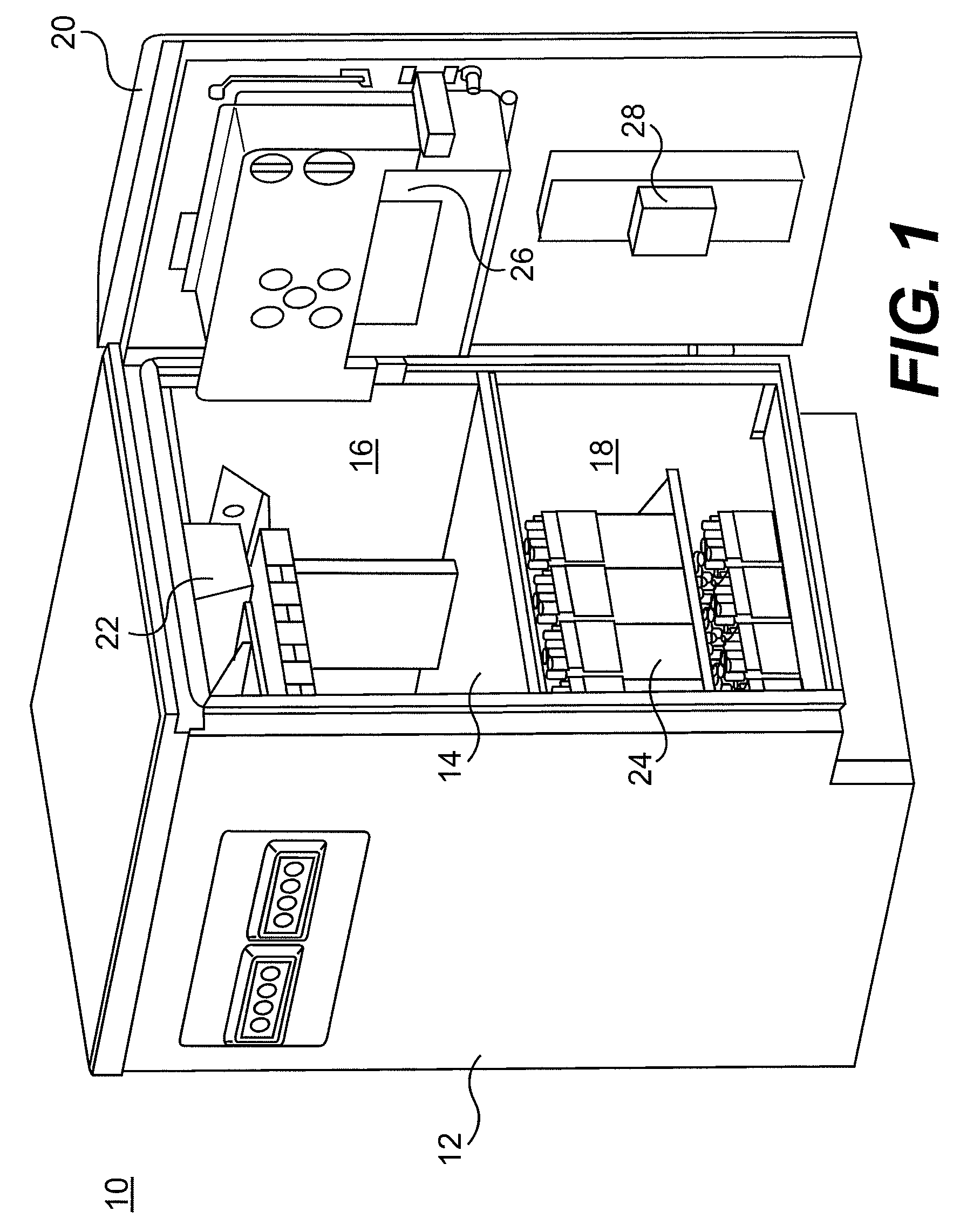

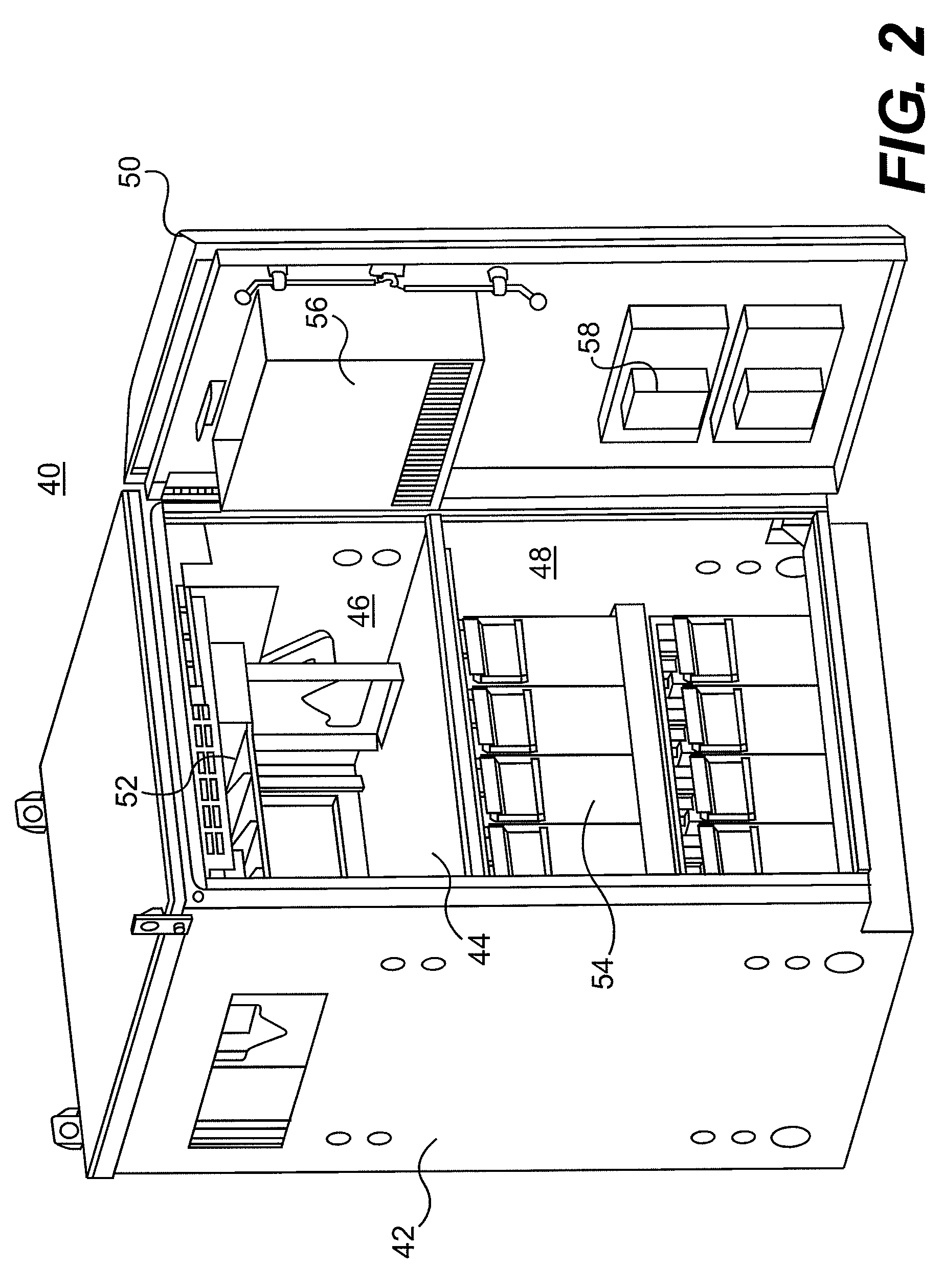

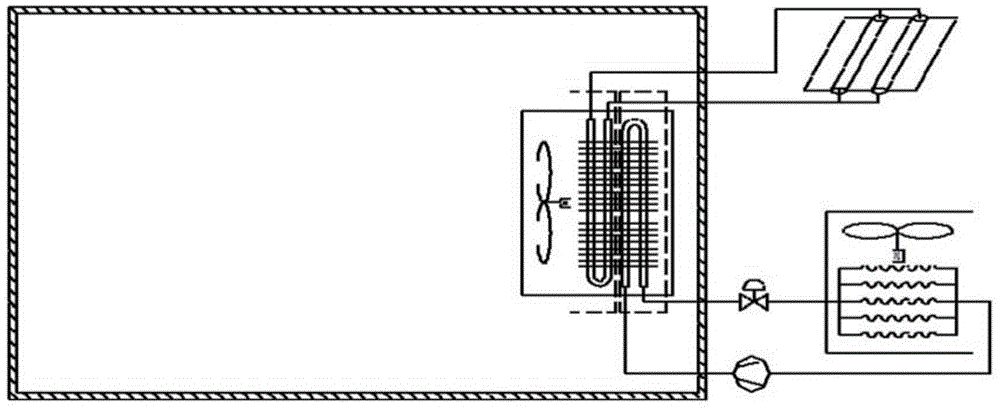

Hybrid cooling system for outdoor electronics enclosure

InactiveUS20100059270A1Increase temperatureExtend battery lifeDomestic cooling apparatusDigital data processing detailsNuclear engineeringElectronics

A cooling system for an outdoor electronic enclosure, with separate compartments for electronics and batteries, includes separate cooling devices for each compartment so that optimal temperatures are provided to each compartment. The batteries are cooled by a thermo-electric type air-conditioner, while the electronics are cooled by direct air cooling device or a heat exchanger.

Owner:COMMSCOPE INC

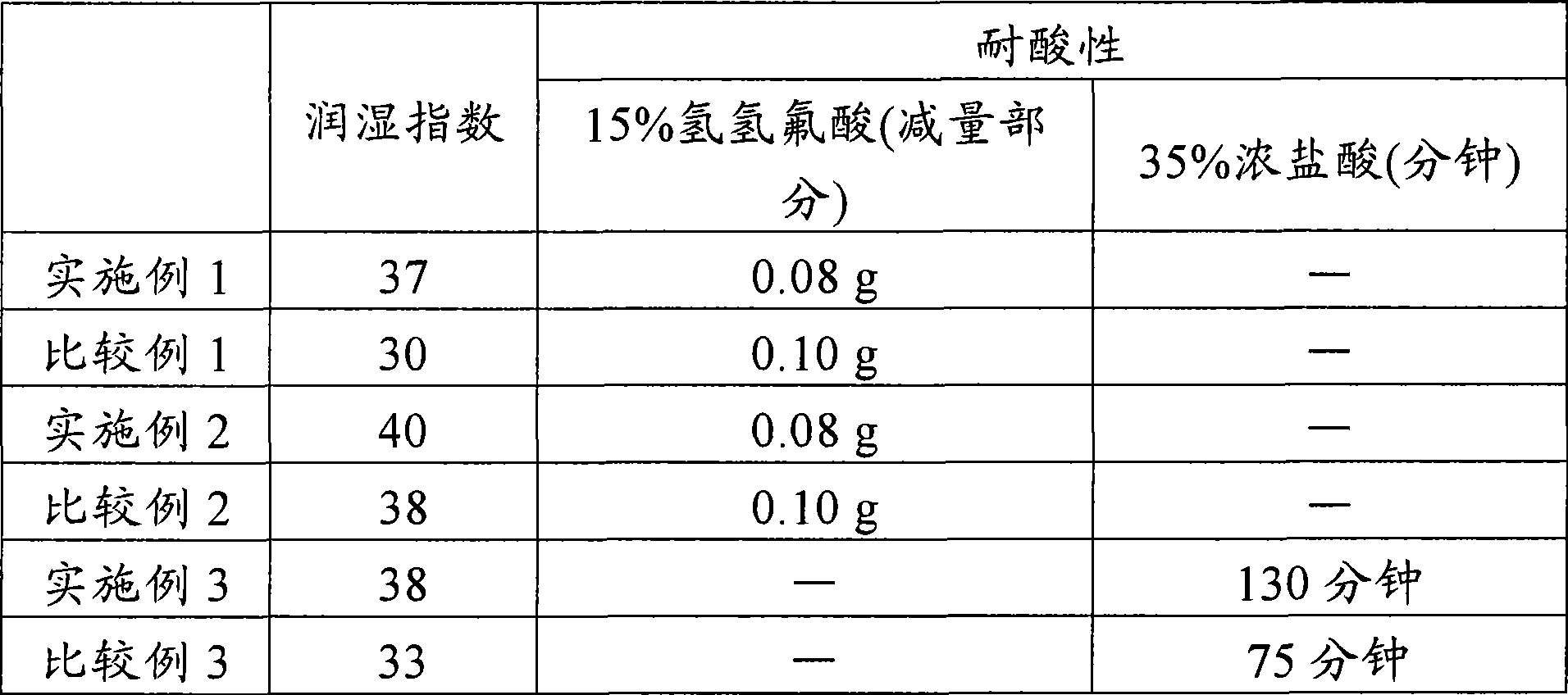

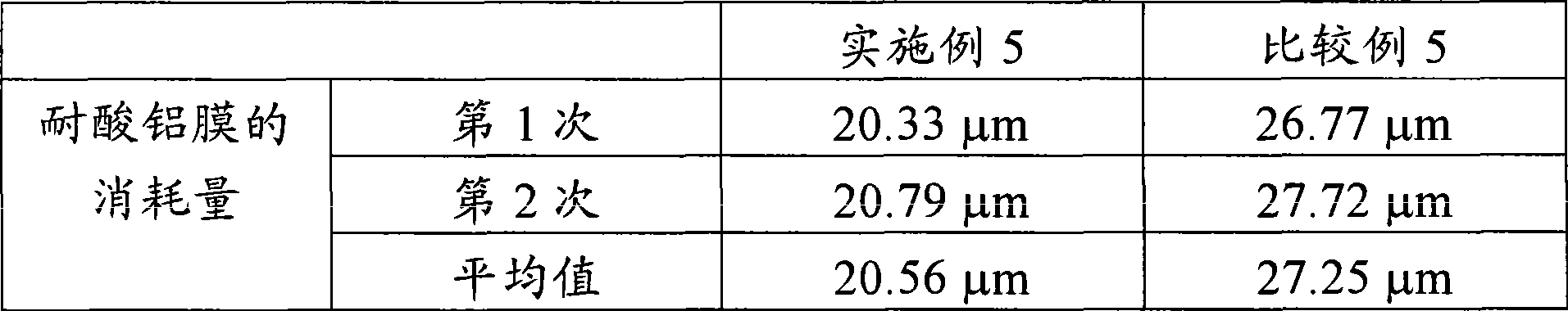

Corrosion-resistant member and method for producing the same

InactiveCN101522946APrevent adhesionExtend your lifeAnodisationMolten spray coatingGas phaseSuperheated water

Disclosed is a corrosion-resistant member which is high in acid resistance, plasma resistance and hydrophilicity. Also disclosed is a method for producing such a corrosion-resistant member. A corrosion-resistant member having high acid resistance, plasma resistance and hydrophilicity is obtained by surface-treating an object member (such as ceramics and metals) by spraying a superheated water vapor at a temperature of 300-1000 DEG C. The corrosion-resistant member may be a member which is in contact with a processing space within a vapor-phase surface treatment apparatus (such as a chamber) for surface-treating a base material by a vapor-phase process such as PVD, CVD or dry etching.

Owner:CANAAN PRECISION

Hybrid cooling system for outdoor electronics enclosure

InactiveUS7929294B2Increase temperatureExtend battery lifeDomestic cooling apparatusDigital data processing detailsNuclear engineeringElectron

Owner:COMMSCOPE INC

Process chamber device and epitaxial equipment with it

ActiveCN102691100AImprove temperature field distributionReduce maintenance timesSemiconductor/solid-state device manufacturingFrom chemically reactive gasesGraphitePulp and paper industry

The invention discloses a process chamber device and epitaxial equipment with the process chamber device. The process chamber device comprises: a top cap and a bottom cap; an inner quartz tube, which is located between the top cap and the bottom cap and provided with exhaust holes, and defines a process chamber together with the top cap and the bottom cap; a graphite sleeve positioned between the top cap and the bottom cap and sleeved outside the inner quartz tube, with an exhaust path defined between the graphite sleeve and the inner quartz tube, communicated with the outside, and communicated with the process chamber through the exhaust holes; and an outer graphite sleeve positioned between the top cap and the bottom cap and sleeved outside the graphite sleeve, with a cooling channel defined between the outer graphite sleeve and the graphite sleeve and communicated with the outside. According to the process chamber in embodiment of the invention, temperature field distribution in the process chamber can be improved, and ultimately, uniformity of the radial temperature in the process chamber and further in a substrate can be realized. Also, the maintenance frequency and the maintenance cost of the graphite sleeve can be reduced.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

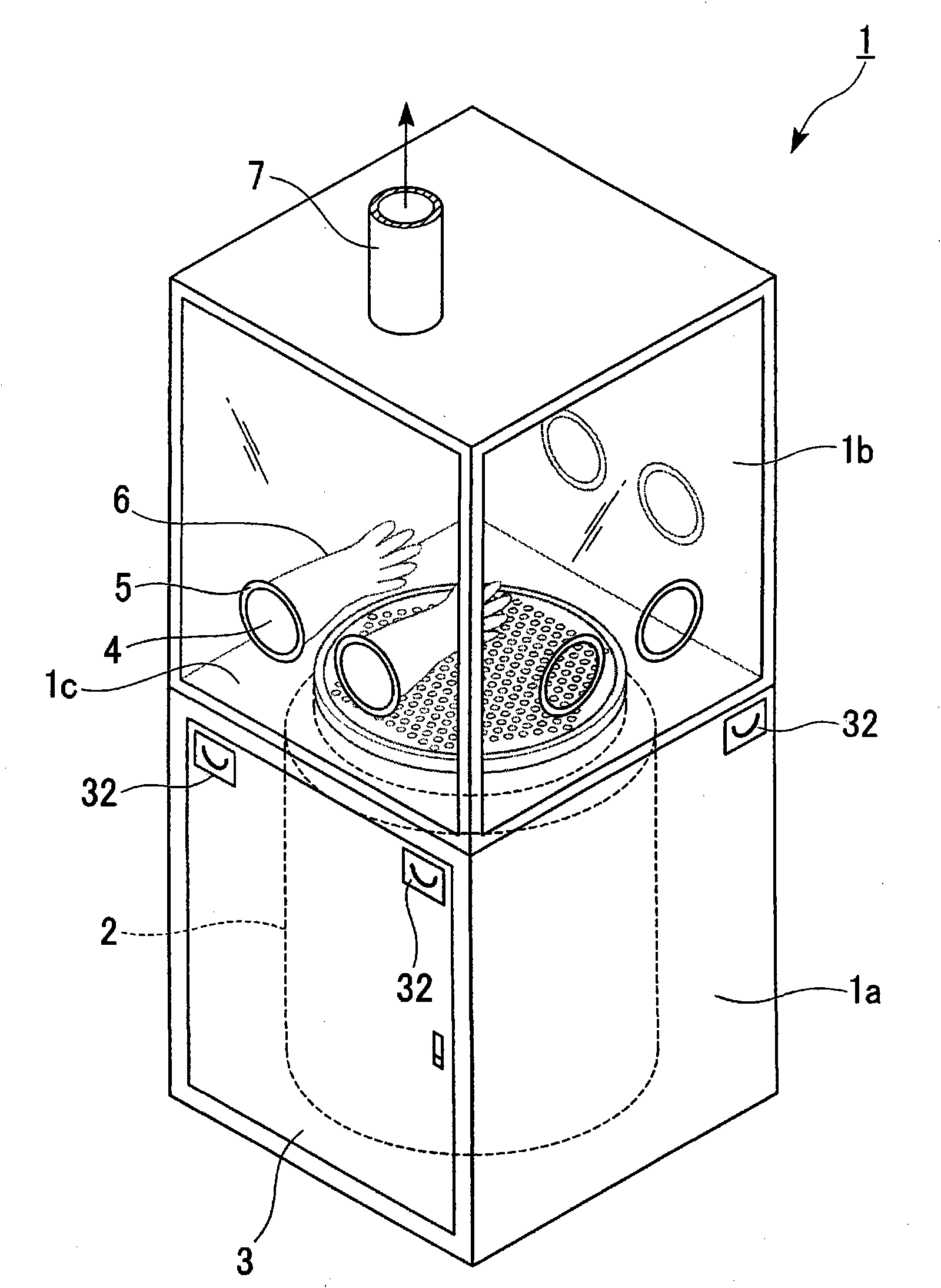

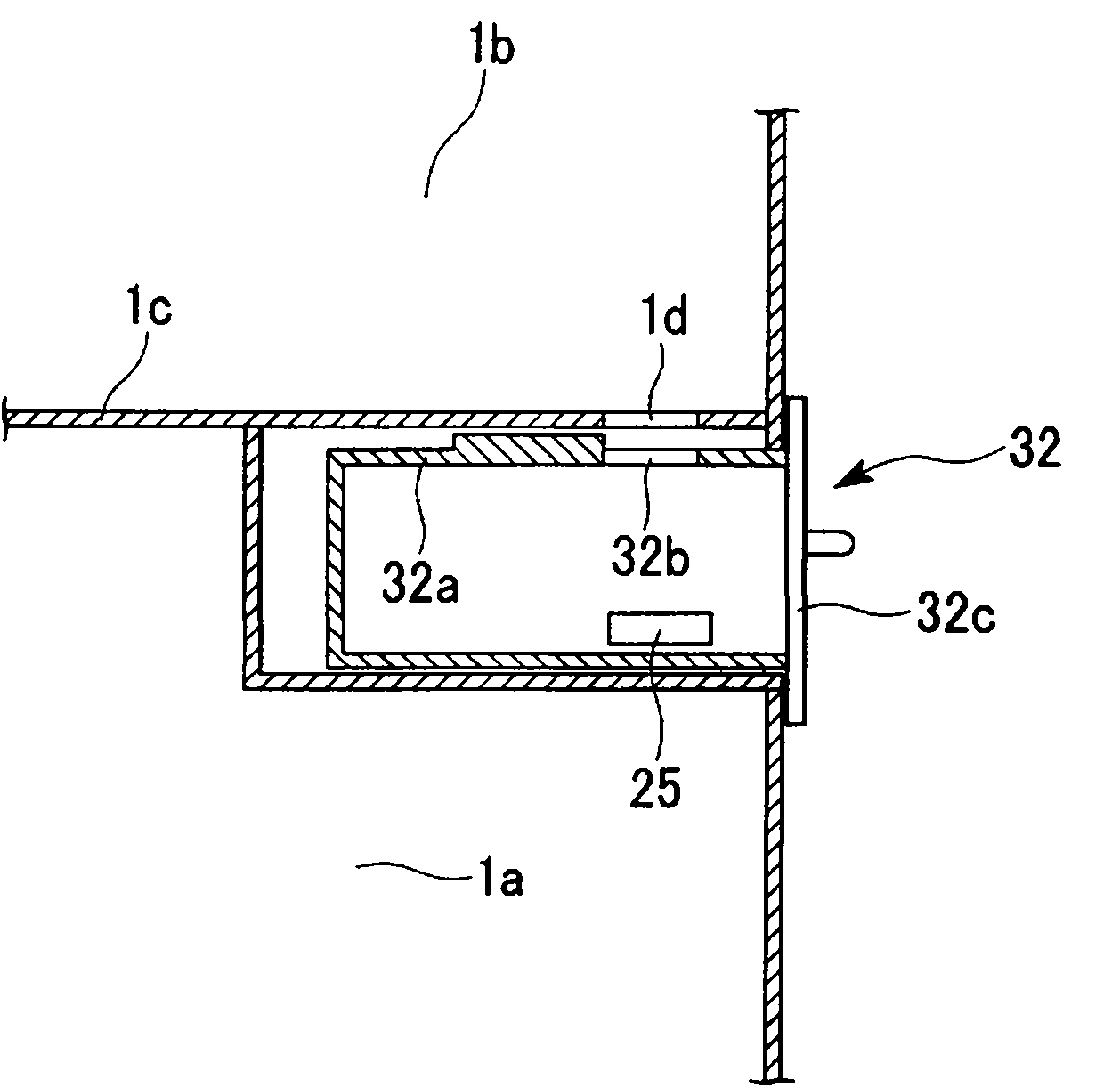

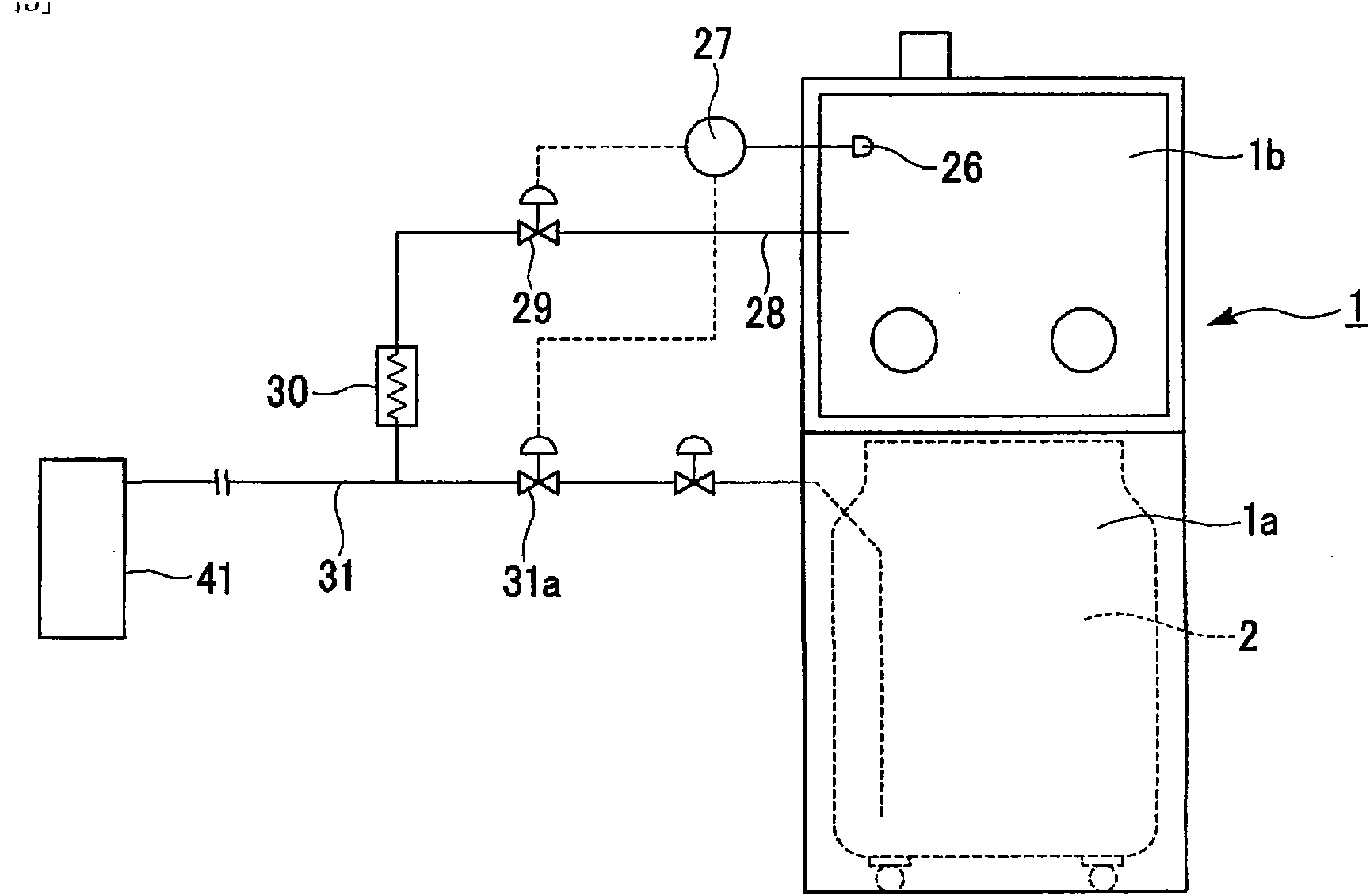

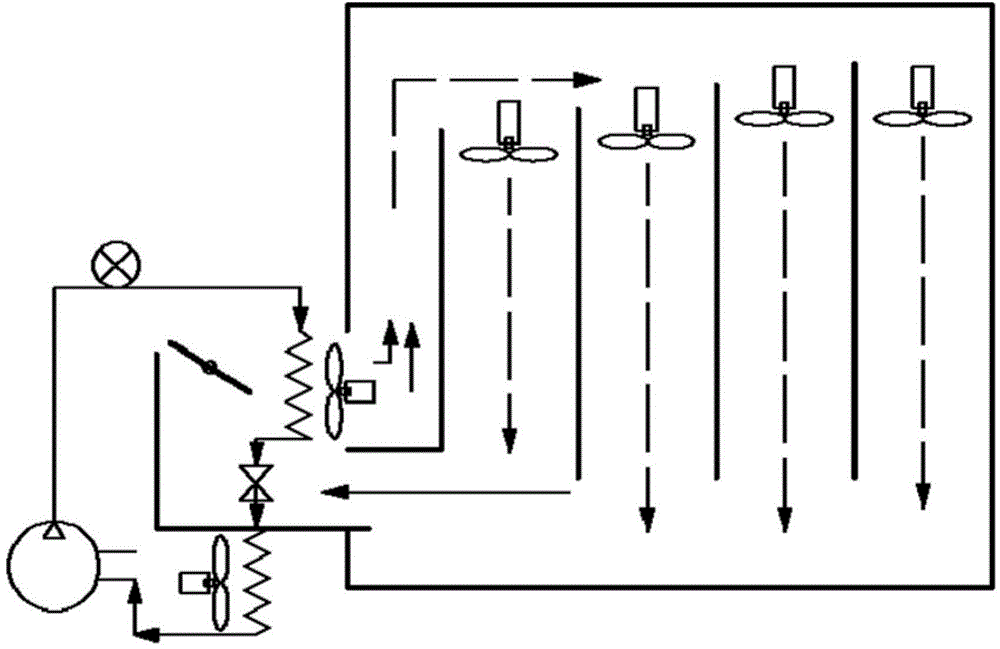

Freezing storage device

ActiveCN101808608AReduce maintenance frequencyInhibition of attachmentDomestic cooling apparatusLighting and heating apparatusEngineeringLiquid gas

A freezing storage device has a container body for storing a low-temperature liquefied gas, a cap for closing a mouth section of the container body and having insertion holes vertically penetrating through the cap, and ampoule receiving devices movably received in the insertion holes in the cap. The ampoule receiving devices each have a support pillar and ampoule receiving sections mounted vertically next to each other on the support pillar.

Owner:NIPPON SANSO CORP

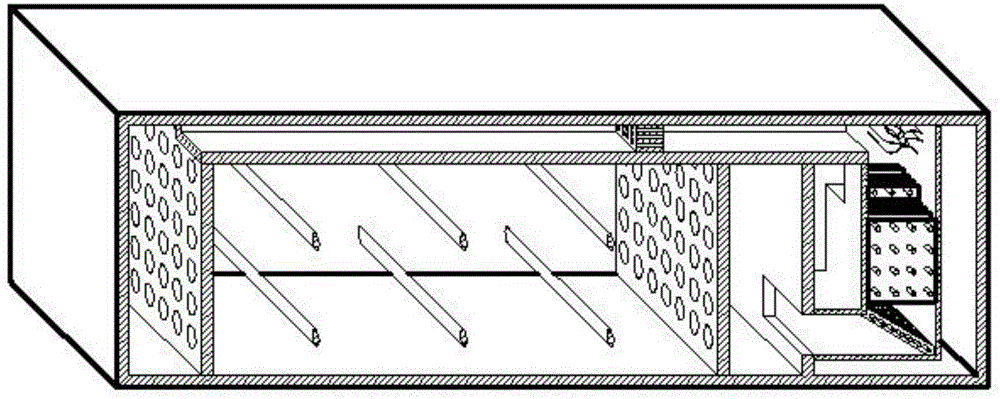

Energy recycling type edible mushroom drying device

ActiveCN104082397AUniform treatmentAchieve recyclabilityFood processingFruits/vegetable preservation by dehydrationAir treatmentFresh air

The invention discloses an energy recycling type edible mushroom drying device. The drying device comprises an external fresh air introducing device, a total heat exchanger, a multistage pressing type airflow-adjustable air hole, an edible mushroom drying device and an induced draft fan, wherein the total heat exchanger is used for recycling the energy; the edible mushroom drying device sequentially comprises a drying room, an air pre-heater, a flow guiding plate, a variable cross-section air flue, an airflow pressure sensor, a blowing pore plate, an air return pore plate, and flow guiding devices arranged on an inlet of the blowing pore plate and an outlet of the air return pore plate, and the blowing pore plate and the air return pore plate are arranged in the drying room in parallel. According to the energy recycling type edible mushroom drying device, by combining a completely-new air supplying drying mode and a direct return-air self-circulation drying mode with a stairstep-energy-supplying air heating manner and the variable cross-section air flue according to different drying conditions of the edible mushroom, the stable distribution of air in the device is guaranteed, meanwhile, the air supplying temperature is decreased, and the drying quality is guaranteed; air is uniformly processed, and the energy consumption is reduced.

Owner:NANJING NORMAL UNIVERSITY

Configuration of dilution openings in a turbomachine combustion chamber wall

ActiveUS7891194B2Improve efficiencyExtended service lifeContinuous combustion chamberGas turbine plantsCombustion chamberAerospace engineering

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

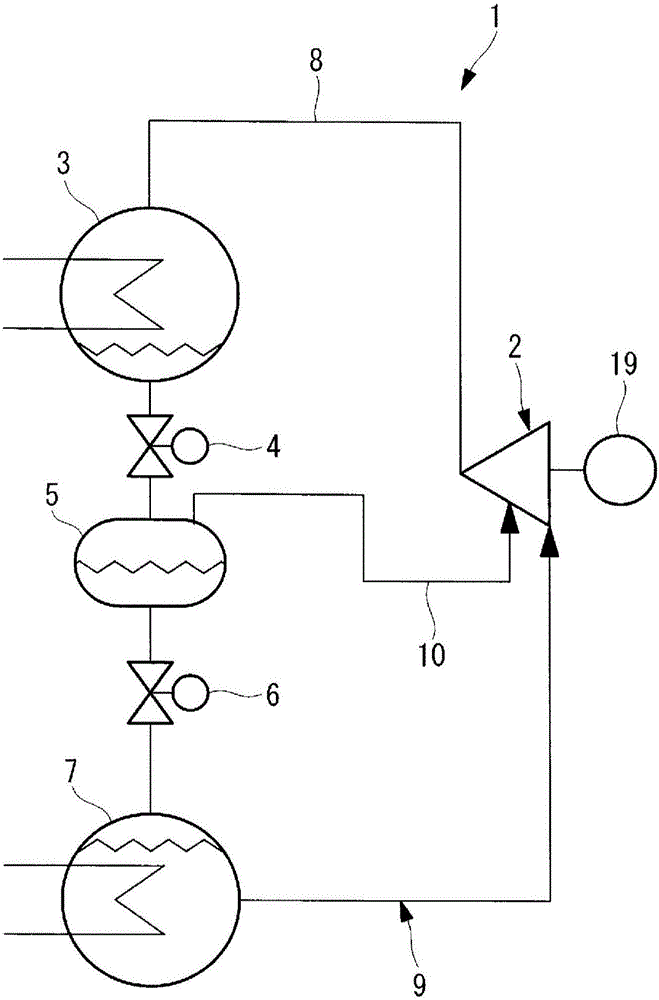

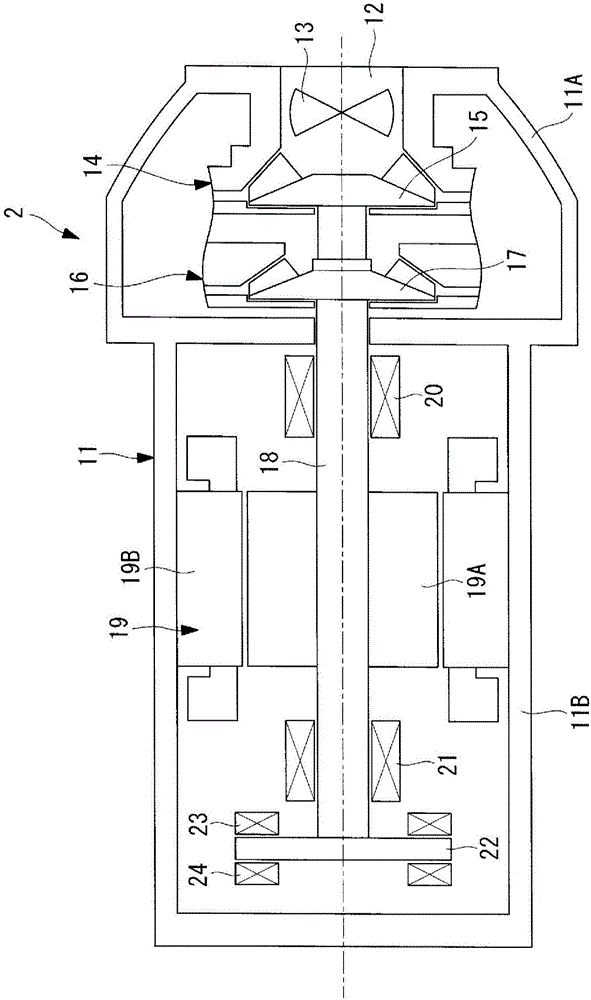

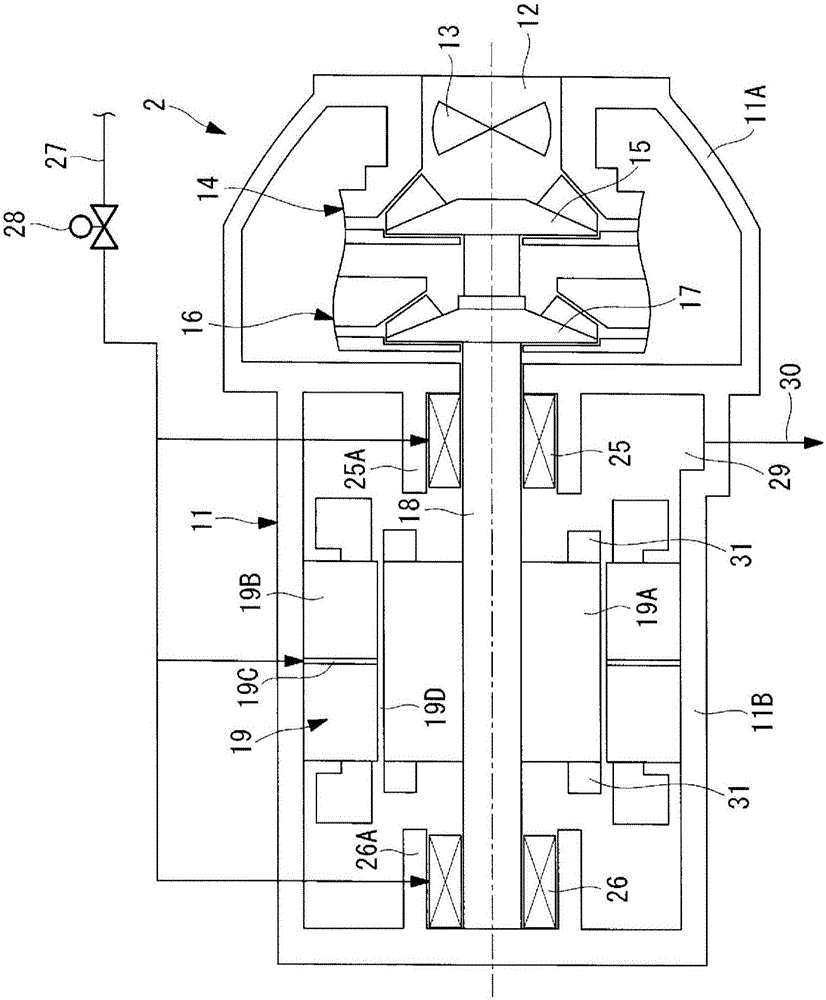

Turbo refrigerator

InactiveCN106662116AReduce power lossReduce maintenance frequencyCompressorPump componentsImpellerMagnetic bearing

The objective of the present invention is to provide a turbo refrigerator in which the frequency of maintenance and the incidence of oil leakage due to maintenance can be reduced by the use of an oil-less system, and in which the characteristics of the refrigerant R1233zd (E) can be used to reduce the impact on the environment, the refrigerant being a low-pressure refrigerant that reaches negative pressure at a saturation temperature of 18 DEG C or less. The turbo refrigerator in which the refrigeration cycle is configured by sequentially connecting, via a pipeline, a turbo compressor (2), a condenser, a pressure-reducing device, and an evaporator, and in which a refrigerant is charged into the cycle, wherein: the refrigerant is refrigerant R1233zd(E), which is a low-pressure refrigerant having both a low global warming potential and a low ozone depletion potential; the turbo compressor (2) is a directly coupled turbo compressor (2) in which a rotation shaft (18) of impellers (15, 17) is directly coupled with a motor (19); and magnetic bearings (20, 21, 23, 24) are used as the bearings for supporting the rotation shaft (18).

Owner:MITSUBISHI HEAVY IND THERMAL SYST

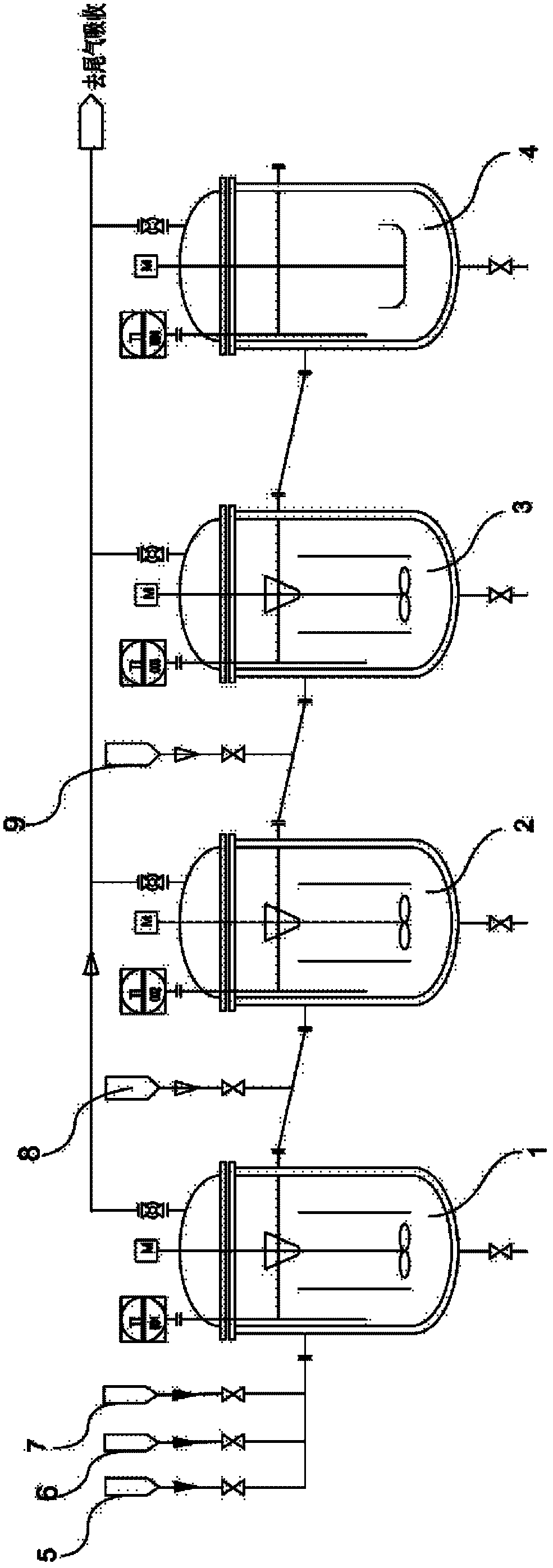

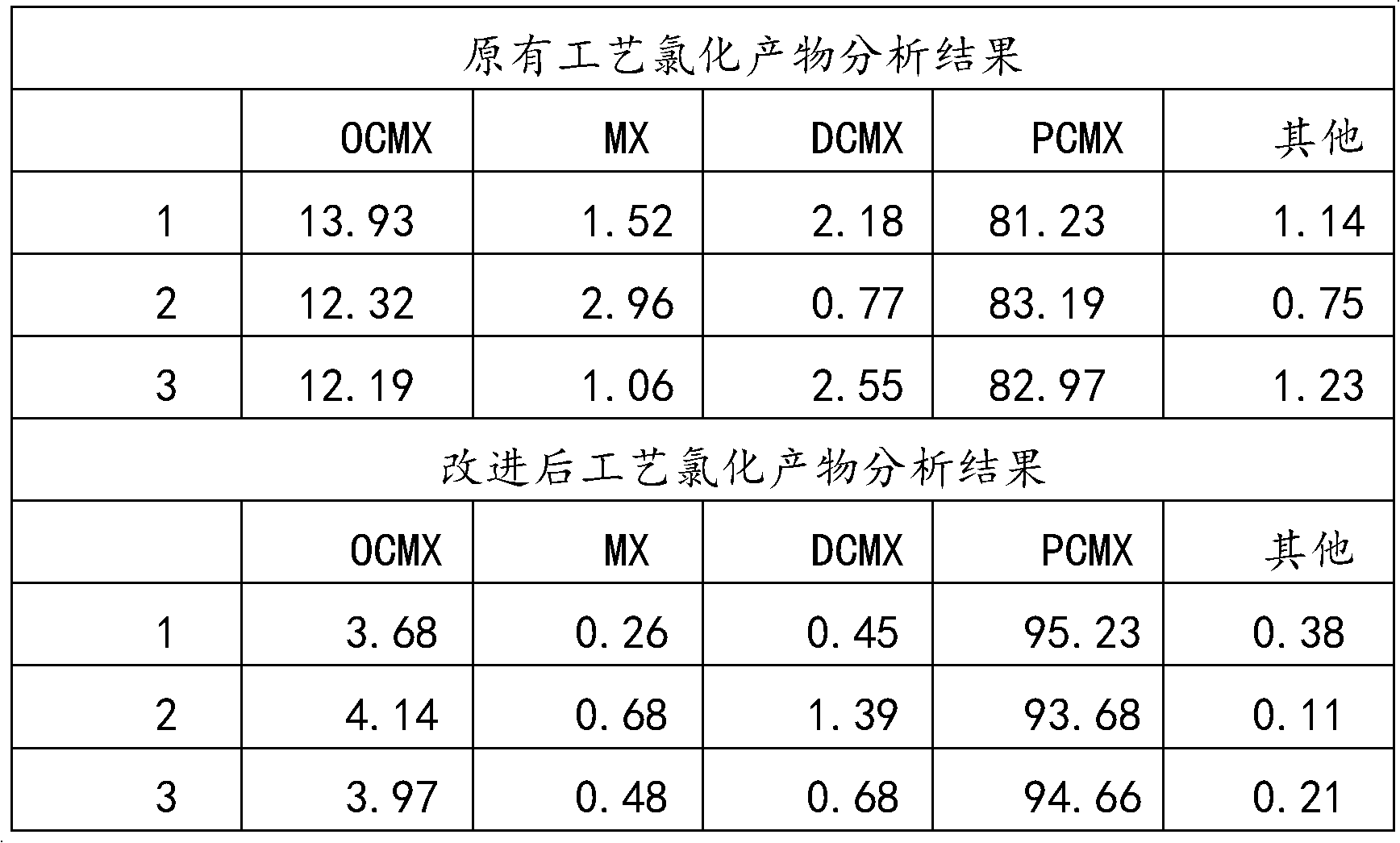

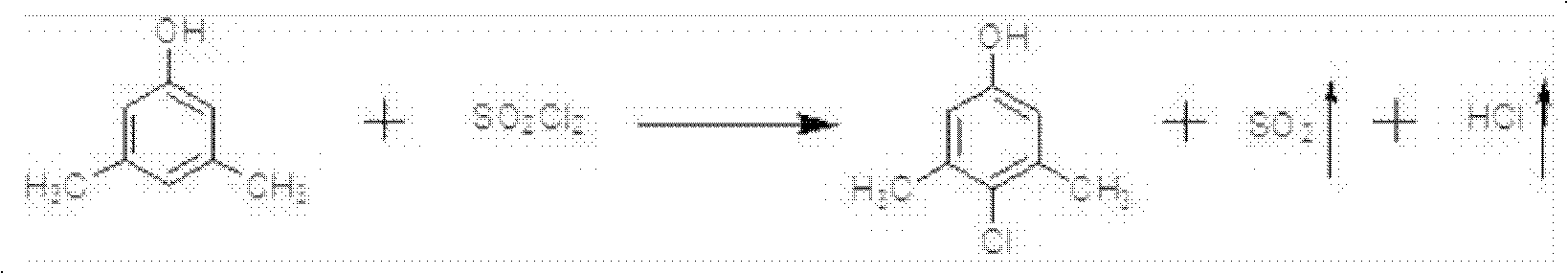

Continuous kettle type chlorination technology

ActiveCN102659528AIncrease reaction rateIncrease profitOrganic chemistryOrganic compound preparationReaction temperatureSolvent

The invention discloses a continuous kettle type chlorination technology. The technology comprises the following steps: adding a certain amount of a solvent to each of chlorination kettles, starting a stirrer, and starting a tail gas absorption system; continuously adding 3,5-dimethylphenol, a chlorinating agent, and the solvent to a chlorination kettle A, setting the reaction temperature at 35-40DEG C, and reacting under normal pressure and stirring conditions; continuously carrying out a chlorination reaction through supplementing the chlorinating agent to a chlorination kettle B after the liquid level in the chlorination kettle A reaches an overflow port and a reaction solution flows into the chlorination kettle B, and controlling the chlorination temperature at 30-35DEG C under stirring; continuously carrying out the chlorination reaction through supplementing the chlorinating agent to a chlorination kettle C after the liquid level in the chlorination kettle B reaches an overflow port and a reaction solution flows into the chlorination kettle C, stirring, and adjusting the reaction temperature to 25-30DEG C; and completing the chlorination process through allowing a liquid in the chlorination kettle C to automatically flow into a receiving kettle after the liquid level in the chlorination kettle C reaches an overflow port. The reaction conversion rate is improved to 90-100% from 60-80% through above continuous stepped reaction, so the finished product (PCMX) yield is greatly improved, and the side reaction generation is effectively reduced.

Owner:JIANGSU HUANXIN NEW MATERIAL CO LTD

Gas sensor chip and gas sensor provided therewith

InactiveUS20090193872A1Accurate detectionReduce maintenance frequencyAnalysing fluids using sonic/ultrasonic/infrasonic wavesMaterial thermal conductivityElectrical conductorEngineering

To provide a gas sensor chip, and a gas sensor provided therewith, capable of producing stable output characteristics over an extended period of time even when installed in a harsh environment such as a boiler smokestack carrying exhaust gasses. There is a backside structure wherein a catalyst carrier that contacts a gas to be measured is disposed on one side of a thermal conductor, a temperature sensing portion is disposed in a location that does not contact the gas to be measured, on the other side of the thermal conductor, and the temperature sensing portion measures the temperature corresponding to the temperature of the catalyst carrier through the thermal conductor, to enable the sensing of the amount of flow over an extended period of time without the temperature sensing portion being negatively affected by the gas to be measured.

Owner:YAMATAKE HONEYWELL CO LTD

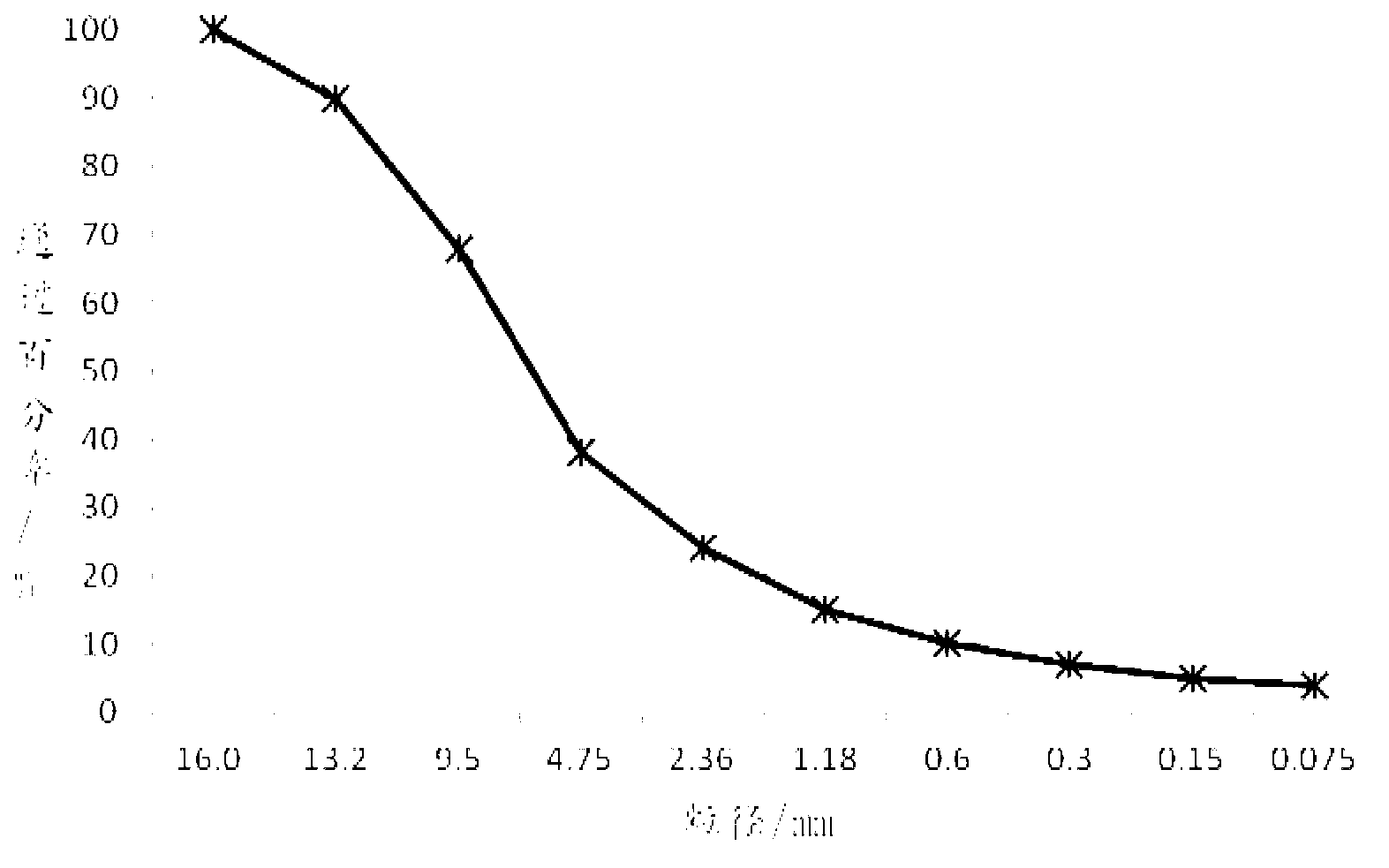

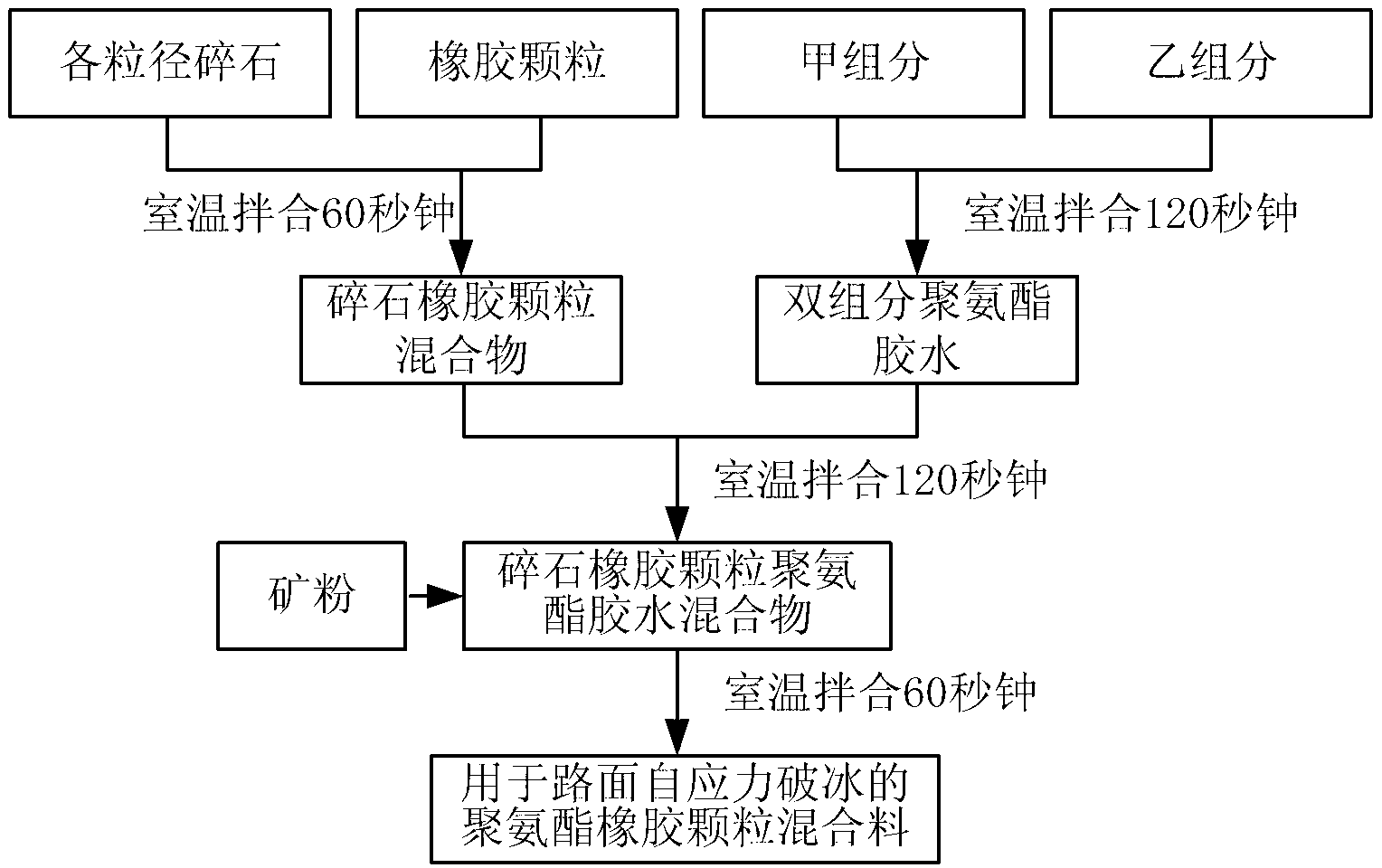

Method for preparing polyurethane rubber granule mixture for pavement self-stress icebreaking

InactiveCN103058585AHighlight substantive featuresAvoid pollutionSolid waste managementPolymer scienceShear stress

The invention discloses a method for preparing polyurethane rubber granule mixture for pavement self-stress icebreaking, and relates to rubber mixture. The method comprises the steps of firstly, mixing various grain sizes of gravels and rubber particles for 60s at room temperature, obtaining gravel and rubber particle mixture, adding bi-component polyurethane glue which is modulated by a component A and a component B mixed for 120s at room temperature, mixing for 120s at room temperature, obtaining mixture of the gravel and rubber particles and the polyurethane glue; adding mineral powder to mix for 60s at room temperature, and preparing the polyurethane rubber granule mixture for pavement self-stress icebreaking. The mixed pavement material generates large compressive deformation in use, resulting in that the tensile stress and the shear stress inside an ice layer are obviously increased, so that the ice layer cracks. The ice layer is damaged under reciprocal action of vehicle tires, so as to overcome the problem that accumulated snow and frozen ice on the pavement cannot be effectively solved in the pavement paving material of inhibiting congelation in the prior art and the defects of poor pavement performance, low durability and non-environmental performance.

Owner:HEBEI UNIV OF TECH

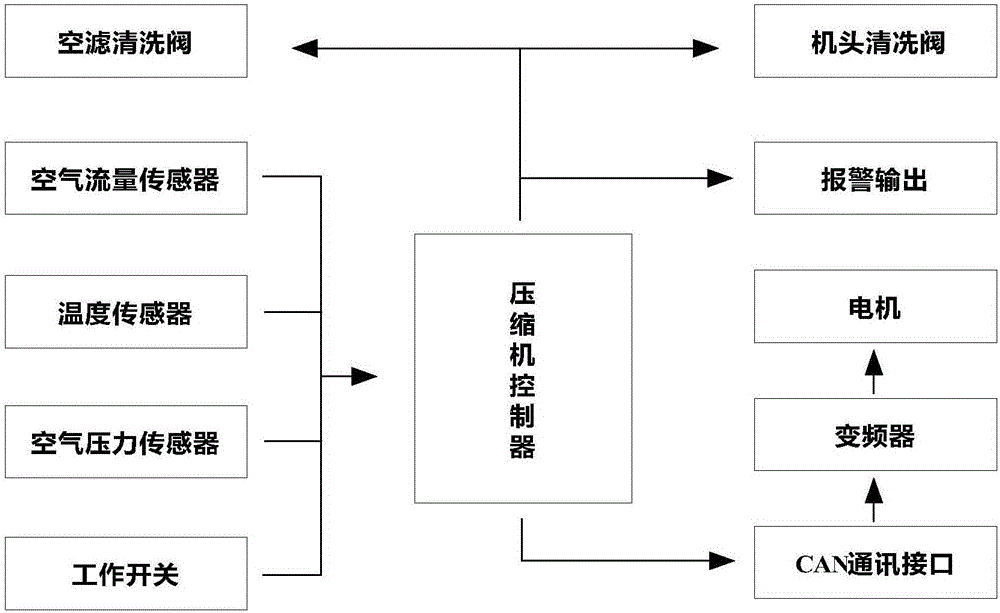

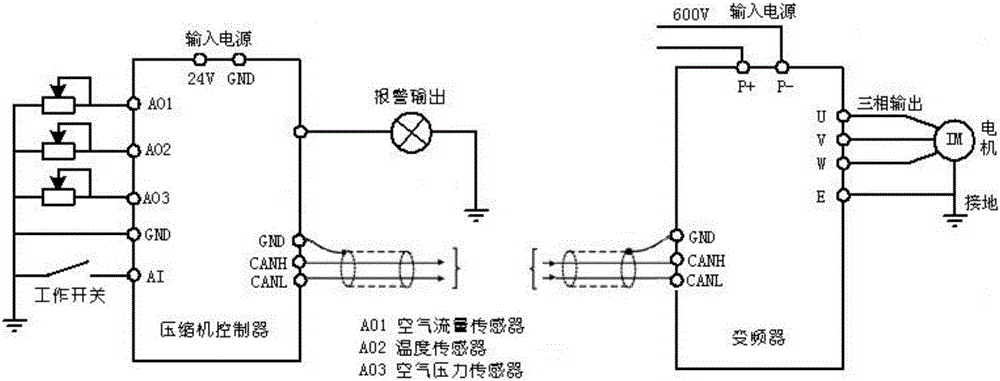

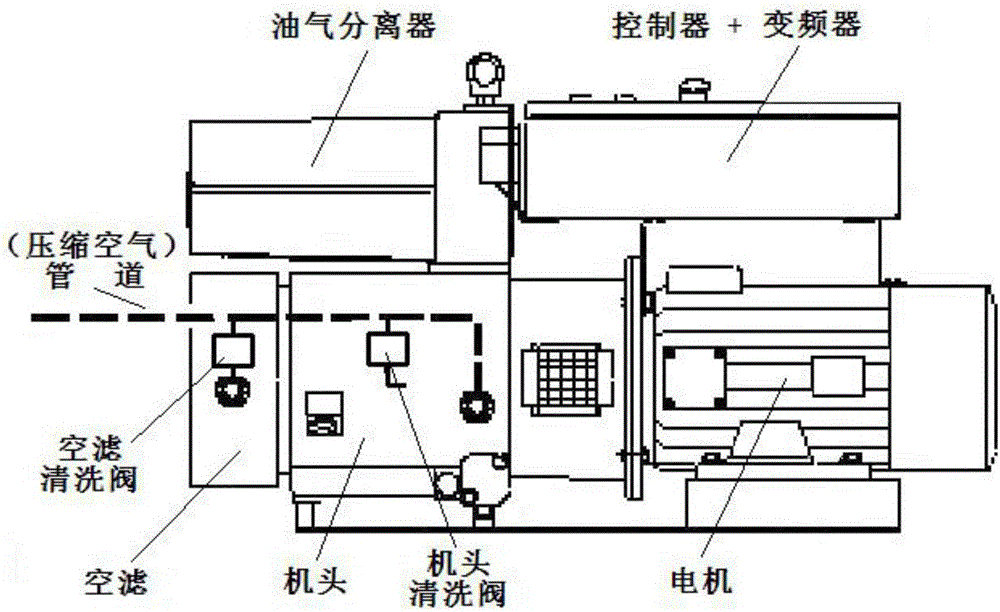

Controller of air compression system of electric passenger car

ActiveCN106194740APrevent and detect abnormal phenomena in timeAvoid start-stop jitterPower-operated mechanismPump controlCommunication interfaceAir compression

The invention provides a controller of an air compression system of an electric passenger car. An air flow sensor, a temperature sensor, an air pressure sensor and an operating switch are all connected with the compressor controller. The compressor controller, a CAN communication interface, a frequency converter and a motor are sequentially connected. An alarm output indicator light is connected with the compressor controller. A compressor head cleaning valve and an air filter cleaning valve are connected to the same compressed air pipeline. The compressed air pipeline is connected with an air filter chamber through the air filter cleaning valve. The compressed air pipeline is connected with a compressor head through the compressor head cleaning valve. The air flow and the air pressure of the air compression system and the temperature of the compressor head are collected through the compressor controller, the operating air pressure and the operating state of a compressor are adjusted in real time, and thus the air compressor is made to operate in the optimal state all the time; and the failure rate of the compressor is decreased, and the service life of the compressor is prolonged.

Owner:ANHUI ANKAI AUTOMOBILE

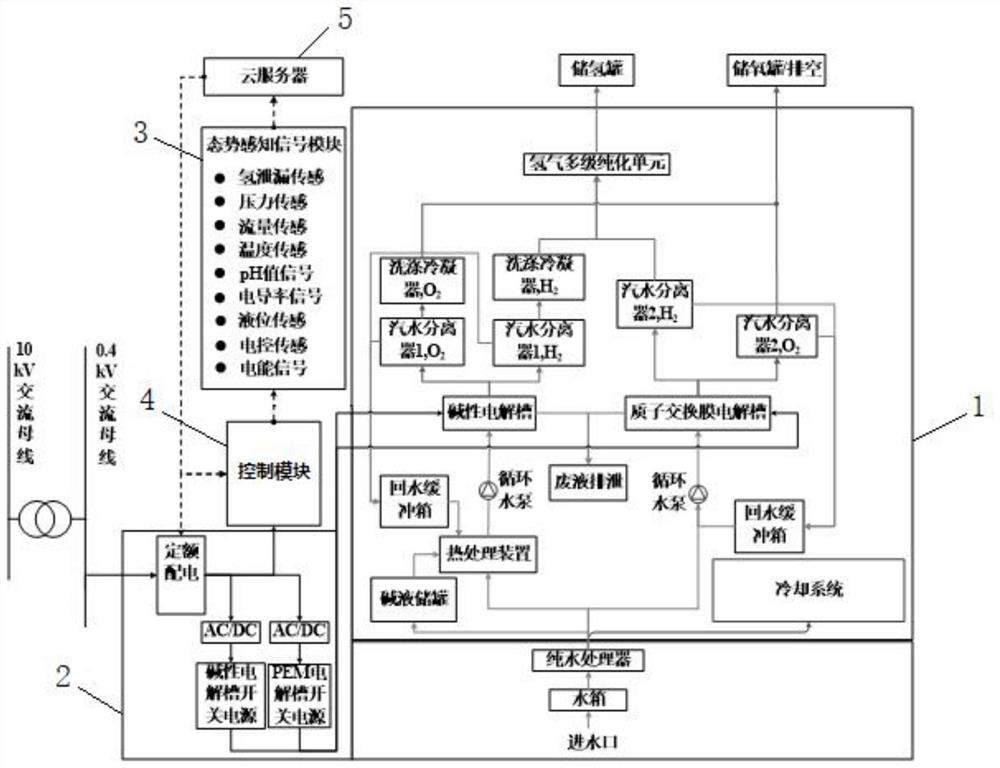

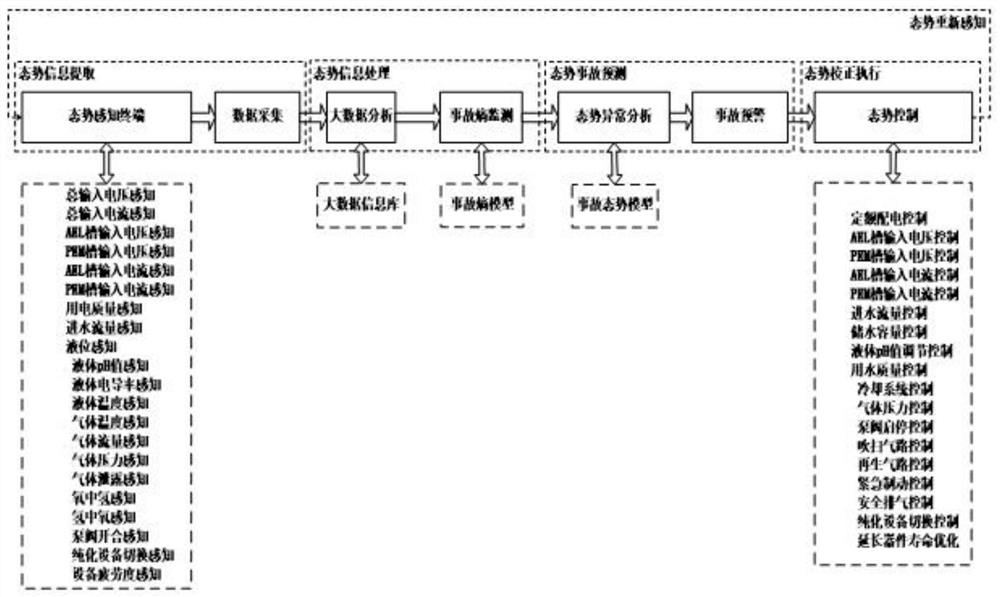

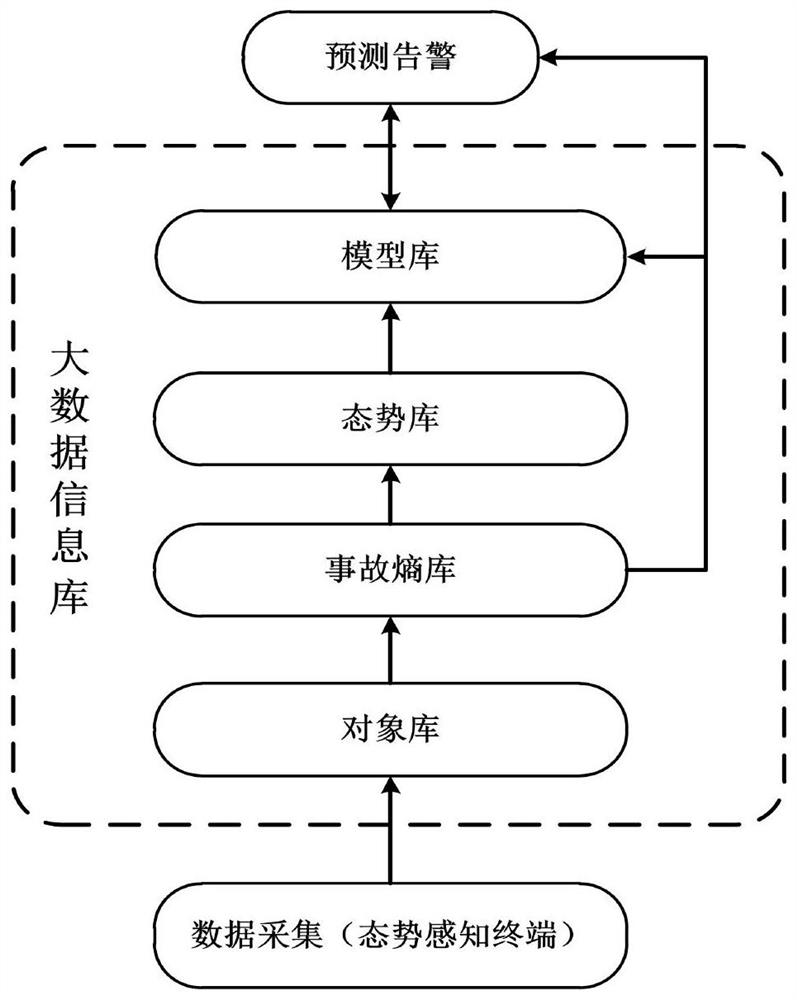

Hydrogen production system based on AEL and PEM water electrolysis and situation control method

ActiveCN113388856AGuaranteed uptimeRealize unattendedCellsEnergy inputElectrolysed waterControl system

The invention discloses a hydrogen production system based on AEL and PEM water electrolysis and a situation control method. According to the hydrogen production system, an AEL water electrolysis tank and a PEM water electrolysis tank are matched with each other and highly integrated in a water electrolysis hydrogen production system, and anaccident early warning monitoring method based on situation awareness is provided in consideration of a related complex management and control system, and is different from the lacking of situation awareness early warning function for detection information in an existing water electrolysis hydrogen production system. According to the invention, an optimal working mode of a hydrogen production system is evaluated based on accident entropy, the situation awareness object category is predicted after the situation awareness information is acquired, and then the increment change of the working mode of the situation awareness object to the accident entropy of the system is evaluated so as to provide the increment direction of the accident situation for accident early warning, so that the system can autonomously obtain a control decision through situation awareness information analysis, adjustment is carried out through different pieces of situation awareness information, and optimal working situation optimization of the system is achieved.

Owner:宝武清洁能源有限公司 +1

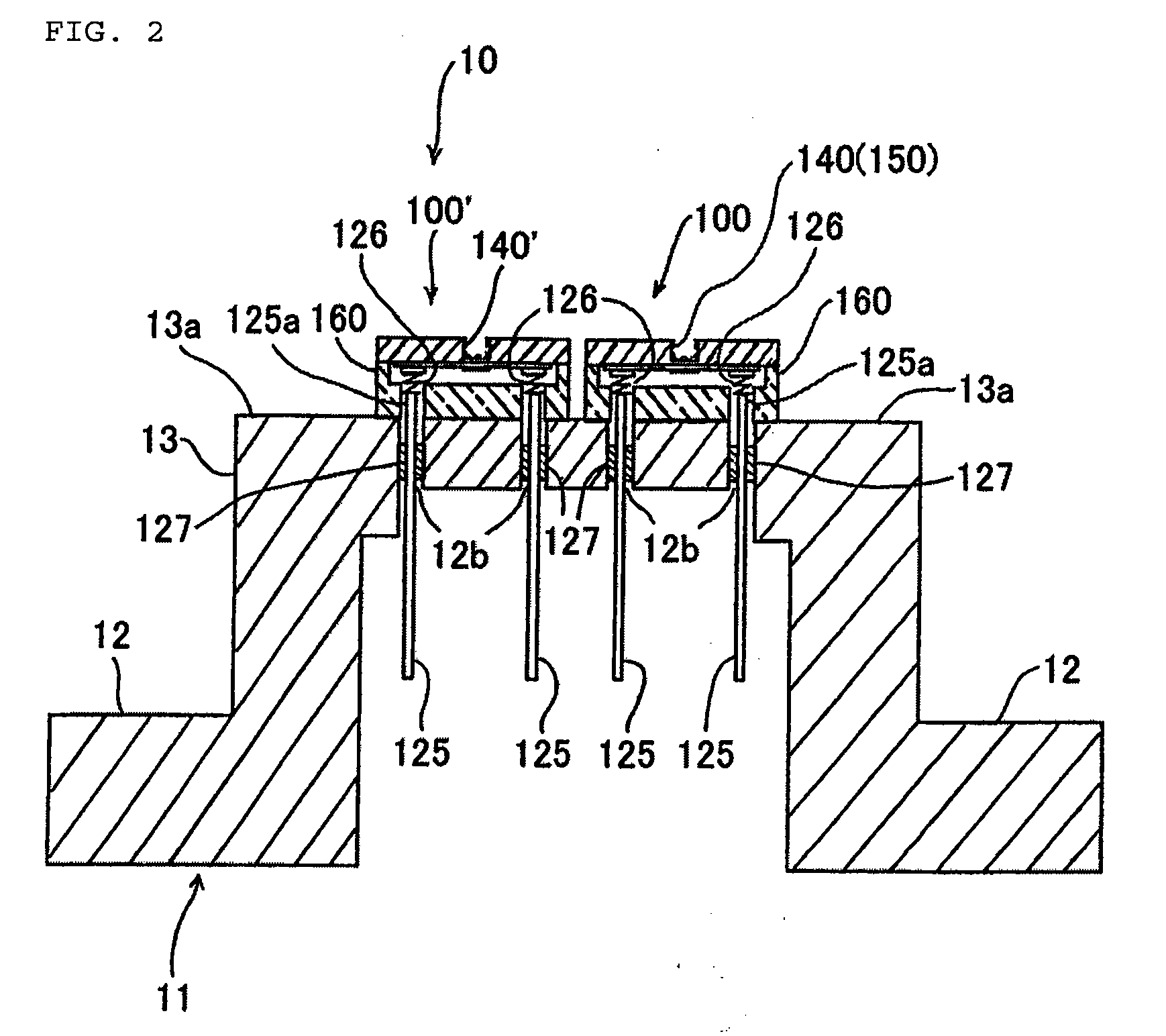

Insulation structure and insulation method

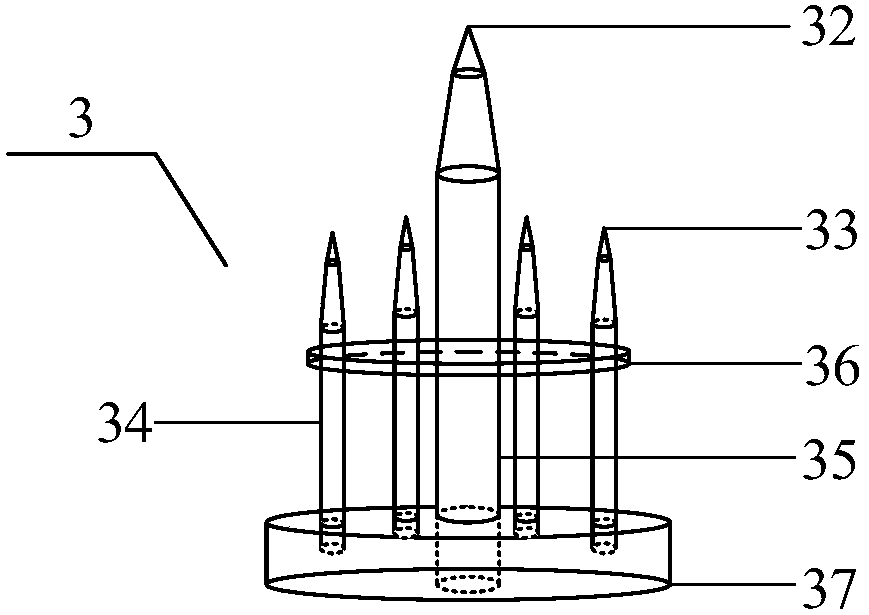

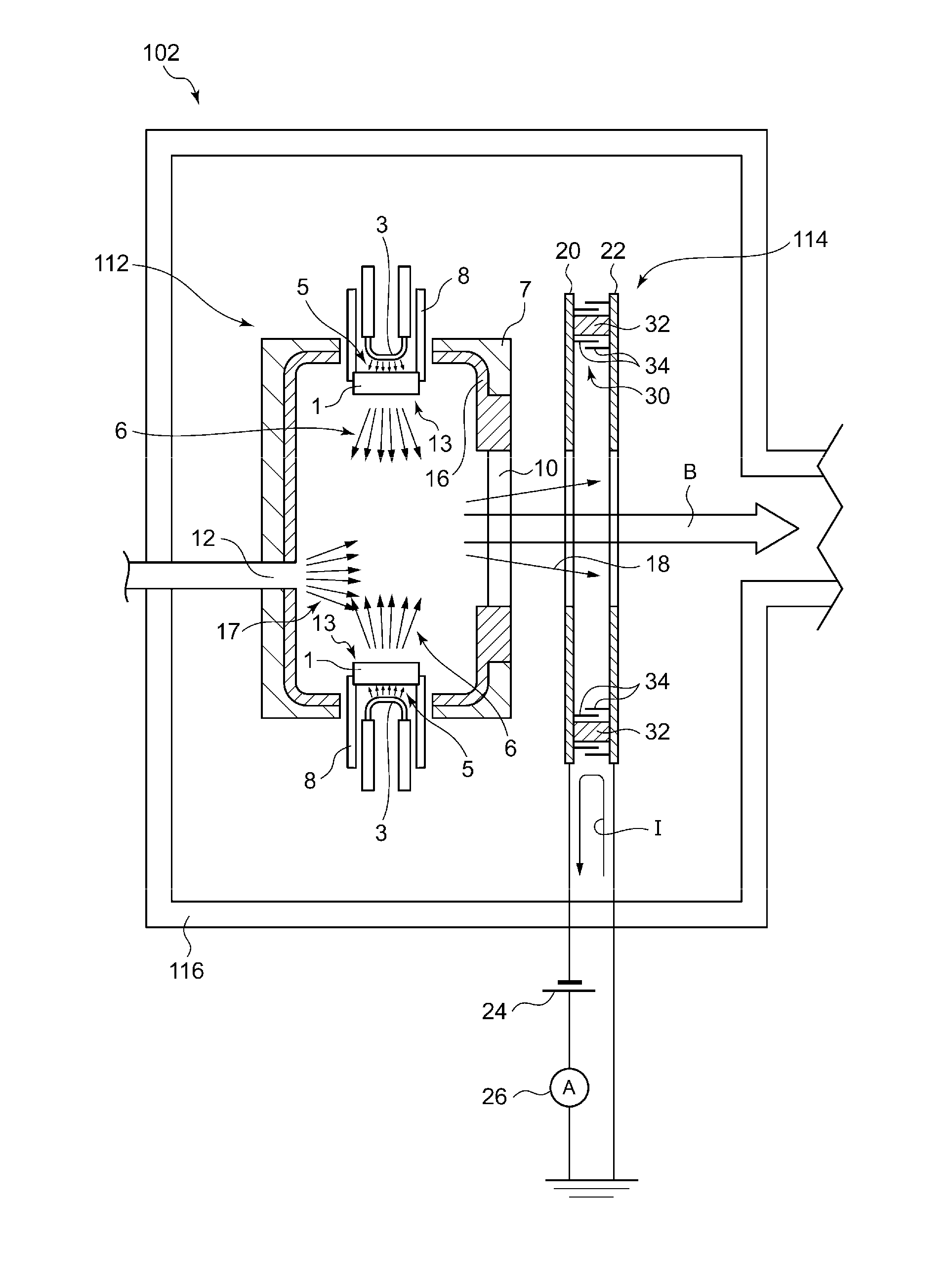

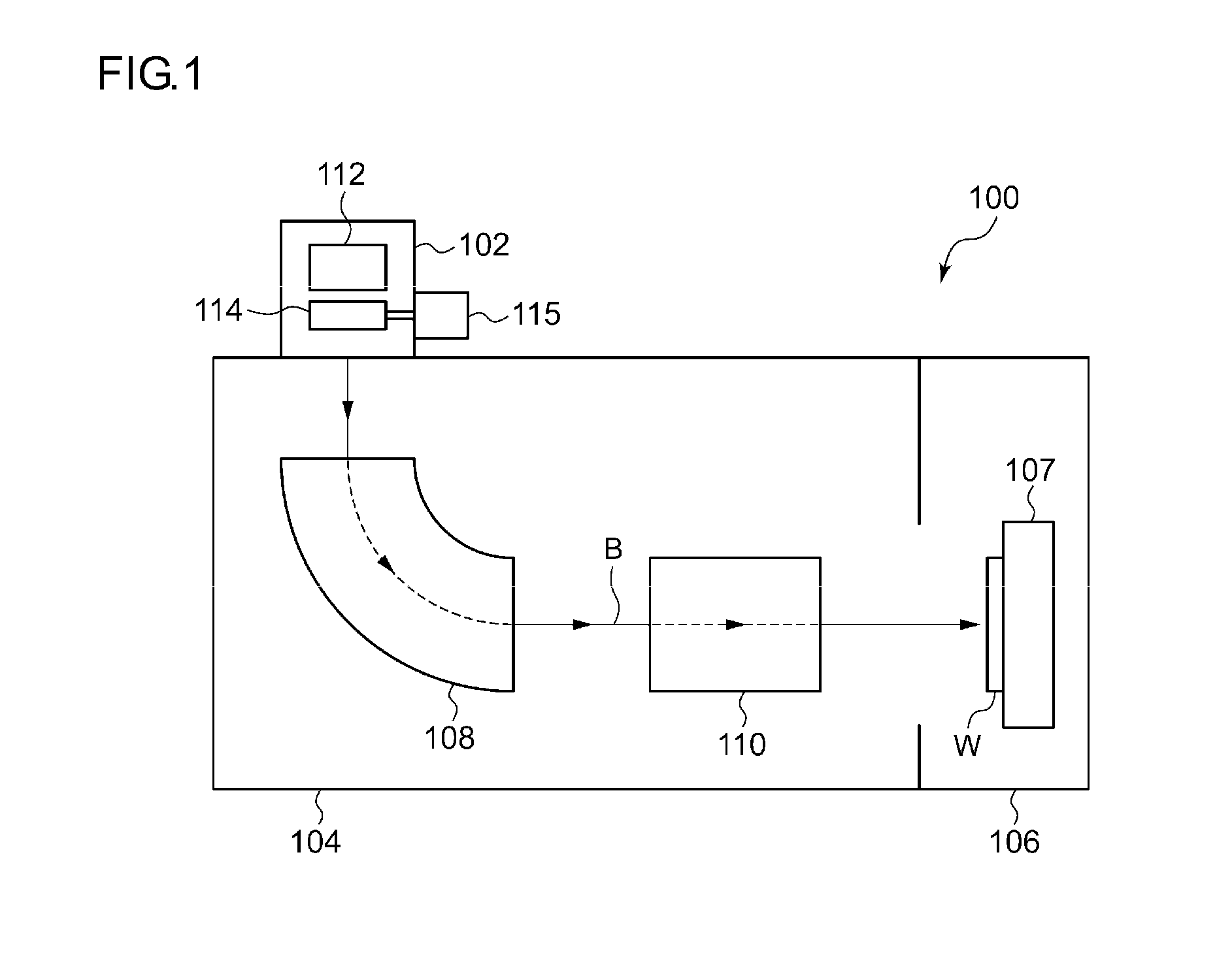

ActiveUS20140353518A1Reduce frequency of maintenanceReduce maintenance frequencyMaterial analysis by optical meansIon beam tubesCOMPONENT IIBiomedical engineering

An insulation structure provided among a plurality of electrodes for extraction of an ion beam from a plasma generating section is provided. The insulation structure includes an insulation member including a first part connected to a first electrode and a second part connected to a second electrode and configured to support the first electrode to the second electrode, a first cover surrounding at least a part of the first part to protect the first part from contamination particles, and a second cover surrounding at least a part of the second part to protect the second part from contamination particles. At least one of the first part and the second part is made of a machinable ceramic or a porous ceramic.

Owner:SUMITOMO HEAVY IND ION TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com