Electric appliance temperature sensor fault detection calibration method, air conditioner and computer readable storage medium

A technology of temperature sensor and calibration method, applied in thermometer testing/calibration, thermometer, instrument, etc., can solve problems such as affecting user experience, affecting the performance of air conditioners, affecting the accuracy of air conditioners, etc., to improve detection accuracy and reduce electrical appliances. Maintenance frequency and the effect of improving user experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

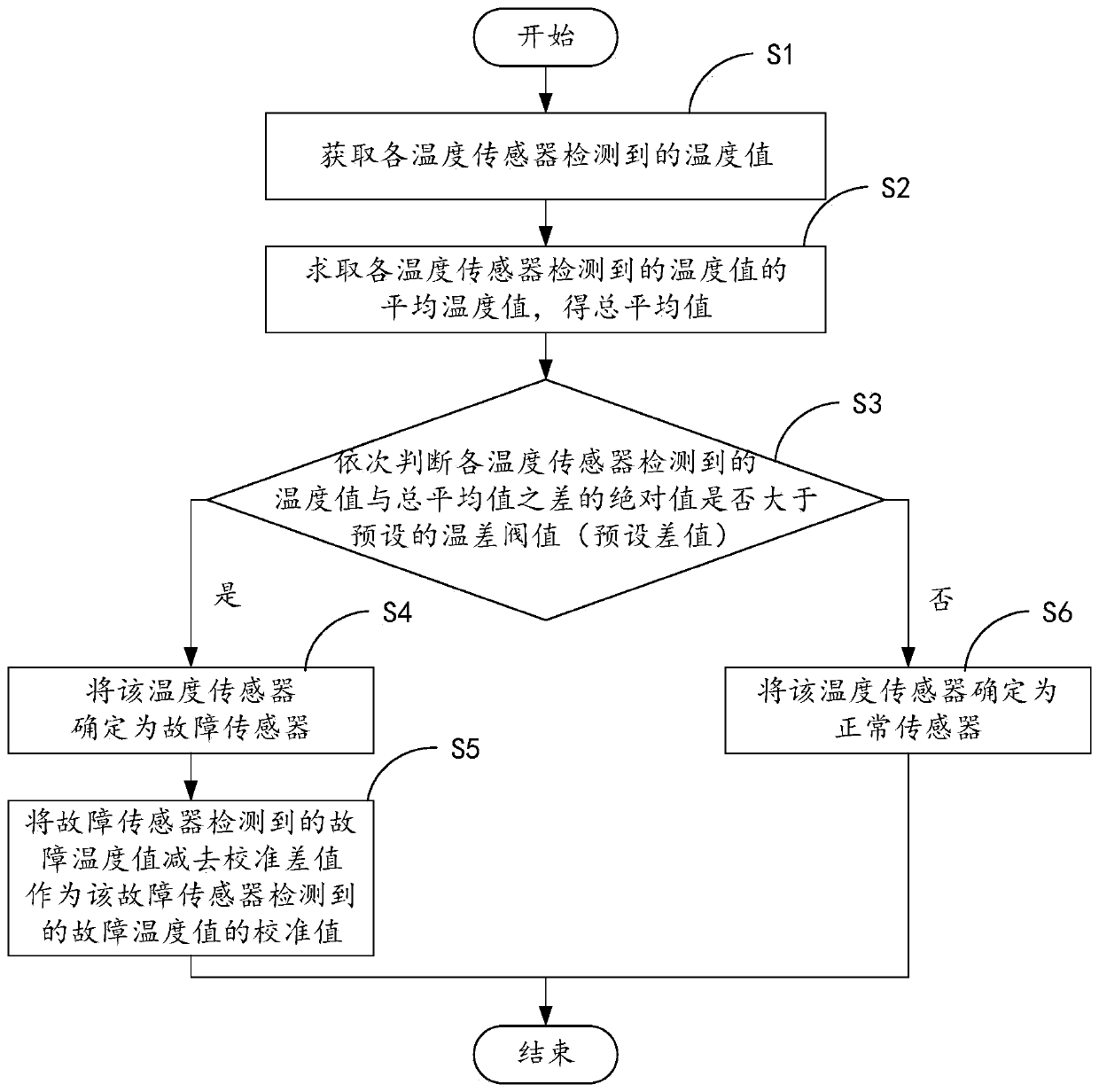

[0024] The fault detection and calibration method of the electrical appliance temperature sensor in this embodiment can be applied to the air conditioner in this embodiment. The air conditioner is equipped with multiple sensors for detecting the indoor ambient temperature, detecting the temperature of the refrigerant in various parts of the heat pump system, and detecting the temperature of the air outlet of the air conditioner. A temperature sensor, because the temperature sensor is prone to failure after long-term use, resulting in a large deviation between the temperature value detected by some temperature sensors and the actual temperature value, which directly affects the accuracy of the temperature control of the air conditioner and affects the user experience.

[0025] The inventor found that among all the temperature sensors (faulty sensors) that have failed in the air conditioner, a large proportion of the faulty sensors only have accuracy drift, and the faulty sensors ...

Embodiment 2

[0040] In this embodiment, the interpolation fitting method is used to fit the functional relationship between the fault temperature value detected by the fault sensor and the average temperature value detected by each temperature sensor, and the fault temperature value detected by the fault sensor is mapped through the functional relationship The obtained average temperature value detected by each temperature sensor is used as the calibration value of the fault temperature value detected by the fault sensor.

[0041] Preferably, because the fault temperature value detected by the fault sensor with accuracy drift basically satisfies a linear relationship with the actual temperature value, so this embodiment preferably uses a linear function to fit the fault temperature value detected by the fault sensor and each temperature The functional relationship of the average temperature value detected by the sensor, the specific steps include:

[0042] First, after the air conditioner ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com