Turbo refrigerator

一种涡轮制冷机、涡轮压缩机的技术,应用在制冷机、制冷组件、制冷和液化等方向,达到防止释放、降低维修频率、降低轴承损失的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

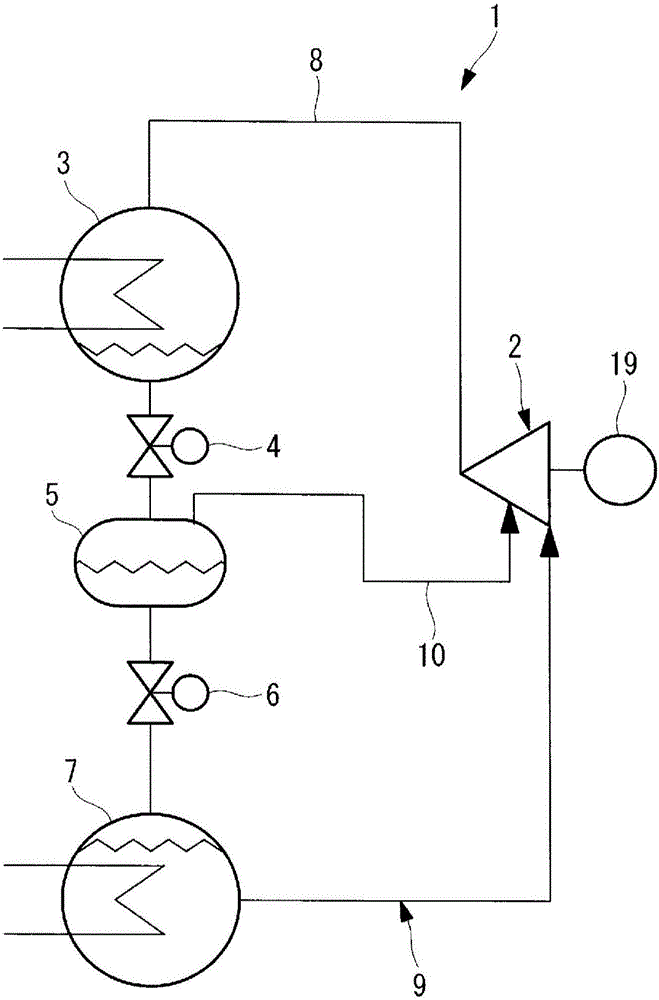

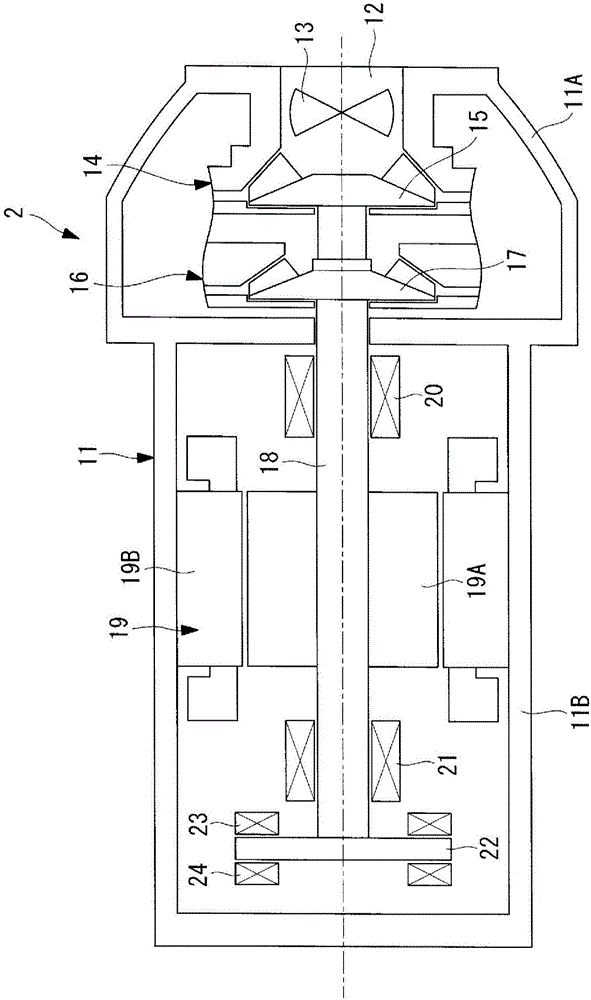

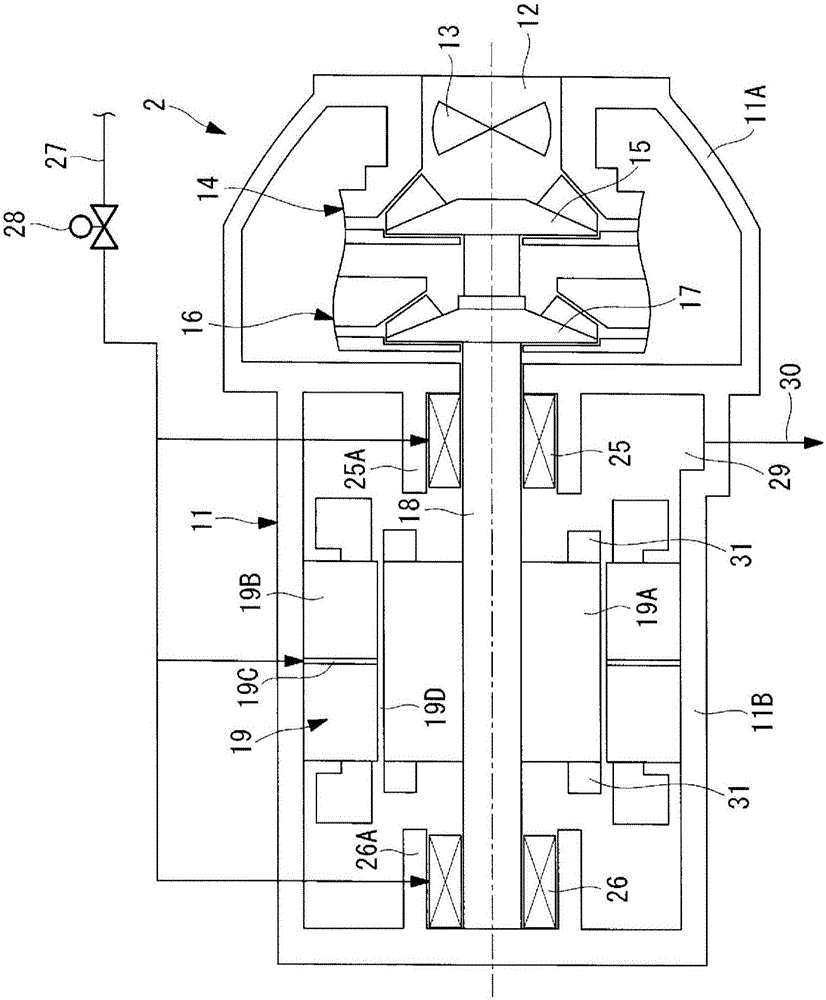

[0032] Below, refer to figure 1 with figure 2 A first embodiment of the present invention will be described.

[0033] figure 1 A configuration diagram showing the turbo refrigerator according to the first embodiment, figure 2 A schematic block diagram showing a turbo compressor applied to a turbo refrigerator.

[0034] Turbo refrigerator 1 such as figure 1 As shown, a closed-cycle refrigeration cycle 9 is provided, and the refrigeration cycle 9 is configured to sequentially connect a turbo compressor 2, a condenser 3, a first decompression device 4, and an air compressor functioning as an economizer via a refrigerant pipe (pipe) 8. Liquid separator 5, second decompression device 6 and evaporator 7.

[0035] The refrigerating cycle 9 of the present embodiment includes a known economizer circuit 10 that sprays the intermediate-pressure refrigerant compressed by the low-pressure-side compression unit 14 of the turbo compressor 2 through the intermediate port and is separat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com