Corrosion-resistant member and method for producing the same

A corrosion-resistant and corrosion-resistant technology, applied in the field of corrosion-resistant components and their preparation, to achieve the effects of reducing maintenance frequency, preventing adhesion and prolonging life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 and comparative example 1

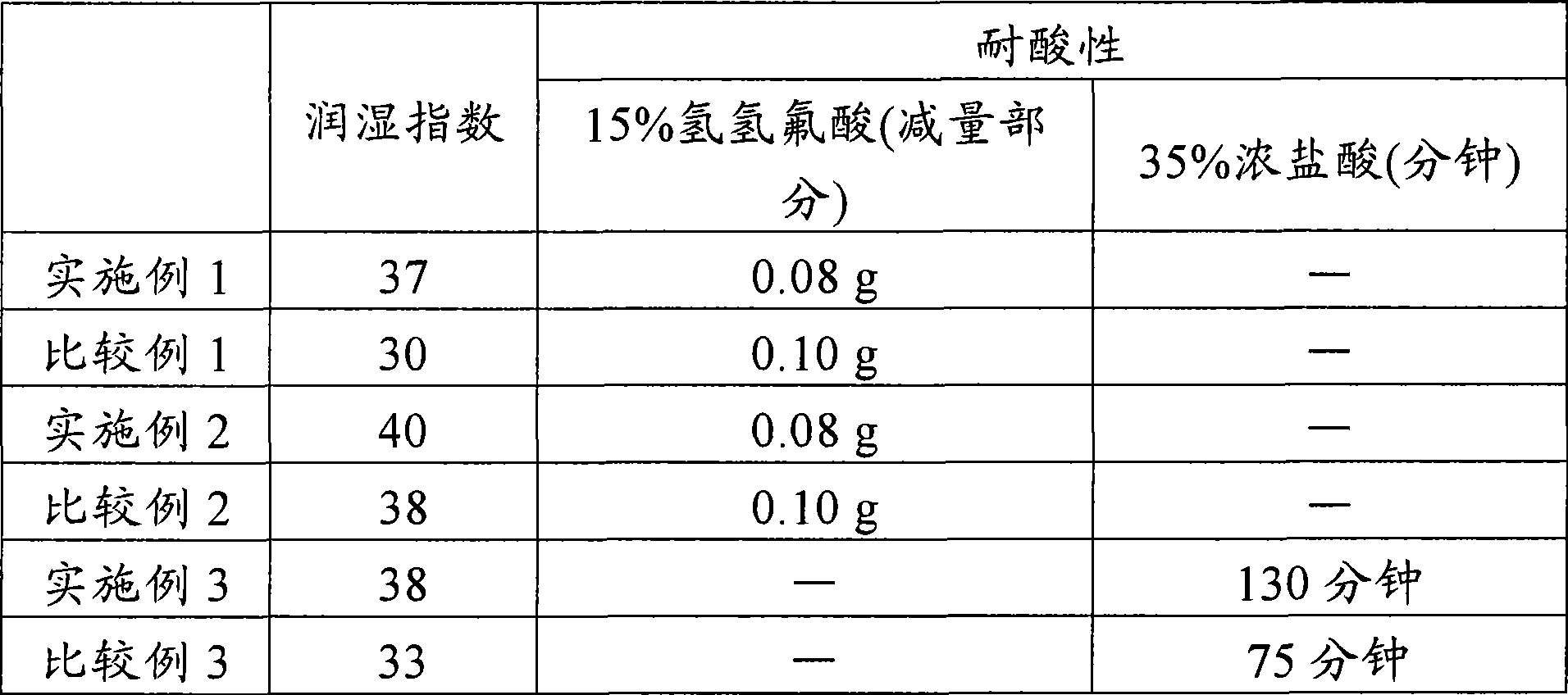

[0125] Spray superheated steam on the polished surface (MFA surface) of quartz glass (250mm×250mm×5mm) for 30 minutes (nozzle outlet temperature 470°C, flow rate 60kg / hour) to perform surface treatment to obtain a corrosion-resistant member . The temperature of the surface to be treated (surface) was measured and found to be 420°C. In Comparative Example 1, the same quartz glass as above was used without superheated steam treatment.

Embodiment 2 and comparative example 2

[0127] On the #320 sandpaper friction surface of quartz glass (250mm * 250mm * 5mm), the superheated steam of spraying 30 minutes (nozzle outlet temperature 470 ℃, flow rate 60kg / hour) is the same as embodiment 1 except that, obtains Corrosion resistant components. The temperature of the surface to be treated (surface) was measured and found to be 420°C. In Comparative Example 2, quartz glass having the same #320 sandpaper friction surface as above was used without superheated steam treatment.

Embodiment 3 and comparative example 3

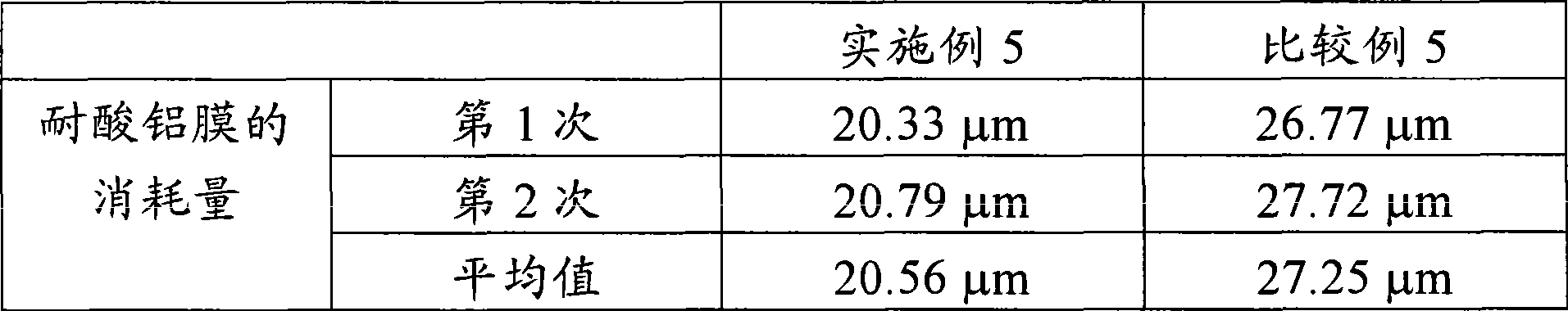

[0129] For the aluminum plate A6061 (aluminum-magnesium-silicon alloy) (aluminum-magnesium-silicon alloy) (dry etching device) with many micropores formed at intervals of 25 mm in the vertical and horizontal directions, and subjected to sulfuric acid alumite processing (hard alumite treatment) and sealing treatment The upper electrode, 250mm×250mm×12mm) is sprayed with superheated steam for 20 minutes (nozzle outlet temperature is 470°C, flow rate is 60kg / hour) for surface treatment. The micropores were formed by a first hole portion having an average diameter of 2 mm×a depth of 9 mm and a second hole portion extending from the bottom of the hole portion with an average diameter of 0.5 mm×a depth of 3 mm. The temperature of the surface to be treated (surface) was measured and found to be 412°C. In Comparative Example 3, the same aluminum plate as above was used without superheated steam treatment.

[0130]For the members of Examples and Comparative Examples, the wettability i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com