Patents

Literature

660 results about "Superheated water" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Superheated water is liquid water under pressure at temperatures between the usual boiling point, 100 °C (212 °F) and the critical temperature, 374 °C (705 °F). It is also known as "subcritical water" or "pressurized hot water." Superheated water is stable because of overpressure that raises the boiling point, or by heating it in a sealed vessel with a headspace, where the liquid water is in equilibrium with vapour at the saturated vapor pressure. This is distinct from the use of the term superheating to refer to water at atmospheric pressure above its normal boiling point, which has not boiled due to a lack of nucleation sites (sometimes experienced by heating liquids in a microwave).

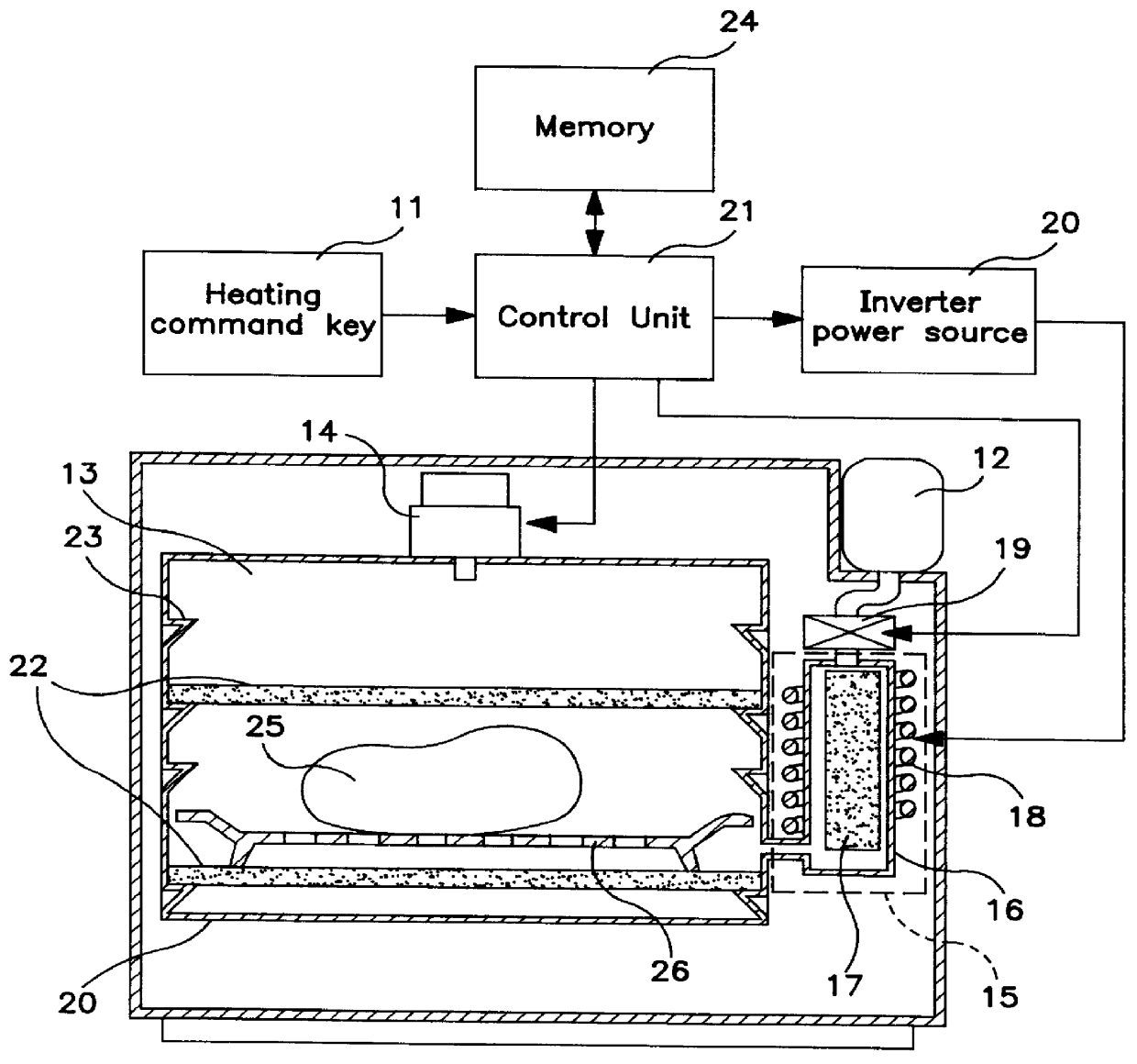

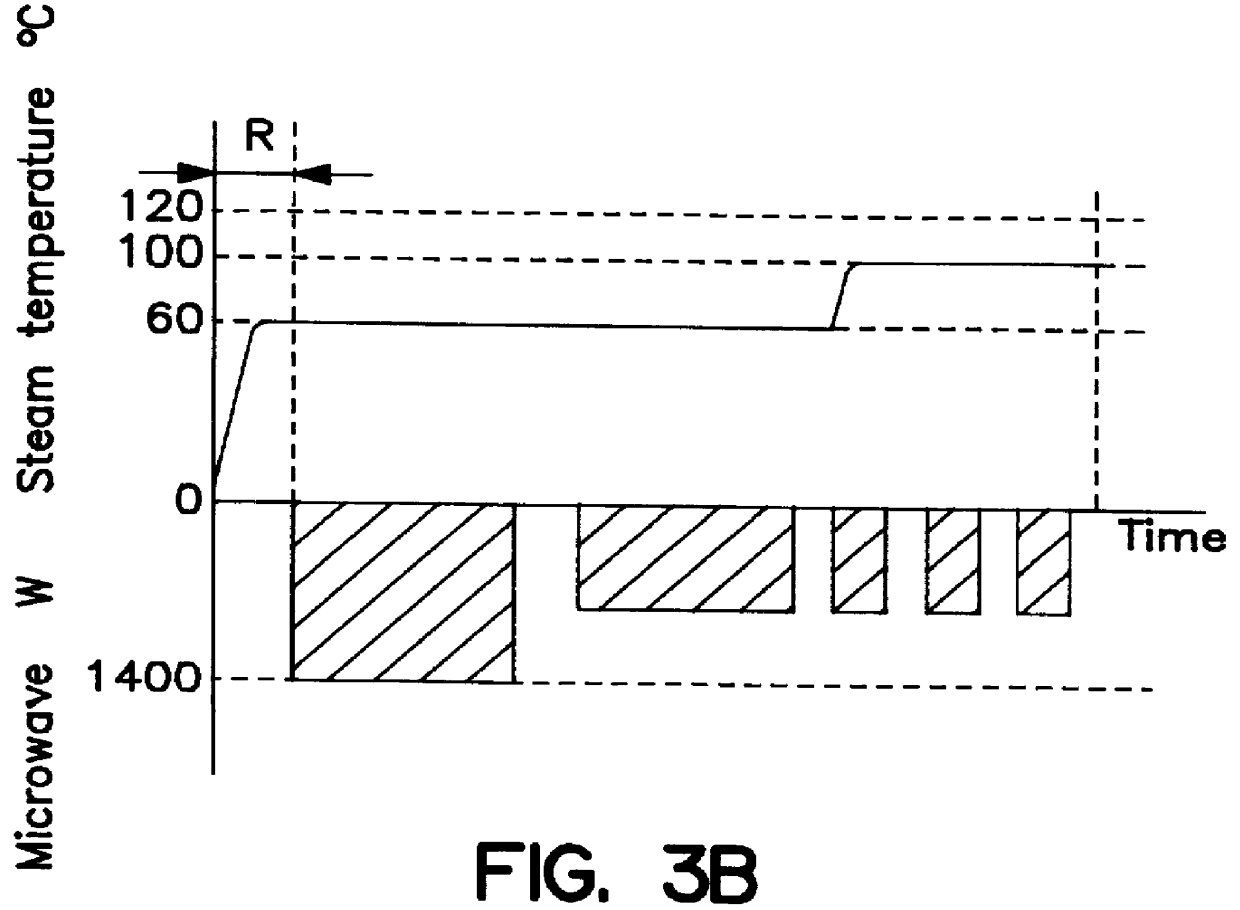

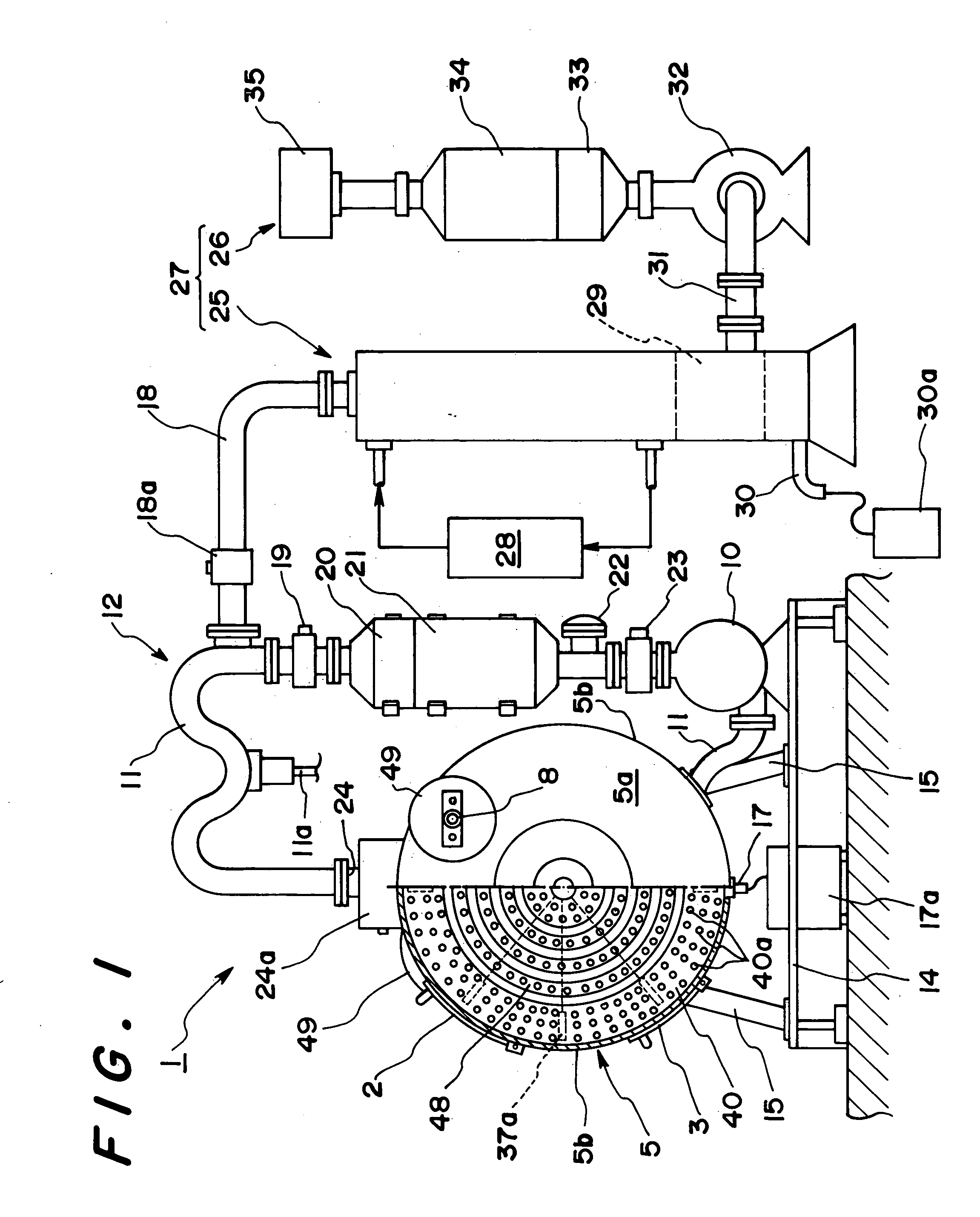

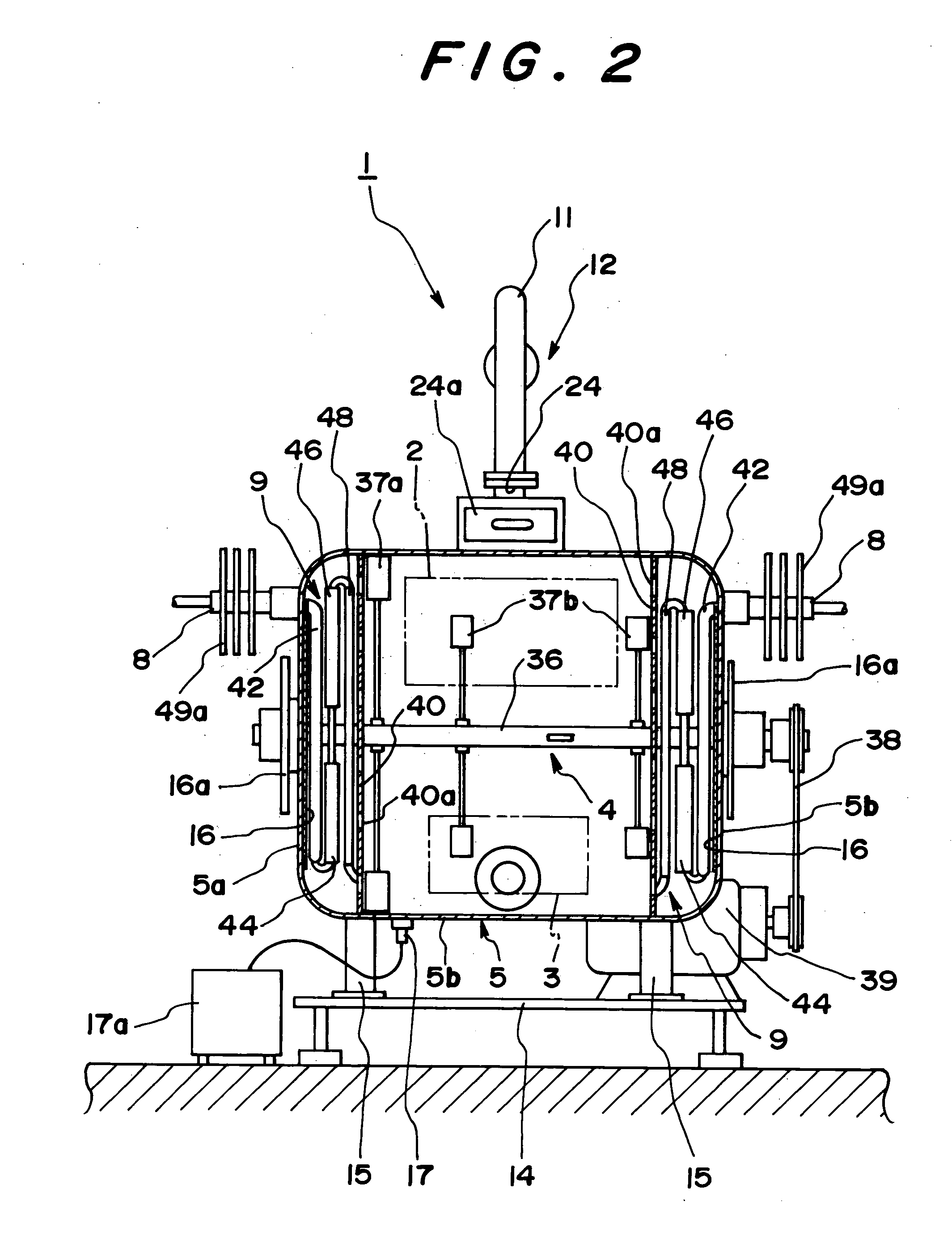

Microwave heating apparatus and microwave heating method

InactiveUS6040564AEfficiently heatPrevent temperatureMilk preservationDomestic stoves or rangesProcess engineeringEngineering

The invention is intended to heat a food or other object to be heated favorably by means of microwaves while enclosing the food with superheated steam. To achieve this purpose, the apparatus comprises a heating chamber in which an object to be heated is put, steam generating means for supplying superheated steam to the heating chamber, superheated steam maintaining means provided in the heating chamber to prevent the temperature of the superheated steam from lowering, and microwave generating means for irradiating the object with microwaves, whereby the object placed in the heating chamber is heated in superheated steam with microwaves, so that the food is efficiently heated from inside and outside and the food is not wetted.

Owner:PANASONIC CORP

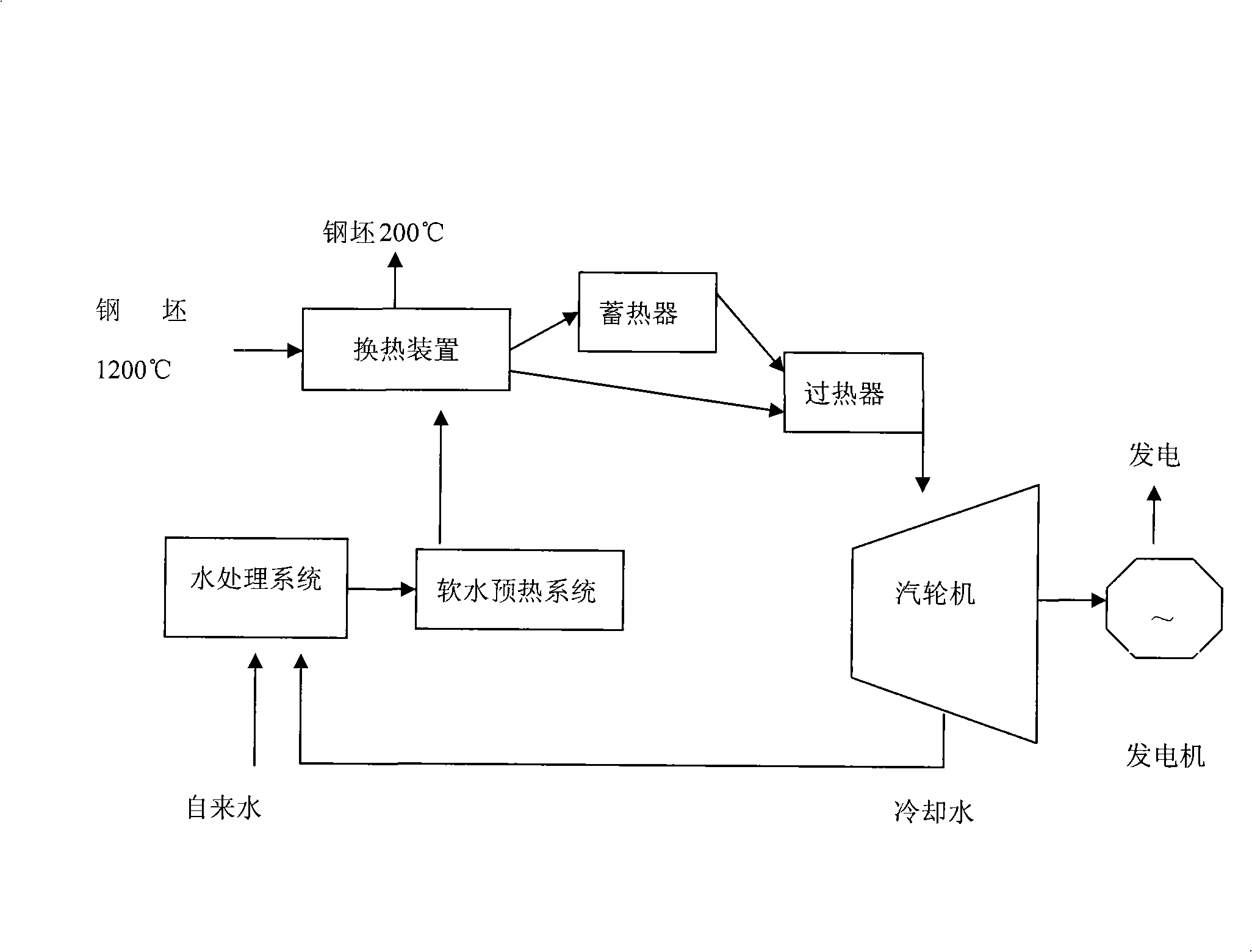

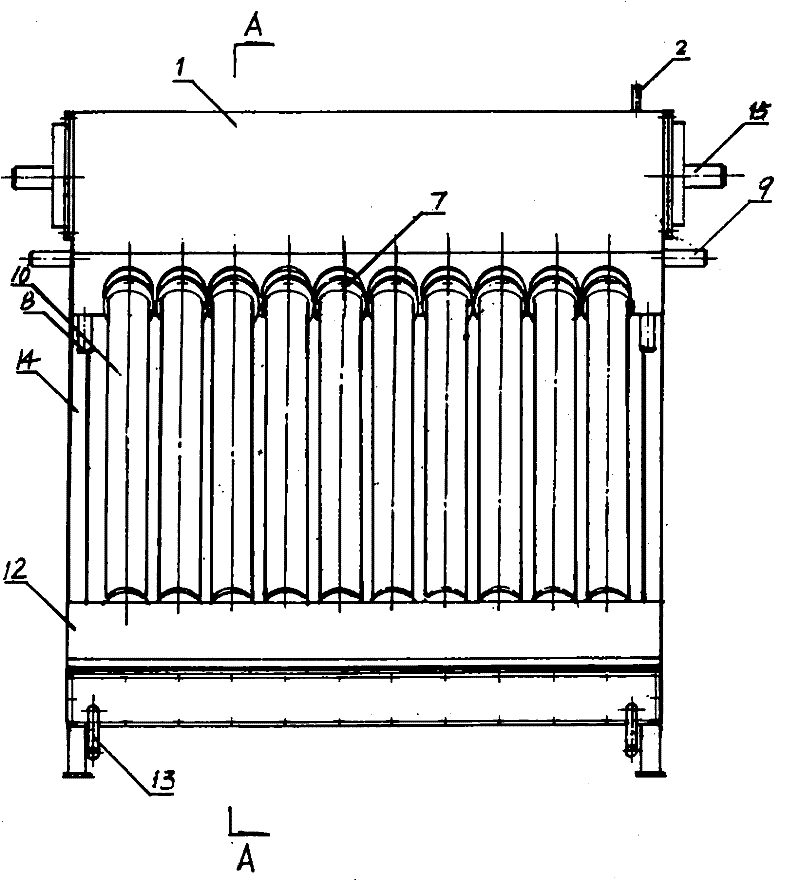

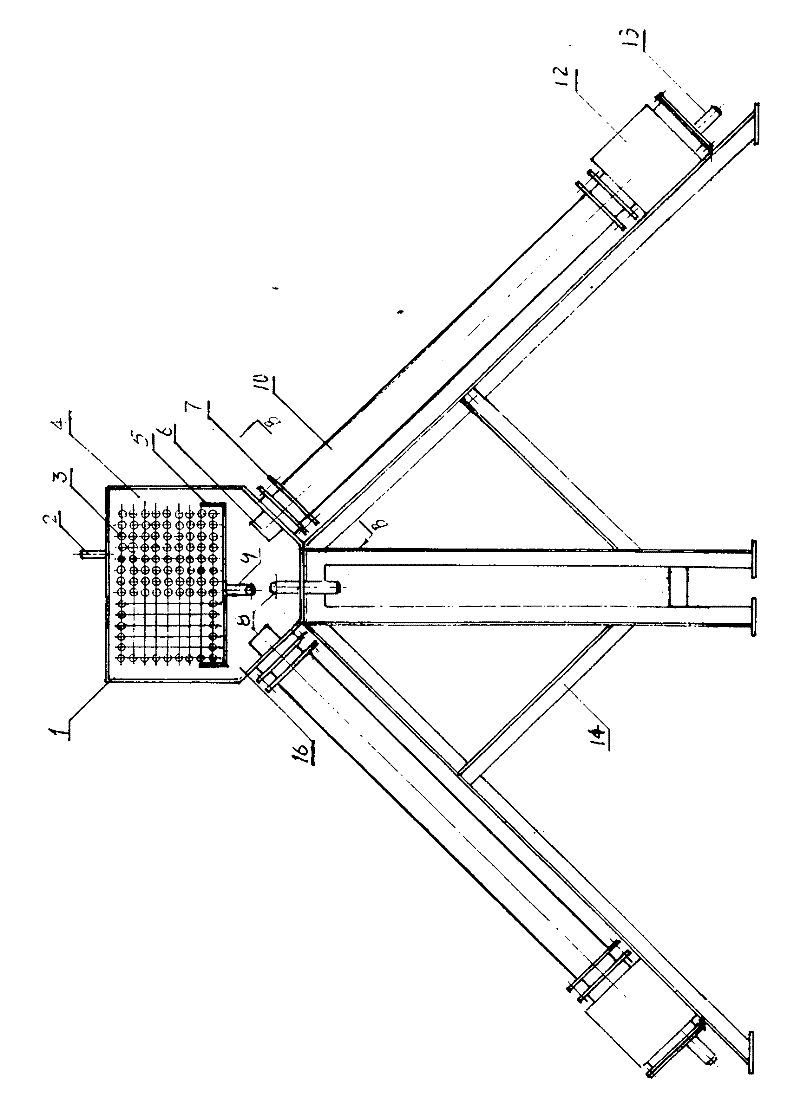

Method and device for reclaiming and utilizing billet residual heat

InactiveCN101260816AGuaranteed uptimeSave electricitySteam engine plantsThermal energyWater storage tank

The invention discloses a method for recycling billet residual heat and a device thereof; water is treated by softening; superheated water is obtained through a steel making cooling system, then the superheated water and discharged billet exchange heat to obtain water vapour; the method comprises the following specific steps: A. superheated water obtained by softening tap water or cooling water is stored in a water storage tank; B. the superheated water in the water storage tank referred in the step A is conveyed to steel tubes of a heat exchange device by a high-pressure water pump through a pipeline; billet is pushed into the heat exchange device surrounded by the steel tubes; heat energy of the billet is dispersed out in order that water in the heat exchange device becomes high-temperature and high-pressure water vapour; C. the high-temperature and high-pressure water vapour passes through a superheater and impels a steam turbine to drive a dynamo to generate power; D. the water vapour after being utilized by the steam turbine is condensed into condensed water; the condensed water enters a water treating system by the pipeline, is treated by the water treating system and conveyed to a cooling water softening system of the step A by the pipeline; through the method, the device recycles cooling water, can dramatically recycle the billet residual heat in high efficiency and is stable and reliable.

Owner:朱学仪

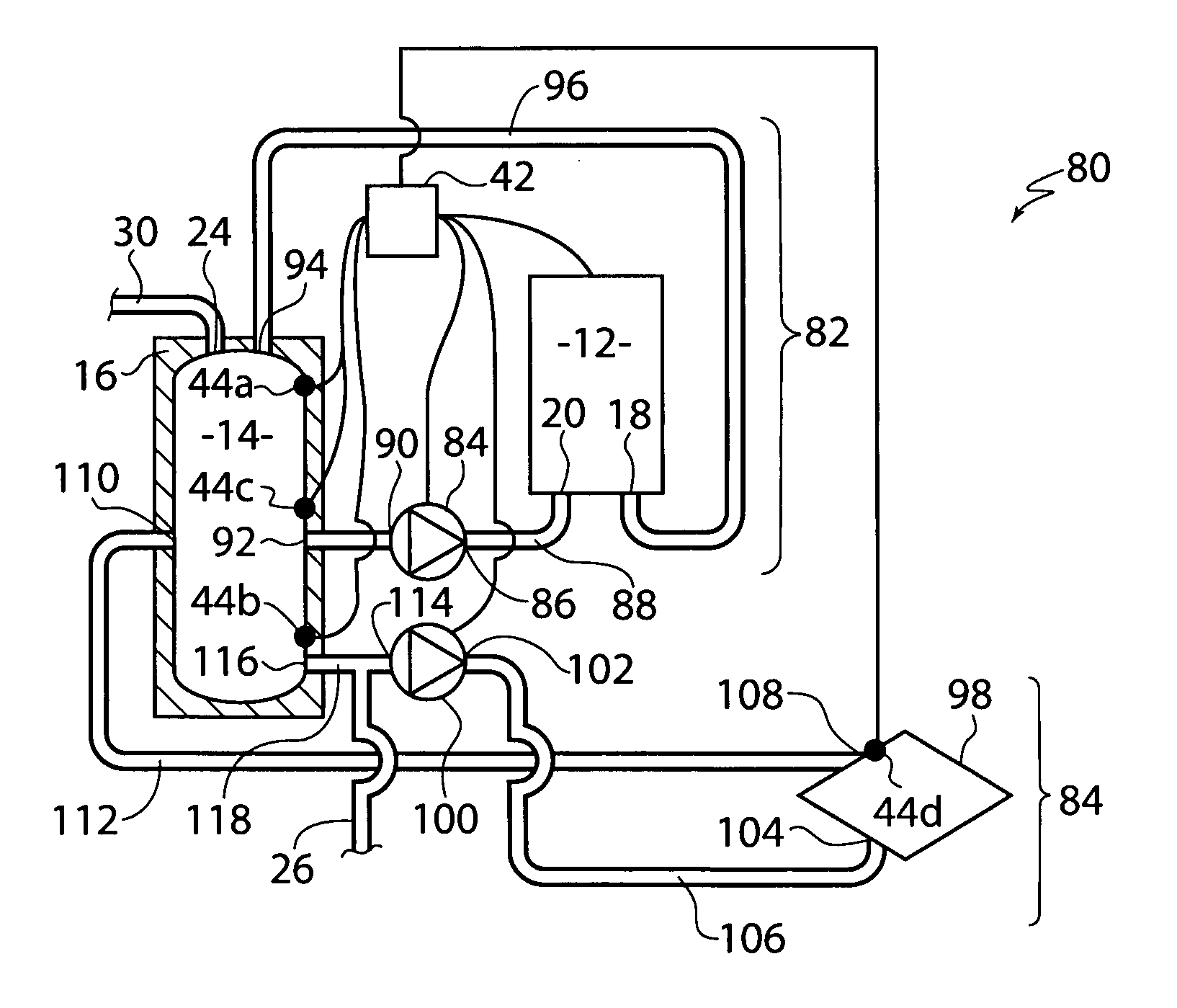

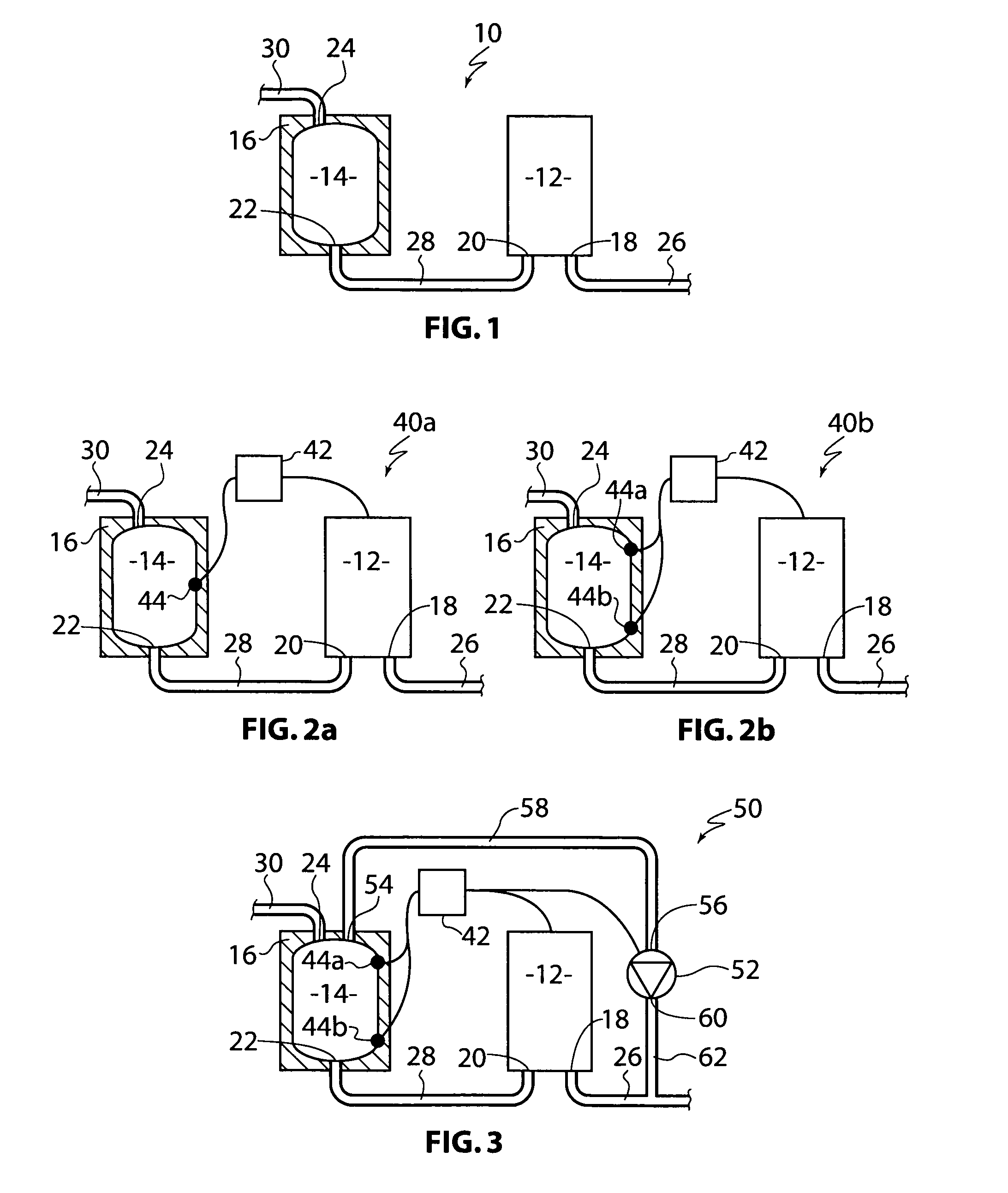

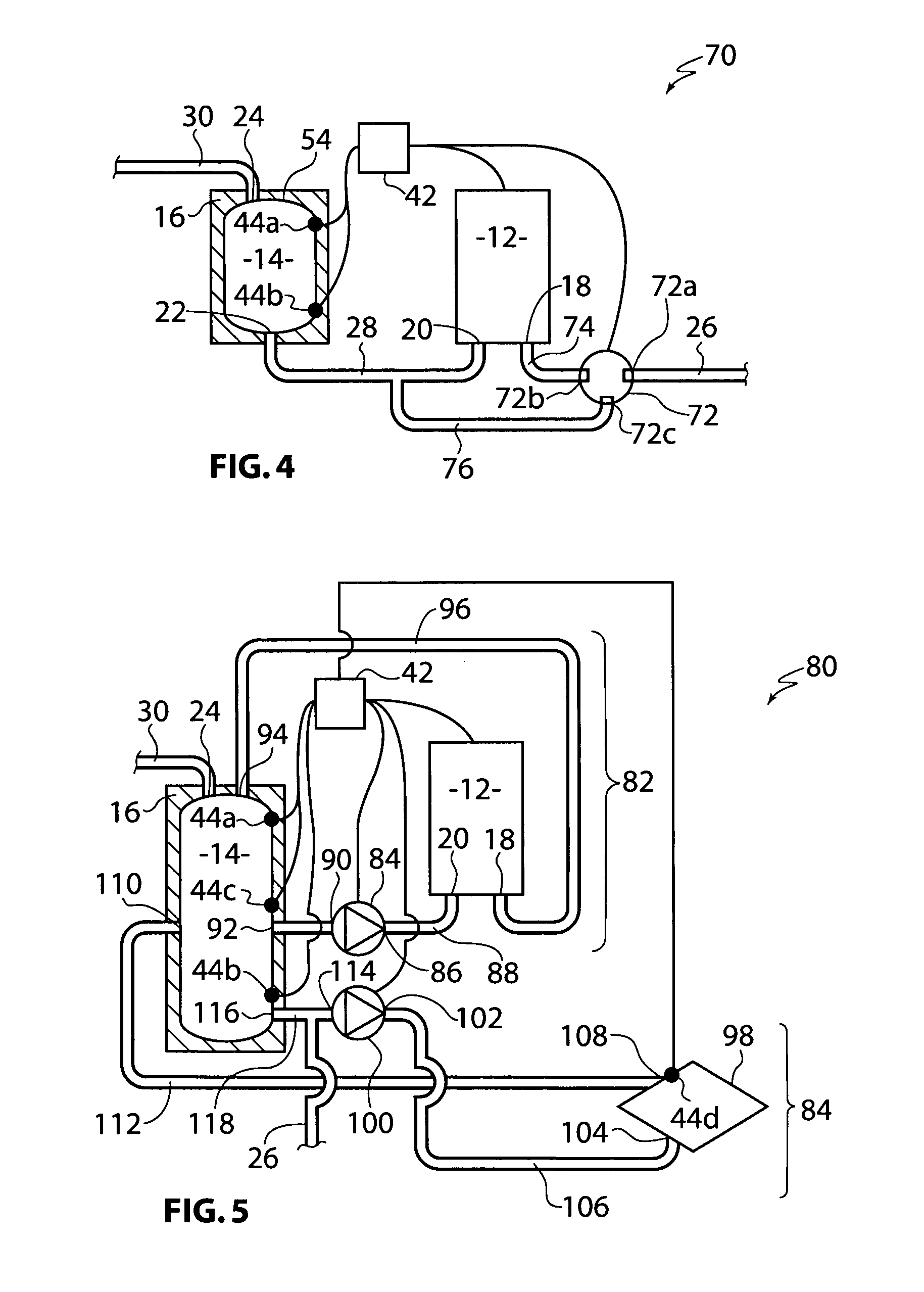

Water heating system and a method of operating same

InactiveUS20110305444A1Domestic stoves or rangesCentral heating component positioningWater storage tankEngineering

A hot water system (10) comprising a water storage tank (14) and an instantaneous-type water heater (12). The water storage tank (14) has an inlet (22) and outlet (24). The instantaneous-type water heater (12) has an inlet (18), in fluid communication with a mains water supply (26), and an outlet (20), in fluid communication with the inlet (22) of the tank (14). The water heater (12) energises in response to a flow of water through the water heater (12).

Owner:DUX MFG

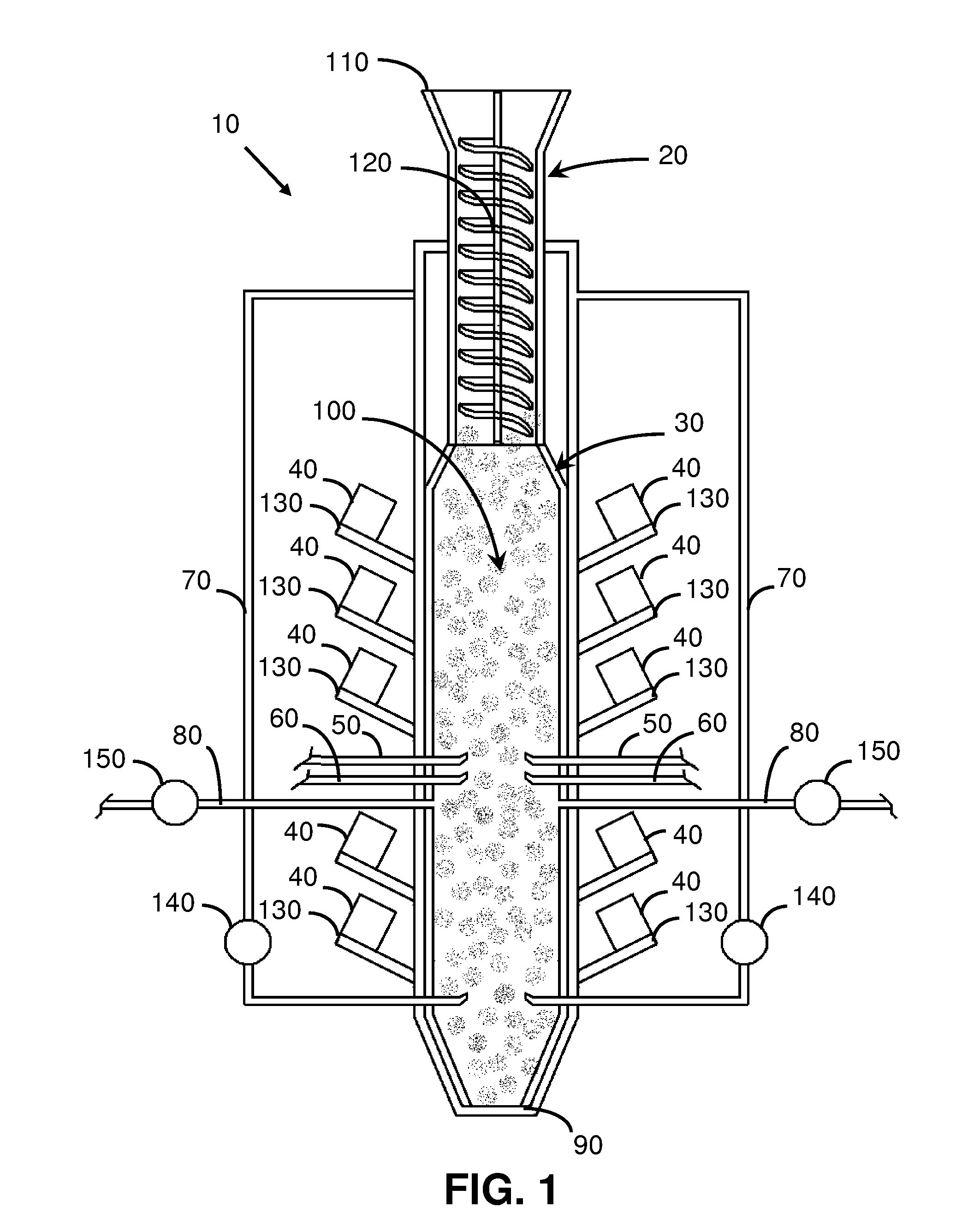

Heat treatment system using superheated steam

The present invention provides a heat treatment system, which includes a treatment chamber having an input port and a discharge port for charging and discharging materials to be treated. A heating system including a plurality of pipe-like heaters positioned one after another in serial arrangement is provided so that the heating temperature is gradually increased for heating the steam or the atomized water introduced from the water feeding system into the heaters by applying voltage on the heaters to turn the steam and the atomized water to superheated steam, and for performing heat treatment on the materials to be treated by injecting the superheated steam into the treatment chamber. A circulating system is provided for sucking the superheated steam and the dry distillation gas in the treatment chamber and for supplying the steam and the gas again into the treatment chamber after deodorizing and filtering, and a control unit is provided for controlling operating conditions such as supply quantity of the steam, duration of treatment, etc.

Owner:AOKI IND +1

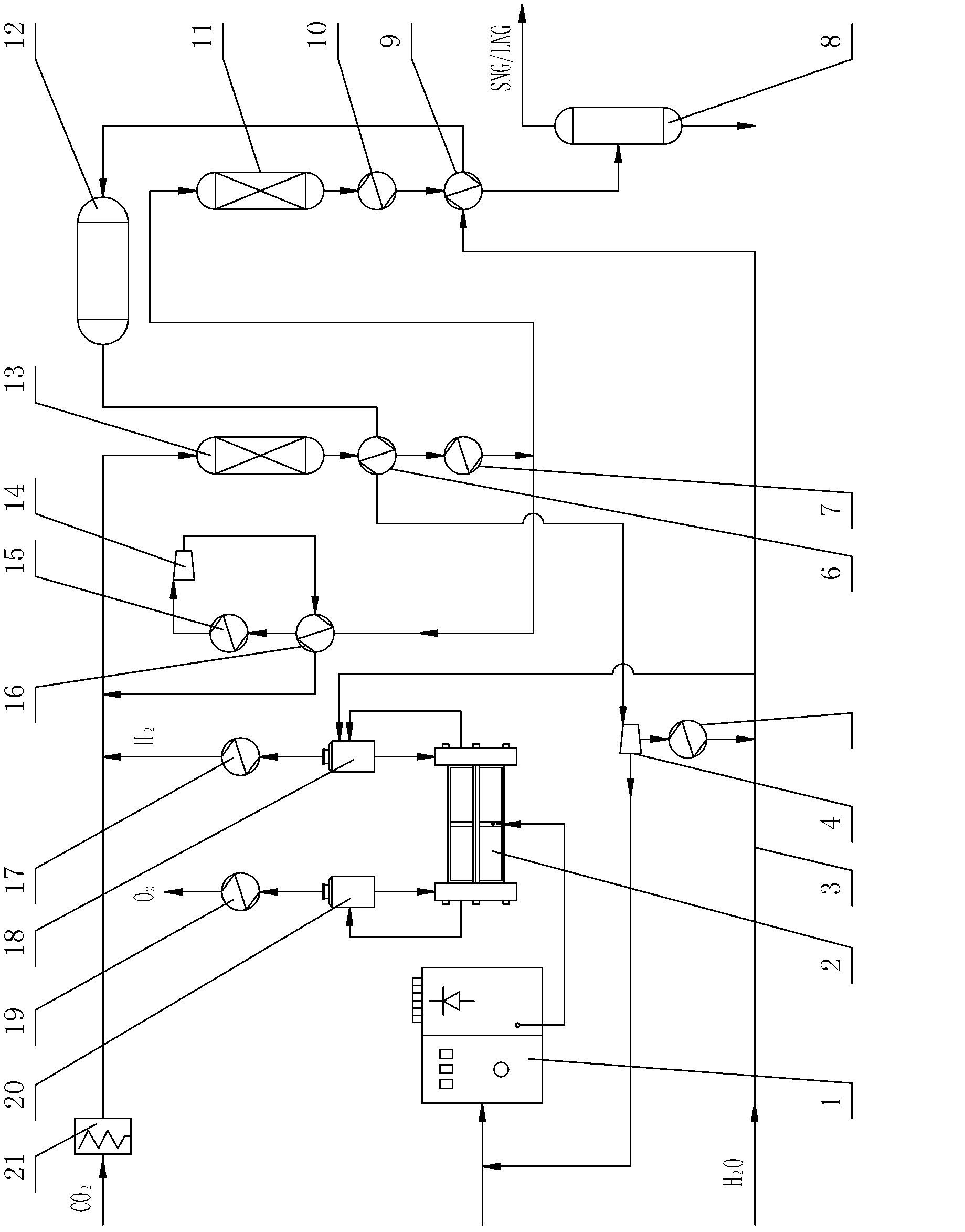

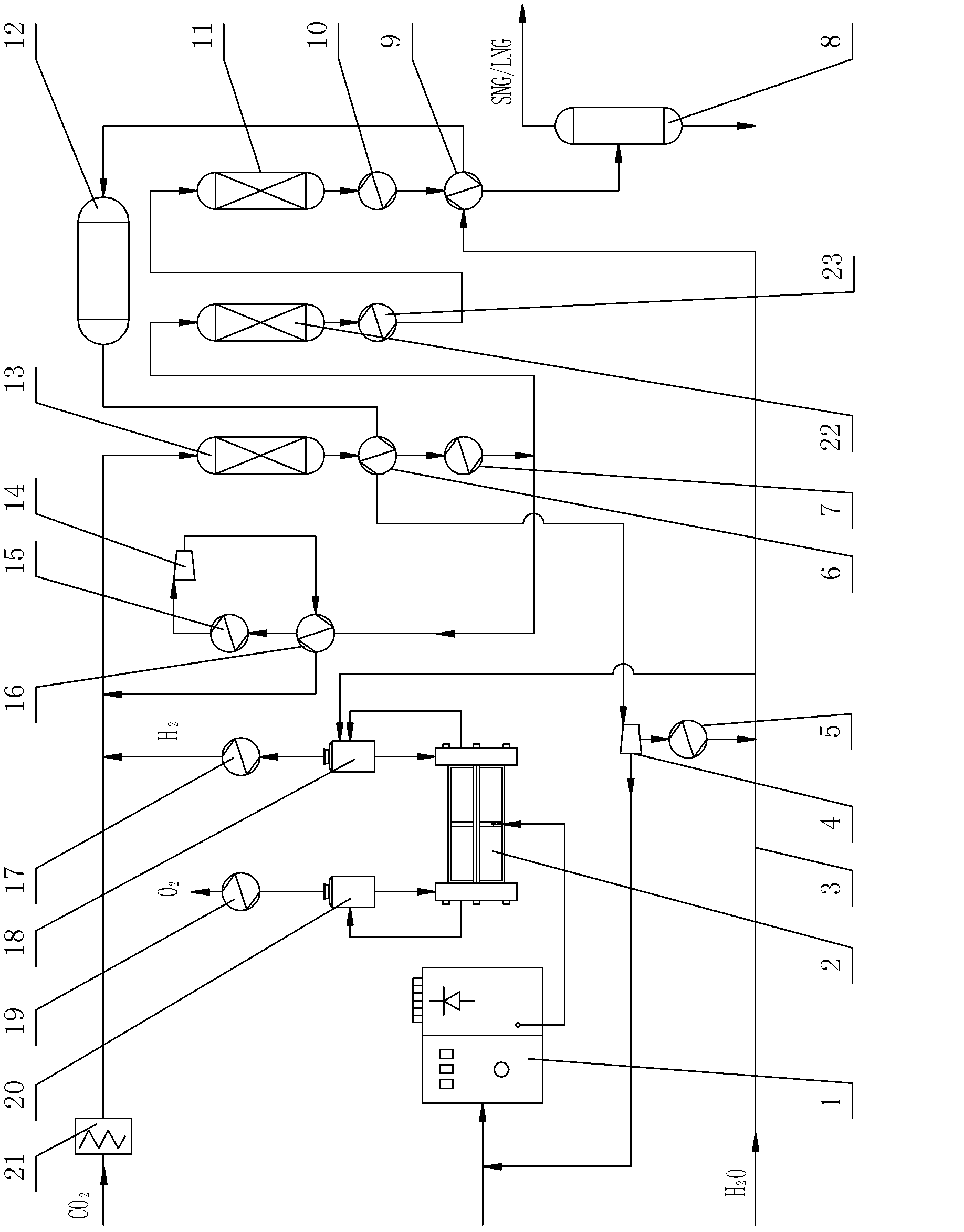

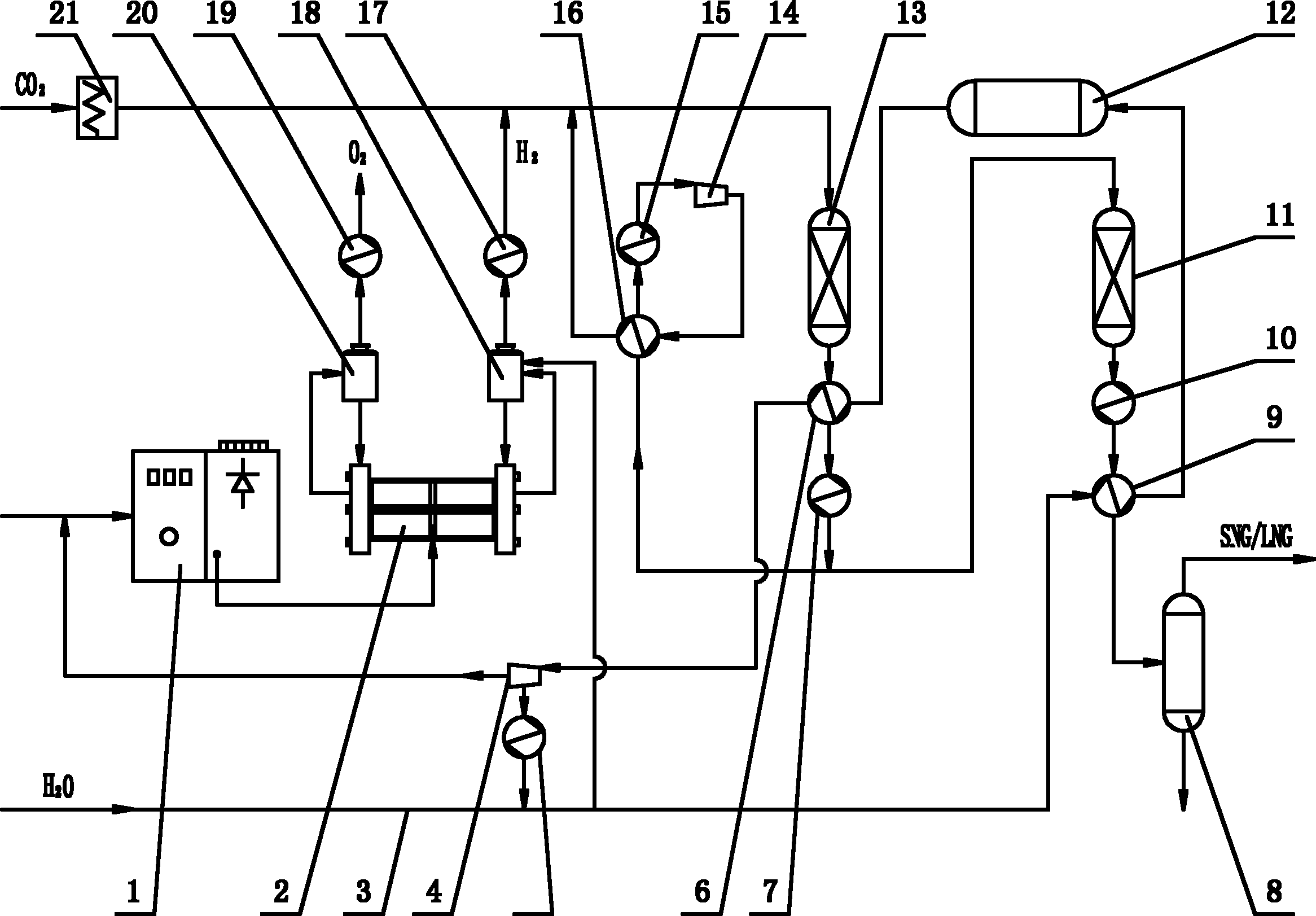

Process and equipment for converting carbon dioxide in flue gas into natural gas by using dump power energy

ActiveCN102660340AEasy to importSolve the problem of difficult power storageCellsHydrocarbon from carbon oxidesElectrolysisWater vapor

The invention discloses a process and equipment for converting carbon dioxide in flue gas into natural gas by using dump power energy. According to the process, water is electrolyzed by using the dump power energy to generate hydrogen gas; the hydrogen gas and carbon dioxide captured from industrial flue gas are enabled to generate methanation reaction; meanwhile, water is heated by using the heat generated by the methanation reaction to generate superheated water vapor for driving a steam turbogenerator to generate power which is used for supplementing power energy for electrolyzing water, and thus natural gas which can be conveniently stored or conveyed is obtained by synthesizing. The equipment is mainly formed by combining a transforming and rectifying device, an electrolytic bath, a steam turbogenerator, a carbon dioxide heater, at least two-stage of fixed bed reactors, various indirect heat exchangers, a steam drum, a natural gas condenser and a process water pipeline. According to the process and equipment disclosed by the invention, the defects that internet obstacles exist or power is excessive in a short time and difficult to store in a mode of generating power by using renewable energy sources are effectively overcome, the problem that the environment is polluted by room temperature gases in a mode of generating power by using fossil energy is effectively solved and the renewable energy sources and carbon dioxide waste gas can be reasonably utilized.

Owner:WUHAN KAIDI ENG TECH RES INST CO LTD

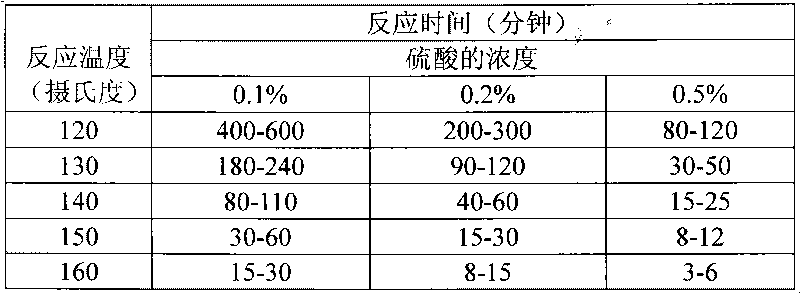

Process for efficiently preprocessing lignocellulose

InactiveCN101736631ALess side effectsReduce usageFermentationPaper material treatmentDecompositionReaction temperature

The invention relates to a process for efficiently preprocessing lignocellulose. The process adopts the following procedures of stepwise optimizing and hydrolyzing: firstly, boiling the lignocellulose in overheated water to ensure that most hemicellulose is dissolved into oligosaccharide; continuously reacting the boiled mixture in a special flash evaporation reactor; and gradually changing reaction temperatures in the process of reaction to slow down xylose decomposition as far as possible and ensure that the hemicellulose is more completely transformed into xylose. The process has the advantages of simpleness, low cost, reasonable energy utilization, no solid-liquid separation in stepwise process, direct hydrolysis on the hot mixture, energy saving and high hydrolysis efficiency of processed cellulose on enzyme.

Owner:熊鹏

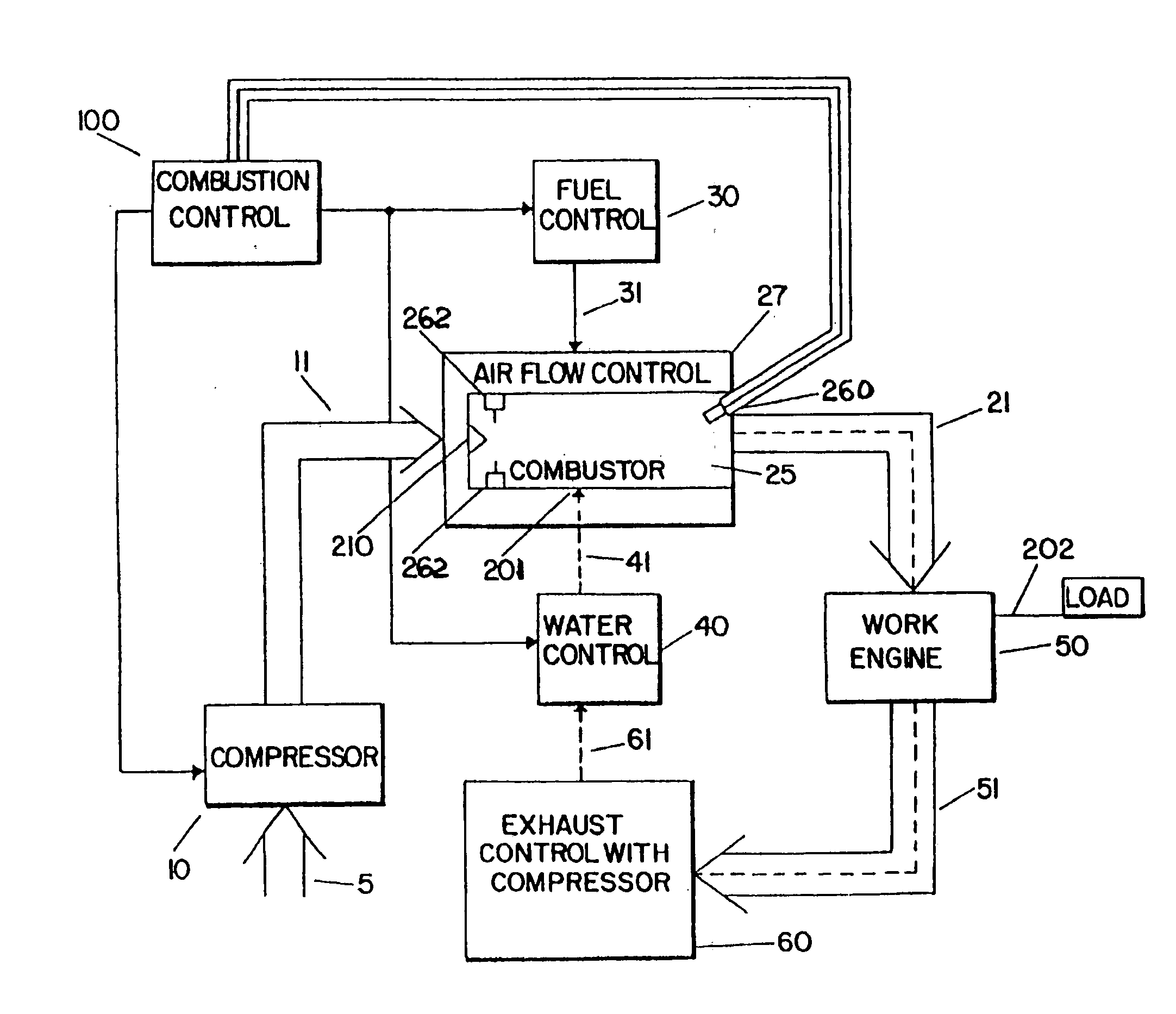

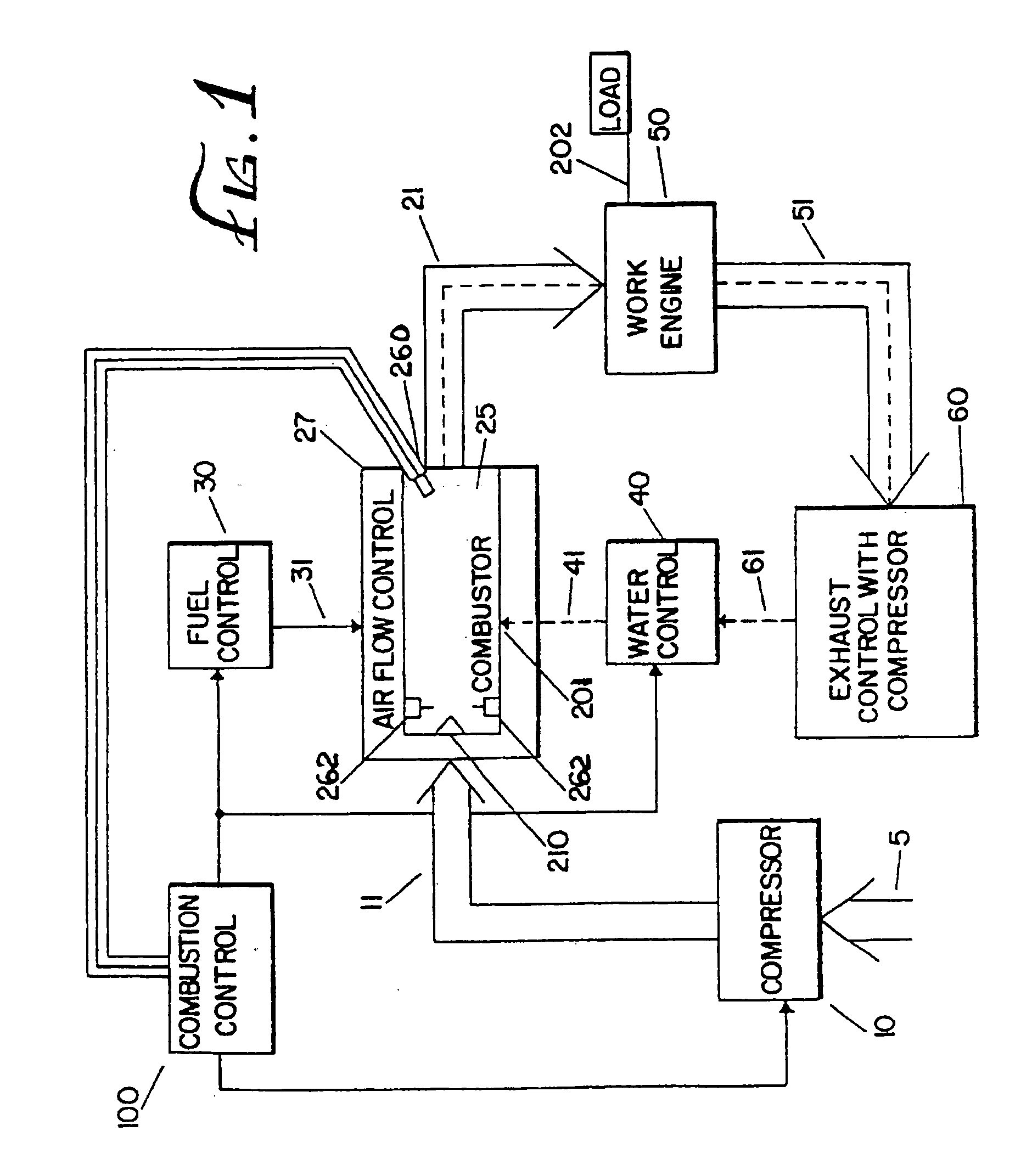

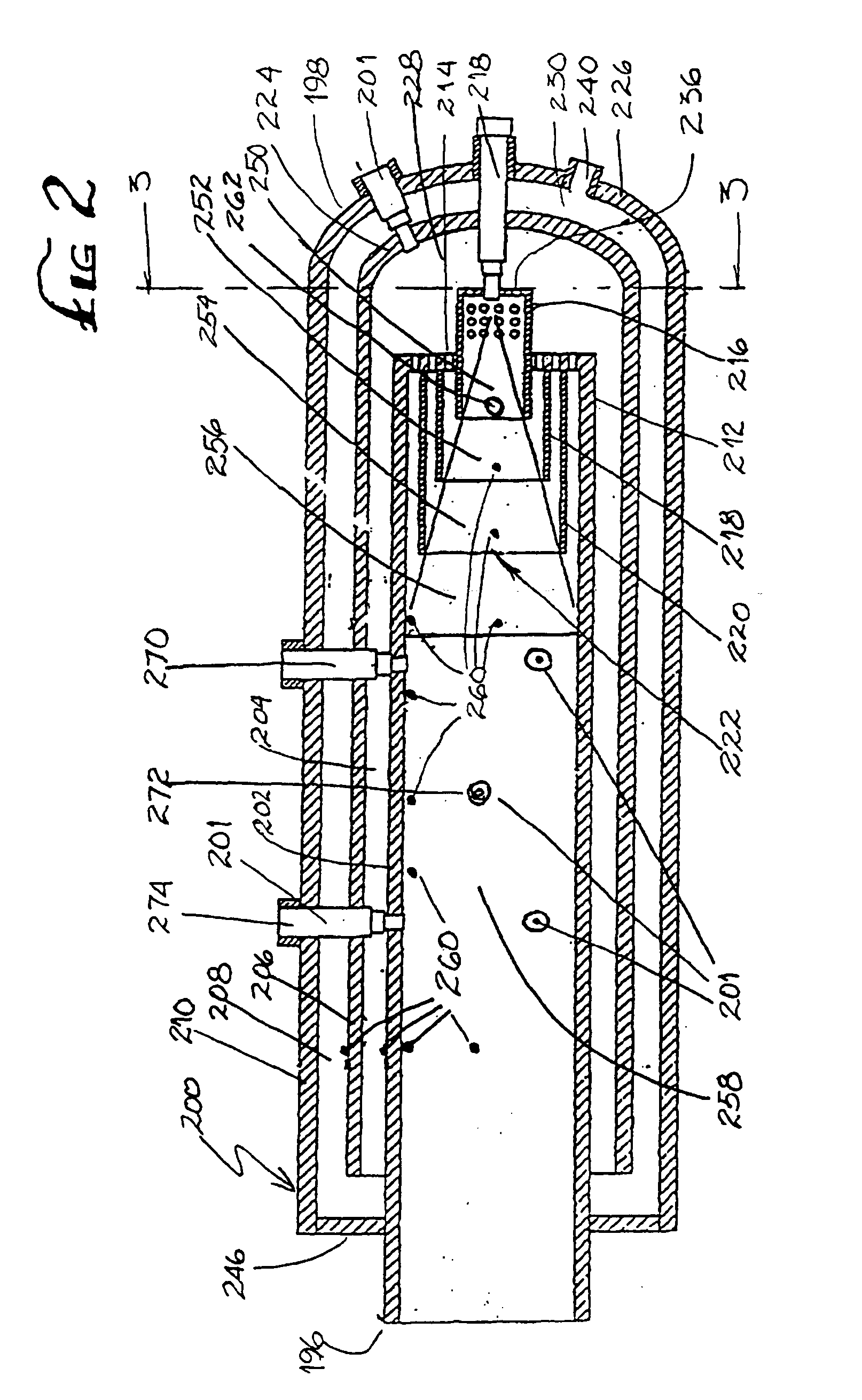

High efficiency low pollution hybrid brayton cycle combustor

InactiveUS20030014959A1Efficient and clean and pollution free powerIncrease horsepowerGas turbine plantsEfficient propulsion technologiesHybrid typeCombustion chamber

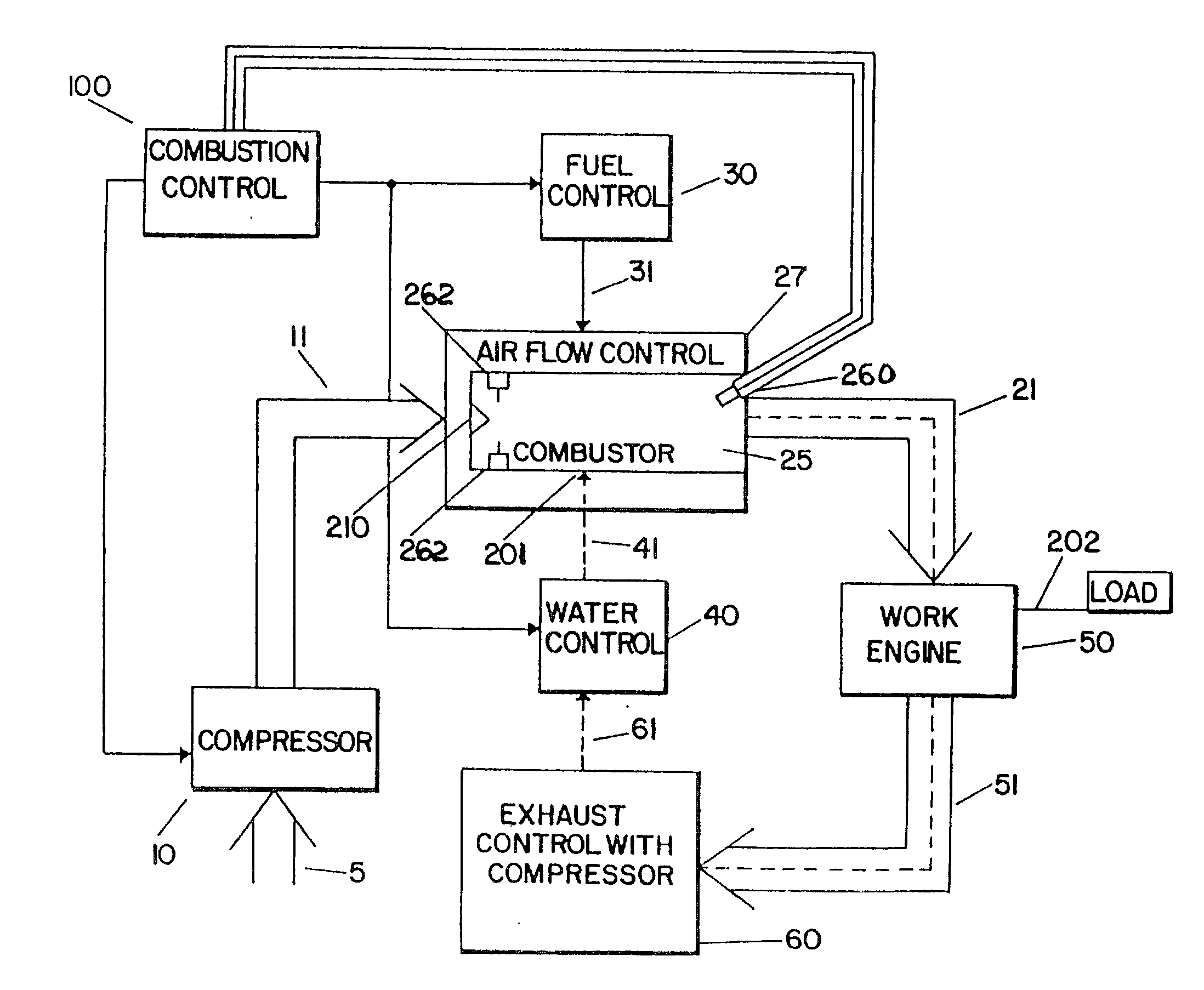

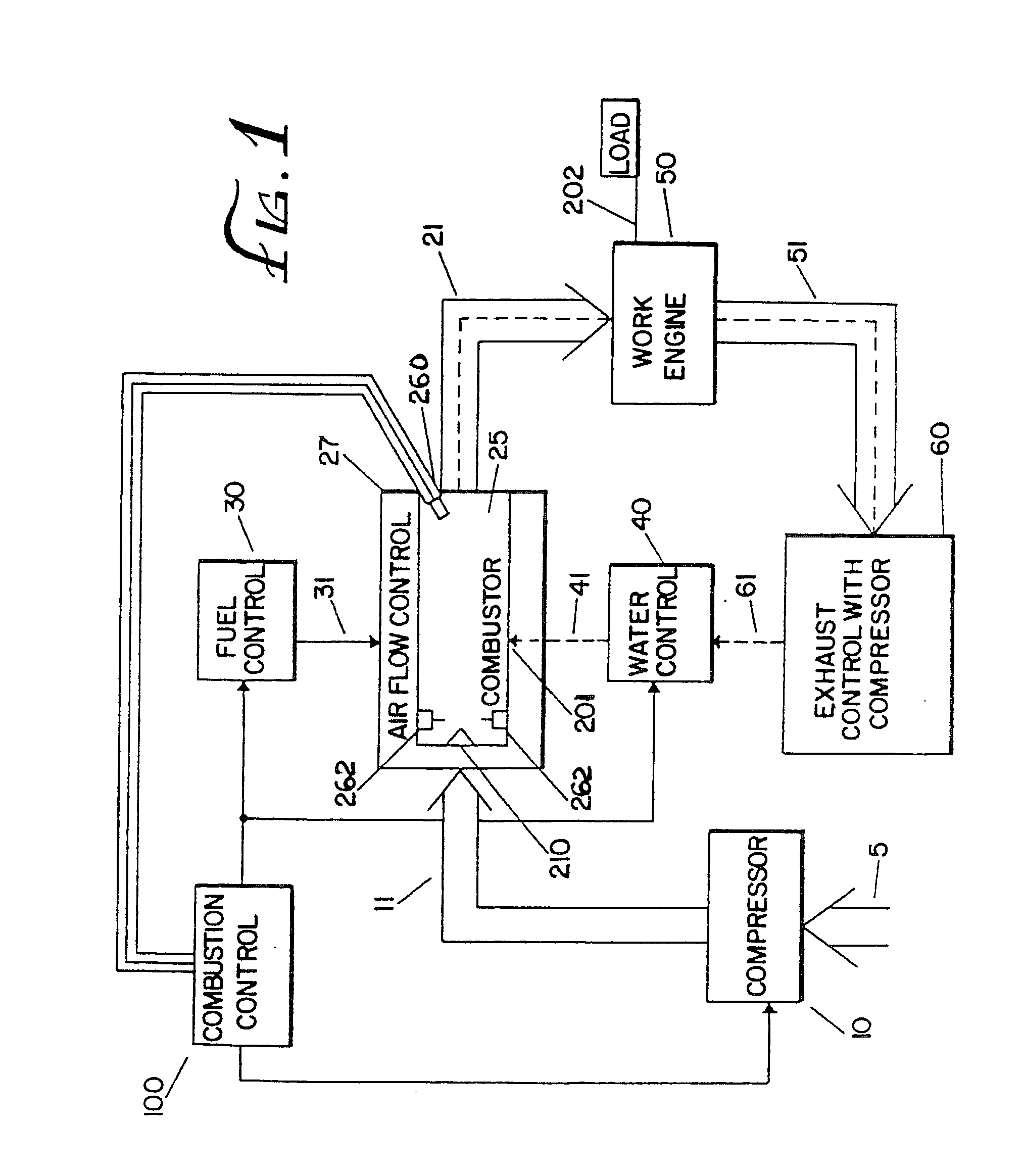

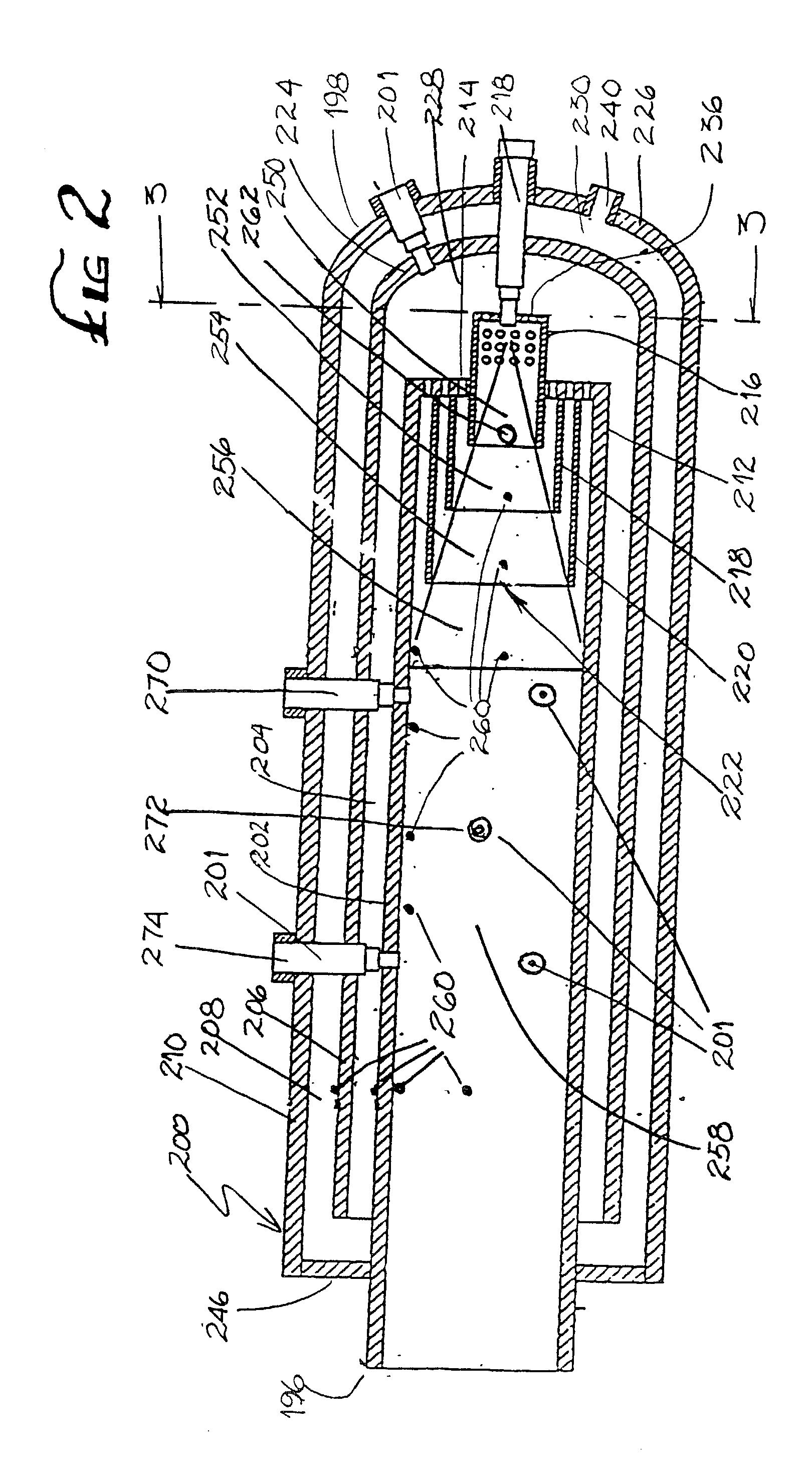

A power generating system and method operating at high pressure and utilizing a working fluid consisting of a mixture of compressed non-flammable air components, fuel combustion products and steam. The working fluid is substantially free of CO and NO.sub.x. Fuel and compressed air at an elevated temperature and at a constant pressure are delivered to a combustion chamber, the amount of air being chosen so that at least about 90% of the oxygen in the air is consumed during combustion. The quantity of air and fuel supplied to the combustion chamber may be varied provided a constant fuel to air ratio is maintained. Superheated water is delivered under pressure to the combustion chamber, and is converted substantially instantaneously to steam. The quantity of water delivered is controlled such that the latent heat of vaporization of the water maintains the temperature of the working fluid at a desired level. Heat may be transferred from the working fluid exiting the work engine to the water to heat the water to the desired temperature for delivery to the combustion chamber. The quantity, temperature and pressure of the air, fuel and water introduced in to the combustion chamber are independently controllable. A zoned burner may be employed in which a portion of the compressed air may be mixed with the fuel in a first zone prior to ignition, with the remaining compressed air being added at one or more locations downstream of the point of ignition.

Owner:GINTER J LYELL

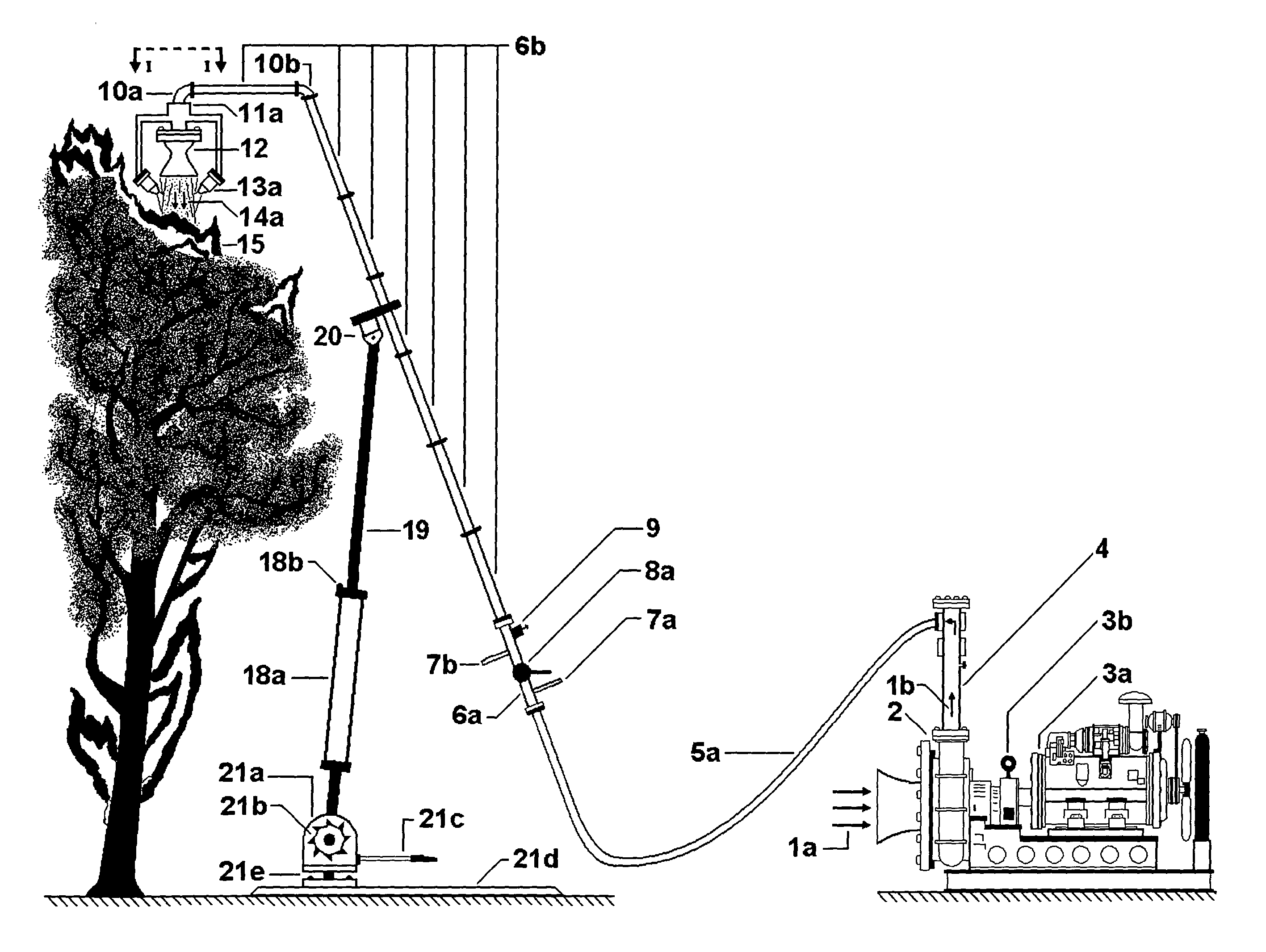

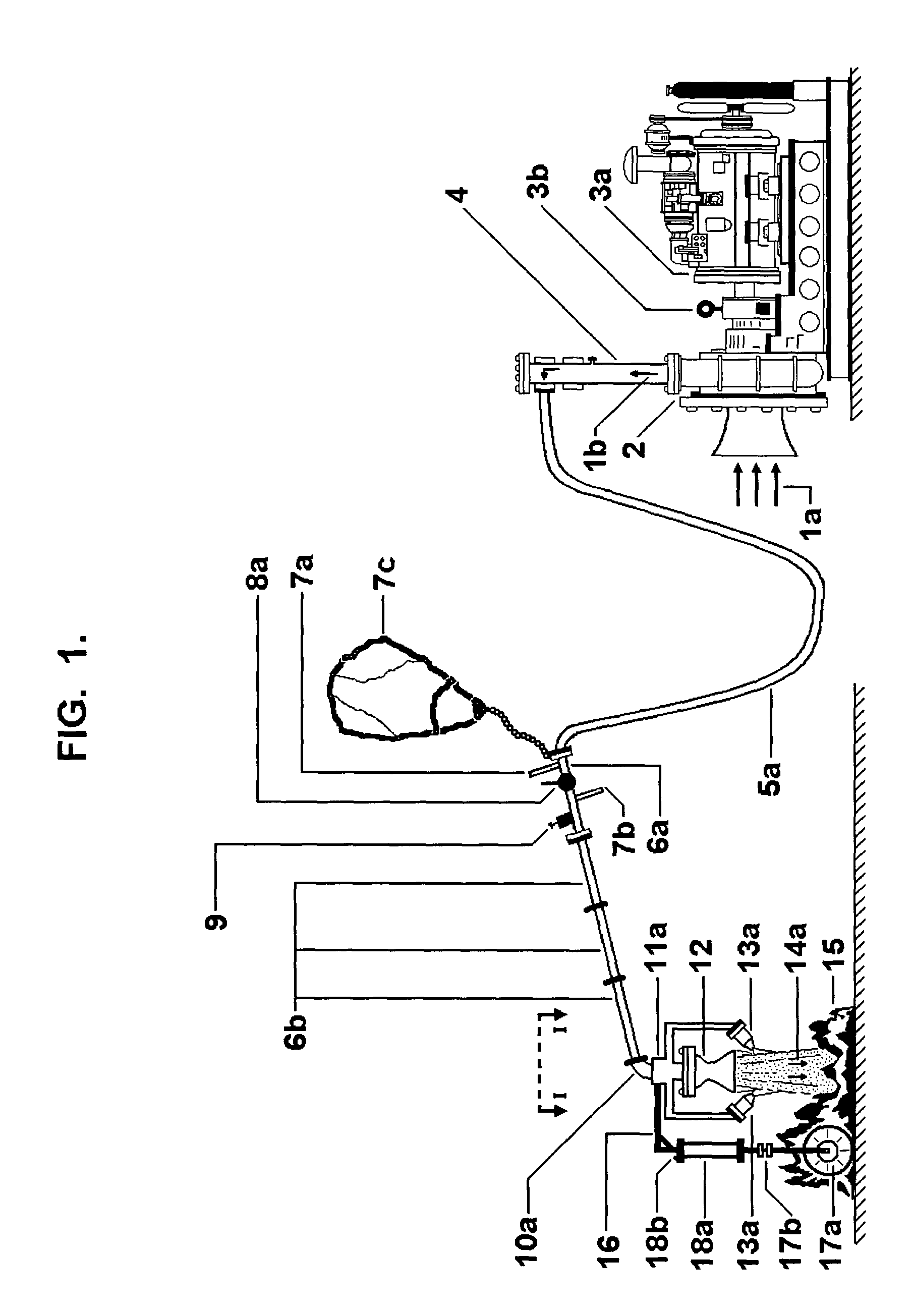

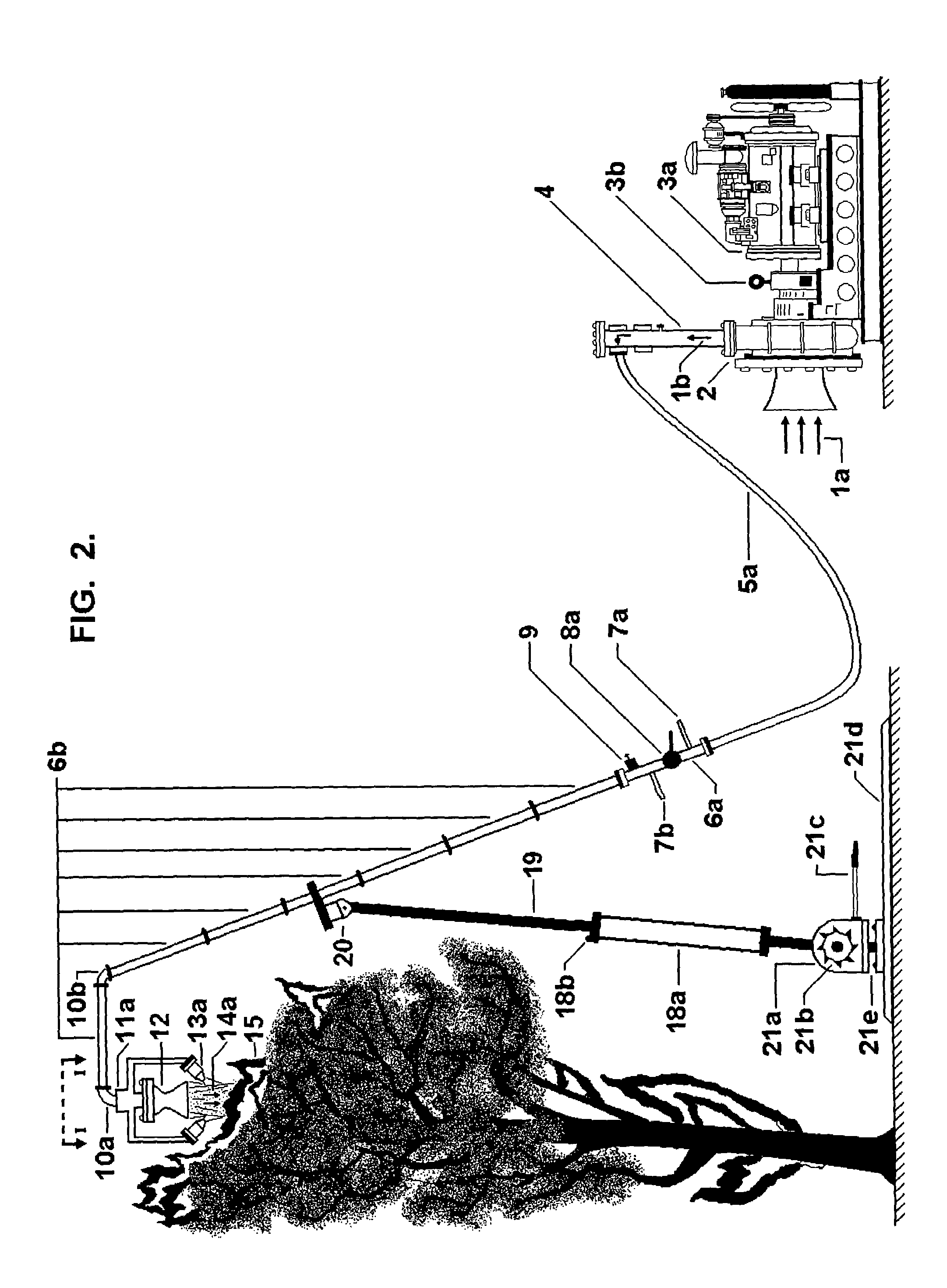

Ambient-air jet blast flames containment and suppression system

InactiveUS7028783B2Enhance improve suppressionImprove practicalitySpray nozzlesFire rescueShock waveWater vapor

In the fire location, an ambient or atmospheric air mass flow (been a gas mixture of dry air and superheated water vapor) is compressed by a compression package. A hose transports this compressed air mass flow a given distance away up to a flames site, where an arrangement of pipes, elbow accessories, throttle valves, nozzles, and a distribution manifold, conforming together a fire fight boom with a “blast-gun”, allow the operator to direct upon the flames, a high speed ambient air jet containing water droplets with a high flame front aerodynamic penetration capability, which brings about the flames blown off and remaining not burned materials combustion inhibition. Such a high speed air jet containing water droplets is generated by the compressed air mass flow expansion in a jacketed convergent-divergent nozzle, whereinto a condensation sock wave is established producing such water droplets from the local ambient air water vapor contents. The air jet proximity to the flames' origin is important, and the operator's movements can be controlled by a wheel, a pneumatic cylinder, supports, and pivoted anchors. To preclude, in this process, the inflammation of surrounding non burning materials and the existence of run-away flame fronts, different aerodynamic flame containment mechanisms are formed by other air jets produced in convergent nozzles air expansions. To allow the low temperatures required and the successful establishment of the condensation shock wave, a cooling air flow insulates, from the hot flame environment, the air flow expansion in the jacketed convergent-divergent nozzle. The aspersion mechanism formed by the air mass flow expansion, is utilized also to deliver different chemical fire fight agents to the flames sites with a high flame front penetration capability.

Owner:CELORIO VILLASENOR ARMANDO

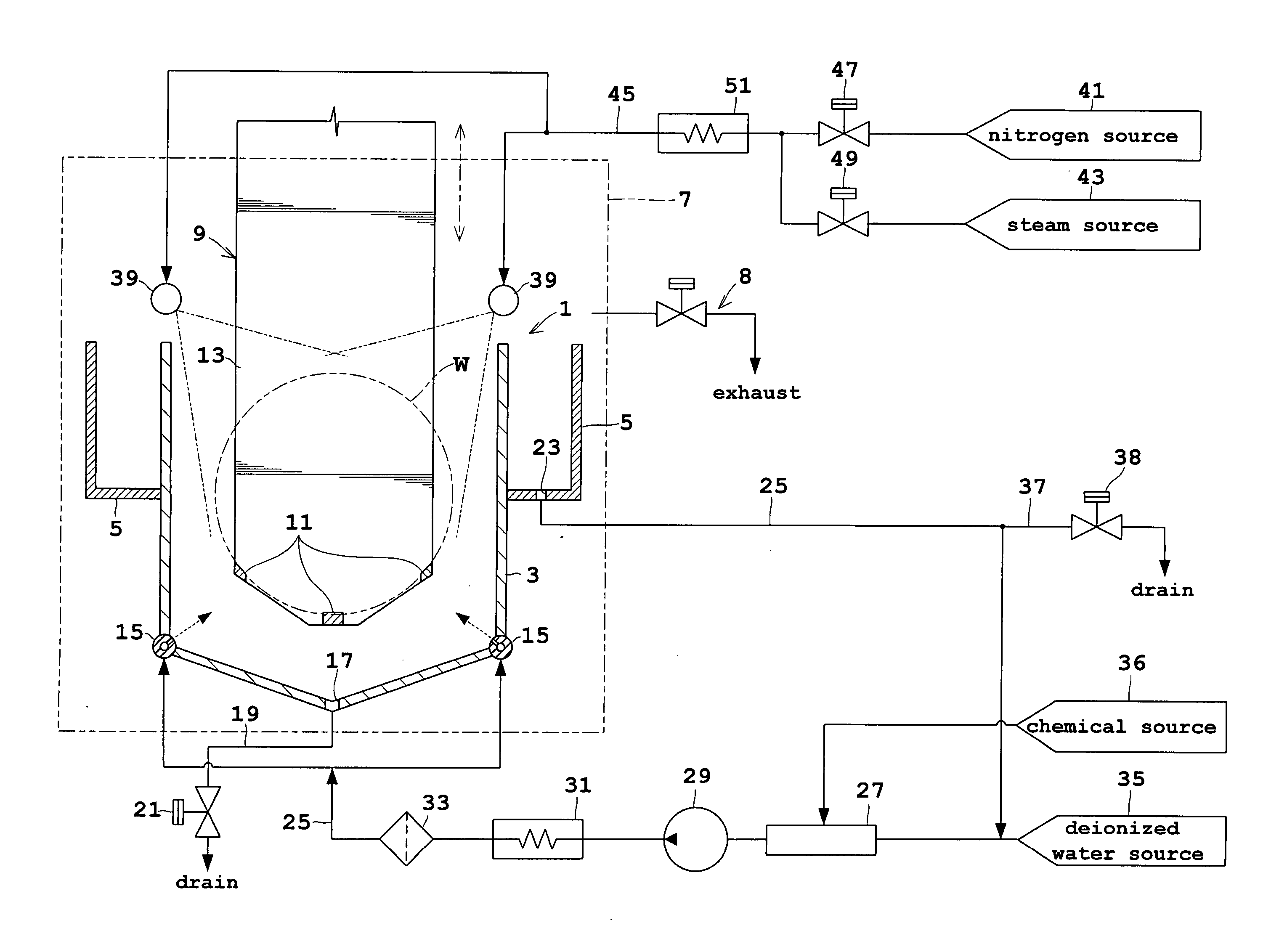

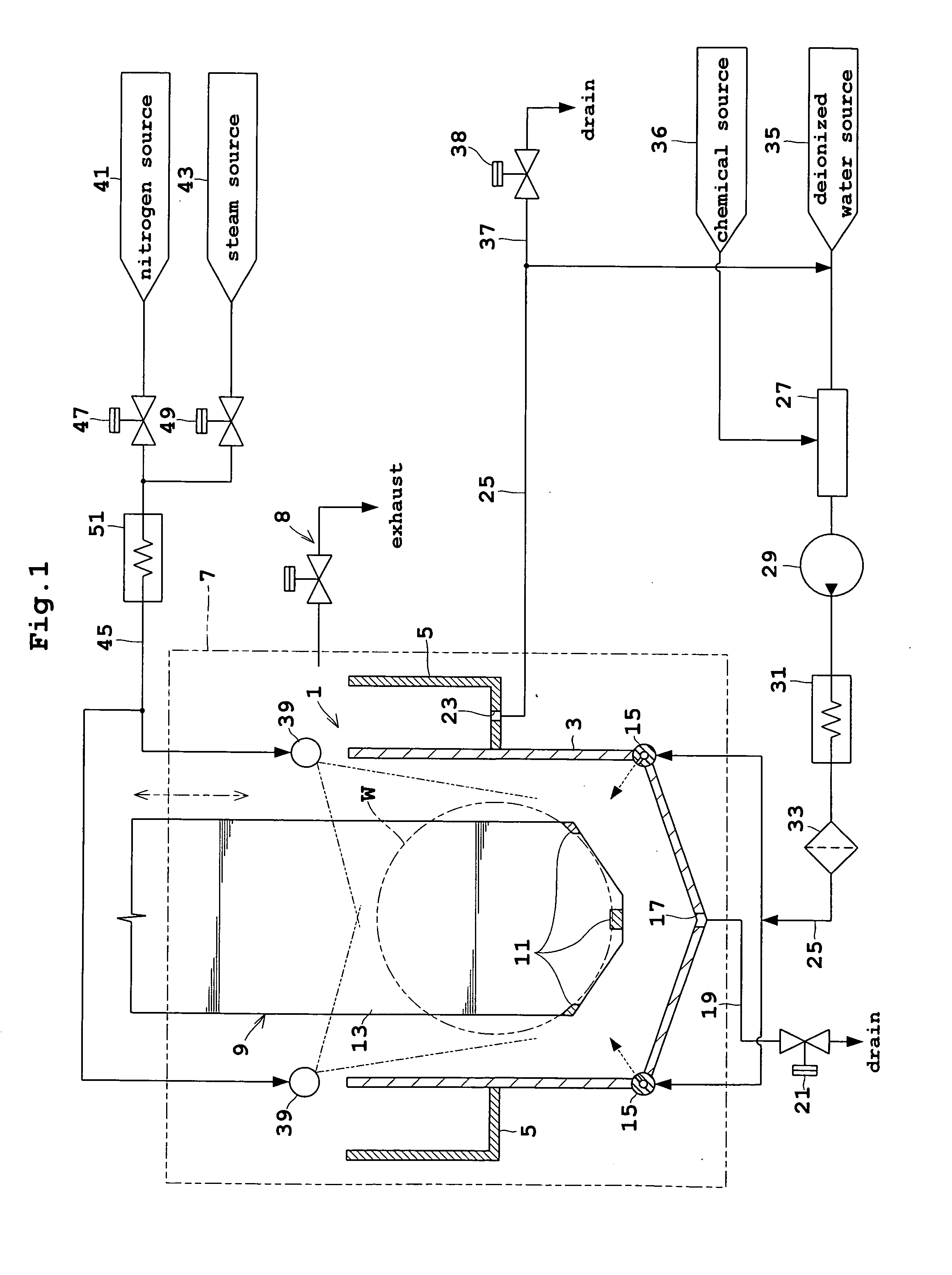

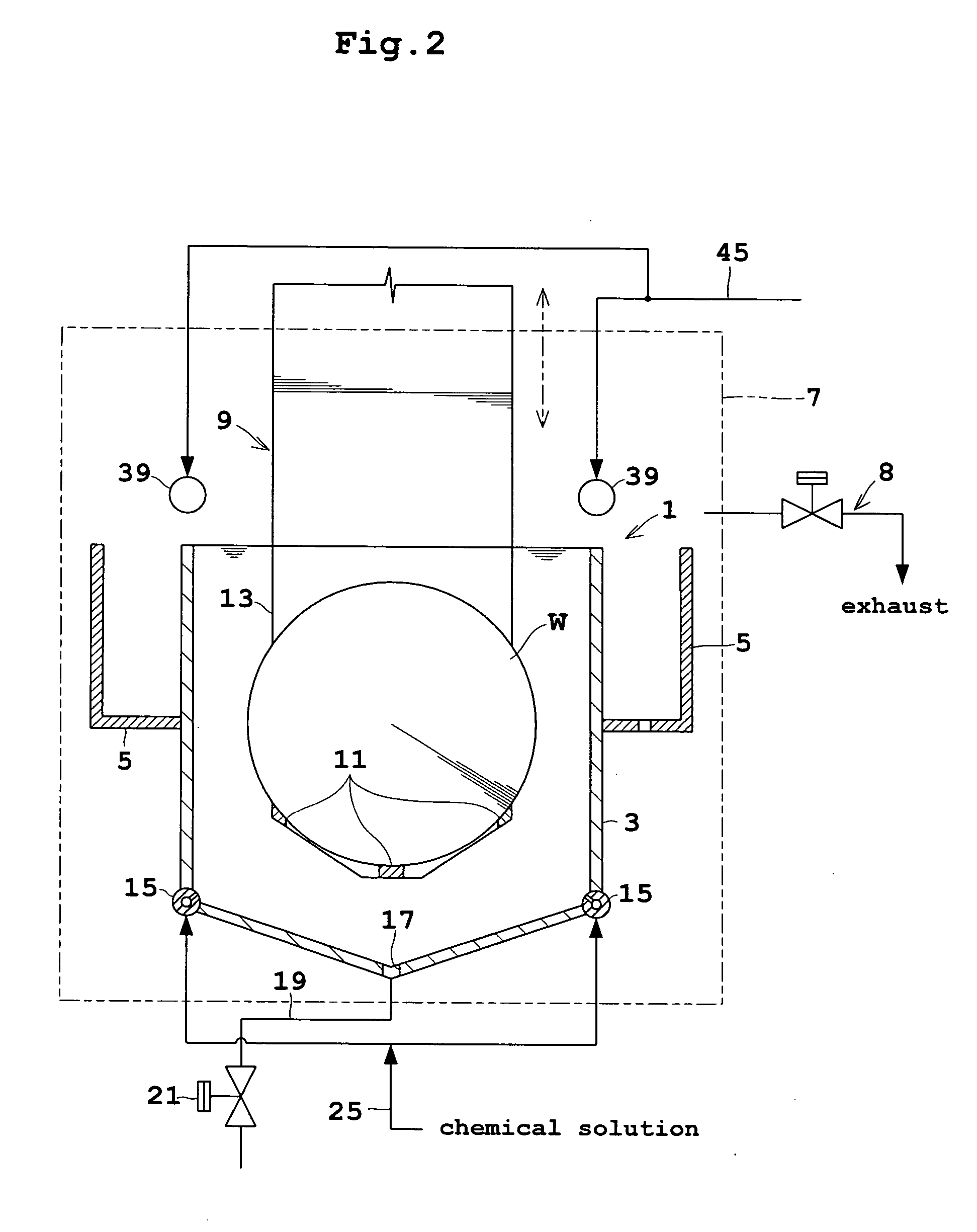

Substrate treating method and apparatus

InactiveUS20050236018A1Reduce consumptionEasy to cleanElectrostatic cleaningSemiconductor/solid-state device manufacturingChemical treatmentCompound (substance)

A substrate treating method for performing a predetermined treatment of substrates. The method includes a step of performing chemical treatment of the substrates with a chemical, and a step of performing deionized water cleaning treatment of the substrates with superheated steam obtained by heating deionized water.

Owner:DAINIPPON SCREEN MTG CO LTD

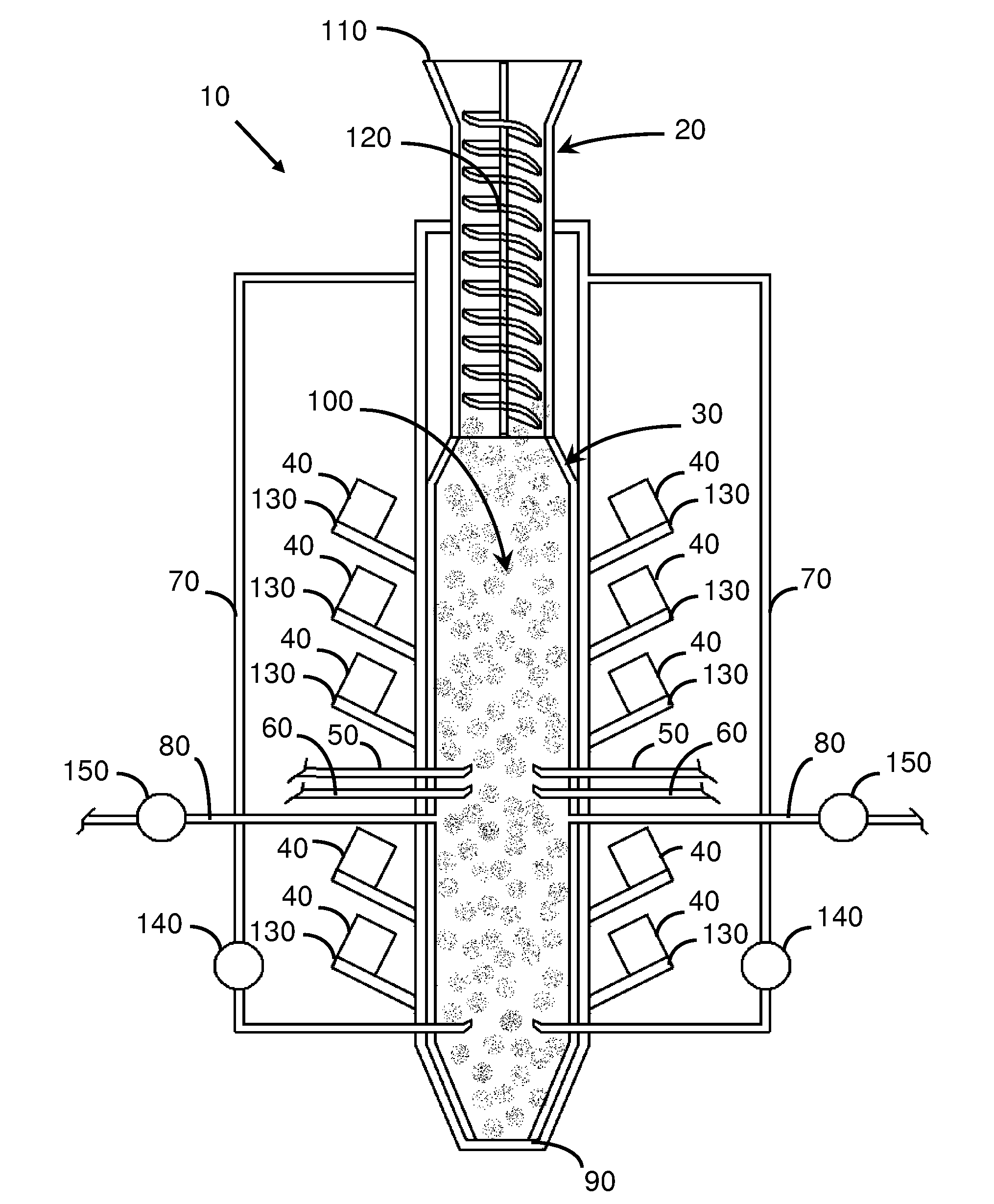

Biomass conversion process

InactiveUS20110232160A1Simple materialUsed economicallyLiquid carbonaceous fuelsLiquid hydrocarbon mixture productionSuperheated waterThermal water

Biomass material is converted into precursors for hydrocarbon transportation fuels by contacting the biomass with liquid superheated water or supercritical water to depolymerize and deoxygenate the biomass into the transportation fuel precursors. Temperatures above 200° C. and preferably above 300° C. are preferred with supercritical water at temperatures above 374° C. and pressures above 22 MPa providing a capability for higher conversion rates.

Owner:EXXON RES & ENG CO

Process for preparing granular active carbon

ActiveCN1634761AHigh surface areaHigh strengthCatalyst carriersCarbon compoundsPhosphoric acidSuperheated water

The present invention provides a method for preparing granular activated carbon, comprising the following steps: charring the granular or shaped shell under 400 to 500 degrees centigrade for 3 to 16 hours; under water vapour and superheated water vapour environment, carrying out a first activation, in which the activation temperature is 400 to 900 degrees centigrade, and the activation time is 6 to 16 hours, then a second activation, in which the activation temperature is 800 to 1200 degrees centigrade, and the activation time is 2 to 10 hours; cleaning the activated granular carbon with hydrochloric acid, nitric acid or phosphoric acid, wherein the said acid, the concentration is 0.1-20% by wt, the cleaning temperature is 50 to 120 degrees centigrade, and the cleaning time is 0.2 to 16 hours; washing the granular carbon cleaned by acid in the foremenioned step with deionized water to be neutral, then drying and screening it to obtain finished activated carbon. The activated carbon prepared from the present invention has both superior specific surface and superior strength, is especially suitable for serving as support of the supported catalyst.

Owner:CHINA PETROLEUM & CHEM CORP

Biomass oil conversion process

ActiveUS20110232161A1Effective resourcesInexpensive materialsSolid fuelsHydrocarbon from oxygen organic compoundsSuperheated waterThermal water

Biomass pyrolysis oil is converted into precursors for hydrocarbon transportation fuels by contacting the oil with liquid superheated water or supercritical water to depolymerize and deoxygenate the components of the oil and form the transportation fuel precursors. Temperatures above 200° C. and preferably above 300° C. are preferred with supercritical water at temperatures above 374° C. and pressures above 22 MPA providing the capability for fast conversion rates.

Owner:EXXON RES & ENG CO

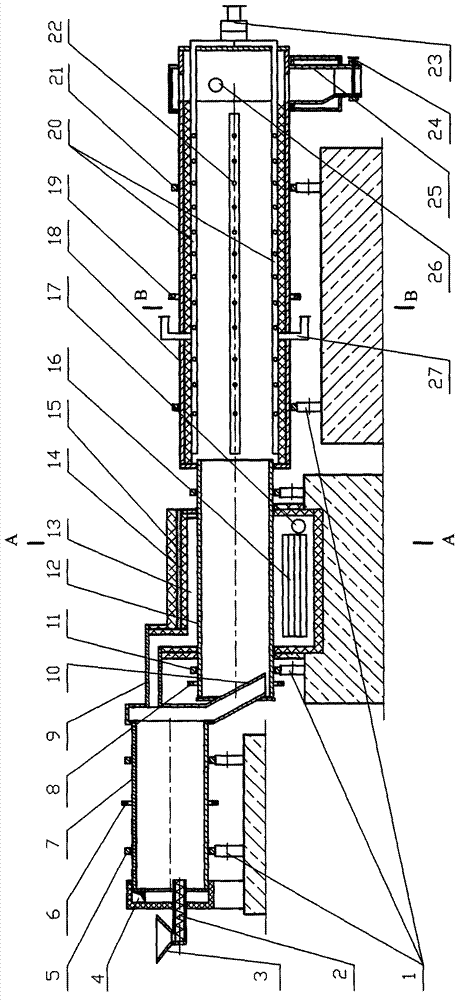

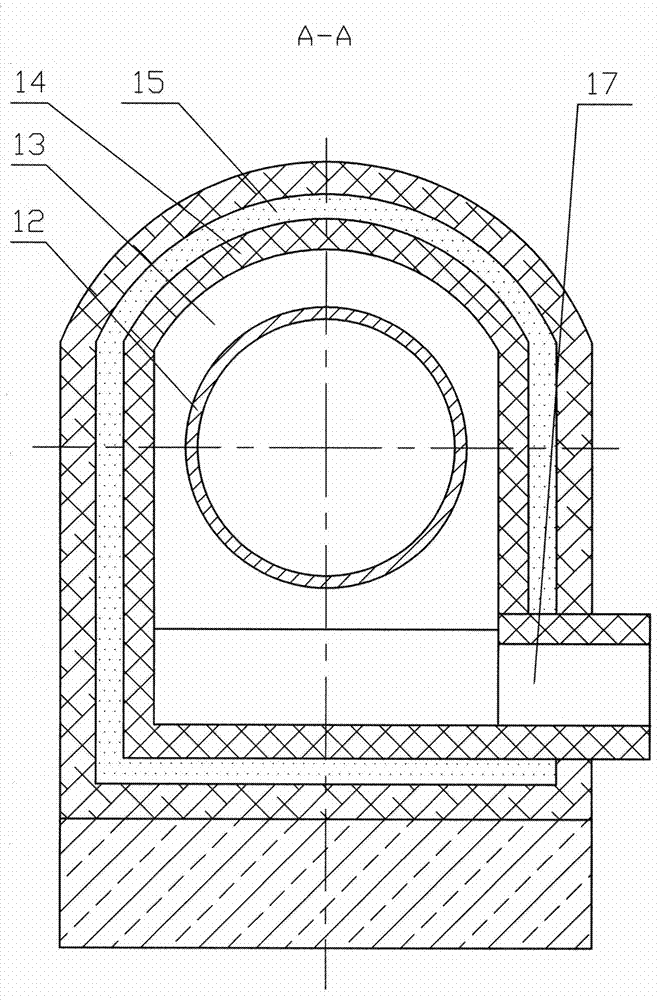

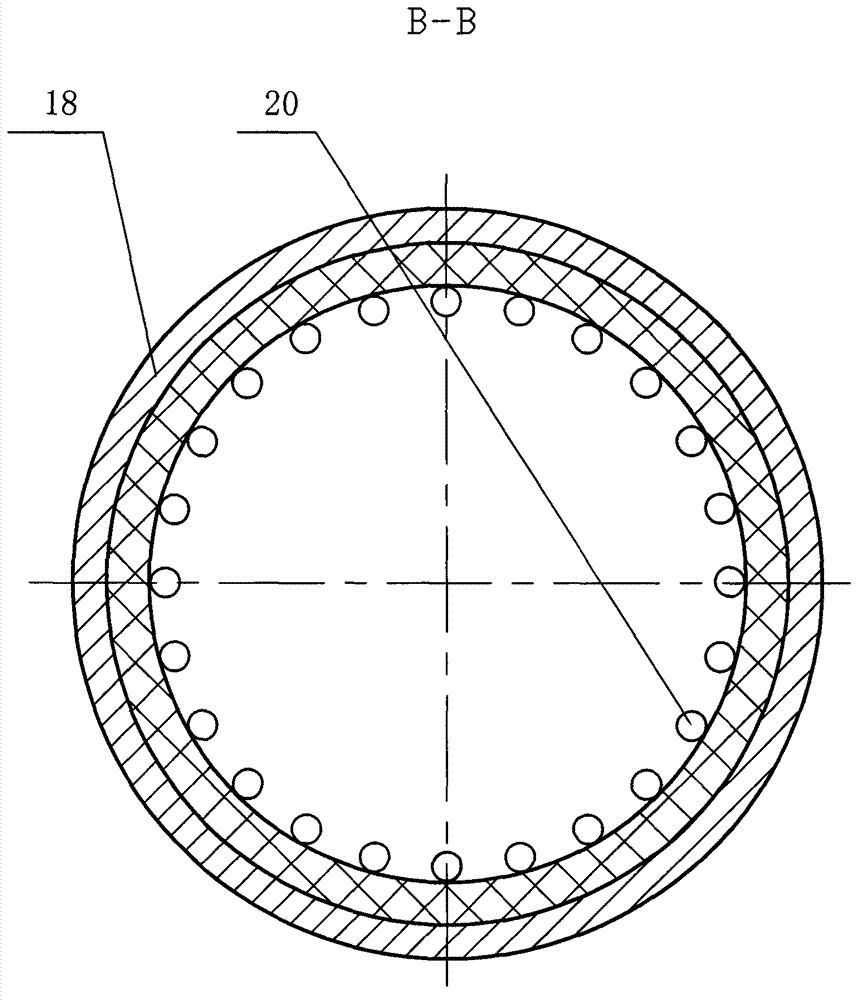

Technique for preparing activated carbon from wood raw material by external-heating-free one-step process and carbon activating device

The invention provides a technique for preparing activated carbon from a wood raw material by an external-heating-free one-step process and a carbon activating device. An internal-heating drying converter, an external-heating carbonization converter and an internal-heating activating converter are utilized to prepare the activated carbon; the wood raw material is dried in the internal-heating converter to remove moisture by using heating exhaust of the external-heating carbonization converter; the generated water vapor is discharged via a chimney came along the drying medium, thereby avoiding influencing the flammability since the water vapor is mixed with the combustible gas generated during carbonization; the dried raw material falls into the external-heating carbonization converter to perform carbonization, wherein the heating medium is high-temperature activated exhaust from the activating converter; the combustible gas generated in the carbonization process is introduced into the activating converter; the inner wall of the activating converter is also provided with a vapor pipe; a right amount of superheated water vapor can be introduced to perform activating reaction with carbon at high temperature so as to generate hydrogen, carbon monoxide and other combustible gases; the inner wall of the activating is provided with an air pipe; and a proper amount of air can be introduced to combust the combustible gas, thereby keeping the activating temperature.

Owner:ZHEJIANG FORESTRY ACAD

High efficiency low pollution hybrid brayton cycle combustor

InactiveUS20060064986A1Increase horsepowerFast accelerationEfficient propulsion technologiesGas turbine plantsHybrid typeCombustion chamber

A power generating system and method operating at high pressure and utilizing a working fluid consisting of a mixture of compressed non-flammable air components, fuel combustion products and steam. The working fluid is substantially free of CO and NOx. Fuel and compressed air at an elevated temperature and at a constant pressure are delivered to a combustion chamber, the amount of air being chosen so that at least about 90% of the oxygen in the air is consumed during combustion. The quantity of air and fuel supplied to the combustion chamber may be varied provided a constant fuel to air ratio is maintained. Superheated water is delivered under pressure to the combustion chamber, and is converted substantially instantaneously to steam. The quantity of water delivered is controlled such that the latent heat of vaporization of the water maintains the temperature of the working fluid at a desired level. Heat may be transferred from the working fluid exiting the work engine to the water to heat the water to the desired temperature for delivery to the combustion chamber. The quantity, temperature and pressure of the air, fuel and water introduced in to the combustion chamber are independently controllable. A zoned burner may be employed in which a portion of the compressed air may be mixed with the fuel in a first zone prior to ignition, with the remaining compressed air being added at one or more locations downstream of the point of ignition.

Owner:GINTER J LYELL +1

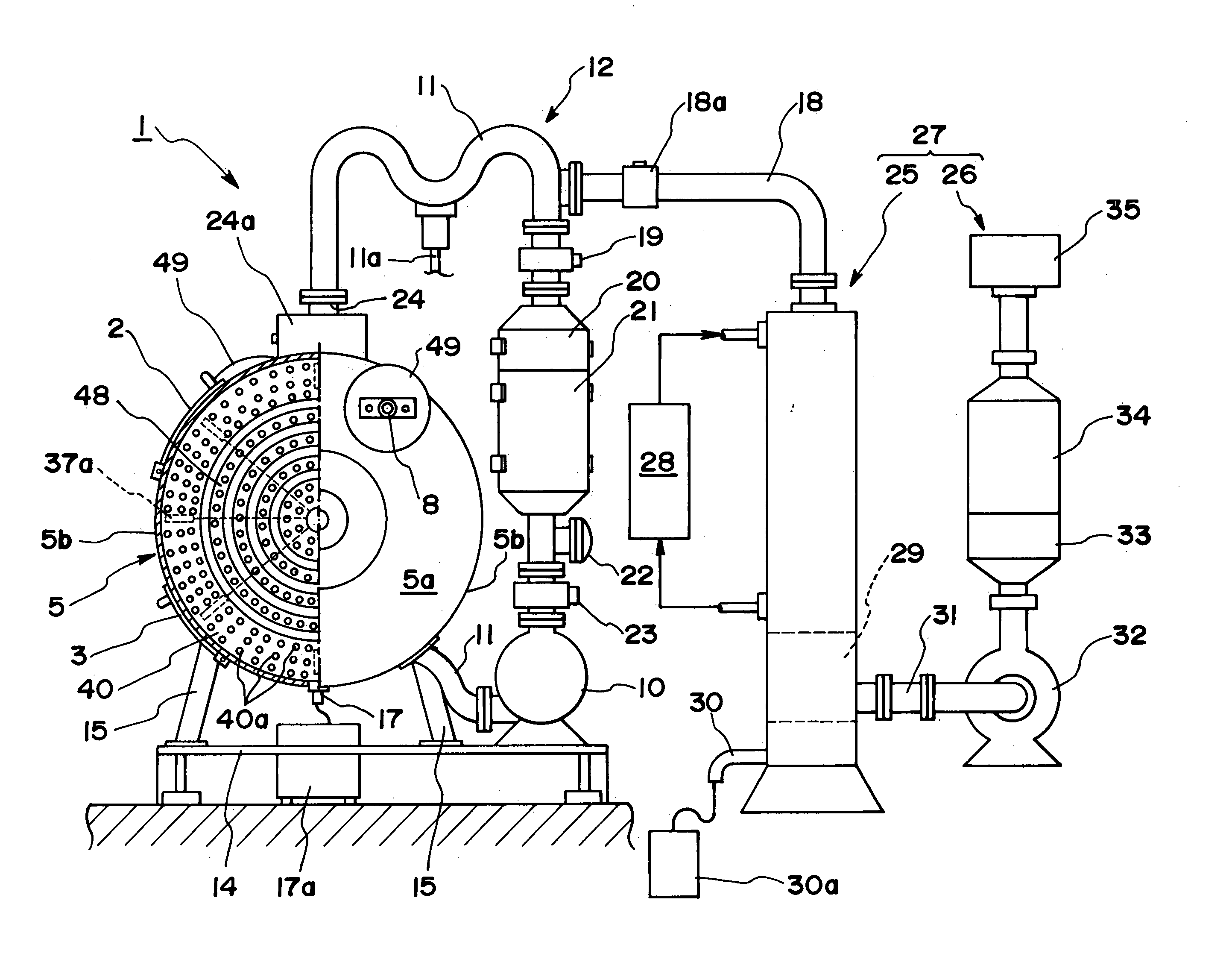

Method and apparatus for plasma gasification of carbonic material by means of microwave radiation

A method and apparatus for gasifying carbonic material in order to produce carbon monoxide and hydrogen; the method comprises the following steps: (a) providing carbonic material; (b) heating, by means of microwave radiation, the carbonic material provided until a plasma point cloud forms in the carbonic material; (c) causing the cloud of plasma points of carbonic material to react with superheated water vapour in order to produce a synthesis gas; and (d) purifying the produced synthesis gas by refeeding it through the cloud of plasma points in the carbonic material wherein it is broken up by microwave radiation of step (b) to achieve the generally complete transformation of the synthesis gas into carbon monoxide and hydrogen. Additionally the cloud of plasma points reacts with oxidation gas (air, oxygen or gas enriched with oxygen) in order to produce the synthesis gas.

Owner:ABA RES DE

Recycled food processing, products therefrom, and devices useful therein

InactiveUS20150164109A1Improve securityAnimal feeding stuffWorking-up animal fodderAnimal foodFood borne

Food waste is converted into animal food by feeding it to insects and then processing the insects into animal food. Biological hazards that may be present in the food waste, the insects, or both is reduced by treating, preferably with superheated water. Data related to the food waste and the insect crops is maintained in a database, allowing for process monitoring and control, and tracking, especially in the case of a food-borne illness that may have contaminated the food waste.

Owner:RUBEN BRADLEY N

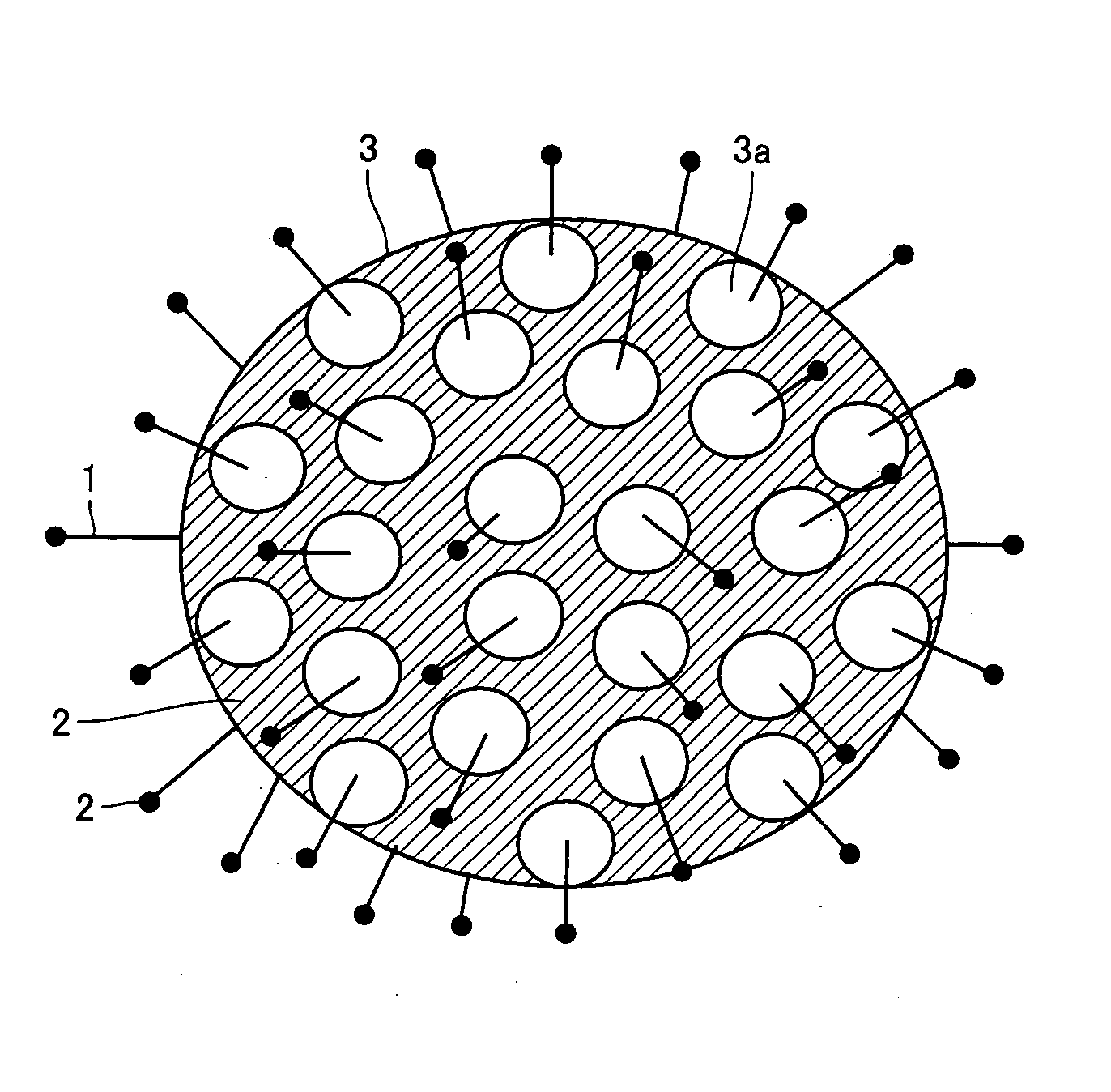

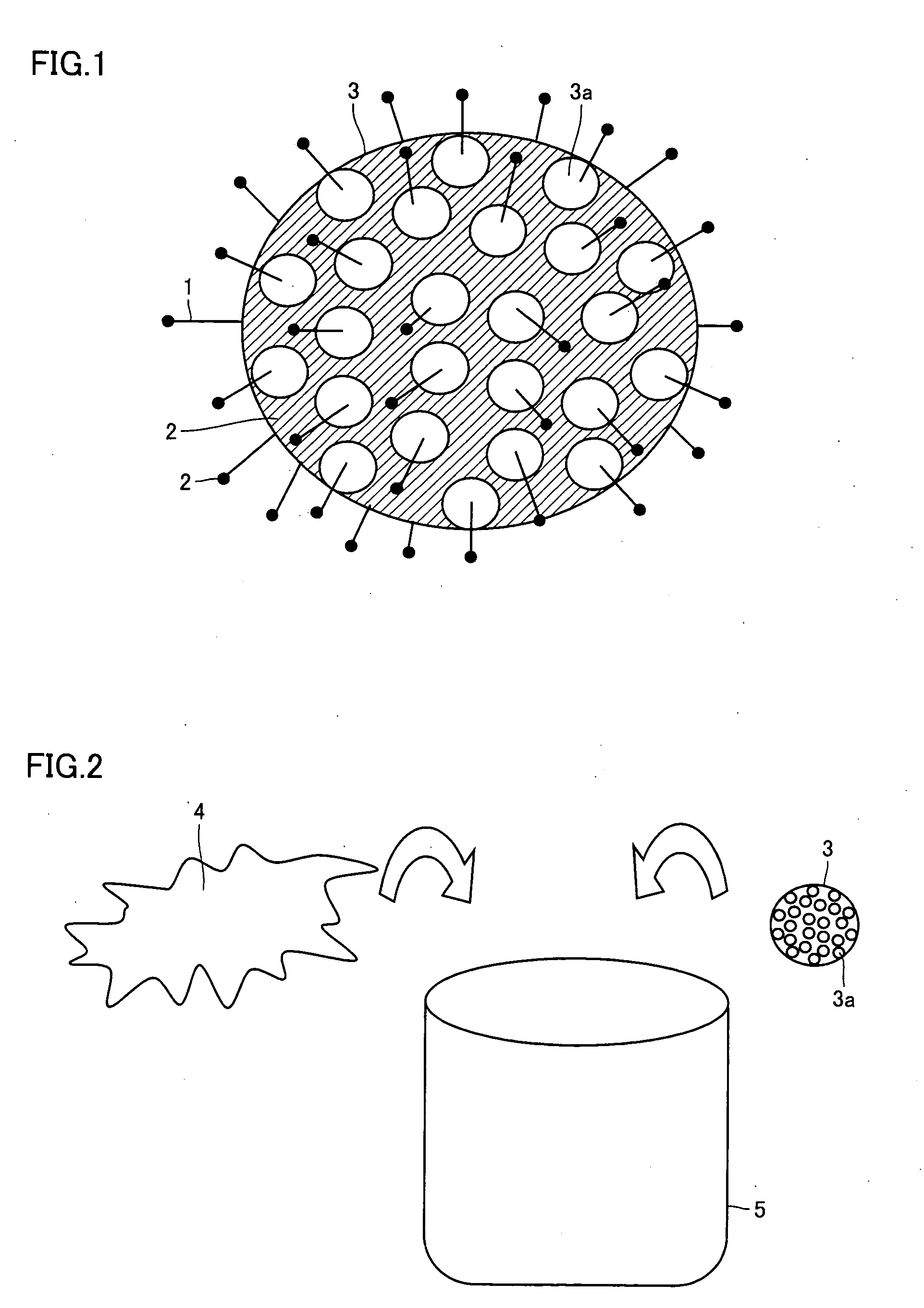

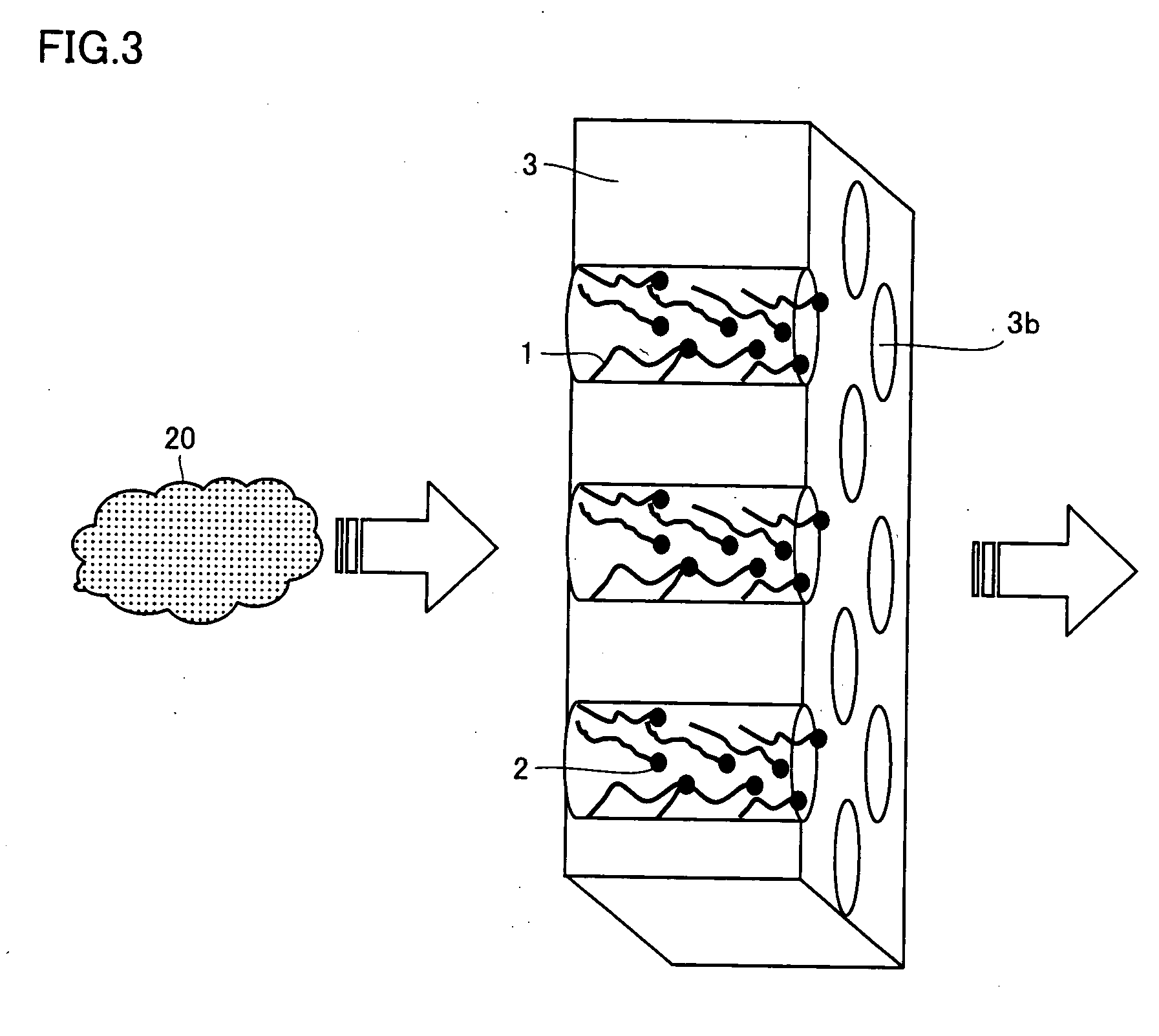

Adsorbent, porous filter, air cleaning device, method of cleaning air, and method of manufacturing porous filter

InactiveUS20060133975A1Not deformEfficient removalMaterial nanotechnologyGas treatmentHazardous substanceDecomposition

An adsorbent including a porous member having holes and a nanostructure formed on at least a portion of a surface of the porous member, and an air cleaning device including the adsorbent. A porous filter including a porous member having holes and a nanostructure formed on at least a portion of a surface of the porous member, and an air cleaning device including the porous filter. A method of cleaning air for decomposing a hazardous substance using the porous filter and a decomposition gas including a superheated water vapor. A method of manufacturing a porous filter including the steps of growing a nanostructure on at least a portion of a surface of a porous member having holes, allowing a catalyst particle to be contained in a dispersion gas including a superheated water vapor, and spraying the dispersion gas on a surface of the nanostructure to attach the catalyst particle thereto.

Owner:SHARP KK

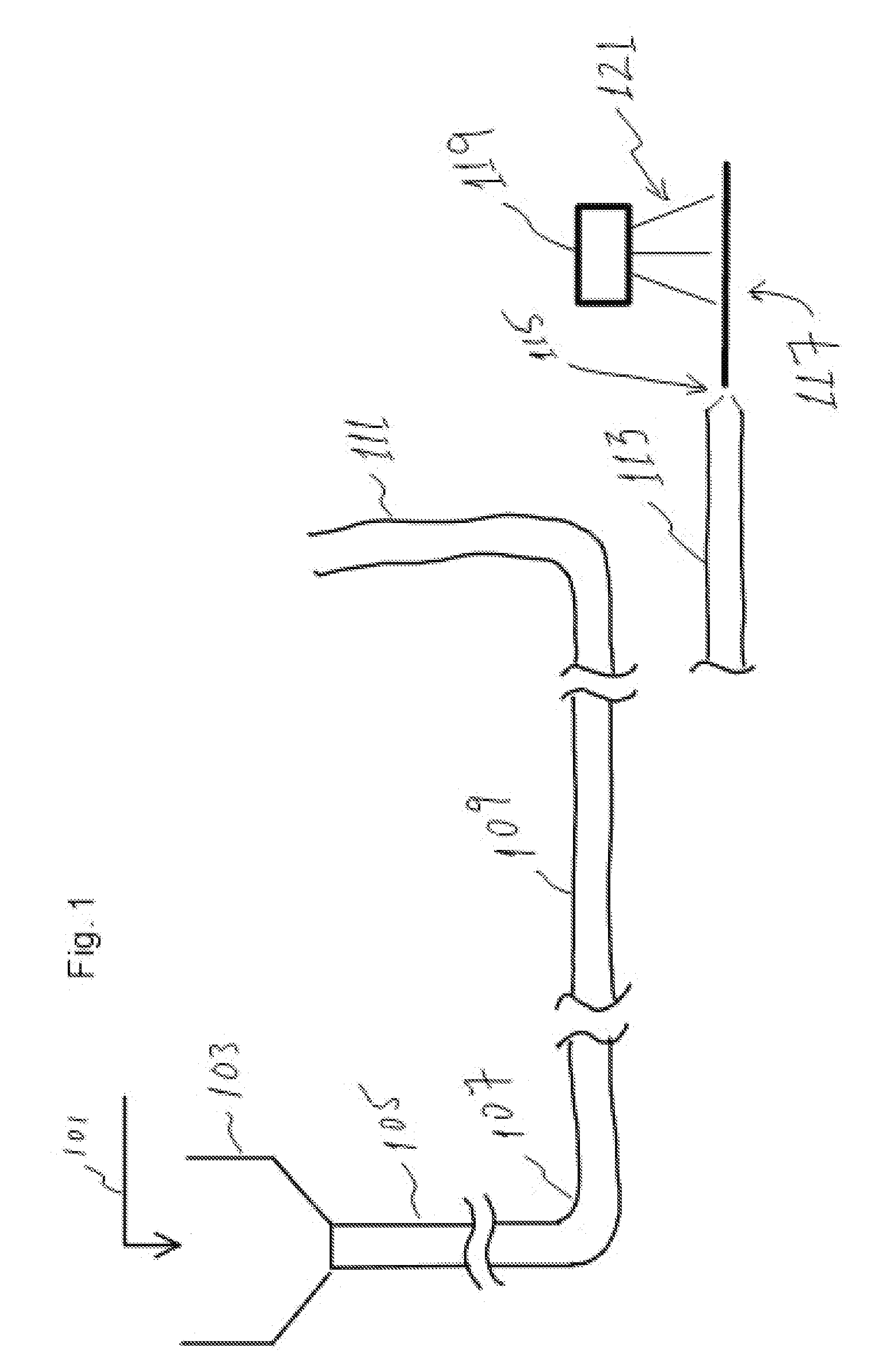

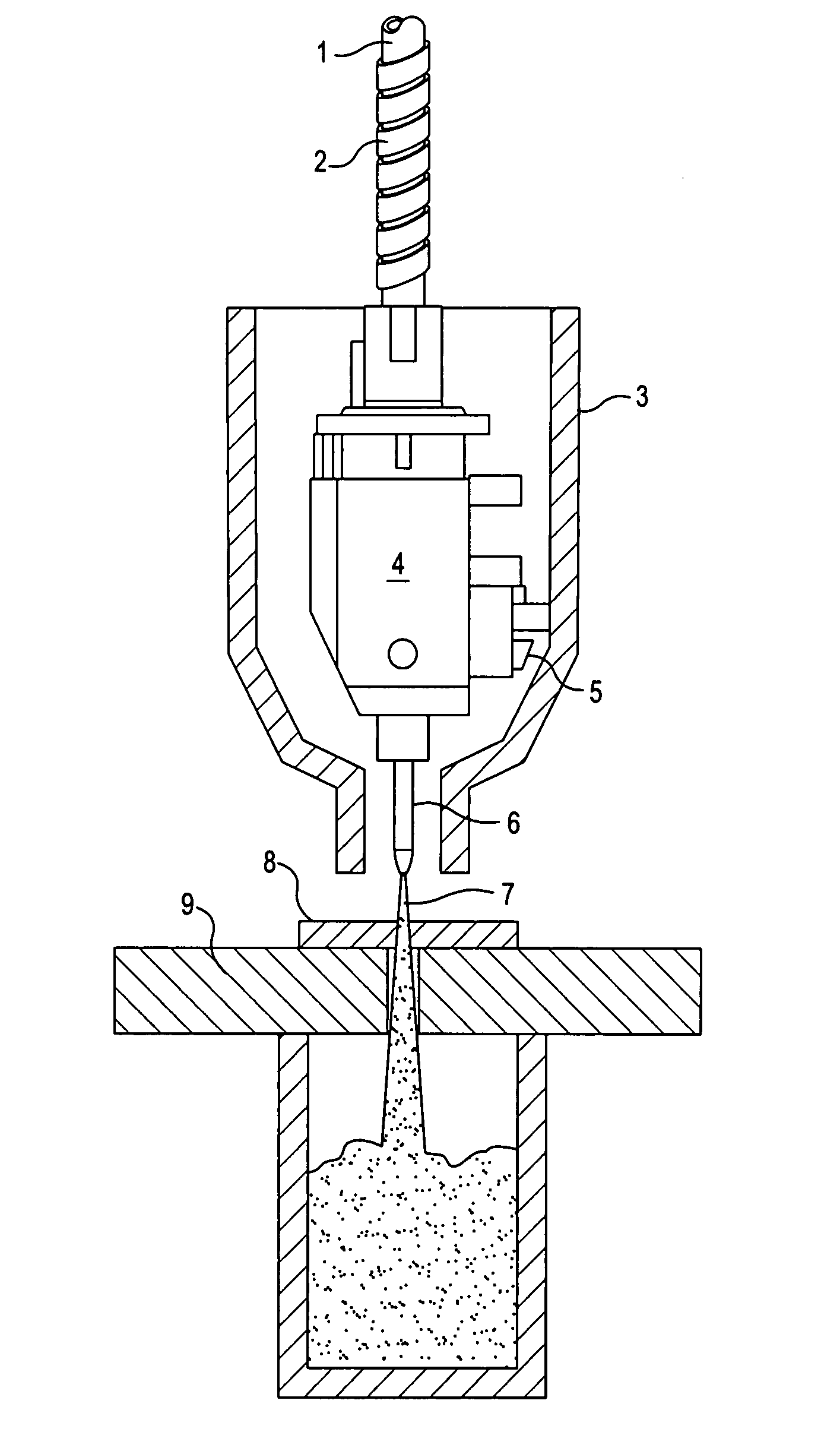

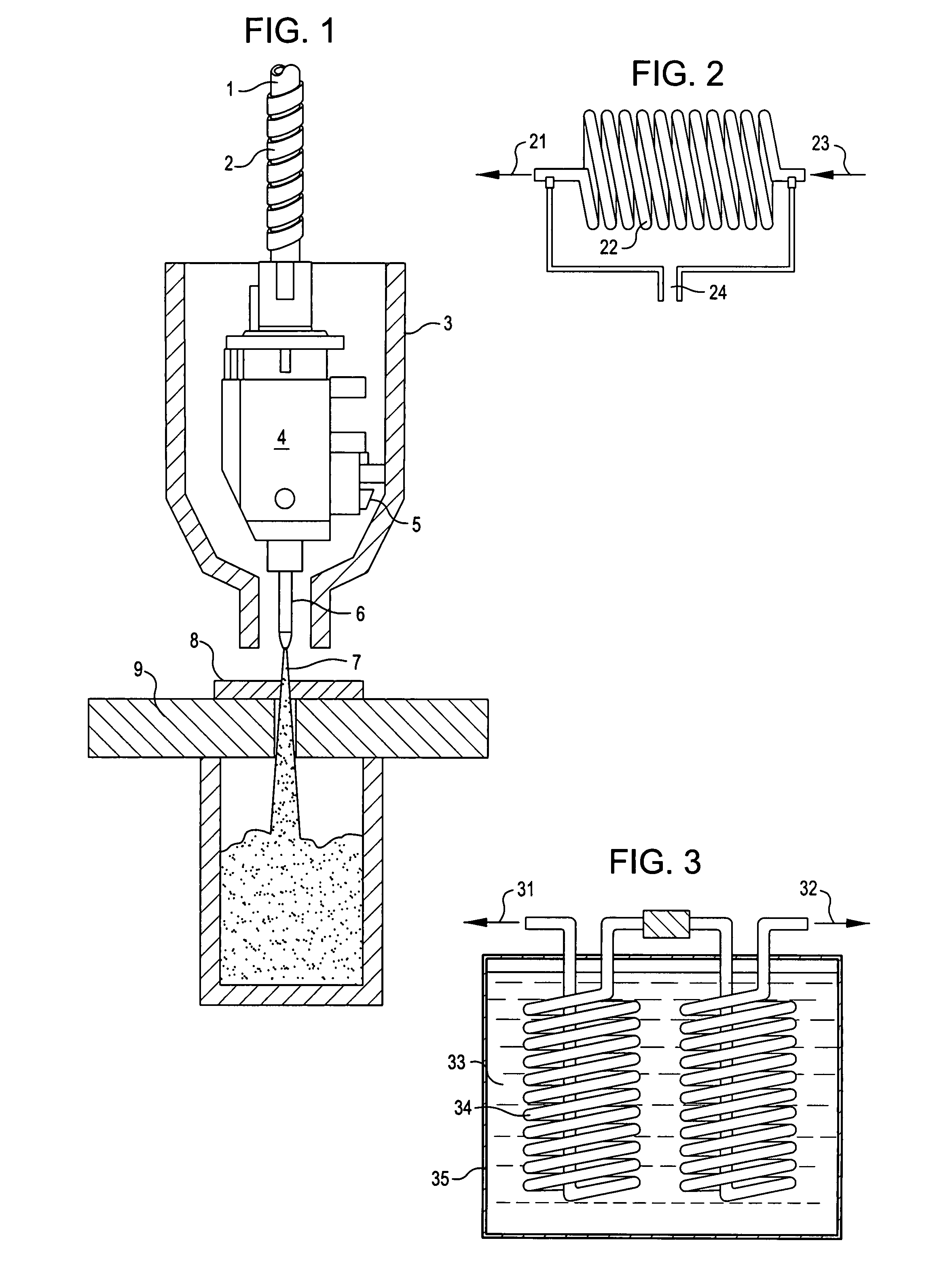

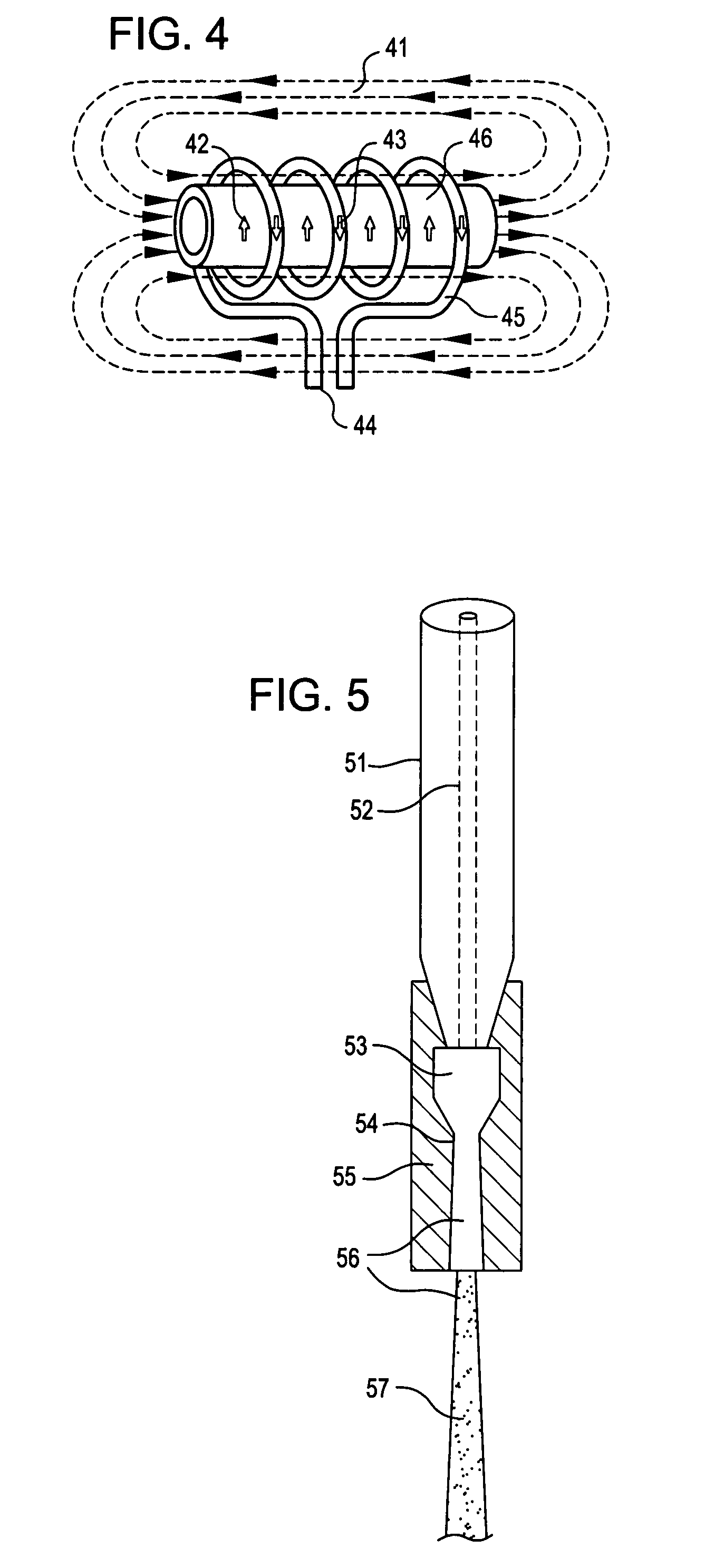

Flash vaporizing water jet and piercing with flash vaporization

ActiveUS7815490B2Minimizing nonuniform secondary damageMore portableGrinding feed controlAutomatic grinding controlLiquid jetSlurry

A flash vaporizing liquid jet cutting tool and method for piercing with minimal damage to the cut material. The liquid is preferably superheated water, typically with abrasive particles added after the jet is expressed through a nozzle (abrasive water jet, AWJ) or with abrasive particles added before the jet is expressed through a nozzle (abrasive slurry jet, ASJ). In piercing, only a portion of water that has not changed phase enters into the cavity or must leave the cavity and the piercing pressure, which can damage the material, is therefore reduced.

Owner:OMAX CORP (US)

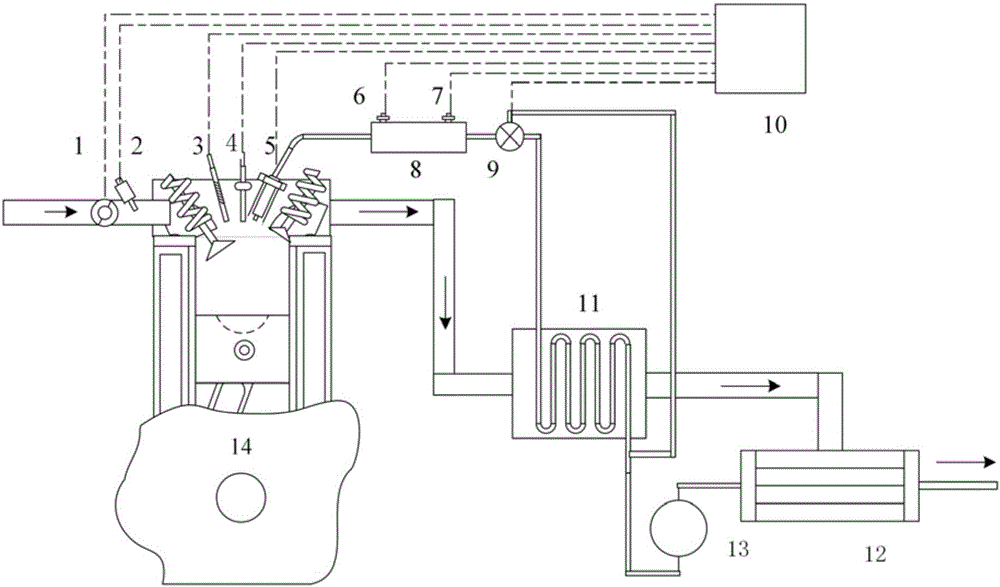

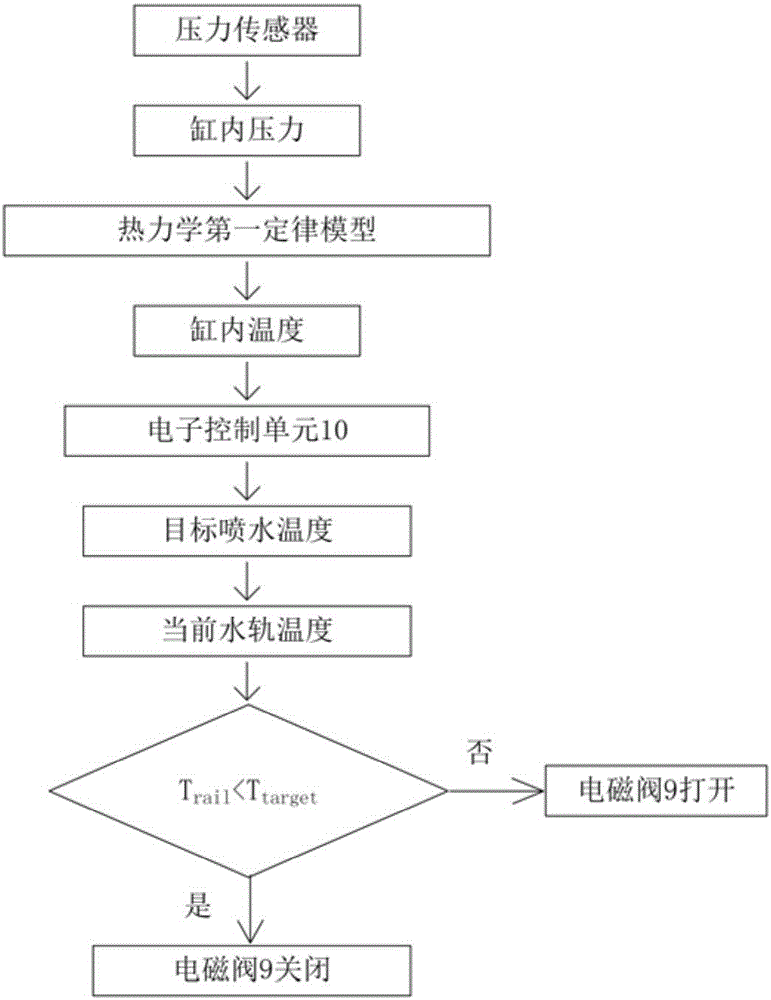

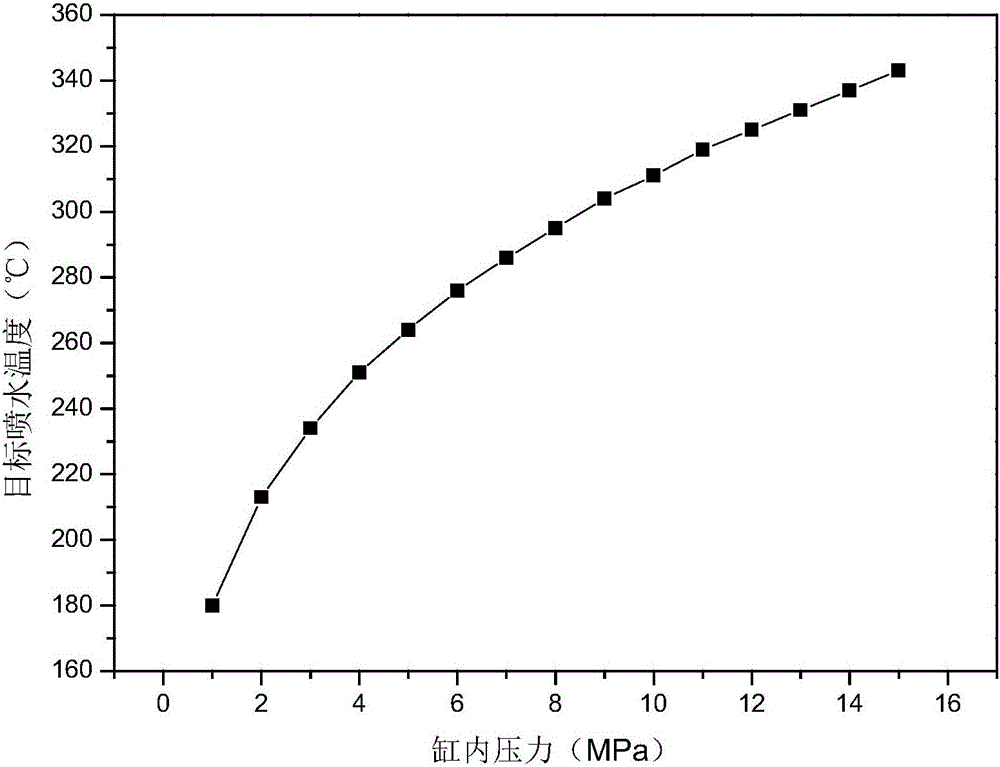

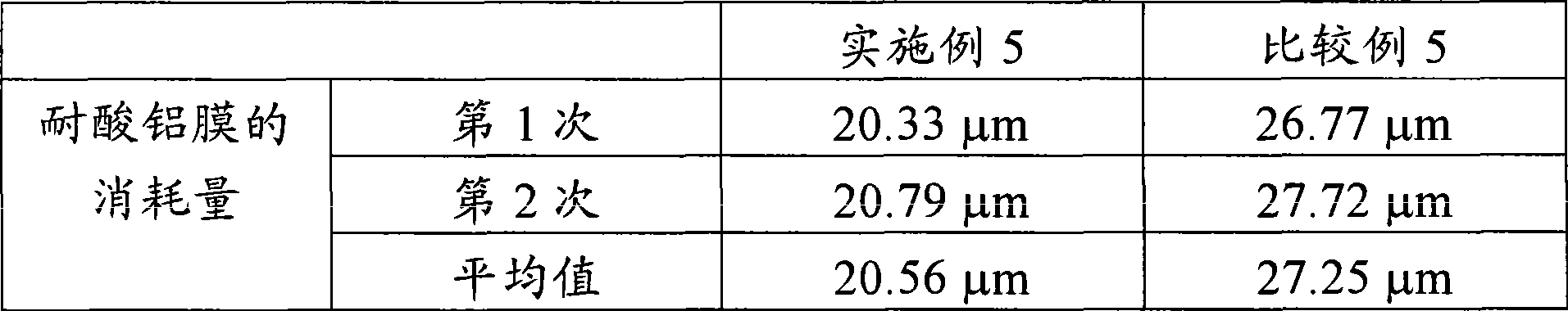

Internal combustion engine structure with superheated water being sprayed into cylinder

ActiveCN106677926AHigh thermal efficiencyAvoid dilutionNon-fuel substance addition to fuelInternal combustion piston enginesSprayerEngineering

The invention relates to an internal combustion engine structure with superheated water being sprayed into a cylinder. The internal combustion engine structure with the superheated water being sprayed into the cylinder comprises an internal combustion engine cylinder block, a throttle valve, an oil sprayer, a sparking plug and a water spraying nozzle and further comprises a condenser, a heat exchanger, a three-way electromagnetic valve, a high-pressure water rail and an electronic control unit. The condenser is connected to the exhaust output end of the internal combustion engine cylinder block. The output end of the condenser is connected with the heat exchanger and a first input end of the three-way electromagnetic valve. The output end of the heat exchanger is connected with a second input end of the three-way electromagnetic valve. The output end of the three-way electromagnetic valve is connected with the high-pressure water rail. The high-pressure water rail is connected with the water spraying nozzle. According to the internal combustion engine structure with the superheated water being sprayed into the cylinder, the high-pressure superheated water is sprayed into the cylinder, high-temperature steam is formed through flashing boiling of the superheated water, heat in the cylinder is further absorbed, the superheated water is used as an extra work doing medium, and the heat efficiency of an internal combustion engine system is improved; a control model is established to achieve real-time calculation of the pressure and temperature inside the cylinder, so that it can be guaranteed that the water sprayed into the cylinder is in the superheated state, and therefore the heat efficiency of the internal combustion engine is improved.

Owner:TONGJI UNIV

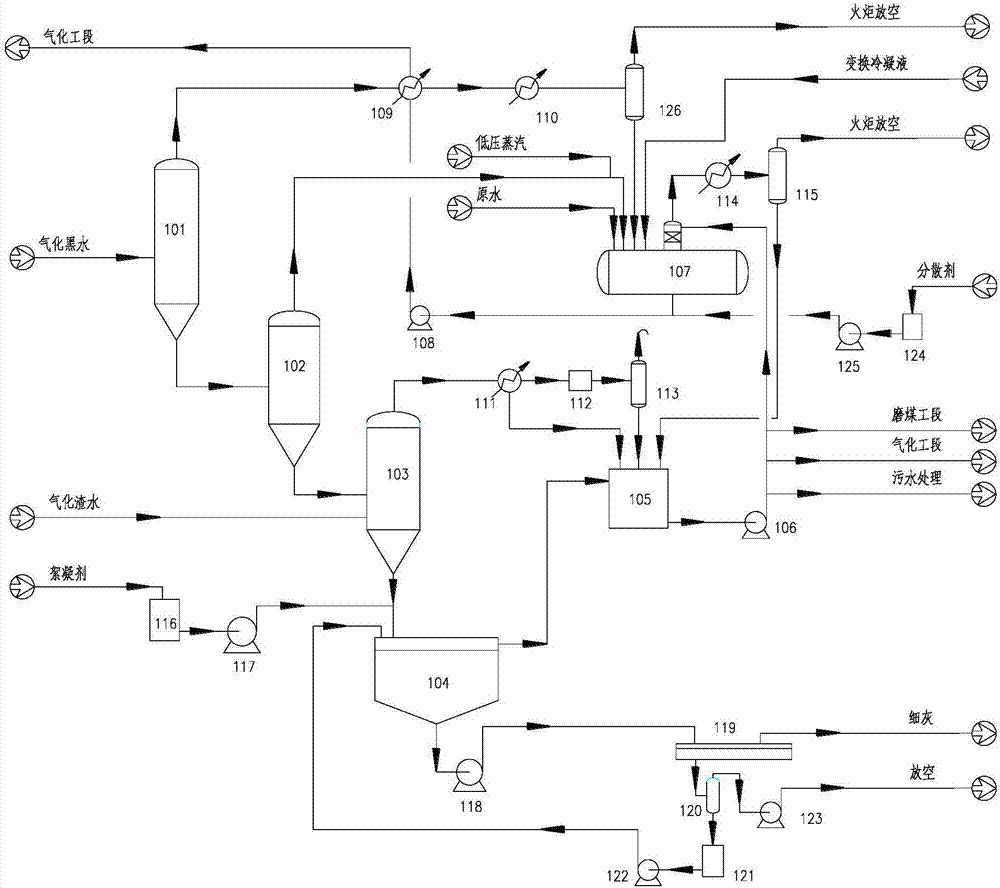

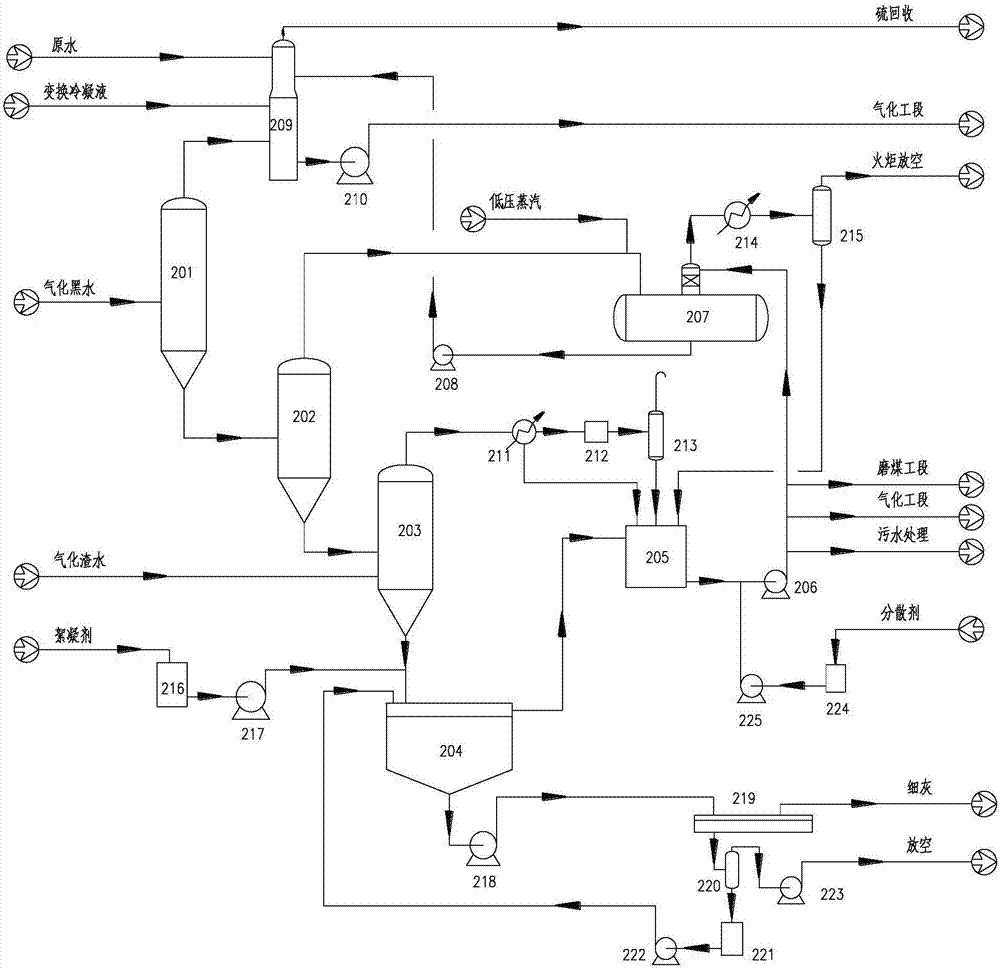

Coal gasification black water and grey water treatment system and method with high heat recovery efficiency

PendingCN106946394AImprove recycling efficiencyReduce indirect heat exchange equipmentSpecific water treatment objectivesTreatment involving filtrationBlackwaterWater treatment system

The invention relates to a coal gasification black water and grey water treatment system with high heat recovery efficiency. The treatment system is characterized in that grey / black water from a gasification segment is subjected to three-stage flash evaporation treatment, namely, high-pressure flash evaporation, low-pressure flash evaporation and vacuum flash evaporation, and direct heat exchange is performed through a hot water tower. In the coal gasification black water and grey water treatment system disclosed by the invention, direct heat exchange equipment is provided, so that indirect heat exchange equipment is omitted, the heat recovery efficiency is increased, and the energy utilization rate is increased; meanwhile, the equipment quantity and work flow are simplified on the whole, so that the equipment blocking risk is lowered, and the equipment overhauling workload is greatly lowered. The invention further provides a coal gasification black water and grey water treatment method with high heat recovery efficiency.

Owner:BEIJING QING CHUANG JIN HUA TECH CO LTD

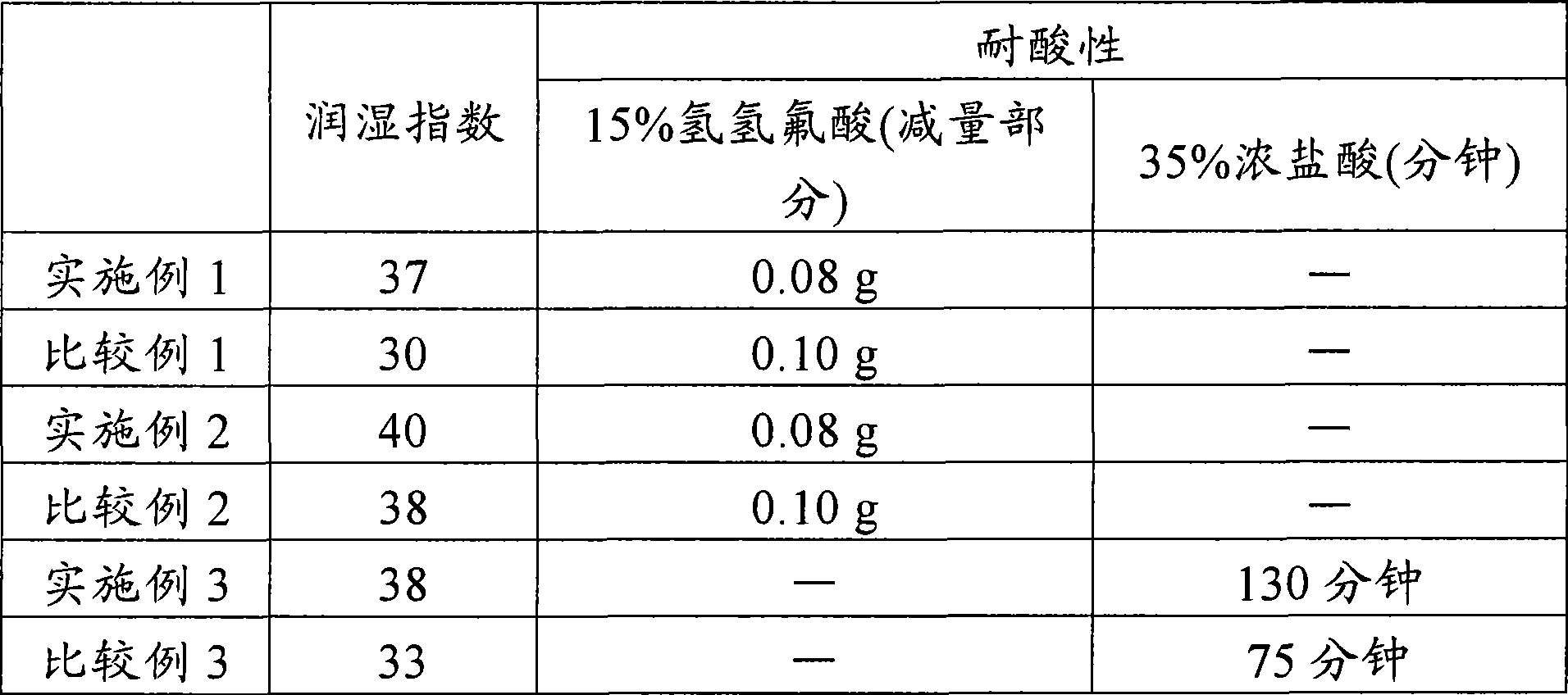

Corrosion-resistant member and method for producing the same

InactiveCN101522946APrevent adhesionExtend your lifeAnodisationMolten spray coatingGas phaseSuperheated water

Disclosed is a corrosion-resistant member which is high in acid resistance, plasma resistance and hydrophilicity. Also disclosed is a method for producing such a corrosion-resistant member. A corrosion-resistant member having high acid resistance, plasma resistance and hydrophilicity is obtained by surface-treating an object member (such as ceramics and metals) by spraying a superheated water vapor at a temperature of 300-1000 DEG C. The corrosion-resistant member may be a member which is in contact with a processing space within a vapor-phase surface treatment apparatus (such as a chamber) for surface-treating a base material by a vapor-phase process such as PVD, CVD or dry etching.

Owner:CANAAN PRECISION

Multistage double effect distillation seawater desalination technology with heating seawater by solar energy

InactiveCN102190340AIncrease productionRelieve pressureGeneral water supply conservationSeawater treatmentDistillationEngineering

The invention relates to a multistage double effect distillation seawater desalination technology with heating seawater by solar energy. The technology comprises the following steps: seawater is delivered to a high cistern by a seawater pump; the seawater in the high cistern is delivered to a system for water supply through a water supply tube and a condenser inlet tube; the seawater is heated to a certain temperature by adsorbing latent heat of steam in an evaporator through all condensers of the system, and enters the evaporator after being heated to a designed temperature by a rapid heater with solar energy; the seawater enters the evaporator, becomes superheated water and is gasified rapidly and partially because a pressure in the evaporator is controlled to be lower than a saturation vapor pressure corresponding to a temperature of hot seawater; and a part of ungasified hot seawater enters a next stage evaporator and a part enters heat-collecting tubes at two sides of the evaporator. The heat-collecting tubes are provided with annular imbibition films, and the hot seawater flows from top to bottom after entering the heat-collecting tubes. In a flow process, the hot seawater is delivered to upper half parts of inner cavities of the heat-collecting tubes because of capillary imbibition actions of the imbibition films. The hot seawater is evaporated to steam because the heat-collecting tubes have a high temperature under the sunlight, the steam rises along the inner cavities of the heat-collecting tubes and enters the condenser to obtain fresh water which flows into a fresh water tank and then is output by a fresh water tube. Unevaporated concentrated seawater enters a concentrated water tank and is ouput by an inlet / outlet tube.

Owner:孙元新

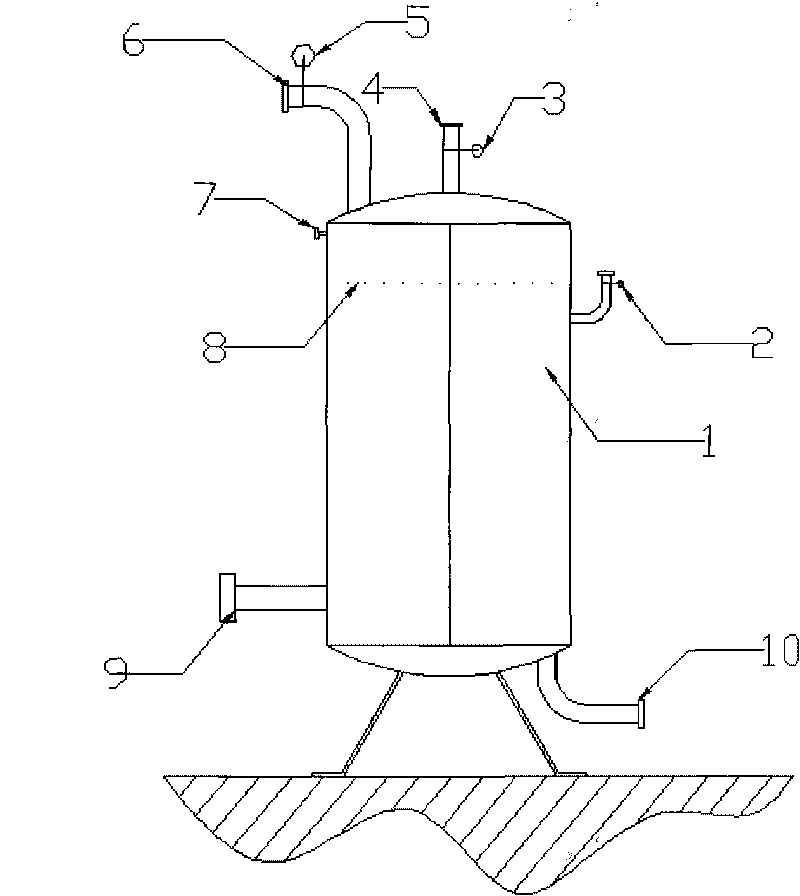

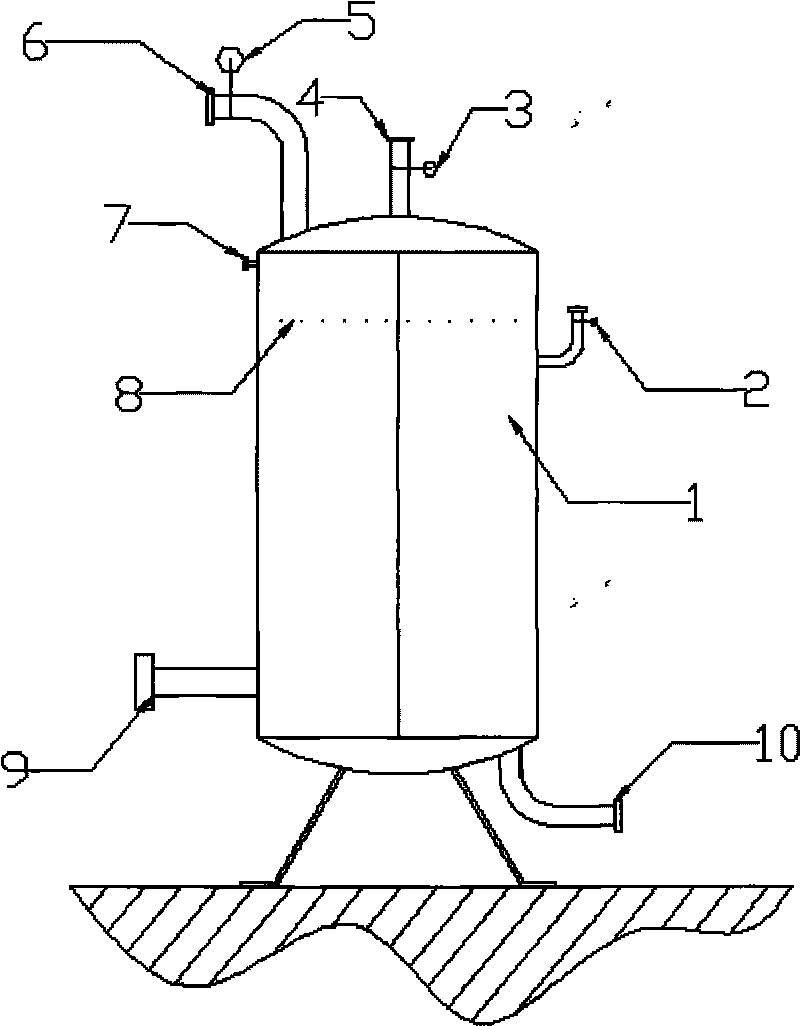

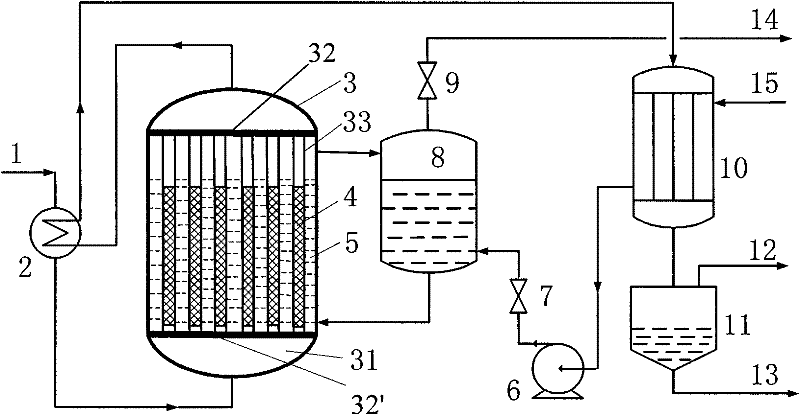

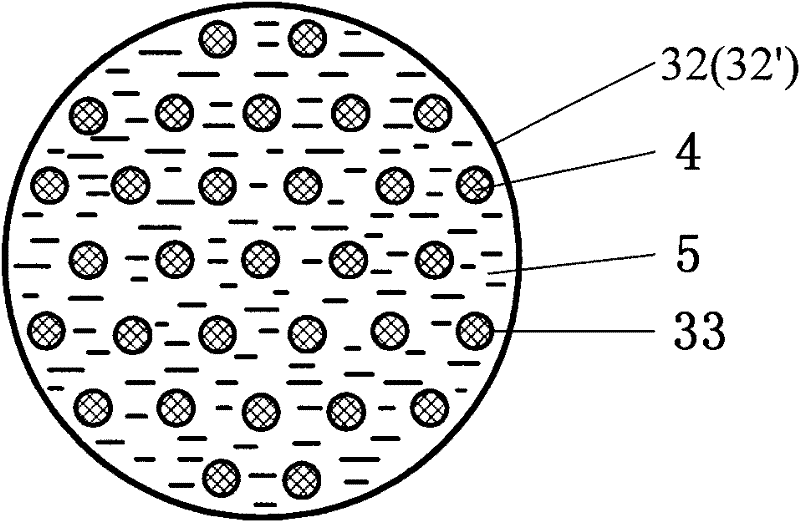

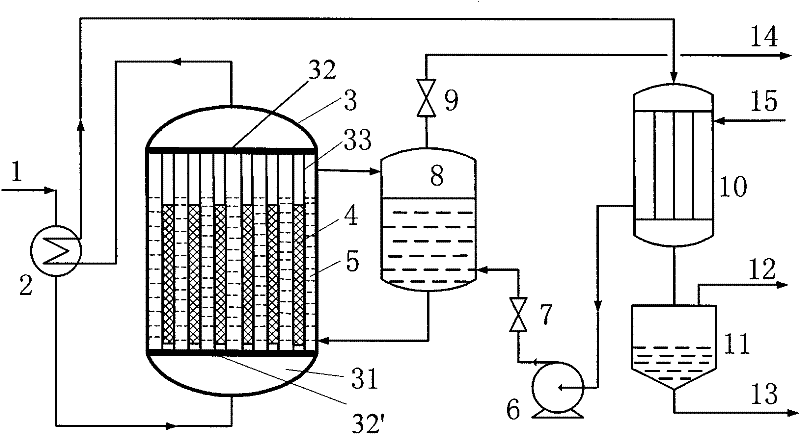

Complete methanation reaction device for synthesis gas

ActiveCN102234213AIncrease production capacityImprove efficiencyHydrocarbon from carbon oxidesChemical industryLiquid productMethanation

The invention relates to a complete methanation reaction device for synthesis gas. The device consists of a tube-shell reactor, a heat exchanger, a steam pocket, a make-up water pump, a condenser and a gas-liquid separator, wherein a catalyst is filled in a tube of the reactor; the shell pass is superheated water for removing heat; heat released in methanation reaction is absorbed through the phase change of high-pressure superheated water in the shell pass of the reactor and taken out of the device; the generated steam enters the steam pocket, is subjected to gas-liquid balance and can directly form superheated steam to be supplied to the outside; the temperature of a catalyst bed in the tube of the reactor is regulated and controlled by controlling the balance pressure of the superheated steam; reaction product exit gas exchanges heat with raw material gas and is continuously condensed; and a gaseous product and a liquid product are separated by the gas-liquid separator. The device can realize the continuous and stable operation of the complete methanation reaction of the synthesis gas, can effectively improve heat transfer efficiency and control the temperature of the reaction bed in a phase change heat transfer mode at a high temperature and under high pressure, expands the operation range of the complete methanation reaction of the synthesis gas, and can effectively recycle the heat released in the reaction.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

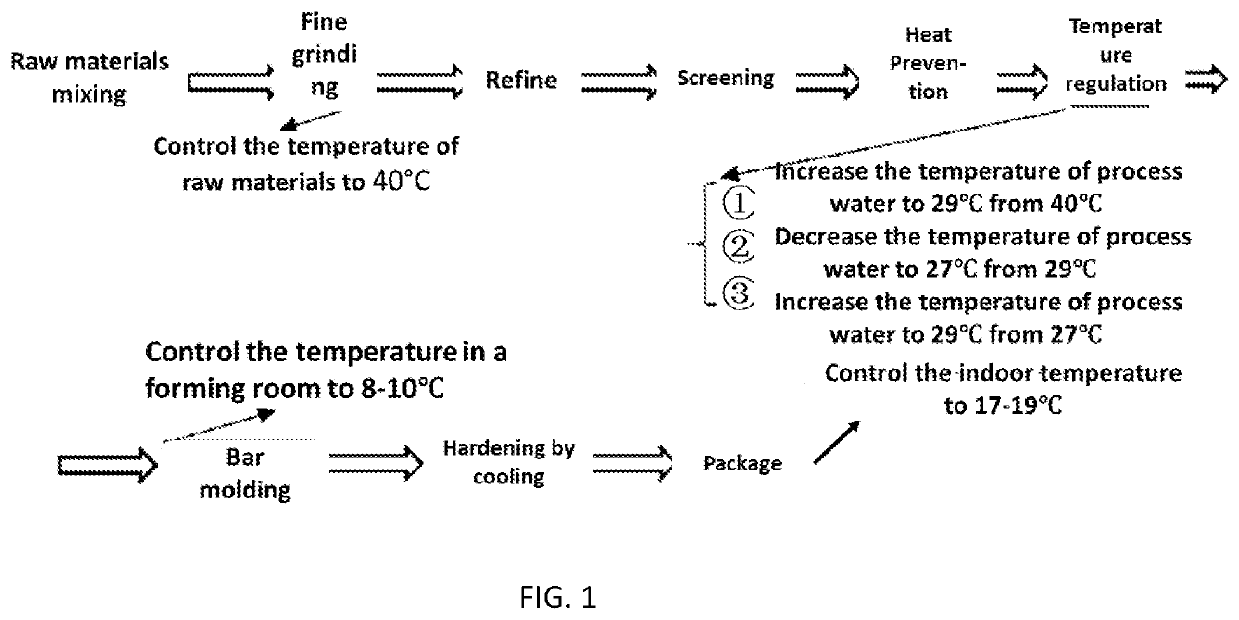

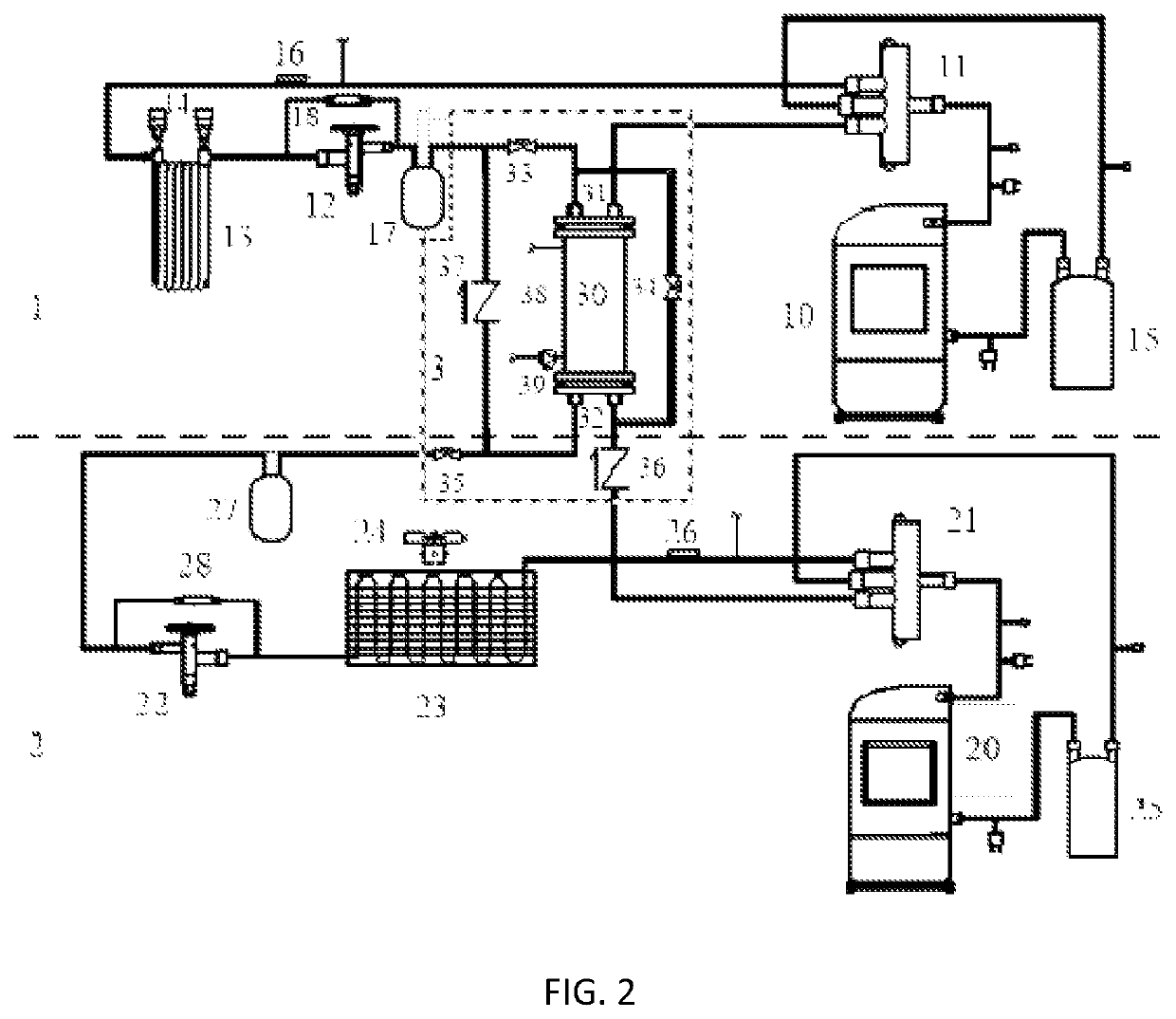

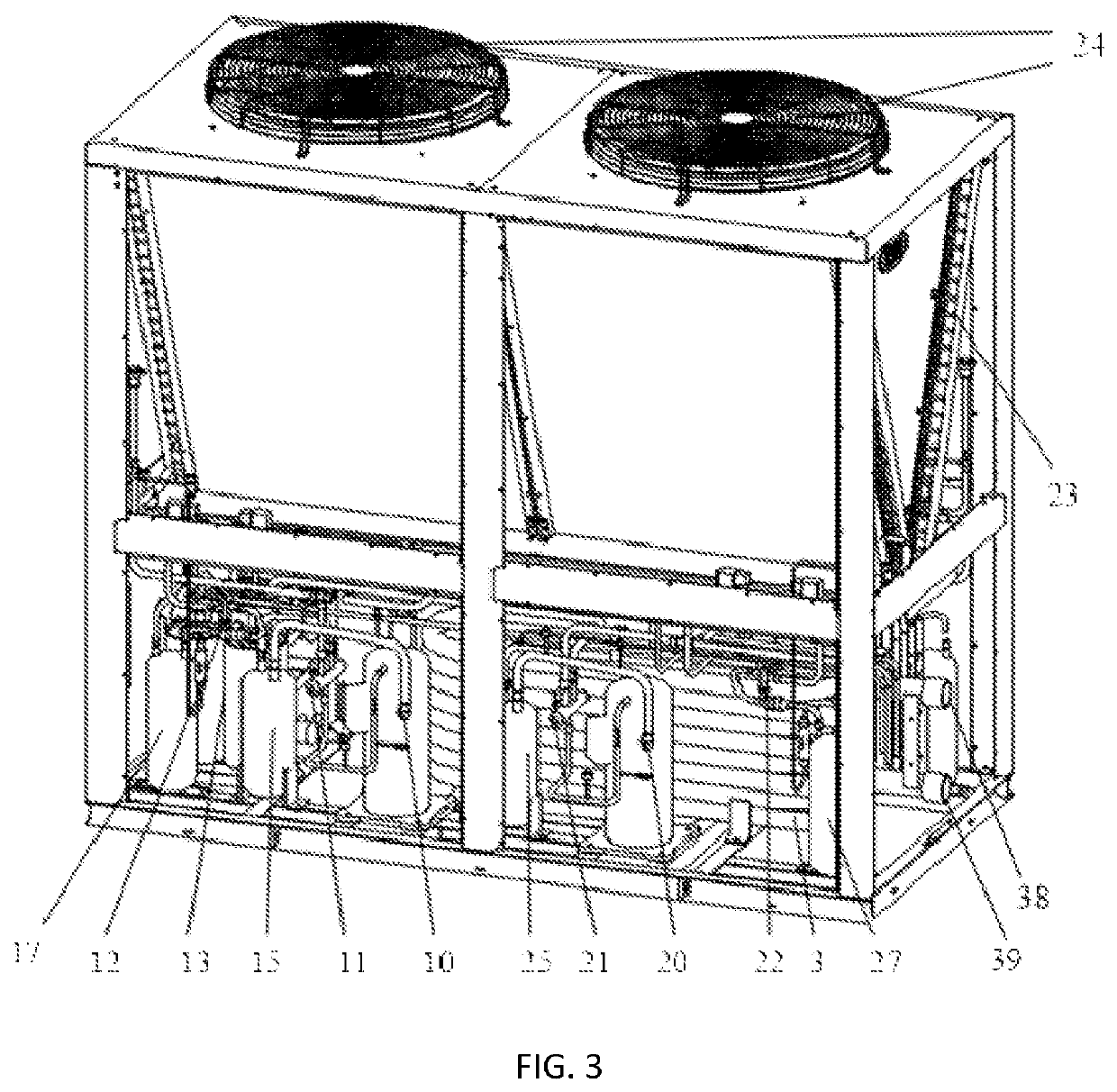

Cold energy recovery-type variable-capacity air-source heat pump system

ActiveUS20200158386A1Reduce equipment investment costsReduce operating costsMechanical apparatusHeat pumpsCirculator pumpEngineering

Disclosed is a cold energy recovery-type variable-capacity air-source heat pump system, relating to combined heating and refrigerating systems running in an alternating or synchronous manner, wherein a first subsystem and a second subsystem share a double-channel variable-capacity heat exchanger; a heat exchanger main body comprises two manually independent refrigerant pipe pass channels, and a refrigerant in the two channels synchronously carries out heat exchange with hot medium water in a shell pass channel; the shell pass channel establishes a water-medium heat-supplying circulation by means of a hot water circulation pipeline and a hot water circulation pump; the first subsystem and the second subsystem are connected to the two refrigerant pipe pass channels via a control valve group.

Owner:JIANGSU TENESUN ELECTRICAL APPLIANCE

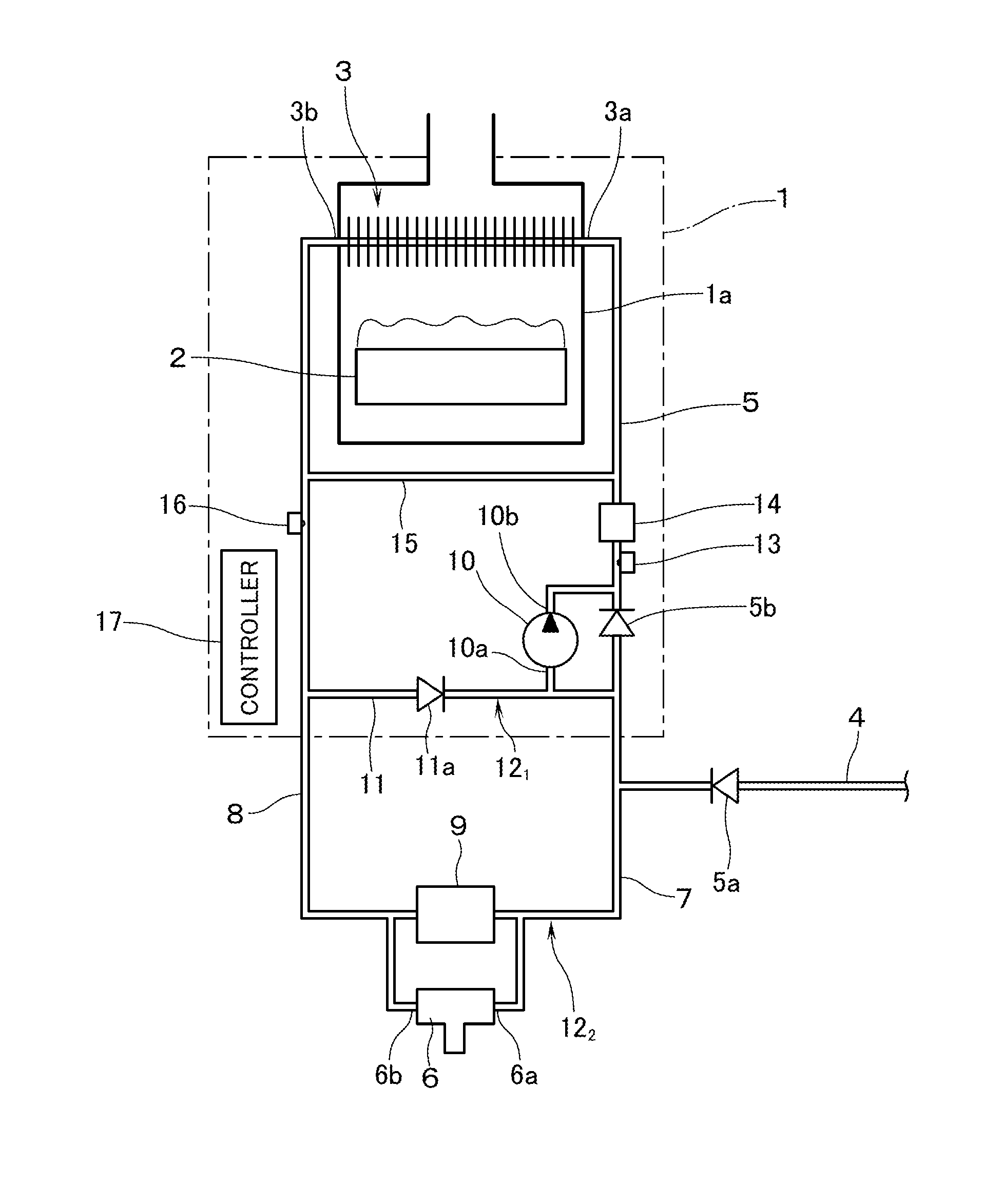

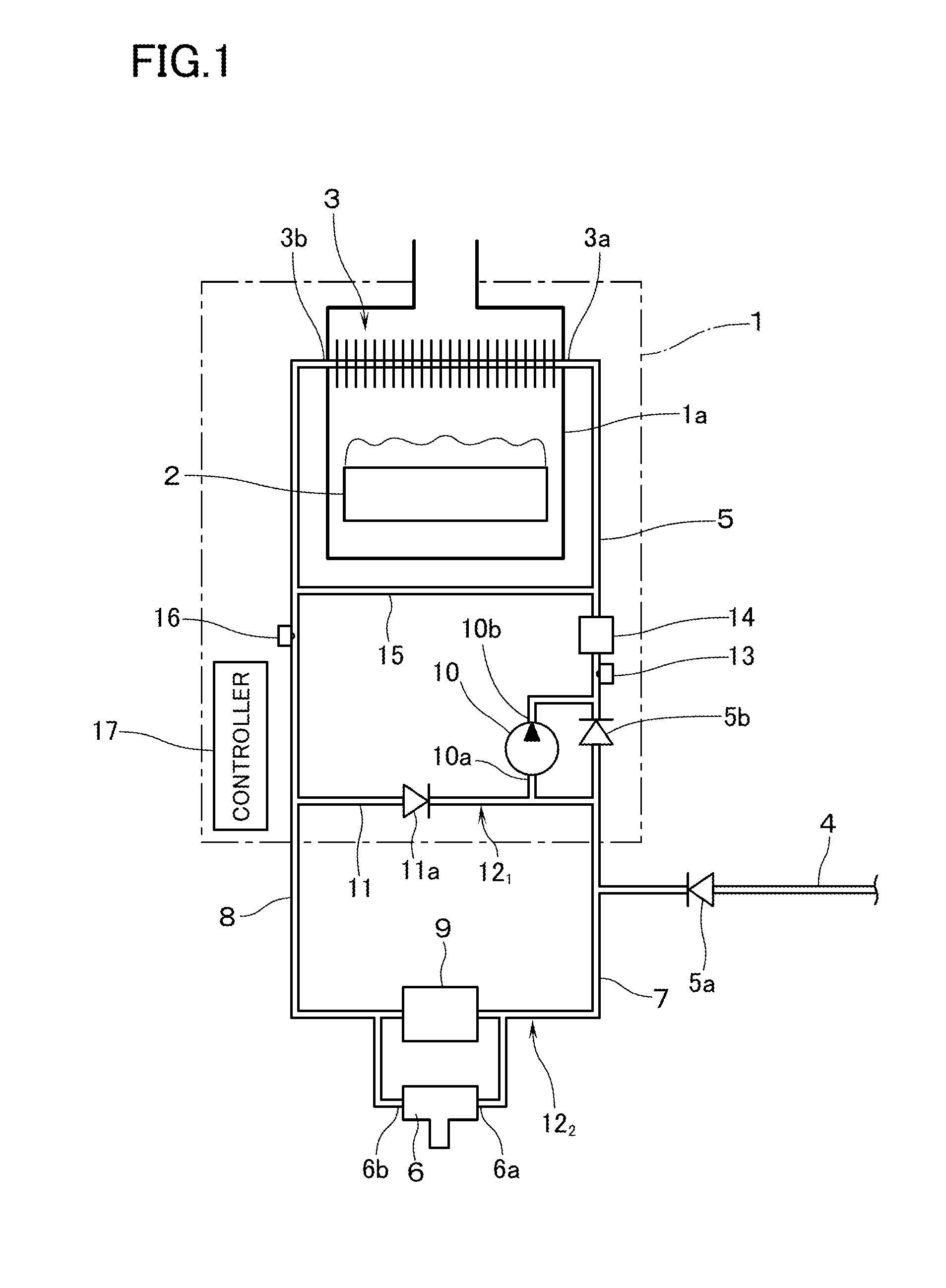

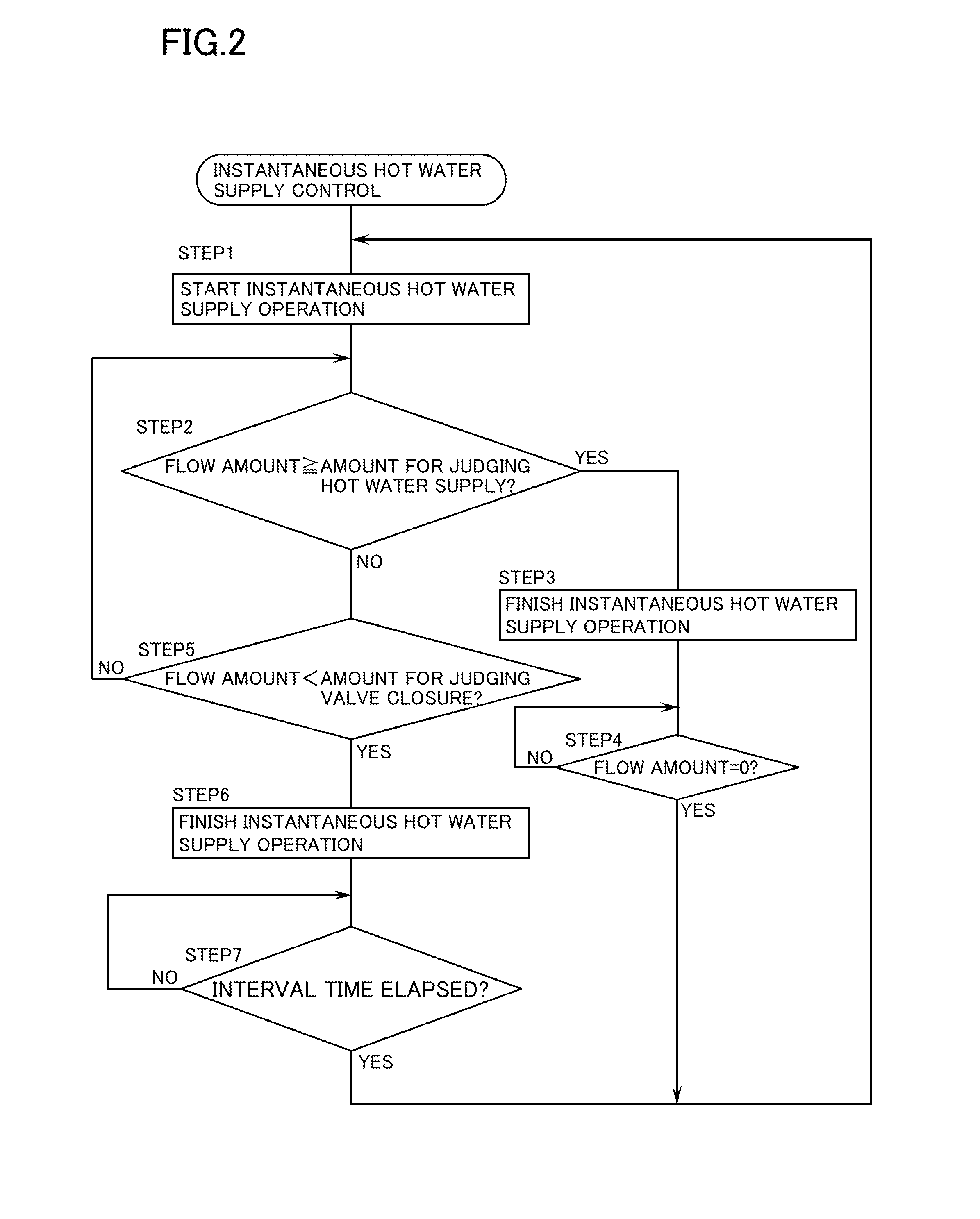

Hot water supply apparatus

ActiveUS20150354832A1Valve members for heating/coolingCentral heating componentsCirculator pumpEngineering

A hot water supply apparatus has: a thermo-sensitive valve which is connected in parallel to a cold water delivery pipe and a hot water delivery pipe and which is closed when the hot water temperature to flow inside the valve is above a predetermined temperature to thereby shut off communication between the cold water delivery pipe and the hot water delivery pipe; and a circulation pump. By operation of the circulation pump, water circulation takes place from a heat exchanger through the hot water delivery pipe, a return pipe, the circulation pump, and a cold water supply pipe back to the heat exchanger. When the thermo-sensitive valve is open, water circulation takes place also through the thermo-sensitive valve. Instantaneous hot water supply operation is finished when an amount detected by a flow sensor falls below a predetermined amount during the instantaneous hot water supply operation.

Owner:RINNAI CORP

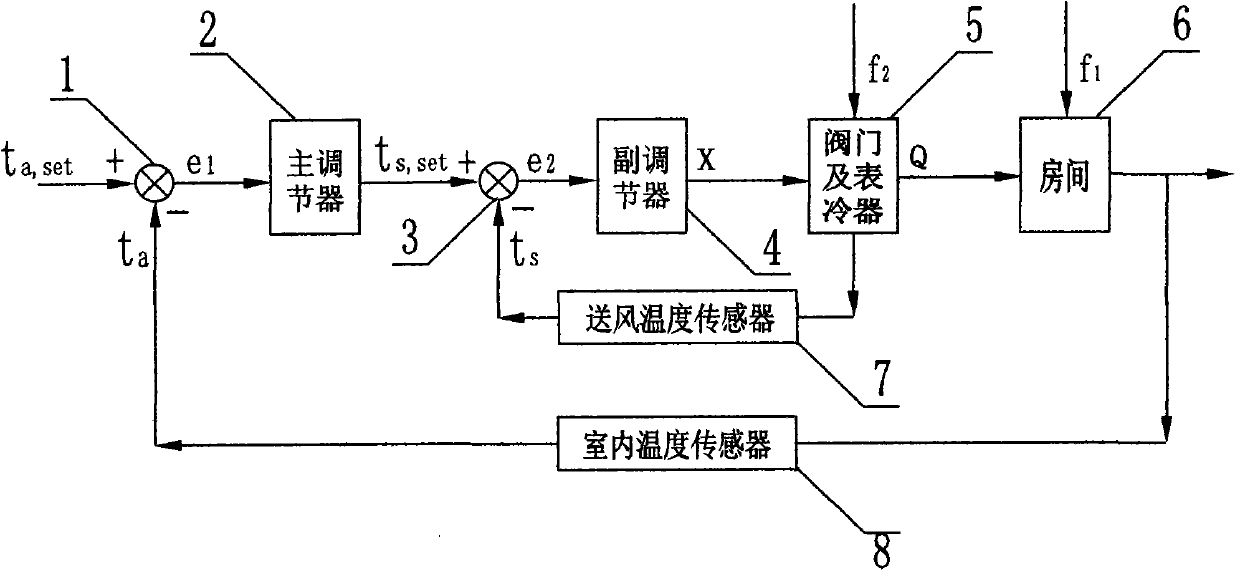

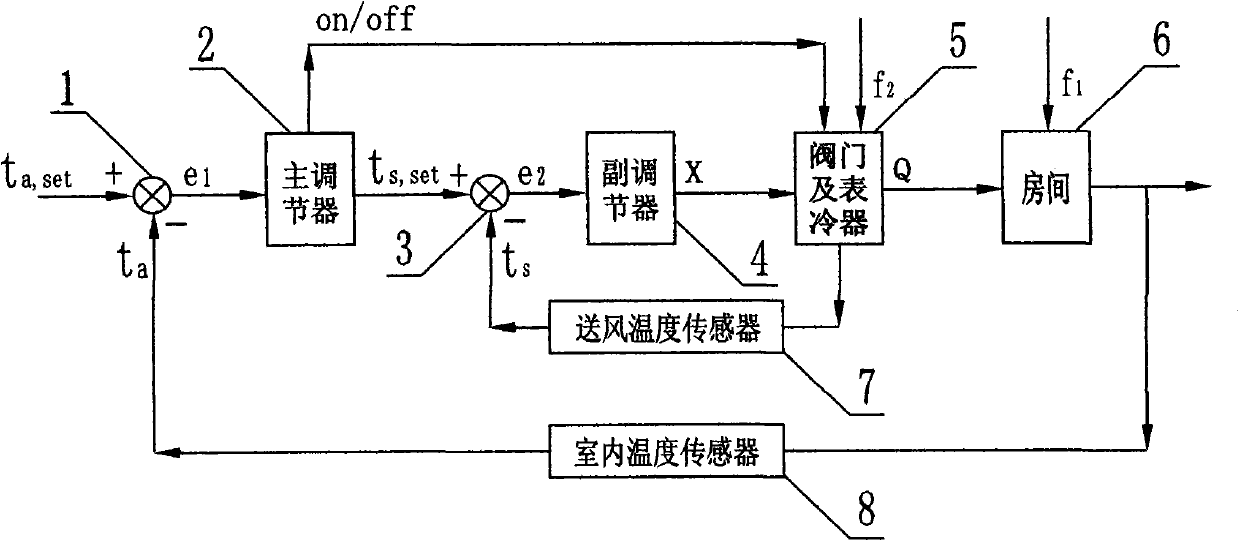

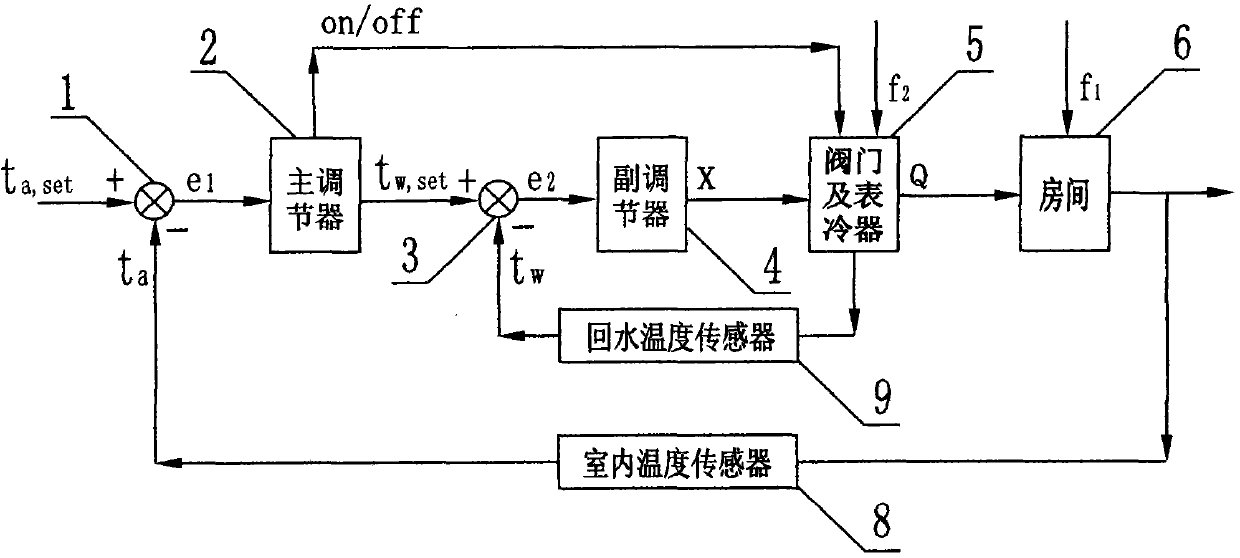

Method for regulating indoor temperature and dual-temperature control valve

ActiveCN103471205AReduce power consumptionReduce indoor temperature fluctuationsSpace heating and ventilation safety systemsLighting and heating apparatusTemperature controlWater flow

The invention relates to a method for regulating the indoor temperature and a dual-temperature control valve for implementing the method. The method is used for regulating the indoor temperature of an air conditioning system in a cascade manner by means of cooling and dehumidifying indoor air by the aid of cold water in summers and heating the indoor air by the aid of hot water in winters, and the dual-temperature control valve is used for implementing the method. The method and the dual-temperature control valve have the advantages that an indoor temperature cascade regulation system comprises two regulators which are serially connected with each other to work, and the temperature of supplied air or the temperature of return water is used as an auxiliary variable, so that the indoor temperature which is a main variable can be stabilized; the auxiliary variable has a largest limiting value when refrigerating and dehumidifying requirements need to be met simultaneously in summers, regulating valves are switched off when the indoor temperature is close or equal to a given value, accordingly, the indoor humidity can be taken into consideration while the requirement on the indoor temperature is met, the refrigerating capacity of the cold water is saved, the comfortableness of an indoor environment can be guaranteed, a water flow rate and the overshoot further can be reduced, the transition time can be shortened, dynamic characteristics of procedures can be improved, particularly, secondary disturbance resistance such as water-temperature resistance and water-pressure-variation resistance can be greatly improved, and purposes of further improving the regulation quality of the system, reducing power consumption of water pumps and improving the efficiency of a main unit can be achieved.

Owner:陈建平

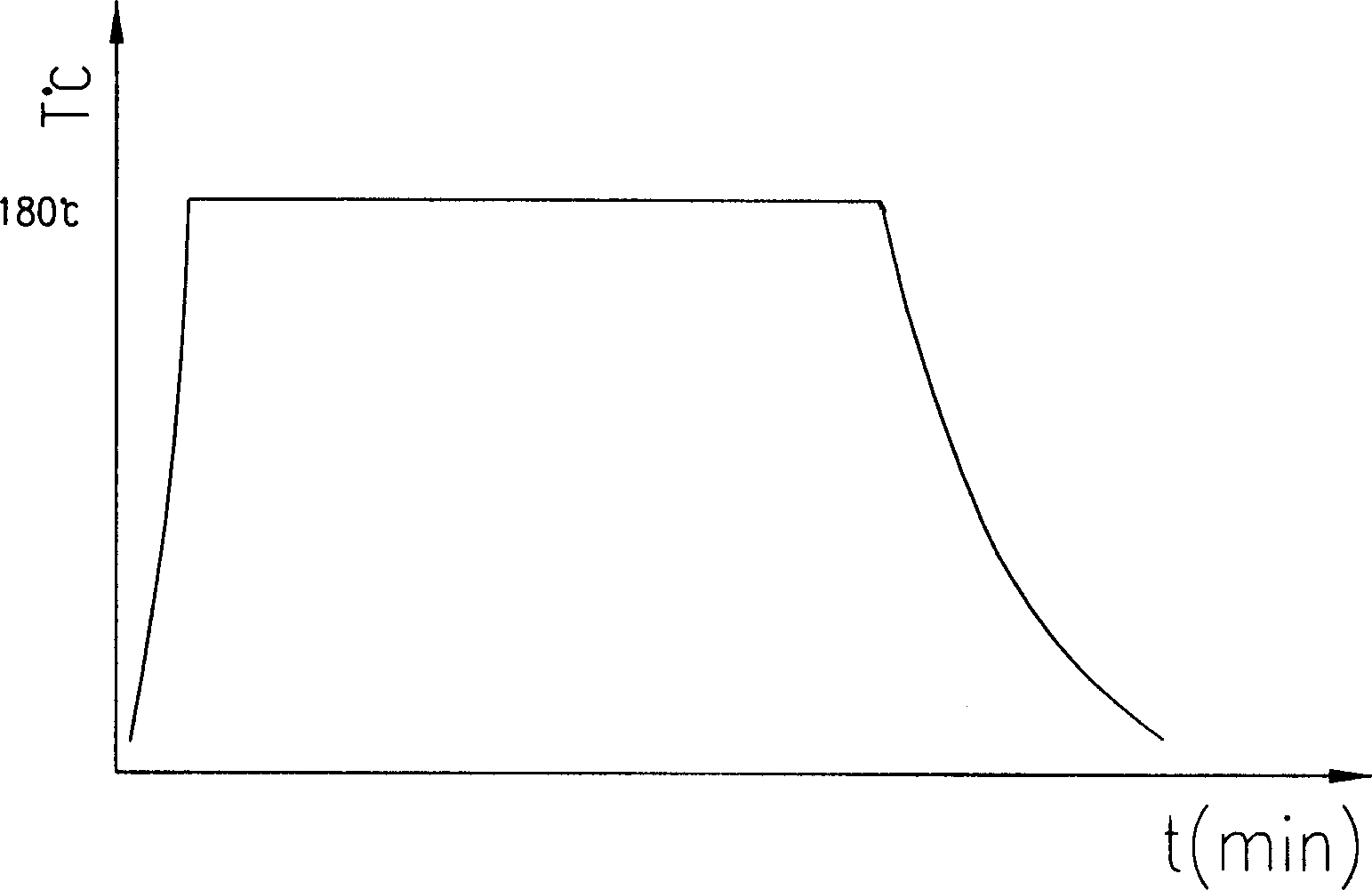

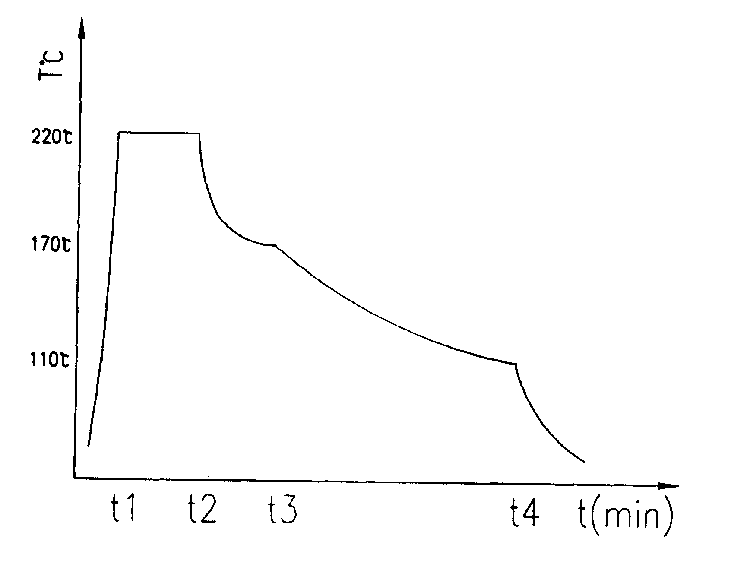

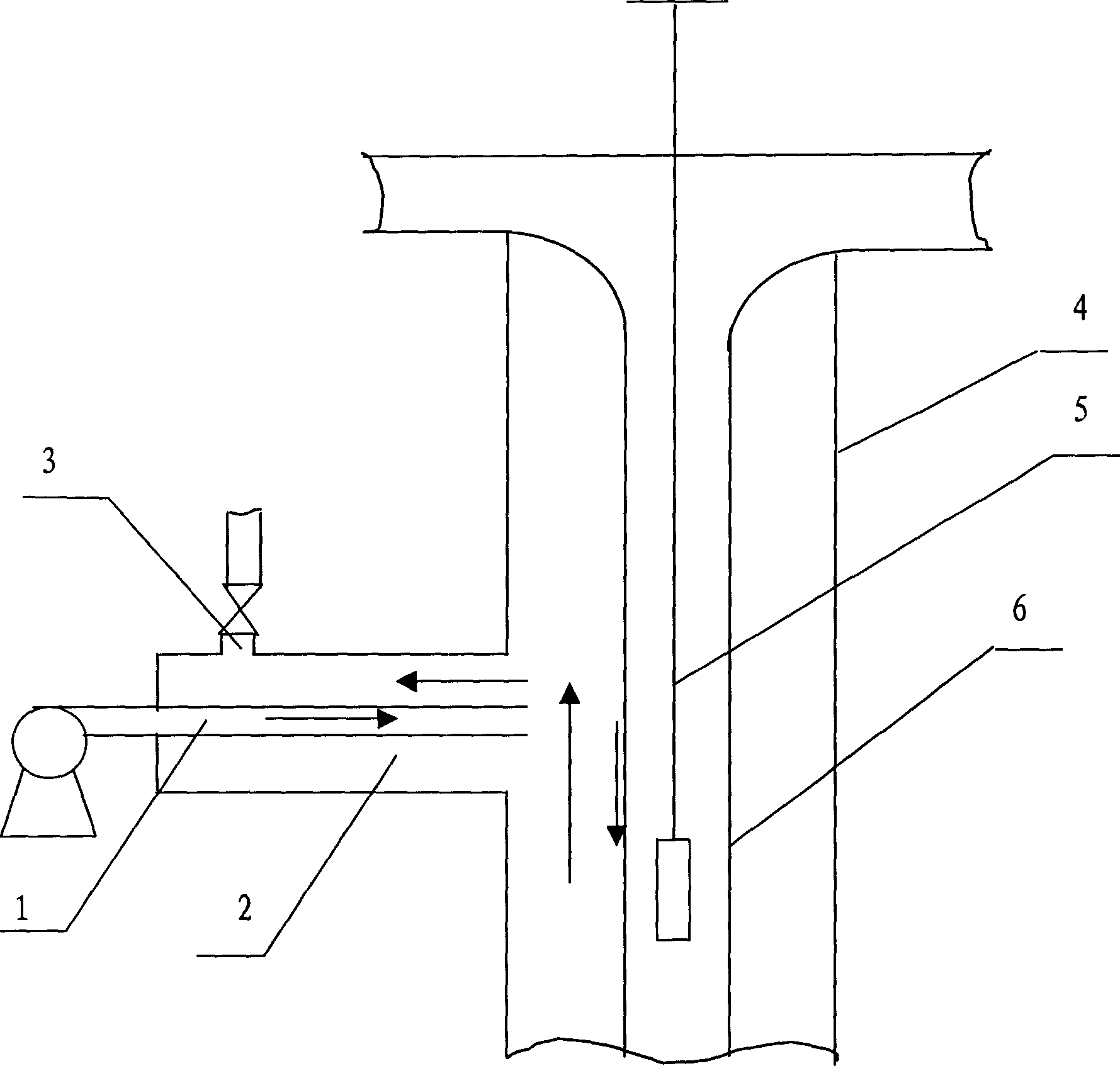

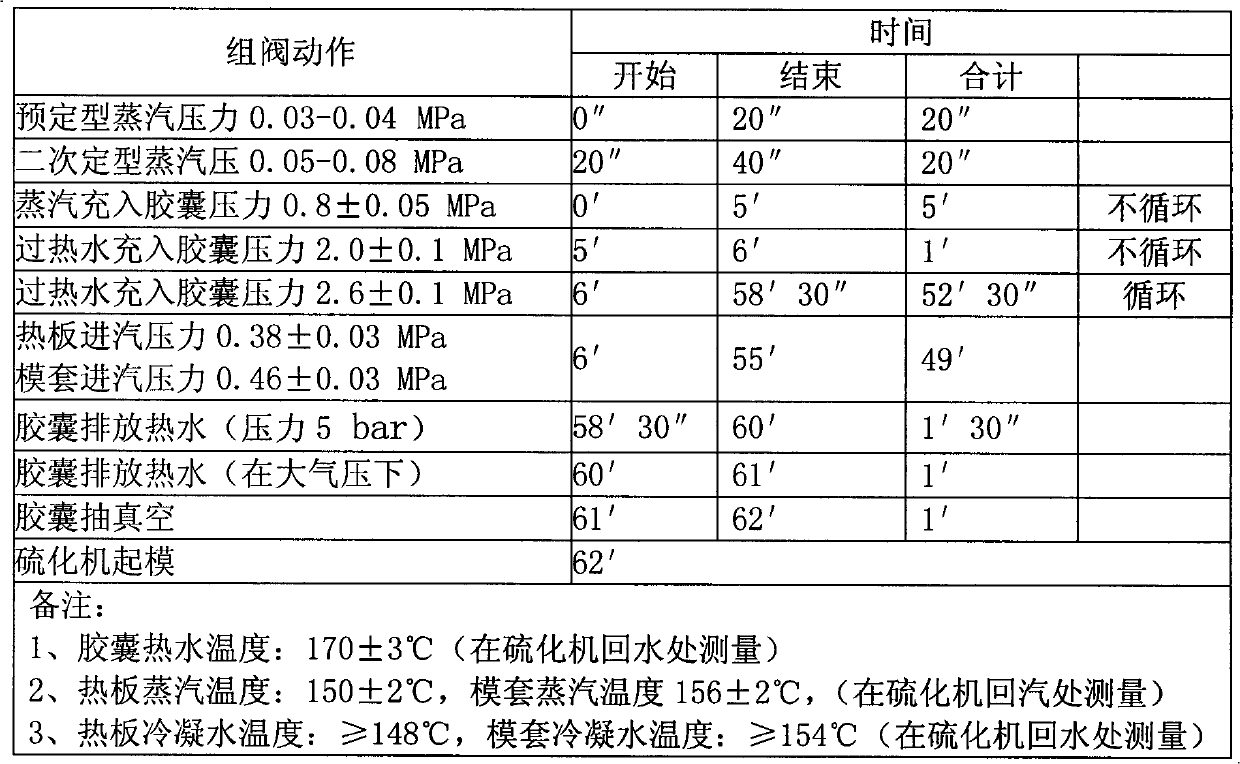

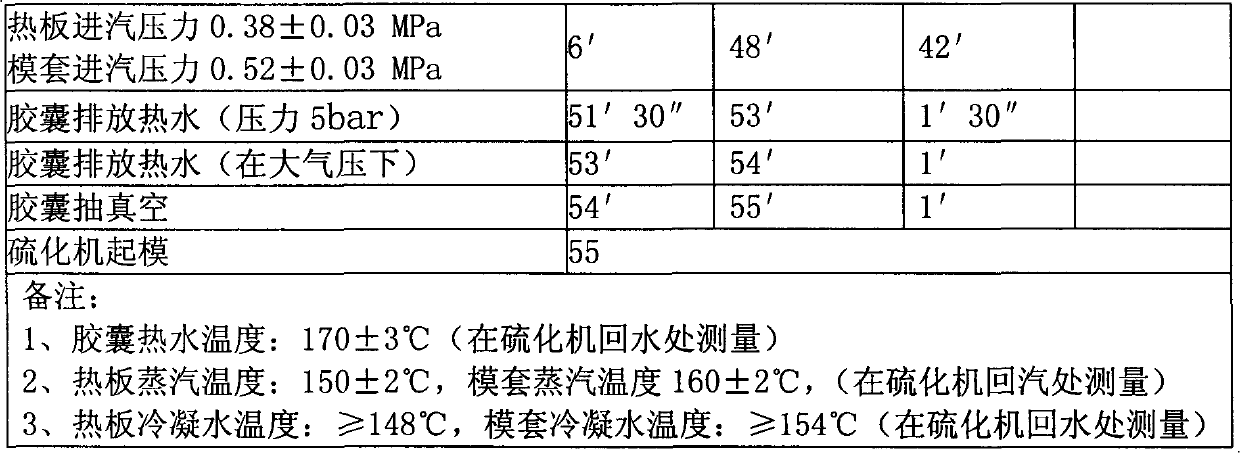

Tyre sulfuration process

The present invention relates to a tyre vulcanization process. Said process includes the following steps: introducing high-temp. medium with 180-220 deg.C which is 15-25% higher than general conventional vulcanization temp. into capsule to heat tyre and accelerate cross-linking reaction; intermittently introducing high-temp. medium, its temp. can be up-down floated in the range of 150-170 deg.C to implement prevulcanization stage; making optimum cure stage, stopping the high-temp. medium from introducing into capsule, retaining pressure, in the course of vulcanization the temp. is lowered by 20%-35% so as to implement isopiestic temp. swing vulcanization. It can shorten vulcanization time by 7-13%, and can obviously raise tyve quality.

Owner:GUILIN RUBBER MACHINERY CO LTD

Method for hot cleanout and paraffin removal of oil well

InactiveCN1702292ADischarge in timeReduce water consumptionCleaning apparatusInsulationWaxParaffin oils

This invention discloses a paraffin removing method of oil well, which comprises the following steps: injecting 100-120 Deg.c superheated water to the tube when the mine pore is insulating; making the superheated water flowing down along the outer wall of oil tube whose inner wall has paraffin; fusing the paraffin. Such method can remove the paraffin deposit in the oil tube of oil well, and can discharge paraffin in time with low water consumption. It injects superheated water near ideal displacement of pumping unit, so it has smaller pollution to oil well ground layer.

Owner:黄灏

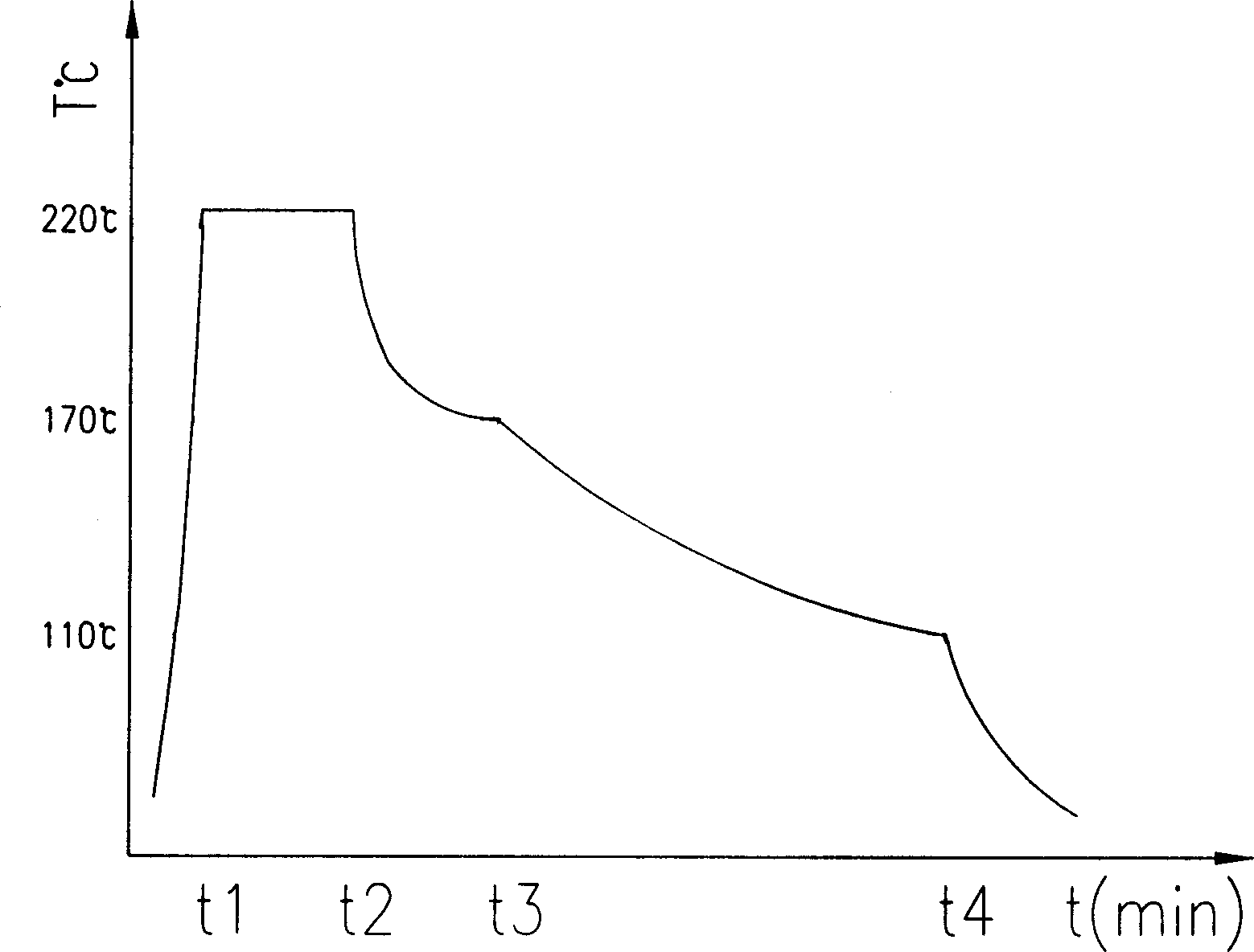

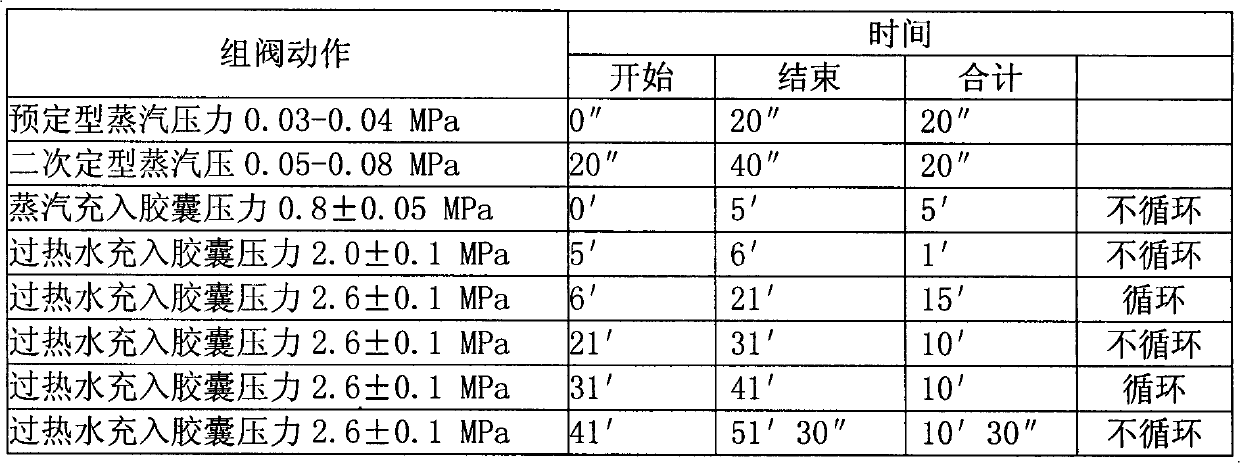

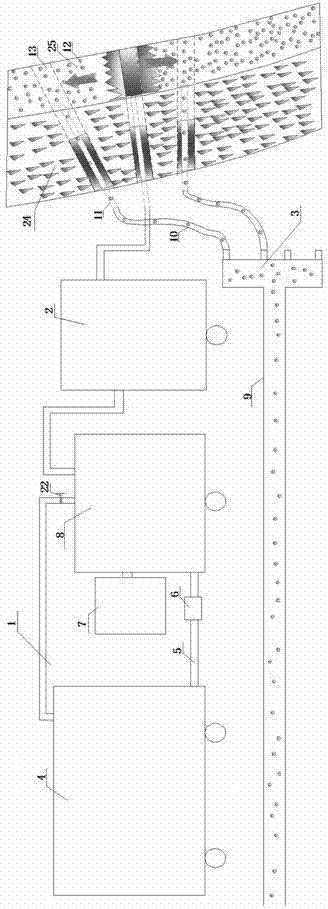

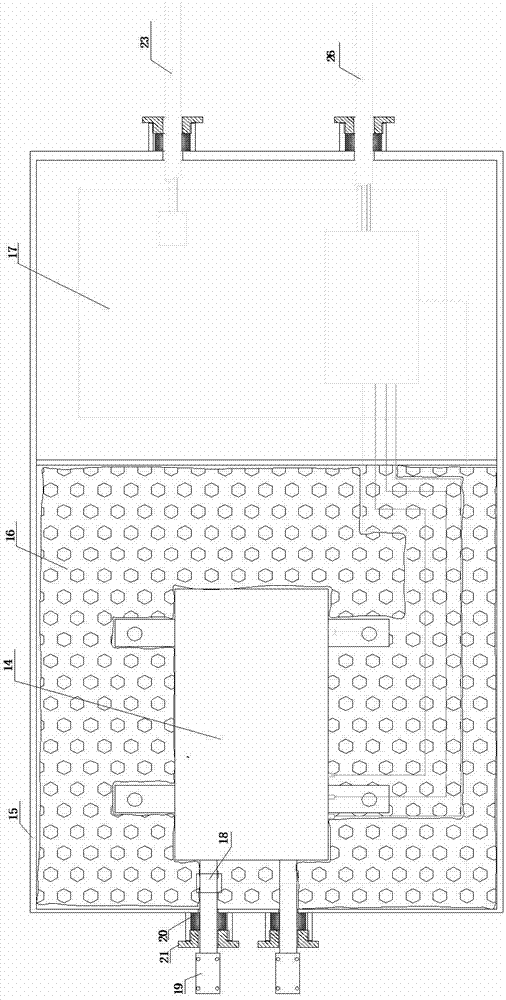

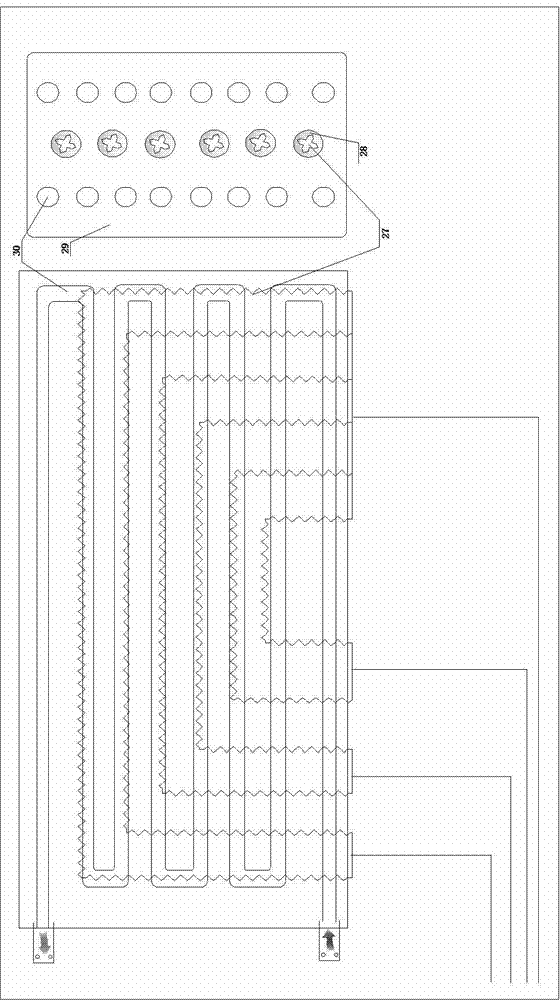

Intermittent hot water circulation pressure stabilization insulation tyre vulcanization technology

The invention discloses an intermittent hot water circulation pressure stabilization insulation tyre vulcanization technology, comprising the following steps: injecting saturated superheated steam to a vulcanizing machine after spotting, injecting primary superheated water without backing, providing internal pressure rapidly to enable a tread rubber material to fill patterns, injecting secondary superheated water and circulating as external pressure steam is entered to heat a green tyre, starting positive vulcanization, stopping the circulation of the secondary superheated water, feeding external pressure steam continuously, carrying out positive vulcanization for a tyre continuously, cycling the secondary superheated water again, feeding external pressure steam continuously, stopping the circulation of the secondary superheated water, keeping the pressure until the vulcanization is finished, stopping the external pressure steam, discharging the external pressure to atmospheric pressure, discharging hot water in capsules and vacuumizing, completing the vulcanization finally and taking the tire out of a mould. The overcure phenomena of carcass and the belt layer are effectively prevented according to the invention. The durability of the tire is enhanced from original 90 hr to over 110 hr. The service life of the tire is prolonged.

Owner:WEIFANG YUELONG RUBBER

Device and method for displacing, exhausting and mining coal seam gas by damp and hot water injection

InactiveCN104500010AAutomatically stop heatingEasy extractionFluid removalGas removalWater storage tankHigh pressure water

The invention relates to a device and a method for displacing, exhausting and mining coal seam gas by damp and hot water injection. The device comprises a high and low pressure water injection device, a high-pressure-resistant explosion-proof heating device and a gas exhausting and mining device, wherein the high and low pressure water injection device comprises a water storage tank, a water pump motor, a flow meter, a high-pressure water pump and a high-pressure water pipe; the high-pressure-resistant explosion-proof heating device comprises an explosion-proof shell, a heating module, a control circuit board, ceramic asbestos filling and a quick coupler; the gas exhausting and mining device comprises a main pipe for exhausting and mining, an exhausting and mining hose and an exhausting and mining branch pipe. According to the whole device, the purposes of coal seam gas displacement by injection of high-temperature water and superheated water under high or low pressure, coal body temperature and moisture increasing and gas exhausting and mining efficiency improvement can be realized, mine and gas outburst prevention and cure and dust prevention can be integrated, and the device is simple to operate. Especially for a low-permeability coal seam or situations that gas content is high after the coal seam is exhausted and mined for a period of time and the gas is difficult to exhaust and mine, purposes that the gas content of the coal seam of an exhausting and mining area can be quickly lowered and the outburst is eliminated in short time can be realized.

Owner:湖南国标检测科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com