Water heating system and a method of operating same

a water heating system and water heating technology, applied in the field of water heating systems and a method of operating same, can solve the problems of water wastage, type of gas wastage, heater takes some time to come up to temperature,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

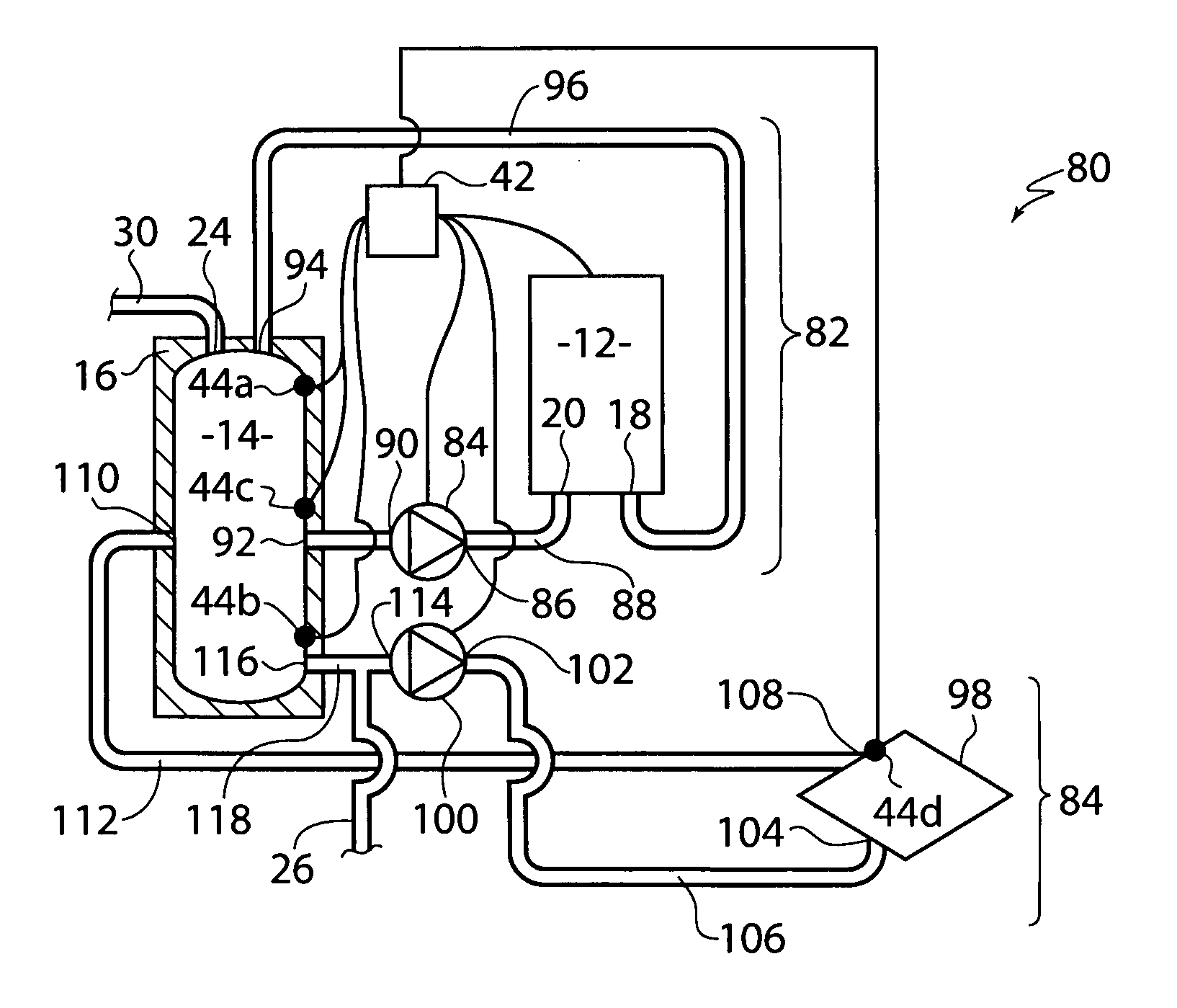

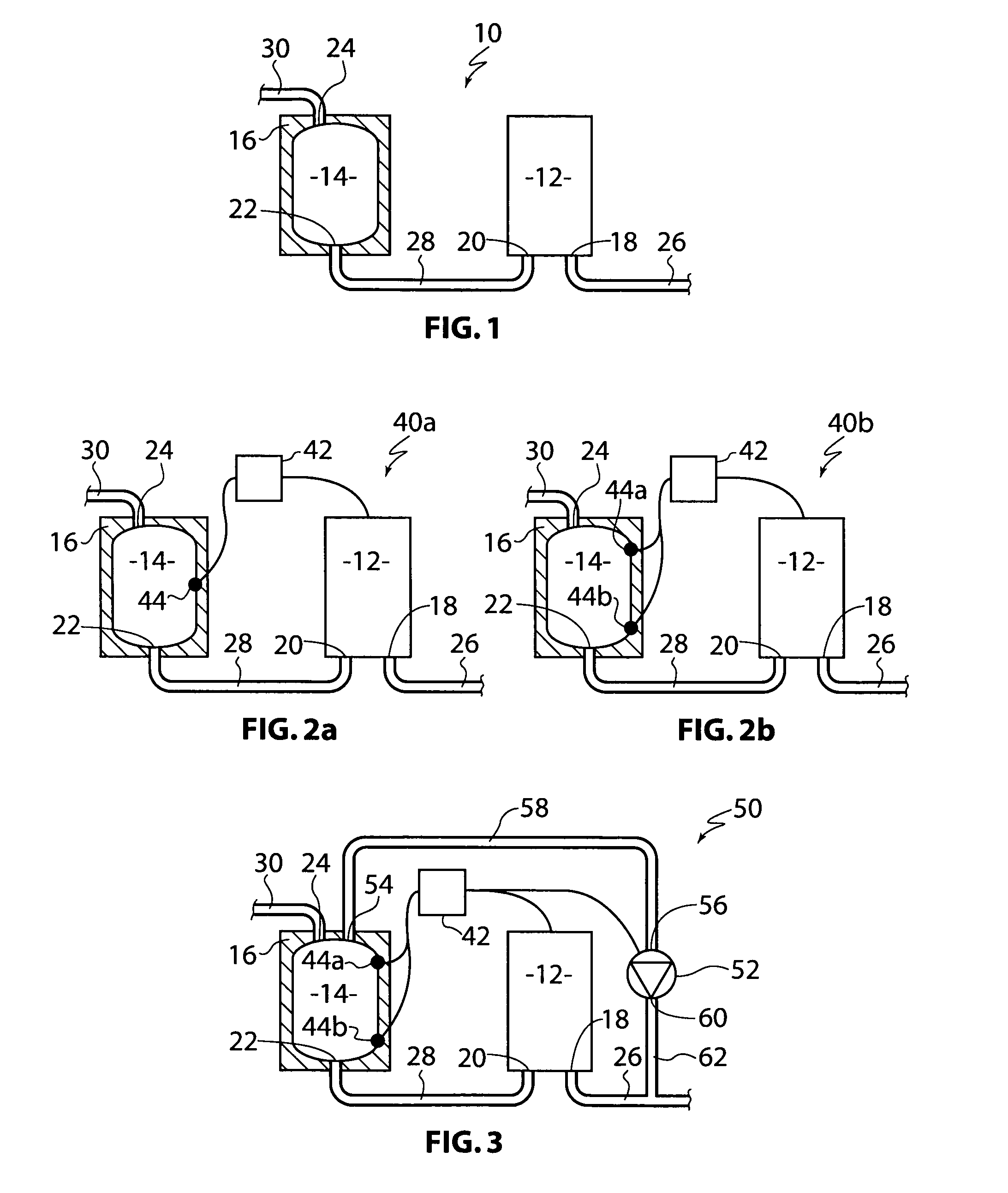

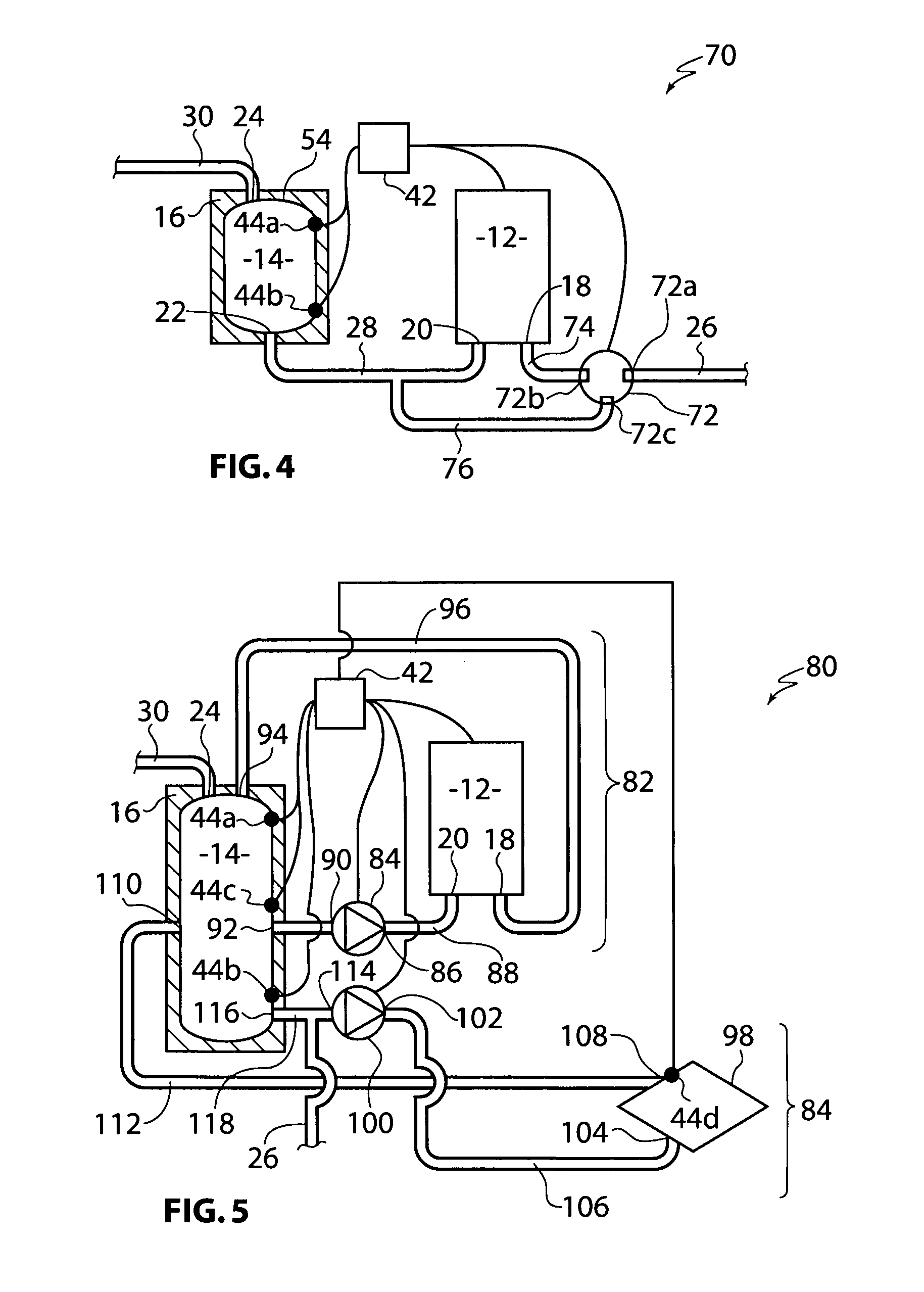

[0116]FIG. 1 shows a water heating system 10 comprising a gas instantaneous-type water heater 12, preferably of 4, 5 or 6-Star rating. The burners in the heater 12 are automatically energised upon sensing flow of water through the heater 12. The system 10 also includes a (buffer) water storage tank 14, preferably 4-50 litres in volume. The tank 14 is encased in insulation 16. The heater 12 has an inlet 18 and an outlet 20. The tank 14 has an inlet 22 and an outlet 24. The inlet 18 of the heater 12 is connected to a mains water supply pipe 26. The outlet of the heater 12 is connected to the inlet 22 of the tank 14 by a pipe 28. The outlet 24 of the tank 14 is connected to a user-controlled outlet device, such as a hot tap (not shown), by a pipe 30.

[0117]When the tap is initially actuated by a user, water flows from the mains supply pipe 26 into the heater 12 and is heated by the gas burners therein. The heated water then flows through pipe 28 into the tank 14 and, after the tank 14 i...

second embodiment

[0118]A first version 40a of water heating system is shown in FIG. 2a. The water heating system 40a is similar to the water heating system 10 shown in FIG. 1 and like features have been indicated with like reference numerals. However, the water heating system 40a also includes a controller 42. The controller 42 receives signals indicative of water temperature in the (4-50 litre) tank 14 from a sensor 44 which is positioned near the middle of the tank 14. The controller 42 is also connected to the heater 12 and is able to control whether or not the heater 12 is energised in response to water flow. As the heater 12 does not energise automatically in response to water flow, it can be simplified and is thus less expensive.

[0119]If the sensor 44 indicates to the controller 42 a water temperature of about 55 Degrees C. or less, then the controller 42 will energise the heater 12. If the sensor 44 indicates to the controller 42 a water temperature between about 55 Degrees C. and about 75 De...

third embodiment

[0123]FIG. 3 shows a water heating system 50. The water heating system 50 is similar to the water heating systems 40a and 40b shown in FIG. 2a and FIG. 2b and like features have been indicated with like reference numerals. However, in the water heating system 50, the controller 42 is also connected to a pump 52. The tank 14 also includes an additional outlet 54 which is connected to an inlet 56 of the pump 52 by a pipe 58. An outlet 60 of the pump 52 is connected to the mains water supply pipe 26 by a pipe 62.

[0124]If the second / bottom sensor 44b indicates to the controller 42 a water temperature of about 55 Degrees C. or less, then the controller 42 will energise the heater 12. If the first / top sensor 44a indicates to the controller 42 a water temperature of about 75 Degrees C. or more, then the controller 42 will not energise the heater 12 or, if operating, de-energise the heater 12. If the second / bottom sensor 44b indicates to the controller 42 a water temperature of about 55 Deg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com