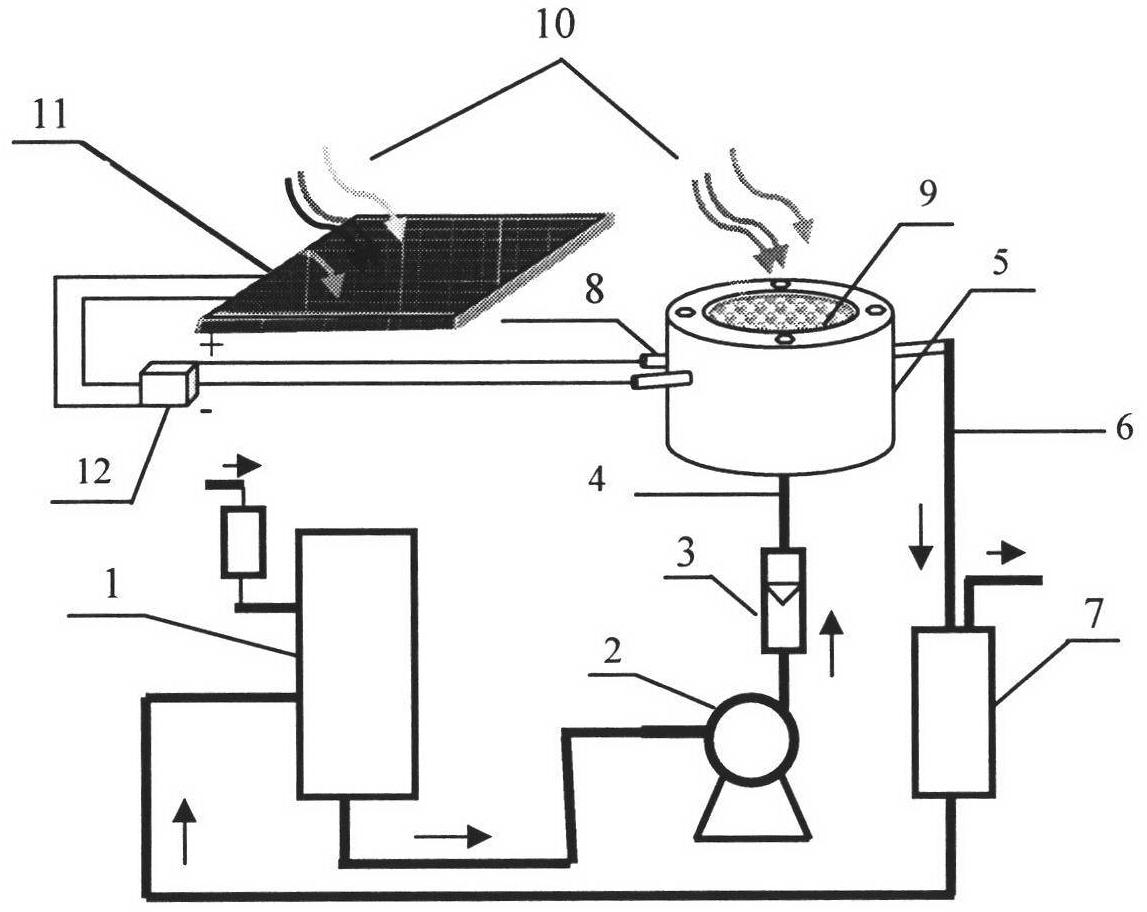

Organic wastewater treatment film reactor utilizing sunlight-assisted electro-catalysis

A technology for organic wastewater treatment and photoelectric catalysis, which is applied in the fields of energy wastewater treatment, light water/sewage treatment, water/sewage treatment, etc. Changes over time, restricting the development of membrane separation technology, etc., achieve the effect of avoiding easy passivation and deactivation, dense surface, and strong interface bonding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

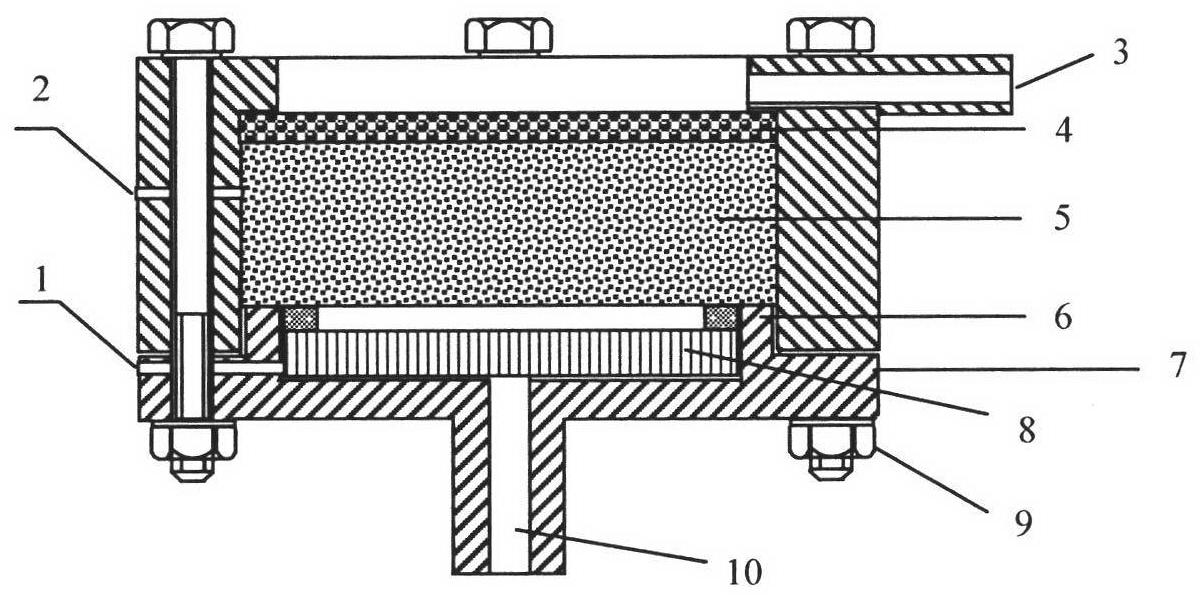

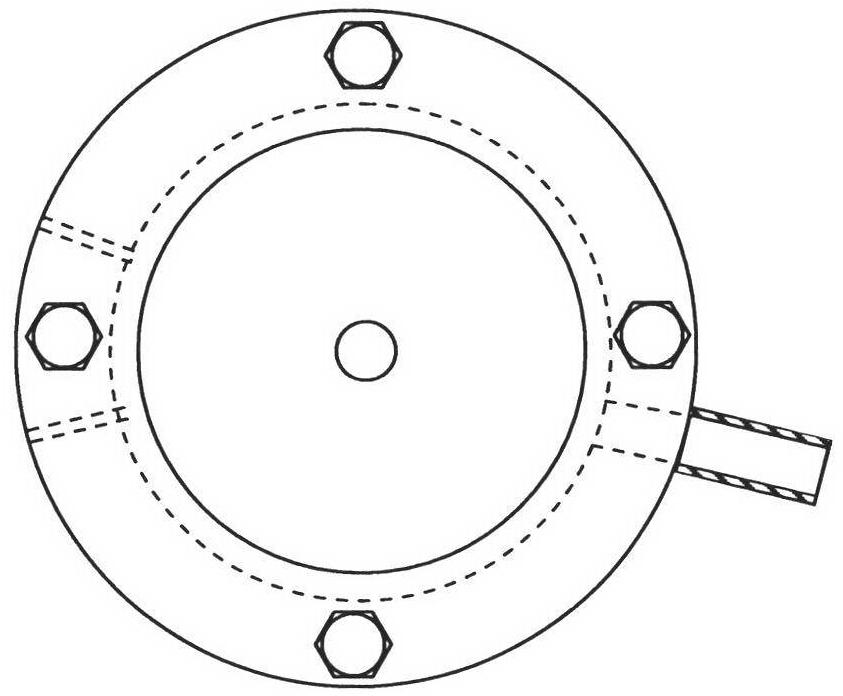

[0030] The photoanode of this embodiment uses cylindrical porous titanium as the substrate, and uses electrochemical anisotropic etching to etch TiO on the surface of the porous titanium. 2 Nanotubes are impregnated with active tin antimony cerium oxide components, and then modified by nitrogen doping to prepare electrodes with photocatalytic activity. The power supply of the device of the present invention is a commercialized polycrystalline silicon solar cell assembly (6W), and the photocatalytic light source is a xenon lamp (or ultraviolet lamp). The organic wastewater treatment device mentioned above was used to carry out the methyl orange simulated wastewater experiment under indoor weak light conditions. In this experiment, no voltage and current were applied between the cathode and anode electrodes, and no irradiation light source required for photocatalysis was provided.

[0031] The initial concentration of methyl orange simulated wastewater is 2.0*10 -5 mol / L, 0.01m...

Embodiment 2

[0033] Using the solar light-assisted electrocatalytic organic wastewater treatment membrane reaction device described in Example 1 to carry out the methyl orange simulated wastewater experiment under indoor weak light conditions, this experiment applies voltage and current between the cathode and anode electrodes, and does not provide the required photocatalysis. of light source. Commercialized polysilicon solar cell modules (6W) are selected as the power supply, the control voltage is 6V, and the current density is 20-40mA / cm 2 . The initial concentration of methyl orange simulated wastewater is 2.0*10 -5 mol / L, add 0.01mol / L sodium sulfate (Na 2 SO 4 ) as a conductive salt. In the experiment, the porous active electrode in Example 1 was used as the photoanode, the nickel sheet was used as the cathode, the distance between the cathode and the anode was 2mm, and the flow rate of the waste water to be treated was controlled to be 0.5ml / s. Using the circulation method, aft...

Embodiment 3

[0035] Using the solar light-assisted electrocatalytic organic wastewater treatment membrane reaction device described in Example 1 to carry out the methyl orange simulated wastewater experiment under the illumination conditions of the solar simulator indoors, this experiment does not apply voltage and current between the cathode and anode electrodes, only Provide the irradiation light source required for photocatalysis. The initial concentration of methyl orange simulated wastewater is 2.0*10 -5 mol / L, add 0.01mol / L sodium sulfate (Na 2 SO 4 ) as a conductive salt. The xenon lamp is used as the radiation source for the photocatalytic reaction, and the light intensity is controlled at 100mW / cm 2 . In the experiment, the porous active electrode in Example 1 was used as the photoanode, the nickel sheet was used as the cathode, the distance between the cathode and the anode was 2mm, and the flow rate of the waste water to be treated was controlled to be 0.5ml / s. Using the ci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com