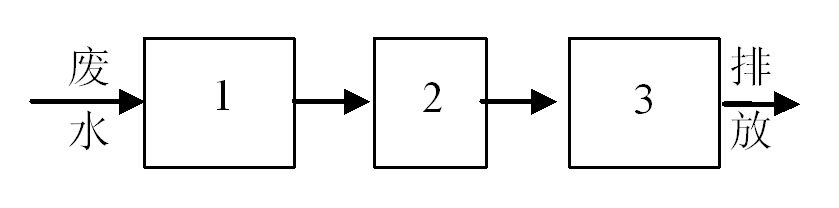

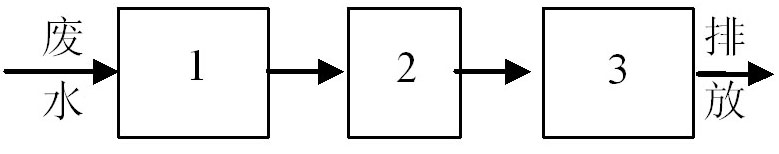

Wastewater treatment process of dimethoate pesticide

A pesticide wastewater and treatment process technology, applied in the chemical field, can solve the problems of high energy consumption and lengthy treatment process, and achieve the effect of shortening the pretreatment time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Embodiment 1: prepare dimethoate pesticide waste water 15L with the former medicine of dimethoate pesticide, its COD cr Concentration is 4000mg / L, after photo-assisted Fenton oxidation pretreatment for 30min, hydrogen peroxide (H 2 o 2 ) and ferrous sulfate (FeSO 4 ·7H 2 O) It is a one-time dosing at the beginning of the reaction. During the reaction, ultraviolet light is always used to irradiate FeSO 4 The dosage is 22mmol / L, H 2 o 2 The dosage is 90mmol / L, the pH value is 3, and the power of the ultraviolet lamp is 20W. Fenton Process Effluent Chemical Oxygen Demand (COD cr ) removal rate was 74.7%. After the pretreatment reaction, the effluent is diluted to twice its volume, and enters the CAST process for biological treatment for 7 hours (1 hour for water inflow, 4 hours for aeration reaction, 1 hour for standing and settling, and 1 hour for decanting (draining) water), During the reaction process, the air-water ratio is controlled at 6:1, the drainage ratio...

Embodiment 2

[0023] Embodiment 2: prepare dimethoate pesticide waste water 15L with the former medicine of dimethoate pesticide, its COD cr Concentration is 4000mg / L, after photo-assisted Fenton oxidation pretreatment for 30min, hydrogen peroxide (H 2 o 2 ) and ferrous sulfate (FeSO 4 ·7H 2 O) It is a one-time dosing at the beginning of the reaction. During the reaction, ultraviolet light is always used to irradiate FeSO 4 The dosage is 15mmol / L, H 2 o 2 The dosage is 75mmol / L, the pH value is 3, and the power of the ultraviolet lamp is 30W. Fenton Process Effluent Chemical Oxygen Demand (COD cr ) removal rate was 71%. After the pretreatment reaction, the effluent is diluted to twice its volume, and enters the CAST process for biological treatment for 6 hours (1 hour for water inflow, 3 hours for aeration reaction, 1 hour for standing and settling, and 1 hour for decanting (draining) water). During the process, the air-water ratio is controlled at 7:1, the drainage ratio is 6:1, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com