High temperature and high pressure water circular corrosion experiment system with automatic control function

A high-temperature, high-pressure, corrosion experiment technology, applied in weather resistance/light resistance/corrosion resistance, measuring devices, instruments, etc., can solve problems such as inability to accurately control pressure, achieve high degree of automatic protection, simplified control procedures, and high degree of automation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

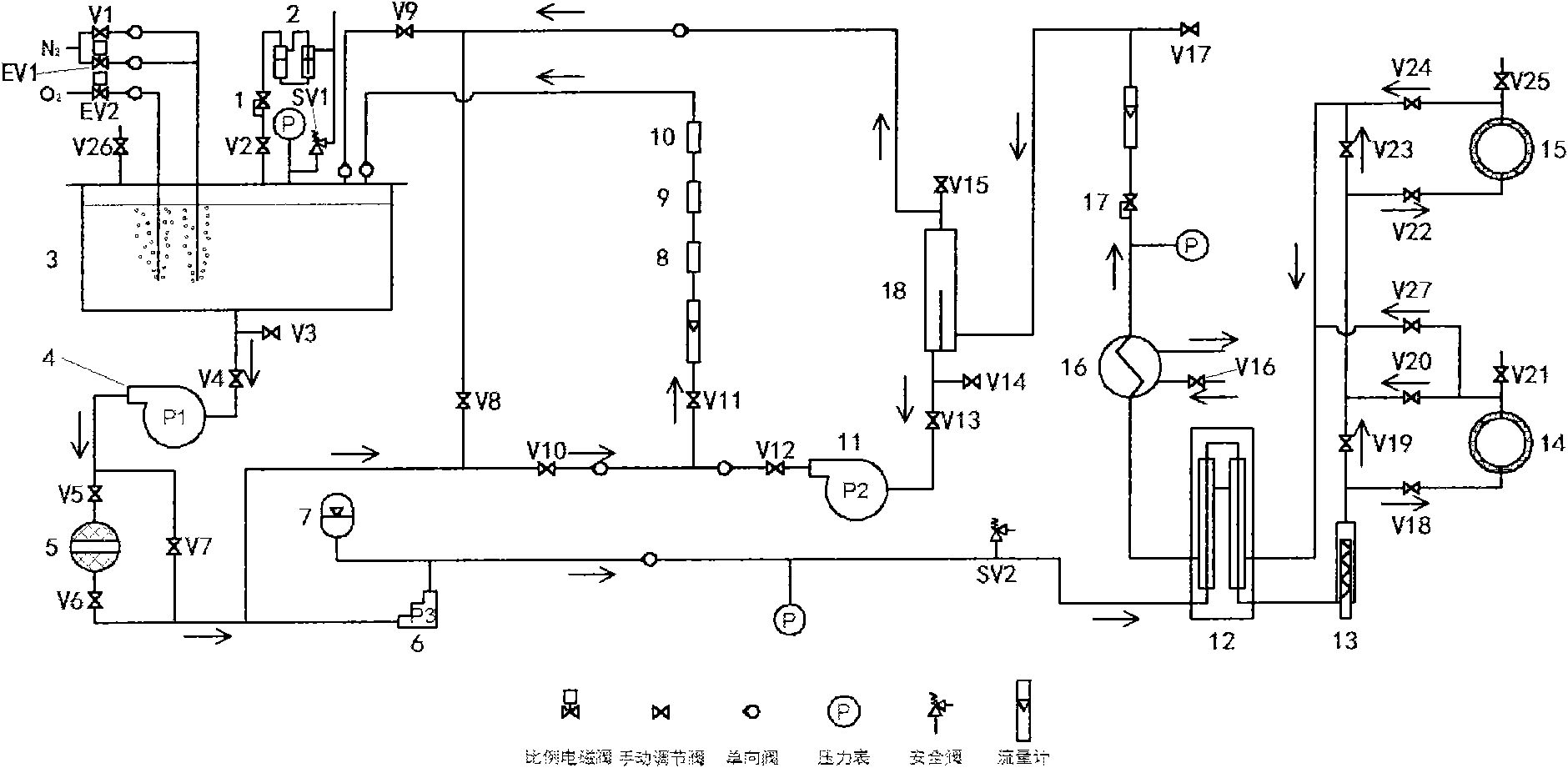

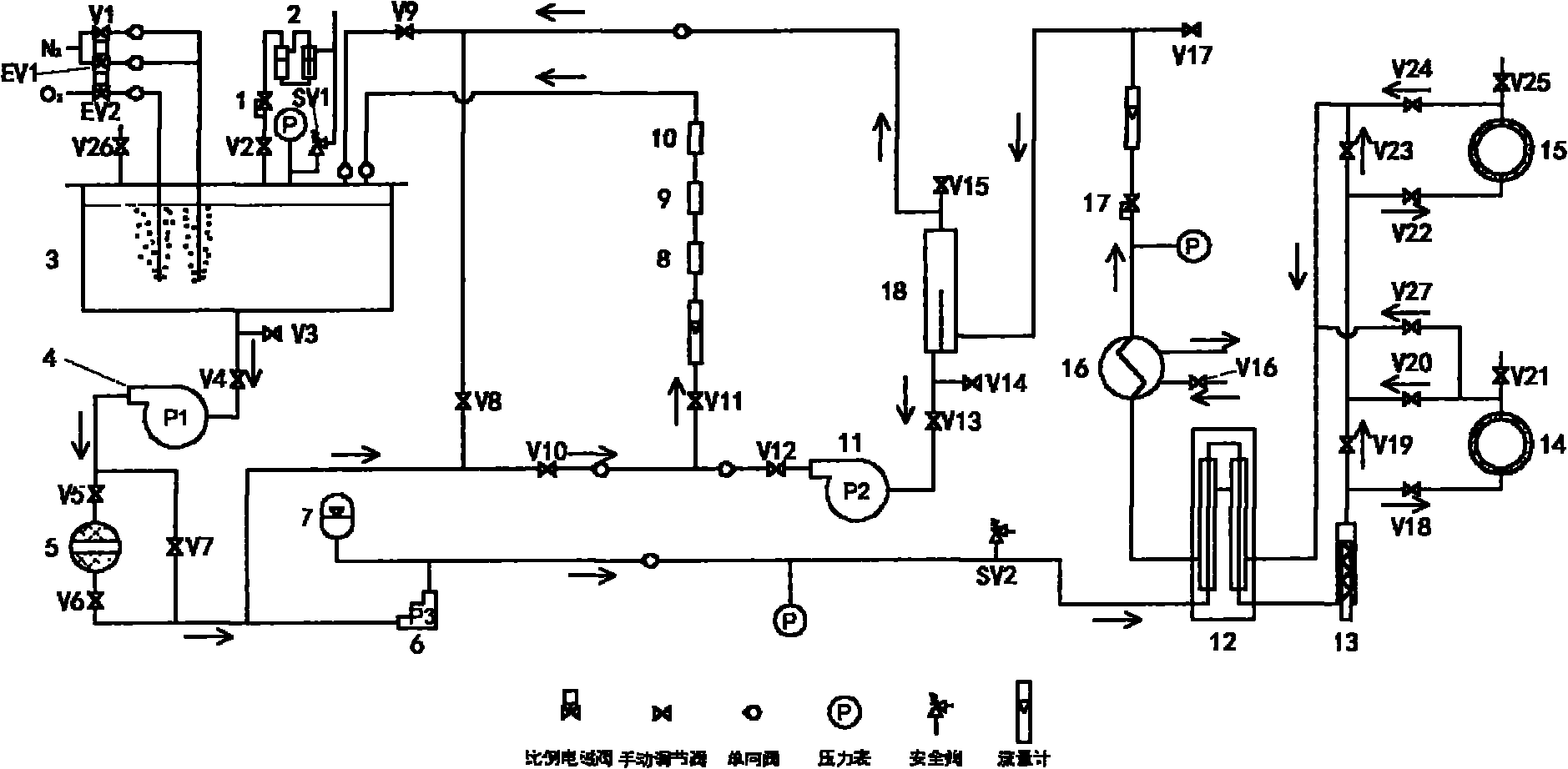

[0036] Such as figure 1As shown, the high temperature and high pressure water circulation corrosion experimental system of the present invention mainly includes: pressure reducing valve 1, exhaust device 2, stainless steel water storage tank 3, conventional pump 14, filter cotton core 5, high pressure pump 6, buffer tank 7, pH probe 8. Dissolved oxygen probe 9, conductivity probe 10, conventional pump II 11, heat exchanger 12, preheater 13, autoclave I 14, autoclave II 15, condenser 16, back pressure valve 17, etc. The specific structure is as follows :

[0037] The stainless steel water storage tank 3 is provided with two air inlets, which can feed oxygen and nitrogen respectively. A nitrogen proportional solenoid valve EV1 and a one-way valve are installed on the pipeline connecting the nitrogen gas inlet with the water storage tank 3, and an oxygen proportional solenoid valve EV2 and a one-way valve are installed on the pipeline connected between the oxygen inlet and the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com