Patents

Literature

178results about How to "Fast acceleration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

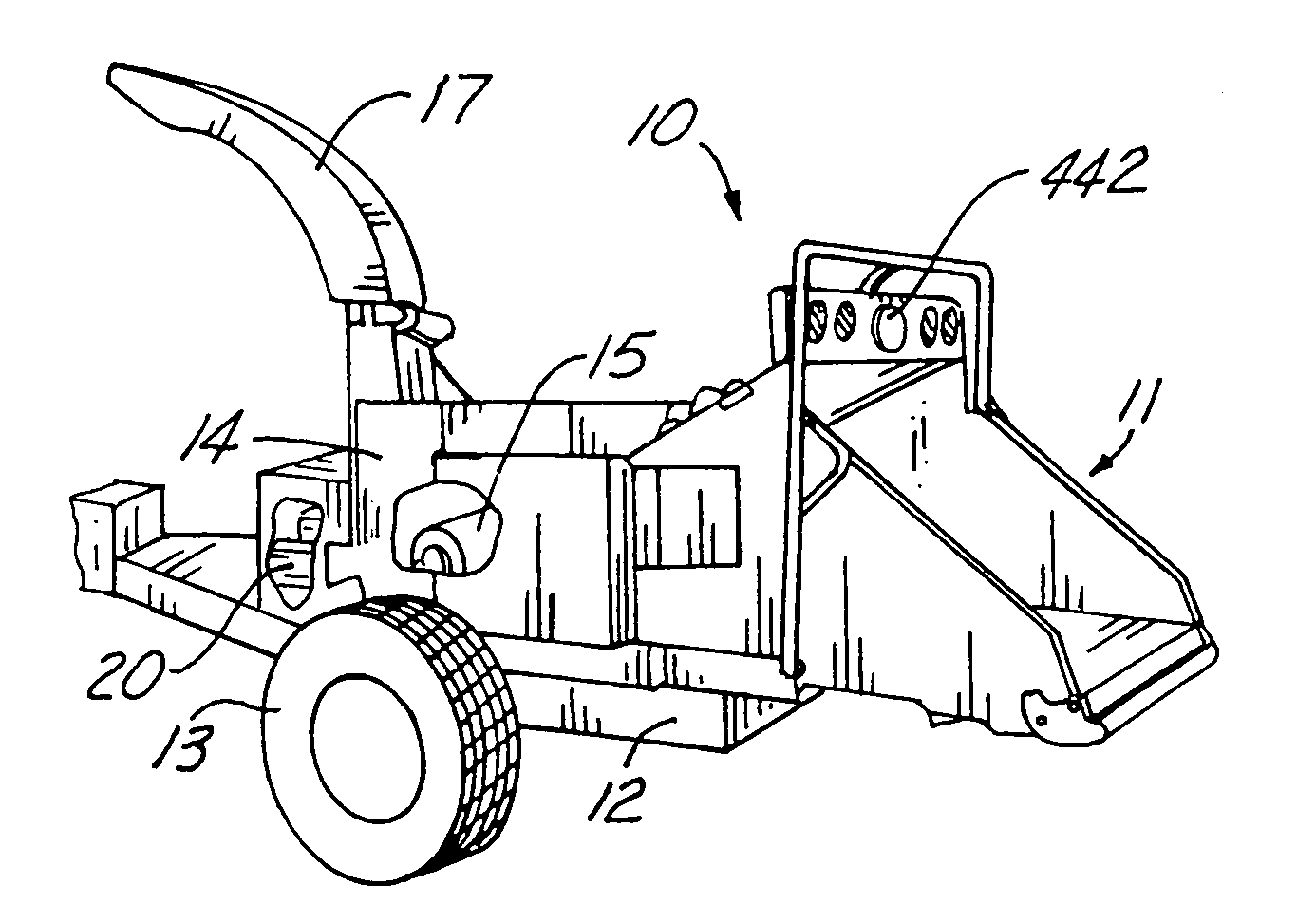

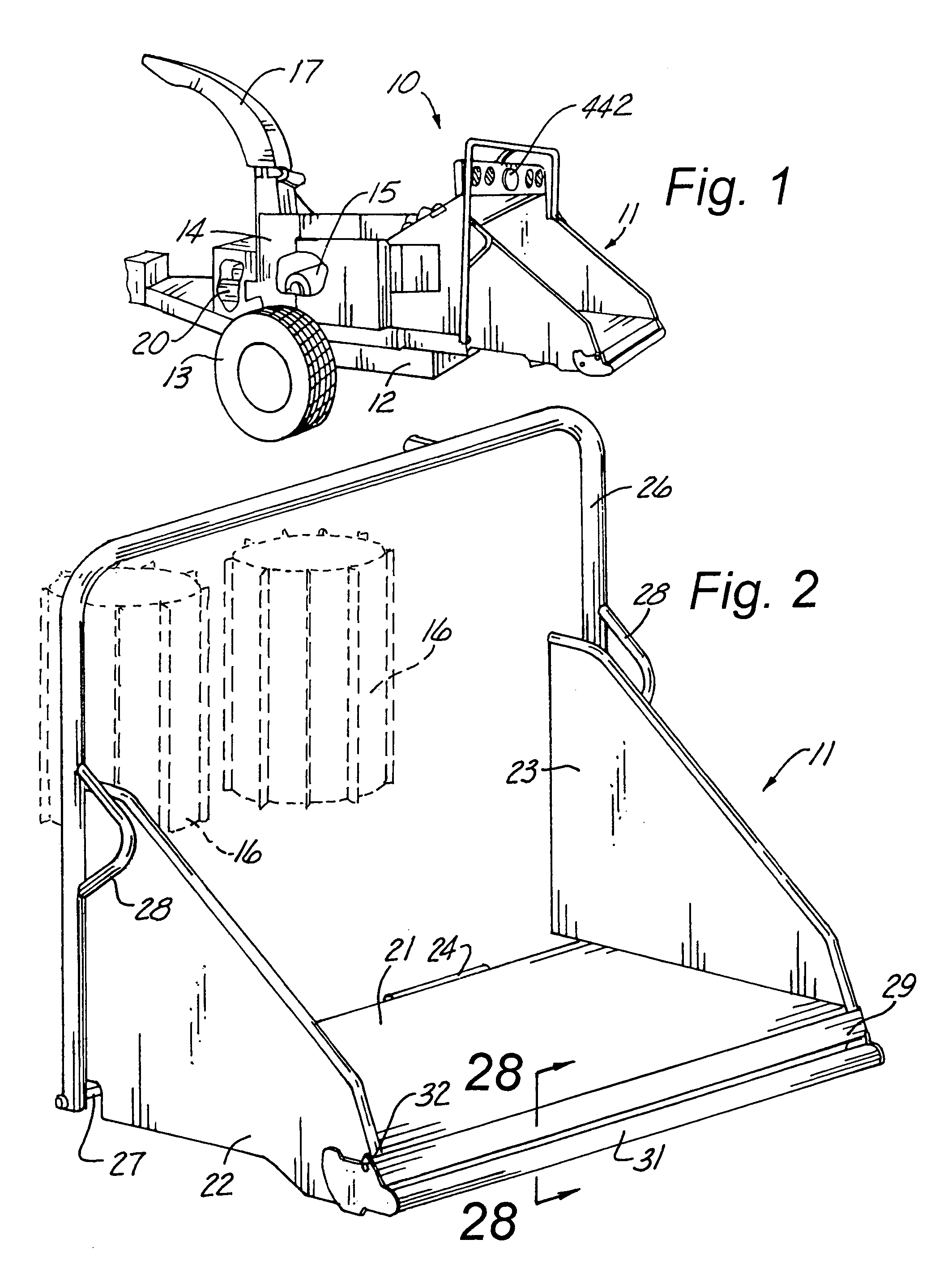

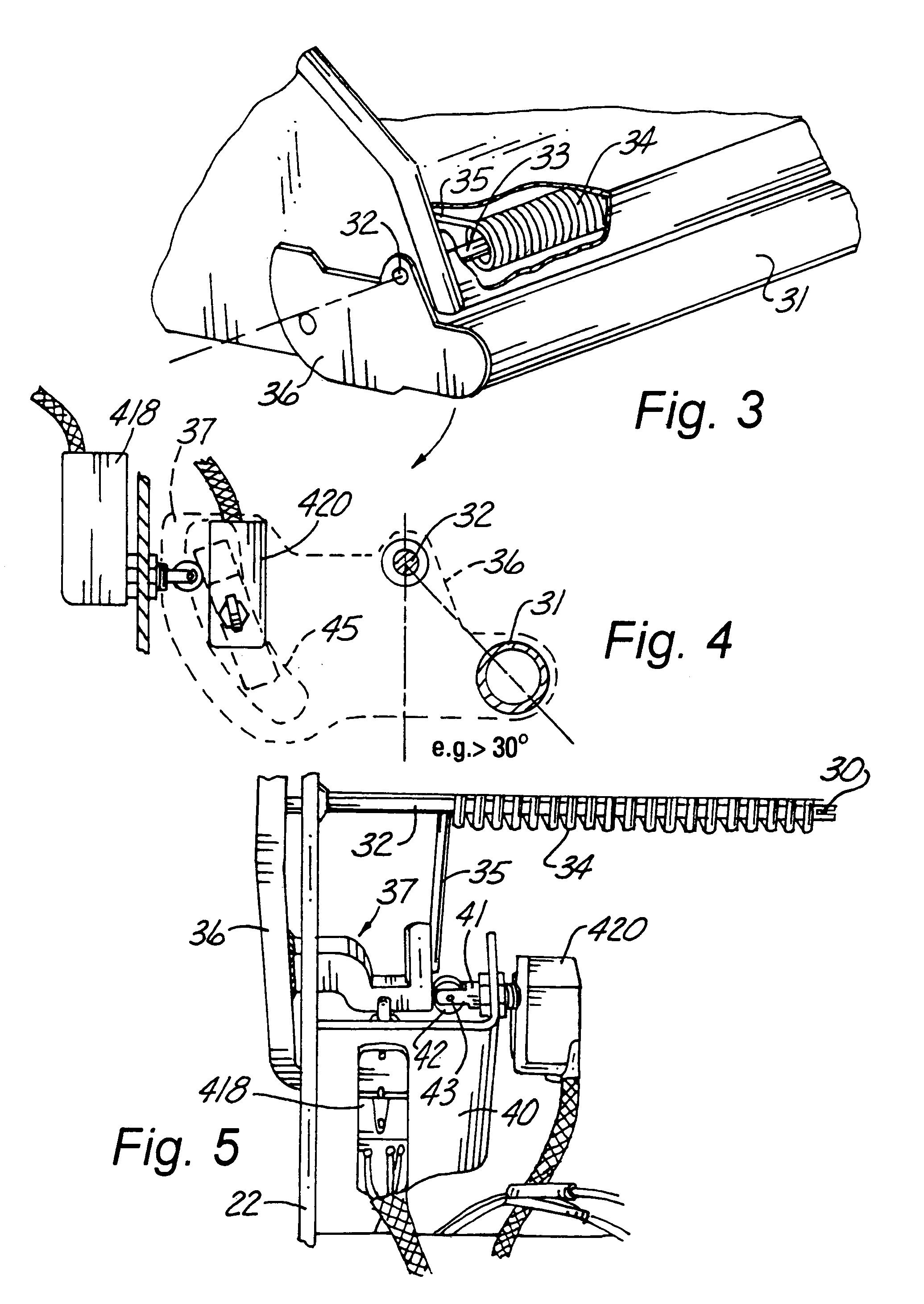

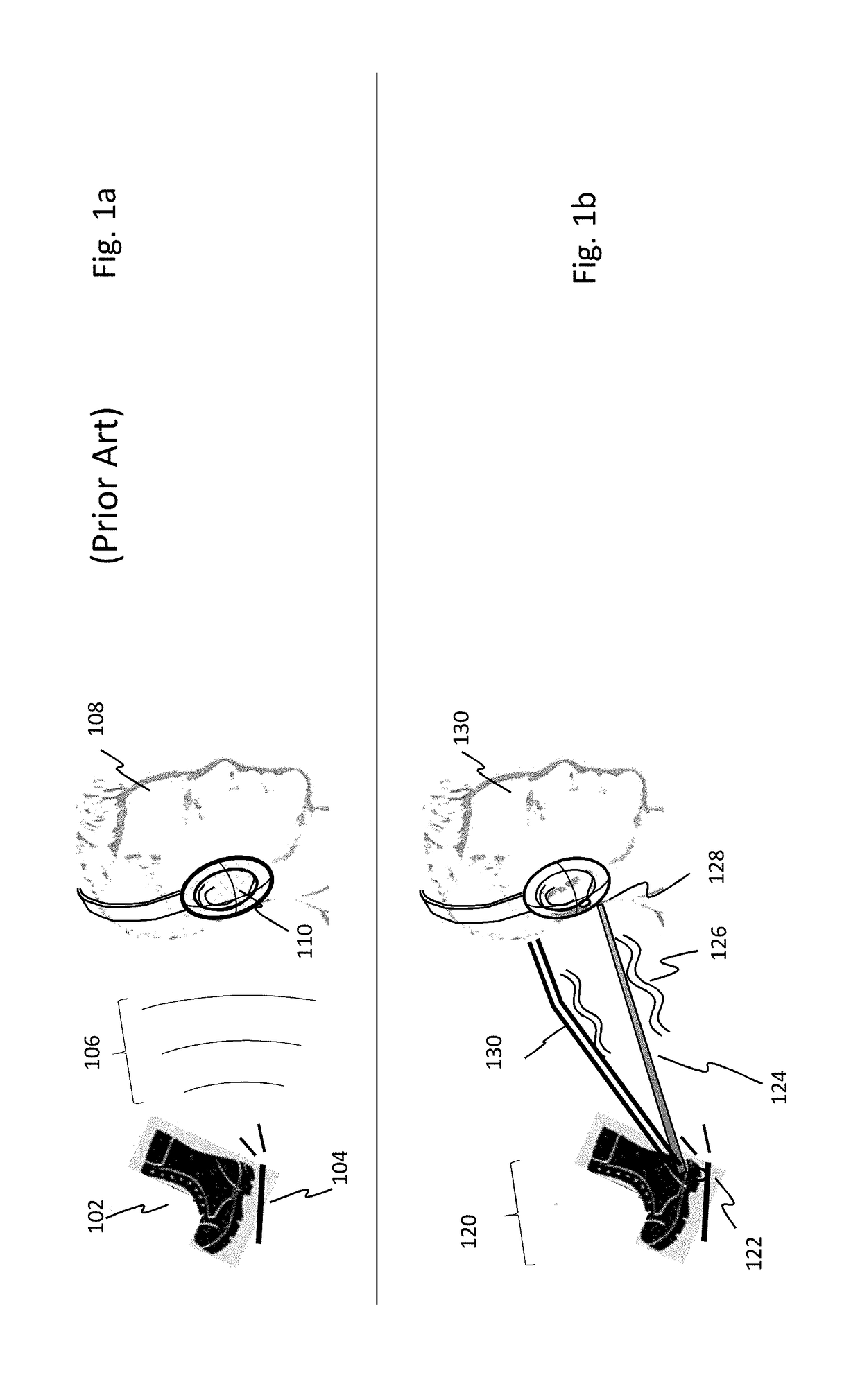

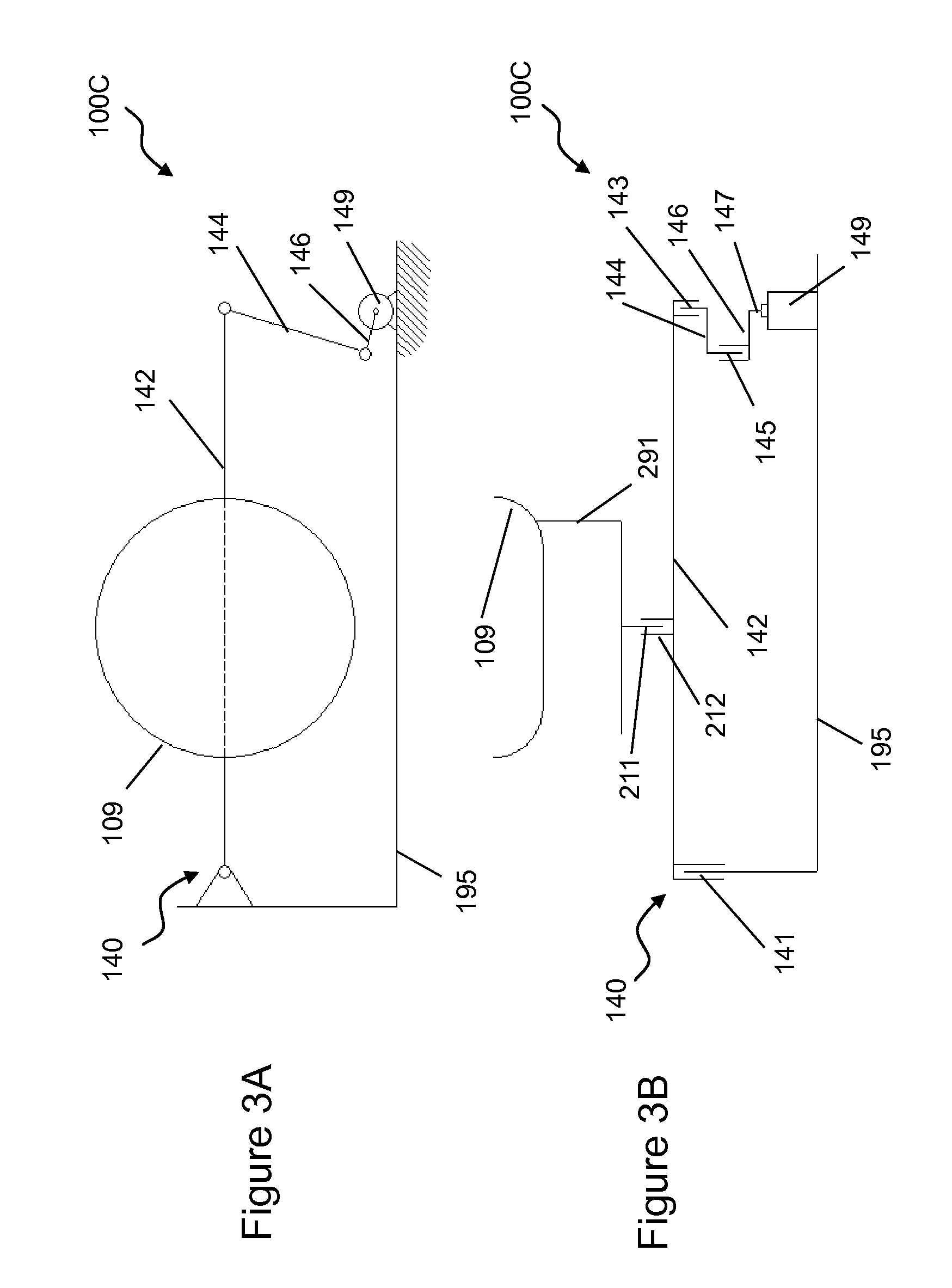

Brush chipper and methods of operating same

InactiveUS7011258B2Mechanism can be overcomeEliminate resistancePlant waste comminutingReed/straw treatmentHydraulic motorControl engineering

An improved brush cutter having an upper feed control member with stop, forward, neutral, and reverse positions also has a lower feed stop member with selectable sensitivity. Another aspect of the invention is to predict the feed roller shutoff point according to the rate of engine deceleration. According to another aspect, when the feed rollers stop feeding material into the cutters, to overcome drag on the cutters, a controller stops the feed rollers and then reverses them for a short time, and then reverses the rollers again if the problem is still present. To prevent jamming, a pressure switch senses when oil in a hydraulic motor system for rotating the feed rollers is too high and the controller momentarily reverses the feed rollers and then causes them to go forward, a cycle which can occur several times until the feed rollers are no longer stalled. By another aspect of the invention, the controller senses characteristics of the brush cutter and chooses an operating system based on the characteristics sensed. The controller can also sense if the brush chipper has not been used for a predetermined period of time and automatically reduce the idle speed of the engine until the brush chipper is used again, and then automatically return the engine to a normal idle speed before the feed rollers will pull brush into the brush chipper.

Owner:VERMEER MFG CO

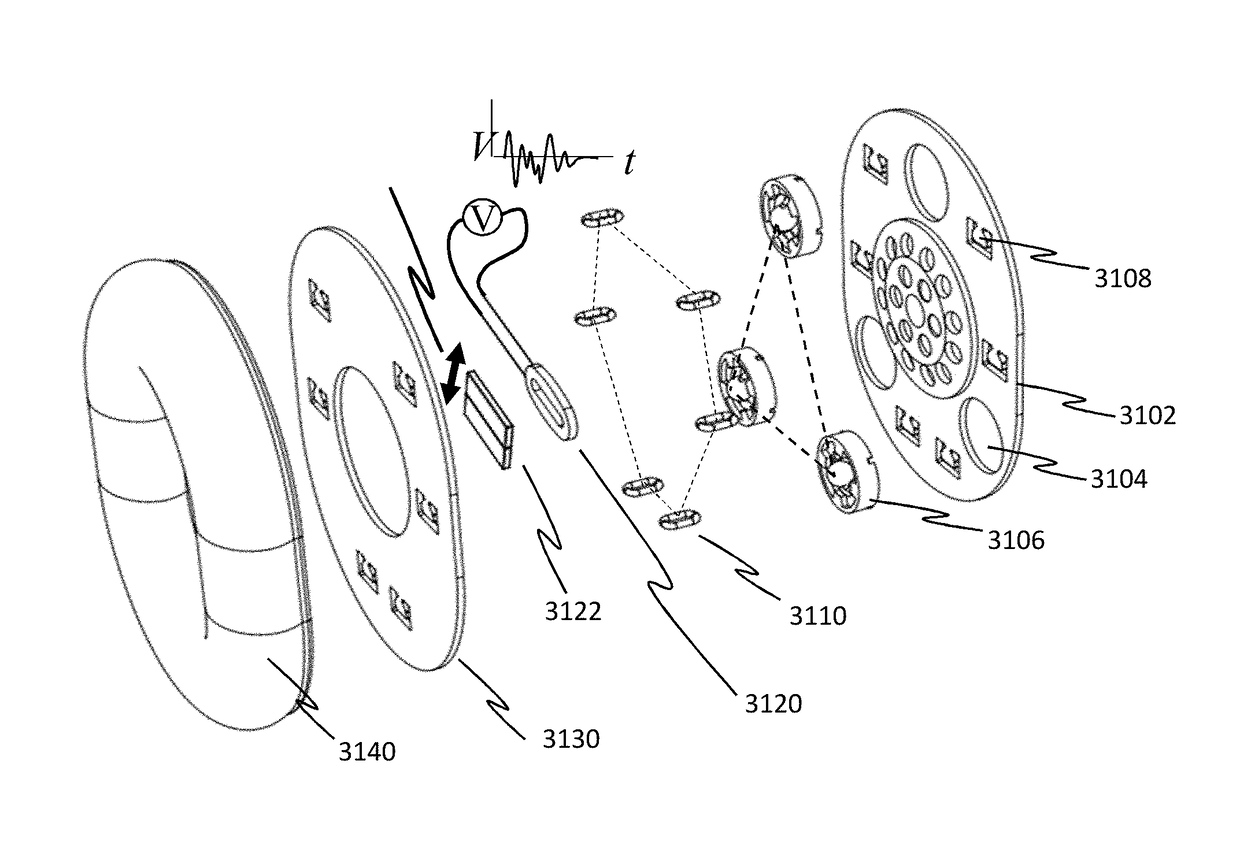

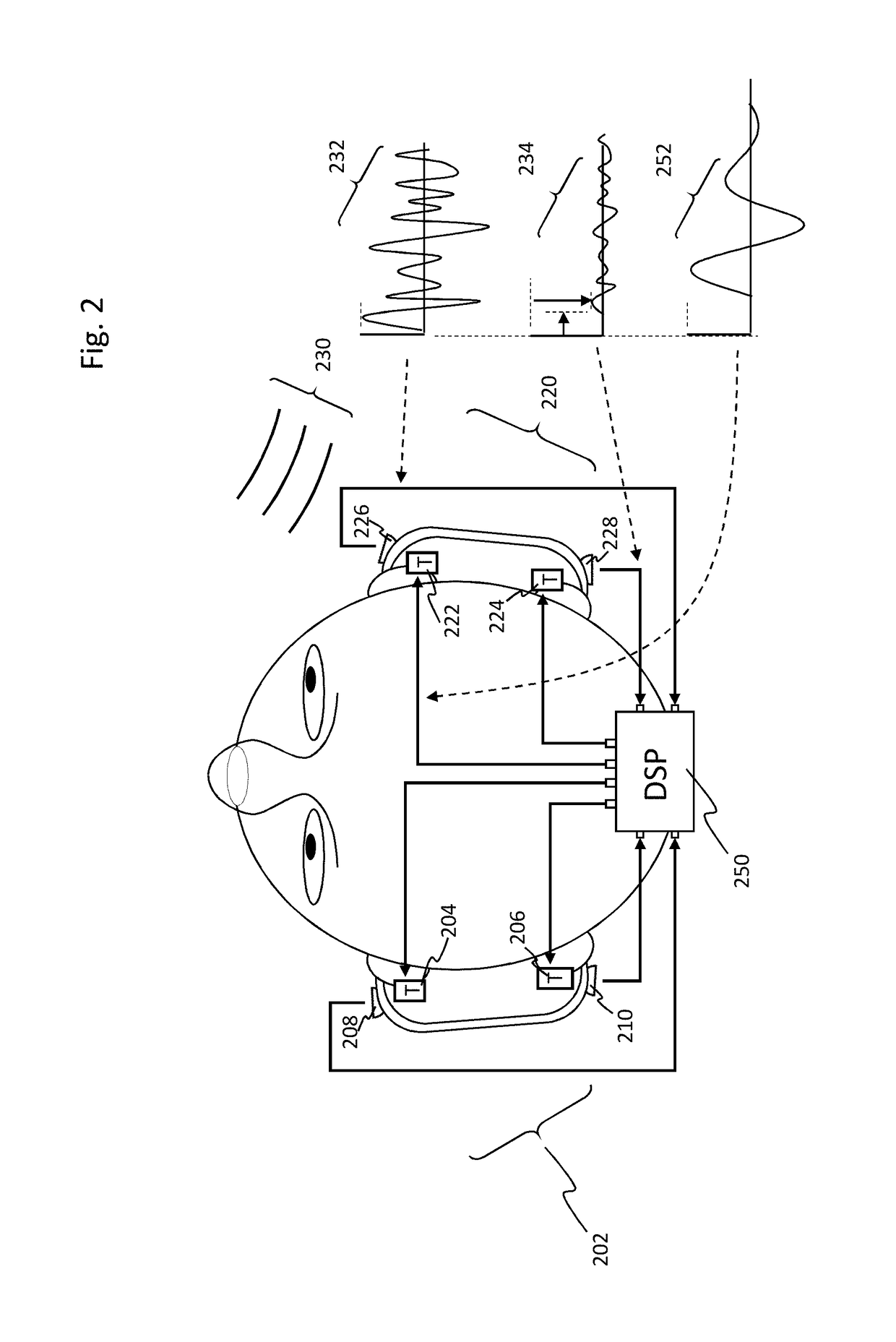

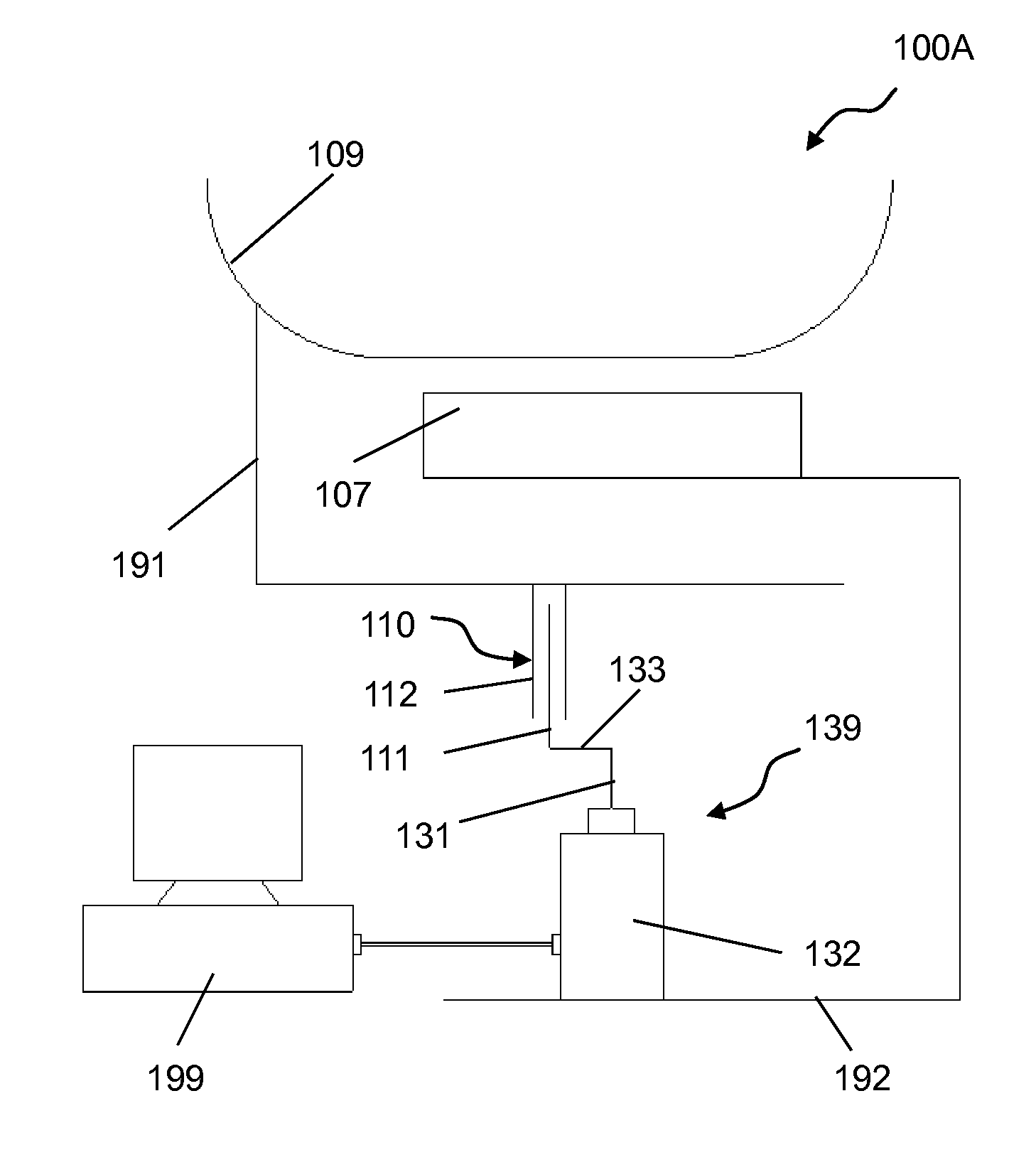

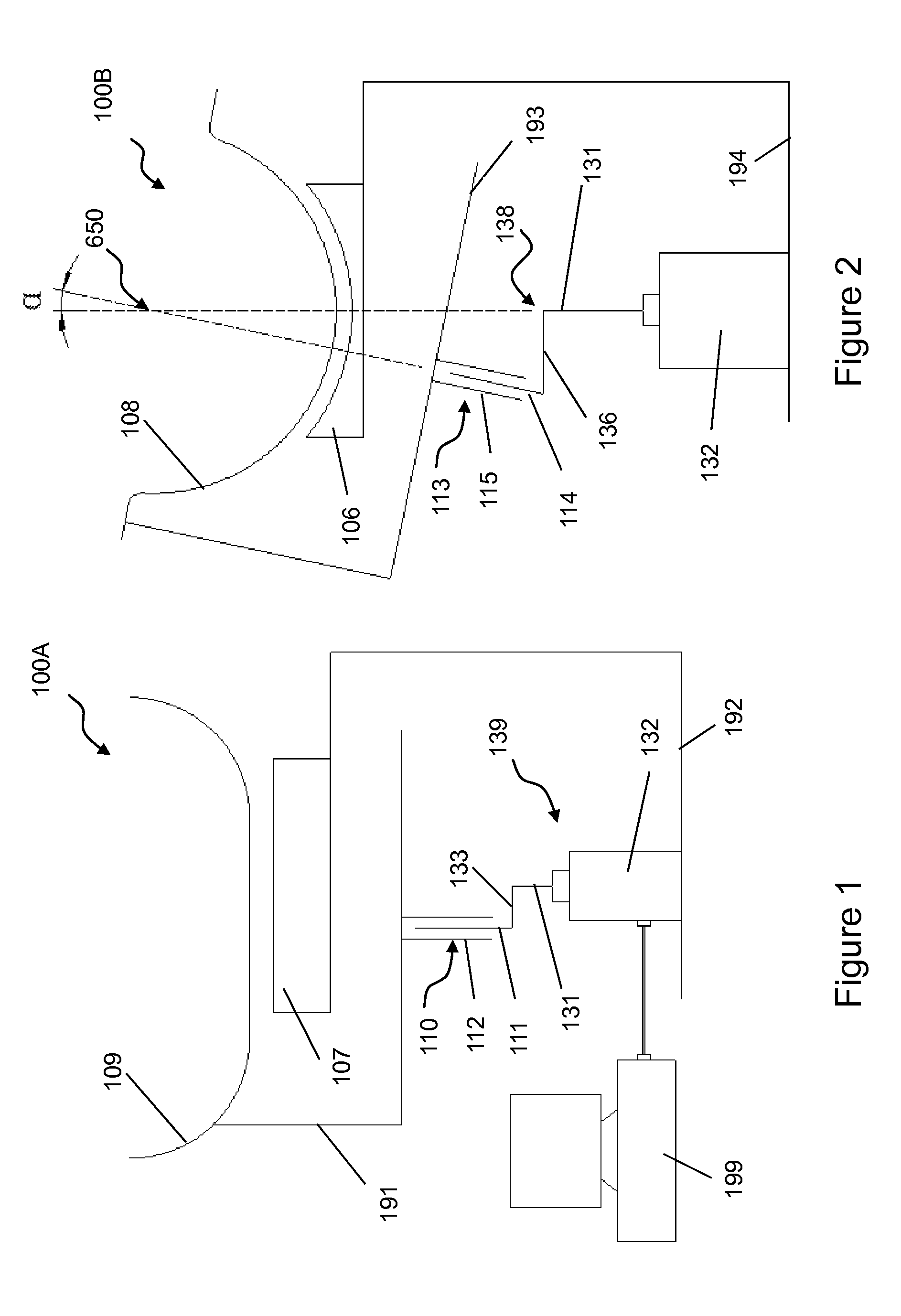

Apparatus and methods for audio-tactile spatialization of sound and perception of bass

ActiveUS20170180863A1Accurately produce wide range of tactile frequencyImprove user experienceHeadphones for stereophonic communicationBone conduction transducer hearing devicesImage resolutionTactile illusions

The apparatus and methods of the present invention provide quiet, compact, robust hardware that can accurately produce a wide range of tactile frequencies at a perceptually constant intensity. For greater expressiveness, some apparatus for moving the skin in multiple axes are also disclosed. Signal processing methods are presented to enhance the user's experience of audio spatialization. The methods transform audio signals into directional tactile cues matched to the time resolution of the skin, and which exploit directional tactile illusions.

Owner:TACTION TECH

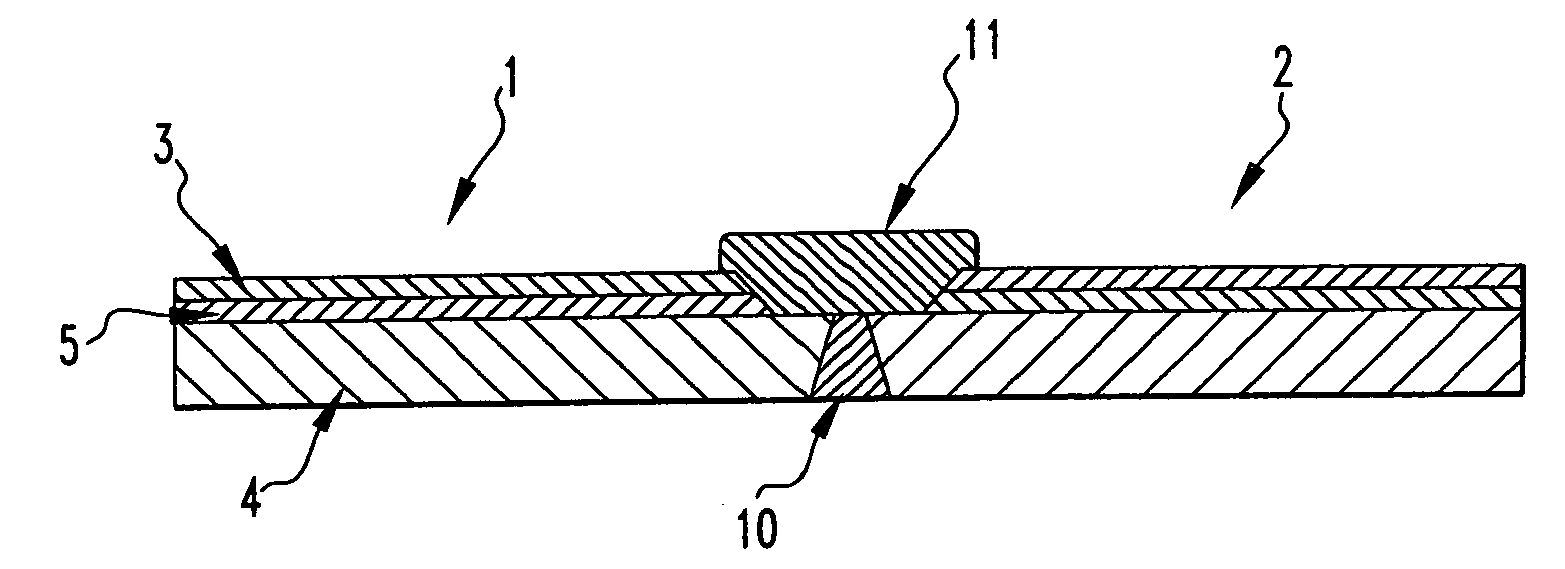

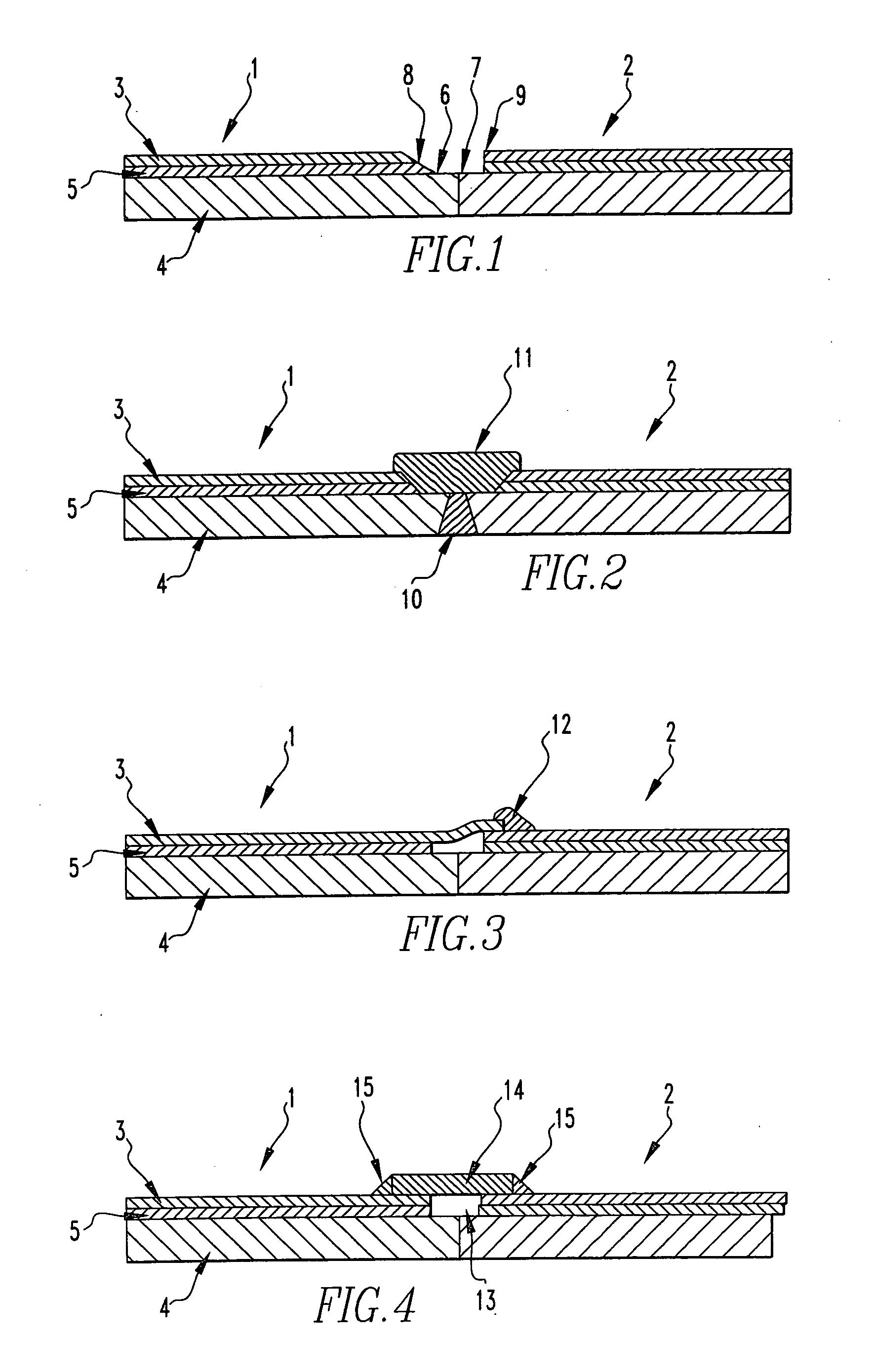

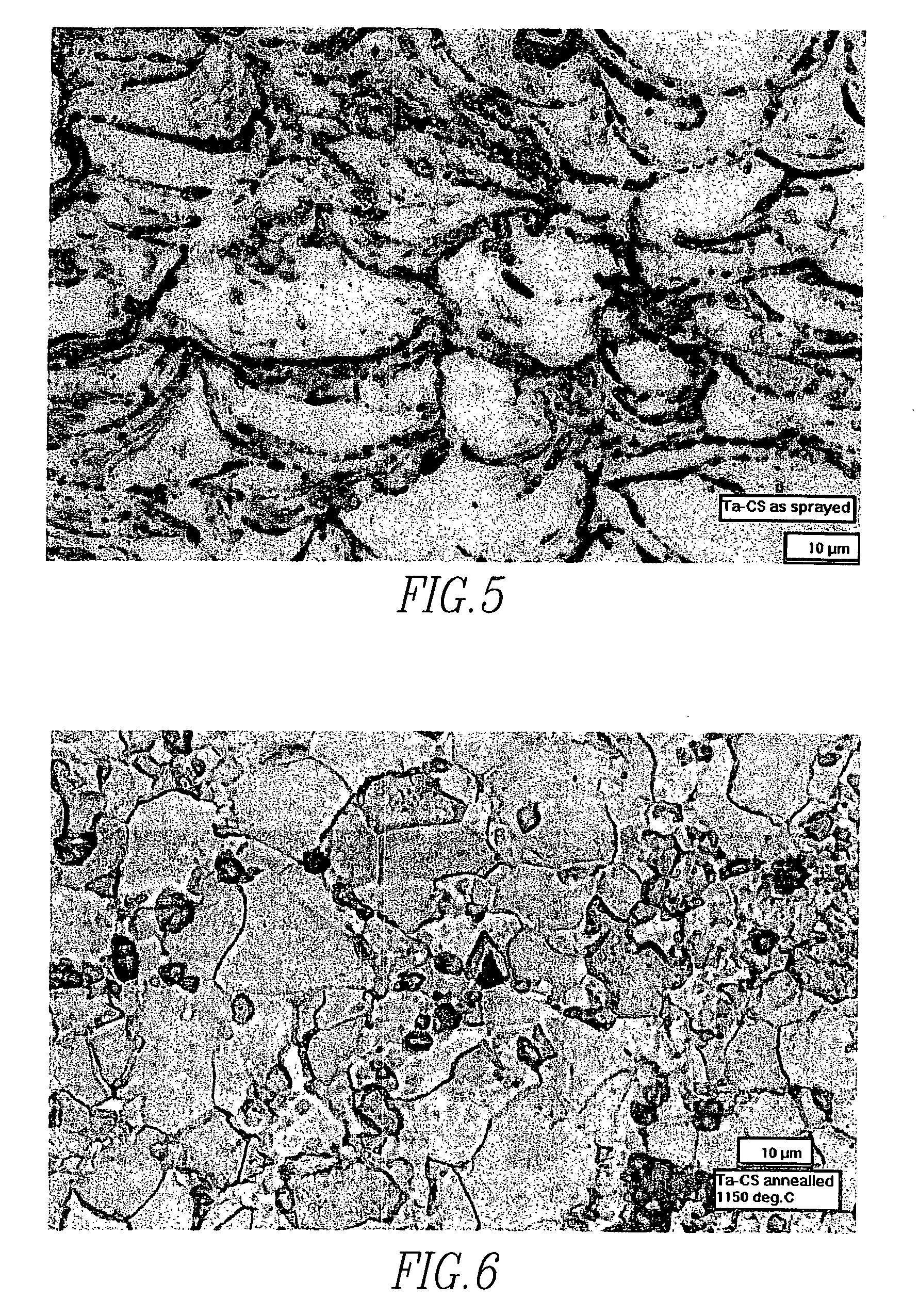

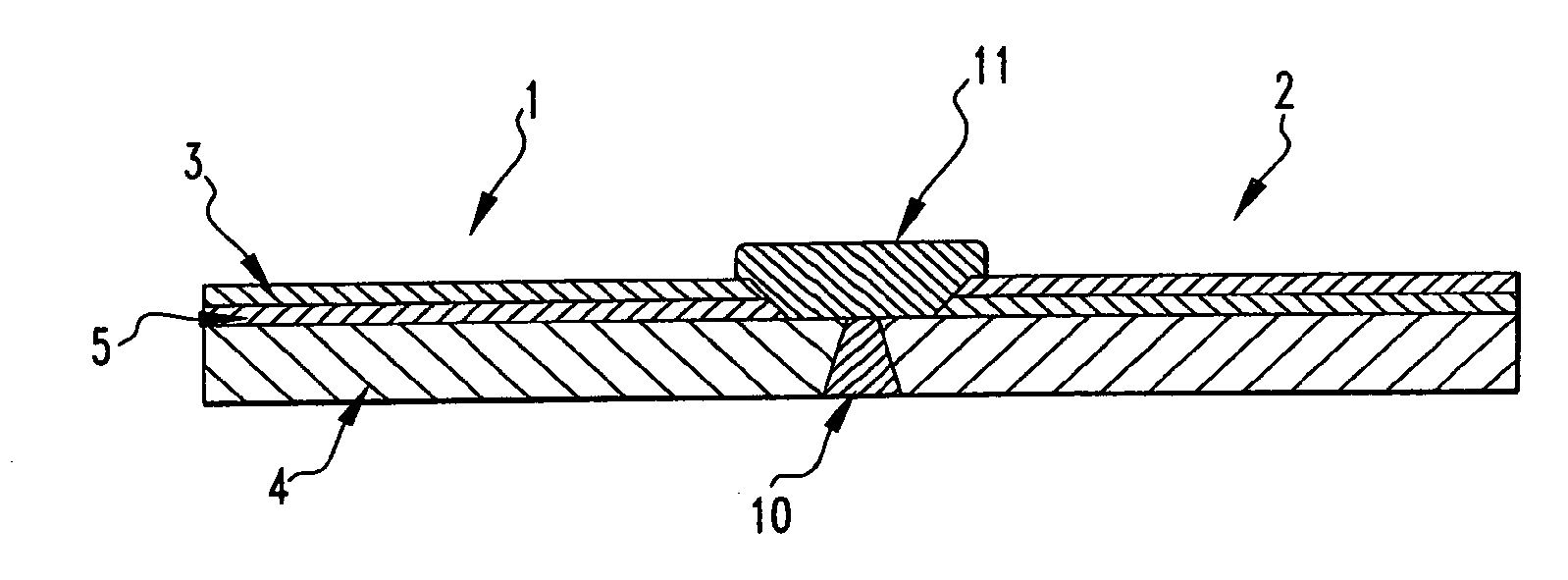

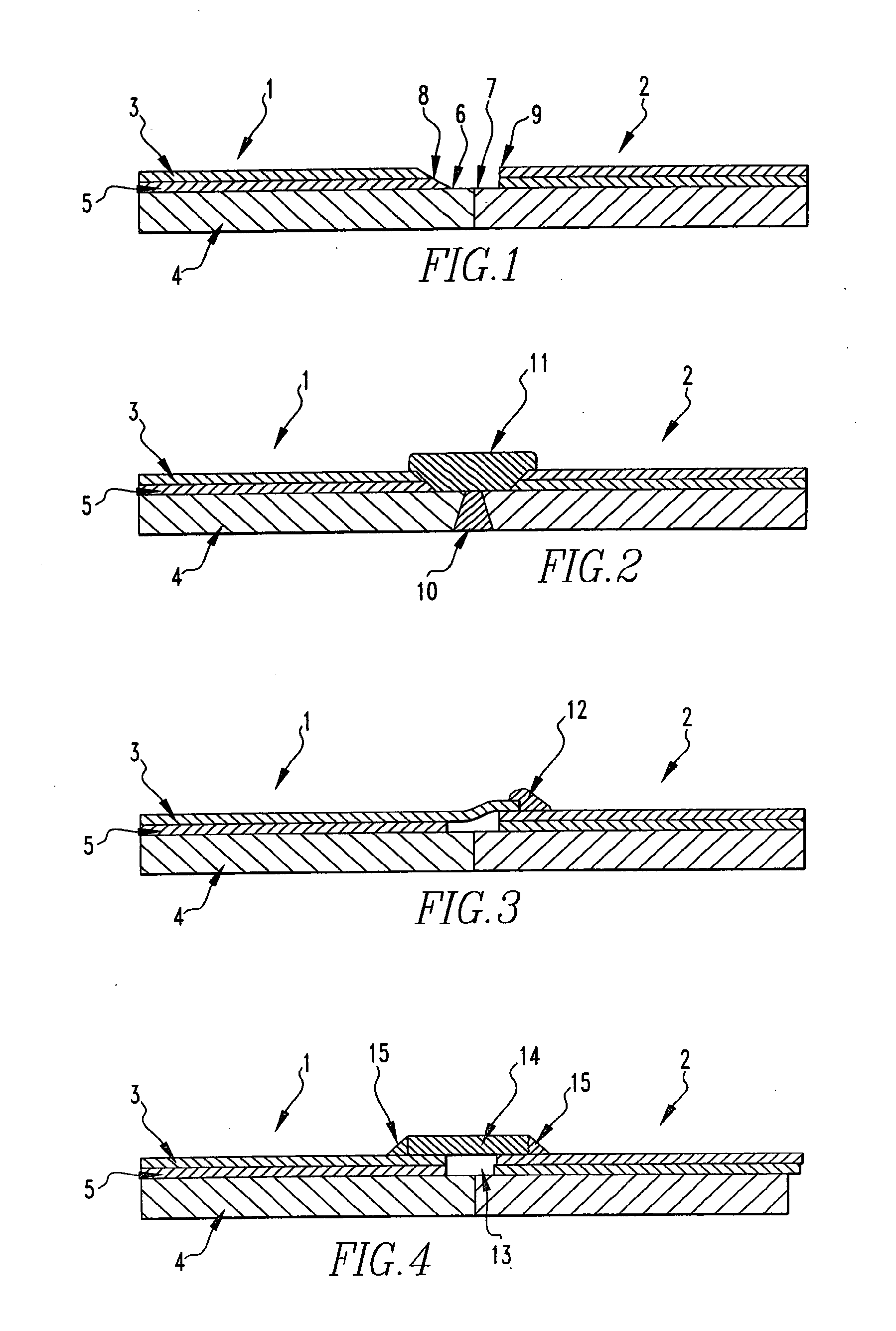

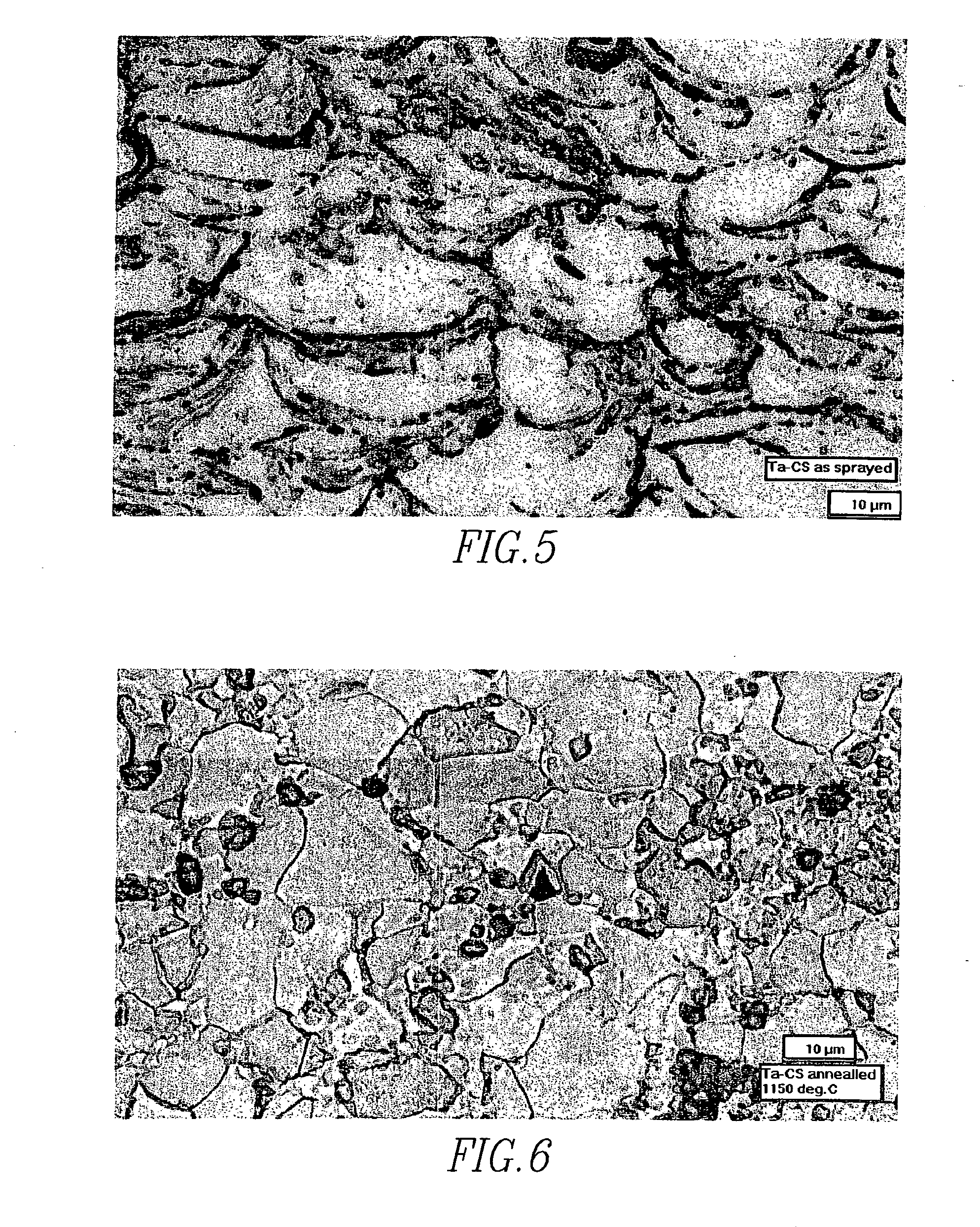

Method of joining tantalum clade steel structures

InactiveUS20080145688A1Reduce oxidationHigh densityLamination ancillary operationsLaminationTantalumEdge region

The present invention is directed to a process for joining tantalum clad steel structures. The process broadly comprises:a) providing a first tantalum clad section, said first tantalum clad section comprising a tantalum layer over a steel layer, with a bonding layer optionally therebetween, with a portion of said steel layer in an edge region not being covered by said tantalum layer or said bonding layer,b) providing a second tantalum clad section, said second tantalum clad section comprising a tantalum layer over a steel layer, with a bonding layer optionally therebetween, with a portion of said steel layer in an edge region not being covered by said tantalum layer or said bonding layer,c) locating said steel edge regions adjacent each other,d) welding the steel edge regions together,e) cold spraying a tantalum powder onto the welded edge regions and over the tantalum layers adjacent said edge regions thereby joining the tantalum clad steel sections.The invention is also directed to tantalum welds or joints formed by cold spraying tantalum powder.

Owner:GLAS TRUST +1

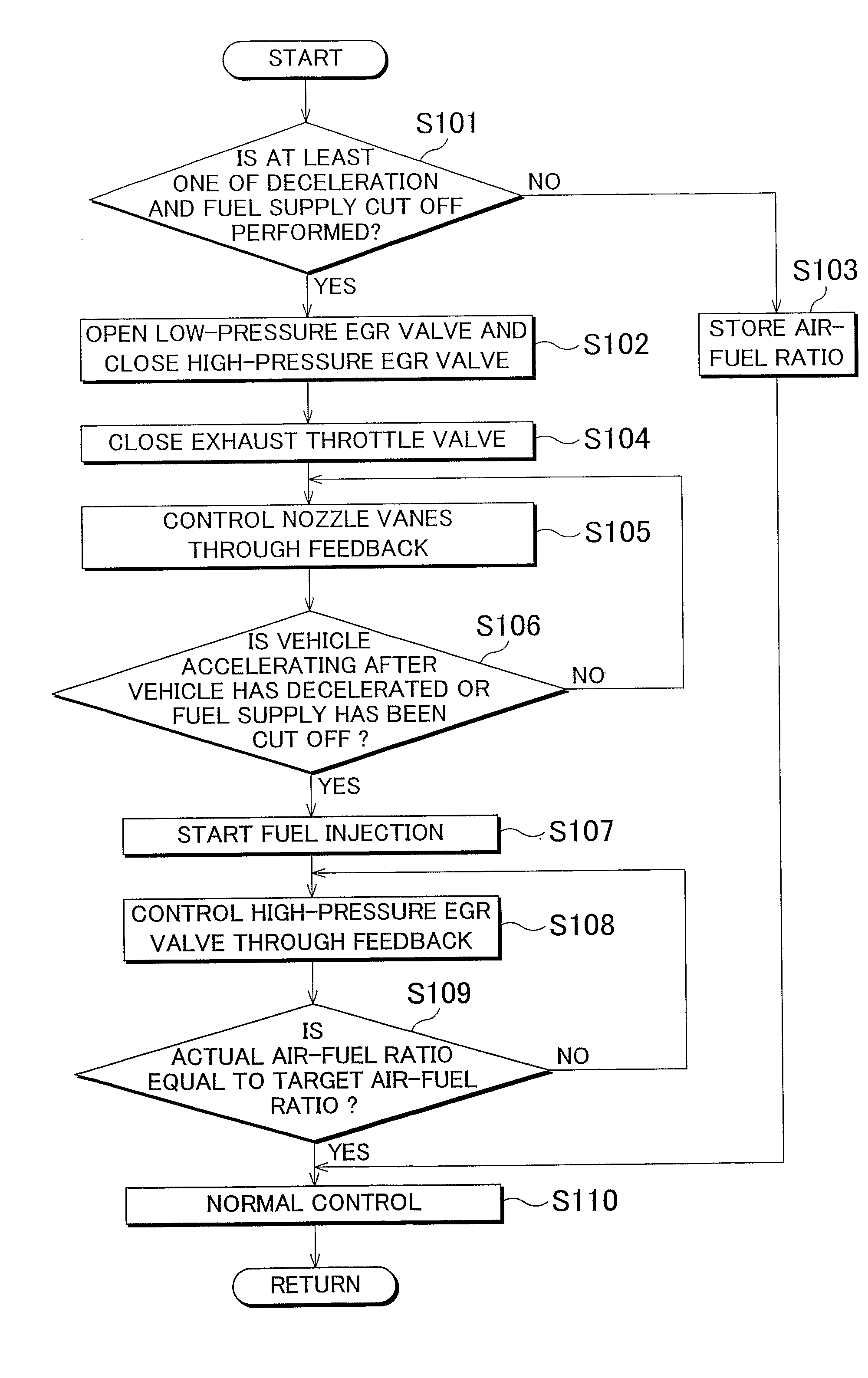

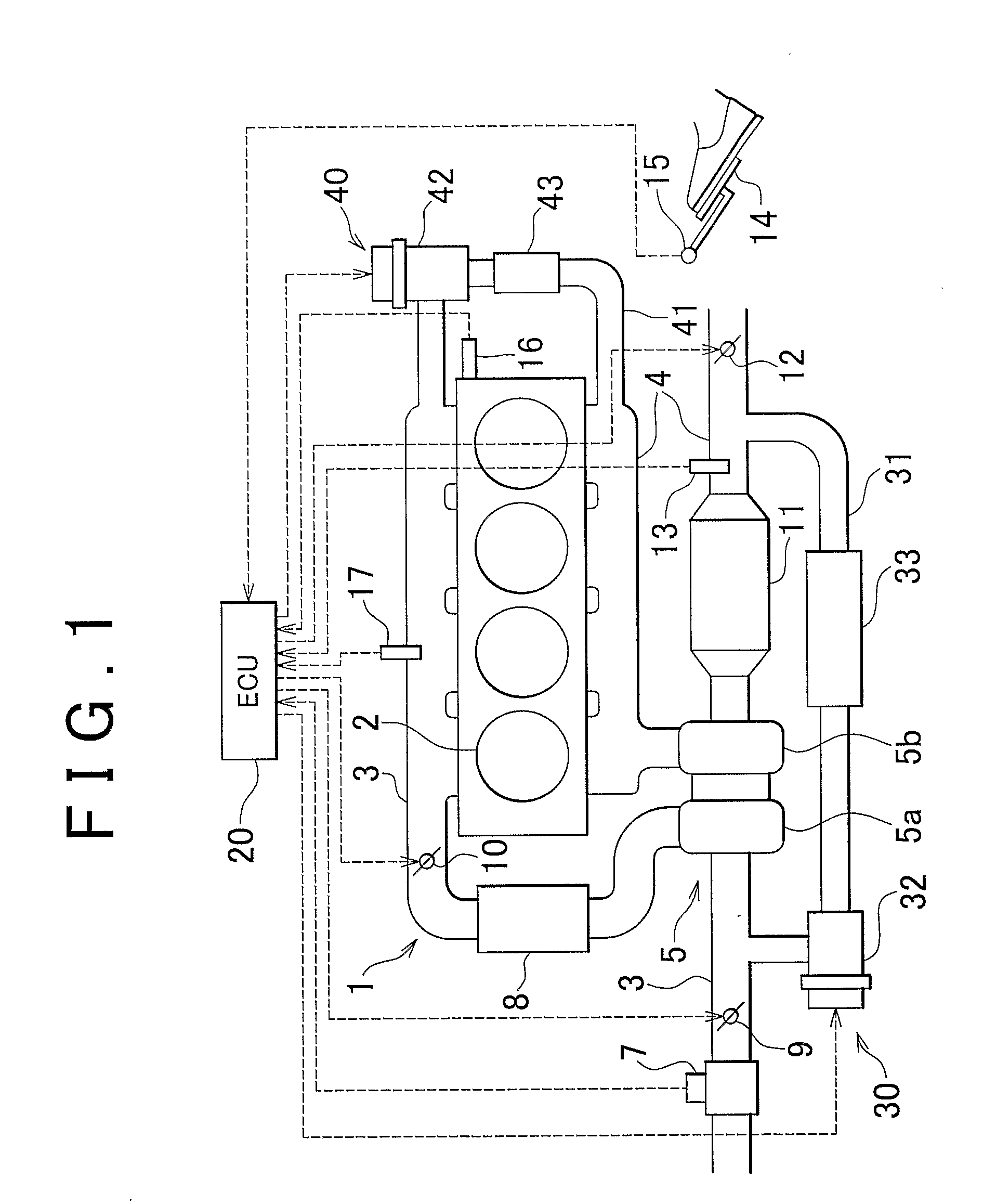

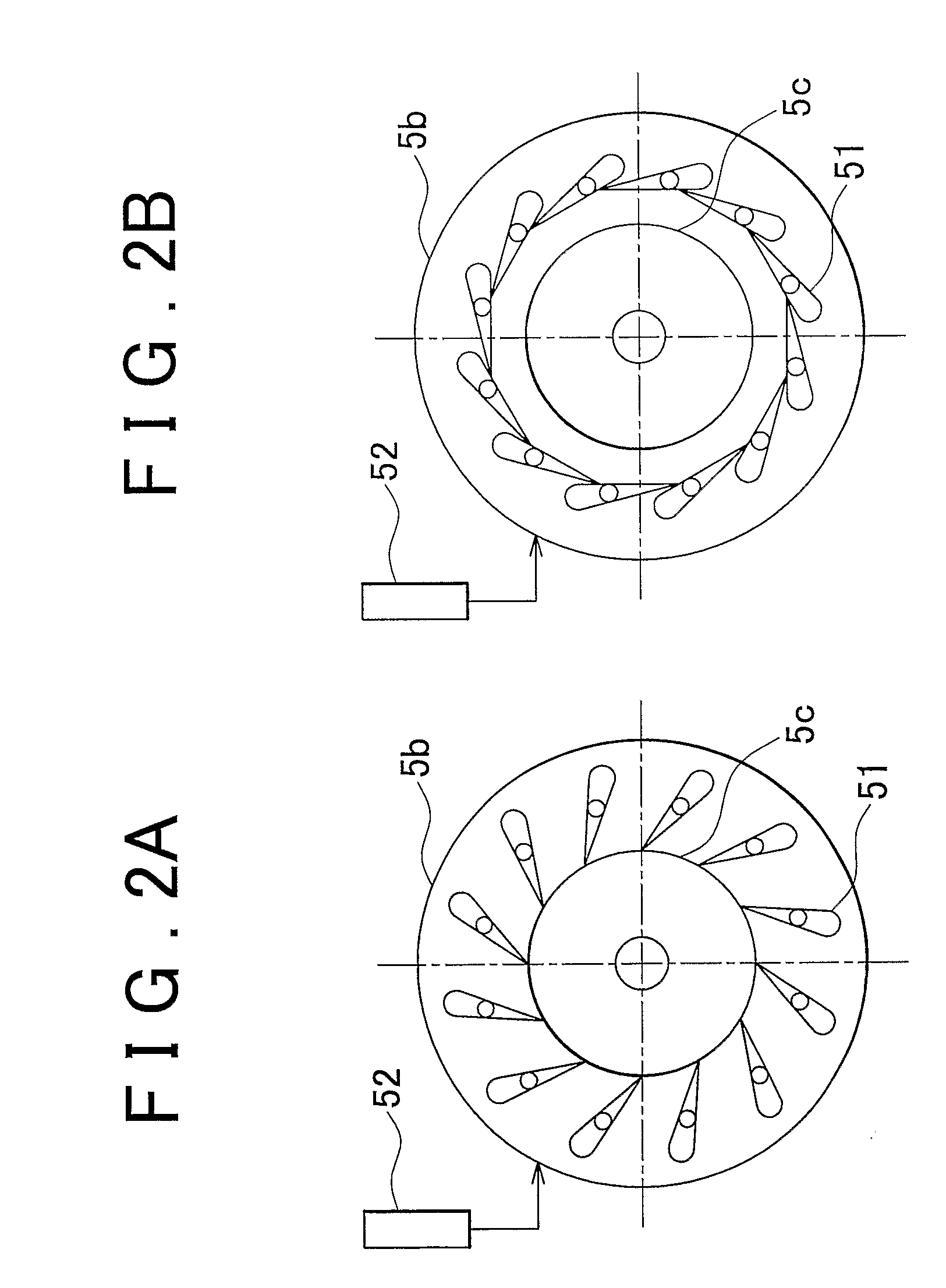

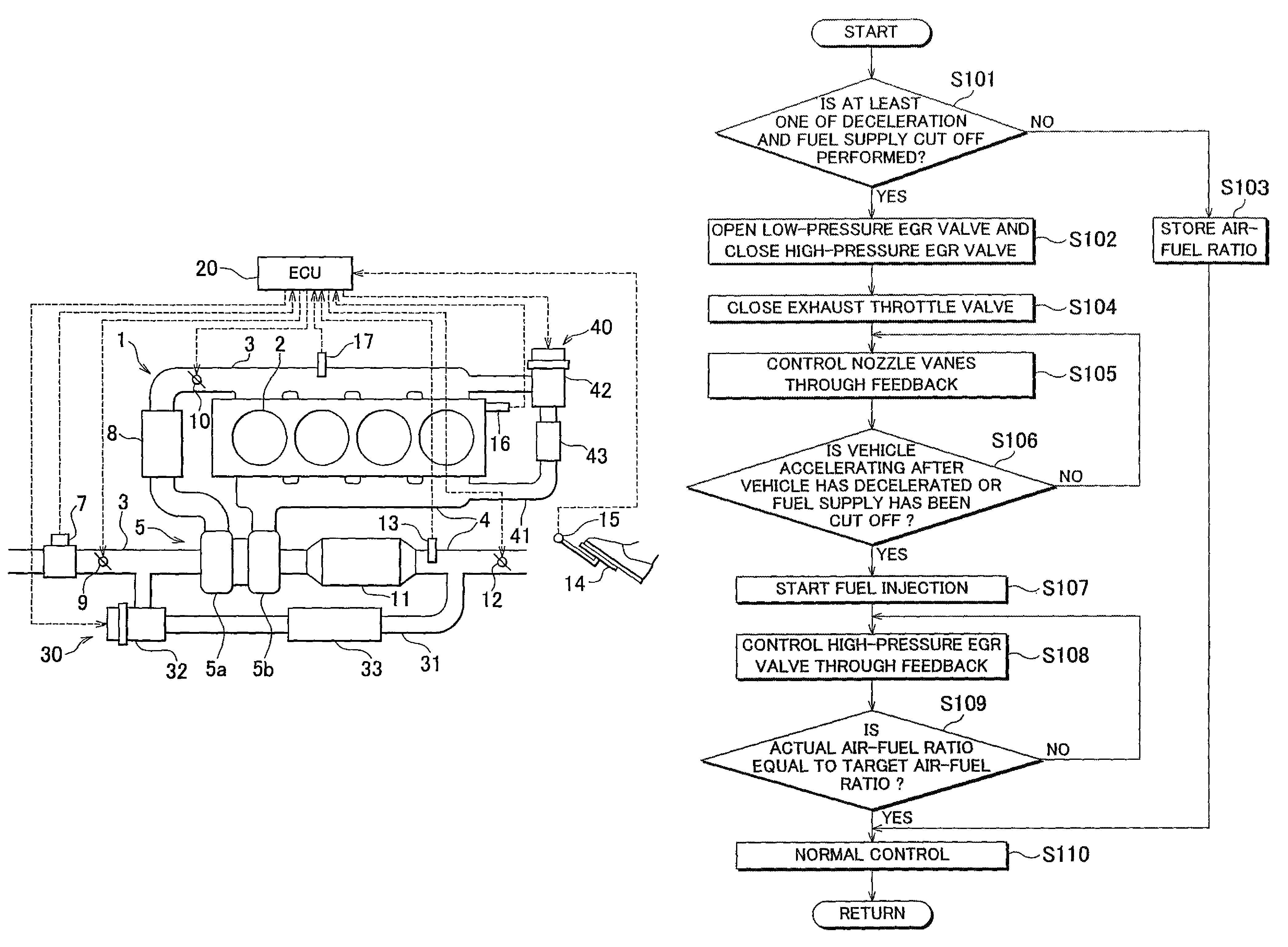

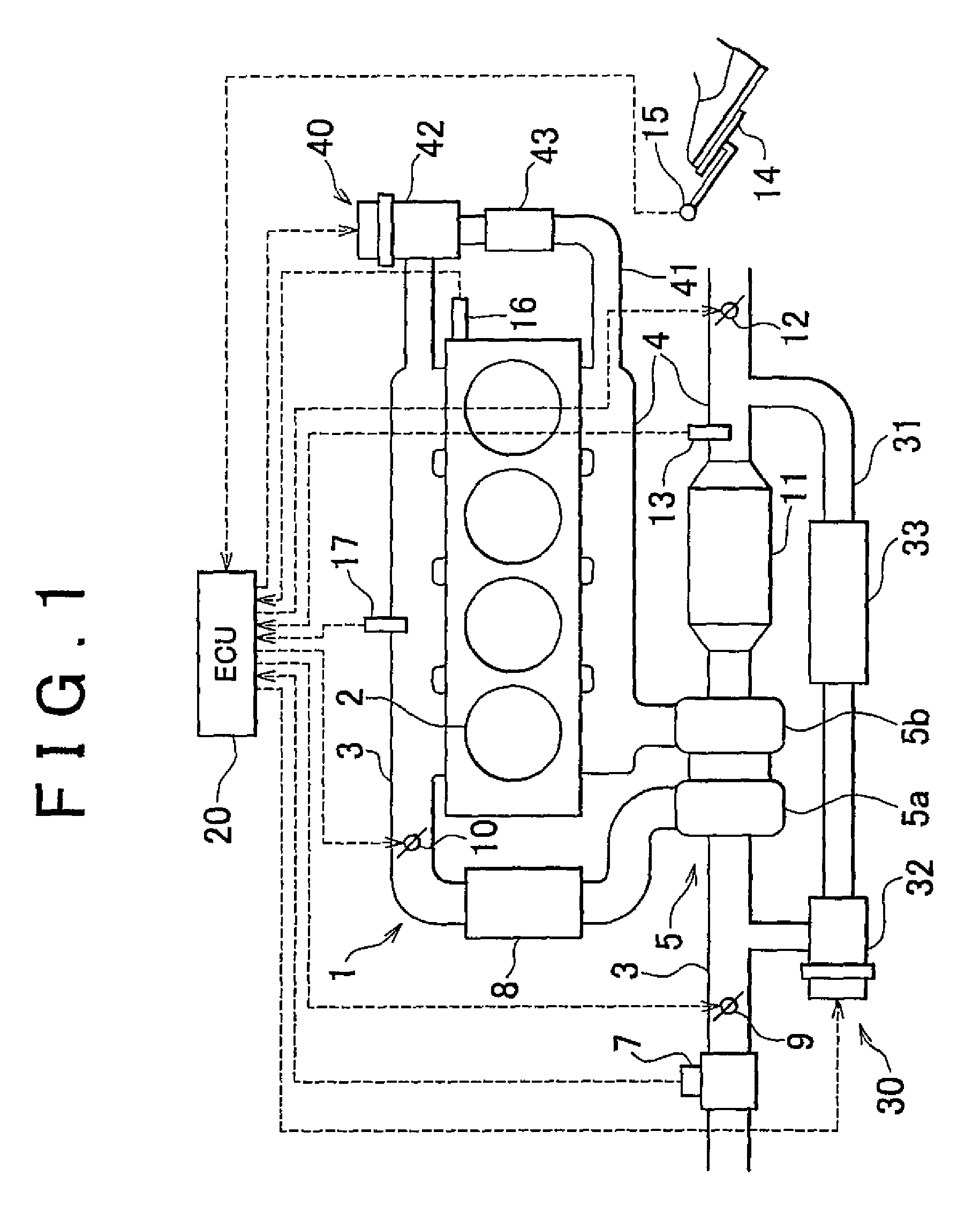

Exhaust gas recirculation apparatus for internal combustion engine and method of controlling exhaust gas recirculation apparatus

ActiveUS20090038308A1Quickly accelerateSuppress dischargeElectrical controlInternal combustion piston enginesFuel supplyVariable-geometry turbocharger

A variable-geometry turbocharger and a low-pressure EGR passage are provided. The variable-geometry turbocharger includes a turbine provided in an exhaust passage, and a compressor provided in an intake passage. In the variable-geometry turbocharger, the cross sectional area of a path through which exhaust gas passes is adjusted by adjusting the opening degree of a nozzle vane. The low-pressure EGR passage connects the area of the exhaust passage downstream of the turbine to the area of the intake passage upstream of the compressor. The EGR gas is recirculated to the intake passage through the low-pressure EGR passage. The EGR gas is directed to flow through the low-pressure EGR passage when a vehicle is decelerating or when fuel supply to the internal combustion engine is cut off. The pressure in the intake passage is adjusted toward a target pressure by adjusting the opening degree of the nozzle vane when the EGR gas flows through the low-pressure EGR passage.

Owner:TOYOTA JIDOSHA KK

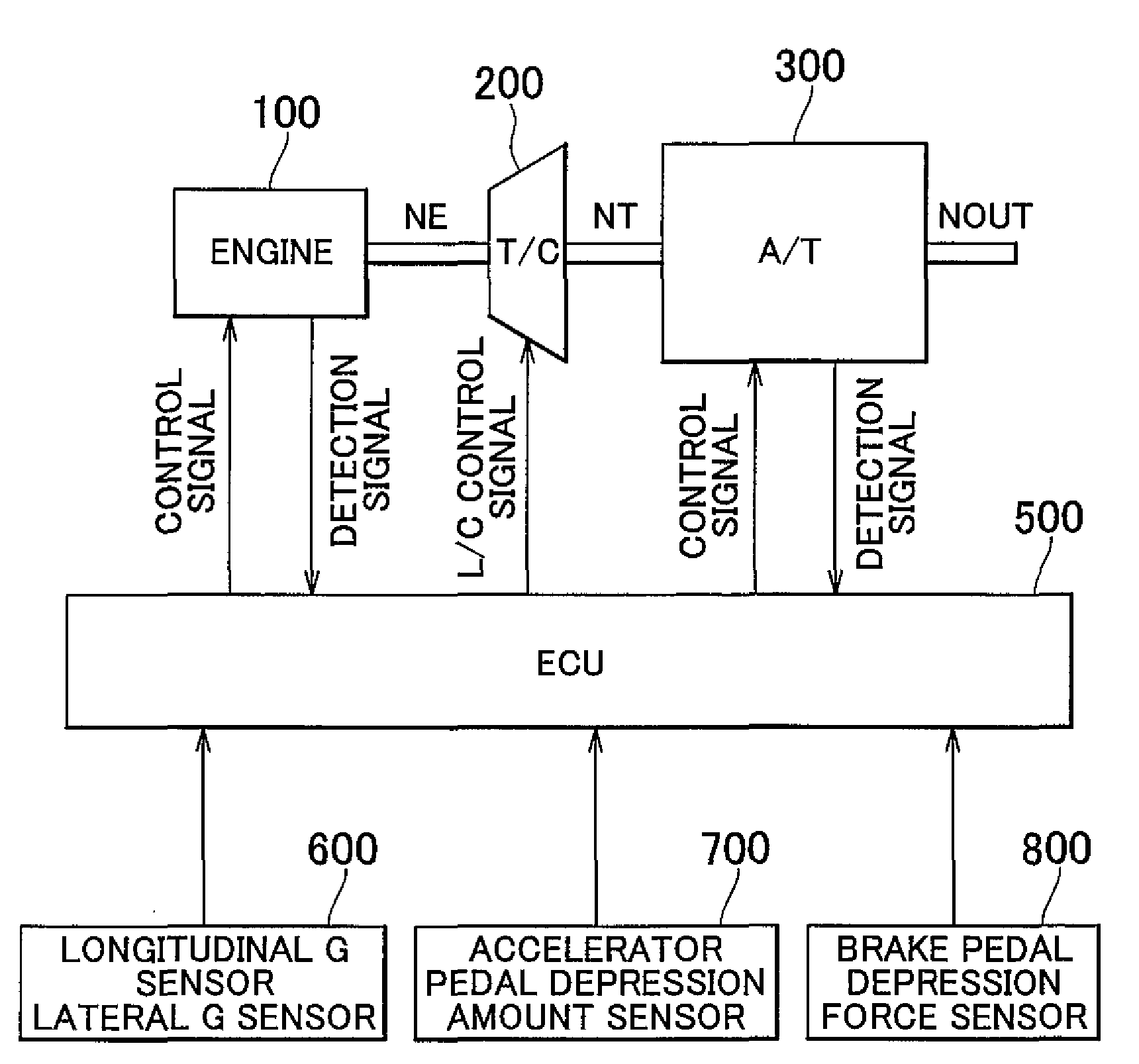

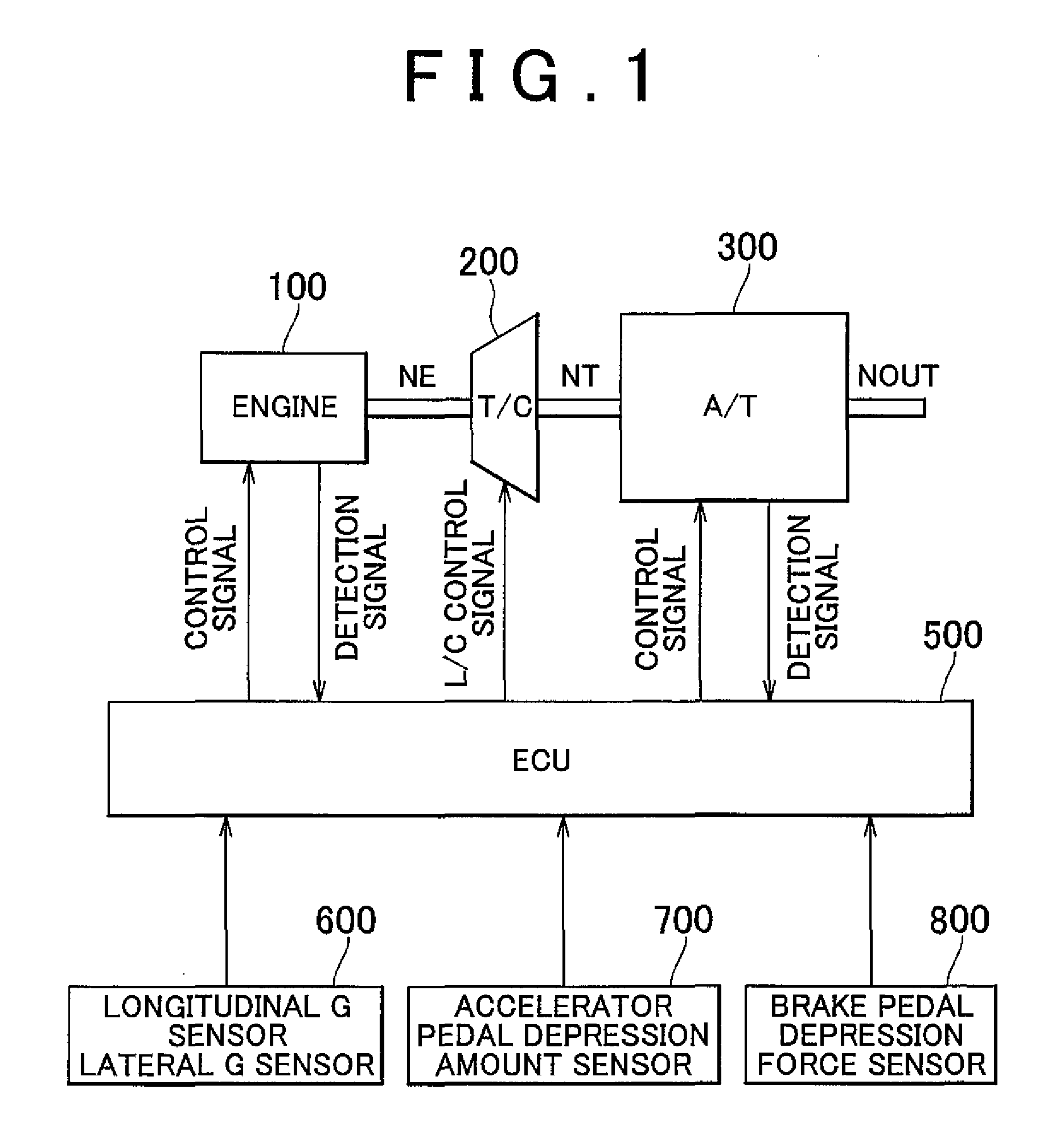

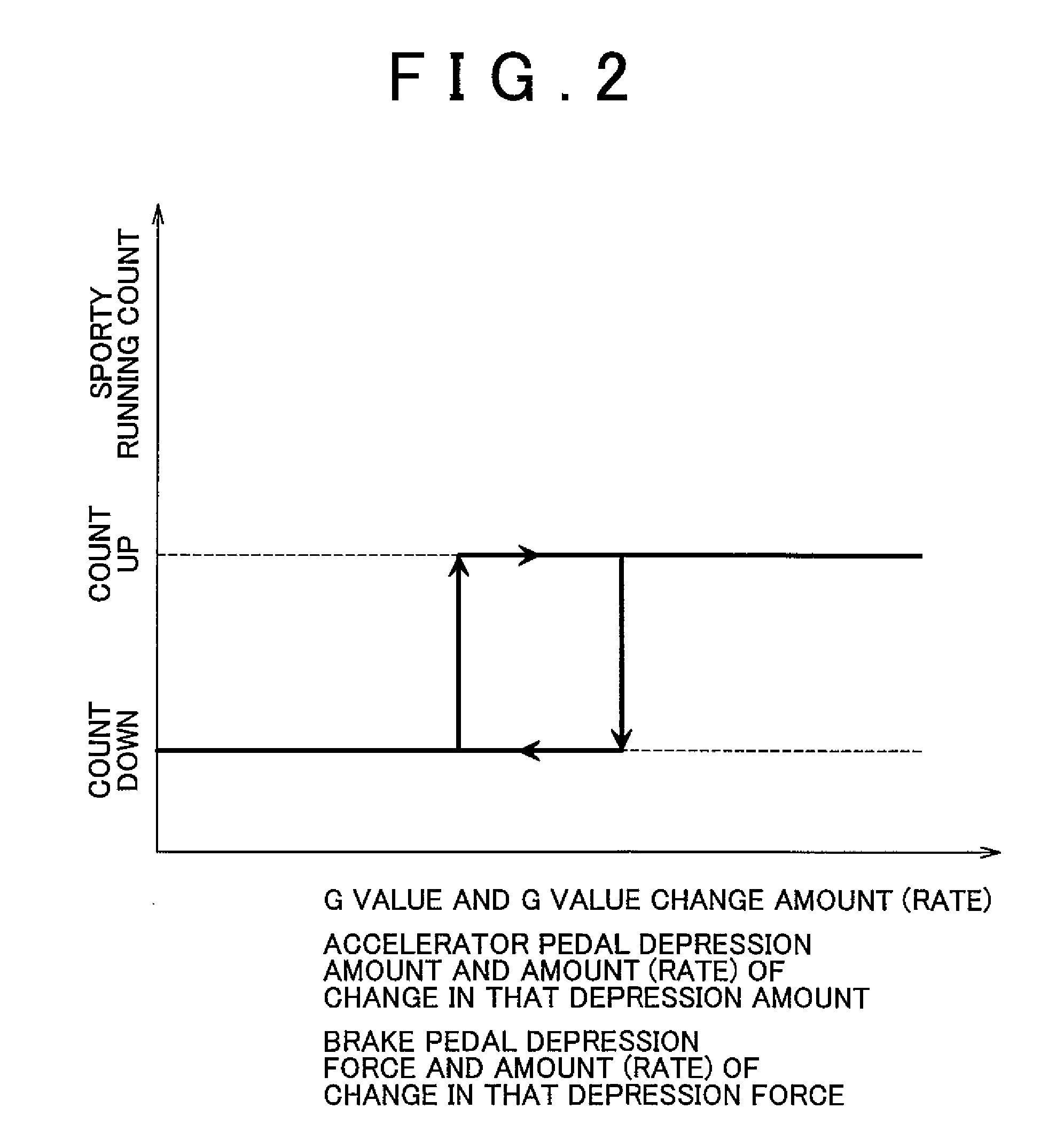

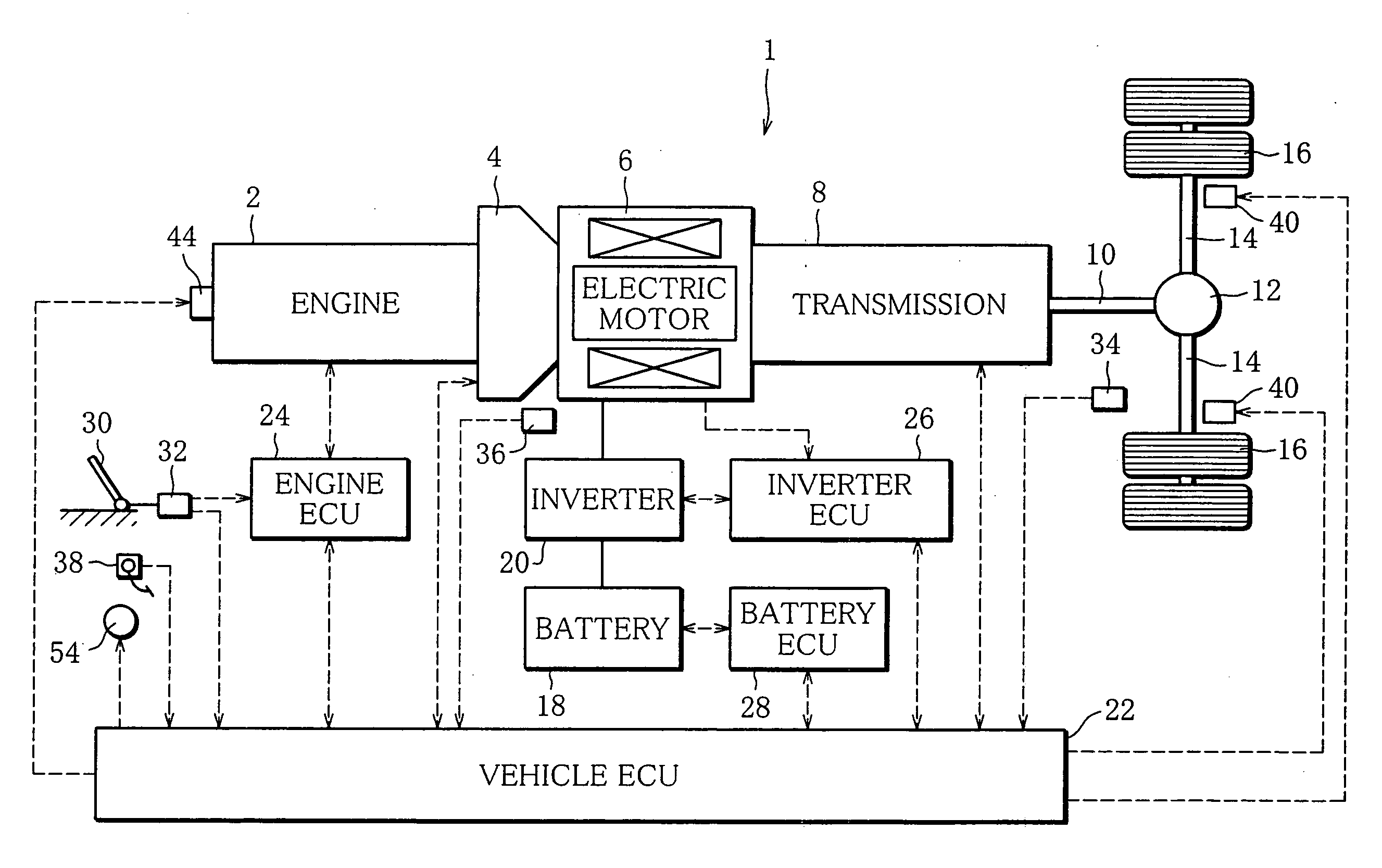

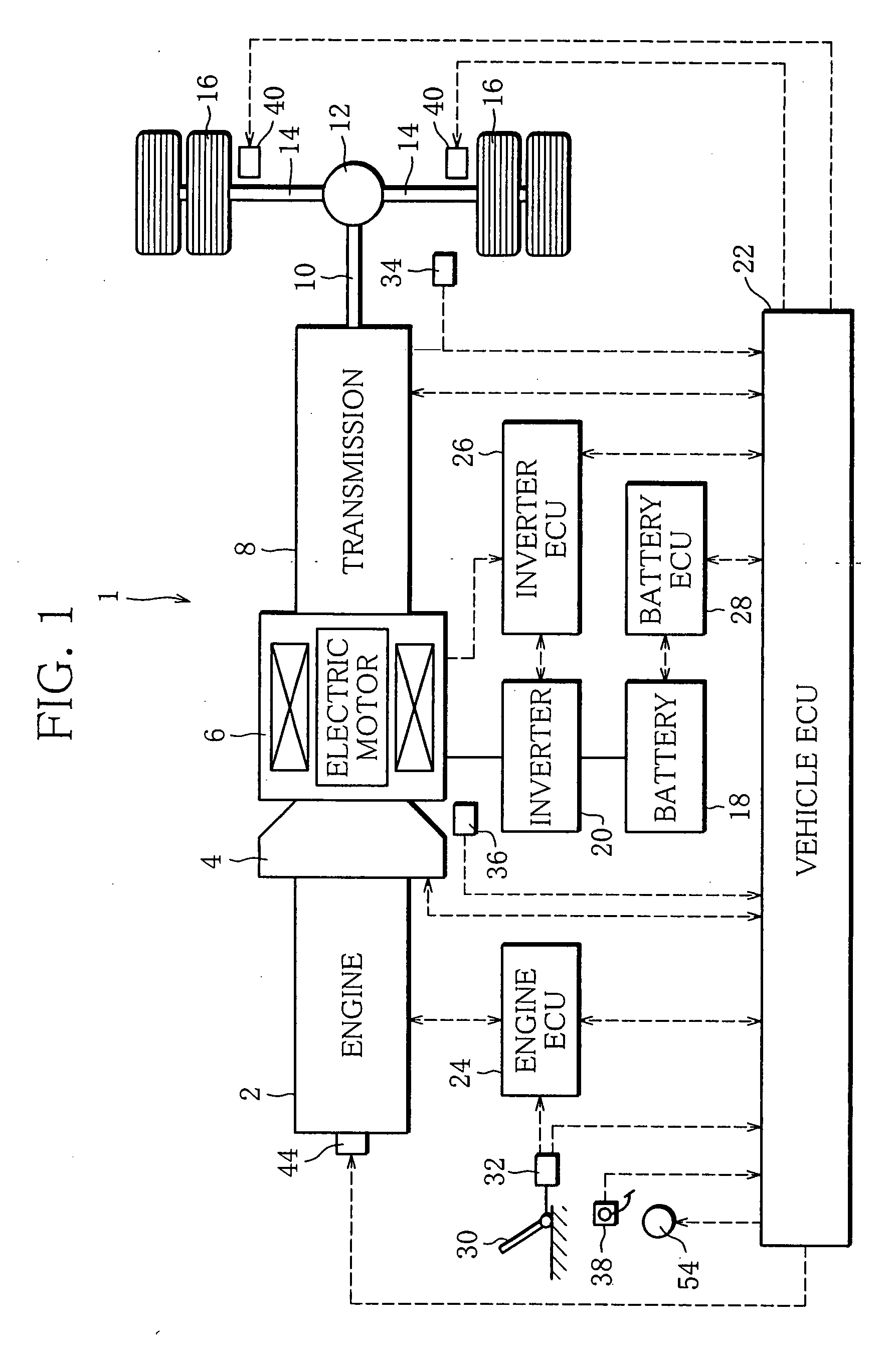

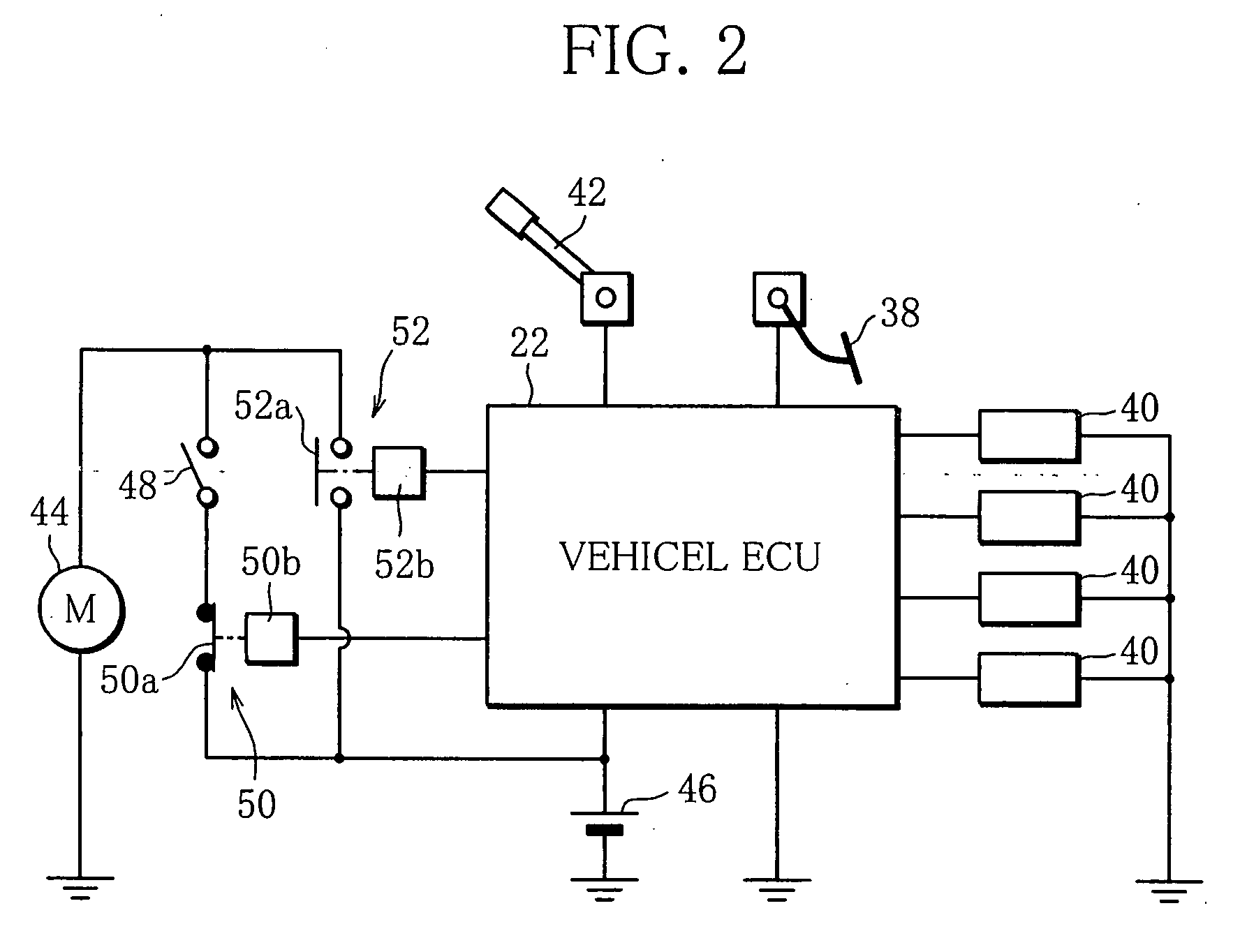

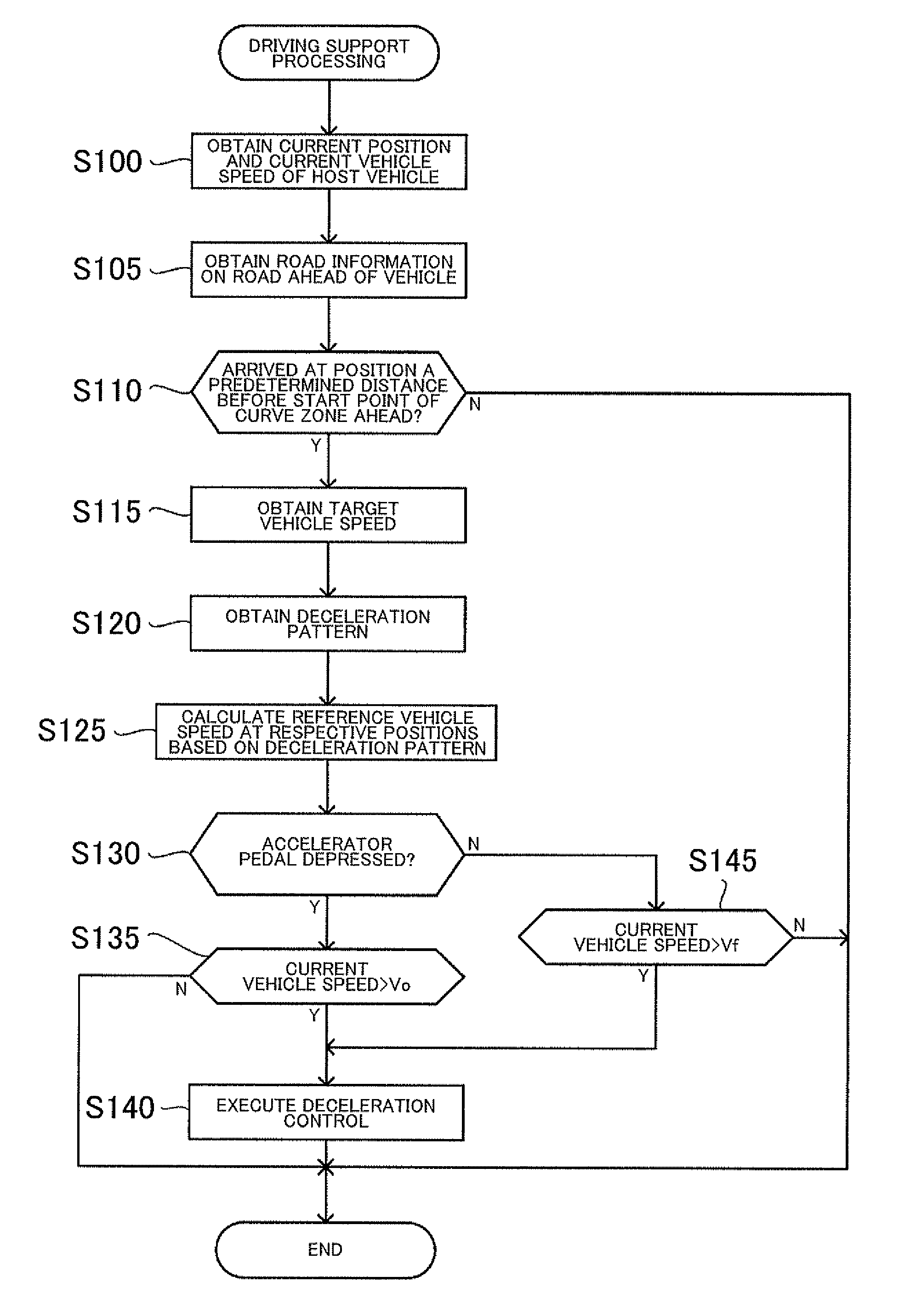

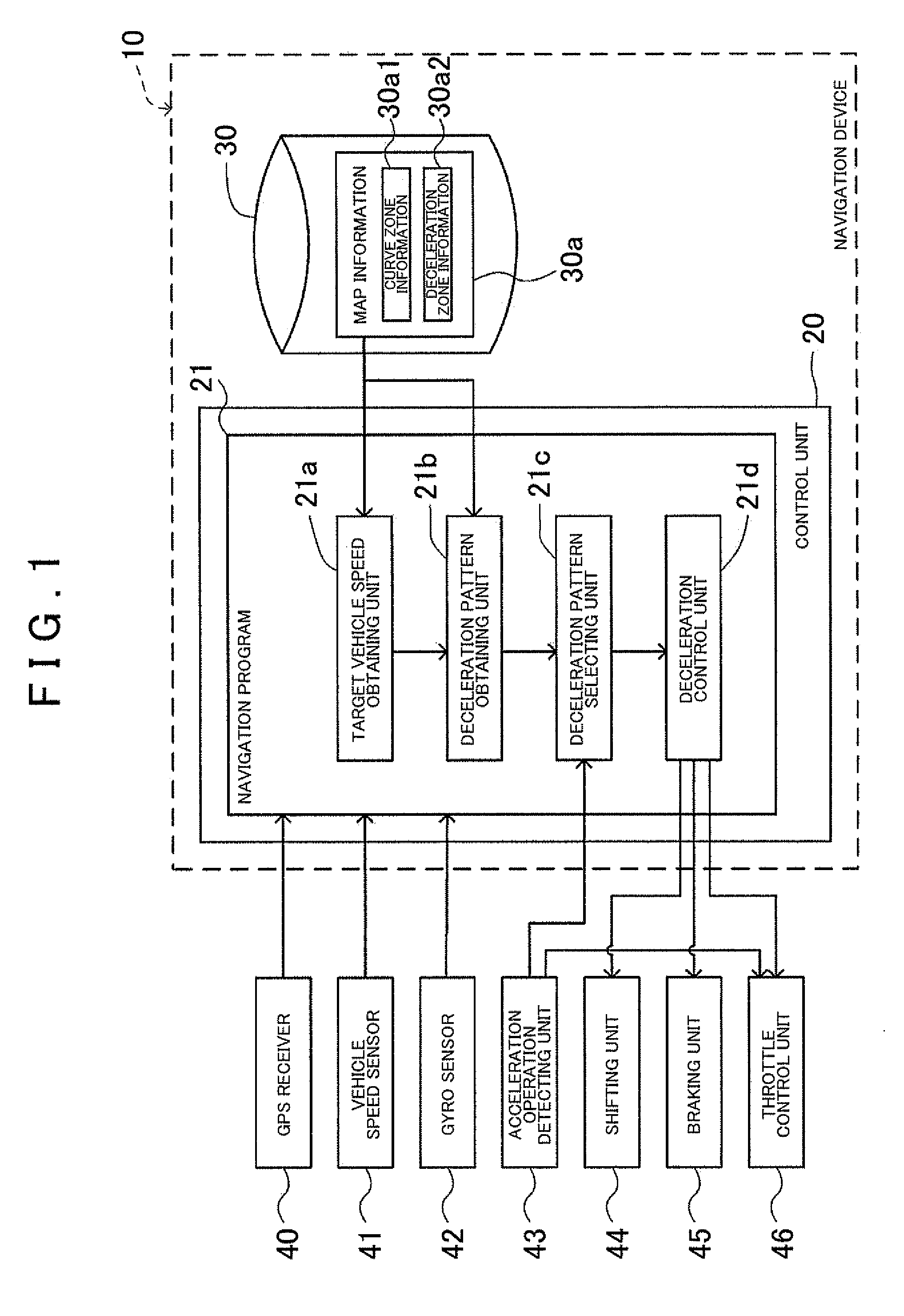

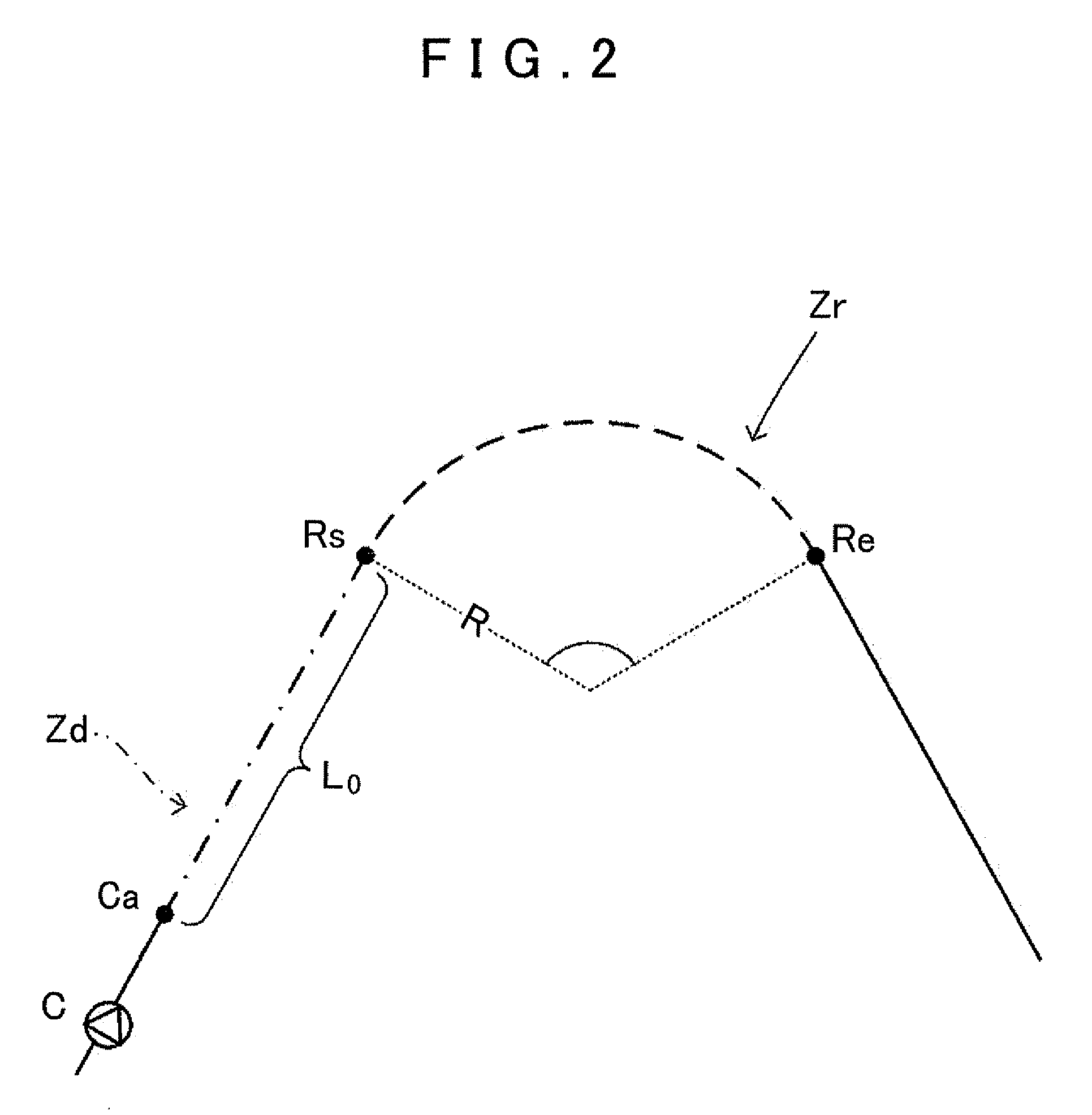

Control apparatus and control method of a vehicle, program for realizing that control method using a computer, and recording medium on which that program is recorded

InactiveUS20080097674A1DegreeShorten speedDigital data processing detailsGearing controlDriver/operatorEmergency brake

Owner:TOYOTA JIDOSHA KK

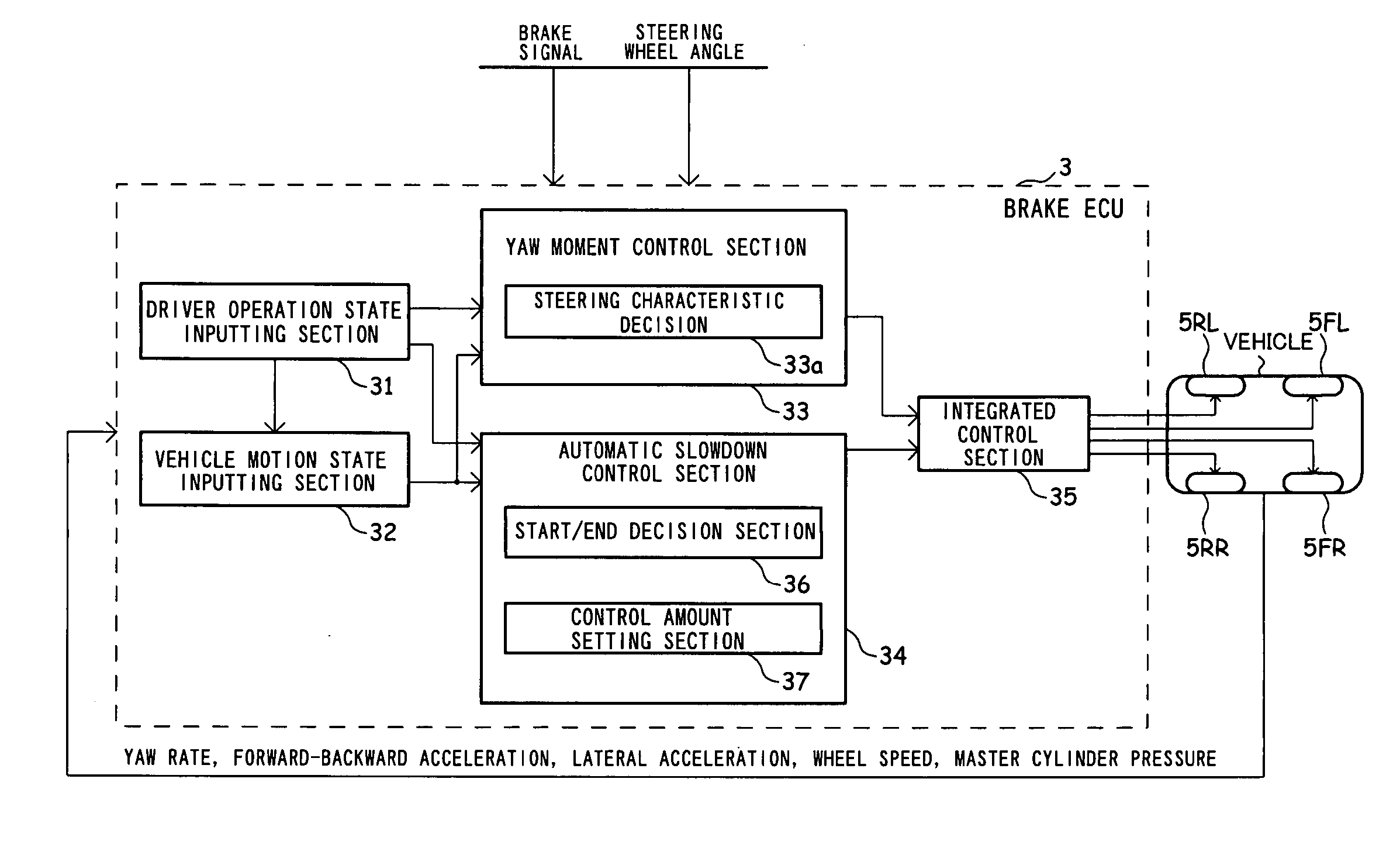

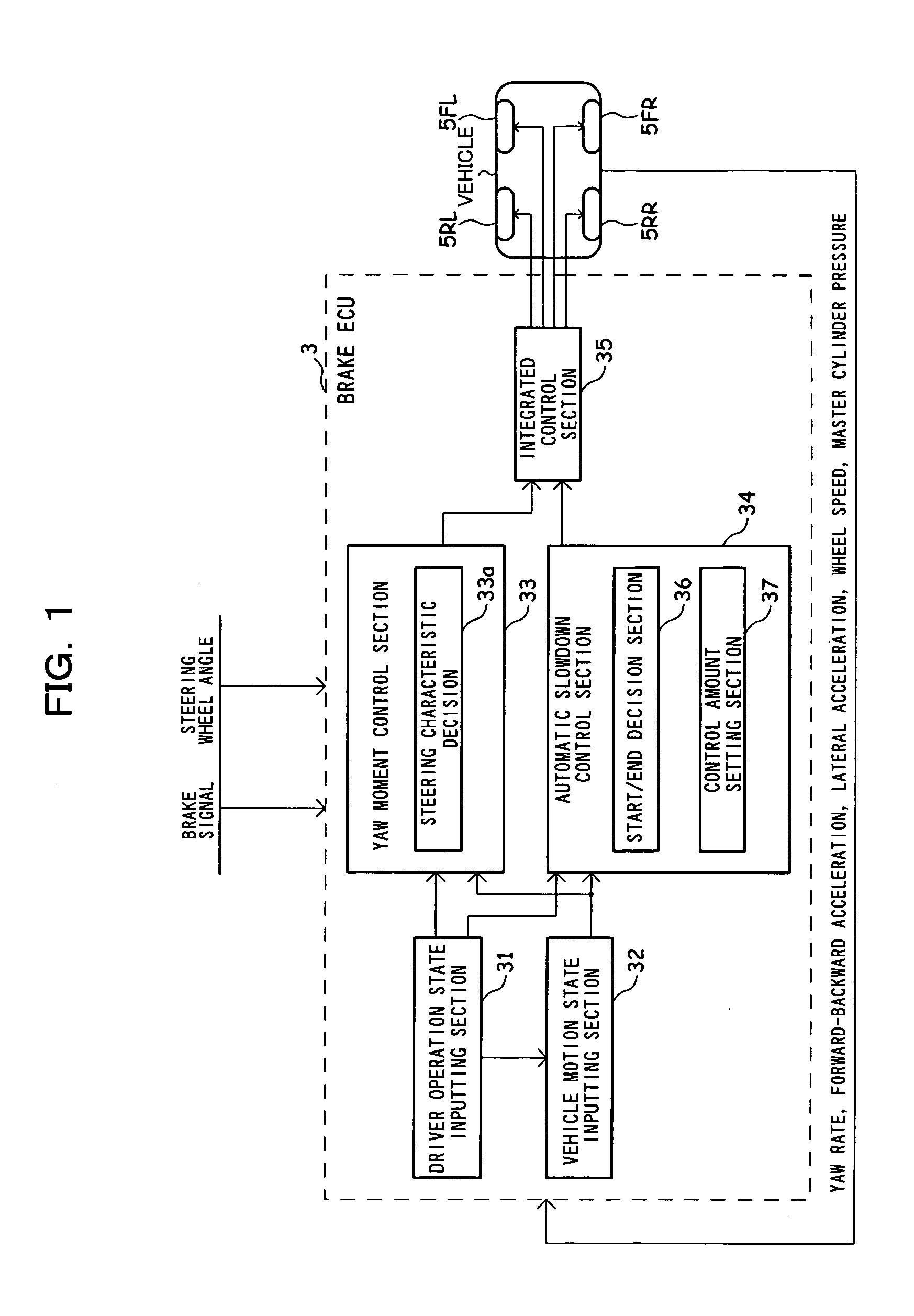

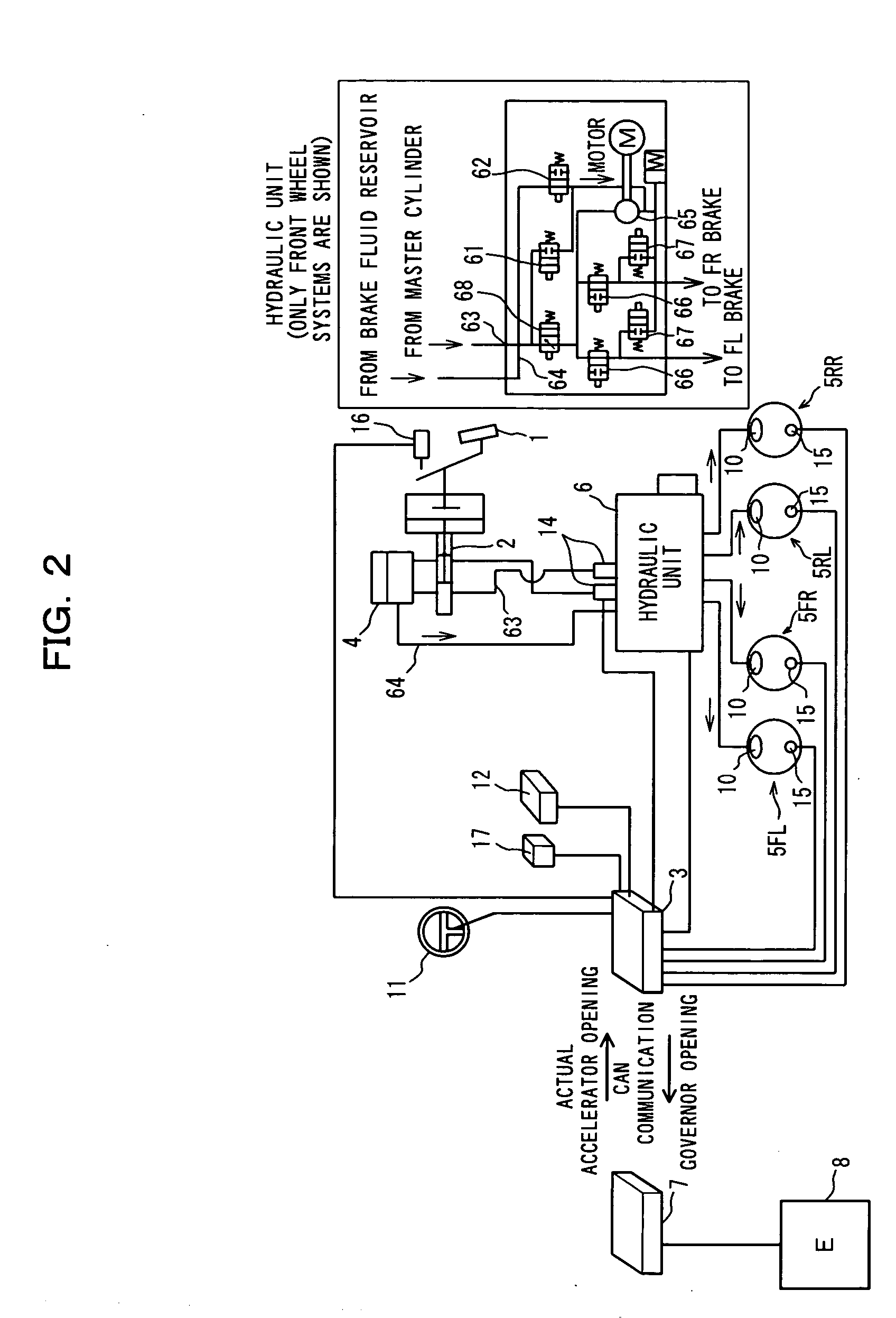

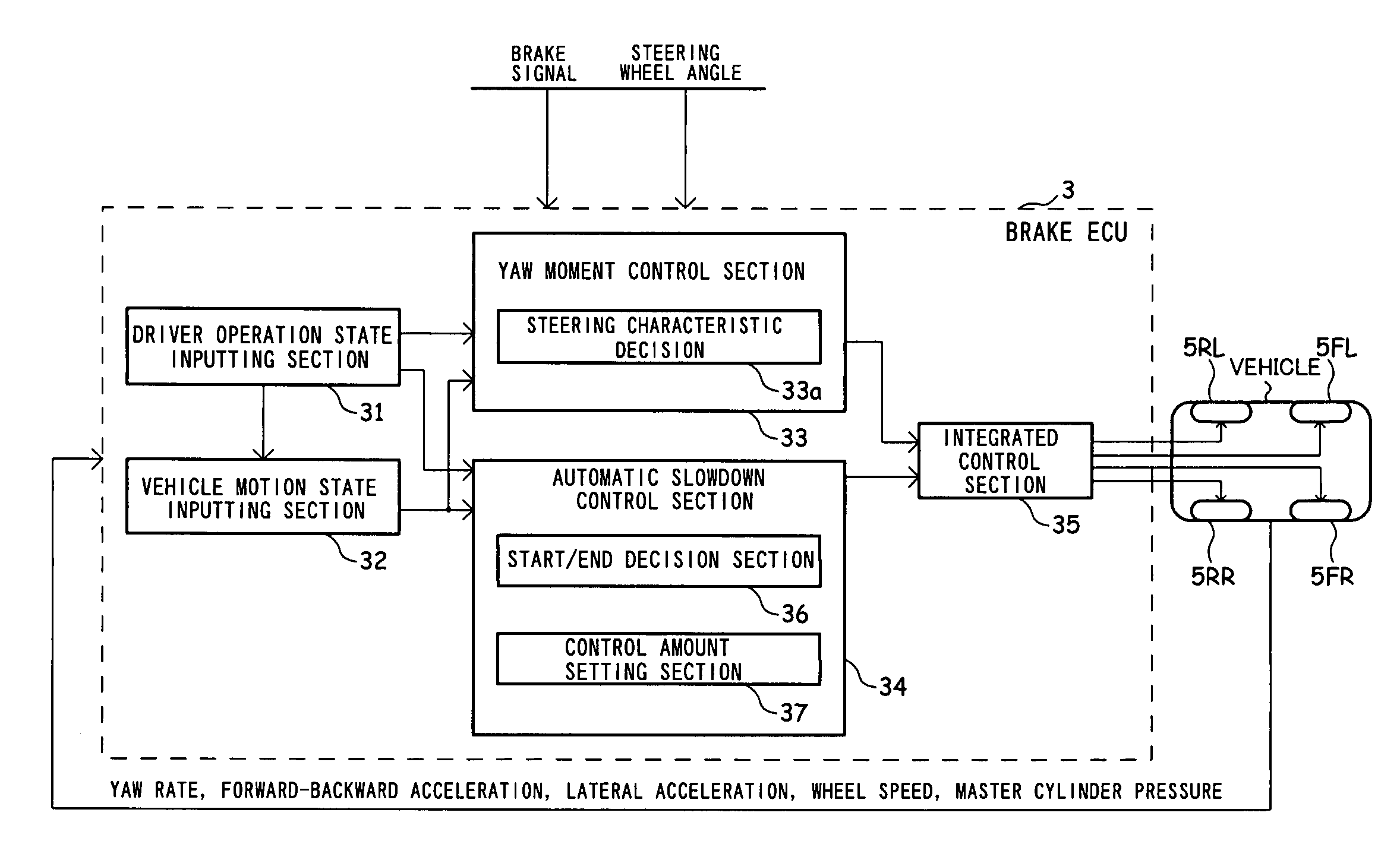

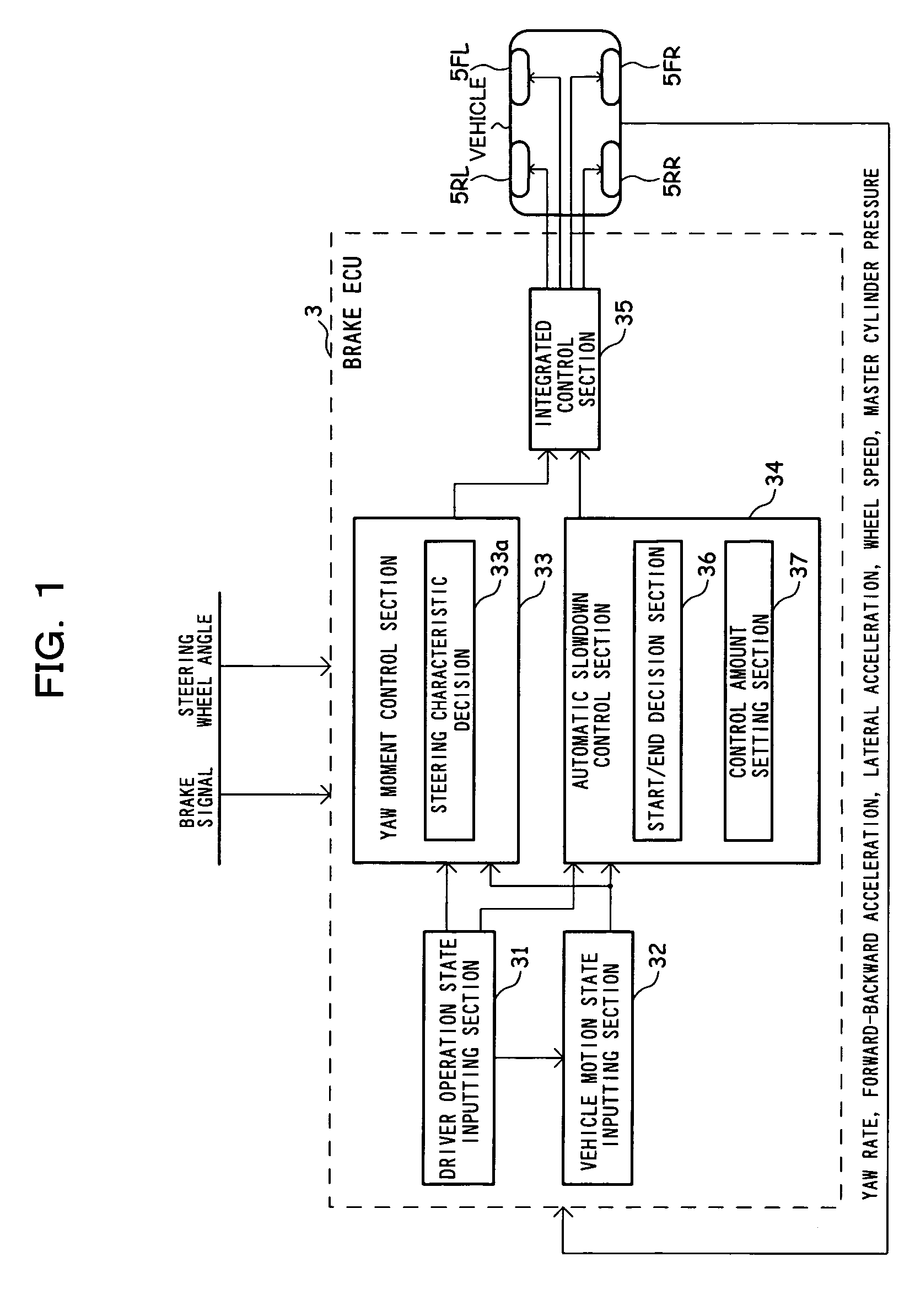

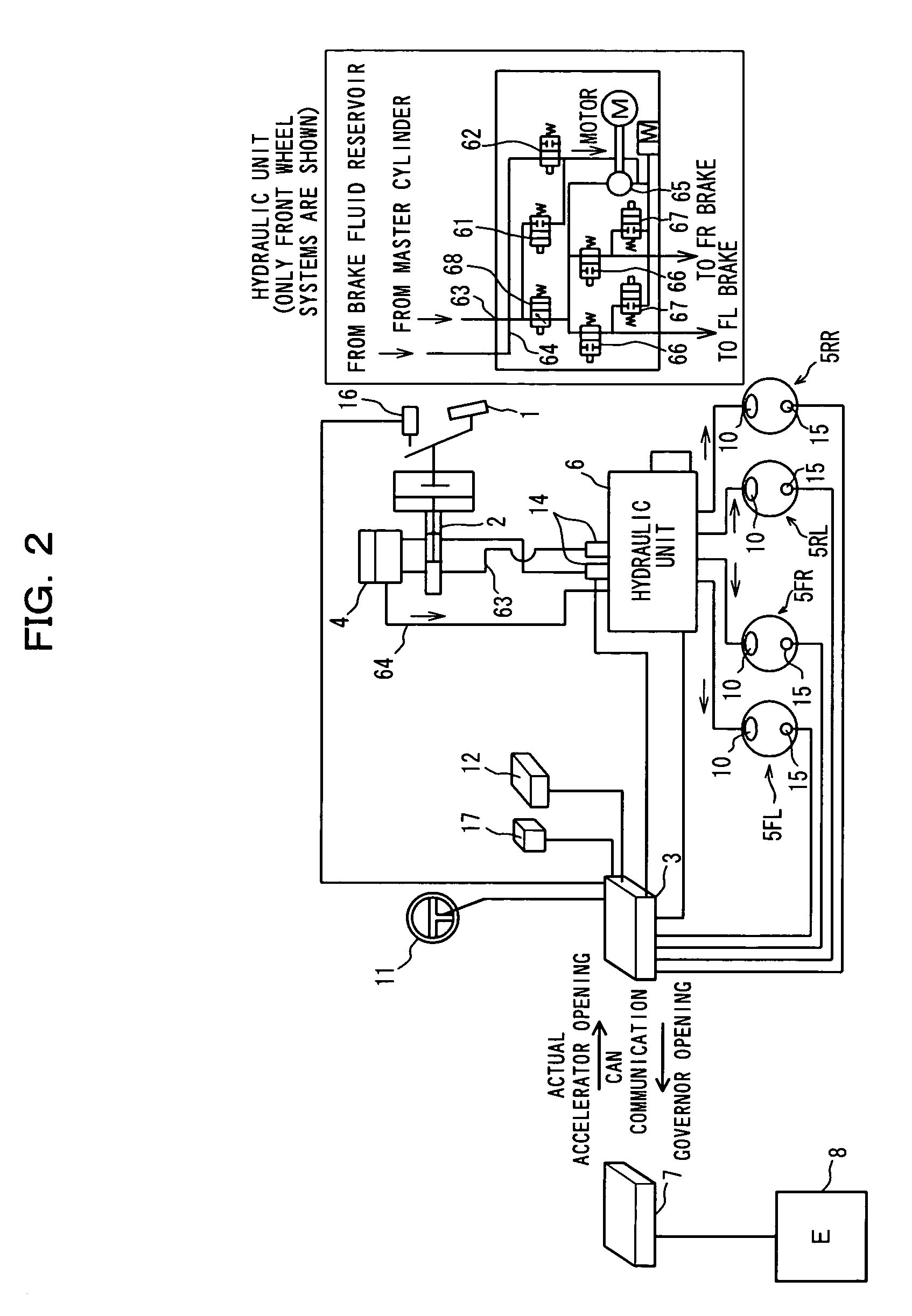

Automatic slowdown control apparatus for a vehicle

InactiveUS20050216164A1Accelerated comparatively rapidlyPosture or the behavior of the vehicle may be rendered unstable is lowHand manipulated computer devicesSewerage structuresInstabilityAutomotive engineering

An automatic slowdown control apparatus for a vehicle is disclosed wherein automatic slowdown control can be ended appropriately and automatic slowdown is prevented from being performed excessively on a road of an ascending gradient. The automatic slowdown control apparatus starts automatic slowdown control of rendering a braking mechanism operative to slow down the vehicle when the stability of the posture and / or behavior of the vehicle upon turning is deteriorated. A control end threshold value is set such that the stability of the vehicle is displaced to the instability side as the ascending gradient of the uphill road increases.

Owner:MITSUBISHI FUSO TRUCK AND BUS CORPORATION

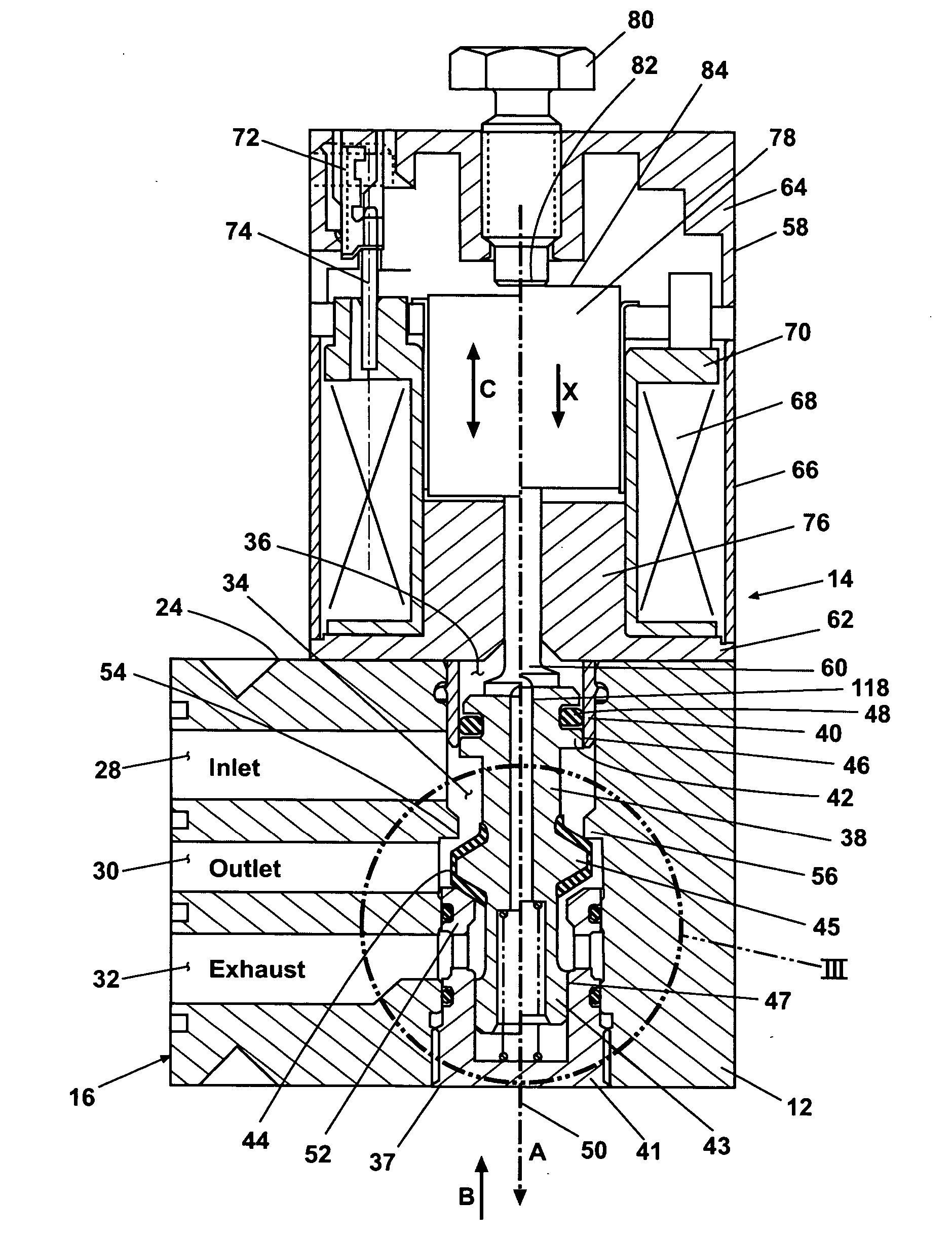

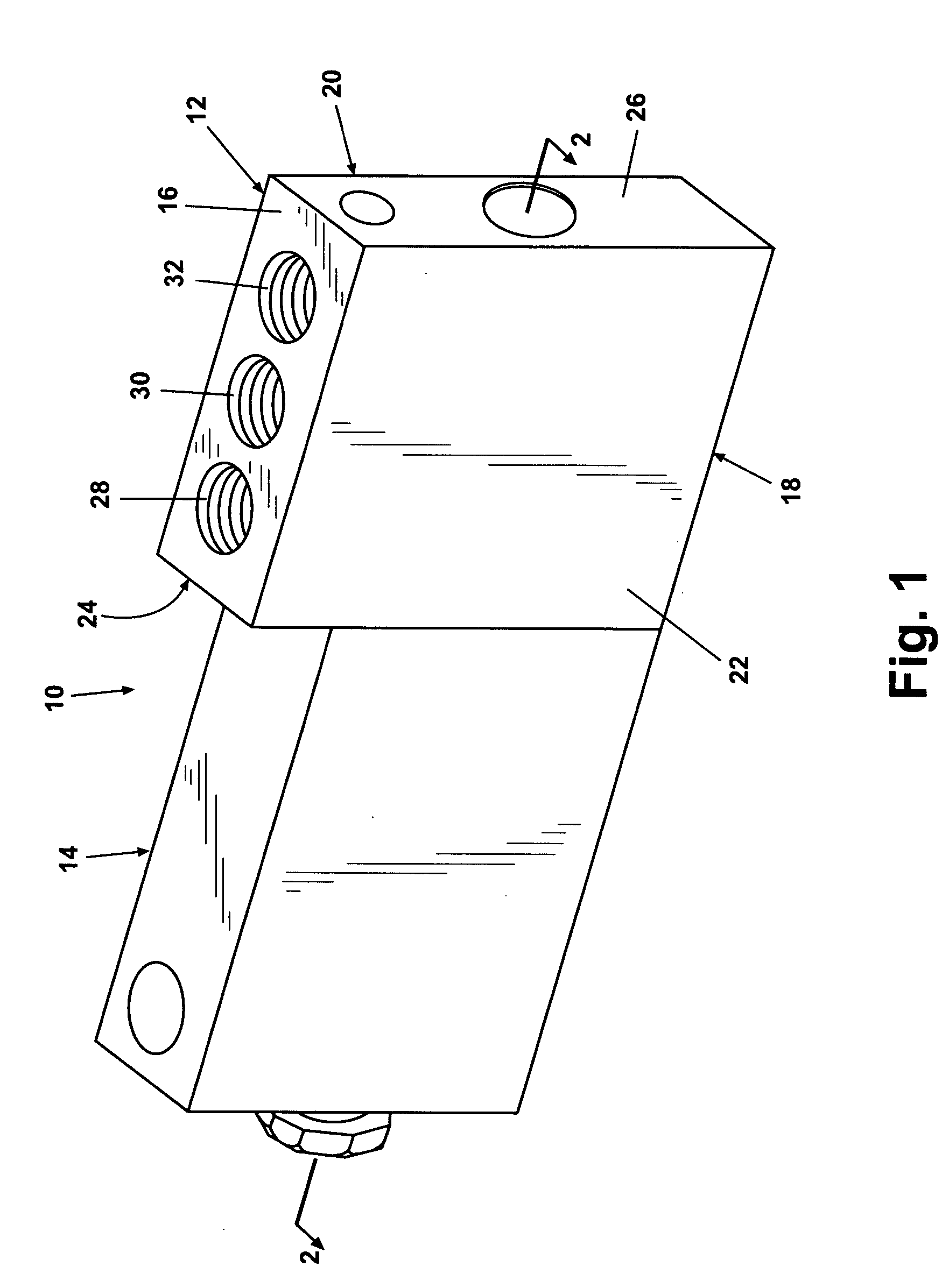

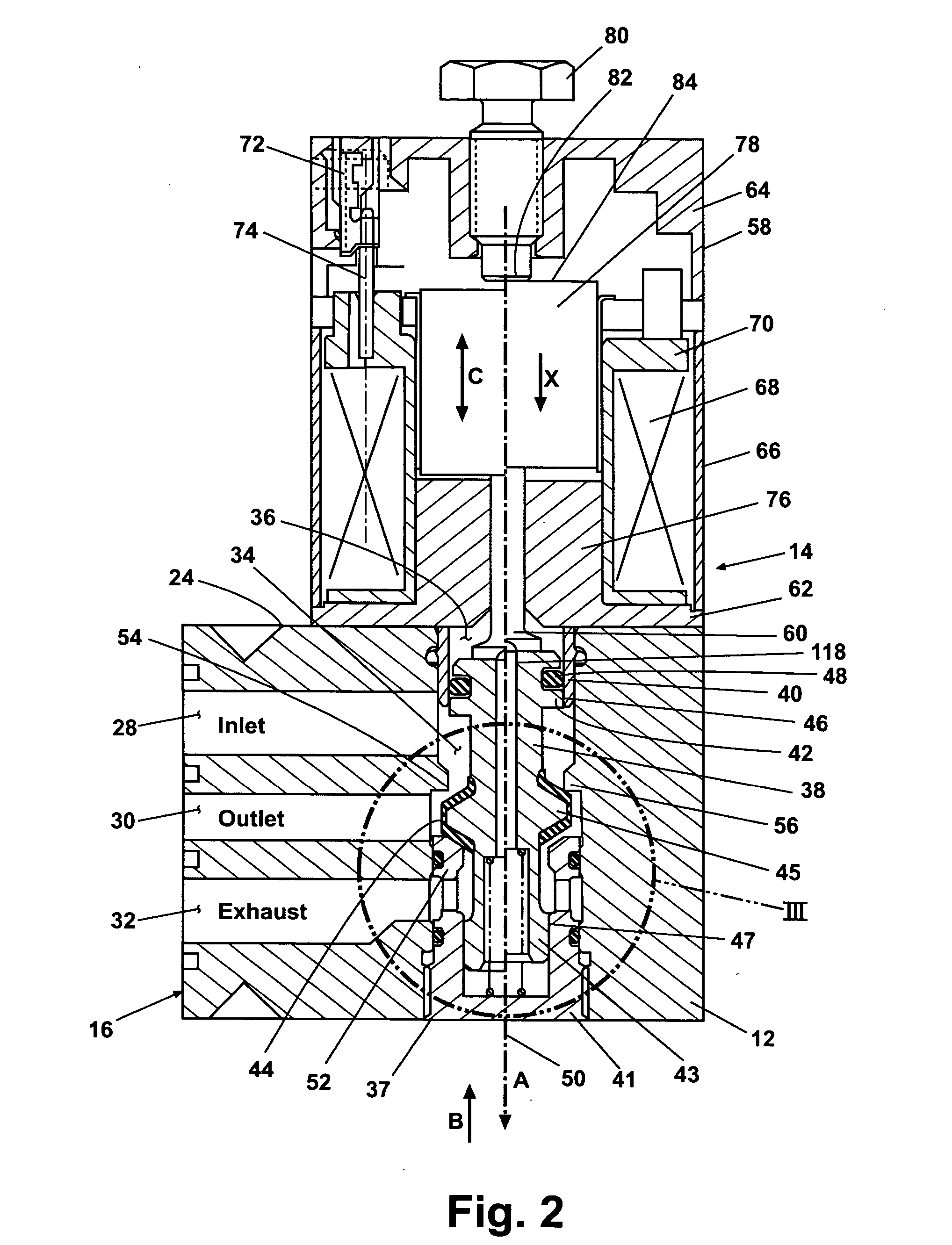

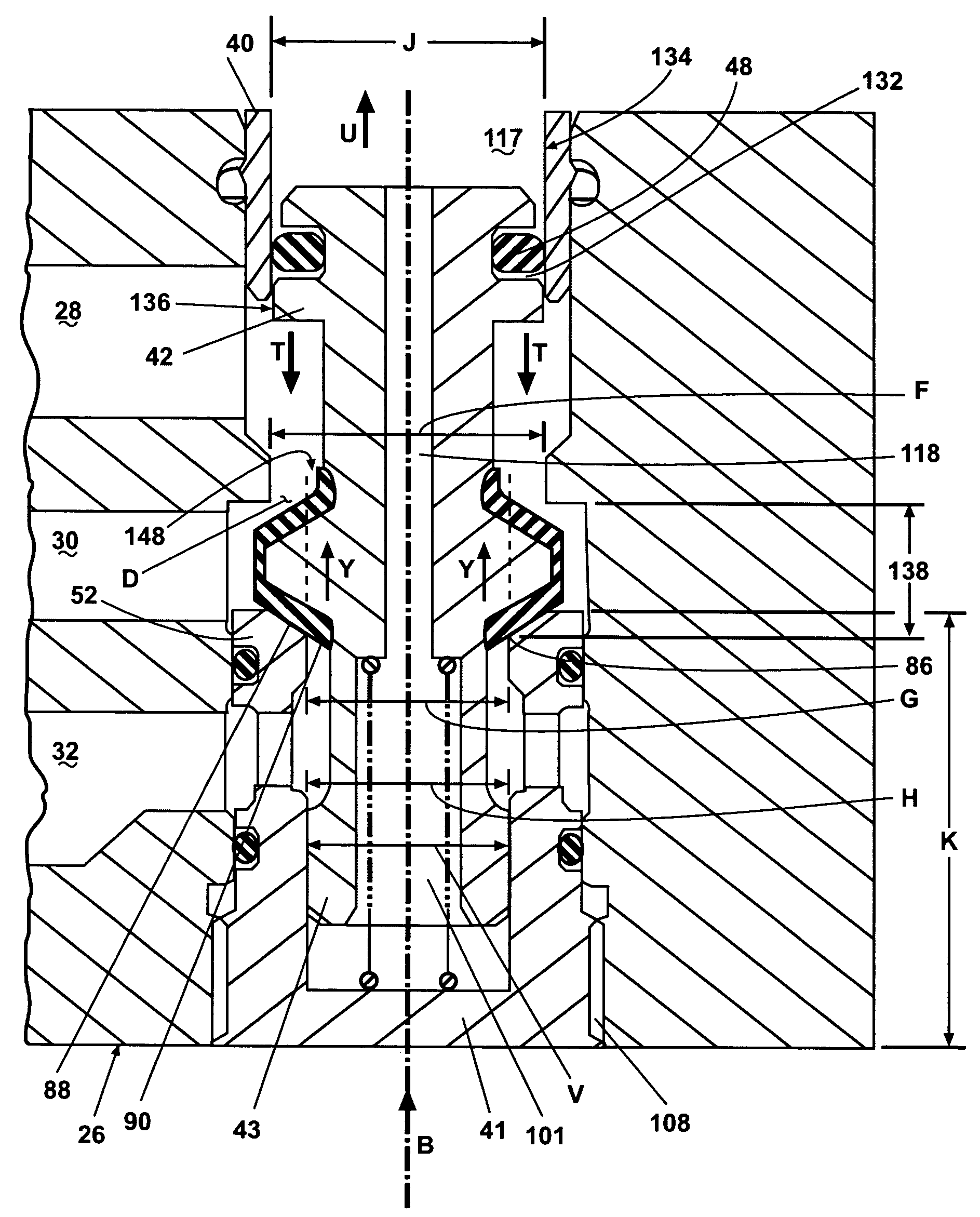

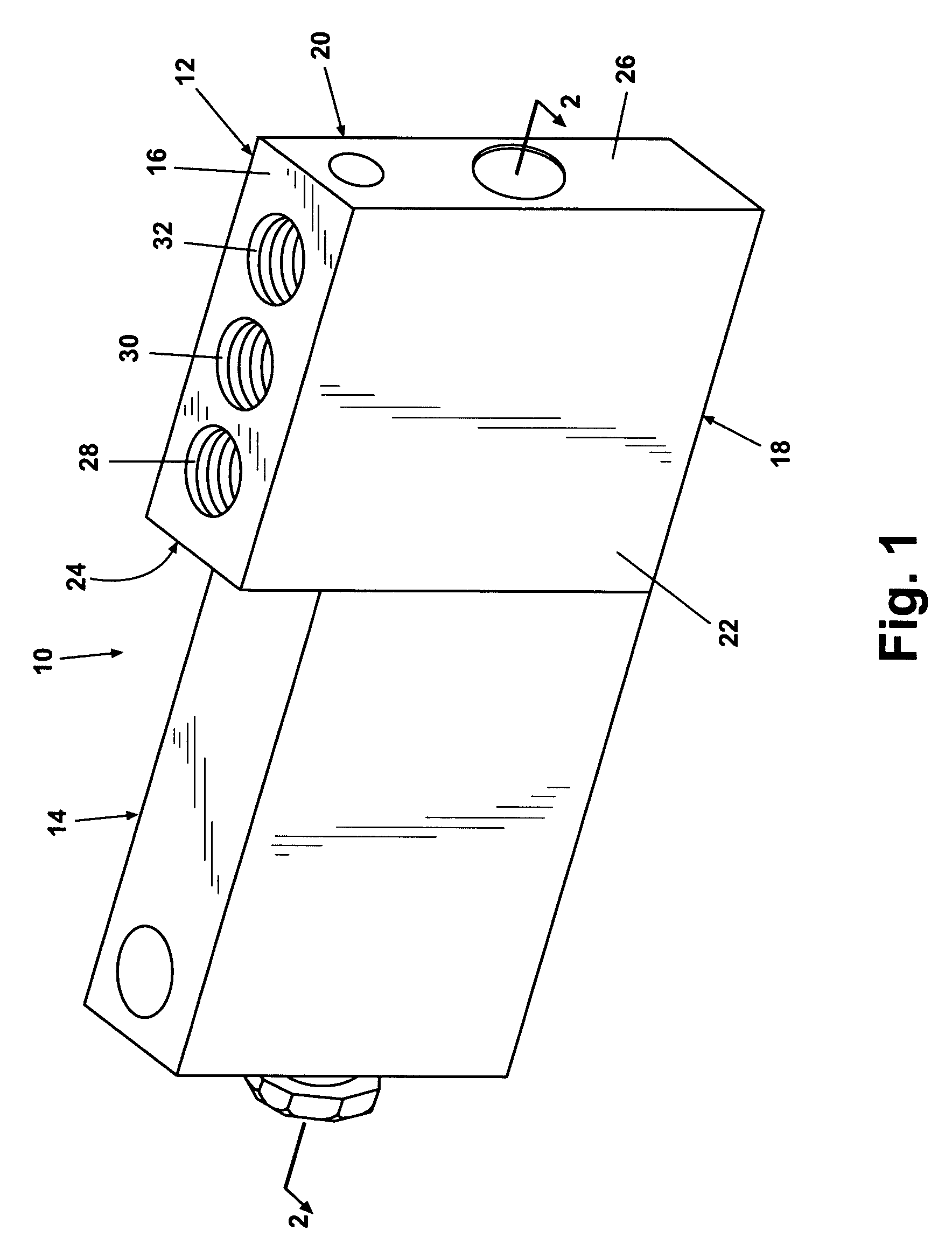

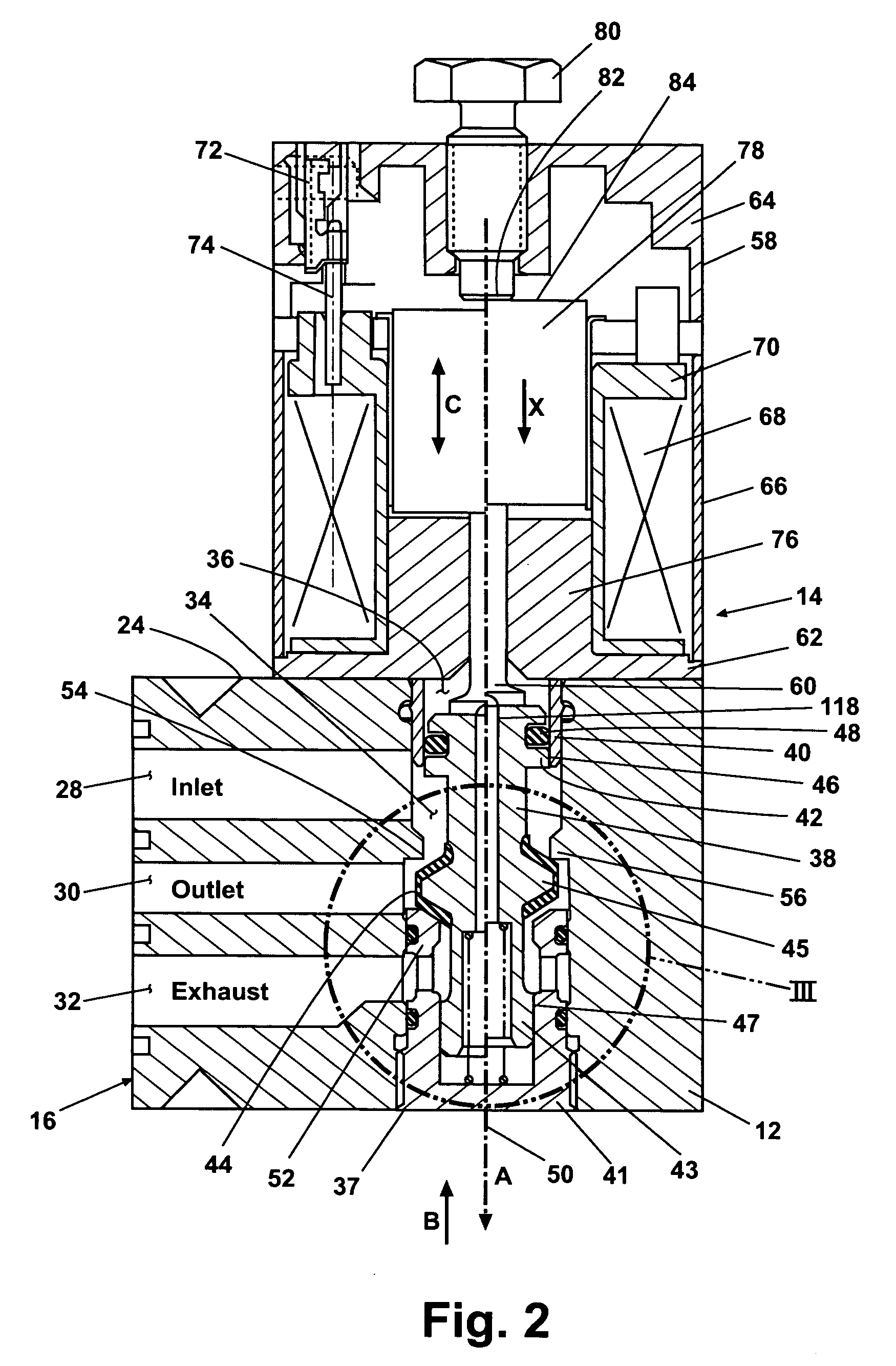

Directly operated pneumatic valve having a differential assist return

ActiveUS20060065315A1Eliminates bypass flowMove quickly and efficientlyOperating means/releasing devices for valvesServomotor componentsFluid controlNet return

A fluid control valve includes a valve body having both fluid inlet and discharge ports. A flow passage axially extending within the valve body communicates with the inlet and discharge ports. A valve member within the flow passage is movable by an actuator force in a first direction to direct a pressurized fluid from the inlet to the discharge port. The valve member includes first and second valve heads having different diameters and a valve seating member. The valve seating member engages first and second sealing diameters of the flow passage, the second sealing diameter being smaller than the first. Fluid pressure acting on the different diameters of the first valve head and valve seating member in contact with the second sealing diameter creates a net return force directing the valve member in a second direction opposite to the first direction upon removal of the actuator force.

Owner:MAC VALVES INC

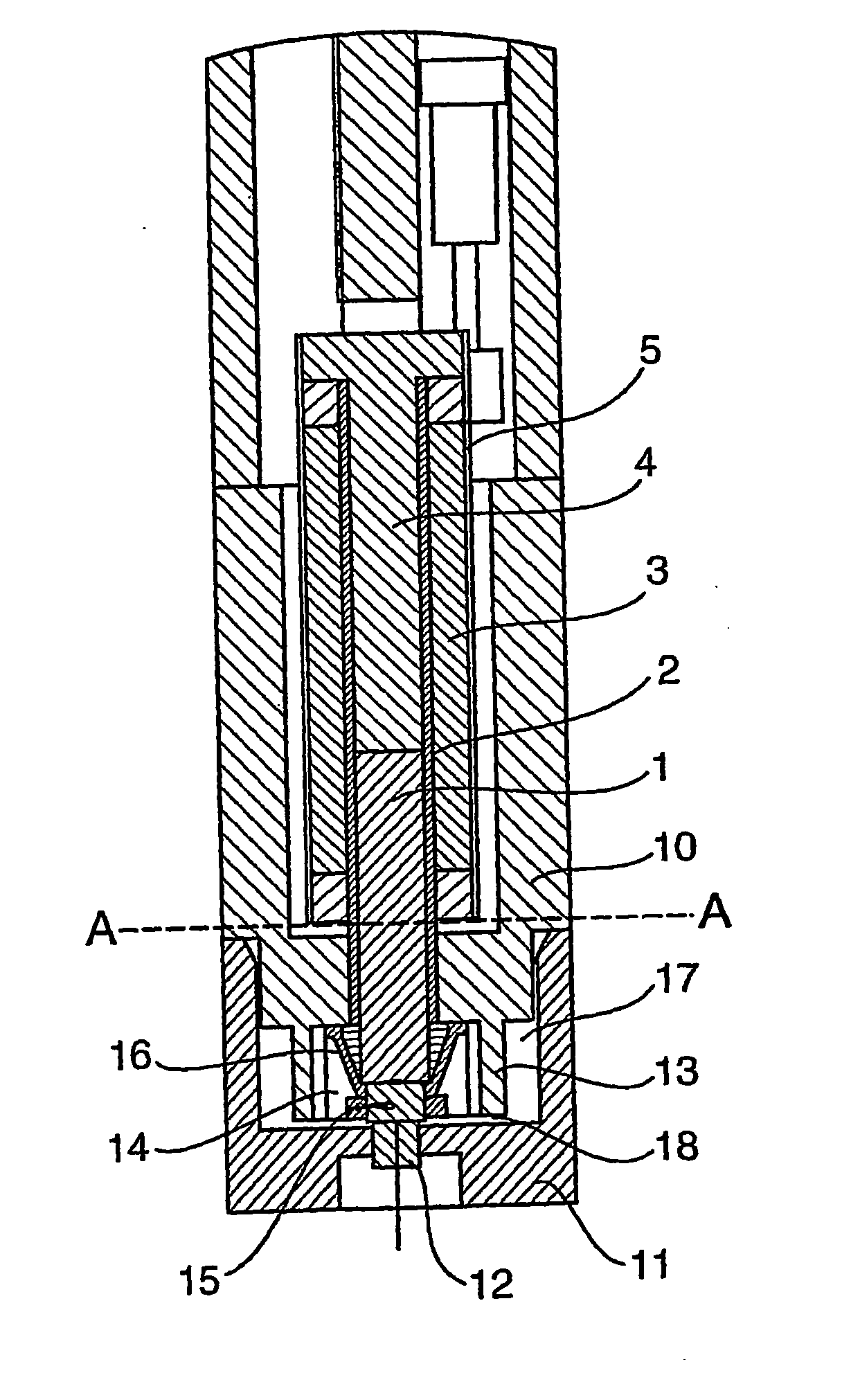

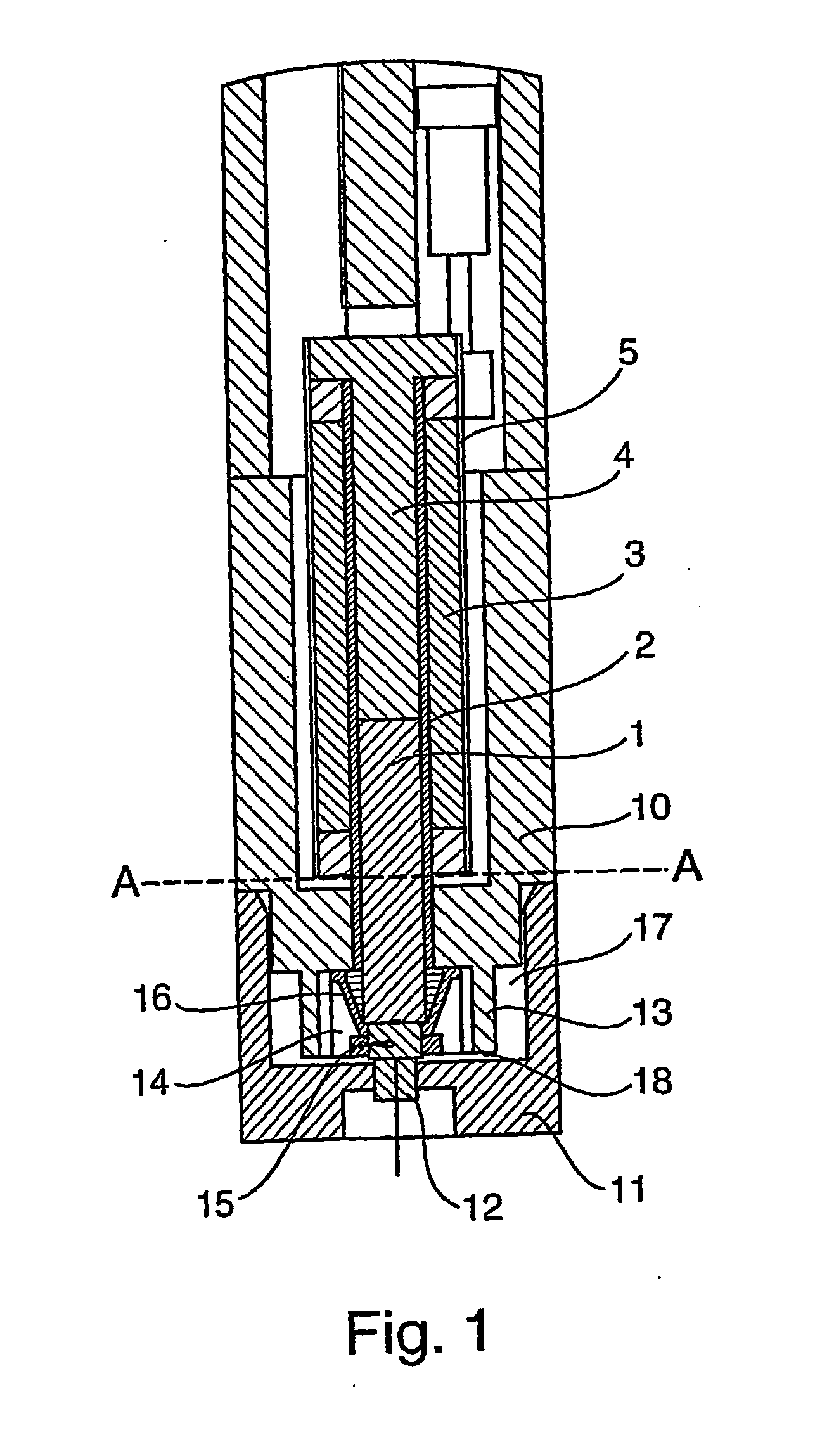

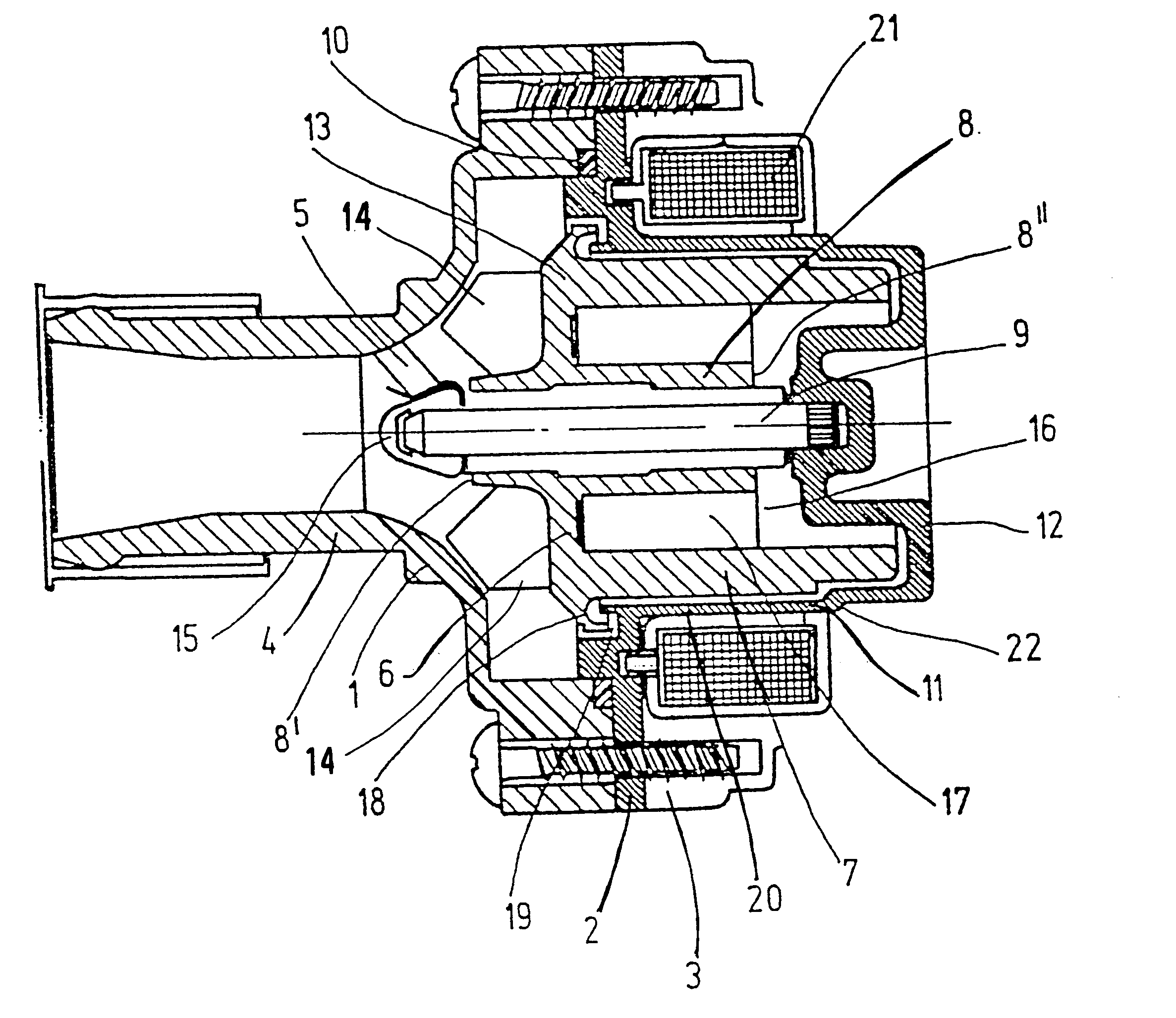

Solenoid valve

InactiveUS20050231553A1Reduce intensityQuality improvementInking apparatusOperating means/releasing devices for valvesSolenoid valveInk printer

A solenoid valve making use of certain materials which is capable of operation at high frequencies and which can be made as a compact unit. The plunger (1) is made from a material having a saturation flux density greater than 1.4 Tesla preferably more than 1.6 Tesla, a coercivity at less than 0.25 ampere per centimeter and a relative magnetic permeability in excess of 10.000; and the nozzle bore leading from the valve head chamber (14) to the nozzle orifice (12) has a length to diameter ratio of less than 8:1 preferably between 2:1 to 4:1 and the nozzle orifice (12) has a diameter substantially the same as that of the nozzle bore. The invention also relates to method for operating a drop on demand ink jet printer incorporating such a valve.

Owner:WILLETT INT

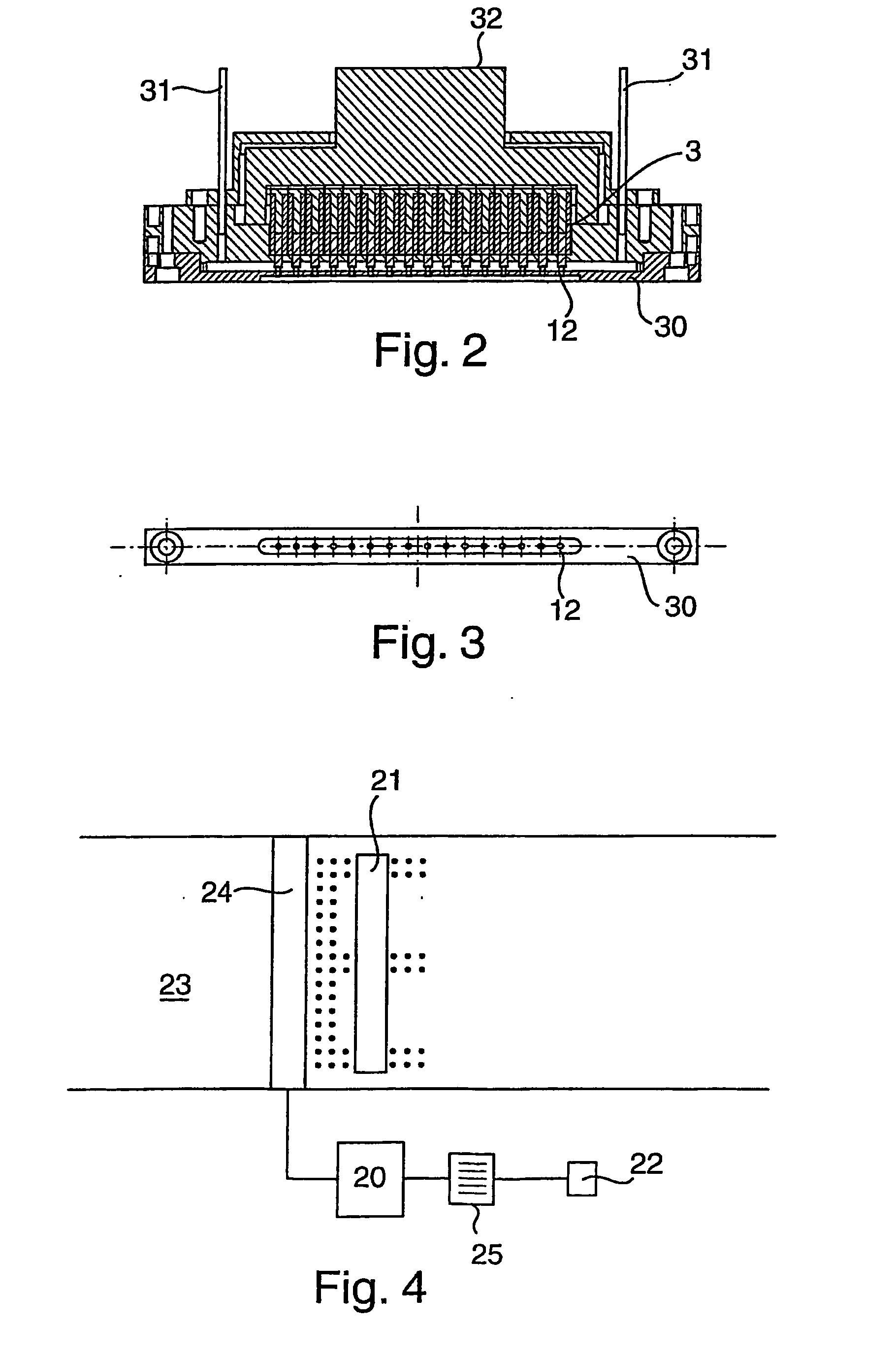

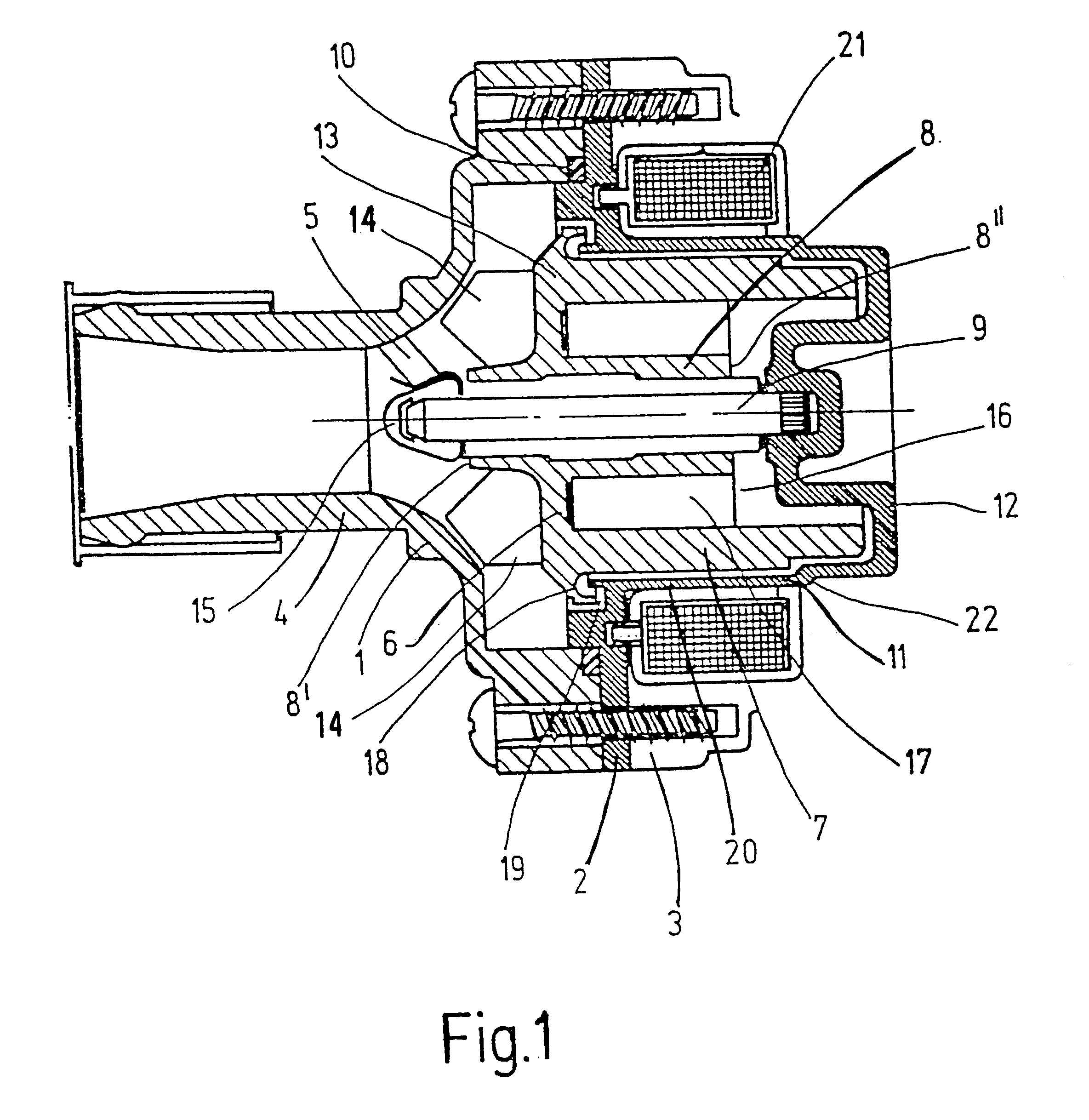

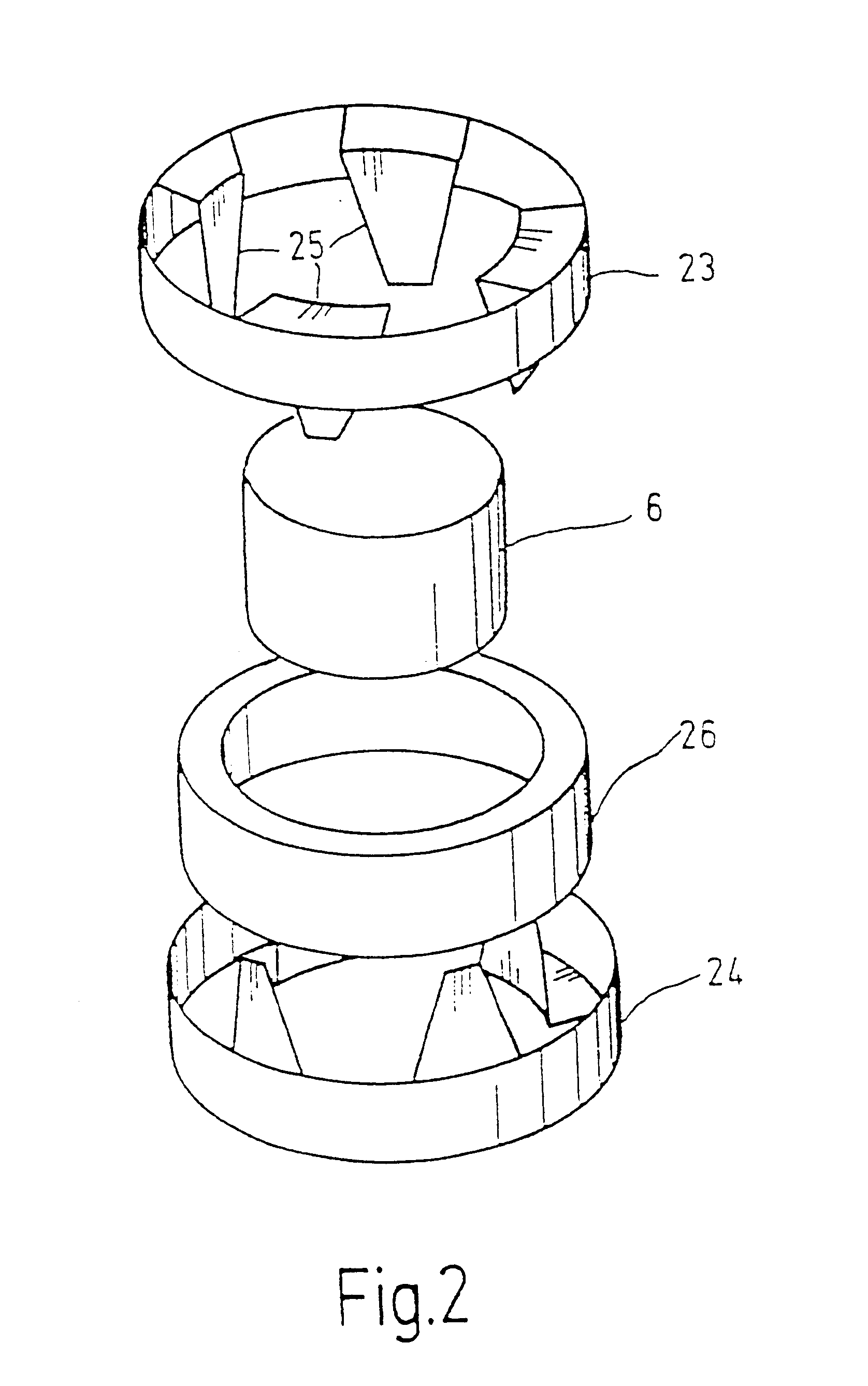

Liquid pump with a claw pole stator

InactiveUS6506034B1Reduced installation depthEffectively limit disruptionManufacturing stator/rotor bodiesMechanical energy handlingEngineeringHeating system

A fluid pump, in particular for the coolant and heating system of a motor vehicle, has a stator (21) of claw pole construction and a rotor (6), separated from the stator (21) by a pipe (11), which is immersed in the coolant and forms a vane wheel. The rotor (6) is disposed radially inside the stator (21).

Owner:ROBERT BOSCH GMBH

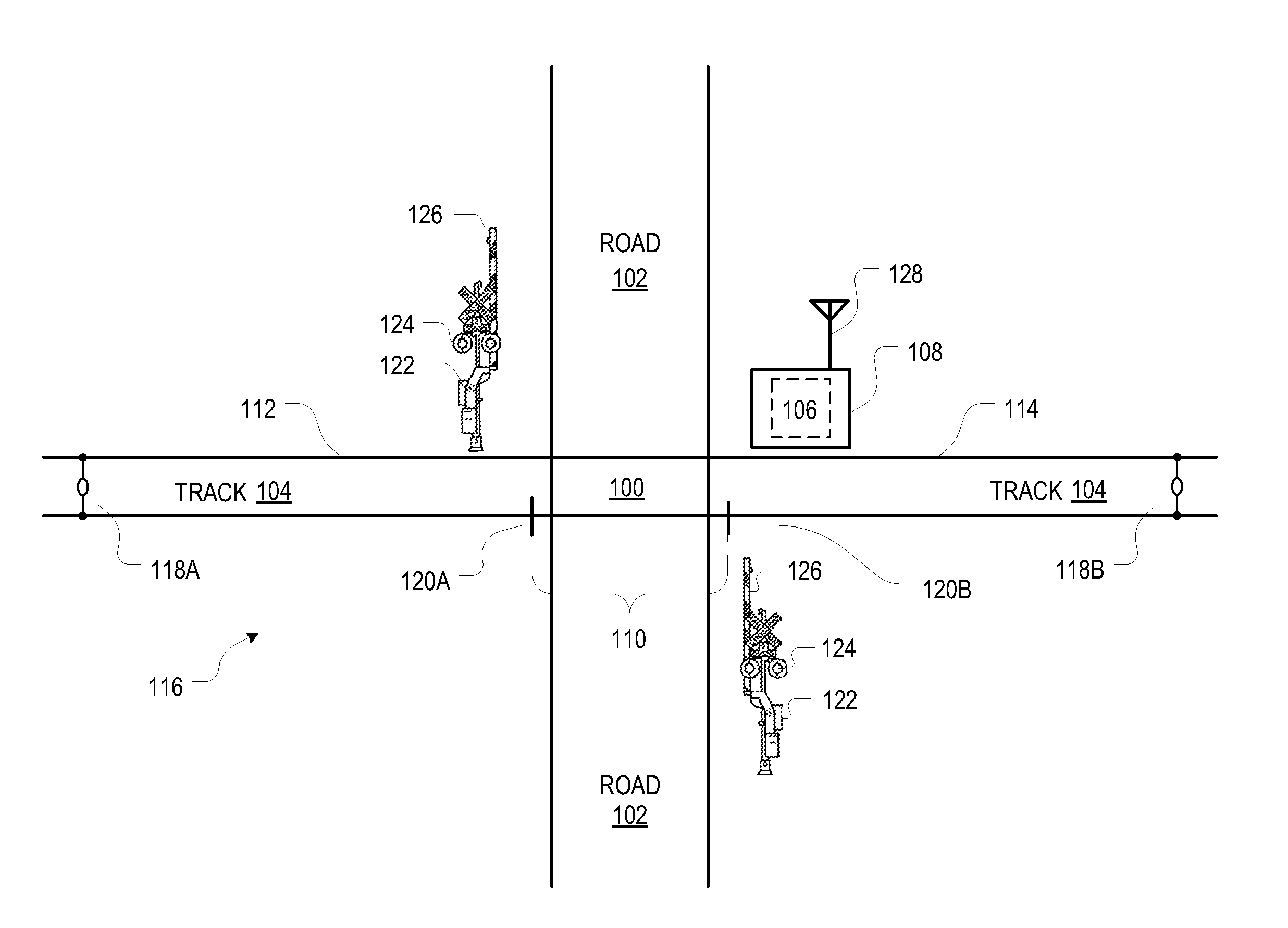

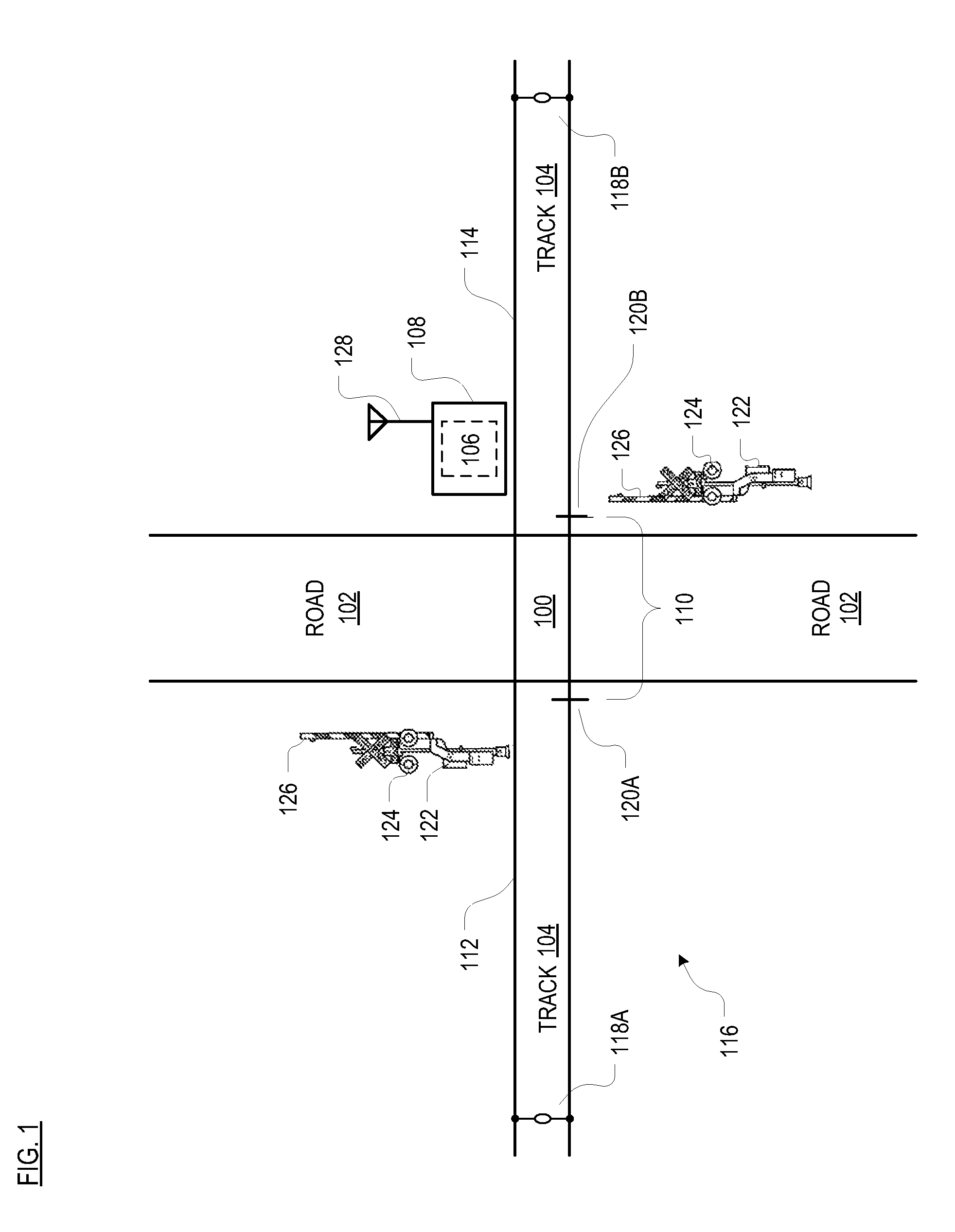

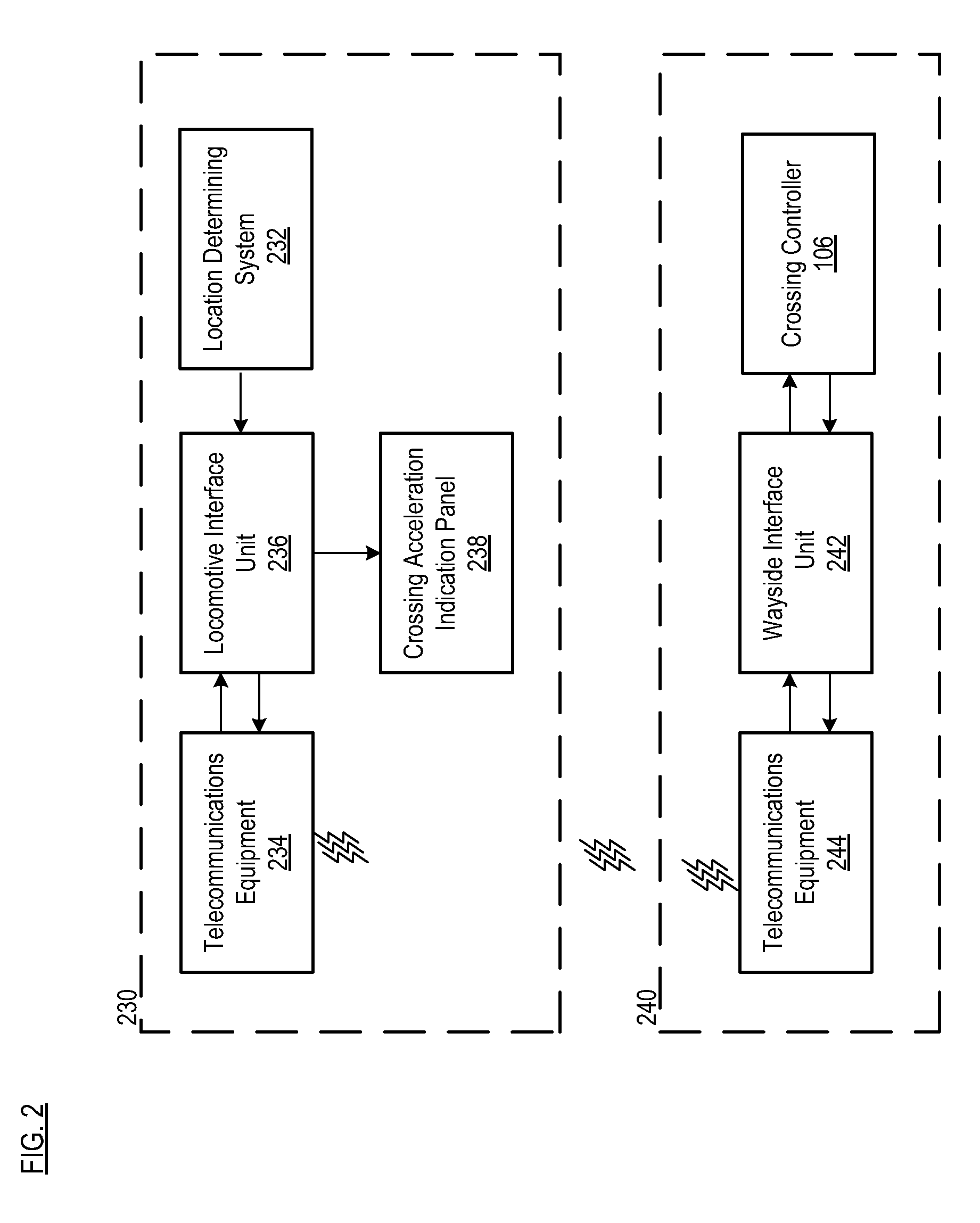

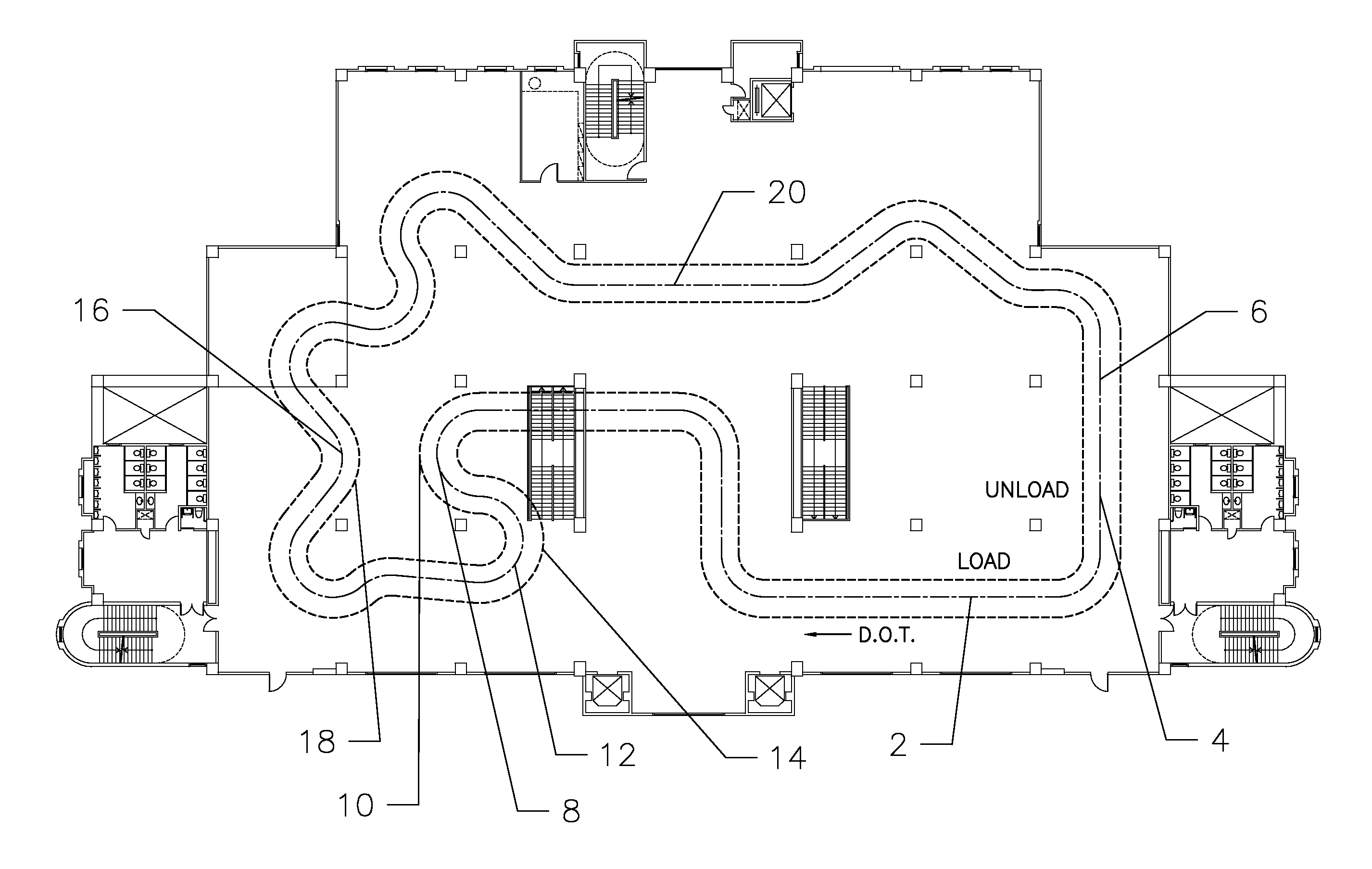

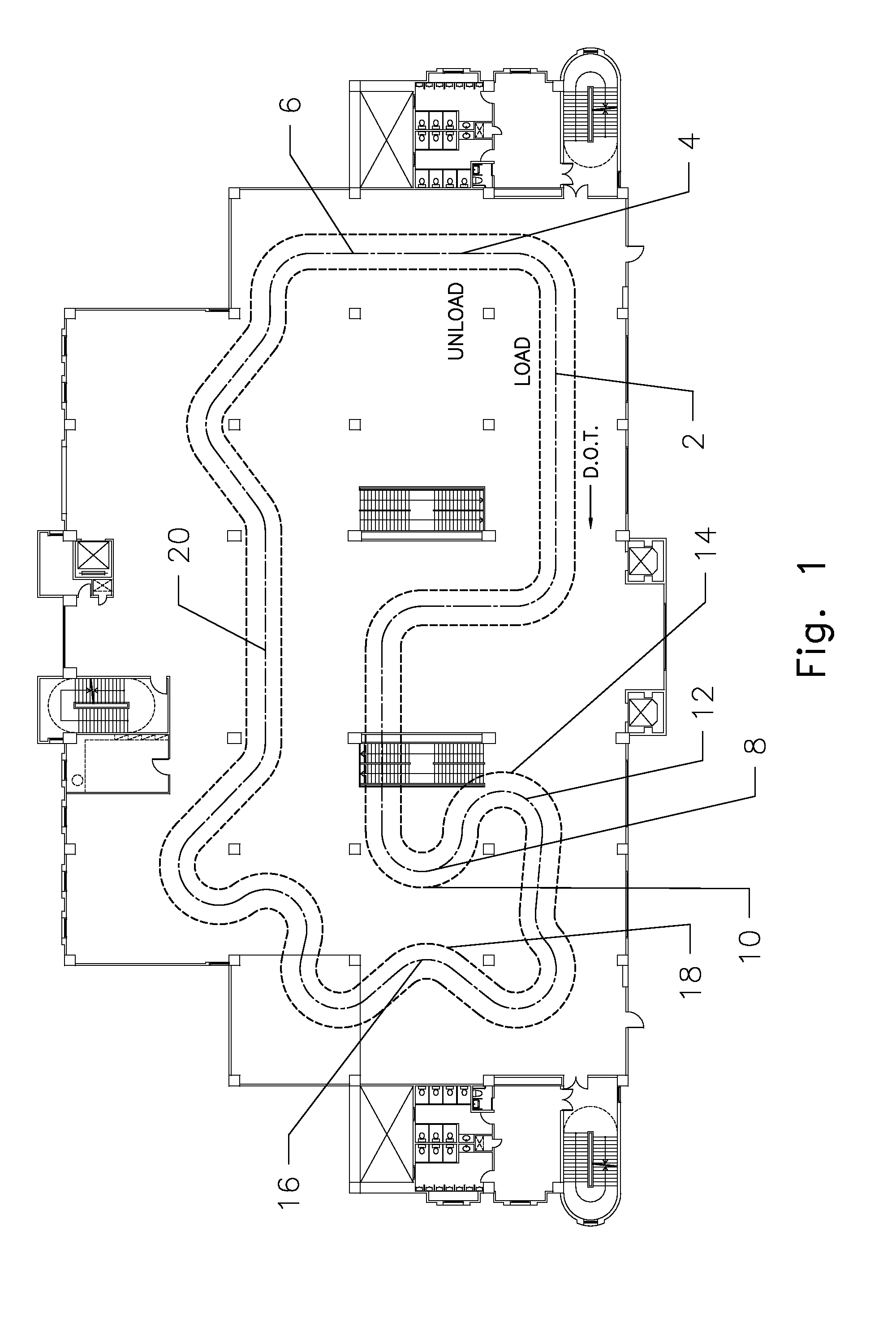

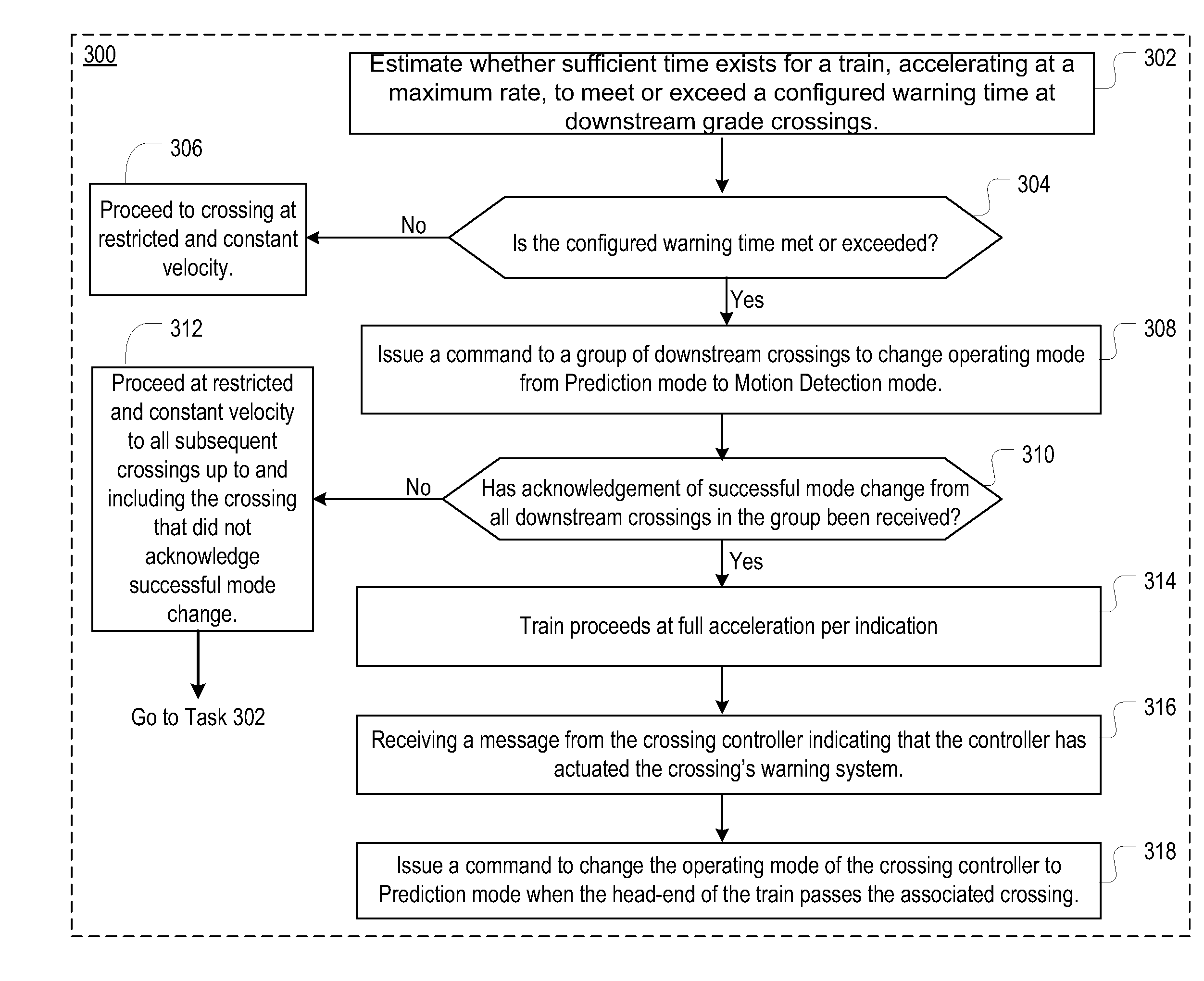

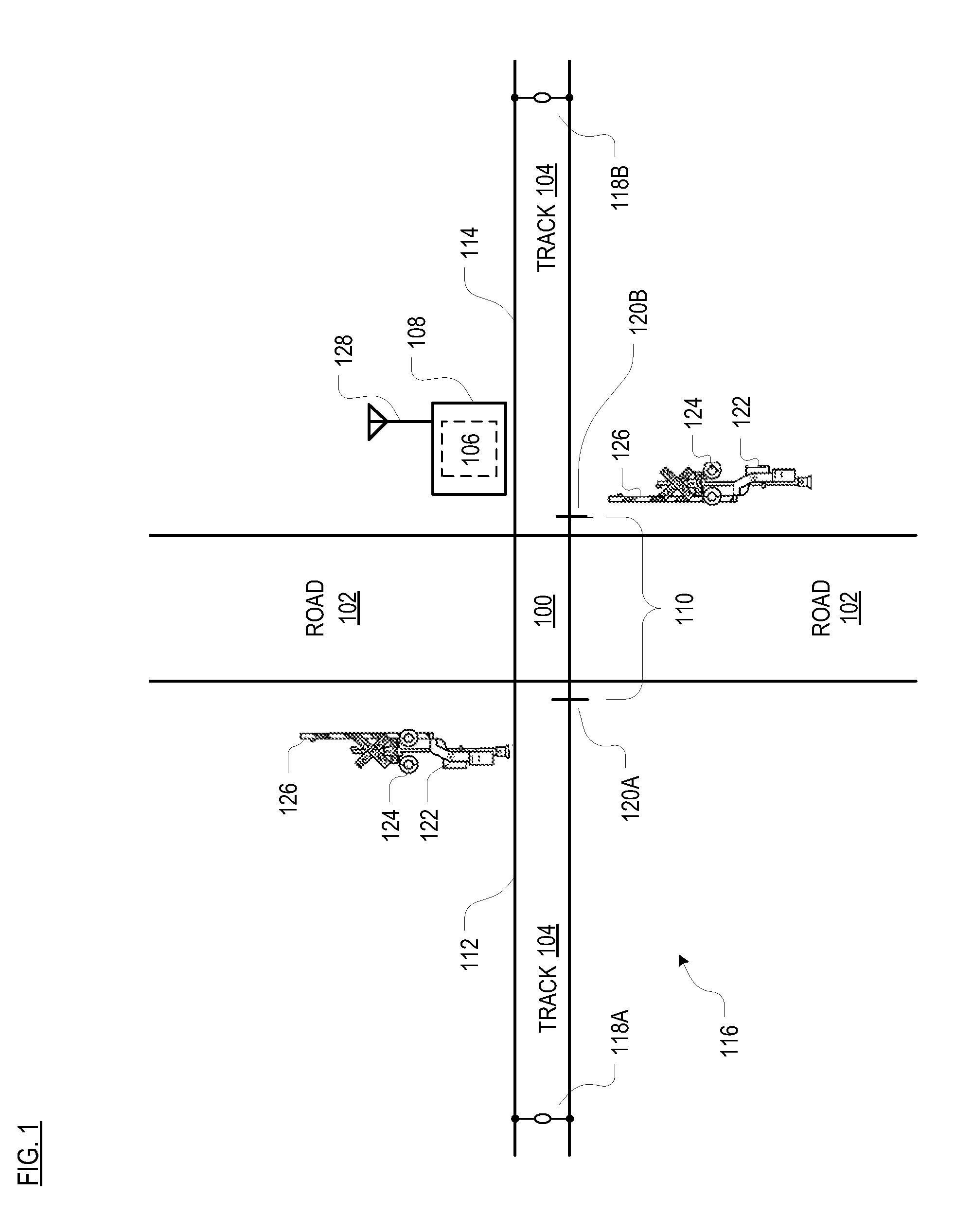

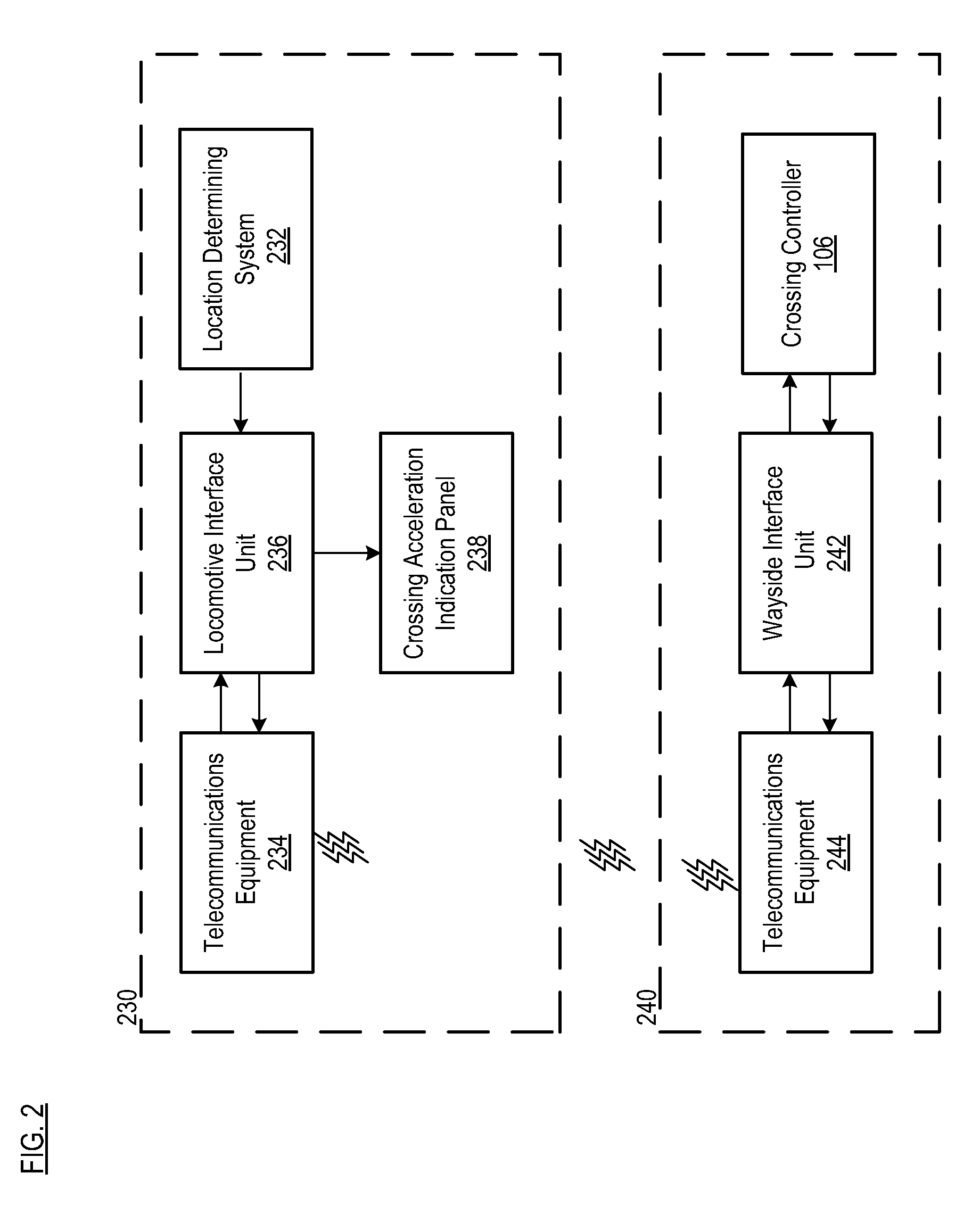

System and method for train operation approaching grade crossings

ActiveUS7832691B2Reduce traffic delaysFast accelerationSignal operation from vehicleVehicle route interaction devicesMotion sensingPredictive controller

A system and method that enables trains to rapidly accelerate through grade crossings from station stops or civil speed restrictions is disclosed. In some embodiments, equipped trains and grade-crossing controllers communicate wirelessly to address operational limitations pertaining to the grade crossings. In conjunction with the train's equipment, conventional crossing controllers are augmented with a communications capability and logic to accept commands to operate in a “Prediction” mode or a “Motion-Sensing” mode. The Prediction mode is the default operating mode for conventional constant-warning grade-crossing prediction controllers. The Motion-Sensing mode is an operating mode whereby the crossing is actuated as soon as an approach circuit detects train motion.

Owner:AUSTRALIAN RAIL TRACK CORP

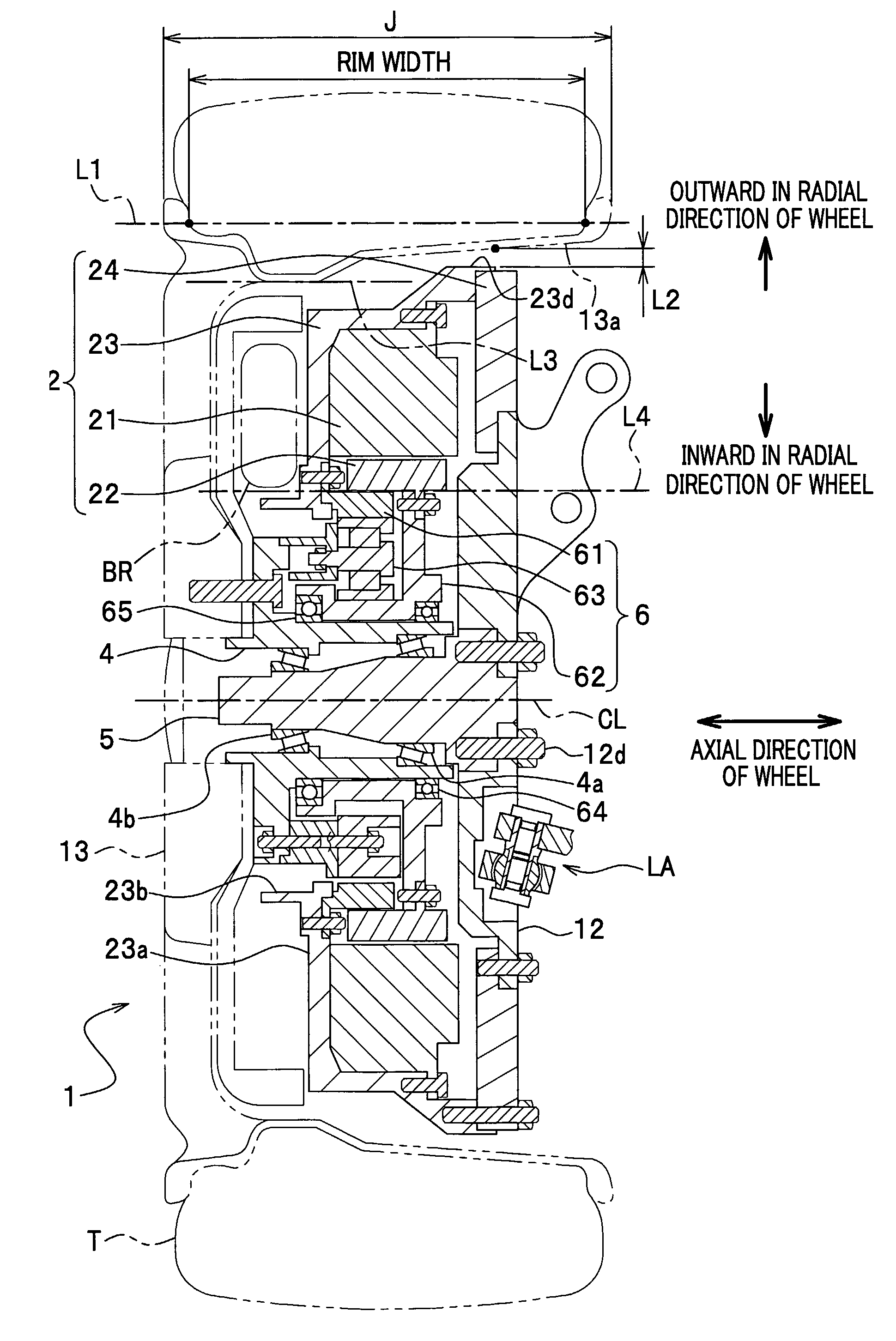

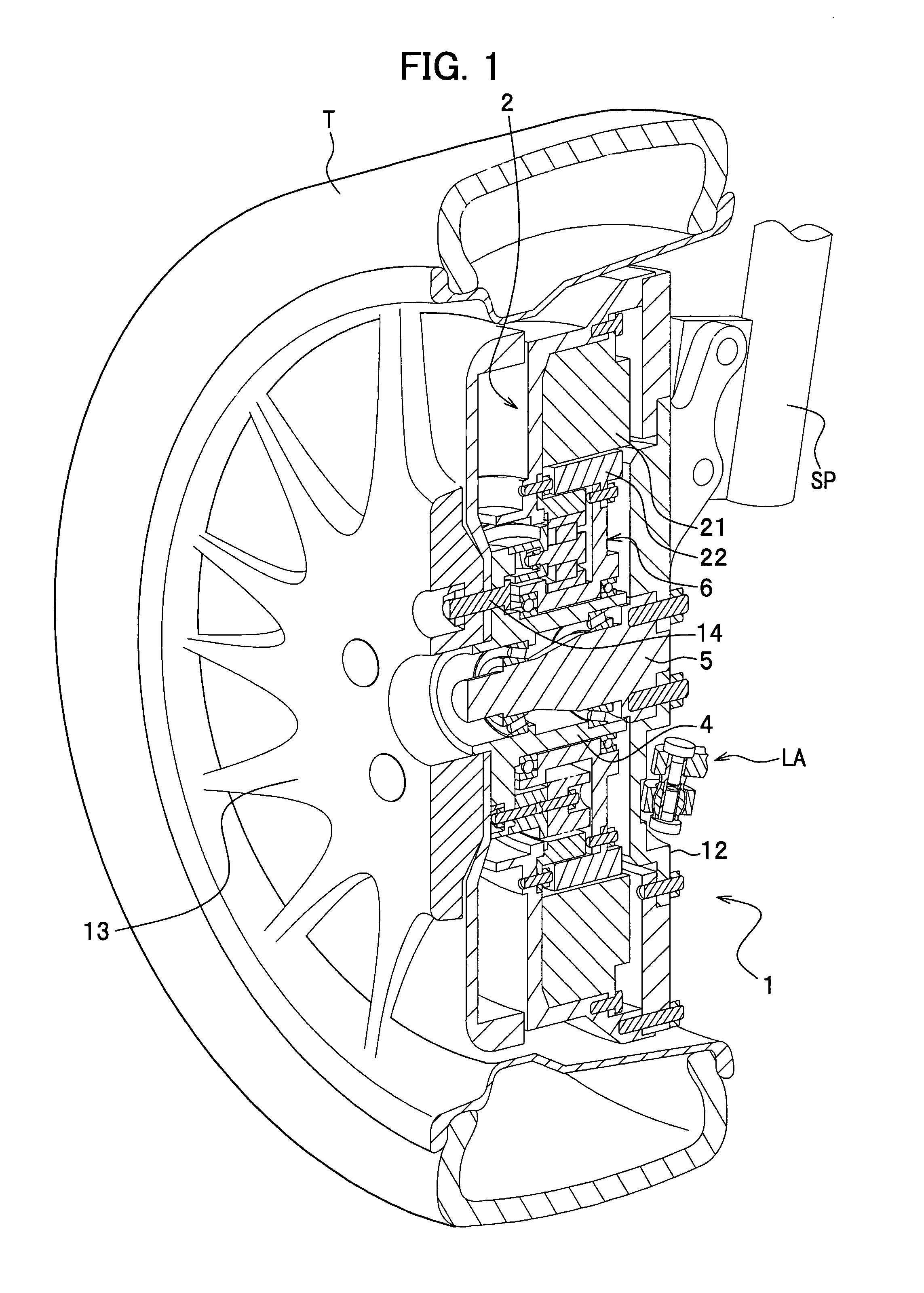

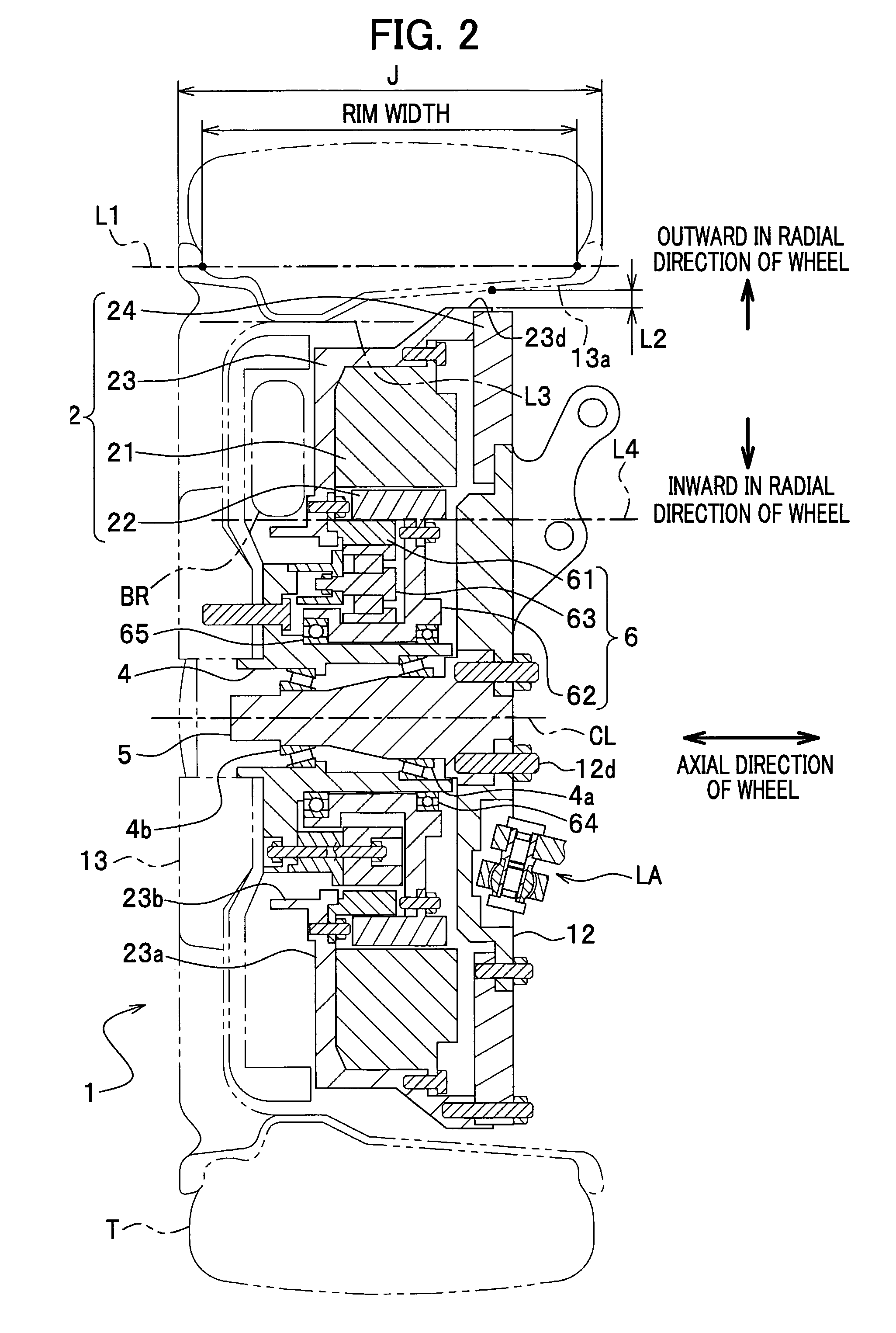

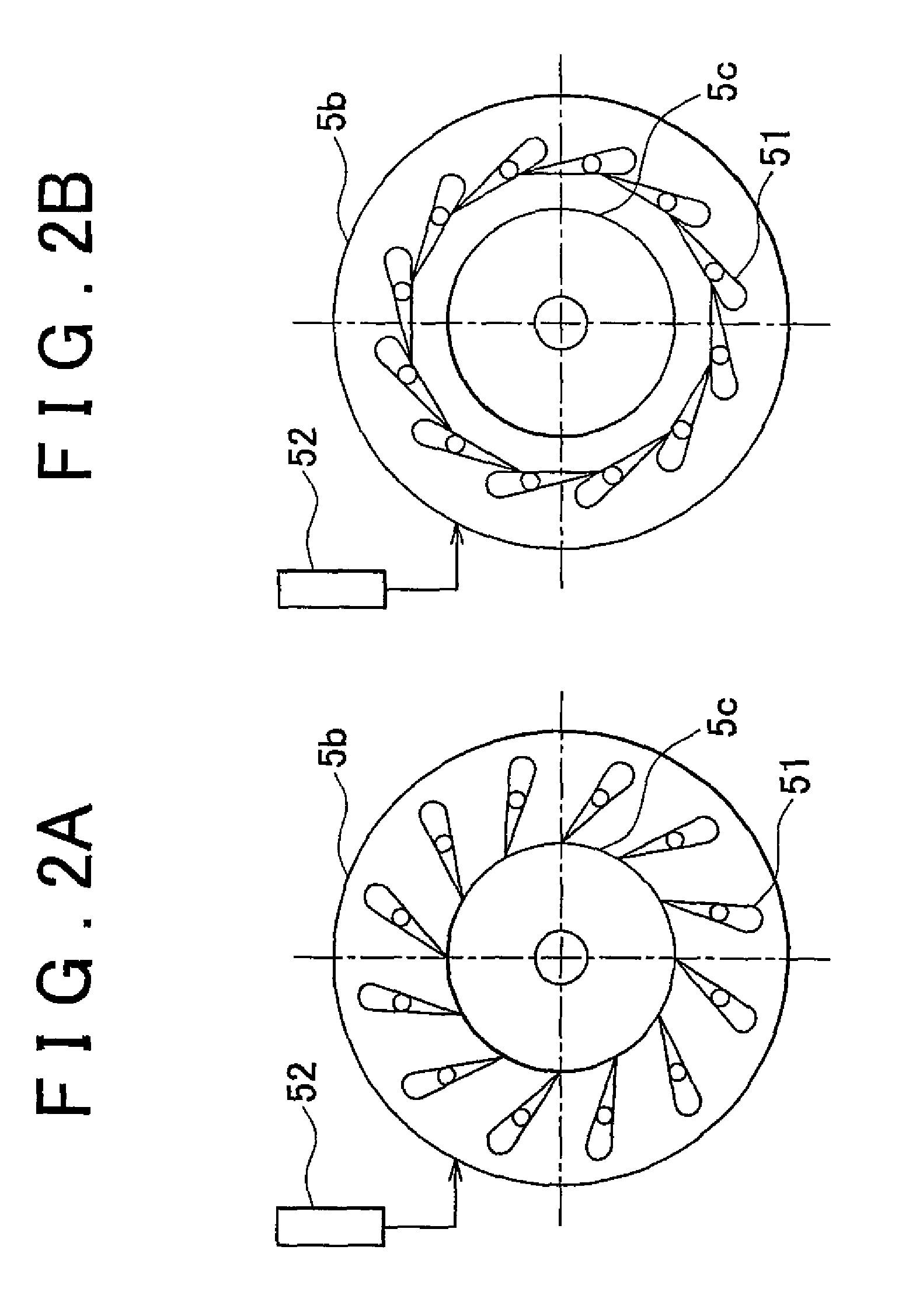

Wheel rotating device for in-wheel motor vehicle

InactiveUS8186467B2Increase the reduction ratioSufficient output performanceHybrid vehiclesElectric devicesReducerMotorized vehicle

A wheel rotating device (1) for an in-wheel motor vehicle includes a motor (2), a speed reducer (6) coupled to an output part of the motor (2), a hub (4) coupled to an output part of the speed reducer (6), and a spindle (5) fixed relative to a vehicle body and supporting the hub (4) in a manner that permits the hub (4) to rotate. The hub (4) is coupled to a wheel (13) to rotate the wheel (13). A stator (21) of the motor (2) is disposed inwardly in radial directions of the wheel (13) along an inner circumferential surface of the wheel (13). A rotor (22) of the motor (2) is disposed inwardly in radial directions of the stator (21). The speed reducer (6) is disposed between the rotor (22) and the hub (4) with bearings provided between the speed reducer (6) and the hub (4).

Owner:HONDA MOTOR CO LTD

Directly operated pneumatic valve having a differential assist return

ActiveUS7210501B2Eliminates bypass flowMove quickly and efficientlyOperating means/releasing devices for valvesServomotor componentsFluid controlNet return

A fluid control valve includes a valve body having both fluid inlet and discharge ports. A flow passage axially extending within the valve body communicates with the inlet and discharge ports. A valve member within the flow passage is movable by an actuator force in a first direction to direct a pressurized fluid from the inlet to the discharge port. The valve member includes first and second valve heads having different diameters and a valve seating member. The valve seating member engages first and second sealing diameters of the flow passage, the second sealing diameter being smaller than the first. Fluid pressure acting on the different diameters of the first valve head and valve seating member in contact with the second sealing diameter creates a net return force directing the valve member in a second direction opposite to the first direction upon removal of the actuator force.

Owner:MAC VALVES INC

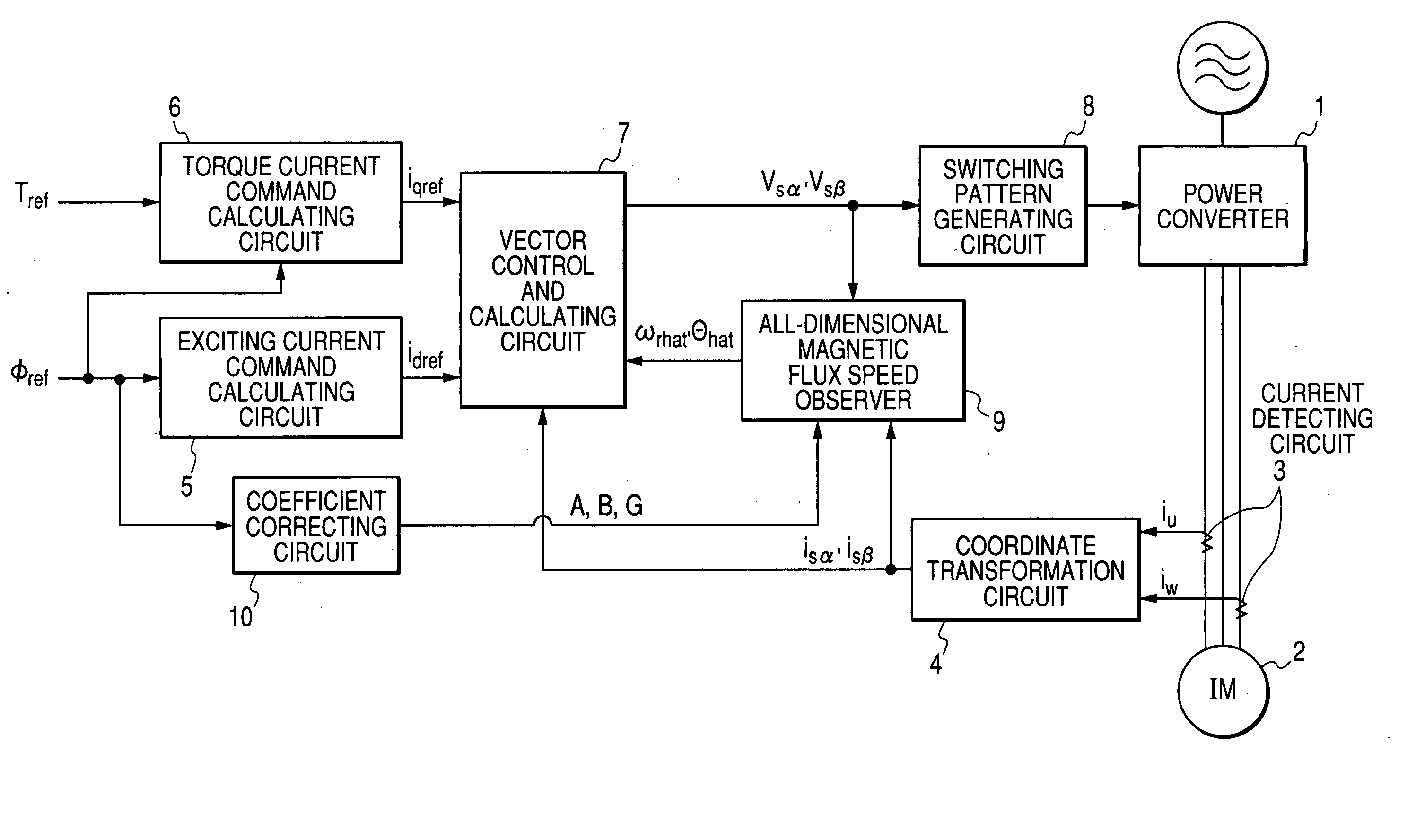

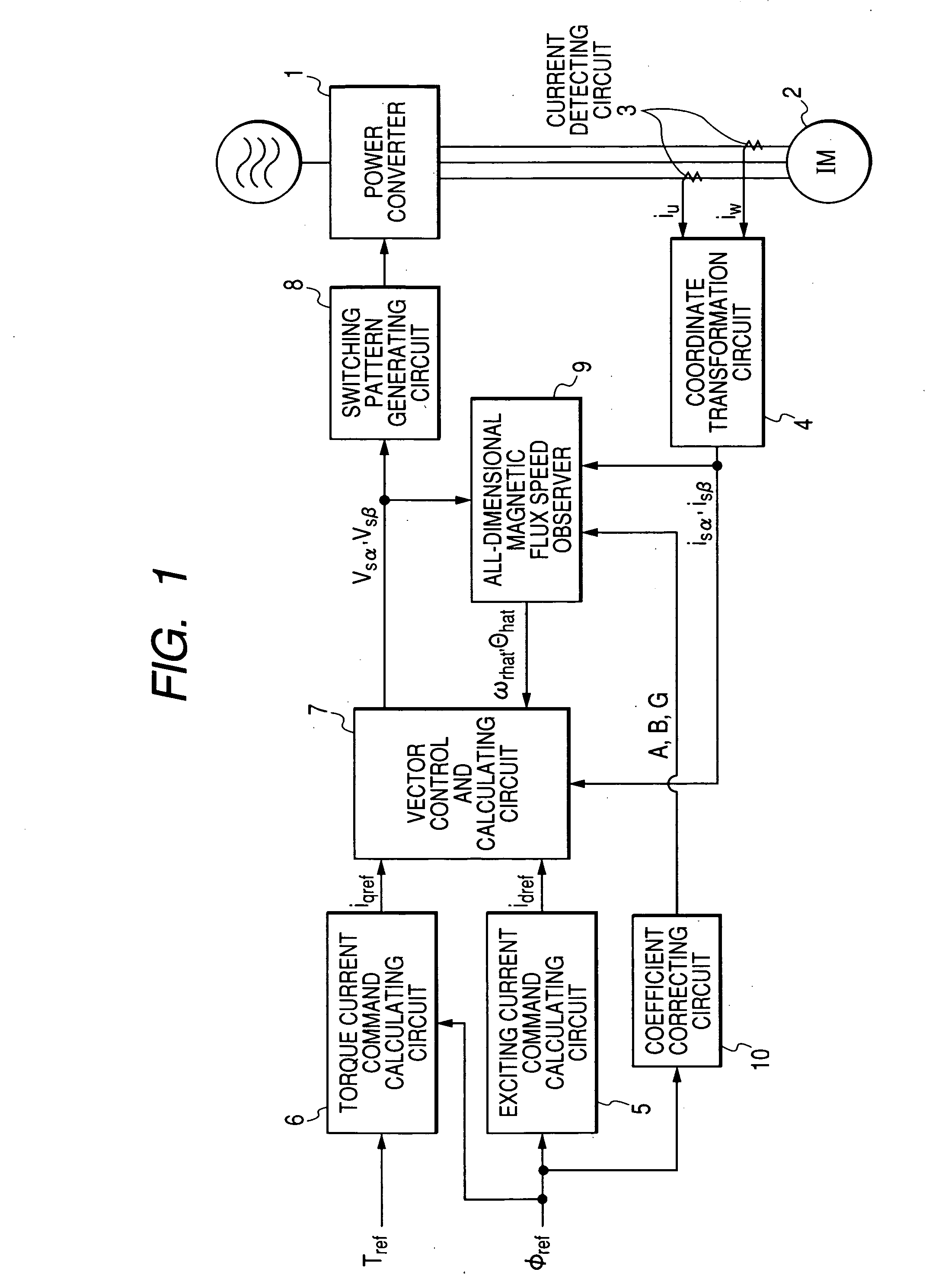

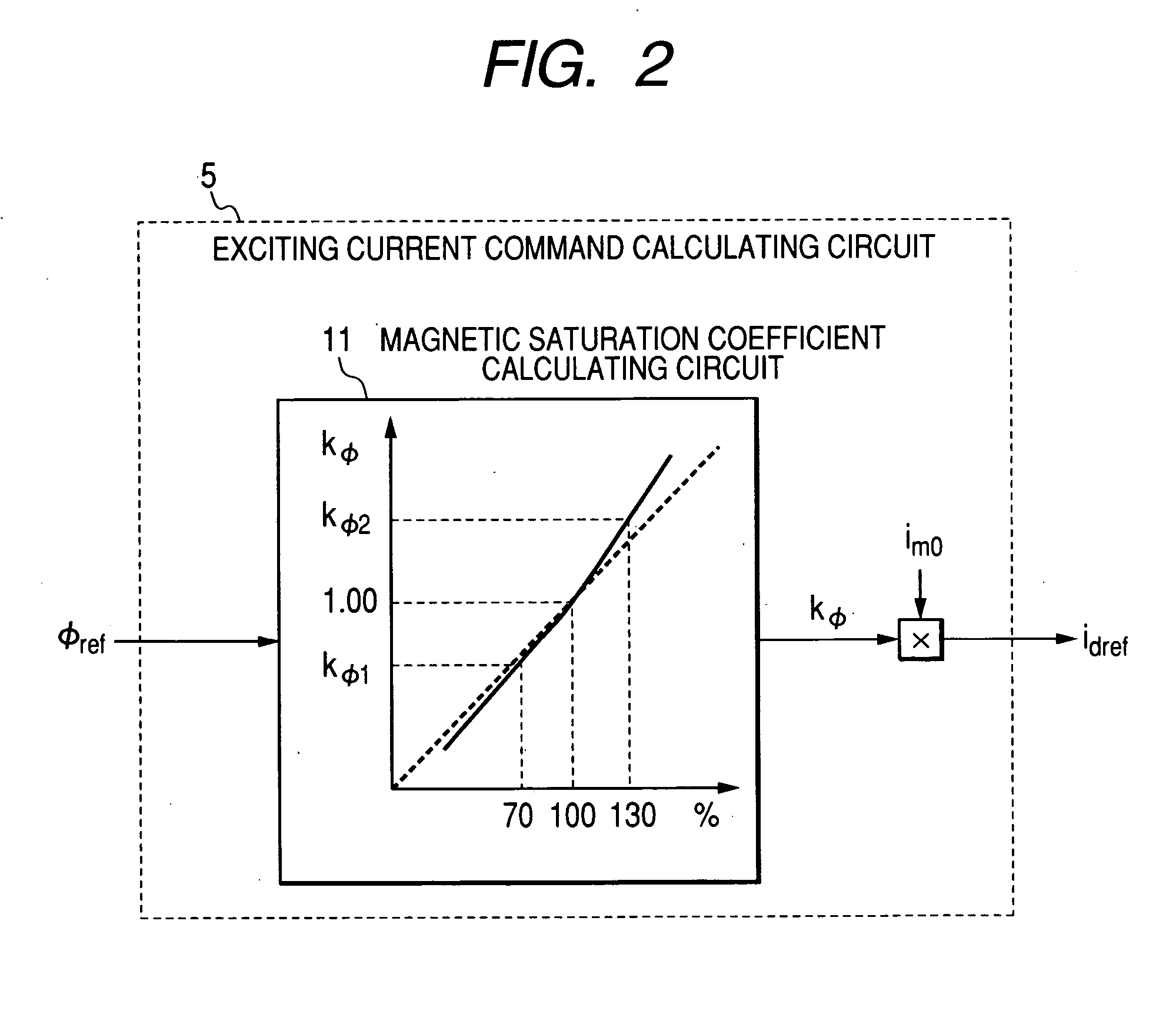

Method and device for sensorless vector control for ac motor

InactiveUS20070018606A1Accurate estimateHigh speed accuracySingle-phase induction motor startersSynchronous motors startersControl vectorExcitation current

To provided a control method and a controller for an a.c. motor without using a speed sensor in which the speed estimated value or the magnetic flux estimated value of an all-dimensional magnetic flux speed observer can be made to correspond to that of an actual a.c. motor. A controller for an a.c. motor includes a vector control and calculating circuit (7) for controlling and calculating a vector from an exciting current command calculated in an exciting current command calculating circuit (5), a torque current command calculated in a torque current command calculating circuit (6), a coordinate transformed current detected value obtained in a coordinate transformation circuit (4), a speed estimated value and a magnetic flux phase estimated value and outputting an output voltage command, a switching pattern generating circuit (8) for generating a signal for PWM driving a power converter (1) from the output voltage command and an all-dimensional magnetic flux speed observer (9) for estimating the speed estimated value and the magnetic flux phase estimated value from the output voltage command and the coordinate transformed current detected value. In the controller for the a.c. motor, a coefficient correcting circuit 10 is provided for correcting the coefficient of a determinant used in the all-dimensional magnetic flux speed observer (9) in accordance with a magnetic flux command.

Owner:YASKAWA DENKI KK

Automatic slowdown control apparatus for a vehicle

InactiveUS7065442B2Accelerated comparatively rapidlyPosture or the behavior of the vehicle may be rendered unstable is lowHand manipulated computer devicesAnalogue computers for trafficInstabilityAutomotive engineering

An automatic slowdown control apparatus for a vehicle is disclosed wherein automatic slowdown control can be ended appropriately and automatic slowdown is prevented from being performed excessively on a road of an ascending gradient. The automatic slowdown control apparatus starts automatic slowdown control of rendering a braking mechanism operative to slow down the vehicle when the stability of the posture and / or behavior of the vehicle upon turning is deteriorated. A control end threshold value is set such that the stability of the vehicle is displaced to the instability side as the ascending gradient of the uphill road increases.

Owner:MITSUBISHI FUSO TRUCK AND BUS CORPORATION

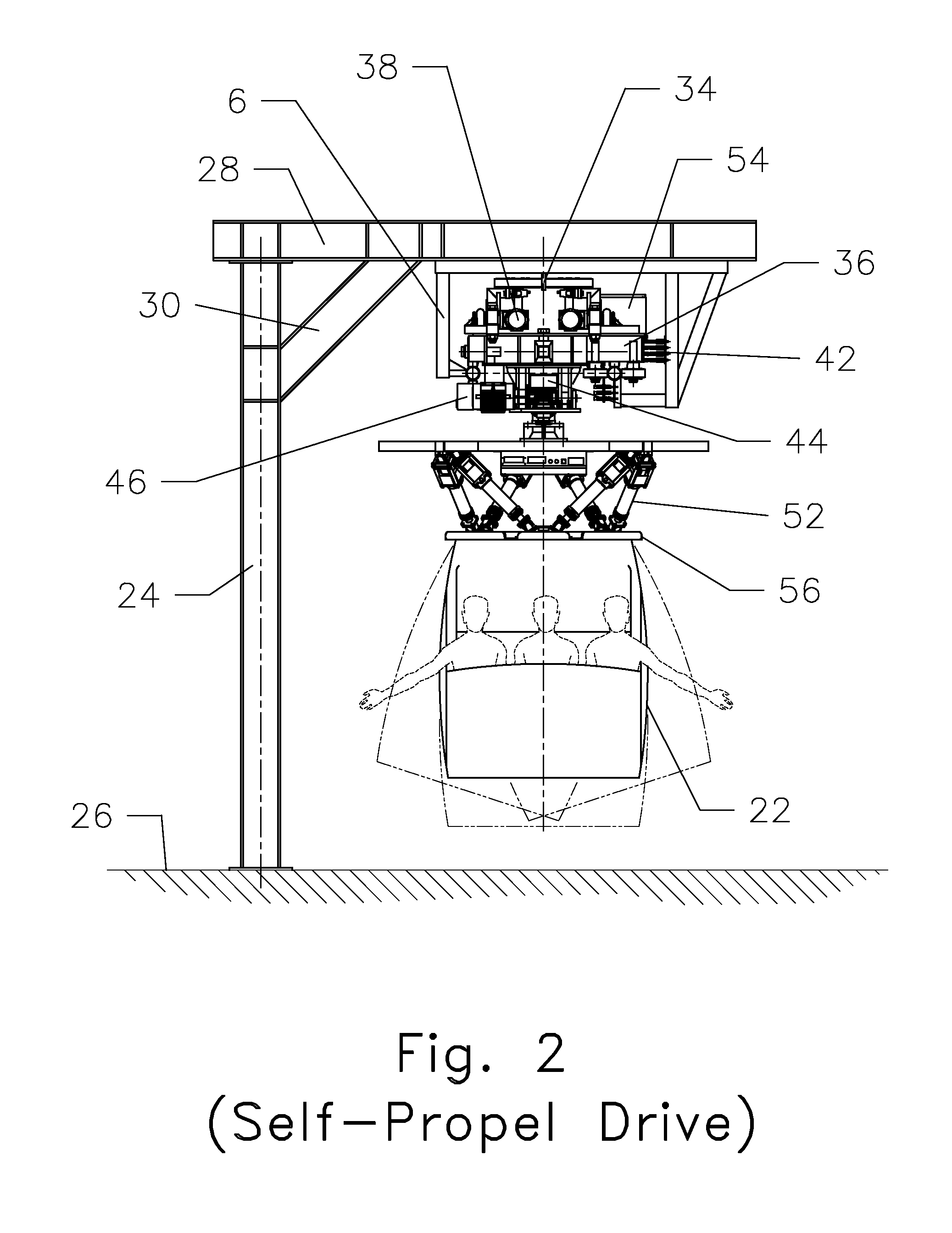

Inverted simulation attraction

ActiveUS8641540B2Fast accelerationFast brakingCosmonautic condition simulationsStage arrangementsViewpointsEngineering

A system for patron movement and entertainment comprising a track, and at least one vehicle engaged with and positioned below the track, capable of carrying at least one patron in a passenger portion and moving along the track. Each vehicle preferably includes a motion base between the track and the passenger portion, and a turntable between the track and the motion base for rotating the passenger portion in the yaw direction, and particularly for directing the patron's viewpoint toward desired show elements.

Owner:RIDE & SHOW ENG INC

System and Method for Train Operation Approaching Grade Crossings

ActiveUS20090184214A1Reduce traffic delaysFast accelerationSignal operation from vehicleVehicle route interaction devicesMotion sensingPredictive controller

A system and method that enables trains to rapidly accelerate through grade crossings from station stops or civil speed restrictions is disclosed. In some embodiments, equipped trains and grade-crossing controllers communicate wirelessly to address operational limitations pertaining to the grade crossings. In conjunction with the train's equipment, conventional crossing controllers are augmented with a communications capability and logic to accept commands to operate in a “Prediction” mode or a “Motion-Sensing” mode. The Prediction mode is the default operating mode for conventional constant-warning grade-crossing prediction controllers. The Motion-Sensing mode is an operating mode whereby the crossing is actuated as soon as an approach circuit detects train motion.

Owner:AUSTRALIAN RAIL TRACK CORP

Methods of joining protective metal-clad structures having low attendant energy consumption

ActiveUS20110132534A1Reduce oxidationHigh densityExhaust apparatusMachines/enginesEnergy consumptionTantalum

The present invention is directed to a process for joining tantalum clad steel structures. The process broadly comprises:a) providing a first tantalum clad section, said first tantalum clad section comprising a tantalum layer over a steel layer, with a bonding layer optionally therebetween, with a portion of said steel layer in an edge region not being covered by said tantalum layer or said bonding layer,b) providing a second tantalum clad section, said second tantalum clad section comprising a tantalum layer over a. steel layer, with a bonding layer optionally therebetween, with a portion of said steel layer in an edge region not being covered by said tantalum layer or said bonding layer,c) locating said steel edge regions adjacent each other,d) welding the steel edge regions together,e) cold spraying a tantalum powder onto the welded edge regions and over the tantalum layers adjacent said edge regions thereby joining the tantalum clad steel sections.The invention is also directed to tantalum welds or joints formed by cold spraying tantalum powder.

Owner:MATERION NEWTON INC +1

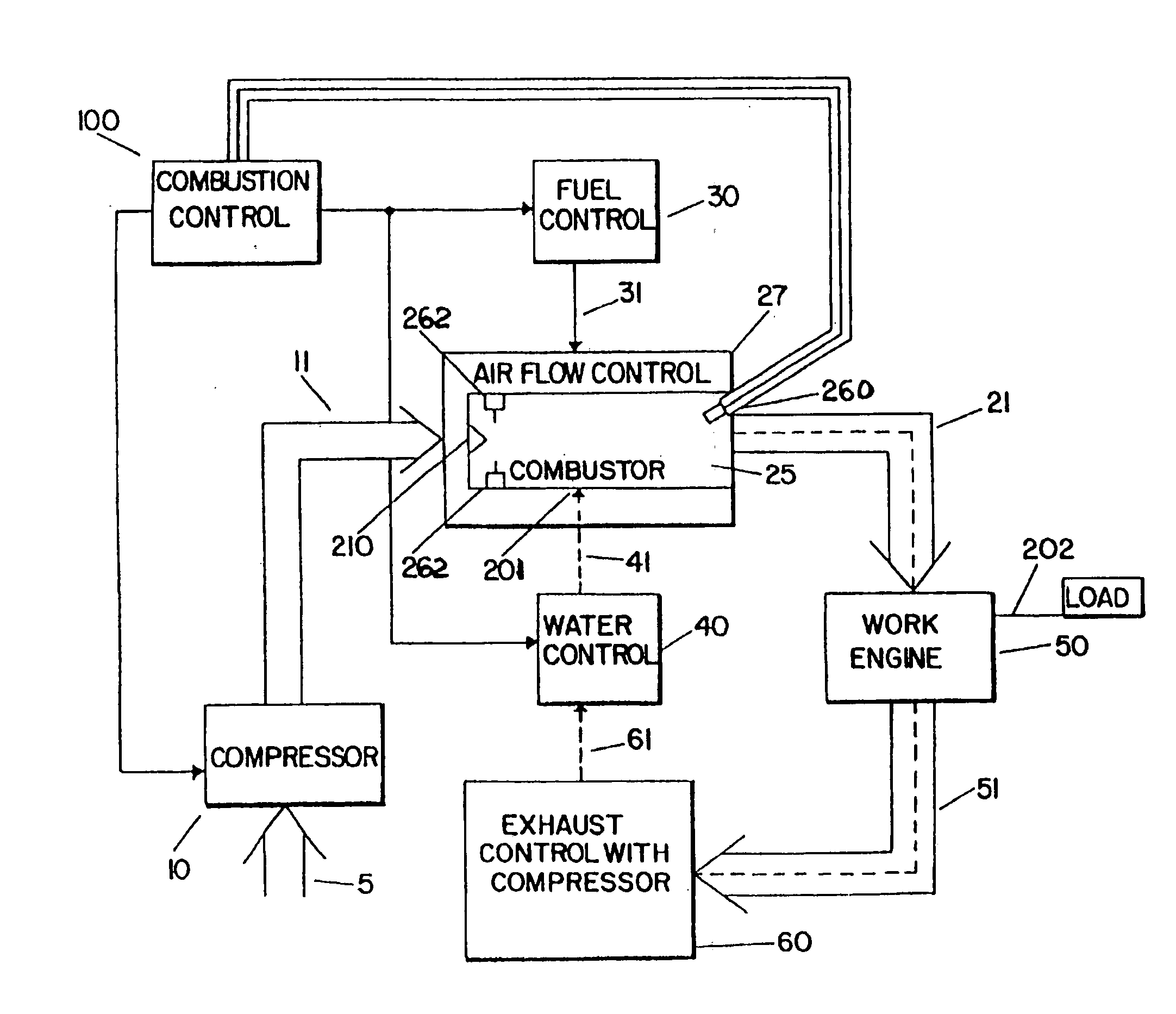

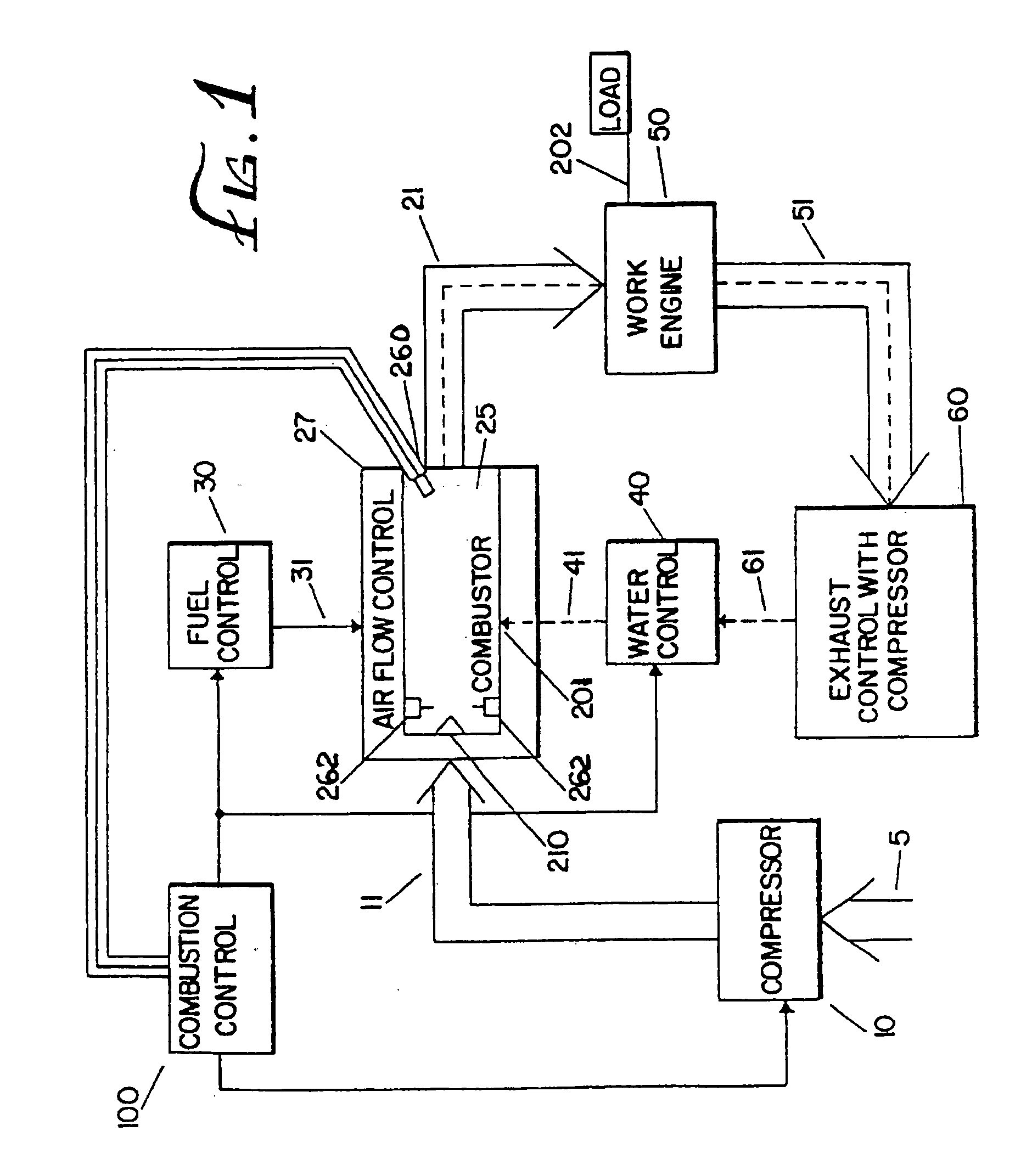

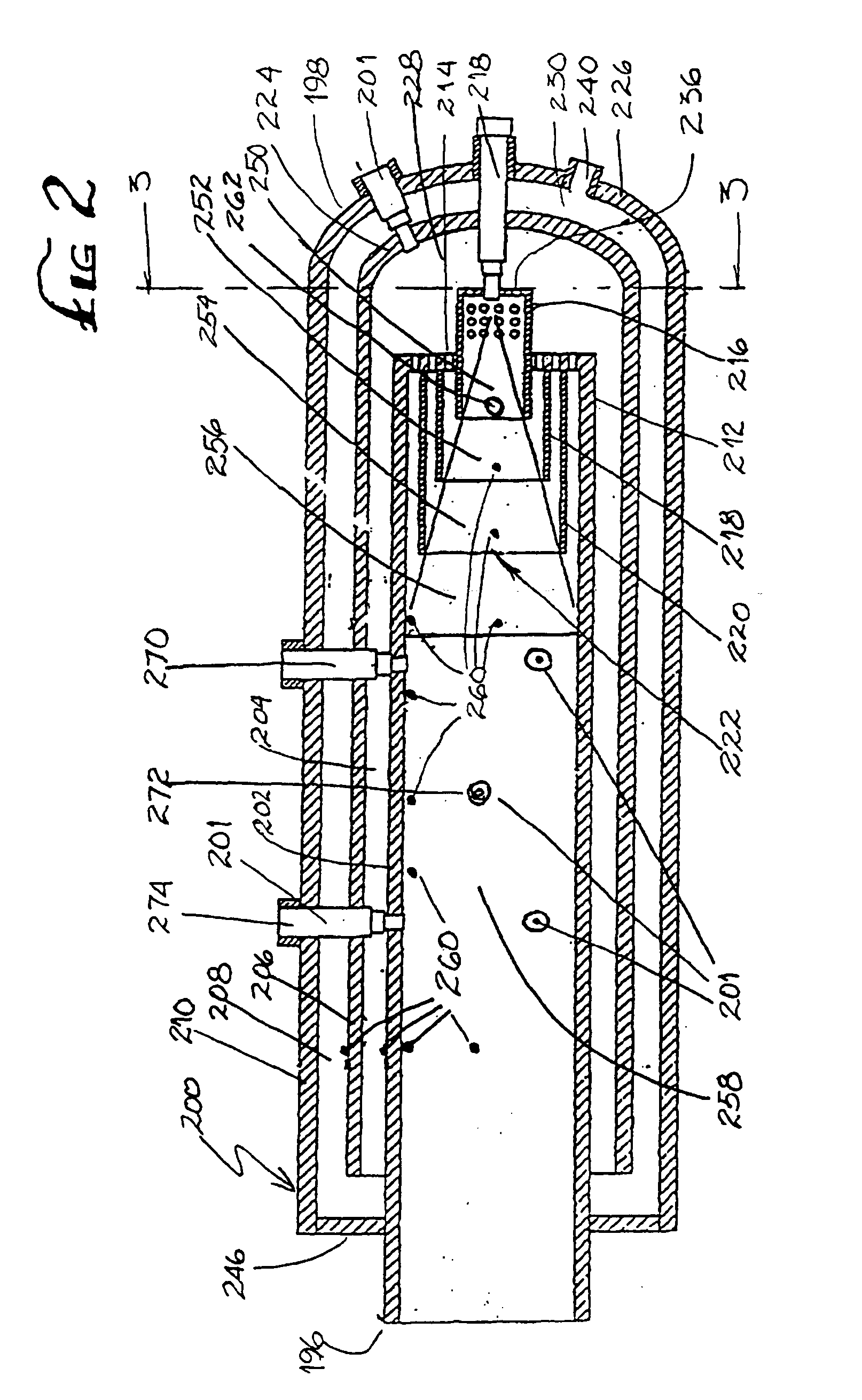

High efficiency low pollution hybrid brayton cycle combustor

InactiveUS20060064986A1Increase horsepowerFast accelerationEfficient propulsion technologiesGas turbine plantsHybrid typeCombustion chamber

A power generating system and method operating at high pressure and utilizing a working fluid consisting of a mixture of compressed non-flammable air components, fuel combustion products and steam. The working fluid is substantially free of CO and NOx. Fuel and compressed air at an elevated temperature and at a constant pressure are delivered to a combustion chamber, the amount of air being chosen so that at least about 90% of the oxygen in the air is consumed during combustion. The quantity of air and fuel supplied to the combustion chamber may be varied provided a constant fuel to air ratio is maintained. Superheated water is delivered under pressure to the combustion chamber, and is converted substantially instantaneously to steam. The quantity of water delivered is controlled such that the latent heat of vaporization of the water maintains the temperature of the working fluid at a desired level. Heat may be transferred from the working fluid exiting the work engine to the water to heat the water to the desired temperature for delivery to the combustion chamber. The quantity, temperature and pressure of the air, fuel and water introduced in to the combustion chamber are independently controllable. A zoned burner may be employed in which a portion of the compressed air may be mixed with the fuel in a first zone prior to ignition, with the remaining compressed air being added at one or more locations downstream of the point of ignition.

Owner:GINTER J LYELL +1

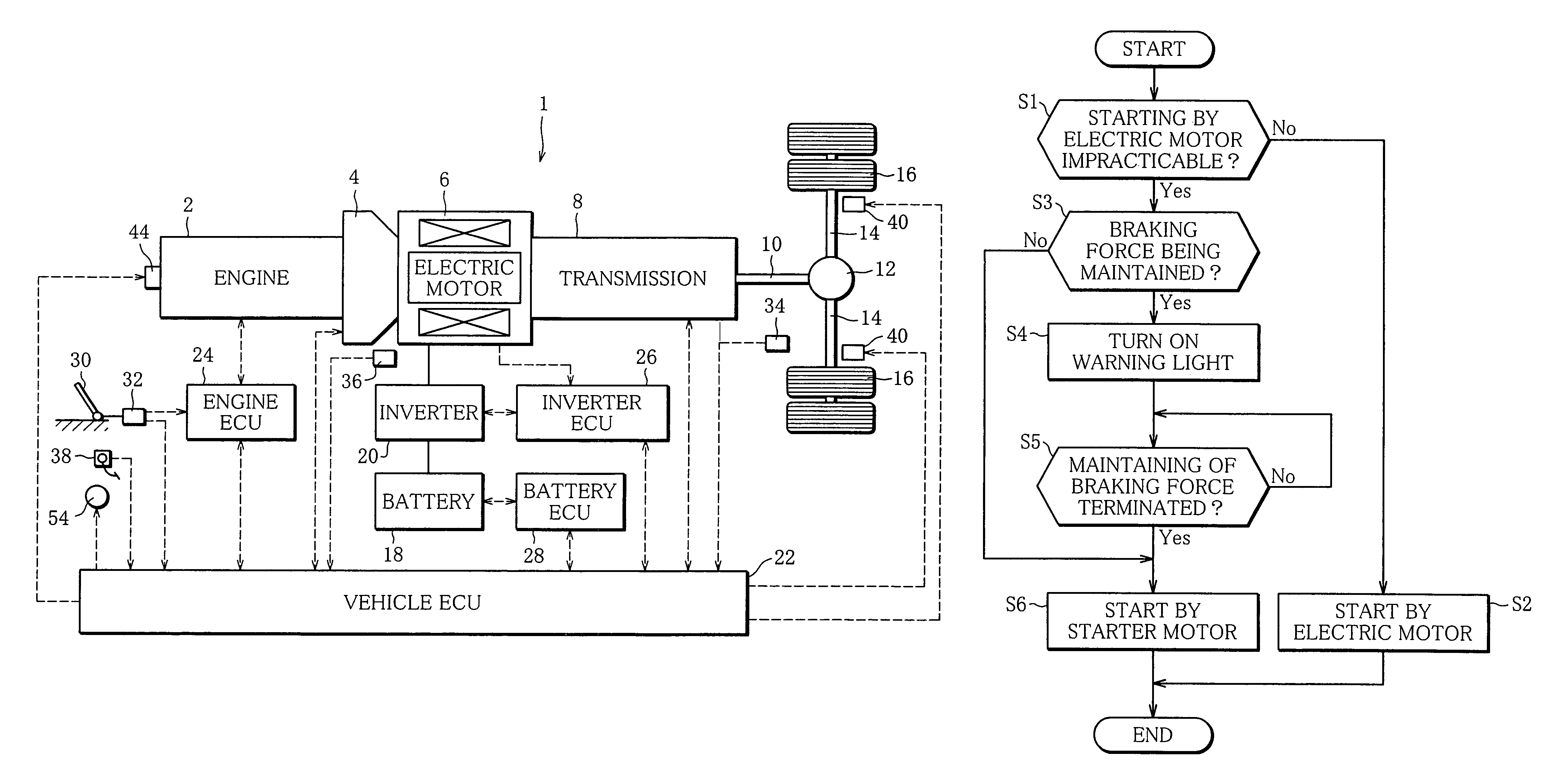

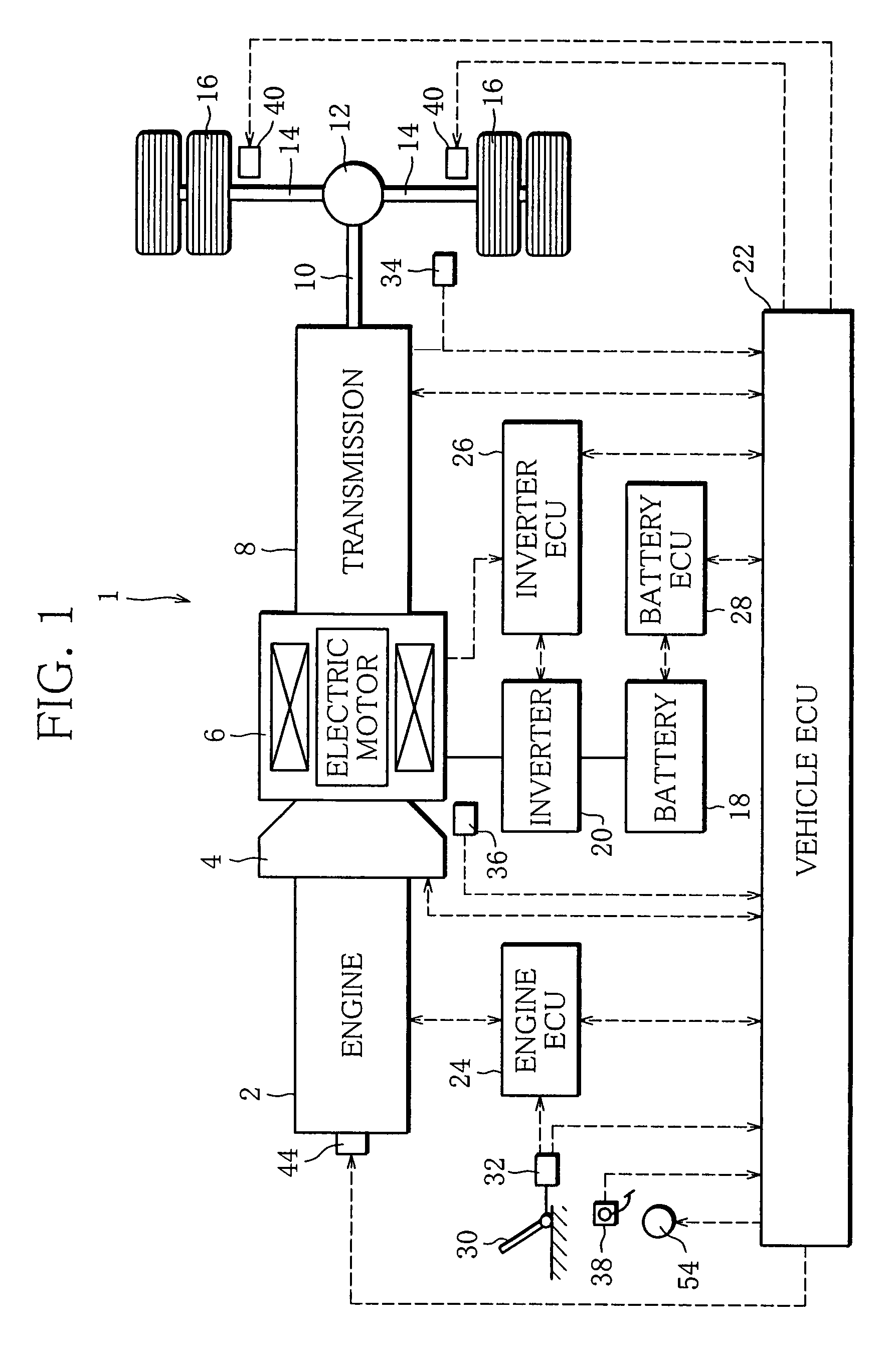

Control device for a hybrid electric vehicle

InactiveUS7823668B2Fast accelerationPower operated startersDigital data processing detailsDrive wheelElectric power system

A hybrid electric vehicle is arranged such that a driving force of an electric motor can be transmitted to driving wheels and that a rotary shaft of the electric motor can be coupled with an output shaft of an engine. The vehicle comprises a starter motor provided separately from the electric motor, an electric power source provided separately from a battery that supplies power to the electric motor, to supply power to the starter motor, and a braking force maintaining device configured to be activated by power from the power source to maintain a braking force on the vehicle. When a request for starting the engine is made, if a specified abnormal condition which makes the starting of the engine by the electric motor impracticable is detected, an ECU causes the engine to be started by the starter motor when the braking force maintaining device is not active.

Owner:MITSUBISHI FUSO TRUCK AND BUS CORPORATION

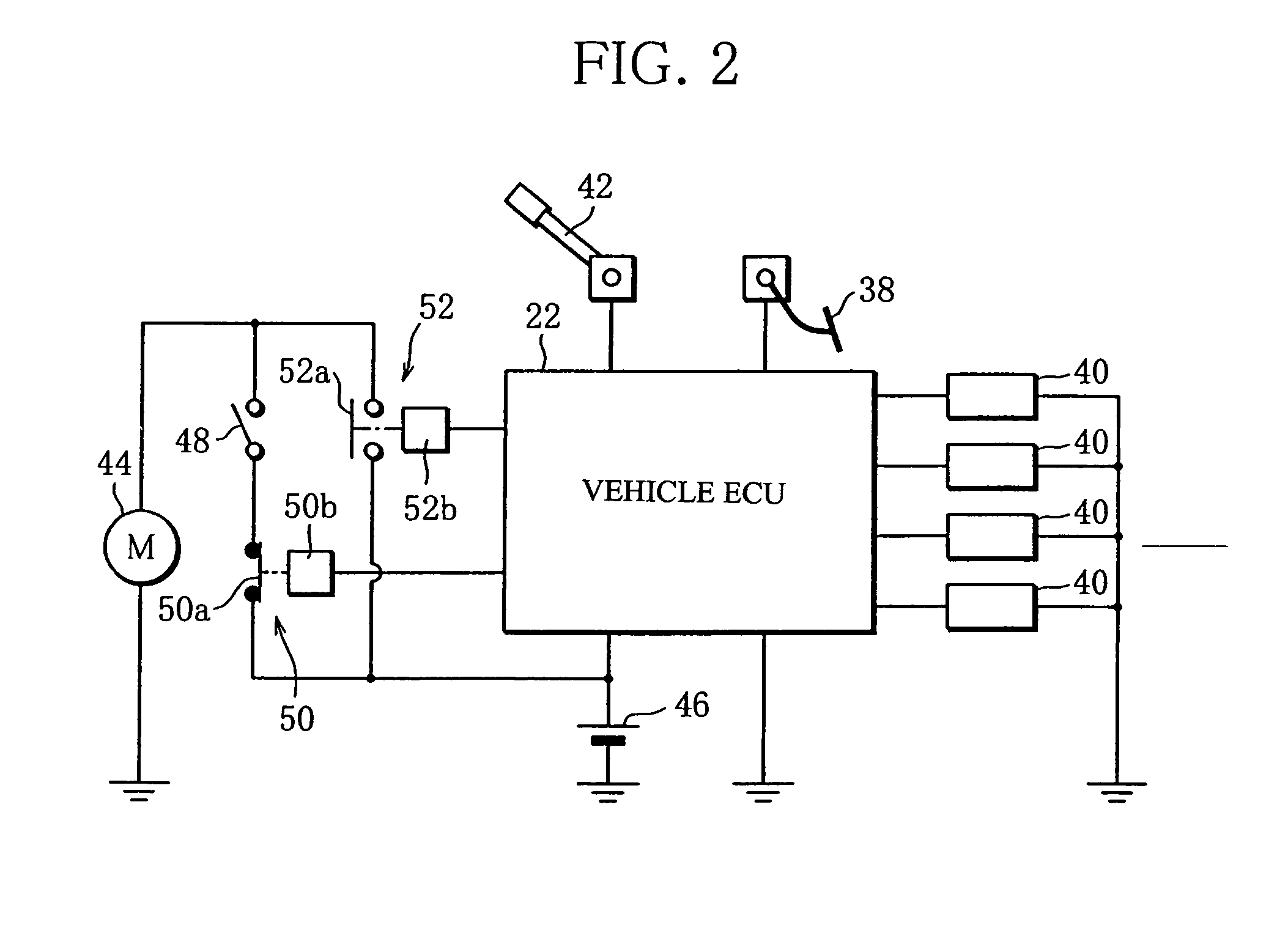

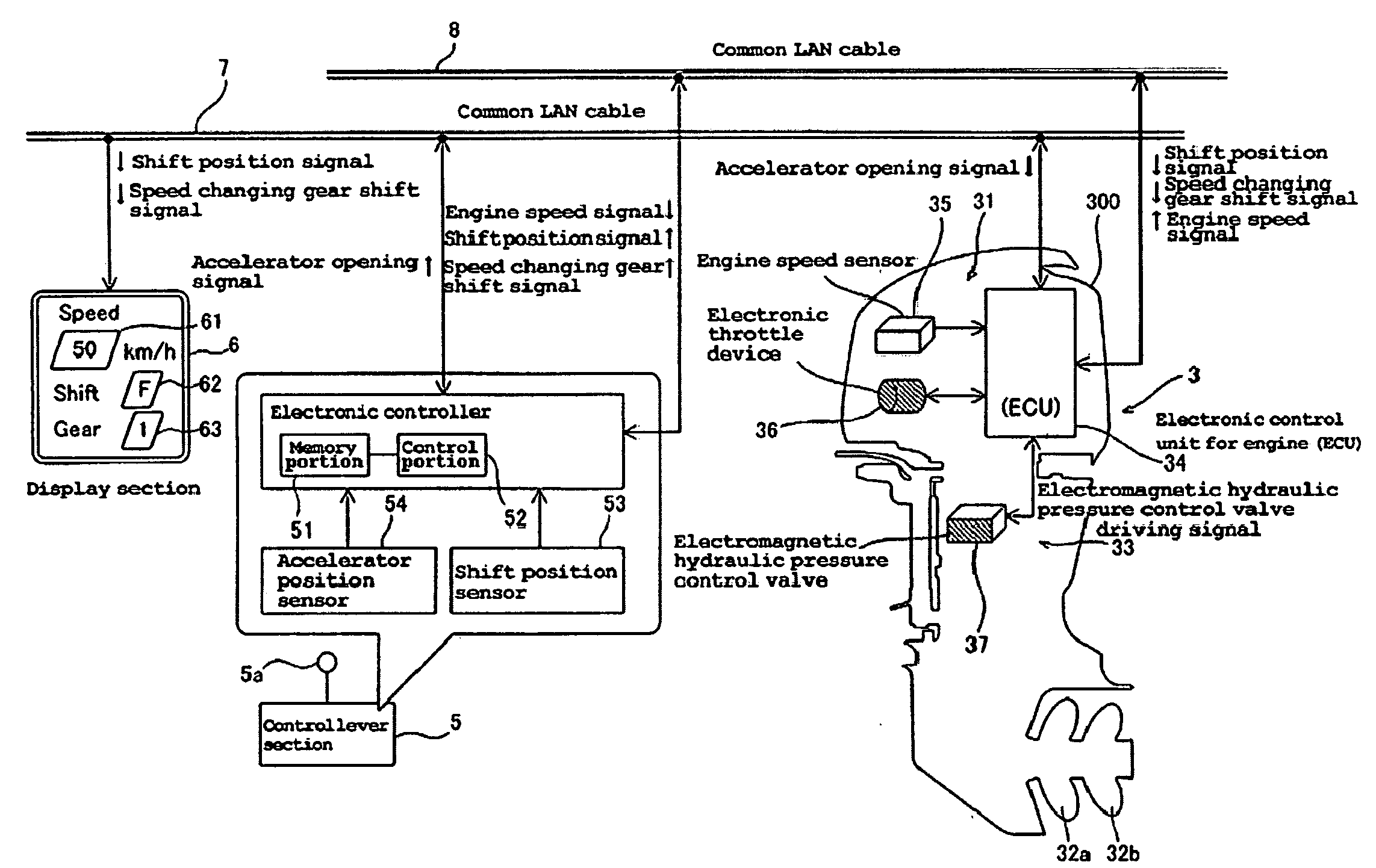

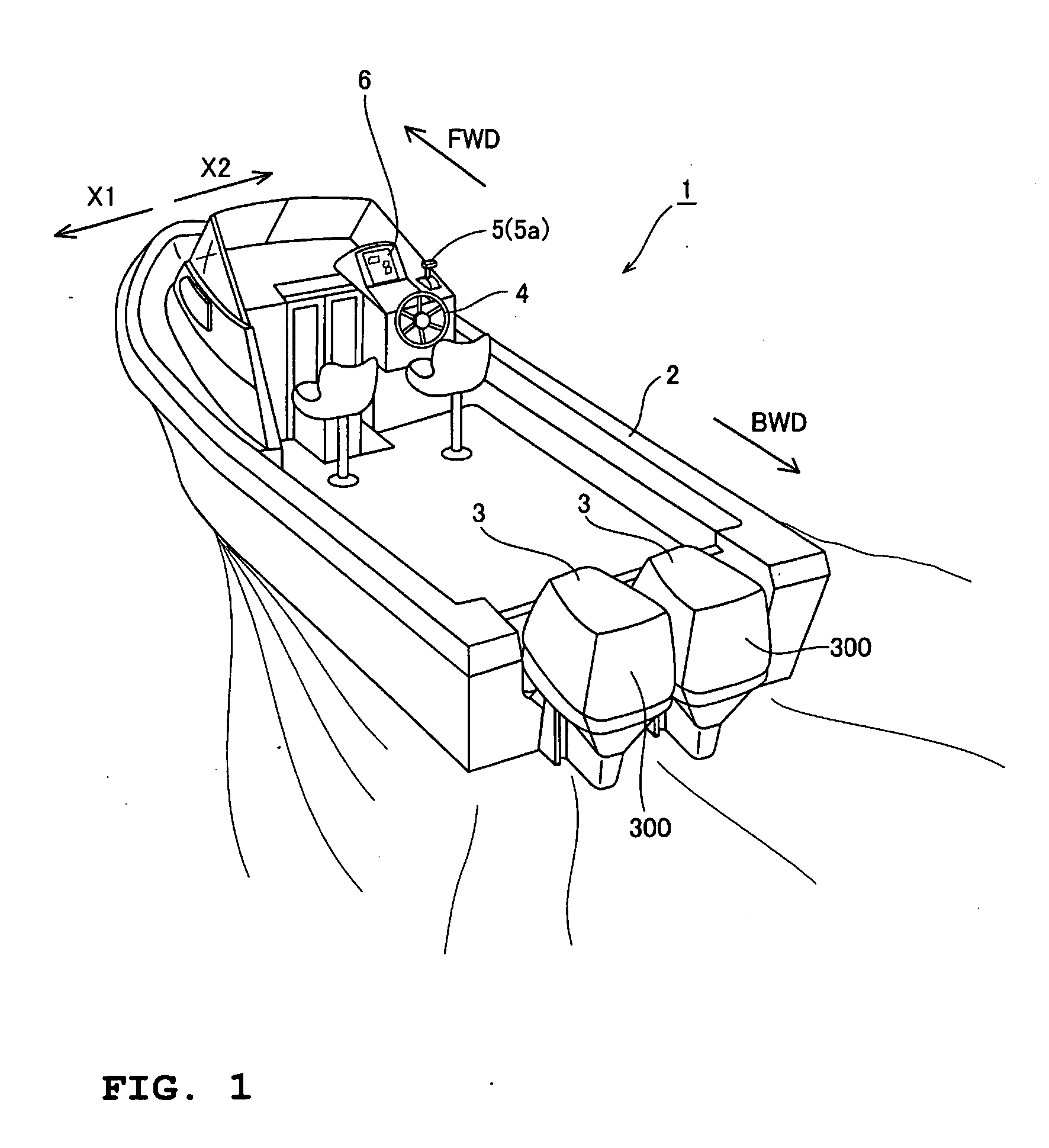

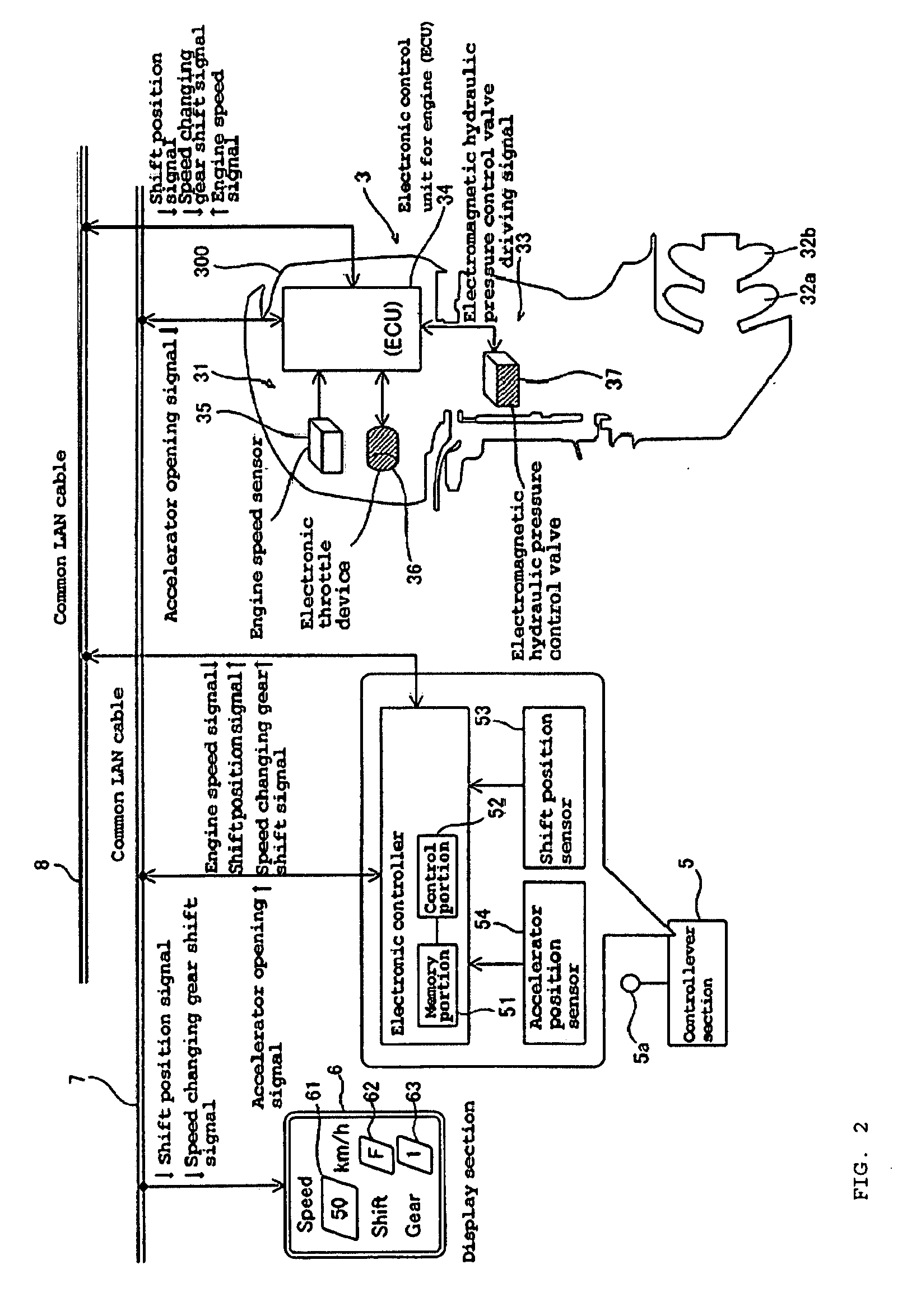

Marine propulsion system

ActiveUS20090209151A1Increase speedMinimize consumptionPropulsion power plantsPropulsive elementsLow speedMarine propulsion

A marine propulsion system includes a transmission mechanism arranged to transmit a driving force generated by an engine to propellers with a speed thereof changed to a low speed reduction ratio and a high speed reduction ratio; a control lever section operated by a user in controlling drive of the engine; and a control portion and an ECU controlling a shift between reduction ratios of the transmission mechanism based on operation of the control lever section by the user. The control portion and the ECU control a shift between reduction ratios of the transmission mechanism based on a transmission control map providing a reference for a shift between reduction ratios of the transmission mechanism taking into consideration an engine speed of the engine and a lever opening of the control lever section. This arrangement provides a marine propulsion system in which both acceleration performance and maximum speed can approach levels that a user desires.

Owner:YAMAHA MOTOR CO LTD

Control device for a hybrid electric vehicle

InactiveUS20070215395A1Fast accelerationPower operated startersDigital data processing detailsDrive wheelElectric power system

A hybrid electric vehicle is arranged such that a driving force of an electric motor can be transmitted to driving wheels and that a rotary shaft of the electric motor can be coupled with an output shaft of an engine. The vehicle comprises a starter motor provided separately from the electric motor, an electric power source provided separately from a battery that supplies power to the electric motor, to supply power to the starter motor, and a braking force maintaining device configured to be activated by power from the power source to maintain a braking force on the vehicle. When a request for starting the engine is made, if a specified abnormal condition which makes the starting of the engine by the electric motor impracticable is detected, an ECU causes the engine to be started by the starter motor when the braking force maintaining device is not active.

Owner:MITSUBISHI FUSO TRUCK AND BUS CORPORATION

Exhaust gas recirculation apparatus for internal combustion engine and method of controlling exhaust gas recirculation apparatus

InactiveUS8006494B2Fast accelerationElectrical controlInternal combustion piston enginesFuel supplyInternal combustion engine cooling

A variable-geometry turbocharger and a low-pressure EGR passage are provided. The variable-geometry turbocharger includes a turbine provided in an exhaust passage, and a compressor provided in an intake passage. In the variable-geometry turbocharger, the cross sectional area of a path through which exhaust gas passes is adjusted by adjusting the opening degree of a nozzle vane. The low-pressure EGR passage connects the area of the exhaust passage downstream of the turbine to the area of the intake passage upstream of the compressor. The EGR gas is recirculated to the intake passage through the low-pressure EGR passage. The EGR gas is directed to flow through the low-pressure EGR passage when a vehicle is decelerating or when fuel supply to the internal combustion engine is cut off. The pressure in the intake passage is adjusted toward a target pressure by adjusting the opening degree of the nozzle vane when the EGR gas flows through the low-pressure EGR passage.

Owner:TOYOTA JIDOSHA KK

Automated stirring and mixing apparatus for cooking

InactiveUS20140069282A1Effective and uniform stirringEffective and uniform and mixingKitchen equipmentBaking plantsAdditive ingredientKinematic pair

The present application discloses an automated cooking apparatus that includes a holder configured to hold a container of food or food ingredients, one or more first kinematic pairs, each comprising a first mating part and a second mating part, wherein the first mating part is connected to the holder; a transport mechanisms that can move the second mating parts of the one or more kinematic pairs; and a driver or controller configured to drive or control the transport mechanism to produce a movement of properly fast speed so that a center point on the internal surface of the container is displaced by properly small distance. The first kinematic pairs and the transport mechanisms in combination can move the holder and the cooking pan to produce fast enough acceleration in the container.

Owner:HE ZHENGXU

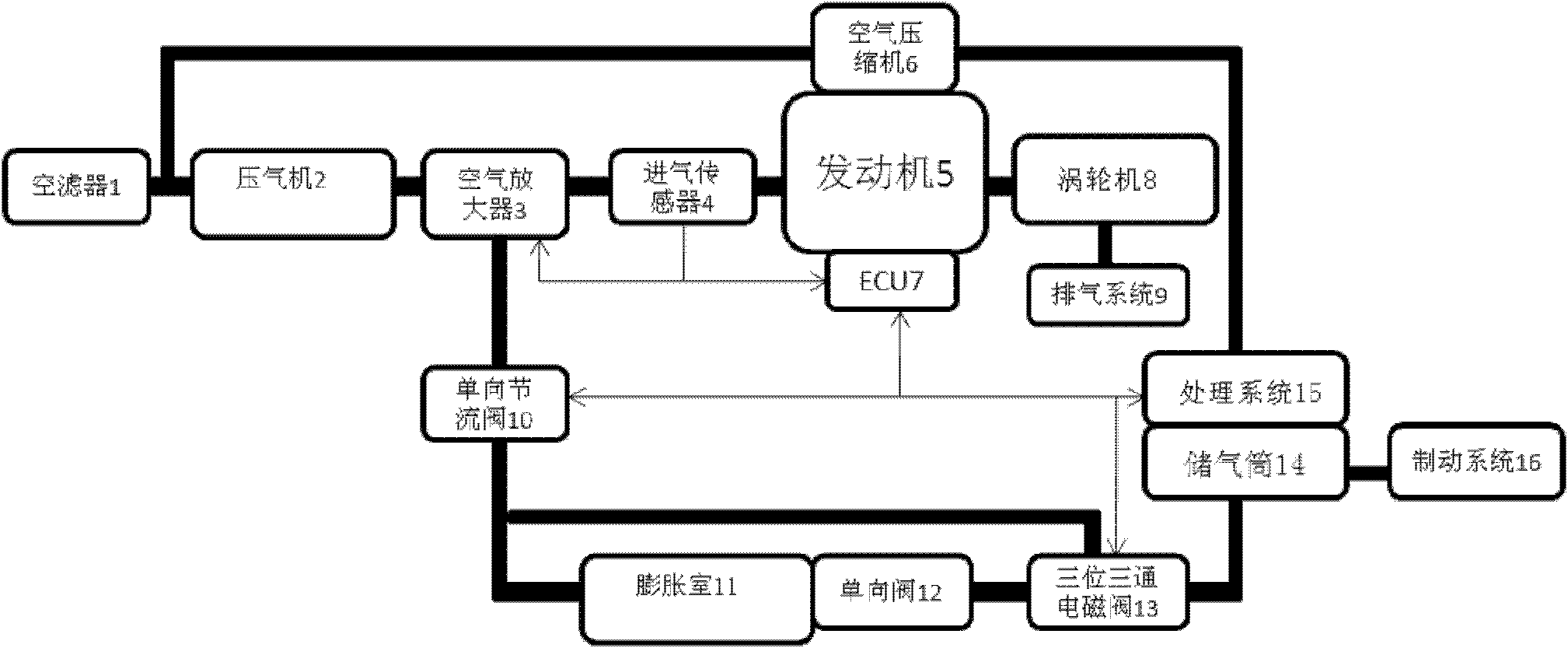

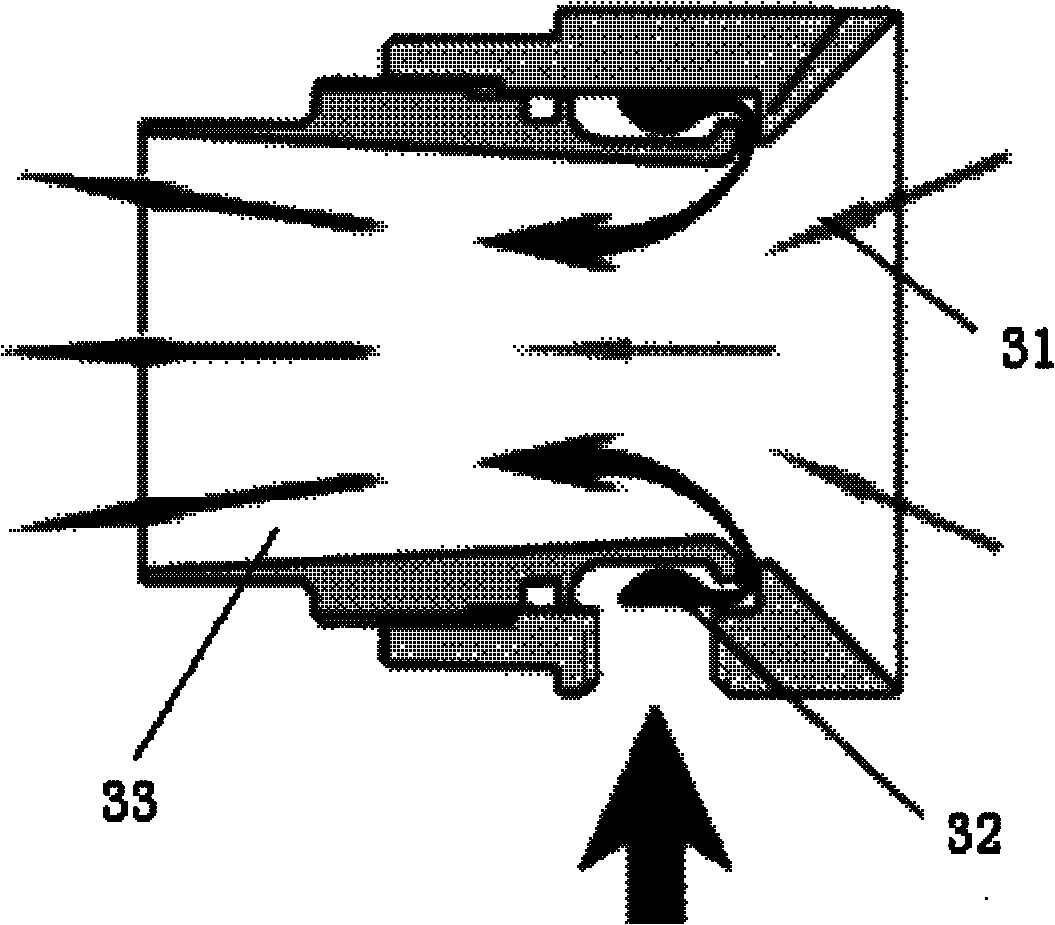

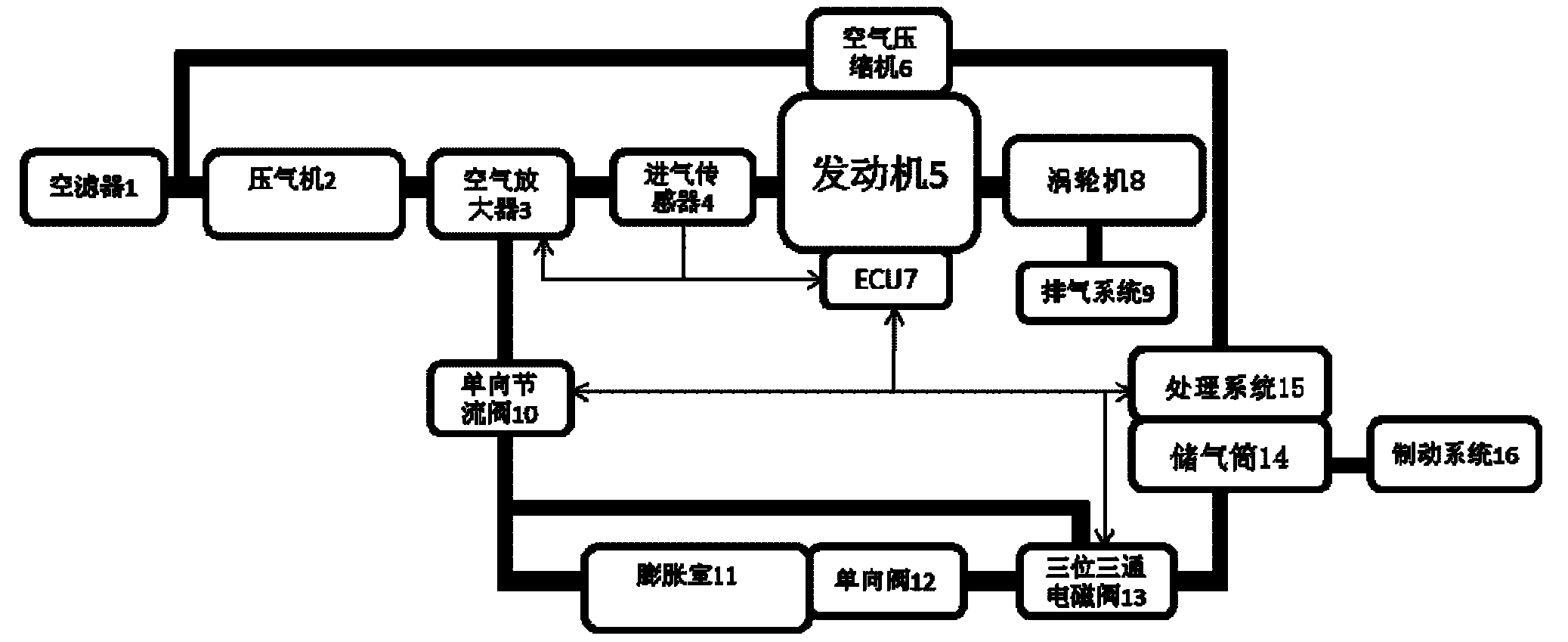

Air inlet system for engine

ActiveCN102182589AIncrease output powerIncrease pressureElectrical controlInternal combustion piston enginesAudio power amplifierTurbocharger

The invention relates to the technical field of engines and discloses an air inlet system for an engine, which comprises a turbo charger, an engine air inlet and an air amplifier, wherein a low-pressure air inlet of the air amplifier is connected with an air outlet of a compressor of the turbo charger, an air outlet of the air amplifier is communicated with an air inlet of an engine, and a high-pressure air inlet of the air amplifier is communicated with a high-pressure air source. When the engine starts or a vehicle accelerates, the air inlet speed of the air inlet system for the engine is higher.

Owner:WEICHAI POWER CO LTD

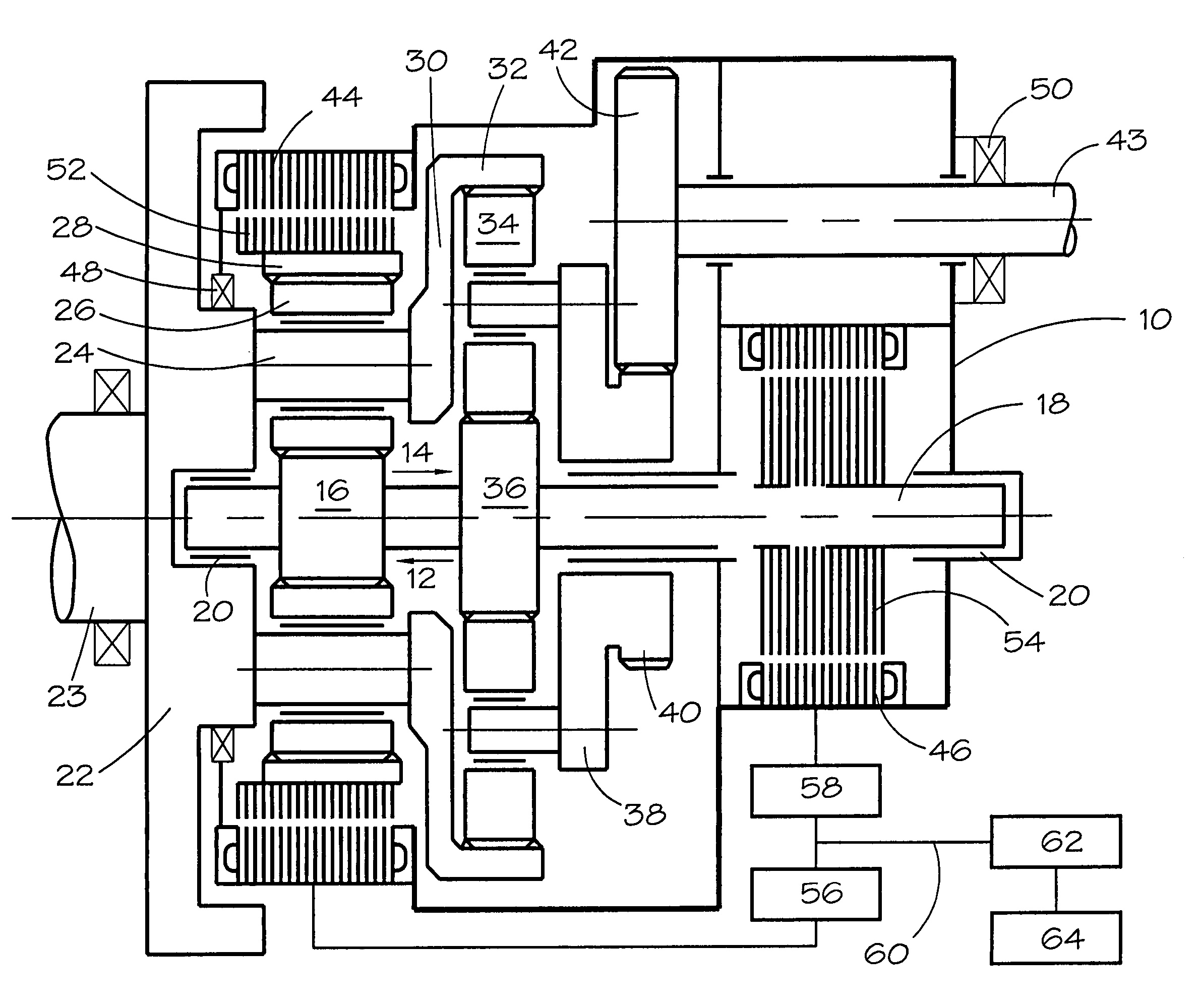

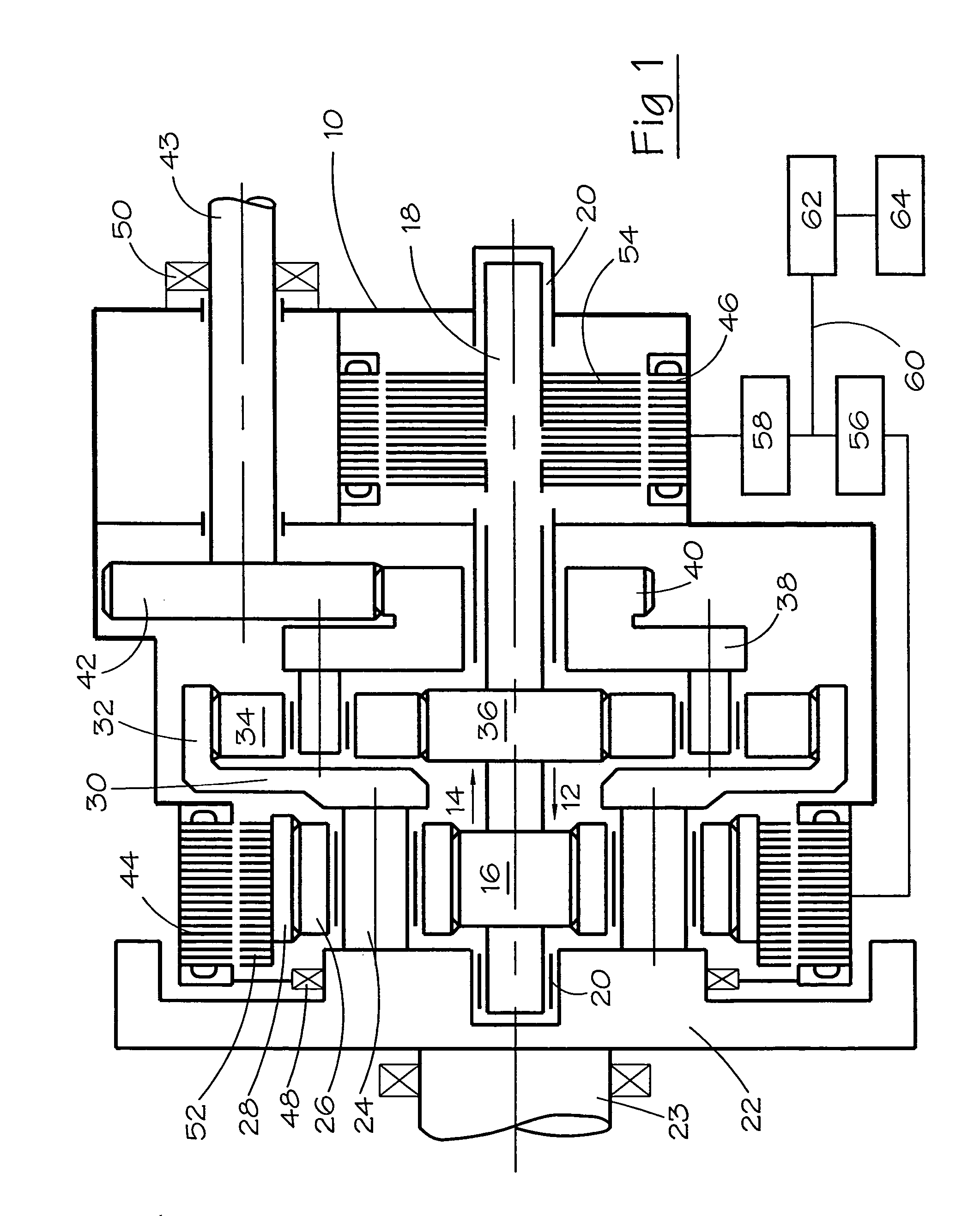

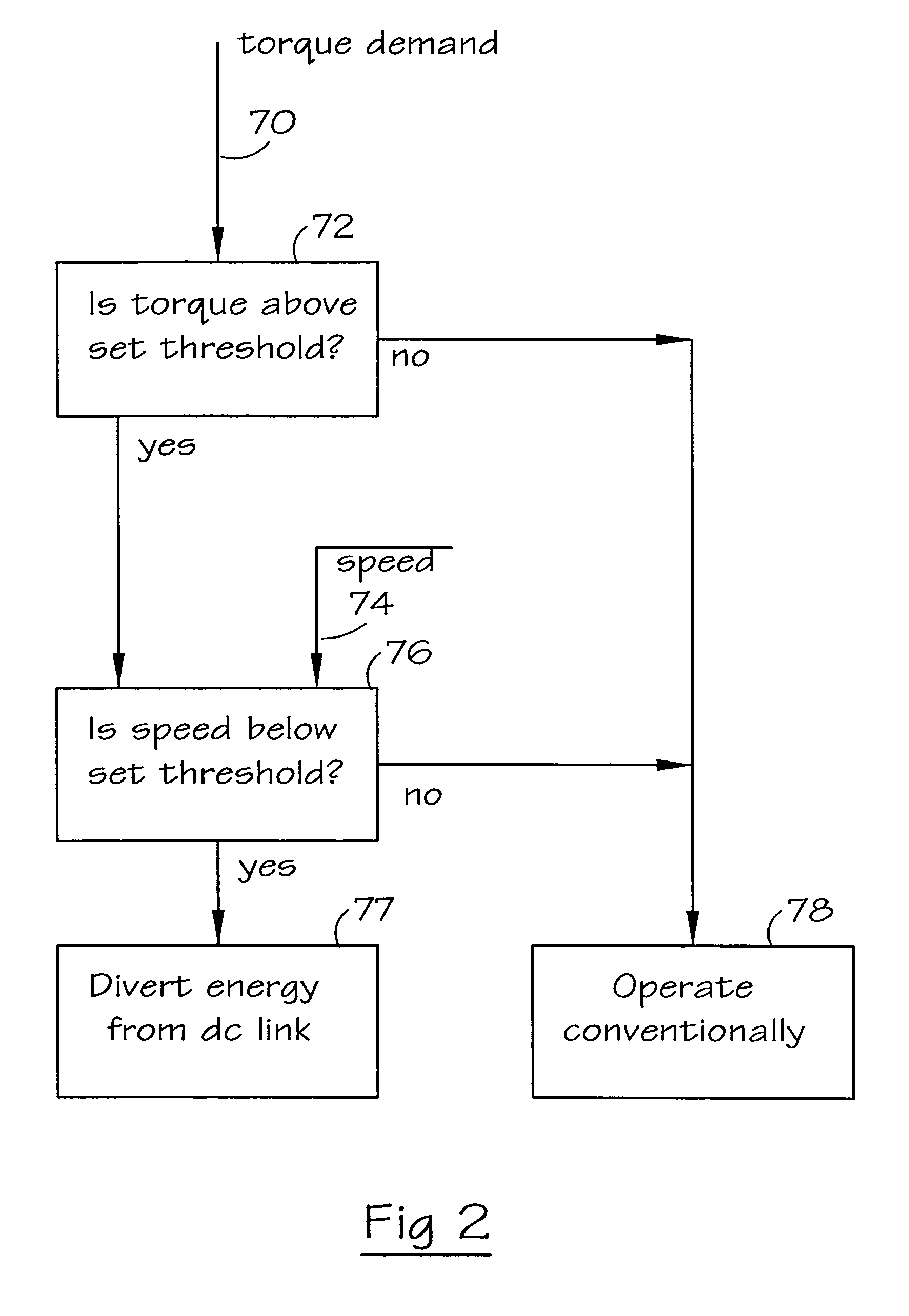

Electro-mechanical transmission systems

InactiveUS7014586B2Increase torqueLow efficiencyHybrid vehiclesElectric propulsion mountingElectric machineControl theory

An electro-mechanical transmission system, driven by a prime mover, includes two epicyclic gearsets connected between input and output shafts, and two electrical machines having their rotors connected to respective elements of the two gearsets. The torque on the output shaft is boosted by a controller, which dumps energy from the system when one of the machines is acting as a generator and the other as a motor.

Owner:NIDEC SR DRIVES

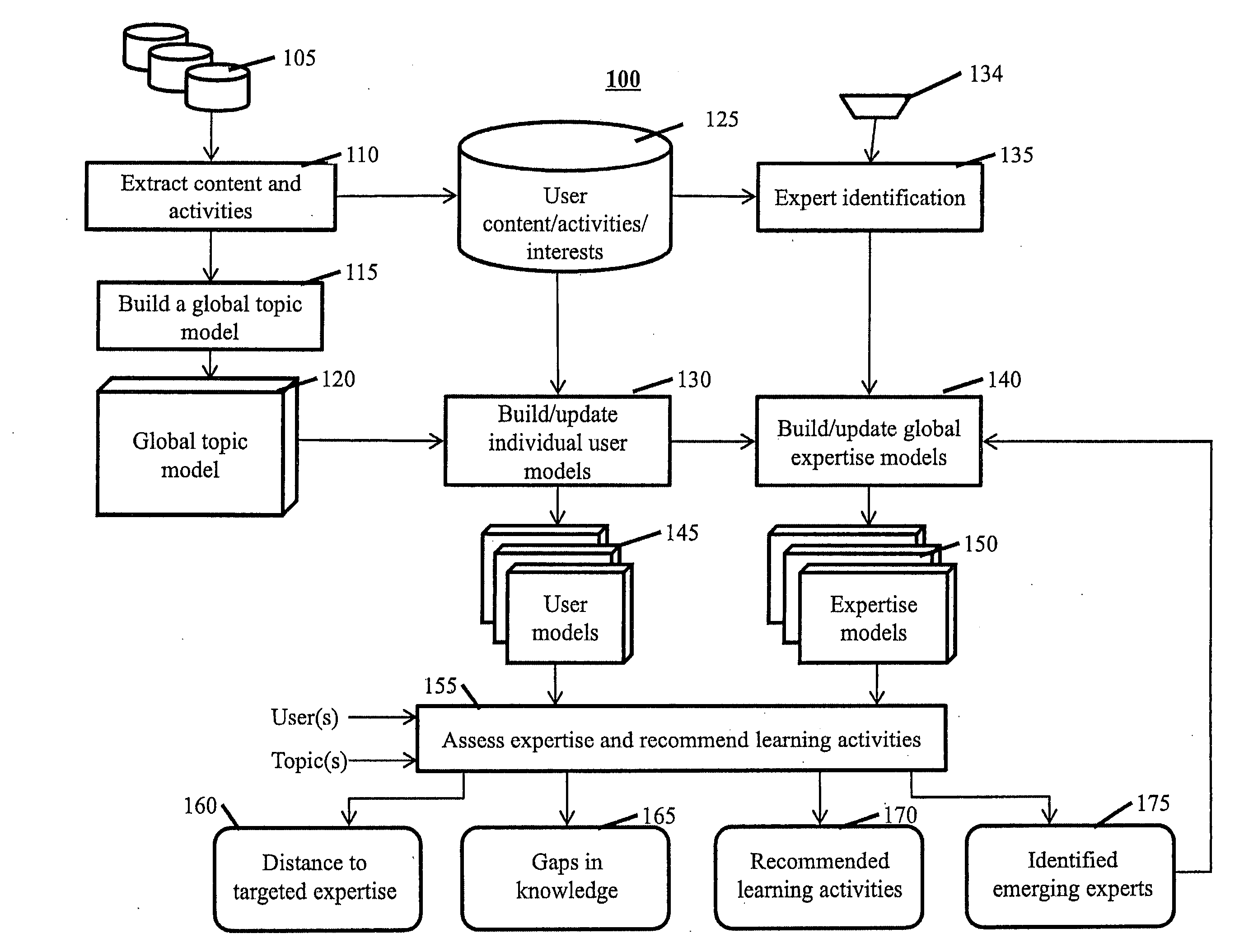

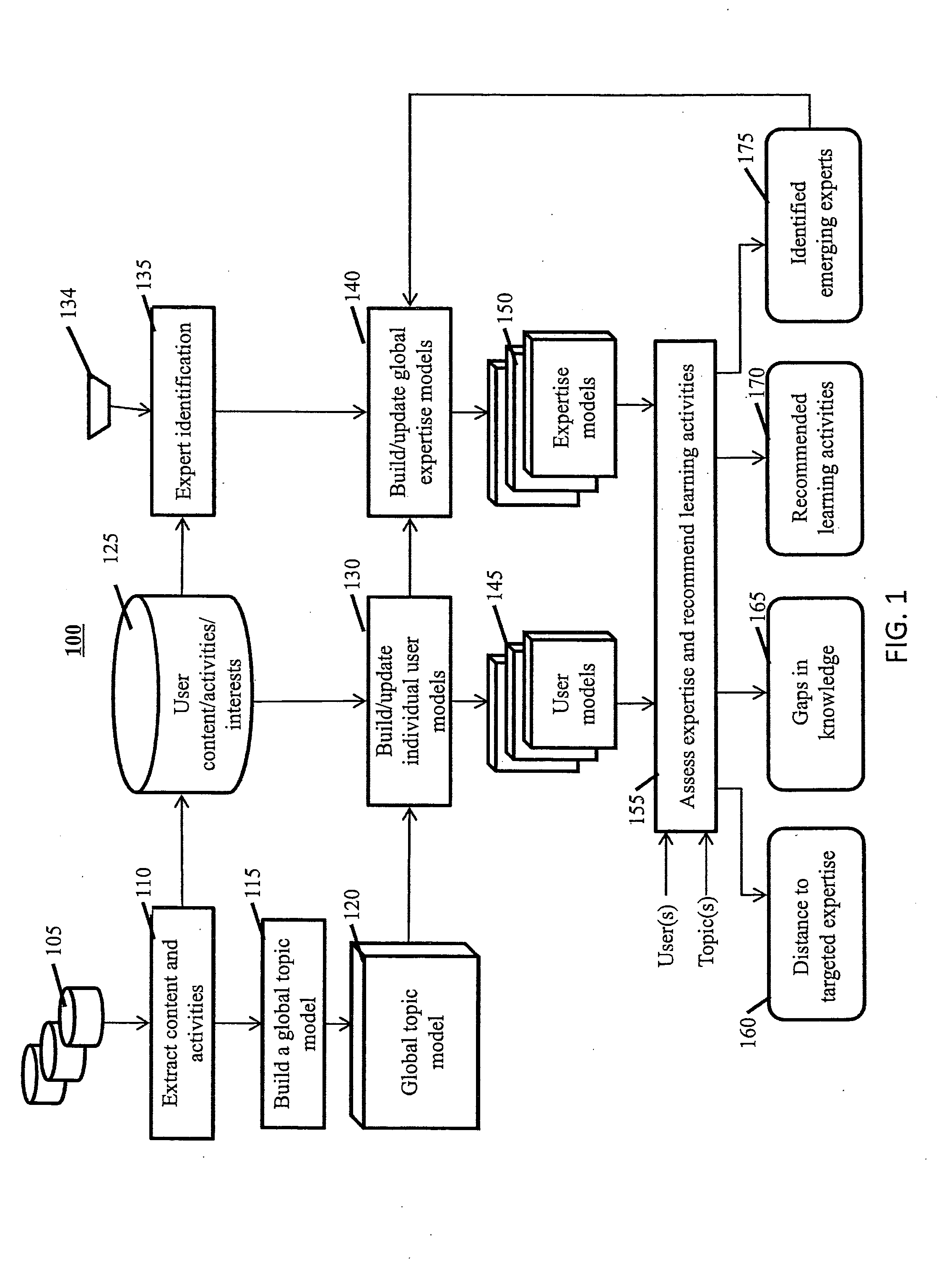

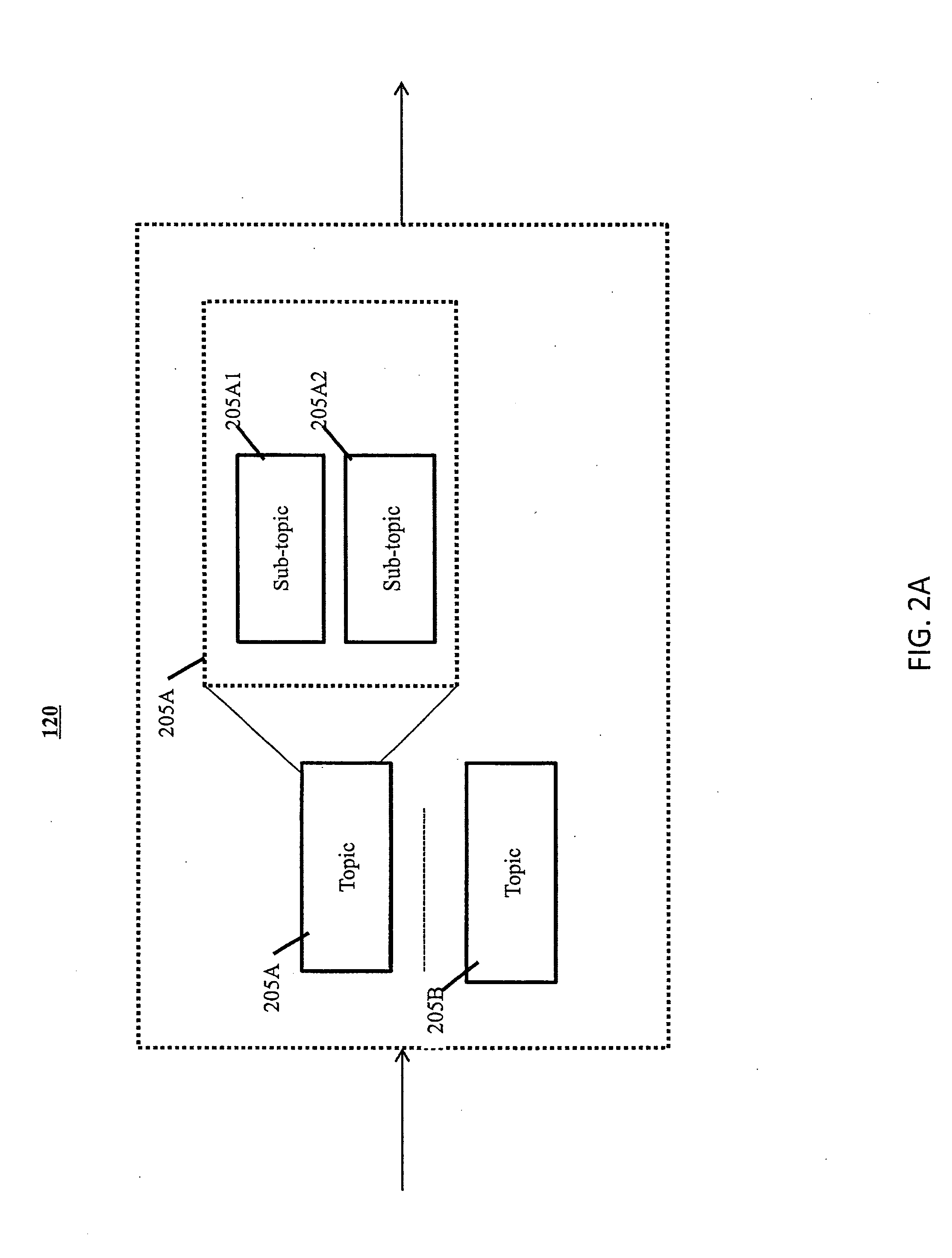

Systems, methods, and computer program products for expediting expertise

InactiveUS20140101086A1Improve abilitiesFast accelerationKnowledge representationResourcesKnowledge managementUser modeling

A system including a global topic model building module that builds a global topic model based on a set of data that is updated according to an activity of each user of a plurality of users, a user model building module that builds a plurality of user models, each user model being built based on an activity of a respective user, an expertise model building module that builds an expertise model for the topic based on the activity of at least one user of the plurality of users, the expertise model for the topic setting a target level of knowledge for a first user of the plurality of users, a processor to compare a user model of the first user with the expertise model for the topic; and an expertise assessment and learning recommendation module that recommends an activity associated with the set of data to the first user based on the comparison.

Owner:IBM CORP

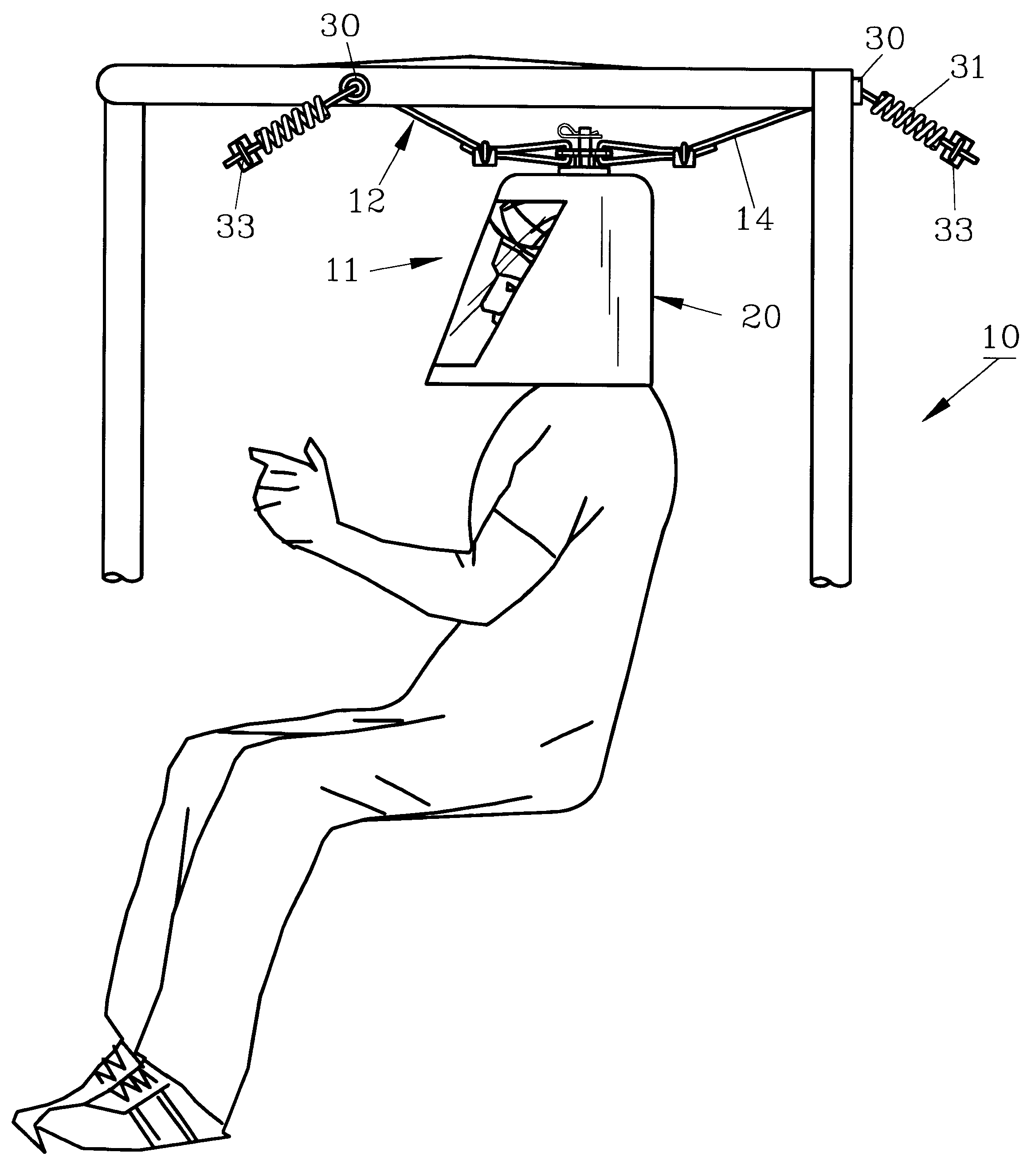

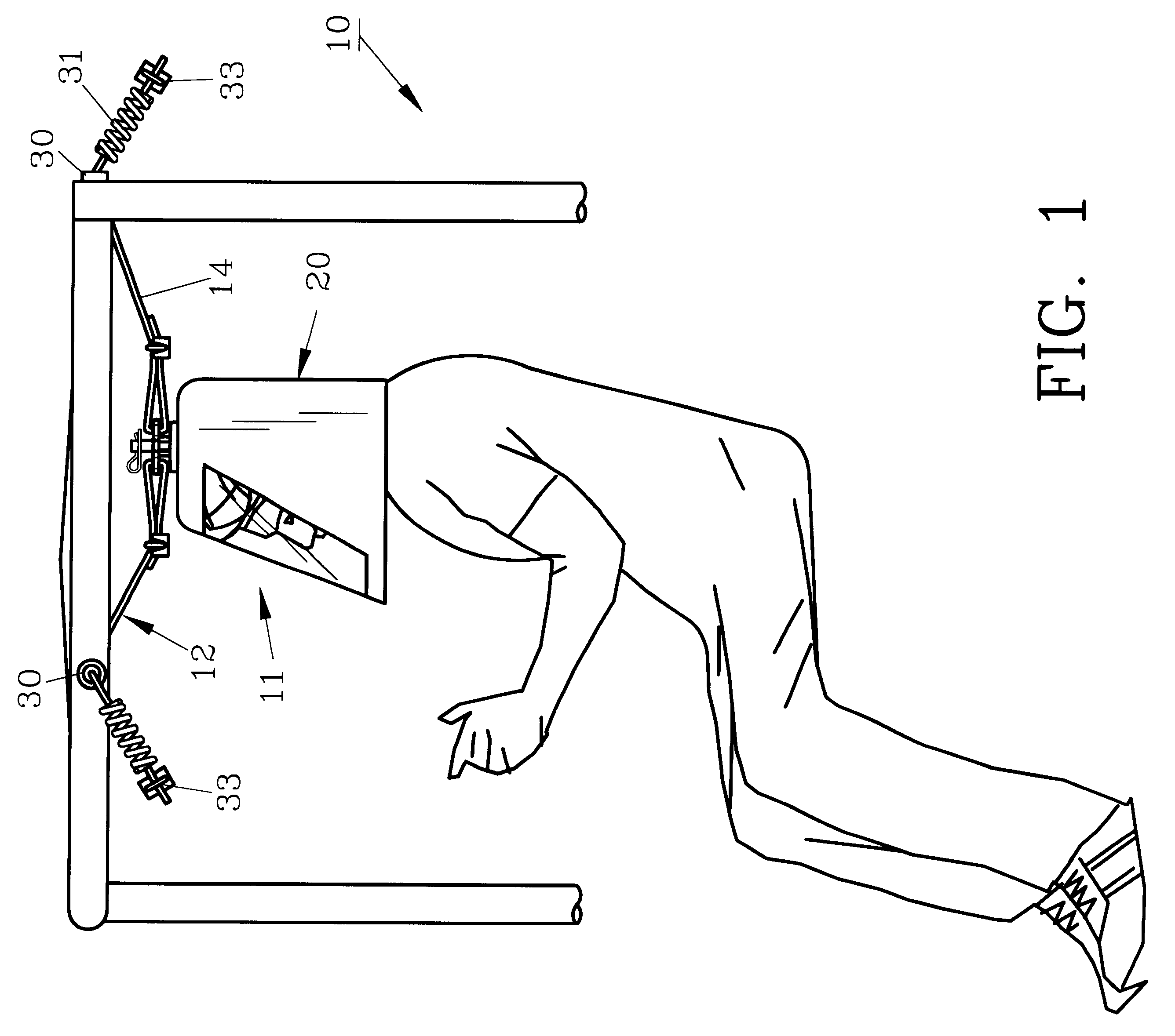

Vehicle head restraint device

A head restraint device is provided for vehicle drivers and the like. The device allows the head to turn from side to side but restricts the forward and rearward movement as may occur during an abrupt stop while traveling at a high velocity. Cables are slidably affixed to the passenger compartment frame and resilient members dampen sudden forward or rearward head movement during vehicle impact.

Owner:WOOTEN ARNOLD GRAY

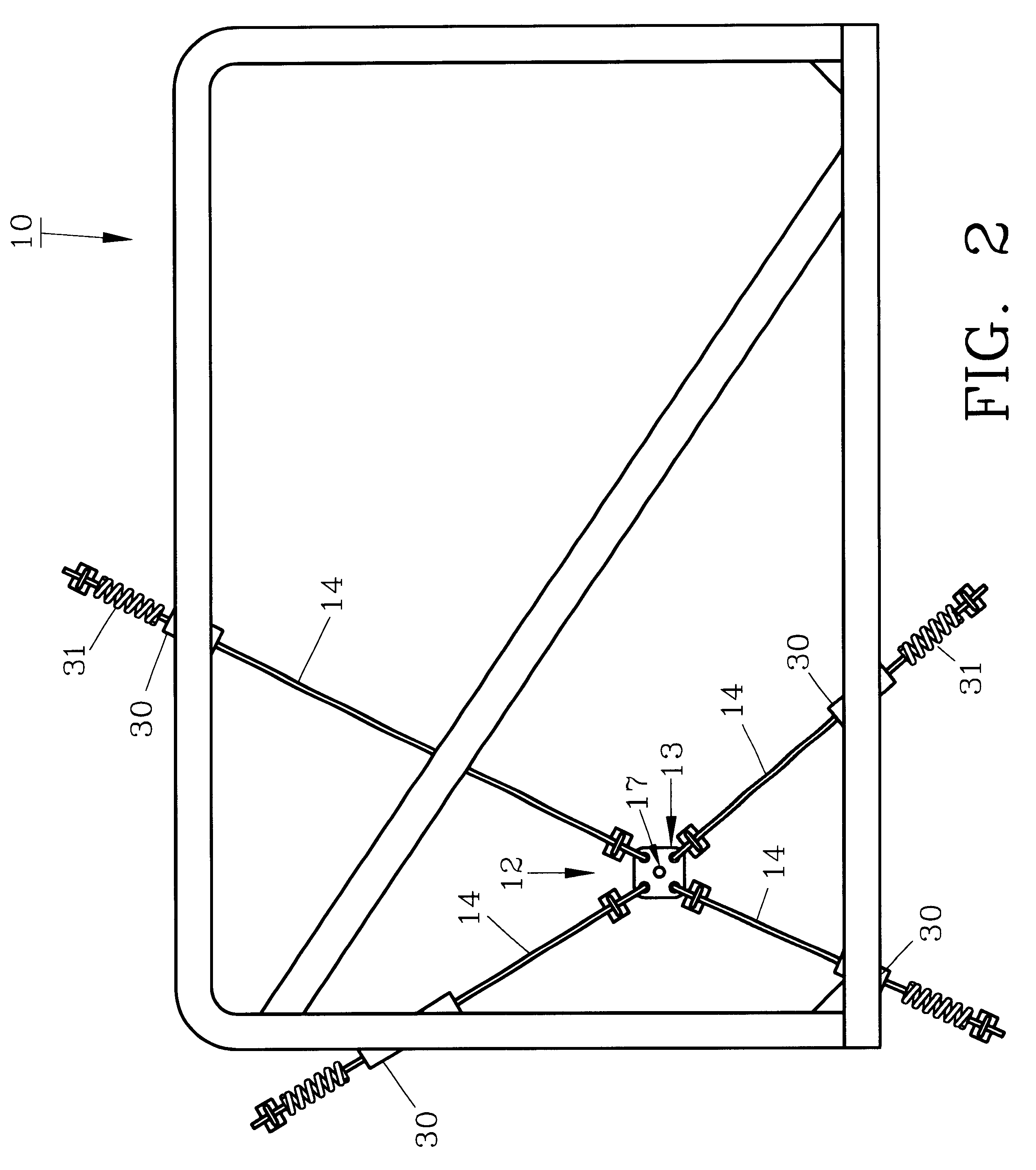

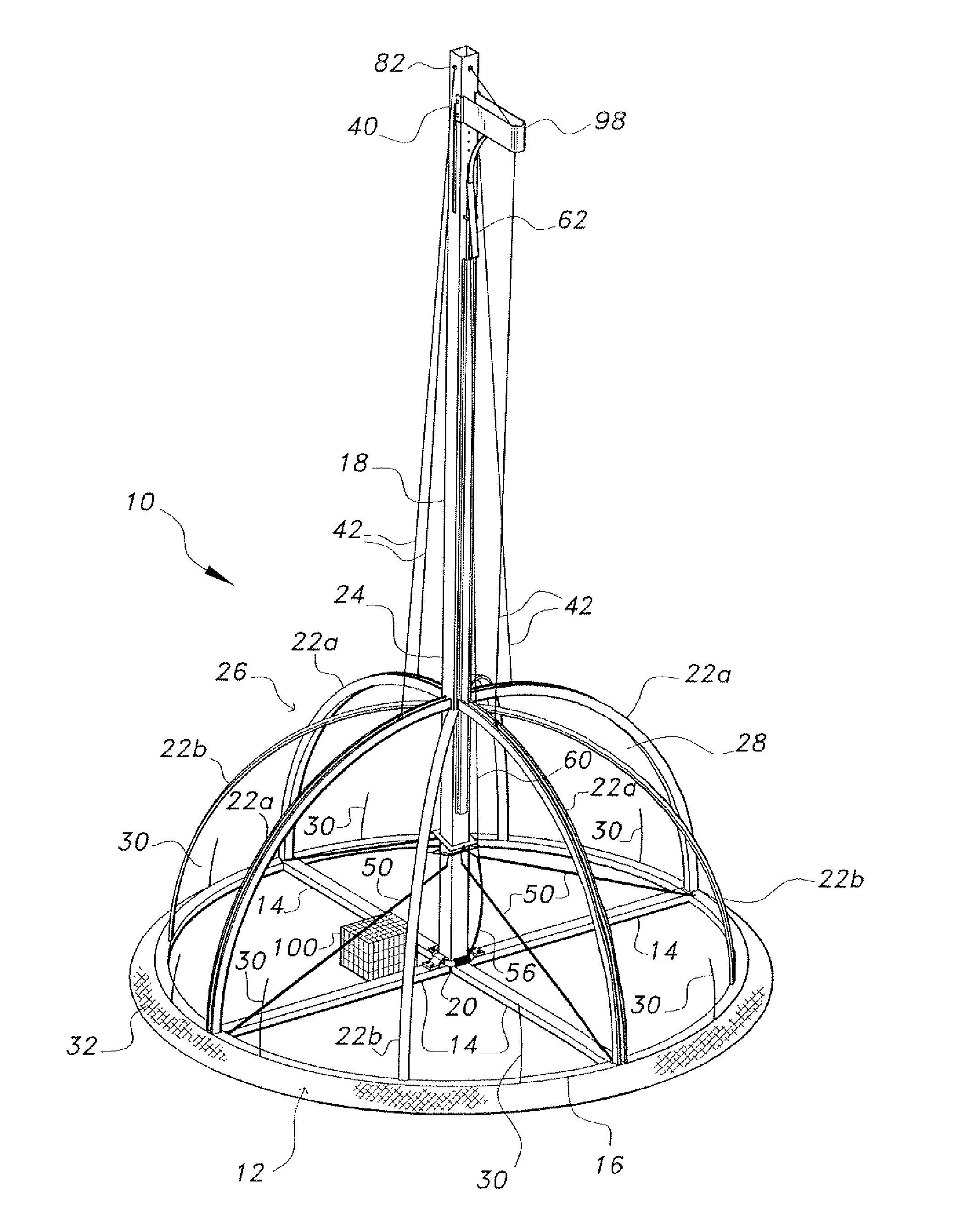

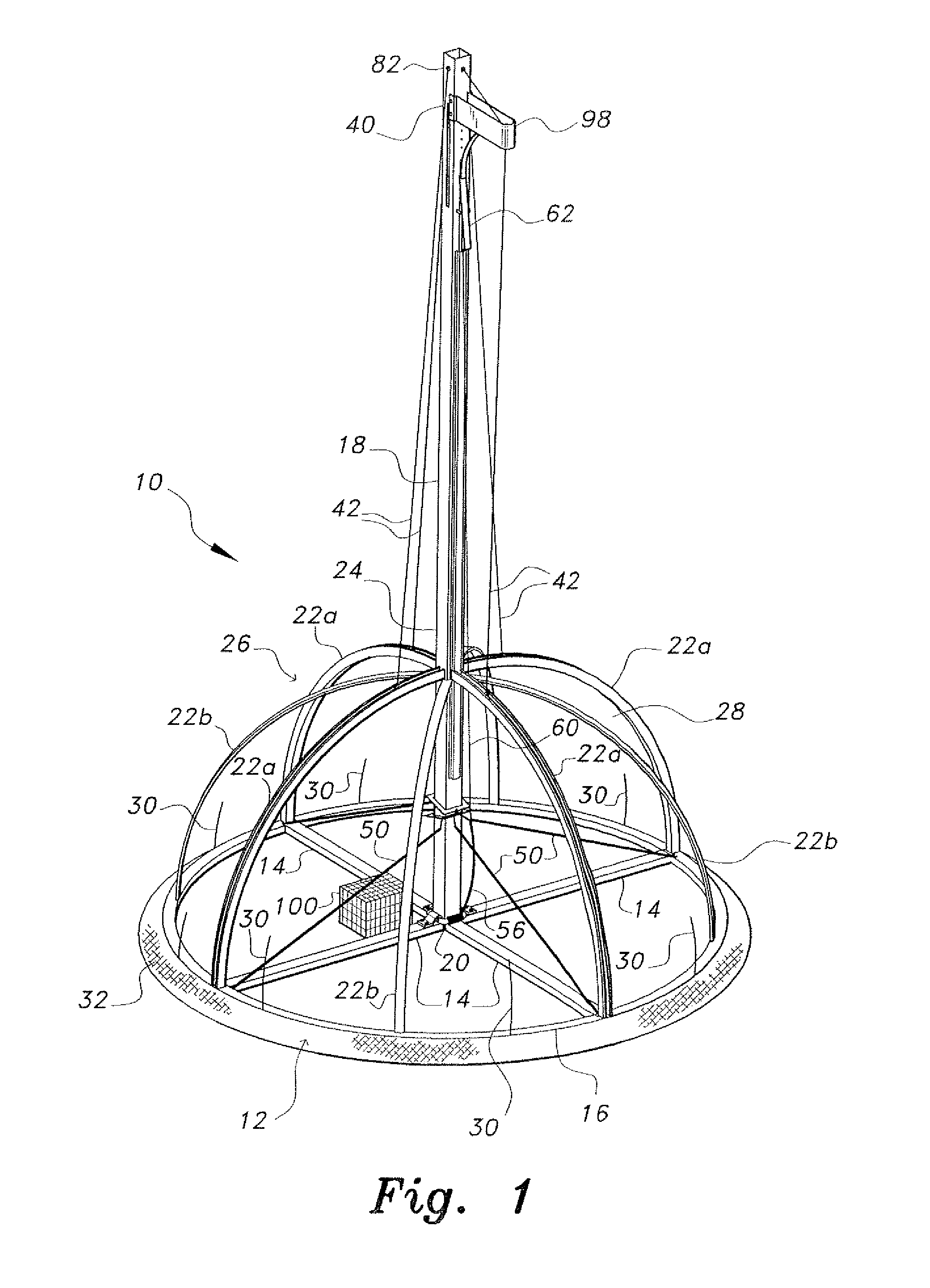

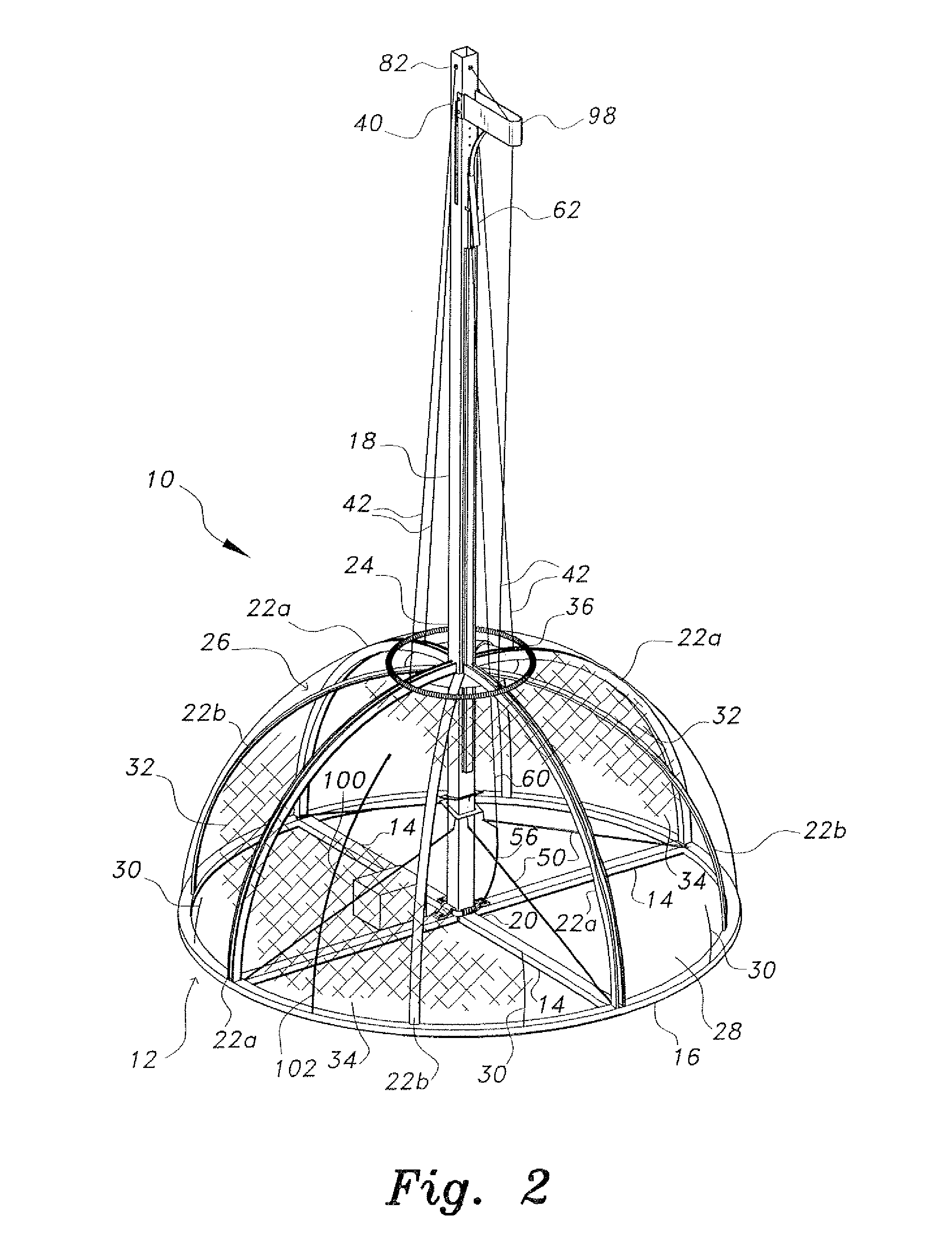

Humane animal trap

The humane animal trap has a circular base and a plurality of arcuate ribs extending upward and inward therefrom to form a generally hemispherical frame. A hollow central column extends upward from the center of the base. A drop weight is installed within the column. A collapsible net is placed about the base when the trap is set, the weight being connected to the net by tensile members. A mechanically or remotely actuated trigger and actuating mechanism is connected to a weight release mechanism at the top of the column. When an animal enters the open volume defined by the hemispherical frame and trips the mechanism or the trapper actuates the mechanism remotely, the mechanism causes the weight to release mechanism to release the drop weight, thereby pulling the net upward and over the arcuate ribs to enclose the hemispherical volume at the lower portion of the trap.

Owner:ALFARHAN ABDULMAJEED F S SH

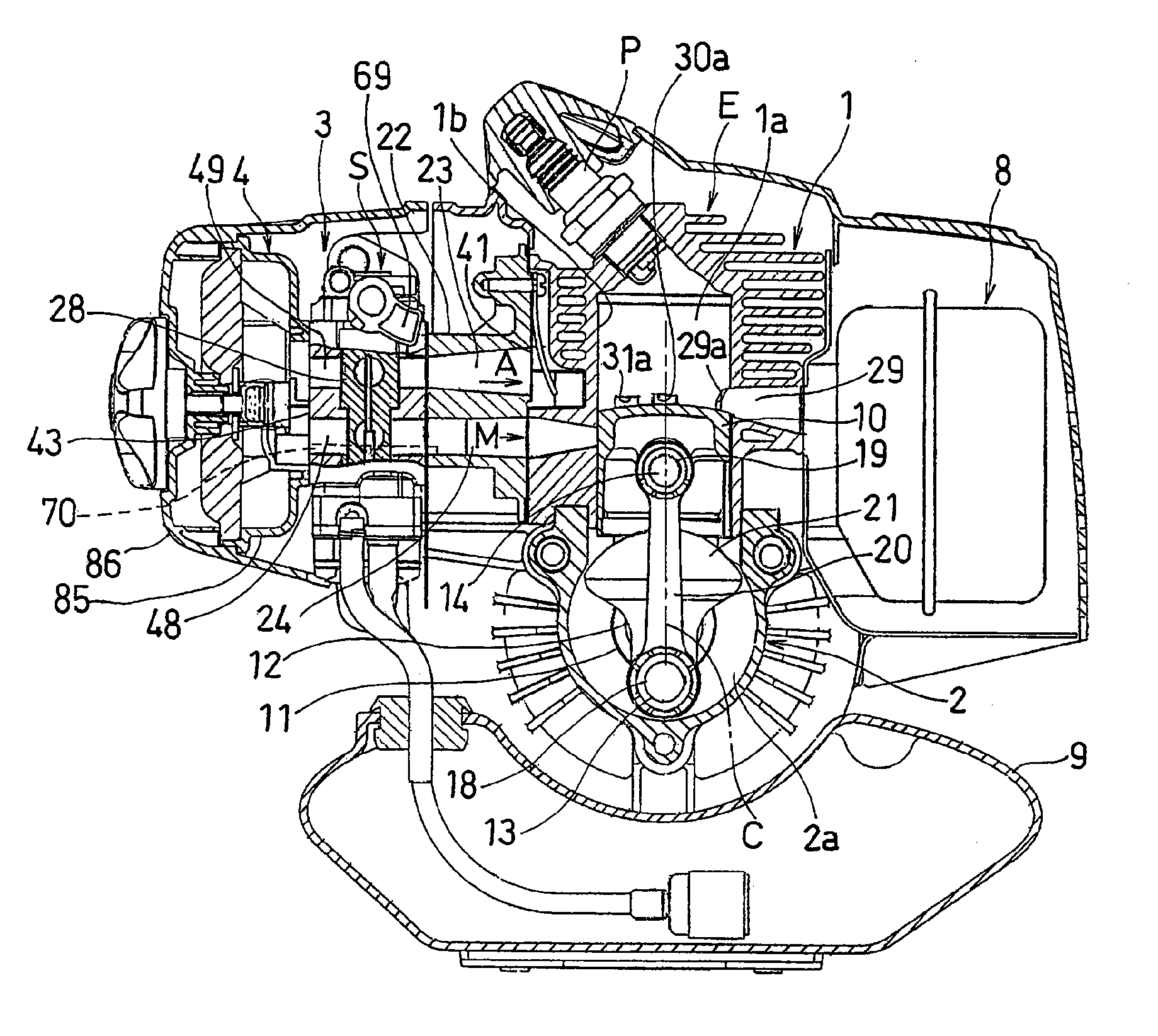

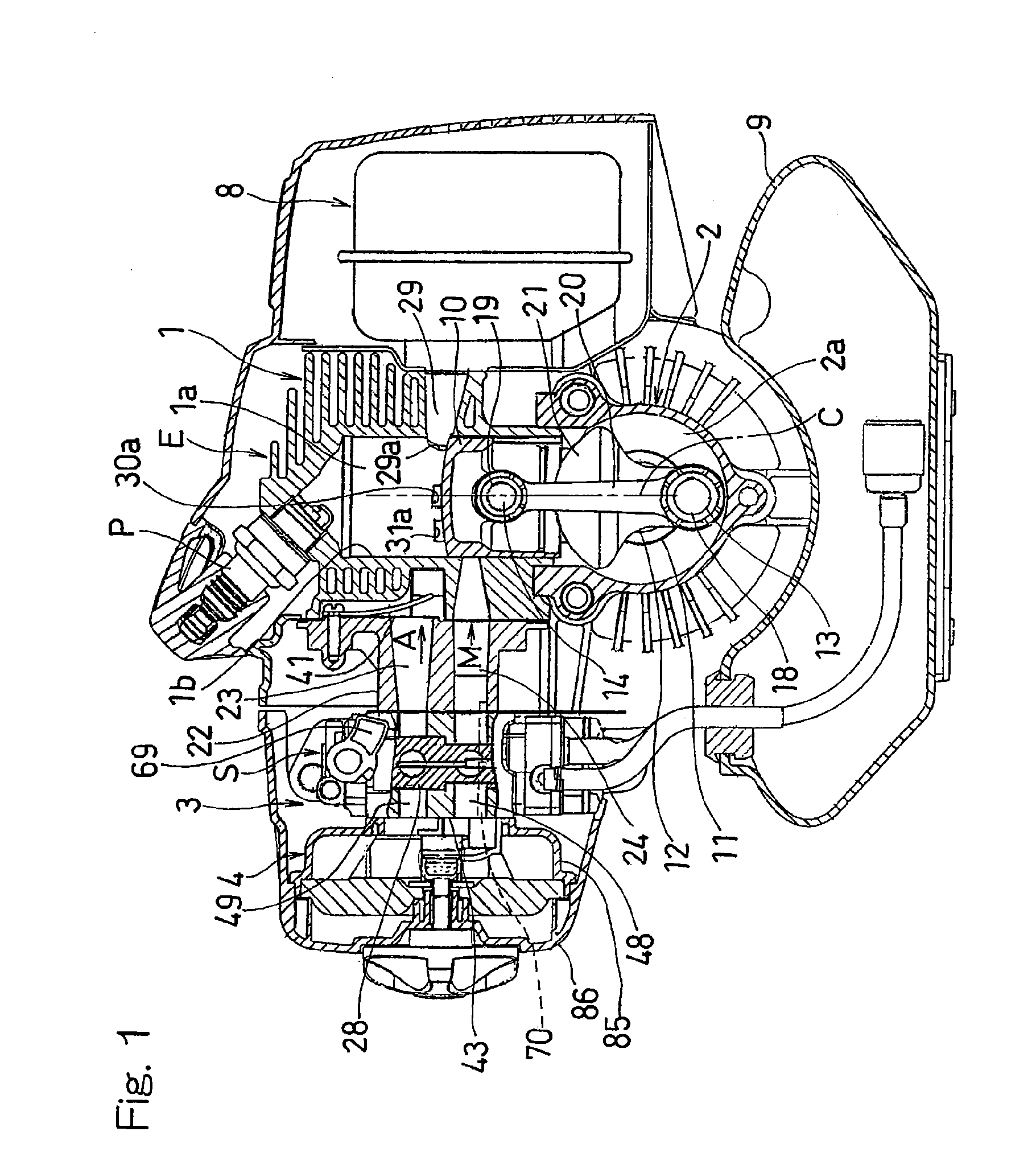

Two-stroke cycle combustion engine of air scavenging type

ActiveUS20100192928A1Increase air volumeFast accelerationCombustion-air/fuel-air treatmentCombustion enginesCombustion chamberInternal combustion engine

To provide a two-stroke cycle combustion engine of an air scavenging type, in which not only can transit from the idling condition to the rapid accelerating condition take place smoothly, but the combustion engine can be smoothly started, there are provided scavenging passages (30, 31) for introducing an air / fuel mixture (M) and an air (A) into a combustion chamber (1a), a valve unit (51, 50) for adjusting the opening of each of an air passage (23) for supplying the air (A) to the scavenging passage (30) and an air / fuel mixture passage (24) for supplying the air / fuel mixture (M) to the scavenging passage (31), and an auxiliary air introducing passage (70) for introducing an auxiliary air to the air / fuel mixture passage (24) at a location downstream of the valve unit (51, 50) in the air / fuel mixture passage (24).

Owner:KAWASAKI MOTORS LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com