Patents

Literature

160 results about "Drop weight" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

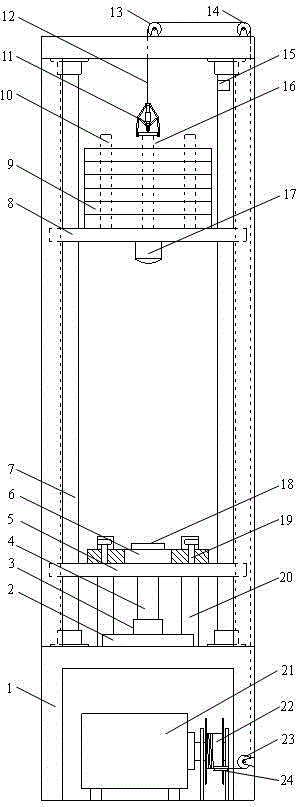

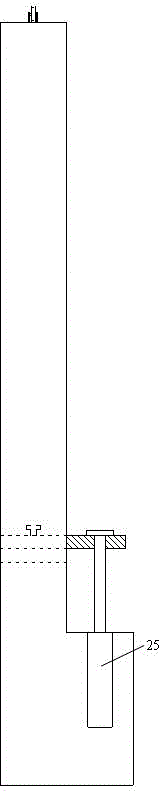

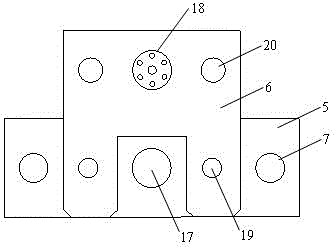

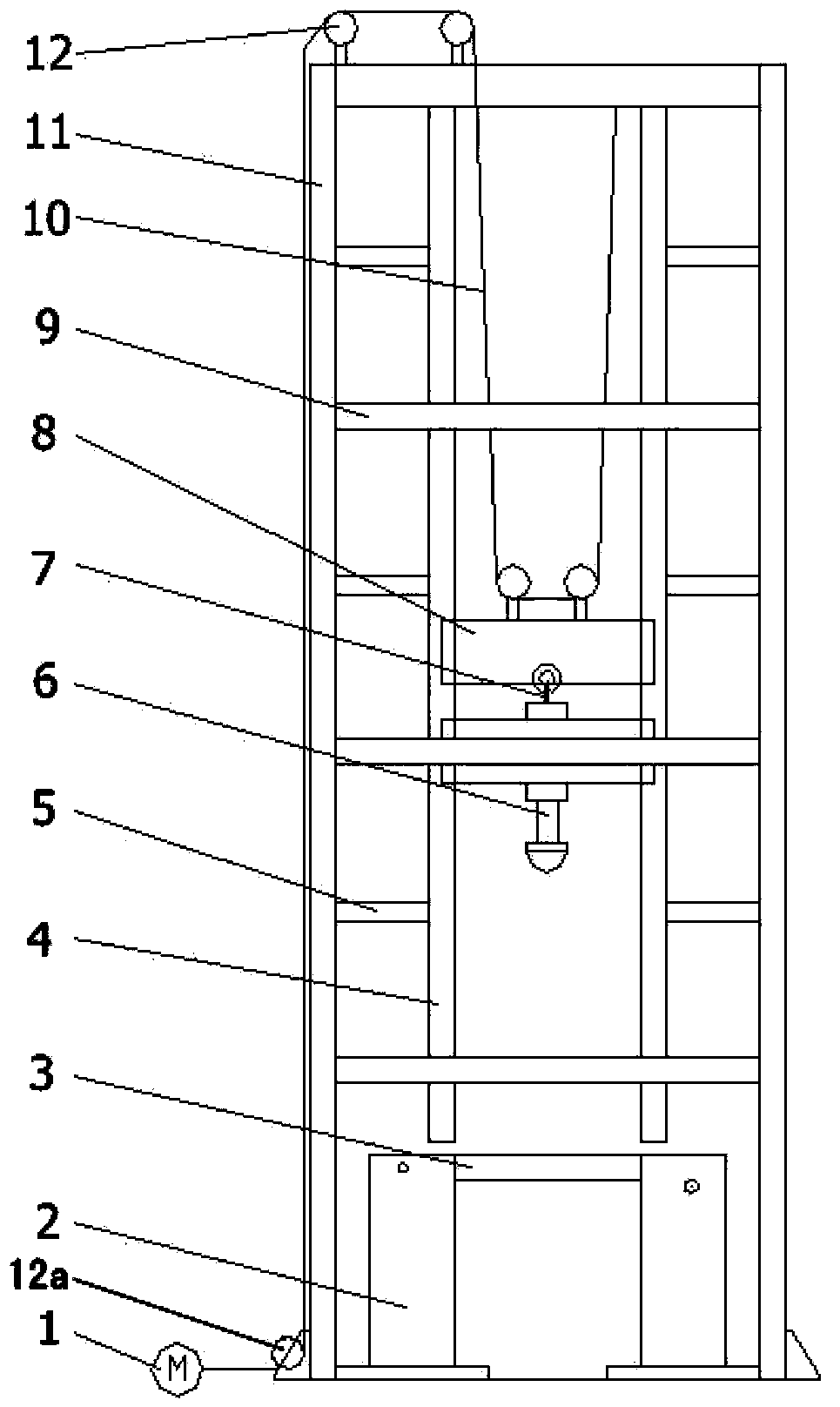

Drop weight type dynamic and static combined load impact experimental device

InactiveCN104142278AAvoid hurtingSimple structureMaterial strength using tensile/compressive forcesDrop weightElectric machinery

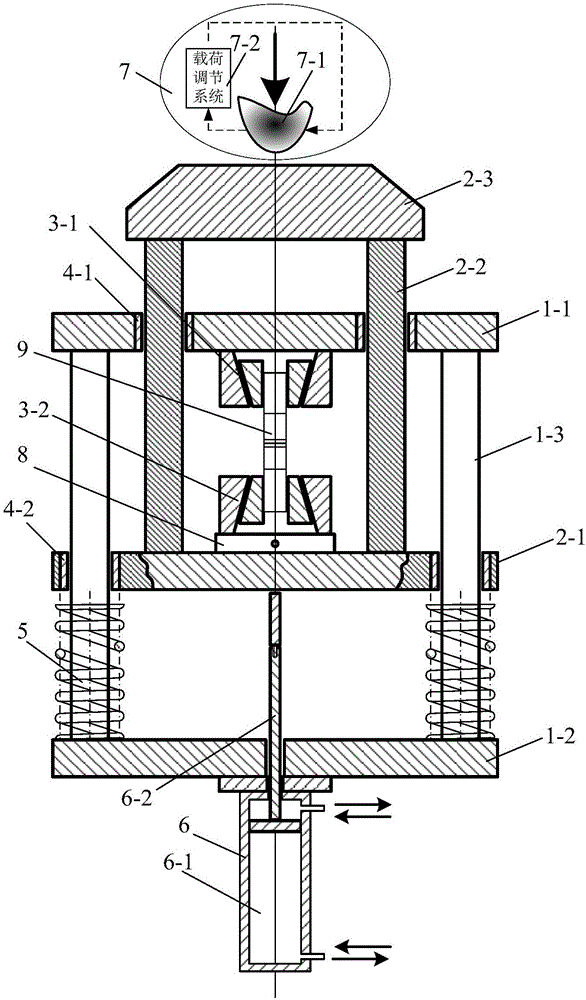

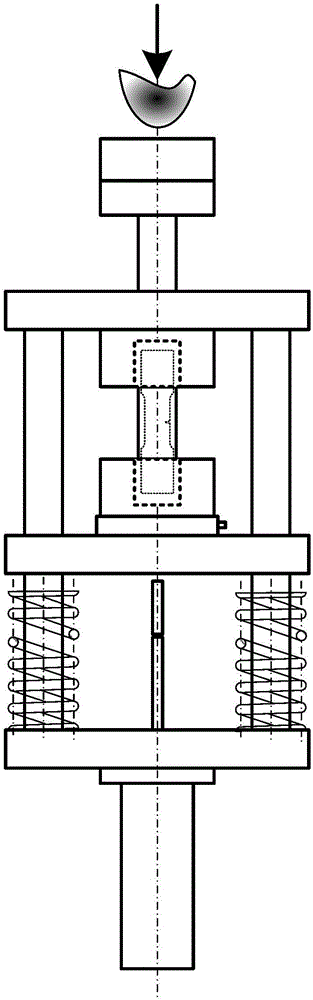

The invention discloses a drop weight type dynamic and static combined load impact experimental device which is characterized by comprising a body (1) and a sample bearing table (2), wherein the sample bearing table (2) is positioned on the body (1); a sample is arranged on the sample bearing table (2) and is connected with a hydraulic static load pressure mechanism which applies static pressure; an impact mechanism which can move up and down along a guide post (7) is arranged on the upper part of the body (1) and is connected with a lifting mechanism arranged on the lower part of the body. According to the experimental device disclosed by the invention, the coal and rock sample can be dynamically and controllably loaded in different dynamic and static combined forms, and multiple stress wave loading modes of coal and rock materials are simulated, so that the experimental result has the high practical engineering significance. The drop weight type dynamic and static combined load impact experimental device is simple in structure, convenient to operate and good in controllability. According to power failure tightening states of a brake driving motor and an electric hook, the impact mechanism is prevented from falling to injure people during unexpected power failures, so that the effective safety protection is realized.

Owner:CHINA UNIV OF MINING & TECH

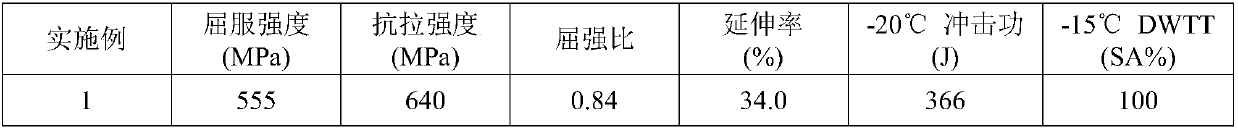

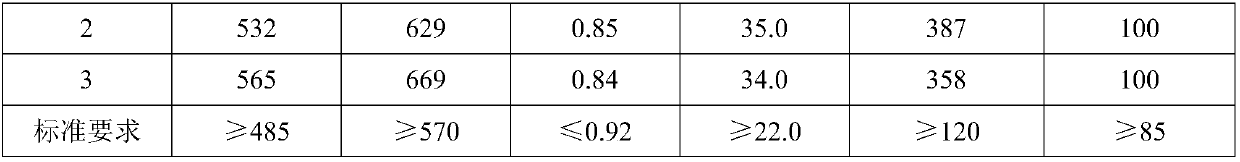

Pipeline steel with a thickness of ≥25mm for deep sea and its production method

ActiveCN102277530ASimple production processAvoid complex production processesDrop weightRoom temperature

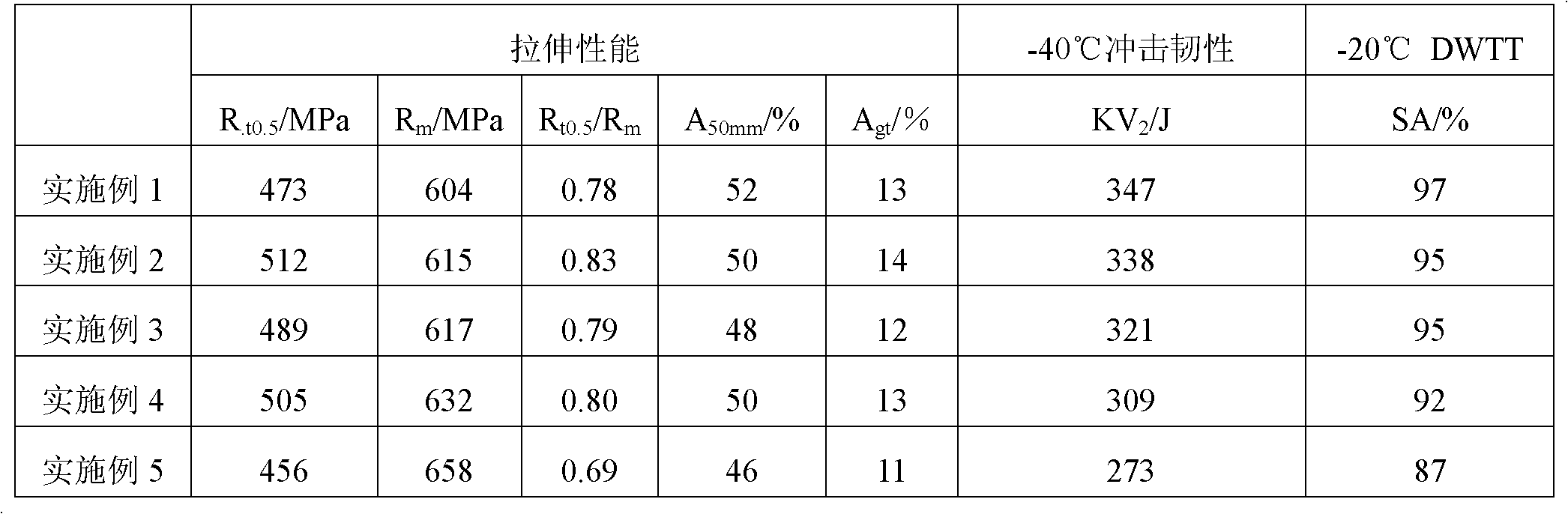

The invention relates to a pipeline steel for deep sea and a production method thereof. The pipeline steel for deep sea comprises the following components in percentage by weight: 0.025-0.080% of C, 0.05-0.50% of Si, 1.20-1.60% of Mn, less than or equal to 0.015% of P, less than or equal to 0.003% of S, 0.05-0.30% of Mo, 0.03-0.06% of Nb, 0.005-0.025% of Ti, 0.01-0.04% of Al, less than or equal to 0.010% of N and 0.0010-0.0050% of Ca used as main components, and less than or equal to 0.03% of As, less than or equal to 0.01% of Sb, less than or equal to 0.02% of Sn, less than or equal to 0.01%of Pb, less than or equal to 0.01% of Bi and less than or equal to 0.0005% of B used as residual elements. The production method comprises the following production steps: smelting according to clean steel, and carrying out continuous casting to obtain a blank; heating the cast blank; carrying out rough rolling; carrying out fine rolling; relaxing; cooling; relaxing again; straightening; and carrying out air cooling to room temperature. The pipeline steel has simple ingredient and technology, the thickness of the pipeline steel is more than or equal to 25mm, and the pipeline steel is used for deep sea pipelines. The Rt05 of the pipeline steel is more than or equal to 450MPa, Rm is more than or equal to 550MPa, Rt05 / Rm is less than or equal to 0.85, A50mm is more than or equal to 40%, Agt is more than or equal to 10%, -40DEG C KV2 is more than or equal to 200J, and -20DEG C DWTT (Drop-Weight Tear Test) SA is more than or equal to 85%.

Owner:武汉钢铁有限公司

Payload delivery units for pressure protecting and delivering a submerged payload and methods for using the same

A payload delivery unit for protecting and delivering a payload submerged in a submersion medium includes an unmanned buoy, a drop weight member, and a retention system. The buoy includes a container. The container includes a pressure-resistant shell defining a sealed containment chamber. The drop weight member is mounted on the shell and has a negative buoyancy with respect to the submersion medium. The retention system is operative to retain the drop weight member on the buoy and selectively release the drop weight member from the buoy.

Owner:IROBOT CORP

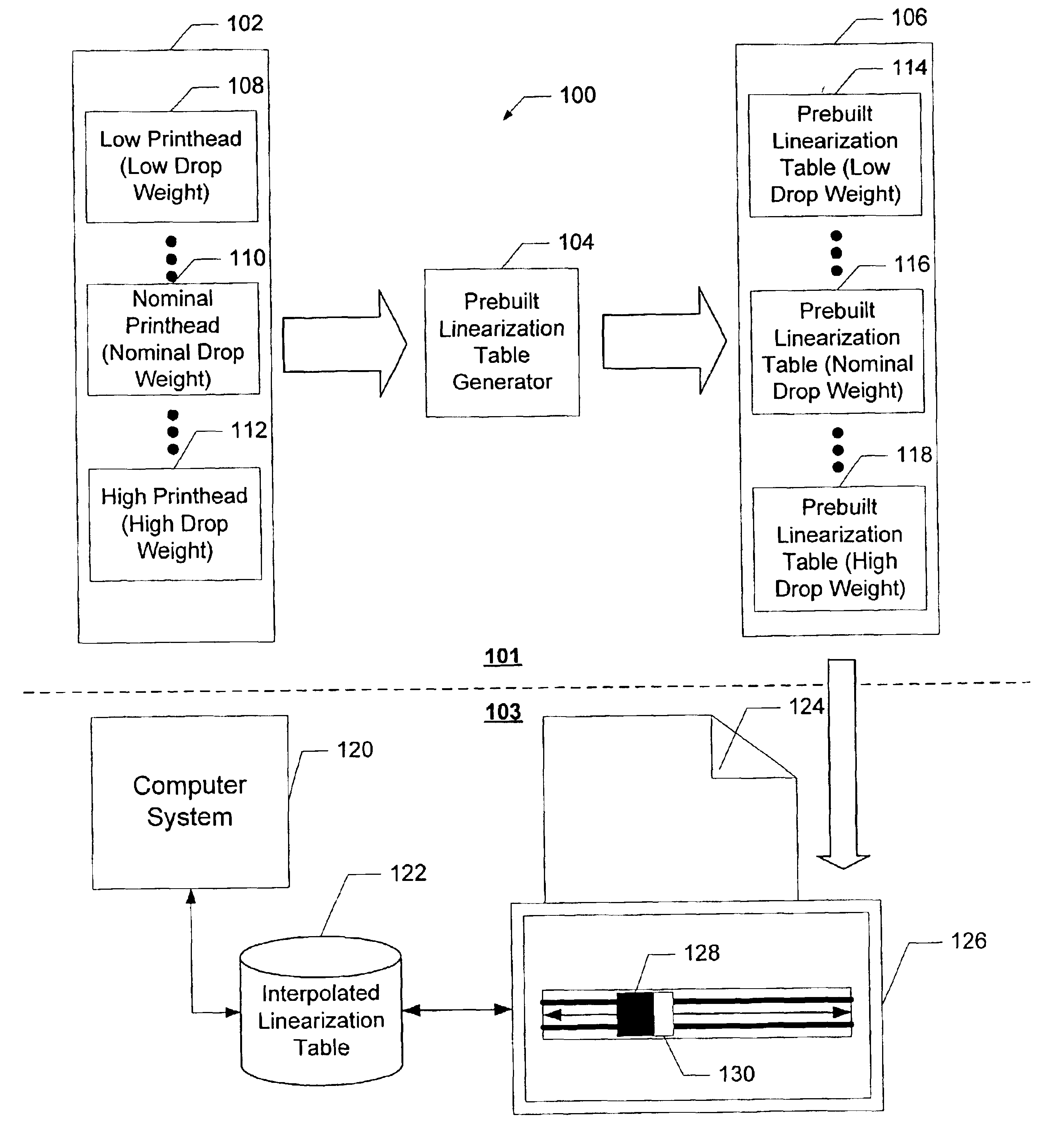

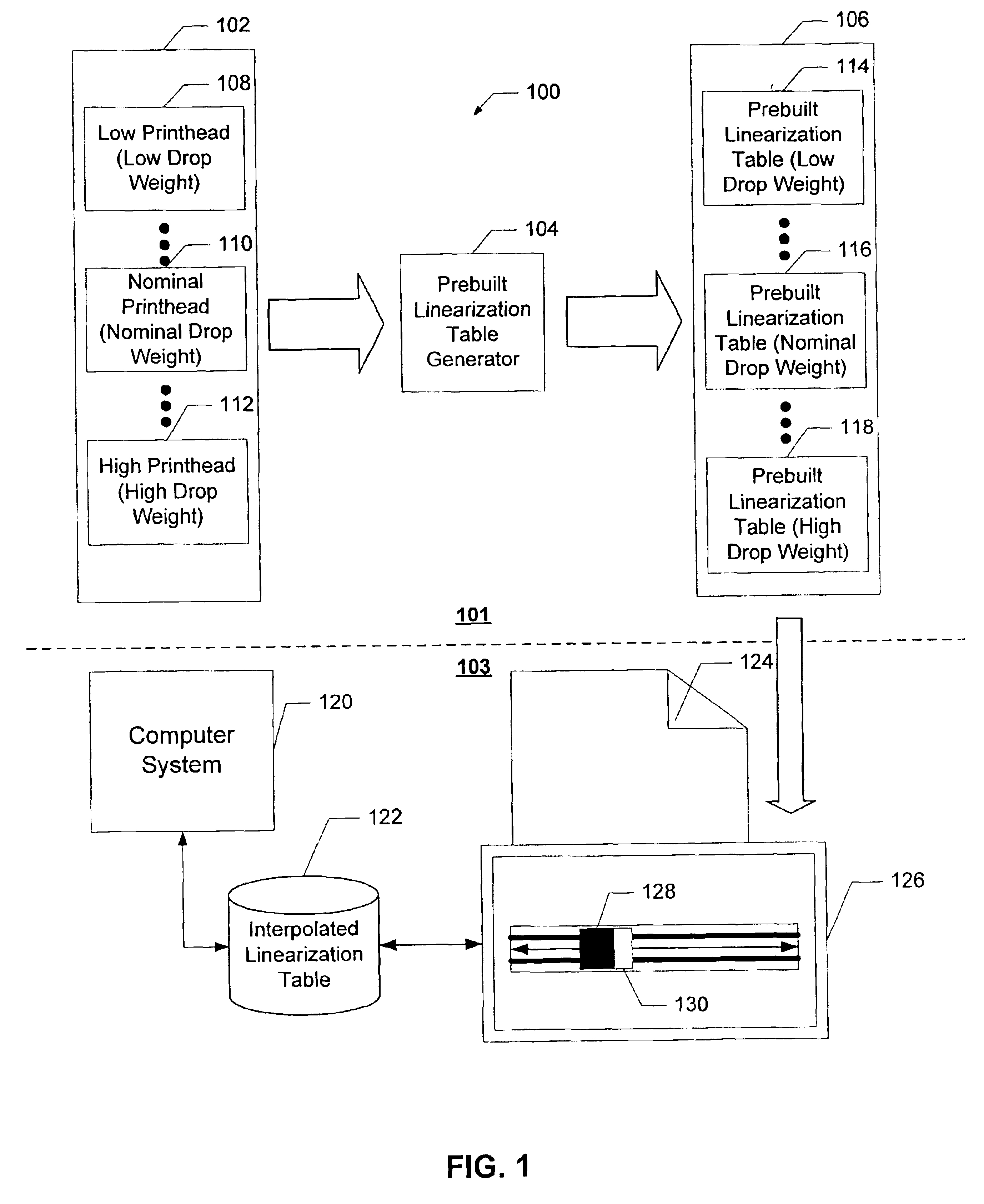

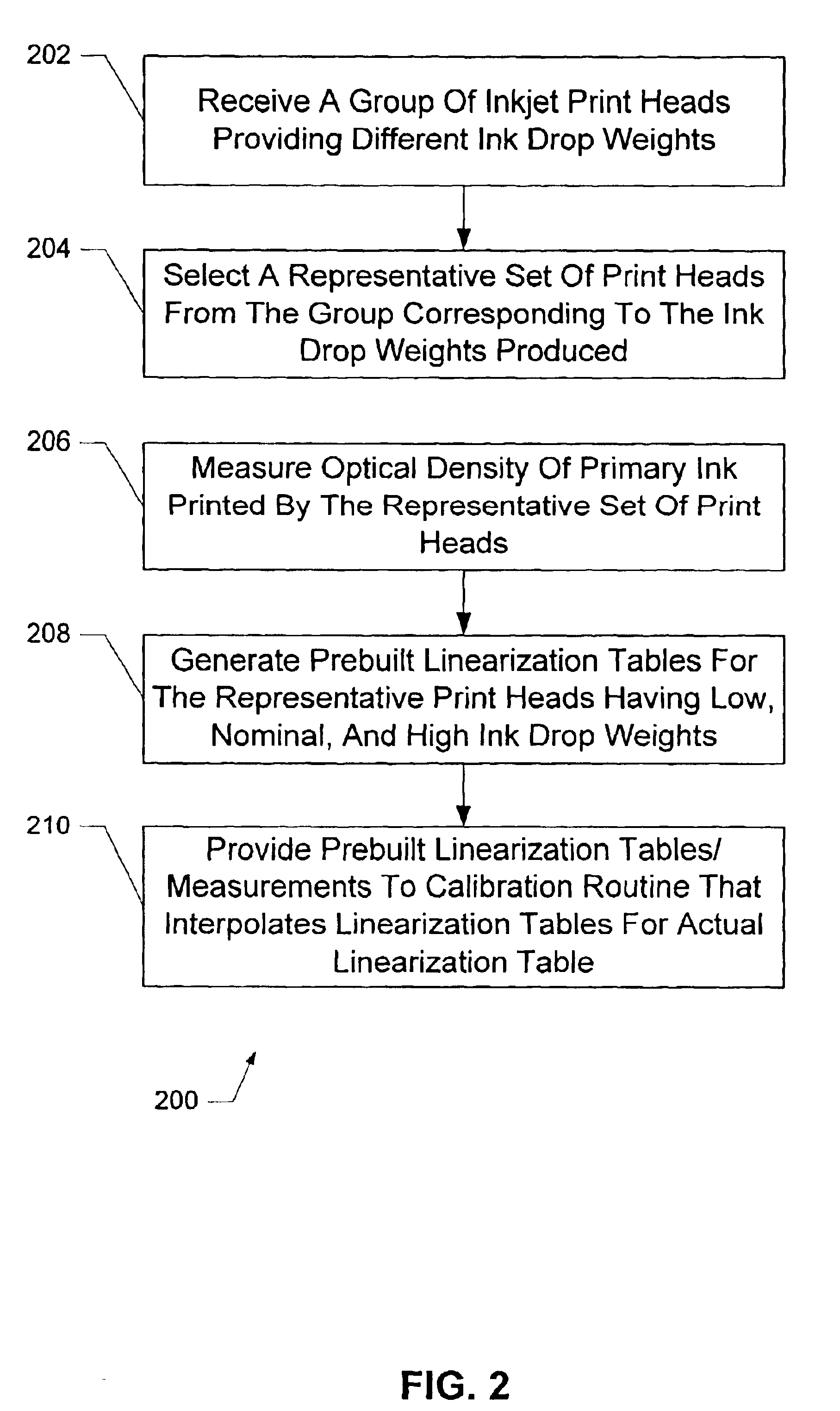

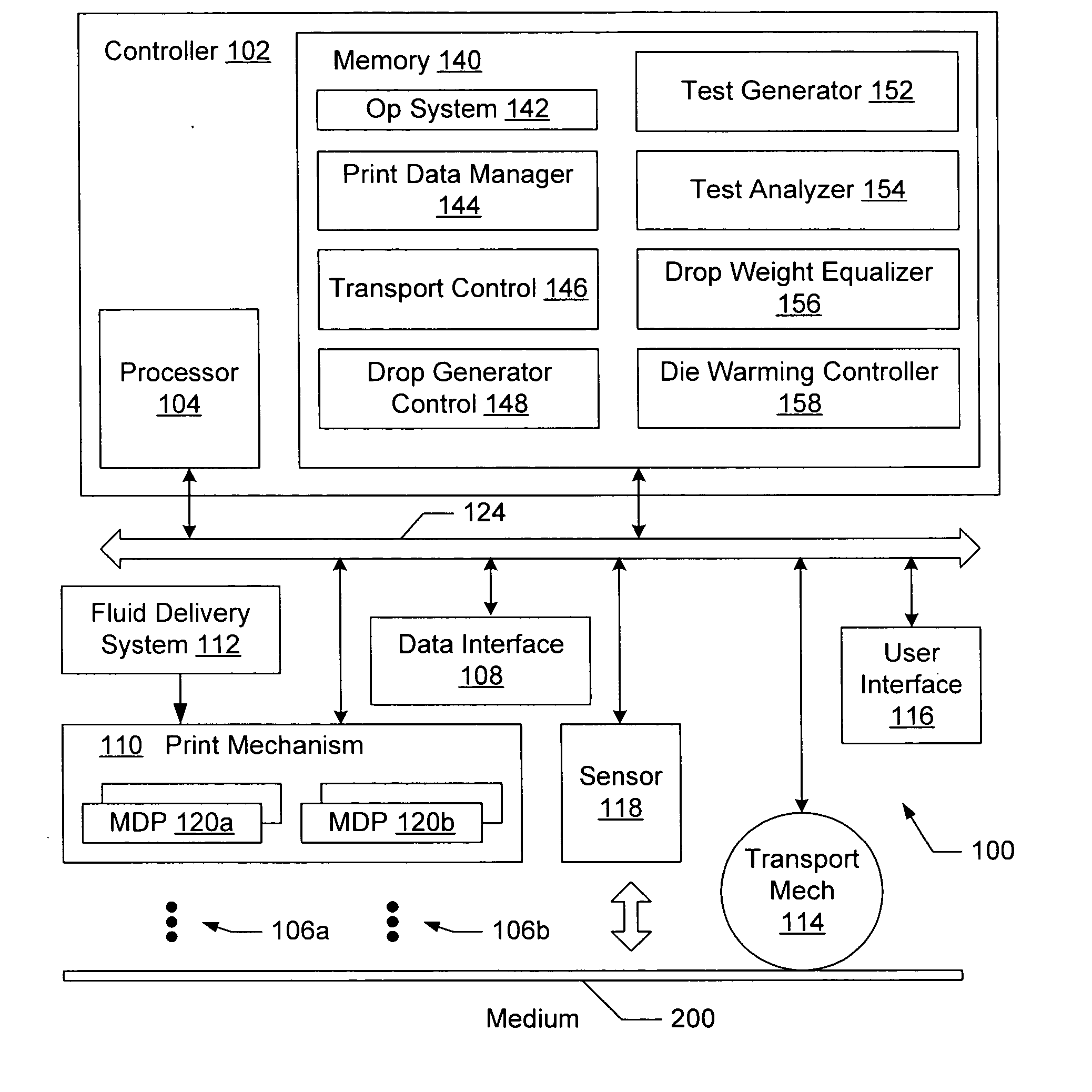

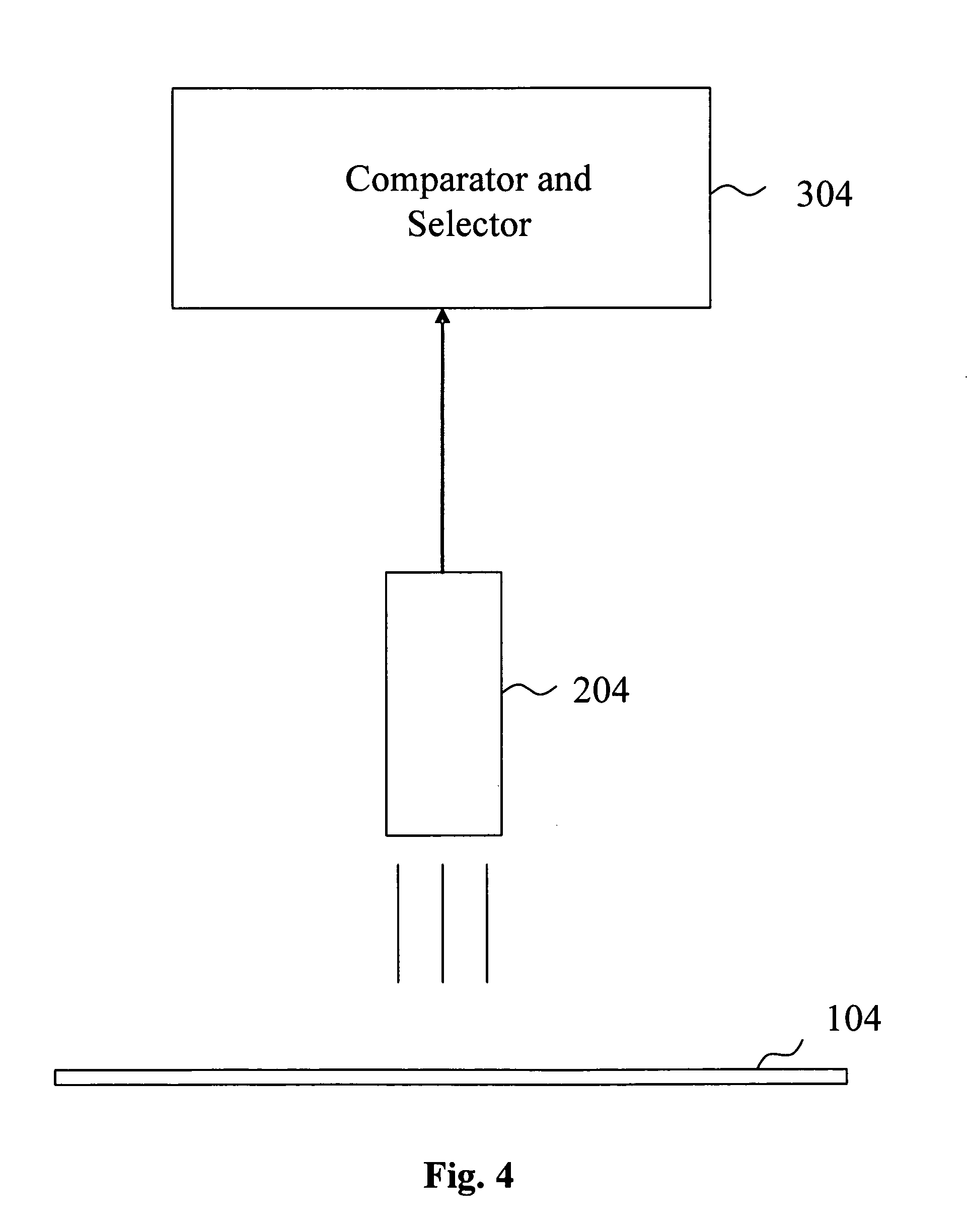

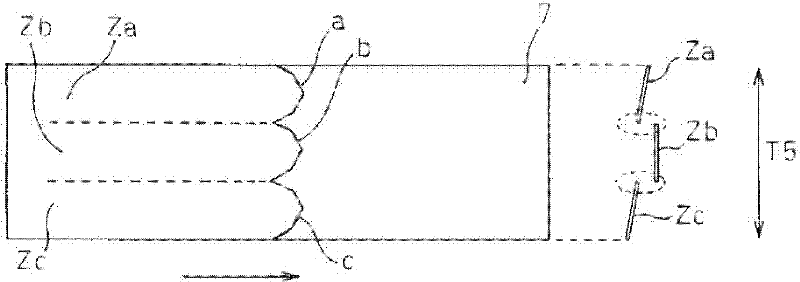

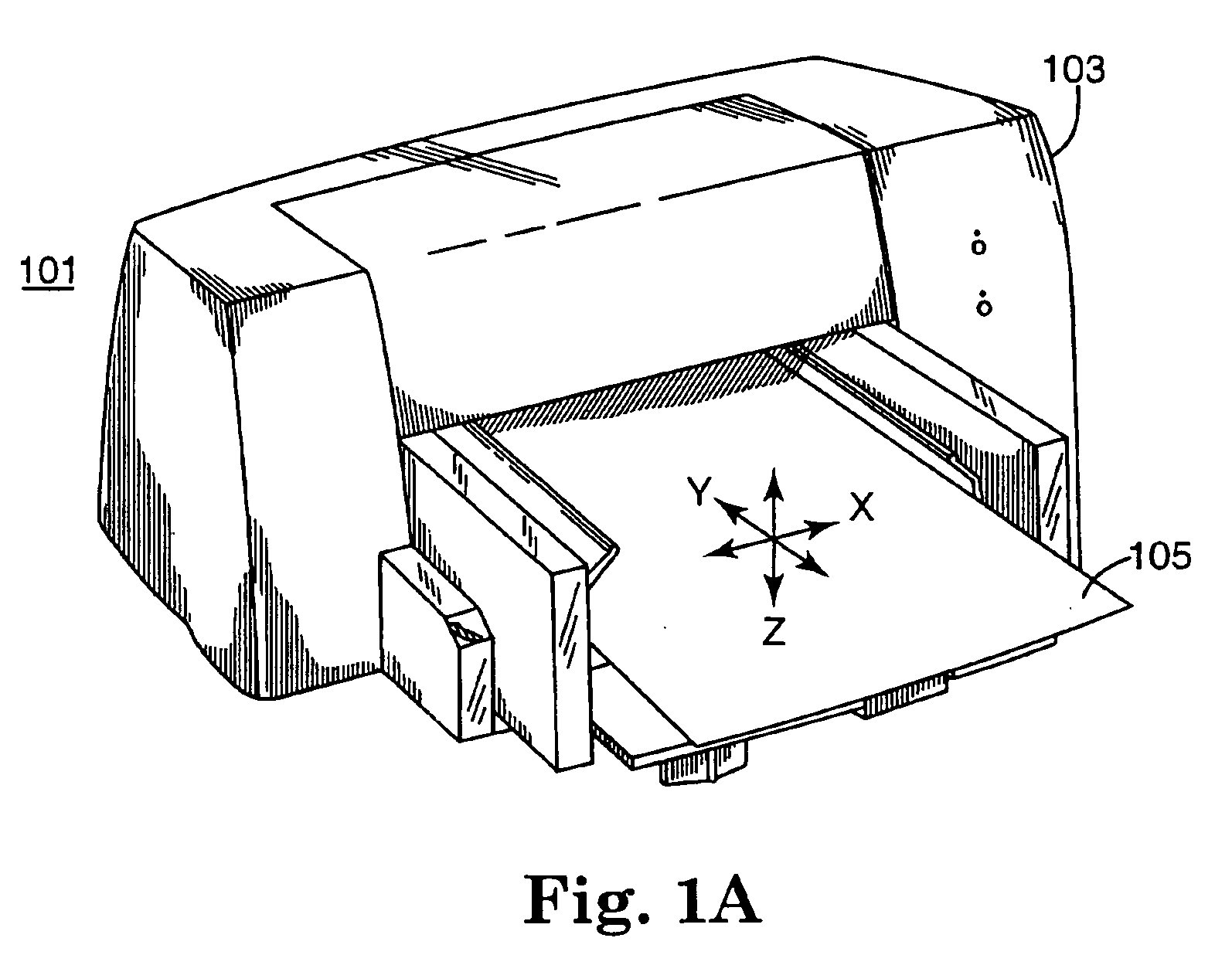

Calibration method and apparatus using interpolation

A systems and method for printer calibration creates linearization tables by receiving optical density related measurements for a primary ink in a group of one or more print heads printing with the primary ink, selecting from the group of print heads at least two print heads that deliver a range of optical densities when printing with the one or more primary ink, generating prebuilt linearization tables corresponding to the at least two print heads that compensate for different ink drop weights printed by the at least two print heads, and providing the prebuilt linearization tables and at least a portion of the optical density related measurements to a calibration routine that interpolates the prebuilt linearization tables to create an actual linearization table for the primary ink printed by a print head. The prebuilt linearization tables and measurements related to optical density calibrate a primary ink printed by a print head, by receiving two or more prebuilt linearization tables for a corresponding two or more print heads that compensate for different ink drop weights printed by the two or more print heads, determining a measurement related to optical density when the print head prints the primary ink at a selected gray level, comparing the measurement related to optical density produced by the print head with measurements related to optical density when the two or more print heads print the primary ink at the selected gray level, and estimating the linearization table for the primary ink based upon the prebuilt linearization tables for the two or more print heads and the comparison of the measurement related to optical density of the print head and the two or more print heads.

Owner:HEWLETT PACKARD DEV CO LP

High-tenacity steel plate for ocean engineering and manufacturing method thereof

The invention relates to a high-tenacity steel plate for ocean engineering and a manufacturing method thereof, belonging to the technical field of steel for ocean engineering. The high-tenacity steel plate comprises the following chemical compositions according to percentages by weight: 0.03-0.08% of C, 0.10-0.30% of Si, 1.0-1.60% of Mn, 0.03-0.04% of Alt, 0.03-0.06% of Nb, 0.05-0.09% of V, 0.010-0.02% of Ti, 0.1-0.4% of Mo, 0.1-0.4% of Ni, 0.1-0.4% of Cu, less than 0.01% of P, less than 0.005% of S, less than or equal to 0.12% of Nb+V+Ti, the rest of Fe and inevitable impurities. The low-temperature tenacity of the steel plate is ensured by adding few Ni and adopting a reasonable controlled rolling and cooling technology, thereby a thermal treatment technology is omitted, and the production cost is reduced; the obtained steel plate with 10-50mm has good strong plasticity, weldability and anti-lamellar tearing performance and excellent comprehensive mechanical performance such as drop weight and the like; and the high-tenacity steel plate is simple in technology and can be widely applied to key positions of permanent, self-elevating and semi-submersible type ocean platforms.

Owner:SHOUGANG CORPORATION

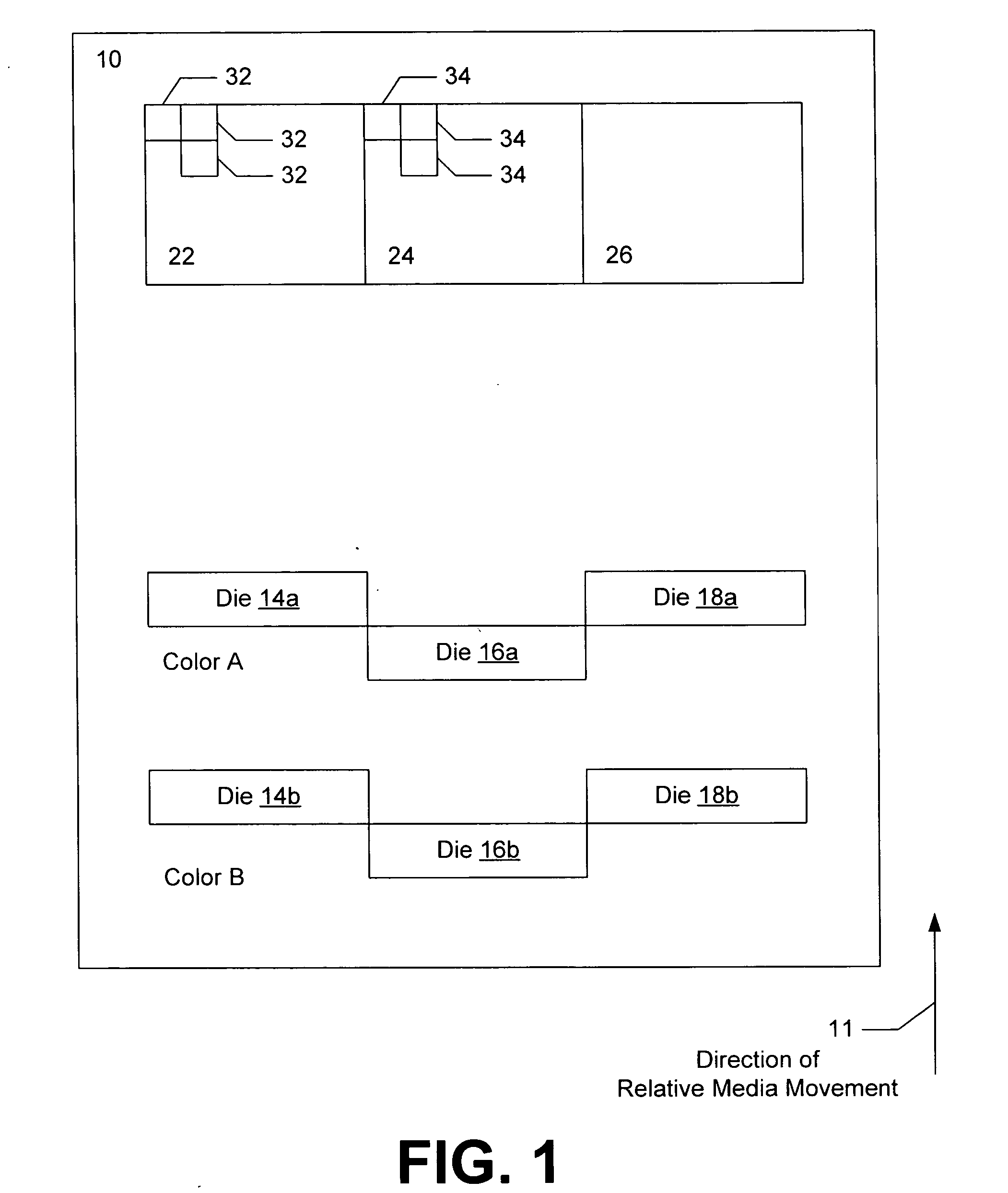

Printhead die warming

A method for printing with a plurality of dies. A plurality of dies is provided, with each die having a plurality of drop generators that are configured to eject drops of a same colored fluid. The drops from each die have a corresponding nominal drop weight at a reference temperature of the die. At least one of the dies is warmed to a corresponding elevated temperature higher than the reference temperature in order to substantially equalize the nominal drop weights of all of the dies.

Owner:HEWLETT PACKARD DEV CO LP

Thermal ink jet ink composition

ActiveUS20120026257A1Shorten drying timeLong decap timeCosmetic preparationsToilet preparationsKetoneDrop weight

A thermal ink jet ink composition includes one or more volatile organic solvents, wherein the one or more volatile organic solvents are selected from C1-C4 alcohols, C3-C6 ketones, C3-C6 esters, C4-C8 ethers, and mixtures thereof; one or more humectants, wherein the humectants are present in an amount not more than 30% by weight of the ink composition; one or more binder resins; and one or more dyes. The ink composition is suitable for use in a thermal ink jet printer and the ink composition has a slow rate of kogation such that it is capable of being printed at least 10 million drops per nozzle from the thermal ink jet printer before drop weight of the ink composition is reduced by more than 10%.

Owner:VIDEOJET TECH INC

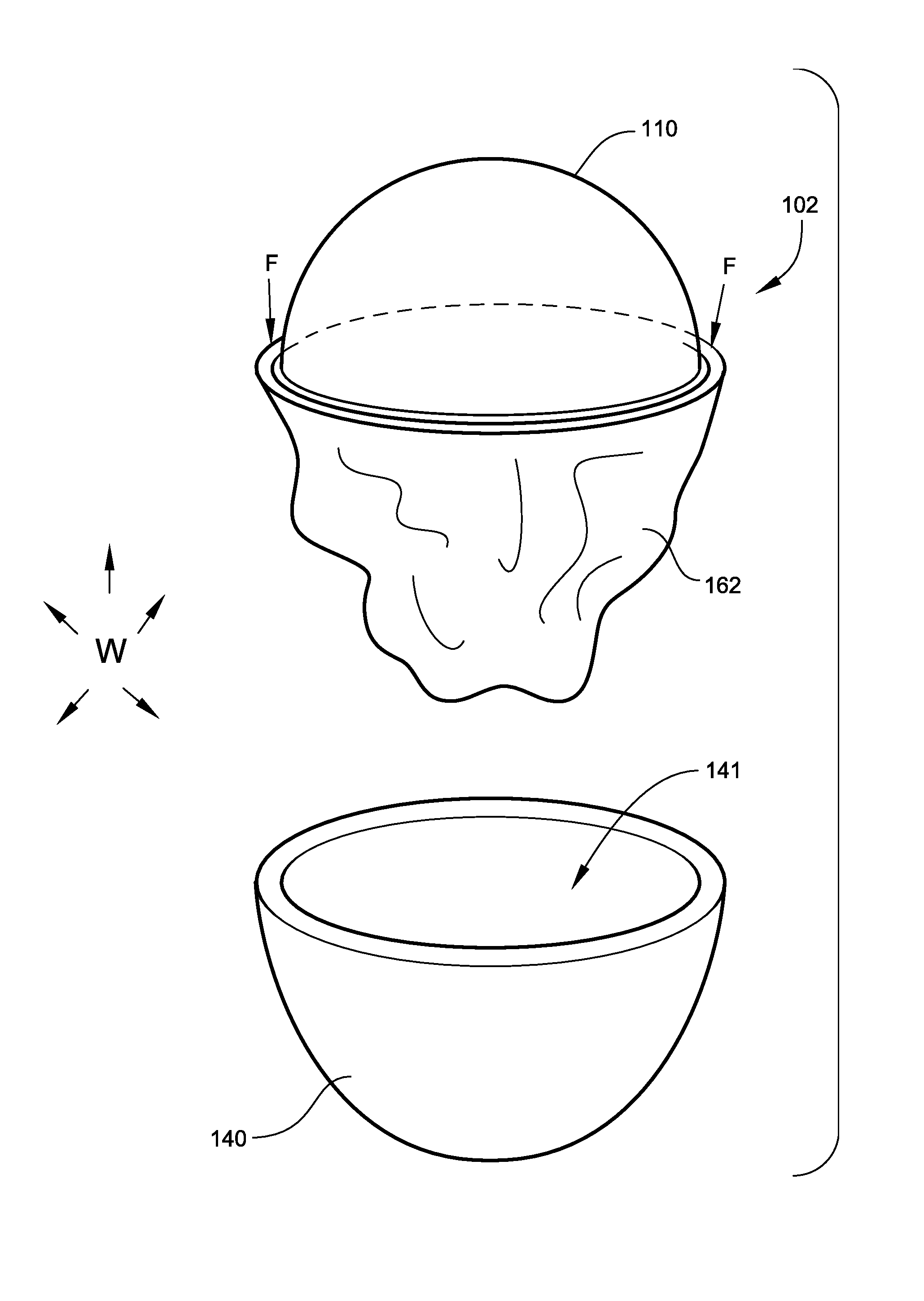

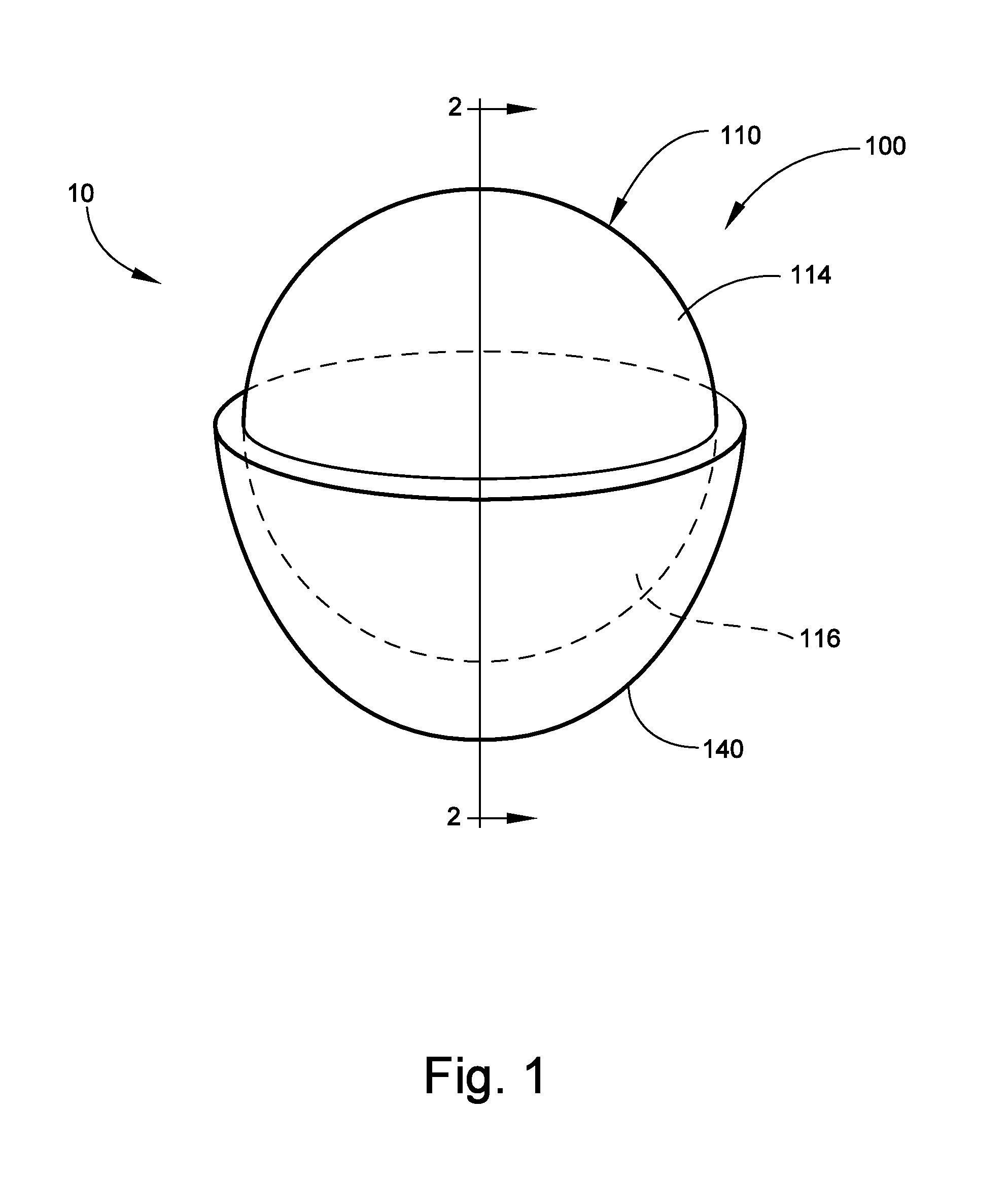

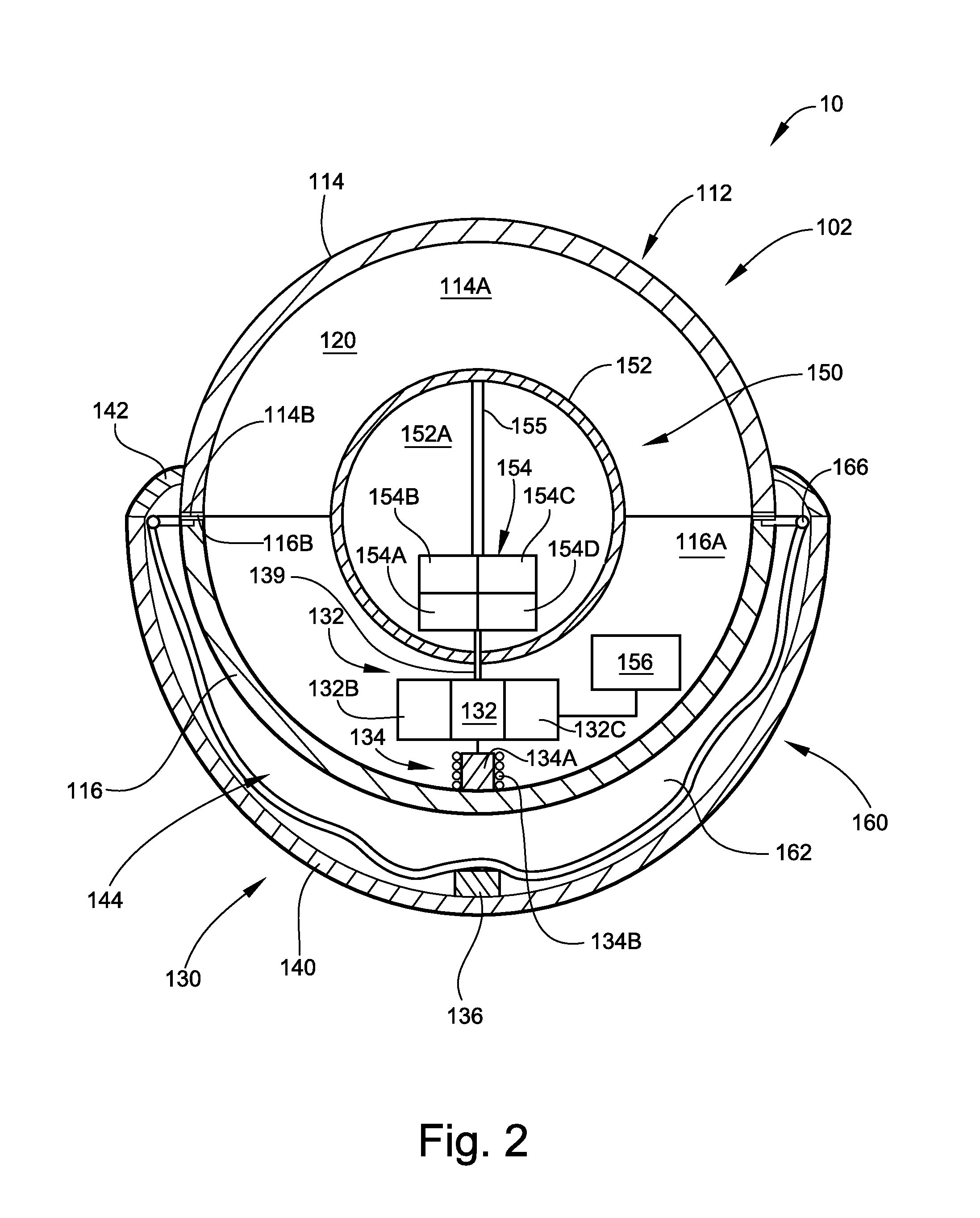

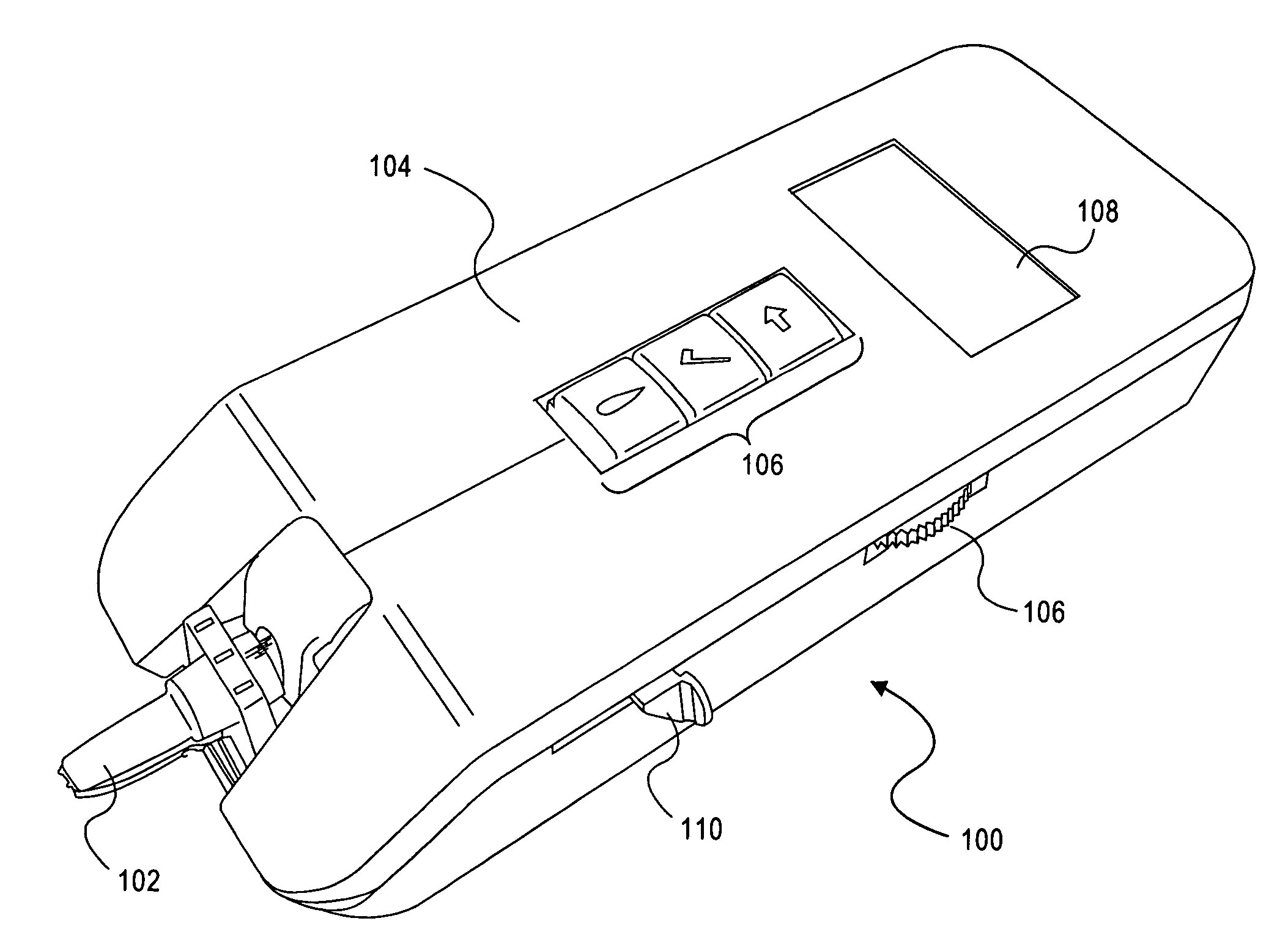

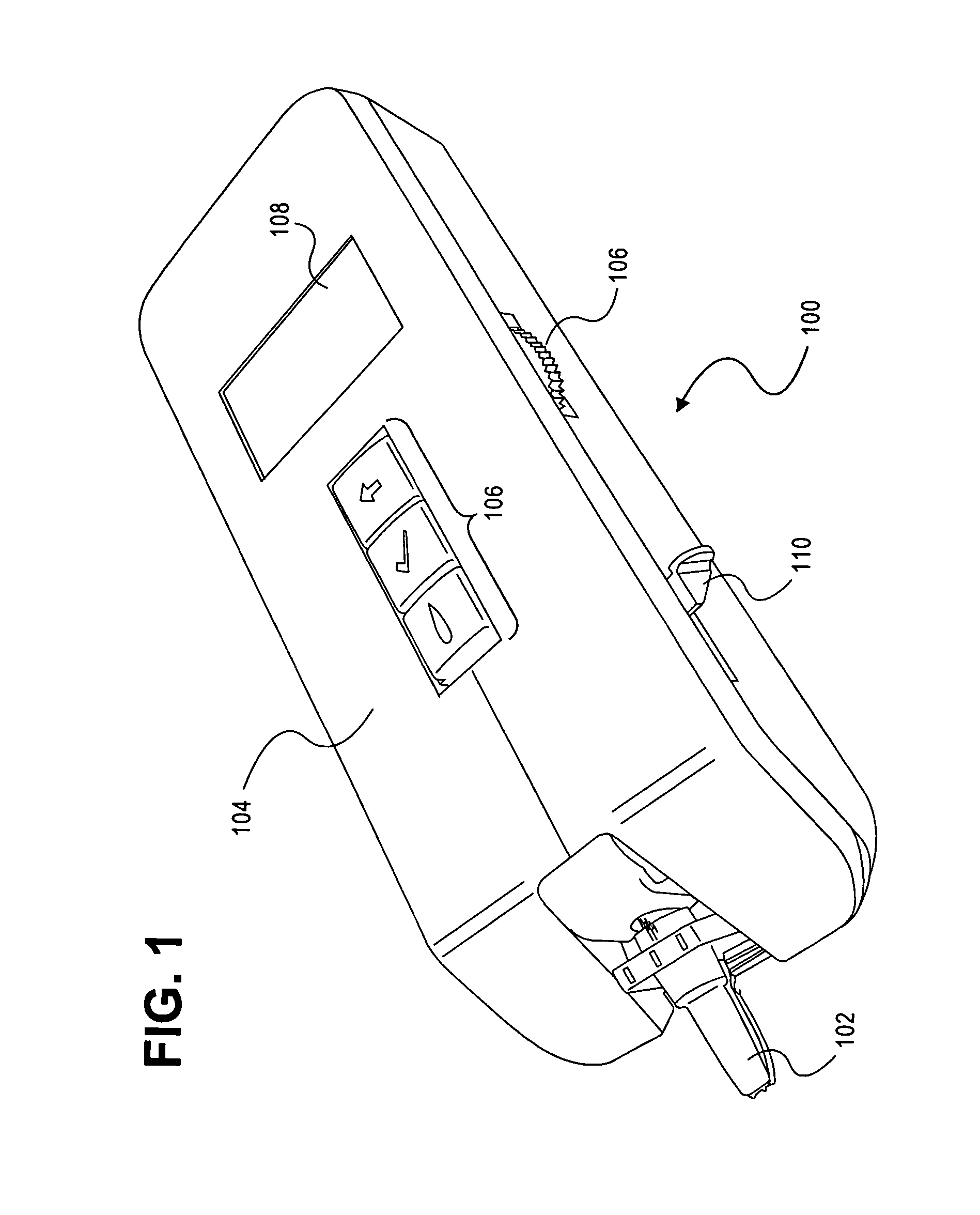

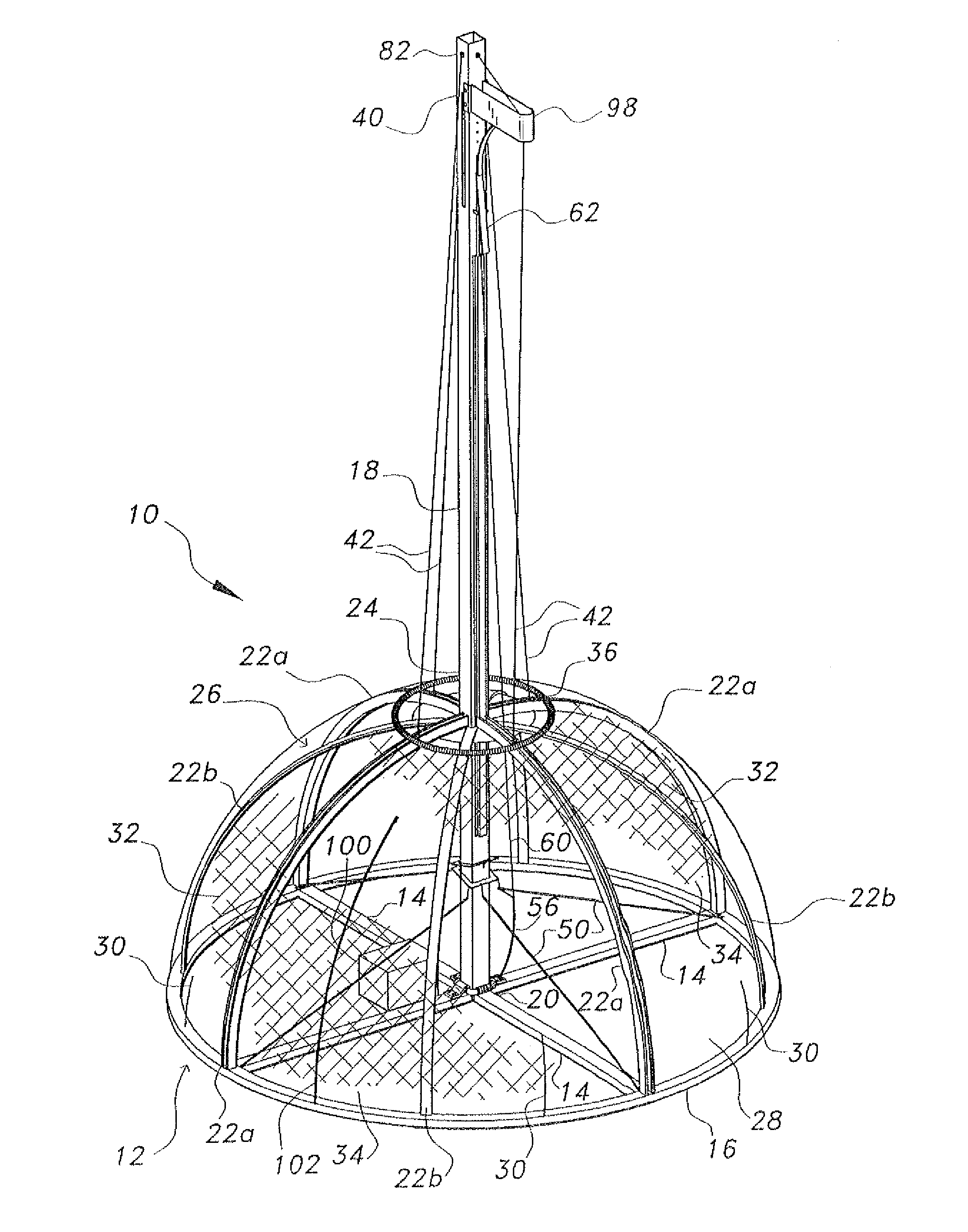

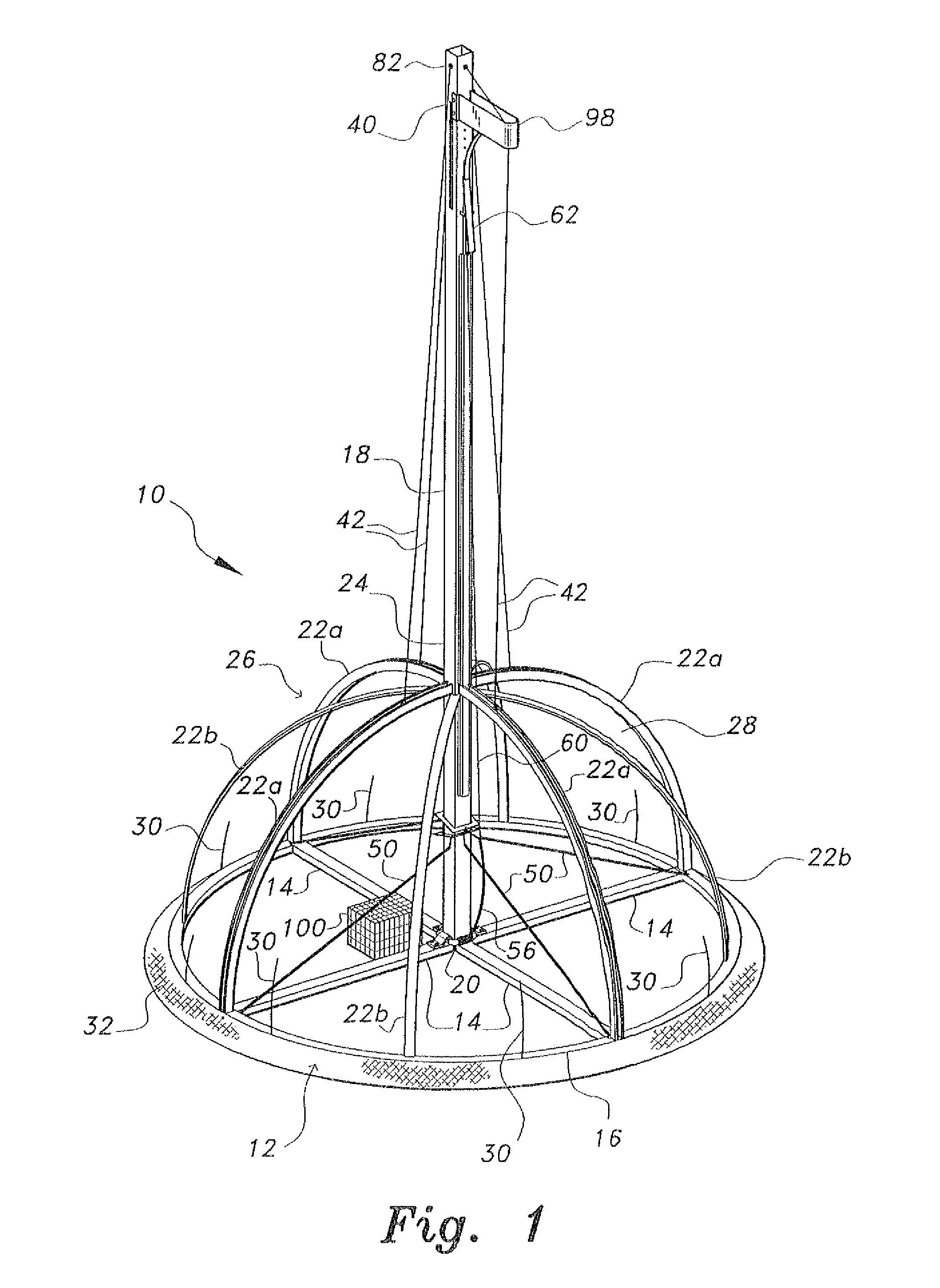

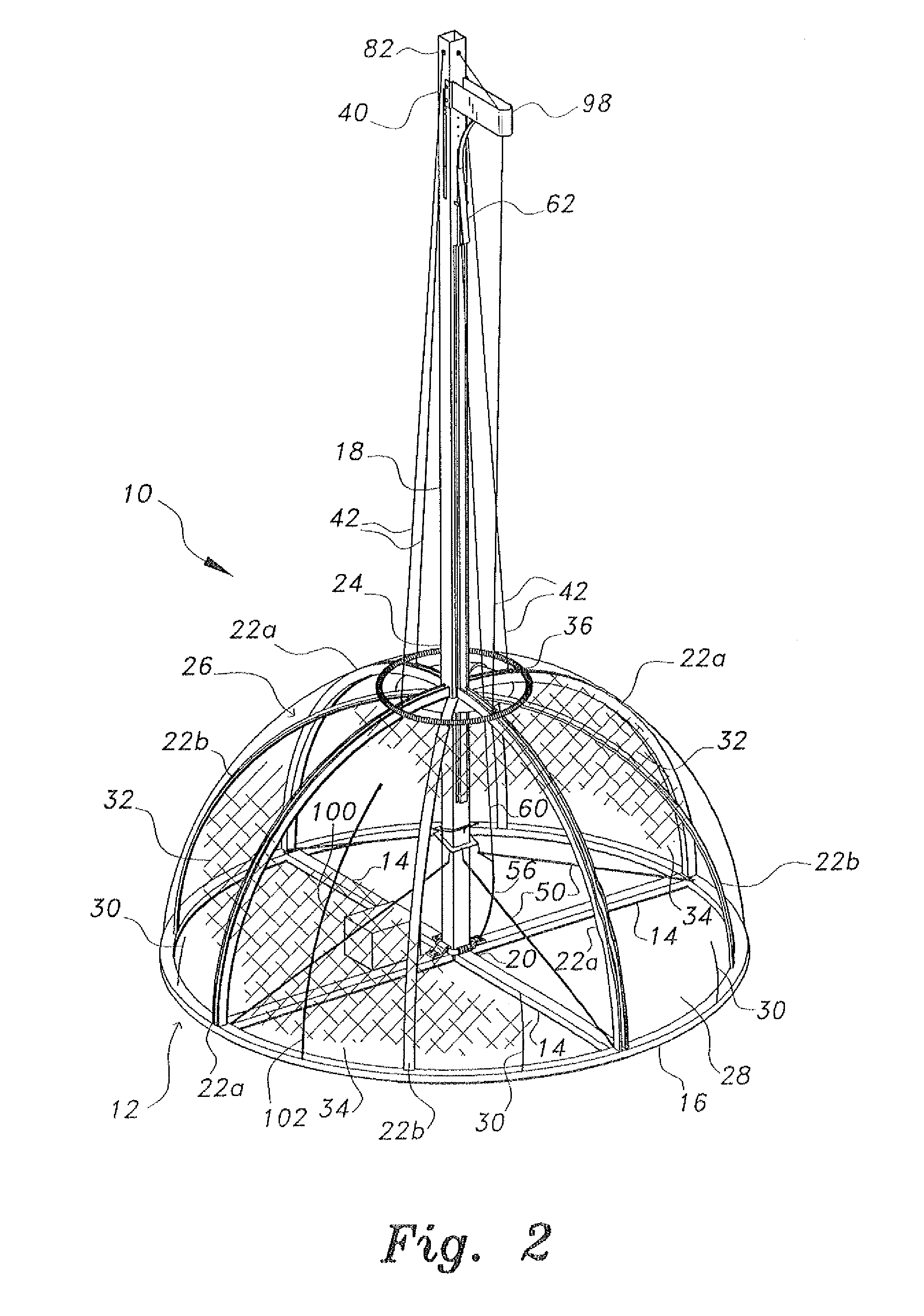

Humane animal trap

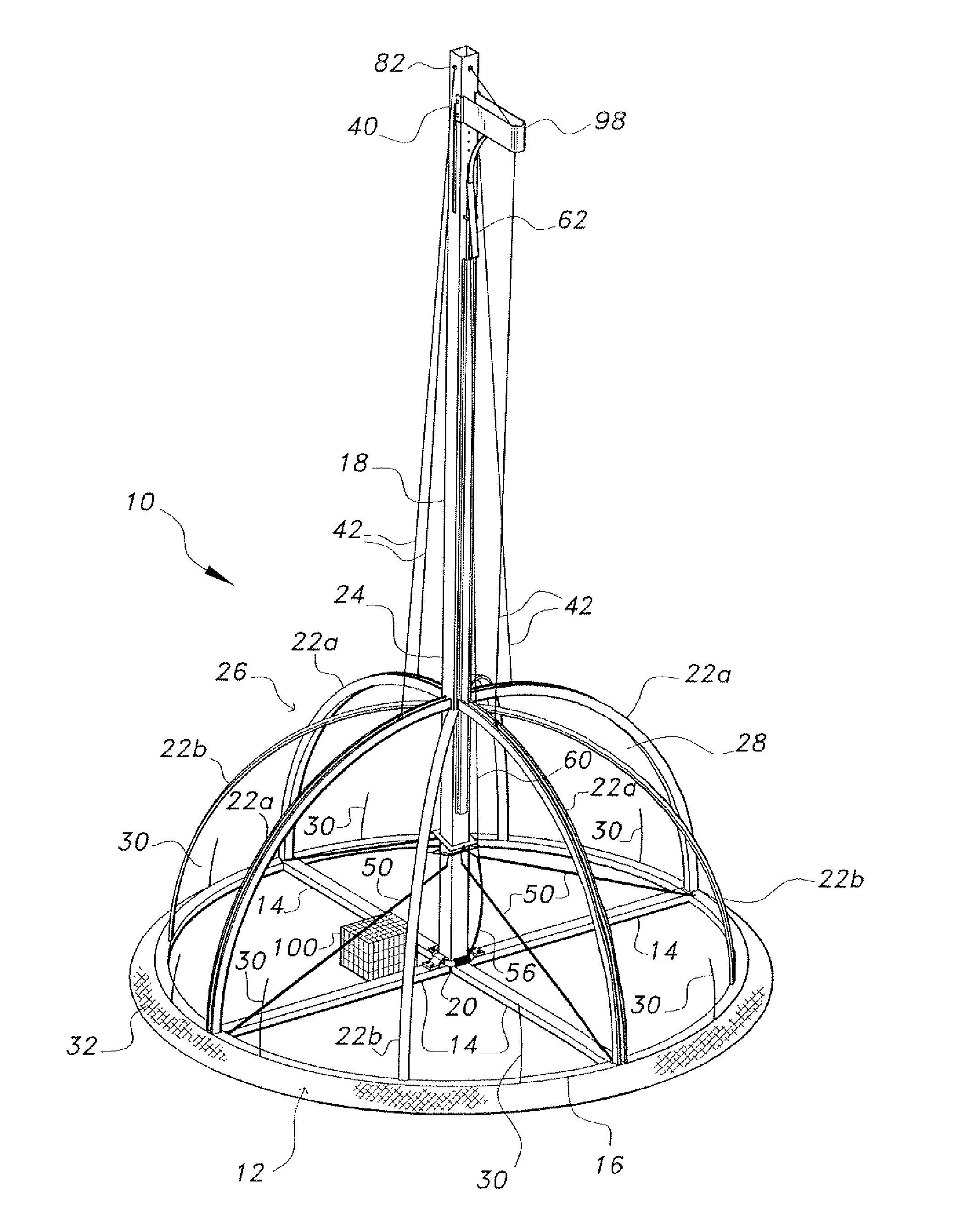

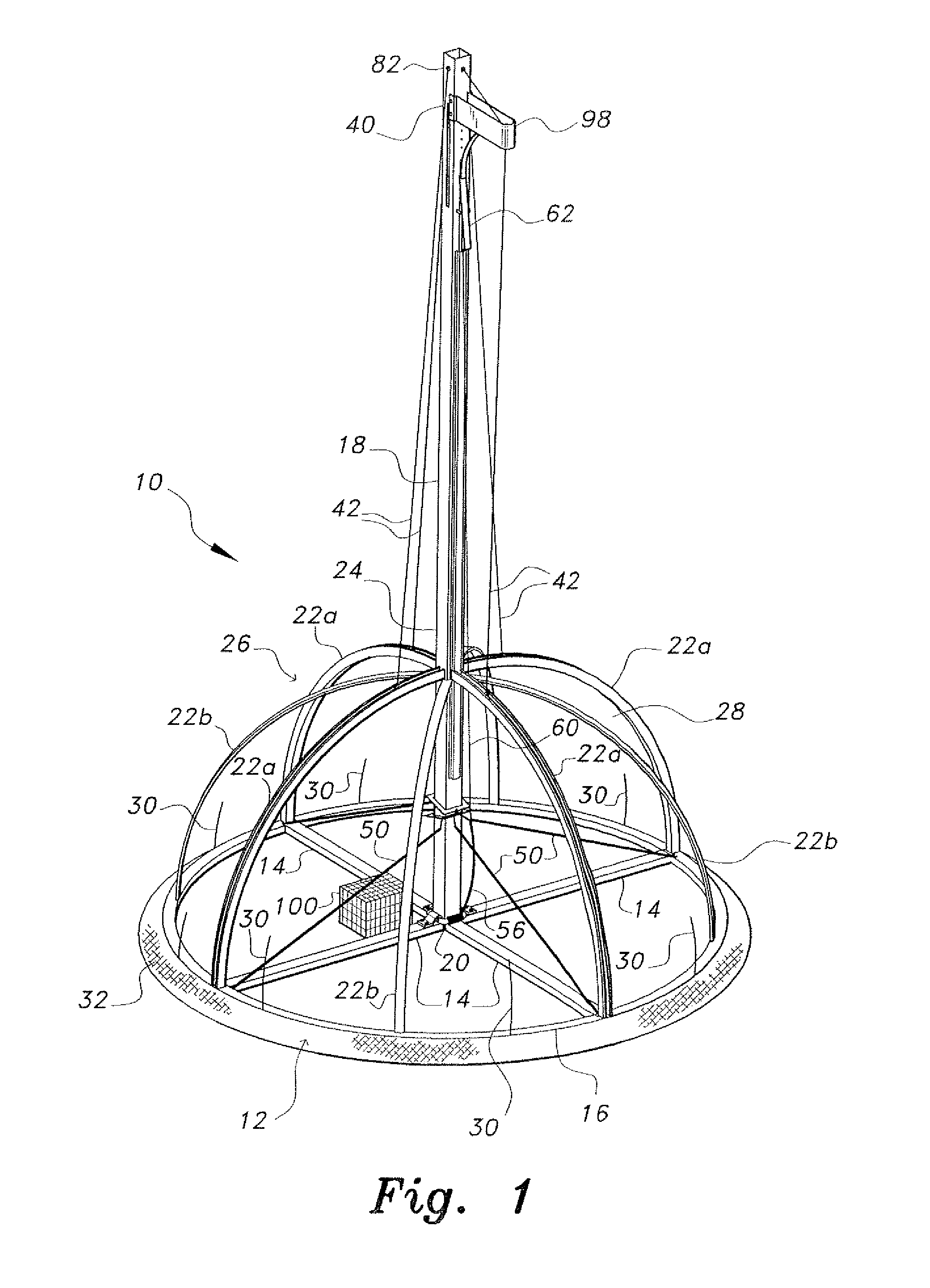

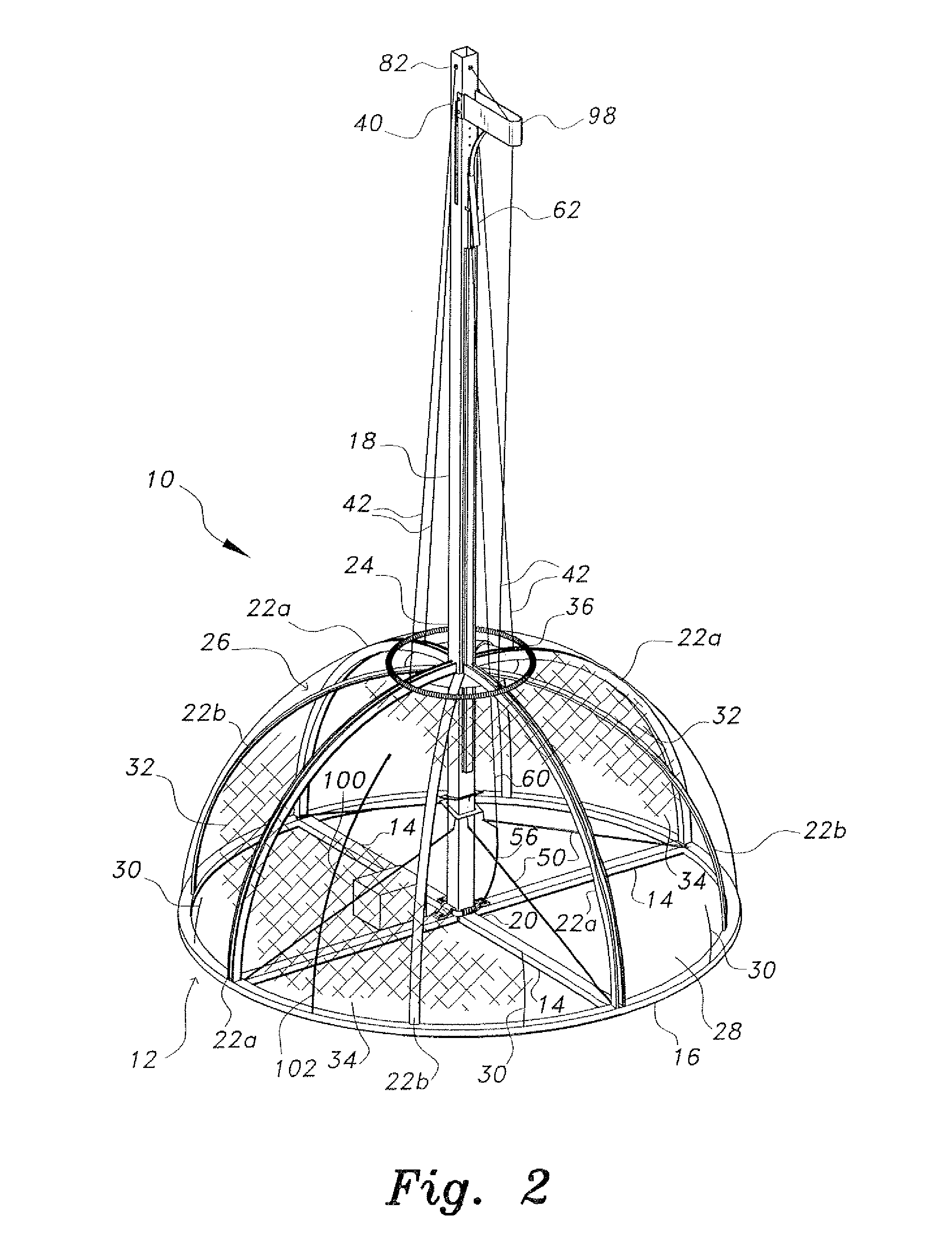

The humane animal trap has a circular base and a plurality of arcuate ribs extending upward and inward therefrom to form a generally hemispherical frame. A hollow central column extends upward from the center of the base. A drop weight is installed within the column. A collapsible net is placed about the base when the trap is set, the weight being connected to the net by tensile members. A mechanically or remotely actuated trigger and actuating mechanism is connected to a weight release mechanism at the top of the column. When an animal enters the open volume defined by the hemispherical frame and trips the mechanism or the trapper actuates the mechanism remotely, the mechanism causes the weight to release mechanism to release the drop weight, thereby pulling the net upward and over the arcuate ribs to enclose the hemispherical volume at the lower portion of the trap.

Owner:ALFARHAN ABDULMAJEED F S SH

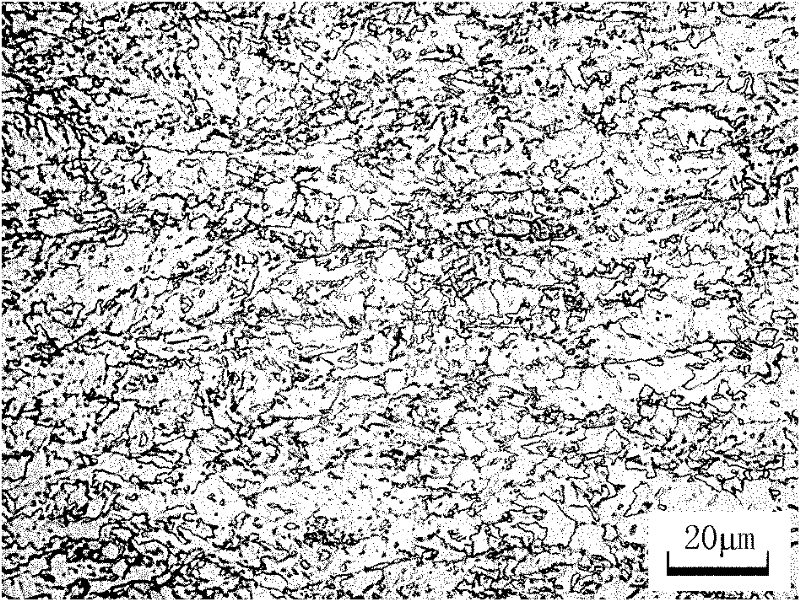

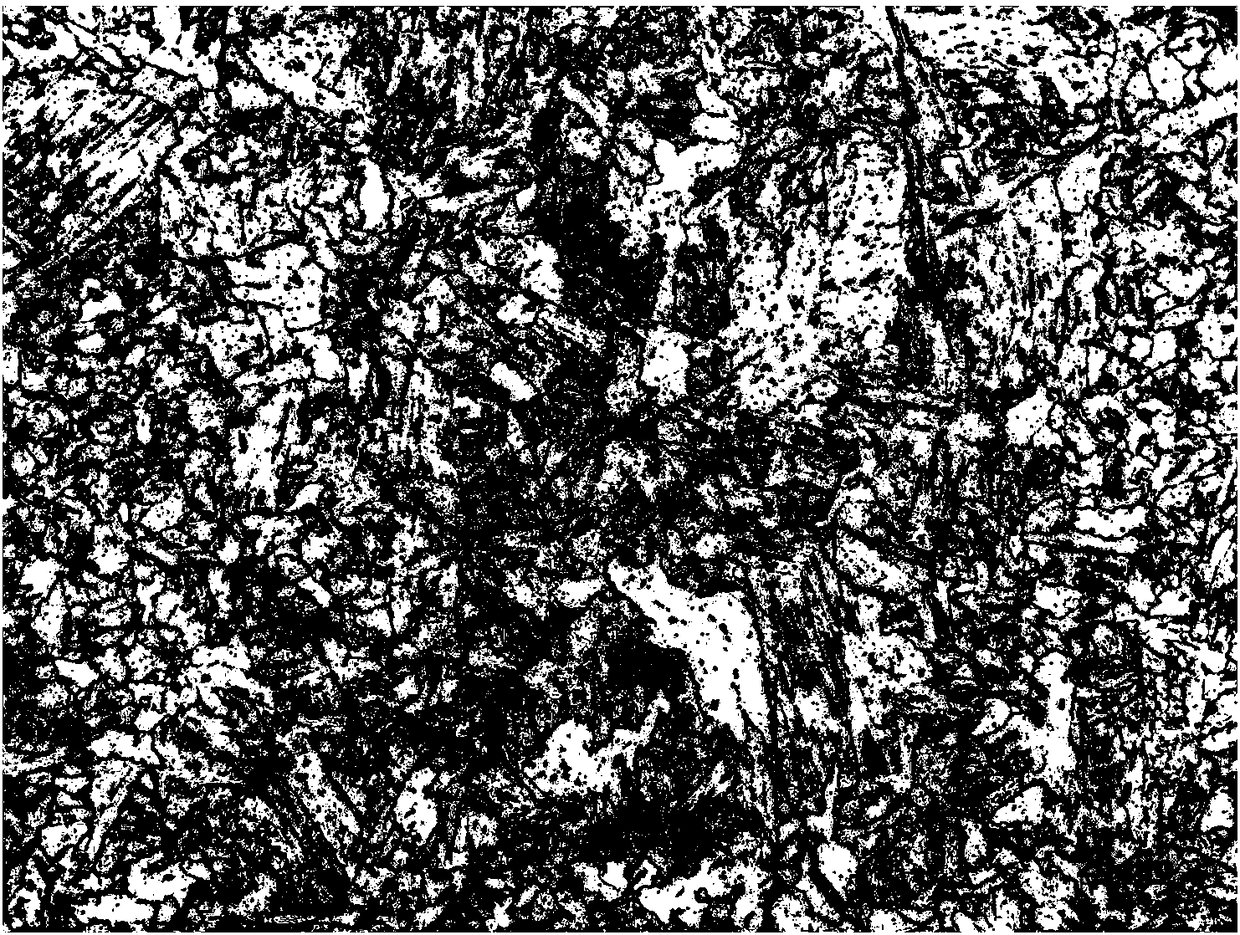

X70 pipeline steel hot-rolled plate roll and production method thereof

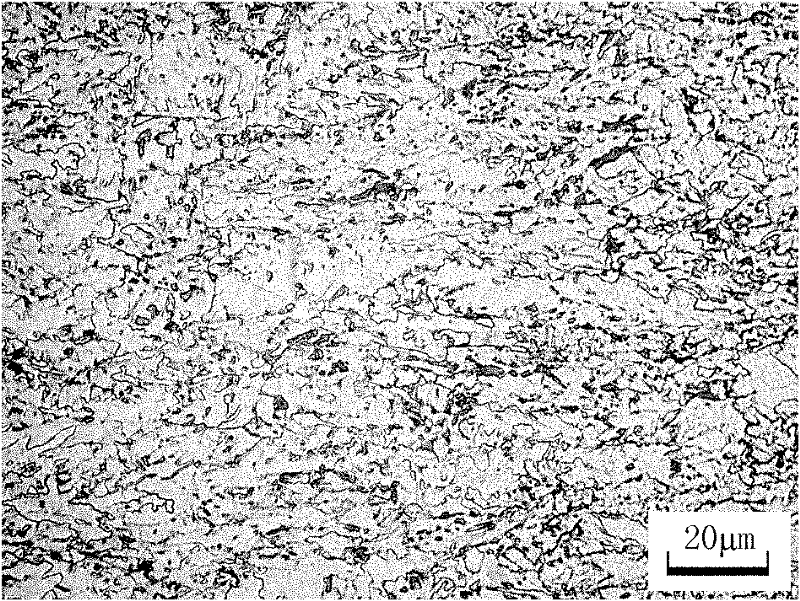

The invention relates to an X70 pipeline steel hot-rolled plate roll and a production method of the X70 pipeline steel hot-rolled plate roll. The production method comprises the steps of smelting andcontinuous casting, heating and rolling, and cooling, wherein the heating temperature is 1160-1180 DEG C, and the total in-furnace time is larger than or equal to 180 minutes. The rolling is divided into first-stage rolling and second-stage rolling, the first-stage rolling is performed in an austenite recrystallization area, in the rolling process, the rolling-starting temperature is 1140-1160 DEGC, pressing-down rate in first pass is larger than 10%, and the pressing-down rate in final pass is larger than or equal to 25%; the second-stage rolling is performed in an austenite non-recrystallization area, the finish-rolling-starting temperature is less than or equal to 930 DEG C, the final rolling temperature is 810-850 DEG C, the finish-rolling compression ratio is larger than 3, and the accumulated pressing-down rate is larger than or equal to 72%. According to the X70 pipeline steel hot-rolled plate roll and the production method of the X70 pipeline steel hot-rolled plate roll, by means of the reasonable chemical ingredient design and the adoption of the above-mentioned controlled-rolling and controlled-cooling process, the X70 pipeline steel with the microscopic tissue being a thin and uniform needle-shaped ferrite and the grain size being the thirteenth grade is obtained, and the X70 pipeline steel is of high strength, high tenacity and the drop weight tear performance andis low in cost.

Owner:BAOTOU IRON & STEEL GRP

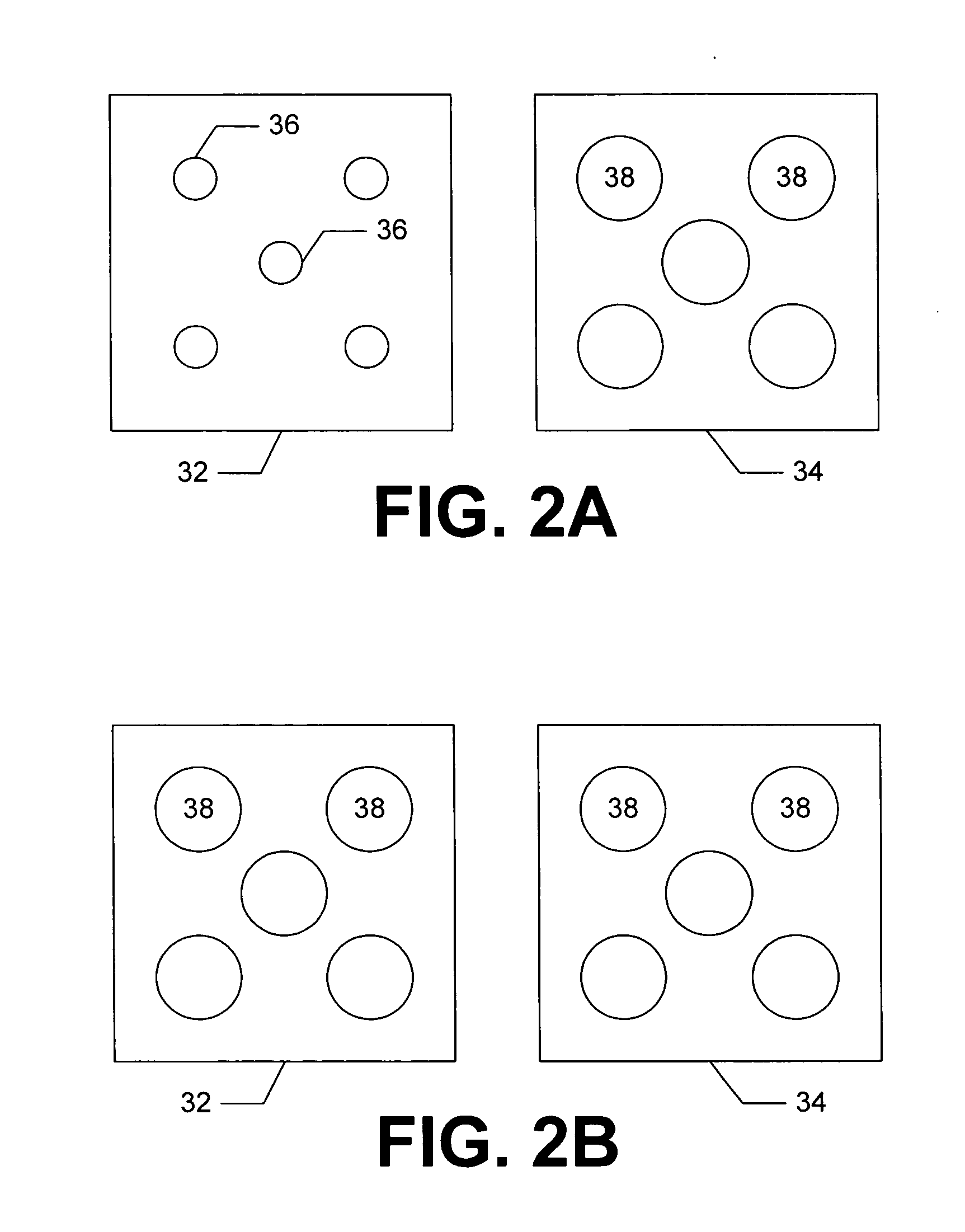

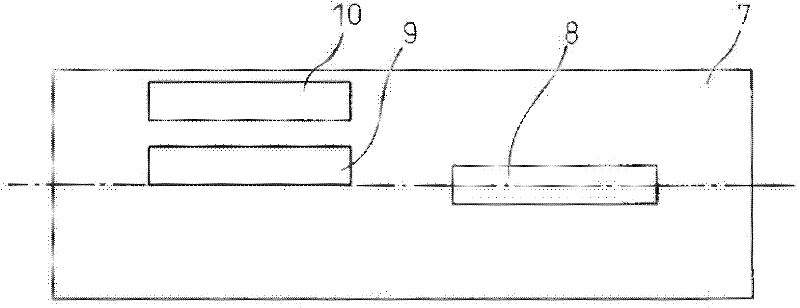

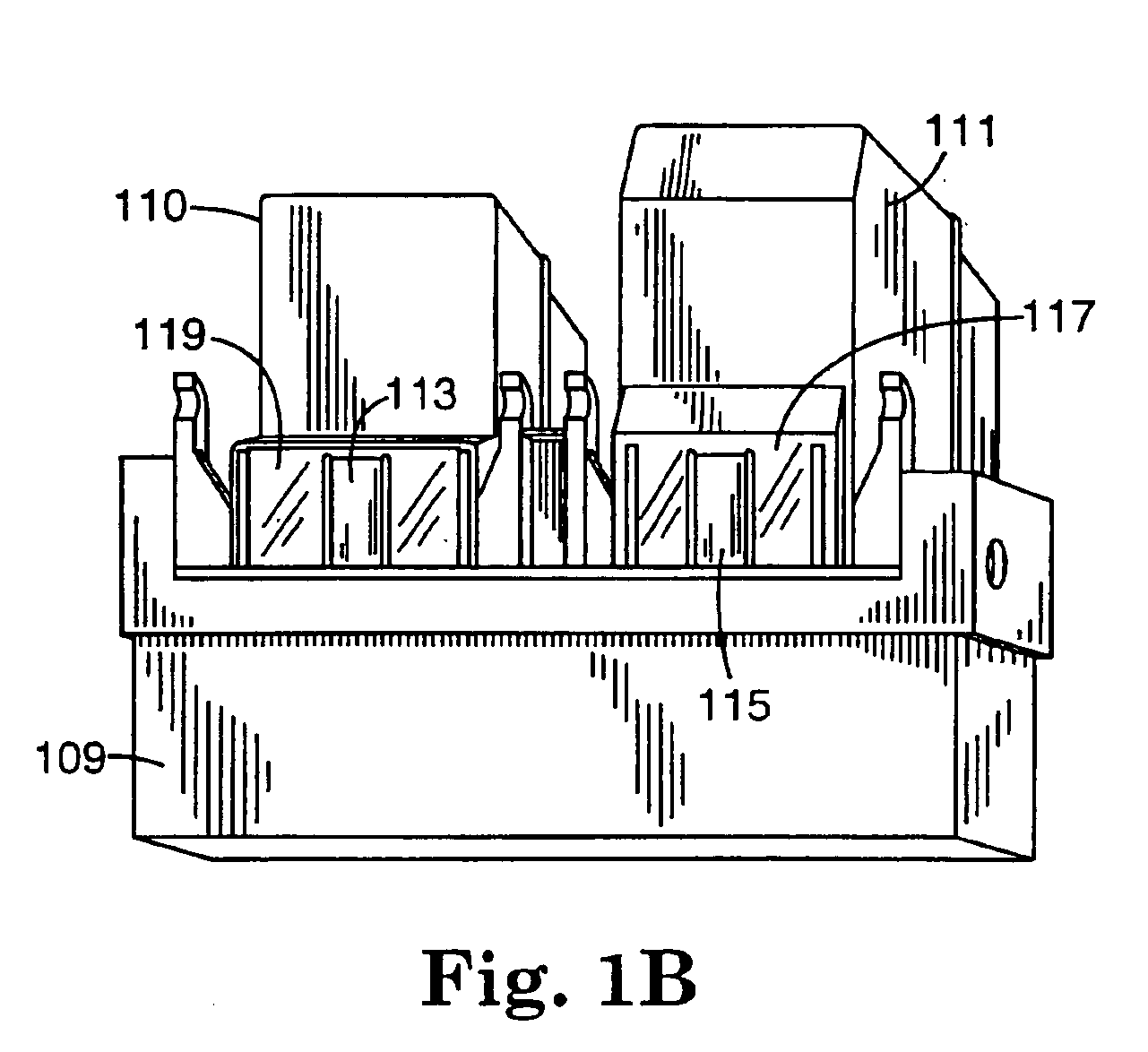

Multiple drop weight printhead and methods of fabrication and use

A printhead includes a chamber layer and at least two orifice layers. A first orifice layer is disposed on the chamber layer, and a second orifice layer is disposed on the first orifice layer. The second orifice layer has at least one counterbore formed therein. A first nozzle is formed through both orifice layers and produces droplets of a first drop weight. A second nozzle is formed through the first orifice layer, coincident with the counterbore, and produces droplets of a second drop weight that is different than the first drop weight. In one embodiment, the printhead is used in a stand-alone fluid-dispensing device.

Owner:HEWLETT PACKARD DEV CO LP

Color calibration chart

ActiveUS7034968B2Digitally marking record carriersDigital computer detailsPattern recognitionDrop weight

A test page produced by ink pens for calibrating drop weights for at least a first and a second printheads, comprising: a page with an area for color swatches; a plurality of color swatches disposed in the area; and a predetermined substantially uniform color background disposed in said area between and around said plurality of color swatches. In a system embodiment of the present invention, a sensor may be used for sensing spectral data for each color swatch in a plurality of color swatches; and a component may be provided for comparing the sensed spectral data for each color swatch in a plurality of the color swatches to spectral data for the background color and selecting one of the plurality of color swatches which has spectral data which is closest to the background color for use in adjusting ink volume for at least one of the ink pens.

Owner:HEWLETT PACKARD DEV CO LP

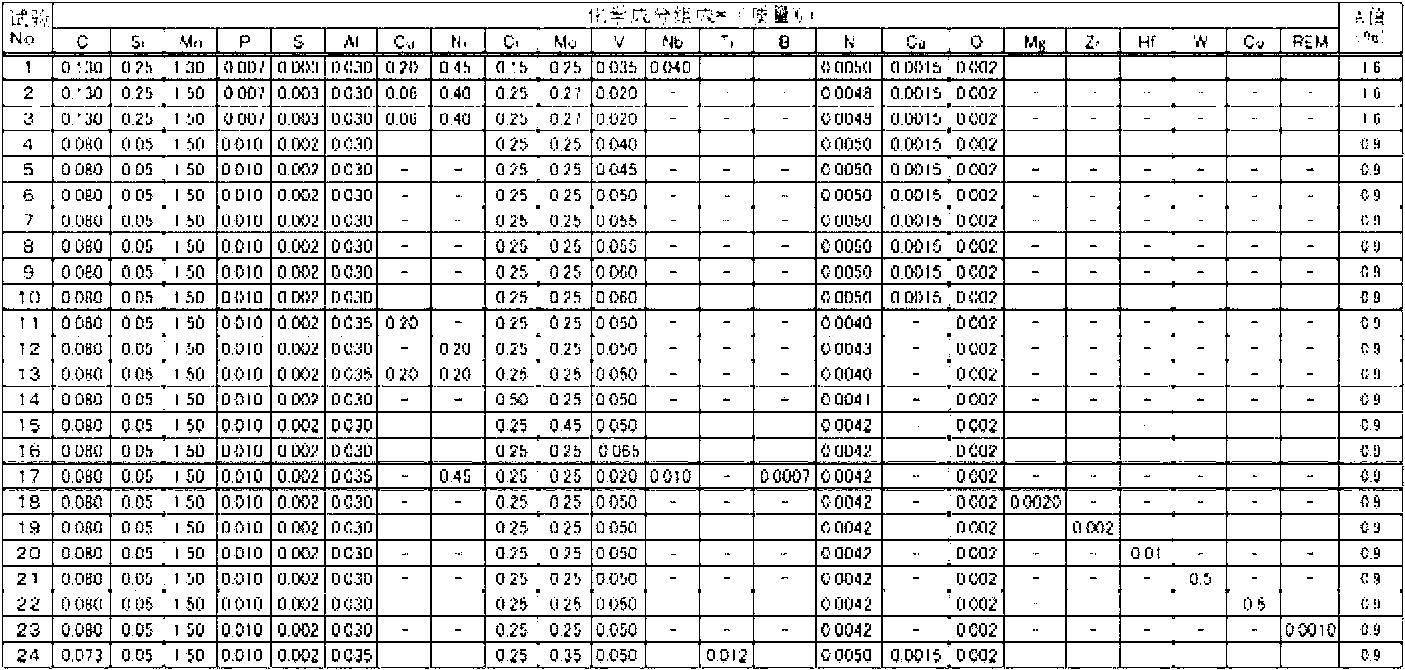

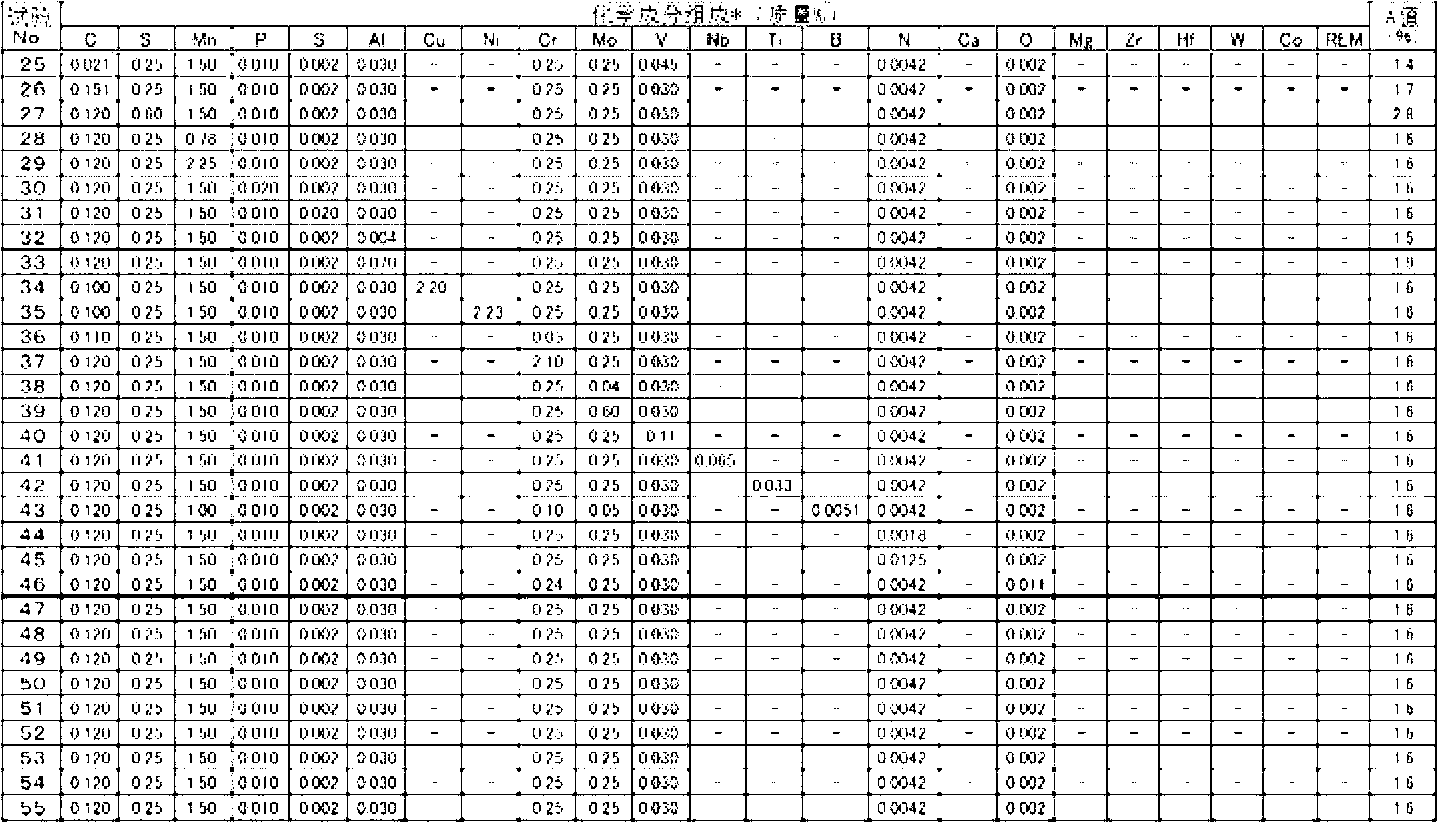

High-strength thick steel plate with excellent drop weight characteristics

The disclosed high-strength thick steel plate satisfies prescribed chemical component composition requirements, and is useful as a structural material in marine structures, ships, bridges, and also as a material in pressure vessels in nuclear power plants. In the microstructure positioned at a depth of t / 4-t / 2 from the surface (t is the plate thickness, same below), the area fraction of bainite is 90% or greater, the average value of the bainite lath width is 3.5 [mu]m or less, and the circle equivalent diameter of island martensite in the bainite has a maximum value of 3.0 [mu]m or less.

Owner:KOBE STEEL LTD

Hot rolling process capable of improving high-grade thick pipeline steel fracture toughness

InactiveCN102172619AIncrease the dislocation densityLower transition temperatureMetal rolling arrangementsDrop weightTemperature difference

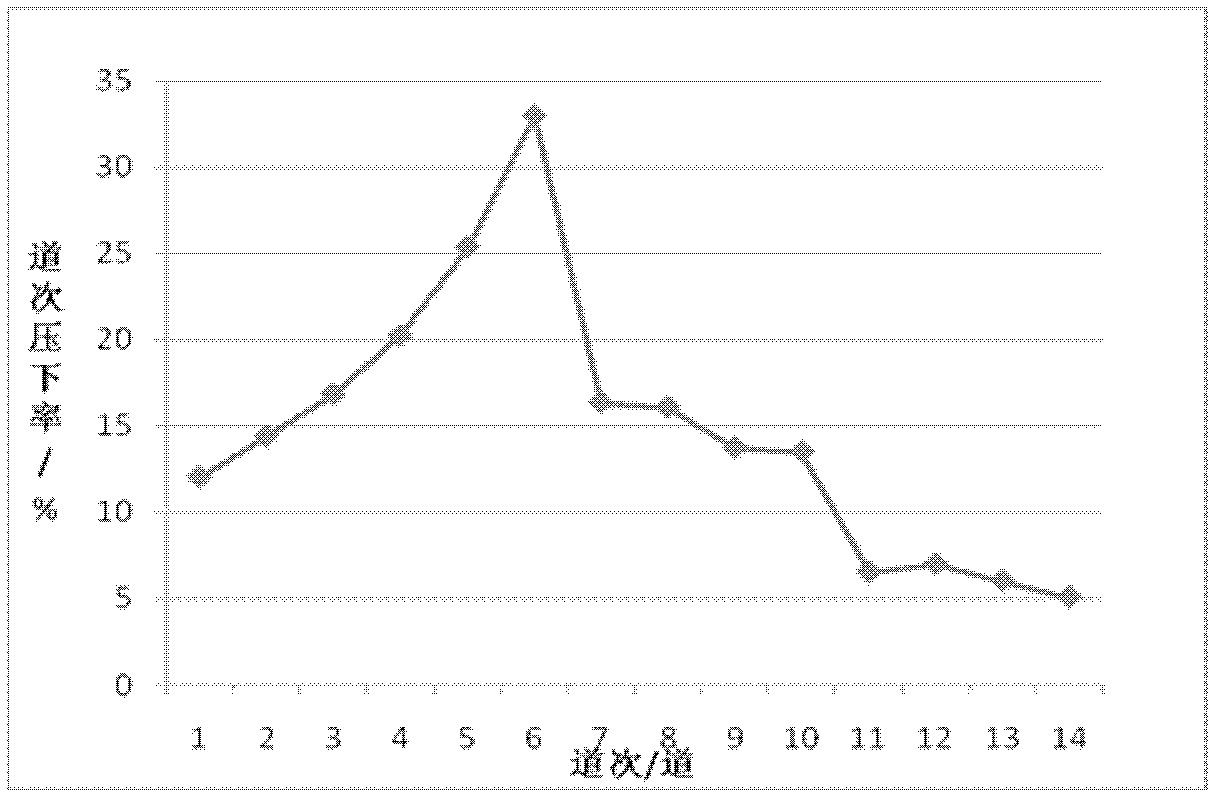

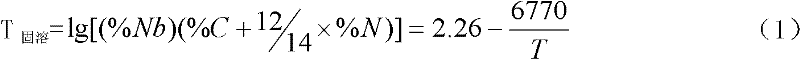

The invention provides a hot rolling process capable of improving high-grade thick pipeline steel fracture toughness, sequentially comprising a plate blank reheating section process, a hot rolling section process, a plate reeling section process and a cooling section process, wherein the concrete processing parameters of each process are as follows: in the plate blank reheating section process, the plate blank heating temperature is equal to T solid solution plus 30-80 DEG C, the relation between in-furnace time and blank thickness is that the total in-furnace time is equal to 0.5t plus 30-50min, and the temperature difference of the upper surface and the lower surface after the plate blank is reheated is less than or equal to 30 DEG C; and in the hot rolling section process, the single track down rate in rough rolling is more than or equal to 15%, the accumulated down rate in fine rolling is more than or equal to 70%, and the finished rolling temperature is equal to Ar3 plus 0-60 DEG C, wherein Ar3 is a phase transformation point temperature. By utilizing the hot rolling process provided by the invention, the problem that DWTT (drop weight tear test) control is difficult to carry out on X70 and X80 steel more than 15mm can be effectively solved. The hot rolling process provided by the invention is practical and feasible and produces less loss on a rolling machine, a reeling machine and the like, and the qualifying rate of the DWTT properties of a product can reach up to more than 99%.

Owner:武钢集团有限公司

Method for improving pipeline steel drop-weight performance

The invention relates to a method for improving pipeline steel drop-weight performance, and belongs to the field of hot rolled steel, solving the technical problem that the method for improving pipeline steel drop-weight performance is provided. The method for improving pipeline steel drop-weight performance comprises the following steps of a steel billet heating step, a rolling step and a rolling step, wherein the steps are specifically as follows: a, steel billet heating: heating the steel billets to 1160-1220 DEG C; b, rolling: carrying out rough rolling on the heated steel billets to obtain intermediate billets, and then carrying out finish rolling on the intermediate billets, wherein deformation at every turn in the rough rolling step is not less than 20%, an inlet temperature in the finish rolling step is 960-1000 DEG C, and a final-rolling temperature is AR<3+>(0-50) DEG C; c, coiling: coiling at 580-630 DEG C. According to the method, on the premise that the original pipeline steel components are not changed, the structure homogeneity of the whole fracture surface is improved by an optimizing process, so that drop-weight performance is improved, and therefore, the method is applicable to low-grade pipeline steel, and can improve problems such as poor homogeneity of a ferrite and pearlite type structure.

Owner:PANGANG GRP XICHANG STEEL & VANADIUM CO LTD

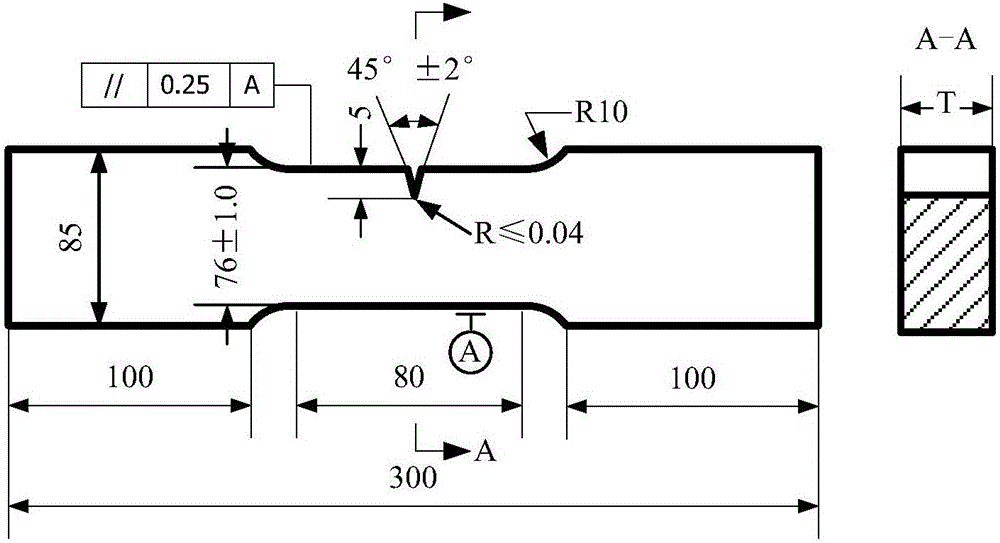

Testing device and testing method capable of simulating pipeline blasting fracture morphology

ActiveCN106769546AIncreasing the thicknessHigh strengthMaterial strength using single impulsive forceDrop weightTest sample

The invention discloses a testing device and a testing method capable of simulating pipeline blasting fracture morphology. The testing device comprises a supporting device, a high-speed impact stretching device, a clamping device, a slide bearing, a damping device, an ejecting mechanism, a high-speed loading device and a data collecting system. A machining method is utilized to process a test material into a tensile sample with the length of 300mm and in a dumbbell shape, and a V-shaped notch is formed in the middle of one side of a parallel section of the test sample in the wall thickness direction. The testing device and the testing method have the advantages that the testing results of the testing device can truly reflect facture morphology of a practical engineering pipeline in blasting, the problem of test failure due to the fact that abnormal fracture completely different from entity blasting fraction morphology is generated by directly hammering the test sample in an original drop weight tear test is solved, can be effectively simulated mechanical response of pipelines in blasting / impact load and is beneficial to engineering application and engineering design of the materials.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

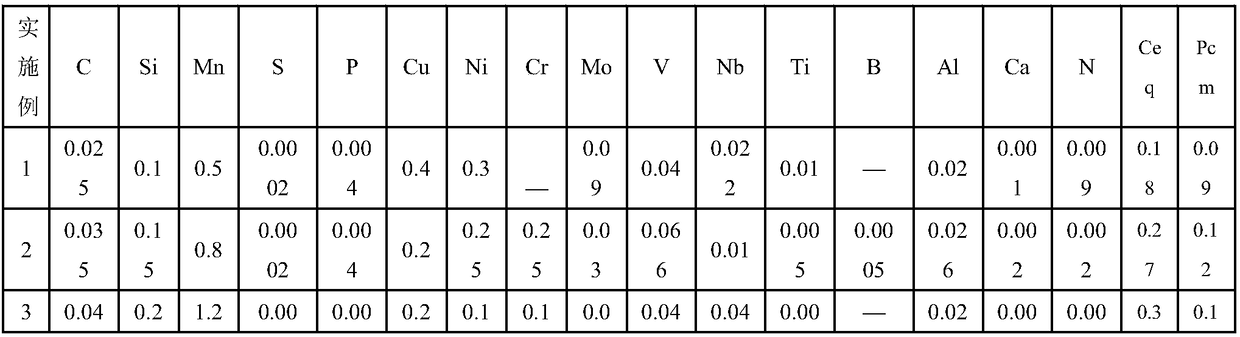

Hardening and tempering type anti-acid pipeline steel and manufacturing method thereof

The invention discloses hardening and tempering type anti-acid pipeline steel which is prepared from the chemical elements in percentage by mass: 0.025 to 0.090 percent of C, 0.1 to 0.5 percent of Si,0.50 to 1.35 percent of Mn, less than or equal to 0.020 percent of P, less than or equal to 0.003 percent of S, 0.01 to 0.09 percent of Mo, 0.01 to 0.06 percent of Nb, 0.005 to 0.02 percent of Ti, 0.001 to 0.006 percent of Ca, 0.02 to 0.045 percent of Al, larger than 0 and smaller than or equal to 0.010 percent of N, and the balance Fe and other inevitable impurities. A microstructure of the hardening and tempering type anti-acid pipeline steel has tempered bainite with the phase proportion being larger than 90 percent, and has the grain size reaching to more than 11 grades. In addition, theinvention further discloses a manufacturing method of the hardening and tempering type anti-acid pipeline steel. The hardening and tempering type pipeline steel provided by the invention has the yieldstrength being 290 to 550MPa, the tensile strength being 415 to 760MPa, the charpy impact work at minus 40 DEG C being higher than 120J, and the shear fracture area percentage under a drop-weight tear test (DWTT) at minus 25 DEG C being larger than 85 percent.

Owner:BAOSHAN IRON & STEEL CO LTD

Humane animal trap

The humane animal trap has a circular base and a plurality of arcuate ribs extending upward and inward therefrom to form a generally hemispherical frame. A hollow central column extends upward from the center of the base. A drop weight is installed within the column. A collapsible net is placed about the base when the trap is set, the weight being connected to the net by tensile members. A mechanically or remotely actuated trigger and actuating mechanism is connected to a weight release mechanism at the top of the column. When an animal enters the open volume defined by the hemispherical frame and trips the mechanism or the trapper actuates the mechanism remotely, the mechanism causes the weight to release mechanism to release the drop weight, thereby pulling the net upward and over the arcuate ribs to enclose the hemispherical volume at the lower portion of the trap.

Owner:ALFARHAN ABDULMAJEED F S SH

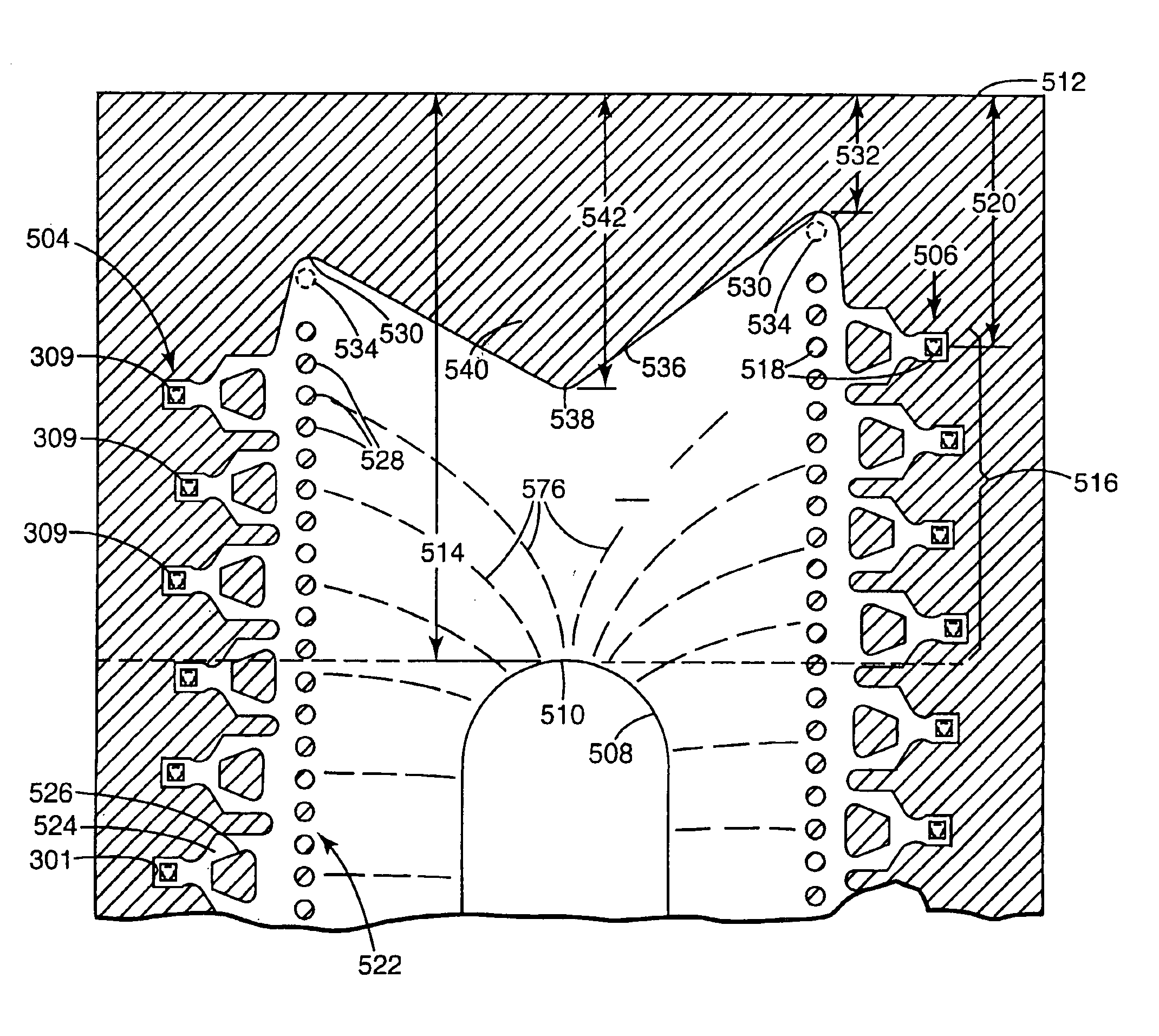

Method for determination of brittle crack propagation stopping performance in high-intensity thick steel plate

ActiveCN102472699AEvaluation omittedAccurate evaluationMaterial strength using single impulsive forceDrop weightSurface layer

Disclosed is a method for determining the brittle crack propagation stopping performance of a high-intensity thick steel plate, comprising: a step of performing a large test and a compound small test using standard steel; a step of calculating a correlation model between the results of the large test and the results of the compound small test using the standard steel; a step of performing the compound small test using sample steel; and a step of estimating the brittle crack propagation stopping performance of the sample steel by substituting the results of the compound small test using the sample steel into the correlation model, wherein the compound small test includes (a) a step of obtaining a surface layer small test piece which includes a portion of the steel plate surface layer; (b) a step of obtaining an inner small test piece respectively from one or no less than two inner regions which do not include the portion of the steel surface layer; (c) a step of performing a drop weight test using the surface layer small test piece; and (d) a step of performing a small test for measuring the percent brittle fracture or the absorption energy using the inner small test piece; and thecompound small test is performed in different fashions for the surface layer small test piece and the inner small test piece respectively.

Owner:NIPPON STEEL CORP

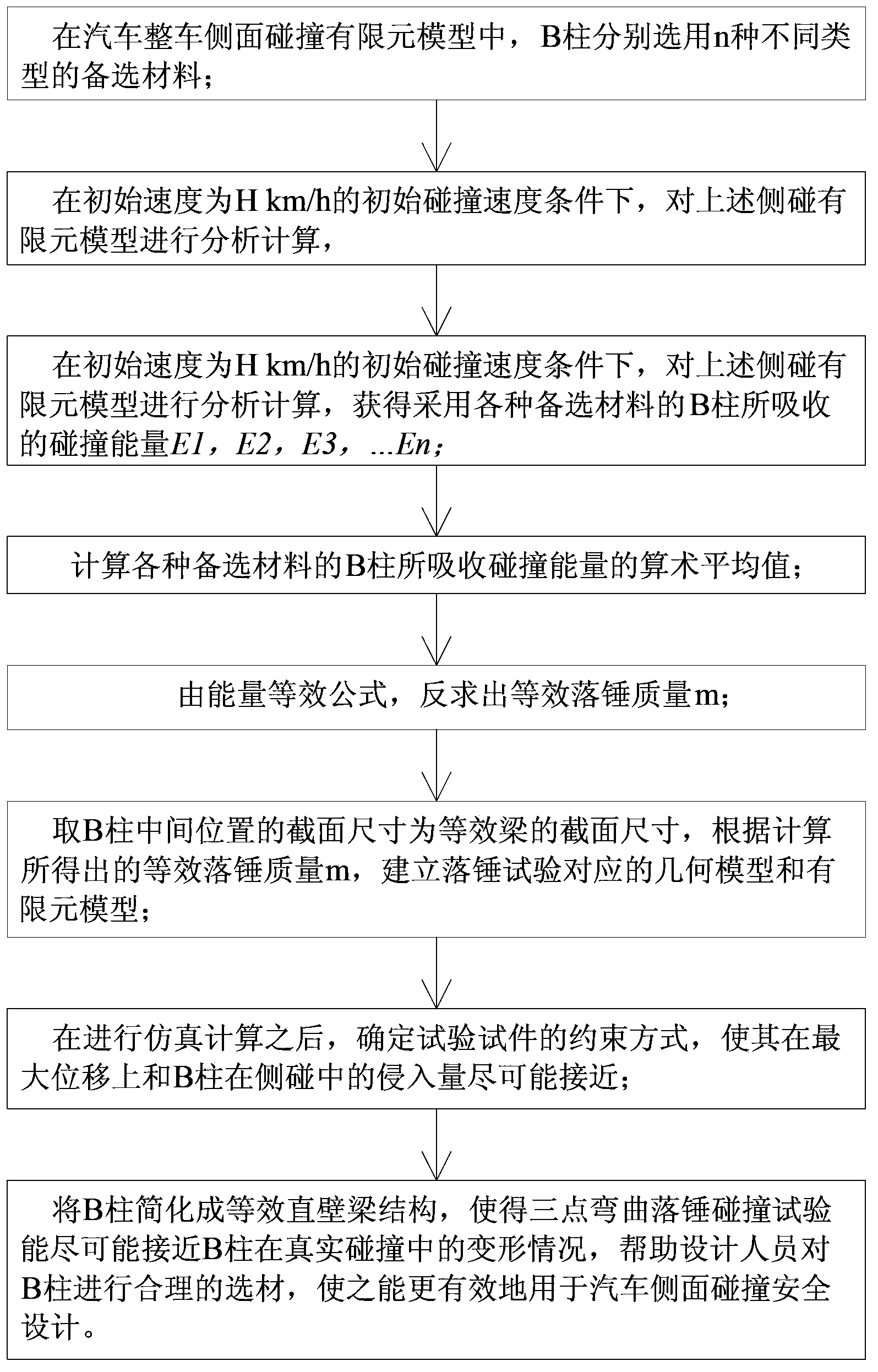

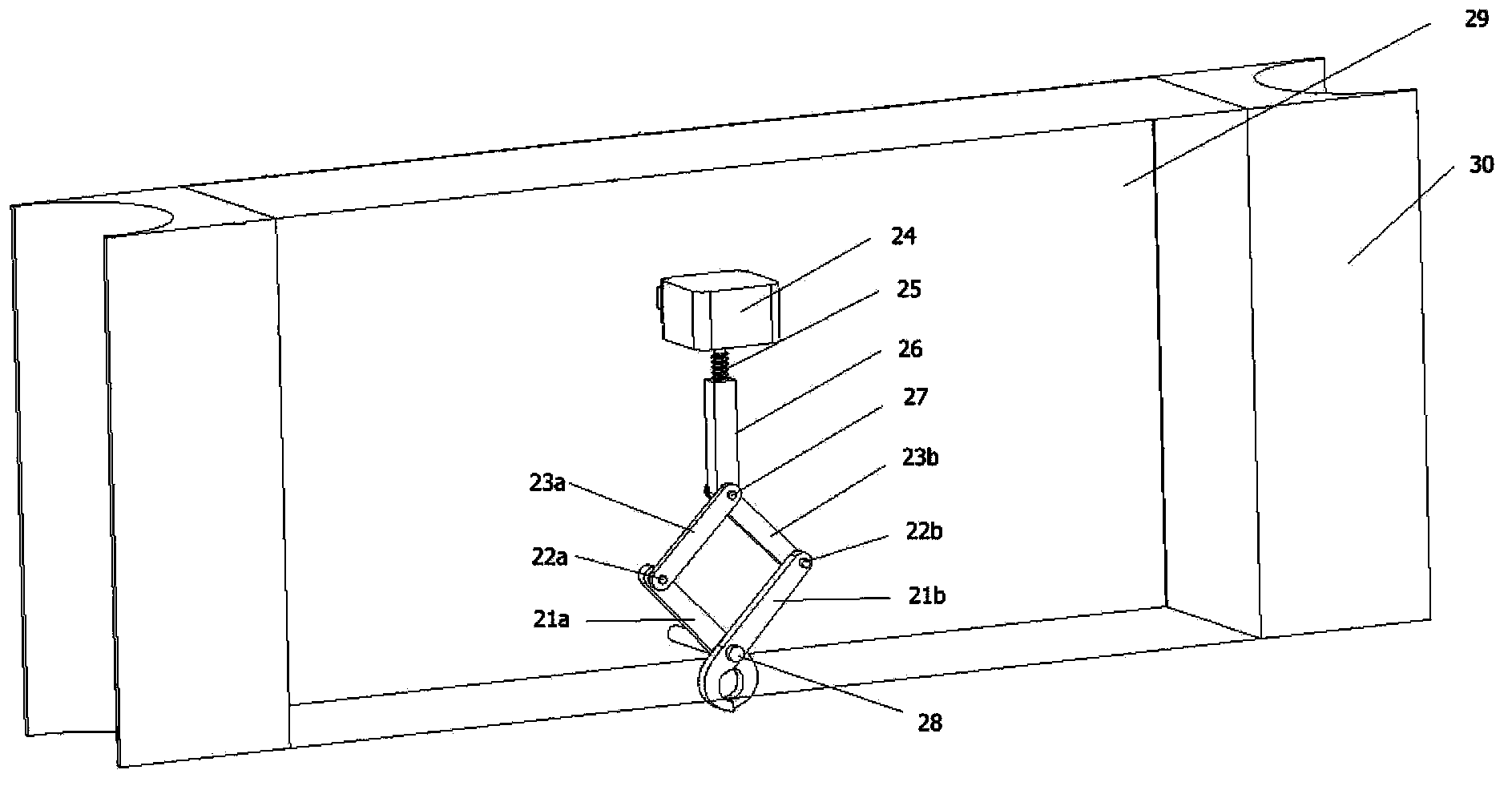

Three-point bending drop collision test method and device for equivalently simplifying beam

ActiveCN104122058AEffective crash safety designEfficiently evaluate crash safety featuresShock testingDrop weightElement model

The invention discloses a three-point bending drop collision test method and device for equivalently simplifying beam and belongs to the collision test field. The three-point bending drop collision test method includes that selecting different types of alternative materials of a post B in a side collision finite element model of an automobile; analyzing and calculating the side collision finite element model under an initial collision speed to obtain collision energy absorbed by each kind of alternative material; calculating the average value of the collision energy absorbed by all the alternative materials; obtaining the average energy absorption level of the post B when using different types of materials; reversely calculating equivalent drop weight according to an energy equivalence formula; using the section size of the middle of the post B as the section size of the equivalent beam, building a geometrical model and a finite element model corresponding to the drop test according to the equivalent drop weight, and confirming test piece restraining ways after performing simulation calculation so as to enable the maximum displacement thereof to get as close as possible to the intrusion amount of the post B in the side collision; reasonably selecting materials of the post B so as to enable the post B to be more effectively used for the side collision safety design for the automobile.

Owner:BAOSHAN IRON & STEEL CO LTD

Tempered high-low-temperature toughness pipeline steel and manufacturing method

InactiveCN105821325AEasy to shapeImprove low temperature toughnessProcess efficiency improvementDrop weightPerformance index

The invention belongs to the field of metal material rolling, and relates to tempered high-low-temperature toughness pipeline steel and a manufacturing method. The steel is characterized by comprising chemical components including, by weight, 0.08-0.11% of C, 0.25-0.45% of Si, 1.60-1.80% of Mn, smaller than or equal to 0.006% of P, smaller than or equal to 0.003% of S, 0.015-0.035% of Nb, 0.010-0.030% of Ti, 0.10-0.30% of Mo, 0.015-0.045% of Alt, 0.010-0.030% of Ce and 0.030-0.050% of V, residual components including, by weight, smaller than or equal to 0.50% of Cu, smaller than or equal to 0.50% of Ni, smaller than or equal to 0.50% of Cr and smaller than or equal to 0.0005% of B, and the balance Fe. The chemical components of the steel meet the equation Pcm=C+Si / 30+Ni / 60+(Mn+Cr+Cu) / 20+Mo / 15+V / 10+5, B is smaller than or equal to 0.24%, and the sum of Nb, V and Ti is smaller than or equal to 0.15%. The finally-obtained produced tempered pipeline steel is fine in texture and excellent in low-temperature performance index charpy impact and drop-weight tear test performance.

Owner:SHANDONG IRON & STEEL CO LTD

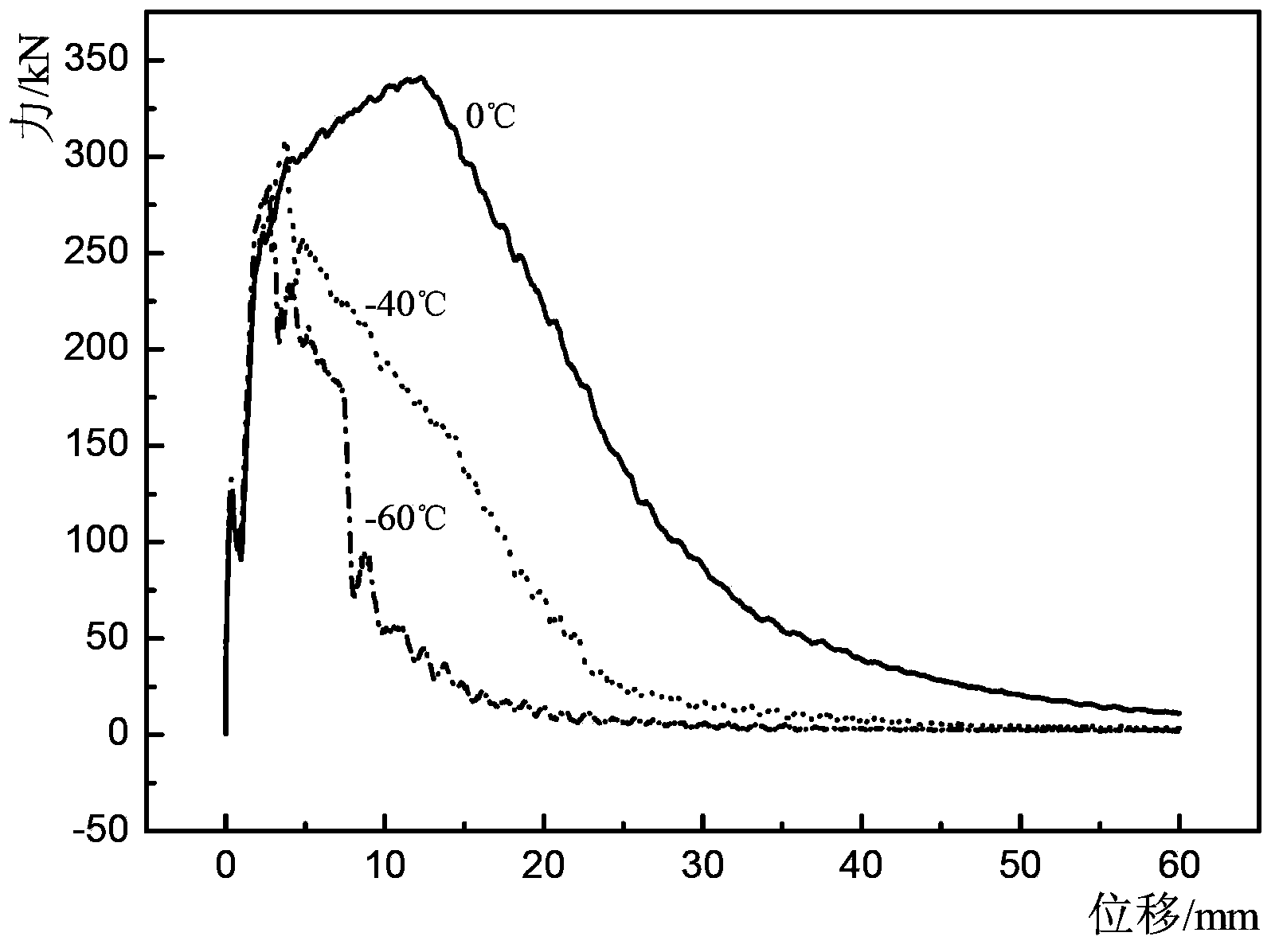

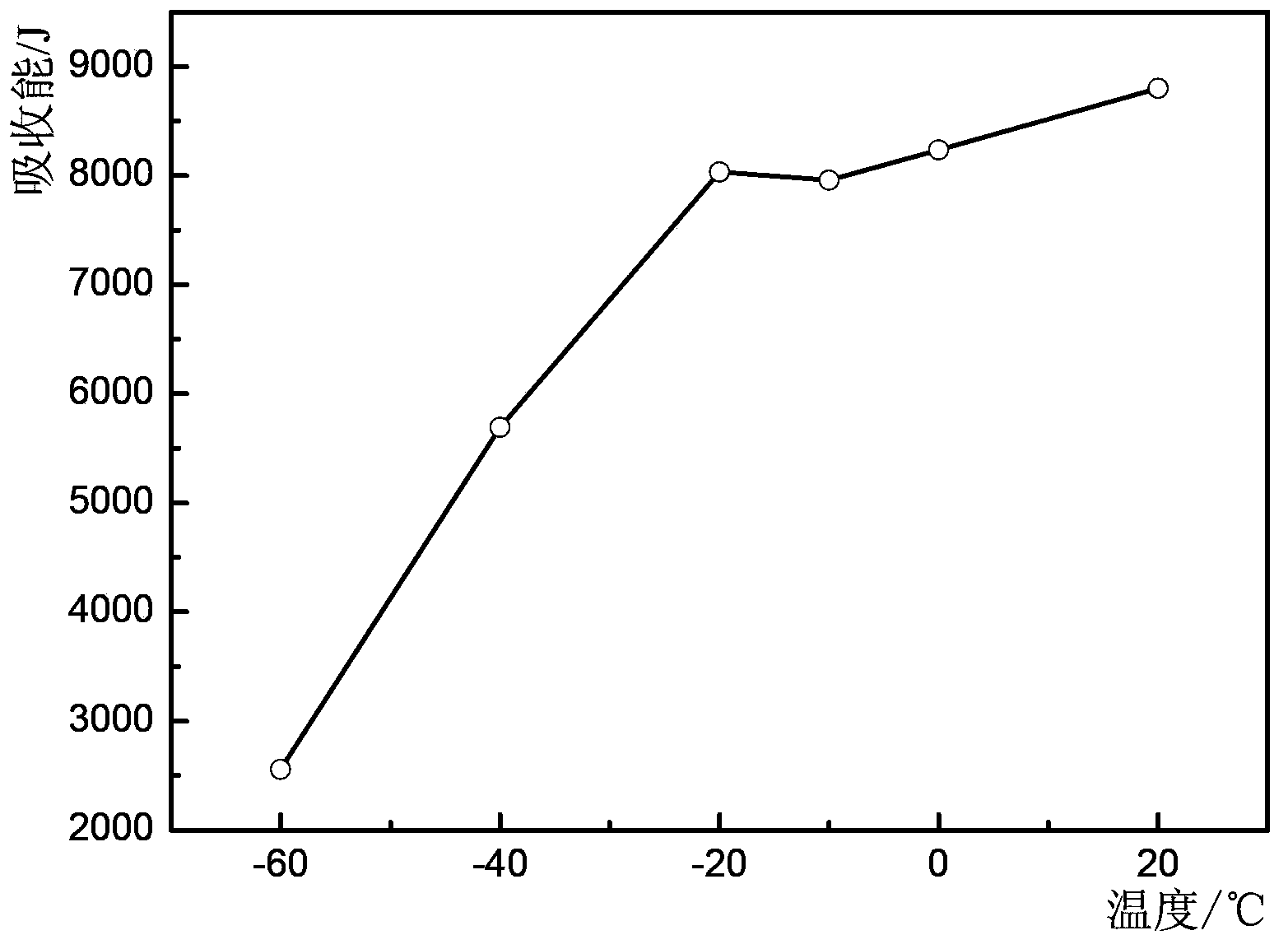

Drop weight tear test system and method thereof

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

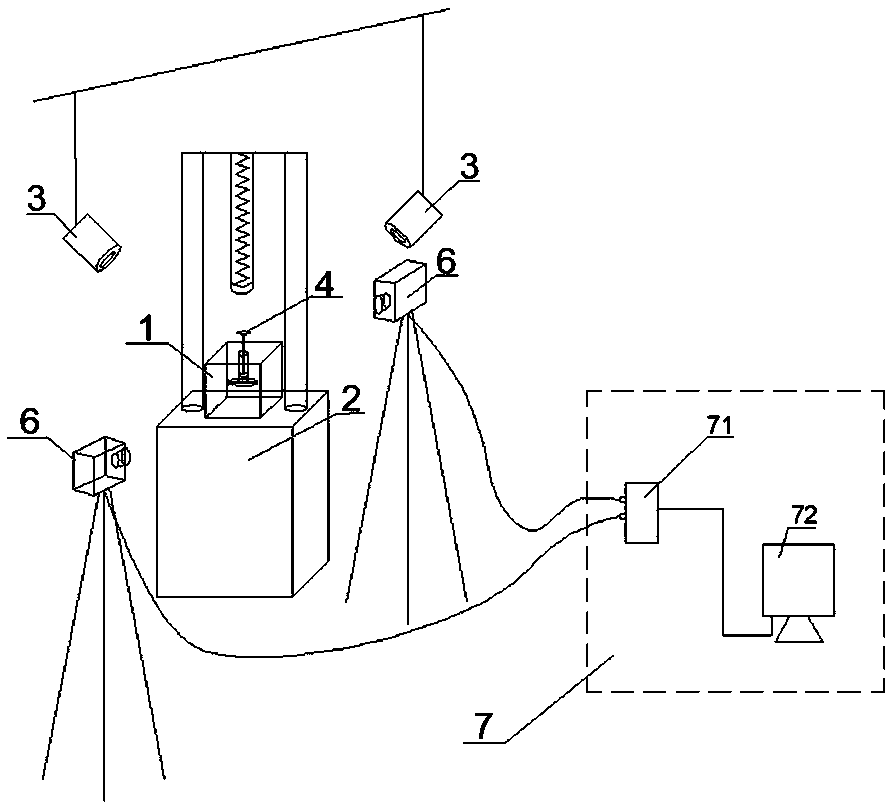

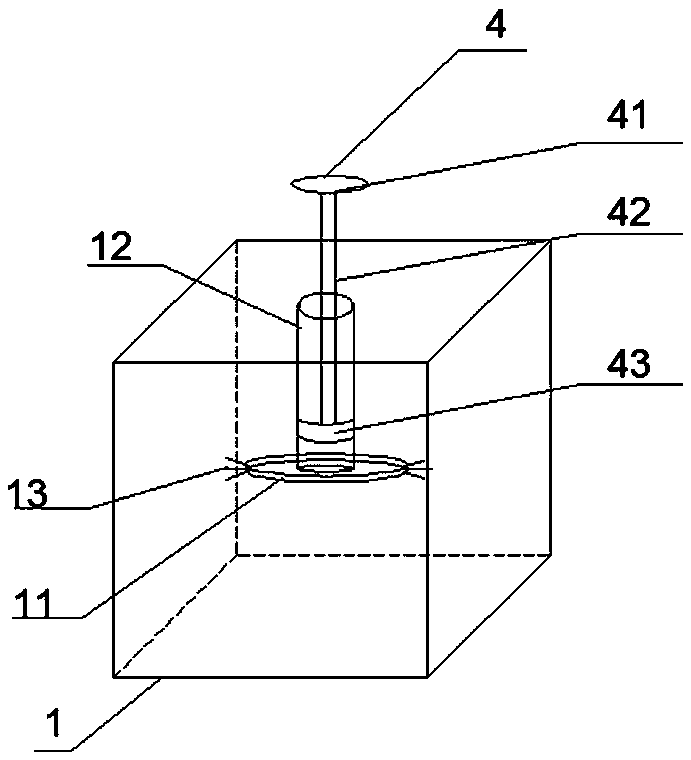

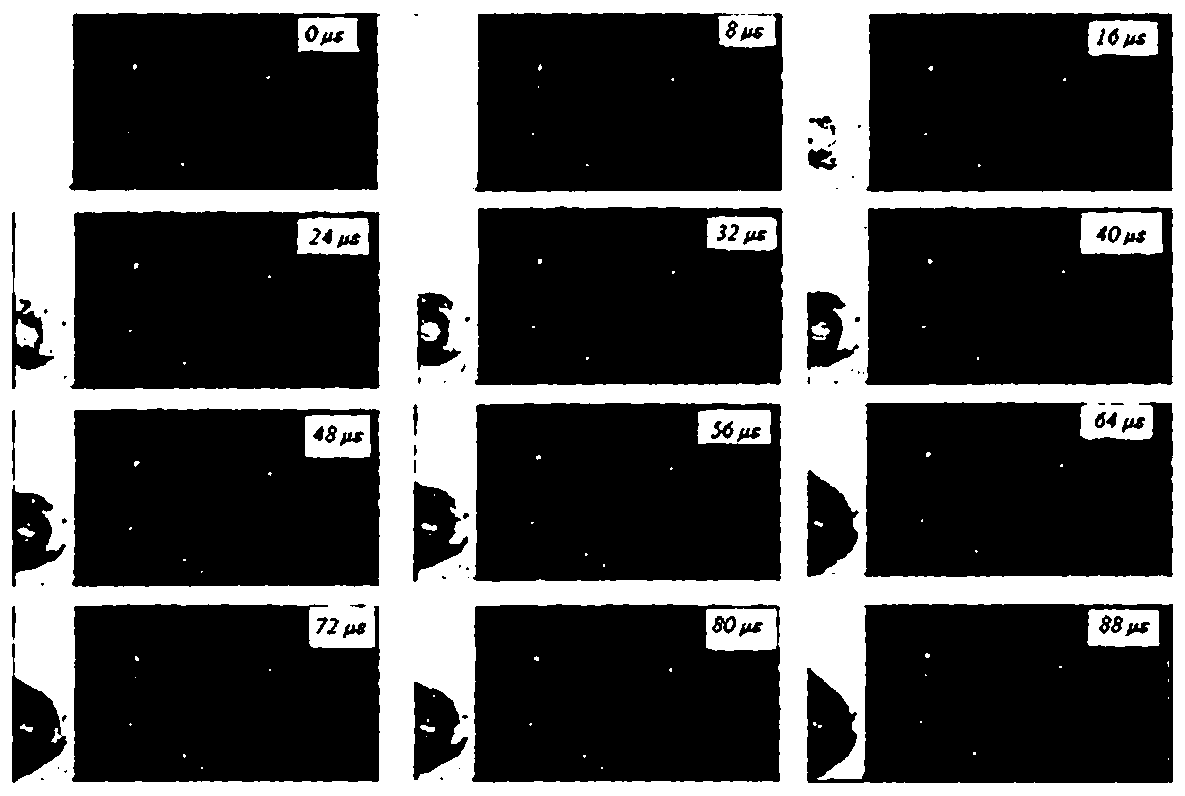

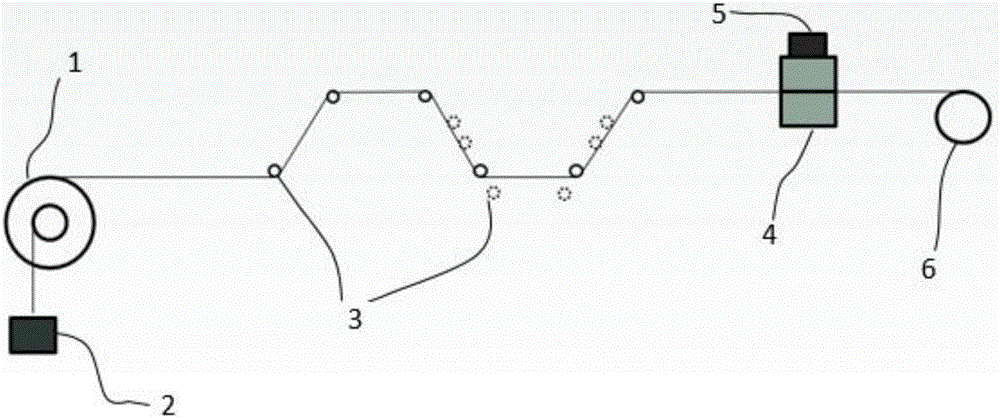

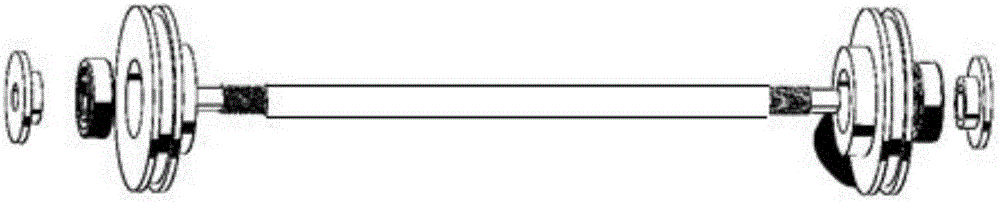

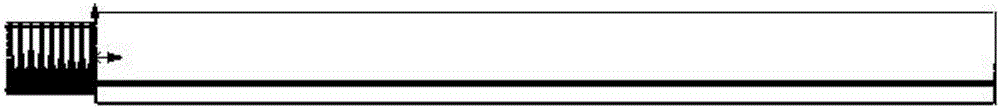

Visualization simulation experiment system and method for rock fracture response under impulsive hydrodynamic pressure

PendingCN109724867ARealize visual simulationValid recordMaterial strength using repeated/pulsating forcesDrop weightImaging processing

The invention relates to the technical field of rock mass physical model tests, in particular to a visualization simulation experiment system and method for rock fracture response under impulsive hydrodynamic pressure. The system includes a rock model, a drop-weight impact testing machine, an image acquisition device and an image processing device. The rock model is a rock model of a transparent cube with fractures filled with tracer particle fluids. The drop-weight impact testing machine can simulate impulse stress applied to rock model by impact load. The image acquisition device comprises acamera mechanism and an illumination mechanism. The camera mechanism can capture the image of the rock model in the whole process, and the illumination mechanism can supplement the light of the camera mechanism. The image processing device includes an image acquisition card and a computer, the image acquisition card is connected with the camera mechanism, and the image collected by the camera mechanism is digitally processed, and the digitally processed image information is transmitted to a computer for storage and analysis, so as to realize the visual simulation of the whole process of the response of the fractured rock mass under the action of dynamic water pressure caused by blasting and other dynamic loads.

Owner:HEFEI UNIV OF TECH

Carbon fiber fuzzing quantity testing device and carbon fiber fuzzing quantity testing method

The invention provides a carbon fiber fuzzing quantity testing device. The carbon fiber fuzzing quantity testing device is characterized by comprising a tow unwinder, a tow spreader, a fuzziness adsorber and a winder which are sequentially connected in a feeding direction, wherein a drop weight is arranged on the tow unwinder, the tow spreader comprises a plurality of spreading bars, and the fuzziness adsorber comprises sponge and a pressurizing weight disposed on the upper surface of the sponge. The carbon fiber fuzzing quantity testing device has the advantages that through the special arrangement of the spreading bars, carbon fibers can be spread according to a fixed angle, carbon fiber fuzziness exposed during carbon fiber spreading can be collected by the fuzziness adsorber, and accordingly the carbon fiber fuzzing quantity testing device is more accurate when carbon fiber fuzzing quantity is computed.

Owner:BEIHANG UNIV

Thermal ink jet ink composition

ActiveUS8632630B2Keep for a long timeReduce rateCosmetic preparationsToilet preparationsDrop weightOrganic solvent

A thermal ink jet ink composition includes one or more volatile organic solvents, wherein the one or more volatile organic solvents are selected from C1-C4 alcohols, C3-C6 ketones, C3-C6 esters, C4-C8 ethers, and mixtures thereof; one or more humectants, wherein the humectants are present in an amount not more than 30% by weight of the ink composition; one or more binder resins; and one or more dyes. The ink composition is suitable for use in a thermal ink jet printer and the ink composition has a slow rate of kogation such that it is capable of being printed at least 10 million drops per nozzle from the thermal ink jet printer before drop weight of the ink composition is reduced by more than 10%.

Owner:VIDEOJET TECH INC

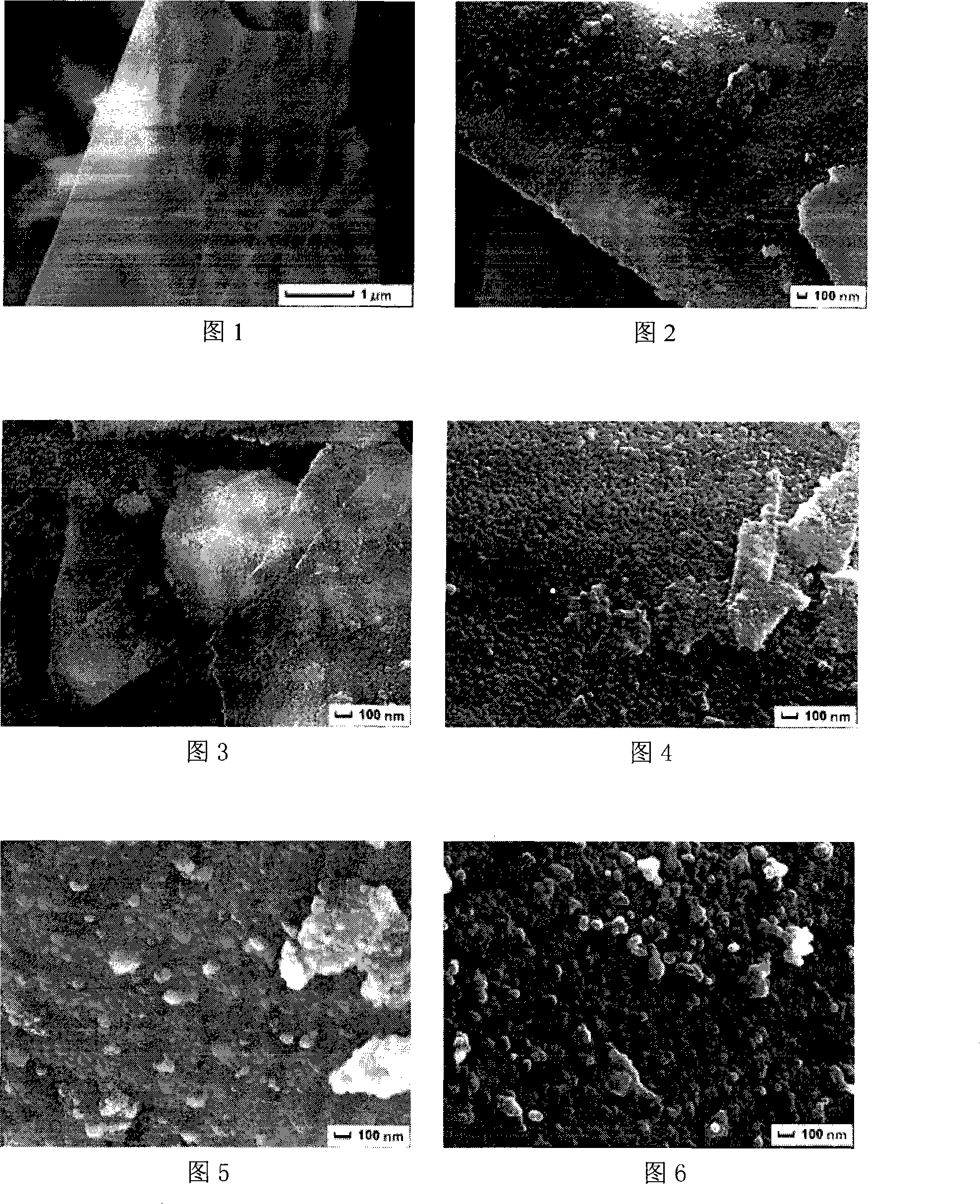

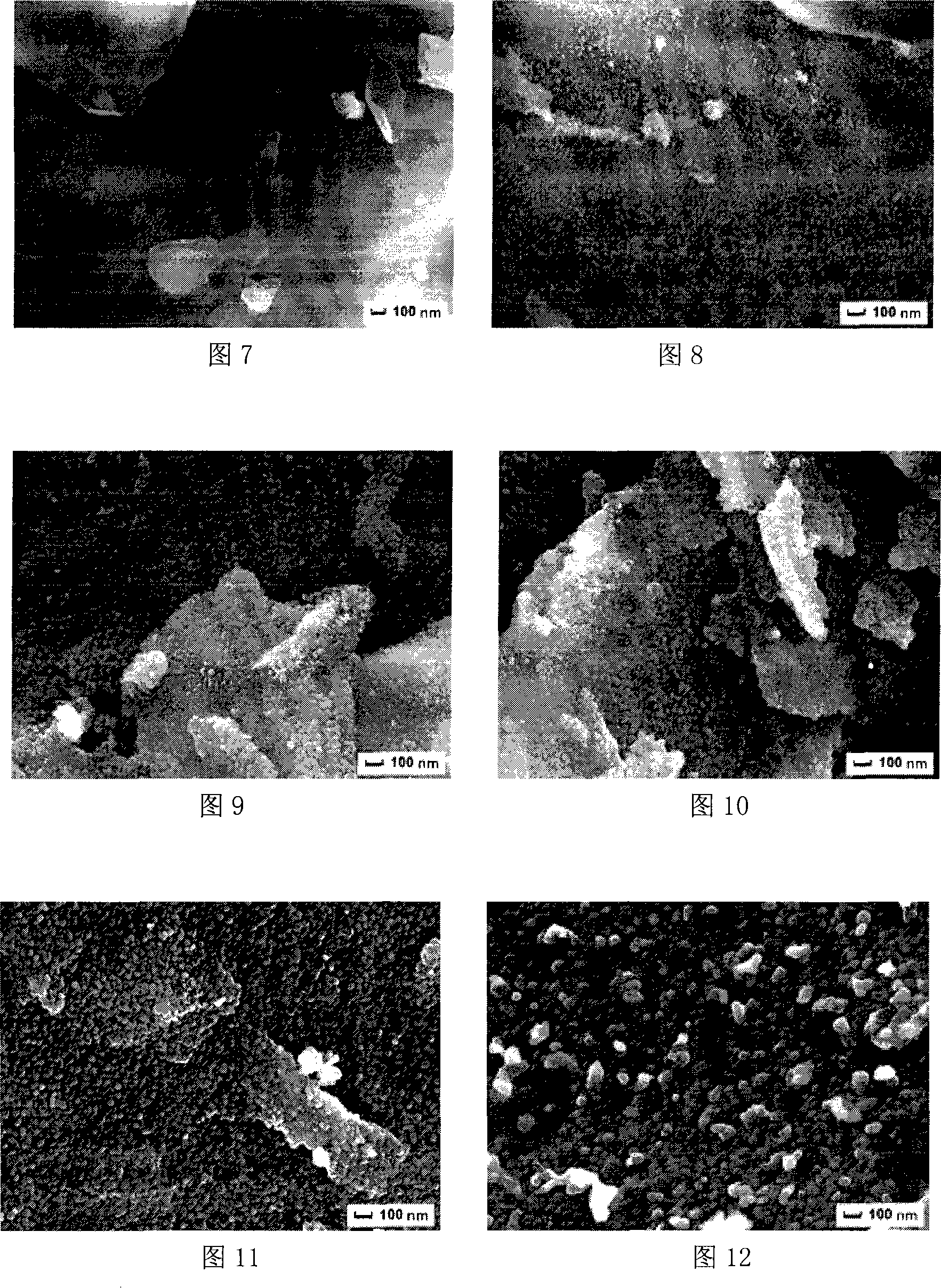

Method for preparing mica titanium material

The invention relates to a method for preparing mica titanium material. The invention comprises the concrete steps that sericite power is evenly scattered in distilled water, and is put in 80-90 DEG C water bath, TiCl4 solution is dropped slowly, the pH value of an adjusting system always maintains 1.8-2.2, the reaction is operated for 2 to 4 hours; the distilled water is used to wash to lead the electric conductivity of filtrate to be lower than 10 ms / s, after drying, the roasting is operated for 0.5-2 hours at 800-1000 DEG C, the product is obtained. The method for preparing the mica titanium material also comprises steps that La (NO3)3 solution is dropped before the TiCl4 solution is added, and the dropping weight is 1 to 5 percent of the weight of the sericite power. The mica titanium nanometer compound material prepared through using the method has the advantages that the cladding is even, the relative scattering strength is high, and the pearly luster effect is obvious; simultaneously, the method has the advantages that the reaction condition is mild, the reaction is easy to be controlled, the cost is low, the process and the process are simple and convenient.

Owner:JIANGSU UNIV

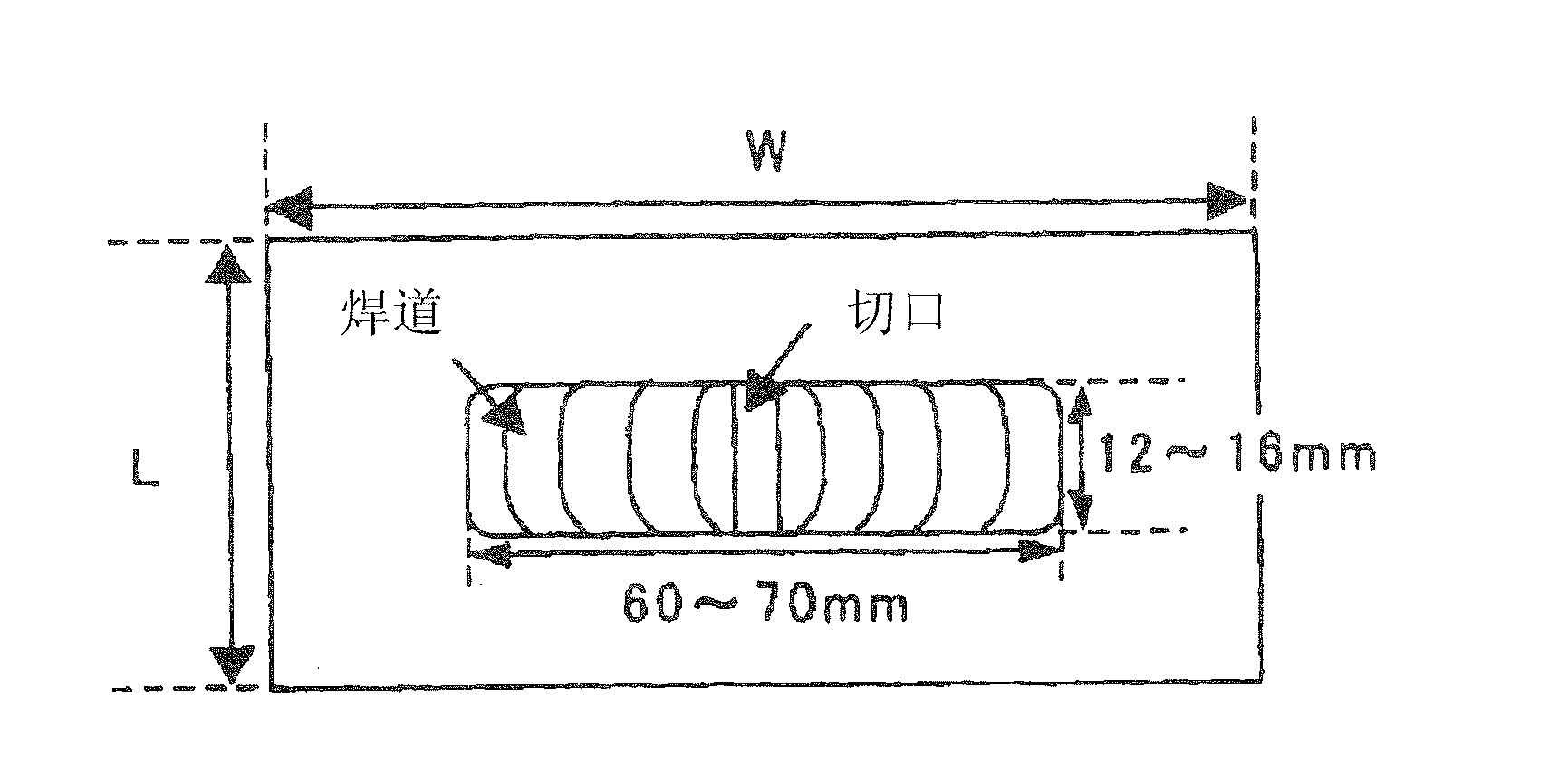

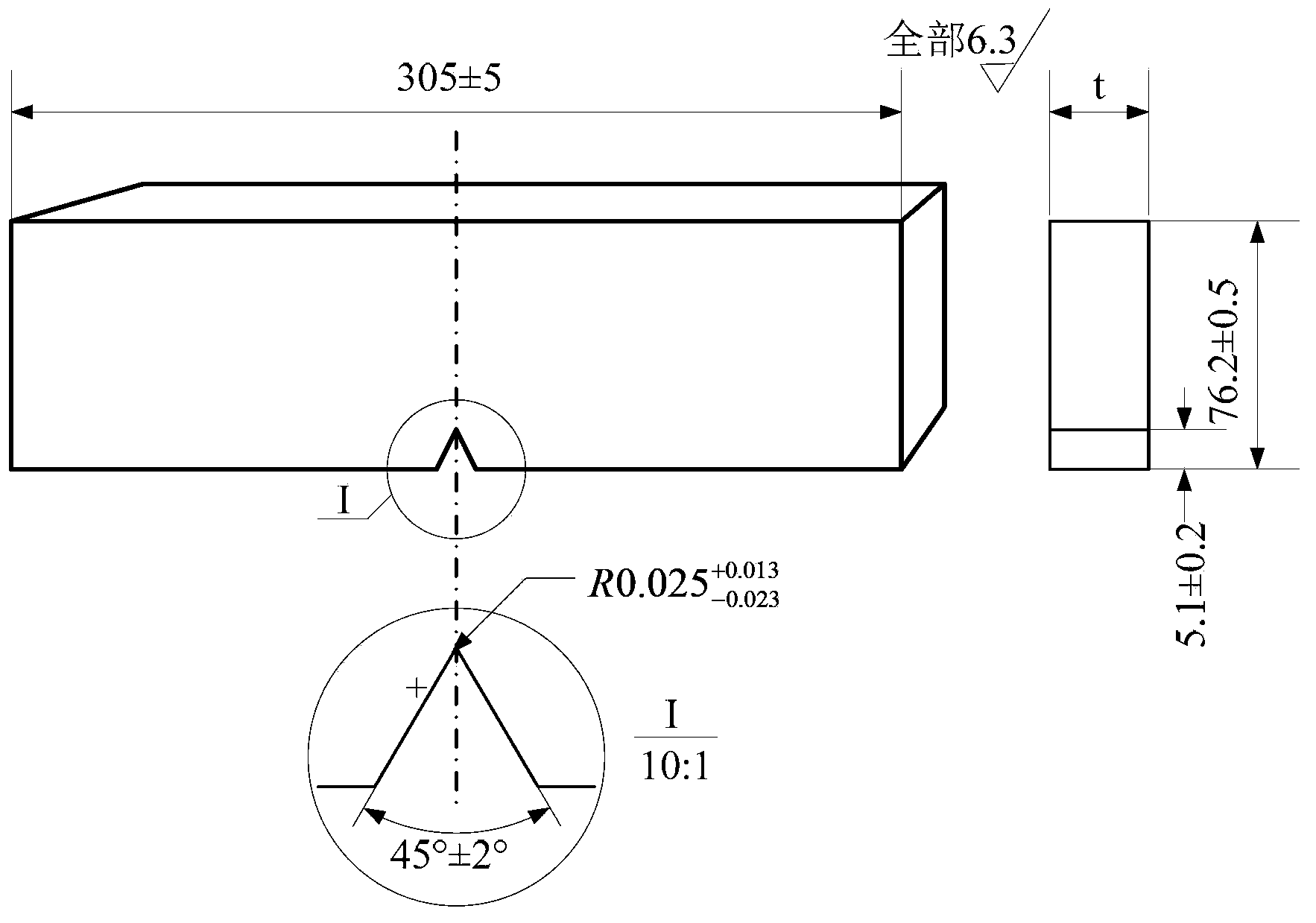

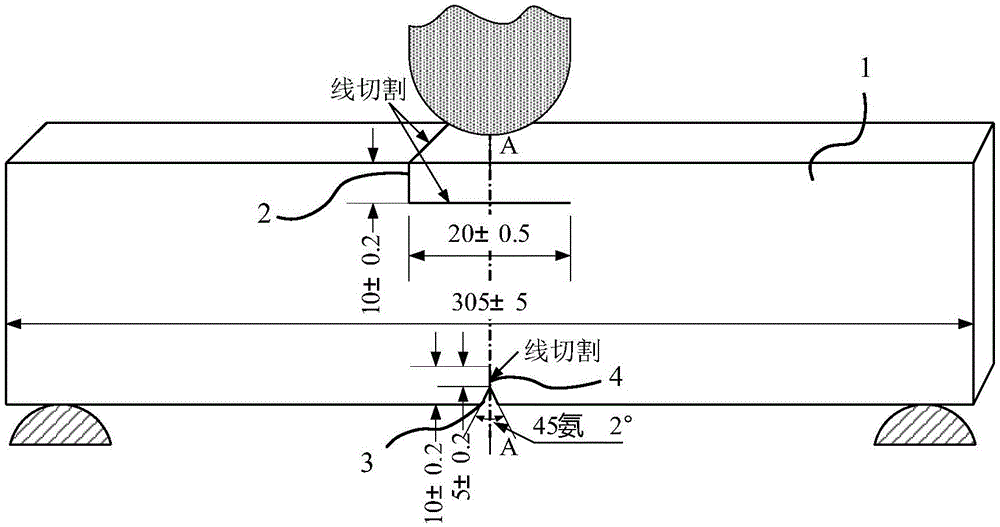

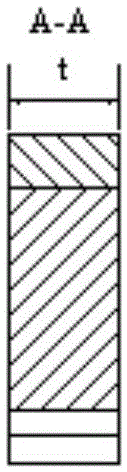

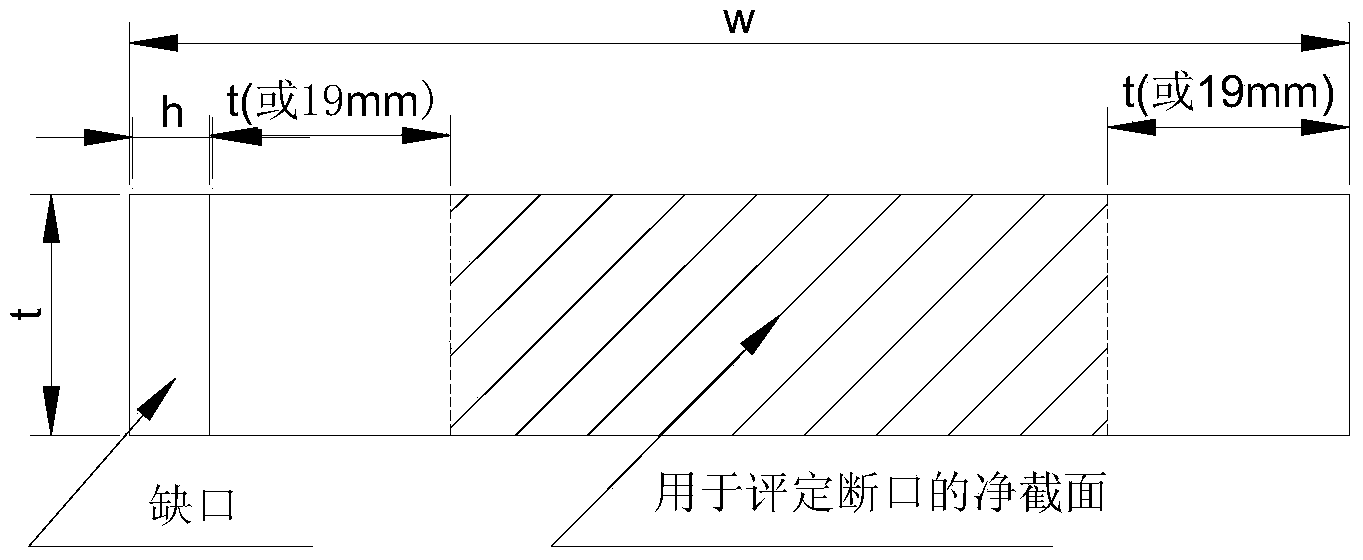

Sample with DWTT (drop weight tear test) abnormal fracture preventing function and method for manufacturing sample

ActiveCN105092335ASmall compression deformationCompression Deformation EliminationPreparing sample for investigationMaterial strength using repeated/pulsating forcesDrop weightElectricity

The invention discloses a sample with a DWTT (drop weight tear test) abnormal fracture preventing function and a method for manufacturing the sample, and belongs to the field of material toughness tests. An L-shaped notch is prefabricated in the middle of a hammering side of a standard sample, and an I-shaped notch is prefabricated in a V-shaped notch root of the standard sample, so that the DWTT sample can be formed. The L-shaped notch and the I-shaped notch are manufactured by the aid of wire-cut electrical discharge machining processes, the depth of the L-shaped notch in the width direction of the sample is 10+ / -0.2mm, and the length of the L-shaped notch along the length of the sample is 20+ / -0.5mm; the depth of the I-shaped notch in the width direction of the sample is 5+ / -0.2mm. The diameters of molybdenum wires for carrying out wire-cut electrical discharge machining on the L-shaped notch and the I-shaped notch need to be smaller than or equal to 0.15mm. The sample and the method have the advantages that crack is easy to start when the DWTT sample is hammered by a heavy hammer, work-hardening of the hammering side can be reduced, DWTT abnormal fracture can be effectively reduced or prevented, test results are similar to actual explosion fracture, and the test cost can be saved.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Ultralow-temperature, large-diameter and WPHY80-level steel plate special for three-way pipe fitting and production method of steel plate

The invention belongs to the technical field of low-alloy and high-strength pipeline steel and particularly relates to an ultralow-temperature, large-diameter and WPHY80-level steel plate special for a three-way pipe fitting and a production method of the steel plate. The steel plate comprises, by weight percentage, 0.04-0.06% of C, 0.50-0.80% of Si, 1.40-1.80% of Mn, not more than 0.008% of P, not more than 0.002% of S, 0.08-0.12% of Nb, 0.04-0.06% of Ti, 0.30-0.40% of Mo, 0.12-0.20% of Cu, 0.30-0.40% of Ni, not more than 0.50% of Cr, 0.050-0.060% of V, not more than 0.0005% of B, and the balance of iron and inevitable impurities. Under the premise that field production efficiency is increased, the produced steel plate is stable in performance, the steel plate has excellent low-temperature drop weight tear test performance: -25 DEG C SA%>=90% and excellent Charpy impact performance: -60 DEG C Charpy impact energy>=260J, -80 DEG C Charpy impact energy>=210J.

Owner:SHANDONG IRON & STEEL CO LTD

Drop-weight tear test sample fracture shearing area detection method

InactiveCN103486985AGuaranteed accuracyAvoid irregular shear lips, hard to identify issues with hammered side boundariesUsing optical meansDrop weightSample image

The invention provides a drop-weight tear test sample fracture shearing area detection method. After a DWTT sample is shorn, a DWTT sample fracture is shot and imaged through a camera, the area of net sections and the area of brittle fracture regions are calculated through image analysis software, and therefore fracture shearing area percentage is worked out. The method is simple and easy to carry out, none equipment needs purchasing, funding is not needed, the brittle fraction regions, especially small brittle fraction regions facilitating brittle fraction region boundary recognition can be freely amplified in the image analysis software, and therefore accuracy of the area of the brittle fraction regions is guaranteed. Due to the adoption of the method that the thickness of the root portion of a sample image notch is measured in the interface of the image analysis software to determine the amplification factor, accuracy of the area of the net sections can be guaranteed, irregular shear lips are prevented from appearing on the hammered side of the sample after sample shearing, calculation accuracy of the area of the net sections is guaranteed, and accordingly scientific and reliable detection data bases are provided for pipeline steel pipe control and fraction prediction.

Owner:ANGANG STEEL CO LTD

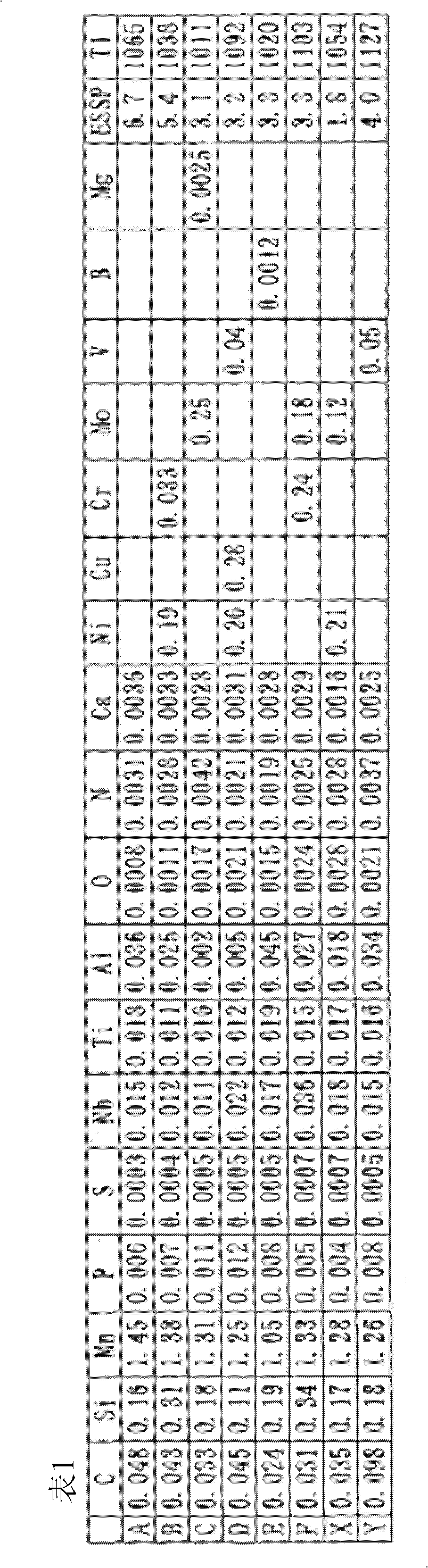

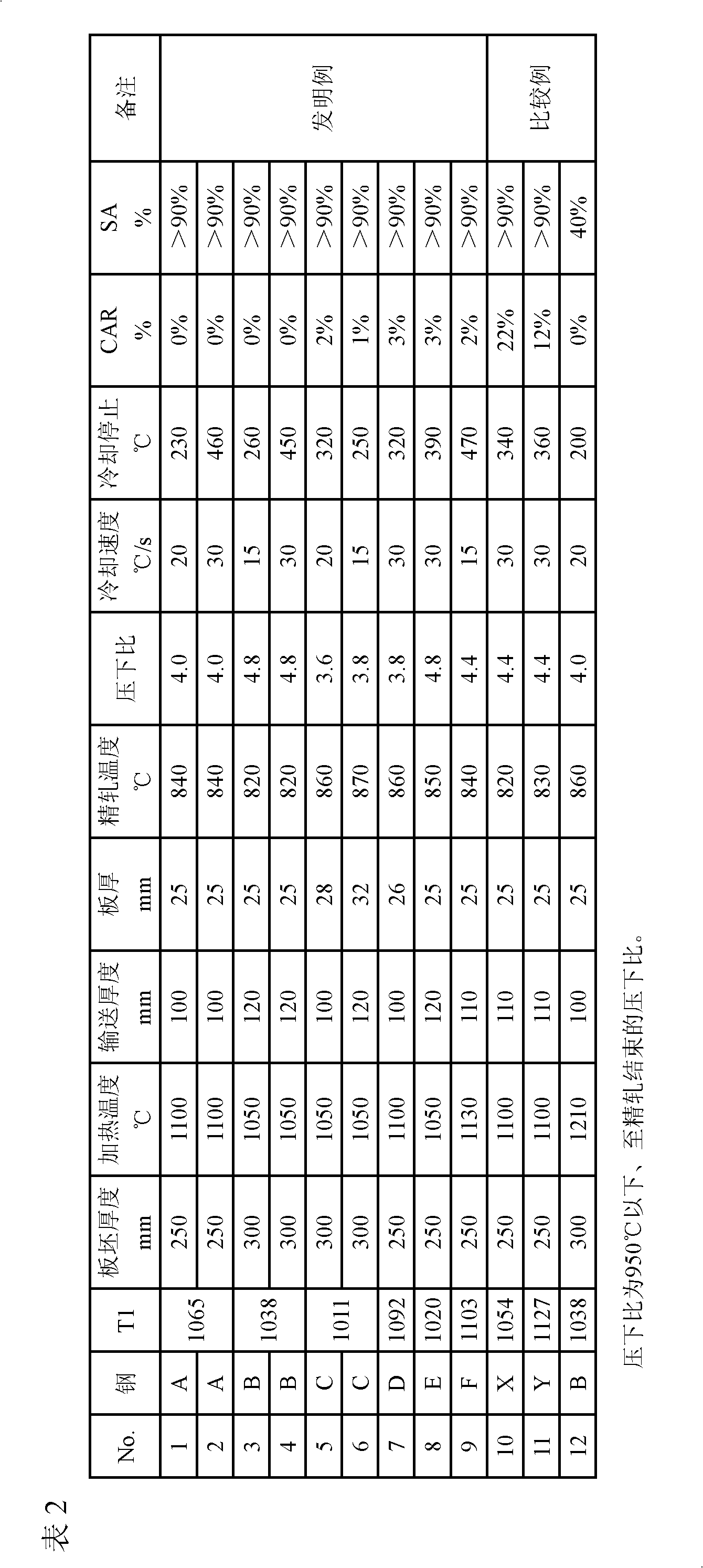

Method of manufacturing sheet steel for thick-walled sour-resistant line pipe of excellent toughness

InactiveCN102325908AImprove toughnessImprove featuresFurnace typesMetal rolling arrangementsDrop weightSheet steel

Sheet steel for line pipe with a wall thickness of not less than 25 mm, and with excellent toughness and sour resistance is manufactured using steel billets that contain C, Si, Mn, Nb, and Ti, while Al, P, and N content is limited. The billets further contain Ca: 0.001-0.004%, there are limitations such that S: not more than 0.0008% and O: not more than 0.0030%, and the Ca, O, and S content meets the condition [Ca](1 - 124[O]) / 1.25[S] > 3.0. The billets are heated to a heating temperature (T1) in the range of 1000-1150 DEG C that meets the condition T1 >= -7970 / (log([Nb] [C]) - 3.31) - 170, and are then rough milled, finish rolled, and subjected to accelerated cooling. The finish rolling therein is performed at a finishing temperature of not less than 800 DEG C and at a 950 DEG C or less reduction ratio of not less than 3 so that the plate thickness is not less than 25 mm, the cooling rate of the accelerated cooling is 10-30 DEG C / s and the stop temperature is 200-500 DEG C. Thus, it is possible to have both sour-resistance properties and drop weight tear properties.

Owner:NIPPON STEEL CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com