Visualization simulation experiment system and method for rock fracture response under impulsive hydrodynamic pressure

A technology of rock fissures and simulation experiments, which is applied in the direction of applying repetitive force/pulsation force to test the strength of materials, measuring devices, instruments, etc., to achieve the effect of effective recording and analysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

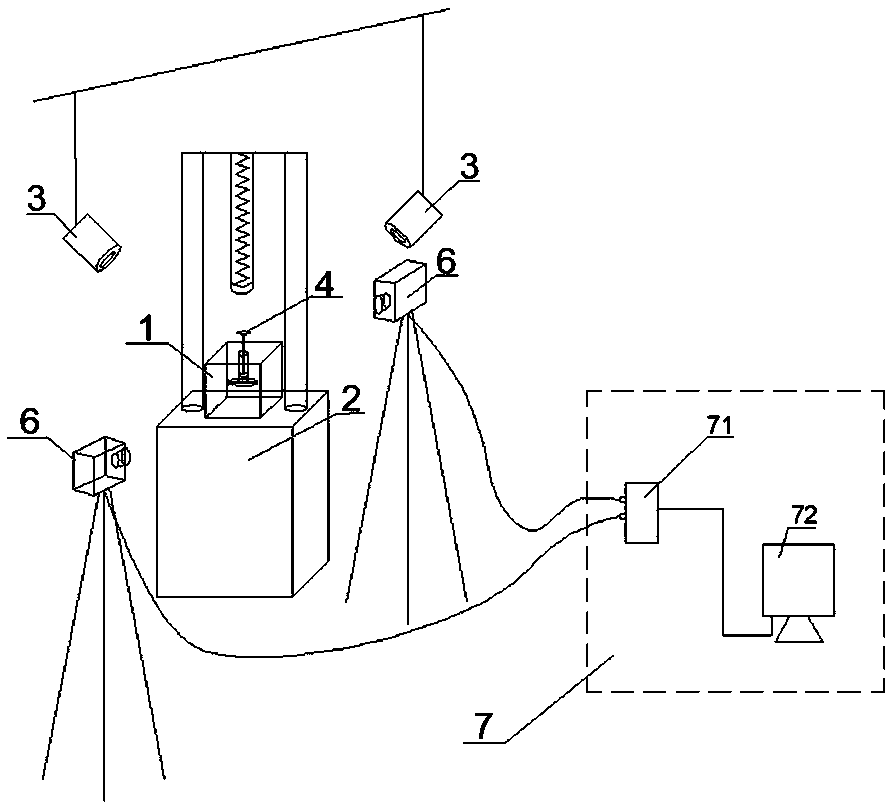

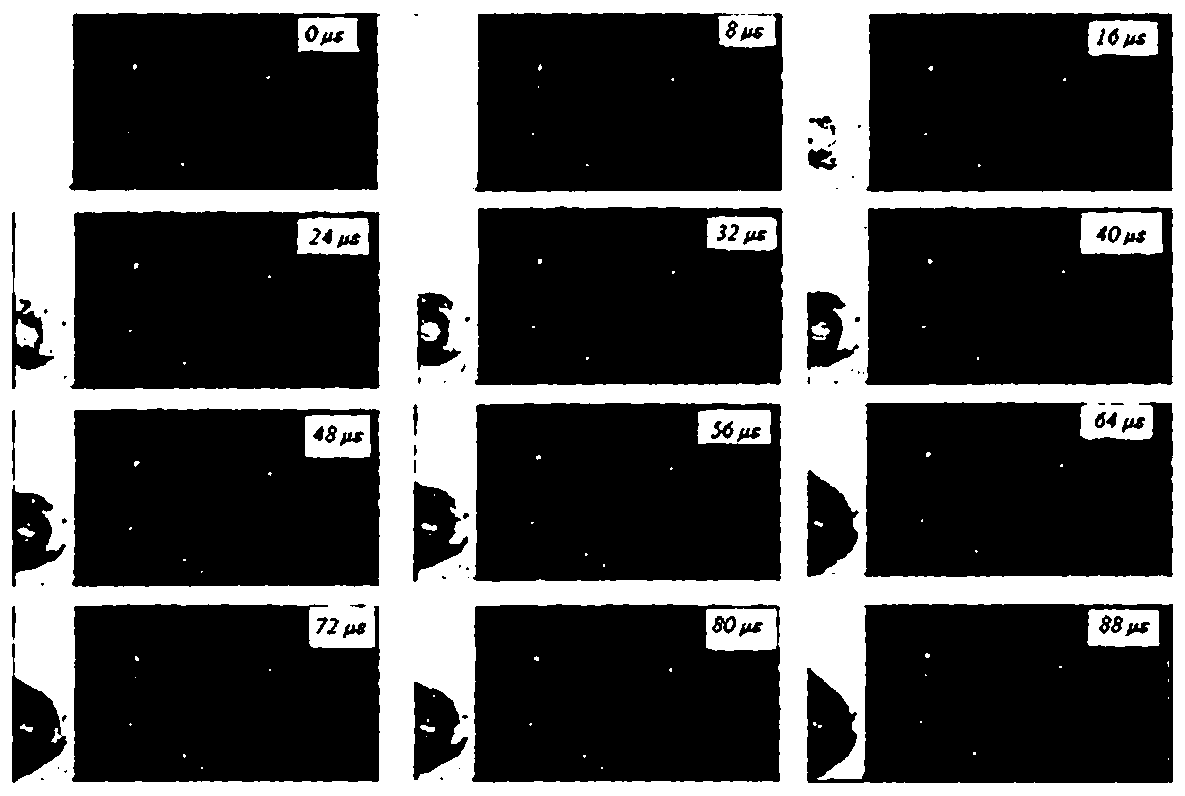

[0036] The rock fracture response visualization simulation experiment system under pulsating water pressure includes a rock model 1, a drop weight impact testing machine 2, a visualization system and an image processing device 7.

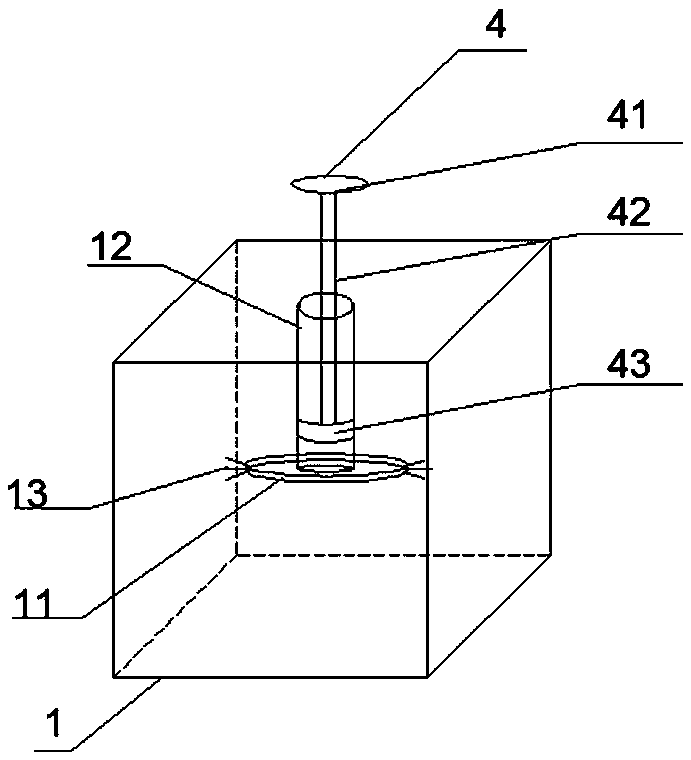

[0037] The rock model 1 is a transparent cubic rock model 1 formed by 3D printing of a transparent photosensitive resin material, with a side length of 40 cm. A cylindrical cavity 12 with an open upper end is provided in the middle of the rock model 1. The cylindrical cavity 12 The height is 20cm, and the diameter is 5cm; the central axis of the cylinder cavity 12 is coaxial with the vertical central axis of the cube; The cavity 11 is a flat cavity structure, and the two ends of the major axis of the elliptical fissure cavity 11 are all provided with a plurality of microcracks 13 inside the rock model 1; The cavities of the cavity 11 are connected.

[0038]A piston mechanism 4 is provided above the liquid level corresponding to the tracer particle ...

Embodiment 2

[0044] Embodiment 1 The experimental method of the rock fracture response visual simulation experiment system under pulsating water pressure, comprising the following steps:

[0045] (1) Put the rock model 1 in the middle of the platform of the drop hammer impact testing machine 2 and fix it.

[0046] (2) Inject the tracer particle fluid into the upper opening of the cylinder cavity 12 of the rock model 1. The tracer particle fluid fills the elliptical fracture cavity 11 and the cracks of a plurality of microcracks 13, and makes the tracer particle fluid reach the cylinder The cavity height of the body cavity 12 is 5 cm; the tracer particle fluid is a water body containing tracer particles, and has good flow field followability.

[0047] (3) Put the piston mechanism 4 into the cylinder cavity 12 of the rock model 1, press the lower end of the piston 43 into the liquid surface of the tracer particle fluid, and the upper end of the piston rod 42 protrudes from the upper end of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com