A Simulation Method of Pipeline Fluid Flow Oriented to Virtual Chemical Experiment Teaching

A fluid flow, simulation method technology, applied in the field of computer simulation, to achieve the effect of visual simulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

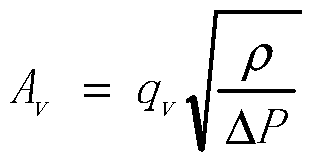

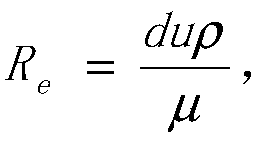

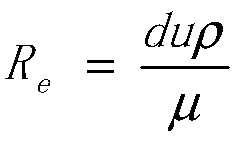

[0025] Take water passing through a DN15 single-piece ball valve in a DN15 (nominal diameter) stainless steel pipeline at 25°C as an example. The density of water at 25°C is 997kg / m 3 , the kinematic viscosity is 9.055*10 -7 m 2 / s, set the flow rate to 1*10 -3 m 3 / s, pipeline length L 1 , L 2 0.5m, valve flow coefficient A v 1.13*10 -6 , when developing the system, set the initial point a 1 pressure P 1a 0.1MPa, P 1b ,P 2a ,P 2b Both are 0MPa, add the script and particle system and release the system. Click the mouse to control the opening of the ball valve during operation. After opening, at this time b 1 Point pressure value P 1b (0MPa) less than a 1 pressure P 1a (0.1MPa), call the particle system, the fluid from a 1 point flow to b 1 Point, take the valve opening as 1 / 10, and the relational equation between flow rate and ball valve opening: Q / Q max =0.94x 3 -0.17x 2 +0.22x-0.01 calculates the flow velocity u=6.4*10 after passing through the valve -2...

Embodiment 2

[0027] Other conditions are the same as in Example 1. When the valve opening becomes 1 / 2, P is obtained through the same calculation. 2a Point speed u=0.99m / s, Re=1.64*10 4 , the flow pattern at this time is turbulent flow, and the system calls the code when Re≥4000 to realize the visual simulation of the turbulent flow of the pipeline fluid at this time, and the effect is as follows image 3 shown.

Embodiment 3

[0029] When the fluid changes into other substances, the realization method of the fluid flowing between the pipeline and the valve is as above, and the simulation of the flow pattern only needs to change the physical parameters of the corresponding fluid and realize it with the same calculation method.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com