Visualization device for scaling and corrosion of tower top system of crude oil distillation device

A technology of crude oil distillation and distillation tower, applied in the direction of measuring devices, weather resistance/light resistance/corrosion resistance, instruments, etc., can solve the problems of scrapping, heavy workload, equipment scaling and corrosion, etc., and achieve simple structure of the device, convenient operation, The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

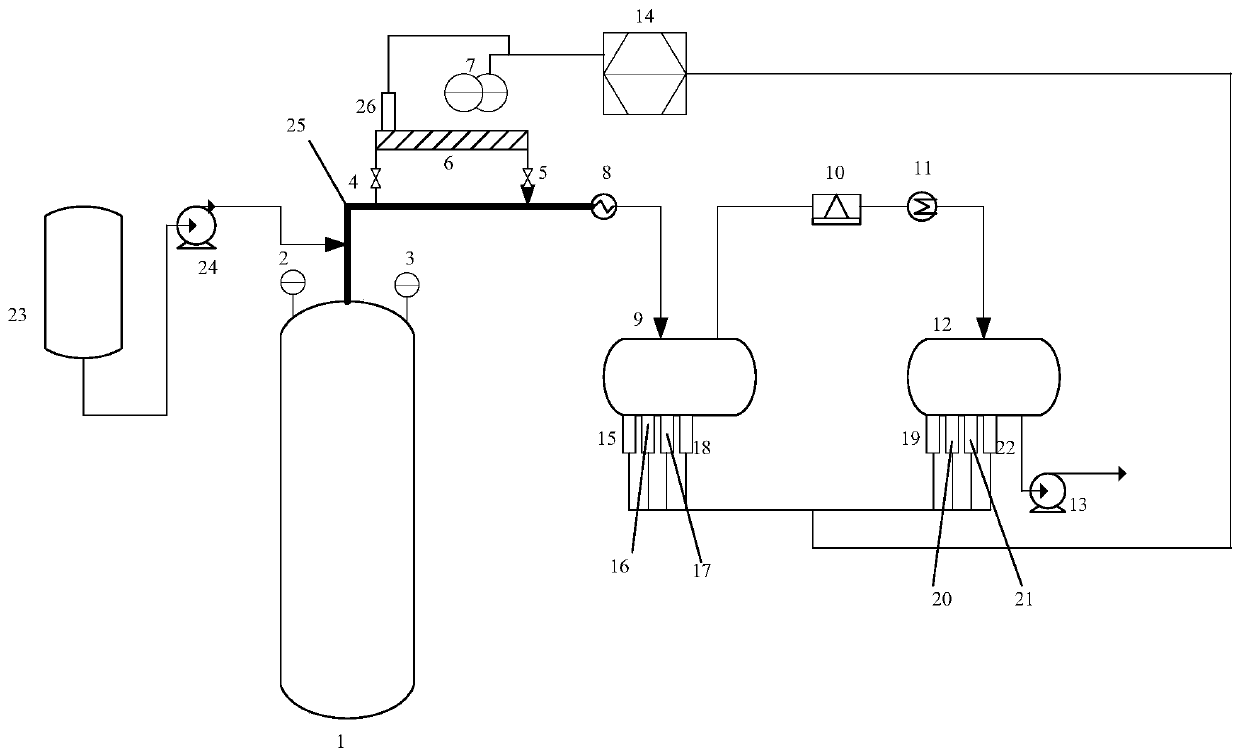

[0020] A visualization device for fouling and corrosion of the tower top system of a crude oil distillation unit, the visualization device includes a temperature sensor C26, a high-magnification camera 7 and a computer 14, the visualization device is arranged on the bypass analog oil and gas pipeline 6 of the tower top system, The overhead system includes a distillation tower 1, a crude oil-oil-gas heat exchanger 8, a primary tank 9, an air cooler 10, a water cooler 11, a secondary tank 12, and a product pump 13 connected in sequence, located between the distillation tower 1 and the The pipeline between the crude oil-oil-gas heat exchanger 8 is the oil-gas volatilization pipeline 25, and the bypass simulated oil-gas pipeline 6 is a branch pipeline drawn from the oil-gas volatilization pipeline 25. Oil and gas volatilization pipeline 25. A pressure gauge 2 and a temperature gauge 3 are also provided on the distillation column 1 .

[0021] The bypass simulation oil and gas pipe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com