Tunnel support system centrifuge test device and its working method and manufacturing method

A test device and centrifuge technology, which is applied in the direction of measuring device, using stable tension/pressure testing material strength, instruments, etc., can solve the problems of invisible observation of surrounding rock and lining stress field and displacement field, and reach the scope of application wide effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

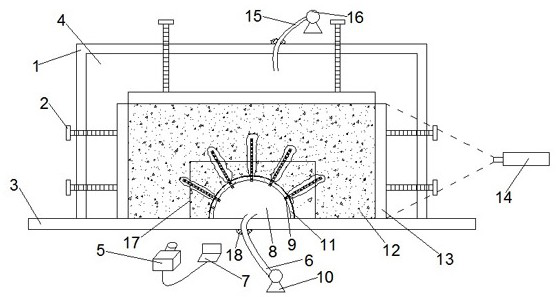

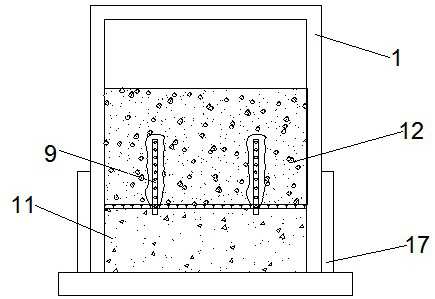

[0052] Such as figure 1 , figure 2 As shown, a centrifuge test device for a tunnel support system includes a base plate 3 and a model test cover 1 fixed on the base plate; symmetrical through holes are arranged on the side walls of the model test cover 1; the base plate 3 is fixed with Transparent rock-12; the inner water chamber 8 between the transparent rock-12 and the bottom plate 3; the inner water chamber 8 and the transparent rock-12 are supported by the lining 11; the two ends of the lining 11 are embedded in symmetrical through holes; the lining 11 The two ends are sealed by the sealing glass plate 17 that is close to the model test cover 1; the outer water chamber 4 is formed between the top of the transparent rock-12 and the top of the model test cover 1; the anchor rod 9 is installed on the lining 11; the anchor rod 9 is buried in transparent rock-12. Fluorescent agent is mixed in the outer water chamber 4 or the inner water chamber 8 .

[0053] The model test c...

Embodiment 2

[0075] Example 1 is a centrifugal test on the long-term combined load bearing effect of the basic support system of the tunnel under the condition that the internal water pressure is greater than the external water pressure. The simulated engineering background is the basic support structure in the Gaoling water tunnel. Long-term working performance; for conventional tunnels where the external water pressure is greater than the internal water pressure, the implementation of step (3) of the working method can be changed on the basis of Example 1. The inner water chamber 8 and the outer water chamber 4 are respectively filled with 66.7% calcium bromide solution, wherein the outer water chamber 4 is mixed with a fluorescent agent; the outer water pressure machine 16 is started to apply a water pressure value of 40.5MPa to the outer water chamber to keep the inner water chamber The water pressure value is 0 MPa constant; when fluorescent particles appear in the inner water chamber ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com