Method of manufacturing sheet steel for thick-walled sour-resistant line pipe of excellent toughness

A manufacturing method and excellent technology, applied in the direction of manufacturing tools, metal rolling, furnace types, etc., can solve problems such as acid resistance deterioration, and achieve the effect of excellent acid resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

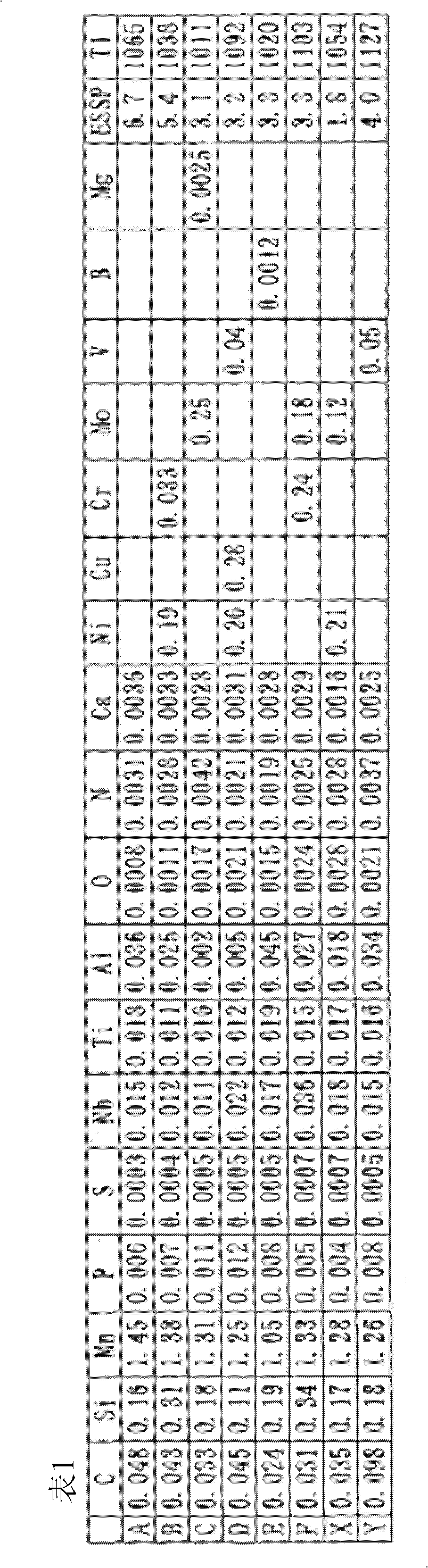

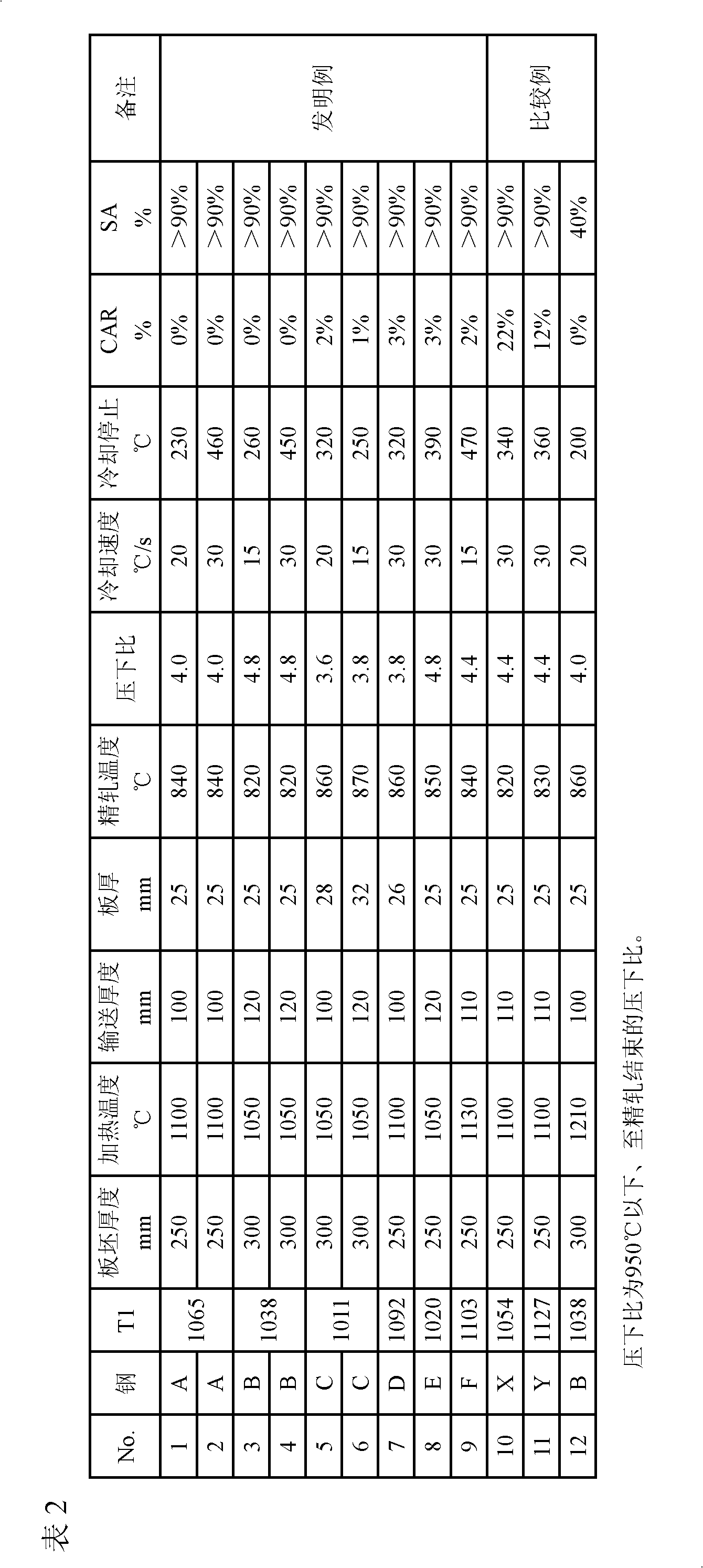

[0122] Steel having the chemical composition shown in Table 1 was smelted by secondary refining in a converter, and a 250 mm thick billet was produced by continuous casting. The obtained slabs were hot-rolled under the conditions shown in Table 2 to form steel sheets. The HIC properties of the manufactured steel sheets were evaluated by the NACE test.

[0123] As the conditions of the NACE test, hydrogen sulfide gas is saturated in a solution of 5% NaCl solution + 0.5% acetic acid, pH 2.7, and the immersion time is specified as 96 hours, the presence or absence of cracks is observed, and the HIC fracture rate (CAR) is measured.

[0124] Toughness was evaluated by DWTT test. From the steel plate, according to API, 5L3, ASTM, E436, the plate width direction is taken as the longitudinal direction, and the pressed notch test piece provided with the notch parallel to the plate thickness direction is produced. DWTT was performed at -35°C, and the ductile fracture ratio (SA) was ob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com