Tempered high-low-temperature toughness pipeline steel and manufacturing method

A low-temperature toughness and manufacturing method technology, applied in the direction of improving process efficiency, etc., can solve the problems that do not involve a series of key process low-temperature key toughness performance indicators, and it is difficult to guarantee the low-temperature toughness performance of steel plates, so as to achieve improved shape, high pass rate, Effect of improving low temperature toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

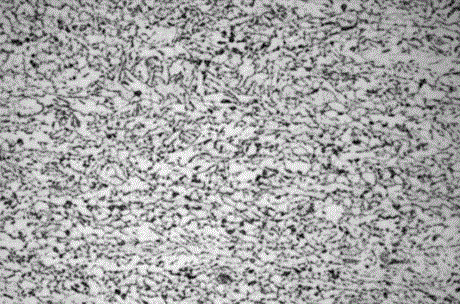

Embodiment 1

[0041] A quenched and tempered pipeline steel plate in this embodiment is prepared from the following components in mass percentage: C: 0.08%, Si: 0.25%, Mn: 1.60%, P=0.004%, S=0.001%, Nb: 0.015%, Ti: 0.010%, Mo: 0.10%, Alt: 0.015%, Ce: 0.010%, V: 0.030%. Residual elements: Cu=0.001%, Ni=0.050%, C=0.001%, B=0.0001%, and the rest contains Fe. The chemical composition of the steel satisfies: Pcm=C+Si / 30+Ni / 60+(Mn+Cr+Cu) / 20+Mo / 15+V / 10+5B=0.18%, Nb+V+Ti=0.055%.

[0042] A quenched and tempered pipeline steel plate in this embodiment and its manufacturing method are as follows:

[0043] 1) Smelting and continuous casting process: In the above-mentioned KR process, P=0.080% of the molten iron into the furnace, S=0.001% after desulfurization treatment of the molten iron; 120t converter smelting oxygen lance position time 1min, steel tapping time 4.5min, converter The end point temperature is controlled at 1640°C; VD / RH is added to the fine-tuning alloy according to the target compo...

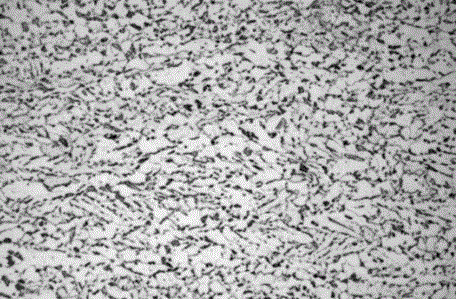

Embodiment 2

[0053]A quenched and tempered pipeline steel plate in this embodiment is prepared from the following components by mass percentage: C: 0.11%, Si: 0.45%, Mn: 1.80%, P=0.006%, S=0.003%, Nb: 0.035%, Ti: 0.030%, Mo: 0.30%, Alt: 0.045%, Ce: 0.030%, V: 0.050%. Residual elements: Cu=0.001%, Ni=0.010%, Cr=0.001%, B=.0002%, and the rest contains Fe. The chemical composition of the steel satisfies: Pcm=C+Si / 30+Ni / 60+(Mn+Cr+Cu) / 20+Mo / 15+V / 10+5B=0.24%, Nb+V+Ti=0.115%.

[0054] A quenched and tempered pipeline steel plate in this embodiment and its manufacturing method are as follows:

[0055] 1) Smelting and continuous casting process: In the above-mentioned KR process, P=0.120% of molten iron in furnace, S=0.003% after desulfurization treatment of molten iron; 120t converter smelting time of oxygen lance position is 2min, tapping time is 6min, the end of converter The temperature is controlled at 1650°C, VD / RH is added to the fine-tuning alloy according to the target composition, VD / RH...

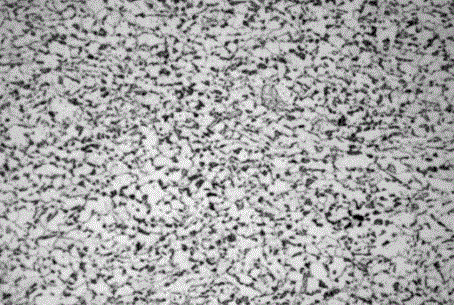

Embodiment 3

[0065] A quenched and tempered pipeline steel plate in this embodiment is prepared from the following components by mass percentage: C: 0.090%, Si: 0.35%, Mn: 1.70%, P=0.004%, S=0.0015%, Nb: 0.022%, Ti: 0.021%, Mo: 0.14%, Alt: 0.035%, Ce: 0.018%, V: 0.032%. Residual elements: Cu=0.001%, Ni=0.030%, C=0.002%, B=.0001%, the rest contains Fe. The chemical composition of the steel satisfies: Pcm=C+Si / 30+Ni / 60+(Mn+Cr+Cu) / 20+Mo / 15+V / 10+5B=0.20%, Nb+V+Ti=0.075%.

[0066] A quenched and tempered pipeline steel plate in this embodiment and its manufacturing method are as follows:

[0067] 1) Smelting and continuous casting process: In the above-mentioned KR process, P=0.090% of the molten iron into the furnace, S=0.002% after desulfurization treatment of the molten iron; the oxygen lance position time is 1.5min during 120t converter smelting, and the tapping time is 5min. The end point temperature is controlled at 1645°C, VD / RH is added to the fine-tuning alloy according to the target...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com