Patents

Literature

902results about How to "Refine the grain size" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

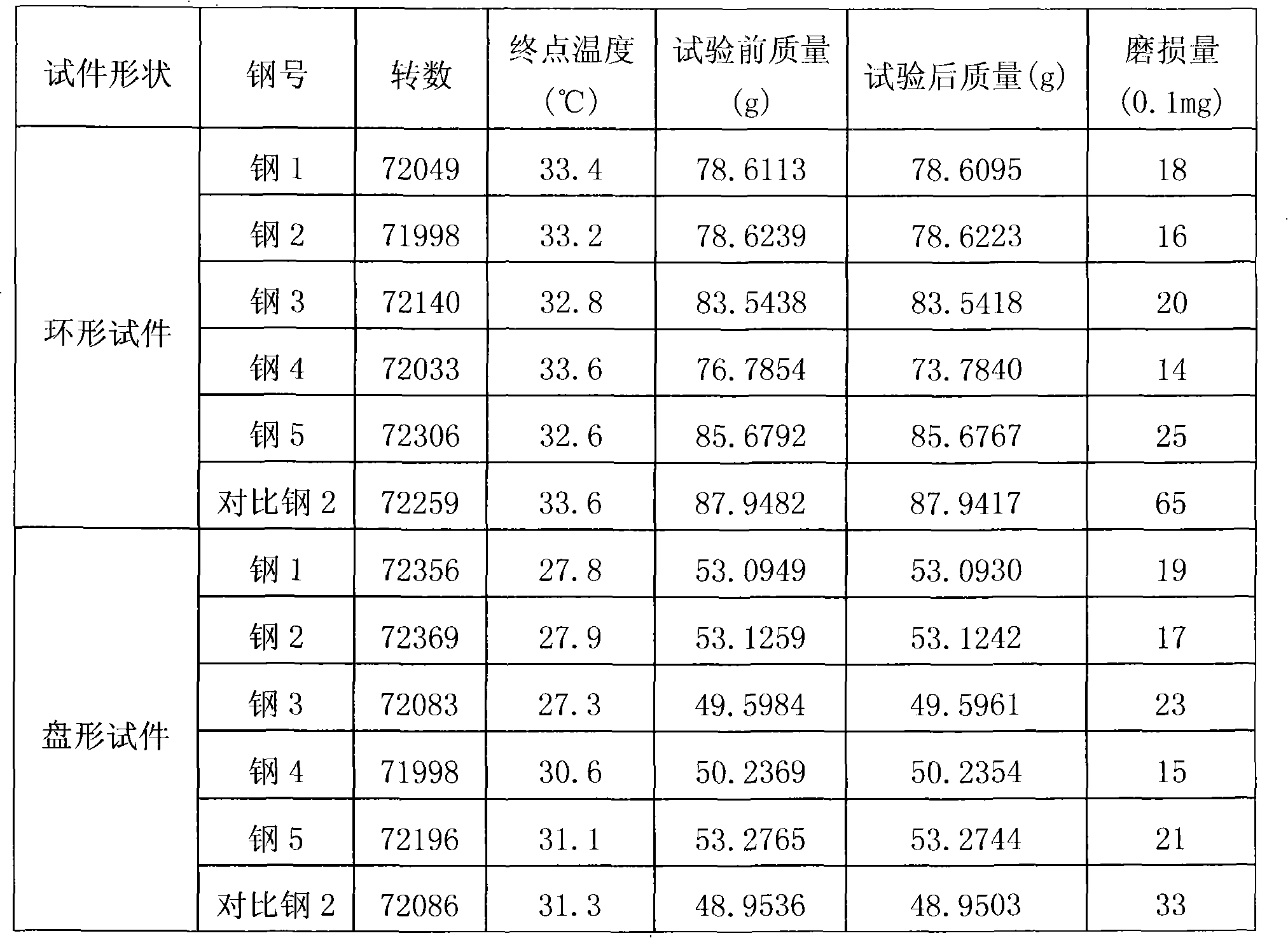

Ultrahigh strength abrasion resistant steel and method of preparing the same

InactiveCN101250673AHigh yield strengthImprove impact toughnessTemperature control deviceFurnace typesChemical compositionWear resistant

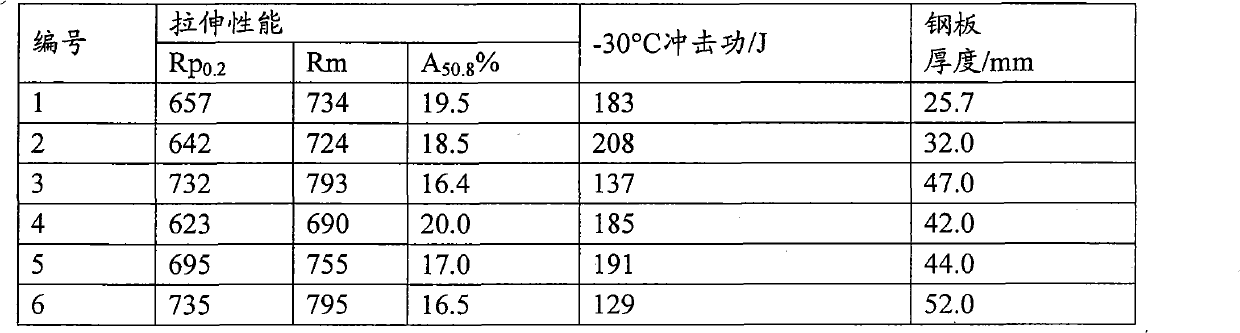

The invention discloses a superhigh intensity wear-resistant steel and the manufacturing method, which belongs to the manufacturing field of low alloying steels, according to percentage by weight, the chemical components of the steel are that C 0.10-0.17%, Si 0.25-0.50%, Mn 1.20-1.50%, P<=0.018%, S<=0.008%, Cr 0.20-0.05%, Ni0.25-0.50%, Mo 0.10-0.40%, Als 0.02-0.06%, B<=0.005%, RE<=150g / t, and the allowance is Fe and unavoidable impurities, and the content of carbon is Ceq(%)<=0.60, Ceq(5)=C+Mn / 6+(Mo+Cr+V) / 5+(Ni+Cu) / 15. The specific method for producing the steel comprises the following steps: smelting ultra-pure steel, desulfurizing molten iron, compounding and converting the top and the bottom of a converter, doing vacuum treatment, feeding rare earth (RE) silk through a crystallizer, casting into bar plates, heating the bar plates, roughing, planishing, air cooling or feeding middle pressure, water cooling, quenching and tempering steel plates. V does not contain in the chemical components of the steel, inner stress of steel is low, steel welding property is improved, and steel has excellent abrasion resistance and ultra-high strength and toughness properties, which is beneficial for popularization and application.

Owner:武钢集团有限公司

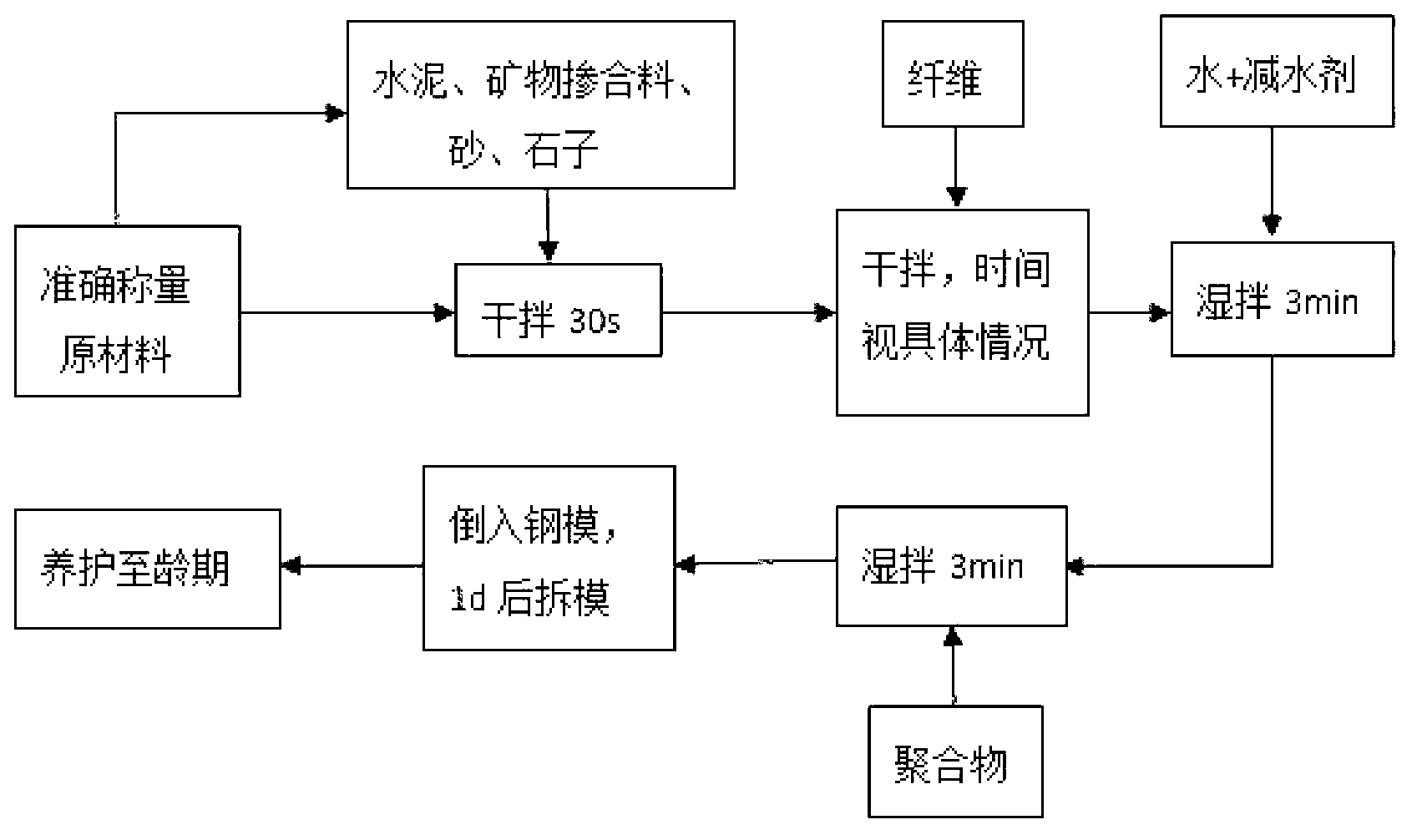

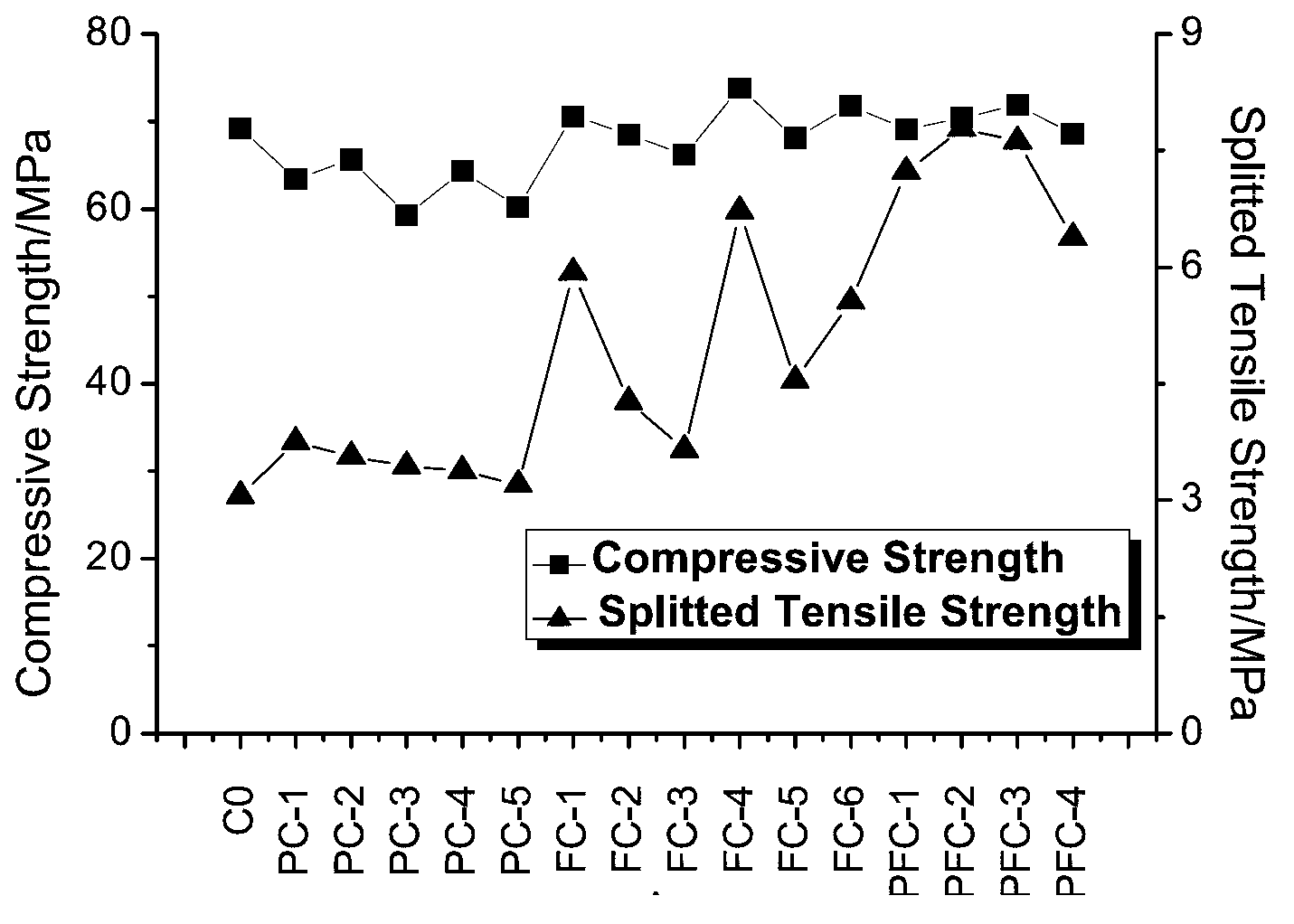

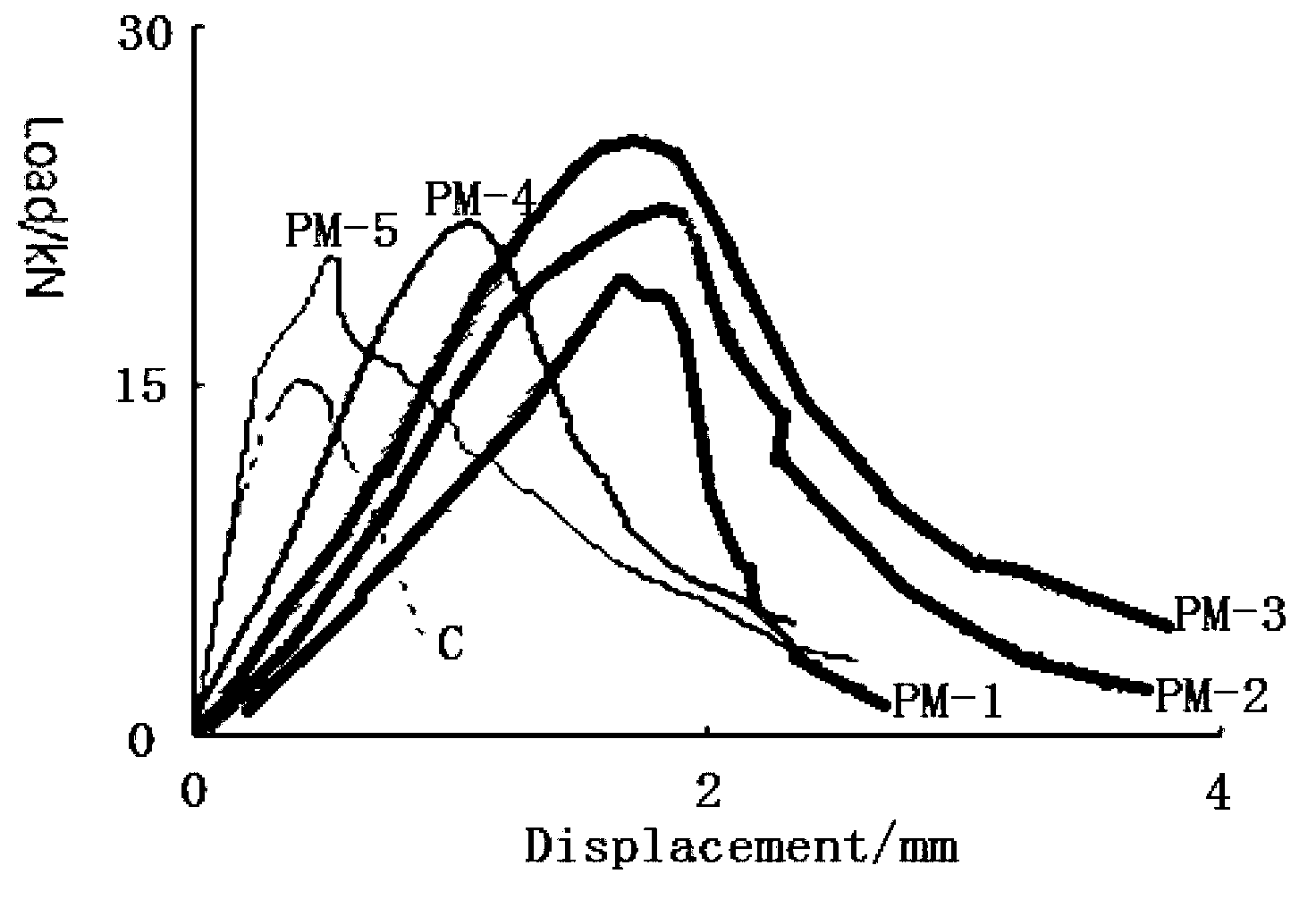

Fibre-polymer compound toughened concrete and preparation method for same

The invention discloses a fibre-polymer compound toughened concrete and a preparation method for the same. The basic raw materials of the concrete are coarse aggregate, fine aggregate, portland cement, fly ash and a polycarboxylic water reducer; moreover, fibres and a polymer are added, the fibres are any one of end-hook type steel fibres, superfine type steel fibres, modified polyester fibres, polyvinyl alcohol fibres, basalt fibres and cellulose fibres, and are doped in a ratio that the volume doped amount in per 1 m<3> concrete is 0.08%; and the polymer is any one of ethylene-vinyl acetate copolymer, ethyl acrylate, styrene-acrylate copolymer, vinyl acetate-acrylate copolymer and organosilicone acrylate, and the doped amount of each polymer is 10% based on the mass of the portland cement and the fly ash. The preparation method comprises the following steps of: pouring stone, sand, a gelling material, fibres, and water dissolved with a water reducer, and then stirring according to a blending mode of pouring dry materials at first and then pouring wet materials; and pouring the polymer, and stirring and forming.

Owner:SOUTHEAST UNIV

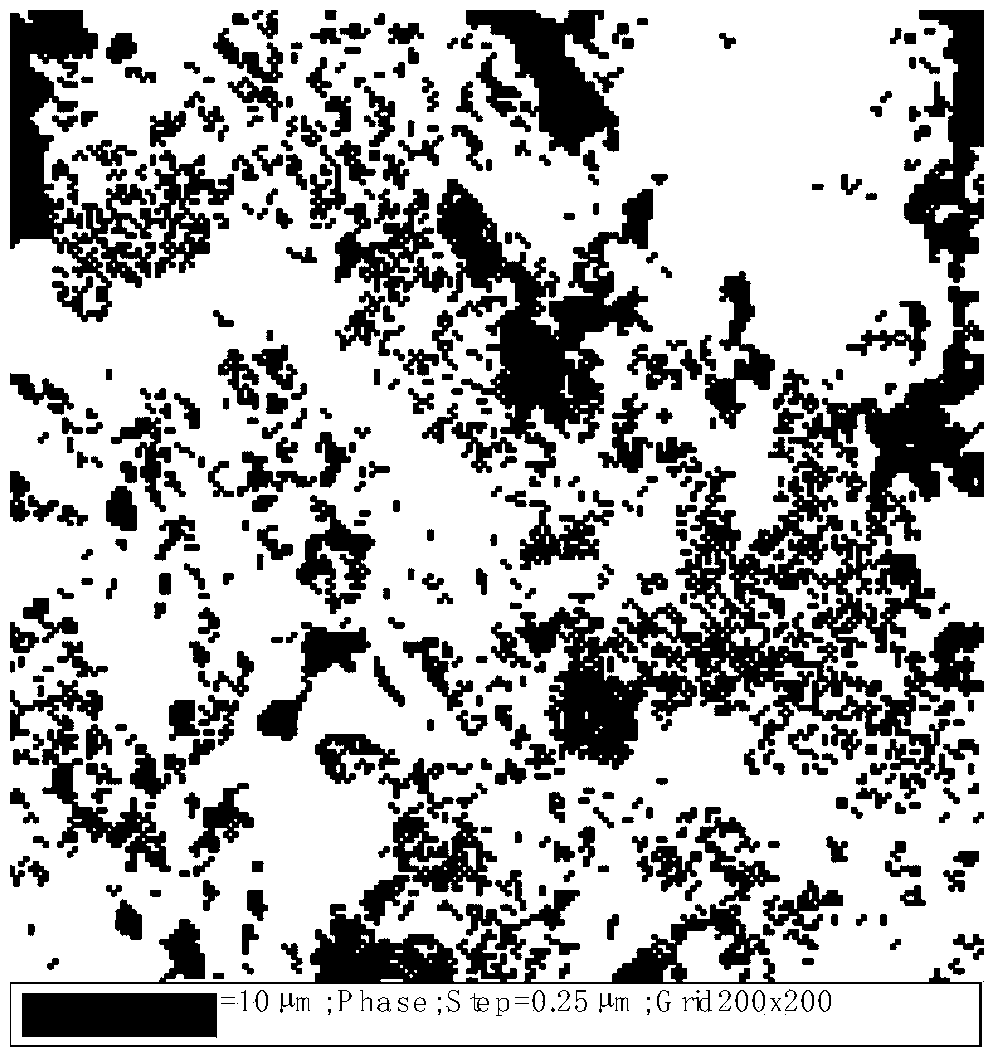

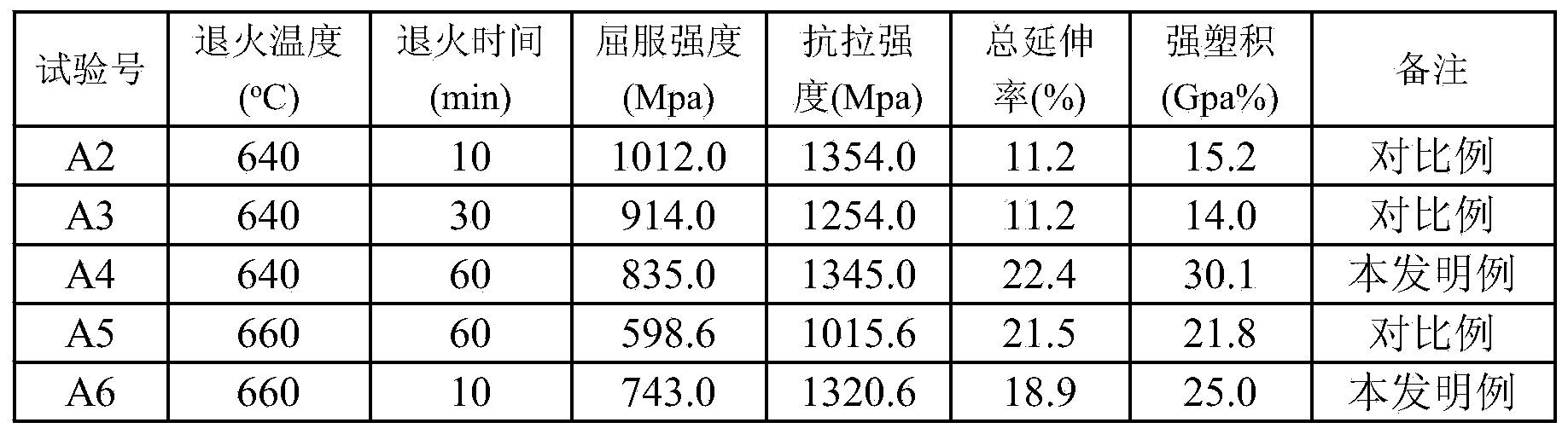

Double-phase twinborn induced plastic super-strength automobile steel plate and preparation method thereof

The invention belongs to the technical field of automobile steel, and in particular relates to a double-phase twinborn induced plastic super-strength automobile steel plate and a preparation method thereof. The steel plate comprises the following chemical elements in percentage by weight: 0.3-0.6% of C, 8-12.00% of Mn, 1.00-3.00% of Al, less than or equal to 0.020% of P, less than or equal to 0.02% of S and the balance of Fe and inevitable impurities. The steel plate can be selectively cold-rolled with 5-25% of rolling reduction after warm-rolling at 100-250 DEG C, or a hot continuous rolled plate coil is cold-rolled after being softened and annealed. The yield strength of the steel plate is greater than or equal to 650MPa, the tensile strength is 1000-1500MPa, the extension rate of short continuous annealing is 15-25%, the product of strength and elongation is 20-35GPa%, the extension rate obtained after cover-type prolonged annealing is 25-40%, and the product of strength and elongation is 30-40GPa%.

Owner:UNIV OF SCI & TECH BEIJING

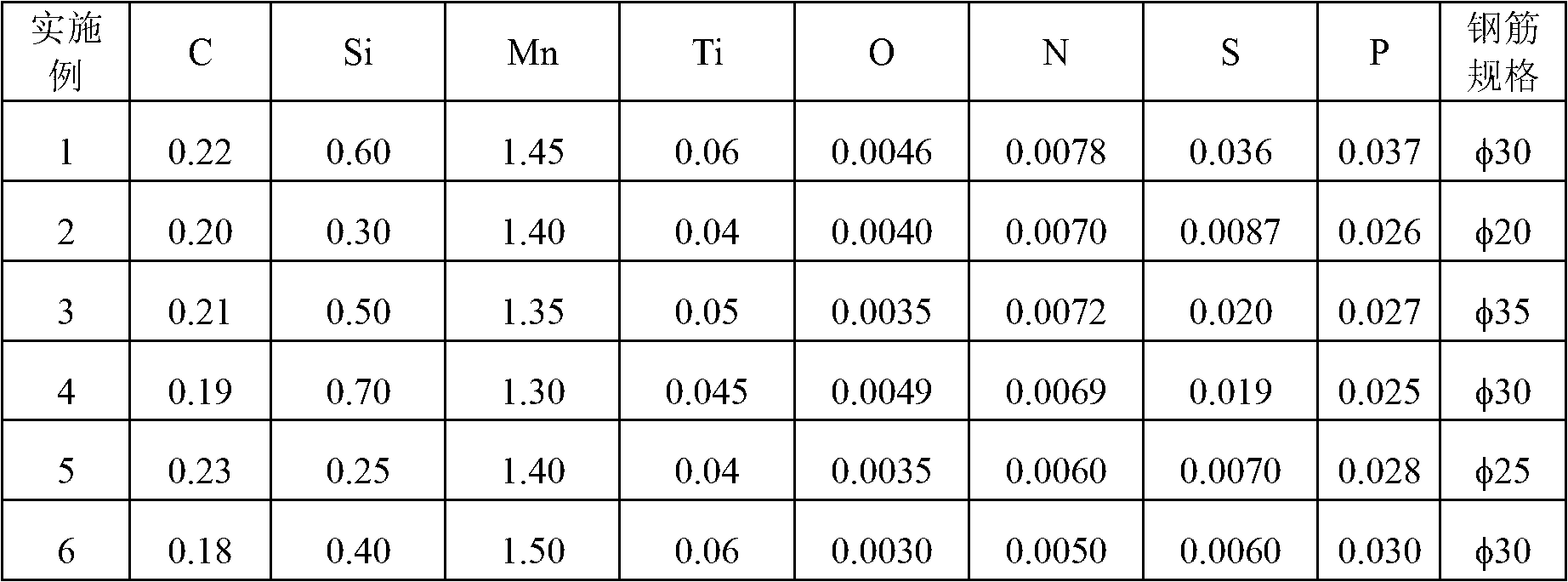

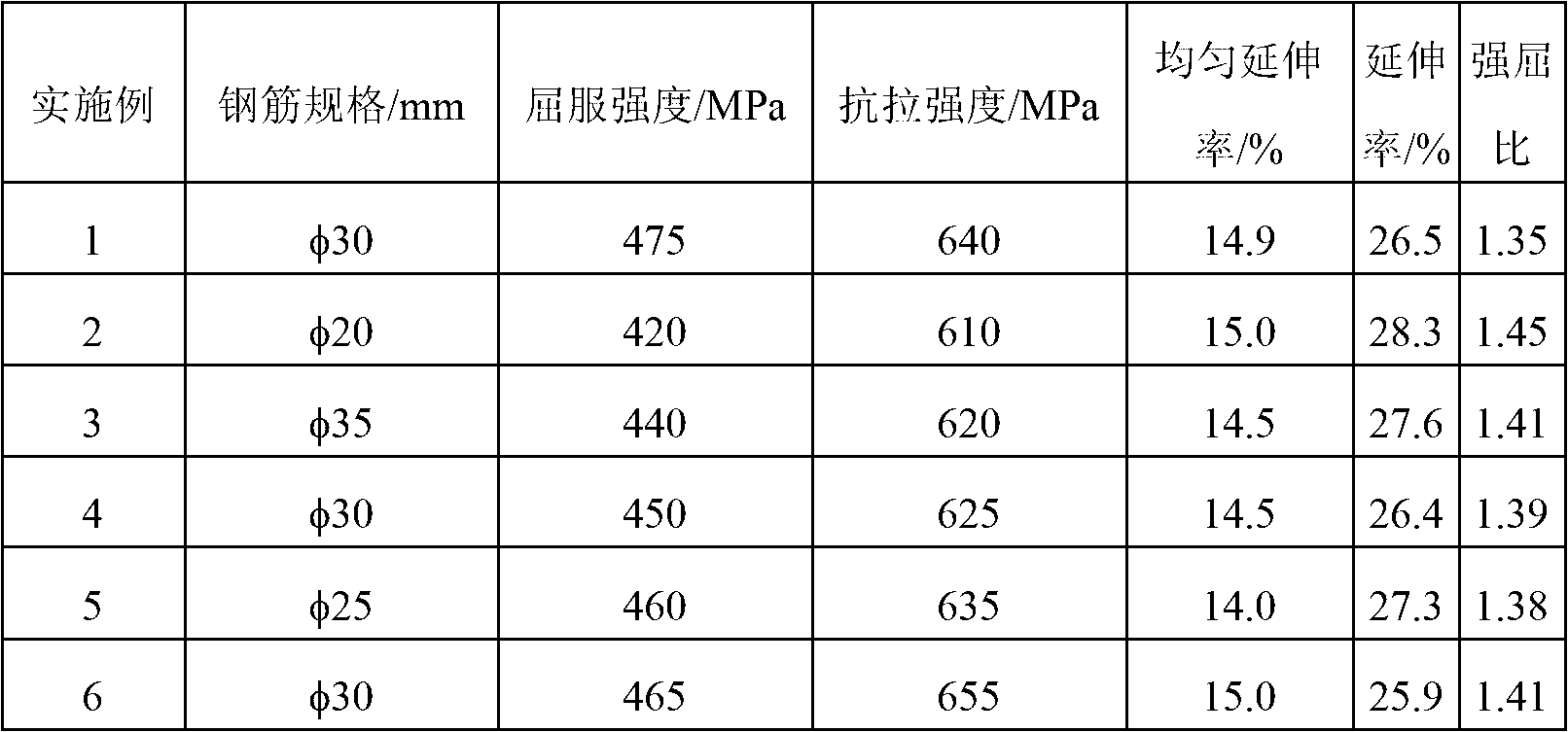

Titanium micro-alloyed 400MPa grade high-strength steel bar and production method thereof

The invention discloses a hot-rolled 400MPa grade high-strength steel bar for reinforced concrete and a production method for the steel bar, and belongs to the technical field of micro-alloying of ferrous metallurgy. The steel in the steel bar comprises the following chemical components in percentage by weight: 0.16 to 0.25 percent of C, 0.20 to 0.80 percent of Si, 1.20 to 1.50 percent of Mn, 0.02 to 0.06 percent of Ti, less than or equal to 0.01 percent of N, less than or equal to 0.045 percent of S, less than or equal to 0.045 percent of P, and the balance of Fe and inevitable impurities. The preparation method for the steel bar comprises the following steps of: a, smelting crude molten steel, tapping, deoxidizing and alloying; b, refining, finely regulating the components, and pouring; and c, hot rolling, wherein titanium is alloyed in the tapping process and after deoxidizing or in the refining process. By using the principle that the titanium plays a role in precipitation and reinforcement in the steel, the mechanical properties of the steel such as yield strength and tensile strength are improved, and the property requirement of the 400MPa grade high-strength steel bar is met..

Owner:PANZHIHUA GANGCHENG GROUP

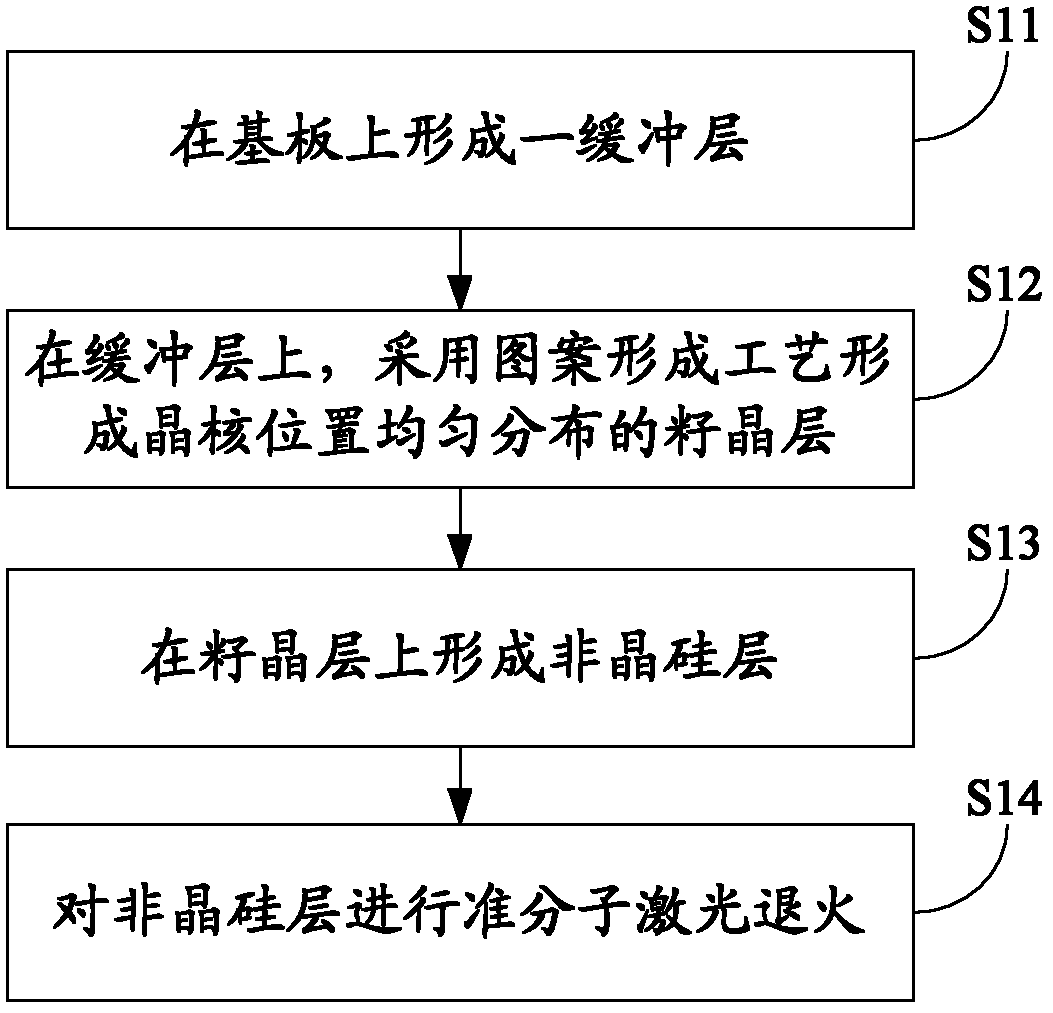

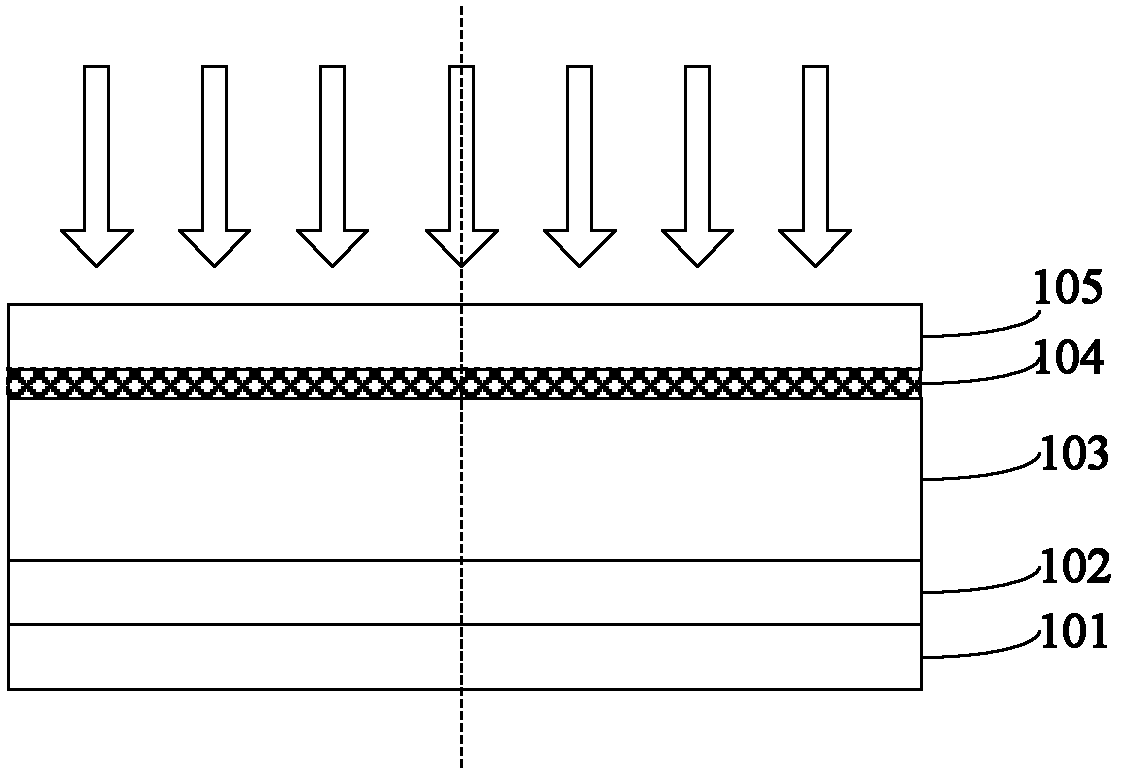

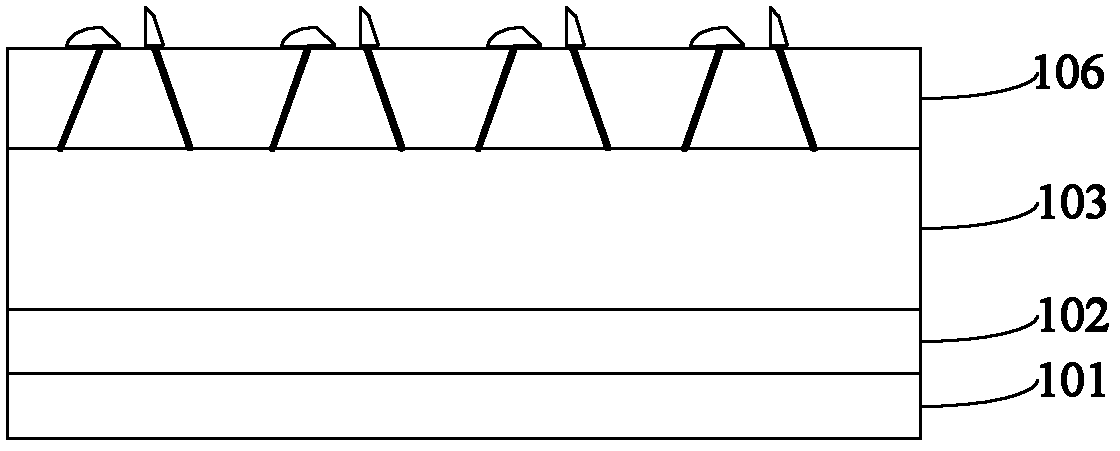

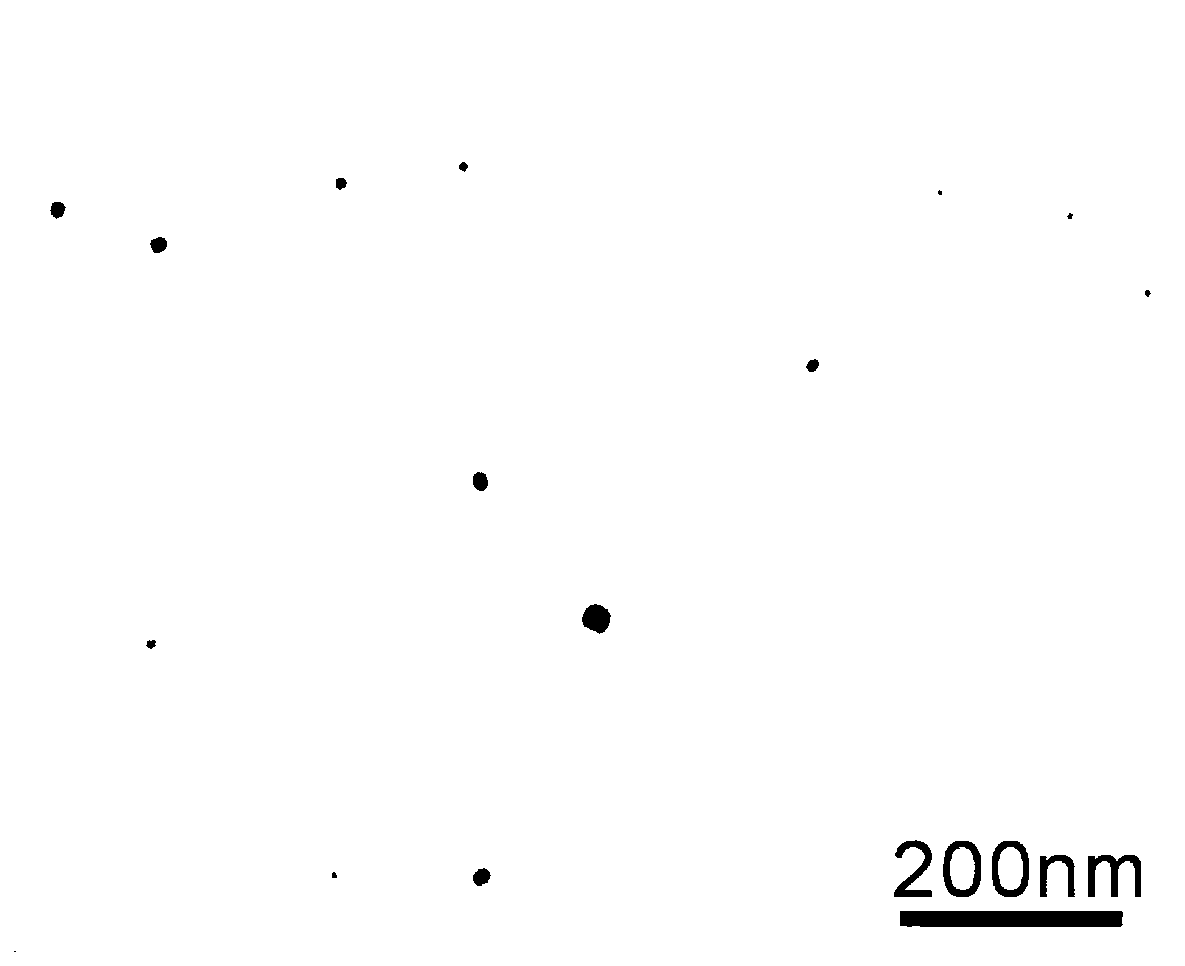

Low-temperature polycrystalline silicon thin film and production method thereof

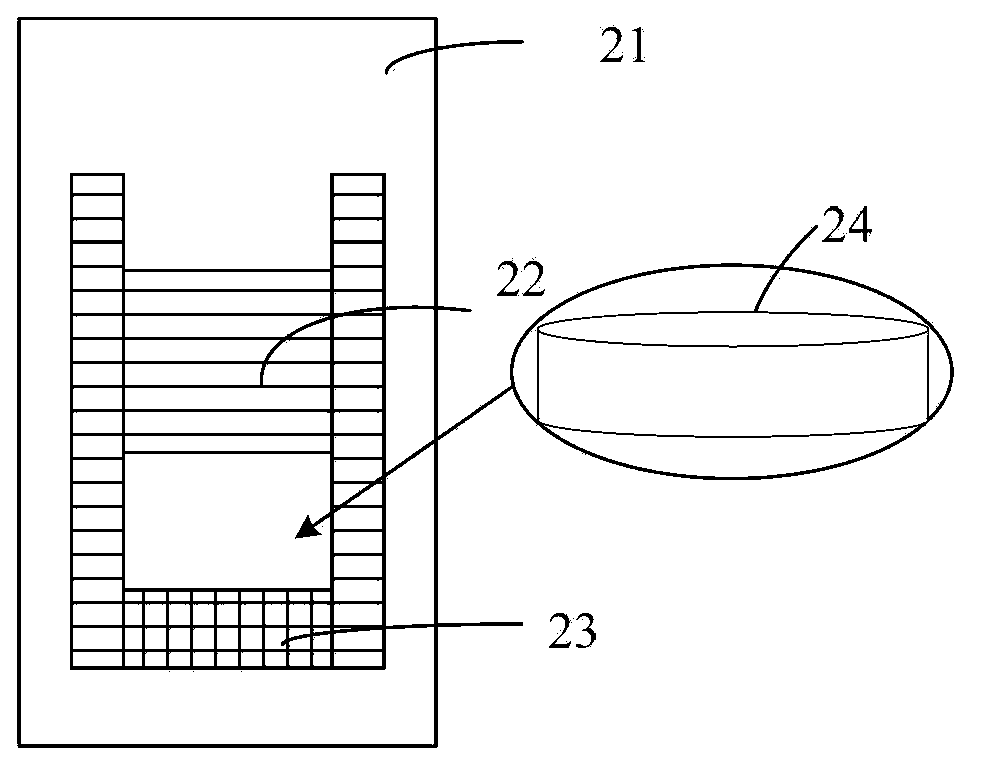

ActiveCN102709160ALarge grain sizeEvenly distributedSemiconductor/solid-state device manufacturingChemical vapor deposition coatingSeed crystalCrystallite

The invention provides low-temperature polycrystalline silicon thin film and a production method thereof. The production method is used for producing low-temperature polycrystalline silicon thin film low in surface roughness, large in crystalline grain size and uniform in crystalline grain distribution and includes forming a buffer layer on a substrate, forming a seed crystal layer with crystal nucleus uniformly distributed on the buffer layer by means of the pattern forming technology; forming a non-crystalline-silicon layer on the seed crystal layer; and subjecting the non-crystalline-silicon layer to excimer laser annealing. The crystalline grains of the low-temperature polycrystalline silicon thin film produced by the production method are large in size and uniform in distribution, and further, the low-temperature polycrystalline silicon thin film is quite low in surface roughness, and accordingly solves the problems of low migration rate, high leakage current of thin-film transistors and unevenness of the migration rate and threshold voltage when being applied to a back plate of a low-temperature polycrystalline silicon display screen.

Owner:BOE TECH GRP CO LTD

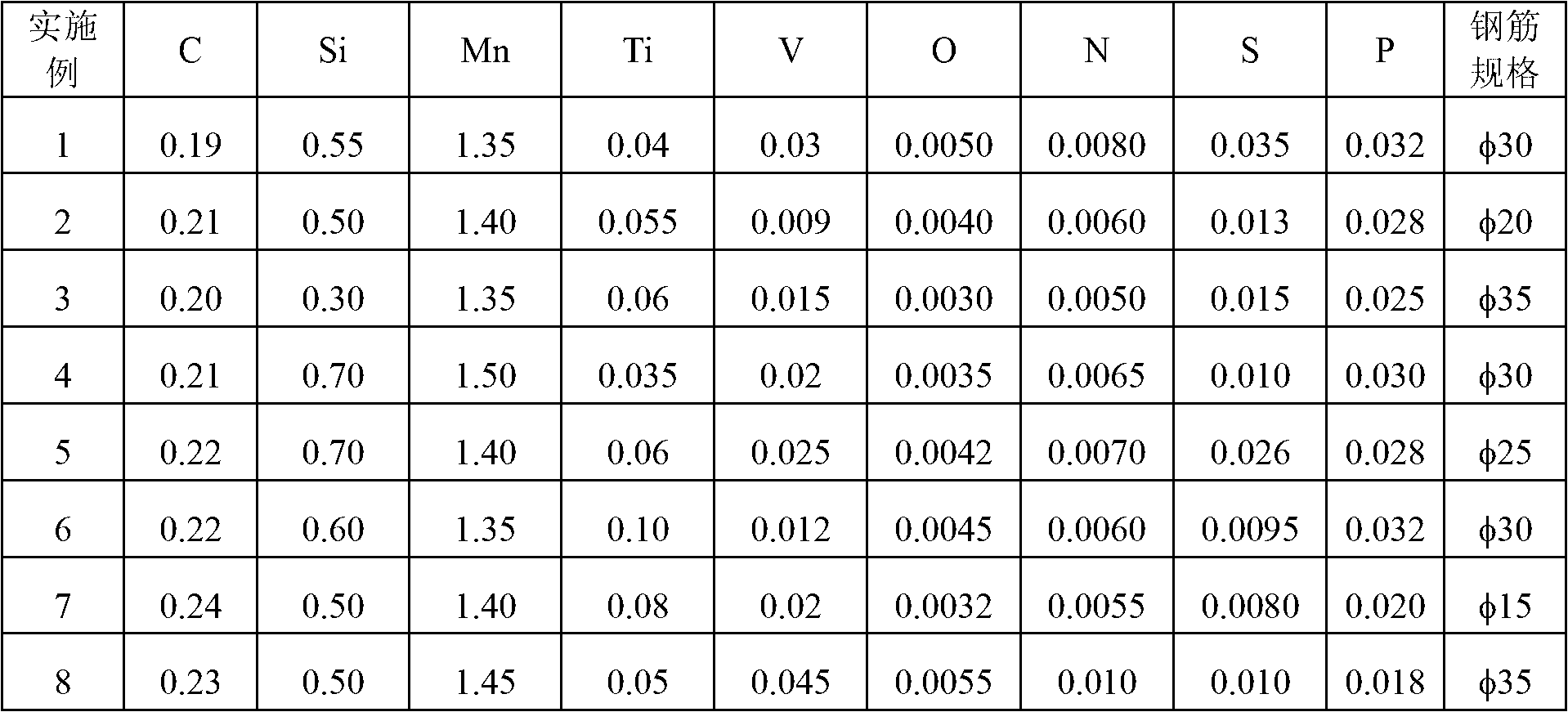

Vanadium and titanium compound microalloyed steel bar and production method thereof

The invention discloses a vanadium and titanium compound microalloyed steel bar and a production method thereof. The steel in the steel bar comprises the following chemical components in percentage by weight: 0.16 to 0.25 percent of C, 0.20 to 0.80 percent of Si, 1.20 to 1.50 percent of Mn, 0.001 to 0.12 percent of Ti, 0.001 to 0.10 percent of V, less than or equal to 0.01 percent of N, less than or equal to 0.045 percent of S, less than or equal to 0.045 percent of P, and the balance of Fe and inevitable impurities. The production method for the steel bar comprises the following steps of: a, smelting crude molten steel, tapping, deoxidizing and alloying; b, refining, trimming the components to make the components meet the component requirement of the steel bar, and casting; and c, performing hot rolling, wherein alloying vanadium and titanium after deoxidizing in the process of tapping, or in the process of refining. According to the vanadium and titanium compound microalloyed steel bar, the yield strength and the tensile strength of the steel are improved under the condition of not changing the ductility of the steel, and the performance requirements of the steel bars in 400 MPa or 500 MPa of grades are met.

Owner:PANZHIHUA GANGCHENG GROUP

Method for producing high-strength and elongation product automobile steel plate by continuous annealing technology

The invention provides a method for producing a high-strength and elongation product automobile steel plate by a continuous annealing technology, belonging to the technical field of an automobile steel plate. The method comprises the following steps: based on the reasonable chemical component design and the alloy element partition, firstly, obtaining transition carbide with fine dispersion distribution by a cold rolled plate coil importantly, and promoting austenite inverse phase transformation through the solid solution of the fine carbide through two-phase region annealing, to obtain more and stable austenite phases to be remained. According to the method, the strict technological conditions for forming the finely-dispersed carbide and the strict interval for carrying out the technological parameters of the two-phase region annealing are given, so that the method has the advantages that the continuous annealing plate coil which is even in performance and good in surface quality can be obtained due to the short-time annealing of the existing continuous annealing production line of a steel factory, wherein the strength of the steel plate is 0.6-1.2GPa, the percentage elongation of the steel plate is 45-20%, and the product of strength and elongation is 25-40GPa%.

Owner:CENT IRON & STEEL RES INST

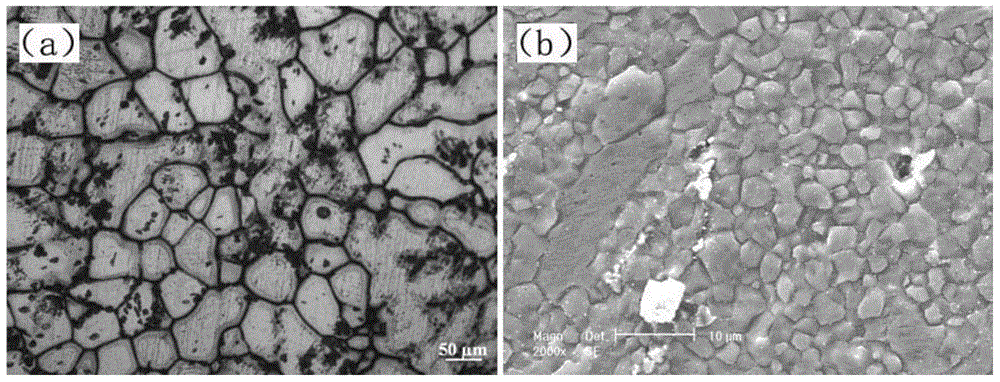

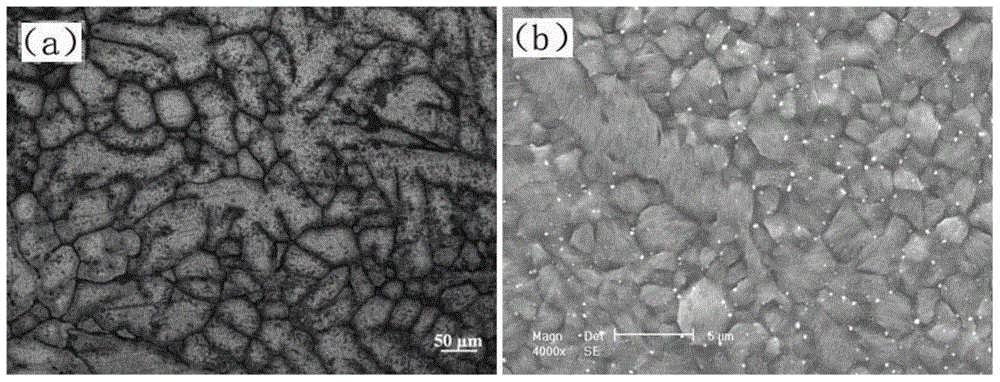

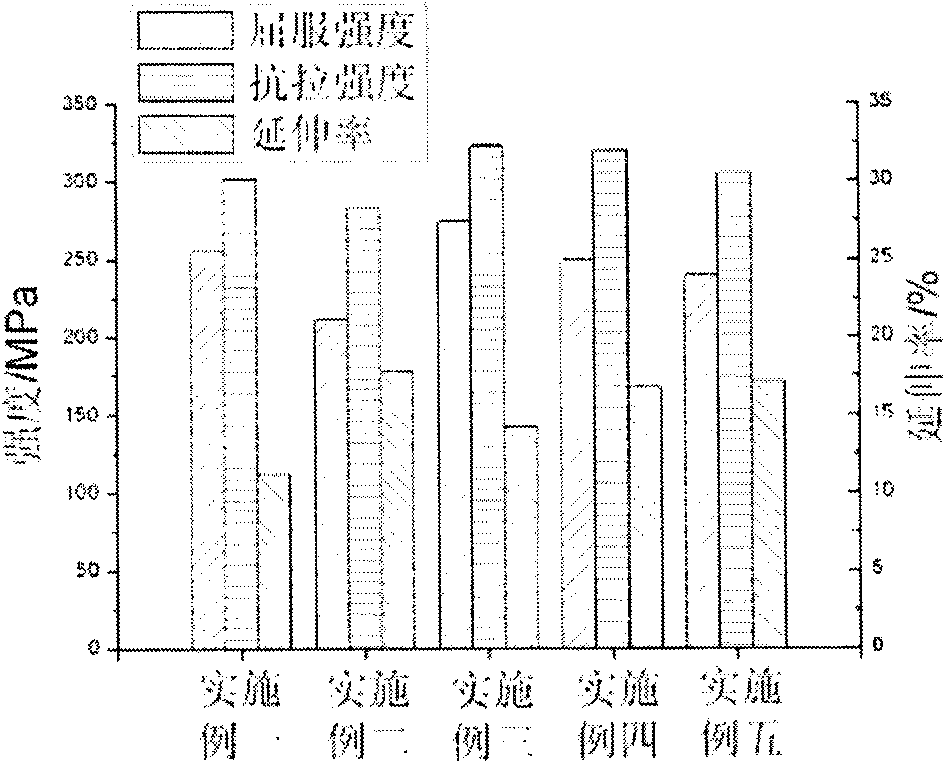

High-strength wrought magnesium alloy and preparation method thereof

ActiveCN105220041AHigh strengthImprove precipitation strengthening effectRare-earth elementCrystallite

The invention discloses high-strength wrought magnesium alloy and a preparation method thereof and belongs to the technical field of light metal materials. The high-strength wrought magnesium alloy comprises the following components in percentage by weight: 2.0-6.5% of Zn, 0.1-3.0% of RE, 0.1-2.0% of Ca and the balance of Mg and inevitable impurities; the high-strength wrought magnesium alloy also can comprise grain refiners Mn and / or Zr. Zn is a main strengthening element in the alloy, and can improve the room temperature strength of magnesium alloy through solid solution strengthening and aging precipitation strengthening; Ca is used for promoting precipitation, refining grains and improving high-temperature strength of alloy; and a small amount of RE is used for restraining recrystallization, refining deformed alloy grains, regulating texture and improving plasticity of alloy. According to the invention, by replacing expensive rare earth elements with cheap common alloying elements, a strengthening effect similar to that of rare earth is generated, the rare earth content is completely replaced or lowered and the cost of alloy is reduced while strength is guaranteed.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

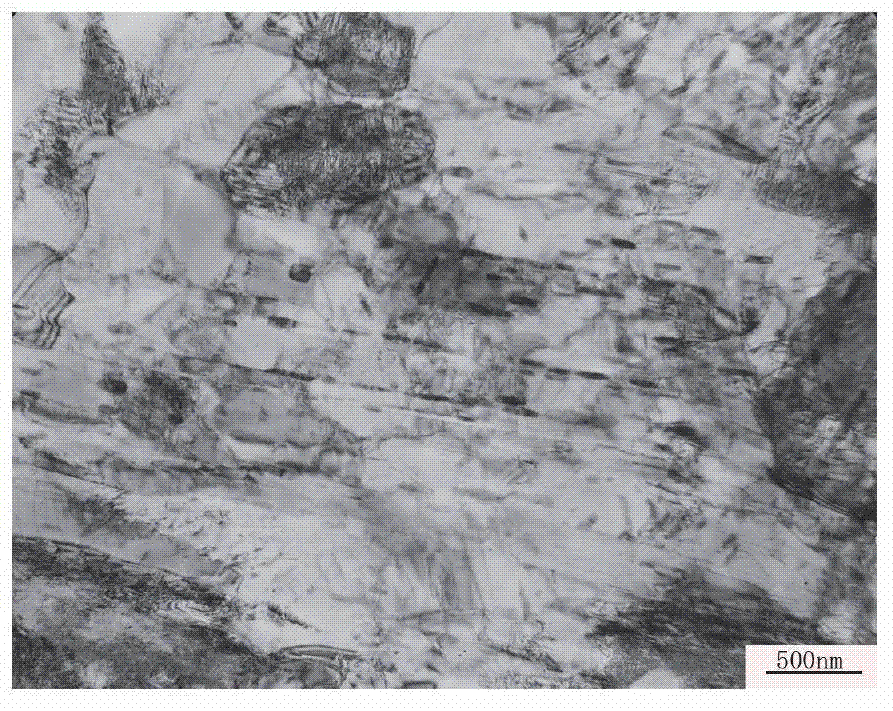

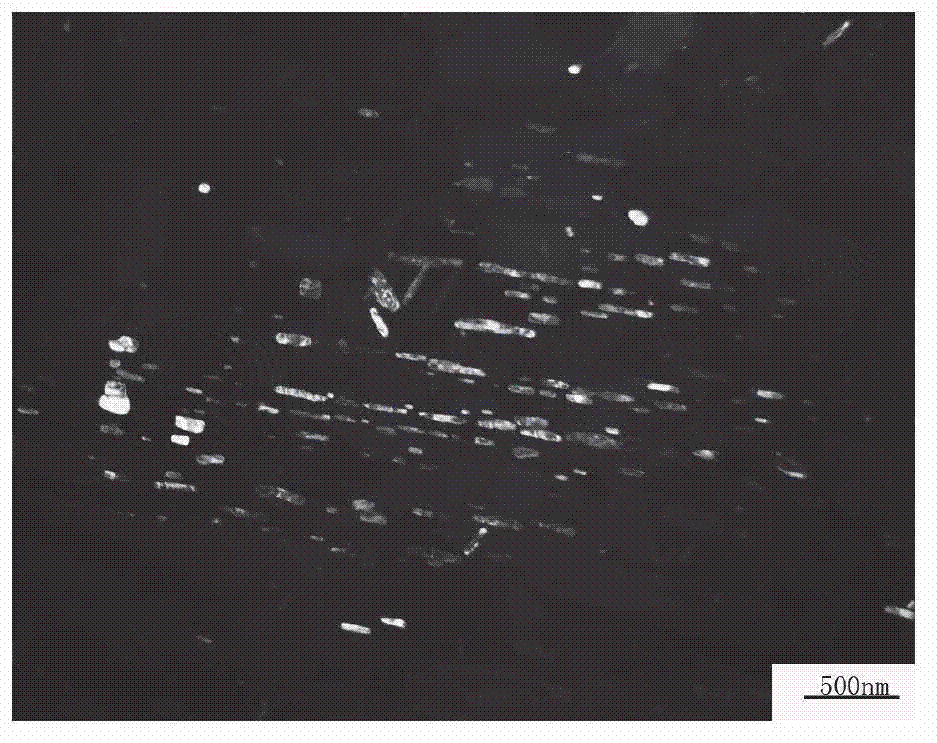

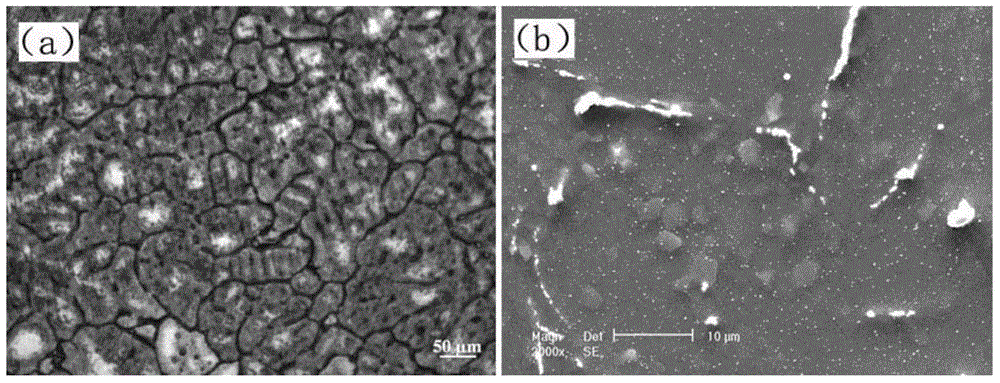

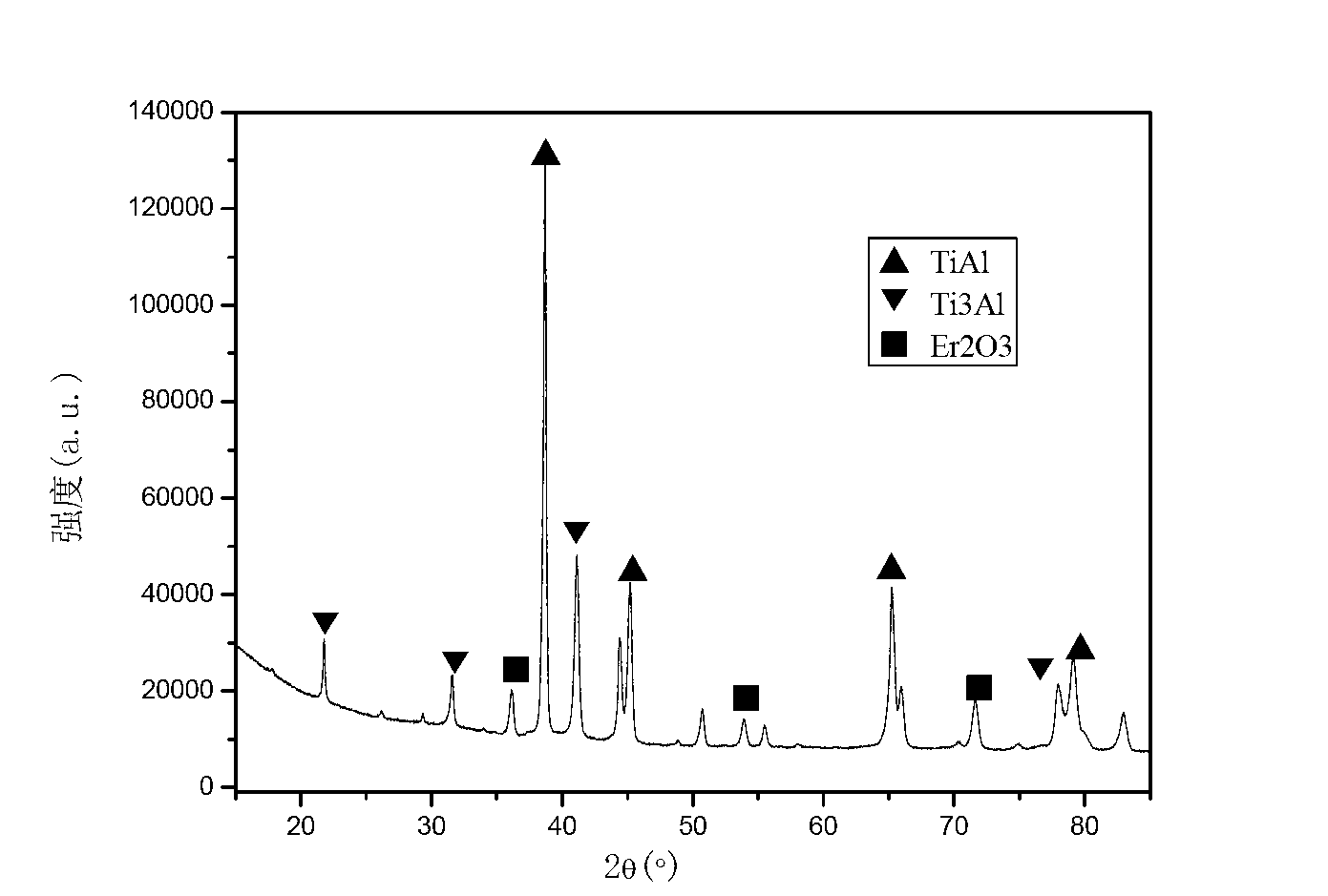

Er-containing high-niobium Ti-Al intermetallic compound material and preparation method thereof

The invention discloses an Er-containing high- niobium Ti-Al intermetallic compound material and a preparation method thereof, and belongs to intermetallic compound materials. The material is composed of the following elements in mole percent: 41-46 percent of Al, 5-15 percent of niobium, no more than 0.4 percent of Er, and the balance of Ti and unavoidable impurities. The preparation method comprises the following steps: adding titanium sponge, high-purity aluminium, Al- niobium intermediate alloy and Al-Er intermediate alloy into a water cooled copper crucible vacuum induction smelting furnace as per the composition, vacuumizing to 2.0-3.0*10<-3>mbar, rising the smelting power to 160-180 kW at the speed of 5-10 kW / min and stopping at 160-180 kW, smelting for 1-3 minutes at a constant power, obtaining melt, mixing the melt uniformly; and casting the melt into a metal mold preheated to 300-350 DEG C, forming an Er-containing high-niobium Ti-Al intermetallic compound material ingot, and cooling together with the smelting furnace. The method enables the crystal size and layer space of the Ti-Al intermetallic chemical combination to be smaller and thinner.

Owner:BEIJING UNIV OF TECH

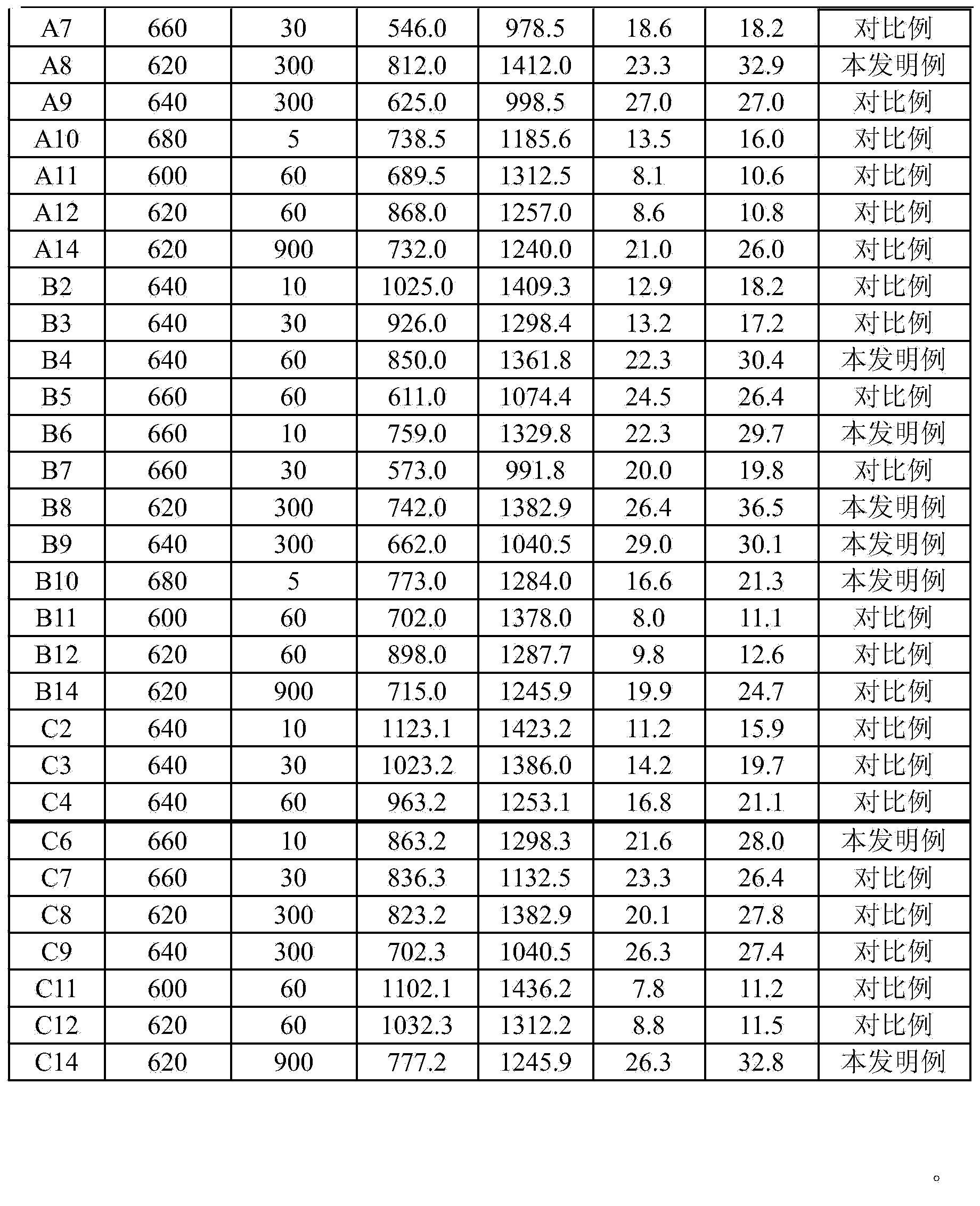

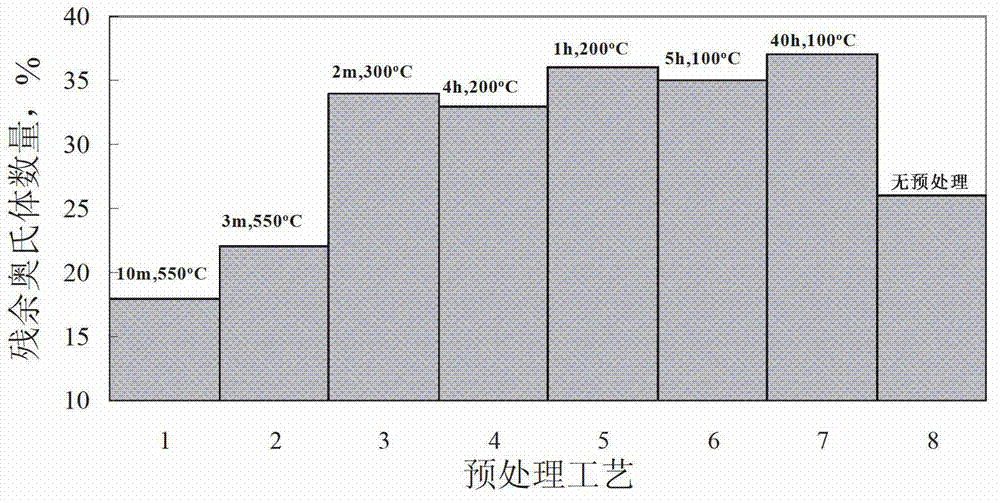

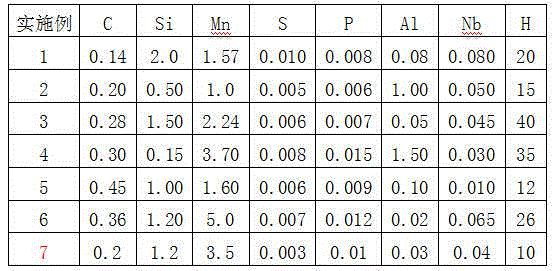

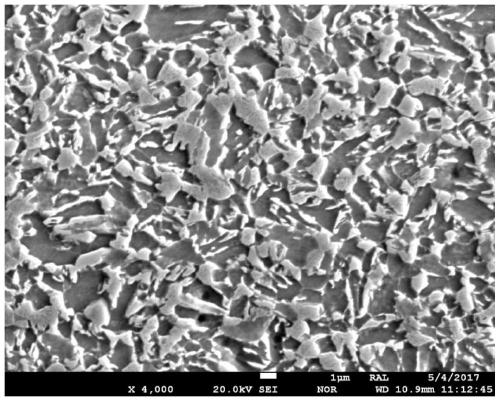

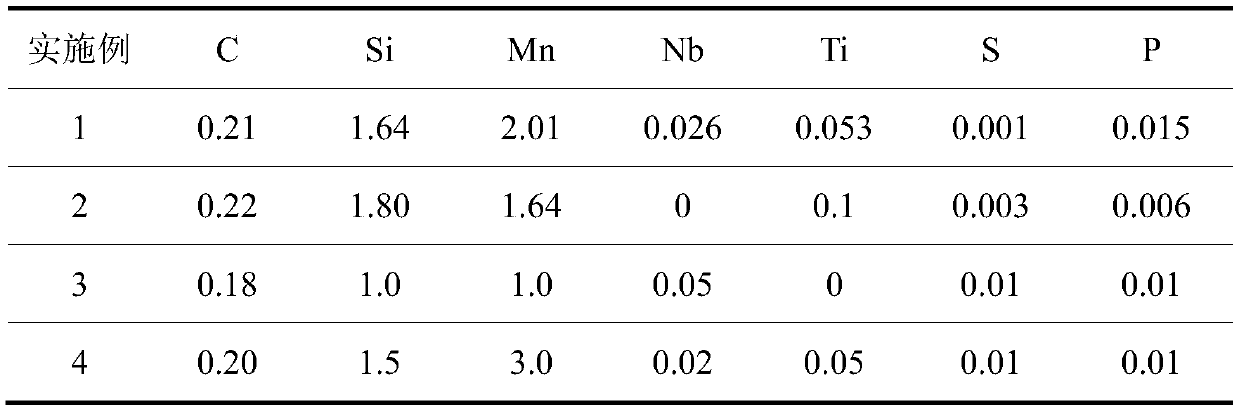

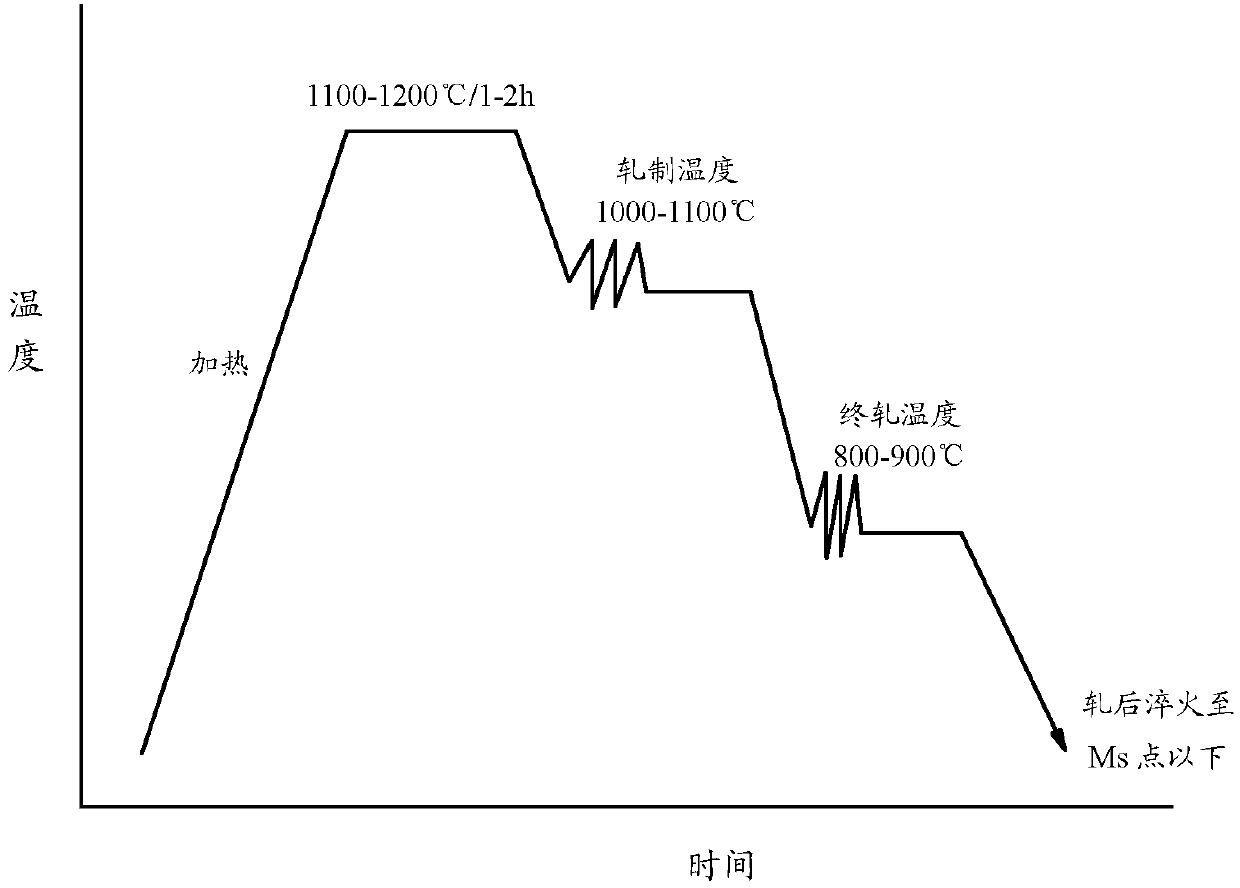

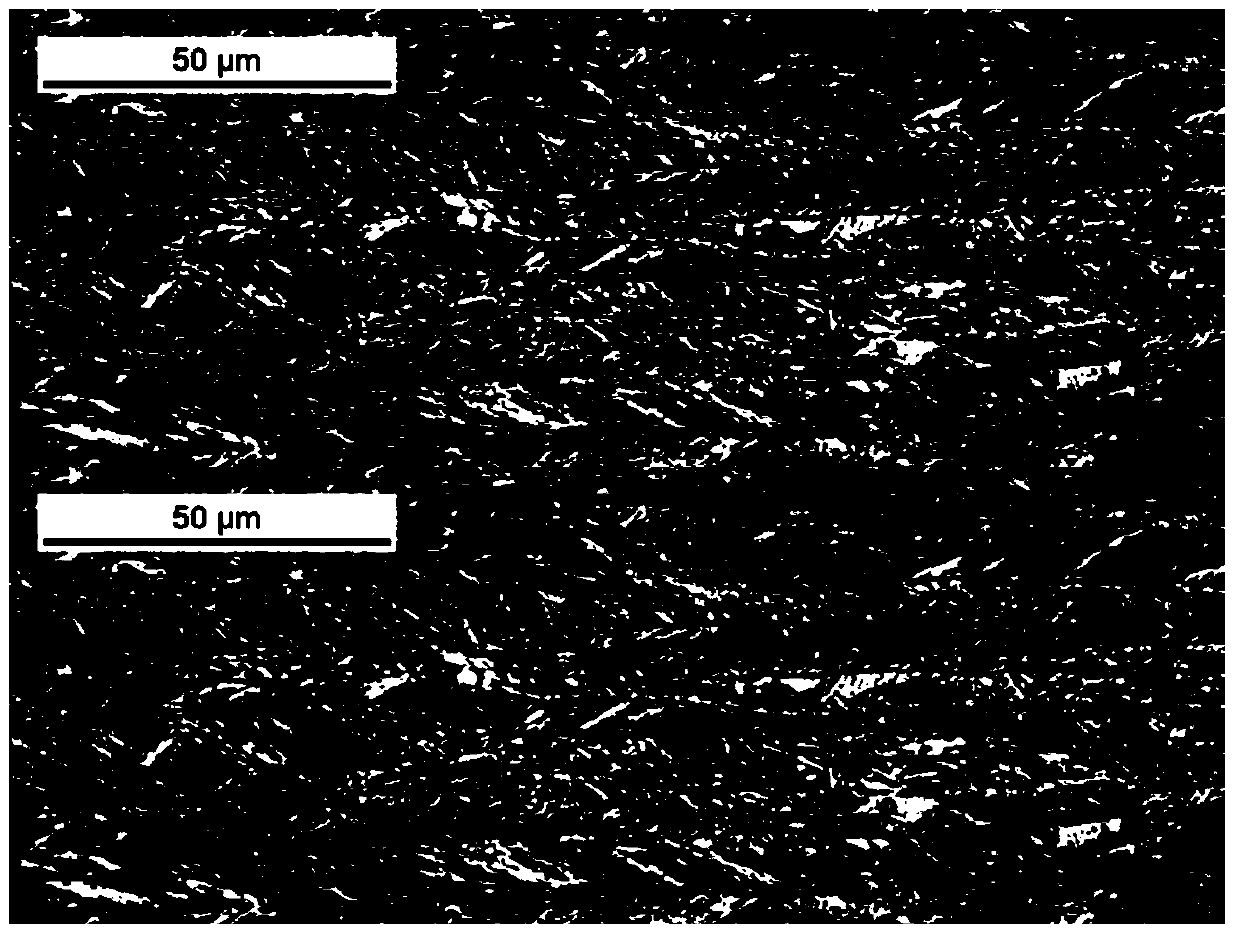

Ultrahigh-strength hot-rolled Q and P steel and production method thereof

InactiveCN105177415AIncrease in sizeIncreased carbon content of austeniteChemical compositionLaminar cooling

The invention discloses ultrahigh-strength hot-rolled Q and P steel and a production method thereof. The production method includes the procedures of smelting, casting and hot rolling. The steel comprises 0.14%-0.45% of C, 0.15%-2.0% of Si, 1.0%-5.0% of Mn, 0.010% or less of S, 0.015% or less of P, 40 ppm or less of H, 0.02%-1.5% of Al, 0.01%-0.08% of Nb, and the balance Fe and inevitable impurities. The hot rolling procedure includes the steps of heating, rough rolling, finish rolling, laminar cooling and reeling. In the heating step, the heating temperature ranges from 1100 DEG C to1200 DEG C, and heat preservation is conducted for 1-3 hours. In the rough rolling step, the rolling starting temperature ranges from 1000 DEG C to 1100 DEG C, and the overall reduction is larger than 40%. In the finish rolling step, the rolling starting temperature ranges from 900 DEG C to 950 DEG C, the rolling finishing temperature ranges from 780 DEG C to 880 DEG C, and the overall reduction is larger than or equal to 60%. In the laminar cooling step, front-end cooling is conducted, the cooling rate is larger than or equal to 45 DEG C / s, and the finish cooling temperature ranges from 150 DEG C to 350 DEG C. In the reeling step, the reeling temperature ranges from 150 DEG C to 350 DEG C. Before the steel coil temperature is 100 DEG C, the cooling rate of 5-20 DEG C / hour is kept. Through the method, the martensite plus retained austenite microstructure with a small grain size can be obtained.

Owner:HEBEI IRON AND STEEL

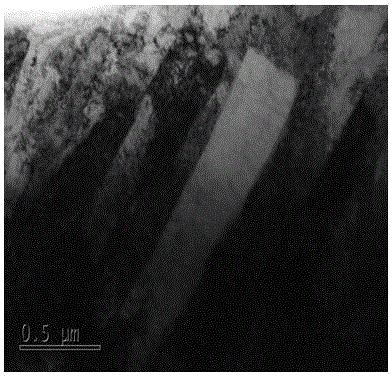

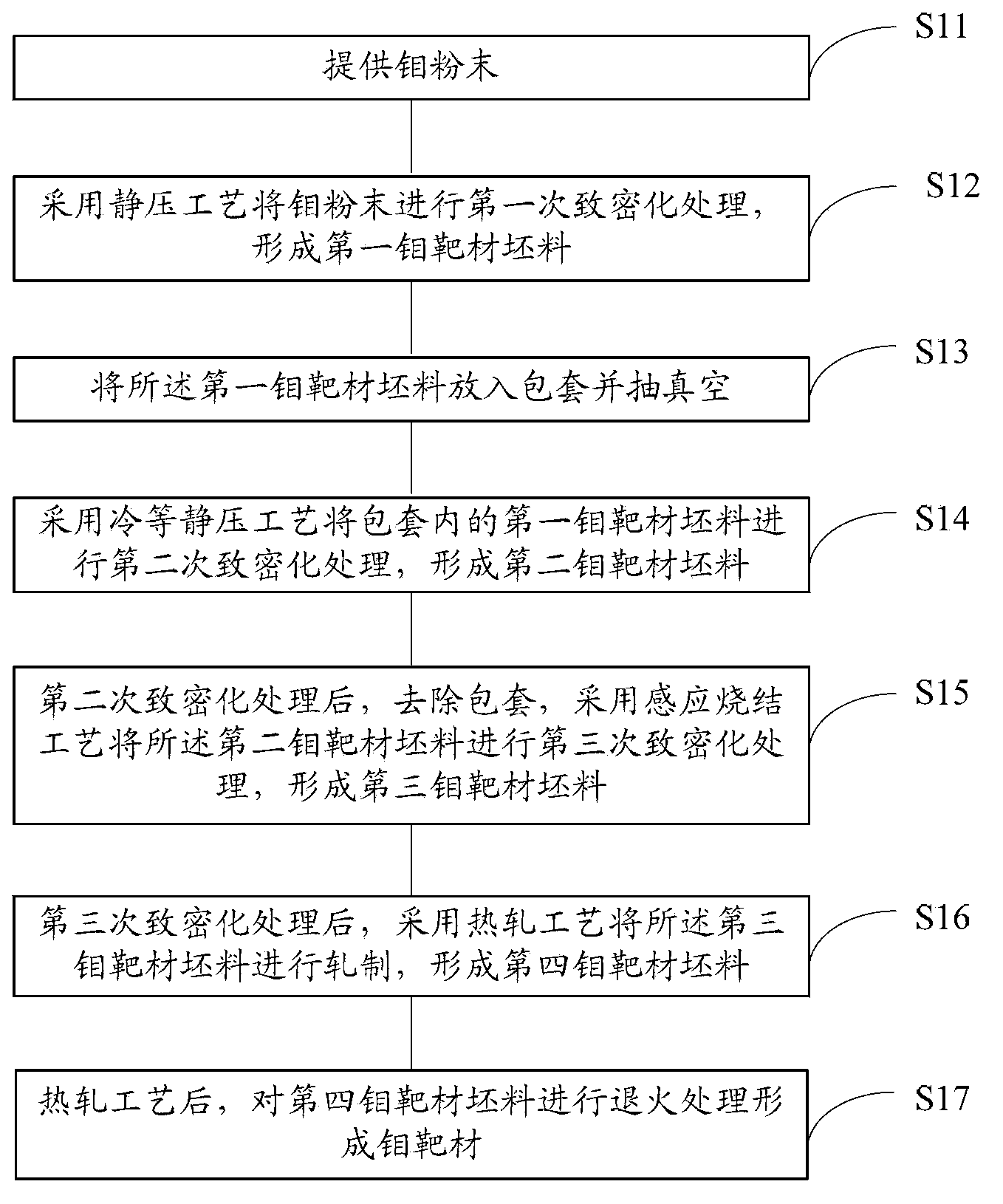

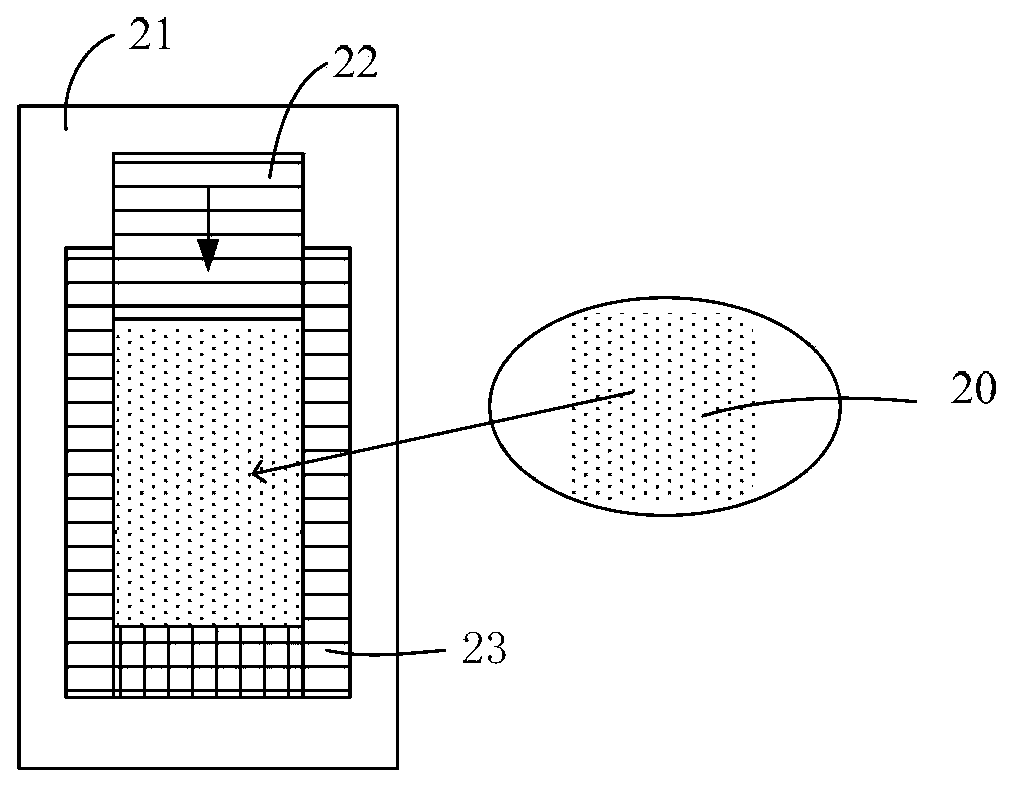

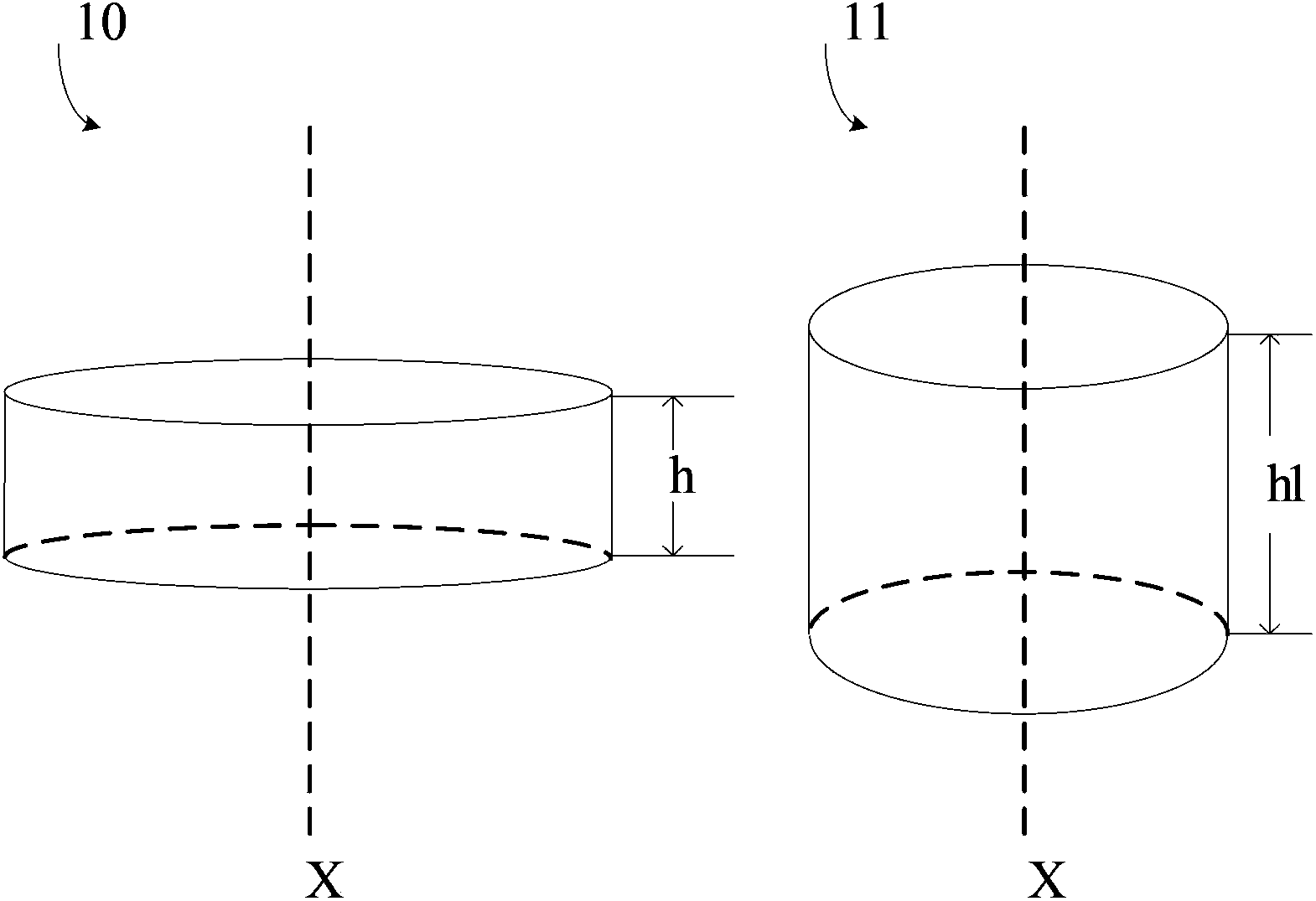

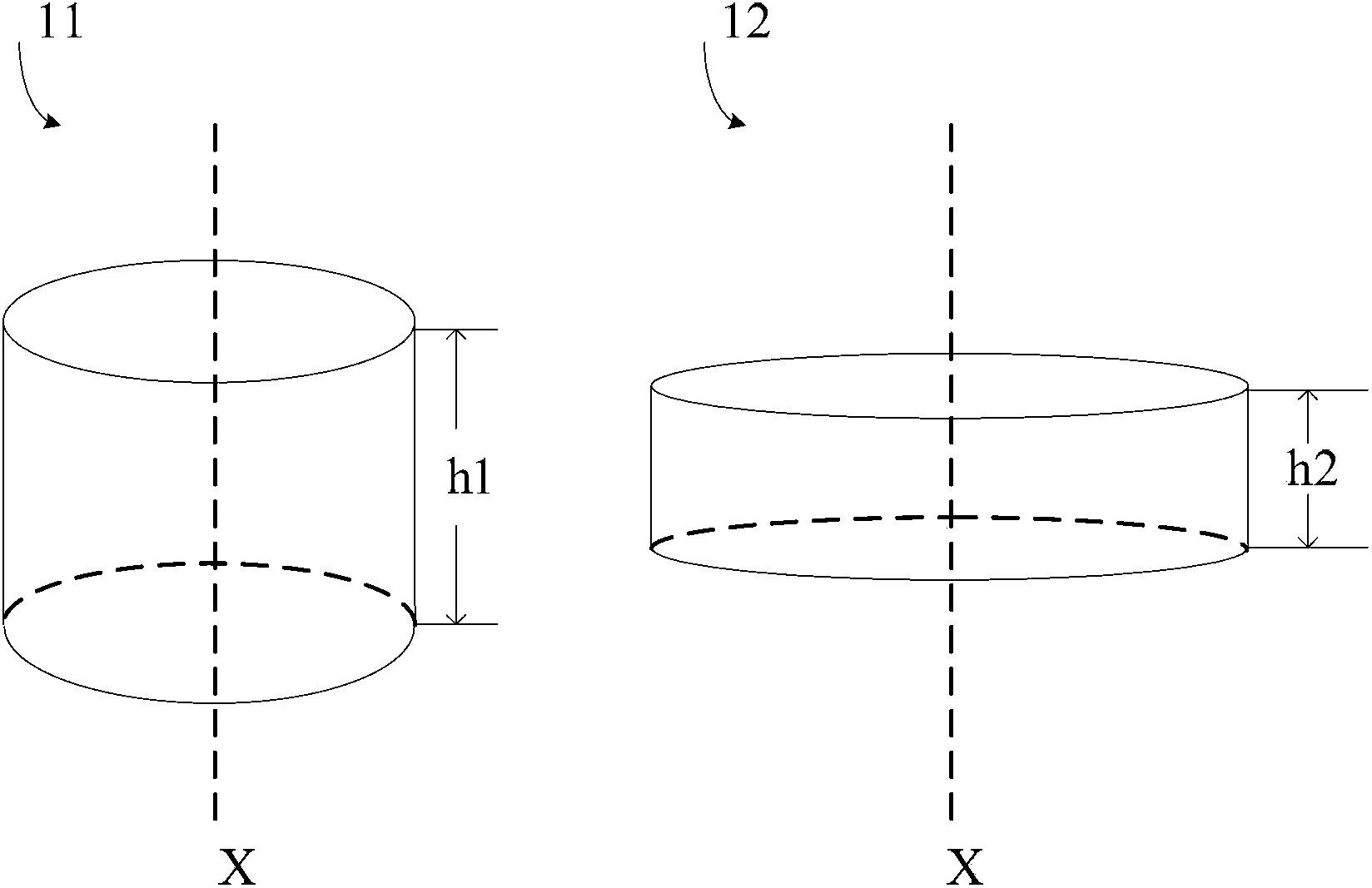

Manufacturing method of molybdenum targets

ActiveCN103567445AIncreased dislocation densityIncrease grain boundary areaVacuum evaporation coatingSputtering coatingMaterials scienceMolybdenum

Disclosed is a manufacturing method of a molybdenum target. The method comprises providing molybdenum powder; performing a first densification process on the molybdenum powder through isostatic pressing to obtain a first molybdenum target blank; putting the first molybdenum target blank into a sheath and vacuumizing the sheath; performing a second densification process on the first molybdenum target blank inside the sheath through cold isostatic pressing to form a second molybdenum target blank; after the second densification process, removing the sheath and performing a third densification process on the second molybdenum target blank through induction sintering to form a third molybdenum target blank; after the third densification process, rolling the third molybdenum target blank through hot rolling to form a fourth molybdenum target blank; after the hot rolling process, performing annealing on the fourth molybdenum target blank to obtain the molybdenum target. The manufacturing method of the molybdenum target can help produce full-density molybdenum targets, the uniformity of the internal organizational structure and the size, the purity and the surface dimension of grains of the molybdenum targets can well meet the ever-increasing requirements of the sputtering technology.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

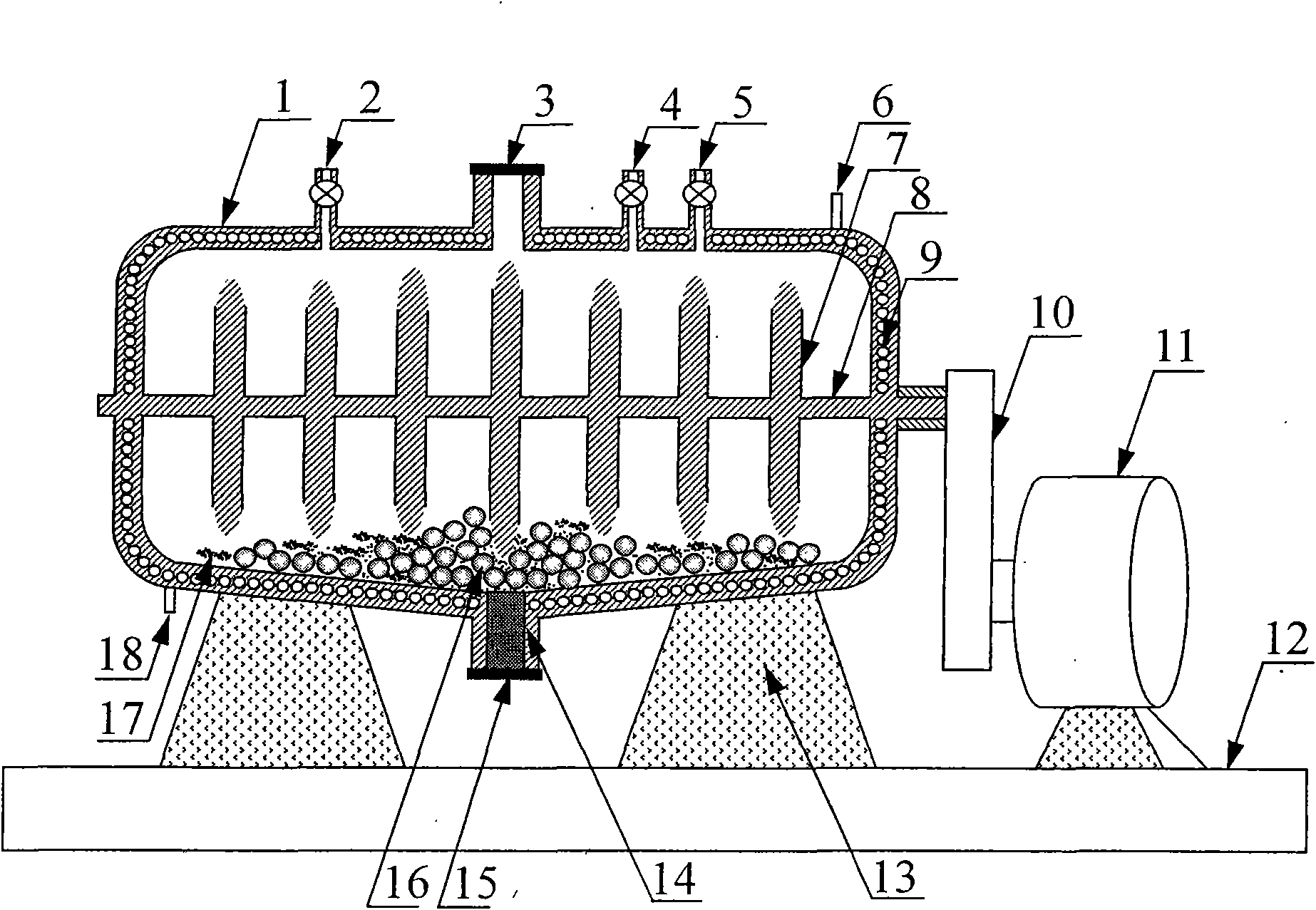

Ball grinder available for solid state reaction of powder

InactiveCN101823013AImprove mechanical energyMeeting the Energy Requirements of Solid-State Chemical ReactionsGrain treatmentsChemical reactionHigh energy

The invention relates to a ball grinder available for the solid state reaction of powder, which mainly comprises a ball grinding cylinder, an electromotor, a driving device, a grinding ball and a material inlet and outlet, wherein the horizontal type ball grinding cylinder is fixedly supported on a bracket; a jar is internally provided with the girding ball; the center of the ball grinding cylinder is provided with a rotatable main shaft; the main shaft is driven by the electromotor through the driving device to rotate; the main shaft is provided with a blade, wherein the rotating speed of the blade is 300-2000 r / min; the mechanical energy is transmitted to the grinding ball through the beating of the blade, so that the grinding ball can irregularly move with high speed; the bottom of theball grinding cylinder is in the shape of gradient with 0-30 degrees from the two ends to the center; the jar body of the ball grinding cylinder is provided with a cooling sleeve and an inlet and an outlet of cooling medium; and the jar body of the ball grinding cylinder is provided with an air exhausting opening and an air inlet. The ball grinder can lead the grinding ball to generate higher mechanical energy to provide high energy for inducing the solid state reaction among materials, thereby smashing, grinding and dispersing the materials and directly reacting to generate nanometer composite oxide.

Owner:BEIJING UNIV OF CHEM TECH

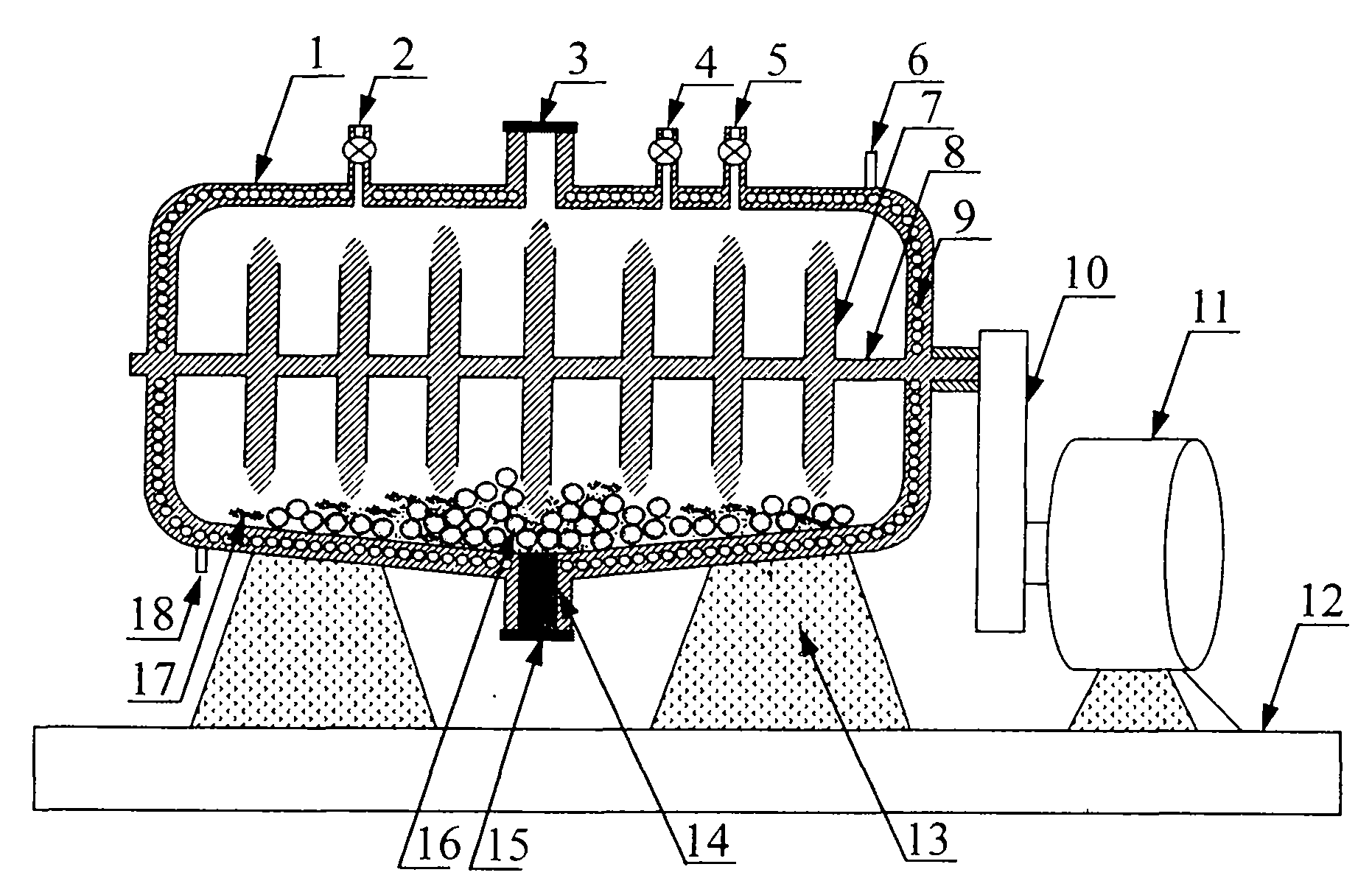

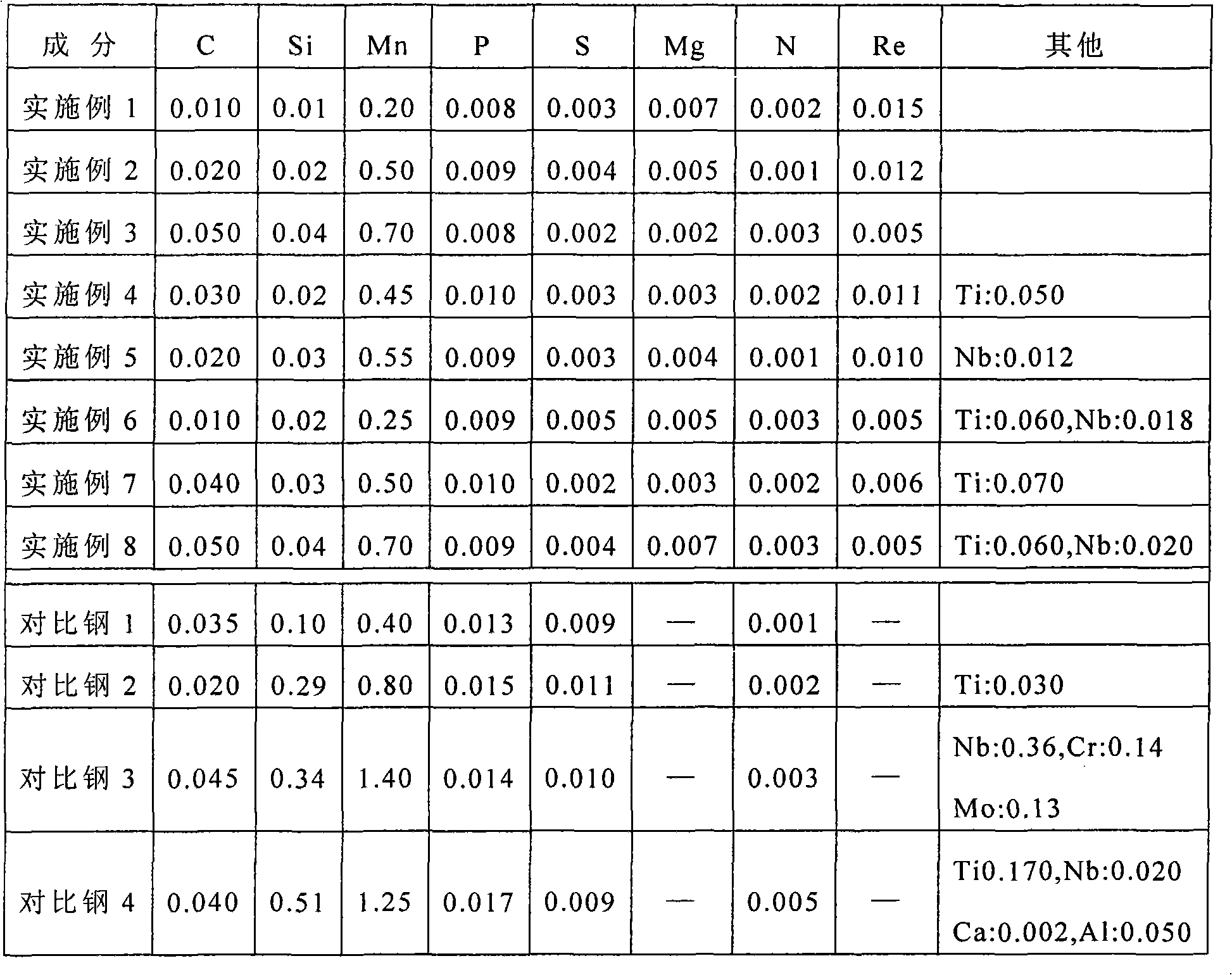

Yield strength 225MPa-level earthquake-resistant construction steel and production method thereof

The invention discloses yield strength 225MPa-level earthquake-resistant construction steel and a production method thereof. The steel comprises the following chemical compositions in percentage by weight: 0.01 to 0.05 percent of C, 0.01 to 0.04 percent of Si, 0.20 to 0.70 percent of Mn, less than or equal to 0.010 percent of P, less than or equal to 0.005 percent of S, 0.002 to 0.007 percent of Mg, 0.001 to 0.003 percent of N, 0.005 to 0.015 percent of Re, less than or equal to 0.070 percent of Ti, less than or equal to 0.020 percent of Nb, less than or equal to 0.0520 percent of Al, and the balance of Fe and inevitable impurities. The production method for the earthquake-resistant construction steel comprises the following steps of hot metal desulphurization, converter blowing, vacuum treatment, continuous casting, hot rolling, cooling, and the like. When the yield strength of the steel products exceeds 245MPa, a step of annealing treatment is added after the cooling step. Experiments prove that the yield strength 225MPa-level earthquake-resistant construction steel has the characteristics of low yield strength, high elongation and excellent impact toughness, and the production method has the advantages of simple process and low production cost.

Owner:武钢集团有限公司

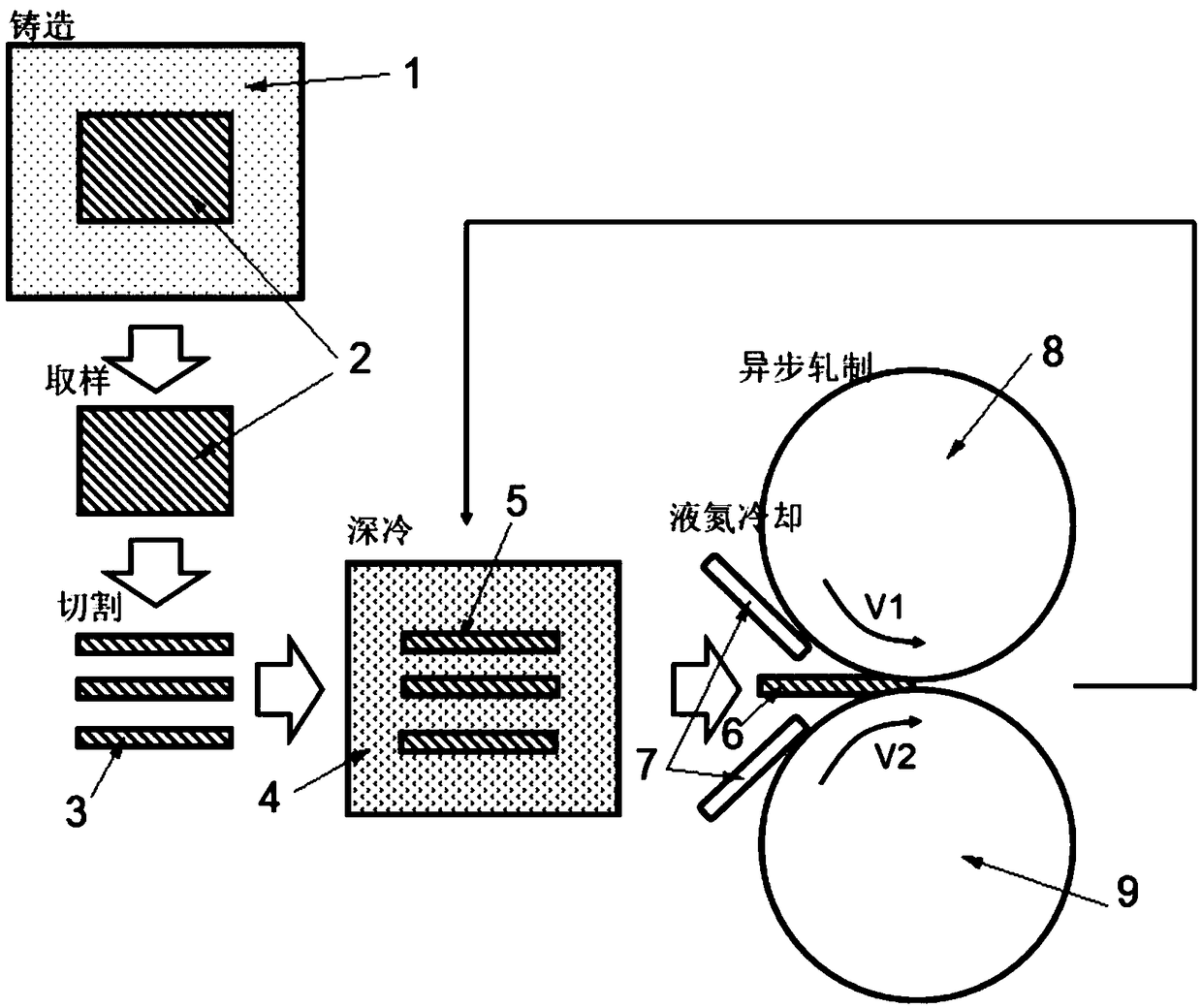

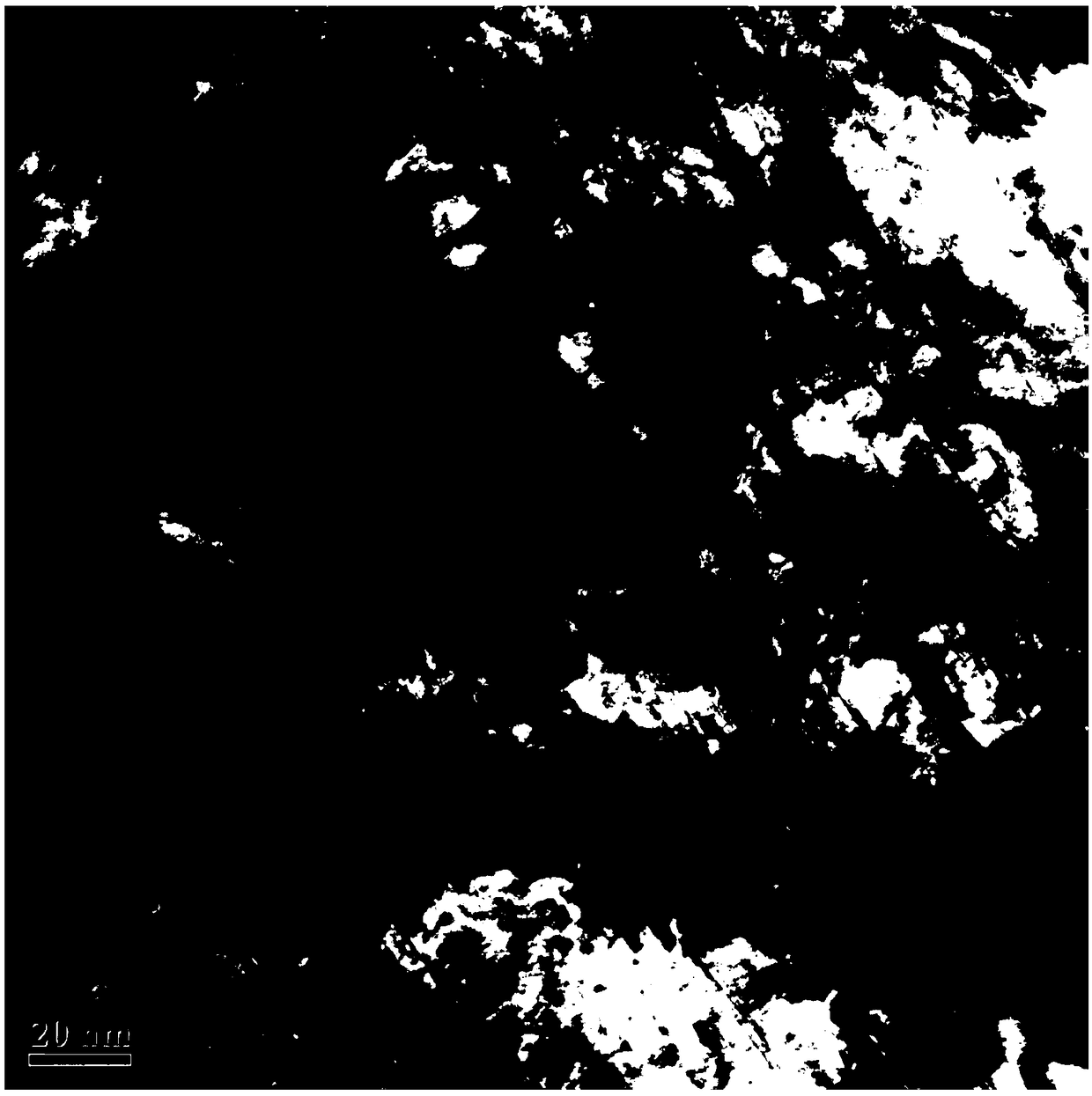

Copious cooling asymmetrical rolling method for preparing entropy alloy foil in high-performance CrCoNi

A copious cooling asymmetrical rolling method for preparing an entropy alloy foil in high-performance CrCoNi comprises the following steps: cutting a CrCoNi alloy bar or plate into sheets; carrying out copious cooling treatment in a copious cooling box at the temperature of minus 190 DEG C to minus 150 DEG C; cooling rolls by using a liquid nitrogen spray gun; carrying out copious cooling asymmetrical rolling on samples after copious cooling; maintaining liquid nitrogen in an asymmetrical rolling process to cool the rolls; cooling the rolled materials in the copious cooling box; and repeatingthe fourth step and the fifth step until the reduction rate of rolled pieces exceeds 85%-95% and the thickness of the foil is 200 mu m-6 mu m. CrCoNi alloy has good plastic deformation capacity underthe condition of ultra-low temperature, dynamic recrystallization behavior of the grain size of a material in a large plastic deformation process is inhibited by ultra-low temperature to reduce the grain size, the thickness of the material is reduced by twisting rolling deformation in a rolled piece deformation region in the asymmetrical rolling process, thus, entropy CrCoNi alloy foil is produced, the strength and plasticity of the material are improved effectively, and thus, the prepared medium-entropy CrCoNi foil has high toughness.

Owner:CENT SOUTH UNIV +1

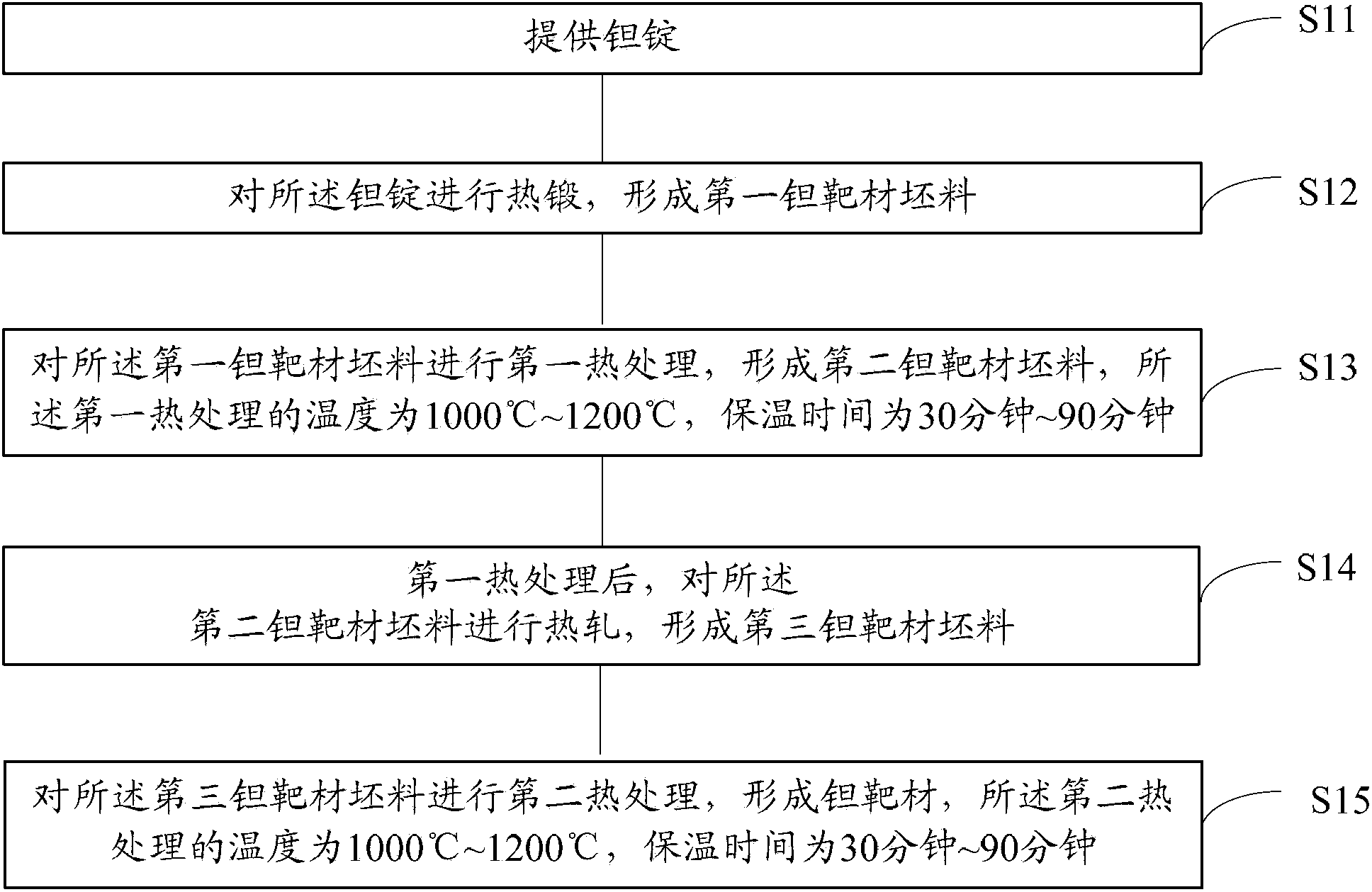

Production method of tantalum target and tantalum target component

ActiveCN103572225ADense tissueReduce unevennessVacuum evaporation coatingSputtering coatingIngotSemiconductor

The invention provides a production method of a tantalum target and a tantalum target component. The production method of a tantalum target comprises the following steps of providing a tantalum ingot; performing hot forging on the tantalum ingot to form a first tantalum target blank; performing first heat treatment on the first tantalum target blank to form a second tantalum target blank, wherein the temperature of the first heat treatment is 1,000-1,200 DEG C, and the temperature is maintained for 30-90 minutes; after the first heat treatment, performing hot rolling on the second tantalum target material to form a third tantalum target blank; performing second heat treatment on the third tantalum target blank to form the tantalum target, wherein the temperature of the second heat treatment is 1,000-1,200 DEG C, and the temperature is maintained for 30-90 minutes. By adopting the technical scheme, the produced tantalum target has relatively uniform internal organization and good magnetic property; moreover, by adopting the tantalum target to produce a tantalum target component for a semiconductor, the formed film has relatively good quality.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

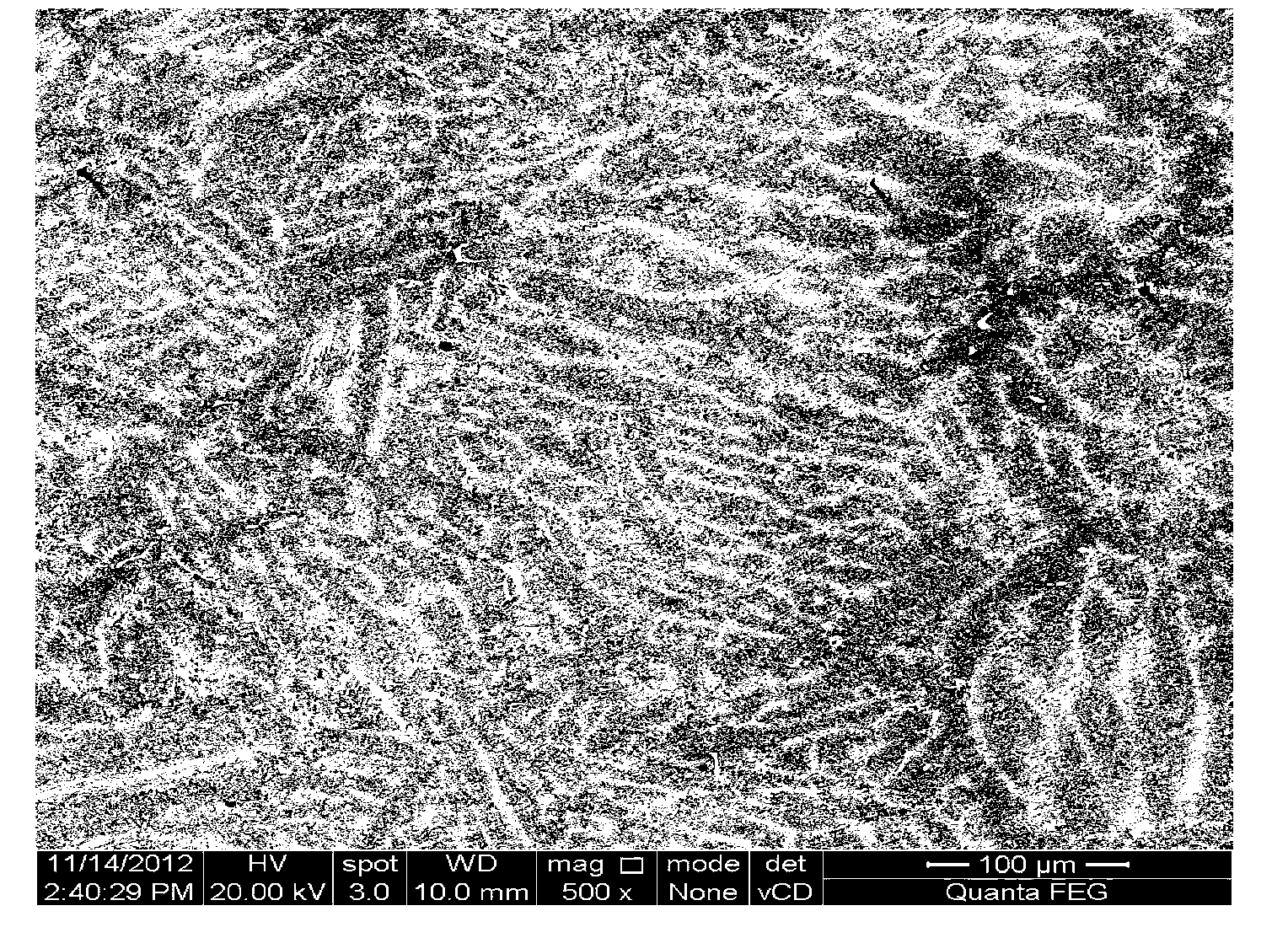

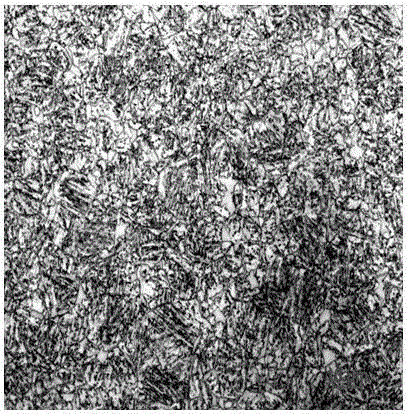

TiAl intermetallic compound materials containing yttebium and preparing method thereof

A TiAl intermetallic compound materials containing rare-earth Y and its preparing method are disclosed. It consists of Ti 40-40at.%, Al 38-50at.%, Y 0.02-1at.%, alloy element 0-15at.%. It is prepared by a. adding metal mould containing rare-earth element, Ti and Al into water-cooled copper crucible vacuum inducing smelting furnace; b. preheating metal mould before smelting and vacuum pumping; c. keeping temperature after alloy melting, and mixing melt; d. pouring melt into metal mould and forming TiAl intermetallic compound casting ingot containing rare-earth Y. It achieves simple process and improvement of materials performance.

Owner:HARBIN INST OF TECH

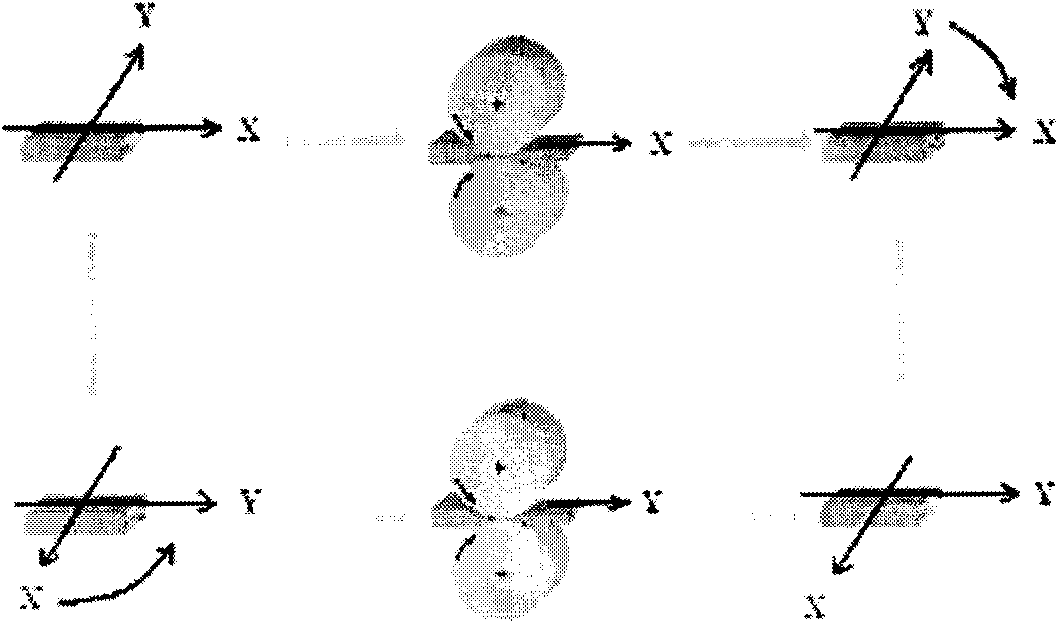

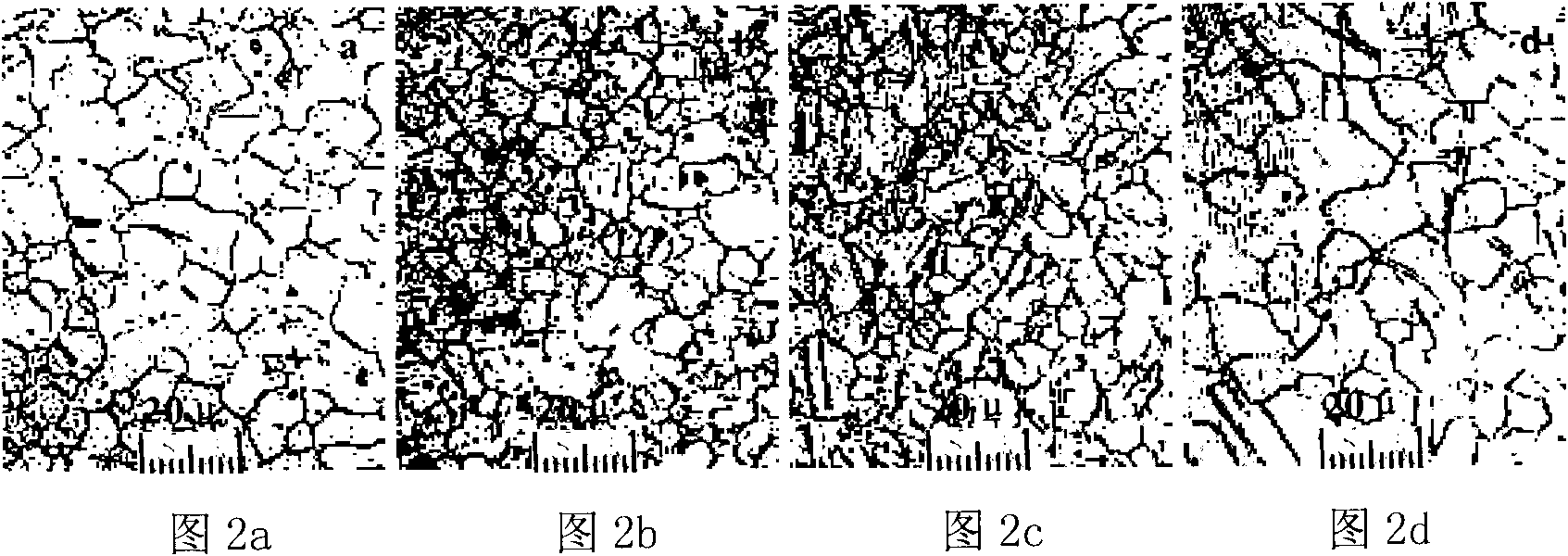

Method for rolling AZ31 magnesium alloy through asynchronous longitudinal and transverse crossing

InactiveCN101569892ARefine the grain sizeImprove mechanical propertiesMetal rolling arrangementsExtensibilityAZ31 alloy

The invention relates to a method for rolling AZ31 magnesium alloy through asynchronous longitudinal and transverse crossing, which belongs to the technical field of metal rolling. The method is characterized by comprising the following steps: calibrating an alloy to be rolled; rolling the alloy for the first time by a dual-roller asynchronous rolling mill; and rolling the alloy for the second time after the alloy is rolled for the first time. The average size of the crystalline grain of the AZ31 alloy rolled by the method is 10 microns, and the mechanical properties of the alloy after optimal rolling can reach that the extensibility is 16.73 percent, the yield strength is 249.2 MPa, and the tensile strength is 319.46 MPa.

Owner:SHANGHAI JIAO TONG UNIV +1

Sheet steel with tensile strength of 1500 MPa levels and used for hot stamping forming and cast steel plate (CSP) production method thereof

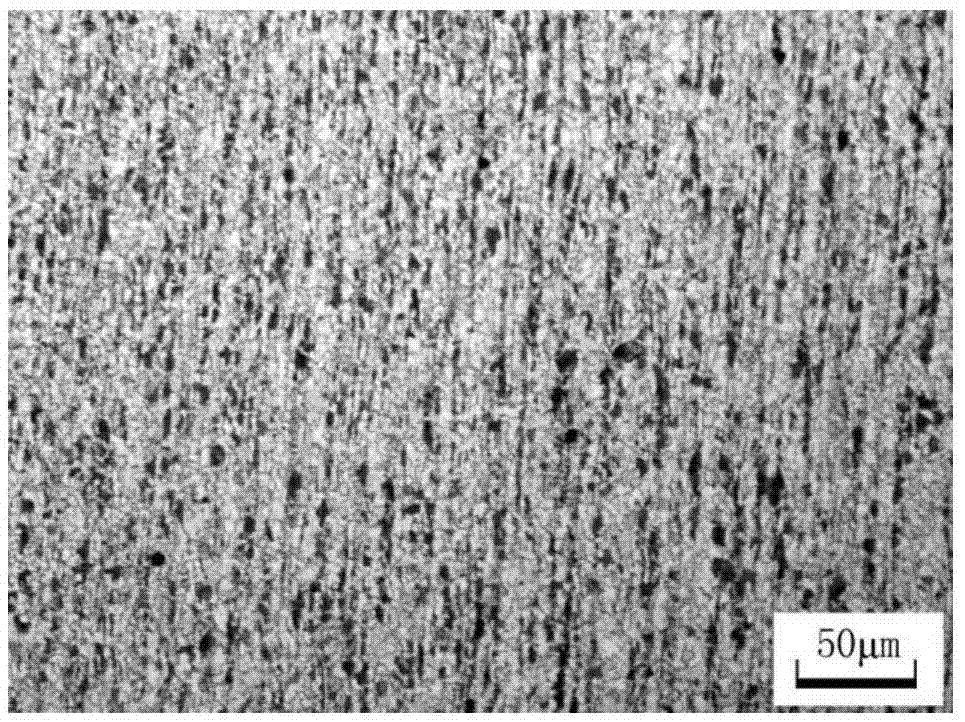

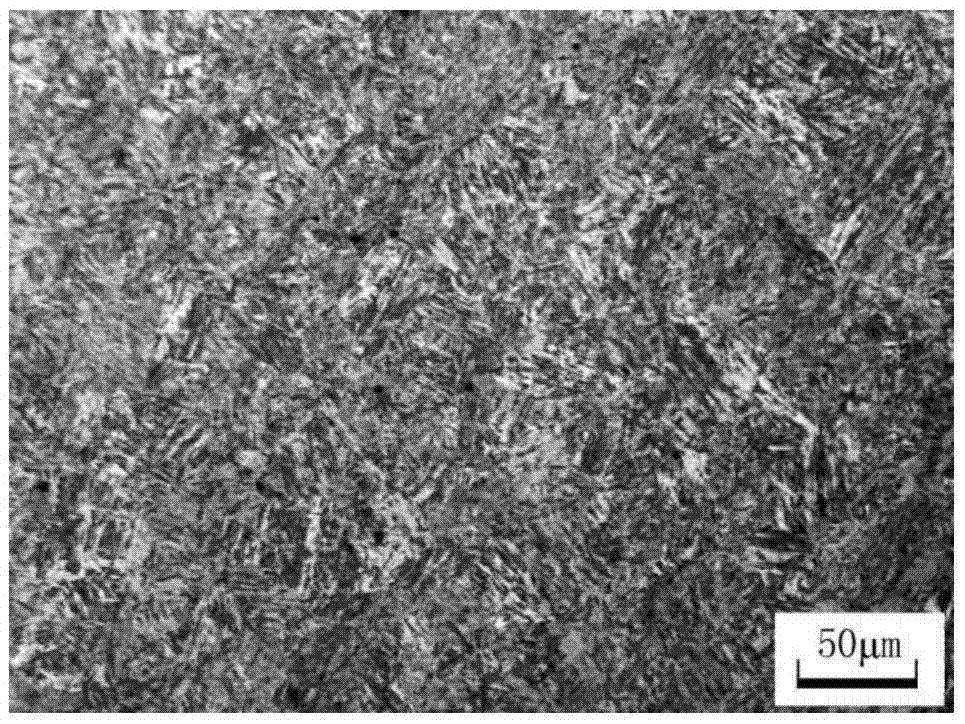

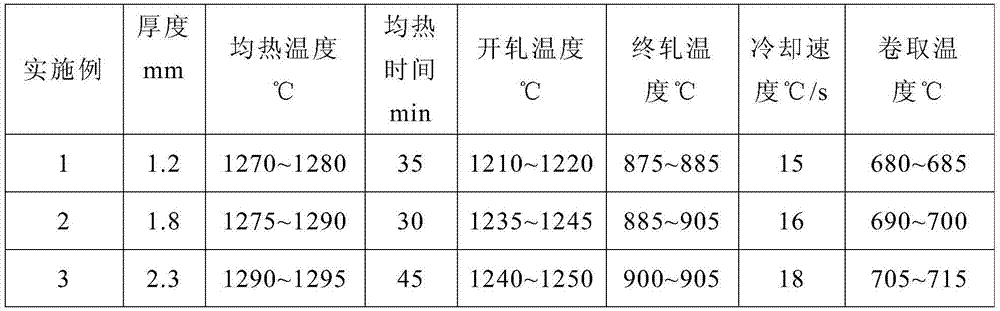

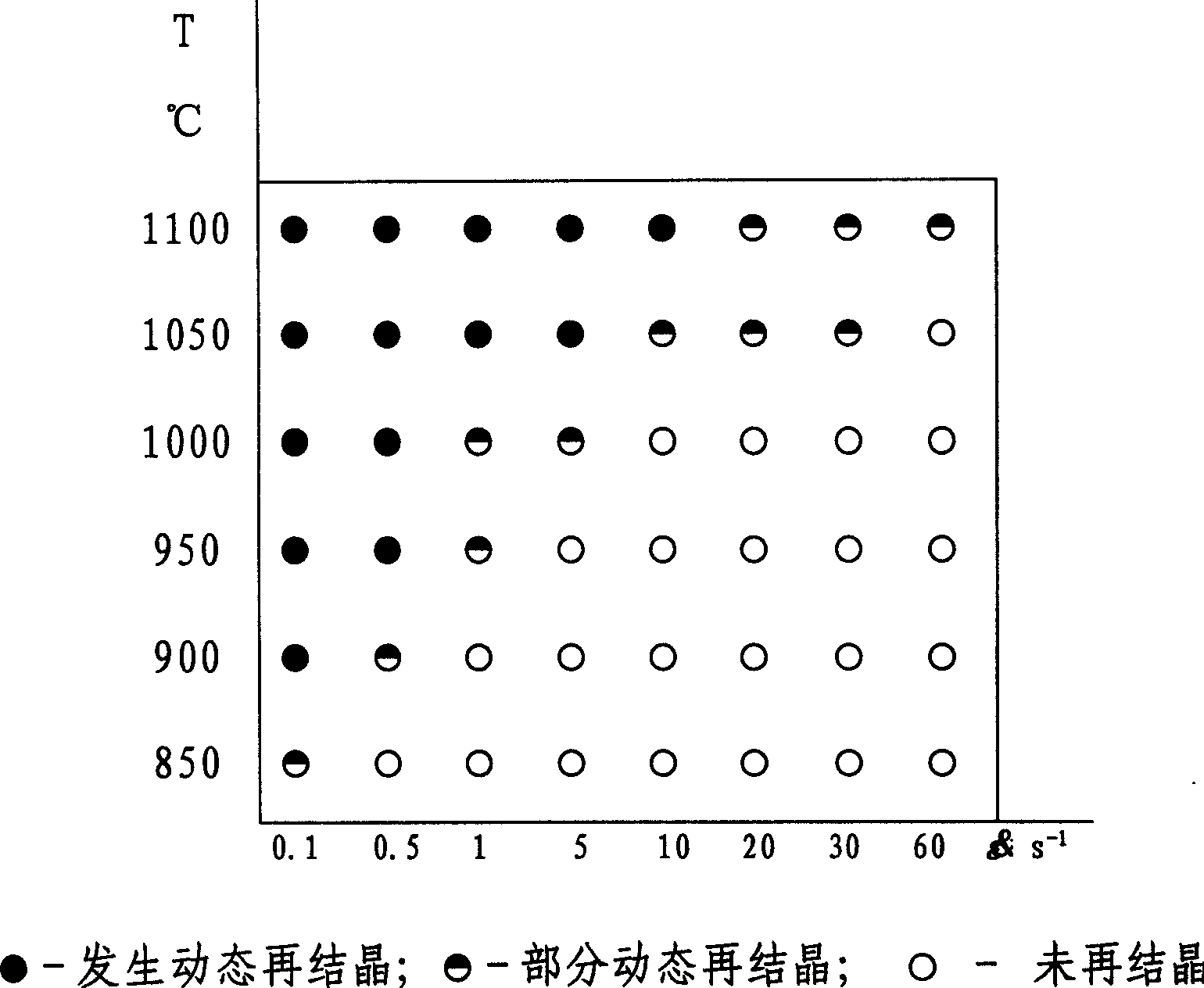

The invention discloses sheet steel with the tensile strength of 1500 MPa levels and used for hot stamping forming and a cast steel plate (CSP) production method thereof. The sheet steel comprises, by weight, 0.20-0.25% of C, 0.25-0.40% of Si, 1.00-1.30% of Mn, 0-0.025% of P, 0-0.01% of S, 0.015-0.035% of Als, 0-0.005% of N, 0-0.005% of B, 0.020-0.060% of Nb, 0.010-0.040% of Ti, and the balance Fe and inevitable microelements. According to the sheet steel with the tensile strength of 1500 MPa levels and used for hot stamping forming and the cast steel plate (CSP) production method thereof, the process steps comprises molten steel smelting, vertical bending type CSP sheet blank continuous casting, descaling, roller bottom type tunnel furnace soaking, thermal mechanical control processing (TMCP) six machine frame hot continuous rolling, laminar cooling, reeling, unreeling pickling, flattening and reeling; sheet material cold rolling and annealing heat treatment are omitted, and a traditional cold-rolled sheet product is replaced by a hot rolled sheet product; the comprehensive production cost is reduced, and the cost of the steel per ton can be reduced by over 600 yuan.

Owner:武汉钢铁有限公司

Rolling method for low carbon twisted steel bar

InactiveCN1586750AControl yield strengthRefine the grain sizeScrew-threads articlesMetal rolling arrangementsCarbon steelSteel bar

The present invention relates to metal rolling technology, and especially the rolling process of twisted low carbon steel bar. The twisted low carbon steel bar has the chemical components of: C 0.17-0.23 wt%, Si 0.20-0.80 wt%, Mn 0.50-1.50 wt%, S not more than 0.035 wt% and P not more than 0.035 wt%. The rolling process with complete or patial temperature control includes the following steps: initial rolling with low temperature cogging at 850-950 deg.c, middle rolling at 750-850 deg.c with accumulated deformation over 50 %, finish rolling at 750-900 deg.c, and subsequent water cooling at lower than 600 deg.c with cooling speed greater than 10 deg.c / sec. Compared with available technology, the present invention has superfine crystal grain structure and high steel bar performance.

Owner:CENT IRON & STEEL RES INST

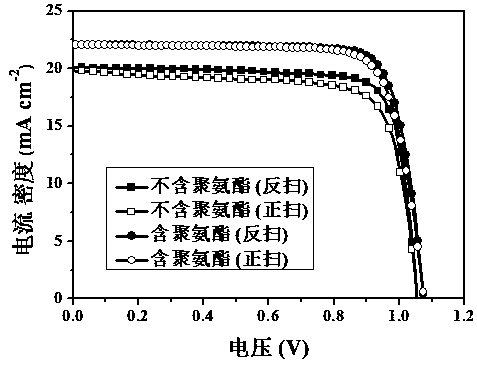

Bend-resistant perovskite solar cell and preparation method thereof

InactiveCN107611190ASlow crystallization rateRefine the grain sizeFinal product manufactureSemiconductor devicesPerovskite solar cellHole transport layer

The invention discloses a bend-resistant perovskite solar cell, comprising a transparent substrate, an anode, an electron transport layer, a perovskite active layer, a hole transport layer and a cathode. The perovskite active layer is composed of a perovskite material and an additive. The additive is polyurethane. The perovskite material is CH<3>NH<3>PbI<3>, CH<3>NH<3>PbI<3>-xClx or (FAPbI<3>)l-x(MAPbBr<3>)x. The additive polyurethane is added to perovskite precursor solution according to mass concentration of 0.01wt%-5wt%. According to the bend-resistant perovskite solar cell, the polyurethane is introduced into perovskite precursor solution, perovskite crystals are controlled to nucleate, a crystallization rate is reduced, the bend-resistance of perovskite film is improved, a new thoughtfor preparing high performance flexible perovskite solar cell is provided, and the flexible roll-to-roll commercialized production of the perovskite solar cell is realized.

Owner:NANCHANG UNIV

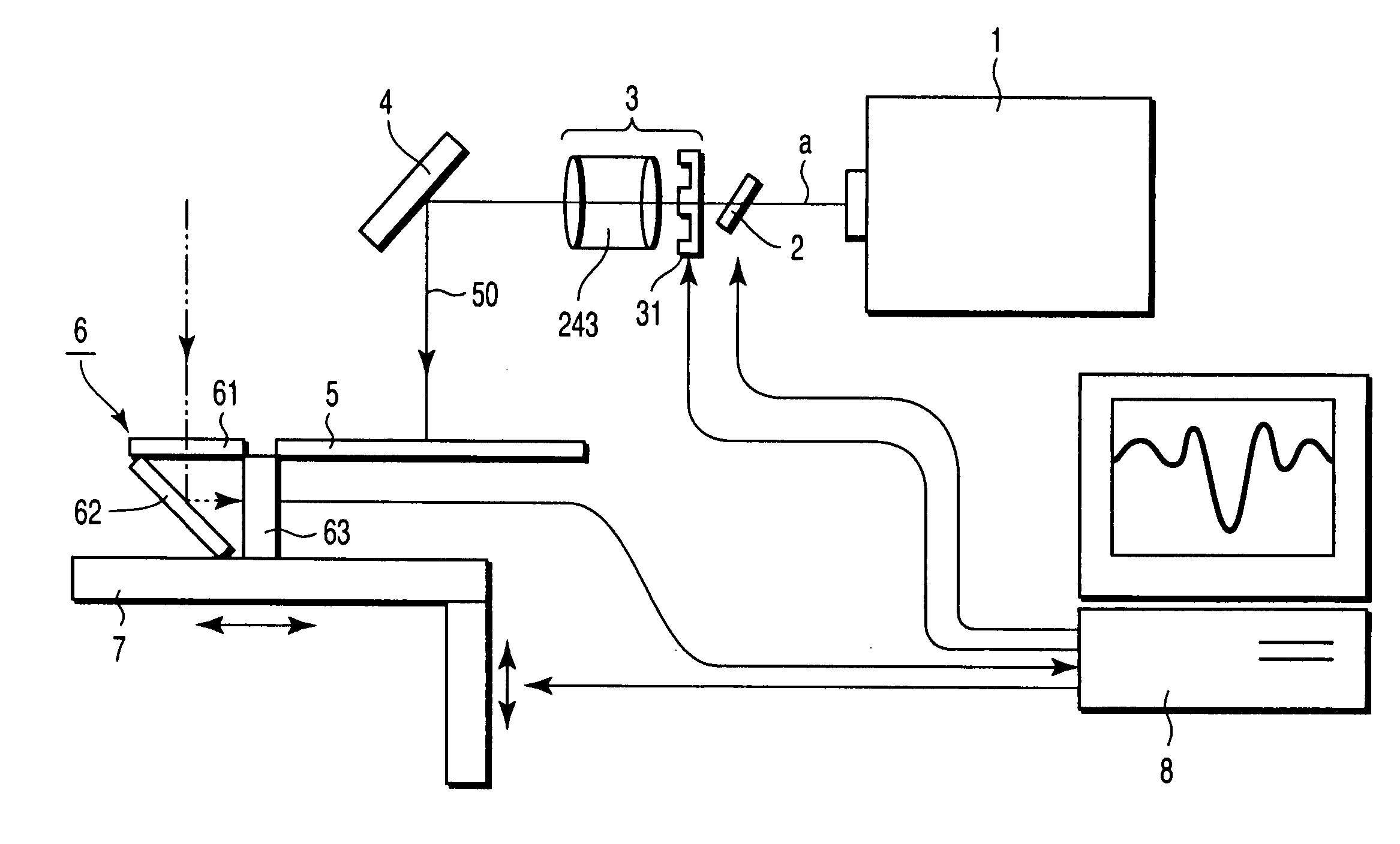

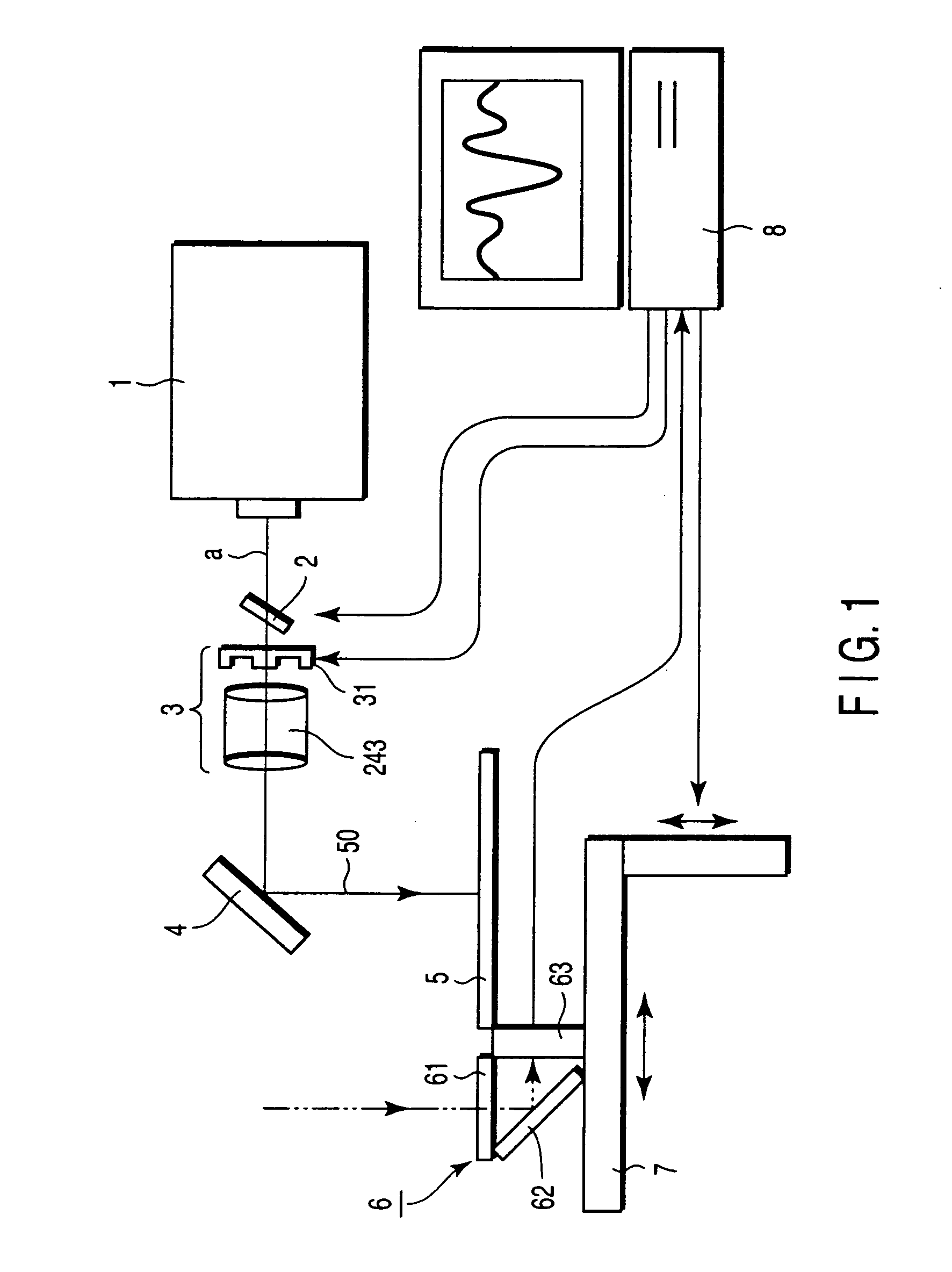

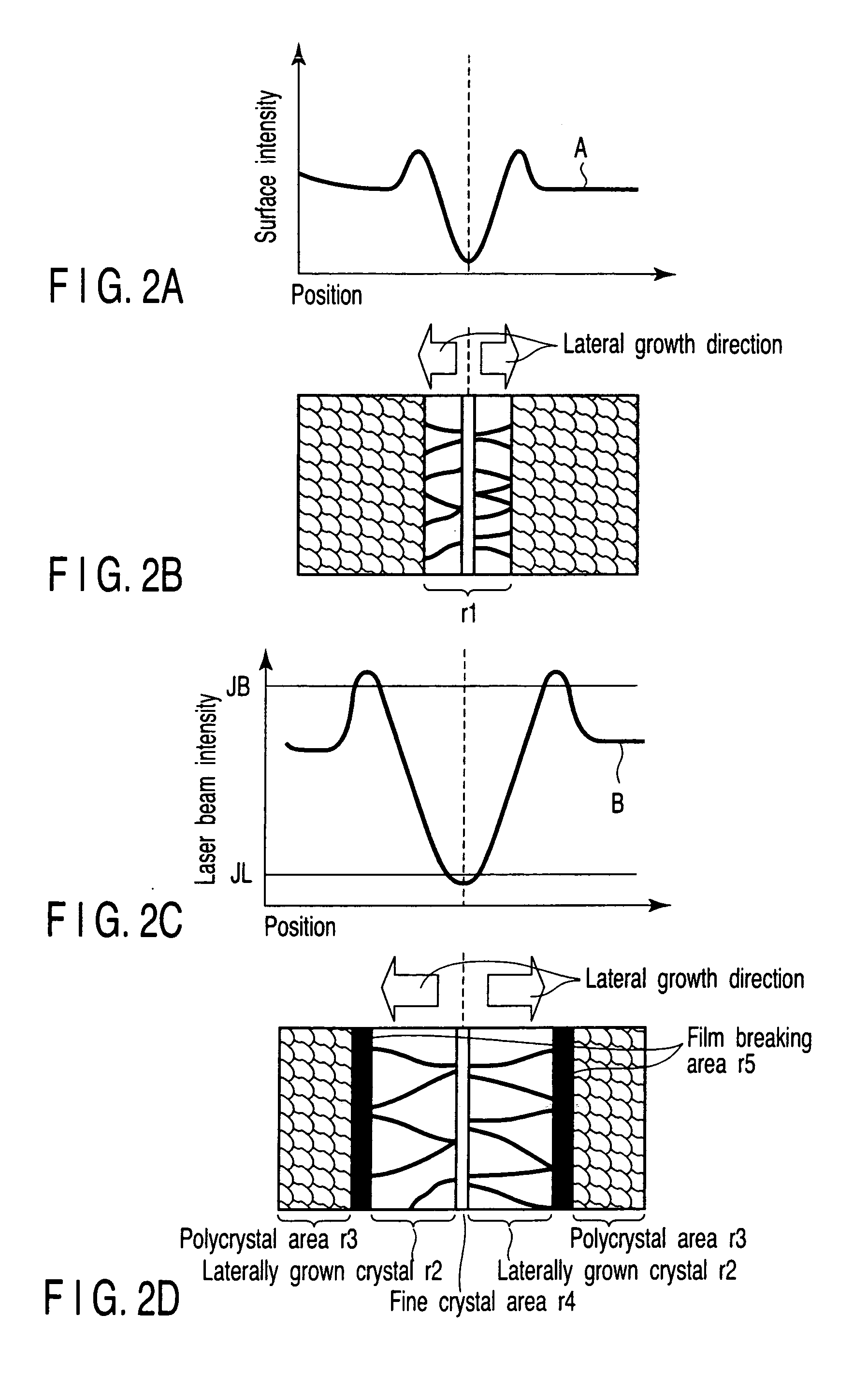

Crystallization method, crystallization apparatus, processed substrate, thin film transistor and display apparatus

InactiveUS20060186412A1Promotes lateral growthLarge grainTransistorBy zone-melting liquidsLight beamSingle crystal

There are provided a crystallization method which can design laser beam having a light intensity and a distribution optimized on an incident surface of a substrate, form a desired crystallized structure while suppressing generation of any other undesirable structure area and satisfy a demand for low-temperature processing, a crystallization apparatus, a thin film transistor and a display apparatus. When crystallizing a non-single-crystal semiconductor thin film by irradiating laser beam thereto, irradiation light beam to the non-single-crystal semiconductor thin film have a light intensity with a light intensity distribution which cyclically repeats a monotonous increase and a monotonous decrease and a light intensity which melts the non-single-crystal semiconductor. Further, at least a silicon oxide film is provided on a laser beam incident surface of the non-single-crystal semiconductor film.

Owner:SHARP KK

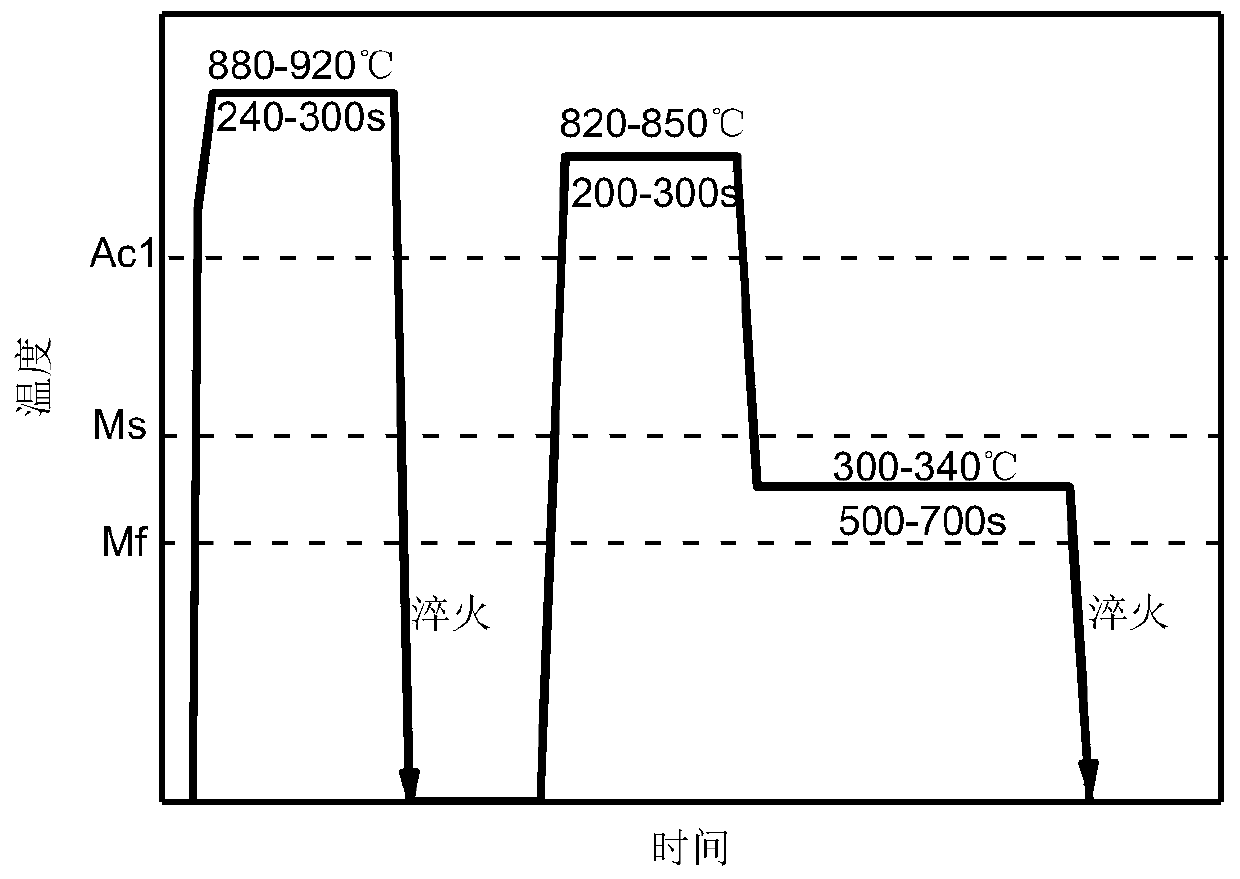

1180 MPa-grade ultrahigh-strength low-cost cold-rolled quenched partition steel and manufacturing method thereof

InactiveCN110093564AIncrease contentOrganizational stabilityUltimate tensile strengthMechanical property

The invention relates to the field of third-generation advanced high-strength steel used for automobiles and discloses 1180 MPa-grade ultrahigh-strength low-cost cold-rolled quenched partition steel and a manufacturing method thereof. A steel plate comprises the chemical components including, by mass percent, 0.18-0.22% of C, 1.0-3.0% of Mn, 1.0-2.0% of Si, not greater than 0.05% of P, not greaterthan 0.02% of S, 0-0.05% of Nb, 0-0.2% of Ti and the balance iron and inevitable impurities. The steel plate manufacturing method relates to the process of steel smelting, hot rolling, cold rolling,pre-quenching and heat treatment, and finally, a ferrite-bainite-martensite-retained austenite mixed structure is obtained. According to the 1180 MPa-grade ultrahigh-strength low-cost cold-rolled quenched partition steel and the manufacturing method thereof, on the basis of traditional C-Mn-Si series quenched partition steel, Nb and Ti elements are added for refining the structure, pre-quenching treatment and a one-step partition process are adopted, finally the ultrahigh-strength quenched partition steel with the yield strength being 500-800 MPa, the tensile strength not smaller than 1180 MPa, the elongation after fracture not smaller than 20% and the product of strength and elongation not smaller than 24GPa.% is obtained, and the mechanical property is quite excellent.

Owner:NORTHEASTERN UNIV

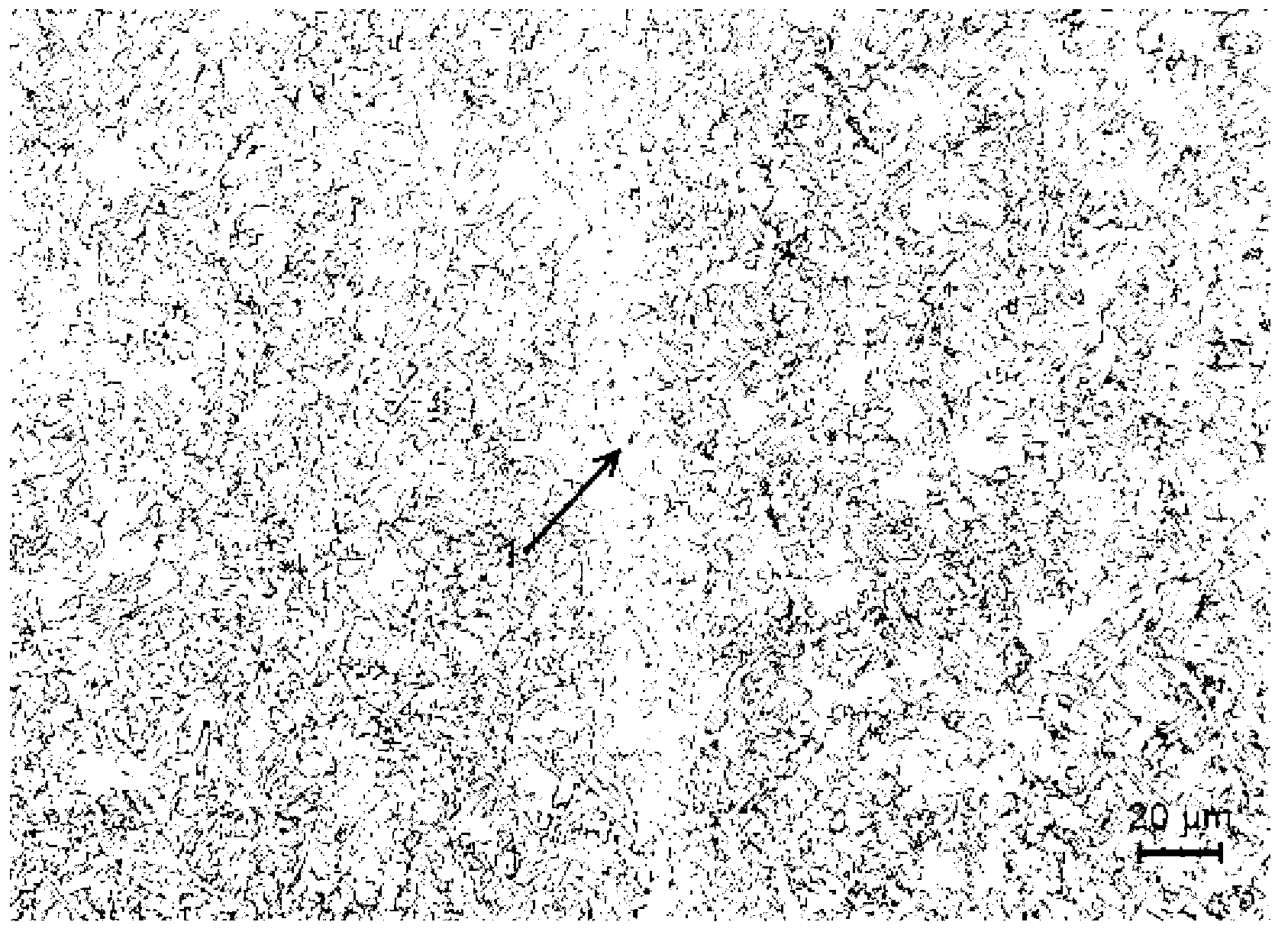

High-toughness hot-rolled high-strength steel with yield strength being 800 MPa and manufacturing method of high-toughness hot-rolled high-strength steel

The invention discloses high-toughness hot-rolled high-strength steel with the yield strength being 800 MPa and a manufacturing method of the high-toughness hot-rolled high-strength steel. The chemical components of the high-toughness hot-rolled high-strength steel comprise, by weight, 0.02-0.05% of C, 0-0.5% of Si, 1.5-2.5% of Mn, 0-0.015% of P, 0-0.005% of S, 0.02-0.10% of Al, 0-0.006% of N, 0.01-0.05% of Nb, 0.01-0.03% of Ti, 0.03-0.06% of Nb and Ti, 0.1-0.5% of Cr, 0.1-0.5% of Mo, 0.0005-0.0025% of B, and the balance Fe and inevitable impurities. According to the high-toughness hot-rolled high-strength steel, the design thinking of ultra-low carbon martensite is adopted, the grain size of austenite is refined through compound addition of Nb and Ti, the hardenability and the temper hardening resistance are improved through compound addition of Cr and Mo, and by utilizing the hot continuous rolling technique, ultra-low carbon martensite structures are obtained through direct quenching or the low-temperature coiling technique; the yield strength of the high-strength structural steel can reach 800 MPa, quite excellent low-temperature impact toughness can still be achieved within the temperature range from minus 80 DEG C to room temperature, and the ballistic work can reach over 100 J at the temperature of minus 80 DEG C.

Owner:BAOSHAN IRON & STEEL CO LTD

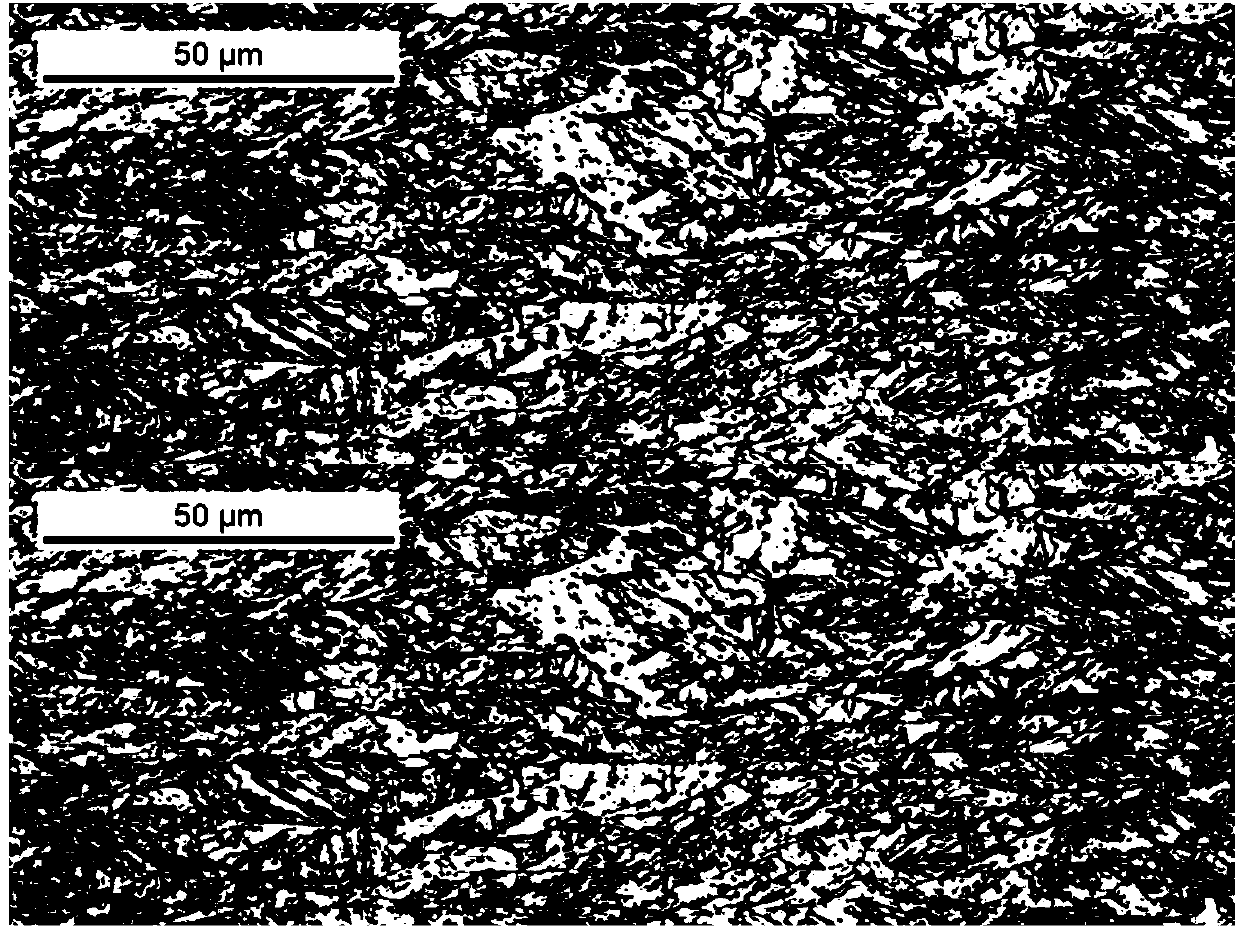

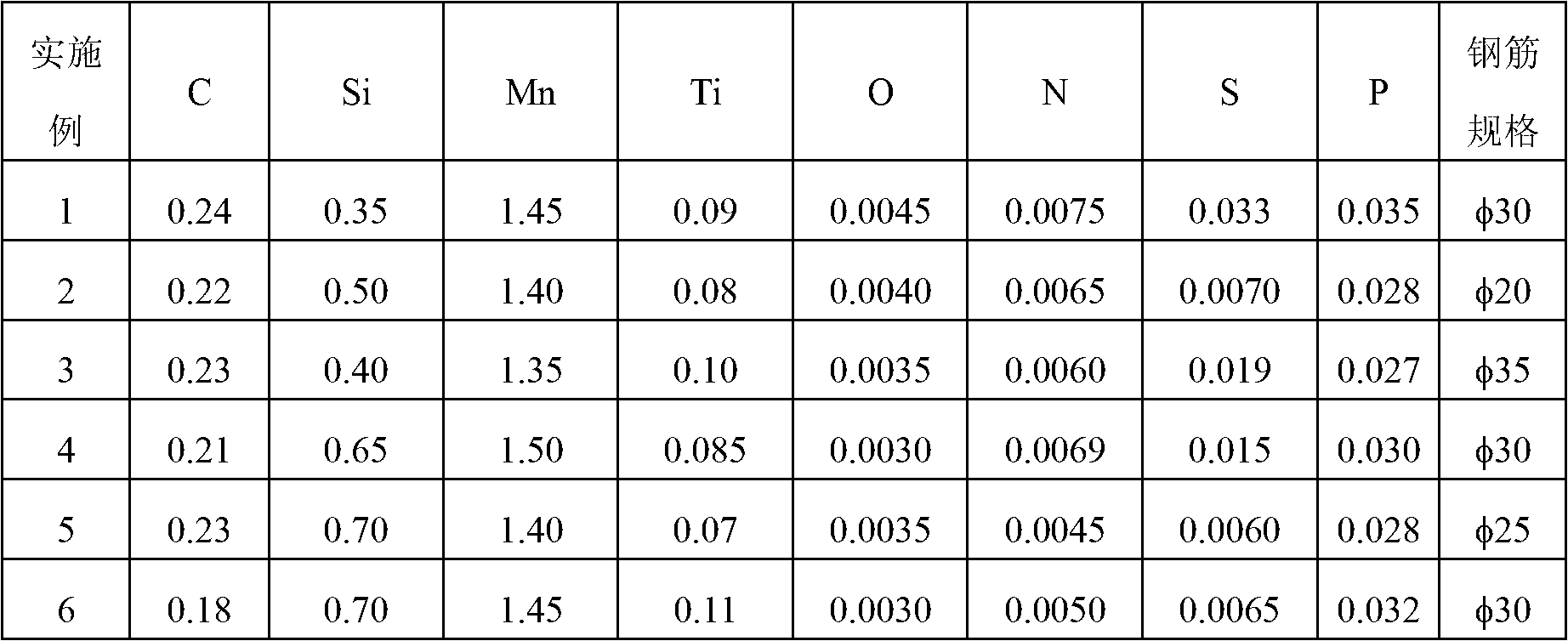

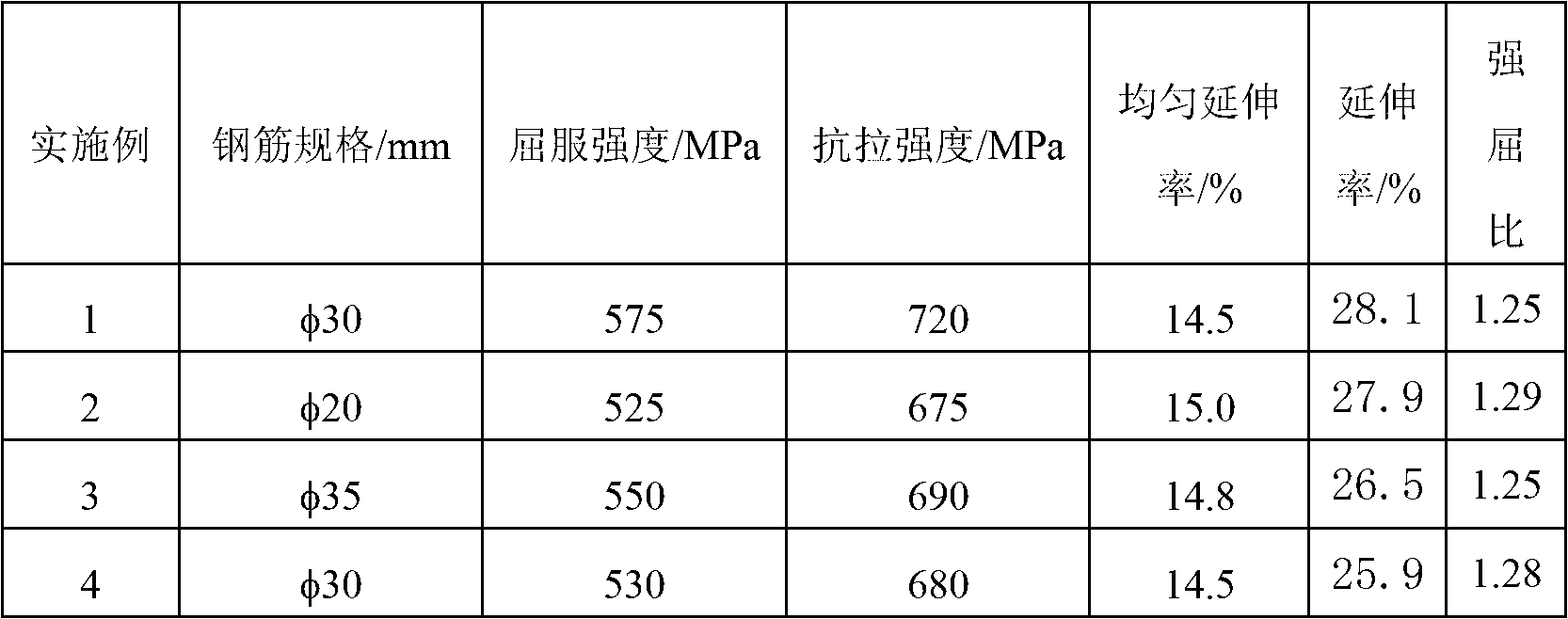

Titanium microalloyed 500-MPa high-strength steel bar and production method thereof

The invention discloses a 500-MPa high-strength steel bar for reinforced concrete and a production method thereof, belonging to the technical field of microalloying in ferrous metallurgy. The steel in the steel bar comprises the following chemical components in percentage by weight: 0.18-0.25% of C, 0.20-0.80% of Si, 1.20-1.50% of Mn, 0.06-0.12% of Ti, at most 0.01% of N, at most 0.045% of S, at most 0.045% of P, and the balance of Fe and inevitable impurities. The preparation method of the steel bar comprises the following steps: a. crude smelting, tapping, deoxidizing and alloying; b. refining and composition fine adjustment, and casting after satisfying the steel bar composition requirement; and c. hot rolling; wherein the titanium is alloyed in the tapping process after deoxidizing or in the refining process. By using the principle that the titanium in steel reinforces the precipitation, the invention enhances the mechanical properties of the steel, and satisfies the performance requirements for 500-MPa high-strength steel bars and even anti-seismic steel bars.

Owner:PANZHIHUA GANGCHENG GROUP

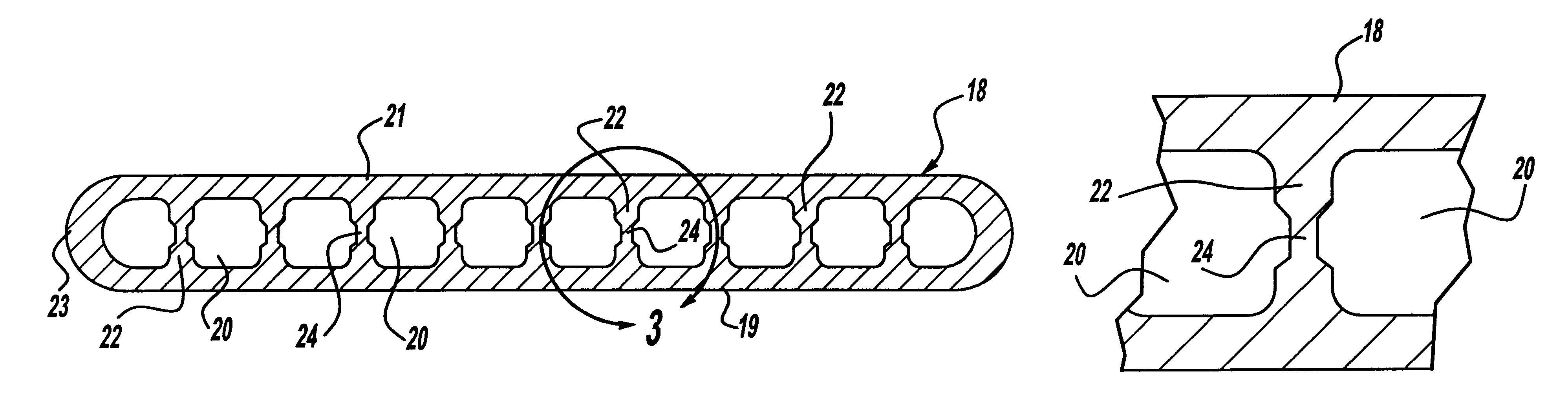

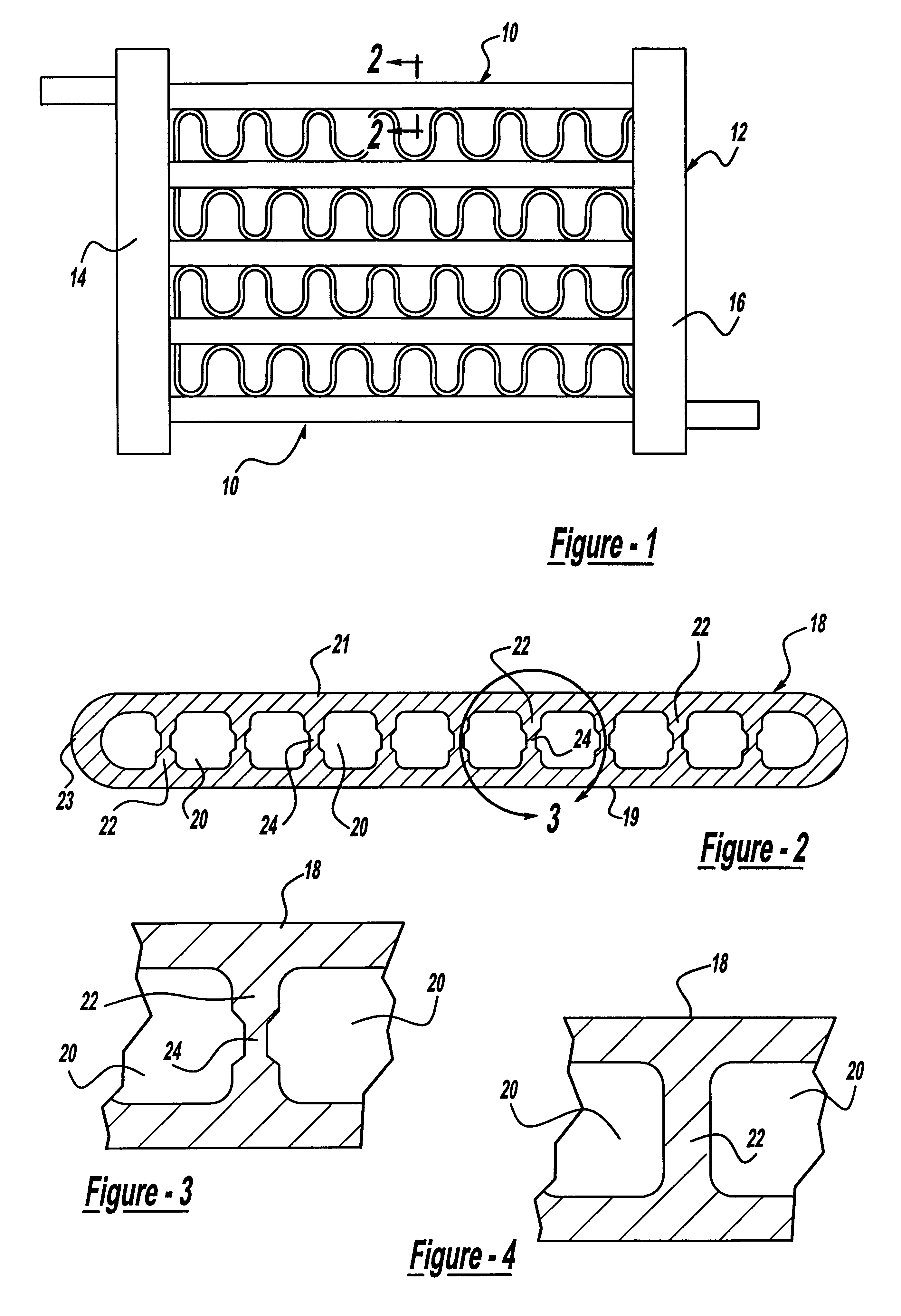

Micro-multiport (MMP) tubing with improved metallurgical strength and method for making said tubing

InactiveUS6192978B1Refine the grain sizeImproves metallurgical strengthMetal-working apparatusStationary conduit assembliesUltimate tensile strengthGrain growth

This invention is a process for making micro-multiport tubing for use in automobile air conditioner heat exchangers. The tubing is a flat body with a row of side-by-side passageways, which are separated by upright webs. Processing of this tubing involves extrusion, a straightening and cutting operation, assembly and furnace brazing of the condenser. This invention improves the grain size of the metal in the tubing and also improves the metallurgical strength of the tubing. Ports are formed in the tubing during extrusion. These ports are separated by webs and the webs are extruded so that they have a reduced thickness at their centers. In response to successive cold working of the body, the webs are changed in shape to a more uniform thickness state. Stated other wise, in this invention, the webs are initially of hour glass shape such that when there is five percent change in material thickness, the strain is concentrated at the center of the web and results in at least fifteen percent cold work. With fifteen percent cold work or more, the amount of grain growth is controlled and the improvement in the metallurgical strength is achieved.

Owner:BRAZEWAY

High-strength pipe steel and method for manufacturing same

ActiveCN102021499AImprove toughnessImprove corrosion resistanceManufacturing convertersElectric furnacePetroleumQuenching

The invention relates to a method for manufacturing pipe steel. The pipe steel comprises the following components in percentage by weight: 0.02-0.12 percent of C, 0.10-0.35 percent of Si, 1.40-2.00 percent of Mn, no more than 0.015 percent of P, no more than 0. 005 percent of S, 0.021-0.05 percent of Ti, 0.05-0.40 percent of Cr, 0.05-0.30 percent of Mo, 0.10-0.30 percent of Cu, 0.10-0.24 percent of Ni, no more than 0. 008 percent of N, 0.02-0.07 percent of Nb, 0.01-0.08 percent of V and the balance of Fe and inevitable impurities. The method comprises the steps of smelting, external refining, casting, slab reheating, controlled rolling, controlled cooling, quenching and tempering in a converter or an electric furnace. The reheating temperature of the slab is 1100-1250 DEG C. The controlled rolling comprises a recrystallization zone rolling step and a non-recrystallization zone rolling step. The quenching and tempering comprises a quenching step and a tempering step. The pipe steel has the characteristics of high strength, excellent low temperature impact toughness and excellent weldability, and can be used for constructing long-distance petroleum and natural gas transmission pipelines, slurry transmission pipeline, city pipeline networks and the like.

Owner:BAOSHAN IRON & STEEL CO LTD

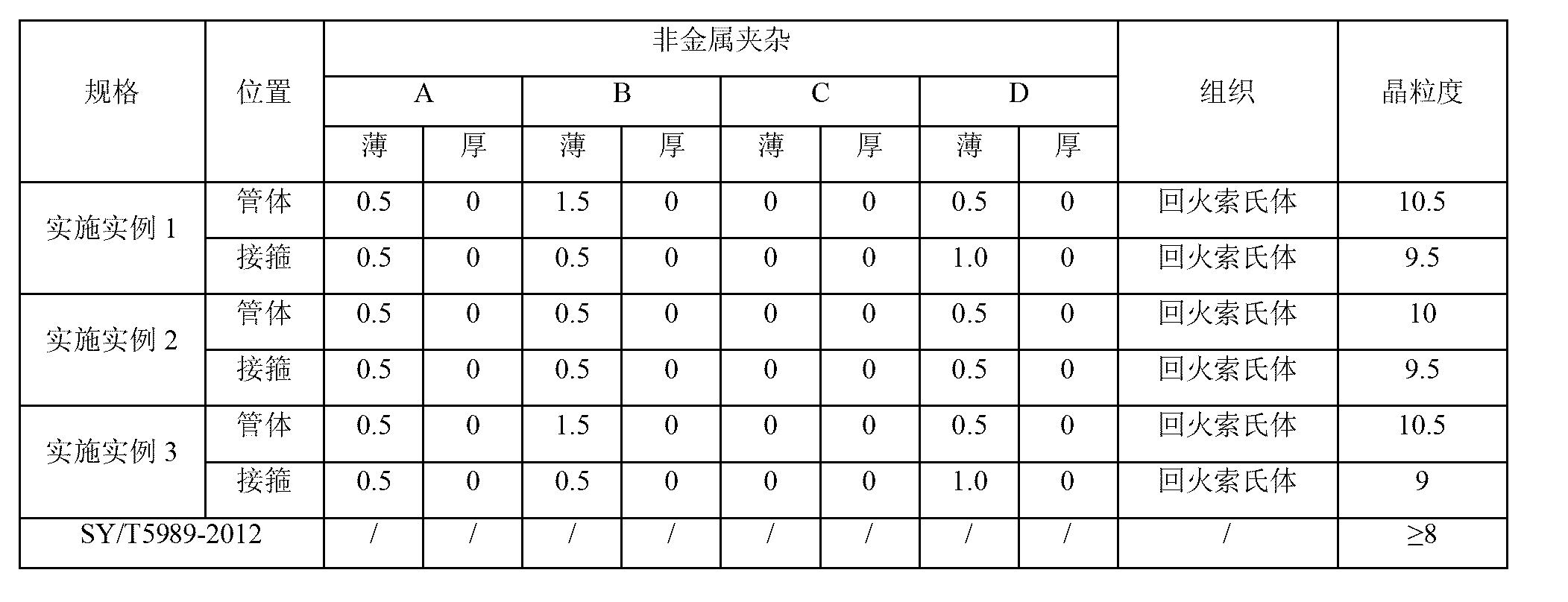

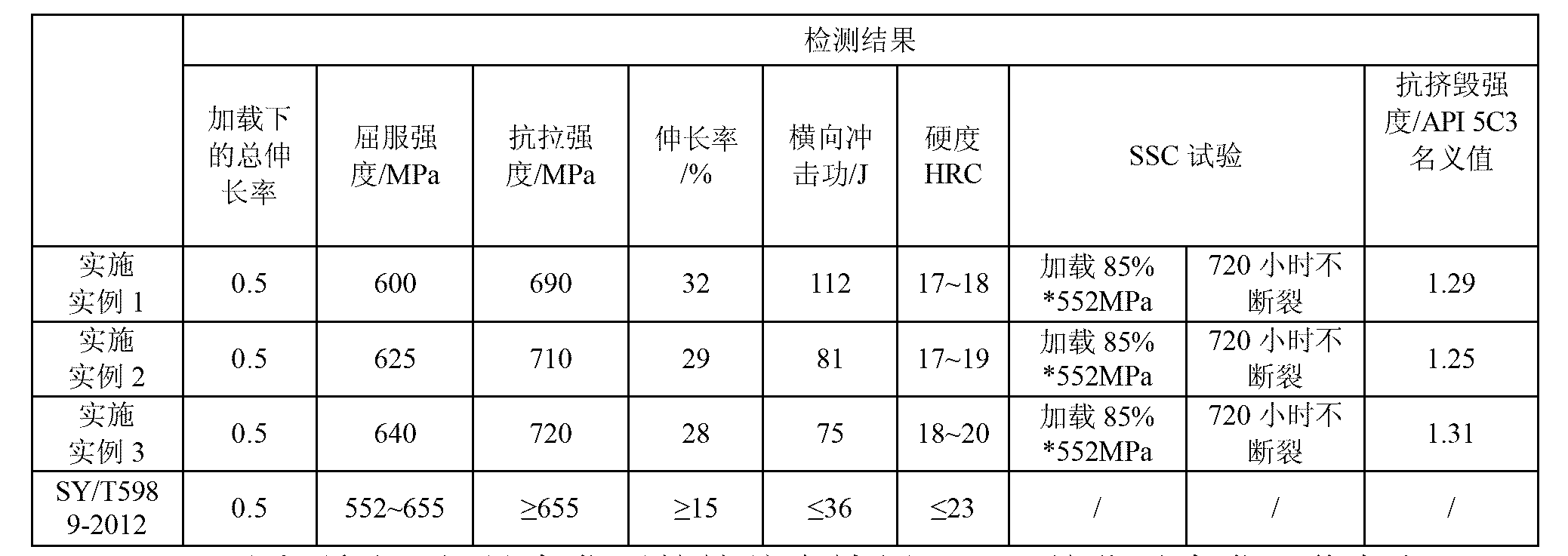

High-strength and high-toughness oil casing and manufacturing method thereof

ActiveCN103194693ARefine the grain sizeConsistent performanceDrilling rodsDrilling casingsChemical compositionThermal treatment

The invention discloses a high-strength and high-toughness oil casing and a manufacturing method thereof. A 'HFW(High Frequency Welding)+welding line on-line thermal treatment+hot tension reducing+whole casing thermal treatment' technology is used for manufacturing a Q125 steel grade oil casing, and the weight percentage of chemical components are as follows: C: 0.18-0.30; Sh: 0.10-0.35; Mn: 1.00-1.30; P: not more than 0.018; S: not more than 0.008; Cr: 0.20-1.20; Mo: 0.20-0.55; Nh: 0.10-0.56; B: 0.0010-0.0015; Nb+V+Ti: not more than 0.08; and the balance of Fe and unavoidable impurities. For the Q125 oil casing produced by the manufacturing method, the yield strength is not less than 865MPa, the tensile strength is not less than 940MPa, the specific elongation is not less than 23.2%, at 0 DEG C, the full-scale transverse impact energy is not less than 105J and the longitudinal impact energy is not less than 110J. The Q125 steel grade oil casing produced by the technology is excellent in comprehensive performance, and has excellent high toughness and high plasticity.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

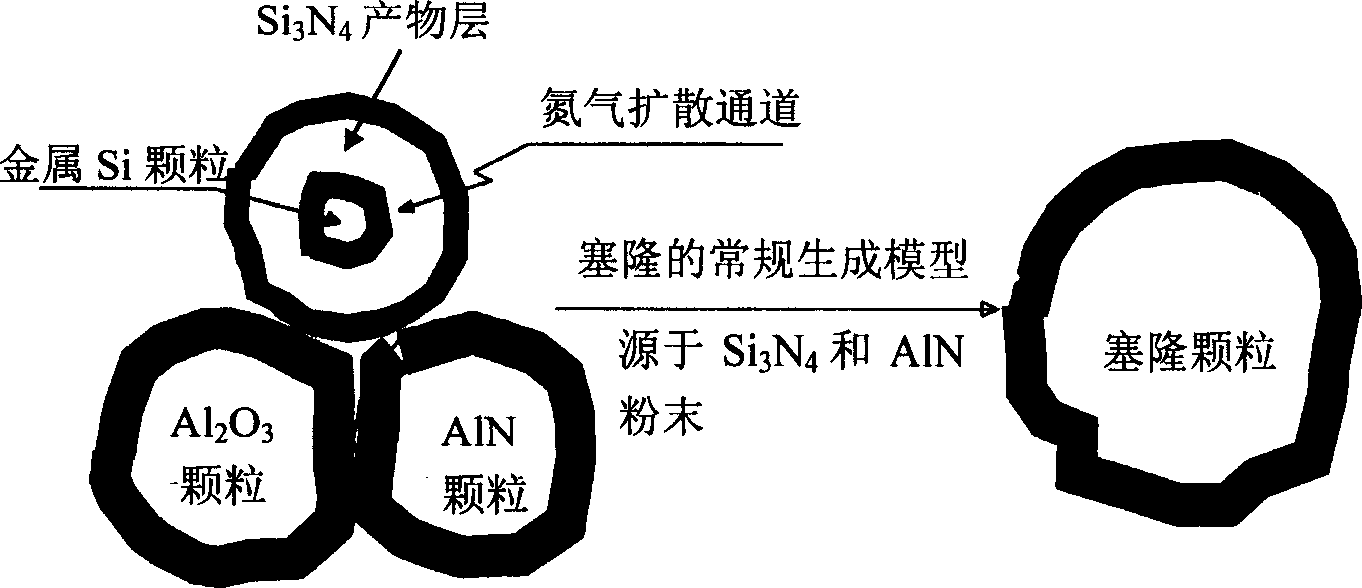

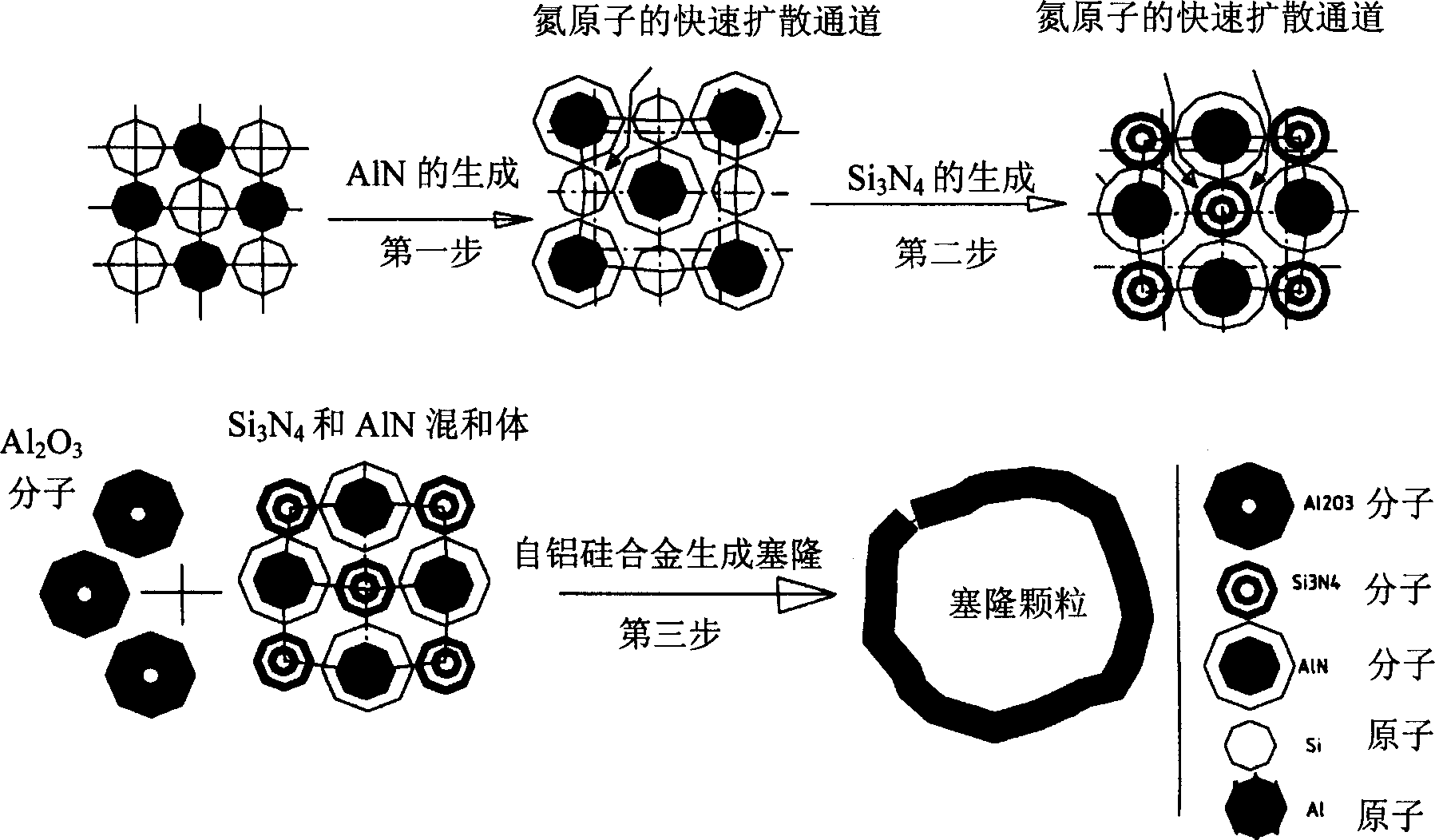

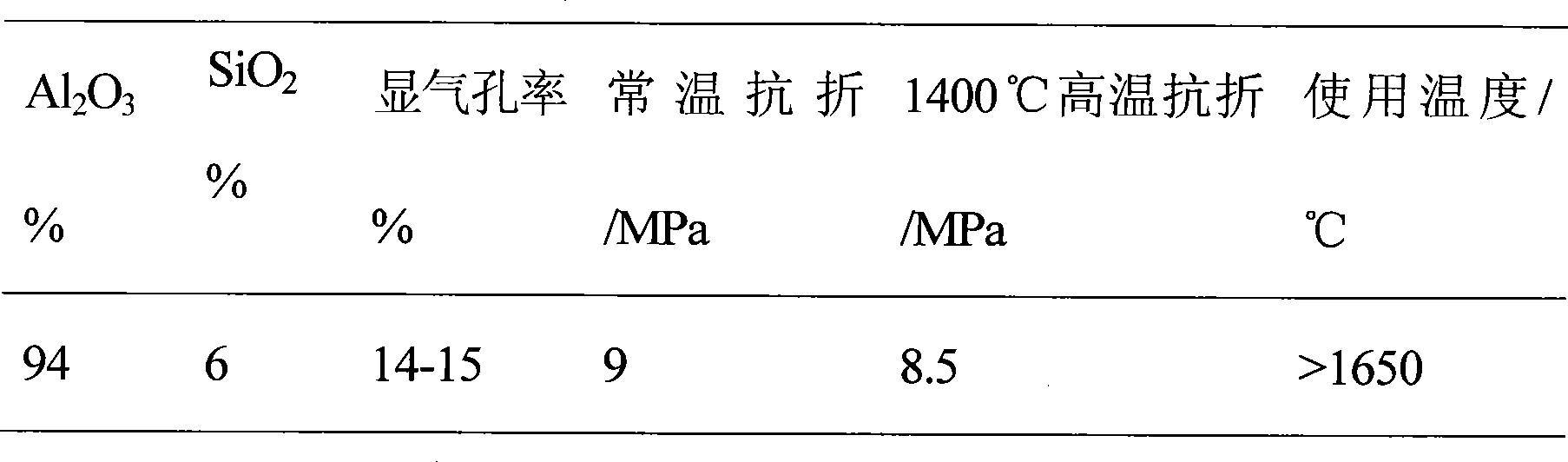

Sialon combined fireproof material containing aluminum silicon alloy

A fireproof material containing aluminum-silicon alloy. the material contains 60-75úÑ corumdum aggregate, 10-20úÑ fine corumdum powder, 5-15úÑ fine powder of aluminum-silicon alloy, 1.5-5úÑ clay, 5-12úÑ aluminum oxide. The fine powder of aluminum-silicon alloy is formed by melting or sintering metallic aluminum and metallic silicon. Due to introduction of fine powder of aluminum-silicon alloy, in producing corundum brick, the coupling phase could be quickly formed, the coupling strength between the coupling phase and brown corumdum aggregate will be improved. Compared the burning temperature of 1500degree C in the conventional process, the burning temperature of the invention is reduced to about 1430degree C , which improves the capacity of resisting rupture and high temperature.

Owner:BAOSHAN IRON & STEEL CO LTD +1

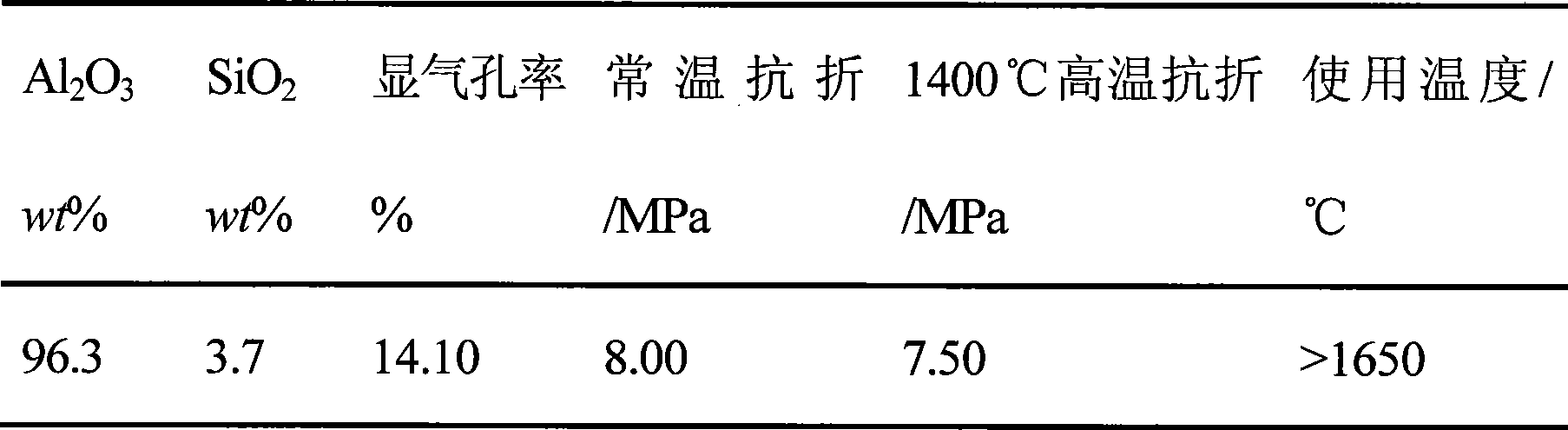

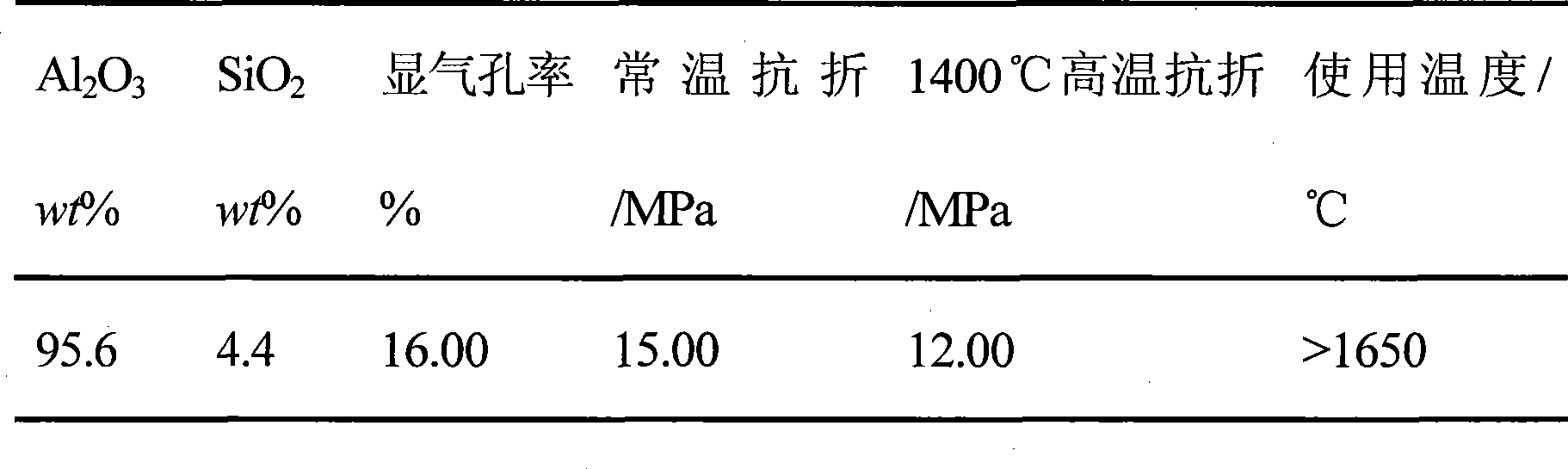

High temperature and creep resistance corundum-mullite load bearing board and preparation method thereof

ActiveCN101423414AIncrease temperatureImprove thermal shock resistanceMulliteHigh-temperature corrosion

The invention belongs to the technical field of ceramic kiln furniture and provides a corundum-mullite load bearing board and a preparation method. The corundum-mullite load bearing board comprises raw material compositions in the following mass percentage: 70 to 85 percent of alpha-Al2O3 particle material with the grain diameter of between 5 and 0.088 mm, 5 to 15 percent of alumina-silica sol fine powder with the grain diameter less than 0.08 mm, 5 to 15 percent of fused mullite fine powder with the grain diameter less than 0.088 mm, and 3 to 5 percent of bonding agent which is externally added. The characteristics of high purity and small particle size of alumina-silica sol are utilized to prepare the high-temperature creep-resistant load bearing board which has high purity and is formed by large-grained mullite bonded with corundum through high-temperature calcination, and the load bearing board does not deform and has good thermal shock resistance when the load bearing board is used at high temperature, and can be taken as the load bearing board used at a temperature higher than 1,650 DEG C in the fields of electronic ceramics and high temperature ceramics.

Owner:SINOSTEEL LUOYANG INST OF REFRACTORIES RES

80ksi-steel-grade hydrogen sulfide stress corrosion resistant petroleum casing pipe and manufacturing method thereof

ActiveCN103255345AHigh dimensional accuracyHigh resistance to external pressure collapse strengthFurnace typesHeat treatment furnacesEngineeringPipe

The invention provides a 80ksi-steel-grade hydrogen sulfide stress corrosion resistant petroleum casing pipe and a manufacturing method thereof. The 80ksi-steel-grade hydrogen sulfide stress corrosion resistant petroleum casing pipe comprises the following chemical components in percentage by weight: 0.15-0.20 of C, 0.15-0.25 of Si, 0.3-0.7 of Mn, less than or equal to 0.020 of P, less than or equal to 0.008 of S, 0.40-0.80 of Cr, 0.30-0.70 of Mo, 0.030-0.070 of Nb, less than or equal to 0.05% of V, 0.005%-0.20% of Ce, 0.001%-0.003% of Ca, and the balance of Fe and inevitable impurities. The manufacturing method comprises the following steps of: rolling the components by a rolling plate, welding and forming a pipe blank, treating welding seams, reducing the diameter through thermal tension, carrying out thermal treatment on a whole pipe body, treating the surface of a coupling, and carrying out thread machining, thus manufacturing the petroleum casing pipe. The 80ksi-steel-grade hydrogen sulfide stress corrosion resistant petroleum casing pipe produced by the manufacturing method has strong toughness and good proportioning, the physical and chemical property index of the casing pipe reaches or exceeds the API (American Petroleum Institute) standard, the hydrogen sulfide stress corrosion resistant property of the casing pipe is superior to the threshold value of the hydrogen sulfide stress corrosion resistance stated in the standard, and the casing pipe can meet the mining requirements on oil and gas fields containing certain hydrogen sulfide.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com