80ksi-steel-grade hydrogen sulfide stress corrosion resistant petroleum casing pipe and manufacturing method thereof

An 80ksi, anti-hydrogen sulfide technology, applied in the direction of manufacturing tools, heat treatment equipment, furnaces, etc., can solve the problem that the anti-hydrogen sulfide stress corrosion performance of the weld area is difficult to guarantee, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

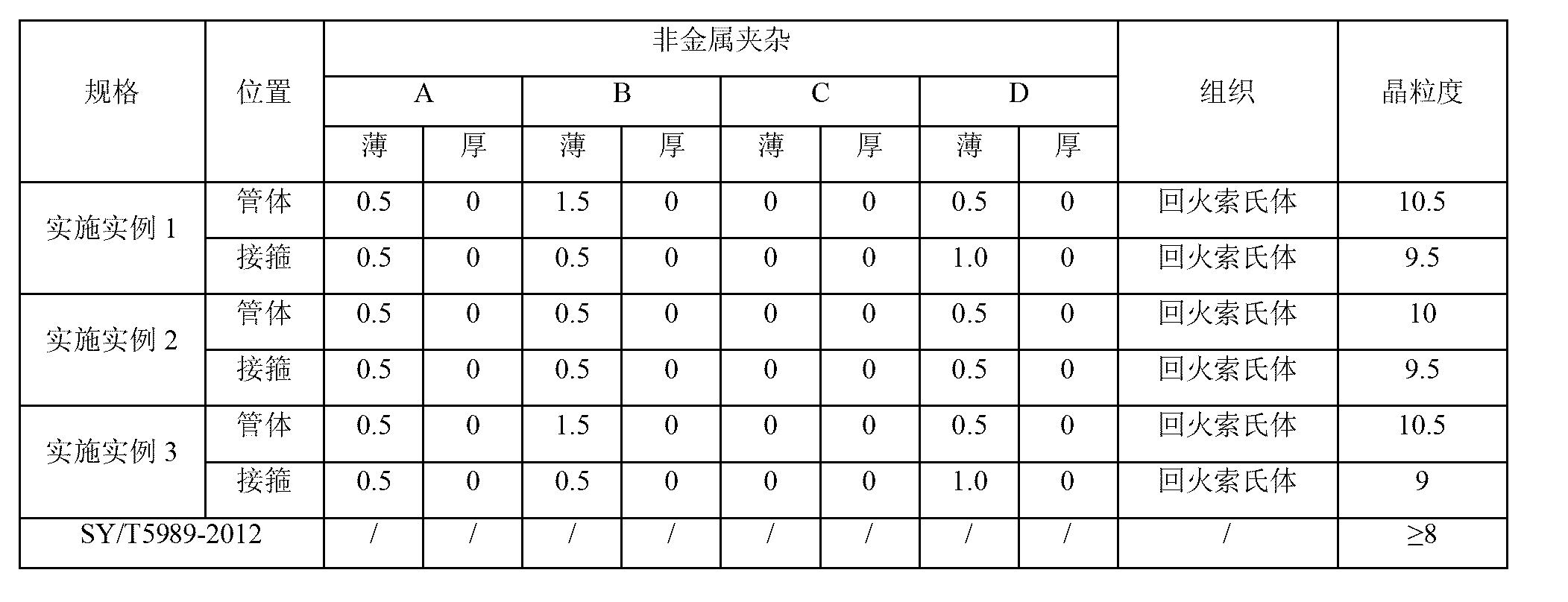

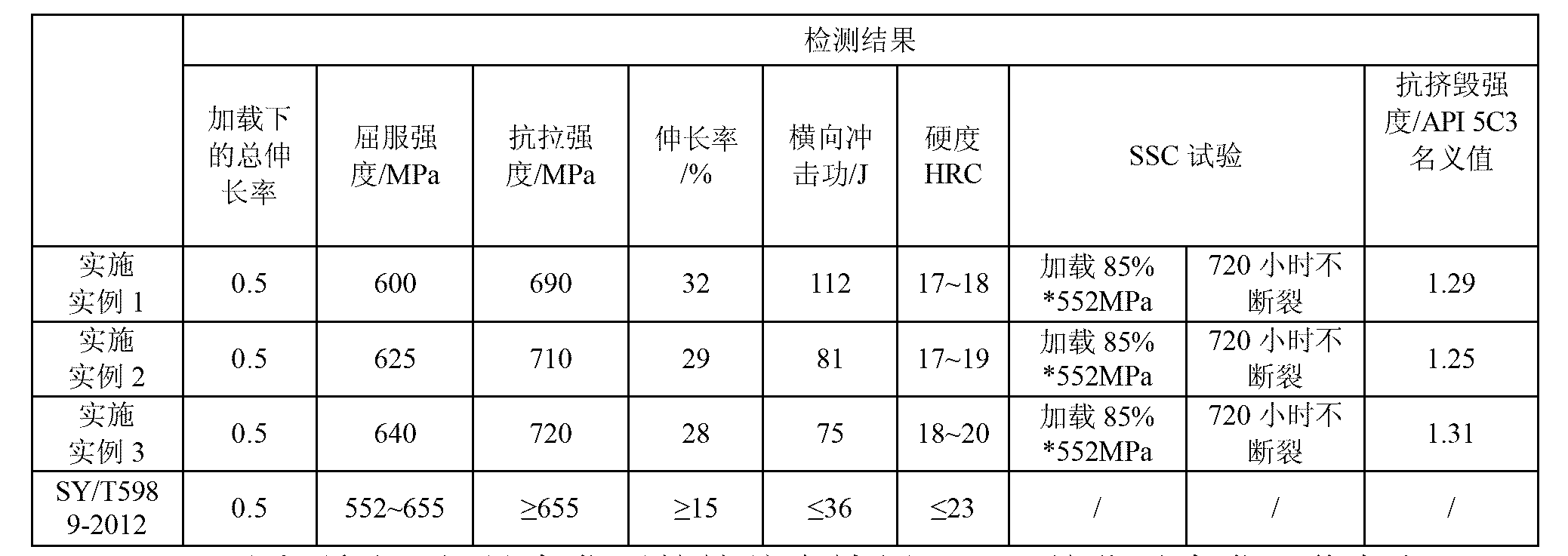

Embodiment 1

[0055] The required specifications and components (wt%) are: C0.16, Si0.25, Mn0.7, P0.011, S0. 001, Cr0.5, Mo0.70, Nb0.03, V0.04; Ce0.0189; Ca0.002 coils for oil casing. The hot-rolled coil is welded into a Φ193.7×7.34mm straight coil through strip slitting, edge milling, FFX forming and HFW welding, adjusting the forming process and controlling the welding parameters (welding power 490KW, welding speed 15m / min). Seam welded pipe, followed by weld normalizing and weld treatment.

[0056] Using the medium frequency induction rapid heating method, reheat the HFW welded pipe with a specification of Φ193.7×7.34mm to 950°C at a heating rate of 40°C / s, and then enter the 12-roller unit at a speed of 1.0m / s for hot rolling and reduction. diameter, to obtain a tube blank with a specification of Φ139.7×7.72mm. Heat and hold the tube blank at 880°C for 45 minutes, then water quench, the quenching cooling rate is ≥50°C / s, and then temper at 680°C for 60 minutes. The bushing is kept wa...

Embodiment 2

[0058] The required specifications and components (wt%) are: C0.20, Si0.15, Mn0.3, P0.008, S0. 001, Cr0.4, Mo0.3, Nb0.05, V0.05, Ce0.0056, Ca0.002 coils for oil casing. The hot-rolled coil is welded into a Φ193.7×8.94mm straight coil through strip slitting, edge milling, FFX forming and HFW welding, adjusting the forming process and controlling the welding parameters (welding power 490KW, welding speed 12m / min). Seam welded pipe, followed by weld normalizing and weld treatment.

[0059] Using the medium frequency induction rapid heating method, the HFW welded pipe with a specification of Φ193.7×8.94mm is heated to 980°C at a heating rate of 40°C / s, and then enters a 12-roller unit at a speed of 0.8m / s for hot rolling reduction. diameter, to obtain a tube blank with a specification of Φ139.7×9.17mm. Heat and hold the tube blank at 920°C for 35 minutes, then water quench, quenching cooling rate ≥ 50°C / s, and then temper at 720°C for 55 minutes. After tempering, it is sent to ...

Embodiment 3

[0061] The required specifications and components (wt%) are: C0.18, Si0.20, Mn0.5, P0.008, S0. 001, Cr0.80, Mo0.5, Nb0.05, V0.03, Ce0.0120, Ca0.002 coils for oil casing. The hot-rolled coil is welded into a Φ193.7×10.05mm straight coil through strip slitting, edge milling, FFX forming and HFW welding, adjusting the forming process, and controlling the welding parameters (welding power 490KW, welding speed 10m / min). Seam welded pipe, followed by weld normalizing and weld treatment.

[0062] Using the medium frequency induction rapid heating method, reheat the HFW welded pipe with a specification of Φ193.7×10.05mm to 1050°C at a heating rate of 40°C / s, and then enter the 12-roller unit at a speed of 1m / s for hot rolling and reducing , to obtain a tube blank with a specification of Φ139.7×10.54mm. The above-mentioned tube blank is heated and kept at 950°C for 30 minutes, then water quenched, the quenching cooling rate is ≥50°C / s, and then tempered at 750°C for 50 minutes. Afte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com