High temperature and creep resistance corundum-mullite load bearing board and preparation method thereof

A creep-resistant and setter technology, applied in the field of refractory material preparation and ceramics, can solve the problems of easy deformation and low use temperature of corundum-mullite setter, so as to improve the service temperature and improve the thermal vibration resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] 85% of α-Al with a particle size of 5-0.088mm 2 o 3 Granular material, 7.5% fused mullite fine powder with particle size less than 0.088mm, 7.5% aluminum-silicon sol 700°C calcined material (Al 2 o 3 Content 72%), plus 4% PVA as a binding agent,

[0029] Its process steps are as follows:

[0030] 1) Mixing: Put the raw materials into the mixer according to the above ratio and mix evenly;

[0031] 2) Trapped material: put the above-mentioned homogeneously mixed material in a closed state for 12 hours;

[0032] 3) Molding: weigh the material prepared in step 2 and put it into a mold for molding with a molding pressure of 150Mpa;

[0033] 4) Drying: the molded green body is first dried naturally for 2 days, and then dried at 110°C for 24 hours;

[0034] 5) Firing: After drying, heat preservation at 1500°C for 6 hours to obtain setter products.

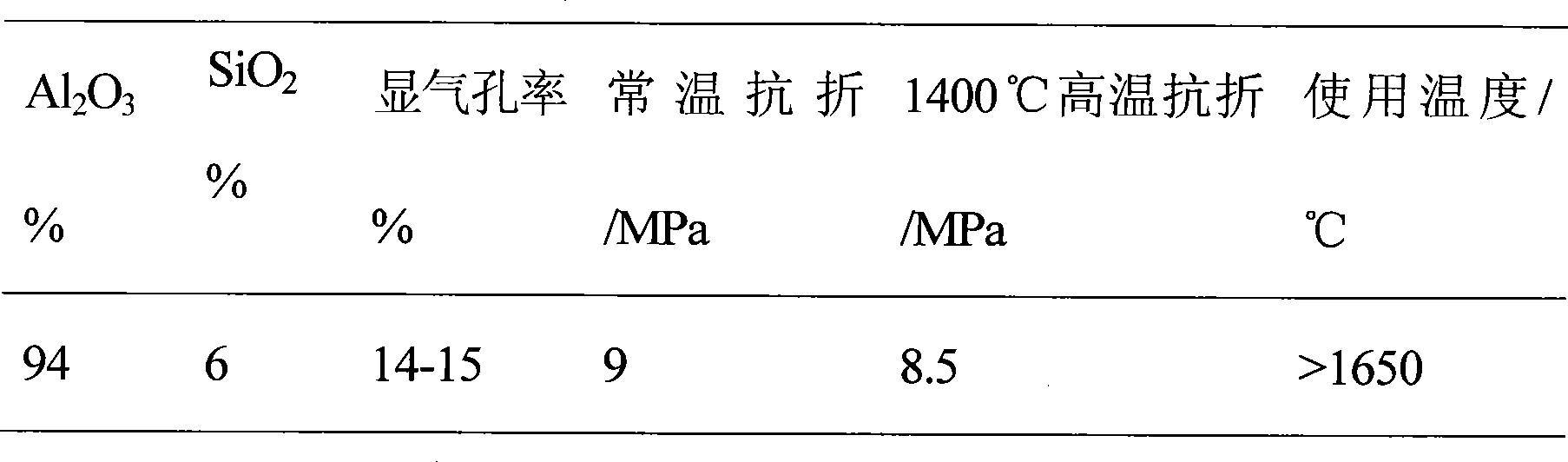

[0035] The properties of the obtained high temperature creep resistant corundum-mullite setter plate are shown in Table 2 ...

Embodiment 2

[0039] 80% of α-Al with a particle size of 5-0.088mm 2 o 3 Granular material, 10% fused mullite fine powder with particle size less than 0.088mm, 10% aluminum-silicon sol 700°C calcined material (Al 2 o 3 Content 78%), plus 4% sulfurous acid pulp waste liquid as a binding agent.

[0040] Its process steps are as follows:

[0041] 1) Mixing: Put the raw materials into the mixer according to the above ratio and mix evenly;

[0042] 2) Trapped material: put the above-mentioned homogeneously mixed material in a closed state for 12 hours;

[0043] 3) Molding: weigh the material prepared in step 2 and put it into a mold for molding with a molding pressure of 100Mpa;

[0044] 4) Drying: the molded green body is first dried naturally for 2 days, and then dried at 110°C for 24 hours;

[0045]5) Firing: After drying, heat preservation at 1600°C for 6 hours to obtain setter products.

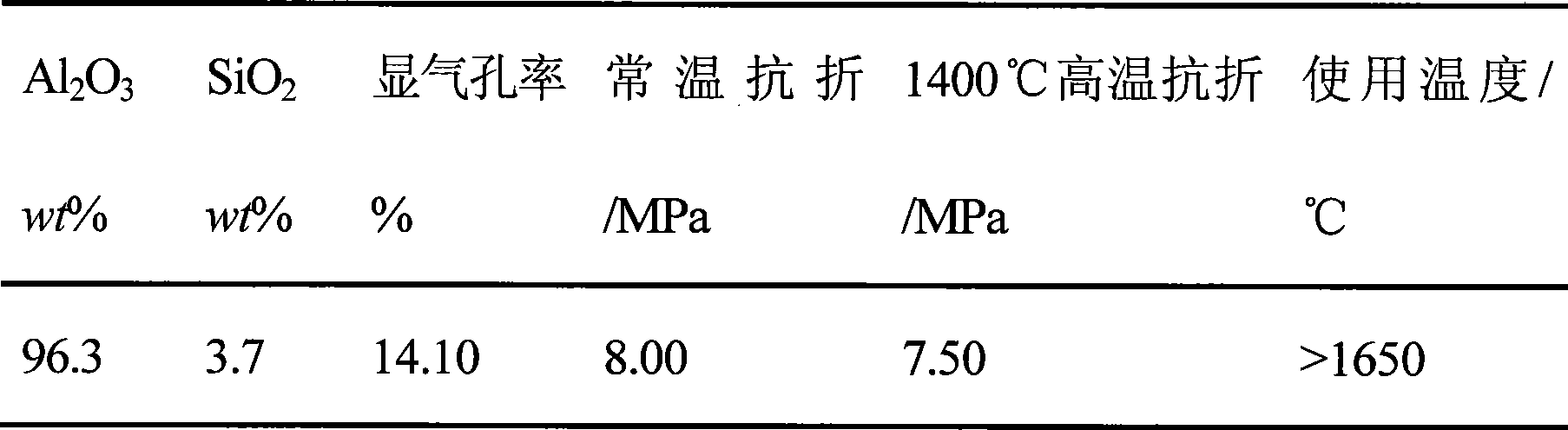

[0046] The properties of the obtained high temperature creep resistant corundum-mullite setter p...

Embodiment 3

[0050] From 70% particle size 5-0.088mm α-Al 2 o 3 Granular material, 15% fused mullite fine powder with particle size less than 0.088mm, 15% aluminum-silica sol 700°C calcined material (Al 2 o 3 Content 76), plus 4% sulfurous acid pulp waste liquid as a binding agent.

[0051] Its process steps are as follows:

[0052] 1) Mixing: Put the raw materials into the mixer according to the above ratio and mix evenly;

[0053] 2) Trapped material: put the above-mentioned homogeneously mixed material in a closed state for 12 hours;

[0054] 3) Molding: weigh the material prepared in step 2 and put it into a mold for molding with a molding pressure of 150Mpa;

[0055] 4) Drying: the molded green body is first dried naturally for 2 days, and then dried at 110°C for 24 hours;

[0056] 5) Firing: After drying, heat-preserve at 1550°C for 4 hours and fire to obtain setter products.

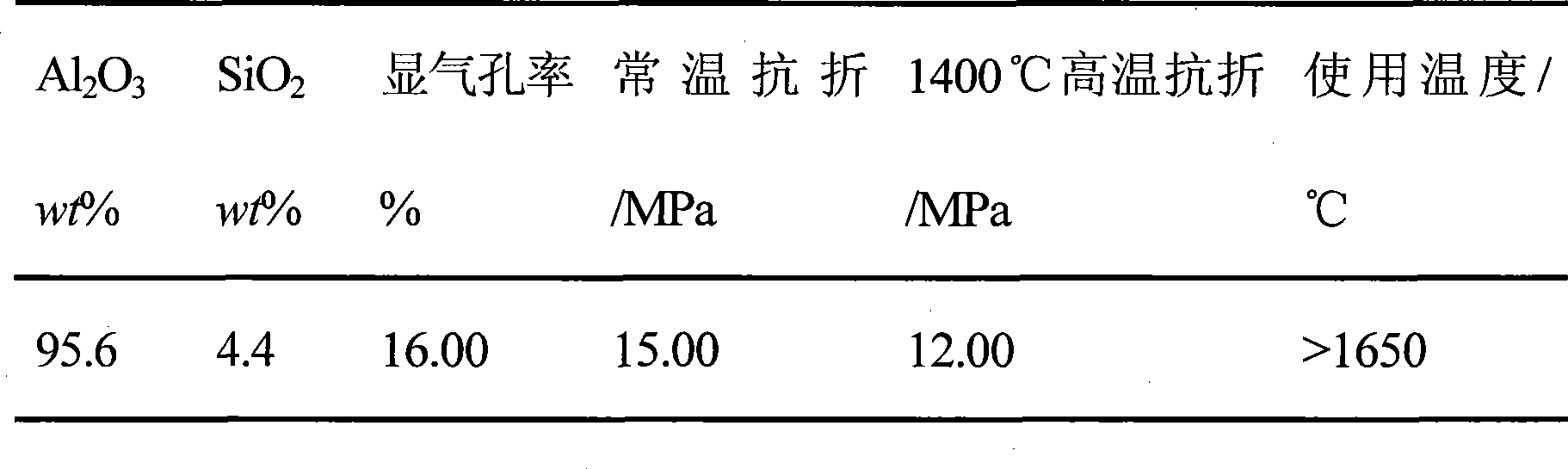

[0057] The properties of the obtained high temperature creep resistant corundum-mullite setter plate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com