Patents

Literature

77results about How to "Purity is easy to control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

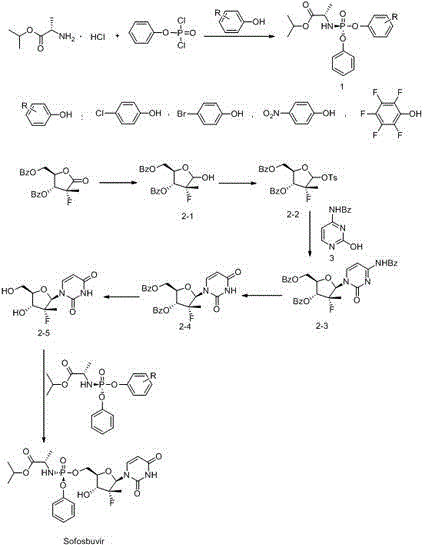

Preparation method of ribofuranose phosphate derivative

ActiveCN104610404APurity is easy to controlHigh yield of docking reactionSugar derivativesSugar derivatives preparationPhosphateGrignard reagent

The invention discloses a preparation method of a ribofuranose phosphate derivative. The preparation method comprises preparation steps as follows: L-alanine isopropyl ester hydrochloride, phenol dichlorophosphate and substituted phenol are taken as starting materials and have a docking reaction under the action of alkali; (2R)-2-deoxy-2-difluoro-2-methyl-D-erythropentonic acid GAMMA-lactone and 3,5-dibenzoate reduce carbonyl in a dichloromethane or ether solvent into an alcoholic hydroxyl group under the action of a strong reducing agent; an intermediate with a formula 2-1 has a reaction with paratoluensulfonyl chloride under the action of alkali to obtain p-toluenesulfonates; an intermediate with a formula 2-2 and a benzoyl cytosine derivative have a docking reaction under the action of a condensing agent; an intermediate with a formula 2-3 converts cytosine into uracil under the action of organic acid; benzoyl protection for an intermediate with a formula 2-4 is released under the action of an alkaline agent; an intermediate with a formula 2-5 and an intermediate with a formula 1 are docked under the action of a Grignard reagent to obtain Sofosbuvir.

Owner:NANTONG CHANGYOO PHARMATECH CO LTD

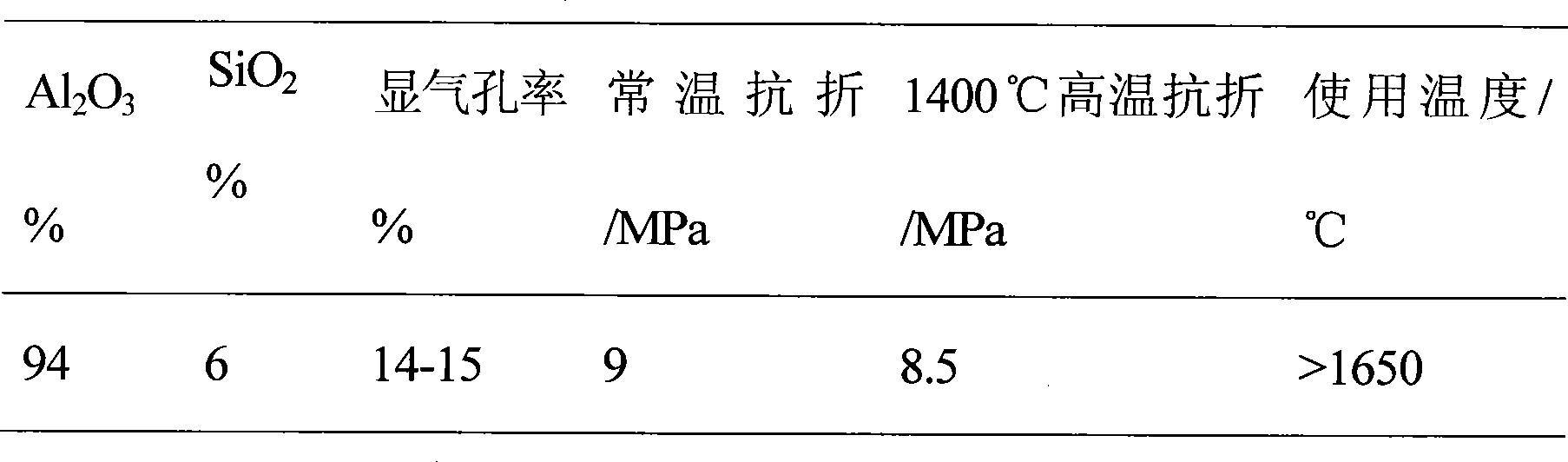

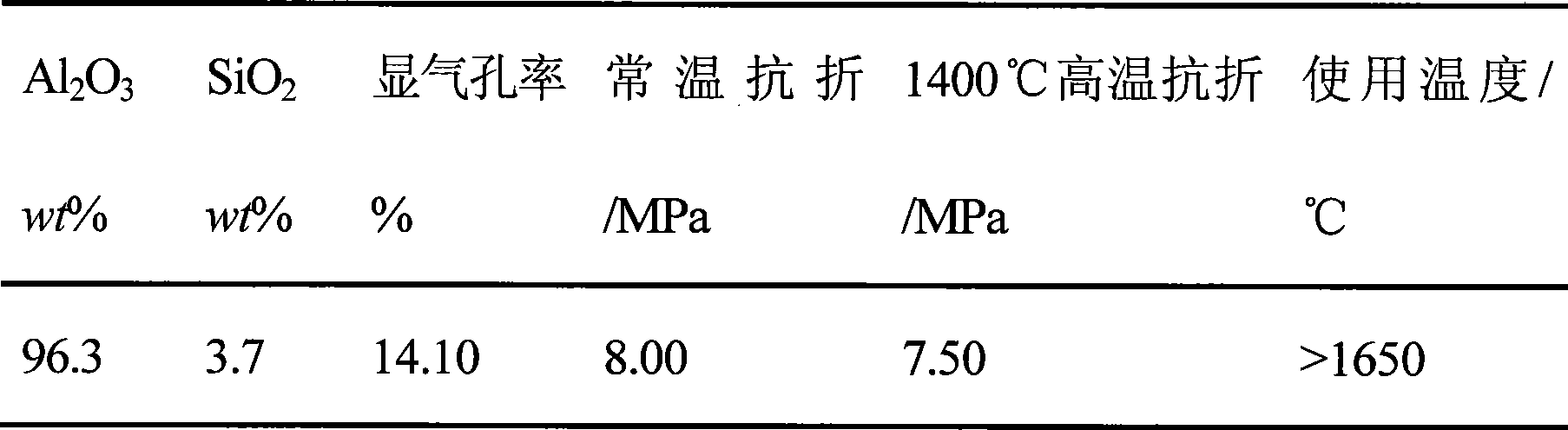

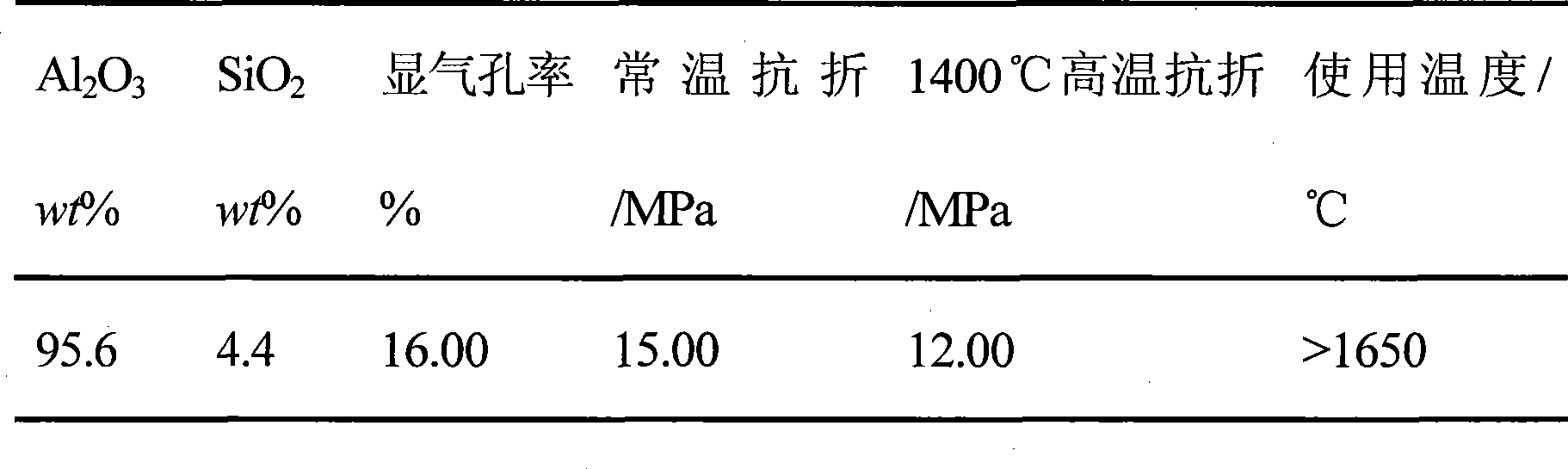

High temperature and creep resistance corundum-mullite load bearing board and preparation method thereof

ActiveCN101423414AIncrease temperatureImprove thermal shock resistanceMulliteHigh-temperature corrosion

The invention belongs to the technical field of ceramic kiln furniture and provides a corundum-mullite load bearing board and a preparation method. The corundum-mullite load bearing board comprises raw material compositions in the following mass percentage: 70 to 85 percent of alpha-Al2O3 particle material with the grain diameter of between 5 and 0.088 mm, 5 to 15 percent of alumina-silica sol fine powder with the grain diameter less than 0.08 mm, 5 to 15 percent of fused mullite fine powder with the grain diameter less than 0.088 mm, and 3 to 5 percent of bonding agent which is externally added. The characteristics of high purity and small particle size of alumina-silica sol are utilized to prepare the high-temperature creep-resistant load bearing board which has high purity and is formed by large-grained mullite bonded with corundum through high-temperature calcination, and the load bearing board does not deform and has good thermal shock resistance when the load bearing board is used at high temperature, and can be taken as the load bearing board used at a temperature higher than 1,650 DEG C in the fields of electronic ceramics and high temperature ceramics.

Owner:SINOSTEEL LUOYANG INST OF REFRACTORIES RES

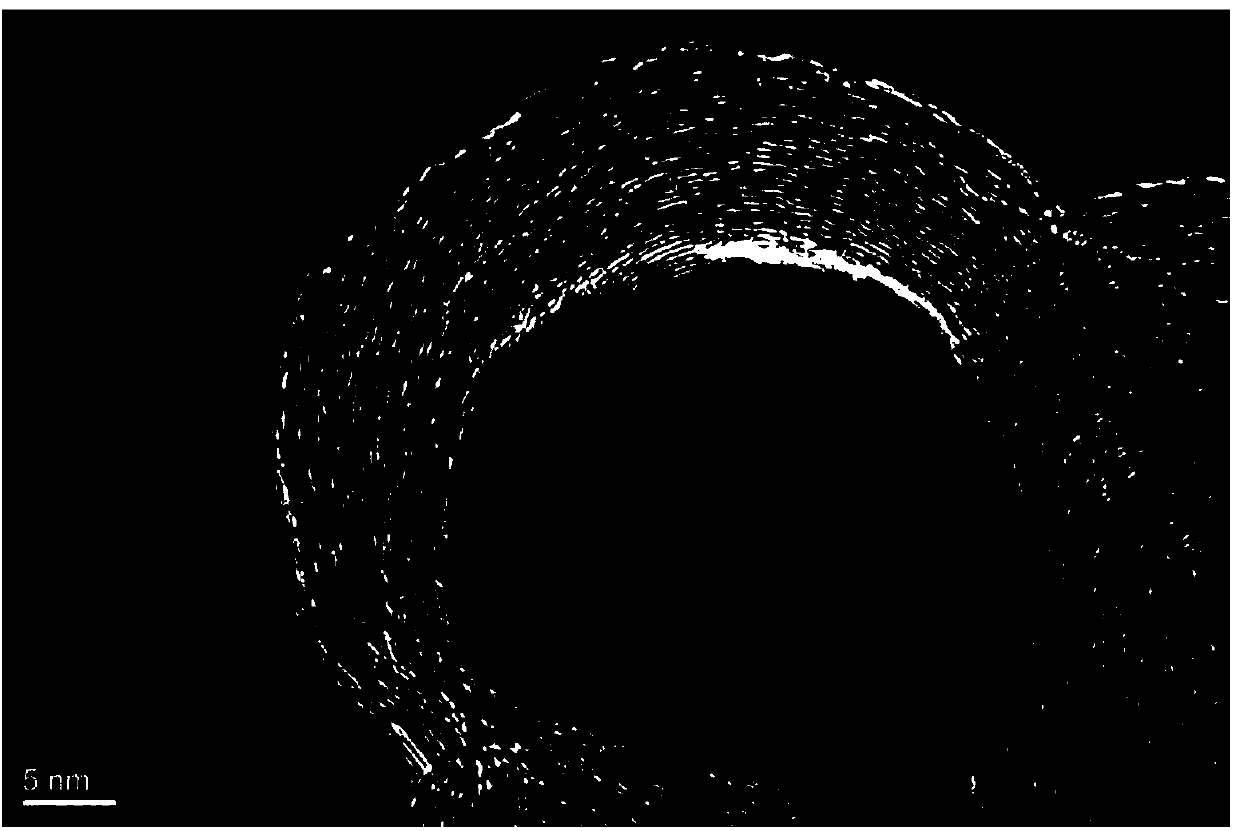

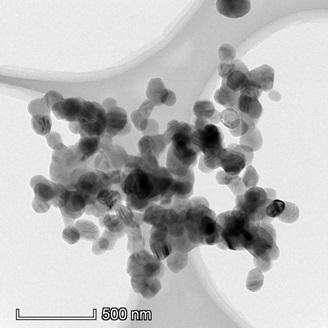

Preparation method of carbon-coated cobalt metal nano-particles

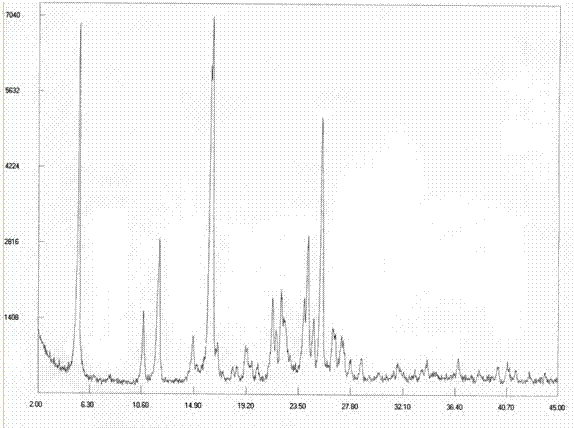

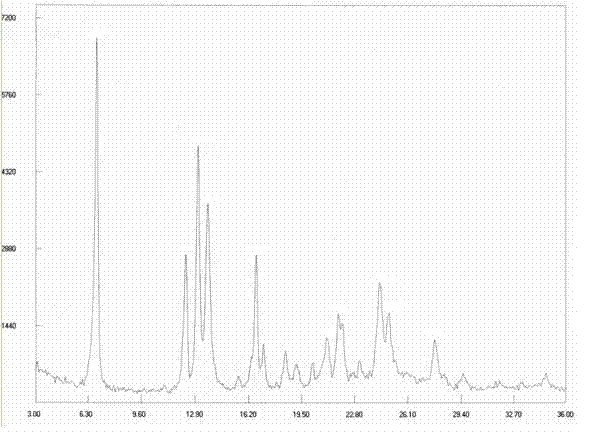

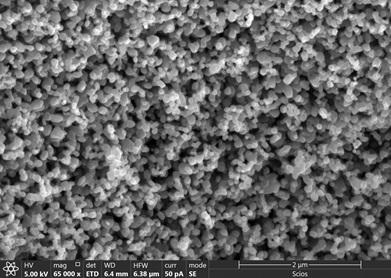

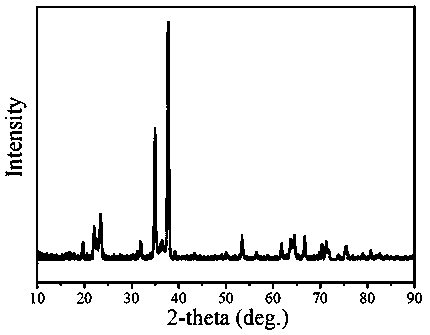

InactiveCN103695864AHigh purityPurity is easy to controlNanotechnologyChemical vapor deposition coatingCobalt metalChemical plating

The invention discloses a preparation method of carbon-coated cobalt metal nano-particles, which relates to a gaseous compound decomposition-based chemical plating by which reaction product of surface material is not preserved in a plating layer and only carbon is deposited, and is a method for decomposing ethyne and synthesizing carbon-coated cobalt metal nano-particles on potassium chloride carrier by means of chemical vapor deposition. The preparation method comprises the following steps: firstly, preparing cobalt-potassium chloride catalyst, then, synthesizing carbon-coated cobalt metal nano-particles, and finally, performing purification to obtain the carbon-coated cobalt metal nano-particles with purity of 95-99%. The preparation method overcomes the defects that the carbon-coated metal nano-particles synthesized by the existing technology have low purity, poor performance and low yield, and contains overmuch impurities, and the impurities are not easy to remove.

Owner:HEBEI UNIV OF TECH

Preparation method for alpha-arbutin

The invention discloses a preparation method for alpha-arbutin. Starch matter and hydroquinone are adopted as raw materials, and biological enzymes are added for an enzyme method conversion reaction; after reaction liquid is subjected to enzyme removal, yeast is added for fermentation to remove glucose in the reaction liquid; after fermentation liquid is degermed, crude alpha-arbutin is obtained after primary crystallization, crude alpha-arbutin is dissolved for secondary or multi-time recrystallization, and alpha-arbutin with the purity of 99% or above can be obtained. Alpha-arbutin is produced through enzyme method conversion, and conversion efficiency is high. Yeast fermentation sugar removal is used for replacing a traditional column chromatography sugar removal process, acid or alkali or organic solvents used in the column chromatography process are avoided, and the use amount of pure water is greatly reduced. The method for purifying alpha-arbutin through the multi-time crystallization process is simple and convenient, and the product purity is controllable.

Owner:HUBEI ARTEC CARBOHYDRATE CHEM

Method for preparing high-purity nanometer silicon dioxide by taking high-purity silicon tetrachloride as material

InactiveCN101804985AReduce manufacturing costSimple production processNanostructure manufactureSilicaPolyvinyl alcoholSolvent

The invention discloses a method for preparing high-purity nanometer silicon dioxide by taking high-purity silicon tetrachloride as the material, which includes the steps of adding high-purity silicon tetrachloride to absolute ethanol solution or methanol solution while stirring under minus 20-20 DEG C, dripping ultrapure water-ethanol solution or methanol solution which contains 0.1-0.5wt% of polyvinyl alcohol to above mixture according to the reaction proportion to produce colorless transparent sol; seasoning or condensing under reduced pressure to obtain colorless transparent gel; and alcohol leaching and deacidifying the colorless transparent gel until the pH reaches 4-7, then filtrating, freezing, drying and dealcoholizing to obtain high-purity nanometer silicon dioxide powder, wherein the ethanol or methanol filtered out in the alcohol leaching process and the ethanol or methanol removed in the freezing and drying processes are rectified to obtain ethanol or methanol which is returned for use again. Through the method, no metal impurity is introduced into the production; the purity of the nanometer silicon dioxide prepared through the method can be above 99.999%; the total content of metal impurities is less than 10ppm; the grain size can reach 20nm-80nm; the production process is simple; the equipment investment is less; the production cost is low; and the method is easy for industrial production.

Owner:BOHAI UNIV

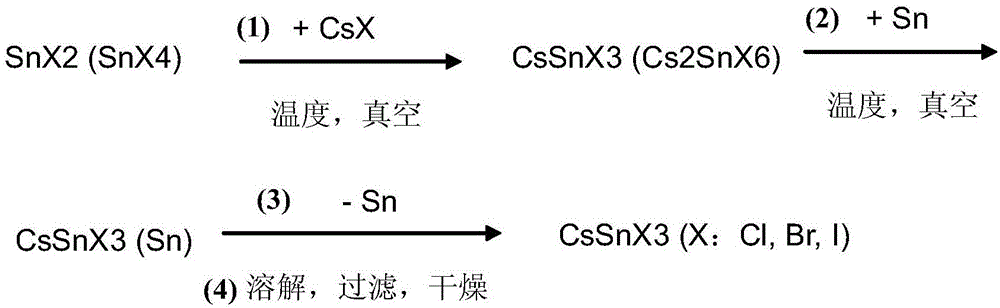

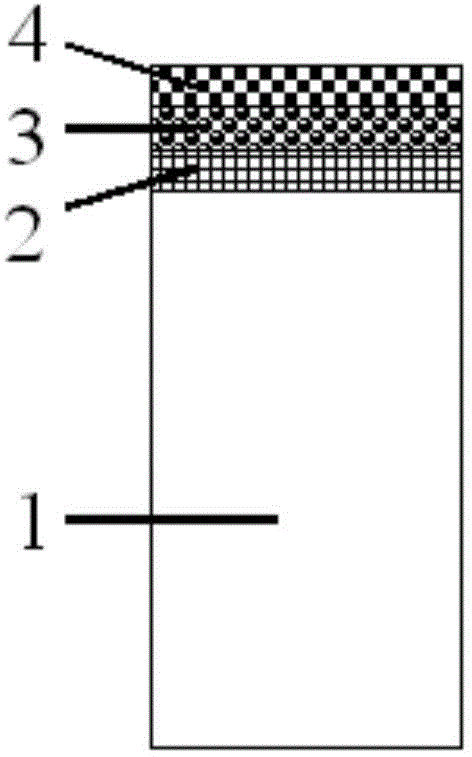

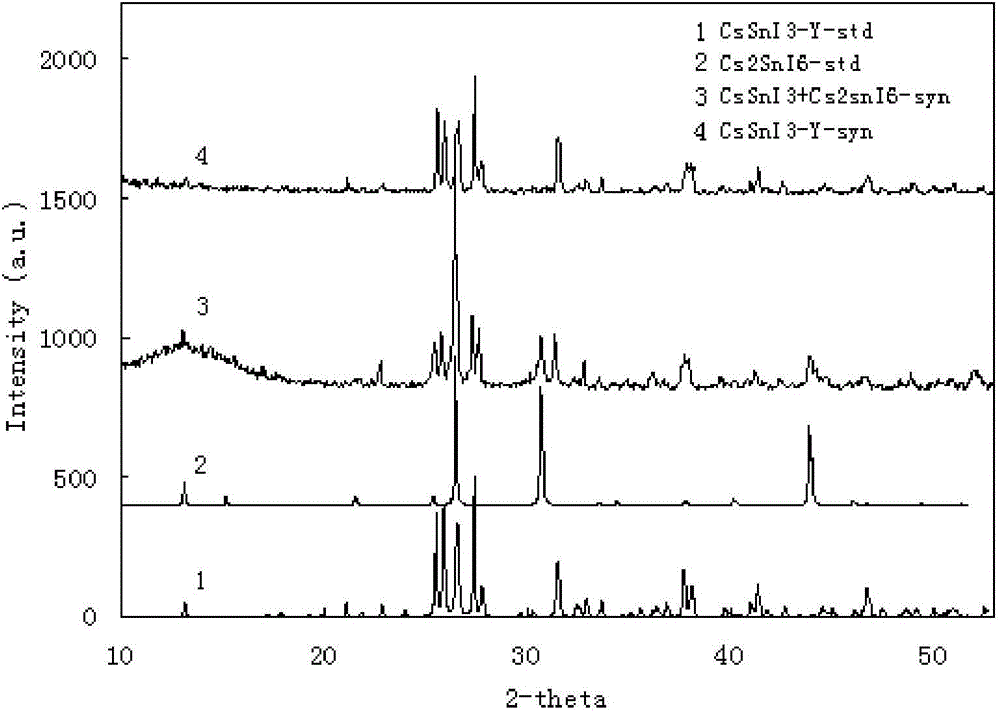

Perovskite type compound preparation method

The present invention relates to a perovskite type compound preparation method, which uses a four-step method, and specifically comprises CsSnX3(Cs2SnX6) synthesis, CsSnX3(Sn) synthesis, removal of tin from CsSnX3(Sn), and high purity CsSnX3 preparation. The invention further provides a CsSnX3 liquid preparation and sealing method. According to the present invention, a purpose of the present invention is to solve the problems of expensive raw materials, harsh process conditions, impure product and difficult separation of the current CsSnX3 preparation method; and the high quality product can be obtained without the high purity raw material and the harsh purification process, the process is simple, and the method is suitable for laboratory preparation, and is further suitable for industrial mass production.

Owner:SHANGHAI ZAOFU NEW MATERIAL TECH CO LTD

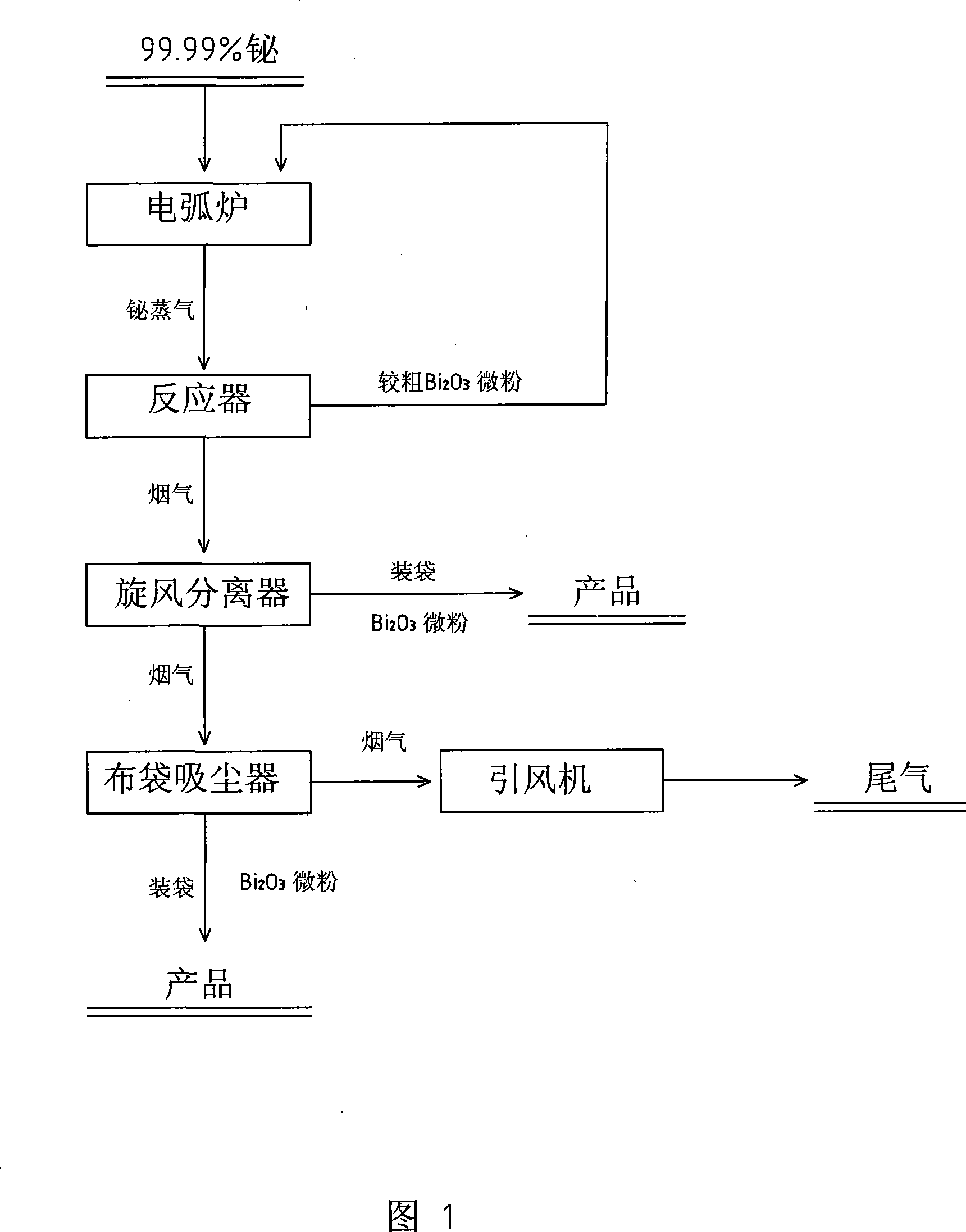

Method for producing high purity nano-level bismuth oxide micro-powder

InactiveCN101186337AFine granularityShorten the timeNanostructure manufactureBismuth compoundsMaterials preparationElectric arc furnace

The invention relates to a manufacturing method of bismuth oxide fine powder with high purity nanometer grade, which pertains to the technical field of nanometer material preparation technology. The invention uses an electric arc furnace for heating, in which metal bismuth is melted and evaporated. The reaction between the bismuth vapor and the oxygen in air produces the bismuth oxide fine powder with high purity nanometer grade. Since the reaction happens in gas phase, the granularity of the bismuth oxide fine powder with high purity nanometer grade is very fine; the average granularity is no more than 1 micron. Then the bismuth oxide fine powder with high purity nanometer grade is gained by two-level dust collecting. The invention has simple technique and low requirements on a device, dispersant is not required to be added and no toxic and hazardous emissions are produced to influence the environment in the production process.

Owner:HUNAN XIANGYUN FINE CHEM MFG

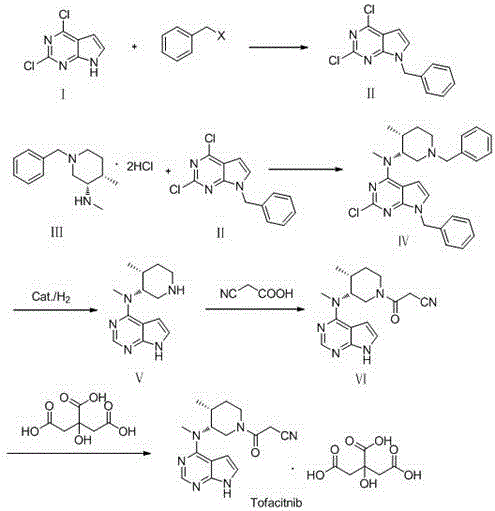

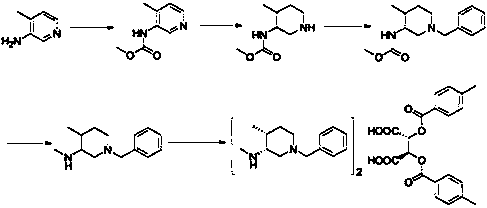

Preparation method of JAKs inhibitor drug tofacitinib

InactiveCN105732641ALess side effectsReduce generationOrganic chemistryAntipyreticAcetic acidTofacitinib

The invention discloses a preparation method of JAKs inhibitor drug tofacitinib, which is characterized in that it comprises the following steps: (1) using 2,4-dichloro-7H pyrrole [2,3-D] pyrimidine as a raw material, Under the action of base, react with halobenzyl to prepare compound II; (2) (3R,4R)-N,4-dimethyl-1-(phenylmethyl)-3-piperidinamine hydrochloride React with 7-benzyl-2,4-dichloro-7H pyrrole [2,3-D] pyrimidine under the action of a base to prepare compound IV; (3) the compound IV obtained in step (2) is catalyzed under the action of a metal catalyst Hydrogenation reaction to obtain compound V; (4) Compound V obtained in step (3) is coupled and docked with cyanoacetic acid under the action of a condensing agent to obtain compound VI; (5) Compound VI obtained in step (4) is prepared by salting with citric acid Get tofacitinib. The synthesis route of the method is short, the reaction process of each step is easy to operate, the solvent can be recycled and used mechanically, the pollution is small, and it is suitable for large-scale industrial production.

Owner:NANTONG CHANGYOO PHARMATECH CO LTD

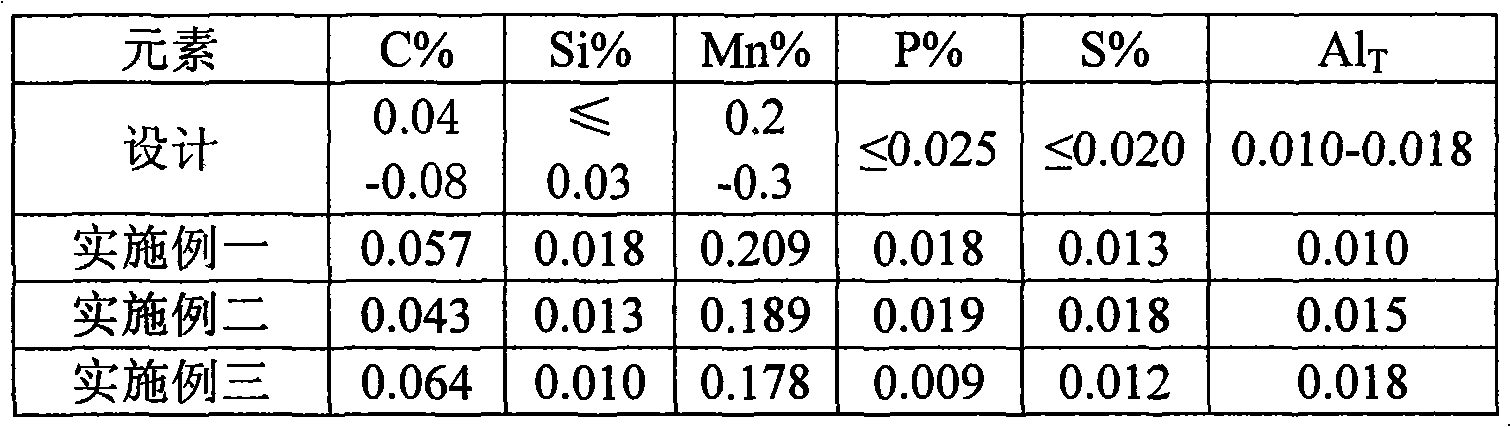

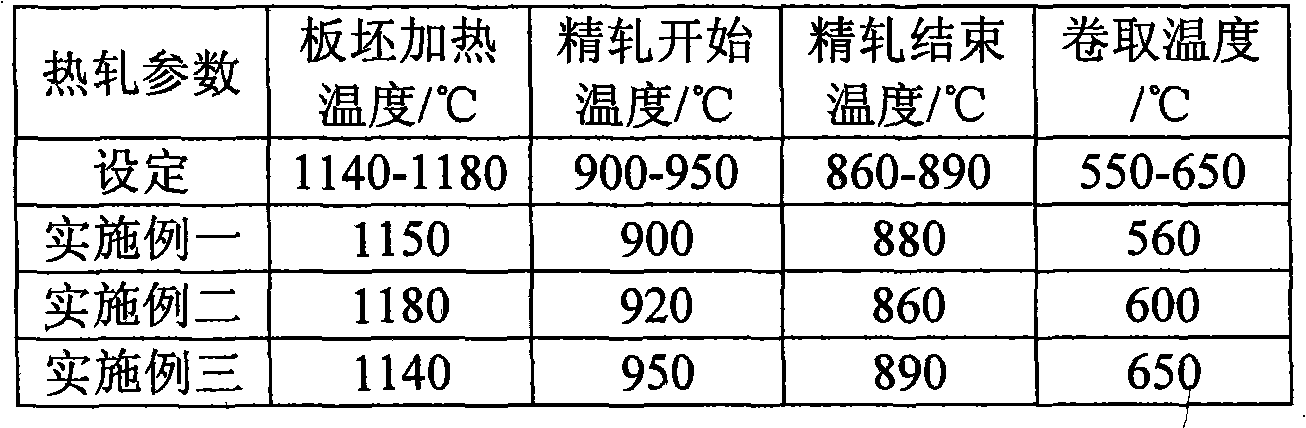

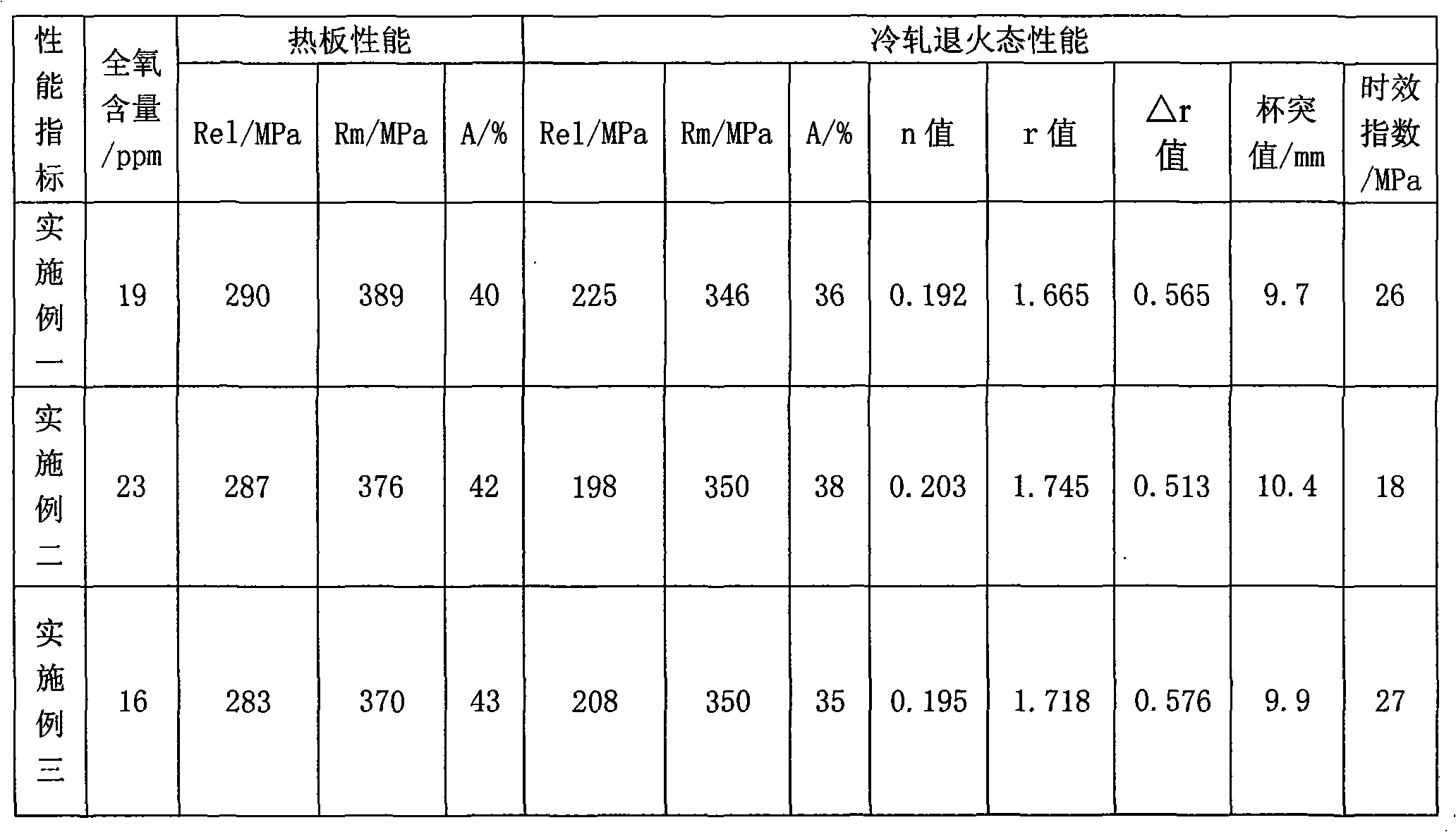

Low-aluminum-content and high-aging-resistance hot-rolling thin steel plate for cold formation and manufacturing method thereof

The invention relates to a hot-rolling thin steel plate for cold formation, in particular to a low-aluminum-content and high-aging-resistance hot-rolling thin steel plate for cold formation and a manufacturing method thereof, mainly solving the technical problems of poor aging resistance and slightly poor product purification degree of the traditional low-aluminum hot-rolling and cold-forming thin plate. The low-aluminum-content and high-aging-resistance hot-rolling thin steel plate for cold formation comprises the following elements in percentage by weight: 0.04%-0.08% of C, not more than 0.03% of Si, 0.2%-0.3% of Mn, not more than 0.025% of P, not more than 0.020% of S, 0.010%-0.018% of AlT and the balance of Fe. In the process control, the heating temperature of the hot-rolling plate is 1130 to 1180 DEG C, the rough-rolling ending temperature is 1000 to 1040 DEG C, the finish-rolling starting temperature is 920 to 950 DEG C, the finish-rolling ending temperature is 850 to 880 DEG C, and the rolling temperature is 550 to 650 DEG C. The hot-rolling thin steel plate obtained in the manufacturing method is directly used for cold formation and punching deformation or used as a raw plate of a cold-roll steel plate.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

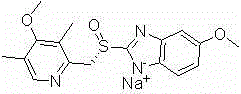

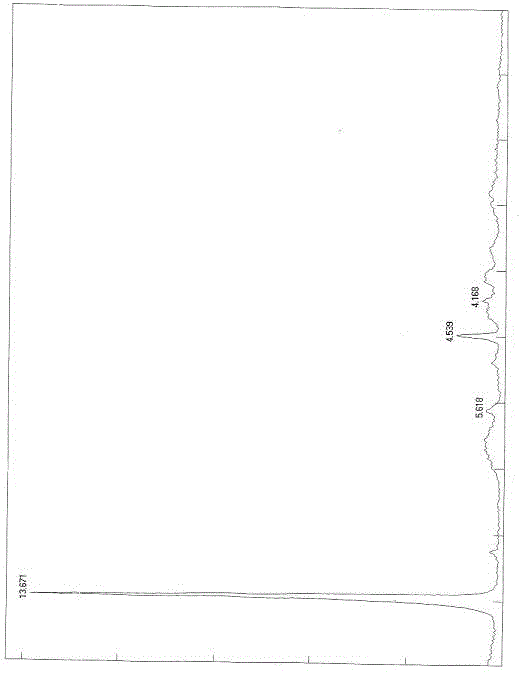

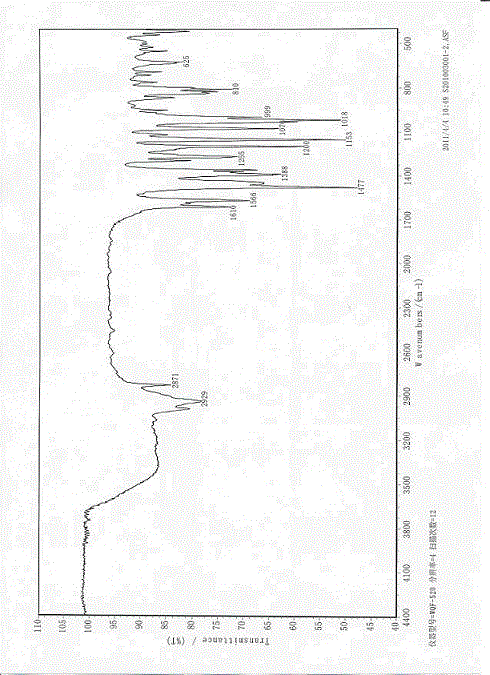

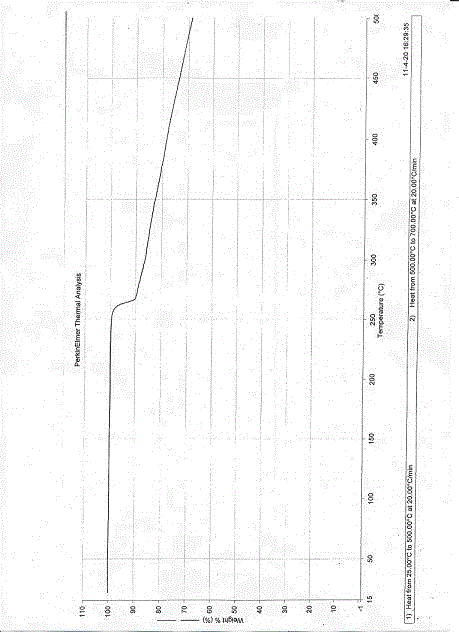

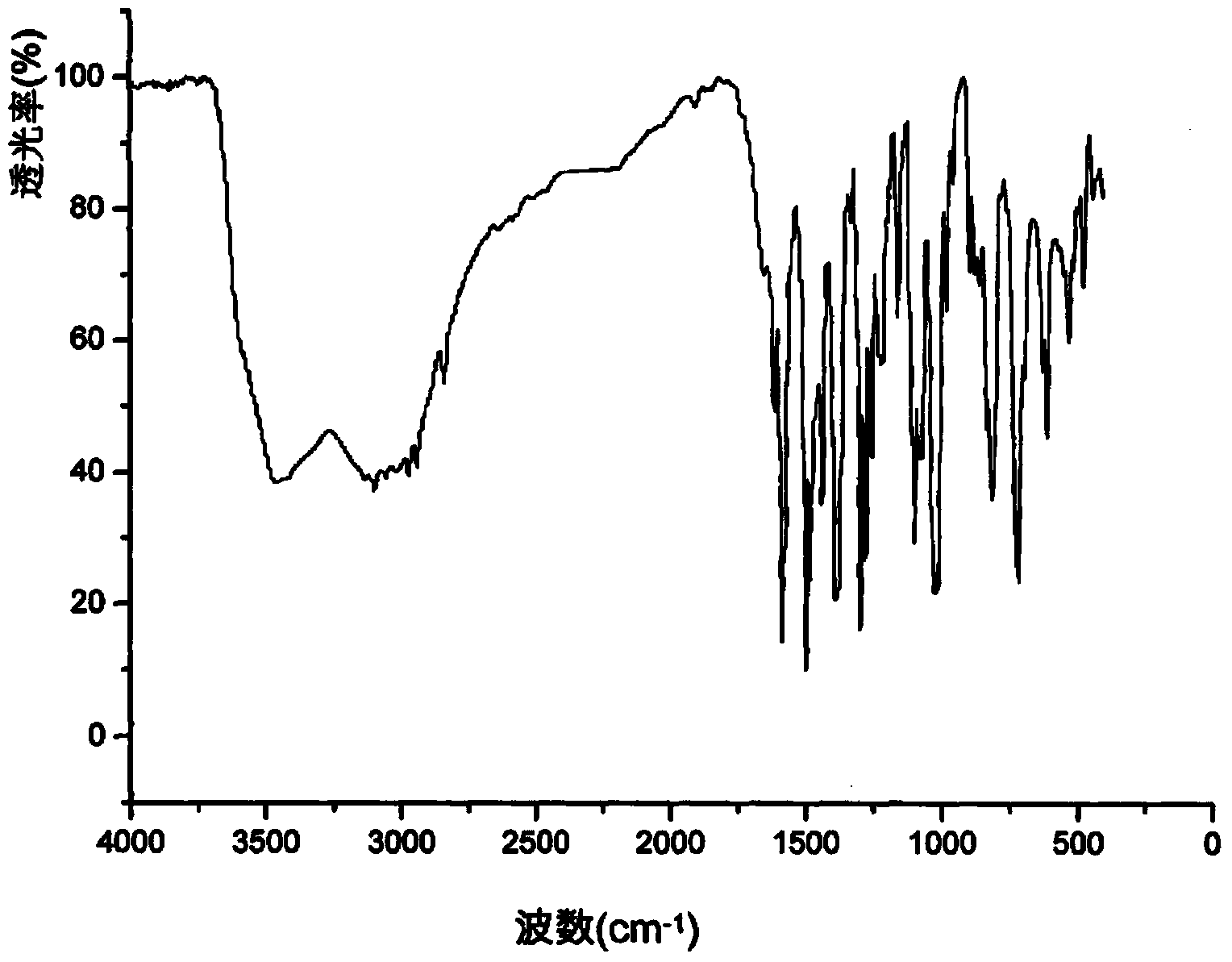

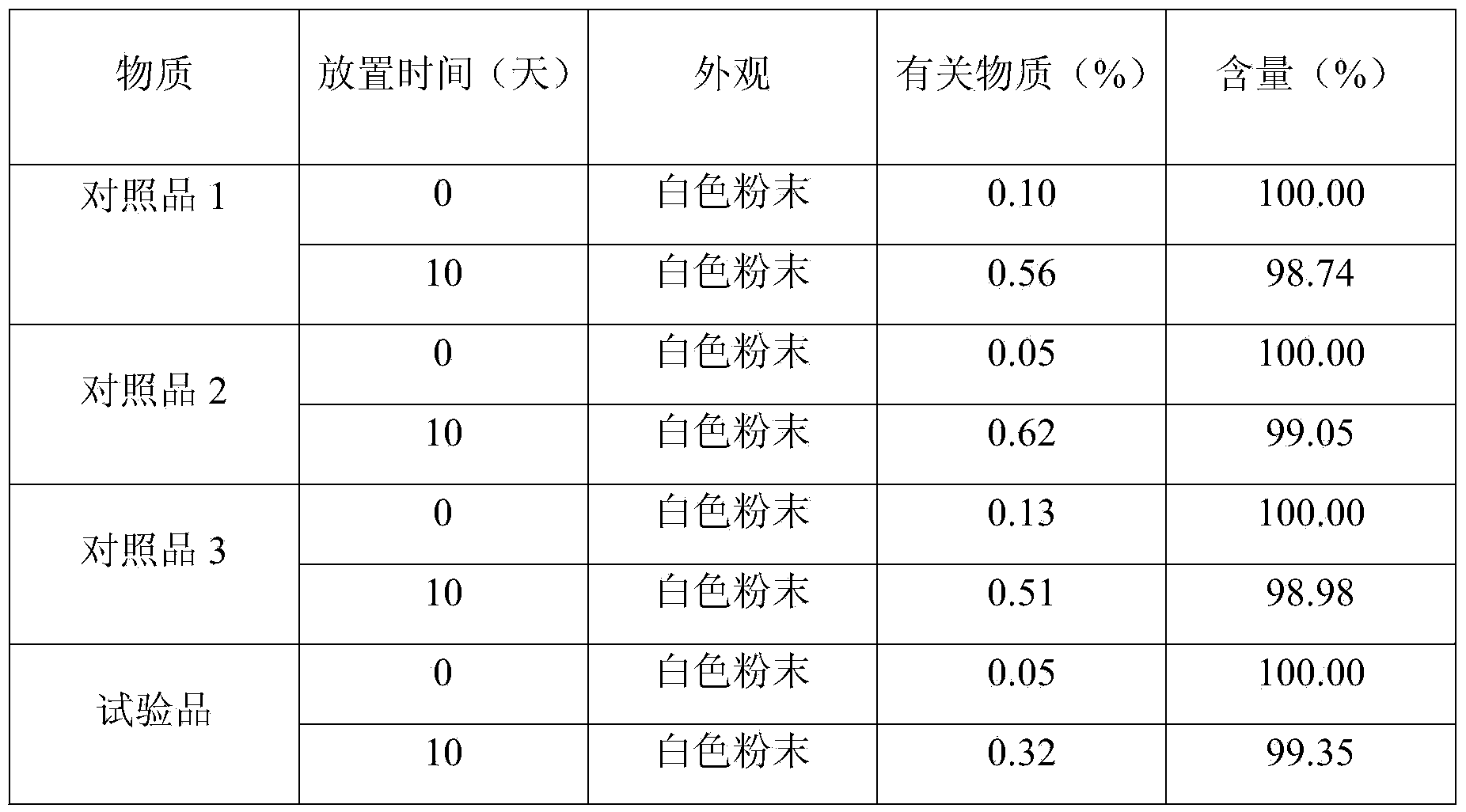

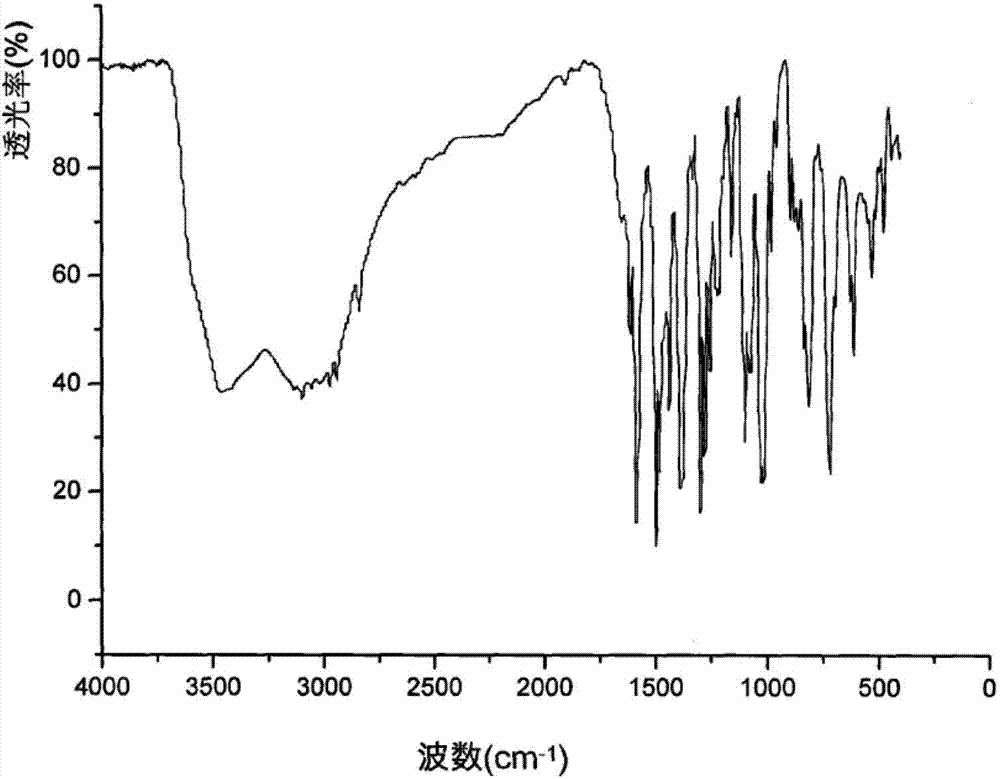

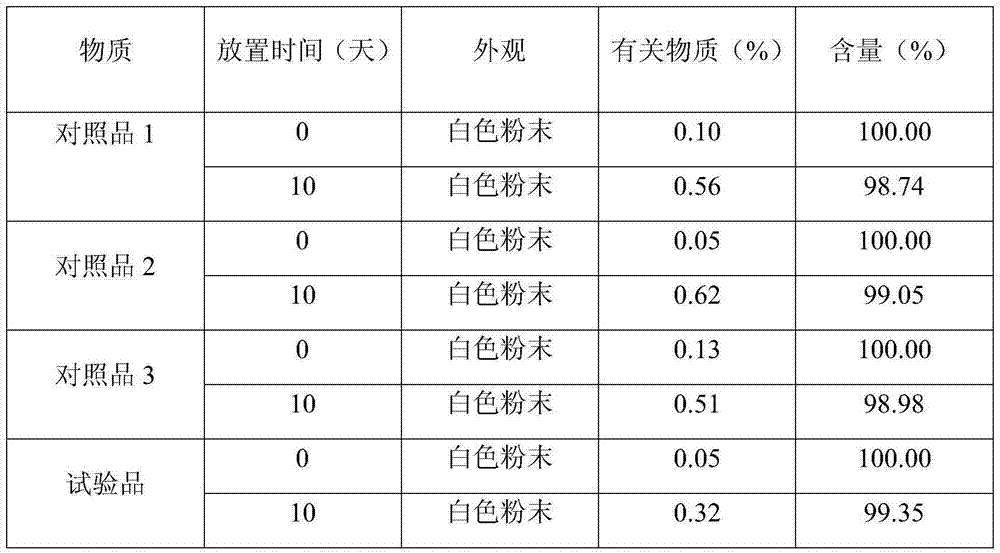

Esomeprazole sodium polymorph, preparation method and application thereof

ActiveCN102746272AImprove solubilityImprove stabilityOrganic active ingredientsOrganic chemistryEsomeprazole SodiumCombinatorial chemistry

The invention belongs to the field of medicinal chemistry, and specifically to an esomeprazole sodium polymorph, a preparation method and an application thereof. The present invention discloses an esomeprazole sodium polymorph having good stability and excellent solubility, wherein a preparation process of the esomeprazole sodium polymorph is easily industrialized, quality reproducibility is good, and product purity is easy to control.

Owner:JIANGSU AOSAIKANG PHARMA CO LTD

Esomeprazole sodium polymorph and application of esomeprazole sodium polymorph in drugs for injection

InactiveCN102746273AImprove solubilityImprove stabilityOrganic active ingredientsOrganic chemistryEsomeprazole SodiumDisease

The present invention relates to an esomeprazole sodium polymorph and an application of the esomeprazole sodium polymorph in drugs for injection. According to the present invention, esomeprazole sodium compositions for injection have characteristics of good stability and high purity, a preparation process of the esomeprazole sodium compositions is easily industrialized, and the esomeprazole sodium compositions can be used for treatments of diseases related to gastric acid parasecretion, wherein the esomeprazole sodium compositions are prepared from the esomeprazole sodium polymorph having good stability and excellent solubility in the present invention.

Owner:JIANGSU AOSAIKANG PHARMA CO LTD

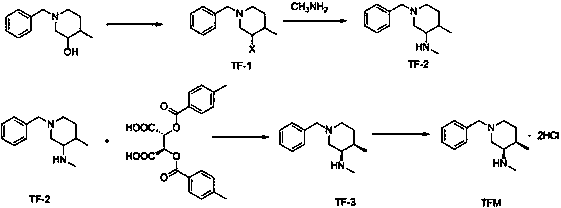

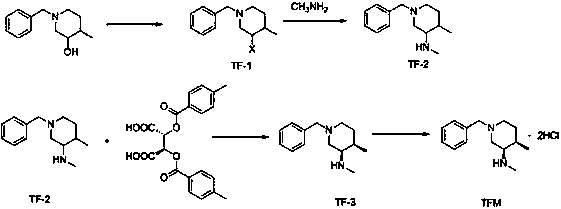

Preparation method for chiral piperylhydrazine compound and recycling method for chiral resolving agent

InactiveCN108976164APurity is easy to controlReduce productionOrganic chemistry methodsSuccinic acidHigh dosage

The invention discloses a preparation method for a chiral piperylhydrazine compound and a recycling method for a chiral resolving agent. In the invention, 1-benzyl-4-methyl-3-pipradrol is taken as aninitial raw material and is subjected to reactions of halogenation, methylamination, chiral resolution, and the like, so as to prepare a (3R, 4R)-N,4-dimethyl-1-(phenyl methyl)-3-piperylhydrazine dihydrochloride product, and meanwhile, a resolving mother solution is subjected to alkalization, refined, purified and recycled, so as to acquire a (2R,3R)-2,3-bi[(4-methyl benzoyl) oxo] succinic acid product meeting the reaction requirement. The invention has the beneficial effects of 1) short synthetic route, easily controlled intermediate purity and benefit to the control on impurity content, and2) simple and convenient technological operation in each step reaction, capability of recycling the high-dosage chiral resolving agent, capability of reducing production cost while reducing yield of solid wastes and suitability for large-scale industrial production.

Owner:NANTONG CHANGYOO PHARMATECH CO LTD

Novel polymorphs of dasatinib, and preparation method thereof

InactiveCN102898424AHigh purityHigh yieldOrganic active ingredientsOrganic chemistryThiazoleMethyl benzene

The invention belongs to the field of pharmaceutical chemistry, and specifically belongs to novel polymorphs of N-(2-chloro-6-methylphenyl)-2-[[6-[4-(2-hydroxyethyl)-1-piperazinyl]-2-methyl-4-pyrimidinyl]amino]-5-thiazole carboxamide (dasatinib), and a preparation method thereof. Four polymorphs I, II, III, IV of dasatinib disclosed by the invention have good stability, excellent solubility, easily industrialized preparation process, good quality reappearance and easily controllable product purity.

Owner:JIANGSU AOSAIKANG PHARMA CO LTD

Preparation for high-purity zinc oxide powder

ActiveCN1613773AEasy to manufactureSimple processZinc oxides/hydroxidesZinc hydroxideChemical reaction

Production for high purity zinc oxide powder is carried out by: 1) mixing zinc powder with pure water, and grinding in ball mill; 2) adding ammonia water to adjust reacting speed, zinc powder hydrolyzing reacting with water to generate insoluble zinc hydroxide; 3) zinc hydroxide dehydrating treating to obtain high purity zinc oxide powder. Its advantages include low cost, simple process and high purity.

Owner:河北恒博新材料科技股份有限公司

Method for preparing nano twin crystal boron carbide powder

ActiveCN110357106AReduce difficultyHigh purityMaterial nanotechnologyCarbon compoundsBoron carbideHeating temperature

The invention discloses a method for preparing nano twin crystal boron carbide powder, and relates to the technical field of superfine ceramic powder preparation, and the method comprises the following steps: (1) using boric acid as a boron source and a carbon source, weighing the boron source and the carbon source, putting the boron source and the carbon source into deionized water, and uniformlystirring until the boron source and the carbon source are completely dissolved to obtain a colorless and transparent solution; (2) heating the obtained solution on a heating table until the solutionis evaporated to dryness, grinding obtained lumps into powder, and collecting for later use; (3) placing the powder in a graphite crucible, placing the graphite crucible in a tube furnace or a carbontube furnace, vacuumizing and then heating, setting the heating temperature at 1000-2000 DEG C, keeping the temperature for 0-180 min, and cooling to obtain the nano twin crystal boron carbide powder.According to the invention, the preparation difficulty of nano boron carbide powder is reduced, the product purity is improved, the yield is improved, the raw material price is low, the preparation process is simple, the prepared powder has high purity, small particle size, mild reaction conditions and low heating temperature.

Owner:YANSHAN UNIV

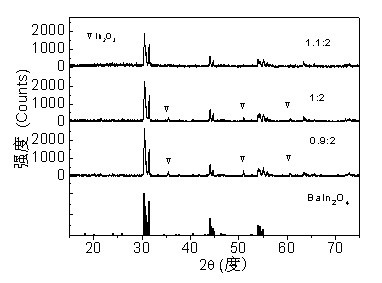

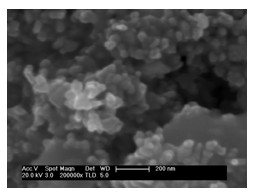

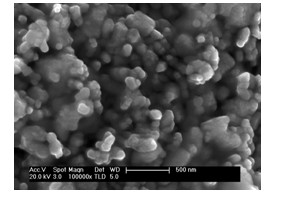

Preparation method of visible light catalyst barium-indium-oxygen

InactiveCN102068977AHigh purityWell mixedCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsPtru catalystBarium nitrate

The invention discloses a preparation method of visible light catalyst barium-indium-oxygen. The method comprises the following steps of: preparing mixed aqueous solution of barium nitrate and indium nitrate in a certain molar ratio; performing a coprecipitation reaction by taking aqueous solution of sodium carbonate and sodium hydroxide as a precipitator so as to prepare a uniformly-mixed precursor; drying the precursor at the temperature of 100 DEG C; and performing high-temperature sintering in a high-temperature furnace at the thermal treatment temperature of between 1,100 DEG C and 1,300 DEG C so as to obtain barium-indium-oxygen with a monoclinic structure. The preparation method of the visible light catalyst barium-indium-oxygen has the advantages of low preparation cost, short period, high product purity, adjustable product particle size, easy operation, and the like.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

Synthesis and purification method of electronic grade arsines

ActiveCN102863023AReduce possible risk factorsPurity is easy to controlArsenic compoundsMolecular sievePurification methods

The invention discloses a synthesis and purification method of electronic grade arsines, wherein zinc arsenide powder is reacted with dilute sulfuric acid to generate coarse arsine gas; the coarse arsine gas passes through a condenser to separate liquid drops in the gas, then passes through an adsorption trap to remove water and carbon dioxides and then is placed into a first liquid nitrogen cold trap to freeze arsines; then arsines are heated and evaporated; chemical adsorption columns are put into arsines to remove impurities containing sulfides, then molecular sieve adsorption columns are put into arsines to remove the impurities containing the water, oxygen and carbon dioxides; at the last, arsine gas is put into a second liquid nitrogen cold trap to freeze arsines and obtain high-purity arsine products. The arsine products prepared by using the synthesis and purification method have the advantages that the purity is 6 N, and the impurity content in the products is less than 0.1 ppm.

Owner:HEFEI ZHENGFAN ELECTRONICS MATERIAL

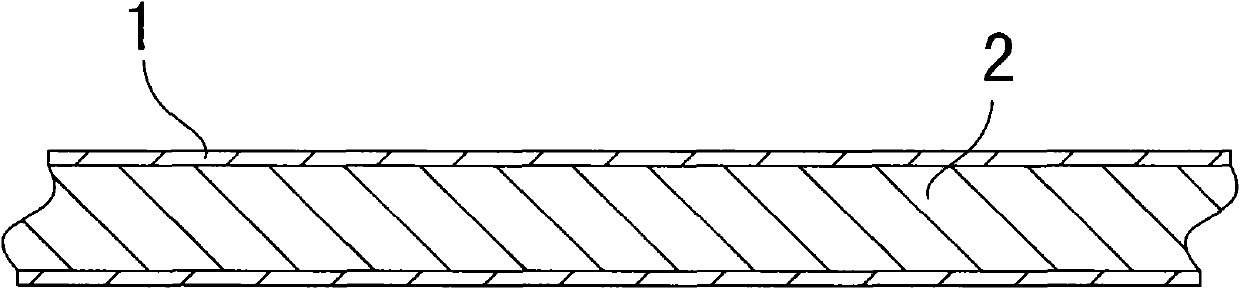

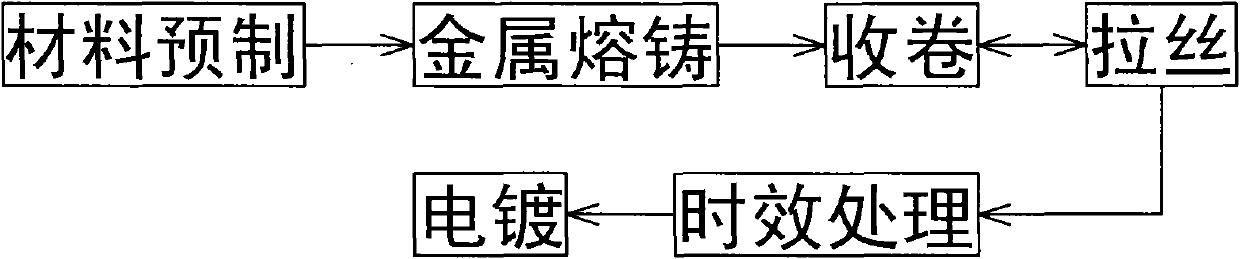

Gradient copper-based alloy cable conductor and manufacturing method thereof

InactiveCN101950602AHigh mechanical strengthImprove conductivitySingle bars/rods/wires/strips conductorsMetal/alloy conductorsElectrical conductorAlloy

The invention discloses a gradient copper-based alloy cable conductor, which consists of a core layer and a skin layer, wherein the core layer and the skin layer form a double-metal concentric circle structure; the core layer is a copper-based alloy; the skin layer is pure copper; and the conductor is cast by a double-layer composite material one-step coating device. With the double-metal concentric circle structure, the gradient copper-based alloy cable conductor has high interface metal atom lattice distribution transitivity, high crystal bonding strength, ordered crystalline phase structure, high purity, high electrical performance, tight core layer and skin layer bonding strength and high mechanical performance compared with the conventional non-gradient copper-based alloy cable conductor such as copper clad steel, copper clad aluminum and aluminum clad steel.

Owner:江苏河阳线缆有限公司

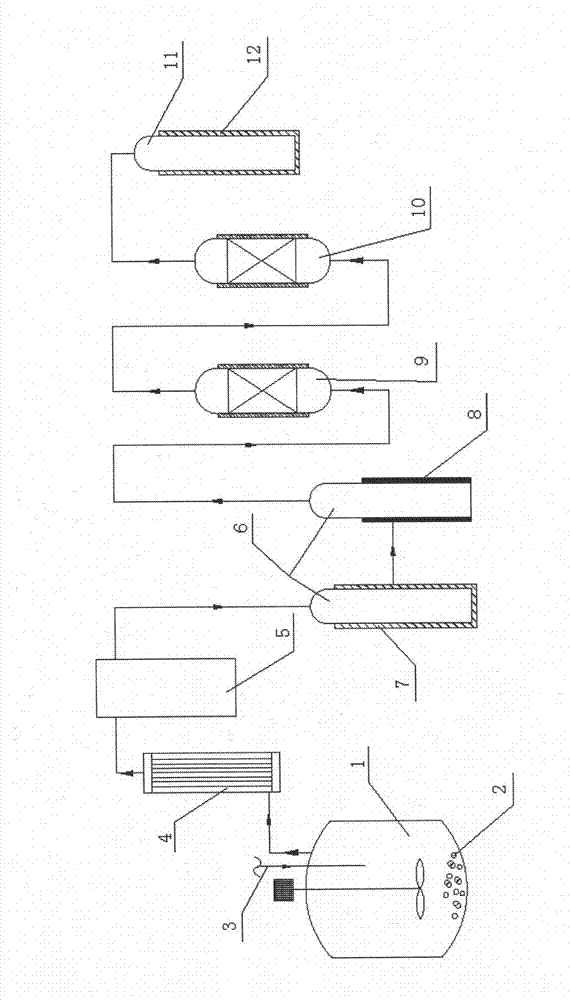

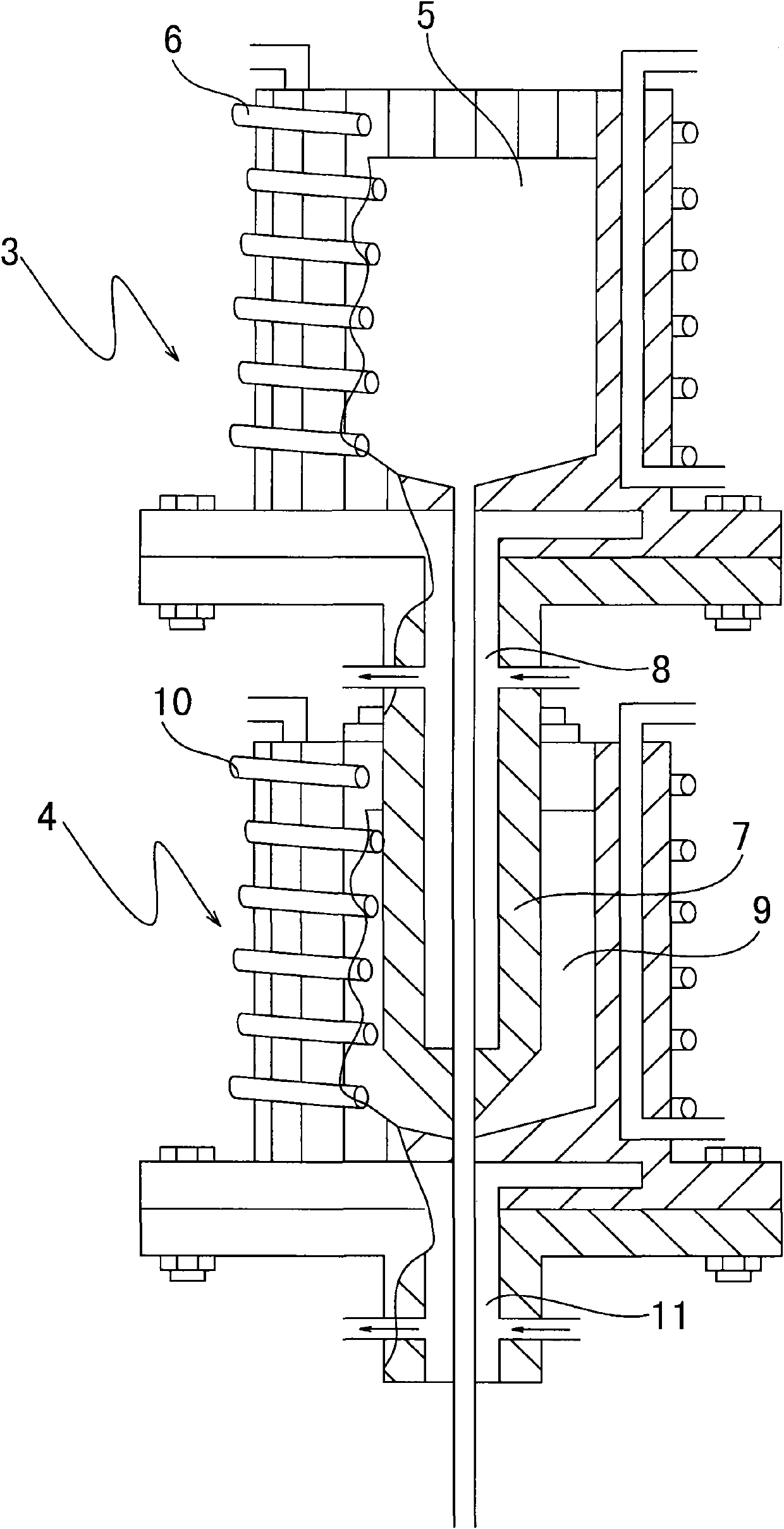

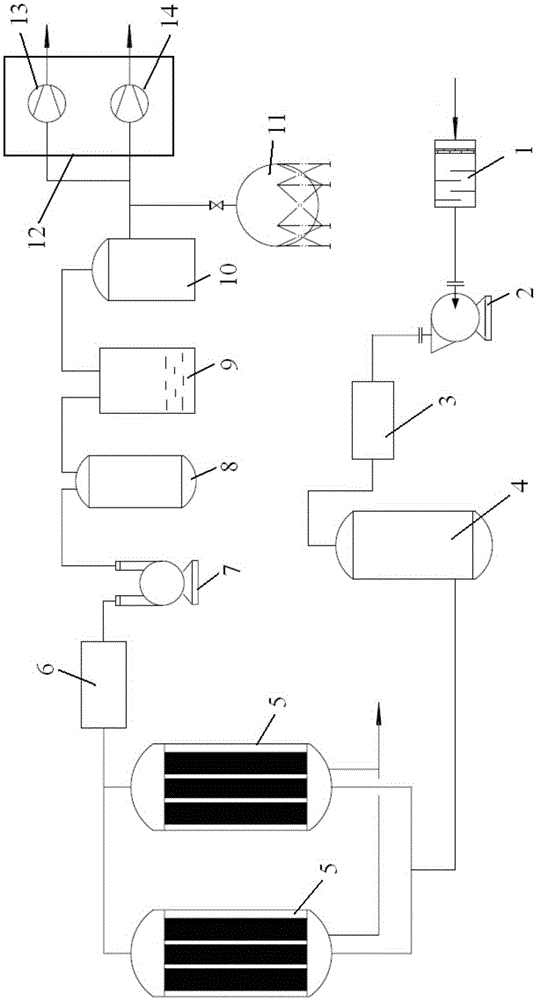

Ionic membrane oxygen generation system

InactiveCN105271128AMeet purity requirementsHigh purityOxygen preparationChemical industryAir filter

The invention provides an ionic membrane oxygen generation system. The ionic membrane oxygen generation system comprises an air filter (1), an air blower (2), membrane separators (5), a pump (7) and an oxygen spherical tank (11), wherein the air filter (1), the air blower (2), the membrane separators (5), the pump (7) and the oxygen spherical tank (11) are sequentially connected through a pipe. The membrane separators (5) are pipe-type ionic membrane separators, and ionic membranes used for separating oxygen in the membrane separators (5) are ceramic membranes. According to the ionic membrane oxygen generation system, the ionic-membrane oxygen generation technology is adopted, scale and purity are both greatly improved, and the requirements for oxygen generation scale and oxygen product purity of the metallurgy industry and the chemical industry can be met.

Owner:CERI ENERGY & AIR PROTECTION TECH CO LTD +1

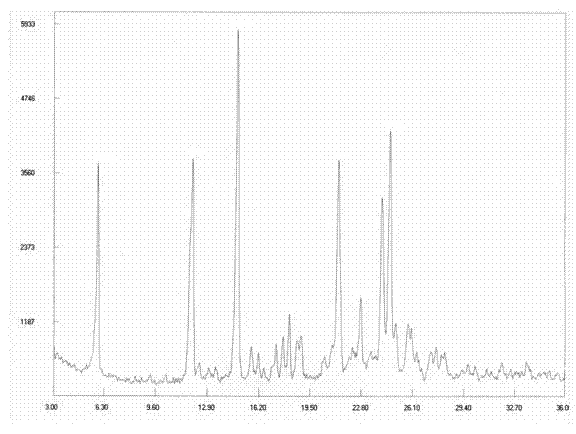

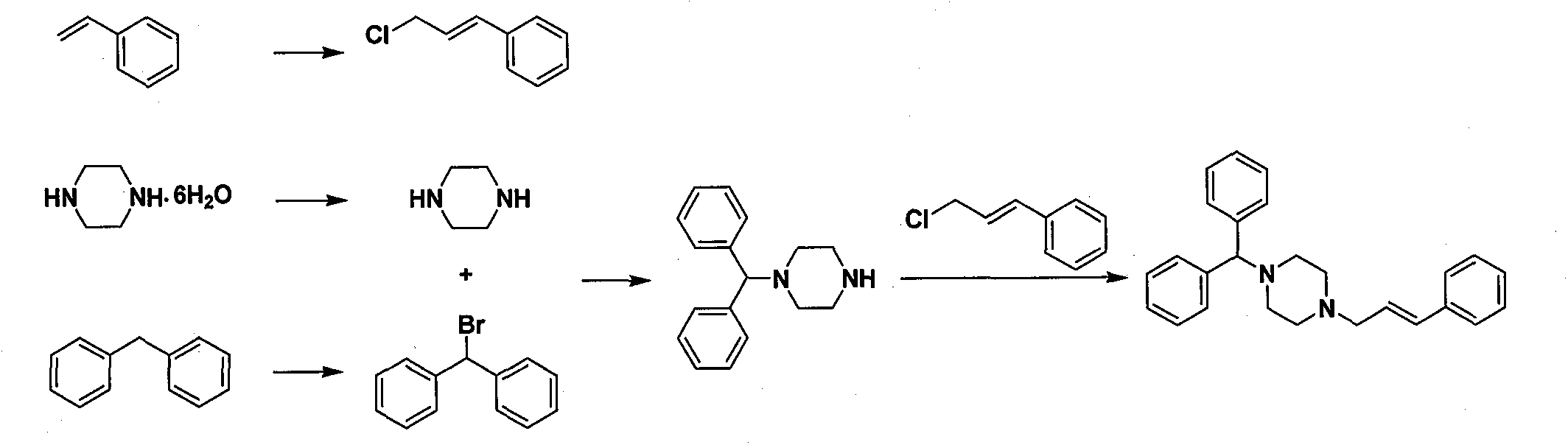

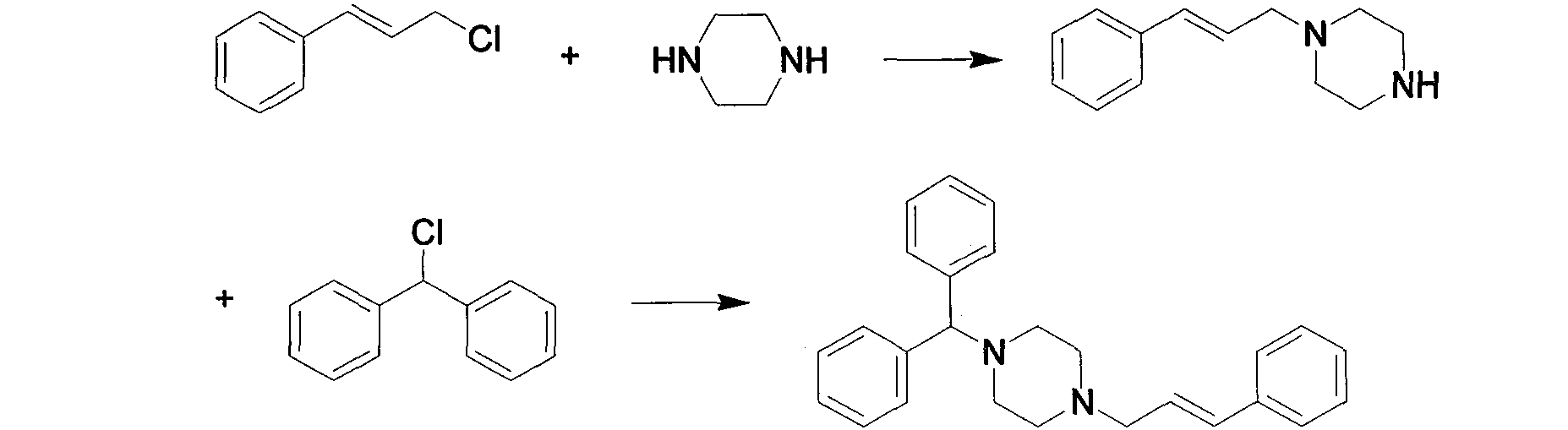

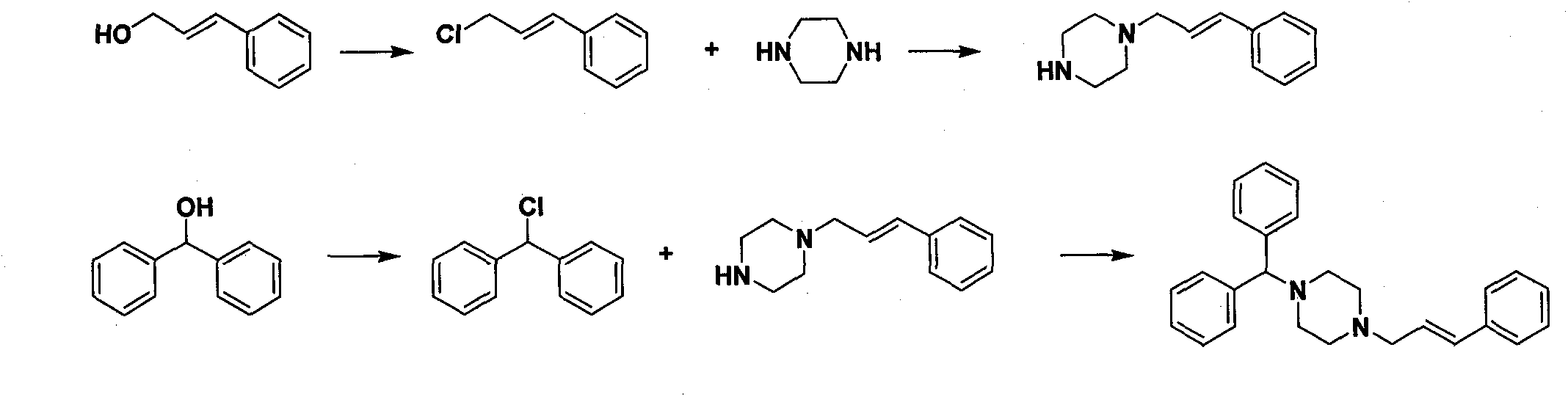

New synthesis method of cinnarizine

The invention provides a new synthesis method of cinnarizine. The method consists of four steps. The method monitors the reaction process through GC and TLC, so that the cinnarizine yield is greatly enhanced up to over 85%. At the same time, the purity of the product of each reaction step is also high.

Owner:珠海保税区丽珠合成制药有限公司

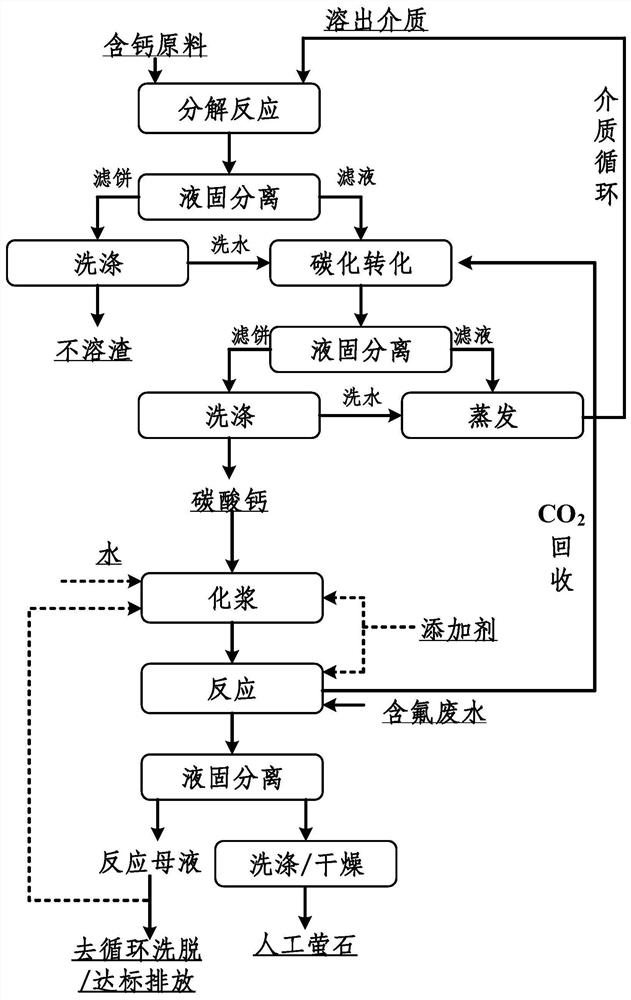

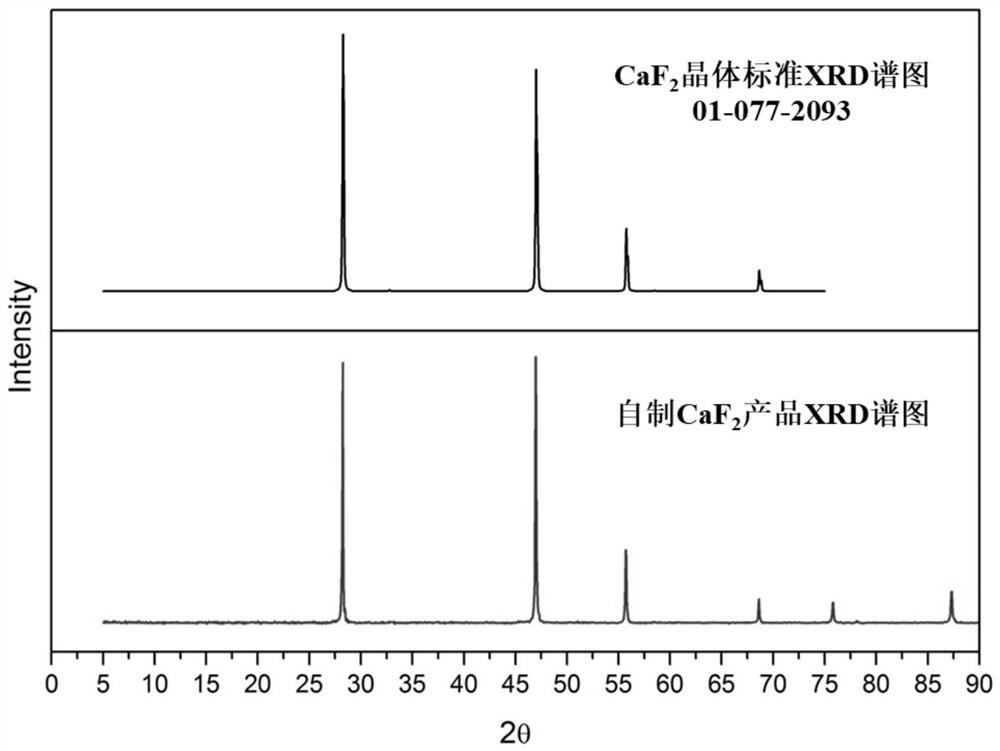

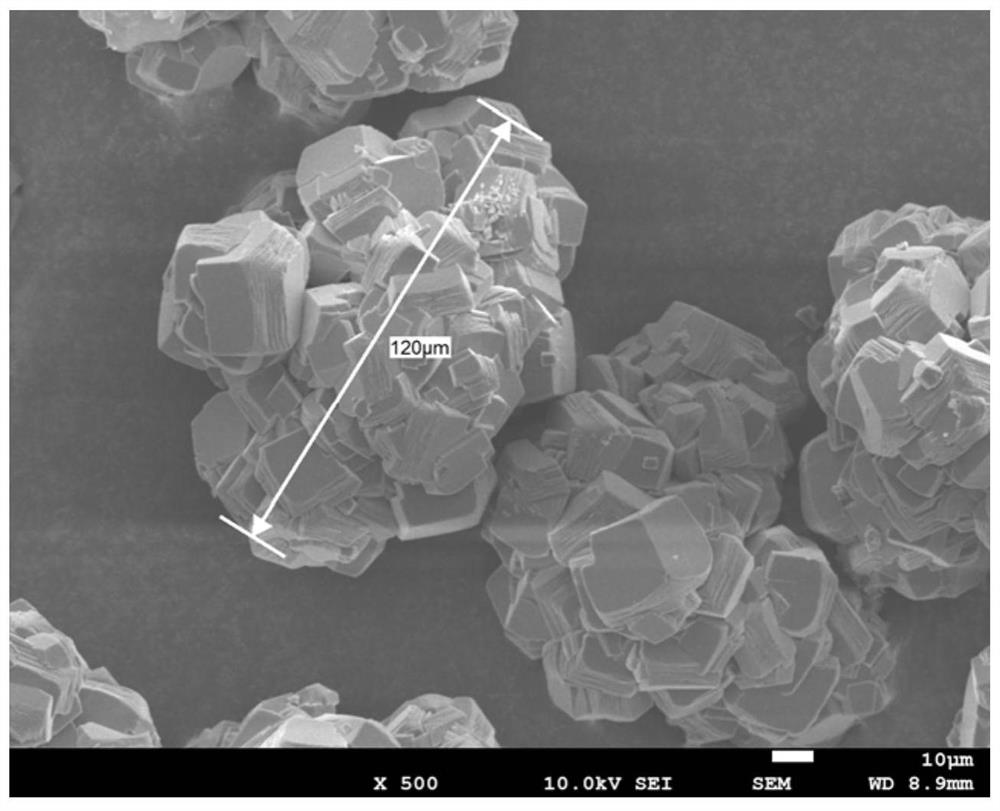

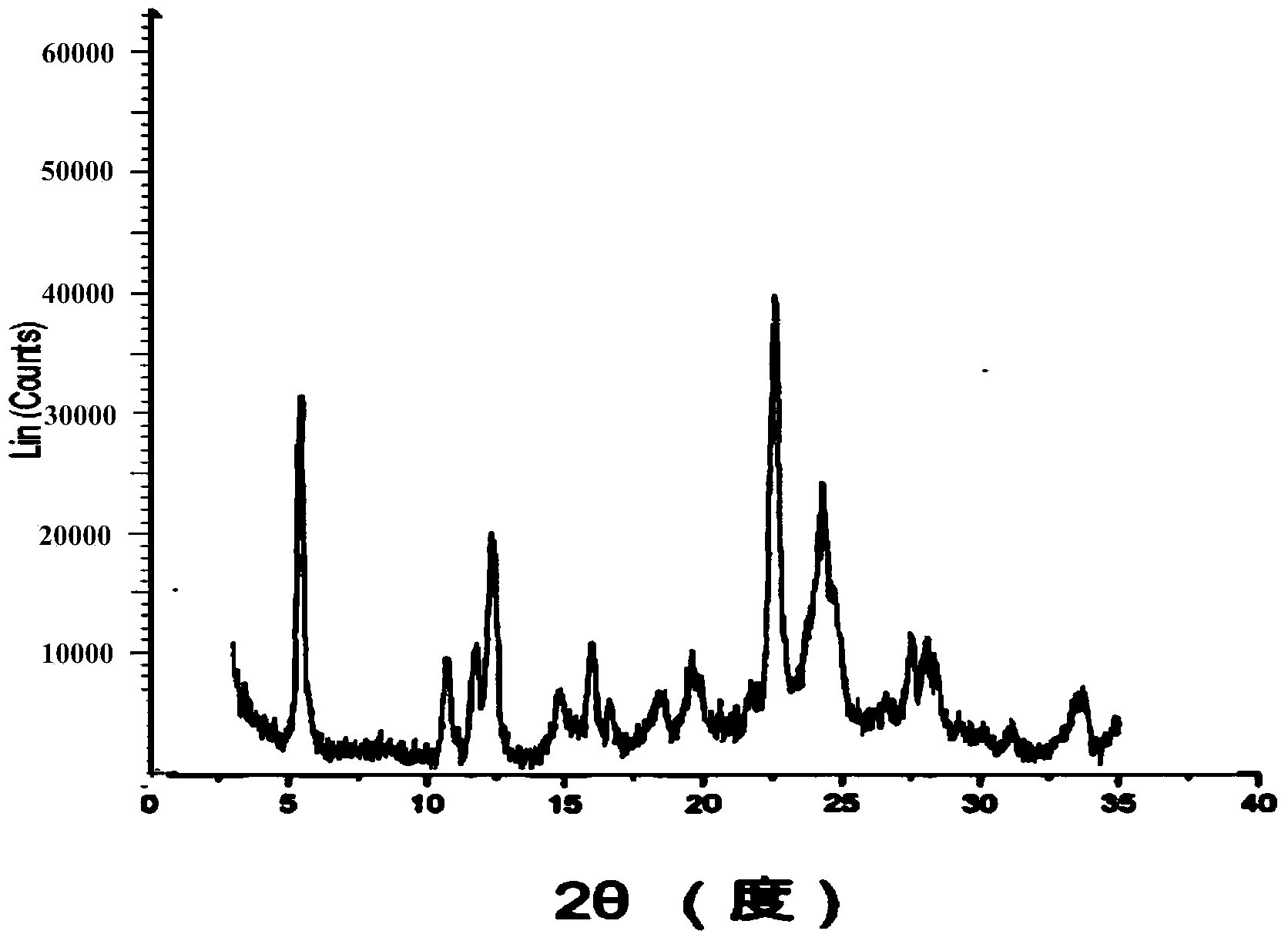

Method for preparing calcium fluoride from fluorine-containing wastewater

ActiveCN113120938AHigh recovery rateZero emissionCalcium/strontium/barium fluoridesSludgeResource recovery

The invention relates to a method for preparing calcium fluoride from fluorine-containing wastewater. The preparation method comprises the following steps: carrying out decomposition reaction on a calcium-containing raw material and a dissolution medium, carrying out carbonization conversion reaction on a calcium-containing solution obtained by the decomposition reaction and carbon dioxide, and mixing and reacting a calcium carbonate solid obtained by the carbonization conversion reaction with the fluorine-containing wastewater and an additive to obtain a calcium fluoride solid. According to the preparation method, a high-quality artificial fluorite product with controllable morphology, controllable granularity and controllable purity can be prepared, and the fluorine resource recovery rate can be increased to 90% or above; and in addition, the preparation method realizes efficient circulation of the medium and carbon dioxide, avoids the generation of fluorine-containing sludge, and has the advantages of mild process conditions, no special requirements on equipment materials and types, strong industrial operability and wide application range.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Calcium zinc gluconate compound

InactiveCN103483181AImprove solubilityNot easy to precipitateOrganic active ingredientsGranular deliverySolubilityZinc

The invention relates to a calcium zinc gluconate crystal compound and a preparation method thereof as well as a pharmaceutical composition comprising the same. The calcium zinc gluconate crystal compound has better stability and solubility, and the preparation process is easy to industrialize, thereby being the best choice for clinical medication.

Owner:洪军 +1

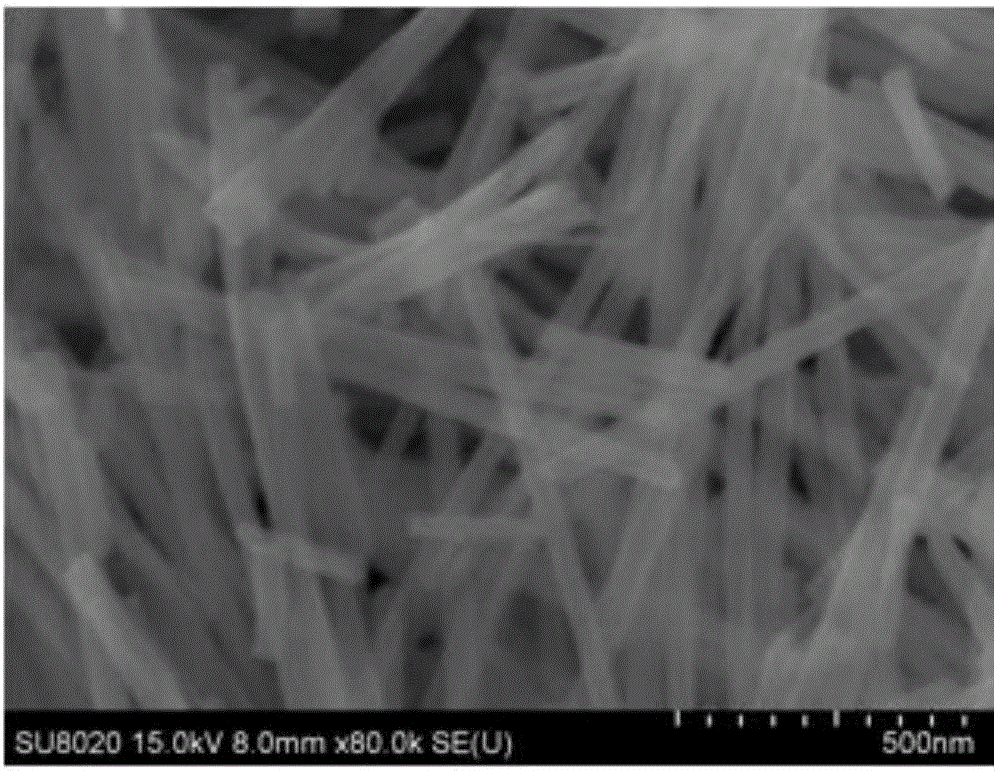

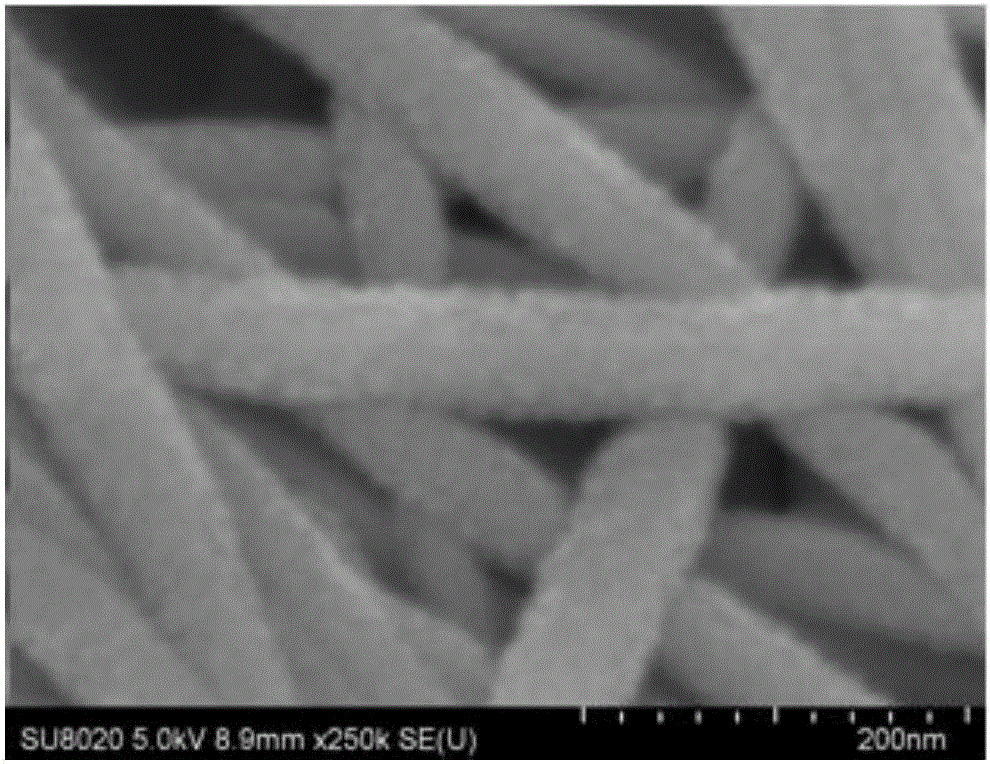

TiN/TiO2 three-dimensional nanowire array with core shell structure and preparation method thereof

ActiveCN106086881AGood electrical conductivityEasy to prepareNanotechnologySuperimposed coating processNanowire arrayCore shell

The invention discloses a TiN / TiO2 three-dimensional nanowire array with a core shell structure and a preparation method thereof. The method comprises the following specific steps: a pretreated Ti net is prepared with a precursor of a TiO2 nanowire array under hydrothermal conditions; then, the precursor is calcined in air to prepare a three-dimensional TiO2 nanowire array; and then, the TiN controllable deposition is performed for the surface of TiO2 by a magnetron sputtering method under high vacuum conditions to obtain a three-dimensional core shell structured TiN / TiO2 nanowire array. The diameter size of TiN / TiO2 nanowires is 40-150 nm. The preparation method has the characteristics of simplicity, stability and size and purity controllability, and facilitates large-scale industrial production.

Owner:HEFEI UNIV OF TECH

Preparation for high-purity zinc oxide powder

ActiveCN1267355CEasy to manufactureSimple processZinc oxides/hydroxidesZinc hydroxideChemical reaction

Production for high purity zinc oxide powder is carried out by: 1) mixing zinc powder with pure water, and grinding in ball mill; 2) adding ammonia water to adjust reacting speed, zinc powder hydrolyzing reacting with water to generate insoluble zinc hydroxide; 3) zinc hydroxide dehydrating treating to obtain high purity zinc oxide powder. Its advantages include low cost, simple process and high purity.

Owner:河北恒博新材料科技股份有限公司

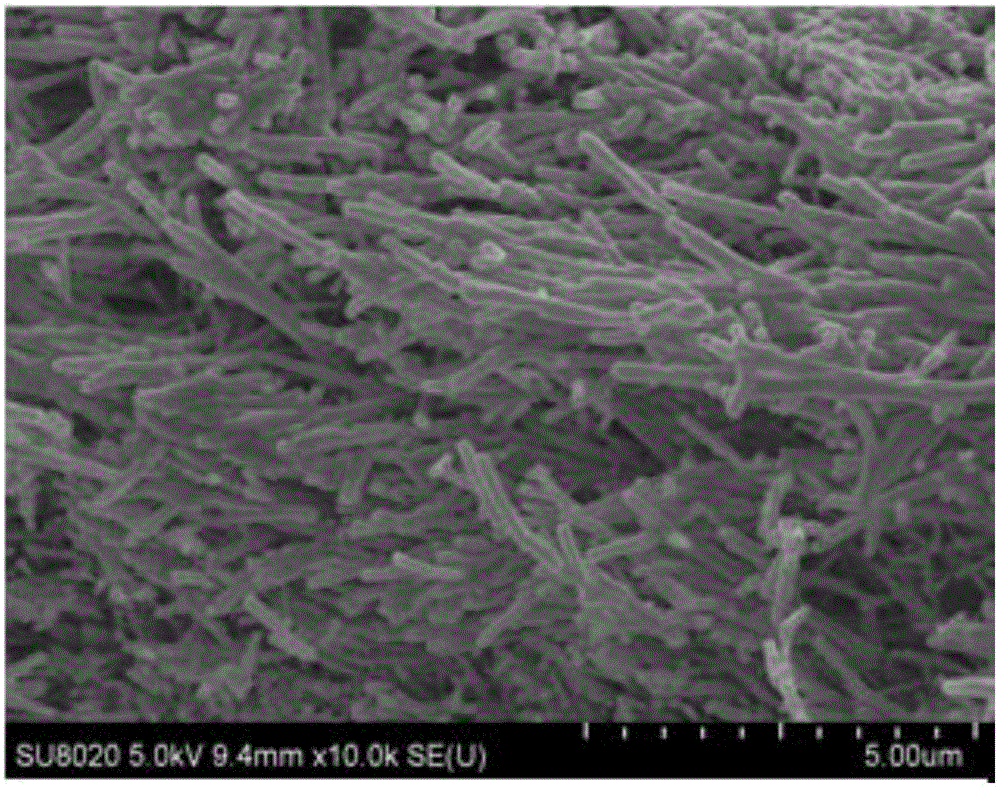

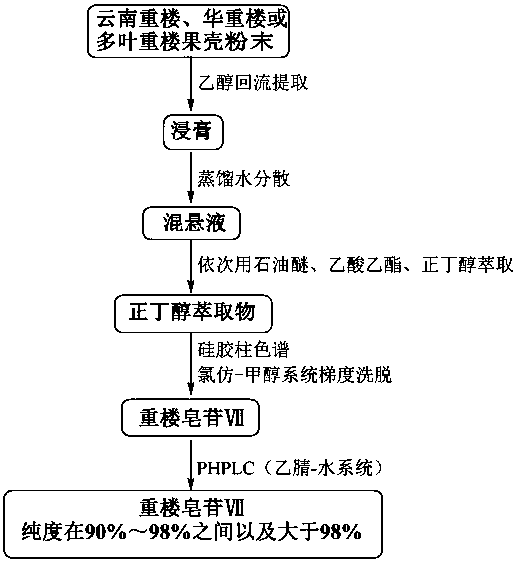

Preparation method and quality control method of high-purity polyphyllin VII

ActiveCN111349140ASolve the problem of high-purity saponin Ⅶ chemical reference substanceReasonable designComponent separationSteroidsBiotechnologyMedicinal herbs

The invention relates to a preparation method and a quality control method of high-purity polyphyllin VII. Dry shells of paris polyphylla smith var.yunnanensis (franch.)hand.-mazz, paris polyphylla smith var. chinensis(franch.)hara or paris polyphylla smith are used as raw materials, reflux extraction is carried out by an ethanol solution, and a batch extraction process of a polyphyllin VII chemical reference substance and an analytical determination method for purity, content and impurity inspection are established, so that the technical standard of the polyphyllin VII chemical reference substance is established, and a scientific basis and guarantee are provided for quality standard research of the polyphyllin VII chemical reference substance as a traditional Chinese medicine chemical reference substance and medicinal materials and preparations. The method is reasonable in process design, simple in process, high in separation speed and short in production period, the obtained productis high in purity, the content reaches 98% or above, the quality is controllable, and the method is suitable for industrial production and has good application prospects.

Owner:GUANGXI INST OF CHINESE MEDICINE & PHARMA SCI

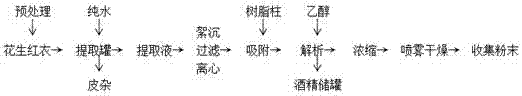

Method for preparing high-purity peanut skin procyanidine

InactiveCN107382948AHigh purityReduce the degree of polymerizationOrganic chemistryBiotechnologyFiltration

The invention belongs to the technical field of biology, and discloses a method for preparing high-purity peanut skin procyanidine. The method comprises the steps of pretreating peanut skin; extracting the pretreated peanut skin by adopting a water immersion method to obtain an extracting solution; carrying out flocculation, filtration and centrifuging on the extracting solution to obtain filtrate; absorbing the filtrate by using macromolecule resin, and eluting by using ethanol to obtain a desorption solution; carrying out high-efficiency concentration on the desorption solution to obtain a concentrated solution; and carrying out spray drying on the concentrated solution to obtain peanut skin procyanidine powder. A product prepared by using the method is high in purity, high in yield and good in quality, and can be widely applied to the fields, such as health products, foods, drugs and cosmetics; and the method is green and environmentally friendly in production technology, low in cost, low in energy consumption, suitable for large-scale industrial production and wide in market prospect.

Owner:金胜粮油集团有限公司 +1

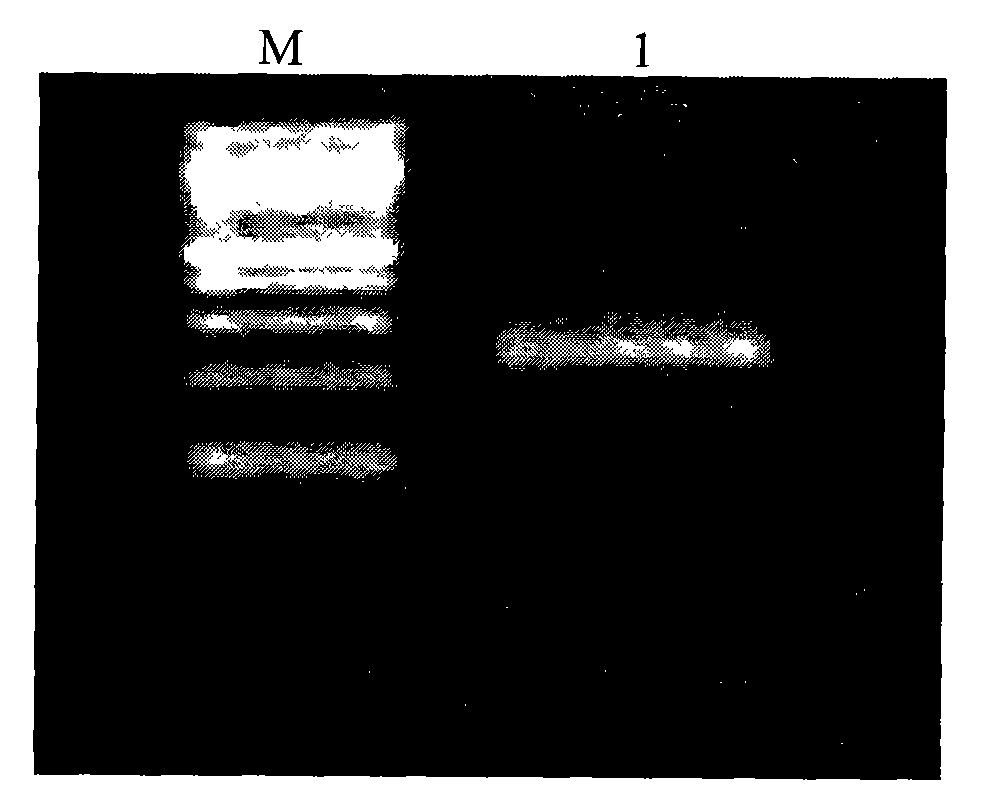

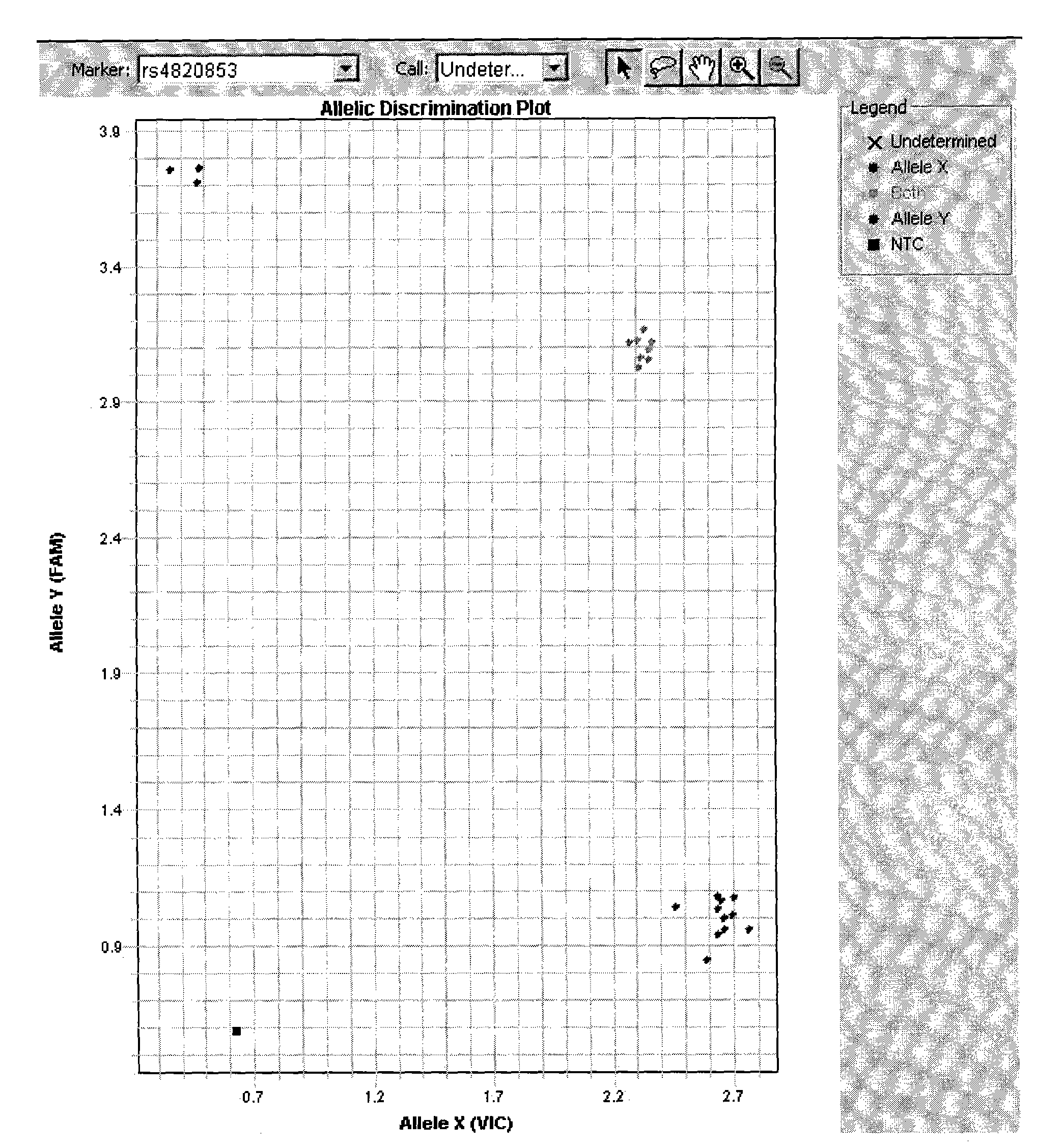

Kit for detecting thiopurine methyltransferase genotype, method and application thereof

InactiveCN101591698AImprove efficiencyMeet testing needsMicrobiological testing/measurementType specificFluorescence

The invention belongs to the gene technical field and relates to a kit for detecting thiopurine methyltransferase genotype, a method and an application thereof. In the invention, the single nucleotide polymorphism Genotyping method of fluorescent quantitative PCR is adopted; in the method, auele specific primers of thiopurine methyltransferase gene polymorphism locus and fluorescently-labeled probes are adopted to carry out polymerase chain reaction on sample DNA, carry out fluorescence scanning and classify the genotype according to fluorescence types; wherein the primers comprise the auele specific primers for detecting thiopurine methyltransferase G460A polymorphism locus and the auele specific primers for detecting A719G polymorphism locus. The probes comprise a thiopurine methyltransferase G460A polymorphism locus wild type specific probe and a mutant type specific probe and a wild type specific probe and a mutant type specific probe for detecting A719G polymorphism locus.

Owner:BEIJING HUAANFO BIOMEDICAL RES CENT +1

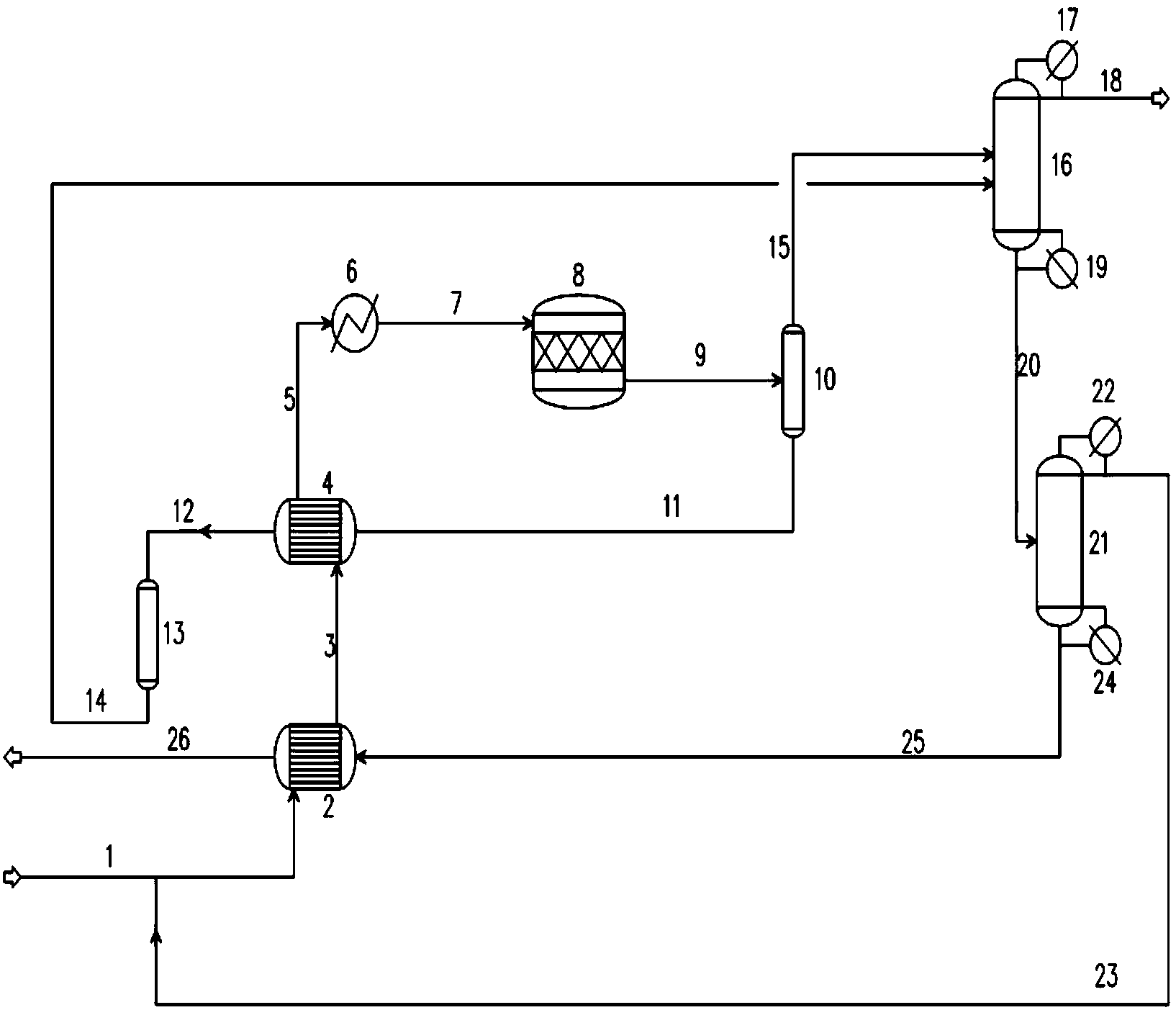

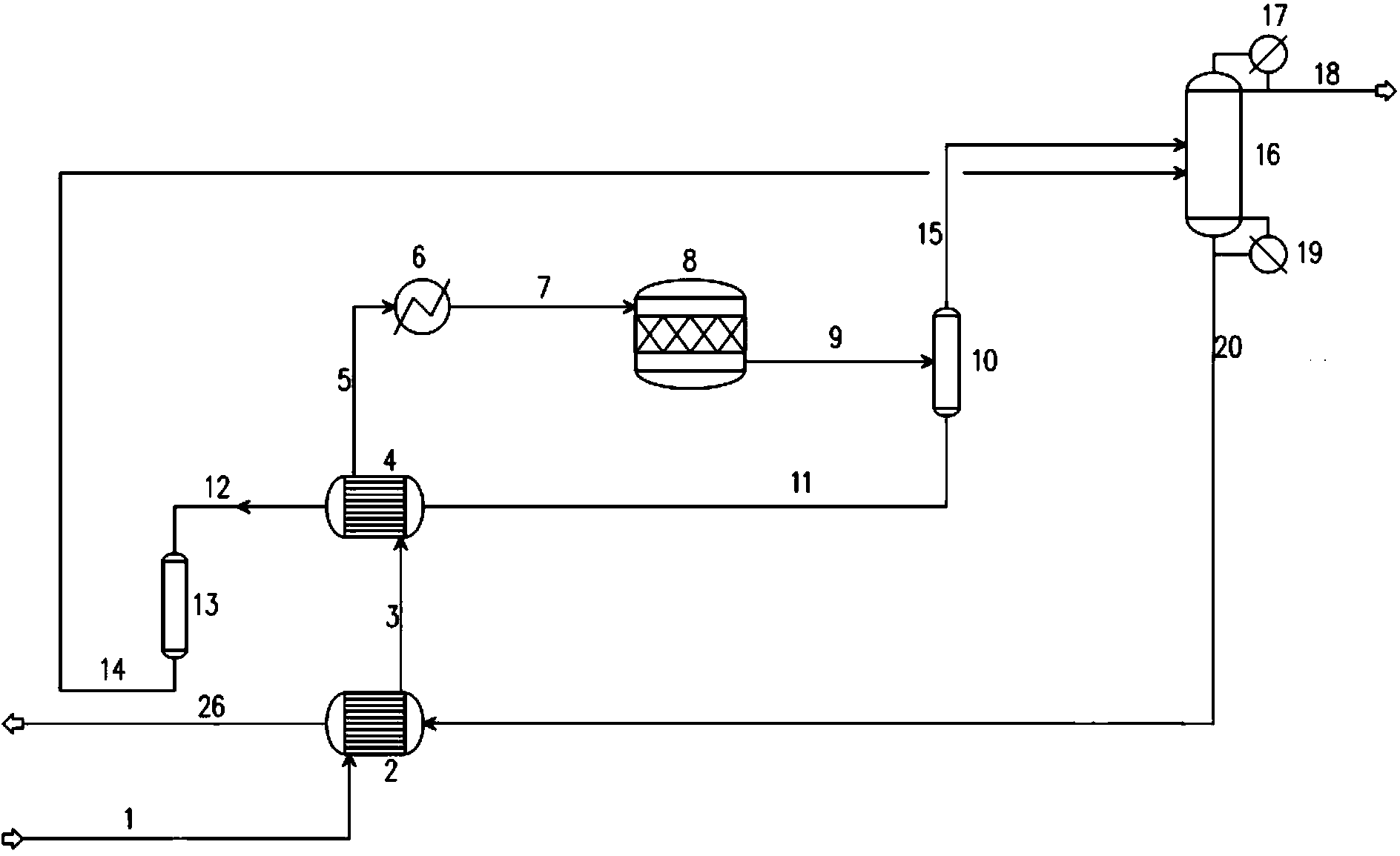

Method for preparing dimethyl ether through methanol dehydration

ActiveCN103435454ASimple processLow reaction temperatureEther preparation by compound dehydrationAlcoholGas phase

The invention relates to a method for preparing dimethyl ether through methanol dehydration. The method comprises the steps: enabling preheated methanol to be subjected to dehydration reaction under the action of a catalyst, so as to obtain a reaction mixture, and carrying out gas-liquid separation; enabling an obtained gas phase to directly enter a dimethyl ether rectification tower; removing anions and cations from an obtained liquid phase, and then, enabling the liquid phase to enter the dimethyl ether rectification tower; condensing an overhead of the dimethyl ether rectification tower, so as to obtain a qualified dimethyl ether product; obtaining alcohol-containing wastewater from the dimethyl ether rectification tower. According to the method disclosed by the invention, the process flow is simple, and methanol reacts in a liquid phase state, so that the method has the advantages of low reaction temperature, high conversion ratio, good selectivity and low energy consumption; in addition, corrosive anions and cations are removed by an ion exchanger, so that the problem of corrosion of liquid phase methods is solved effectively.

Owner:KAIRUI ENVIRONMENTAL PROTECTION TECH

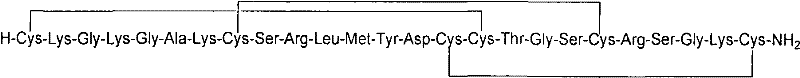

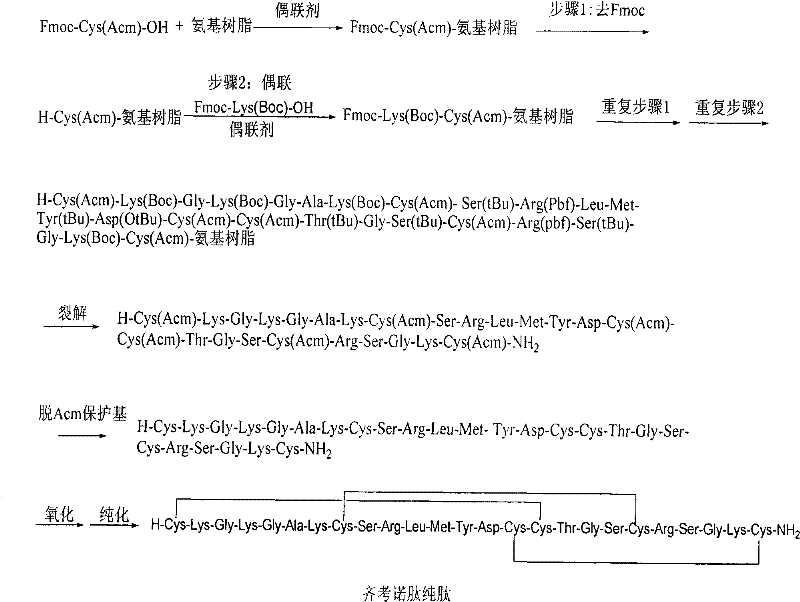

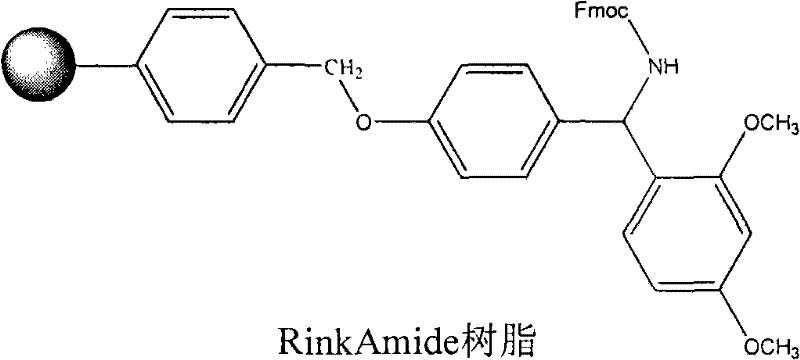

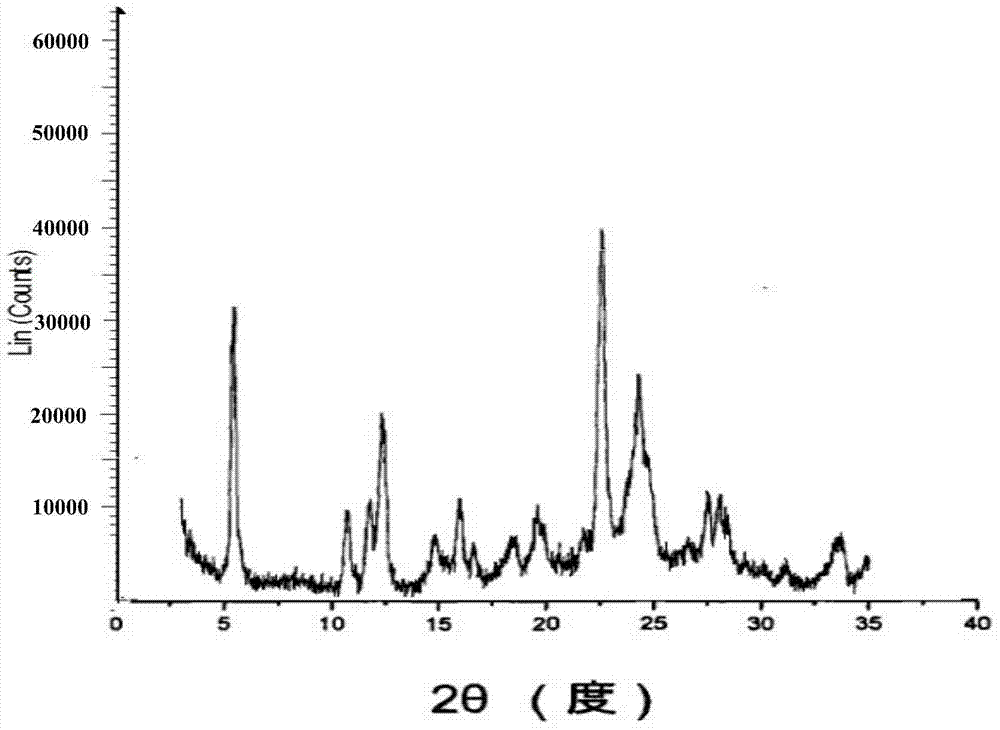

Method for preparing ziconotide

InactiveCN101709082BPurity is easy to controlPrecise positioningPeptide preparation methodsAnimals/human peptidesFreeze-dryingSide chain

The invention discloses a method for preparing ziconotide. The technical scheme of the invention comprises the following steps: (1) obtaining an Fmoc-Cys(Acm)-amino resin from Fmoc-Cys(Acm)-OH and an amino resin; (2) obtaining a linear-ziconotide-amino resin of which a Cys side chain comprises Acm by performing the solid phase synthesis on the Fmoc-Cys(Acm)-amino resin and an amino acid adopting Fmoc group protection; (3) obtaining a linear crude peptide of which the Cys side chain comprises the Acm by performing cracking on the linear-ziconotide-amino resin of which the Cys side chain comprises the Acm, and obtaining linear ziconotide by removing the Acm, purifying and freeze-drying; (4) and obtaining the ziconotide by performing cyclization, purifying and freeze-drying on the linear ziconotide. The method for preparing ziconotide has the characteristics of simple reaction operation, easy subsequent treatment, low raw material investment, low cost, high yield and the like, and has considerable economic and practical value, and also has wide application prospect in the field of design synthesis of polypeptide drugs.

Owner:HYBIO PHARMA

A kind of calcium zinc gluconate compound

InactiveCN103483181BImprove solubilityEasy to industrializeOrganic active ingredientsGranular deliveryCompounds of zincPharmaceutical drug

The invention relates to a calcium zinc gluconate crystal compound and a preparation method thereof as well as a pharmaceutical composition comprising the same. The calcium zinc gluconate crystal compound has better stability and solubility, and the preparation process is easy to industrialize, thereby being the best choice for clinical medication.

Owner:洪军 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com