Method for preparing calcium fluoride from fluorine-containing wastewater

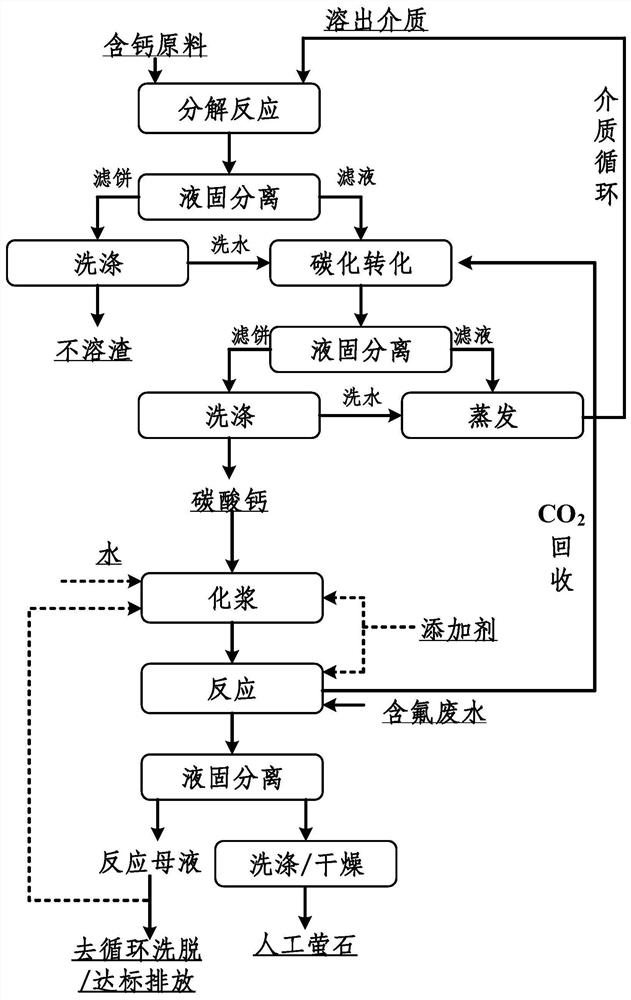

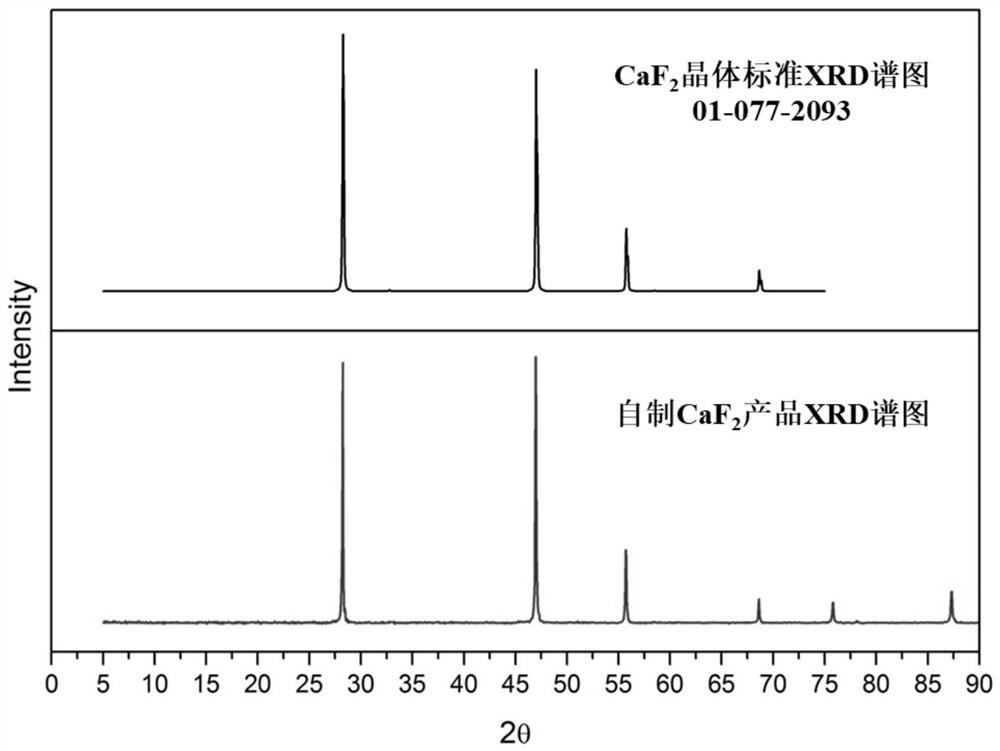

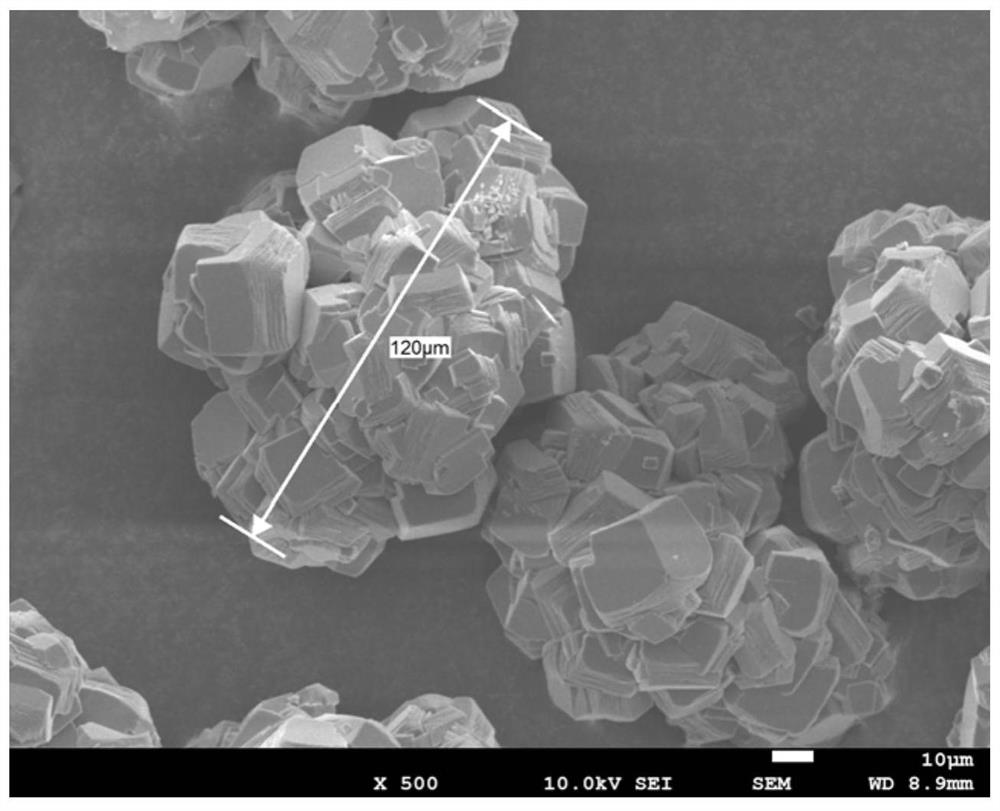

A calcium fluoride and wastewater technology, applied in the direction of calcium/strontium/barium fluoride, calcium/strontium/barium halide, etc., can solve the problem that calcium fluoride solid cannot achieve controllable morphology, controllable particle size, purity, fluorine-containing Sludge secondary pollution, cumbersome process flow and other problems, to achieve the effect of good liquid-solid separation performance, controllable purity, and short process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0079] This example provides a method for preparing calcium fluoride by utilizing fluorine-containing wastewater, which is fluorine-containing wastewater obtained from the condensation of fluidized bed waste gas from an aluminum fluoride factory in Henan, wherein the mass concentration of HF is 6.1 wt%; described preparation method adopts industrial lime as calcium-containing raw material, and its chemical composition is as shown in table 1:

[0080] Table 1

[0081]

[0082] Described preparation method comprises the steps:

[0083] (1) Mix industrial lime with an aqueous solution of ammonium chloride, and carry out a decomposition reaction at 95° C. for 0.05 h. After the reaction, the calcium chloride-containing feed liquid is subjected to liquid-solid separation to obtain a calcium chloride-containing solution and insoluble slag;

[0084] Wherein, the ratio of the ammonium chloride to the amount of CaO in the industrial lime is 1.6:1; the washing water obtained by washi...

Embodiment 2

[0091] This example provides a method for preparing calcium fluoride by utilizing fluorine-containing wastewater, which is a fluorine-containing wastewater from a fluorine chemical industry in Shandong, wherein the molar concentration of HF is 5.26 mol / L, and the molar concentration of HCl is 0.053 mol / L; The preparation method adopts calcium hydroxide as calcium-containing raw material:

[0092] Described preparation method comprises the steps:

[0093] (1) Calcium hydroxide is mixed with an aqueous solution of ammonium nitrate, and a decomposition reaction is carried out at 25° C. for 3 hours. After the reaction, the calcium nitrate-containing feed liquid is subjected to liquid-solid separation to obtain a calcium nitrate-containing solution and insoluble slag;

[0094] Wherein, the ratio of the amount of ammonium nitrate to calcium hydroxide is 2.4:1; the washing water obtained by washing the insoluble slag is mixed with the calcium nitrate-containing solution;

[0095] (...

Embodiment 3

[0101] This example provides a method for preparing calcium fluoride by using fluorine-containing wastewater, the fluorine-containing wastewater is fluorine-containing wastewater from a stainless steel factory in Jiangsu, wherein the mass concentration of HF is 7.66wt%, HNO 3 The mass concentration is 4.23wt%; Described preparation method adopts milk of lime as calcium-containing raw material:

[0102] Described preparation method comprises the steps:

[0103] (1) Mix milk of lime with an aqueous solution of ammonium chloride, and carry out a decomposition reaction at 60°C for 0.5h, and the reacted calcium chloride-containing feed liquid undergoes liquid-solid separation to obtain calcium chloride-containing solution and insoluble slag;

[0104] Wherein, the ratio of the ammonium chloride to the amount of CaO in the milk of lime is 2:1; the washing water obtained by washing the insoluble slag is mixed with the calcium chloride-containing solution;

[0105] (2) Contacting the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com