Patents

Literature

485results about "Calcium/strontium/barium fluorides" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Single-crystal-like materials

InactiveUS7022303B2Improve fracture toughnessReadily apparentMagnesium fluoridesCalcium/strontium/barium fluoridesMetallurgySingle crystal

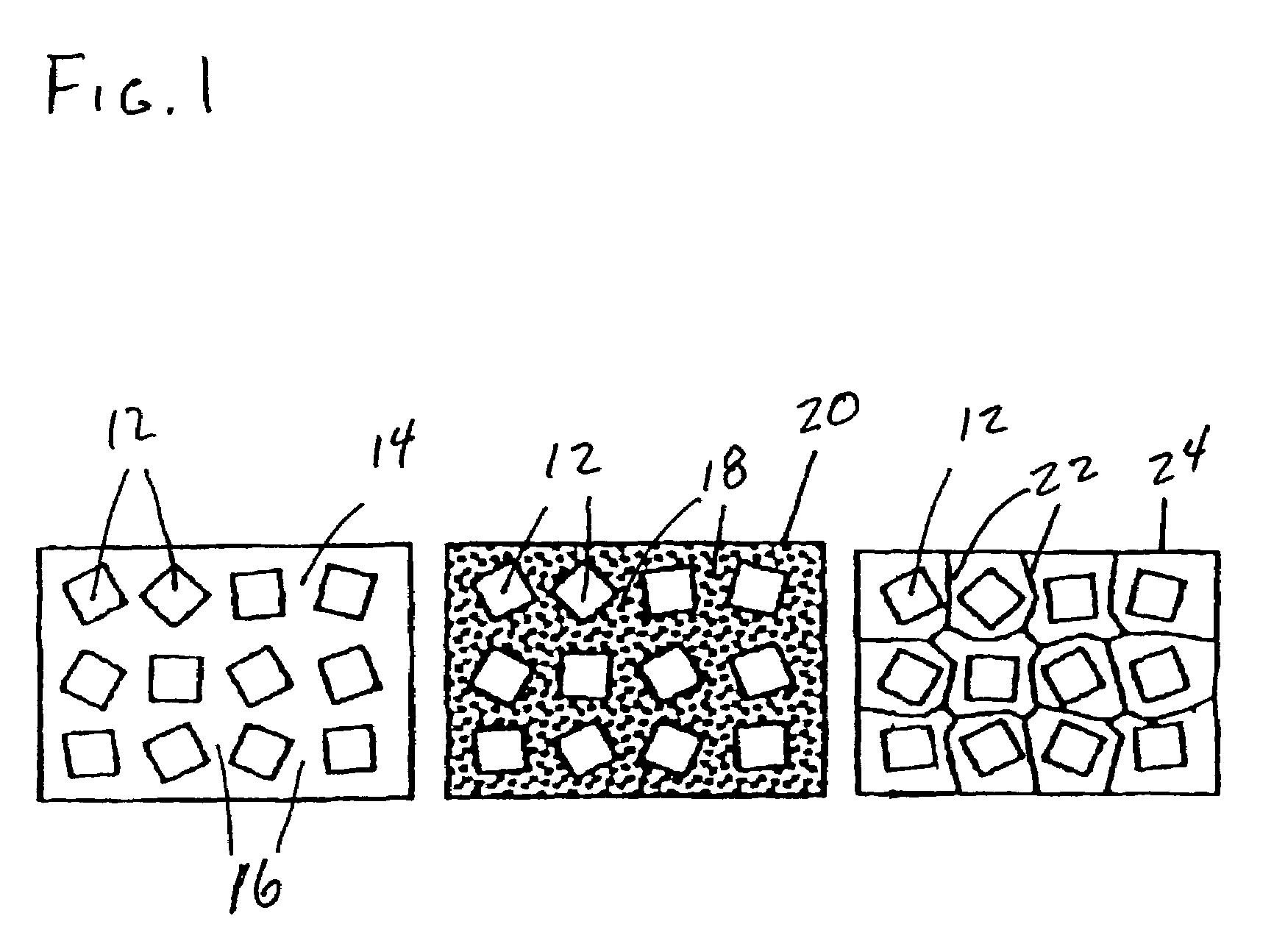

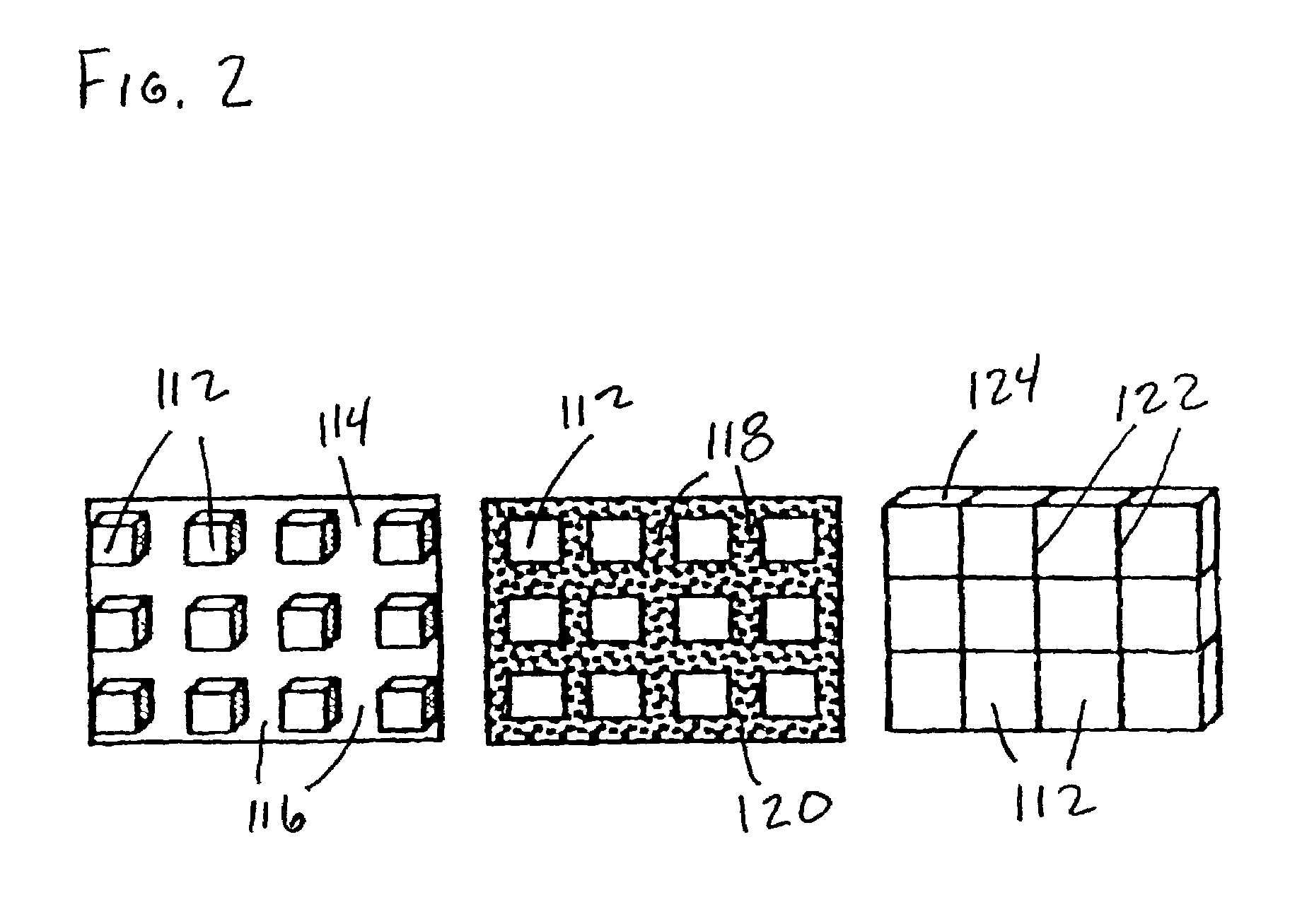

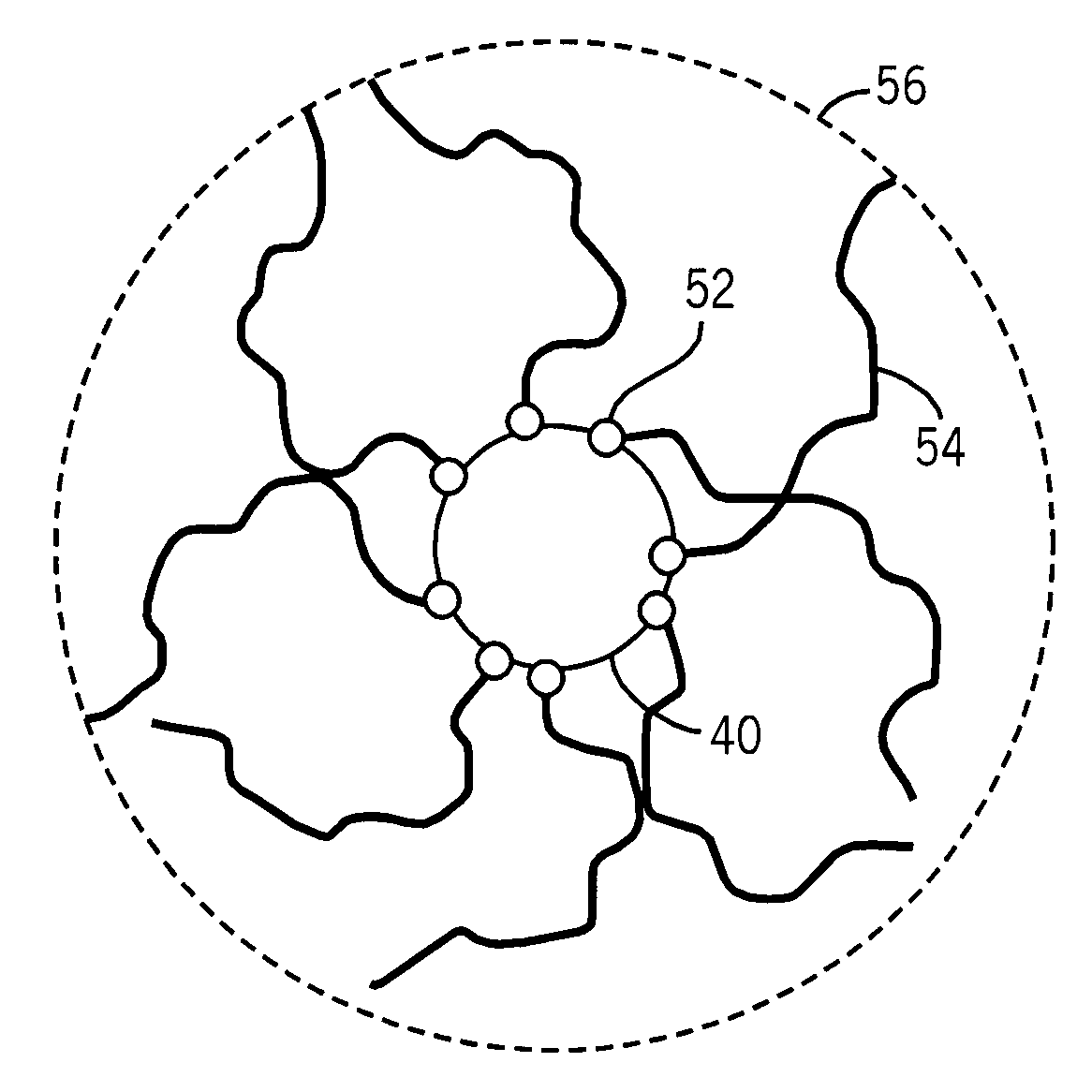

Polycrystalline materials of macroscopic size exhibiting Single-Crystal-Like properties are formed from a plurality of Single-Crystal Particles, having Self-Aligning morphologies and optionally ling morphology, bonded together and aligned along at least one, and up to three, crystallographic directions.

Owner:RUTGERS THE STATE UNIV

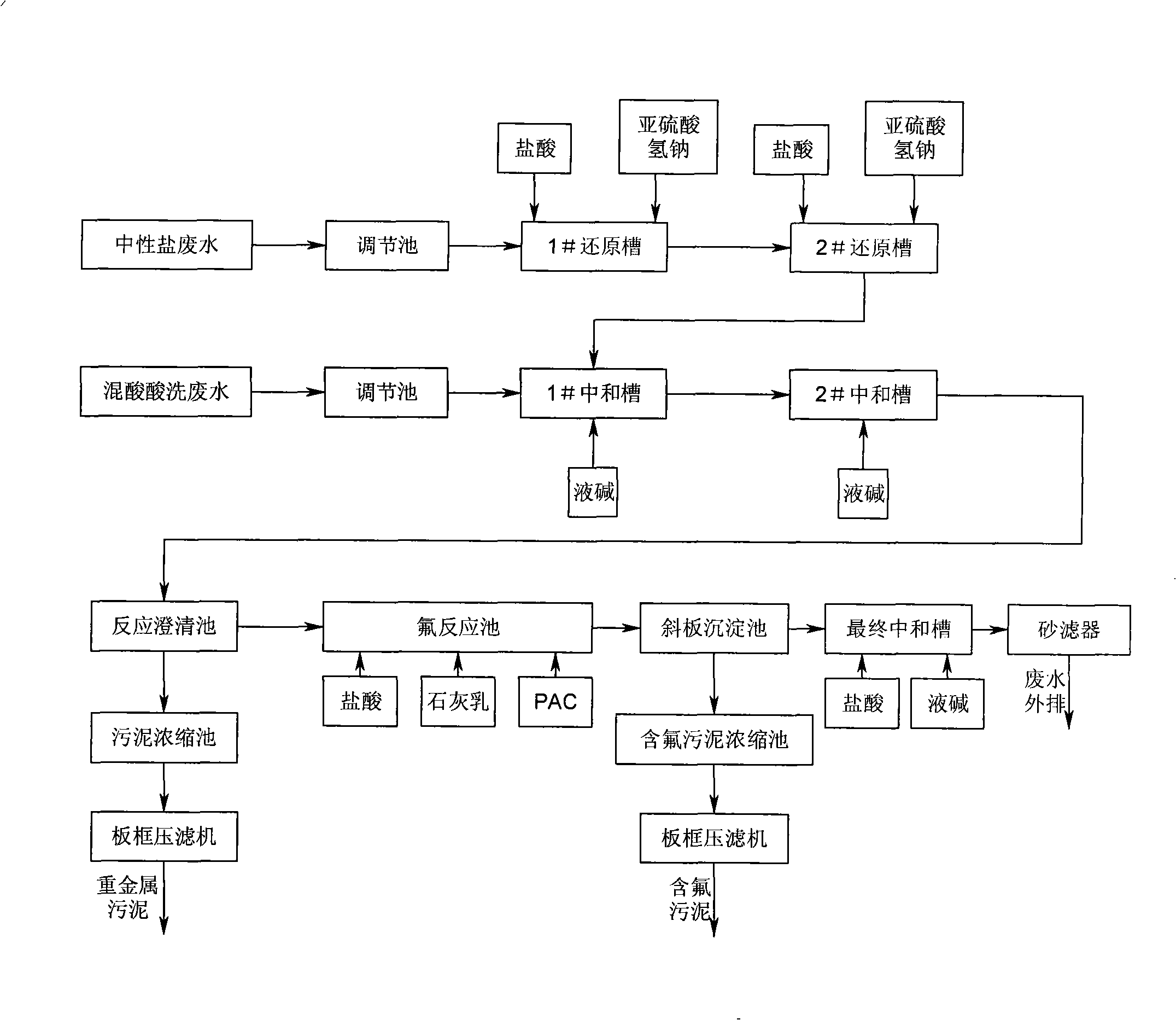

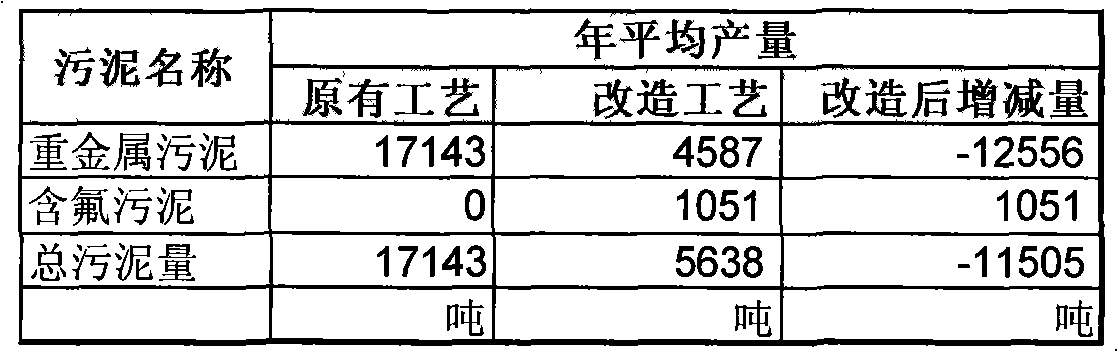

Processing method for stainless steel acid cleaning waste water and liquid

InactiveCN101269889AMeet emission compliance requirementsMeet compliance requirementsSludge treatment by de-watering/drying/thickeningIron oxides/hydroxidesLiquid wasteSludge

The invention relates to a processing method of stainless steel pickling waste liquid, which is characterized in that the processing method includes the steps that: neutral salt wastewater flows into a neutral reduction cell, and mixed acid pickling waste waters flow into a neutralizing tank; reducing agent is added into the neutral reduction cell, and then the reduced wastewater liquid is put into the neutralizing tank and is mixed with the adjusted mixed acid pickling waste waters, and liquid alkali is added into the neutralizing tank; the separated clear waste liquid removes fluorin ions in a settlement tank; neutralizing liquid is added into a final neutralizing tank to cause the pH value of treatment liquid to adjust to be neutralized wastewater liquid which passes through a sand filter to be discharged. The processing method has the advantages that metal ions and fluorin ions are performed the subsection treatment, and neutralizing agent is changed into the liquid alkali from lime cream, the requirement of reaching the standard of the waste liquid emission is not only achieved, but also the mud quantity produced by a mass of lime cream is greatly reduced, heavy metal mud of a retention pond only contains heavy metal compound, the salts of calcium fluoride and calcium sulphate, etc. are separated from the inclined plate settlement tank during the fluoridation stage, thereby the treatment cost is effectively lowered.

Owner:NINGBO BAOXIN STAINLESS STEEL

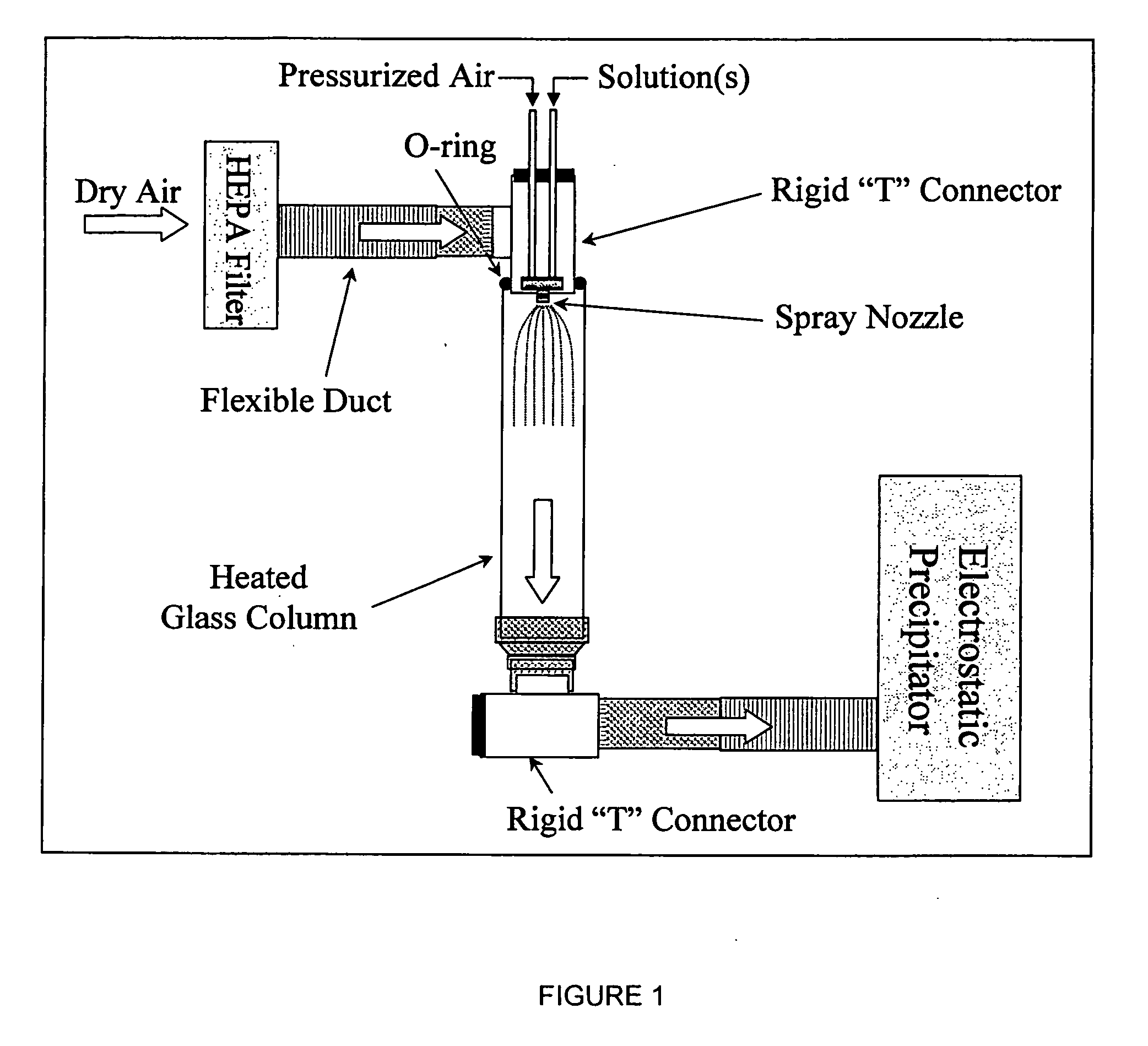

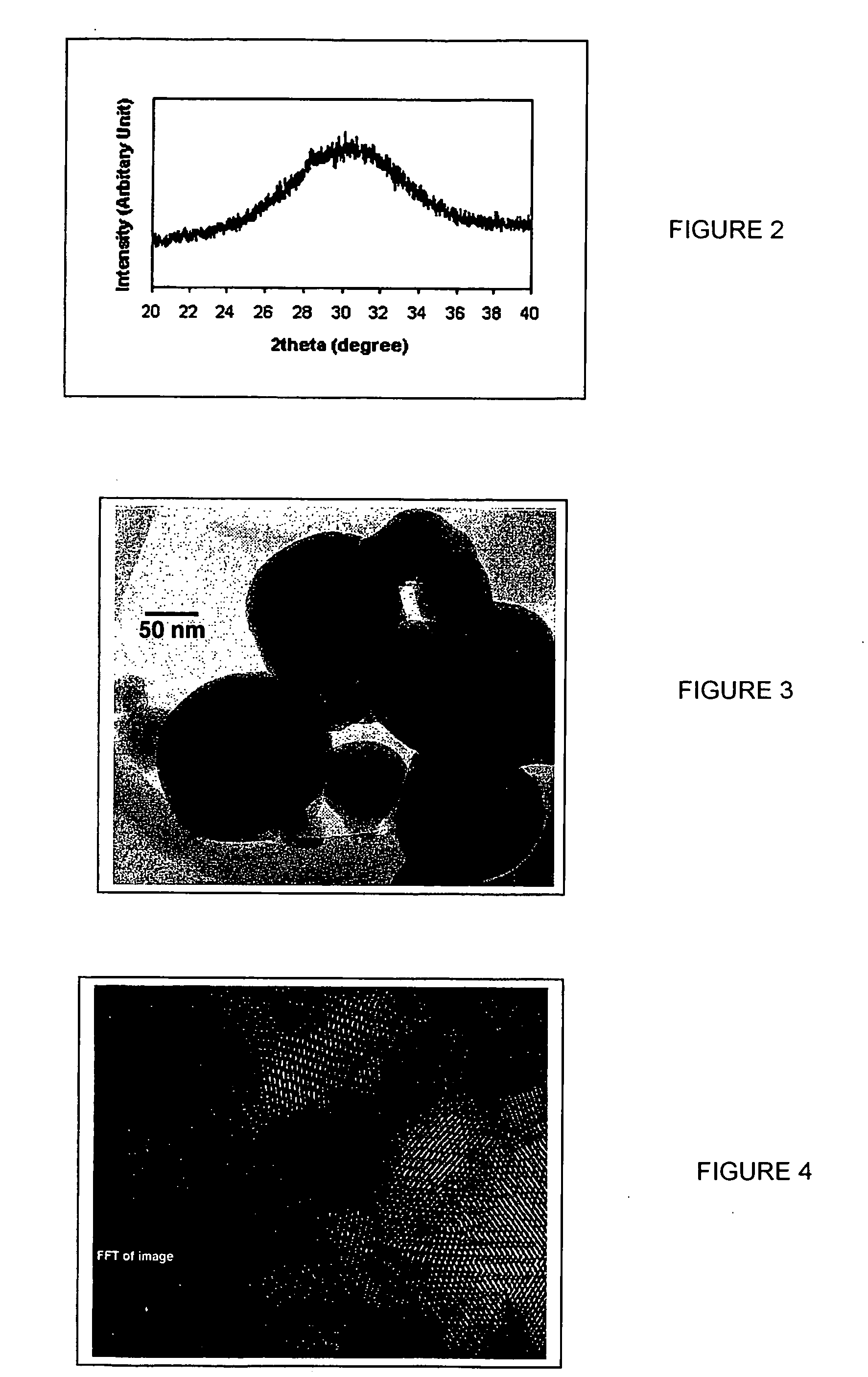

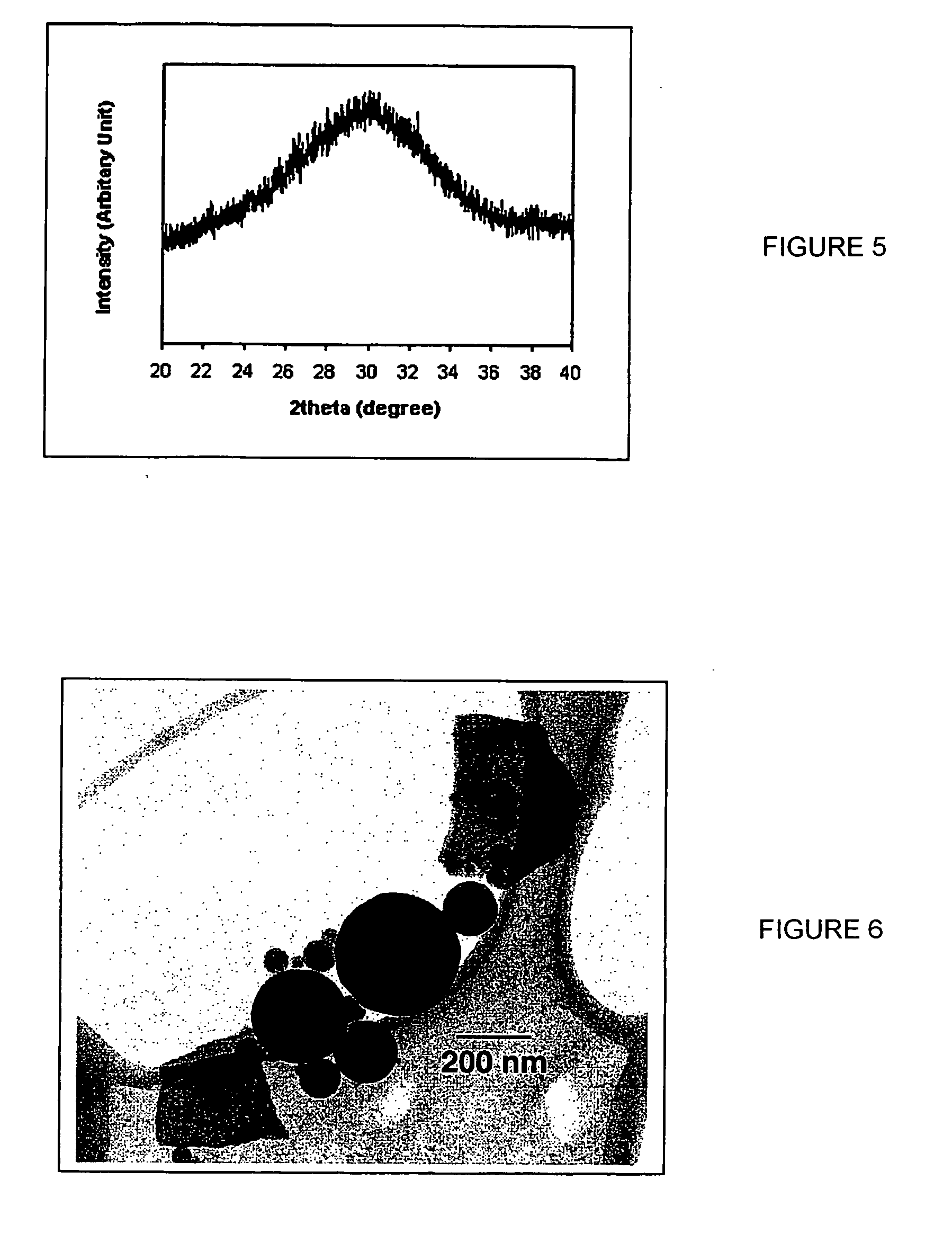

Nanostructured bioactive materials prepared by dual nozzle spray drying techniques

ActiveUS20060110306A1Easy to evaporatePromote formationMagnesium fluoridesImpression capsNanoparticleNanostructure

Nano-particles of calcium and phosphorous compounds are made in a highly pure generally amorphous state by spray drying a weak acid solution of said compound and evaporating the liquid from the atomized spray in a heated colunm followed by collection of the precipitated particles. Hydroxyapatite (HA) particles formed by such apparatus and methods are examples of particle manufacture useful in bone and dental therapies. Dual nozzle spraying etechniques are utilized for generally insoluble compounds.

Owner:ADA FOUND

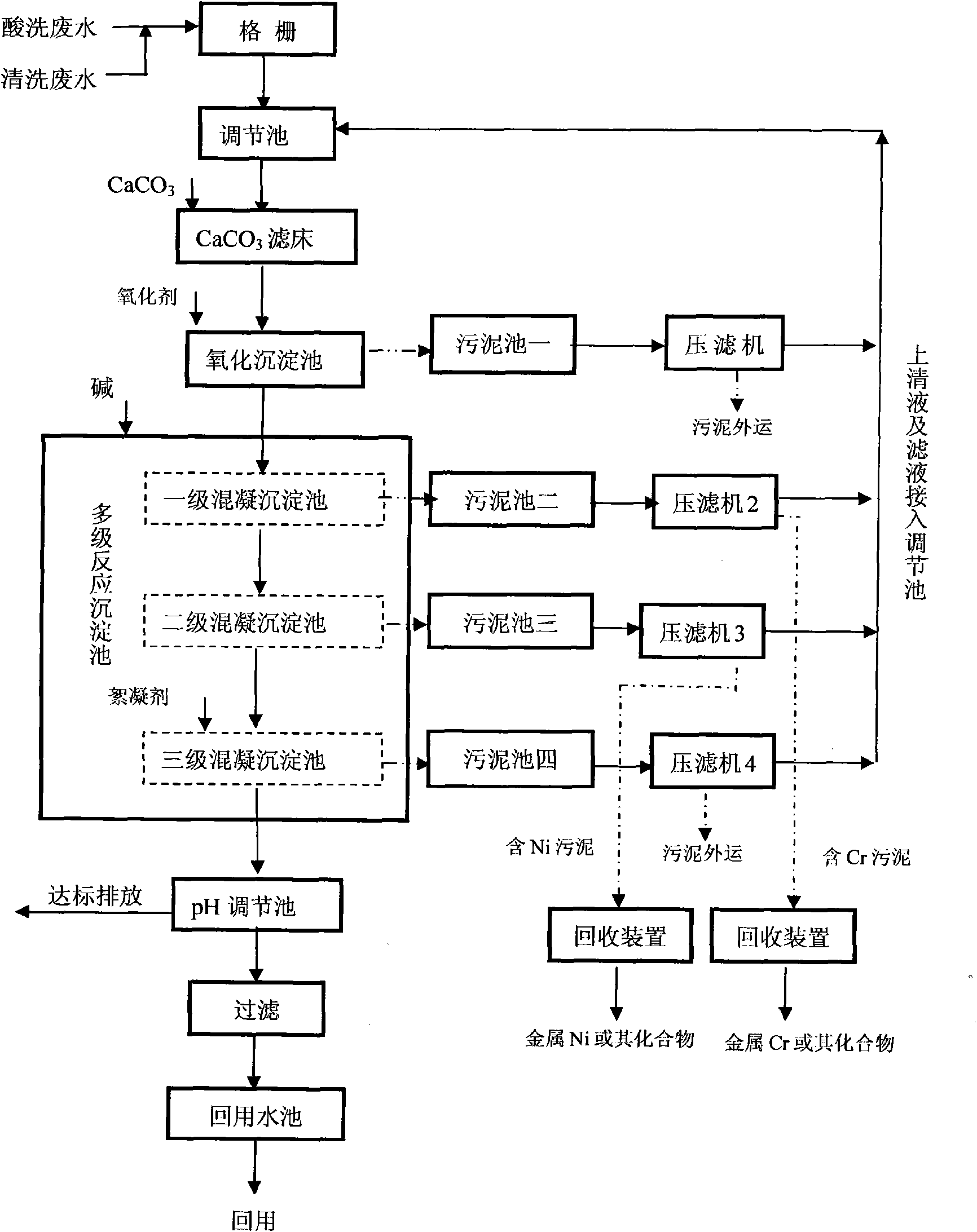

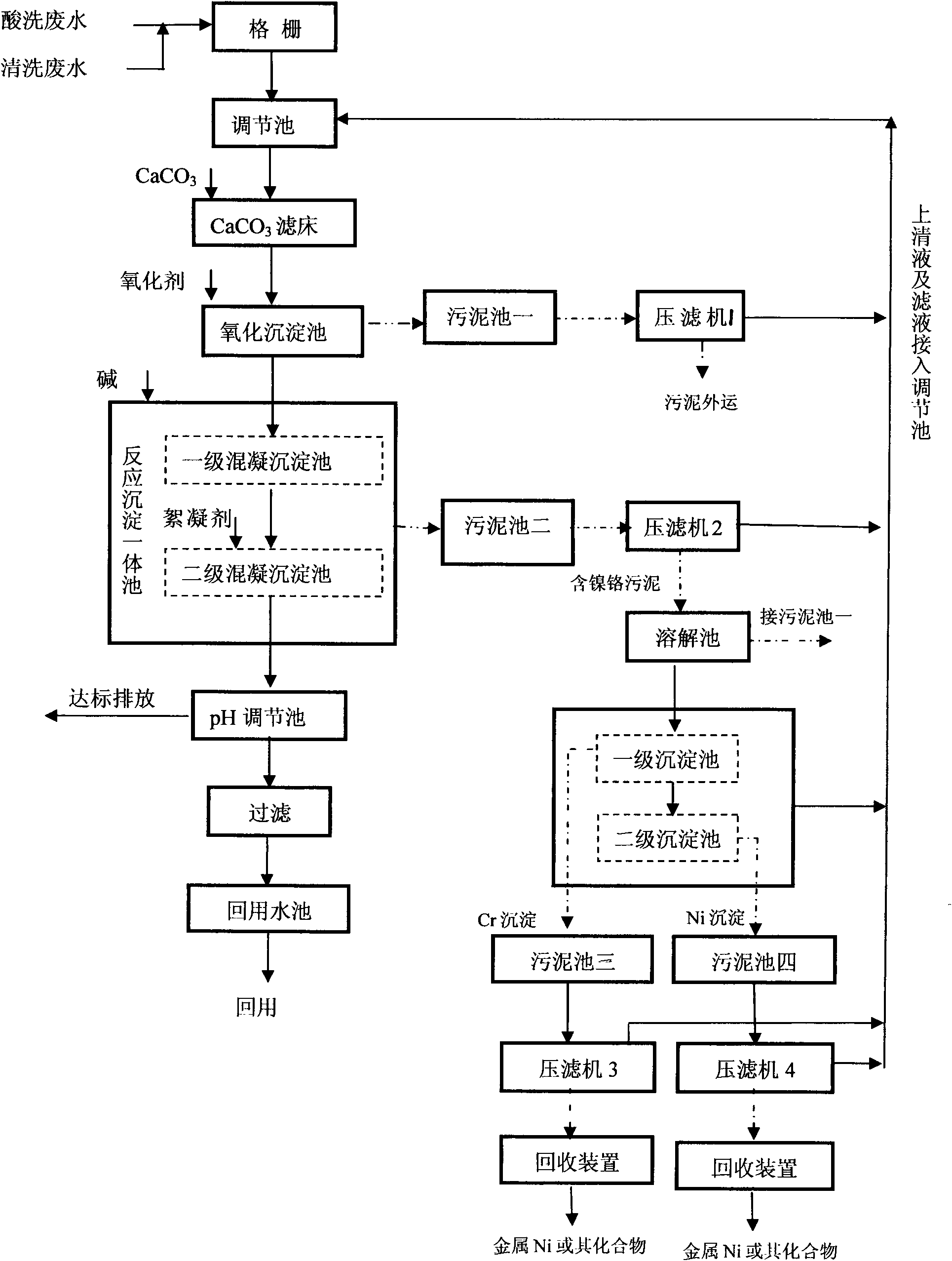

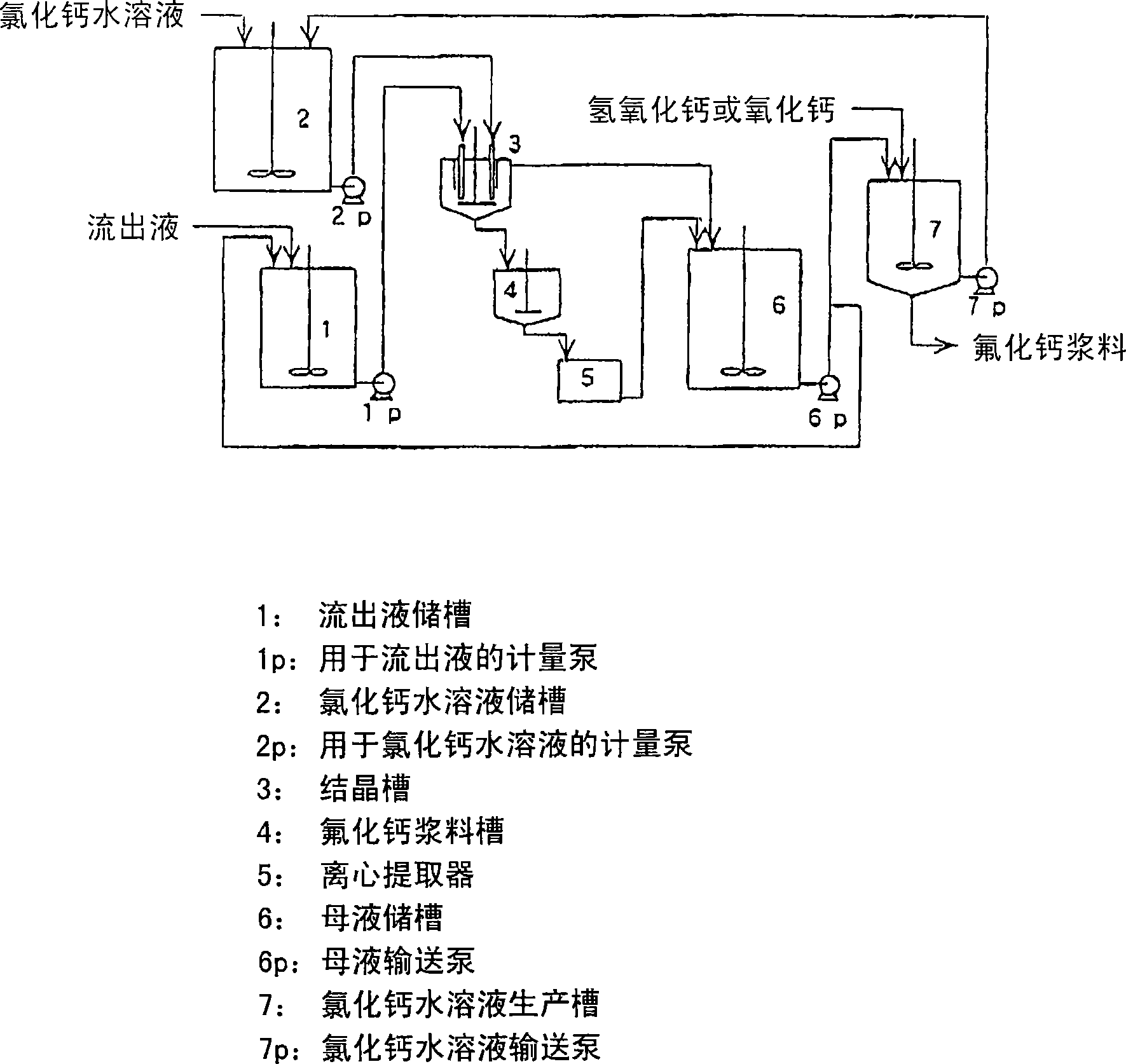

Recycling processing method for stainless steel processing process wastewater grading precipitation

InactiveCN101648757AHigh recycling valueSludge treatment by de-watering/drying/thickeningPhotography auxillary processesThree levelAcid washing

The invention relates to a recycling processing method for a stainless steel processing process wastewater grading precipitation, which comprises the following steps: (1) deslagging and homogenizing acid-washing residual liquid and washing wastewater; (2) adjusting the pH to 4.0-5.5 by a CaCO3 filter bed to generate CaF2; (3) oxidizing Fe<2+> into Fe<3+> by an oxidizing agent to generate sedimentsof Fe(OH)2 and Fe(OH)3; after the Fe(OH)2 , the Fe(OH)3 and the CaF2 are deposited, recovering; (4) carrying out three-level alkali adding coagulation precipitation on the supernatant liquid of an oxidation precipitation pool; adjusting the pH to obtain a Cr sediment in the first-level alkali adding coagulation precipitation; acquiring a Ni sediment in the second-level alkali adding coagulation precipitation; carrying out the third-level alkali adding coagulation precipitation and adding a flocculating agent to remove residual heavy metal ions so that discharge water reaches the standard, wherein the alkali added into a grading reaction precipitation pool is NaOH, Ca(OH)2, CaO or Na2 CO3; (5) regulating the pH of the discharge water of the grading reaction precipitation pool to 6.0-8.0; discharging 0-20 percent of wastewater and filtering residual F<-> and suspended matters of 80-100 percent of wastewater to reach the standard and recycle; and (6) recycling the Cr-Ni metal or the compound thereof from the Cr sediment and the Ni sediment acquired by a third-level coagulation precipitation pool by a recycling device.

Owner:ZHEJIANG UNIV

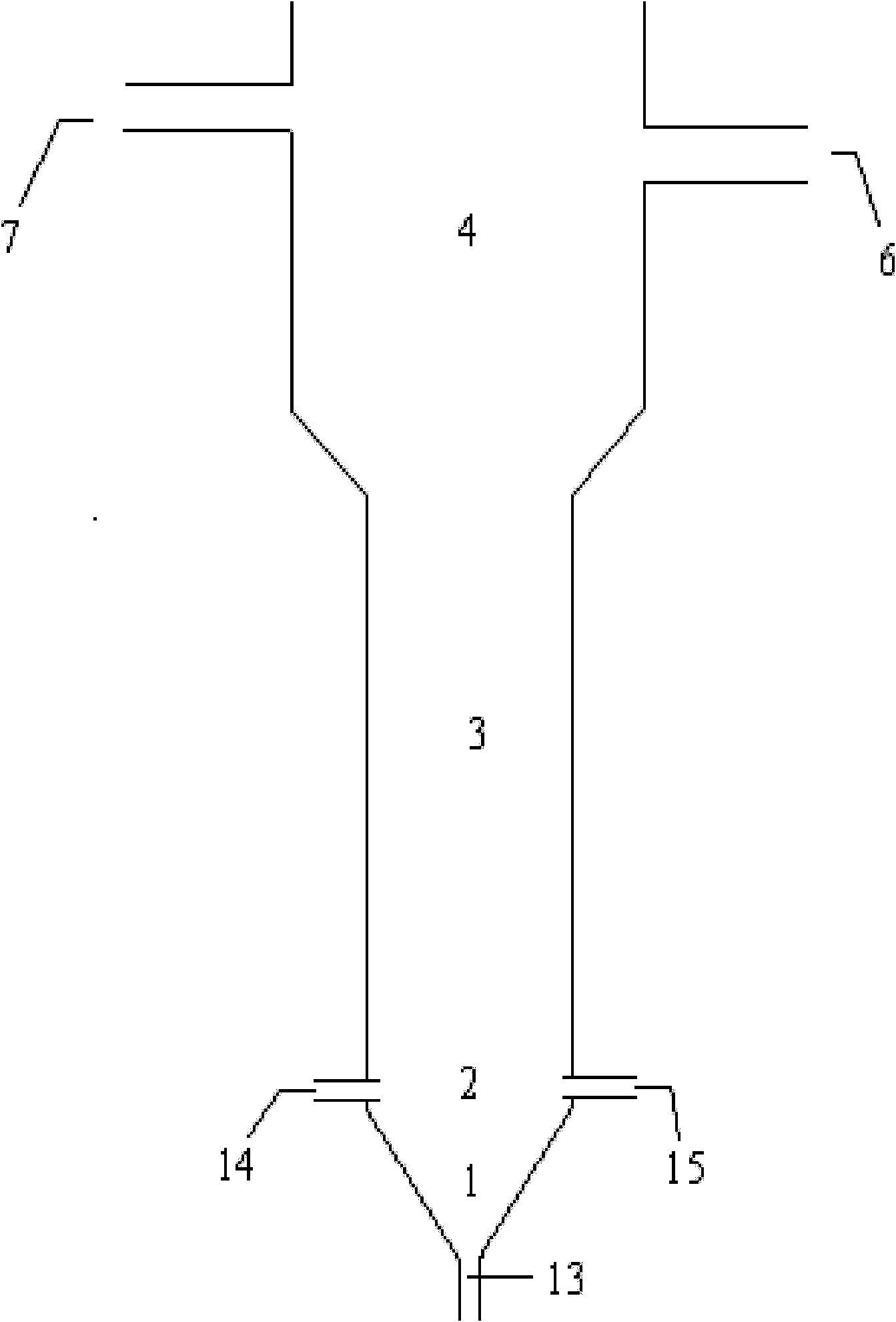

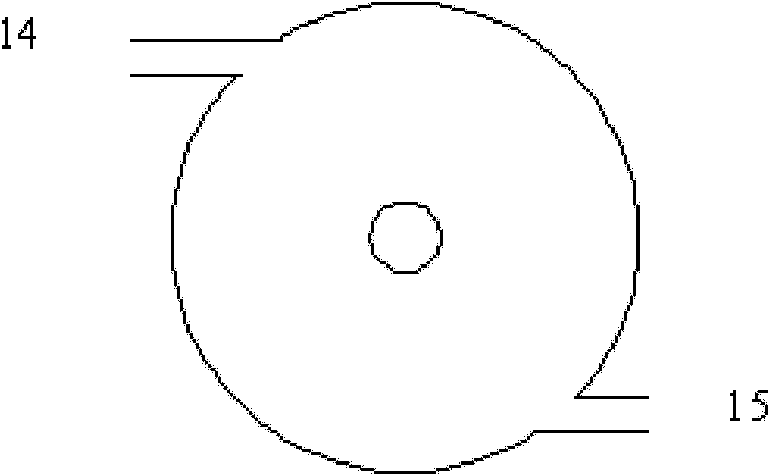

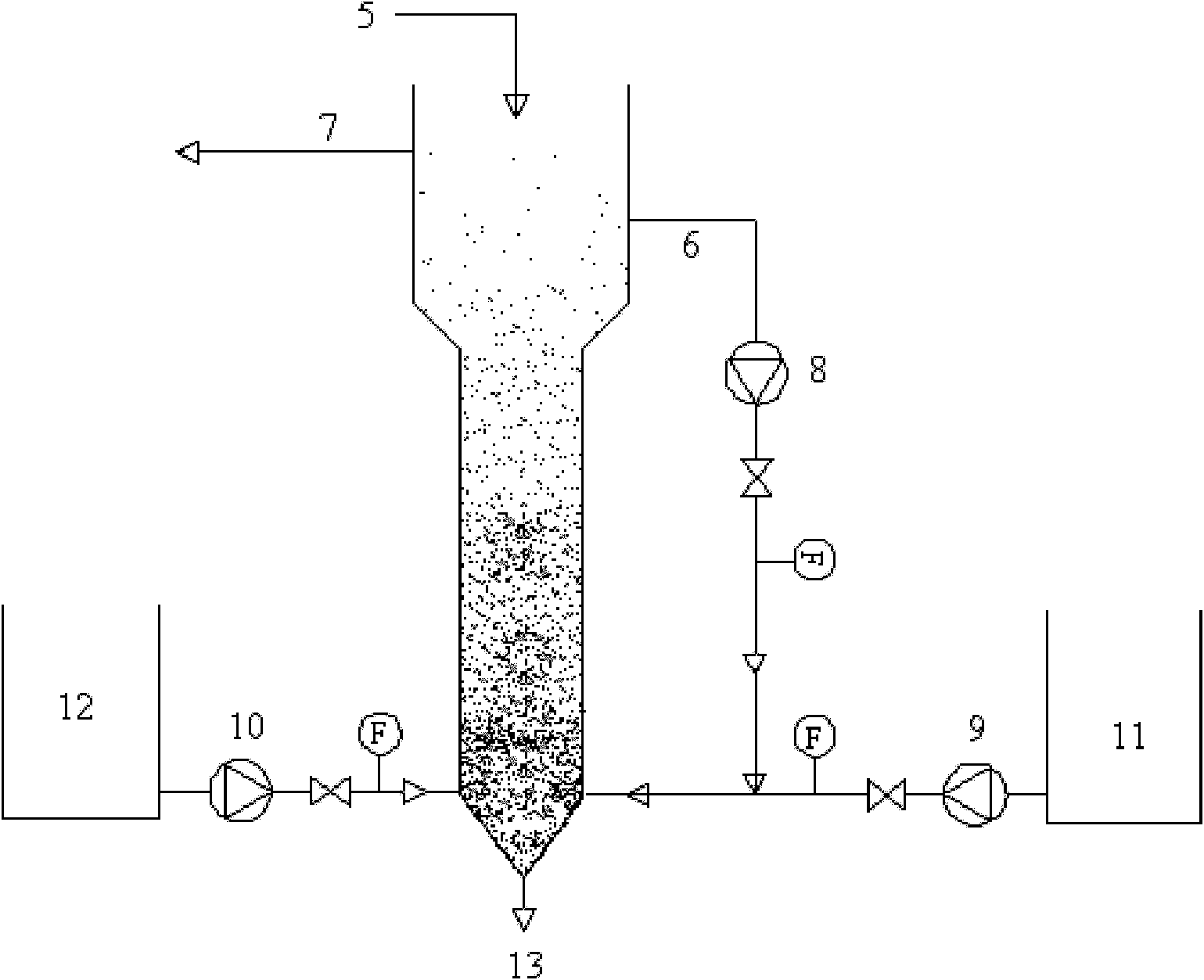

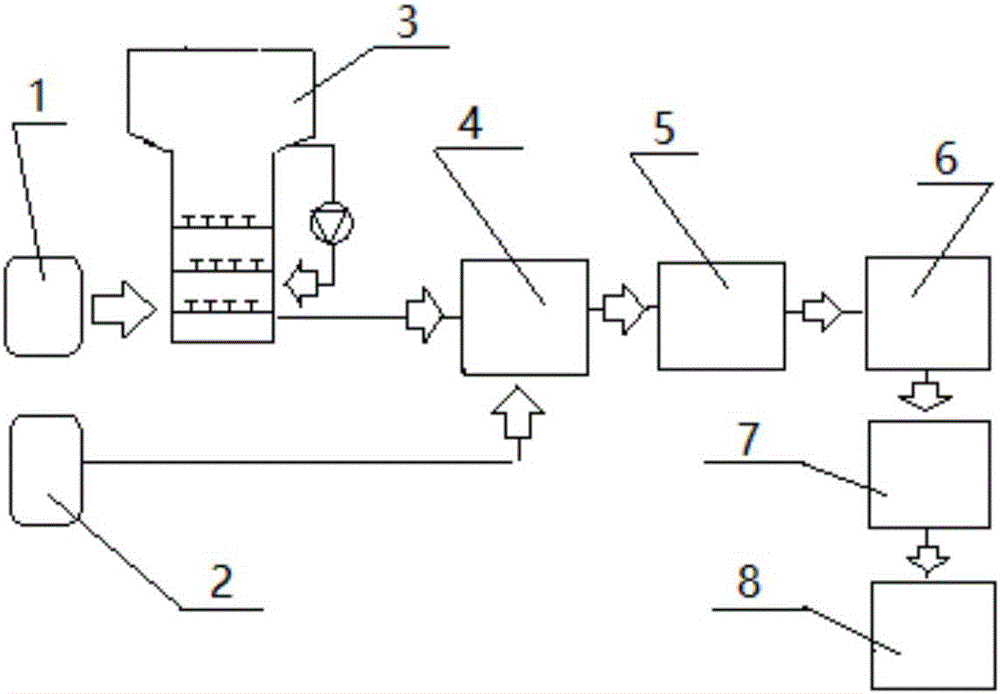

Method and device for treating fluorine-containing waste water

InactiveCN101941752AReduce processing costsHigh purityWater contaminantsCalcium/strontium/barium fluoridesFluidized bedResource recovery

The invention provides a method and a device for treating fluorine-containing waste water. In the method, a solid-liquid fluidized bed is used as a crystal reactor; a certain amount of calcium fluoride seed crystal is added into the reactor; the fluorine-containing waste water and a calcium-containing precipitator are delivered into a treatment device of the solid-liquid fluidized bed in a reacting ratio to ensure that fluorinions are precipitated on the surface of the calcium fluoride seed crystal; the prepared sand-shaped calcium fluoride precipitated slurry after precipitation is reclaimed; and primarily treated water is subjected to flocculent precipitation further to meet the emission standard. By adopting the method, most fluorinions can be precipitated in the crystallization and precipitating process in the fluidized bed, the generated sand-shaped calcium fluoride has low content of water and high content of calcium fluoride and can be used as fluorine resources for recycling; and in the flocculent precipitating process of the primarily treated water, the consumption of the fluorescent is low, and the yield of slurry is low. Therefore, the comprehensive cost for waste watertreatment is low.

Owner:CENT SOUTH UNIV

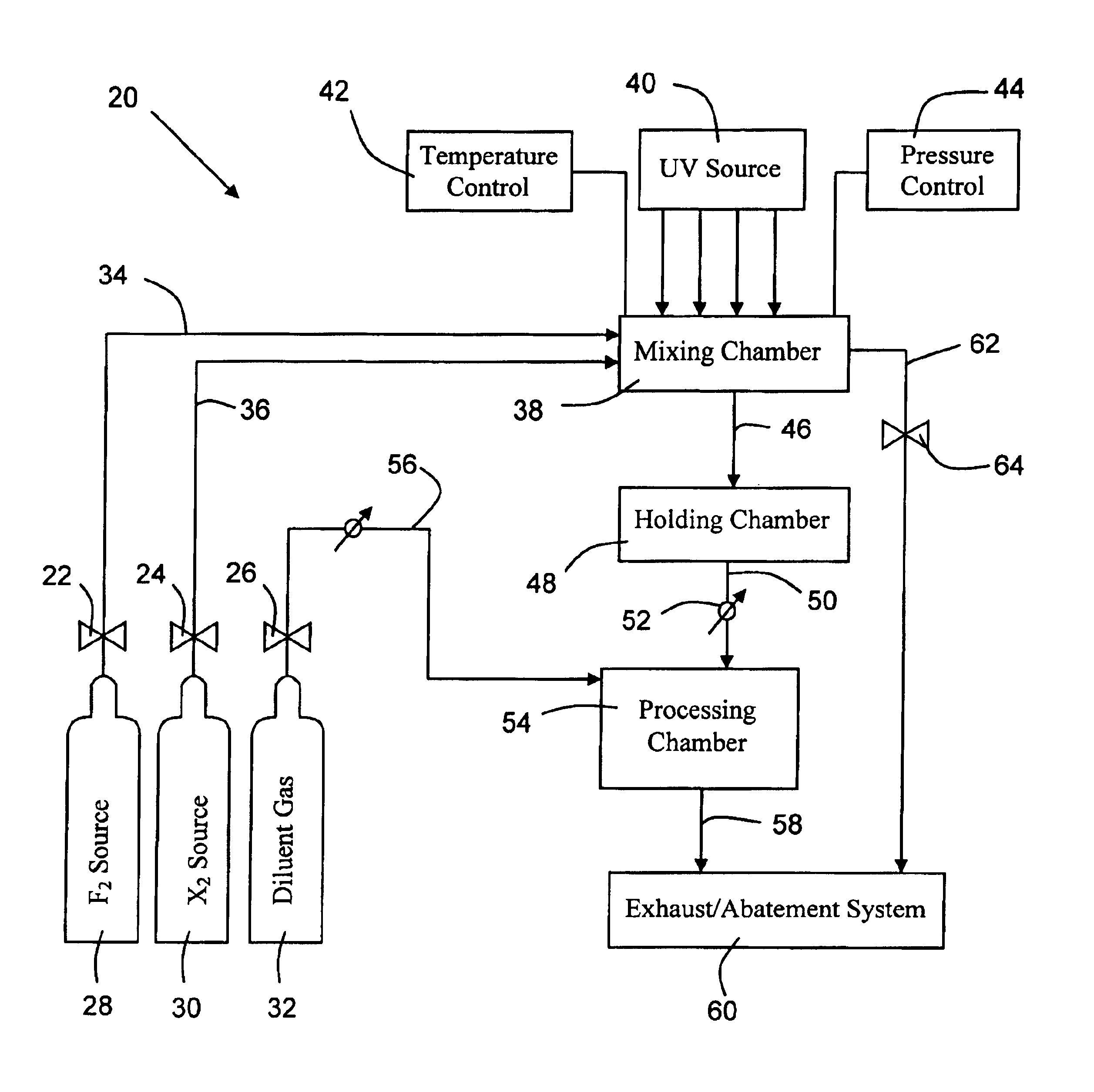

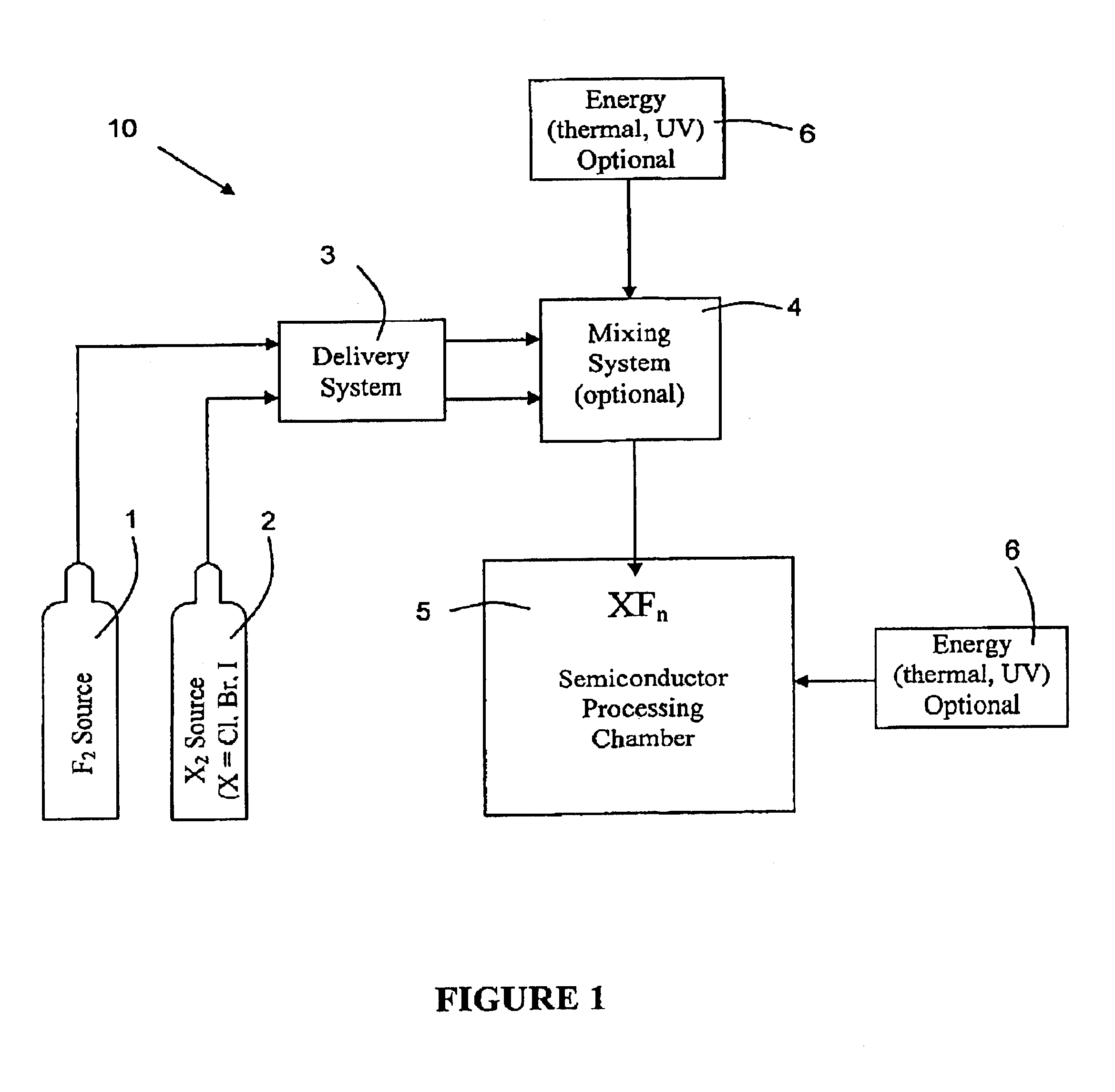

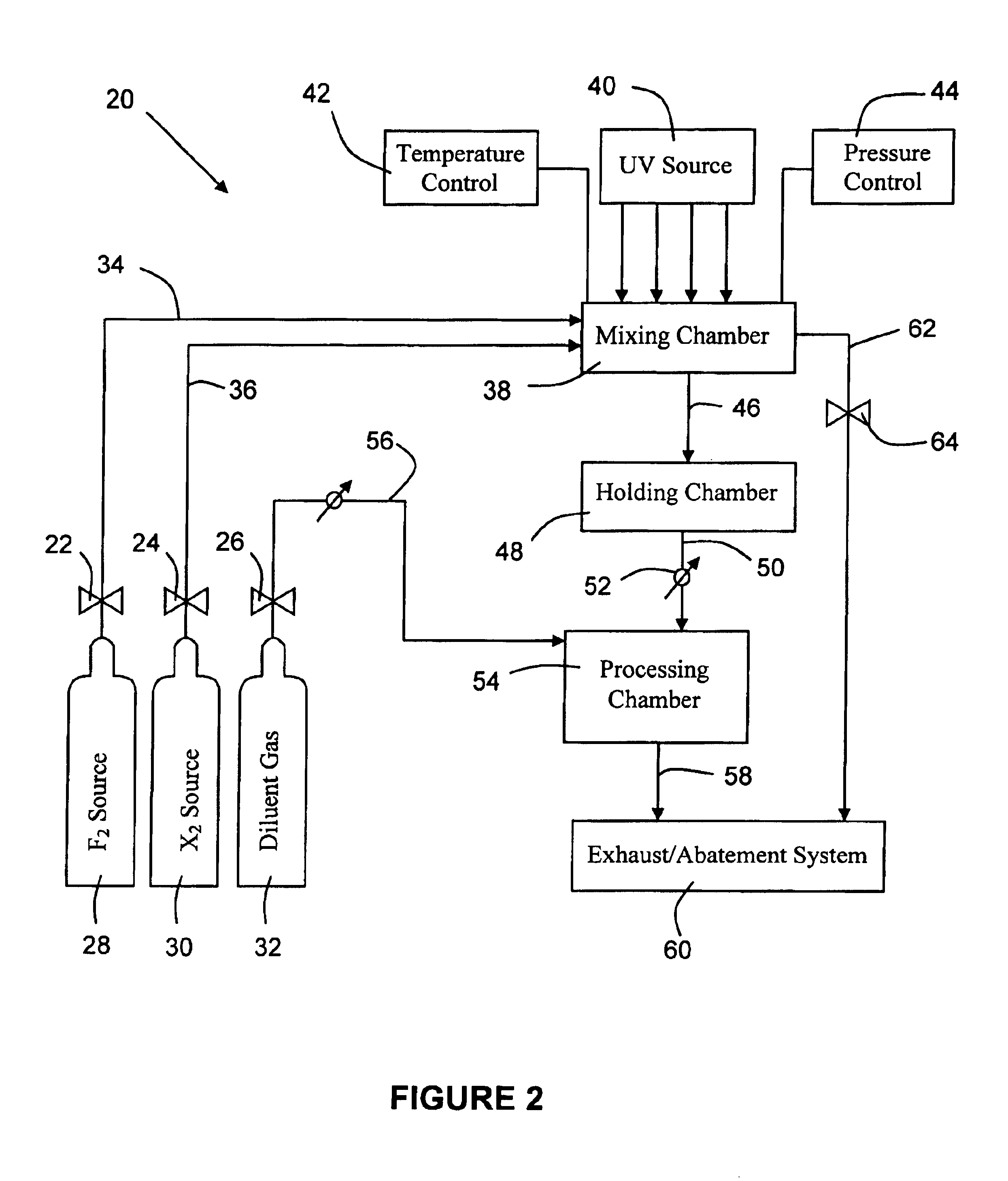

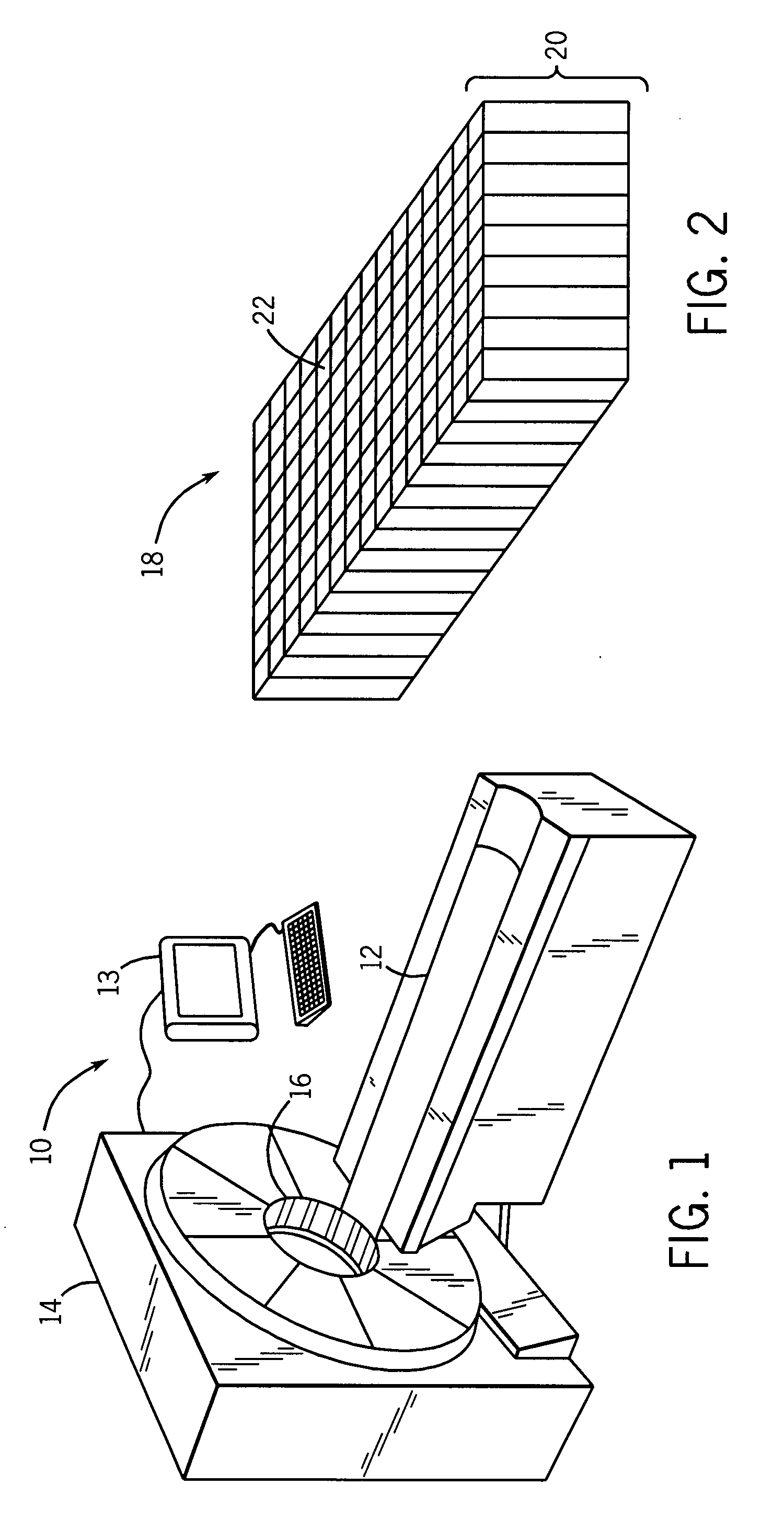

System for in-situ generation of fluorine radicals and/or fluorine-containing interhalogen (XFn) compounds for use in cleaning semiconductor processing chambers

InactiveUS6841141B2Shorten “ waiting-period ”Improve reaction speedMagnesium fluoridesCalcium/strontium/barium fluoridesChemistrySupply energy

A system for in-situ generation of fluorine radicals and / or fluorine-containing interhalogen compounds XFn (wherein X is Cl, Br, or I, and n is an odd integer). Such system comprises a fluorine source, a halogen source for supplying halogen species other than fluorine, a chamber for mixing fluorine with halogen species other than fluorine, and an energy source to supply energy to such chamber to facilitate reaction between fluorine and the halogen species other than fluorine. The chamber may be a semiconductor processing chamber, wherein the in situ generated fluorine radicals and / or fluorine-containing interhalogens are employed for cleaning the processing chamber.

Owner:ENTEGRIS INC

Recycling processing method for wastewater produced by processing stainless steel

InactiveCN101648759AHigh recycling valueIron oxides/hydroxidesCalcium/strontium/barium fluoridesStrong acidsOxidizing agent

The invention relates to a recycling processing method for wastewater produced by processing stainless steel, which comprises the following steps: after acid-washing residual liquid and washing wastewater are carried out wastewater deslagging, homogenizing; pumping into a CaCO3 filter bed to adjust the pH to 4.0-5.5 and removing F<->; adding an oxidizing agent into discharge water, oxidizing Fe<2+> into Fe<3+> and generating Fe(OH)2 and Fe(OH)3; after the Fe(OH)2, the Fe(OH)3 and CaF2 are deposited, recovering; adopting two-level coagulating sedimentation on supernatant liquid; adding alkali to adjust the pH to 8.0-9.5 in the first level; continuously adding the alkali to adjust the pH to 10.0-11.0 in the second level and adding CaCl2 and a flocculating agent to deposit sludge containing chromium and nickel; adding acid liquor into the discharge water to adjust the pH to 6.0-9.0 and filtering residual F<-> and suspended matters to reach the standard and recover; carrying out dehydration separation on the sludge containing ferrum and the sludge containing chromium and nickel; adding strong acid into the sludge containing chromium and nickel to dissolve; adopting two-level alkali adding coagulating sedimentation on the wastewater of a dissolving pool to obtain a Cr(OH)3 sediment and a Ni(OH)2 sediment or a NiCO3 sediment; carrying out sludge-water separation and recovering to obtain chromium and nickel metal or the compound thereof; and using supernatant liquid and the discharge water of a press filter for homogenization.

Owner:ZHEJIANG UNIV

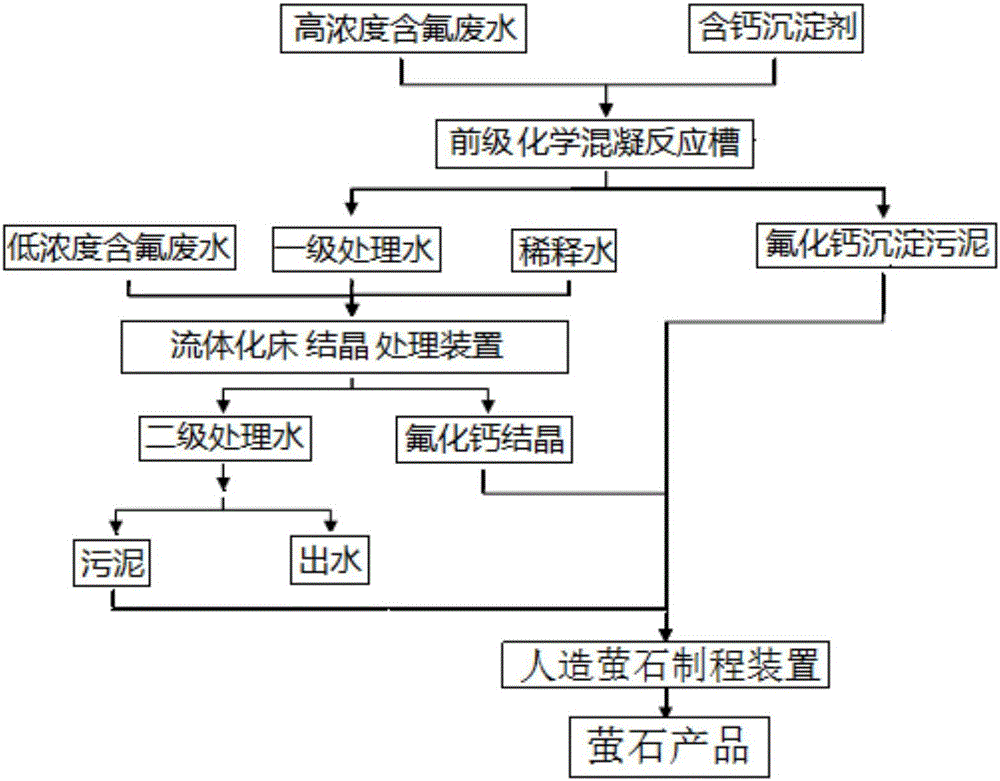

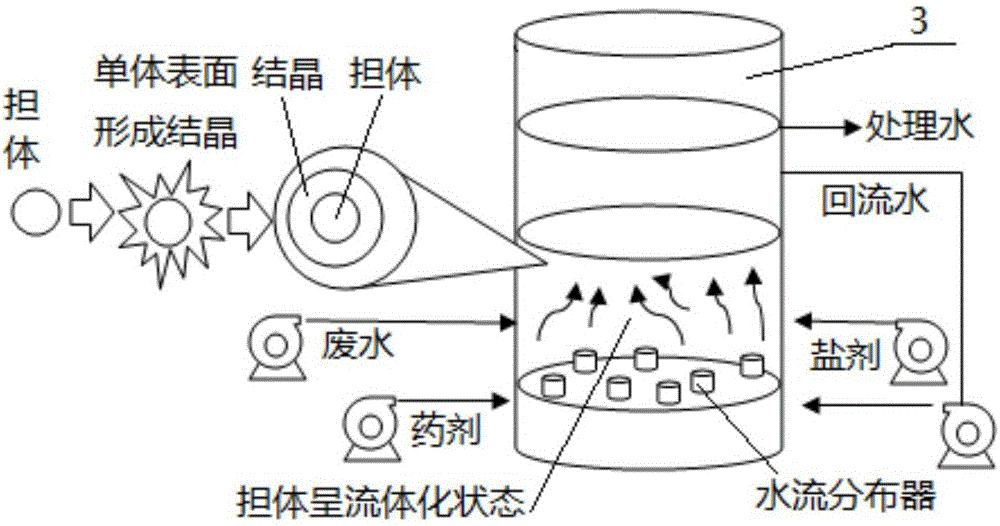

Process for preparing high-purity artificial fluorite by recovering fluoride-containing wastewater

ActiveCN105905933ASolve pollutionAvoid wastingCalcium/strontium/barium fluoridesWater contaminantsHigh concentrationPollution

According to a process for preparing high-purity artificial fluorite by recovering fluoride-containing wastewater, a fluidized bed serves as a crystallization treatment device, fluoride components in wastewater are efficiently extracted in a supporter crystallization mode, a high-purity calcium fluoride artificial fluorite product is prepared, fluoride-containing wastewater can be treated to reach the standard, no secondary pollution exists, the problems of land occupation and environment pollution of bottom mud produced during treatment of industrial fluoride-containing wastewater are solved, fluoride resources in the bottom mud are effectively used, circulation is short, operation is simple, implementation is easy, fluoride pollution and fluoride resource waste are reduced, and process efficiency is high; good balance can be achieved between making emission not exceed the standard and controlling wastewater treatment cost. Produced calcium fluoride crystals are suitable for preparing artificial fluorite to serve as the substitute of natural fluorite, calcium fluoride crystals produced in the technological process are low in water content, fluoride-containing waste reducing or resourceful using aim is effectively achieved, and the process is an environment-friendly method for treating high-concentration fluoride-containing wastewater and is wide in industrial application prospects.

Owner:KUNSHAN YANGCHENG LANGU ENVIRONMENTAL INST CO LTD

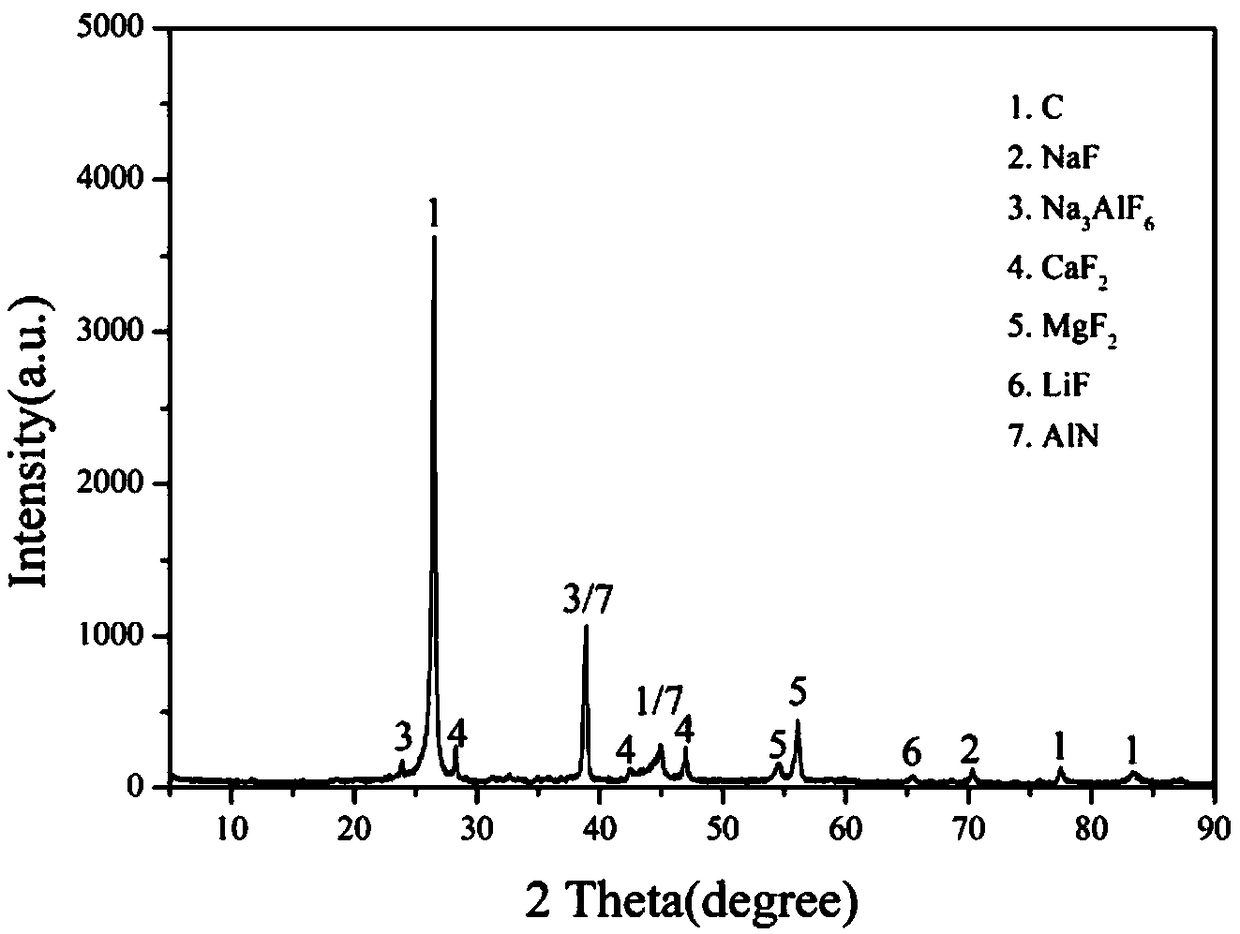

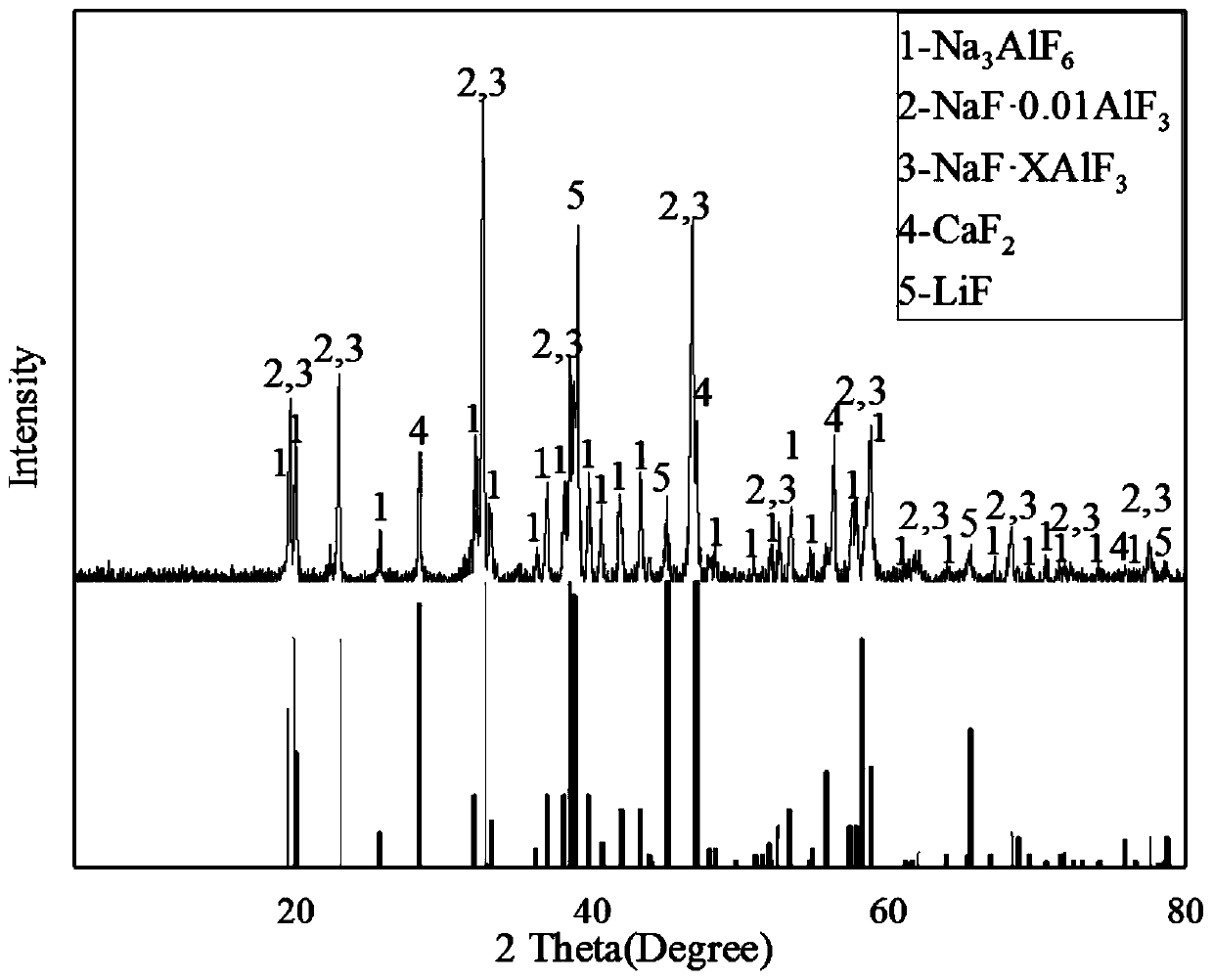

Method for recycling carbon and electrolytes from waste cathode carbon block of aluminum electrolytic cell

InactiveCN105821445AReduce dosageReduced dosage of chemicals (reduced amount of collectorElectrolysis componentsCalcium/strontium/barium fluoridesKeroseneFuel oil

The invention discloses a method for recycling carbon and electrolytes from a waste cathode carbon block of an aluminum electrolytic cell. The method comprises the following steps that 1, the cathode carbon block is crushed and grinded; 2, cathode carbon powder obtained from the cathode carbon block subjected to crushing and grinding in the step 1 is stirred and leached in alkali liquor and then filtered, so that a filter cake A1 and filtrate B1 are obtained; and a precipitating agent is added into the filtrate B1, so that a filter cake A2 and filtrate B2 are obtained after filtering is conducted; and 3, the filter cake A1, the filter cake A2, a flotation medium and flotation reagents are subjected to mixing and pulp conditioning, and thus the carbon and electrolytes are obtained through flotation and separation; the flotation reagents comprises the collecting agents, the foaming agents and the conditioning agents; the collecting agents are composed of the collecting agent C1 and the collecting agent C2 at the mass ratio of 0.65-0.75:0.25-0.35; the collecting agent C1 is selected from at least one of coal tar, heavy oil, kerosene and diesel oil; and the collecting agent C2 is selected from at least one of dodecylamine, sodium dodecyl benzene sulfonate, sodium oleate and sodium dodecyl sulfate. According to the method for recycling the carbon and the electrolytes from the waste cathode carbon block of the aluminum electrolytic cell, the carbon powder and the electrolytes are effectively separated and recycled from the waste cathode carbon block.

Owner:CENT SOUTH UNIV

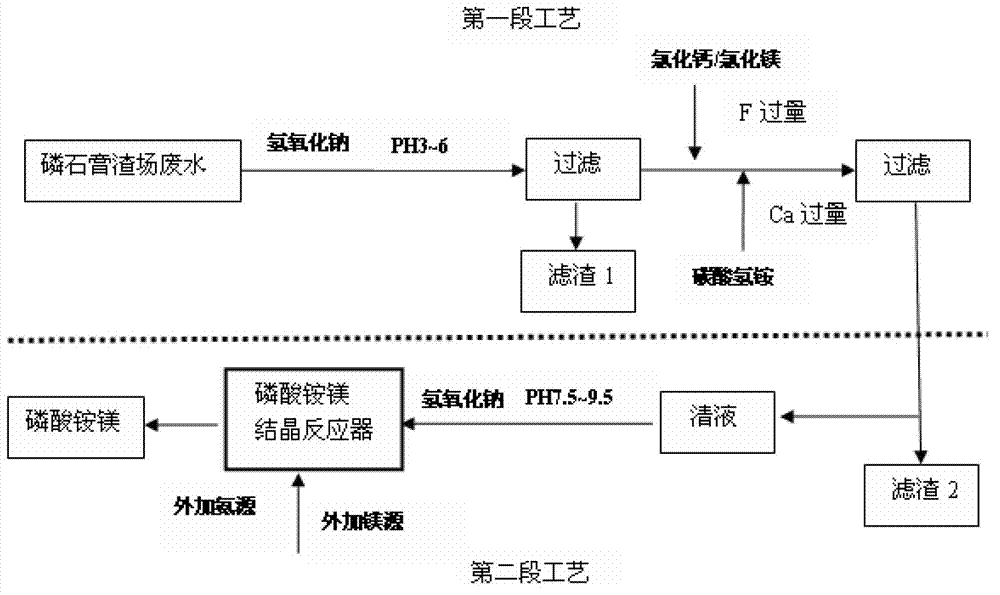

Method for recycling high-purity fluorine and phosphorus from wastewater of phosphogypsum residue field

InactiveCN102887535AAchieve recyclingHigh recovery rateCalcium/strontium/barium fluoridesMultistage water/sewage treatmentIonFluoride calcium

The invention relates to a method for recycling high-purity fluorine and phosphorus from a wastewater of phosphogypsum residue field. According to the different reaction conditions of calcium fluoride and magnesium ammonium phosphate, the implementation of the method is divided into two stages: in the first stage of recycling high-purity calcium fluoride: adjusting the pH (Potential Of Hydrogen) value of the wastewater of the phosphogypsum residue field by a sodium hydroxide solution to 3-6 to enable the fluoride ions and calcium ions in the wastewater to be reacted to generate calcium fluoride precipitate, filtering and recycling calcium fluoride; and the second stage of recycling high-purity magnesium ammonium phosphate: adjusting the pH value of the wastewater after the first section of recycling high-purity calcium fluoride by the sodium hydroxide solution to 7.5-9.5, adding a magnesium source and an ammonia source at the same time, generating magnesium ammonium phosphate, magnesium ammonium phosphate analogs or phosphate compounds in a crystalline state in a magnesium ammonium phosphate crystallization reactor, filtering and recycling magnesium ammonium phosphate. The water treated by the method disclosed by the invention has low impurity content and can be directly used as the industrial water and circulating cooling water in a phosphorus chemical production system.

Owner:HUBEI FORBON TECH

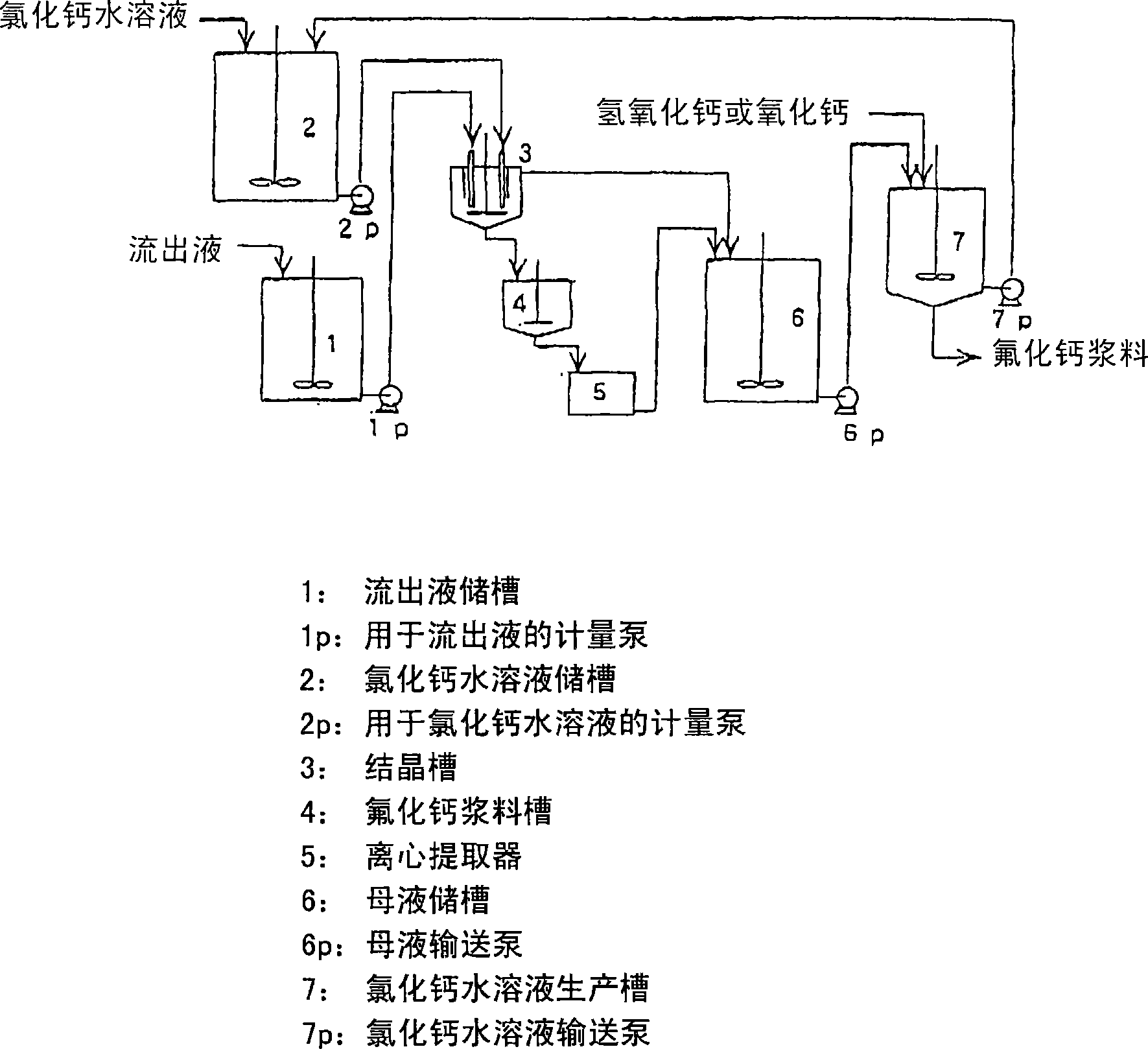

Method for producing calcium fluoride, reusing method and recycling method thereof

ActiveCN1906129AWater treatment parameter controlSpecific water treatment objectivesSolubilityLarge particle

In order to recycle the fluoride, calcium fluoride having a particle size and purity suitable for the production of hydrogen fluoride is recovered from the fluoride-containing effluent or the hydrofluoric acid-containing effluent. The method involves reacting a fluoride-containing effluent or a hydrofluoric acid-containing effluent with an aqueous solution of calcium chloride under acidic conditions formed by hydrochloric acid, under which calcium fluoride has a relatively high solubility. Calcium fluoride can be precipitated with high purity and large particle size. The hydrochloric acid residue from or formed by the reaction reacts with inexpensive calcium compounds such as calcium hydroxide, calcium oxide, and calcium carbonate to produce an aqueous calcium chloride solution that is reused to treat effluents containing hydrofluoric acid . The obtained calcium fluoride can be used as a raw material for producing hydrogen fluoride, and the remaining calcium chloride aqueous solution can be provided for other industrial purposes.

Owner:MORITA CHEMICAL IND CO LTD

Nano-scale metal halide scintillation materials and methods for making same

Crystalline scintillator materials comprising nano-scale particles of metal halides are provided. The nano-scale particles are less than 100 nm in size. Methods are provided for preparing the particles. In these methods, ionic liquids are used in place of water to allow precipitation of the final product. In one method, the metal precursors and halide salts are dissolved in separate ionic liquids to form solutions, which are then combined to form the nano-crystalline end product. In the other methods, micro-emulsions are formed using ionic liquids to control particle size.

Owner:GENERAL ELECTRIC CO

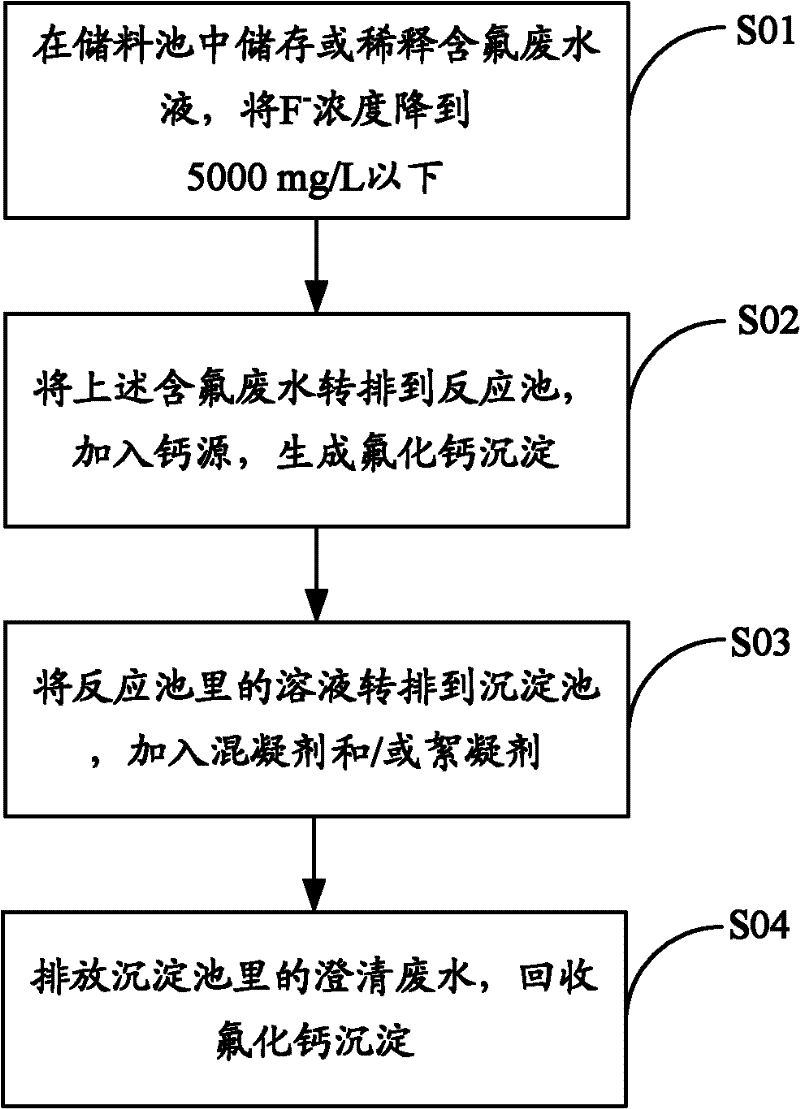

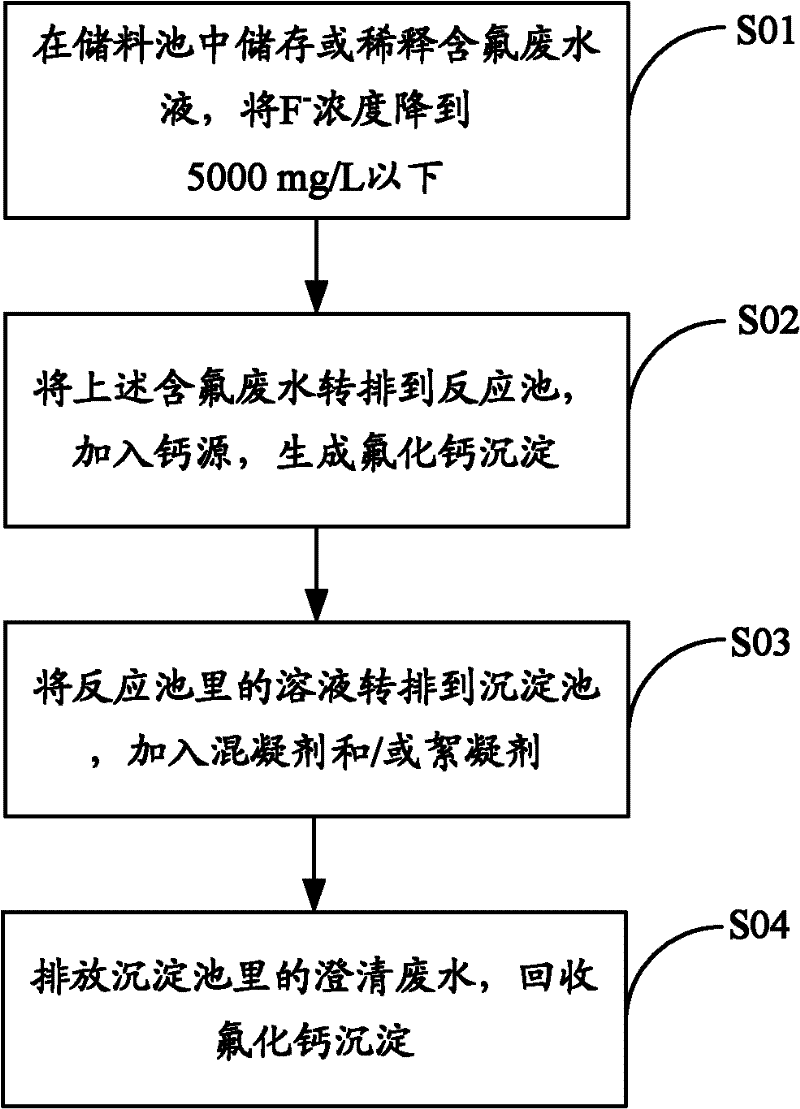

Treatment method of fluorine-containing waste water of solar cell plant

ActiveCN102452738AImprove use valueEasy to operateGeneral water supply conservationCalcium/strontium/barium fluoridesWastewaterSolar cell

The invention is applicable to industrial fluorine-containing waste water treatment, and provides a treatment method of fluorine-containing waste water of solar cell plants; the method comprises the following steps: storing or diluting fluorine-containing waste water in a material-storing tank, decreasing the F- concentration to below 5000 mg / L; discharging the fluorine-containing waste water into a reaction tank, adding excessive calcium sources; discharging the solution in the reaction tank into a sedimentation tank, adding a coagulant and a flocculant; discharging the clarified waste water from the sedimentation tank, recovering calcium fluoride sediments. The calcium sources used in the invention has a wide source, is economical and cheap; the operation process is simple and practical; the fluorine-removing efficiency is high; and the treated product has high application value.

Owner:SHENZHEN TOPRAY SOLAR

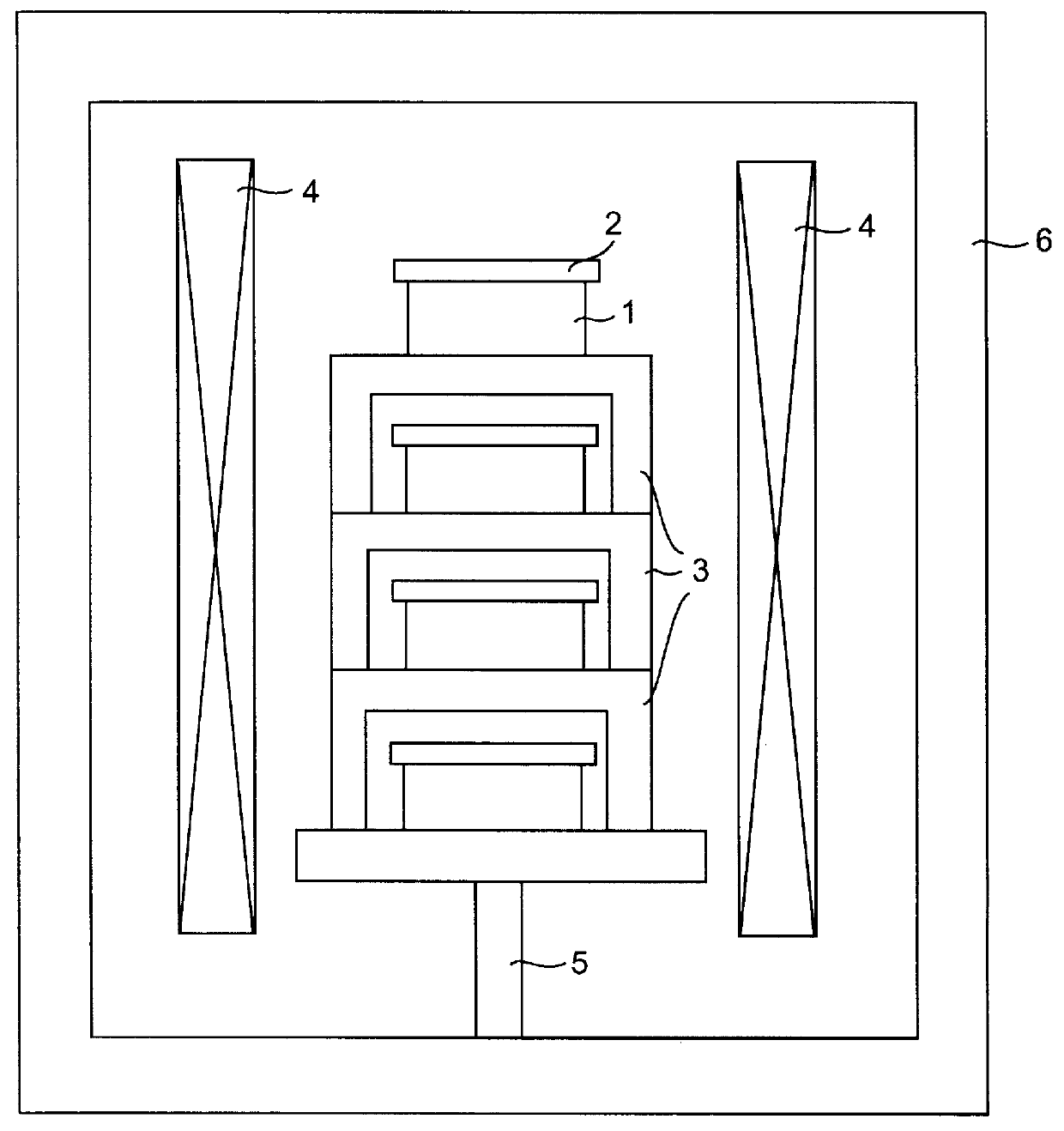

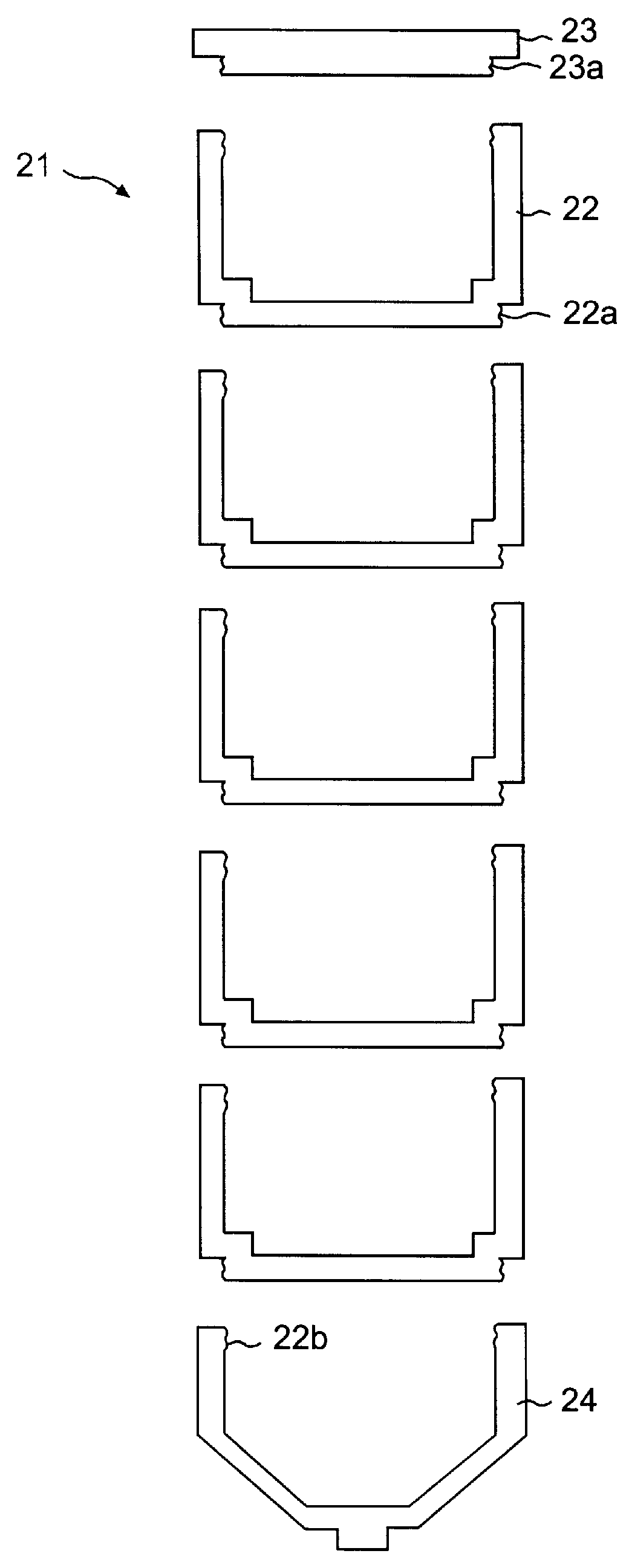

Manufacturing method for calcium fluoride crystal and processing method for calcium fluoride powder

InactiveUS6123764AImprove efficiencyHeat treatmentsPolycrystalline material growthCrucibleSingle crystal

A manufacturing method for a single crystal of calcium fluoride includes the steps of degassing calcium fluoride powder particles to desorb impurities from surfaces of the calcium fluoride powder particles, preprocessing the degassed calcium fluoride powder particles by fusing the degassed calcium fluoride powder particles in a crucible to obtain a preprocessed product, and re-fusing the preprocessed product in a crucible to grow a single crystal of calcium fluoride.

Owner:NIKON CORP

Method for separating lithium carbonate from electrolyte acidic leachate

InactiveCN107935015AEfficient extractionReduce energy consumptionMagnesium fluoridesCalcium/strontium/barium fluoridesEvaporationCarbonate

The invention discloses a method for separating lithium carbonate from electrolyte acidic leachate. The method comprises the following steps of: S1, adding a soluble salt solution to aluminum electrolyte acidic leachate while stirring and heating are performed, monitoring the acidity and the concentration of fluoride ions, and stopping the addition when the pH value is greater than 5 and the concentration of the fluoride ions is less than 0.01 g / L, wherein the soluble salt is one or more selected from MeSO4, MeNO3 and MeCl, and Me is metal which can produce precipitate with F<->; S2, performing filtration on reactants, performing washing and drying on filter residues to obtain a fluoride salt of the metal Me, adding a soluble carbonate solution into the obtained filtrate with stirring andheating, and terminating the reaction when the concentration of lithium ions is less than 0.08 g / L; S3, filter the filtrate, performing washing and drying on the filter cake to obtain lithium carbonate, and performing evaporation, crystallization, washing and drying on the filtrate to obtain inorganic salts. According to the method for separating lithium carbonate from the electrolyte acidic leachate, the reaction process is controlled by controlling the concentration of the fluoride ions and the acidity, so that the lithium ions are separated from other ions, lithium carbonate with high recovery rate is obtained, and meanwhile high-purity fluoride and inorganic salt products are obtained.

Owner:NORTHEASTERN UNIV

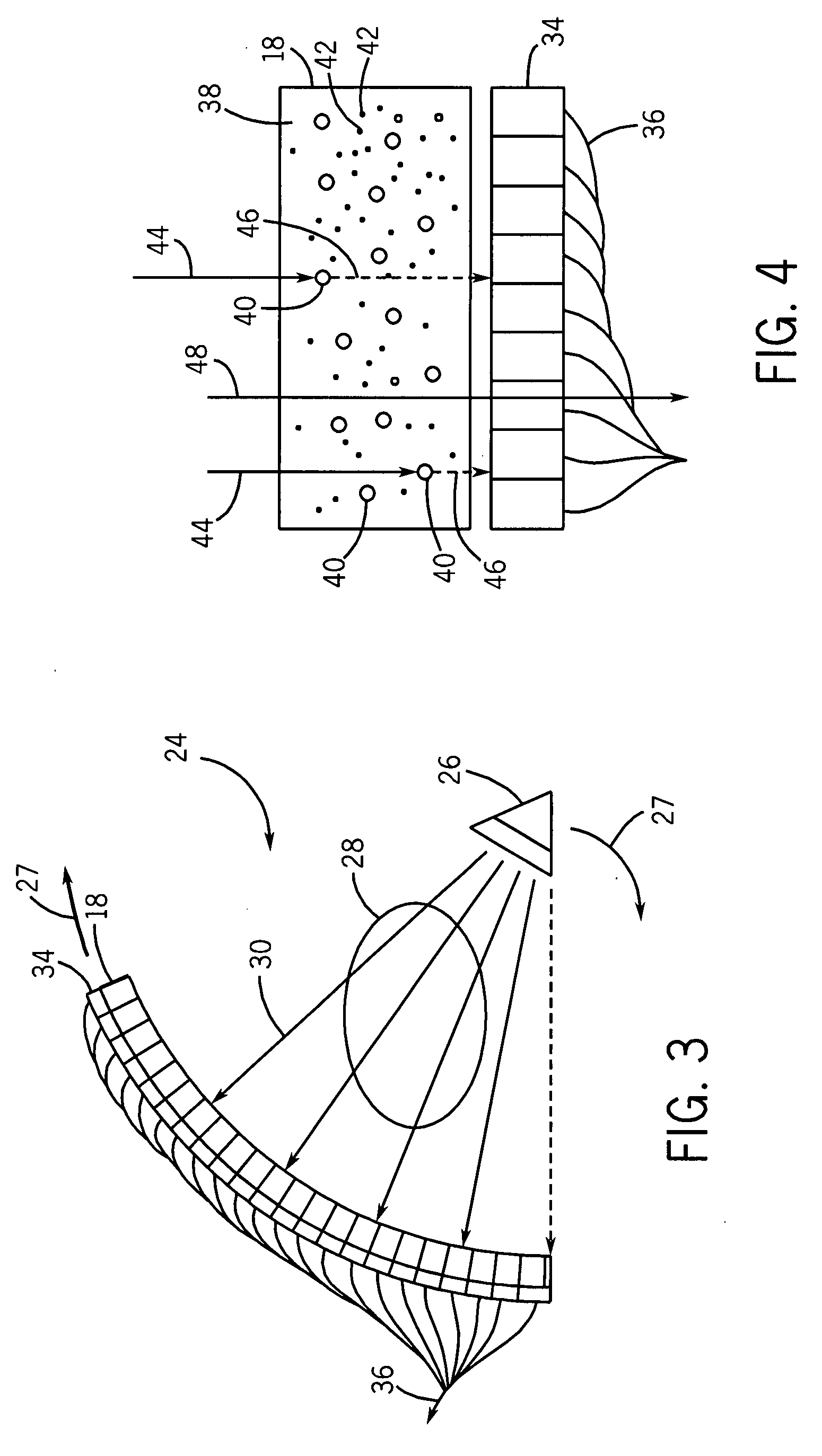

Making a dispersion managing crystal

InactiveUS6630117B2Magnesium fluoridesCalcium/strontium/barium fluoridesLithography processCrystalline materials

The present invention provides fluoride lens crystals for VUV optical lithography systems and processes. The invention provides a barium fluoride optical lithography crystal for utilization in 157 nm optical microlithography elements which manipulate below 193 nm optical lithography photons. The invention includes a barium fluoride crystalline material for use in dispersion management of below 160 nm optical lithography processes.

Owner:CORNING INC

Chemical deashing method for coal

ActiveCN102041128AGood deashing effectImproved deashing efficiencyCalcium/strontium/barium fluoridesDispersed particle separationHydrofluoric acidReaction temperature

The invention discloses a chemical deashing method for coal, belonging to the technical field of clean coal. A novel deashing acid solution is adopted for deashing coal and is a mixed acid of hydrofluoric acid and at least one other inorganic acid, wherein the mass percentage content of the hydrofluoric acid is 5-30%, the mass percentage content of other inorganic acids is 10-40%, and total acid concentration is 10-40%; during acid leaching, the mass ratio of the deashing acid solution to the raw material coal is (1-6):1, reaction temperature is 10-80DEG C, and the process of acid leaching lasts for 4-24 hours; and meanwhile, after exhaust gas and scouring water, generated in a defluorination processing, are graded and reused and a waste mixed acid solution is repeatedly reused, a lime solution is adopted for absorption. The method provided by the invention is suitable for deashing larger coal particles of which the diameter is 1-5mm, and can achieve a better deashing effect. A moderate reaction condition is adopted to ensure that the deashing mixed acid containing hydrofluoric acid is difficult to volatilize, so that energy consumption and cost are lowered and environmental pollution is lightened at the same time.

Owner:YIBIN TIANYUAN GRP CO LTD

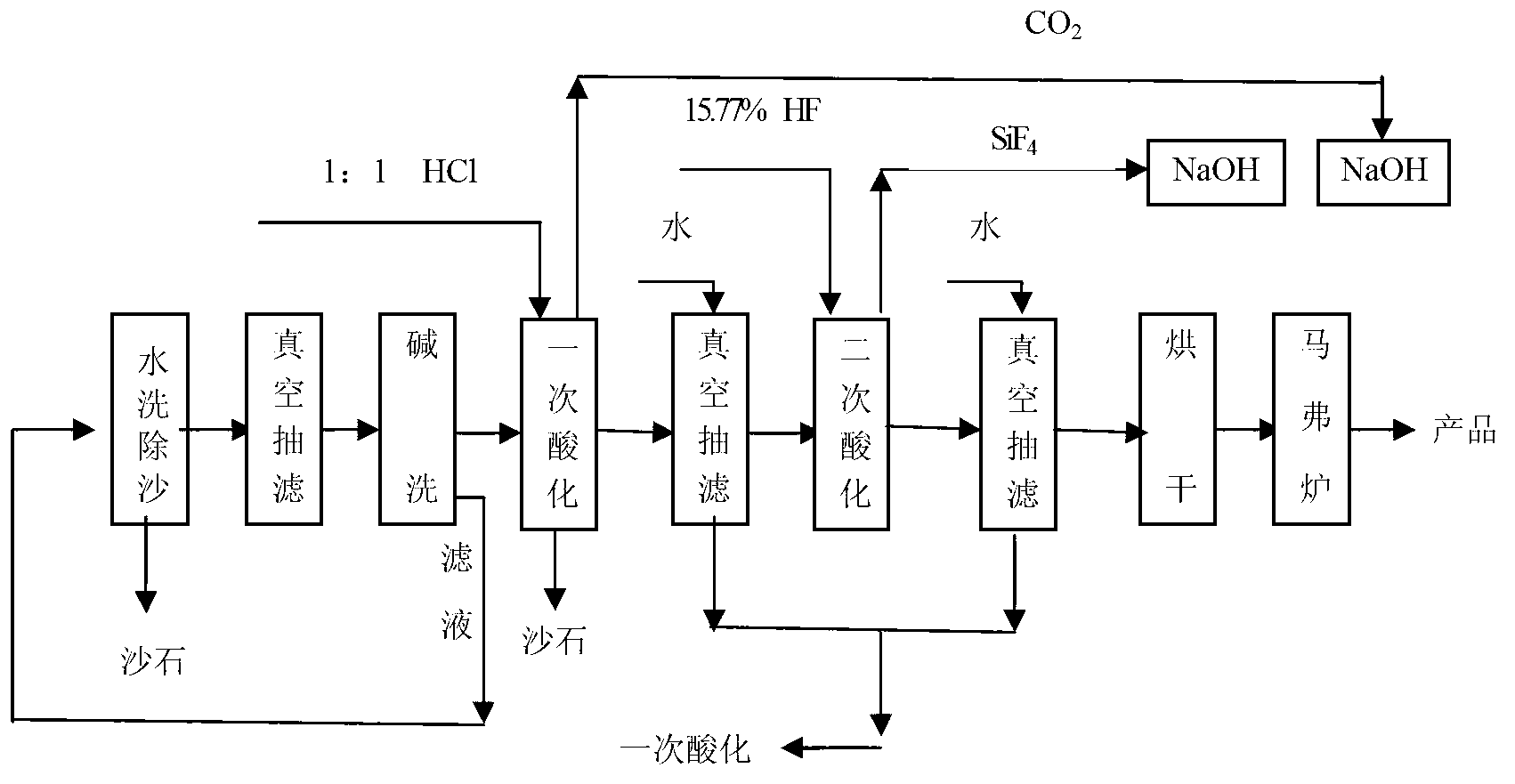

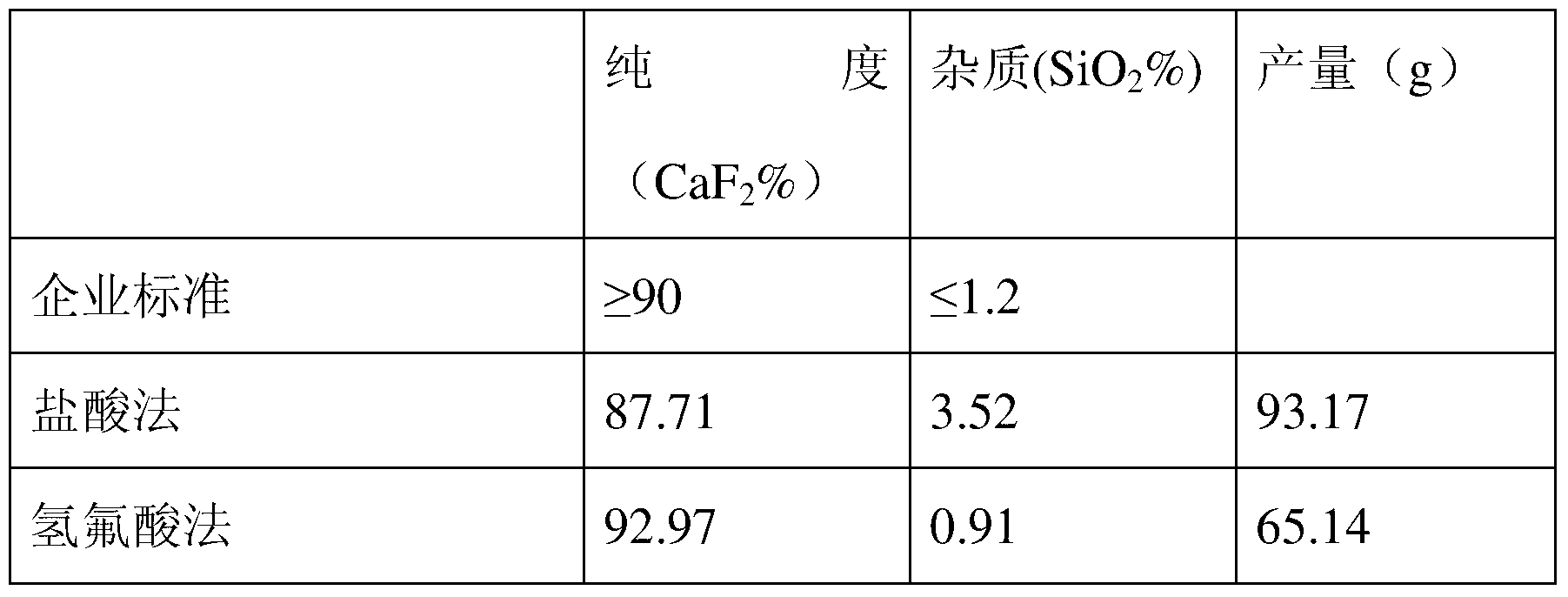

Method of producing calcium fluoride through bottom mud generated by fluoride waste

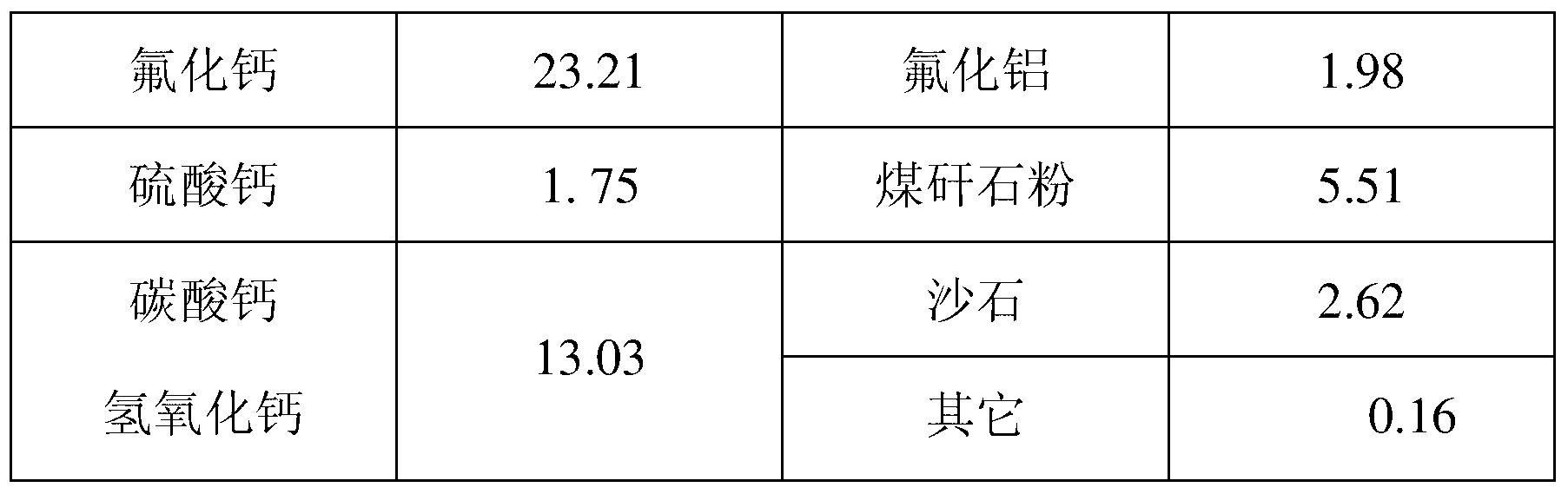

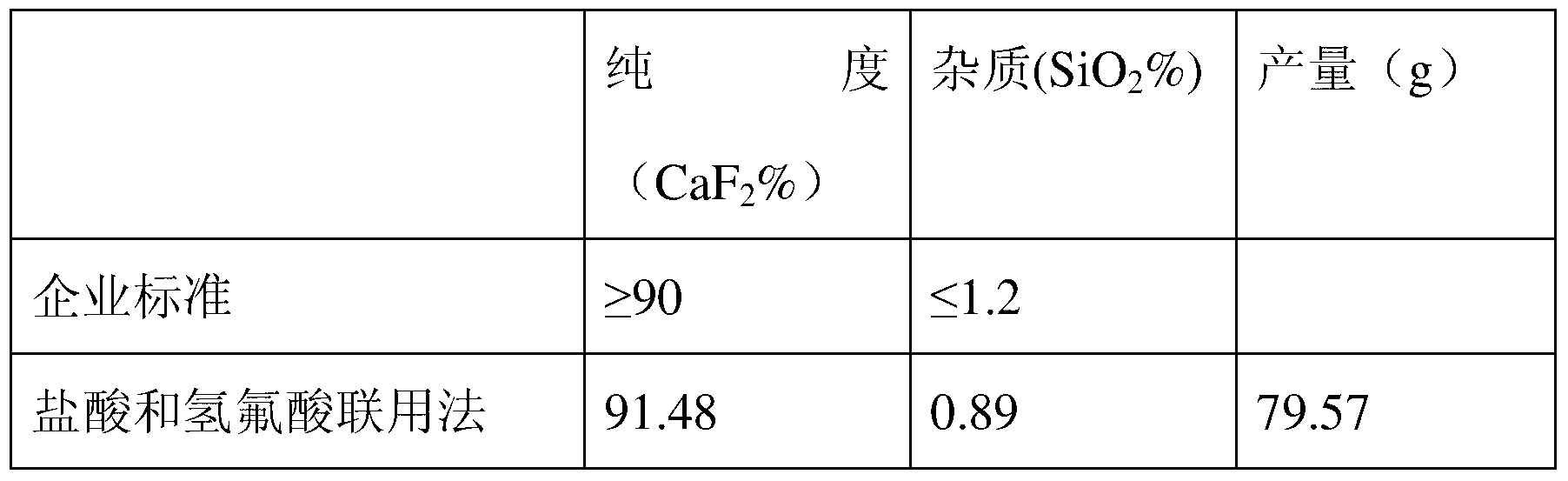

InactiveCN103241758AReduce pollutionSolve the problem of land occupationCalcium/strontium/barium fluoridesSolubilitySulfate

The invention discloses a method of producing calcium fluoride through bottom mud generated by treating industrial fluoride waste. The method comprises the following step of: separating the ingredients according to different solubility of bottom mud in acids through a one-step alkaline washing and two-step acidification separating method to obtain a calcium fluoride product; the treatment step comprises: alkaline washing, primary acidification separating, secondary acidification separating, drying and burning; in the alkaline washing procedure, a sodium carbonate solution acts with the bottom mud to convert calcium sulfate in the bottom mud into calcium carbonate; the bottom mud is used as a raw material in the primary acidification separating procedure; filtrate obtained in the secondary acidification separating procedure is mixed with washing water to serve as an acid source of the primary acidification; a new acid serves as the acid source of the secondary acidification; and an obtained filter cake is treated in the drying and burning steps. The method provided by the invention both can be used for solving the area occupation and environmental pollution problems of bottom mud produced by treating the industrial fluoride waste, effectively utilizing the fluorine resource in the bottom mud and providing the calcium fluoride product having utilization value.

Owner:崔岷

Comprehensive utilization method of wastewater containing phosphorus and fluorine

InactiveCN104445730ALow costMaximize recyclingCalcium/strontium/barium fluoridesWater contaminantsSolubilitySilica gel

The invention relates to the field of wastewater comprehensive utilization, and particularly relates to a comprehensive utilization method of wastewater containing phosphorus and fluorine. The comprehensive utilization method comprises the following steps: carrying out twice neutralization on the wastewater containing phosphorus and fluorine, and controlling the final pH value after each time of neutralization; separating calcium fluoride from wastewater according to the solubility product of calcium fluoride and calcium orthophosphate, so as to enable the main ingredients of wastewater to be calcium orthophosphate and silica gel; separating silica gel by centrifugal separation to obtain a waste liquid containing phosphorus; carrying out secondary neutralization on the waste liquid containing phosphorus to enable the pH value to be 4-7; after generating calcium hydrophosphate, carrying out cooling crystallization treatment; separating calcium hydrophosphate to obtain a clear liquid, so as to realize treatment on wastewater containing phosphorus and fluorine. By adopting the comprehensive utilization method, maximal reutilization of the phosphorus fluorine resource is realized, the by-product silica gel is generated, the product additional value is increased, and the cost of treatment on wastewater containing phosphorus and fluorine is reduced.

Owner:GUIZHOU KAILIN GRP CO LTD

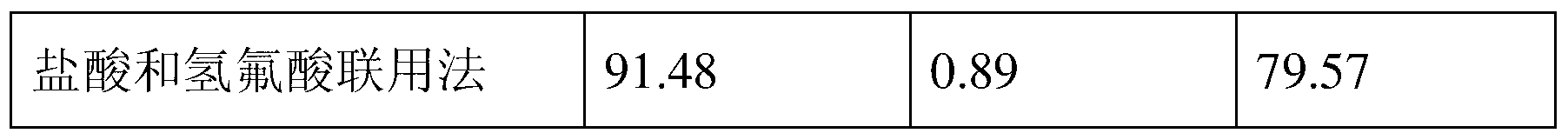

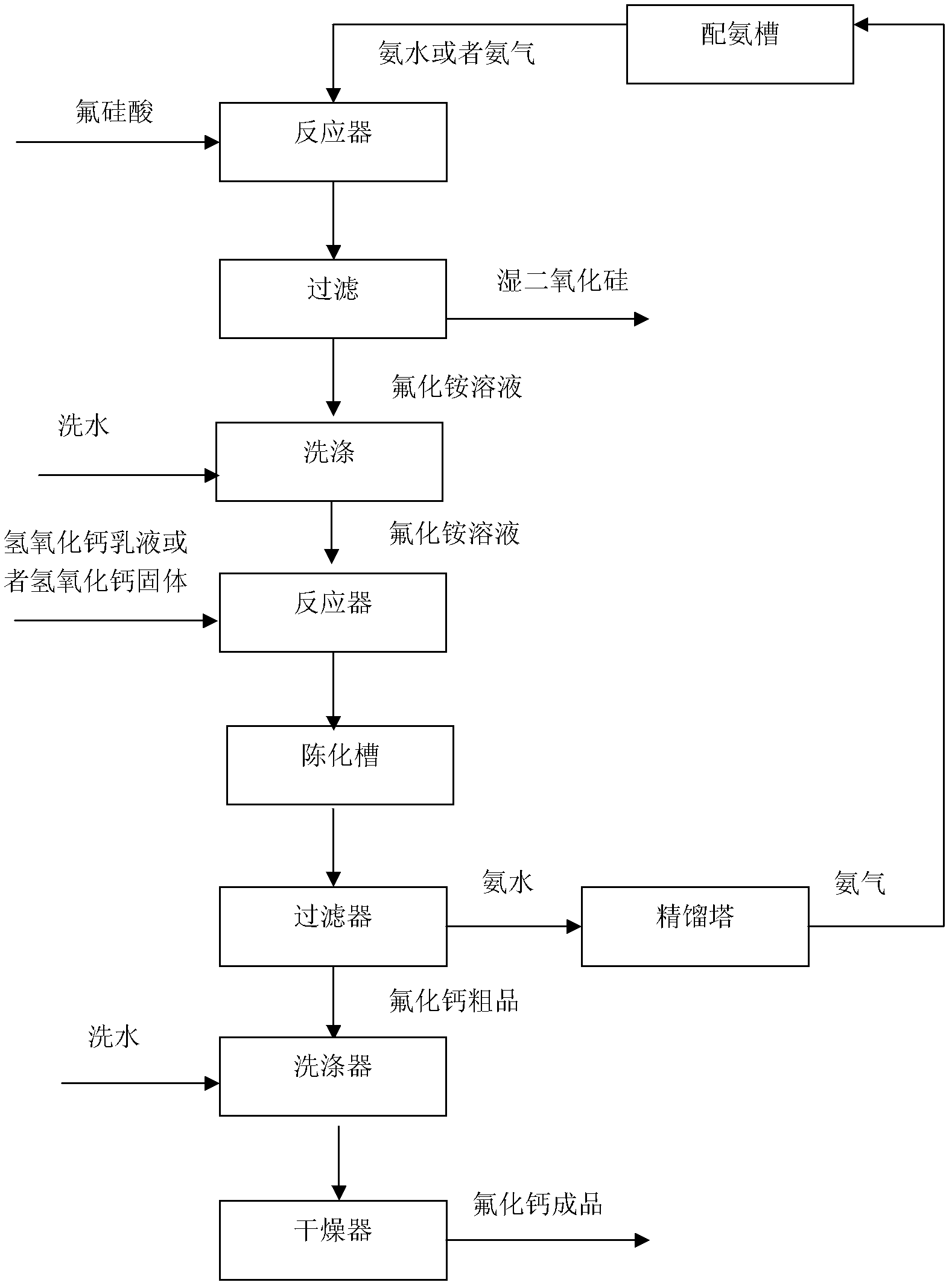

Synthetic method of calcium fluoride

ActiveCN102502753AImprove solubilityAchieve separationCalcium/strontium/barium fluoridesSolubilityTwo step

The invention relates to a synthetic method of calcium fluoride, hydrofluosilicic acid produced during a phosphate fertilizer production process is adopted as raw materials so as to synthesize calcium fluoride through two steps of reaction, the first step of reaction is that ammonium fluoride and silicon dioxide are produced through the reaction of fluosilicic acid and ammonia gas or ammonia water, the solubility of ammonium fluoride is high, and the separation of ammonium fluoride from silicon dioxide is achieved through the method of filtering and washing; the second step of reaction is that calcium fluoride and ammonia water are produced through the reaction of ammonium fluoride solution and calcium hydroxide, the separation of calcium fluoride from ammonia water is achieved through the filtering way, ammonia gas is obtained by rectifying the ammonia water, and calcium fluoride is produced by taking ammonium fluoride as an intermediate product. Therefore, the invention overcomes defects of insufficient reaction during the process of synthesizing calcium fluoride through the reaction of hydrofluosilicic acid and calcium hydroxide, and mass of calcium fluosilicate contained in calcium fluoride products, further solves the problem of difficulty separation of calcium fluoride from silicon dioxide mixture, and achieves efficient utilization of by-product hydrofluosilicic acid ofphosphate fertilizer.

Owner:KUNMING DAOERSEN TECH

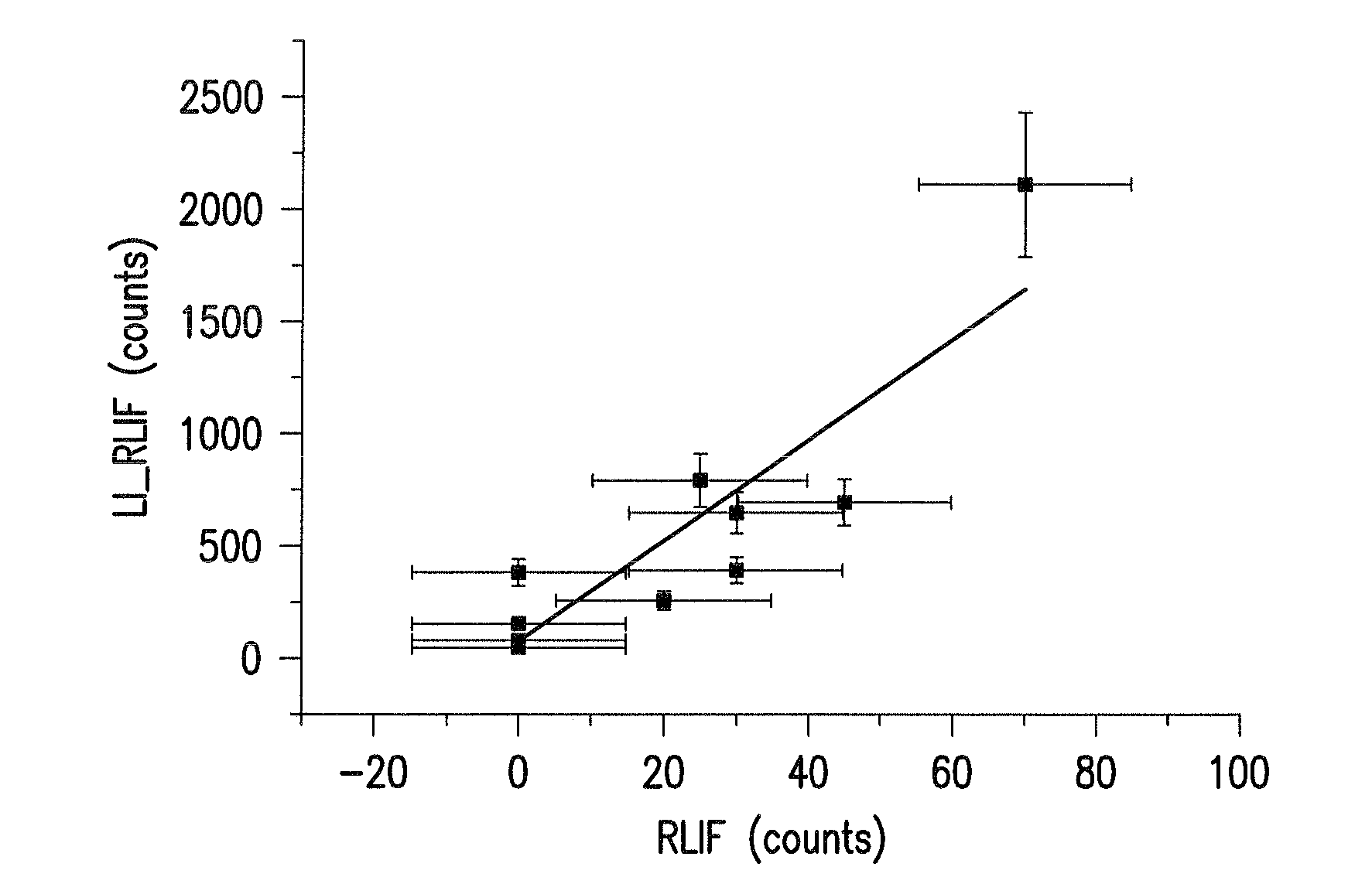

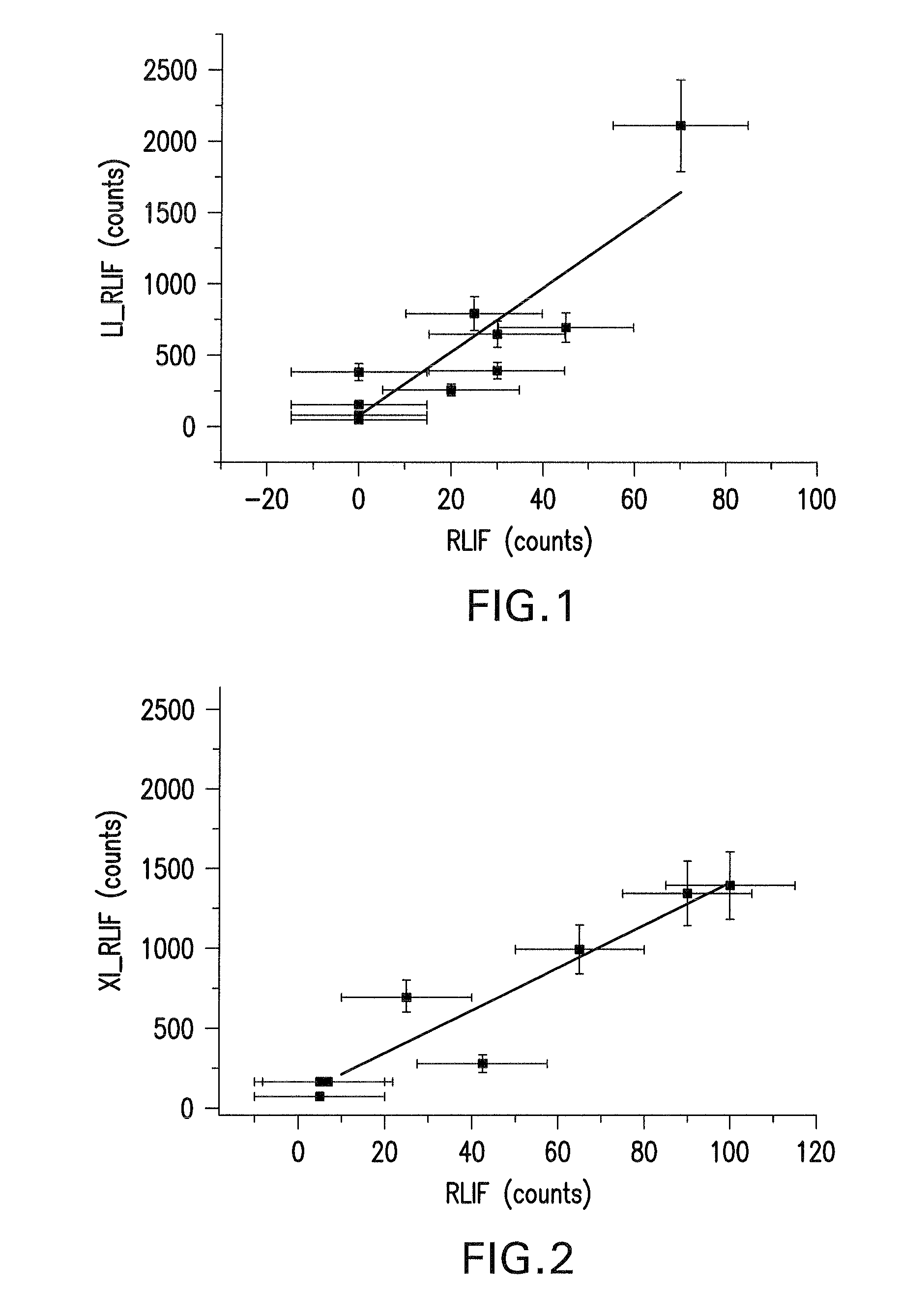

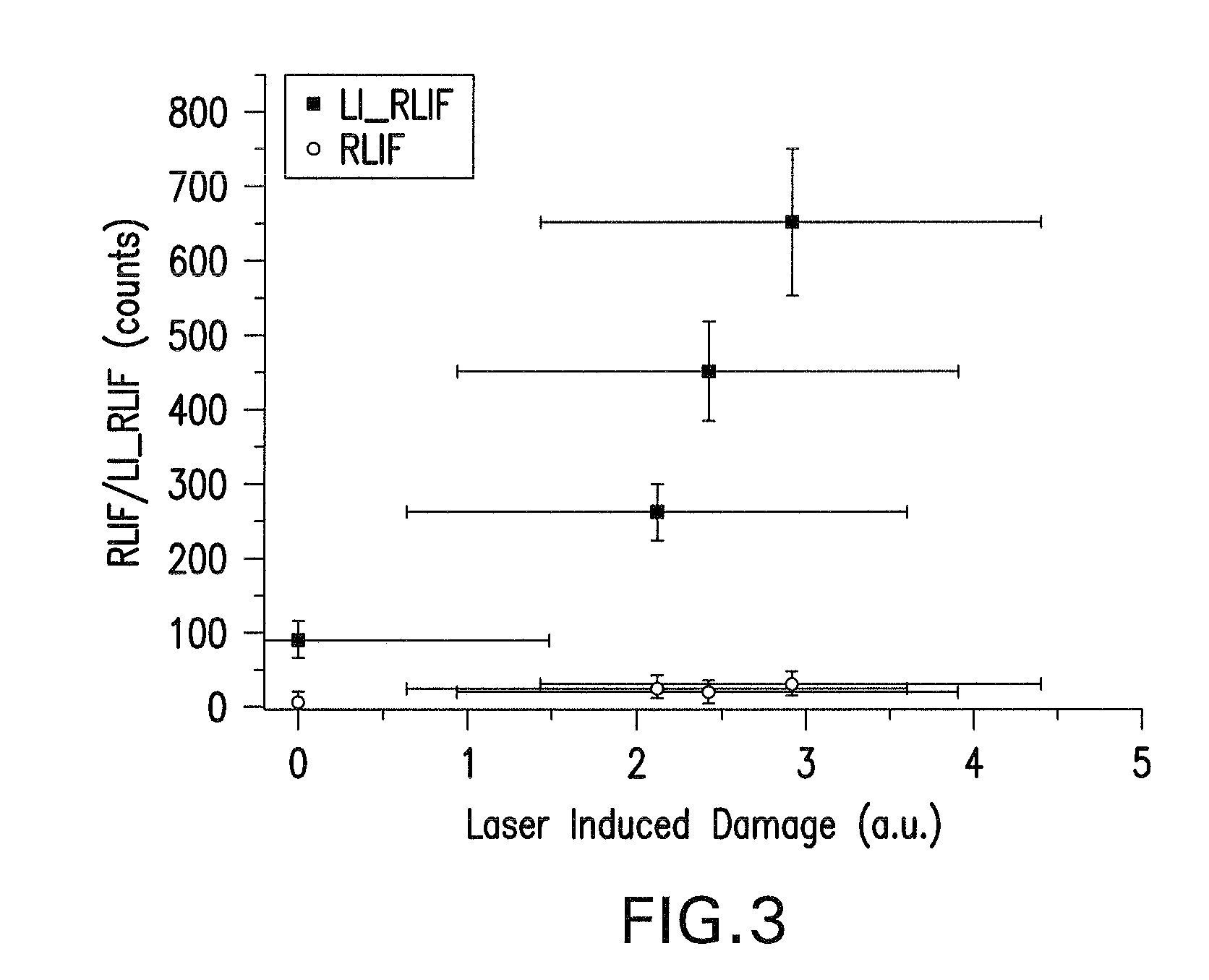

Method of determining laser stabilities of optical material, crystals obtained with said method, and uses of said crystals

InactiveUS20100111820A1Simple methodLong durationMagnesium fluoridesCalcium/strontium/barium fluoridesPre irradiationHigh energy

A method of selecting suitable laser-stable optical material for making an optical element, especially for transmission at wavelengths under 200 nm, is described. It includes a first pre-irradiation to produce radiation damage, subsequent excitation of induced fluorescence with light at between 350 to 700 nm at least ten minutes after the first pre-irradiation and measurement of induced fluorescence intensities at one or more wavelengths between 550 nm and 810 nm. After the fluorescence intensity measurement a second pre-irradiation is performed with an at least 1000-fold higher energy than in the first pre-irradiation and then induced fluorescence intensities are again measured to determine the increase in the fluorescence intensities. The materials determined to have suitable laser stability are used for making lenses, prisms, light-conducting rods, optical windows and optical devices for DUV lithography, especially steppers and excimer lasers, integrated circuits, computer chips as well as other electronic devices.

Owner:HELLMA MATERIALS

Method for producing calcium fluoride

InactiveCN101134595AReduce total usageSave resourcesCalcium/strontium/barium fluoridesCalcium silicateSilicon tetrafluoride

The process of producing calciumfluoride with fluorosilicic acid and calcium oxide as material includes the following steps: 1. reacting fluorosilicic acid solution and calcium oxide for 10-60 min, filtering to obtain solid calcium fluorosilicate; 2. decomposing calcium fluorosilicate at 200-600 deg.c for 1-5 hr to produce solid calcium fluoride product and silicon tetrafluoride gas; and 3. absorbing silicon tetrafluoride gas with water and hydrolyzing, filtering to obtain fluorosilicic acid solution to be returned to the step 1 and solid silica, and washing and drying silica to obtain carbon white. The process utilizes fluorosilicic acid as one side product of phosphate fertilizer production as one main material, and has low cost and environment friendship.

Owner:DO FLUORIDE CHEM CO LTD

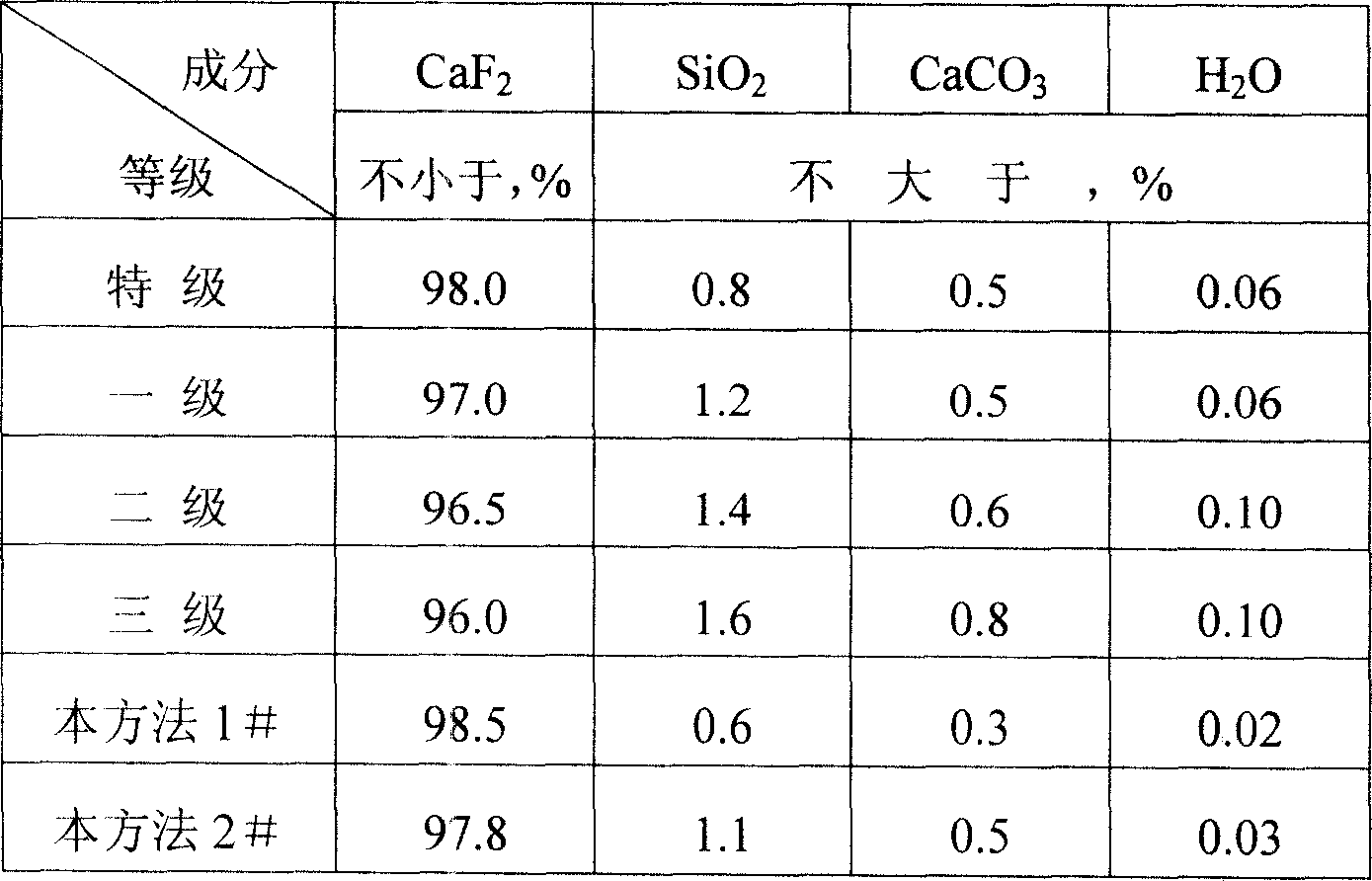

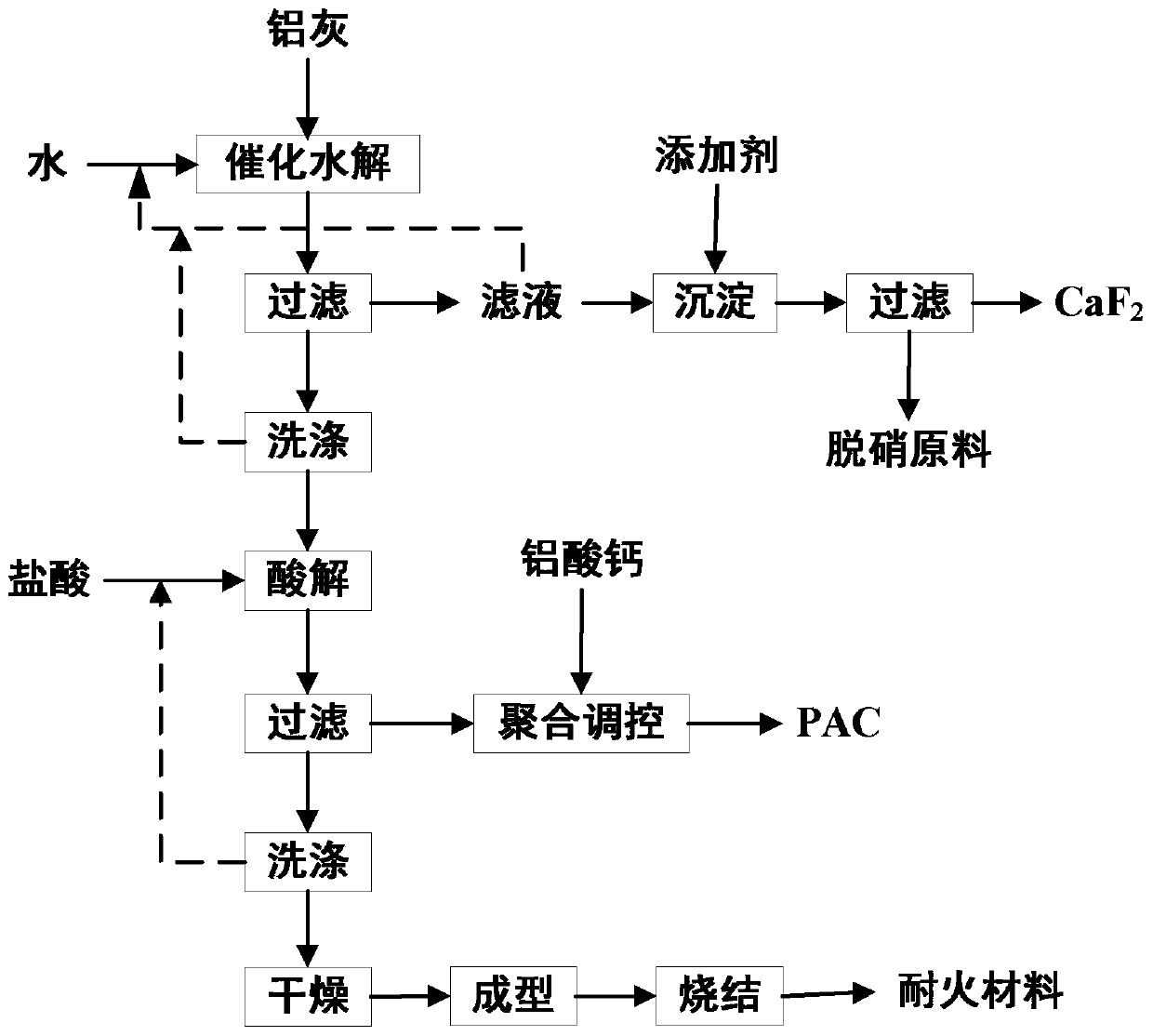

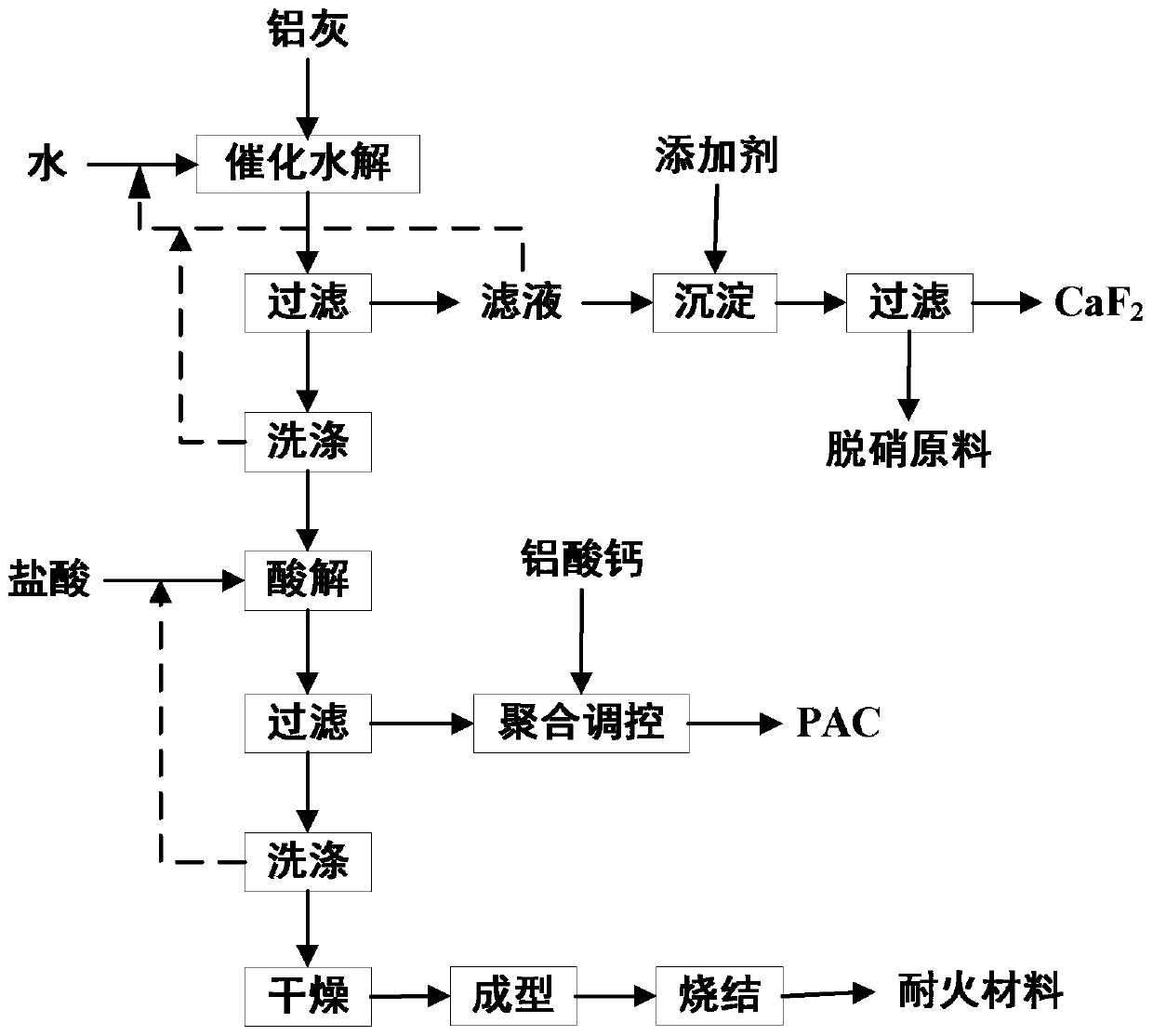

Method for using aluminum ash to prepare aluminum polychlorid and co-produce calcium fluoride

InactiveCN110040755AAddressing Safe Disposal IssuesRealize resource utilizationCalcium/strontium/barium fluoridesAluminium chloridesResource utilizationPerformance index

The invention discloses a method for using aluminum ash to prepare aluminum polychlorid and co-produce calcium fluoride. The method comprises the steps that filtrate and a filter cake are obtained through catalytic hydrolysis, filtration and washing of aluminum ash, and a fluorine rich solution is obtained through multiple recycling of the filtrate; an aluminum rich solution, washing liquid and acidolysis residue are obtained through acidolysis, filtration and washing of the filter cake; calcium fluoride and denitration ammonium hydroxide are prepared through precipitation and filtration of the fluorine rich solution; an aluminum polychlorid water purifying agent is prepared through polymerization mediation of the aluminum rich solution obtained through acidolysis, and a fireproof materialis prepared through drying and sintering of acidolysis residue. The method disclosed by the invention achieves thorough hydrolysis of aluminum nitride and directional enrichment and separation of impurity ions, the ammonia-nitrogen content of the aluminum polychlorid is low, the quality is high, the performance indexes are completely superior to the requirement of GB / T22627-2014 standard, the calcium fluoride purity is high, and the aluminum polychlorid can replace industrial calcium floride. The method solves the problem of safe treatment of aluminum ash, and achieves resource utilization, and the environmental, economical and social benefits are outstanding.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

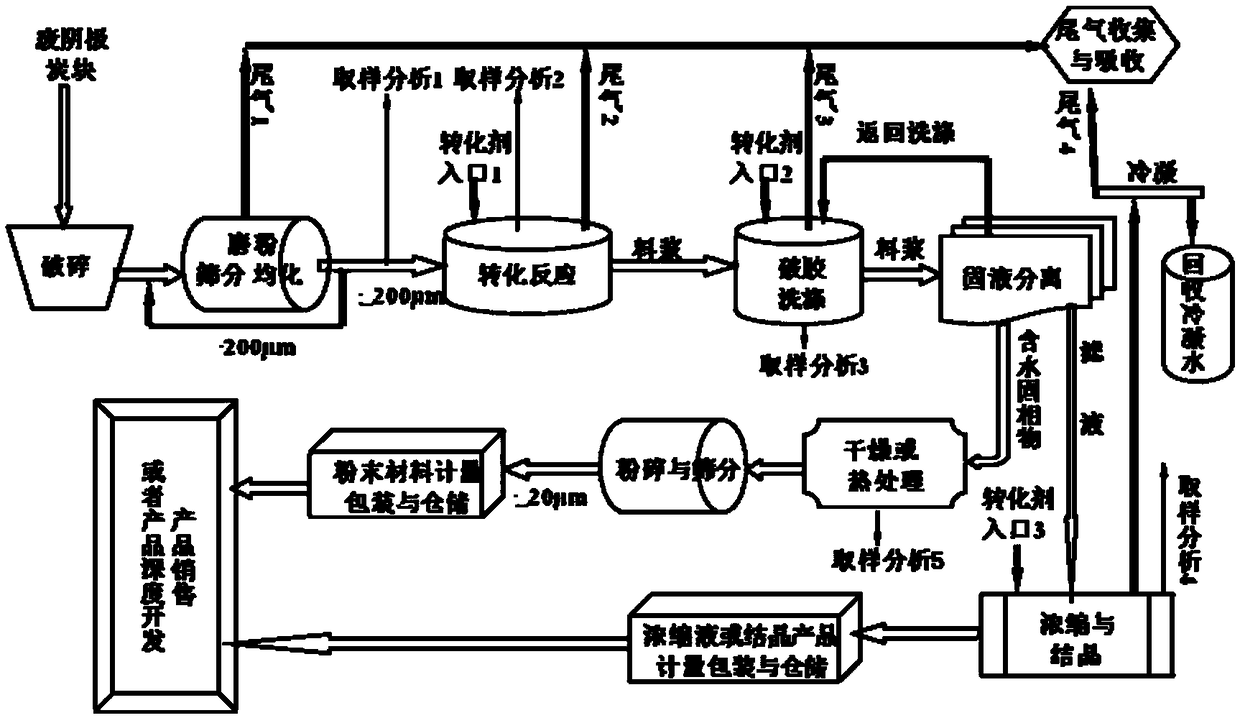

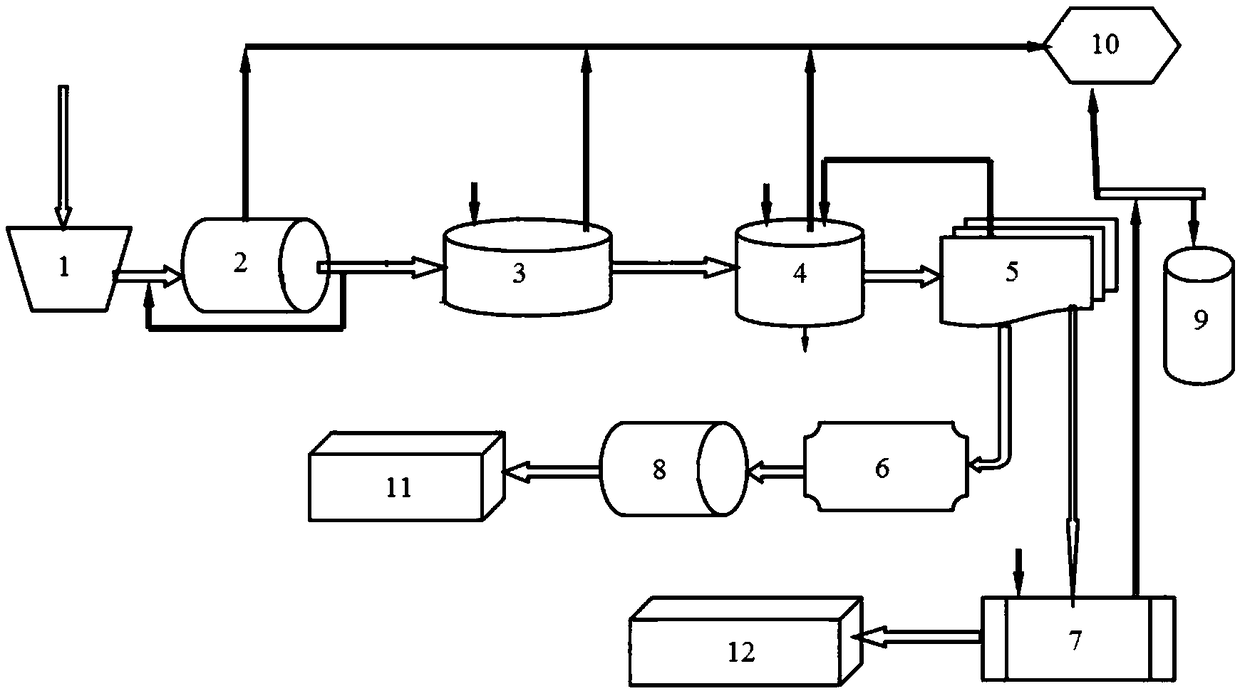

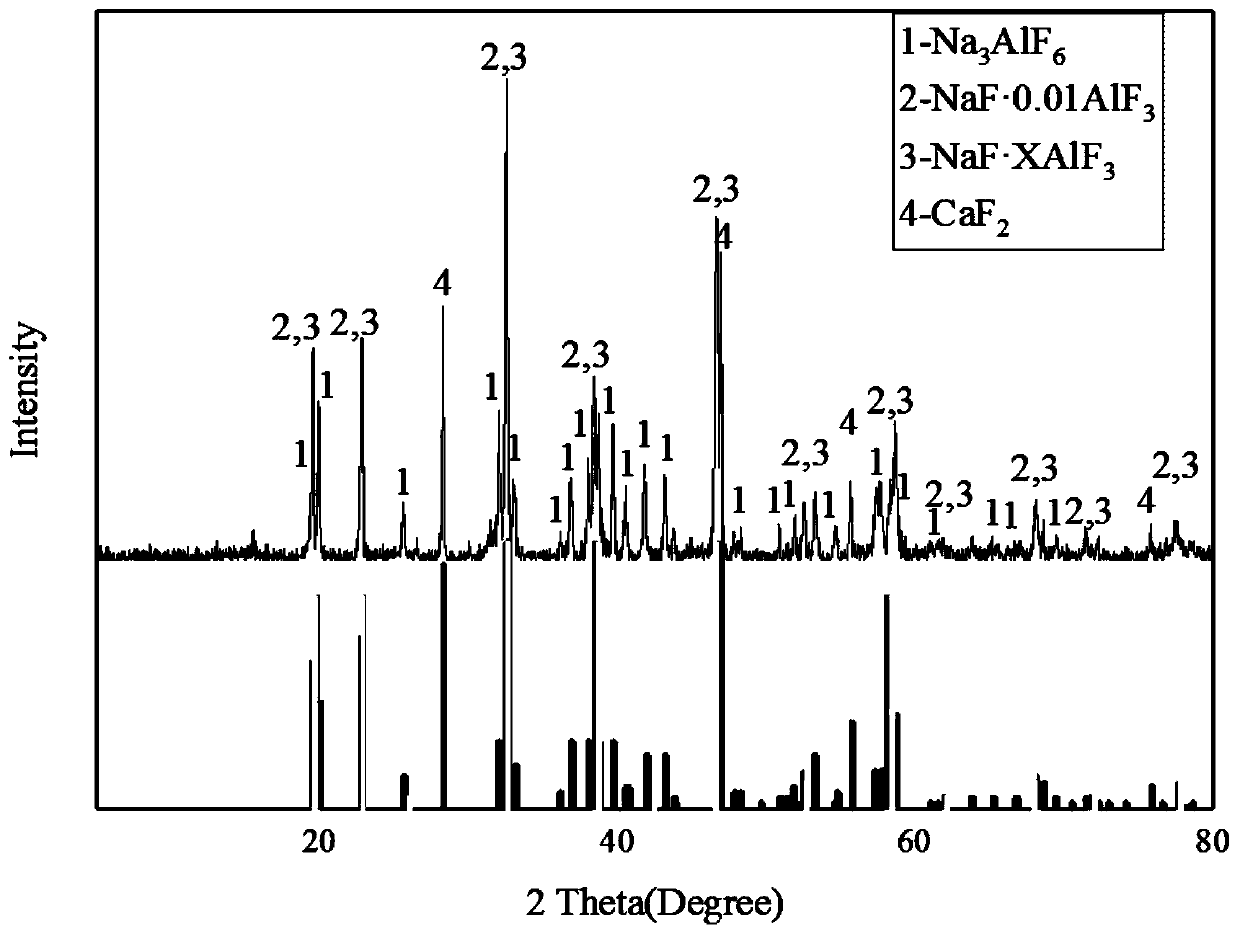

Method and system for converting sodium-containing and fluorine-containing compounds in waste cathode carbon block of aluminum electrolytic cell

ActiveCN109047285AEasy to controlEasy to industrializeMagnesium fluoridesTransportation and packagingPollutionHeat treated

The invention relates to a method and system for converting sodium-containing and fluorine-containing compounds in a waste cathode carbon block of an aluminum electrolytic cell. The conversion methodcomprises the step that a conversion agent is used for converting the sodium-containing compound in the waste cathode carbon block of the aluminum electrolytic cell into a fluorine-free soluble sodiumcompound, converting the fluorine-containing compound into an insoluble and harmless mineral fluorine compound and converting a cyanide-containing compound into harmless N2 or NH3 and CO2 in an oxidized manner through a mechanochemical conversion reaction in a conversion mill, and therefore the hazards of fluoride and cyanide in the waste cathode carbon block of the aluminum electrolytic cell arecompletely eliminated. The conversion system comprises a waste cathode carbon block crushing device, a milling device, the conversion mill, a stirred reactor and a solid-liquid separation device which are sequentially connected in series, and the solid-liquid separation device is then directly connected with a concentration or crystallization device and a drying or heat treatment device, and thedrying or heat treatment device is connected to the crushing device. By means of the method and system, the process is simple, mass production is easy, the production cost is low, pollution of three wastes is avoided, and the method and system are environmentally friendly.

Owner:XIANGTAN UNIV

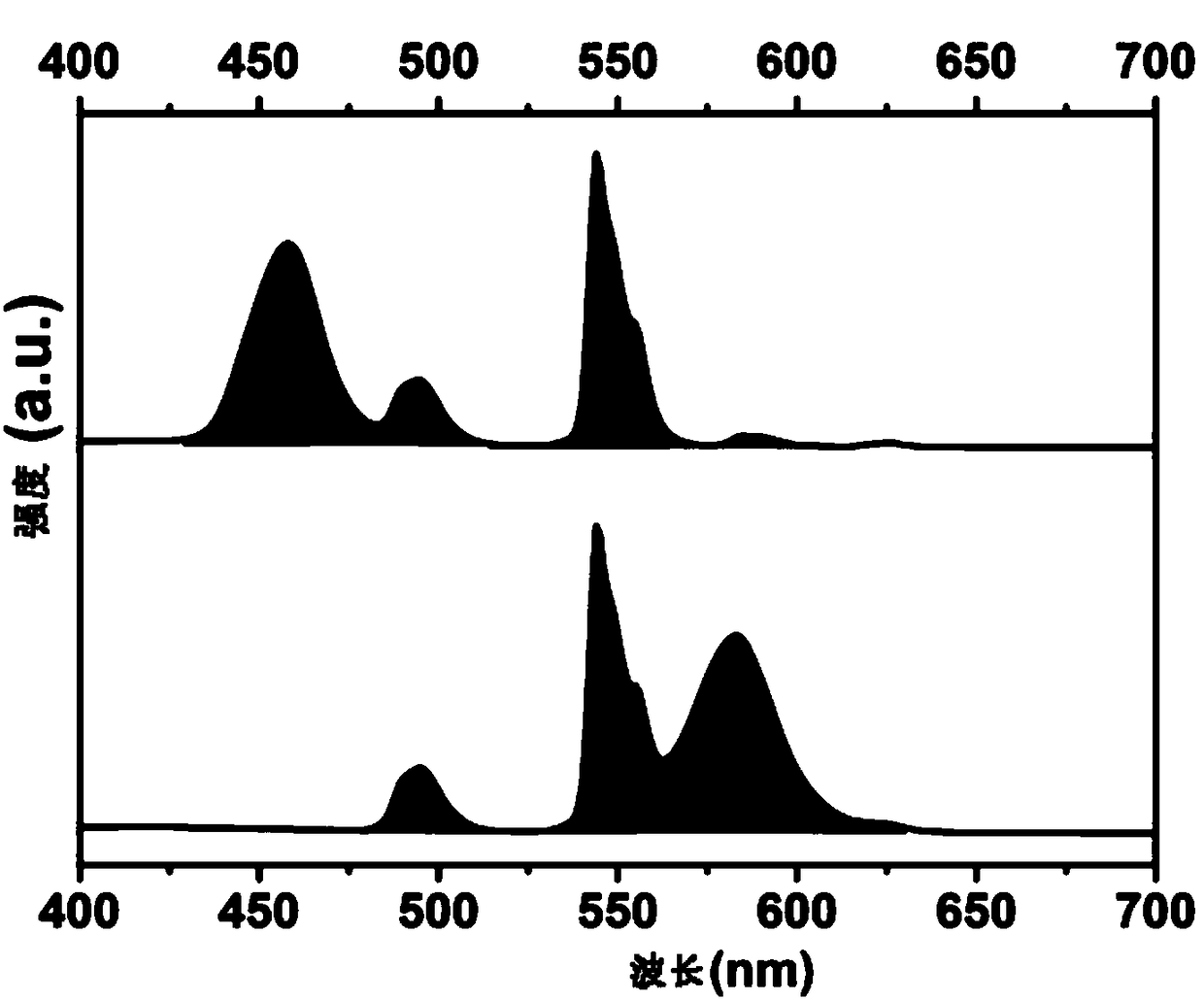

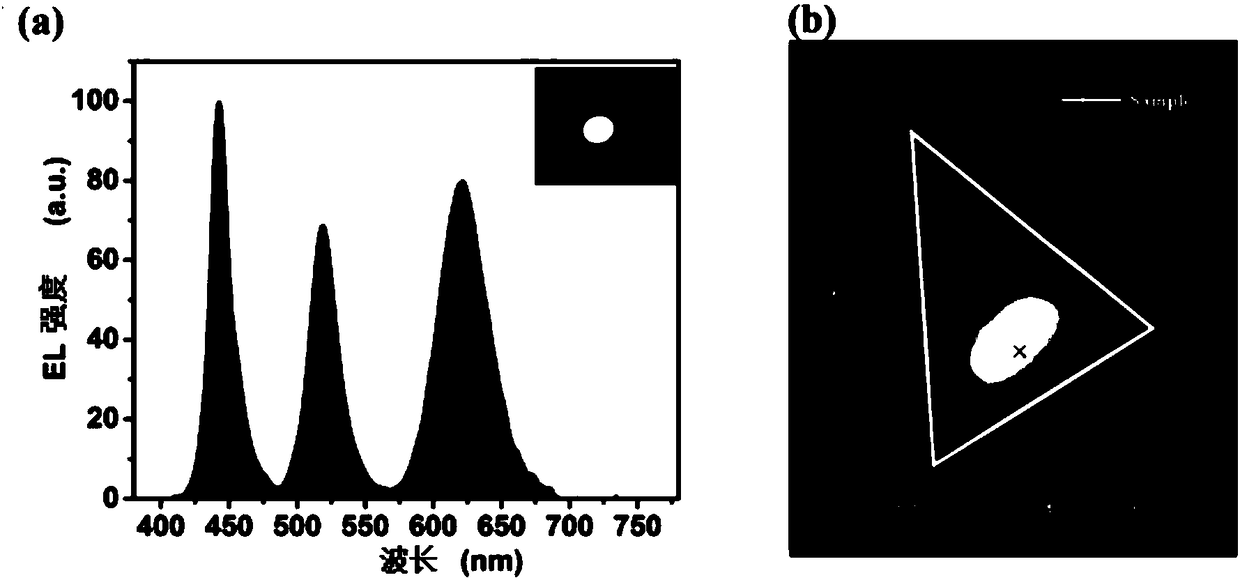

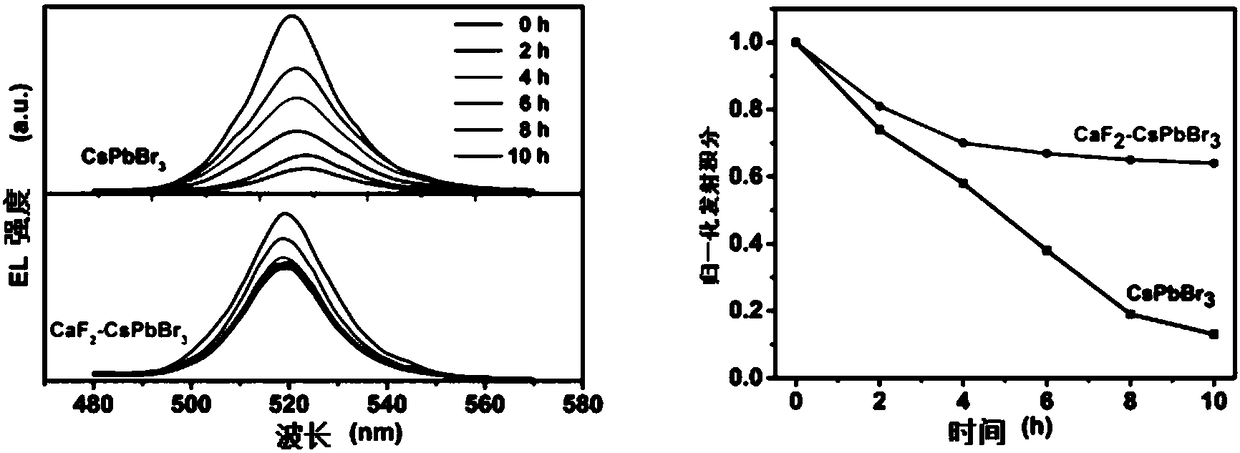

Perovskite quantum dot material and preparation method thereof

ActiveCN108251109AImprove stabilityAchieve two-color light emissionOrganic compound preparationCalcium/strontium/barium fluoridesFluorescenceRare earth

The invention discloses perovskite quantum dots and a preparation method thereof. The product is blue, green, yellow and red full-spectrum adjustable fluorescent powder for white-light LEDs (Light Emitting Diodes) suitable for ultraviolet / blue light excitation. By utilizing higher stability of mesoporous hollow CaF2 nanospheres, pre-prepared lead-halogen perovskite quantum dots are adsorbed into the cavities of the CaF2 nanospheres by virtue of the capillary principle, and then, residual solvents are removed under mild conditions so as to finally form the perovskite quantum dots with good stability. The preparation method is simple and fast; furthermore, only one non-polar organic solvent is used, so that the original high fluorescence efficiency of the perovskite quantum dots is well kept; and by combination of traditional rare earth luminescent materials with novel high-efficiency perovskite quantum dots, the obtained product has excellent optical properties and has certain popularization value in solid-phase white-light LEDs for illumination and display.

Owner:WUYI UNIV

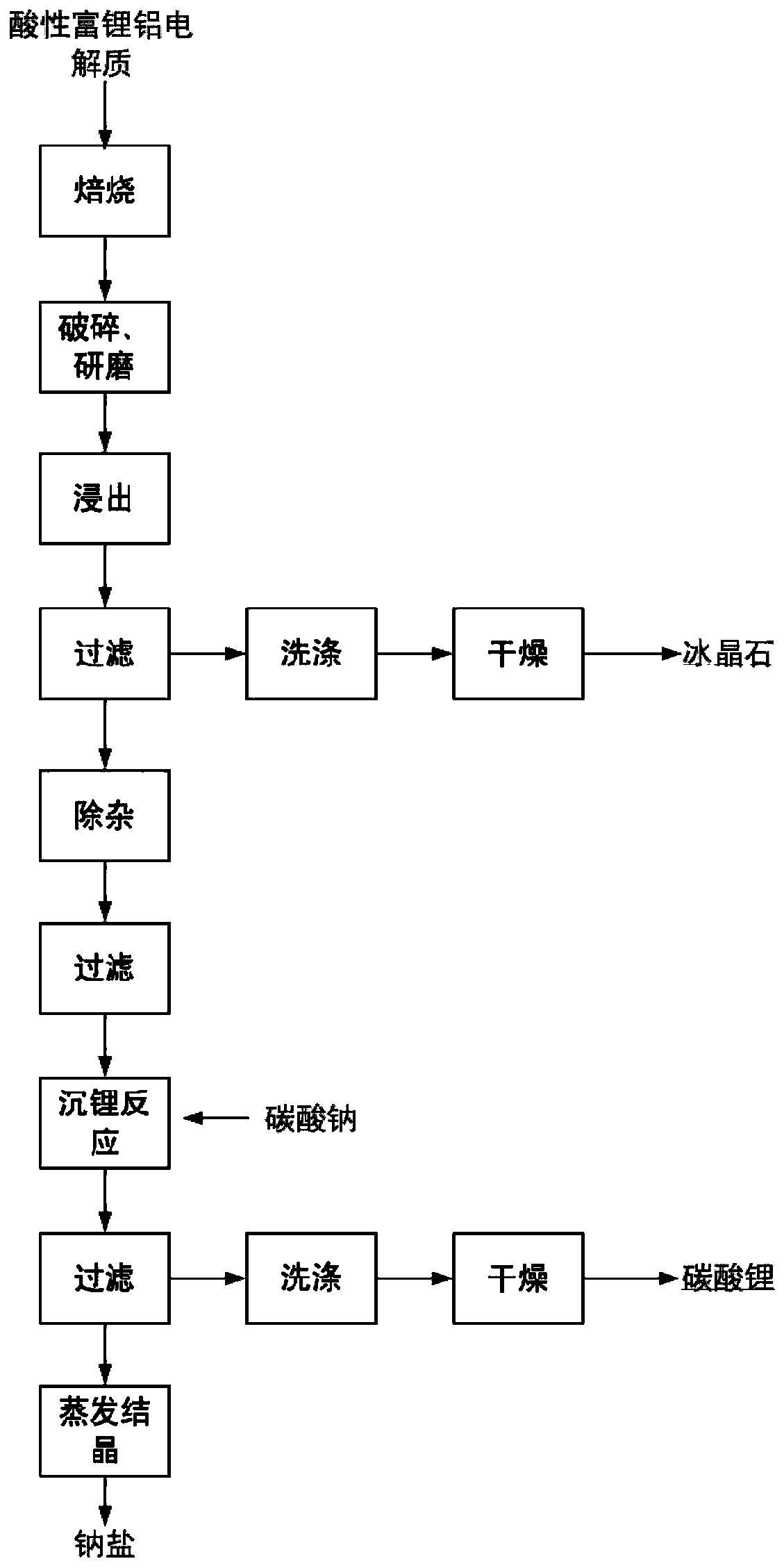

Resource treatment method for lithium-rich aluminum electrolyte

ActiveCN110240182AChange molecular ratioEasy to operateCalcium/strontium/barium fluoridesAlkali metal nitratesAluminum IonInorganic salts

The invention relates to a resource treatment method for a lithium-rich aluminum electrolyte. The method comprises the following steps: firstly performing heat treatment on the lithium-rich aluminum electrolyte to obtain a product A; performing leaching treatment on the roasting product A with a water-soluble inorganic salt as a leaching agent in water, and performing filtering to obtain a filter residue B and a filtrate B; adding an alkali or an aqueous solution of the alkali to the filtrate B to remove aluminum ions in the filtrate B to obtain a filtrate C; and adding a water-soluble carbonate or an aqueous solution of the carbonate to the filtrate C to make lithium ions in the filtrate C be converted into lithium carbonate precipitation, and then performing filtering to obtain lithium carbonate and a filtrate D. The technical problem perplexing aluminum electrolysis industry of rich and high content lithium in an excess aluminum electrolyte and inefficient utilization of valuable metals is solved, the economic benefit is improved, and stable production of an electrolytic aluminum enterprise is promoted.

Owner:CENT SOUTH UNIV

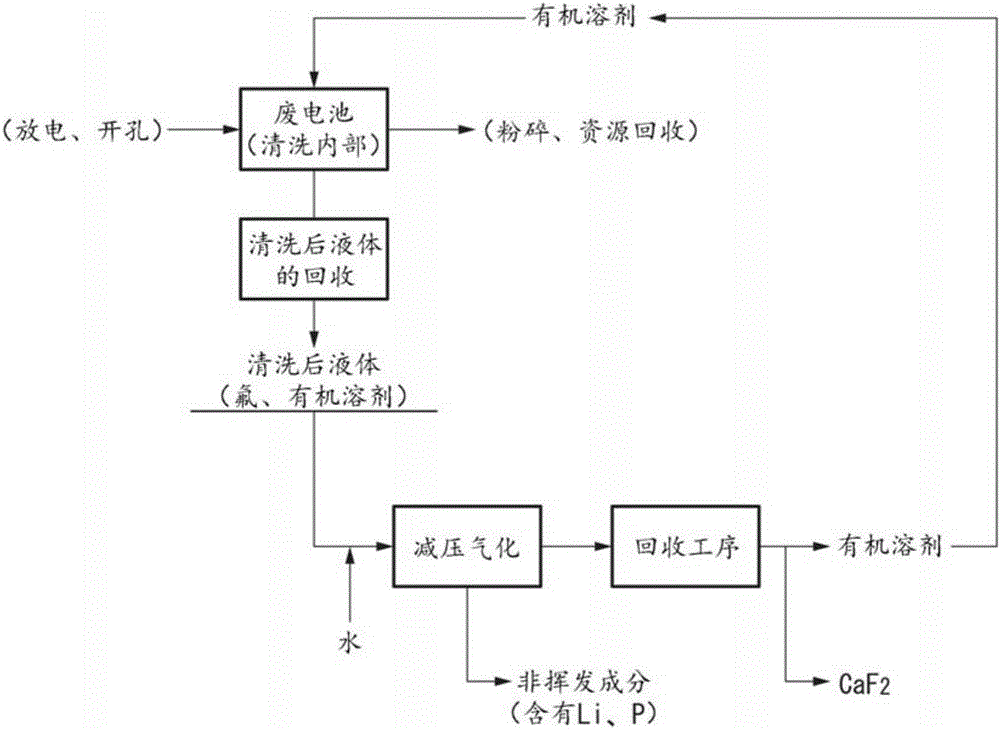

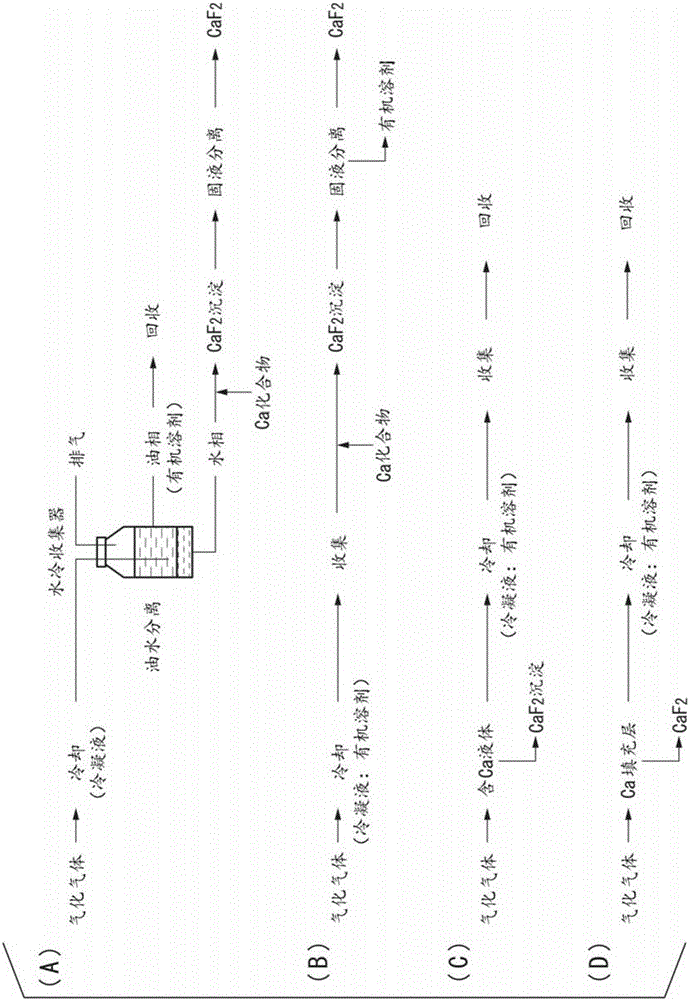

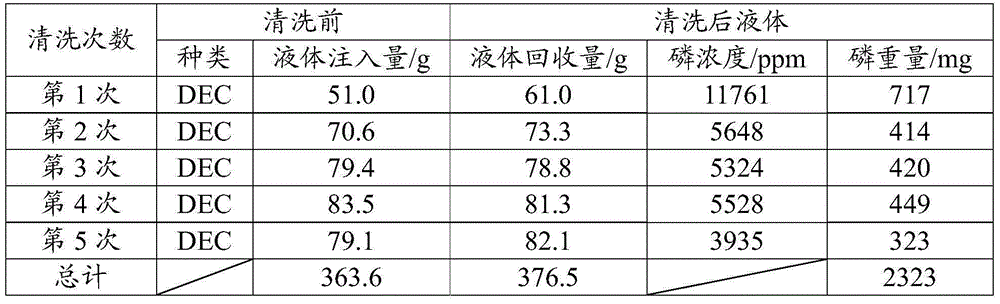

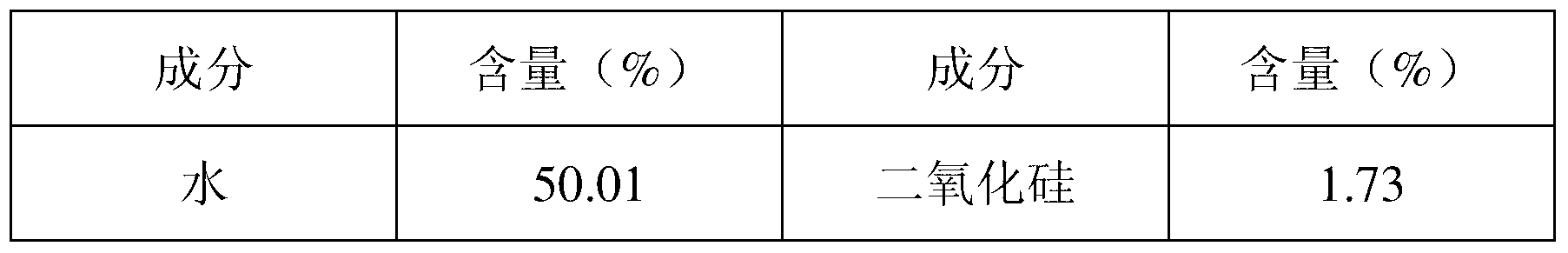

Method for processing fluorine-containing electrolyte solution

ActiveCN105229843ASafe handlingLess quantityCalcium/strontium/barium fluoridesWaste accumulators reclaimingOrganic solventPhysical chemistry

Owner:MITSUBISHI MATERIALS CORP

Method for producing calcium fluoride by bottom sludge generated during treatment of industrial fluoride-containing wastewater

InactiveCN103232053ASolve the problem of land occupationEfficient use ofSludge treatmentCalcium/strontium/barium fluoridesSludgeWastewater

The invention relates to a method for producing calcium fluoride by bottom sludge generated during treatment of industrial fluoride-containing wastewater. Calcium fluoride in the bottom sludge is obtained through combination of hydrochloric acid, sodium carbonate and caustic soda and two-time acidification seperation. The method has the advantages of solving the land occupation problem of bottom sludge generated during treatment of industrial fluoride-containing wastewater, effectively utilizing fluorine resources in the bottom sludge and providing calcium fluoride products with utilization value.

Owner:BEIFANG UNIV OF NATITIES

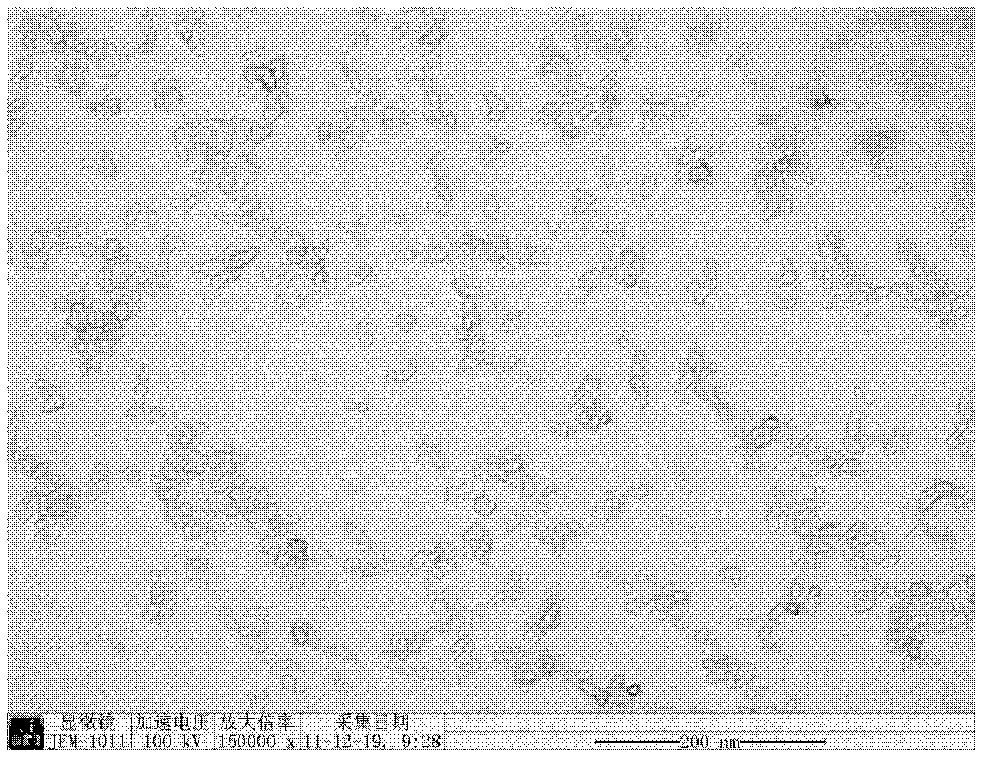

Preparation method of nano calcium fluoride for self-lubricating tool material

InactiveCN102583486AHigh purityComplete crystal formCalcium/strontium/barium fluoridesNanotechnologyAlcoholSolvent

The invention relates to a preparation method of nano calcium fluoride for a self-lubricating tool material. According to the preparation method, an ultrasonic reduction method is adopted. The preparation method comprises the following steps of: preparing calcium nitrate and ammonium fluoride serving as raw materials into aqueous or alcohol solution respectively; adding PEG 6000-abslute ethyl alcohol composite solvent; performing ultrasonic dispersion; mixing the dispersed calcium nitrate solution and the ammonium fluoride solution under ultrasonic and stirring conditions; and reacting, aging, centrifuging, cleaning and drying to obtain nano calcium fluoride powder. The prepared nano calcium fluoride has the particle size of 15-50 nm and has high purity, complete crystal form, high crystallinity, uniform size distribution and high dispersion. The preparation method also has the advantages of simple technical process, convenience for operation and low equipment requirements.

Owner:QILU UNIV OF TECH

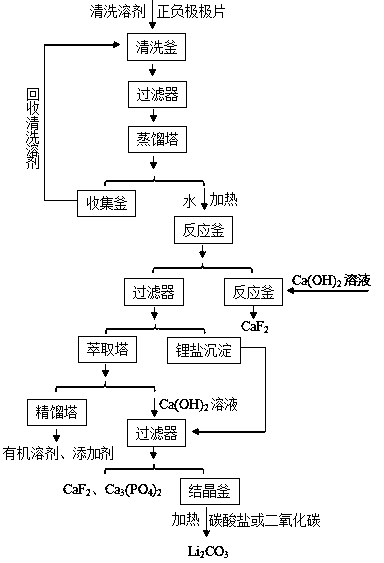

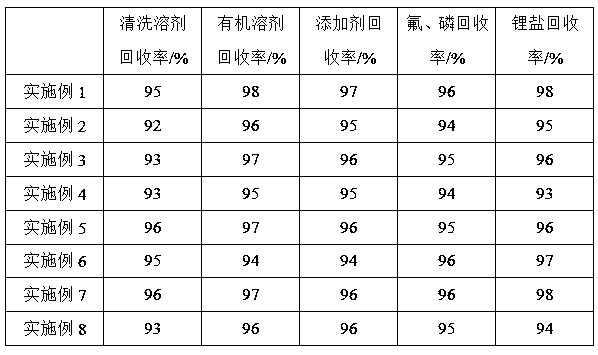

Full recovery method of waste lithium ion battery electrolyte

ActiveCN110203949ASimple processHigh feasibilityCalcium/strontium/barium fluoridesWaste accumulators reclaimingRecovery methodOrganic solvent

The invention provides a full recovery method of waste lithium ion battery electrolyte, aiming at recovering valuable lithium salts, organic solvents and additives in the waste electrolyte, and recovering harmful impurities such as fluorine, phosphorus and the like after harmless treatment. According to the invention, after cleaning, cleaning solvent recovery, organic solvent and additive recovery, fluorine and phosphorus recovery and lithium salt recovery processes, lithium salt is finally recovered in the form of lithium carbonate, organic solvent and additive are separated, purified and recycled, and fluorine and phosphorus are recovered in the form of precipitation. The process is simple and feasible. Waste electrolyte is fully recycled and has no pollution to the environment. The recovery rate of components of waste electrolyte is over 95%, which is suitable for large-scale industrial application.

Owner:中科行发医疗科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com