Perovskite quantum dot material and preparation method thereof

A technology of quantum dot materials and perovskite, which is applied in the direction of luminescent materials, preparation of amino compounds, chemical instruments and methods, etc., to achieve the effects of high stability, simple operation steps and short reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

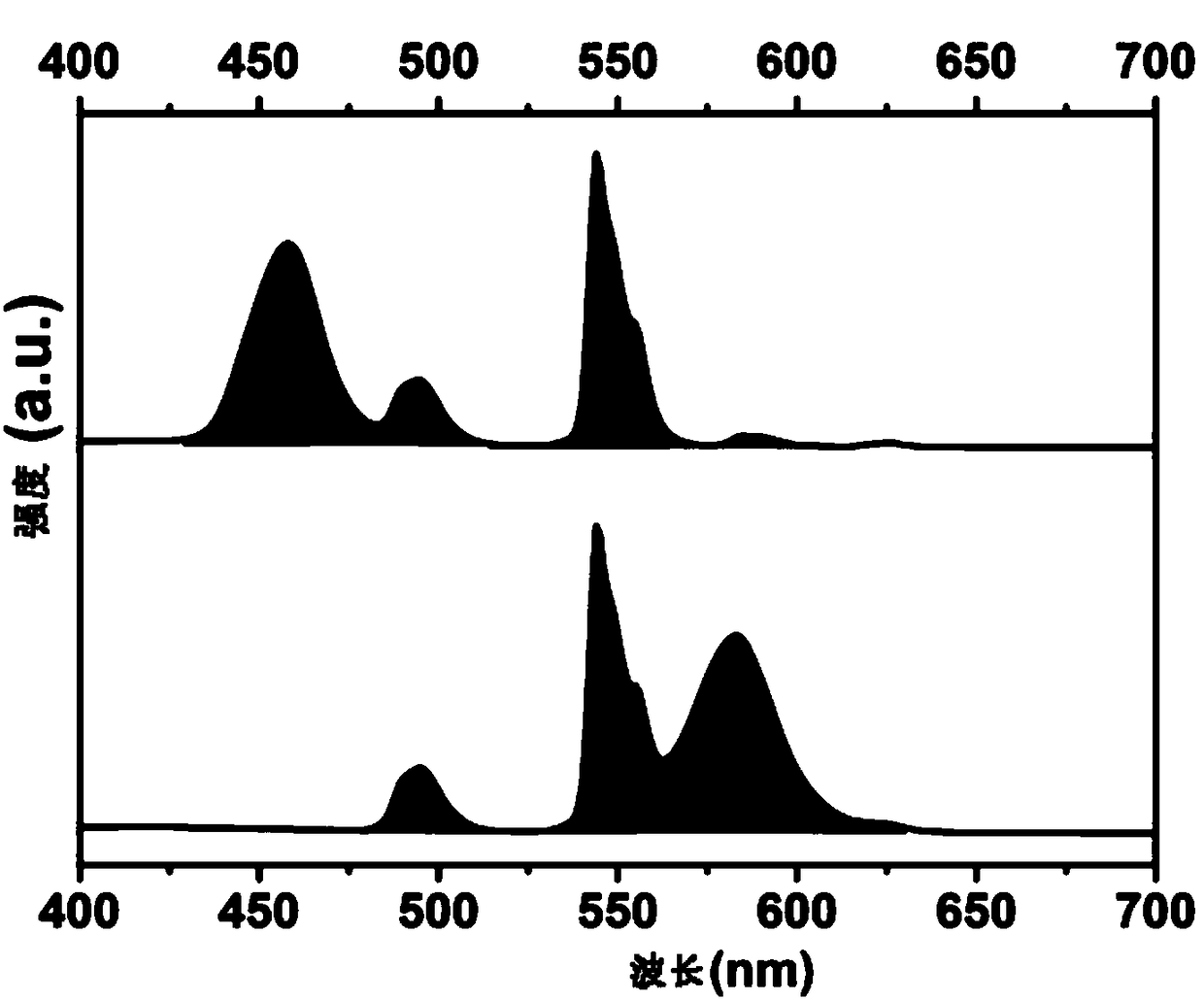

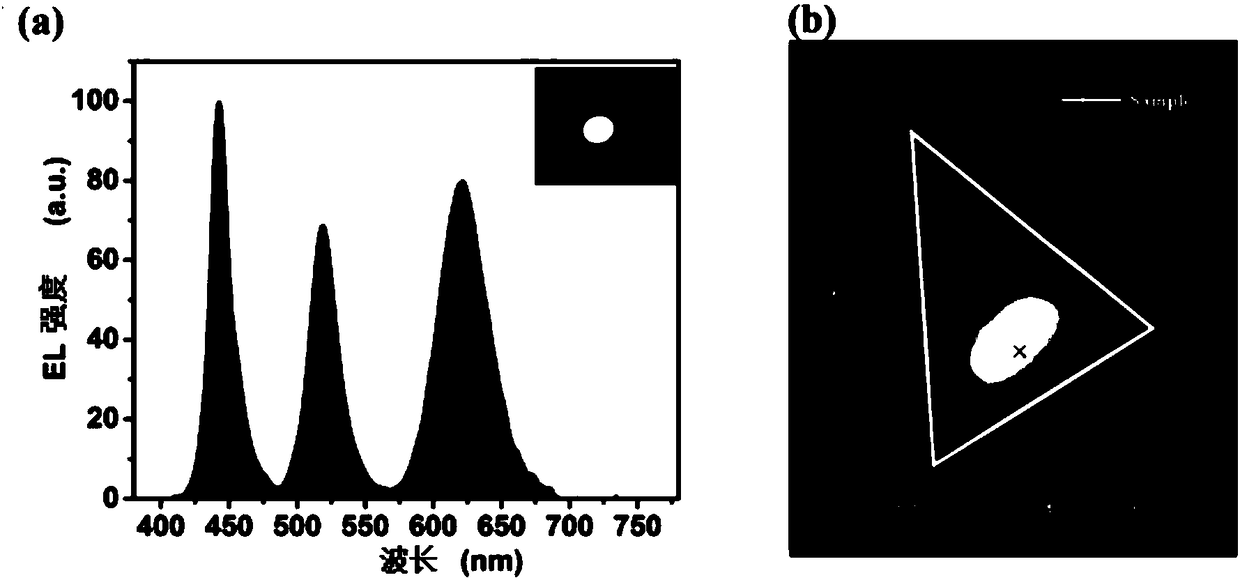

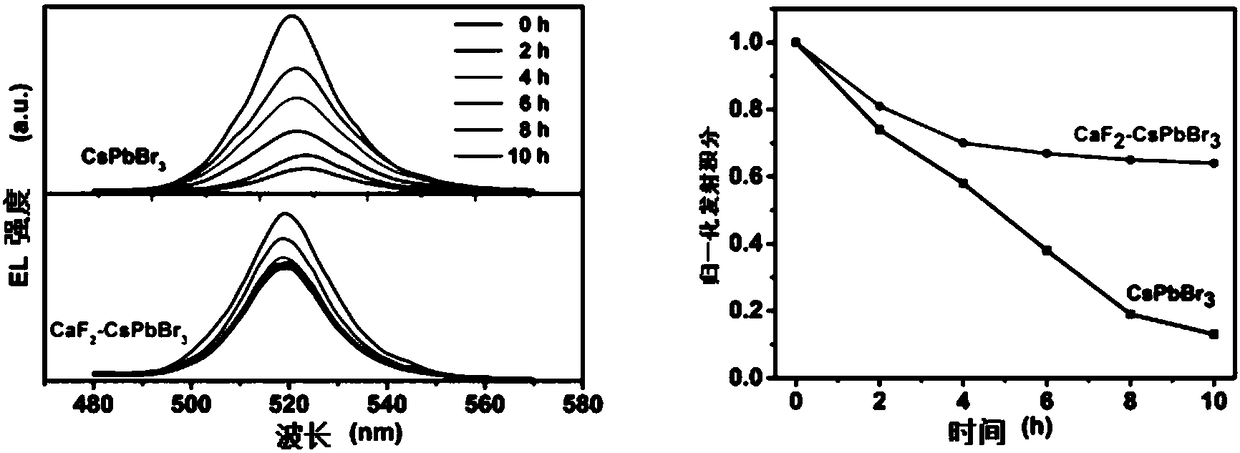

Image

Examples

Embodiment 1

[0040] A kind of inorganic cesium lead halide quantum dot CsPbX 3 , prepared by the following steps:

[0041] (1) 81.5mg Cs 2 CO 3 , 0.25mL oleic acid and 4mL octadecene were placed in a 25mL three-necked flask, degassed at 120°C for 30min, then heated to 150°C under nitrogen protection, and reacted until Cs 2 CO 3 Dissolving to obtain the precursor solution of Cs-OA;

[0042] (2) 69mg PbBr 2 Add it to the mixed solution of 0.5mL oleic acid, 0.5mL oleylamine and 5mL octadecene, degas at 120°C for 30min, then raise the temperature to 180°C under the protection of nitrogen, and quickly inject 0.4mL of the obtained product in step 1) into it Cs-OA precursor solution, and immediately quench the reaction with an ice-water bath, and then centrifuge at 10000r / min for 10min to obtain CsPbBr 3 .

Embodiment 2

[0044] A kind of inorganic cesium lead halide quantum dot CsPbX 3 , prepared by the following steps:

[0045] (1) 81.5mg Cs 2 CO 3 , 0.25mL oleic acid and 4mL octadecene were placed in a 25mL three-necked flask, degassed at 120°C for 30min, then heated to 150°C under nitrogen protection, and reacted until Cs 2 CO 3 Dissolving to obtain the precursor solution of Cs-OA;

[0046] (2) 29 mg of PbBr 2 and 55 mg of PbI 2 Add it to the mixed solution of 0.5mL oleic acid, 0.5mL oleylamine and 5mL octadecene, degas at 120°C for 30min, then raise the temperature to 180°C under the protection of nitrogen, and quickly inject 0.4mL of the obtained product in step 1) into it Cs-OA precursor solution, and immediately quench the reaction with an ice-water bath, and then centrifuge at 10000r / min for 10min to obtain CsPb(Br 0.4 I 0.6 ) 3 .

Embodiment 3

[0048] An inorganic-organic hybrid perovskite quantum dot MAPbX 3 , prepared by the following steps:

[0049] (1) 17.9mg MABr, 73.4mg PbBr 2 Dissolved in a mixed solvent of 0.5mL oleic acid, 20μL octylamine and 5mL DMF to obtain a precursor solution;

[0050] (2) Take 200 μL of the precursor solution and slowly drop it into 25 mL of toluene, stir vigorously and then centrifuge at 7000r / min for 3min to discard the precipitate, and centrifuge the supernatant again at 15000r / min for 10min to obtain inorganic-organic hybrid perovskite Quantum dot MAPbBr 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com