Patents

Literature

150results about How to "Solve the problem of land occupation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

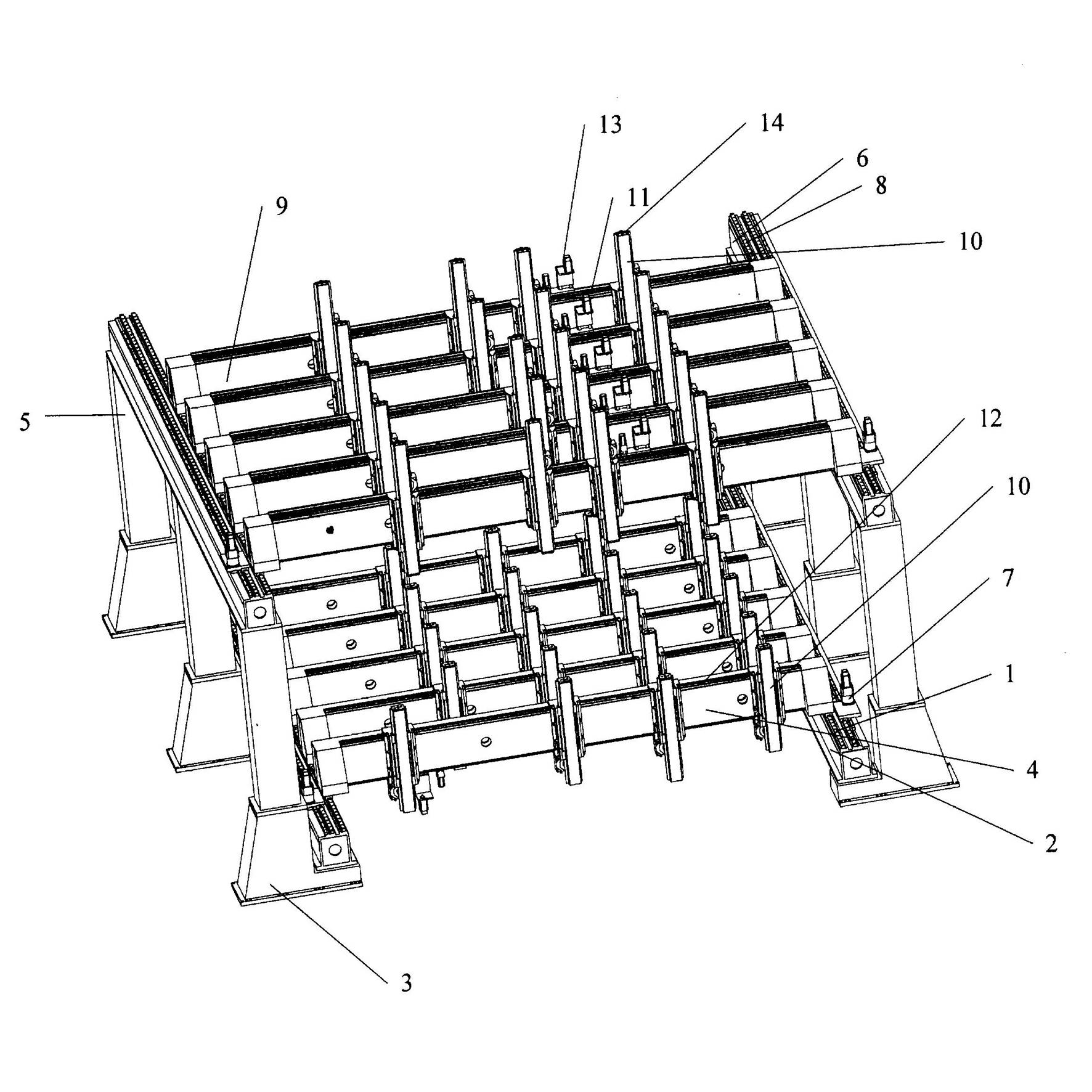

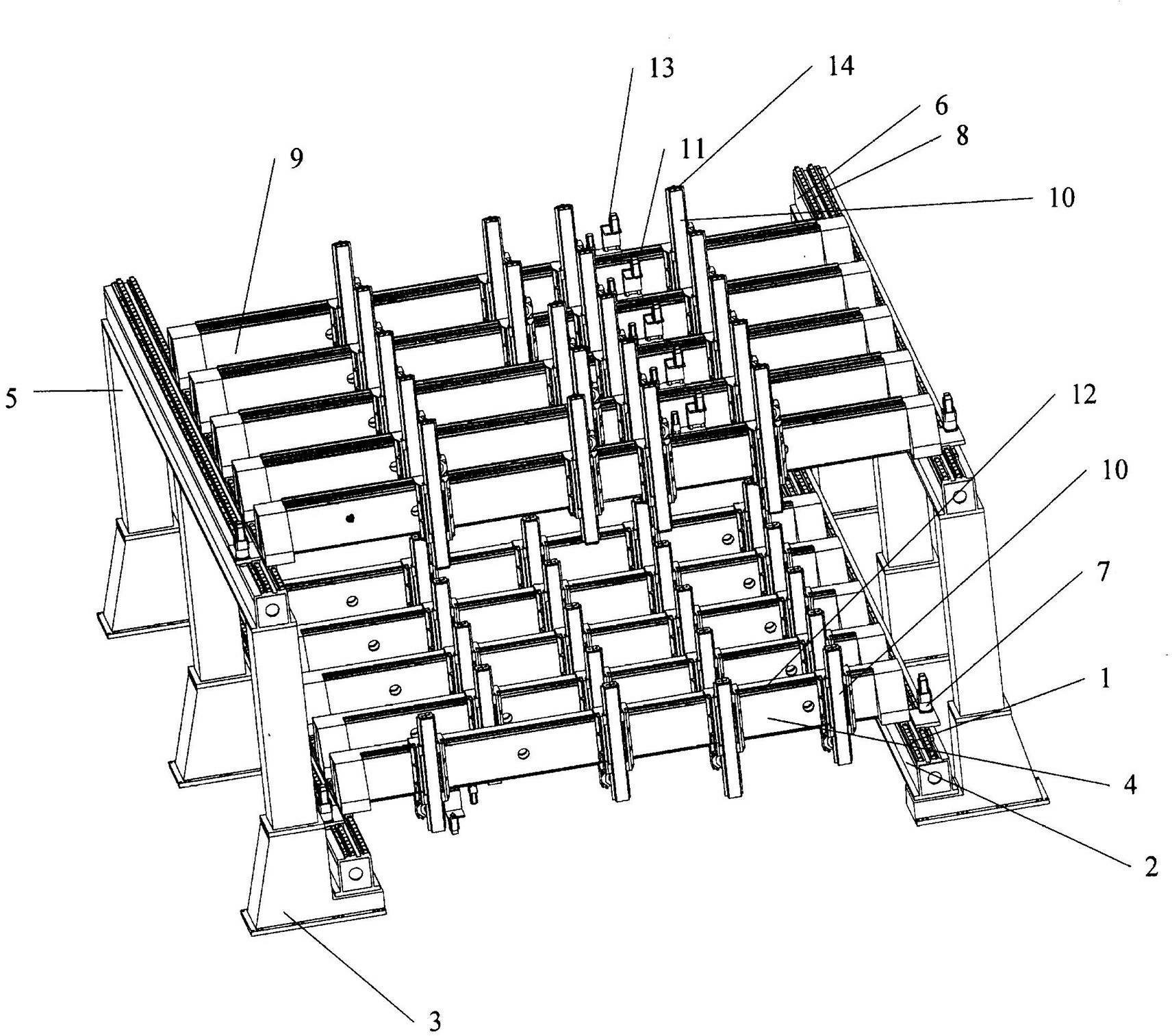

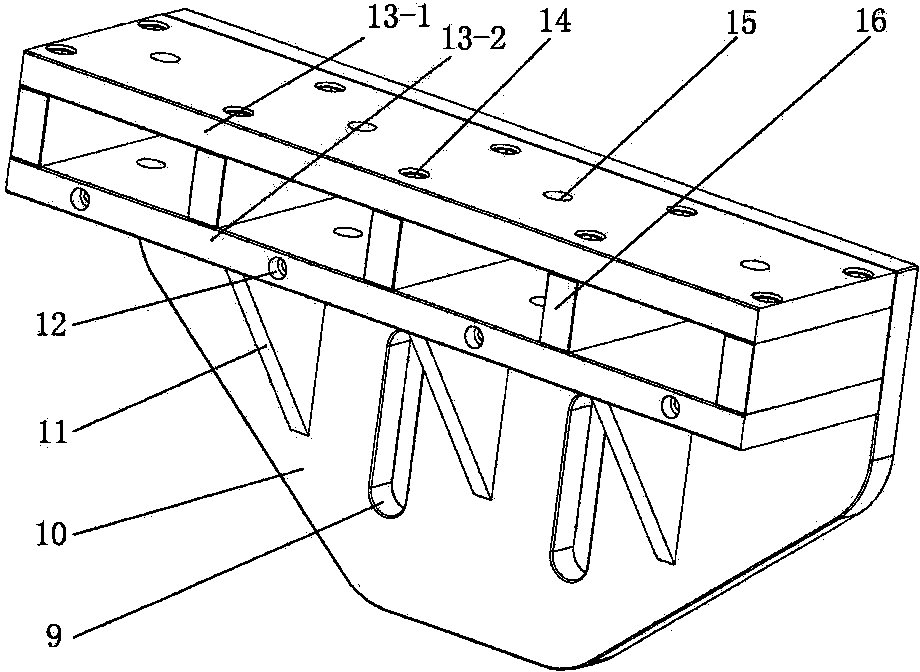

Flexible assembling tooling

InactiveCN102430993ASolve the problem of land occupationImprove assembly manufacturing efficiencyWork holdersAircraft assemblyModularityAirplane

The invention relates to a flexible assembling tooling. Six framework bases are divided into two groups, a framework upright column is arranged on the upper portion of each framework base, each row of framework upright columns is connected with a framework crossbeam, longitudinal guide rails I are arranged on upper surfaces of the framework crossbeams and connected mutually by upper movable crossbeams and horizontal linear guide rails II, a supporting framework is disposed at the inner side end of each group of framework bases, the supporting frameworks are connected with lower movable crossbeams by linear guide rails II, horizontal linear guide rails II are disposed on the lower movable crossbeams, and four modular positioning units are arranged on each of the horizontal linear guide rails and the horizontal linear guide rails II. The flexible assembling tooling can position main force bearing frames of afterbodies of various types of military planes by means of adjusting and reconstructing various modular positioning units, accordingly, the tooling for assembling the planes is used for various structural assembling modes, assembly and manufacture efficiency of the planes are greatly improved, manufacturing cost of the planes is saved, and simultaneously, the problem of large occupied area of an existing tooling is solved.

Owner:SHENYANG AIRCRAFT CORP

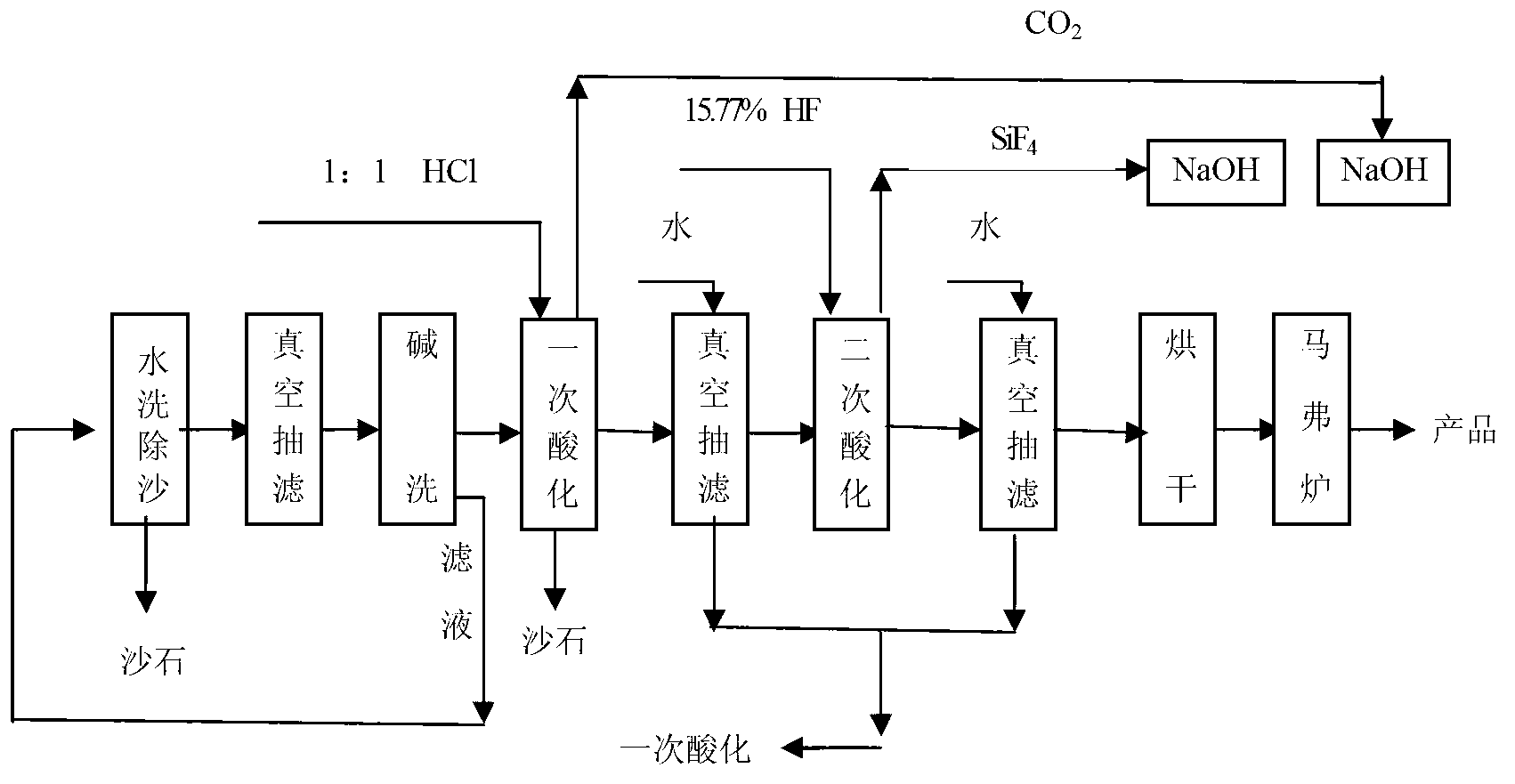

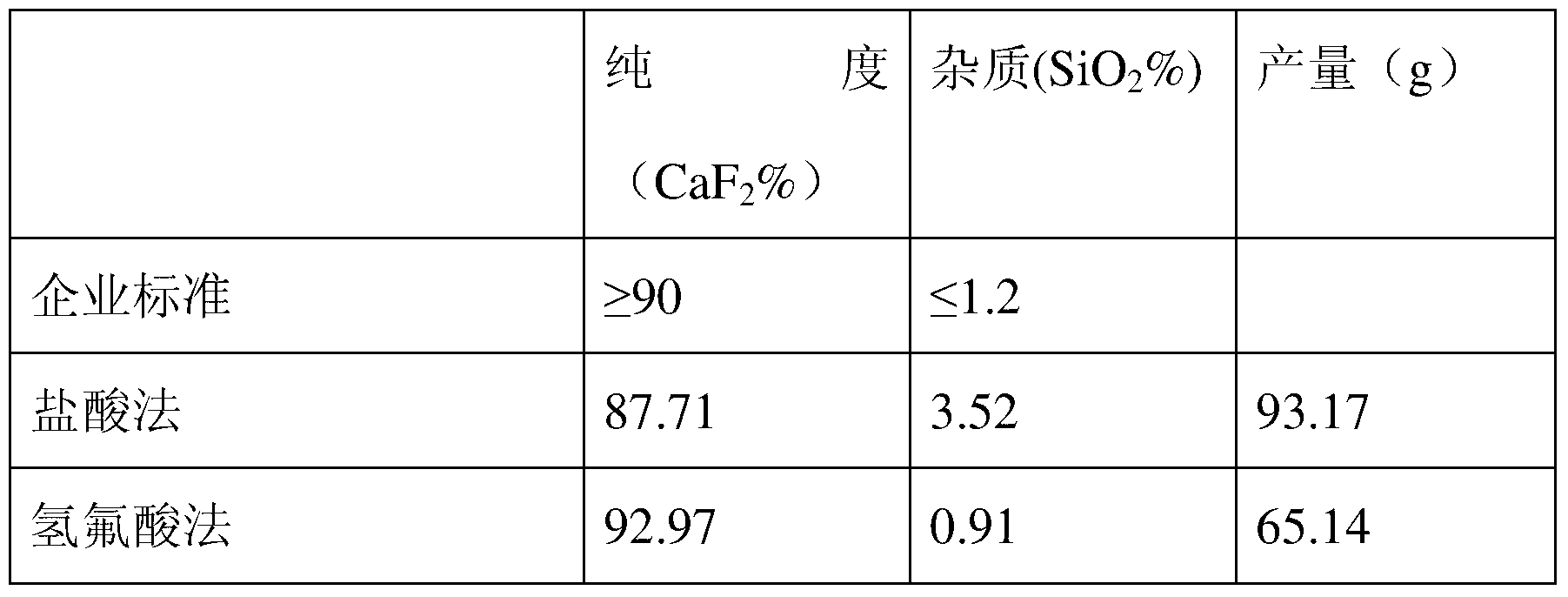

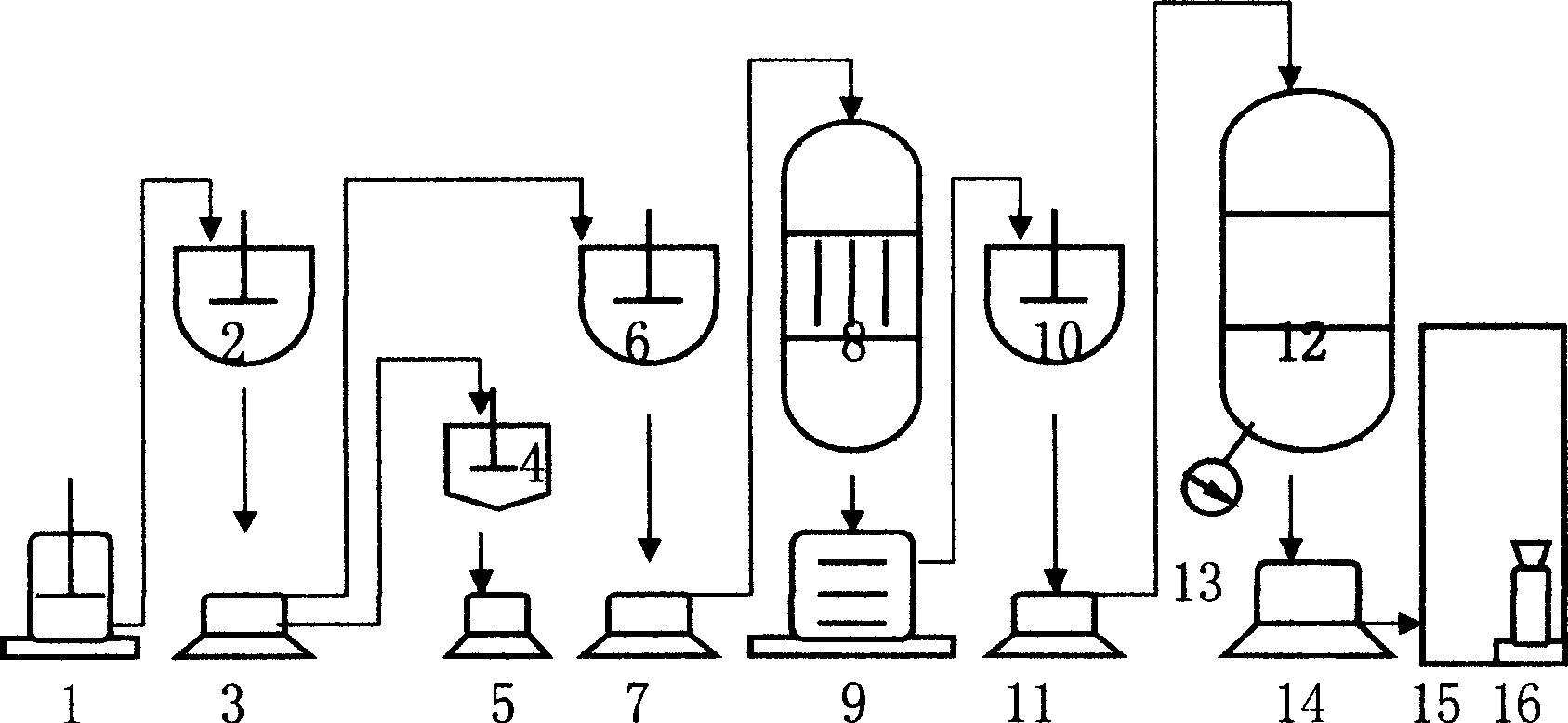

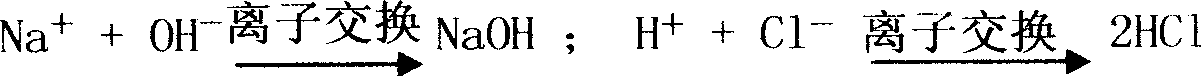

Method of producing calcium fluoride through bottom mud generated by fluoride waste

InactiveCN103241758AReduce pollutionSolve the problem of land occupationCalcium/strontium/barium fluoridesSolubilitySulfate

The invention discloses a method of producing calcium fluoride through bottom mud generated by treating industrial fluoride waste. The method comprises the following step of: separating the ingredients according to different solubility of bottom mud in acids through a one-step alkaline washing and two-step acidification separating method to obtain a calcium fluoride product; the treatment step comprises: alkaline washing, primary acidification separating, secondary acidification separating, drying and burning; in the alkaline washing procedure, a sodium carbonate solution acts with the bottom mud to convert calcium sulfate in the bottom mud into calcium carbonate; the bottom mud is used as a raw material in the primary acidification separating procedure; filtrate obtained in the secondary acidification separating procedure is mixed with washing water to serve as an acid source of the primary acidification; a new acid serves as the acid source of the secondary acidification; and an obtained filter cake is treated in the drying and burning steps. The method provided by the invention both can be used for solving the area occupation and environmental pollution problems of bottom mud produced by treating the industrial fluoride waste, effectively utilizing the fluorine resource in the bottom mud and providing the calcium fluoride product having utilization value.

Owner:崔岷

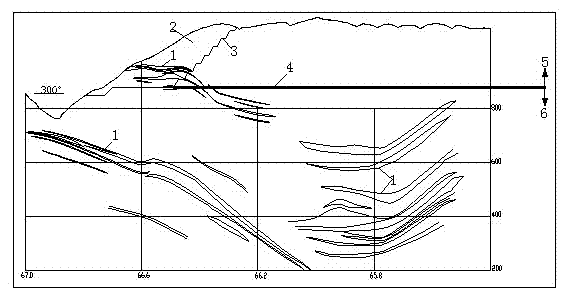

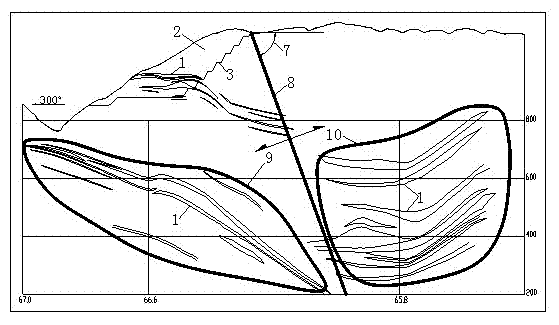

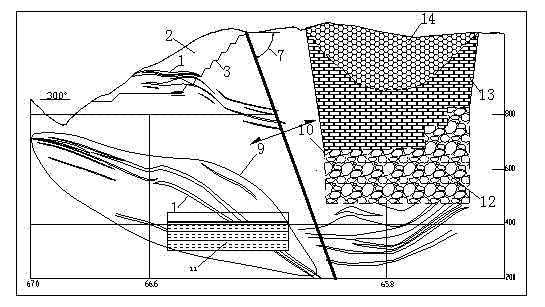

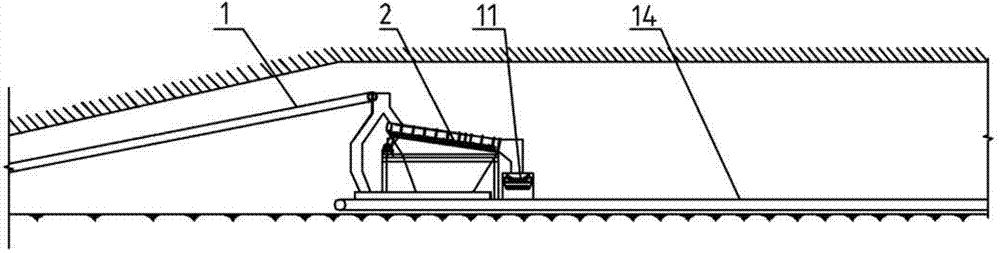

Open pit and underground space-time synchronous mining method for multiple-ore body

ActiveCN103590830ASafe miningGuaranteed thicknessUnderground miningSurface miningOpen-pit miningTime space

The invention discloses an open pit and underground space-time synchronous mining method for a multiple-ore body. According to the technical scheme, the method comprises the following steps: marking the demarcation line of the ore bodies at the shallow and deep positions so as to divide the multiple-ore body into a shallow-position ore body and a deep-position ore body according to an economical and reasonable stripping ratio; delineating the demarcation line of an open-pit mining protection zone according to a moveable angle (7) determined by underground mining by taking the largest demarcation ring of the open-pit mining as a protection line, wherein the deep-position ore body in the protection zone is a filling-process mining zone section (9) and the deep-position ore body outside the protection zone is a caving-process mining zone section (10); filling the waste stone stripped in open pit back to a waste stone back filled region (14) in a rubber belt conveying manner and carrying out cemented filling on the dead zone of the filling-process mining zone section (9) with tailings so as to form a tailings cemented filling region (11). According to the method, the technological characteristics of different mining manners such as open-pit mining, filling-process milling and caving-process mining are organically combined, so that the open-pit, underground space-time synchronous, environment-friendly and efficient mining of the multiple-ore body can be realized.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES

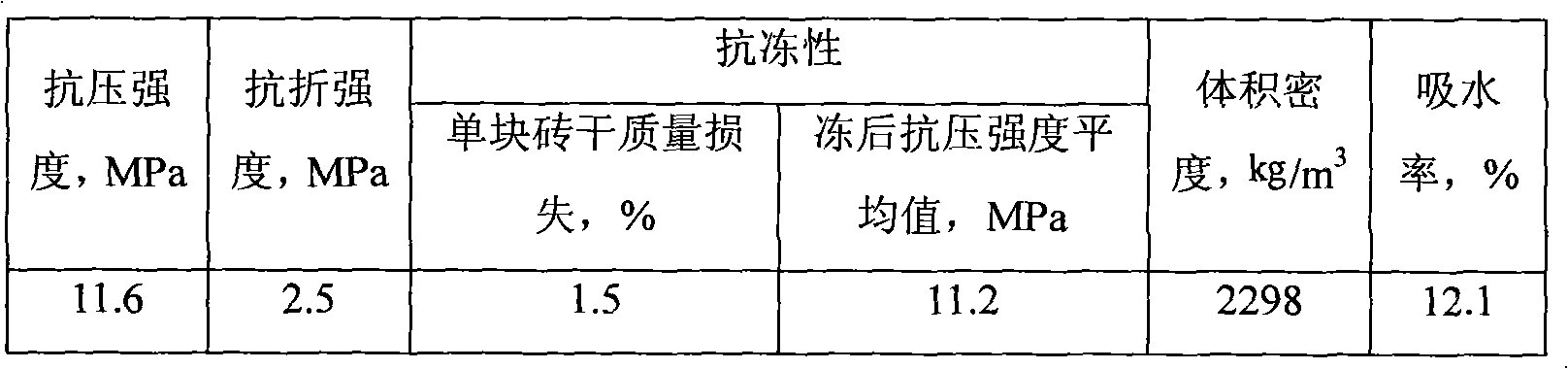

Method for producing baking-free slag bricks by using steel slag sludge of rotating furnace

ActiveCN101927524AReduce free calcium oxide contentLow iron contentSolid waste managementMixing operation control apparatusBrickSlag

The invention relates to a method for producing baking-free slag bricks by using steel slag sludge of a rotating furnace. The bricks are produced by taking tailings and tailing sludge of the rotating furnace as raw materials, taking slag silicate cement as an auxiliary material, adding a small amount of water into the raw materials and the auxiliary material, stirring the raw materials and the auxiliary material to uniformly mix the raw materials and the auxiliary material, pressing the mixture on a brick press, and naturally curing the pressed mixture. The bricks comprise the following compoennts in part by weight: 20 to 50 parts of tailings of the rotating furnace, 50 to 80 parts of tailing sludge of the rotating furnace and 0 to 5 parts of slag silicate cement. The adding amount of the added water is 0 to 5 percent of the total weight of the raw materials. The baking-free bricks are produced by taking the tailings and the tailing sludge of the rotating furnace as main raw materials, adding a small amount of slag silicate cement and water into the main raw materials, and pressing the mixture. The raw materials do not need to be treated and can be directly used and the mouled product is naturally cured, so that the energy is saved; and no any equipment is added, so that the problem that the tailings of the rotating furnace and the tailing sludge of the rotating furnace occupy space and pollute environment is solved by producing the baking-free slag bricks.

Owner:鞍钢绿色资源科技有限公司

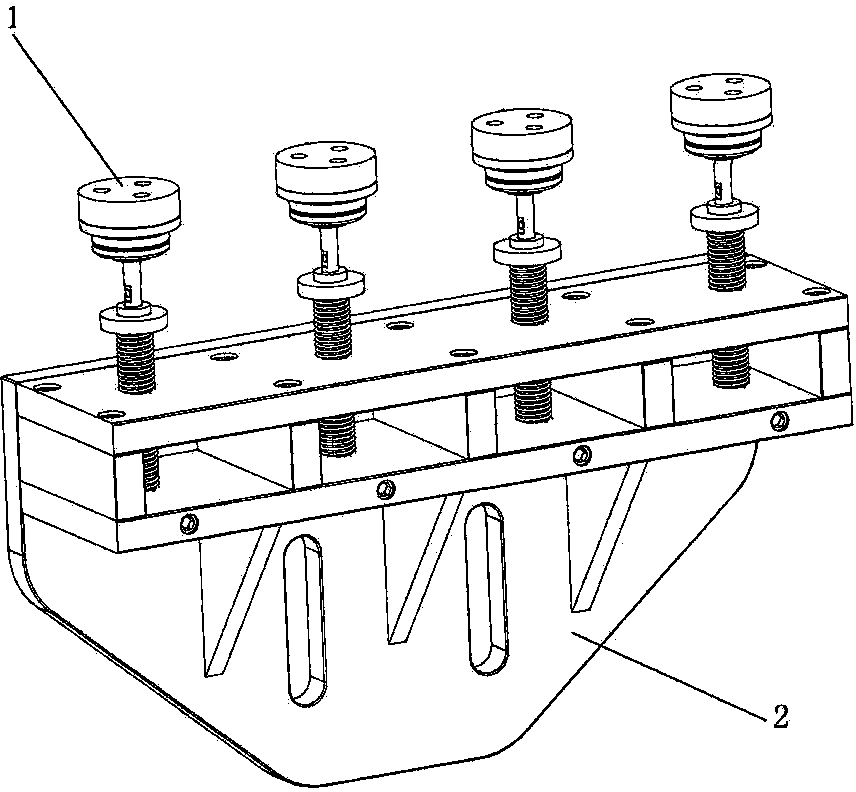

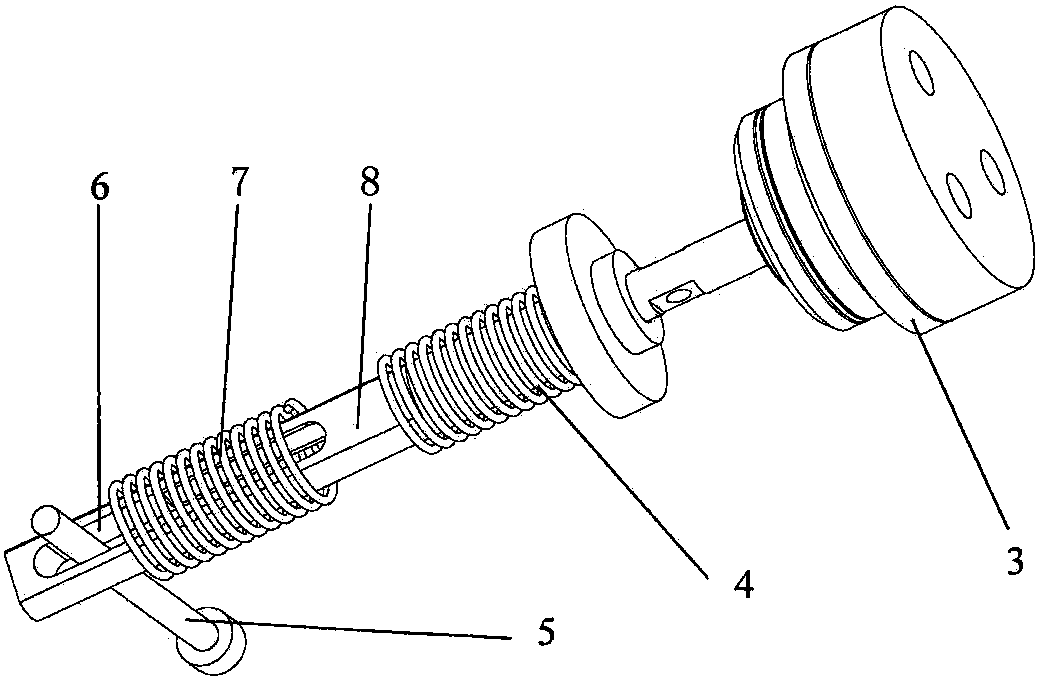

Self-adaptive flexible supporting and positioning mechanism

ActiveCN103447988ASupport positioning realizationMeet the needs of multi-state supporting positioningWork holdersAircraft assemblyEngineeringSelf adaptive

The invention discloses a self-adaptive flexible supporting and positioning mechanism which comprises self-adaptive flexible positioning units and a supporting frame component. The self-adaptive flexible positioning units are connected with the supporting frame component. Through supporting and positioning of the supporting frame component and adjusting of the self-adaptive flexible positioning units, a supporting and positioning function for riveting and assembling of drilling machines of various airplane models by using one supporting and positioning mechanism can be realized, universality and convenience of a supporting positioner are realized, airplane manufacturing cost is saved, the problem that space is occupied by tools is solved to a large extent, riveting, assembling and manufacturing efficiency of an airplane drilling machine is improved, and the self-adaptive flexible supporting and positioning mechanism is simple and reliable in structure.

Owner:SHENYANG AIRCRAFT CORP

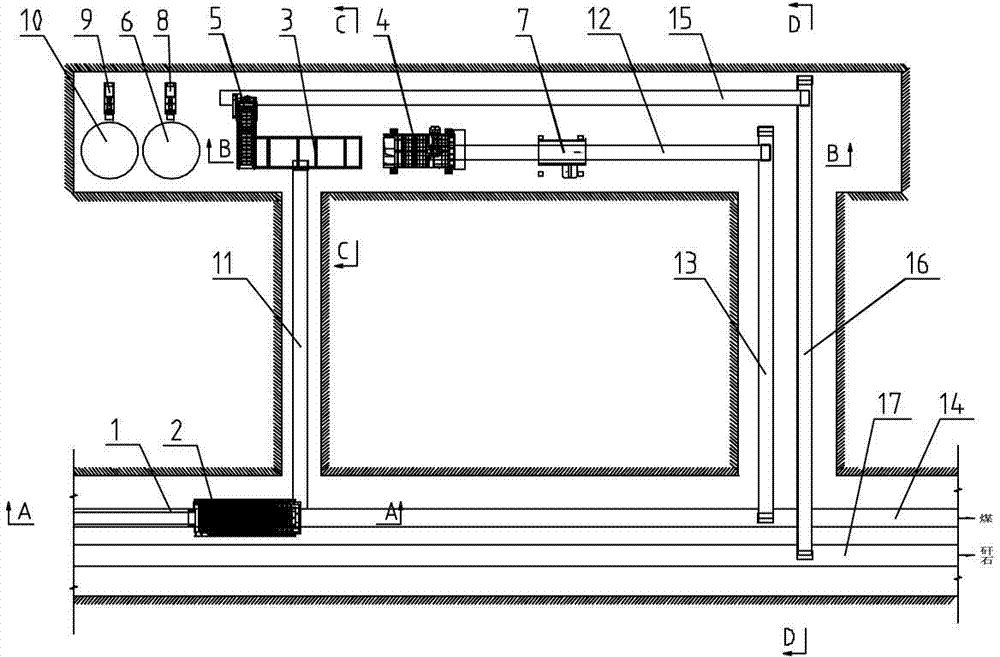

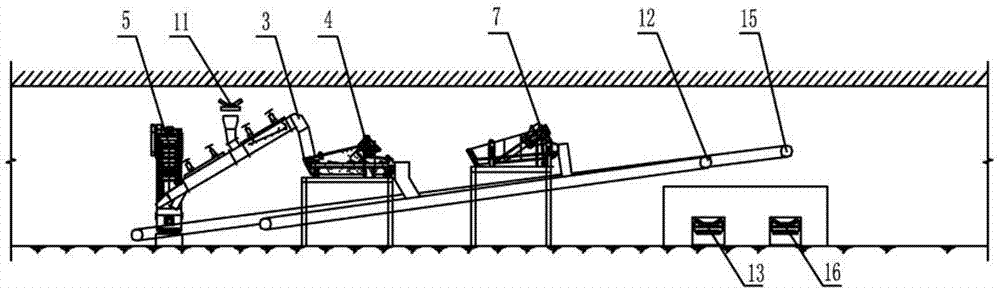

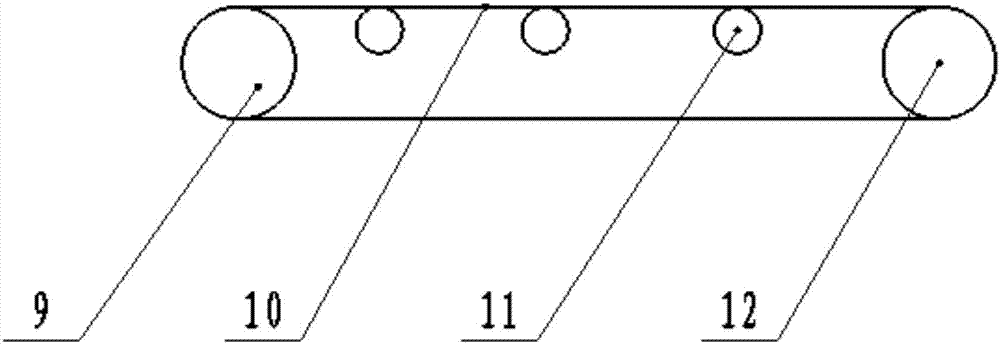

Flowing current separation process coal mine underground gangue dumping system

ActiveCN103480482AIncrease production capacityImprove efficiencyWet separationEngineeringBucket elevator

The invention relates to a flowing current separation process coal mine underground gangue dumping system. The technical scheme includes that a run-of-mine coal conveyor is mounted on one side of a feeding end of a roller screen, two ends of an on-screen selected raw material coal conveyor are connected with a front-screen chute of the roller screen and a feeding port of a flowing current separation machine respectively, a block coal of the flowing current separation machine is connected with a dewatering screen, an oversize material discharging end of the dewatering screen is sequentially connected with a block coal conveyor, a block coal transferring conveyor and a pulverized coal conveyor, a high frequency screen is mounted in the middle of the block coal conveyor, under-screen water of the dewatering screen is connected with a concentration tank through a pipeline, the concentration tank is connected with the high frequency screen, a gangue outlet of the flowing current separation machine is connected with a bucket elevator, a discharging end of the bucket elevator is sequentially connected with a gangue conveyor, a gangue transferring conveyor and a gangue warehousing conveyor, under-screen water of the high frequency screen and overflow of the concentration tank are connected with a circulating water tank through pipelines respectively, and the circulating water tank is connected with a water inlet of the flowing current separation machine through a circulating water pump and a pipeline. The flowing current separation process coal mine underground gangue dumping system is simple in process, good in separation effect, low in power consumption and low in operating cost.

Owner:沈阳科迪通达工程技术有限公司

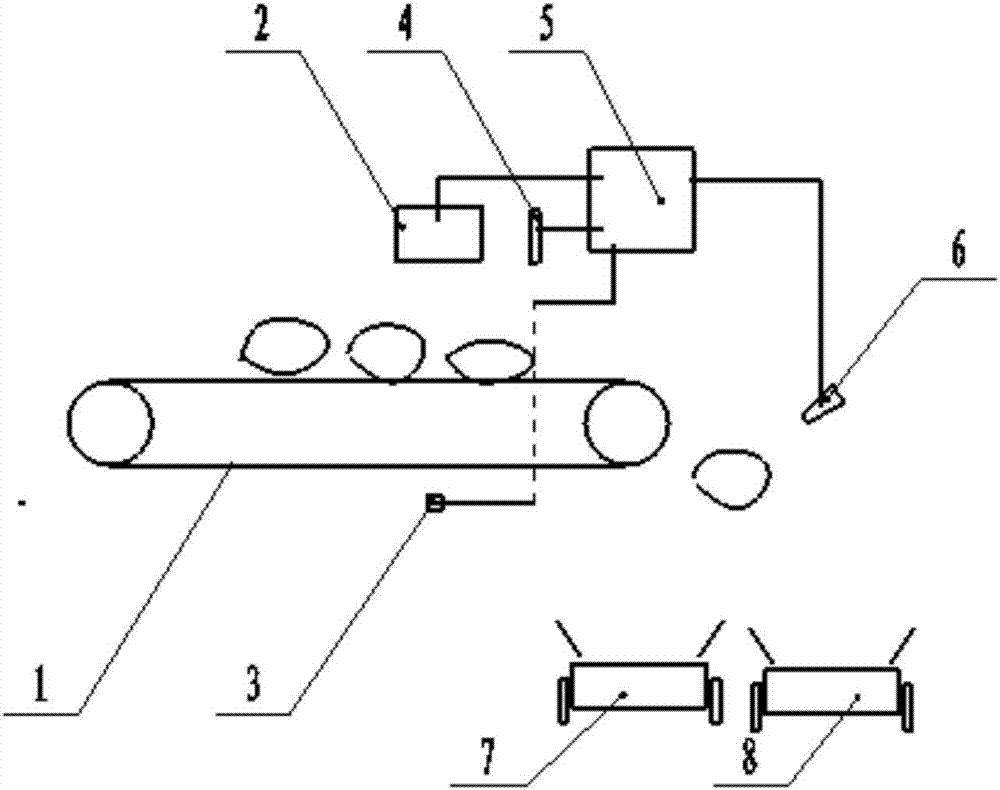

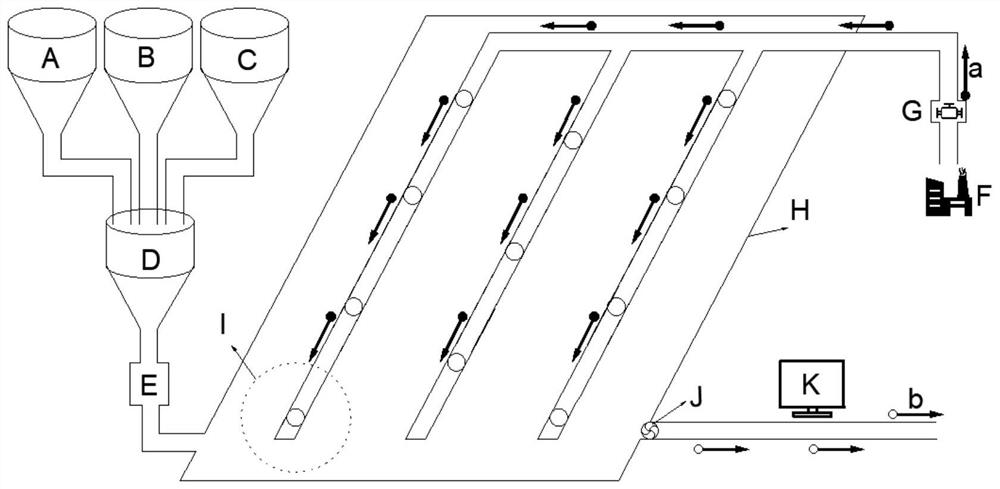

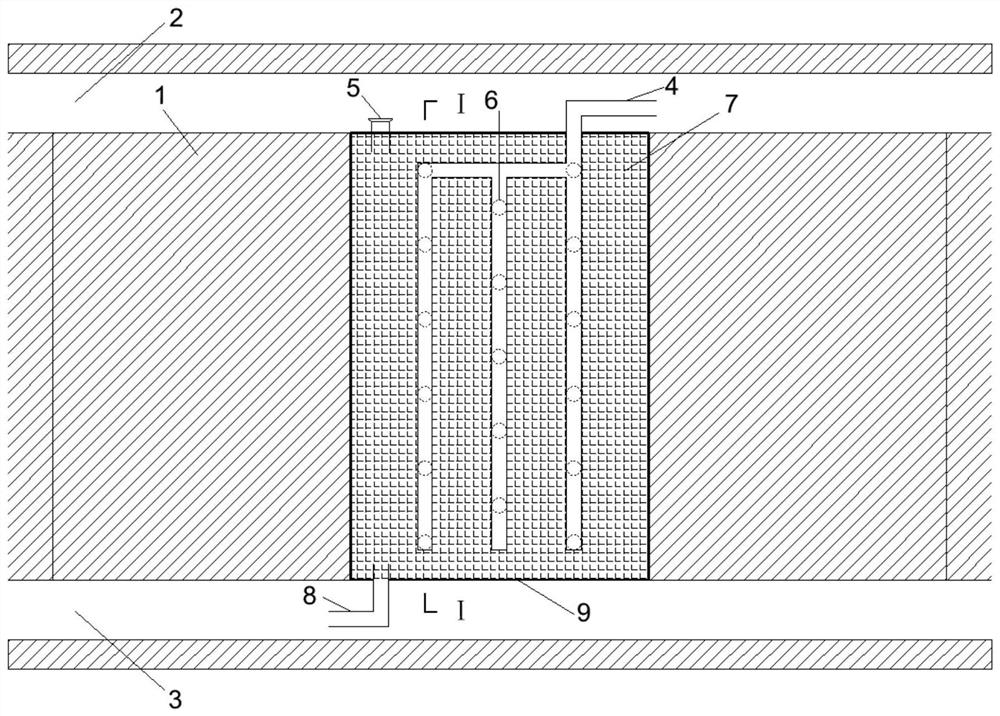

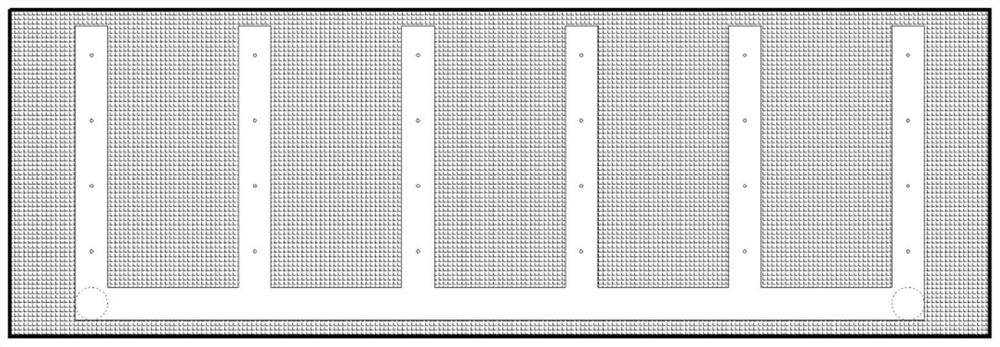

Intelligent dry method gangue discharge system and method applied to underground coal mine

InactiveCN106862103ASolve production practice problemsNot affected by particle sizeSortingX-rayKinetic energy

The invention provides an intelligent dry method gangue discharge system and method applied to an underground coal mine. The intelligent dry method gangue discharge system and method are suitable for preferential separation of underground coal gangue, on-line identification of coal and the coal gangue and sorting based on different densities of the coal and the coal gangue through the synergistic effect of an X-ray and lattice detector and an ultrasonic ranging device. The intelligent dry method gangue discharge system and method are simple in process, high in intelligent level, good in separation effect and small in investment. With the adoption of the intelligent dry method gangue discharge system and method, the gangue can be discharged underground directly on the spot and does not need to be conveyed to the ground. Kinetic energy consumption and transport cost are reduced, due to the fact that the gangue is not lifted out of a well, ineffective transport can be canceled, transport expense is reduced, and transport cost is reduced.

Owner:TANGSHAN SHENZHOU MFG

Treatment method of newly built high way railway engineering soft foundation

InactiveCN1948626AImprove bearing capacityImprove stabilityRoads maintainenceSoil preservationLarge particleSilt

This invention relates to a new highway and railway projects soft ground process method. The method squeezes soft mud opening in the face of weak foundation through the following steps :a,equipments filling stone with the largest particle diameter of not more than 60cm; b,spreads 40-70cm thick layer stone in the soft ground surface-paved; c,adopts hammer ram, use hammer ram tamping force to tamping stone layer by point tamping or separate tamping and plus tamping, tamping out 2-3m tamping pit in selected tamping spots ; d,for every tamping pit ,follows filling -- tamping.,filling -- tamping until the tamping the settlement is in less than 2-7 after consecutive 2-3 tamping, and then stops tamping. This invention squeezes the soft and mud silting open in the soft surface of 2-6 meters, achieves the purpose of squeezing mud replacement, and finally forms hard shell replacement layer of 2-6 m thickness, enhances the bearing capacity of the ground, increases the stability of the ground.

Owner:周洪文 +1

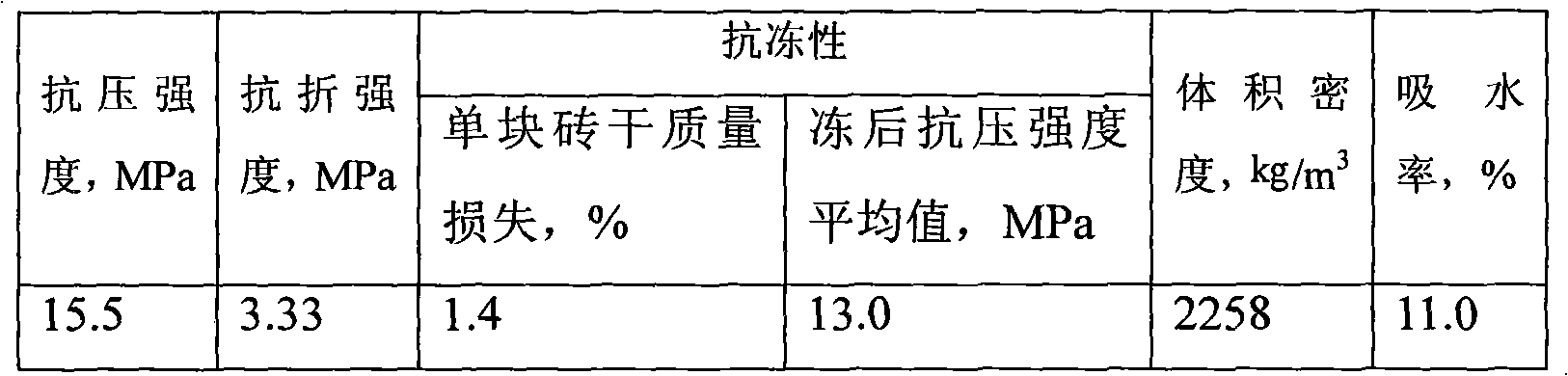

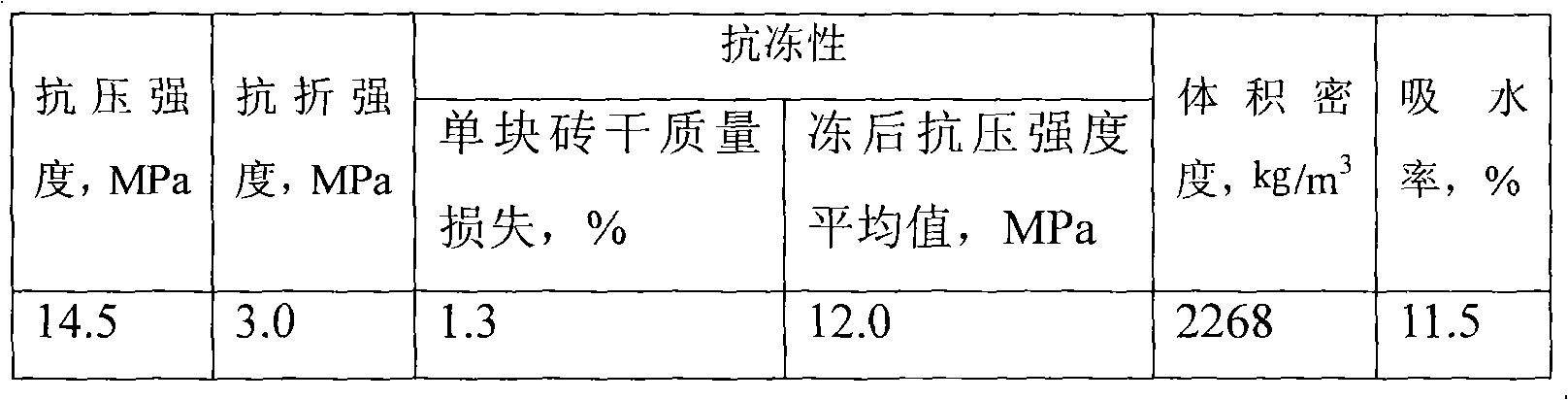

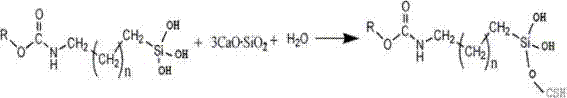

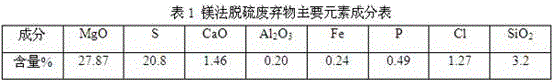

Semidry-process sintering desulphurization slag autoclaved building block and production method thereof

InactiveCN102674799ASolve the problem of land occupationSolve secondary pollutionCeramic shaping apparatusBrickSlag

The invention relates to a semidry-process sintering desulphurization slag autoclaved building block and a production method thereof. The building block is made of the following components in percent by weight in a combined autoclaving way: 5-30 percent of semidry-process sintering desulphurization ash, 30-60 percent of steel slag, 25-30 of superfine slag powder and 1-10 percent of pebble. The production method comprises the steps of vibrating and molding the components according to the percent by weight and autoclaving after molding to obtain the semidry-process sintering desulphurization slag autoclaved building block. The semidry-process sintering desulphurization slag autoclaved building block and the production method thereof have the advantages that the desulphurization ash, waste steel slag and slag of iron and steel enterprises are fully utilized, the wastes are turned into valuable things, the materials such as lime, carbide slag, binder, early strength agent and cement are not added, the energy is saved, the mixing quantity of the waste slag is high, the strength of the produced bricks are higher, the production cost is low, the product quality is high and all technical indexes satisfy the national standard on building bricks; and the treatment and disposal efficiency of the waste slag of the iron and steel enterprises is improved, the development level of secondary resources is improved, the quantity of the used cement in the building material industry can be reduced and the economic and environmental values are higher.

Owner:武钢集团有限公司

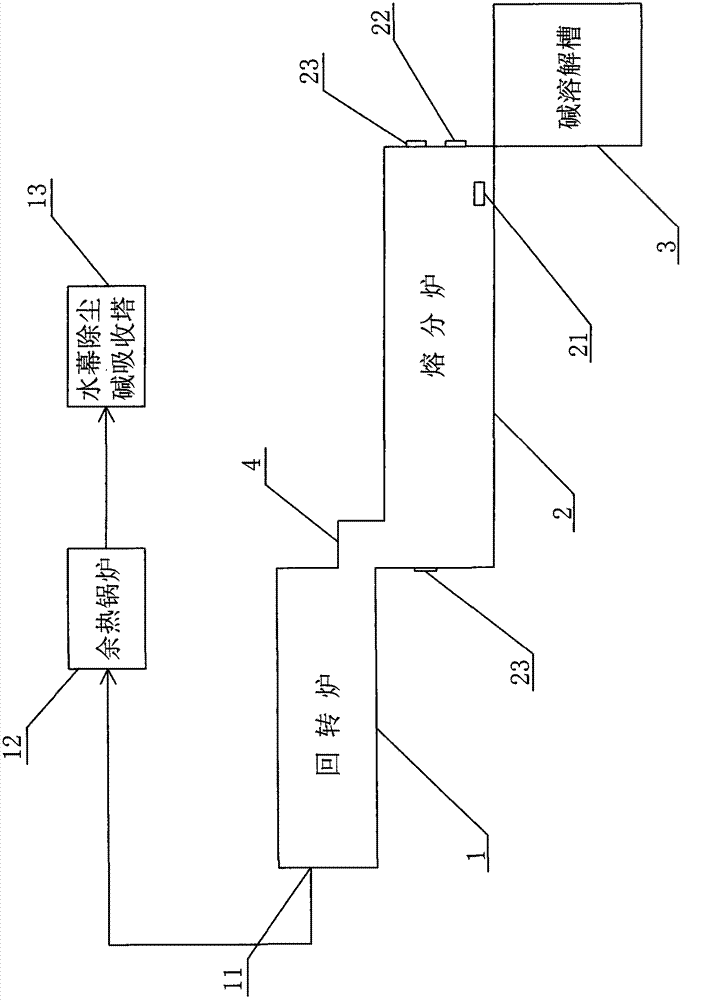

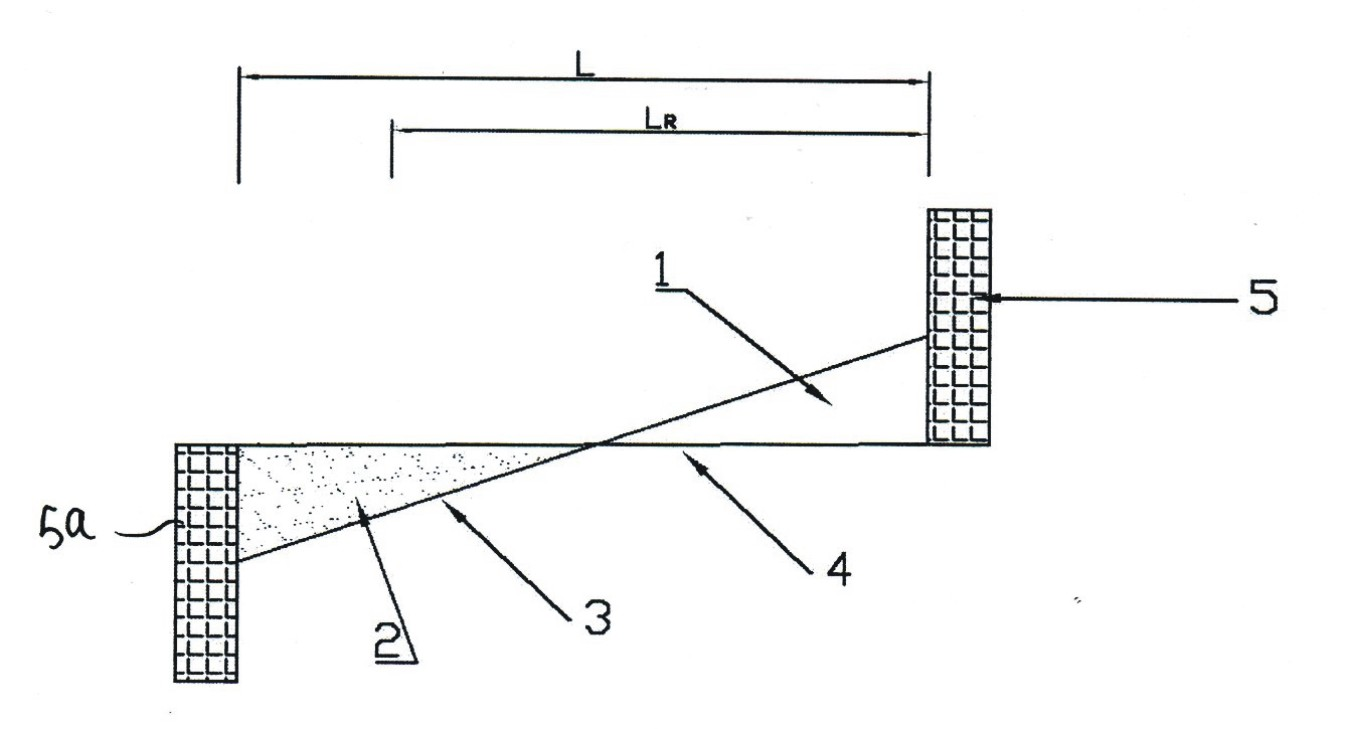

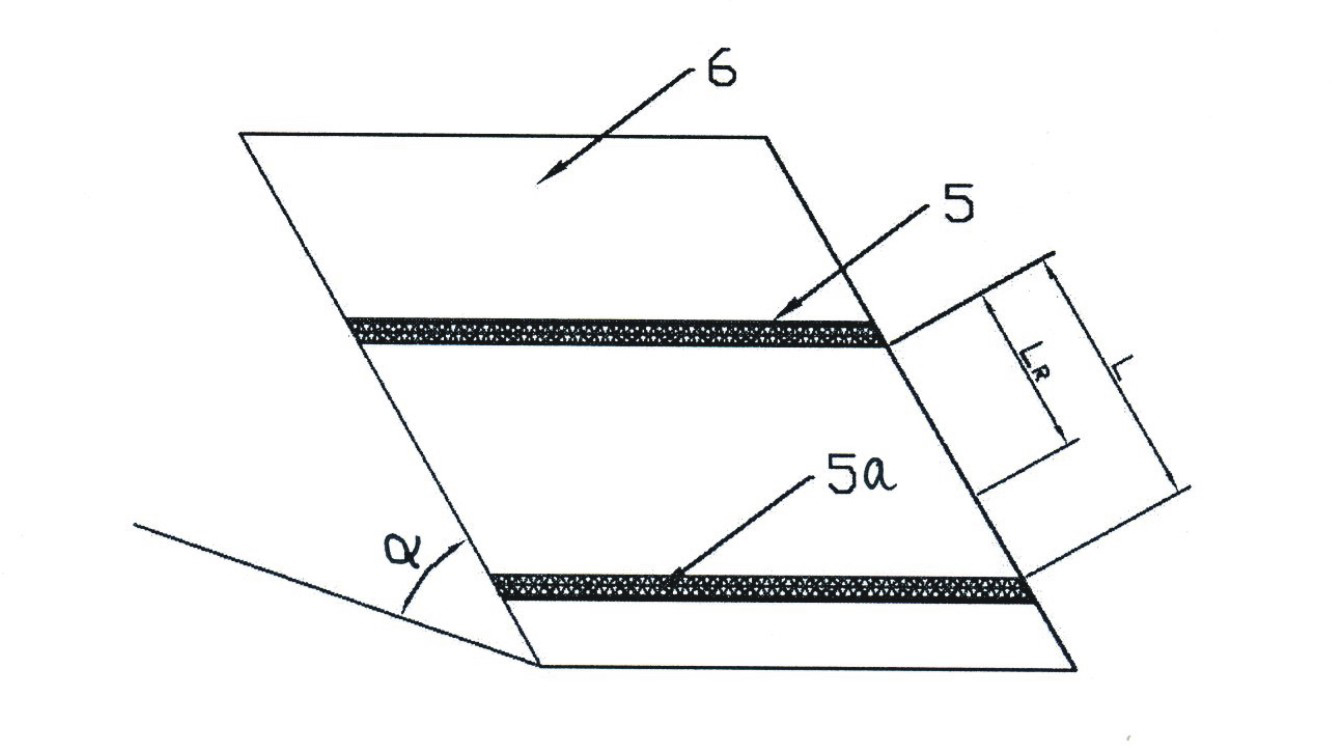

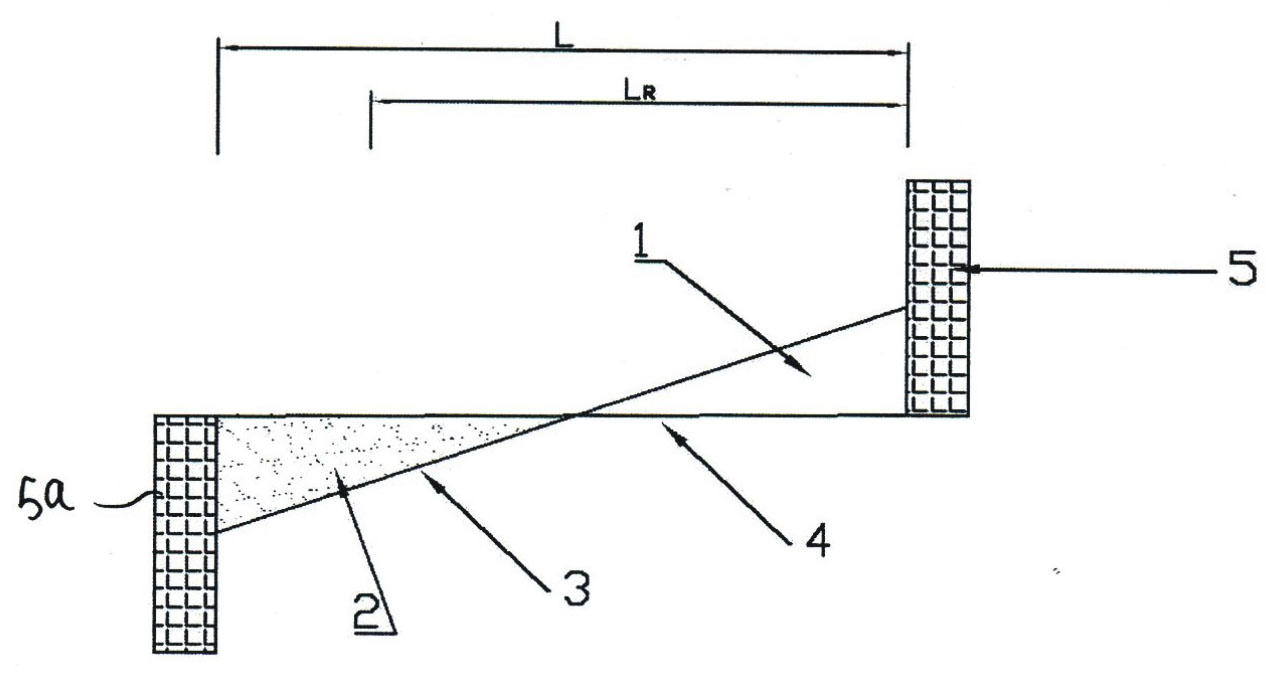

Slag-free production process using bauxite or red mud

InactiveCN102732662ASolve the problem of land occupationSolve the pollution of the environmentRotary drum furnacesProcess efficiency improvementMolten stateResource utilization

The invention provides a slag-free production process using bauxite or red mud. The method comprises the following steps: a) preparing a mixed raw material from bauxite or red mud, lime and coal in proportion; b) adding the mixed raw material into a rotary kiln for drying and pre-reduction so as to obtain a reduced material in a semi-melting state; c) adding the reduced material into a melting-separation furnace for melting and separation of slag and iron, wherein high-alumina clinker at an upper layer is discharged from a high-alumina clinker outlet, and hot molten iron at a lower layer flows out from a hot molten iron outlet; and d) allowing the high-alumina clinker discharged from the high-alumina clinker outlet to enter into an alkali dissolution tank containing a proper amount of alkali liquor and carrying out stirring and solid-liquid separation so as to obtain a sodium aluminate solution and solid light metal oxides of silicon, calcium, magnesium and titanium. The process provided in the invention has the following advantages: production cost is reduced, resource utilization of red mud is realized, alumina and iron in alumogoethite can be separated and extracted, and pollution to environment caused by generation of red mud is eradicated; separation and utilization of all the elements in bauxite and red mud are realized, operation cost is low, economic benefits are high, and the slag-free production process is green and environment friendly and has recyclicity.

Owner:胡长春 +1

Method for constructing artificially natural slope-type terrace land in Three Gorges reservoir area

The invention discloses a method for constructing an artificially natural slope-type terrace land in the Three Gorges reservoir area. The method comprises the following steps of: (1) calculating rill erosion critical slope length of a gentle slope by utilizing a rill erosion generation critical value and a tillage erosion theory; and (b) sequentially constructing sand-blocking terrace banks along the slope according to interval positions larger than the rill erosion critical slope length, wherein the bottom surfaces of all the sand-blocking terrace banks extend into soil below an original slope line, the top surfaces of all the sand-blocking terrace banks are higher than the original slope lines, and between every two adjacent sand-blocking terrace banks, the top surface of the next-stage sand-blocking terrace bank and the bottom surface of the last-stage sand-blocking terrace bank are located on the same isohypse line. The sand-blocking terrace banks are ridge-type sand-blocking terrace banks or simple civil-engineering-type sand-blocking terrace banks or plant-fence-type sand-blocking terrace banks. The method has the characteristics of low cost, easiness for popularization, high benefit and the like.

Owner:INST OF MOUNTAIN HAZARDS & ENVIRONMENT CHINESE ACADEMY OF SCI

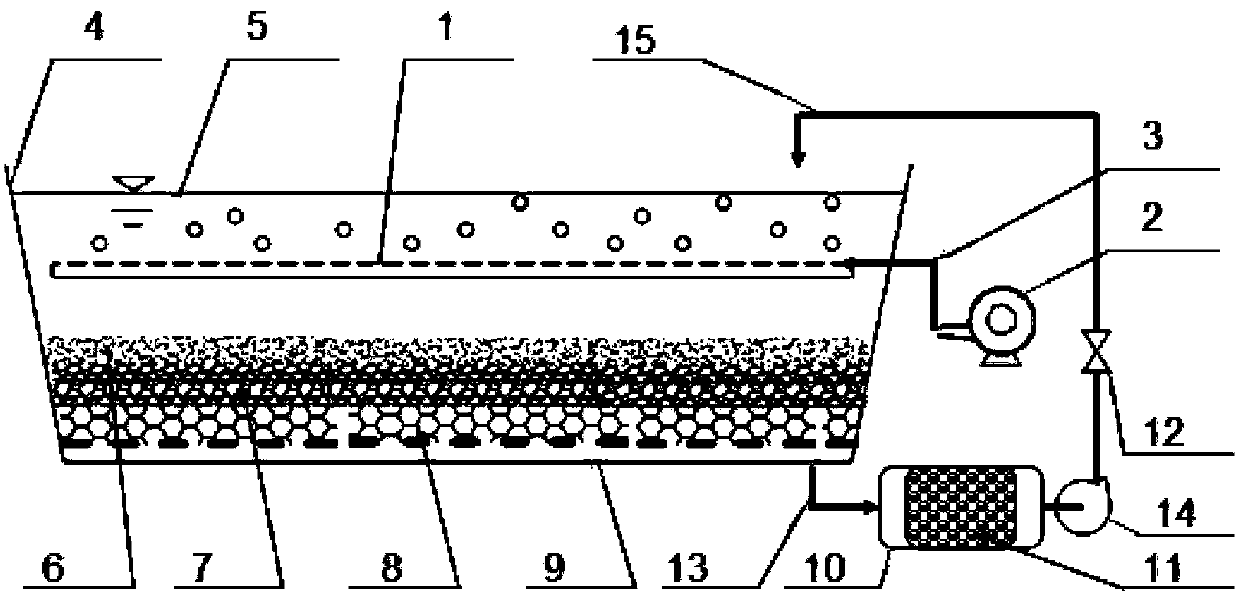

In-situ water repair method for clean aquaculture

InactiveCN103420544AEfficient purificationBiochemical improvementMultistage water/sewage treatmentAeration systemSludge

The invention relates to an in-situ water repair method for clean aquaculture. Polluted aquaculture water is pushed by liquid level difference, and organic pollutants are removed by ecological infiltration in forms of interception, absorption and degradation which are in coordination. When water discharged from the pool-bottom water collecting tank enters a solidified bioreactor, solidified microaerobic microorganism in a carrier is activated to provide a rich microaerobic microbial community source for the ecological infiltration system. The water containing the microbial community is pumped back to the water system of the aquaculture pool, the microorganism reproduces massively under the action of a shallow aerating system, the microorganism uses the pollutants of the required nutrients, and accordingly aquaculture water can be purified effectively, and clean aquaculture is achieved. The ecological infiltration pool-bottom system is built by directly using the bottom space of the aquaculture pool, the processing system does not occupy floor space, sludge is not generated, cost is saved, the solidified microorganism carrier in long in service life, in-situ aquaculture water purification and up-to-standard pollutant discharge are achieved, and evident comprehensive benefits are achieved.

Owner:GUANGXI UNIV

Boric sludge fire resistant ceramsites

The invention provides boric sludge fire resistant ceramsites, relates to a fire resistant ceramsite aggregate formed by taking boric sludge as a main raw material. The boric sludge fire resistant ceramsites are invented mainly to solve the problem that at present, the boric sludge occupies a vast area and causes environmental pollution, the problem that the conventional boric sludge ceramsites is poor in high temperature resistance and the like. The boric sludge fire resistant ceramsites are prepared form the following raw materials in percentage by volume: 60 to 75 percent of boric sludge, 20 to 30 percent of magnesium slag, and 5 to 10 percent of bonding agent. The production method comprises the following steps of: grinding all raw materials, mixing the ground raw materials and addingwater; granulating the mixture by a granulator; and baking the granules in a rotary kiln to obtain the boric sludge fire resistant ceramsites. The boric sludge fire resistant ceramsites have the advantages of replacing clay ceramsite and high-aluminum ceramsite, prolonging the service life of a hearth when used for building the hearth and reducing the building cost of the hearth and producing various fire resistant concrete, fire resistant building blocks, fire resistant filling materials and the like; and the boric sludge fire resistant ceramsites also solve the problems that the boric sludge occupies a vast area as well as causes environmental pollution and also have quite obvious social benefits.

Owner:聂立武

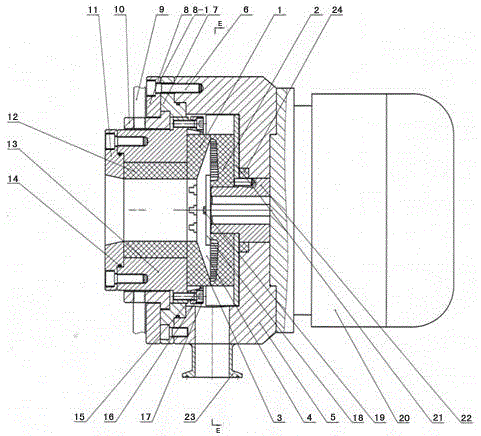

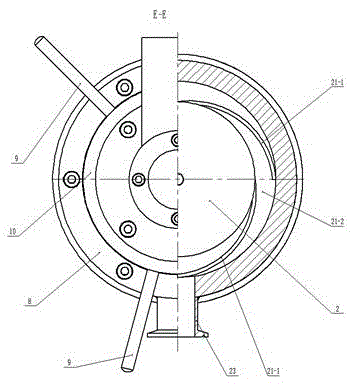

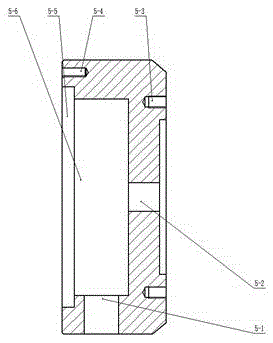

Ceramic pipe grinder for food grinding processing

A ceramic pipe grinder for food grinding processing solves the problems that in the prior art, the idle grinding area is large, the material discharge resistance is large, the grinding efficiency is low, the processing capacity is small, the processing effect is poor, the wear-resisting property of grinding discs is poor, the service life is short, and the application range is narrow. The ceramic pipe grinder is characterized in that a movable grinding disc and a semi-open type vane wheel are installed at the shaft end of a motor shaft extending into a shell, a fixed grinding disc is installed in a fixed grinding disc installation clip clutch, the joint surfaces of the fixed grinding disc and the movable grinding disc inwards form an internally-concave cone-shaped grinding cavity, a fixed grinding disc adjusting seat is connected with an adjusting nut in a threaded mode, the internally-concave conical surface of the fixed grinding disc is provided with symmetrical step-shaped oblique teeth, and the internally-concave plane of the movable grinding disc is provided with material guide grooves and trapezoid teeth. The ceramic pipe grinder for food grinding processing has the advantages that the fixed grinding disc and the movable grinding disc have the synergistic action of extruding, smashing, shearing and grinding on foodstuffs, the wear-resisting property is good, the manufacturing cost is low, the service life is long, the whole machine production efficiency is high, the production capacity is large, and the requirements for ultra-fine processing, dry material slurrying and industrialized continuous production can be met.

Owner:LIAONING YINGGUAN HIGH TECH CERAMIC CO LTD

Tailing carbonization cemented filling method

ActiveCN113213829ASolve the problem of land occupationSolve protection problemsMining engineeringCarbonization

The invention provides a tailing carbonization cemented filling method, and belongs to the technical field of tailing filling. The method comprises the following steps: firstly, crushing and grinding solid wastes with high calcium and magnesium contents and low hydration activity as a cementing material, and fully mixing in proportion to prepare filling slurry; secondly, pumping filling slurry to a filling goaf through a conveying pipeline, and after the goaf is filled, closing and blocking a filling area; injecting CO2 into a closed filling area, and performing carbonization curing on the filling body; and finally, in the carbonization maintenance process, monitoring the solid, liquid and gas states of the top and bottom plates, the surrounding rock and the filling body in the filling areain real time, the stability of the surrounding rock is ensured, and the filling effect reaches the standard. Solid waste which is high in calcium and magnesium content, low in hydration activity and difficult to recycle is used as a cementing material, and the raw material cost of tailing cemented mining is greatly reduced. The tailing carbonization cemented filling method is simple in process, low in cost, simple in process, clean and environmentally friendly.

Owner:UNIV OF SCI & TECH BEIJING

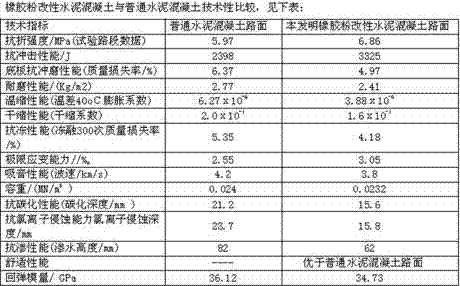

Rubber powder modified cement concrete pavement and manufacturing method thereof

ActiveCN107188488AEffective digestionExtended service lifeIn situ pavingsSolid waste managementCelluloseWear resistant

The invention discloses a rubber powder modified cement concrete pavement and a manufacturing method thereof. The rubber powder modified cement concrete pavement is characterized by being prepared from the following raw materials in parts by weight: 25 to 30kg / m<3> of rubber powder, 300 to 330kg / m<3> of 425 cement, 550 to 590kg / m<3> of river sand, 1080 to 1180kg / m<3> of broken stone, 135 to 165kg / m<3> of water, 5 to 7kg / m<3> of water reducing agents, 3 to 4kg / m<3> of phthalic ester coupling agents, 2 to 3kg / m<3> of rubber latex, 3 to 4kg / m<3> of hydrophobic modification cellulose, 15 to 20kg / m<3> of lignin, 80 to 110kg / m<3> of granulitic blast-furnace ore slag powder and the like. The raw materials are effectively mixed to obtain the concrete. The rubber powder modified cement concrete pavement has the characteristics that the properties of anti-folding intensity, anti-impact performance, bottom plate anti-impact and anti-abrasion performance, wear-resistant performance, temperature shrinkage, dry shrinkage performance, freezing resistance performance, ultimate strain capability, noise reducing performance, volume weight, corrosion resistance and the like of the rubber powder modified cement concrete pavement are superior to those of the ordinary cement concrete pavement; the later-stage maintenance cost is lower than that of the ordinary cement concrete pavement, and the like.

Owner:广西航务建设工程有限公司

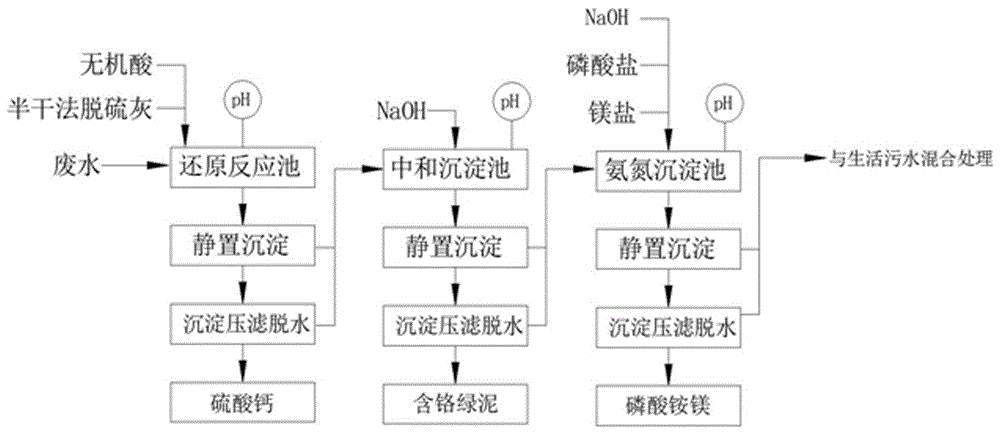

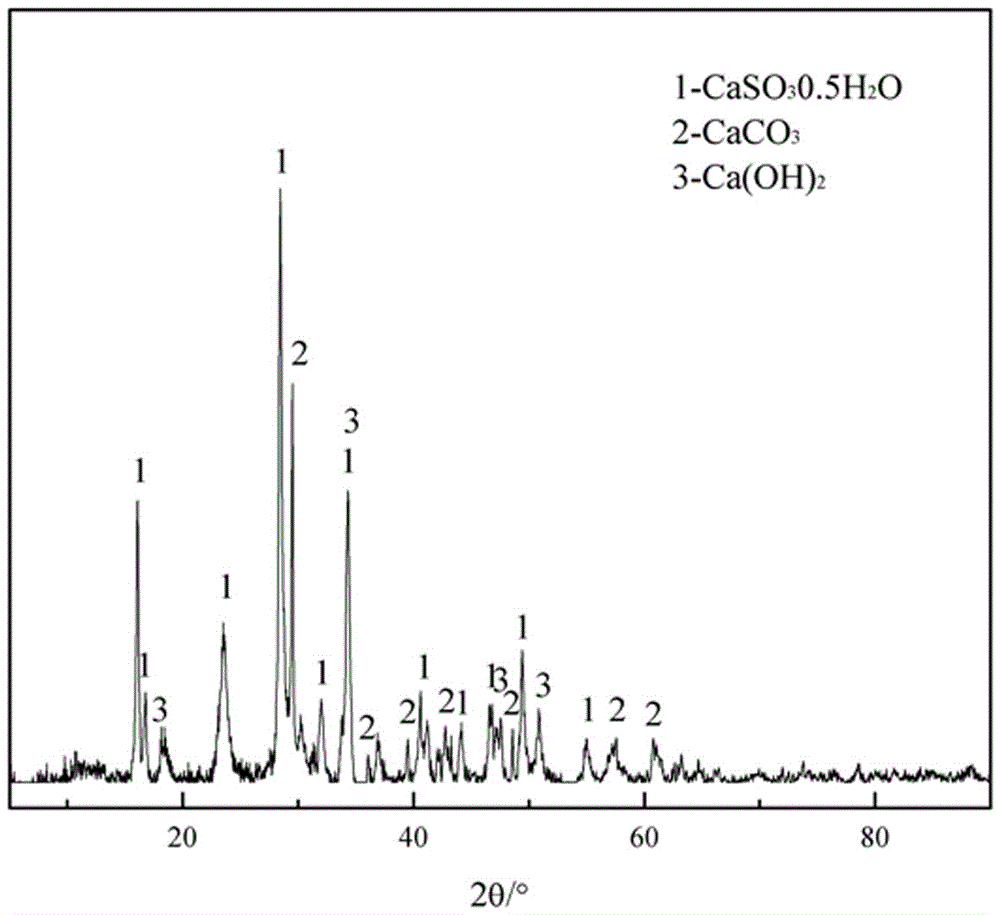

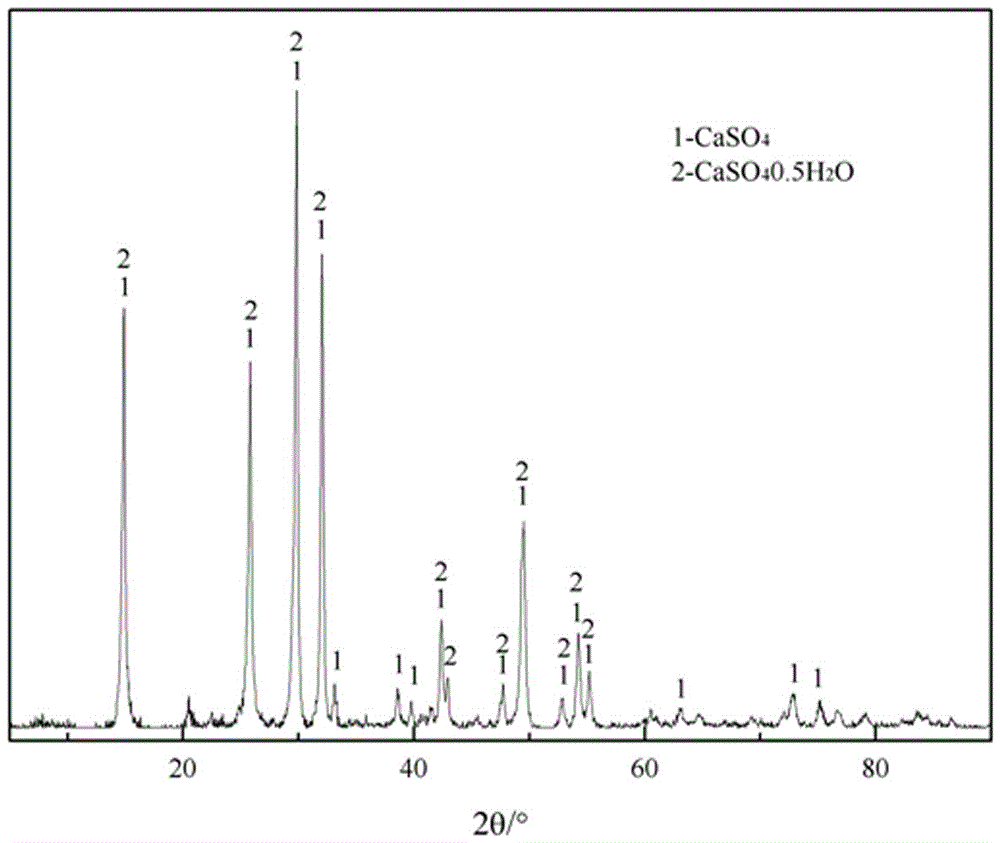

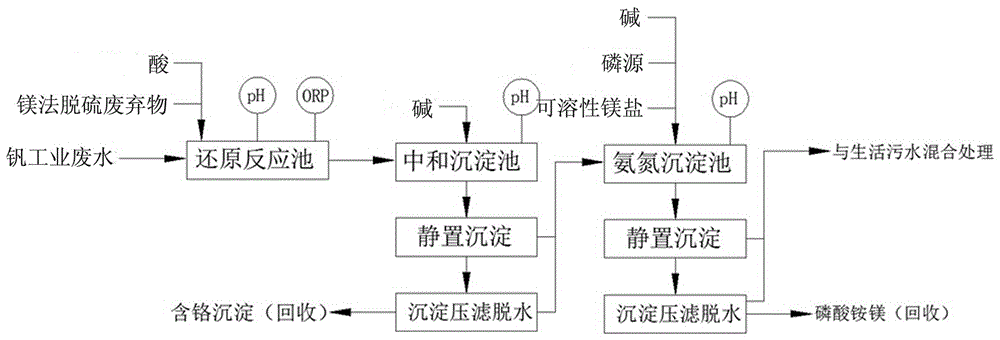

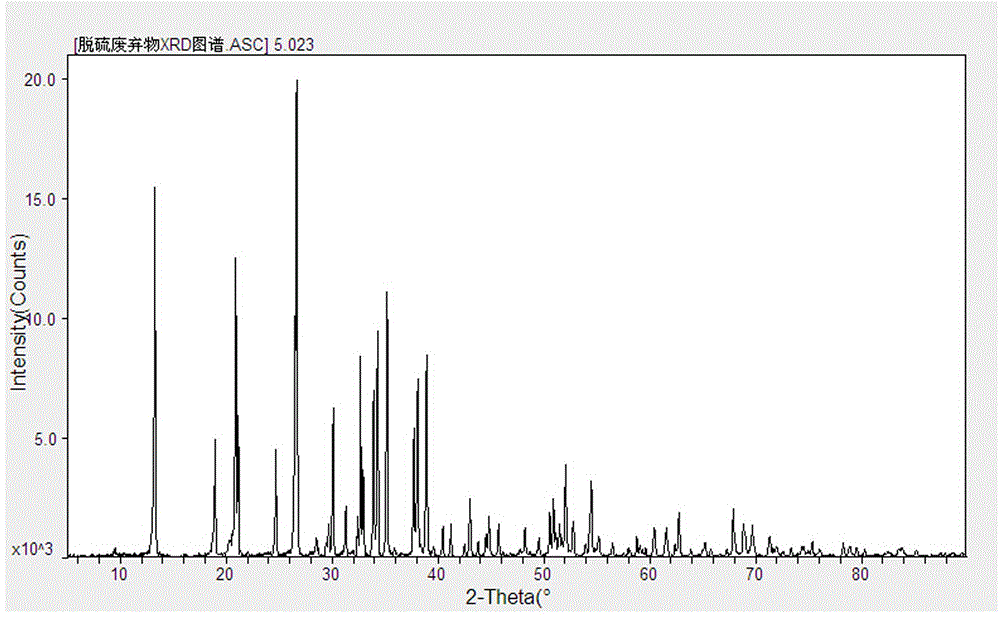

Method for treating vanadium industrial wastewater by aid of semi-dry flue gas desulfurization ash

ActiveCN106809989AAmmonia nitrogen and phosphorus reductionIncrease chromium contentCalcium/strontium/barium sulfatesMultistage water/sewage treatmentMagnesium saltFiltration

The invention discloses a method for treating vanadium industrial wastewater by the aid of semi-dry flue gas desulfurization ash. The method includes steps of (1), adding the semi-dry flue gas desulfurization ash into the vanadium industrial wastewater; (2), adding inorganic acid into the vanadium industrial wastewater to regulate a pH (potential of hydrogen) value of the vanadium industrial wastewater and stirring the inorganic acid and the vanadium industrial wastewater to obtain mixtures; (3), allowing the mixtures to stand still, separating supernatant from precipitates, carrying out pressure filtration on the precipitates to obtain calcium sulfate and mixing filter liquid and the supernatant with each other to obtain first mixed liquid; (4), adding sodium hydroxide into the first mixed liquid, stirring the first mixed liquid and the sodium hydroxide to obtain second mixed liquid, adding flocculating agents into the second mixed liquid and continuing to stir the flocculating agents and the second mixed liquid to obtain third mixed liquid; (5), allowing the third mixed liquid to stand still, separating supernatant from precipitates, carrying out pressure filtration on the precipitates to form chromium-containing green mud and mixing filter liquid and the supernatant with each other to obtain fourth mixed liquid; (6), leading the fourth mixed liquid into an ammonia nitrogen precipitating tank, stirring the fourth mixed liquid, adding magnesium salt and phosphate into the fourth mixed liquid to obtain fifth mixed liquid, regulating a pH value of the fifth mixed liquid and then continuing to stir the fifth mixed liquid; (7), allowing the fifth mixed liquid to stand still and separating supernatant from precipitates. The method has the advantages that semi-dry desulfurization solid waste can be recycled, accordingly, the wastewater treatment cost can be reduced, the problems of secondary pollution and land occupation of semi-dry desulfurization ash can be solved, and the method has high environmental benefits, economic benefits and social benefits.

Owner:NORTHEASTERN UNIV

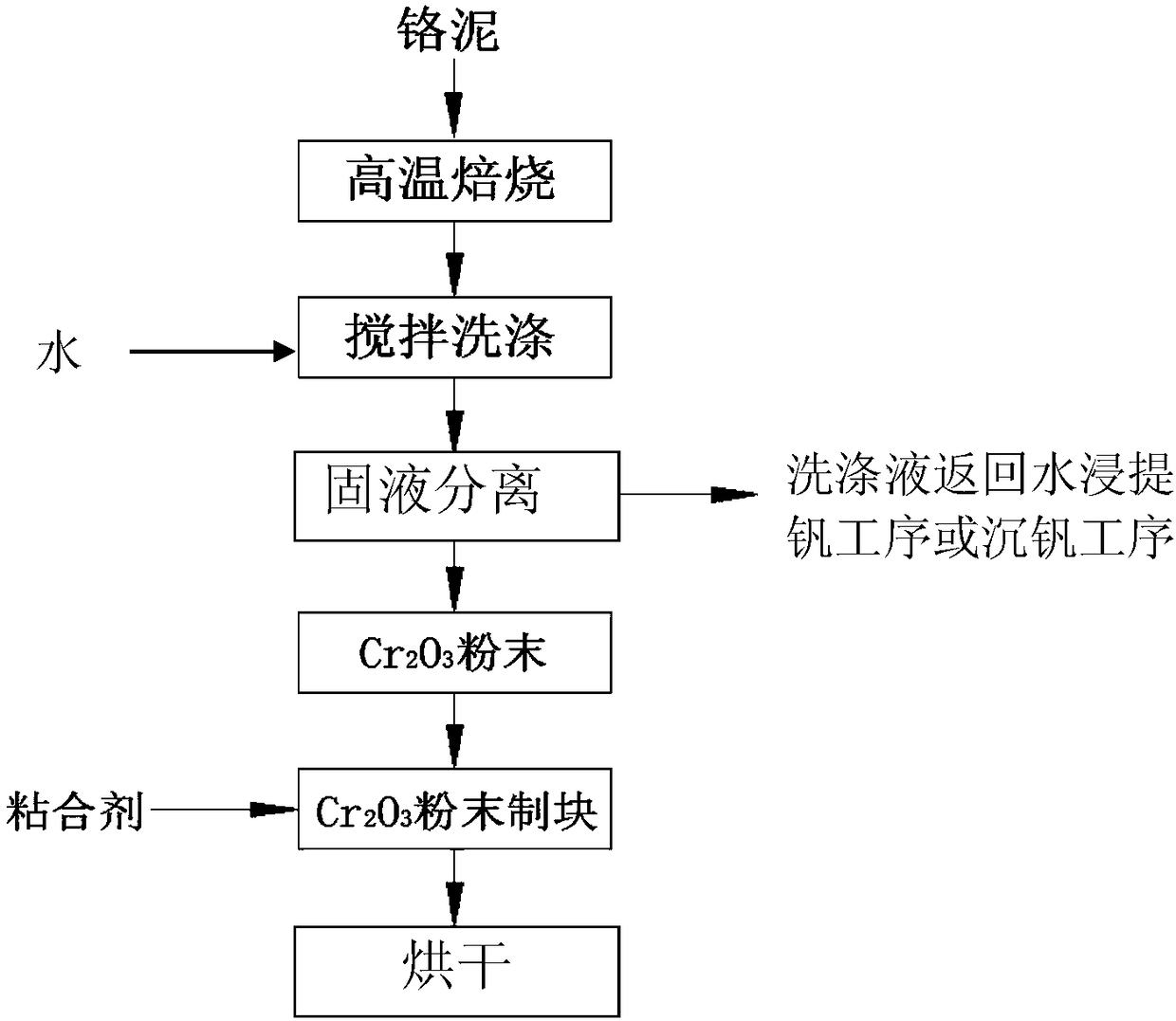

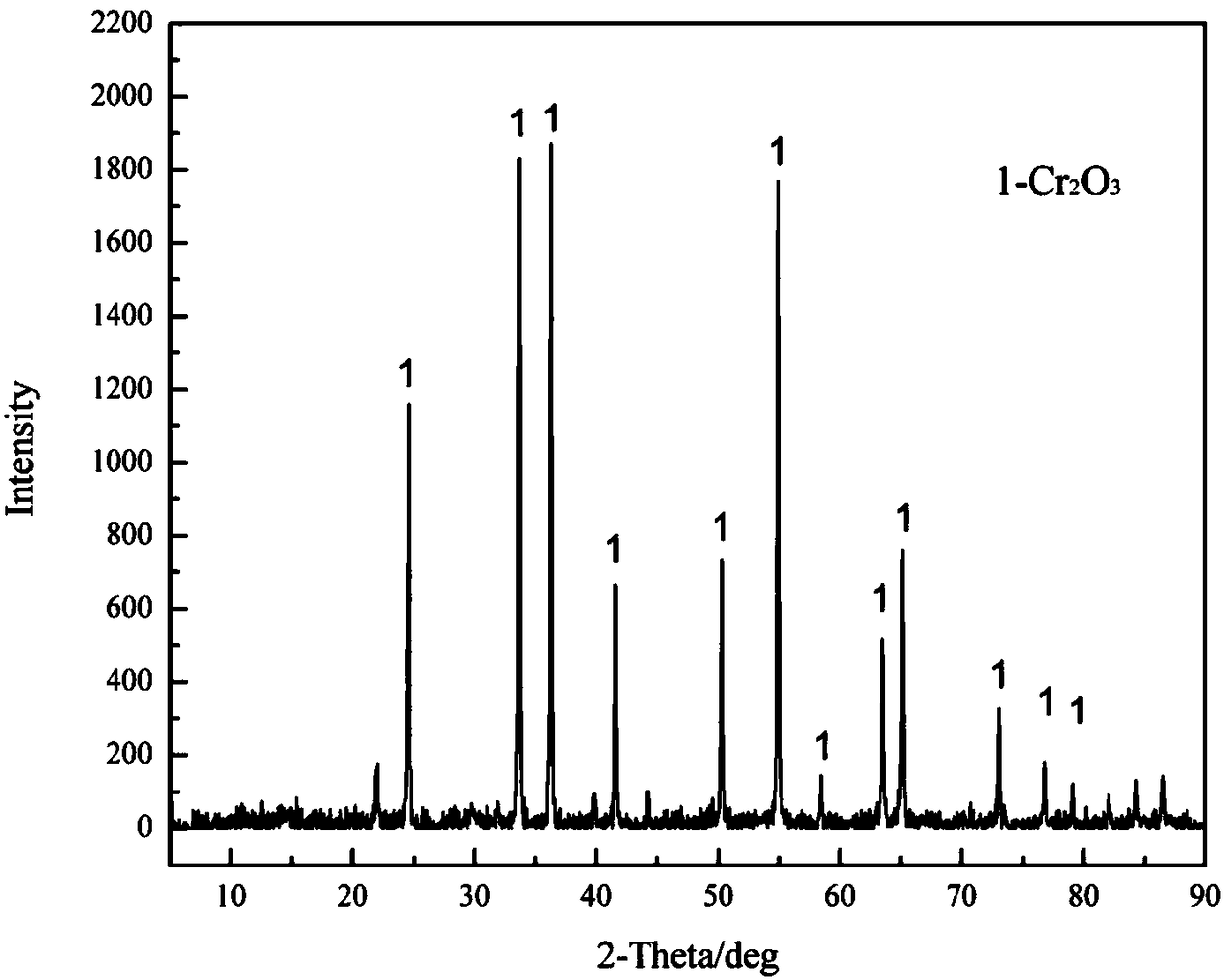

Resource utilization method for chrome sludge of vanadium extraction waste water treatment sediment

The invention provides a resource utilization method for chrome sludge of vanadium extraction waste water treatment sediment and belongs to the technical field of solid waste treatment and resource utilization. The method includes the steps that (1) the chrome sludge of the vanadium extraction waste water treatment sediment is roasted at a high temperature of 400-1000 DEG C for 0.5-5 h, sodium salt and vanadium remaining in the chrome sludge of vanadium extraction waste water generate a sodium salt roasting reaction again in the roasting process, and a roasted product is obtained; (2) water which is 2-10 times the mass of the roasted product is added into the roasted product, stirring washing is carried out for 0.5-3 h, solid and liquid separation is conducted, and the roasted product obtained after washing is deep green chromium sesquioxide powder; (3) a binding agent is added into the deep green chromium sesquioxide powder, briquetting and drying are carried out, and chromium sesquioxide particles with the effective grain size being larger than or equal to 3 mm are obtained; and (4) chromium containing steel is produced by taking the chromium sesquioxide particles as raw materials. According to the method, high value-added vanadium and chromium resources in the chromium sludge are recycled at low cost, so that remarkable economic benefits, social benefits and environmental benefits are generated.

Owner:NORTHEASTERN UNIV

Method for treating vanadium industrial wastewater through magnesium-process desulfurization waste

ActiveCN105923836AEfficient removalIncrease chromium contentWater contaminantsMultistage water/sewage treatmentMagnesium saltTherapeutic effect

The invention belongs to the technical field of wastewater and solid waste treatment and particularly relates to a method for treating vanadium industrial wastewater through magnesium-process desulfurization waste, comprising: adding magnesium-process desulfurization waste into vanadium industrial wastewater, reducing high-valence vanadium and chromium in the wastewater into low-valence vanadium and chromium during reacting, continuing to stir the reduced wastewater, adjusting pH with alkali, adding a flocculant, and standing and precipitating to obtain precipitate, and press-filtering and dewatering the precipitate to form primary chromium hydroxide precipitate, charging the obtained filtrate and precipitate into an ammonia nitrogen precipitating tank, adding an easily-soluble magnesium salt into the ammonia nitrogen precipitating tank, continuing to stir and adding a phosphorus source after the easily-soluble magnesium salt dissolves, forming magnesium ammonium phosphate precipitate from ammonia nitrogen during reacting, standing for 20-50 min, press-filtering and dewatering precipitate to obtain slow-release fertilizer material for recycling, and using obtained filtrate and supernate as effluent. The method has good treatment effect, short process, high treatment speed and low cost and may be applied via existing equipment with no additional capital expenditure.

Owner:NORTHEASTERN UNIV

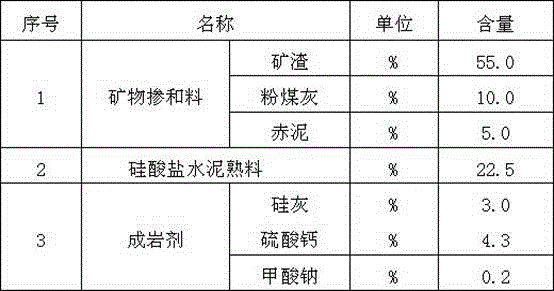

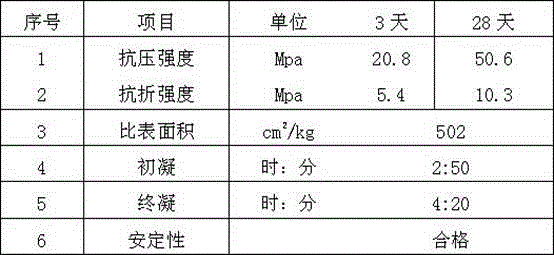

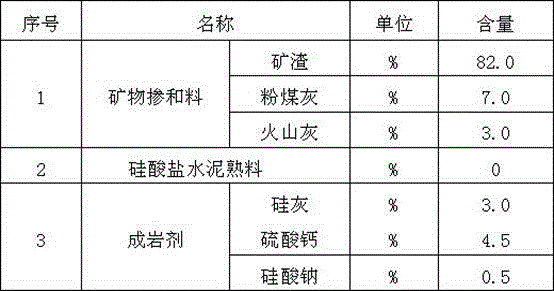

Silicon-aluminum base marine concrete material and preparing method thereof

InactiveCN106431026AReduce construction costsReduce energy consumptionCement productionCorrosionConstruction aggregate

Disclosed are a silicon-aluminum base marine concrete material and a preparing method thereof. The preparing method comprises the steps of weighing mineral admixtures, portland cement clinker and diagenetic agent and conducting mixing and grinding on the mineral admixtures, portland cement clinker and diagenetic agent, wherein weight ratio of the mineral admixtures to the portland cement clinker to the diagenetic agent is (60-95):(0:30):(1-10), and preparing the mixture into a silicon-aluminum base binding material for use; weighing the prepared binding material, aggregate and admixture for use, wherein the weight ratio of the binding material to the aggregate to the admixture is 1:(4-7):(0.01-0.10); mixing the obtained mixture with water and stirring evenly the mixture; casting silicon-aluminum base marine concrete slurry prepared after the mixture is stirred into a mould to be subjected to maintenance, and finally obtaining the silicon-aluminum base marine concrete material. The prepared silicon-aluminum base marine concrete material has high durability and sea water corrosion resistance, and has a long service life and a low cost.

Owner:ARCHITECTURAL DESIGN & RES INST OF TSINGHUA UNIV +1

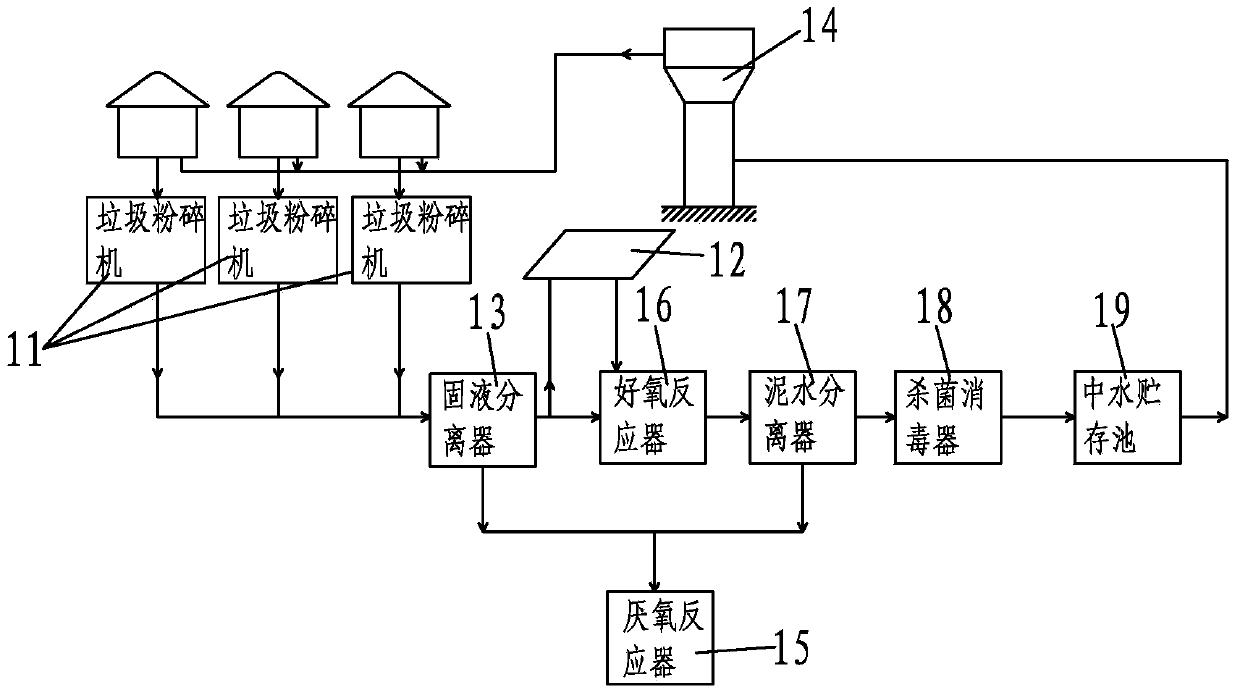

Rural urbanization residential domestic sewage and biomass garbage treatment system and method

InactiveCN103466886AAvoid pollutionAvoid land occupationWaste processingSolid waste disposalWater storageReclaimed water

The invention discloses a rural urbanization residential domestic sewage and biomass garbage treatment system and method. The system comprises a plurality of garbage crushers and a solid-liquid separator, wherein the plurality of garbage crushers are all connected with the solid-liquid separator through pipelines; a solid outlet of the solid-liquid separator is connected with an anaerobic reactor through a pipeline; a liquid outlet of the solid-liquid separator is connected with an aerobic reactor through a pipeline; the downstream side of the aerobic reactor is connected with a sludge-water separator through a pipeline; a sewage outlet of the sludge-water separator is sequentially connected with a sterilizer and a recycled water storage pool through pipelines and is also connected with the anaerobic reactor through a pipeline. By using the comprehensive treatment system and method disclosed by the invention, the biomass garbage and the sewage can be recycled after being treated, thus the no-waste treatment is realized; in addition, space occupation and environment pollution caused in biomass garbage stacking, transporting and sorting processes are avoided, thus residents are urged to classify garbage from the source.

Owner:烟台亿源环保科技有限公司

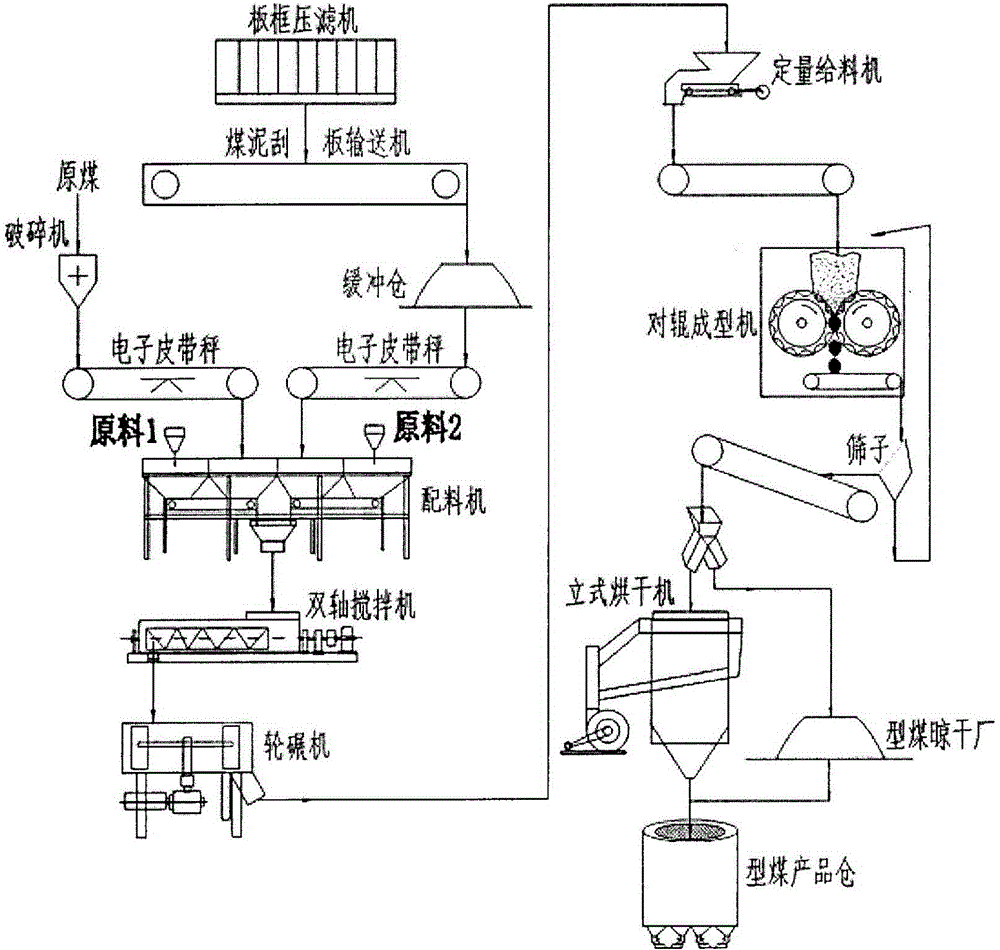

Process of directly forming and utilizing coal slime of coal cleaning plant

The invention discloses a process of directly forming and utilizing coal slime of a coal cleaning plant. The process comprises the following steps: directly transporting the coal slime from a filter-pressing workshop of the coal cleaning plant to a dosing machine; adding a certain amount of raw coal and an adhesive in percentage by mass; adopting a double-roller forming machine or a screw extruder to form after stirring and uniformly mixing. According to the process disclosed by the invention, the filter-pressing coal slime is not needed to be dried, and can be directly transported to a forming site, so that the coal slime is prevented from occupying land and being polluted. The forming process is simple, a briquette coal product is good in mechanical strength, so that the calorific value of the coal slime briquette coal can be adjusted by matching with the raw coal, and therefore, the use requirements of different users are satisfied. The process disclosed by the invention can be used for effectively solving the problems that the coal slime of the coal cleaning plant is in excess of demand, occupies land, and is polluted.

Owner:HENAN POLYTECHNIC UNIV

Blast furnace dust recycling utilization method

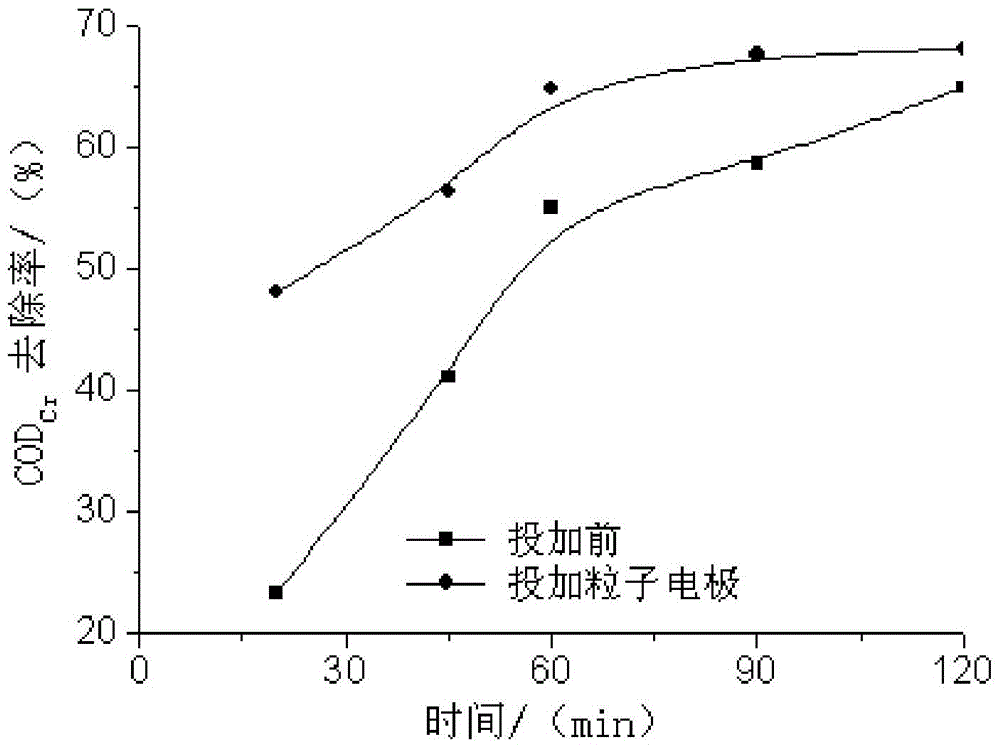

ActiveCN104402097ALoose structureLarge specific surface areaWater treatment parameter controlWater contaminantsElectrolysisSlag

The invention discloses a blast furnace dust recycling utilization method, which comprises the following steps: 1) screening out blast furnace dust with the diameter of 200-400 mesh; 2) mixing the blast furnace dust and ammonium salt in the ratio of 6-10:1, then adding water and tar slag for granulate into particles with the particle size of 1.5-3.0mm; 3) after drying the particles at 60 to 80 DEG C for 25-40min, transferring into a muffle furnace, heating to 400 to 700 DEG C in 10 to 15 DEG C / min speed for roasting for 30min-1H to prepare iron carbon micro electrolysis particles; and 4) pouring the iron carbon micro electrolysis particles into coking biochemical efflux water, adjusting the PH value to 3-5 for fully degrading organic matters, then adjusting the pH value to 6-9 for the removal of precipitate to complete advanced treatment; or putting the iron carbon micro electrolysis particles into a three-dimensional electrode reactor to be used as a particle electrode for treatment of the coking biochemical efflux water. The blast furnace dust recycling utilization method not only solves the problems of blast furnace dust environmental pollution and land occupation, also realizes the advanced treatment of the coking biochemical efflux water, and greatly reduces the processing cost.

Owner:武汉钢铁有限公司

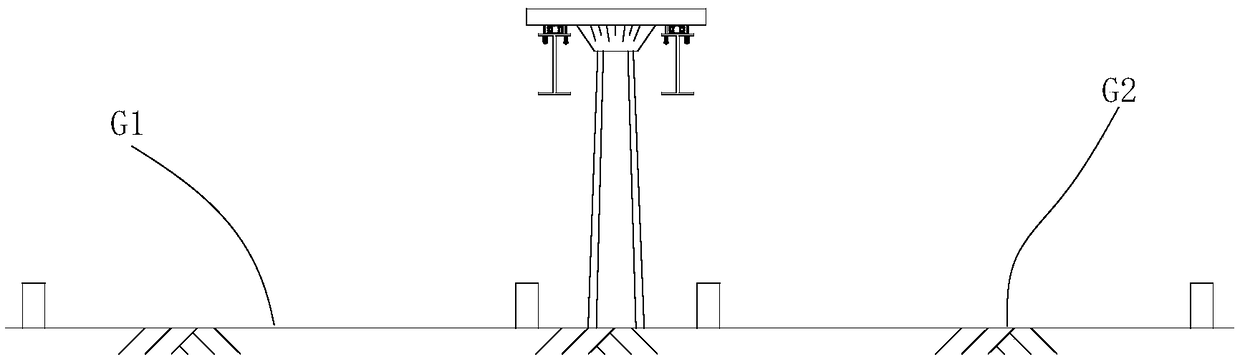

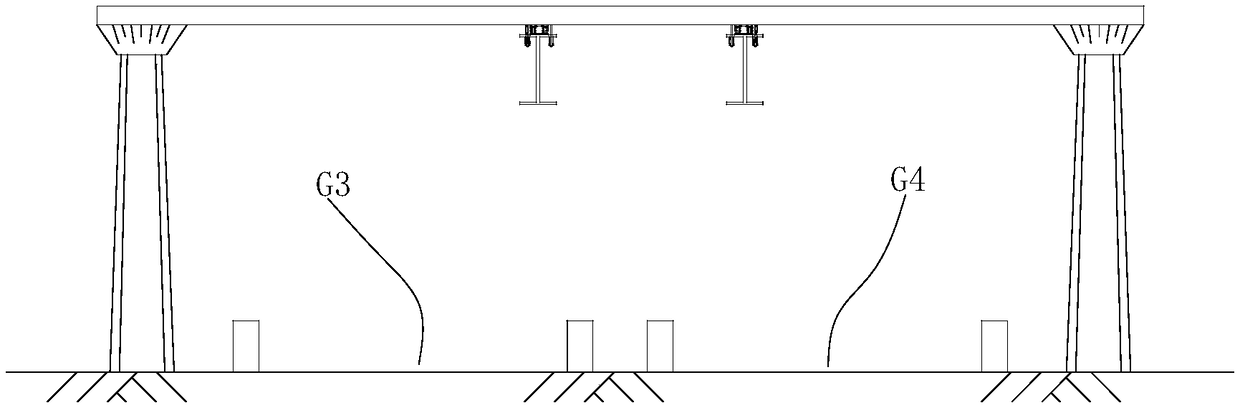

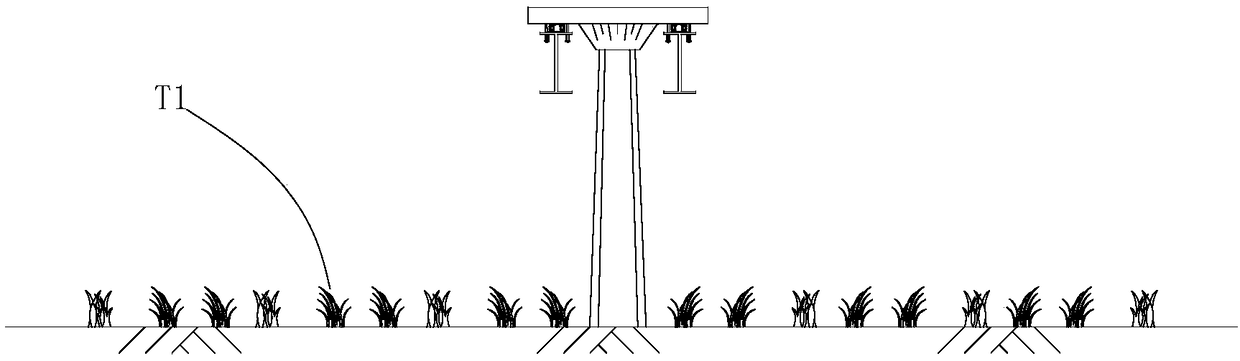

Suspension-type logistic monorail transportation system

The patent discloses a suspension-type logistics monorail transportation system, belonging to the monorail transportation field. By proposing a hanging logistics monorail transportation system, and byadopting the a suspension-type logistic monorail girder bridge system, a suspension-type logistic monorail girder bridge system suspended logistics monorail vehicle system, a suspension-type logistics monorail switch system, a suspension-type logistics monorail loading and unloading system and suspended logistics monorail signal system, the problems of short distance, large size, high cost and low speed of the existing maglev transportation are solved, and the goals of long distance, lightweight, low cost and high speed suspension logistics monorail transportation system are achieved.

Owner:BEIJING JIAOTONG UNIV

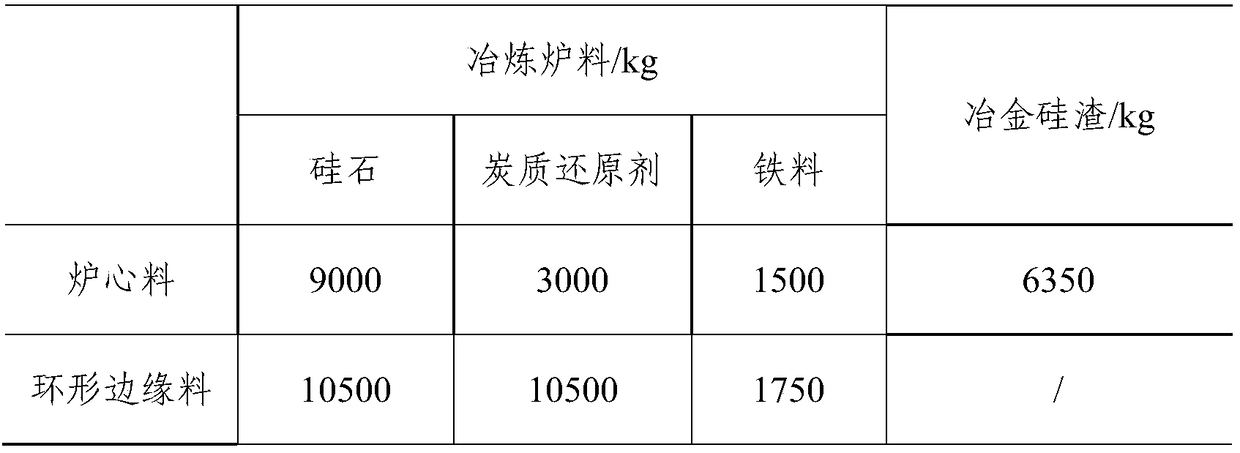

Method for producing ferrosilicon alloy by means of metallurgical silicon slag

The invention discloses a method for producing ferrosilicon alloy by means of metallurgical silicon slag. A smelting area of a submerged arc furnace is divided into a furnace core area and an annularedge area surrounding the outer side of the furnace core area, the metallurgical silicon slag and a smelting furnace material are evenly mixed and then used as a furnace core material, and after smelting, drossing, pouring and finishing for slag removing, the ferrosilicon alloy is obtained; the content of Si in the metallurgical silicon slag is larger than 30.0 wt%, the contents of P, Al and Ca are smaller than 0.02 wt%, 7.0 wt% and 7.0 wt% respectively, and the adding amount of the metallurgical silicon slag accounts for smaller than 18 wt% of the total amount of the furnace core material andan annular edge material. According to the method, the metallurgical silicon slag can be adopted as a raw material directly, and thus resource recycling is achieved; by using the material characteristic that the monatomic silicon in the metallurgical silicon slag is the silicon component in the ferrosilicon alloy, the raw material usage amount and electricity consumption are reduced; moreover, the improvement of equipment investment is not needed, implementation is convenient, the method has significant social and environment-friendly effects and great economic benefits, and the practical application prospects are wide.

Owner:ORDOS XIJIN MINING & METALLURGY CO LTD

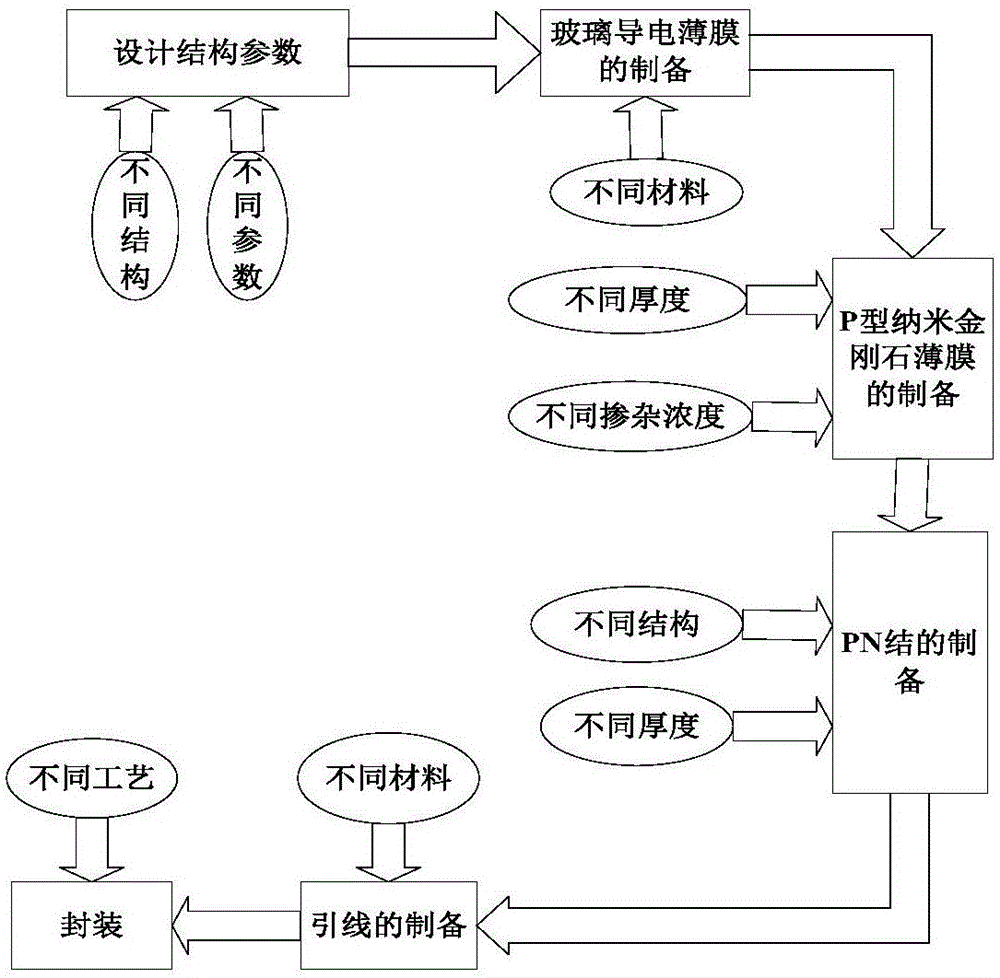

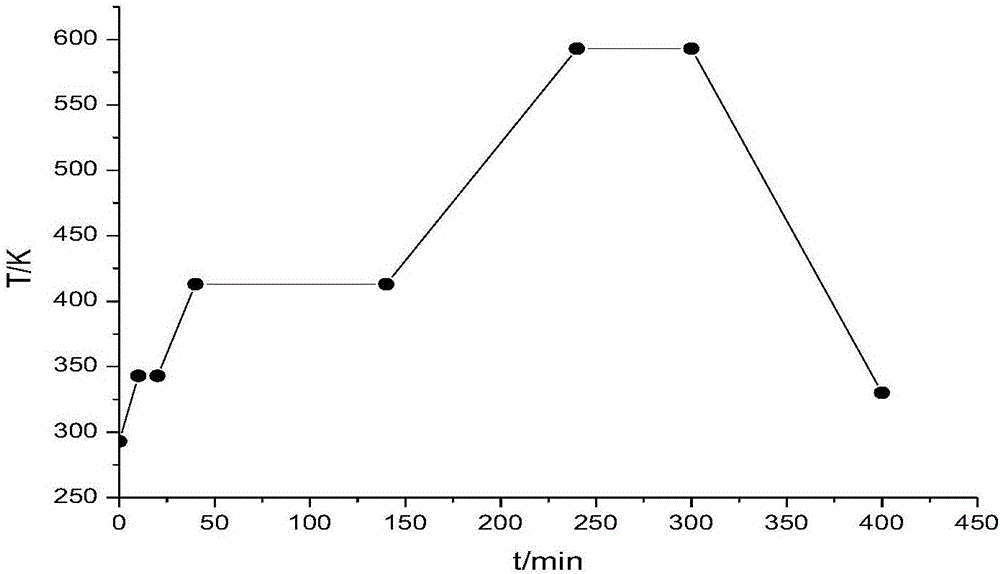

Household glass based on 3D printing nano-diamond transparent thin-film battery and preparation method

InactiveCN106449809AAchieve protectionGuaranteed light transmissionMaterial nanotechnologyFinal product manufacturePolyesterThin film electrode

The invention discloses household glass based on a 3D printing nano-diamond transparent thin-film battery and a preparation method. The household glass comprises glass and an anode layer, a P-type nano-diamond thin film, a PN junction layer, an N-type nano-diamond thin film and a cathode layer sequentially arranged on the glass close to the indoor side. The method comprises the following steps of: (1) cleaning the glass for later use; (2) preparing a Ti / SnO2 thin-film electrode as an anode for later use; (3) establishing a 3D digital model of the glass according to the size and shape of the glass, and printing P-type and N-type nano-diamond thin films; and forming the PN junction layer by use of a diffusion tube to obtain a battery substrate; (4) preparing a ZnO / Al transparent thin-film battery as a cathode by FDM-based 3D printing equipment on the battery substrate to obtain a nano-diamond transparent thin-film battery; and (5) performing lamination encapsulation of the glass, anode and nano-diamond transparent thin-film battery through a flexible polyester film.

Owner:BEIFANG UNIV OF NATITIES

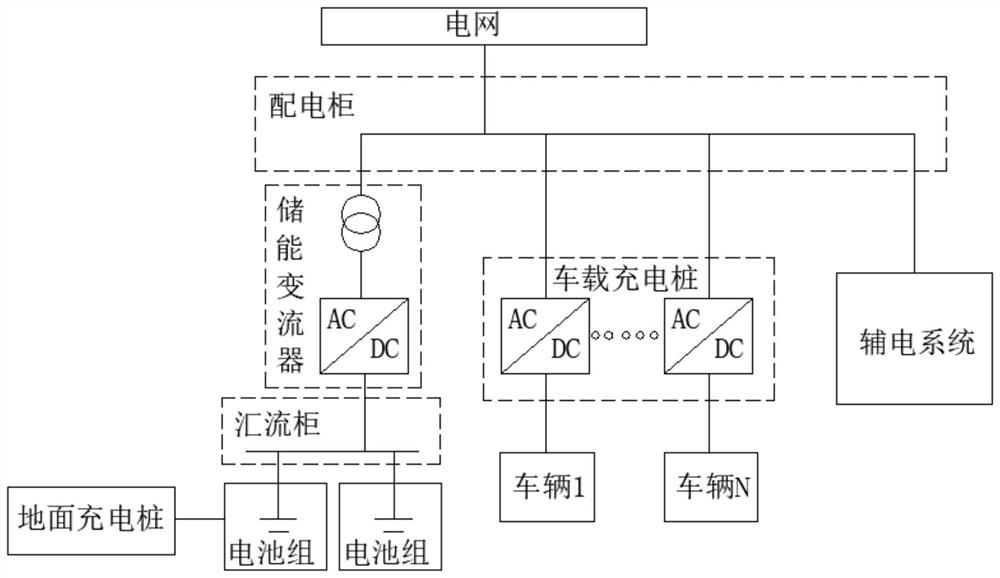

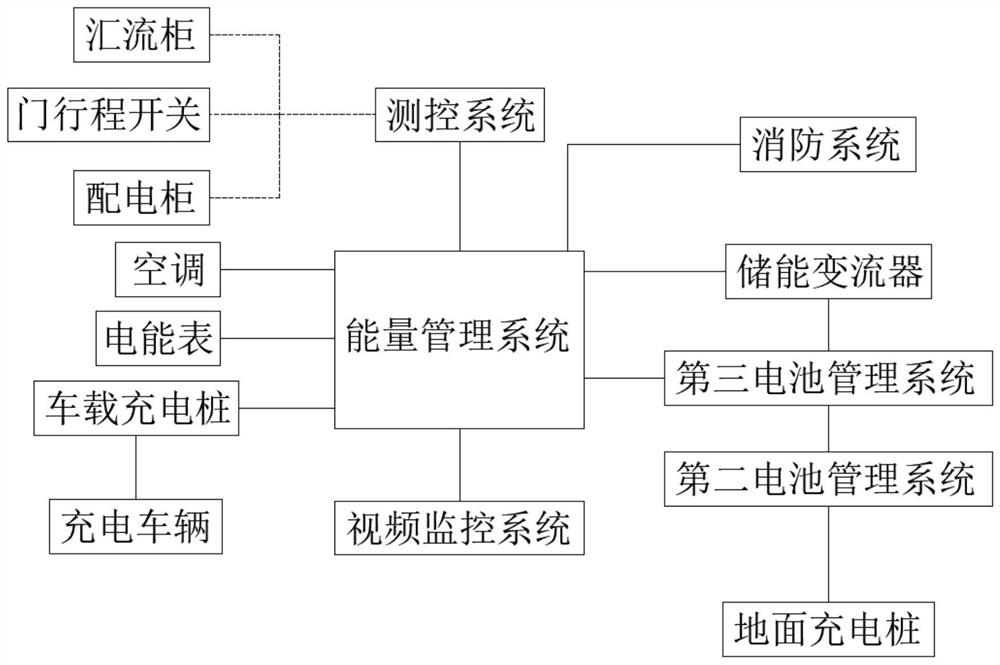

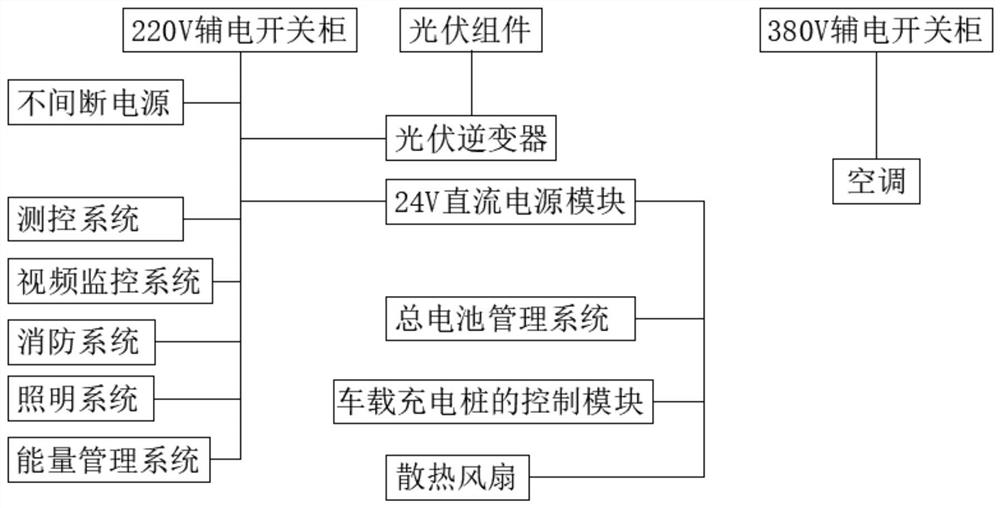

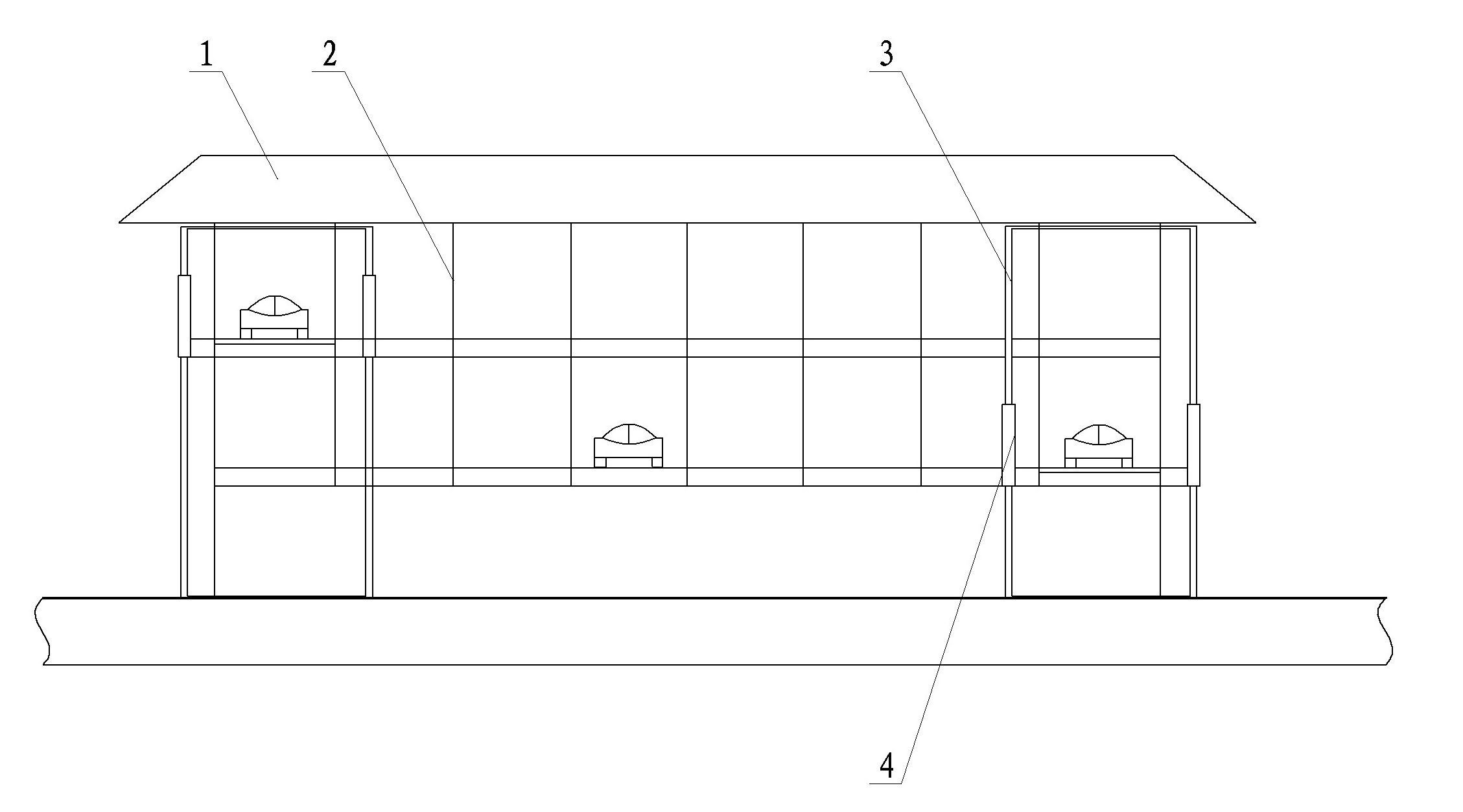

Common-bus multifunctional mobile energy storage vehicle and control strategy

PendingCN111717052AIncrease the installed capacityImprove consistencyCharging stationsAc network load balancingControl systemIn vehicle

The invention discloses a common-bus multifunctional mobile energy storage vehicle and a control strategy, and belongs to the power supply equipment field. The common-bus multifunctional mobile energystorage vehicle comprises a vehicle body and an energy storage assembly. The energy storage assembly is arranged on the vehicle body. The energy storage assembly comprises a battery assembly, a confluence cabinet, an energy storage converter, a power distribution cabinet, a vehicle-mounted charging pile, a control system and an auxiliary power system. The battery assembly is electrically connected with the confluence cabinet; the confluence cabinet is electrically connected with the energy storage converter; and the energy storage converter is electrically connected with the power distribution cabinet, the power distribution cabinet is electrically connected with a plurality of vehicle-mounted charging piles, the auxiliary power system is electrically connected with the power distributioncabinet, the control system is connected with the battery assembly, the confluence cabinet, the energy storage converter, the power distribution cabinet, the vehicle-mounted charging piles and the auxiliary power system, and the battery assembly is formed by connecting multiple clusters of battery packs in parallel. According to the common-bus multifunctional mobile energy storage vehicle and thecontrol strategy, the multiple clusters of battery packs are arranged in parallel in a common-bus mode, a charging amount is large, and the vehicle is suitable for more application scenes.

Owner:福建巨电新能源股份有限公司

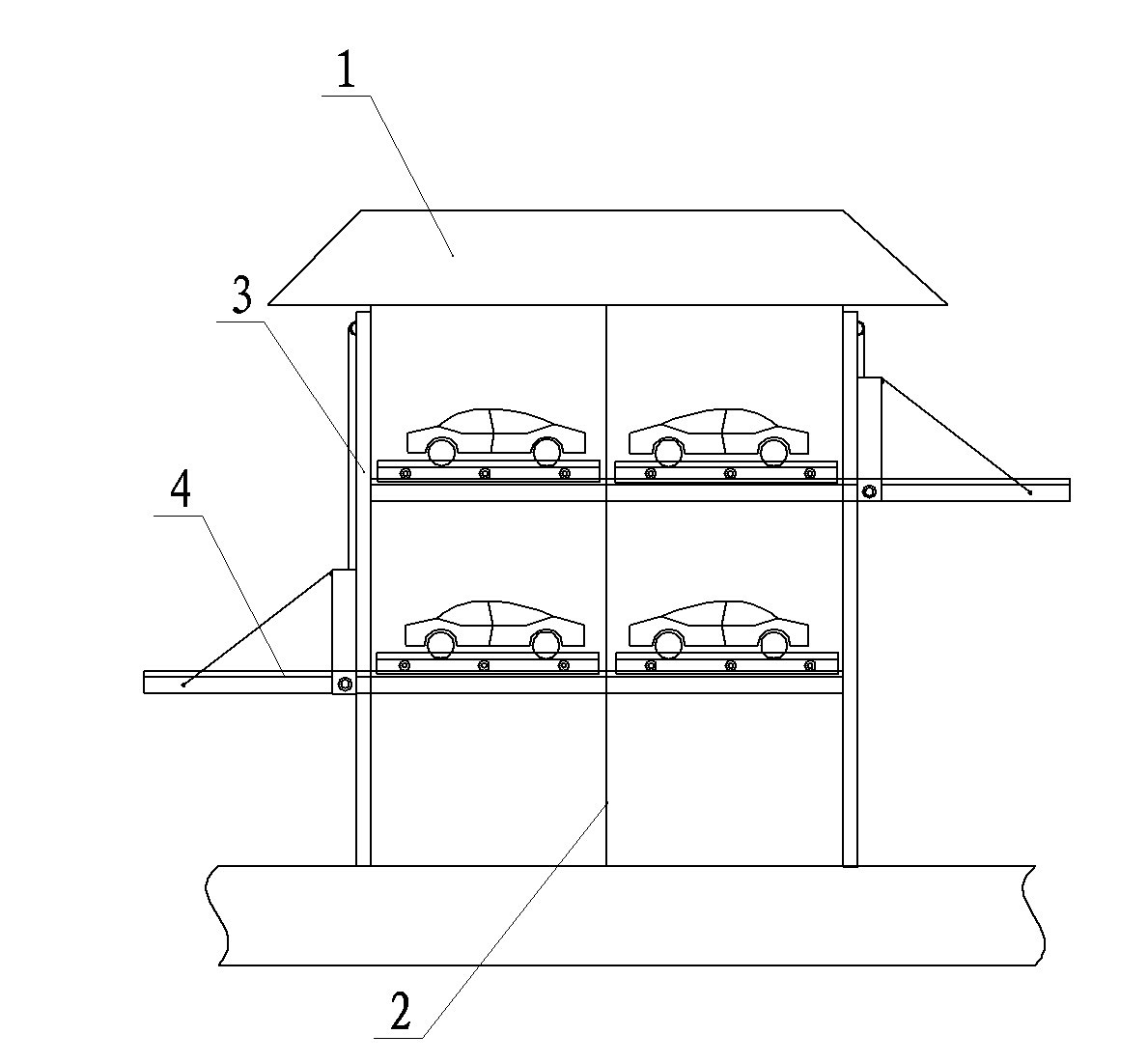

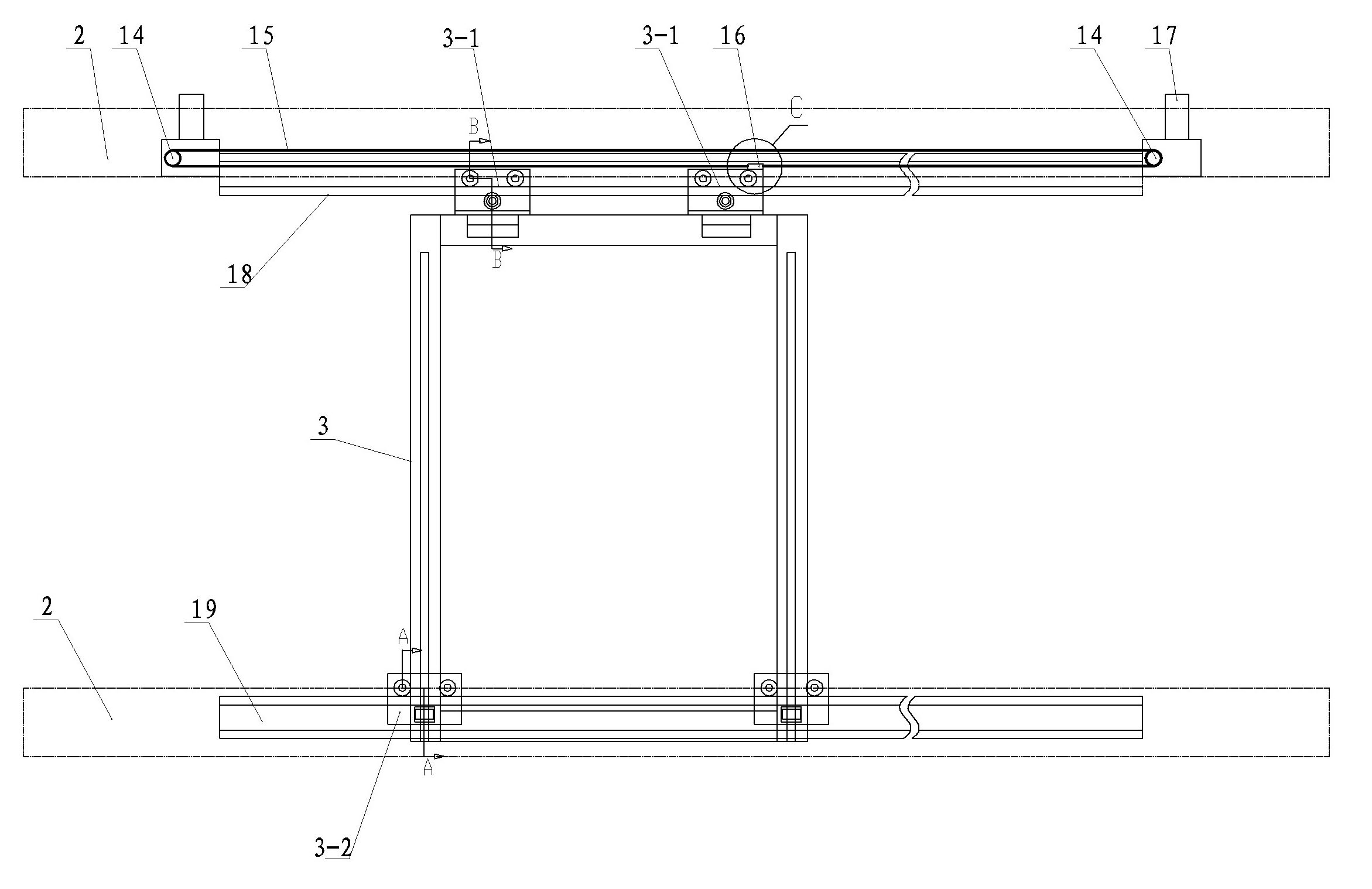

Stereoscopic garage of overhead bridge across street or along street

InactiveCN102587709ASolve the problem of land occupationSolve parking problemParkingsEngineeringRoad surface

A stereoscopic garage of an overhead bridge across a street or along the street comprises a multilayer box type garage main body frame, a ceiling and transfer movable rack. The ceiling is mounted on the upper portion of the frame, the bottom of the garage main body frame is distanced from a road surface by a certain altitude, the transfer movable racks are transversely slidably connected with the garage main body frame, lifting trays are vertically slidably connected with the transfer movable racks, a lifting driving device is disposed on each transfer movable rack and connected with the corresponding lifting tray, guide tracks A and a rotary disc are disposed on a bottom plate of each lifting tray, a fixing tray is arranged in each box of the main body frame, guide tracks B are arranged on each fixing tray, the garage is further provided with vehicle carrying plates, and rollers which match with the guide tracks A and the guide tracks B are disposed under the vehicle carrying plates. The stereoscopic garage is built above the street, does not affect traffic, not only solves parking problems, but also solves the problem that an existing stereoscopic garage occupies large area, vehicles can be parked and taken automatically by the aid of matching of the lifting trays and the transfer movable racks, drivers do not need to give way to other vehicles when parking or taking the vehicles, and efficiency is high.

Owner:HENAN AUSPIC TECH

Method for coproduction of bleaching powder, active carbon, sodium chloride and sulphuric acid from waste gypsum plaster

InactiveCN101486446AAvoid feesEliminate secondary pollutionSulfur-trioxide/sulfuric-acidAlkali metal chloridesChemical reactionDistillation

The invention discloses a method for producing bleaching powder concentrate and activated carbon co-production sodium chloride and sulphuric acid by using waste gypsum mud. The method comprises the following specific steps: after being pretreated, the waste gypsum mud reacts with hydrochloric acid, a mixed solution of calcium chloride and sulphuric acid and a filter cake are obtained by filtration; the filtrate reacts with sodium sulfate to generate pure white plaster deposit and sodium chloride; a sodium chloride solution and a pure plaster filter cake are obtained by filtration; sodium chloride crystal and a sulphuric acid solution are obtained by the slight distillation of the filtrate, and the sulphuric acid solution can be made into concentrated sulfuric acid products by slight concentration; the plaster filter cake continues to react with sodium hydroxide to generate pure calcium hydroxide and a sodium sulfate solution, the sodium sulfate solution can be reused and the bleaching powder concentrate is obtained by the chlorination, separation, drying and crushing of the pure calcium hydroxide. The method effectively and reasonably utilizes chemical reaction principle to treat waste gas, waste water and waste residues and changes waste into valuables, thus not only saving the cost of treating waste acid, but also creating remarkable economic value. The method can be considered to be canonical in the comprehensive utilization of waste gas, waste water and waste residues, deeply embodies the advantage of circular economy, and simultaneously, greatly improves the deep processing capability of enterprises.

Owner:LIWANG CHEM NANTONG

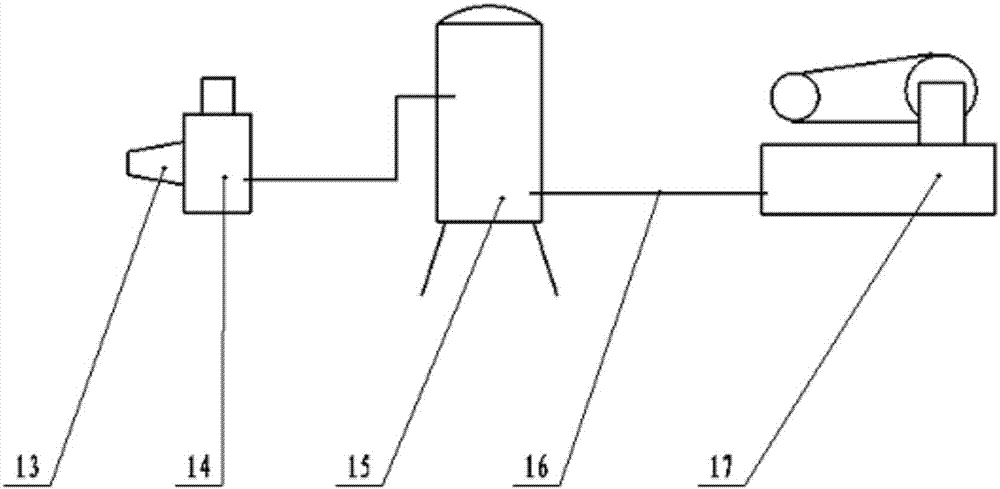

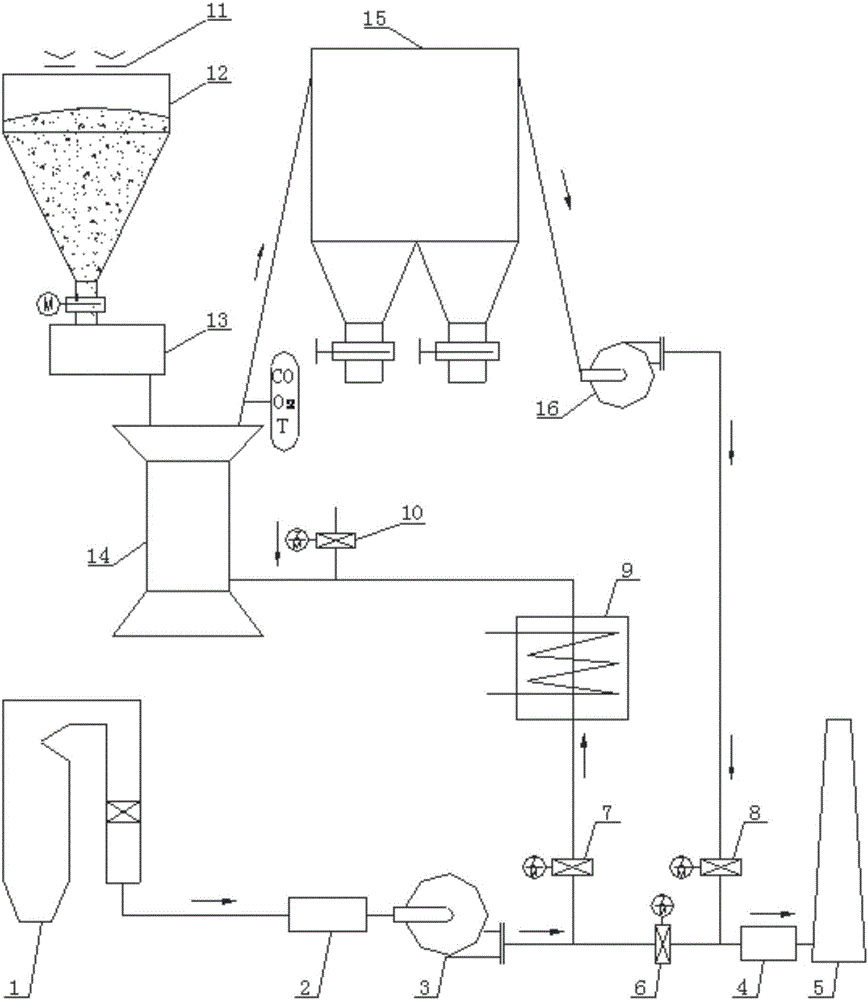

Energy-saving and environment-friendly flue gas waste heat pulverized coal preparation system

InactiveCN106196134AImprove explosion-proof performanceImprove securitySolid fuel pretreatmentDrying gas arrangementsFlue gasCoal dust

An energy-saving and environment-friendly flue gas waste heat pulverized coal preparation system comprises a belt coal feeder, a raw coal bunker, a coal feeder, a coal mill and a powder recovery bunker, wherein the dry air inlet of the coal mill communicates with the outlet of a first induced draft fan which is used for inputting high-temperature flue gas at the tail part of a boiler to the coal mill; an inert gas input passage is arranged in front of the dry air inlet of the coal mill; a first control valve is mounted on the inert gas input passage; the outlet of the coal mill communicates with the inlet of the powder recover bunker; a gas temperature detector and a gas concentration detector are mounted behind the outlet of the coal mill and connected with an alarm controller; a pulverized coal collection device is arranged in the powder recovery bunker; a second induced draft fan is mounted behind the flue gas outlet of the powder recovery bunker; and the outlet of the second induced draft fan communicates with the inlet of a flue gas desulfurization device or a chimney. The energy-saving and environment-friendly flue gas waste heat pulverized coal preparation system is a special production line for providing coal dust fuels for the pulverized coal boiler, the security of the pulverized coal preparation system can be guaranteed while the waste heat of flue gas at the tail part of the boiler is effectively utilized, energy saving and consumption reduction are realized and the environment is protected.

Owner:SHANDONG HUANNENG DESIGN INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com