Blast furnace dust recycling utilization method

A blast furnace dust removal and recycling technology, applied in the field of solid waste recycling, can solve problems such as land occupation and environmental pollution of blast furnace dust removal, and achieve the effect of strong adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] 1) Sieve the blast furnace dust removal dust, and sieve out the blast furnace dust removal dust whose particle size is 200 mesh;

[0028] 2) Combine the sieved blast furnace dust with (NH 4 )HCO 3 Mix according to the mass ratio of 6:1, then add water with a mass fraction of 8% and tar residue with a mass fraction of 10% as a binder, stir and mix, extrude and granulate to make spherical granules, granules The diameter is 3.0mm:

[0029] 3) Place the particles obtained in step 2) in an oven at 80° C. for 30 minutes and then transfer them to a muffle furnace. 2 In the medium, the temperature was raised to 450°C at a heating rate of 15°C / min, and then roasted for 30 minutes, and the iron-carbon micro-electrolytic particles were obtained by sintering, and then heated in N 2 Cool to room temperature under atmosphere and set aside;

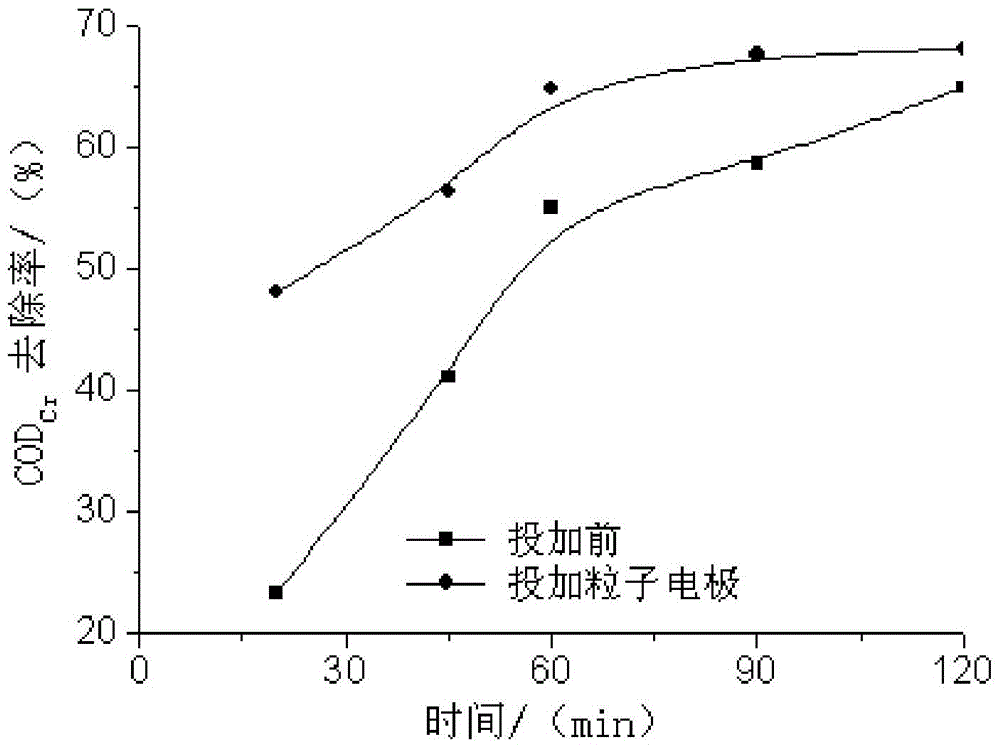

[0030] 4) Put 10g of the iron-carbon micro-electrolysis particles obtained in step 3) into 100ml of coking biochemical external drainage, ad...

Embodiment 2

[0035] 1) Sieve the blast furnace dust removal dust, and sieve out the blast furnace dust removal dust whose particle size is 200 mesh;

[0036] 2) Combine the sieved blast furnace dust with (NH 4 )HCO 3 Mix according to the mass ratio of 10:1, then add water with a mass fraction of 15% and tar residue with a mass fraction of 25% as a binder, stir and mix, extrude and granulate to make spherical particles, granules The diameter is 1.5mm:

[0037] 3) Place the particles obtained in step 2) in an oven at 60° C. for 40 minutes and then transfer them to a muffle furnace. 2 In the medium, the temperature was raised to 700°C at a heating rate of 10°C / min, and then roasted for 60 minutes, and the iron-carbon micro-electrolytic particles were obtained by sintering, and then in N 2 Cool to room temperature under atmosphere and set aside;

[0038]4) Put 10g of the iron-carbon micro-electrolysis particles obtained in step 3) into 100ml of coking biochemical external drainage, adjust ...

Embodiment 3

[0042] 1) Sieve blast furnace dedusting ash, and sieve out blast furnace dedusting ash whose particle size is 300 mesh;

[0043] 2) Combine the sieved blast furnace dust with (NH 4 )HCO 3 Mix according to the mass ratio of 8:1, then add water with a mass fraction of 12% and tar residue with a mass fraction of 16% as a binder, stir and mix, extrude and granulate to make spherical particles, granules The diameter is 2.5mm:

[0044] 3) Place the particles obtained in step 2) in an oven at 60°C for 30 minutes and then transfer them to a muffle furnace. 2 In the medium, the temperature was raised to 500°C at a heating rate of 12°C / min, and then roasted for 60 minutes, and the iron-carbon micro-electrolytic particles were obtained by sintering, and then in N 2 Cool to room temperature under atmosphere and set aside;

[0045] 4) Put 10g of the iron-carbon micro-electrolysis particles obtained in step 3) into 100ml of coking biochemical external drainage, adjust the pH value to 4,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com