Electrostatically-enhanced electric-bag compound dust remover

A technology of electric bag compounding and electrostatic dust removal, which is applied in the direction of combined devices, chemical instruments and methods, and separation of dispersed particles, can solve the problems of unreasonable spatial distribution of electric field intensity and limited effect of electric field force, etc., so as to facilitate dust removal and reduce Filtration resistance, the effect of prolonging the cleaning cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The structure, principle and working process of the present invention will be described in detail below in conjunction with the accompanying drawings.

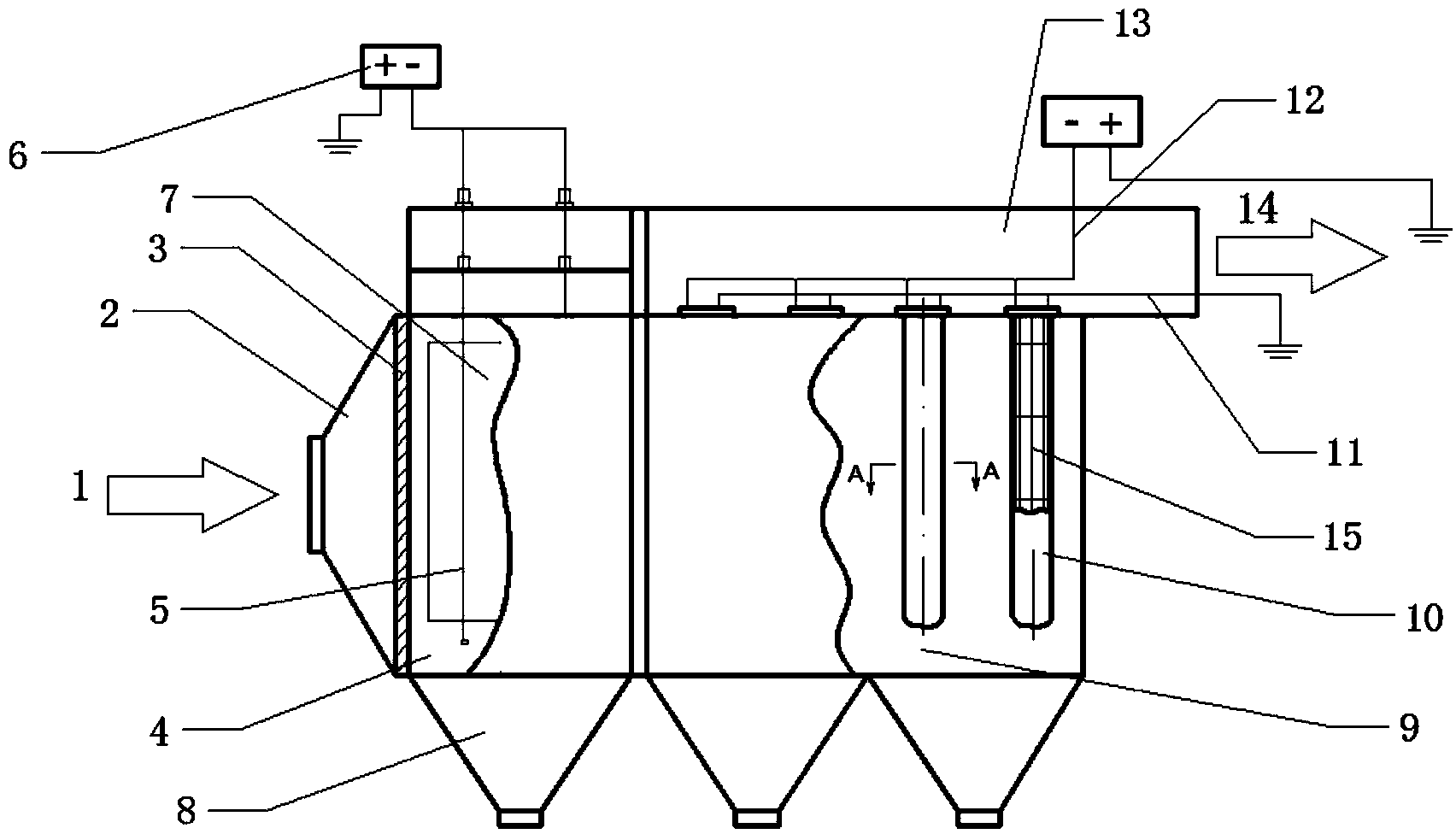

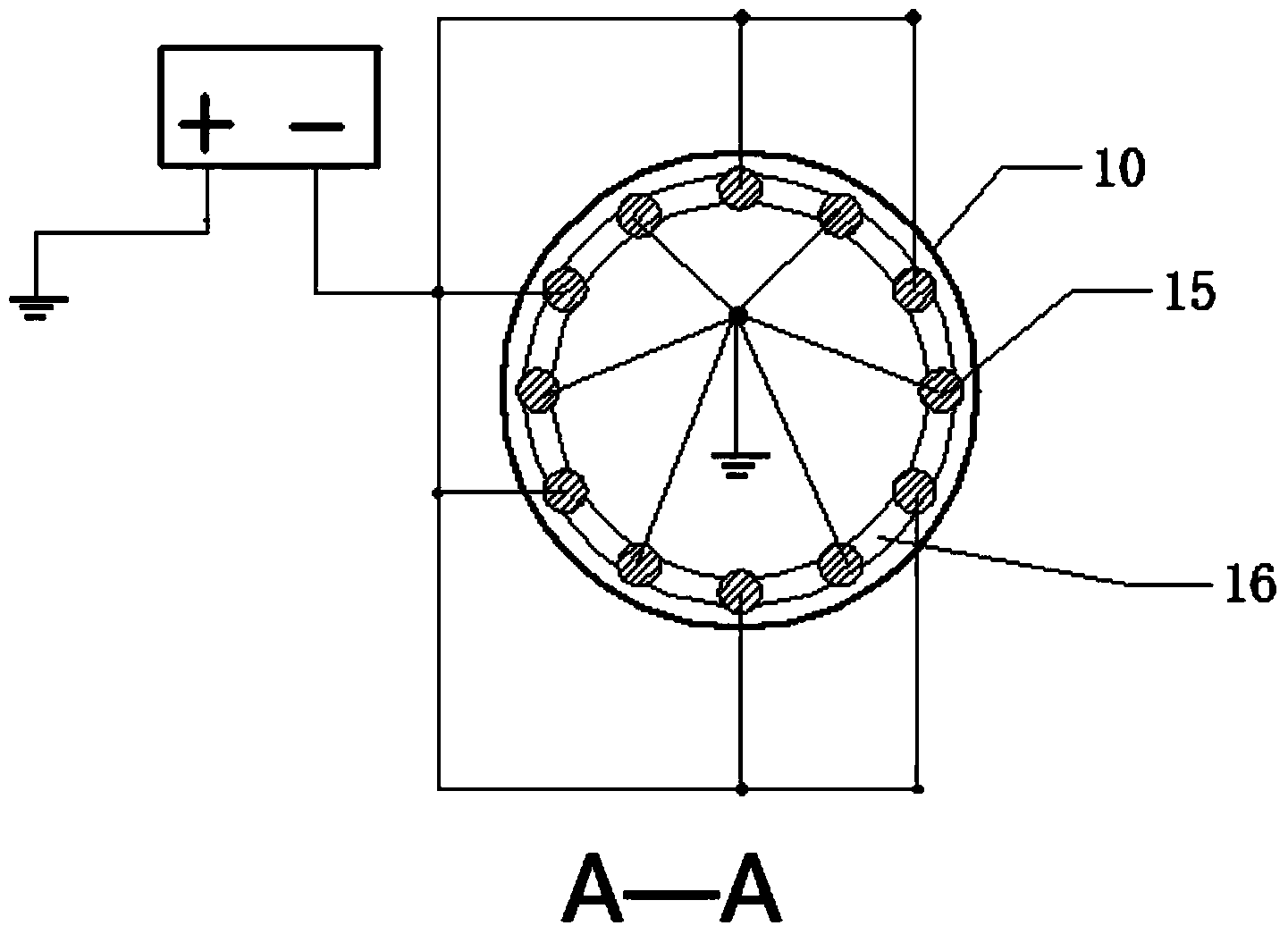

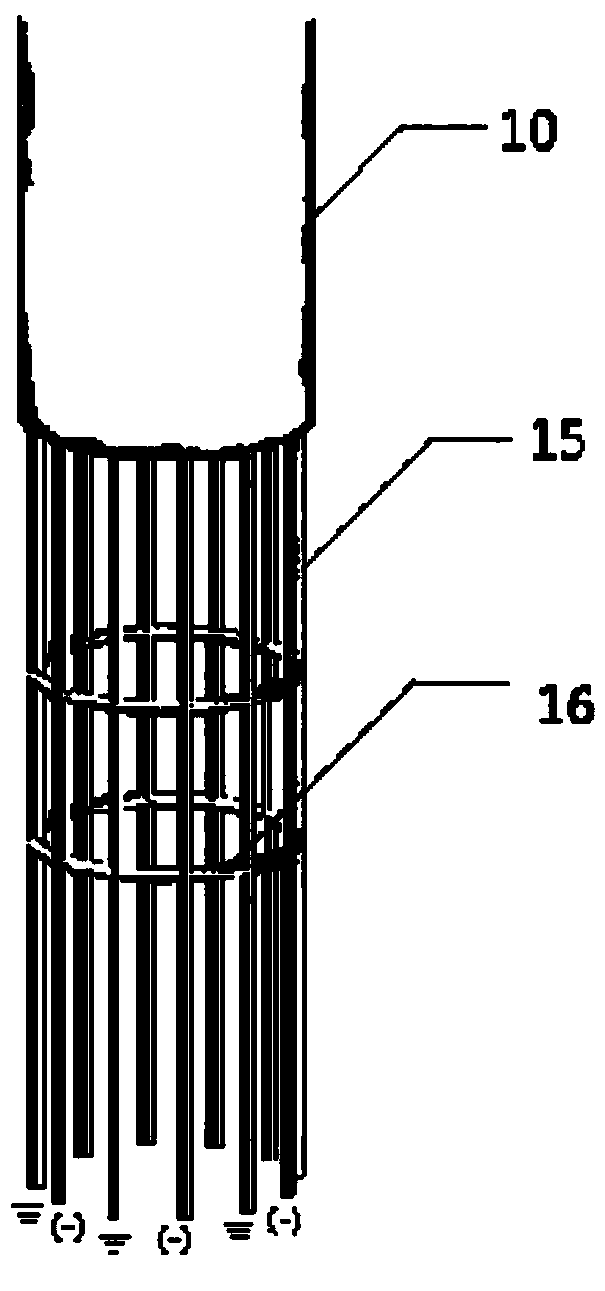

[0021] The present invention is composed of a front-stage electrostatic dust removal area 4 and a rear-stage bag-type dust-removal area 9 connected in series. The filter bag 10 contains cage bones. The cage frame is composed of a plurality of vertical steel bars 15, the vertical steel bars are evenly distributed along the circumference, the number of vertical steel bars is an even number, the number of vertical steel bars is preferably 10, 12 or 14, and two adjacent The polarity of the vertical steel bars is opposite, respectively connected to the negative pole and the ground of the high-voltage DC power supply. The voltage value of the high-voltage DC power supply is negative 10-20 kV. A plurality of insulating rings 16 are vertically arranged in the filter bag, and a plurality of vertical steel bars are fixed on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com