White-light LED COB with CSP chip andlip blue-light chip encapsulation and preparation method thereof

A LED chip and flip-chip technology, which is applied in the field of lighting, can solve problems such as complex and difficult COB technology for color matching, and achieve the effects of uniform distribution, small near-field color temperature change, and improved product reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

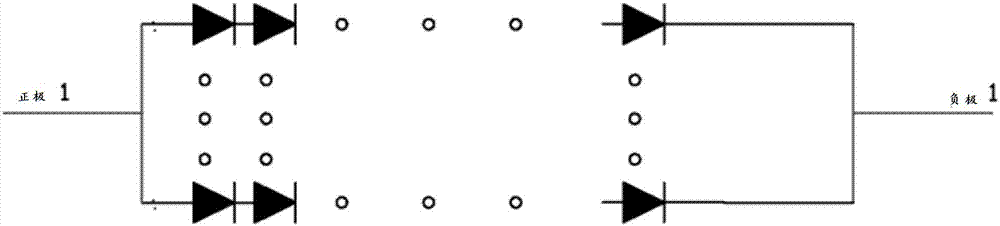

[0076] Embodiment 1. Dual circuit scheme:

[0077] Such as Figure 6 As shown, the structure of a white LED COB packaged with a CSP chip and a flip-chip blue LED chip includes a square COB substrate 3-5, and a flip-chip blue LED chip array 3-5 is soldered to the middle of the COB substrate 3-5 by reflow soldering. 12 and warm color temperature CSP arrays 3-10, the two arrays are arranged in an orderly manner as required. On the four corners of the COB substrate 3-5, the positive electrode 1 and the negative electrode 1 of the CSP circuit 3-11 for controlling the warm color temperature are correspondingly provided, and the positive electrode 2 and the negative electrode 2 of the flip-chip blue LED chip circuit 3-14 are controlled. The peripheral area is provided with a circuit layer 3-3 and a solder resist layer 3-6. The CSP circuit 3-11 for controlling the warm color temperature and the circuit 3-14 for controlling the flip-chip blue LED chip are respectively connected to th...

Embodiment 2

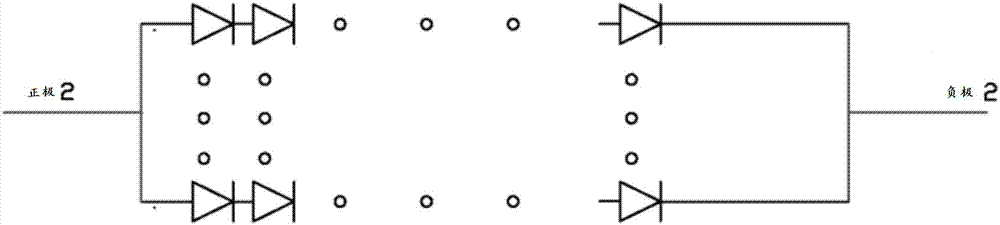

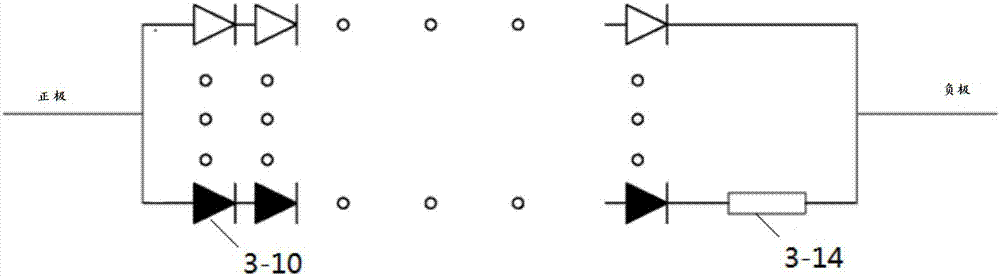

[0083] Embodiment 2. Single circuit solution:

[0084] Such as Figure 7 As shown, the structure of a white LED COB packaged with a warm color temperature CSP array 3-10 and a flip-chip blue LED chip array 3-12 includes a square COB substrate 3-5, and the middle part of the COB substrate 3-5 is welded by reflow soldering There are flip-chip blue LED chip arrays 3-12 and low color temperature CSP light source arrays, and the two arrays are arranged in an orderly manner as required. On the two corners of the diagonal line of the COB substrate 3-5, the anode and cathode for simultaneously controlling the low color temperature CSP circuit and the flip-chip blue LED chip circuit are correspondingly provided, and the circuit layer 3-3 and Solder mask 3-6. The low color temperature CSP circuit and the flip-chip blue LED chip circuit are respectively connected to the corresponding electrodes after the serial-parallel connection of the circuit on the COB substrate. Around the two ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com