Patents

Literature

46results about How to "Good exfoliation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Intercalates formed with polypropylene/maleic anhydride-modified polypropylene intercalants

InactiveUS20010033924A1Good dispersionImprove distributionThin material handlingWater-setting substance layered productPolyolefinPolymer science

A nanocomposite concentrate composition comprising about 10 weight percent to about 90 weight percent of a layered silicate material and about 10 weight percent to about 90 weight percent of a matrix polymer comprising about 90-99.8% by weight of a polyolefin and about 0.2% to about 10%, preferably about 0.2% to about 3%, more preferably about 1% to 3% by weight, of a maleic anhydride-modified polyolefin, based on the total weight of polyolefins, wherein the layered silicate material is dispersed uniformly throughout the matrix polymer. Shearing of the concentrate and later (after shear) addition of an added matrix polymer avoids thermal degradation of the added matrix polymer and optimizes the dispersion of the nanomer throughout the matrix polymer; provides increased tensile strength; and reduces degradation of the polymer by melt formation of a concentrate thereby decreasing heat degradation of added matrix polymer.

Owner:AMCOL INTERNATIONAL CORPORATION

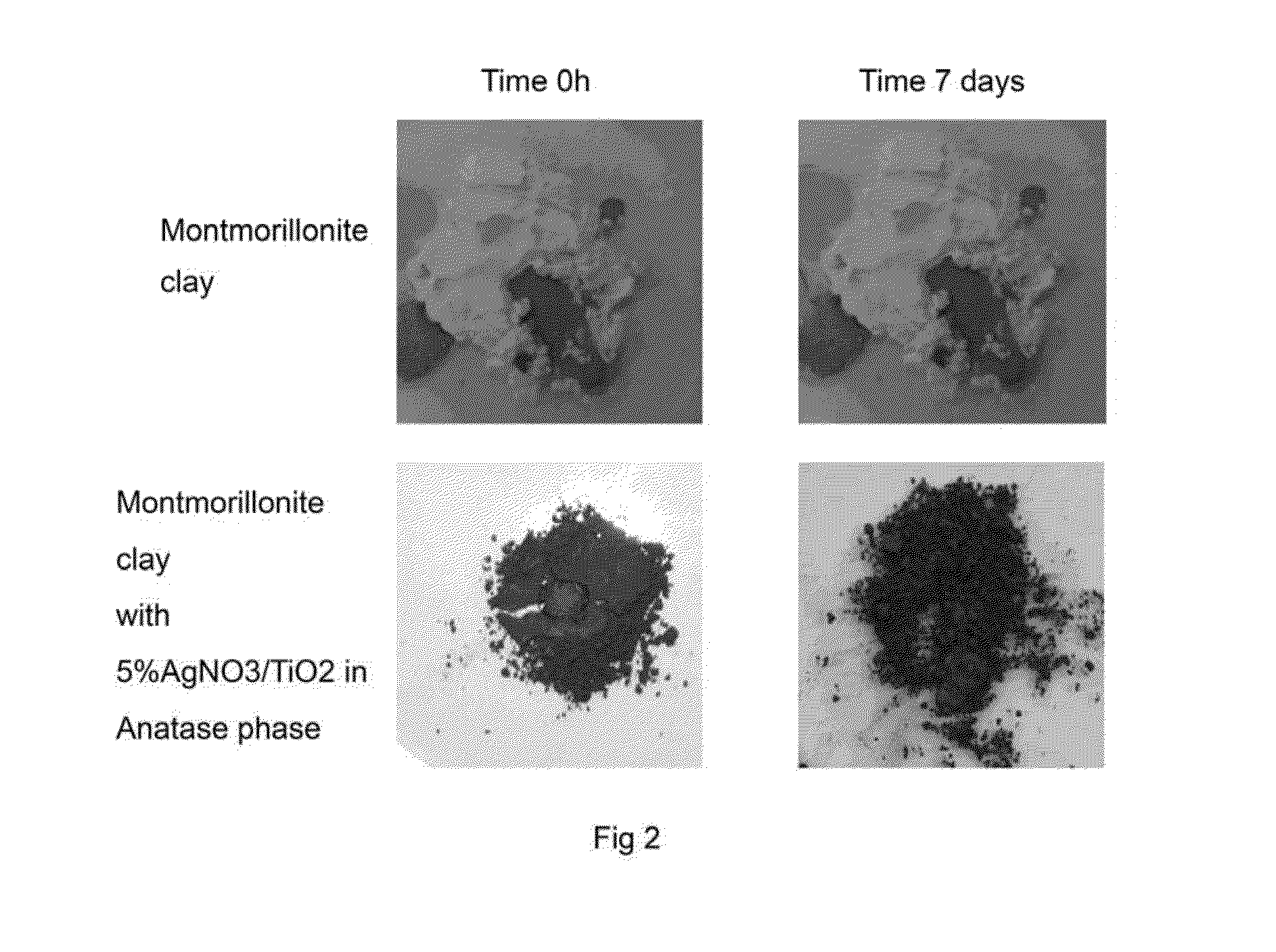

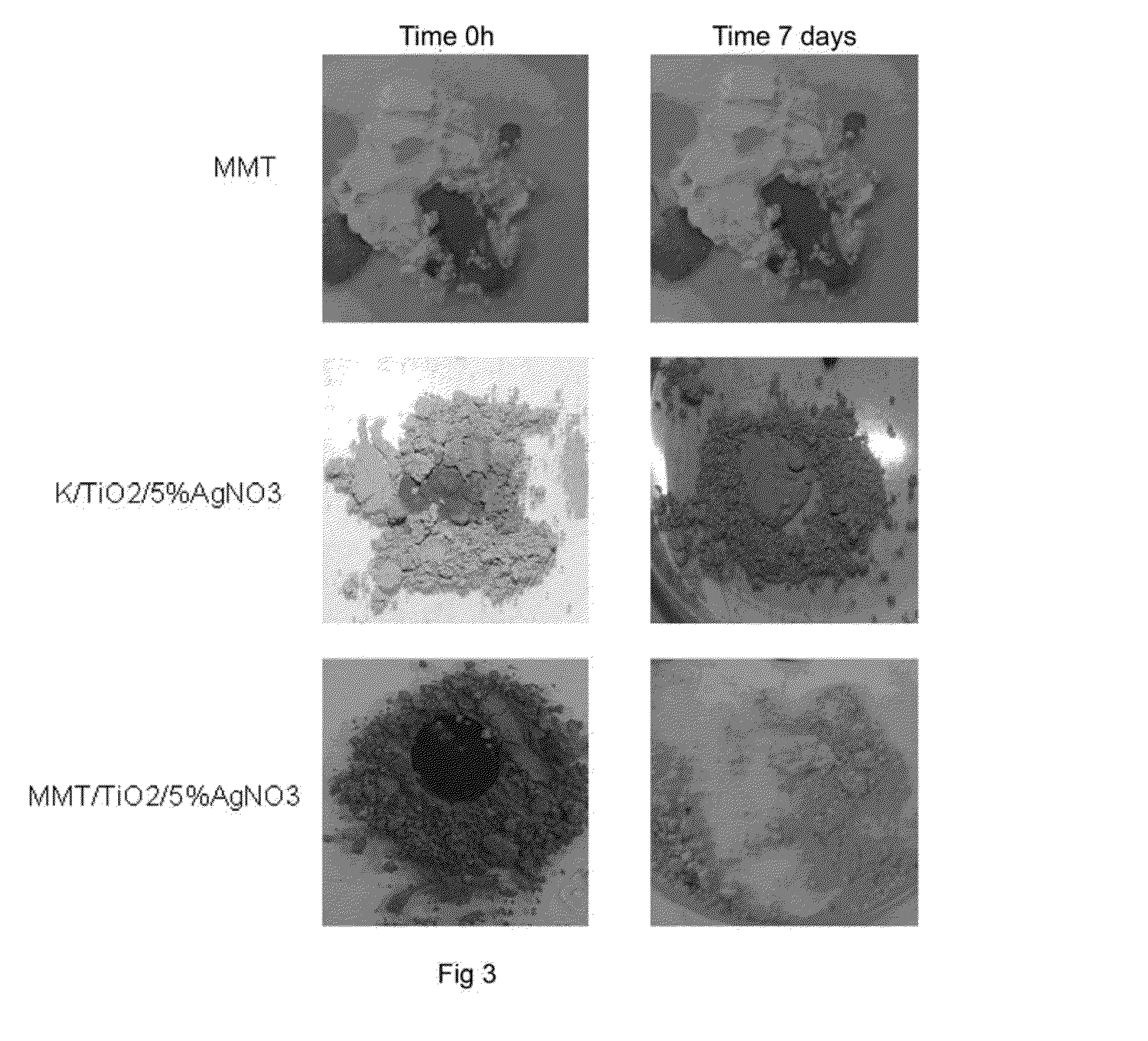

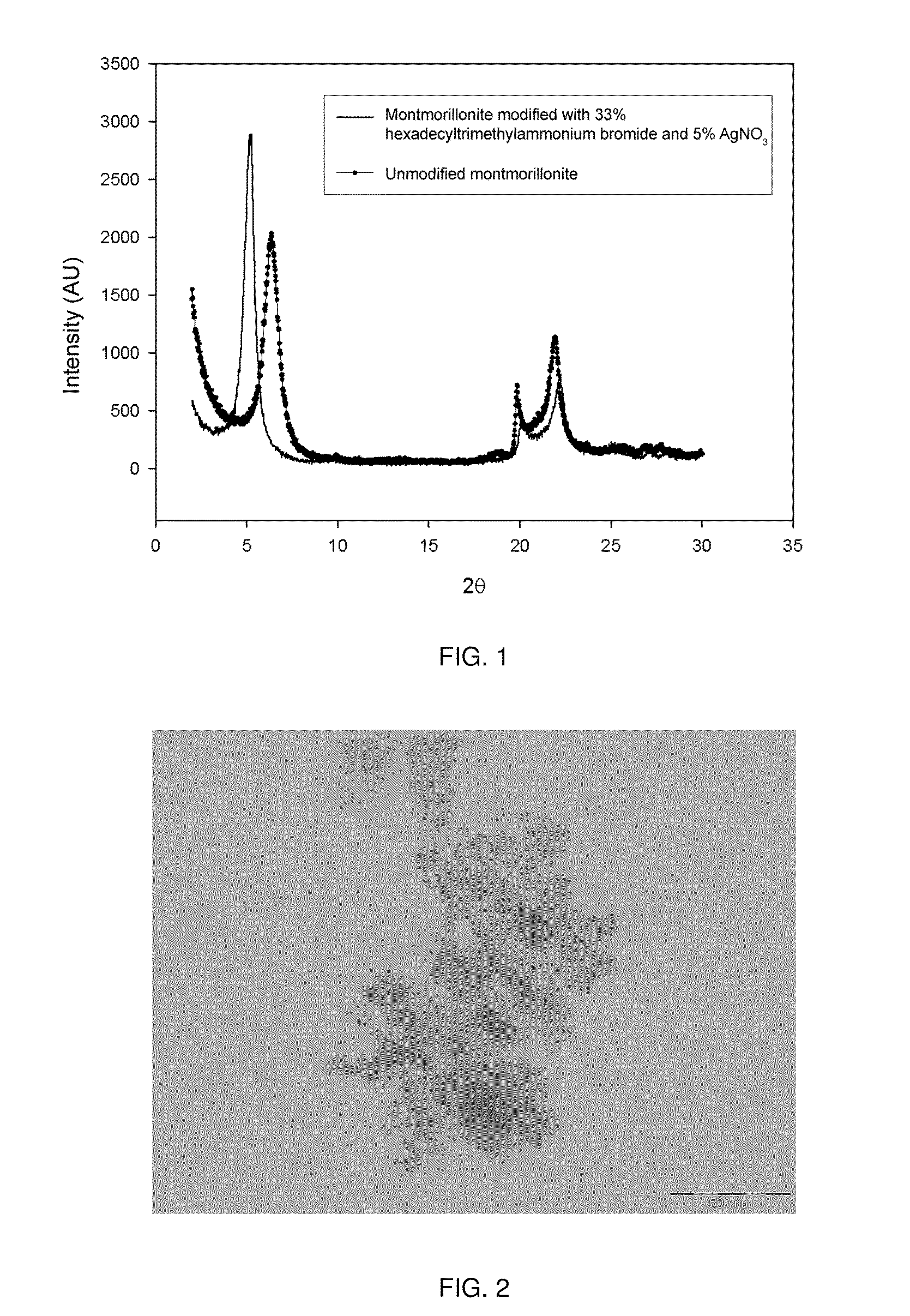

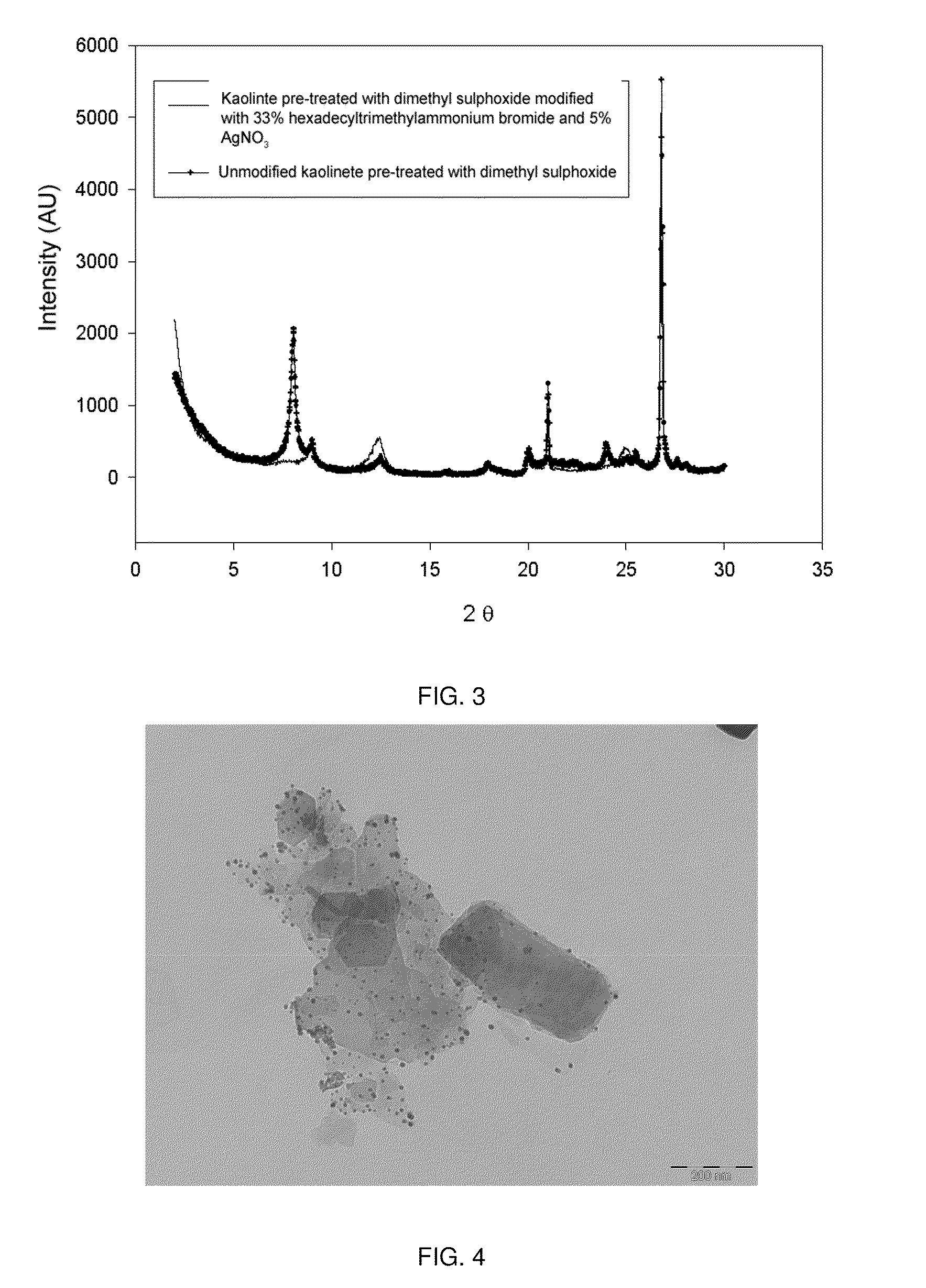

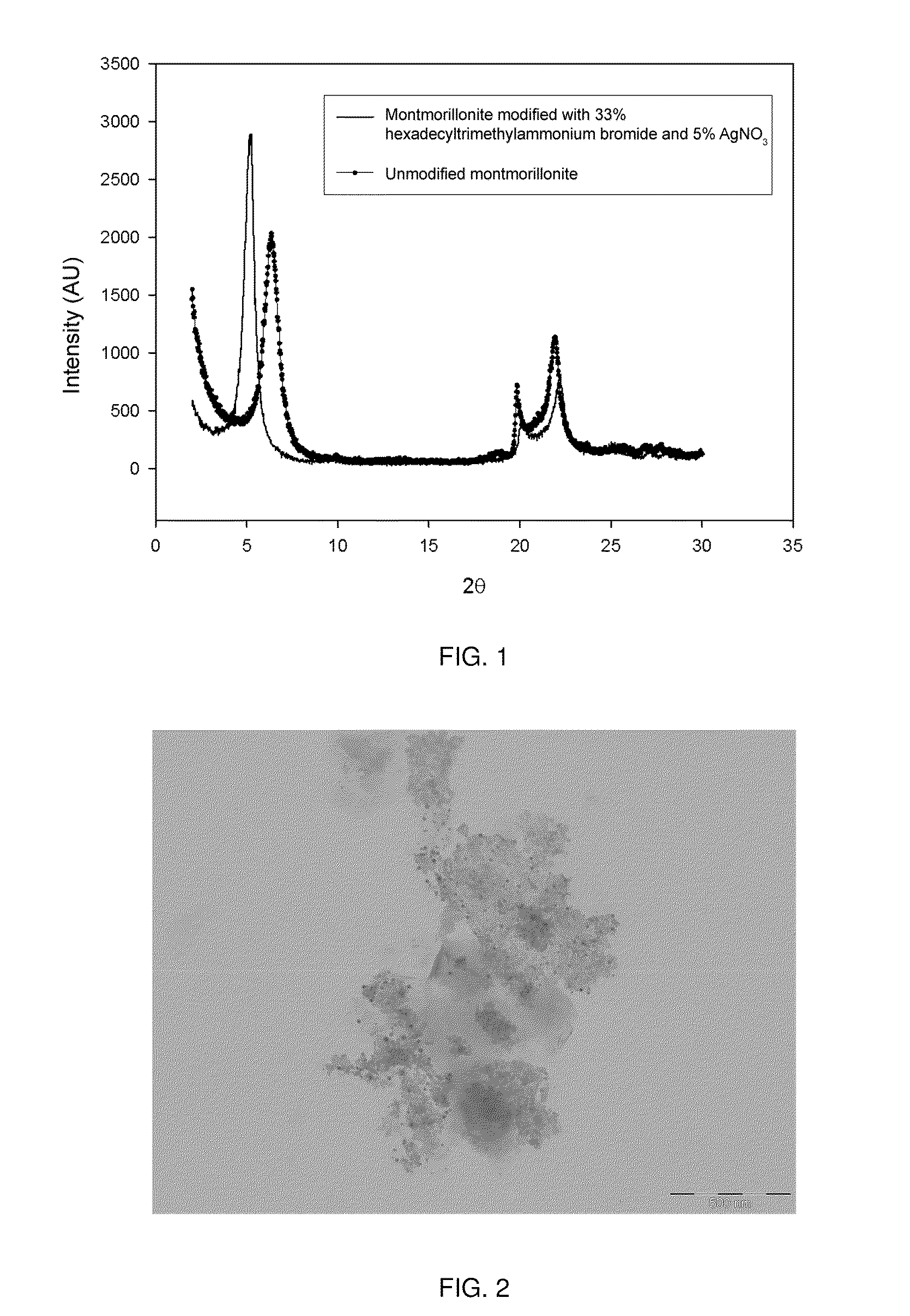

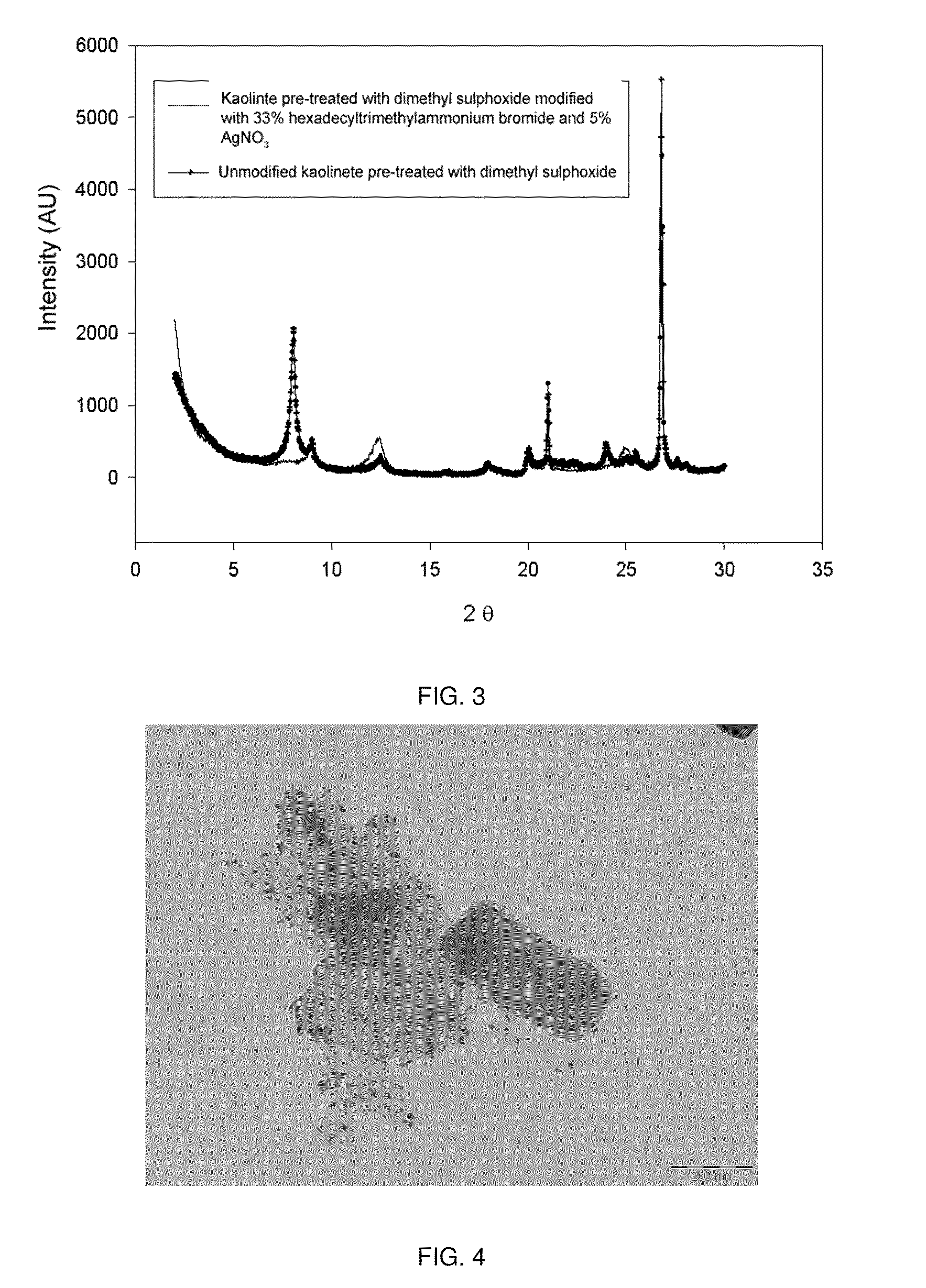

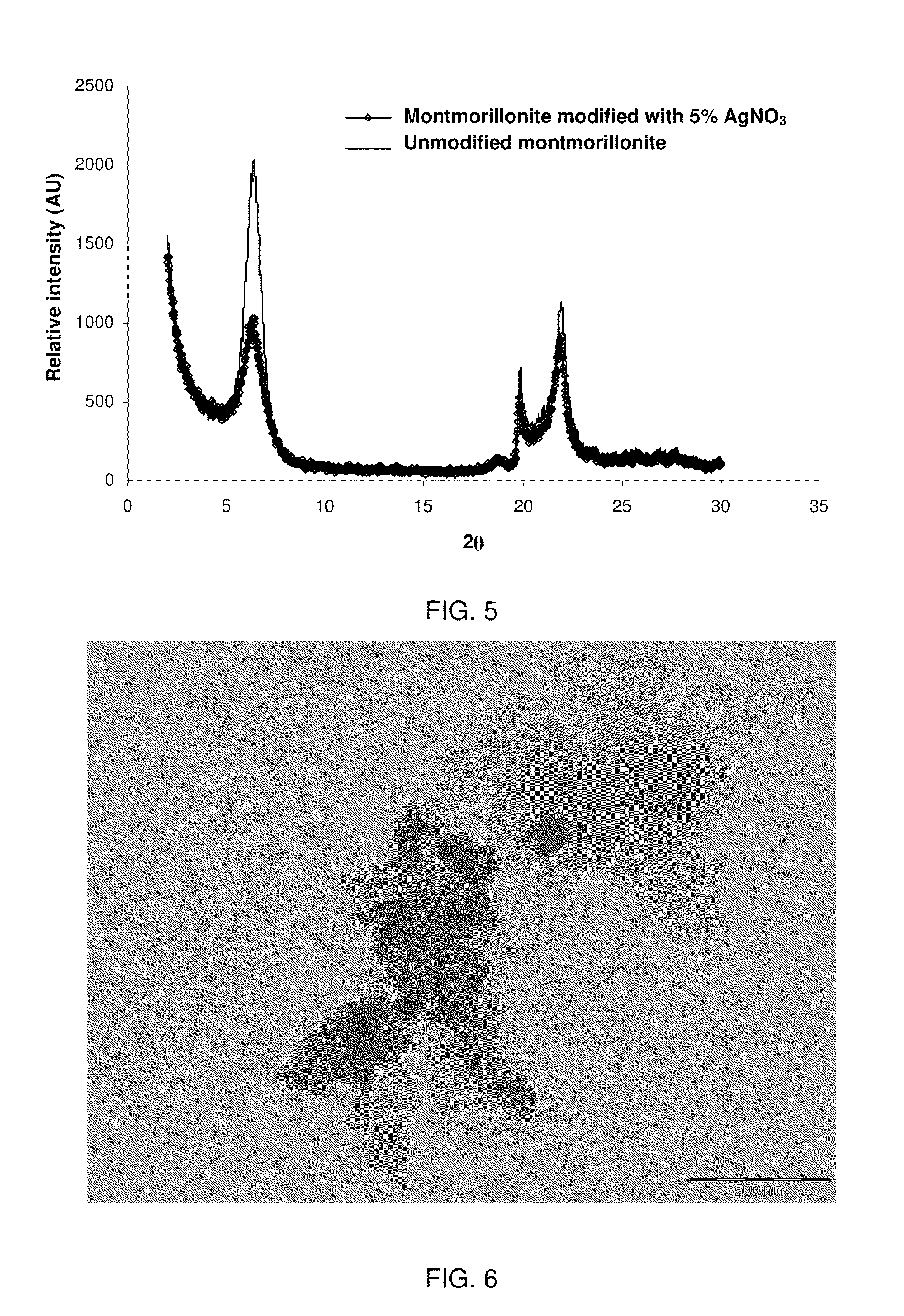

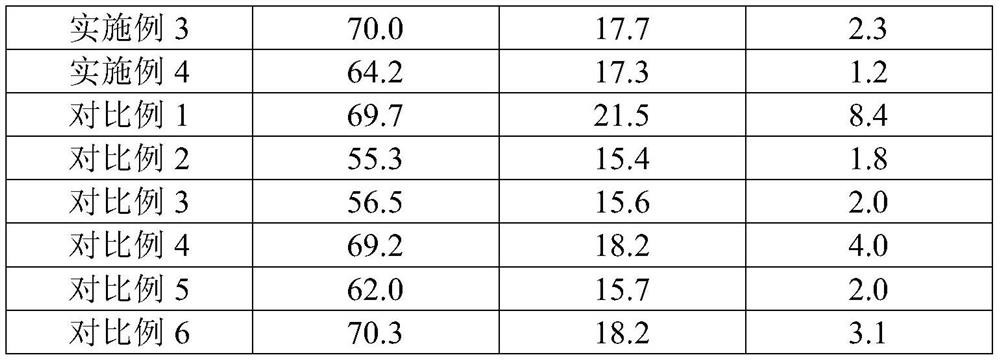

Nanocomposite materials based on metal oxides having multi-functional properties

InactiveUS20140187413A1Improved gas and vapour, flame retardant, mechanical and thermal propertiesLimit fixationPigmenting treatmentMaterial nanotechnologyAntioxidantActive agent

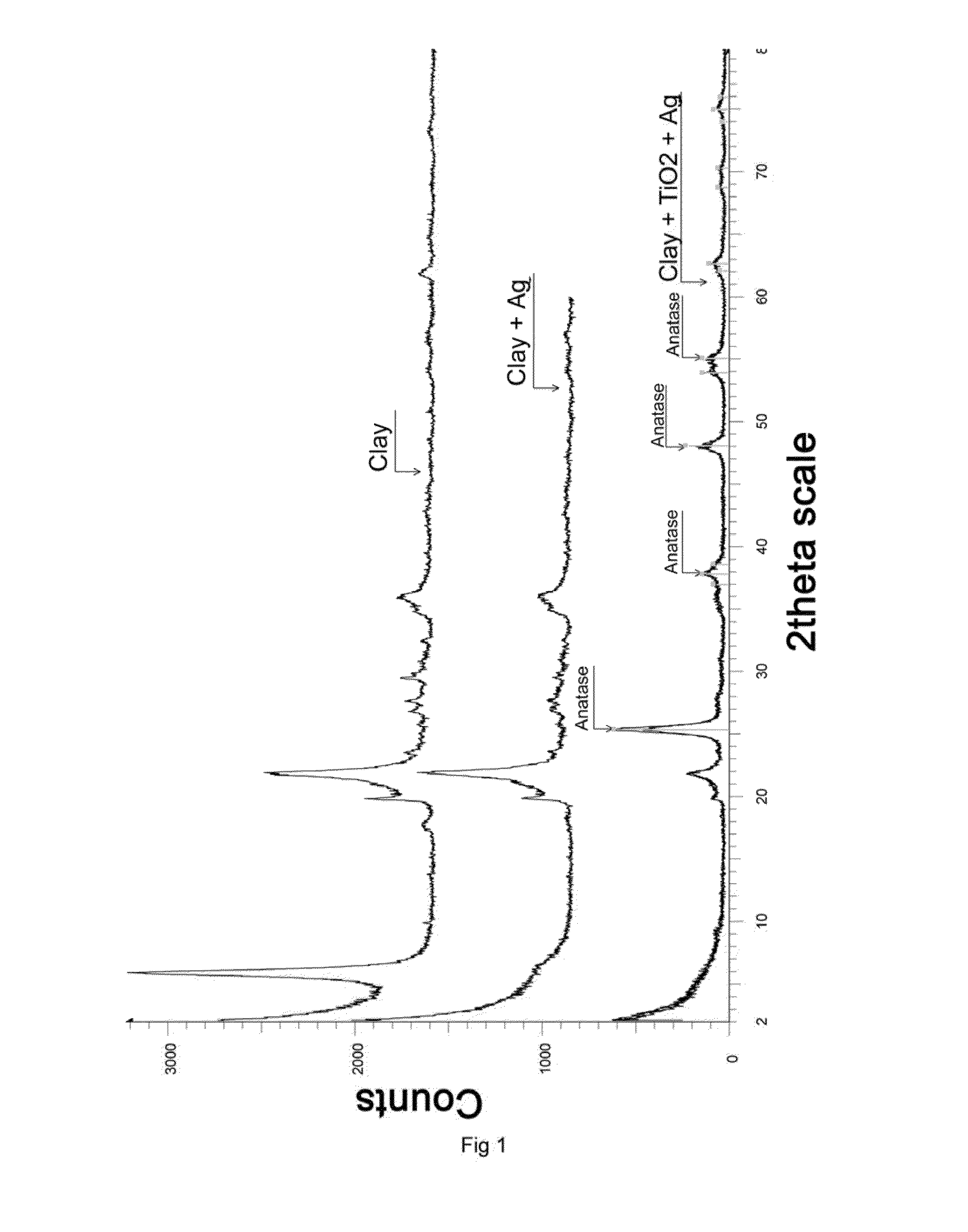

The present invention relates to nanocomposite materials comprising nanoclays as support of metal oxide particles which give the materials multi-functional properties. Said properties are obtained through the formulation of a specific type of additives based on layers of natural and / or synthetic clays which are intercalated with metal oxides with antimicrobial and / or oxygen sequestrating and / or catalytic and / or self-cleaning and / or anti-abrasive capacity; and which may optionally contain other organic, metal, inorganic compounds or combination thereof which may exercise a role of compatibilization and / or dispersion and / or increase in the functionality of the metal oxides and / or providing new functionalities, both passive of physical strengthening and active such as biocide character, antioxidant and chemical-species absorbers.Furthermore, the present invention discloses the use of said materials for multi-sector applications.

Owner:NANOBIOMATTERS RES & DEV

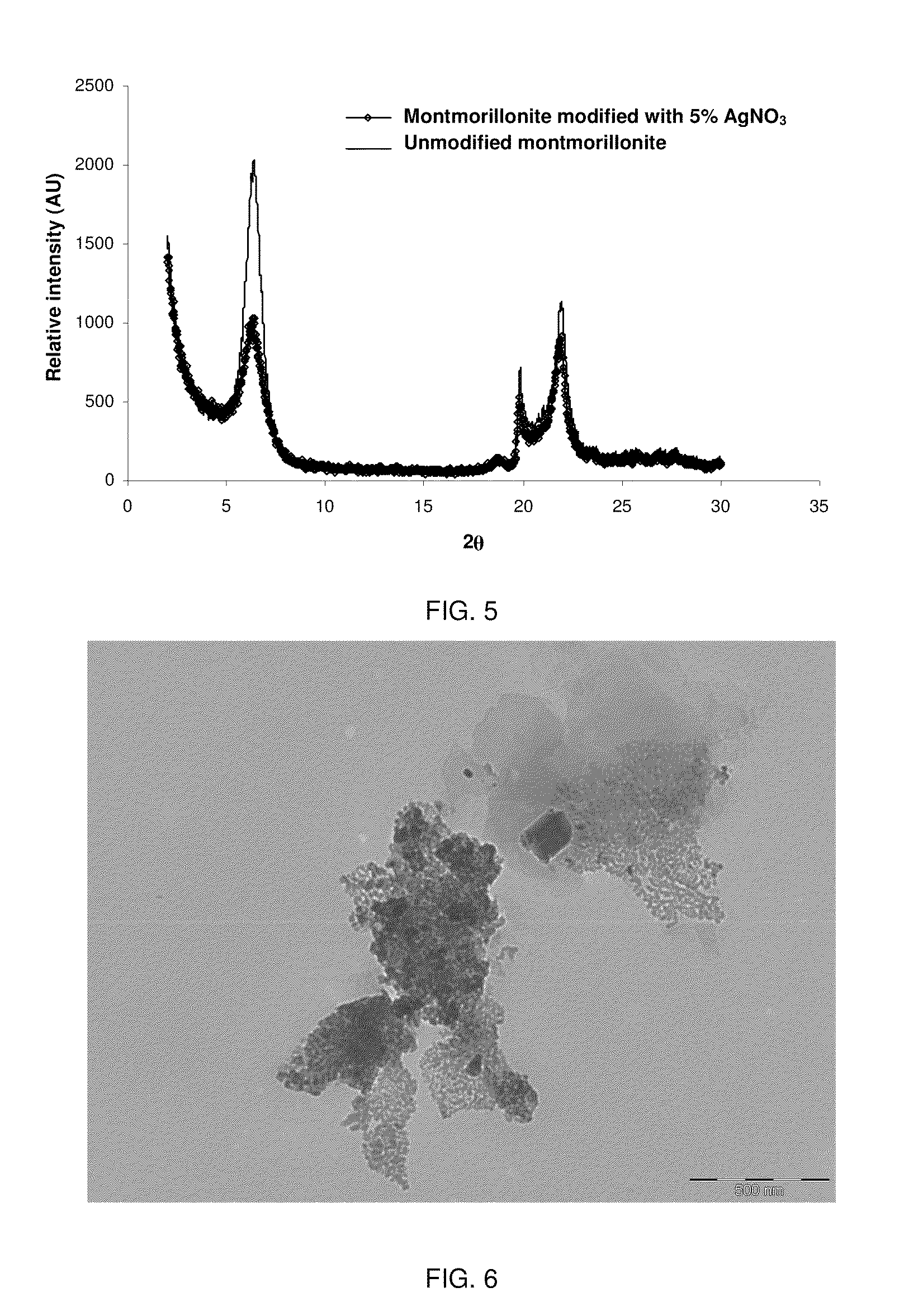

Active nanocomposite materials and production method thereof

ActiveUS20110142899A1Easy to oxidizeImprove efficiencyPigmenting treatmentMaterial nanotechnologyMaterials scienceIndustry sector

SUMMARY The present invention refers to new active nanocomposite materials, comprising a matrix and additives. The present invention also describes a process for obtaining these nanocomposite materials and their use in various industry sectors.

Owner:LAB ARGENOL

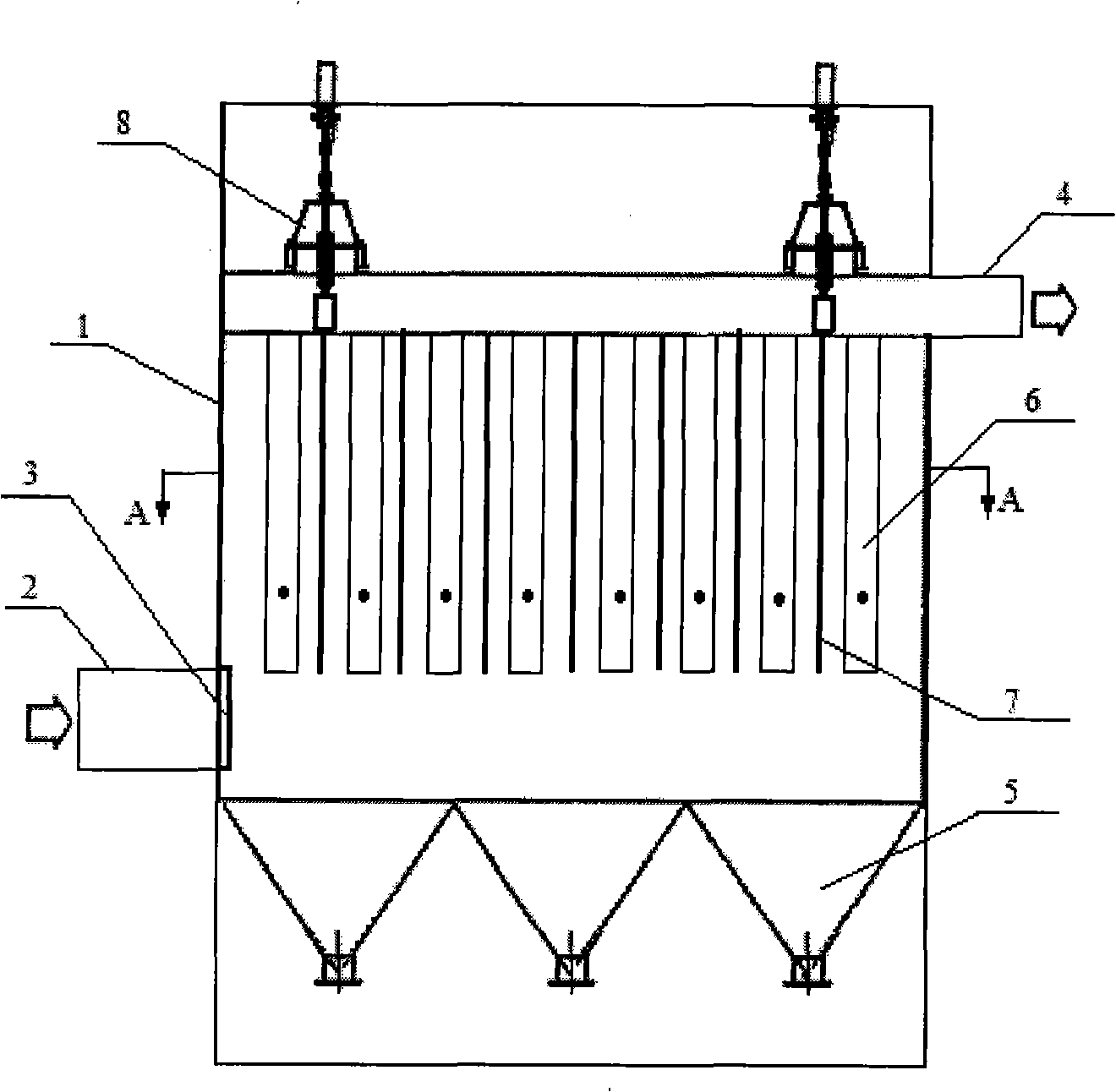

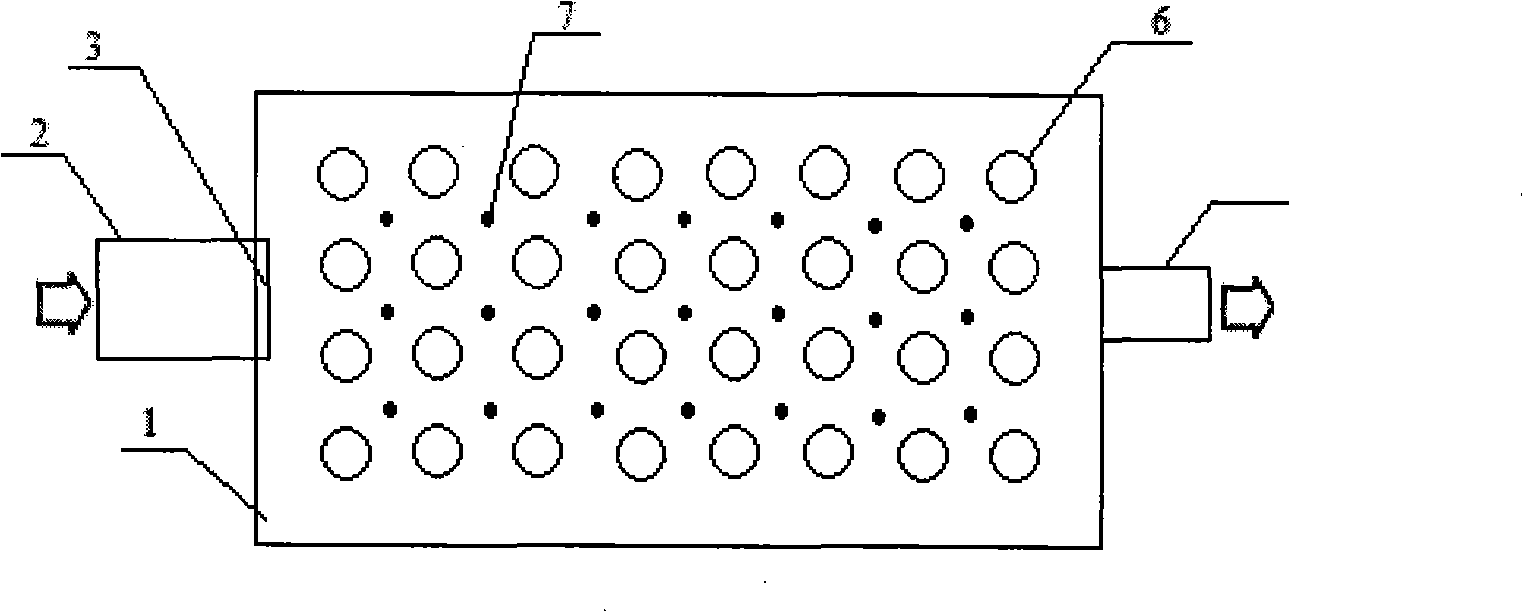

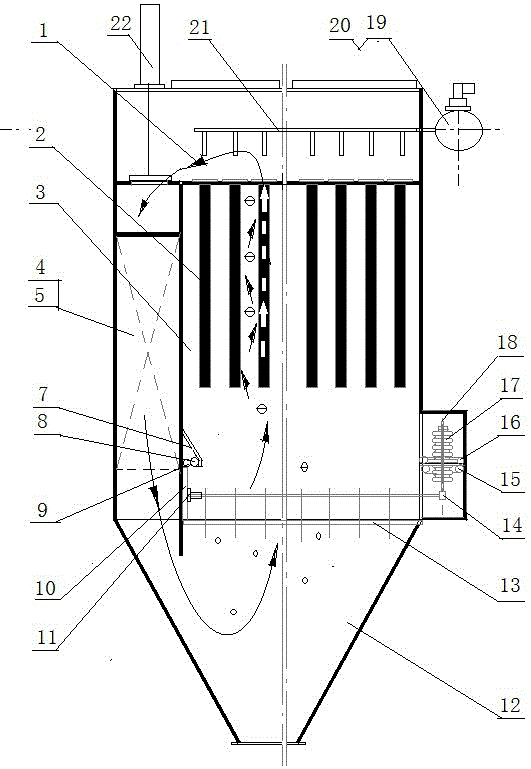

Bag type dust arrest pole electric dust-collecting device

InactiveCN101274305AEfficient removalSmall running resistanceCombination devicesElectrostatic separationElectricityHigh pressure

The invention discloses a polar electricity dust removing device with bagged dust collection, which comprises a dust remover shell, a smoke gas inlet, a uniform air board, a smoke gas outlet, dust buckets, filtering bags, electrode wires and a high-voltage insulating compartment, wherein, a plurality of rows of cloth bags are evenly arranged at interval inside the shell, and the high-voltage electrode wires are arranged at the circle center of a concentric circle of every four cloth bags and connected with a power source through the high-voltage insulating compartment arranged at the top of a dust remover; the uniform air board is arranged under a plurality of rows of filtering bags at the lateral wall of the dust remover shell close to the smoke gas inlet, multiple levels of dust buckets are arranged under the multiple rows of filtering bags, and the smoke gas outlet is arranged above the multiple rows of filtering bags at the lateral wall of the dust remover shell. The polar electricity dust removing device with bagged dust collection has the advantages of simple and unique structure, superior technical performance, smaller resistance, effective overcoming of the reverse corona phenomenon and good dust removing effect, etc. The polar electricity dust removing device with bagged dust collection improves the integral dust removing efficiency under the agglomeration action of electrostatic fields and the interception action of the cloth bags, effectively protects the filtering bags from being burned out by discharge sparks by adopting protective cage structure, and reduces device cost by substituting the steel polar plates with the filtering bags.

Owner:ZHEJIANG GONGSHANG UNIVERSITY

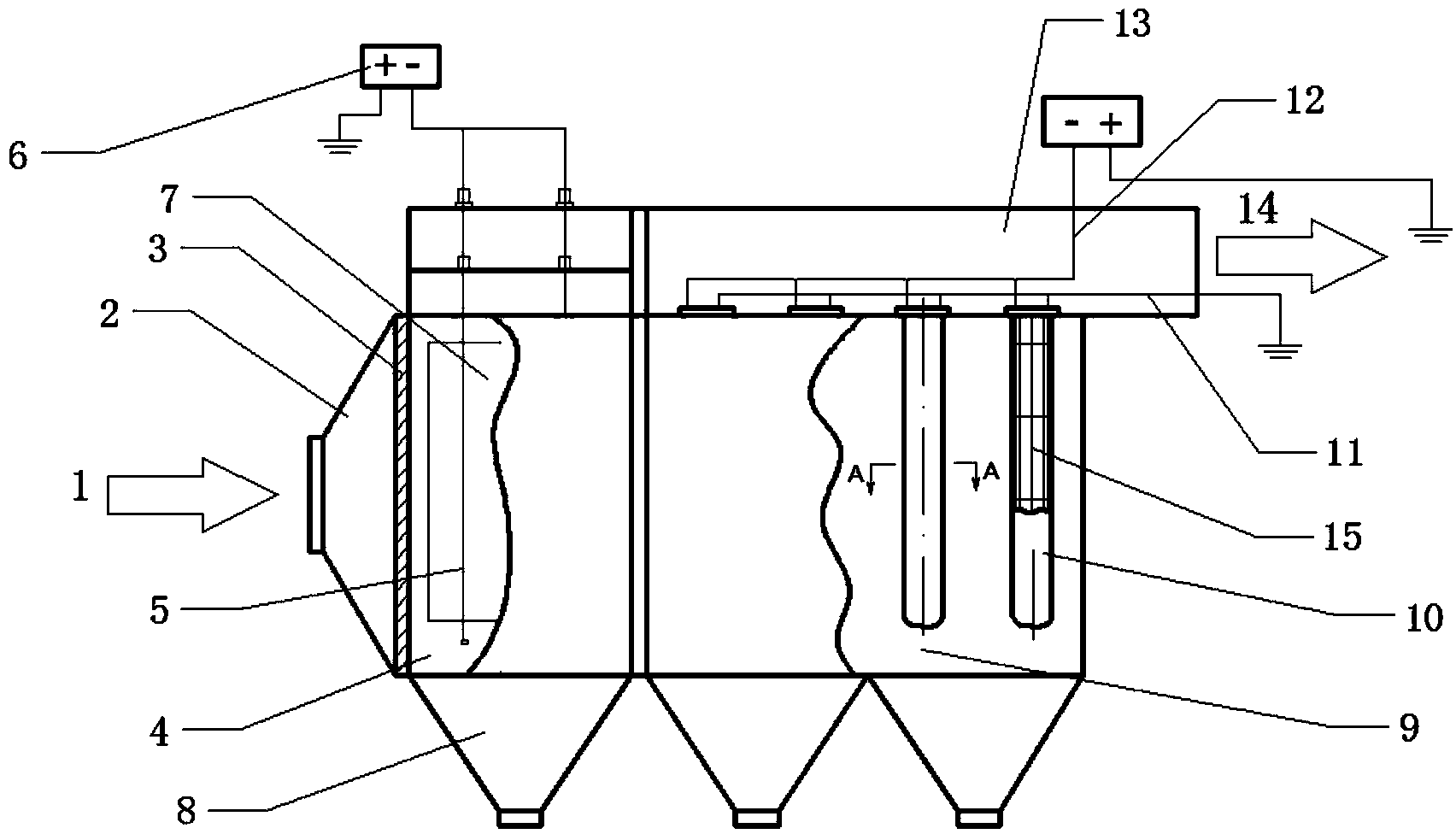

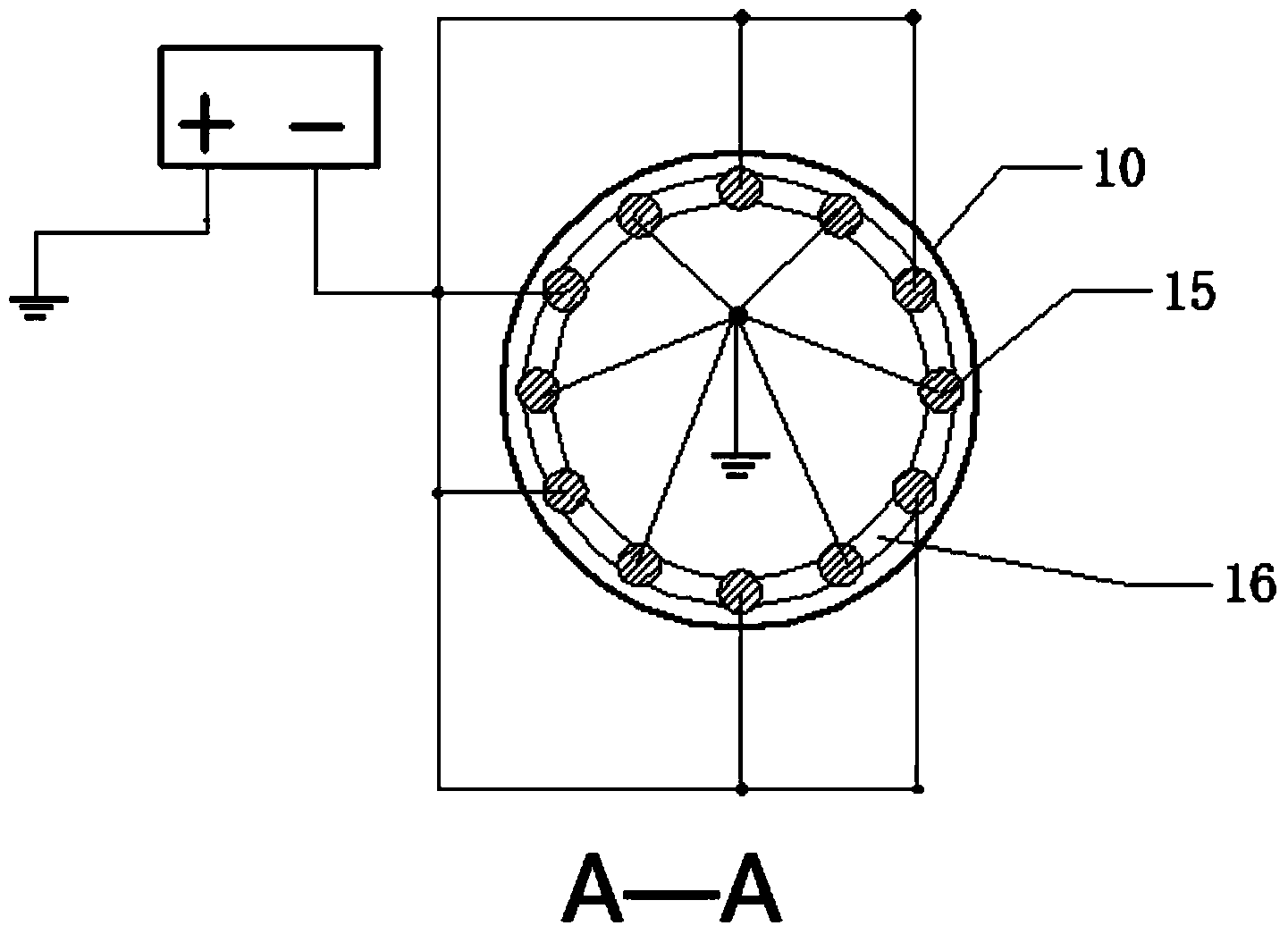

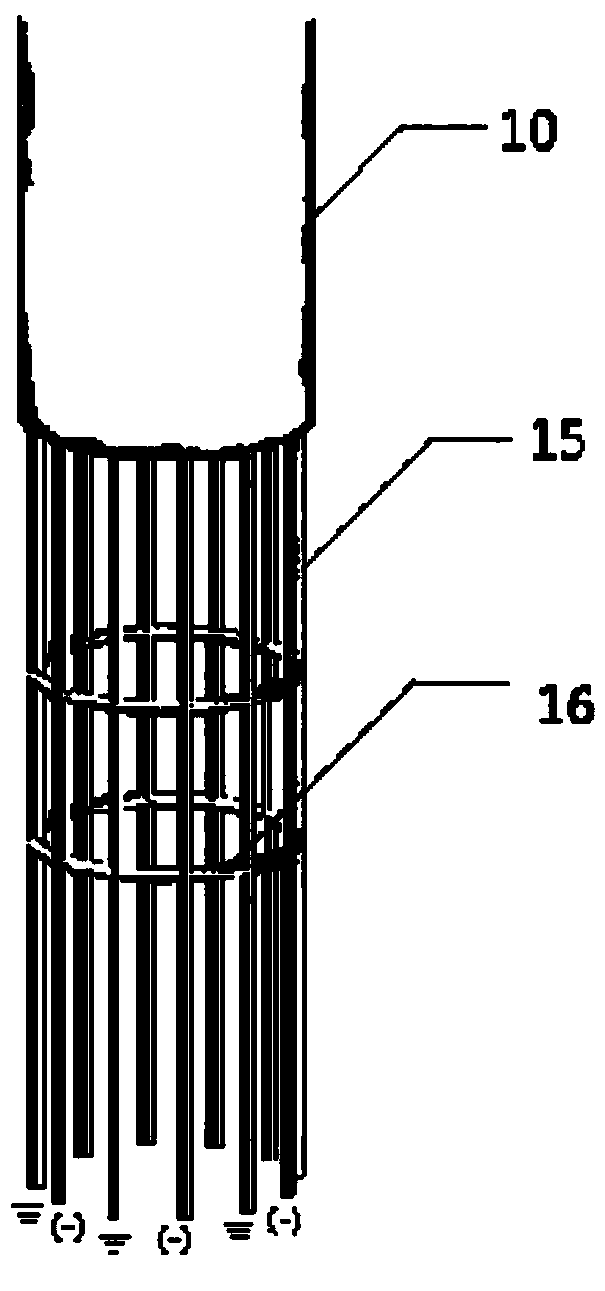

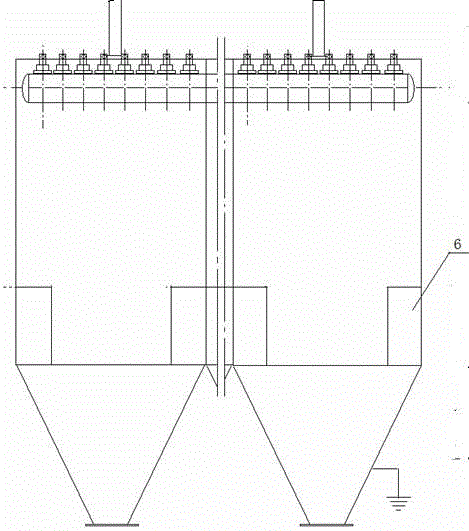

Electrostatically-enhanced electric-bag compound dust remover

ActiveCN103657316ADifficult to enterExtend your lifeCombination devicesFiltrationHigh-voltage direct current

An electrostatically-enhanced electric-bag compound dust remover comprises a high-voltage power supply arranged outside a casing and a compound dust removing area arranged in the casing; the compound dust removing area comprises a forestage electrostatic dust removing area and a rear-stage bag type dust removing area, wherein the forestage electrostatic dust removing area comprises a high-voltage discharge polar line and a dust collecting pole plate; filtering bags uniformly distributed are arranged in the bag type dust removing area; conductive cage bones are arranged in the filtering bags; vertical reinforcement bars in the conductive cage bones are connected with the ground and the negative pole of a high-voltage direct-current power supply, and each two adjacent vertical reinforcement bars are opposite in polarity; a plurality of insulating rings are arranged in the vertical direction; the vertical reinforcement bars are fixed on the insulating rings. The electrostatically-enhanced electric-bag compound dust remover has the characteristics that a non-uniform electric field is added in the bag type dust removing area, so that charged dust particles are distributed non-uniformly on the surfaces of the filtering bags; meanwhile, the particles are polarized into chains through the electric field, and then the probability of collecting the particles can be increased, so that the air-to-cloth ratio can be improved, the filtration resistance can be lowered at the same time, the soot cleaning frequency can be reduced, and the dust remover has the advantages of low energy consumption and long service life.

Owner:TSINGHUA UNIV

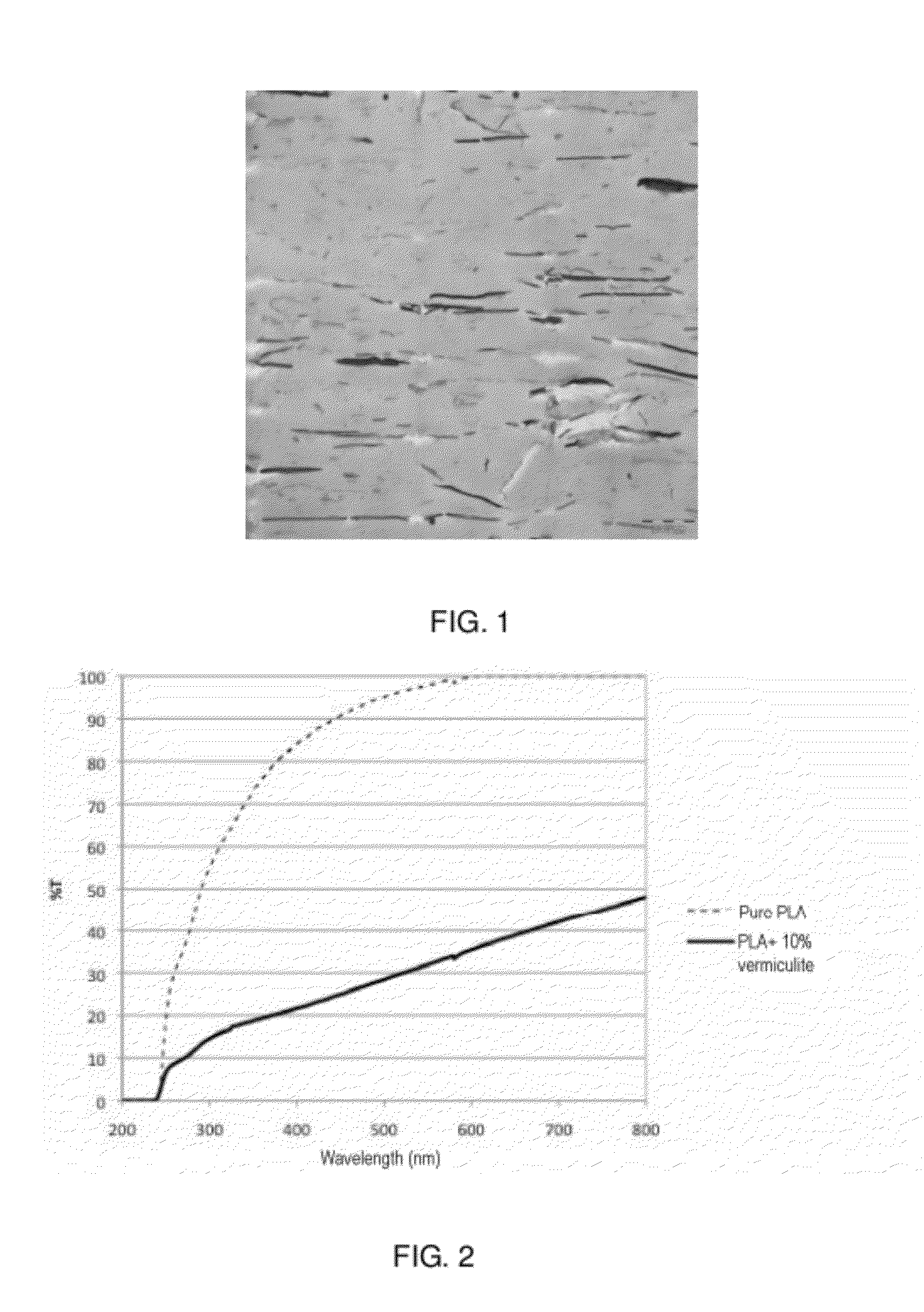

Nanocomposite materials having electromagnetic-radiation barrier properties and process for obtainment thereof

InactiveUS20120039975A1Small sizeImprove functionalityPowder deliveryBiocidePolymer scienceElectromagnetic radiation

Nanocomposite materials having electromagnetic-radiation barrier properties comprising layered nanoadditives with or without organic and / or inorganic surface modification; and a polymeric matrix, process for obtainment thereof and use of said nanocomposite materials in applications of packaging, greenhouse films, coatings, etc.

Owner:NANOBIOMATTERS

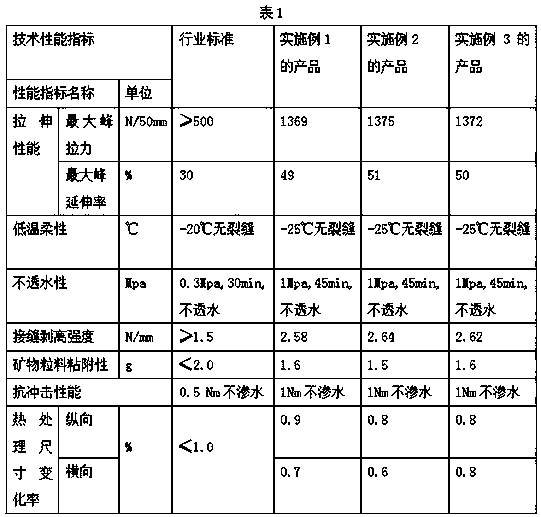

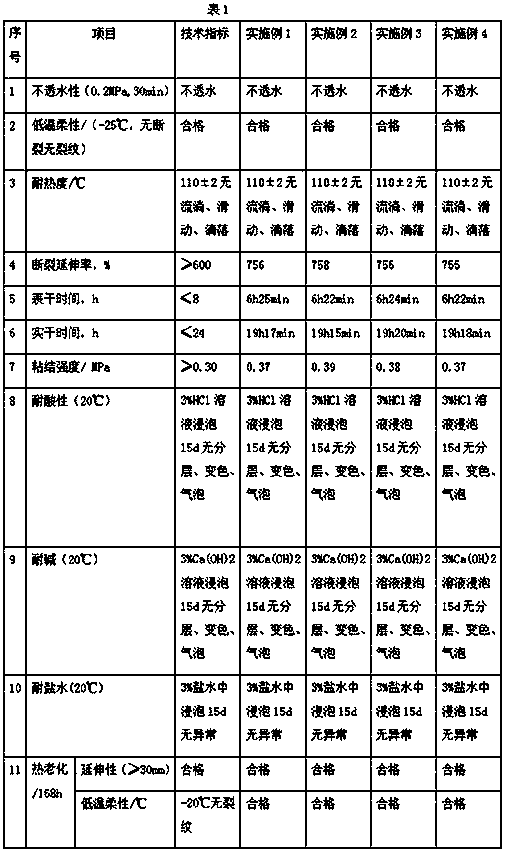

Polyurethane modified asphalt waterproof roll and production method thereof

InactiveCN108099306AStable hydrolysisStable light fadeSynthetic resin layered productsLaminationWater leakageBituminous waterproofing

The invention relates to a polyurethane modified asphalt waterproof roll. The polyurethane modified asphalt waterproof roll is of a five-layer structure which comprises, from top to bottom, a top isolating layer, an upper modified asphalt layer, a padding layer, a lower modified asphalt layer and a bottom isolating layer, wherein the upper modified asphalt layer and the lower modified asphalt layer are prepared from modified asphalt. The polyurethane modified asphalt waterproof roll is greatly improved in tearing strength, adhesion, water resistance, aging resistance and the like, has high elongation at break, and overcomes the disadvantages of tedious preparation, weak adhesion and the like of conventional waterproof rolls. A production method for the polyurethane modified asphalt waterproof roll is simple. As the polyurethane modified asphalt waterproof roll is applied to a building, a contact surface of the polyurethane modified asphalt waterproof roll and the base surface of the building has good bonding strength and waterproof effect, so the waterproof roll is effectively prevented from water seepage and water leakage.

Owner:GUANGXI WUXUAN JINPAI WATERPROOF MATERIAL SCI & TECH CO LTD

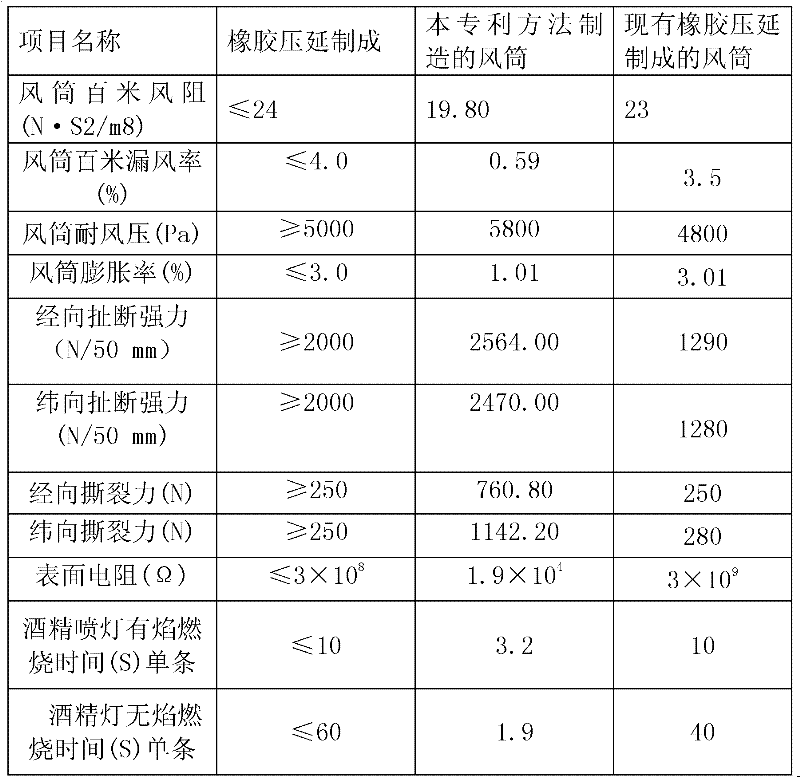

Coal mine air cylinder and manufacturing method thereof

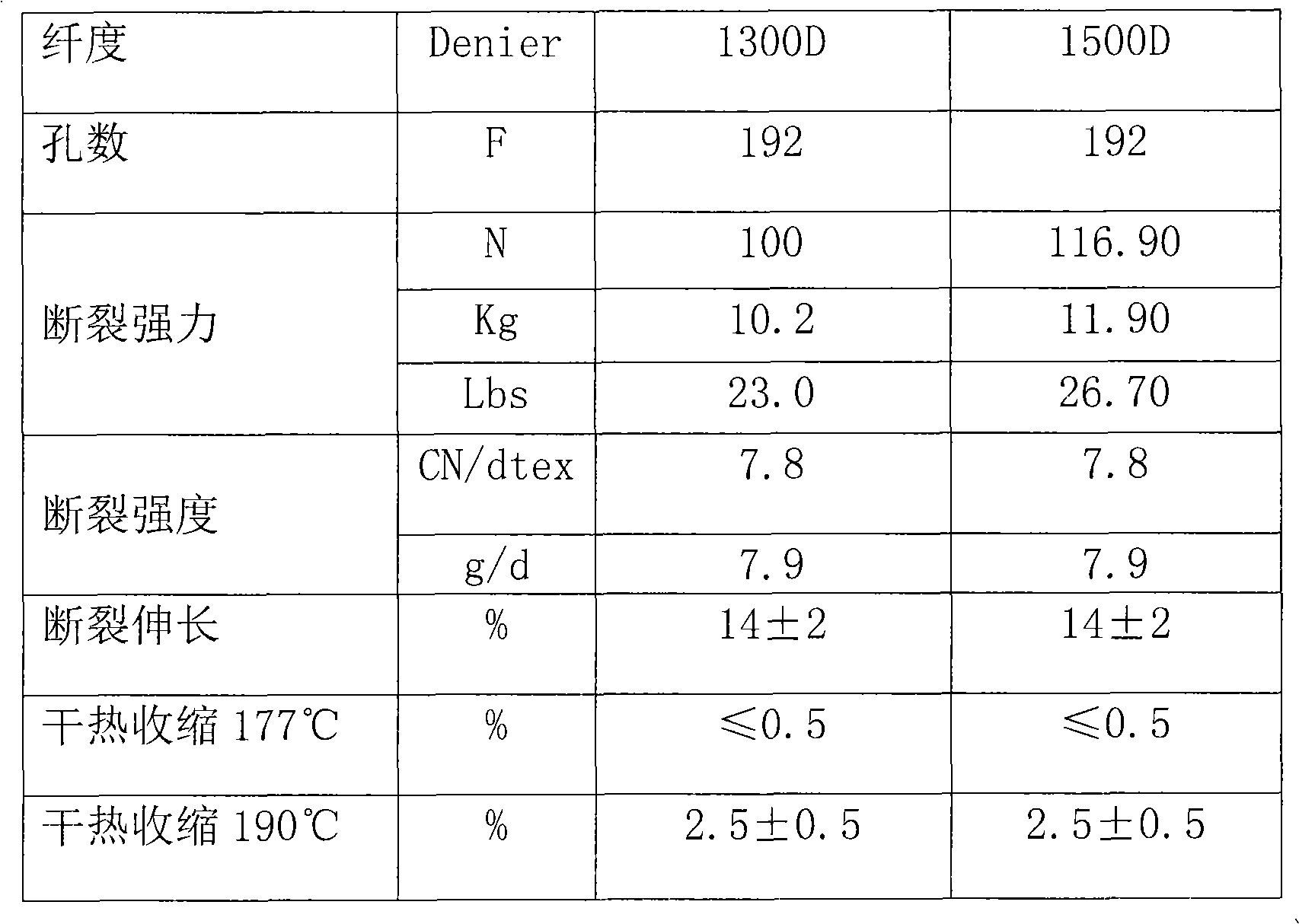

InactiveCN101644164AGood abrasion and tear resistanceReduce weightTunnel/mines ventillationTextiles and paperPlasticizerAntistatic agent

The invention relates to a coal mine air cylinder which comprises gridding base cloth and a PVC calendered coating covered on the base cloth, wherein the PVC calendered coating is coated with antistatic agent, and the gridding base cloth is spun by taking twisting polyester fiber filament yarn as warp and weft; the PVC calendered coating comprises the components based on the parts by weight: 100 parts of SG-70 resin, 73-112 parts of plasticizer, 8-12 parts of inorganic fire retardant, 60-65 parts of inorganic filler, 0.2-1 part of anti-aging agent, 0.1 part of antiseptic, 20-25 parts of pigment and 6-12 parts of coupling agent. The coal mine air cylinder has the advantages of good abrasive resistance, tear resistance, light weight, water resistance, pollution and mould prevention, inflaming retarding, good antistatic effect, ageing resistance, long service life and single-width formation.

Owner:浙江天地塑业有限公司

Boron-containing die steel and heat treatment method thereof

InactiveCN101880836AImprove toughnessGood anti-fatigueQuenching agentsChemical compositionBoron containing

The invention provides a boron-containing die steel and a heat treatment method thereof. The boron-containing die steel comprises the following chemical compositions in percentage by mass: 0.35 to 0.45 percent of C, 1.2 to 1.6 percent of B, 0.6 to 0.8 percent of Al, 1.8 to 2.5 percent of Cr, 0.4 to 0.6 percent of Mo, 0.3 to 0.5 percent of Ni, 0.05 to 0.30 percent of Ti, 0.02 to 0.15 percent of Ta, 0.05 to 0.20 percent of Nb, 0.5 to 1.0 percent of Mn, 0.3 to 0.5 percent of Si, 0.03 to 0.06 percent of Y, 0.008 to 0.020 percent of Ca and the balance of Fe, wherein Ti+Ta+Nb is greater than 0.30 and less than 0.55; S is less than 0.03; and P is less than 0.03. The heat treatment method of the boron-containing die steel of the invention comprises the following steps: heating the die steel in a heating furnace to the temperature of between 880 DEG C and 920 DEG C and then carrying out heat preservation for 4 to 8 hours; then continuously heating the die steel at the temperature of between 1,050 DEG C and 1,080 DEG C, carrying out heat preservation for 2 to 4 hours, carrying out furnace cooling to the temperature of between 950 DEG C and 980 DEG C and carrying out heat preservation for 1 to 3 hours; next, cooling the die steel in quenching oil; and finally, heating the processed die steel in the heating furnace to the temperature of between 220 DEG C and 250 DEG C, carrying out heat preservation for 8 to 15 hours, carrying out furnace cooling to the temperature of 150 DEG C, discharging the processed die steel and carrying out air cooling on the processed die steel. The die steel of the invention has the advantages of low cost and better toughness. The heat treatment method has simple process.

Owner:XI AN JIAOTONG UNIV

Coating for centrifugal casting high alloy furnace tube metal mould and method thereof

InactiveCN1520951AHigh low temperature strengthImprove plasticityFoundry mouldsFoundry coresCelluloseSodium Bentonite

The present invention is metal type paint for centrifugal casting high-alloy furnace tube and its production process. The material includes zirconite powder, silica sol, fluotrite powder, cellulose, PVA and bentonite; and the mixing production process includes dry mixing zirconite powder, fluotrite powder and bentonite inside a crushing roller mill for 15 min, dissolving cellulose and PVA in water and mixing and milling for 3 hr, and adding silica sol and mixing and milling for 30 min. The paint can form coating with increased low temperature strength, increased low temperature plasticity, raised flush resistance and vibration resistance.

Owner:BC P INC CHINA NAT PETROLEUM CORP

High-temperature-resistant environment-friendly metal casting coating and preparation method thereof

InactiveCN105642821AImprove high temperature resistanceImprove crack resistanceFoundry mouldsFoundry coresSodium BentoniteCrack resistance

The invention discloses high-temperature-resistant environment-friendly metal casting coating and a preparation method thereof. The coating comprises, by weight, 3-5 parts of attapulgite clay, 12-15 parts of quartz powder, 5-12 parts of talcum powder, 4-10 parts of superfine glass powder, 1.5-4 parts of sodium silicate, 3-5 parts of bauxite, 3-8 parts of diatomaceous earth, 2-4 parts of bentonite, 6-10 parts of polyethylene glycol, 3-9 parts of organic siloxane, 5-9 parts of silicon resin, 6-12 parts of linseed oil water-soluble alkyd resin, 4-6 parts of triphenyltin hydroxide, 2-6 parts of lignosulfonic acid, 1-3 parts of oxidizing agents, 1-2 parts of wetting agents, 2-5 parts of defoaming agents, 4-9 parts of preservatives, 2-6 parts of bonding agents, 5-8 parts of curing agents and 75-90 parts of deionized water. Compared with the prior art, the casting coating prepared through the method has excellent high temperature resistance, crack resistance and scouring resistance, and is good in adhesiveness and air permeability; meanwhile, the produced coating is uniform, environmentally friendly, free of pollution, good in stability and adsorbability, and capable of meeting the requirements for mass production of large castings, and improves the surface quality of the castings.

Owner:TONGLING ANDONG CAST STEEL

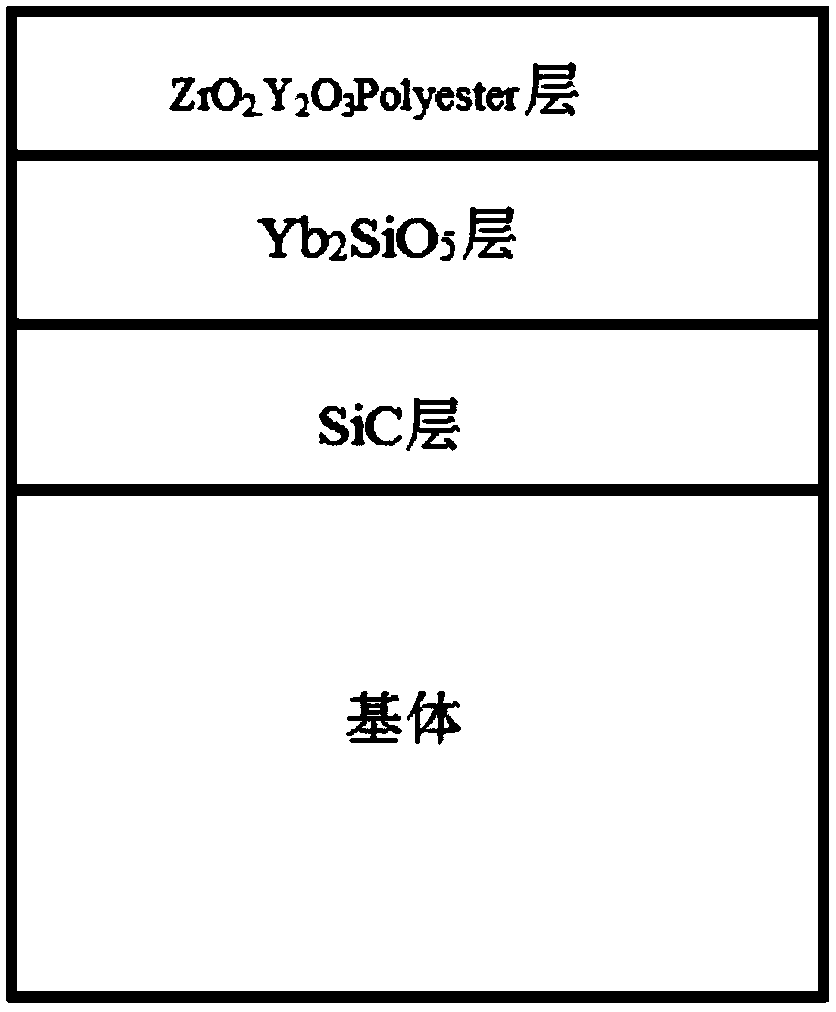

Ceramic-based composite turbine outer ring high-temperature sealing coating and preparation process thereof

InactiveCN109371353AAchieve lifeAchieve reliabilityMolten spray coatingPlasma technologyCeramic coating

The invention relates to the technical field of aero-engines, in particular to a ceramic-based composite turbine outer ring high-temperature sealing coating and a preparation process thereof. The ceramic-based composite turbine outer ring high-temperature sealing coating comprises a bonding layer, a transition layer and a wearing layer coating from inside to outside in sequence. The bonding layercomprises SiC. The transition layer comprises Yb2SiO5. The wearing layer coating comprises ZrO2.Y2O3Polyester. The coating provided by the invention is a composite coating capable of being matched with a SiC / SiC ceramic-based composite and has the advantages of 1200-DEG C wear consumption sealing and heat insulation. The problems that mechanical damage caused by mutual friction between SiC / SiC ceramic-based composite turbine components, and high-temperature oxidation, structure degradation and other damages to a ceramic-based composite can be solved. The plasma technology has the advantages ofhigh-energy density, high production efficiency, low cost, little equipment investment and the like and belongs to the optimal process for preparing high-temperature-resistant ceramic coating materials.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

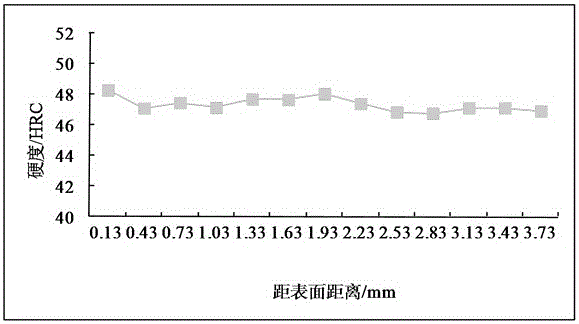

Heat treatment method of cold work die steel used for blanking die

The invention discloses a heat treatment method of cold work die steel used for a blanking die. The heat treatment method includes: firstly putting the die steel into a heating furnace, conducting heating to 860-870DEG C and then performing heat preservation for 2-4h; then, carrying out furnace cooling to 450DEG C, then conducting discharge from the furnace and air cooling; performing heating to 1010-1030DEG C in a heating furnace, and carrying out heat preservation for 2-4h; then, performing furnace cooling to 920-930DEG C and conducting heat preservation for 0.5-1.5h; then conducting cooling in quenching oil at 30-60DEG C; and finally, carrying out heating to 270-290DEG C in the heating furnace, then performing heat preservation for 6-7h, and conducting furnace cooling to 100DEG C, and then conducting discharge from the furnace and air cooling.

Owner:锡山区鹅湖慧盾机械厂

Heat treatment method for high-speed steel for rollers

InactiveCN102766745ASimple production processOptimize heat treatment processProcess efficiency improvementSurface finishChemical composition

The invention discloses a heat treatment method for high-speed steel for rollers. The chemical composition of the high-speed steel consists of the following components in percentage by weight: C: 3.2 to 3.6; W: 1.2 to 1.6; Mo: 5.0 to 7.0; V: 2.0 to 3.0; Cr: 8.0 to 10.0; Al: 0.1 to 0.4; Ni: 2.2 to 2.6; Co: 6.5 to 7.5; Nb: 0.2 to 0.4; Ti: 0.2 to 0.4; Ce: 0.4 to 0.6; Zr: 0.05 to 0.20; Si: less than 0.8; Mn: less than 1.5; S: less than 0.03; P: less than 0.04; and the balance of Fe. After the high-speed steel is cast to form a billet and the billet is roughly machined, the billet is quenched, the quenching process is carried out when a furnace is heated to 1260 DEG C to 1280 DEG C, the temperature is kept for 3 to 5 hours, the billet is then quenched in oil, and is tempered after being quenched, the tempering process is carried out when the furnace is heated to 620 DEG C to 650 DEG C, the temperature is kept for 5 to 7 hours, the furnace is cooled and then heated to 610 DEG C to 630 DEG C again, the temperature is kept for 5 to 7 hours, and after air cooling and tempering, finish machining is carried out, so that a roller, the dimensional precision and surface roughness of which come up to requirements, is obtained.

Owner:无锡市钻通工程机械有限公司

Anti-carburizing painting capable of being removed through washing after quenching and preparation method thereof

The invention discloses an anti-carburizing painting capable of being removed through washing after quenching. The anti-carburizing painting is prepared from, by mass, 25%-35% of boric acid, 15%-25% of filling, 15%-25% of aluminum dihydrogen phosphate, 1%-5% of tinting pigment and 30%-40% of water. The invention further discloses a preparation method of the anti-carburizing painting capable of being removed through washing after quenching. The anti-carburizing painting can be removed through washing after carburizing heat treatment, so that the problem that a traditional anti-carburizing painting is difficult to peel off after the carburizing heat treatment is solved. An inorganic heat-resisting material serves as an anti-carburizing agent in the formula of the anti-carburizing painting, so that an anti-carburizing coating formed after the anti-carburizing agent is brushed on the surface of a workpiece is good in cohesiveness, capable of not peeling and capable of not flowing at a high temperature, and the carburizing atmosphere is not influenced.

Owner:NANJING KERUN LUBRICANTS +1

Dust-electrical-charge bag dust collector

The invention discloses a dust-electrical-charge bag dust collector. Single chambers of the dust collector are of rectangular, three-dimensional and inverted-conical structures, gas purifying chambers are located on dust gas chambers, filtering bags are located between the gas purifying chambers and the dust gas chambers, and gas injection pipes for recycling blowback dust removing of the filtering bags; bag and bag cage assemblies for filtering gas are arranged in the dust gas chambers, dust-falling partition plates are installed on the side walls of the lower portions of the dust gas chambers and located at the upper portions of insulating-plate pulse dust cleaning pipes, the insulating-plate pulse dust cleaning pipes are connected with insulating-plate heaters, and insulating plates are fixed at the portions, on the sides of gas inlets and gas outlets, inside bodies; the gas inlets and the gas outlets are formed in one sides of the dust gas chambers, and corona heat preservation boxes are arranged on the other sides of the dust gas chambers, wherein the dust gas chambers and the corona heat preservation boxes are integrated; corona areas are arranged at the lower ends in the dust gas chambers, and ash buckets are arranged below the corona areas. Dust-gas separating is carried out through the negative pressure effect of fluid and the filtering function of the filtering bags, and purified gas is attached to the outer surfaces of the filtering bags through electrical-charge dust; dust layers formed by the filtering bags have small airflow resistance, and dust is easy to clean.

Owner:冷鑫磊

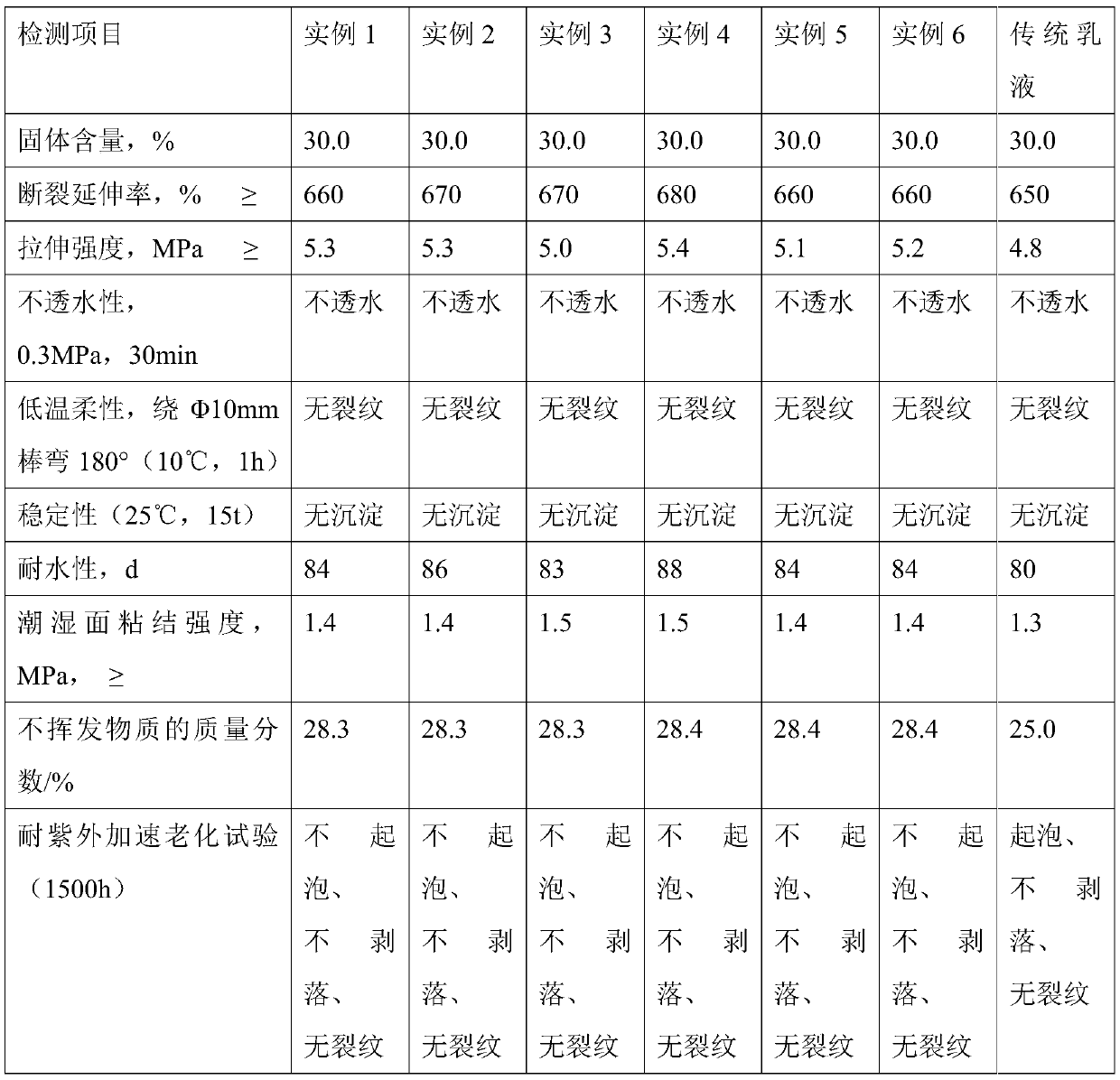

Polyurethane modified asphalt waterproof paint for buildings and production method thereof

InactiveCN108047949AGood storage stabilityImprove high temperature resistanceFireproof paintsAntifouling/underwater paintsBituminous waterproofingPolyvinyl alcohol

The invention relates to a polyurethane modified asphalt waterproof paint, which is composed of the following raw materials by weight: 25-30 parts of a polyurethane prepolymer; 70-75 parts of 90# petroleum asphalt; 40-60 parts of water; 20-25 parts of polychloroprene latex; 4-7 parts of an emulsifier; 2-4 parts of polyvinyl alcohol; 1-3 parts of a coupling agent; 1-2 parts of polypropylene glycol;3-5 parts of trihexyl o-acetylcitrate; 0.1-0.5 part of pentaerythritol ester of hydogenated rosin; 1-3 parts of polyacrylamide; and 10-15 parts of modified nano calcium carbonate. The polyurethane modified asphalt waterproof paint prepared by the method provided by the invention has good film compactness and high stability, a waterproof layer formed by the waterproof paint in a building has largebonding strength with a building base surface and good waterproof effect, moreover, after modification, the product has substantially improved water tolerance, aging resistance, acid and alkaline resistance and the like, has a simple making process, and overcomes the disadvantages of tedious making, poor film compactness, poor waterproofness and aging resistance in previous water emulsified asphalt paint.

Owner:GUANGXI WUXUAN JINPAI WATERPROOF MATERIAL SCI & TECH CO LTD

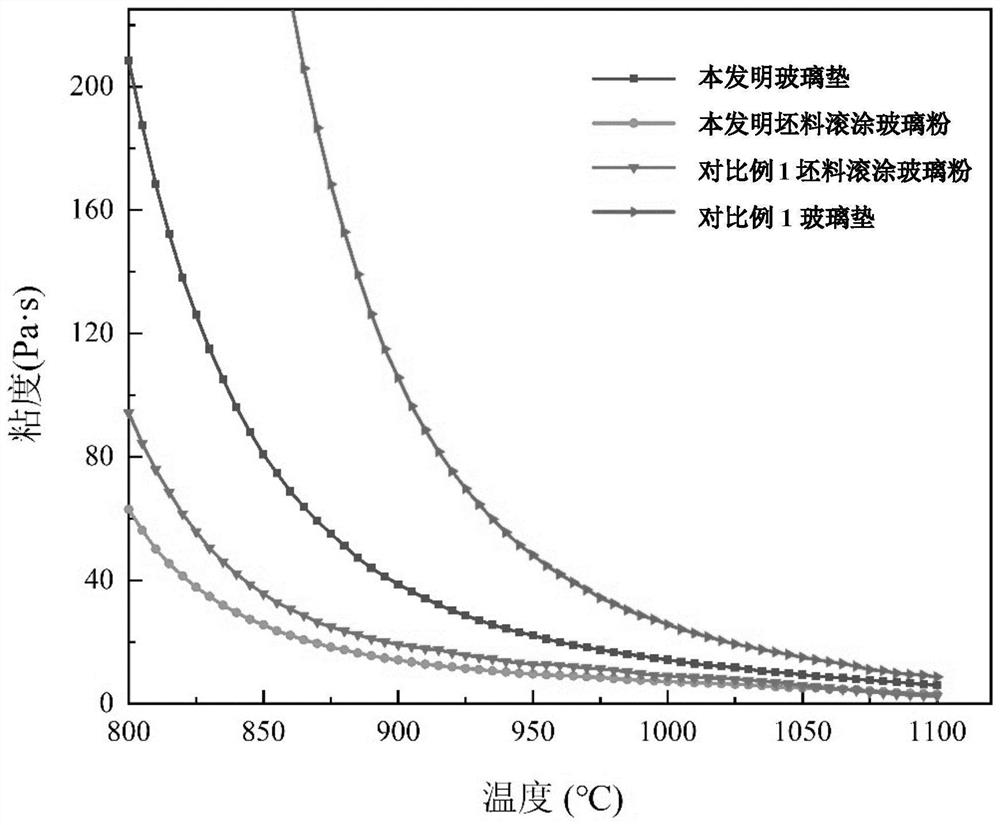

Glass lubricant for hot extrusion of titanium and titanium alloy as well as preparation method and application of glass lubricant

The invention relates to a glass lubricant for titanium and titanium alloy hot extrusion and a preparation method and application thereof, in the glass lubricant, blank roll coating glass powder comprises the following raw material components: 25-55% of SiO2, 2-35% of B2O3, 1-12% of Al2O3, 0-5% of TiO2, 3-27% of Na2O, 0-15% of K2O, 2-20% of CaO, 1-10% of MgO, 0-10% of BaO, 0-5% of ZnO, 1-10% of CaF2 and 0-5% of C; the glass pad comprises the following raw material components: 30-65% of SiO2, 2-25% of B2O3, 1-12% of Al2O3, 0-5% of TiO2, 3-27% of Na2O, 0-15% of K2O, 2-20% of CaO, 1-10% of MgO, 0-10% of BaO, 0-5% of ZnO, 0-10% of CaF2, 0-5% of Na3AlF6 and 0-5% of C. By adding new components and adjusting the use amount of the components, the glass lubricant has the advantages of large temperature interval, low softening point, high melting speed, good peeling performance, good lubricating effect, weak corrosion to titanium and titanium alloy, high corrosion resistance, high corrosion resistance, high corrosion resistance, high corrosion resistance and the like. The surface quality of titanium and titanium alloy is good, and the service life of the die is long.

Owner:NORTHEASTERN UNIV +1

Method for preparing cation ester-based type soap-free emulsion polymer

The invention discloses a method for preparing a cation ester-based type soap-free emulsion polymer. According to the method, a cation type and an ester-based monomer are adopted as raw materials, a soap-free emulsion polymerization method is implemented, meanwhile, a pH value adjusting agent is adopted to control the pH value of a reaction environment within 8-8.5, a soap-free cation hydrophilicmonomer, a soap-free ester-based hydrophobic monomer and an initiator a are enabled to react to synthesize a soap-free polymer, and the soap-free polymer is further reacted with other raw materials tosynthesize a polymer emulsion. The preparation method has the advantages of being rapid in polymerization speed, small in reaction step, small in environment pollution and mild in reaction condition,the synthesized product is good in permeation resistance, good in peeling effect and excellent in waterproof effect and weather resistance, no expensive emulsifier is added in the synthesis process,and thus the production cost is also greatly reduced.

Owner:HUBEI UNIV OF TECH

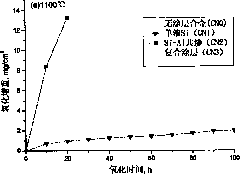

Method for preparing Nb/NbCr2-based high-temperature alloy surface anti-oxidation composite coating

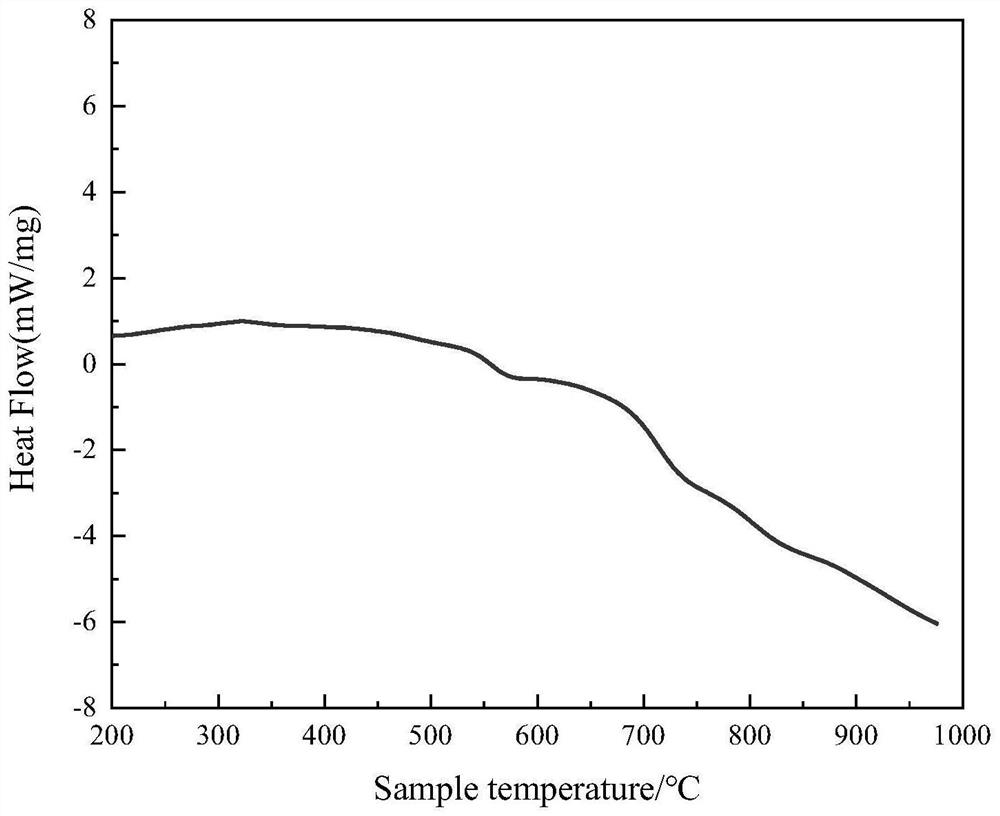

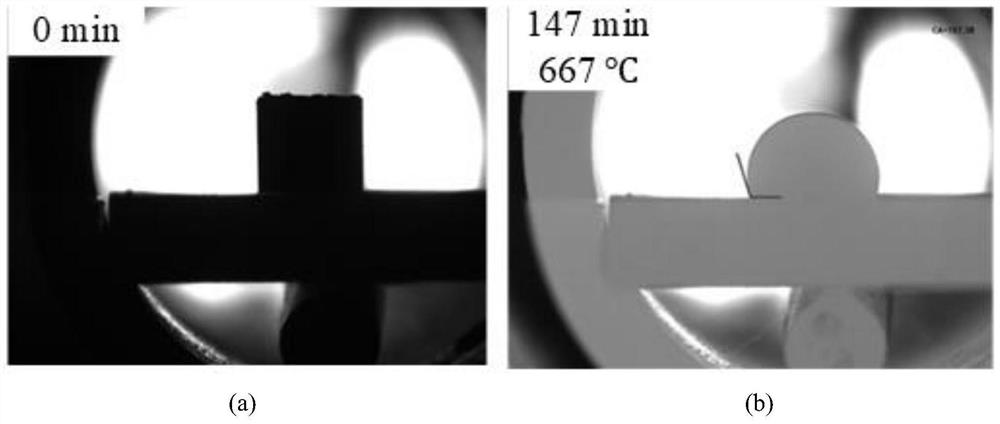

InactiveCN101824590AImprove high temperature oxidation resistanceGood exfoliationSolid state diffusion coatingSquare MillimeterOxidation resistant

The invention discloses a method for preparing an Nb / NbCr2-based high-temperature alloy surface anti-oxidation composite coating, which is characterized by comprising the following steps of: (1) preparing a Si-Al coating; (2) preparing Al(OH)3 sol by the sol-gel method; and (3) performing hot pressing. The method has the advantages that: (1) the coating is closely combined with a base and is compact so as to form a composite structure with an outer Al2O3 layer and an inner Si, Al, Cr and Nb diffusion layer; (2) the oxide film strips off seriously at the beginning of the oxidation at the temperature of 1,200 DEG C so as to cause disastrous oxidation; (3) the composite coating has the optimum effect of preventing the oxide film from stripping, namely only 0.049mg of the oxide film per square millimeter strips off after the oxidation is carried out ten times for 100 hours at the temperature of 1,100 DEG C, and particularly, only 0.13mg of the oxide film per square millimeter strips off at the temperature of 1,200 DEG C and only a weight of 3.38mg / cm2 is increased; therefore, the high temperature oxidation resistance of the Cr-50Nb alloy is greatly improved.

Owner:NANCHANG HANGKONG UNIVERSITY

High-speed steel for roller

The invention discloses a high-speed steel for a roller. The chemical composition of the high-speed steel comprises the following components by weight percent: 3.2-3.6% of C, 1.2-1.6% of W, 5.0-7.0 of Mo, 2.0-3.0% of V, 8.0-10.0% of Cr, 0.1-0.4% of Al, 2.2-2.6% of Ni, 6.5-7.5% of Co, 0.2-0.4% of Nb, 0.2-0.4% of Ti, 0.4-0.6% of Ce, 0.05-0.20% of Zr, less than 0.8% of Si, less than 1.5 % of Mn, less than 0.03% of S, less than 0.04% of P, and the balance of Fe.

Owner:无锡市钻通工程机械有限公司

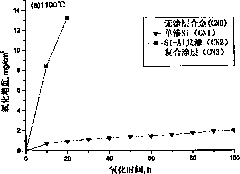

Cleaning Cream Containing PVA Particles and Producing Method Thereof

InactiveUS20180042833A1Good exfoliationFunction increaseCosmetic preparationsToilet preparationsGlycerolMoisture

A cleaning cream containing PVA particles has PVA particles being uniformly dispersed in a cleaning cream. Moisture content of the cleaning cream is at the range of 0.1˜23%. The cleaning cream comprises a least a surfactant. The PVA particles has glycerol and PVA in which molecular weight of the PVA is 110,000˜120,000. The PVA particles remain as particle form in the cleaning cream.

Owner:XING YAN PLASTIC CO LTD +1

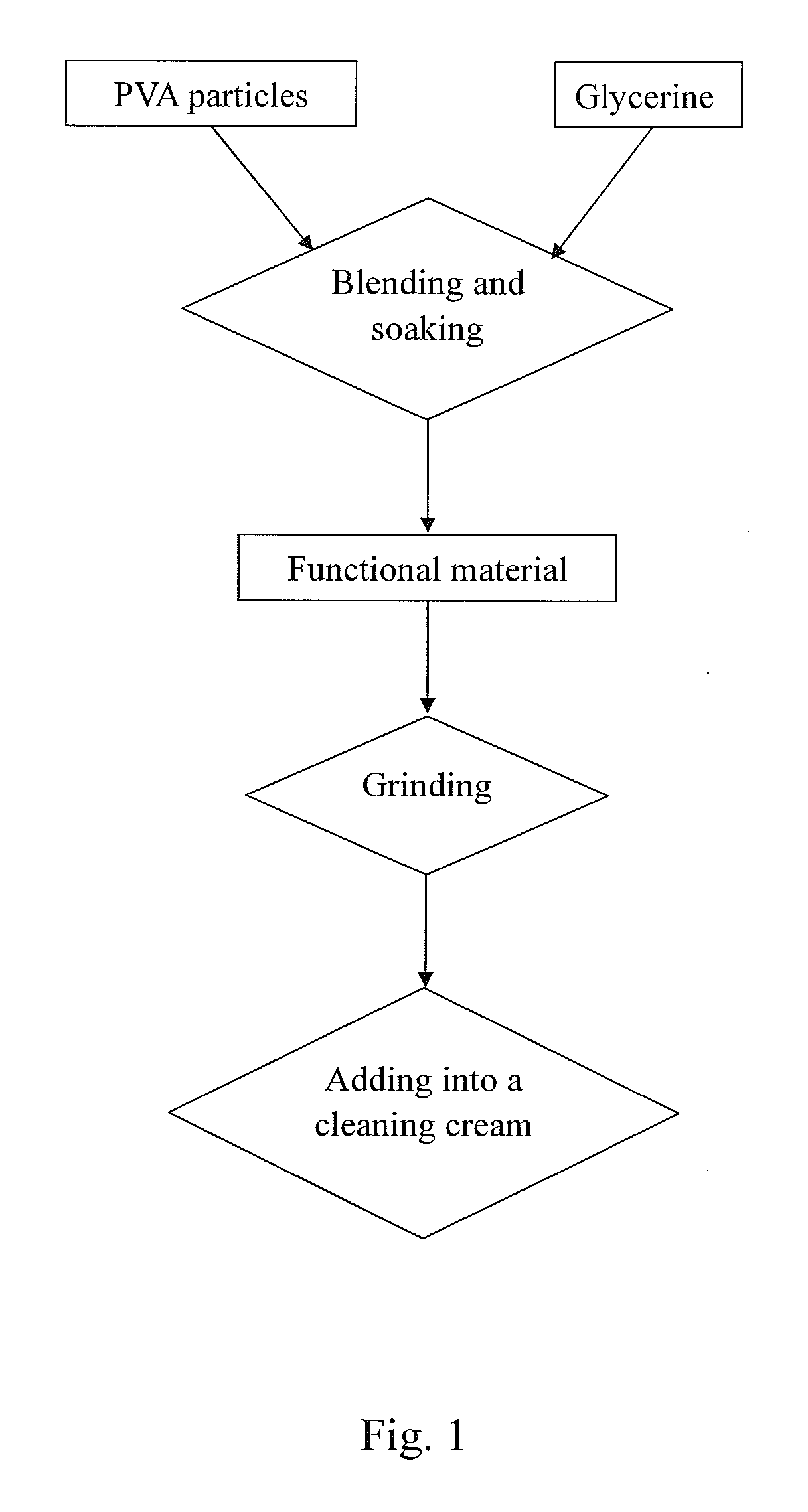

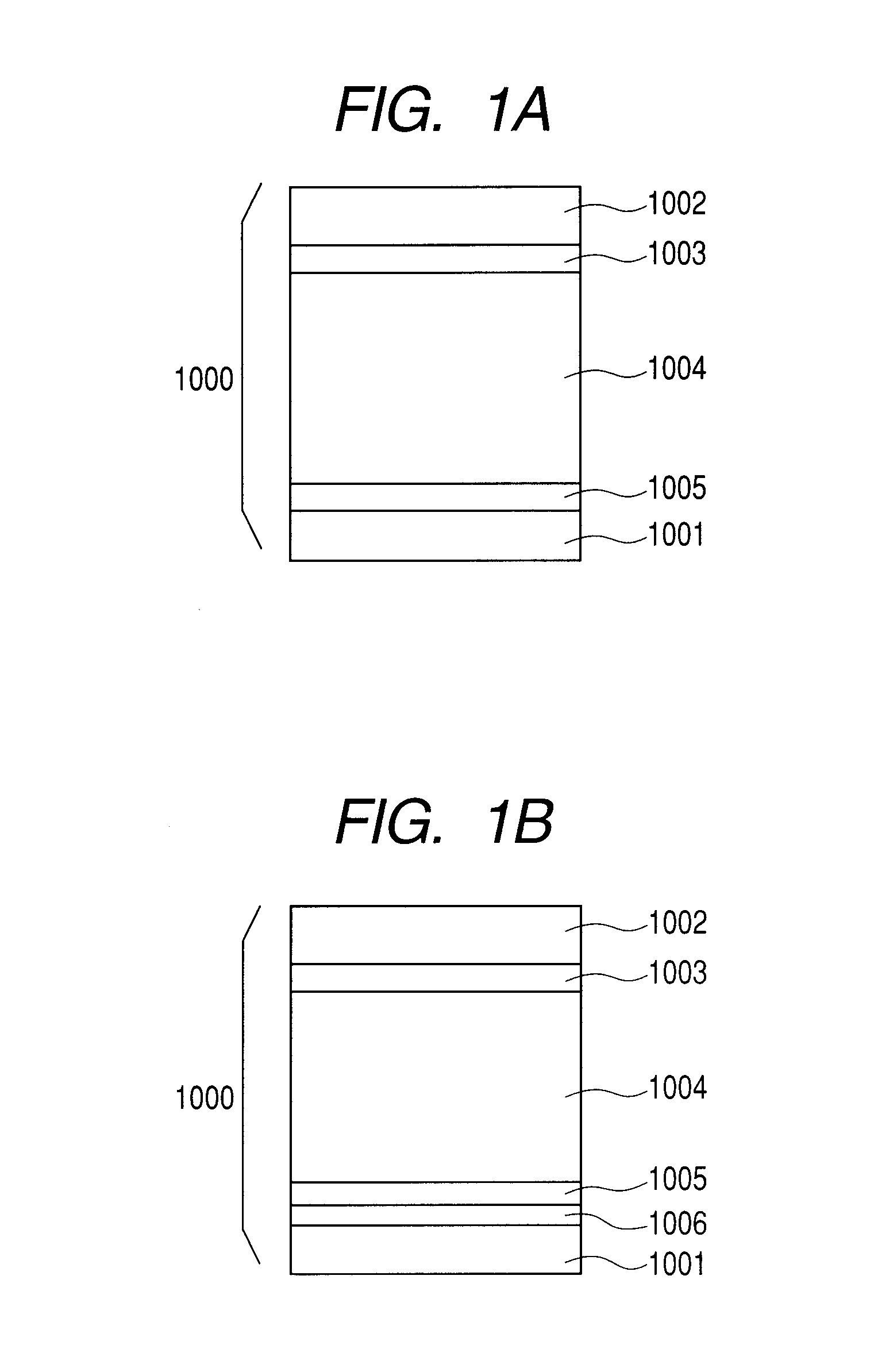

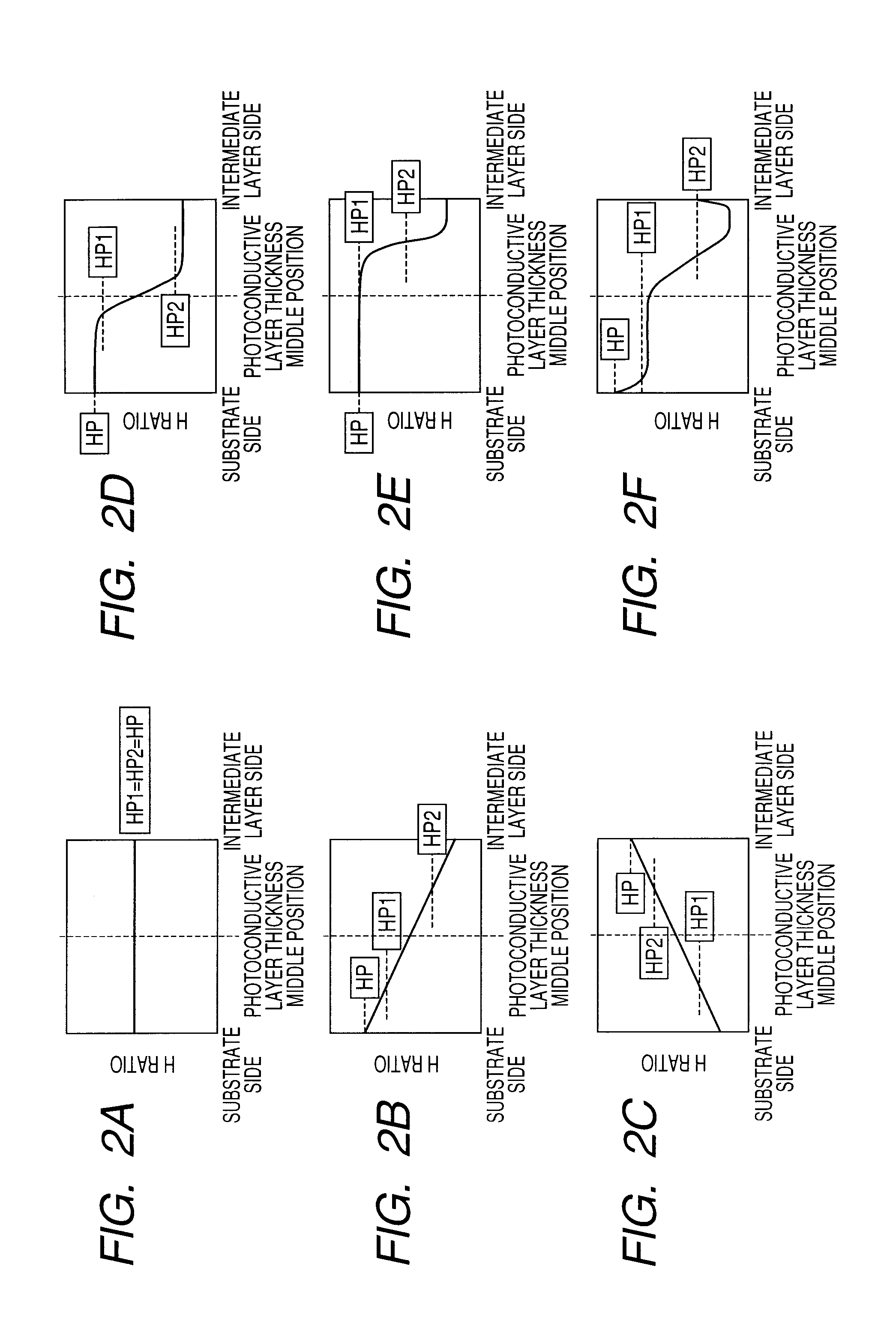

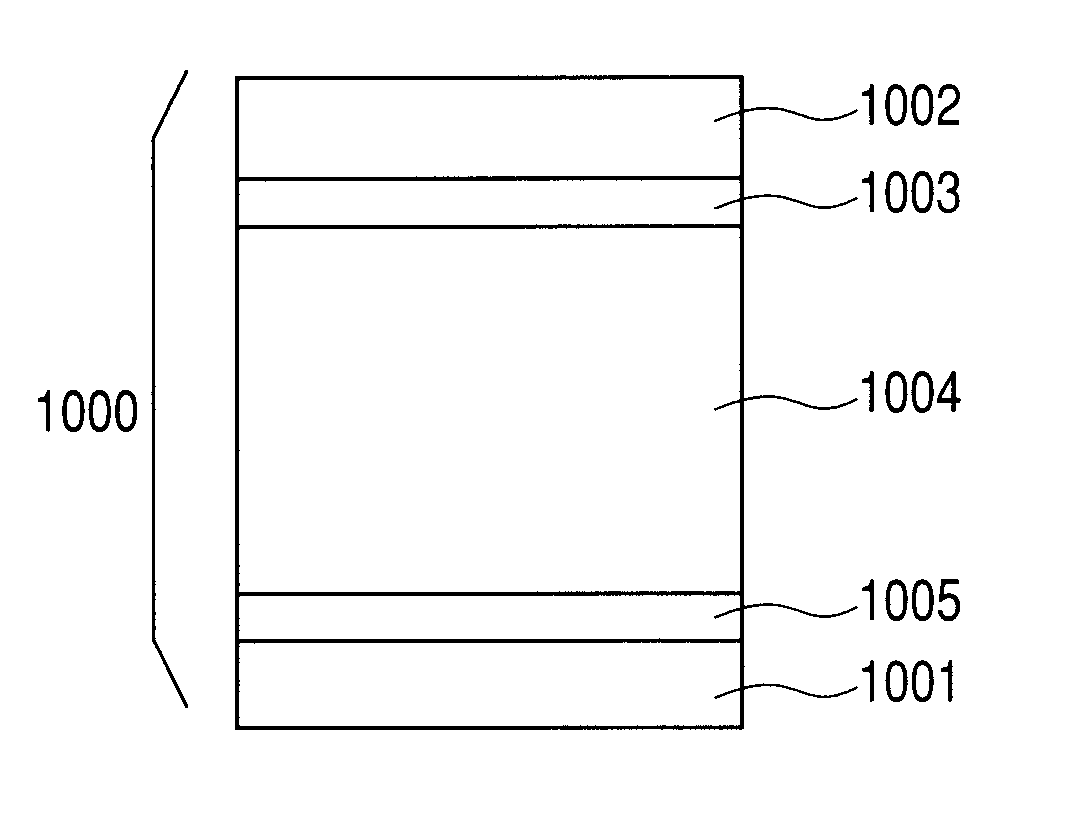

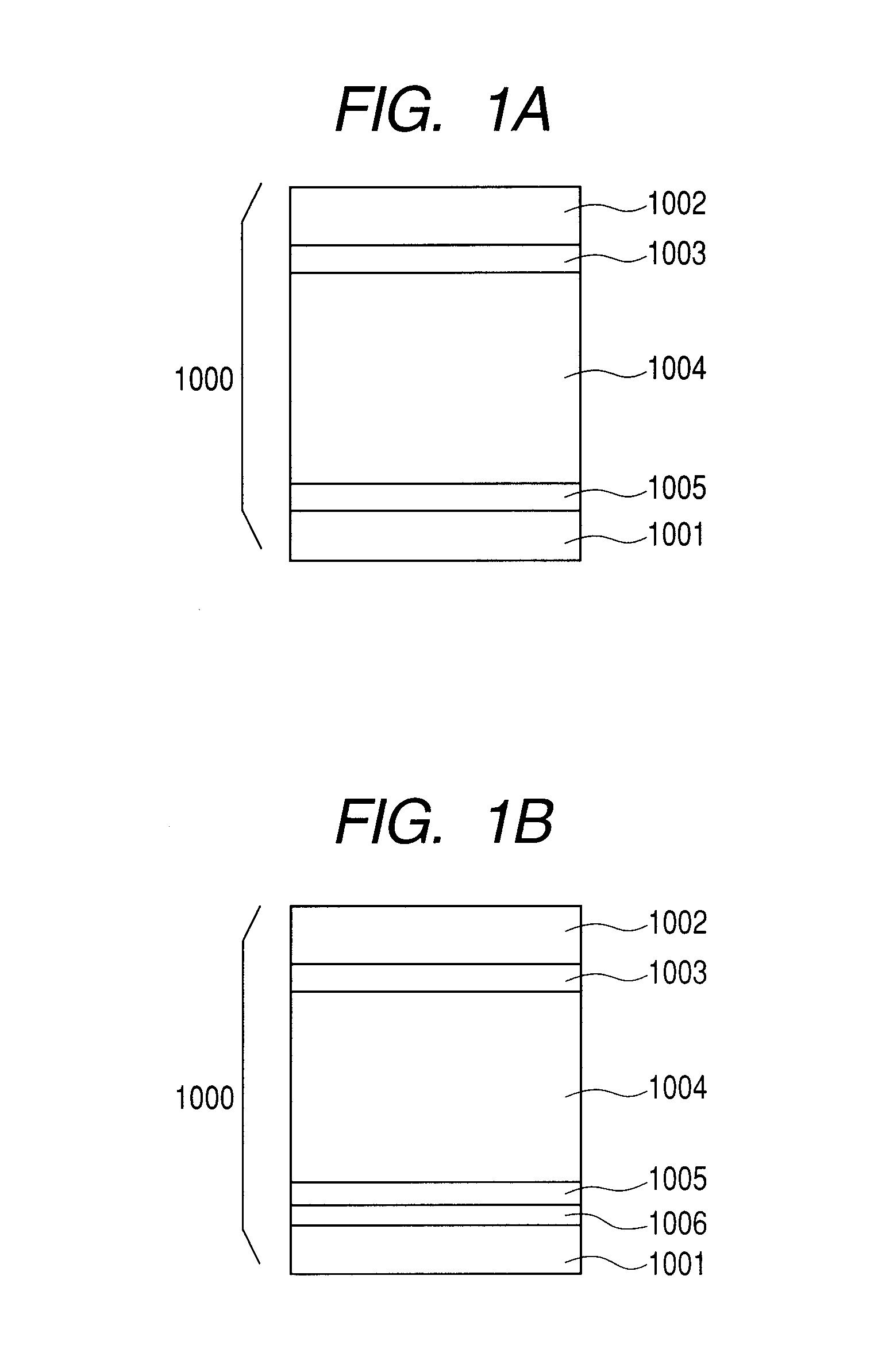

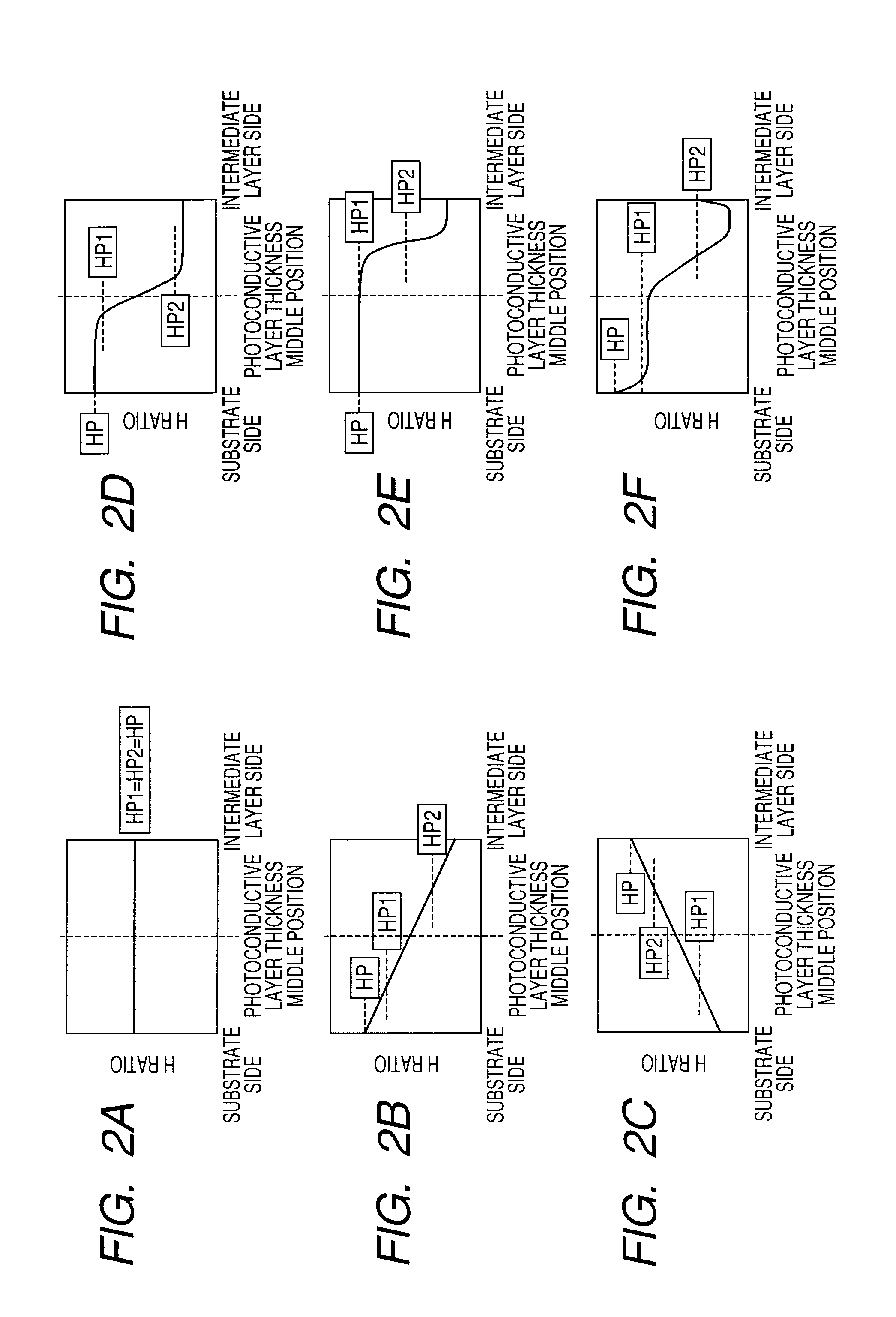

Electrophotographic photosensitive member and electrophotographic apparatus

InactiveUS8465891B2Good exfoliationIncrease resistanceElectrographic process apparatusCorona dischargeLayer thicknessChemistry

An electrophotographic photosensitive member includes a photoconductive layer, an intermediate layer, and a surface layer. When Si+C atom density in the surface layer is represented by DS×1022 atoms / cm3, the DS is 6.60 or more, and when the maximal value of H / (Si+H) in a distribution of hydrogen quantity in the photoconductive layer in a layer thickness direction is represented by HPmax, the average value of the H / (Si+H) in the second photoconductive region is represented by HP2, the DS and the HP2 satisfy the following expression (1) and the DS and the HPmax satisfy the following expression (2).HP2≧0.07×DS−0.38 Expression (1)HPmax≦0.04×DS+0.60 Expression (2)

Owner:CANON KK

Boron-containing die steel and heat treatment method thereof

InactiveCN101880836BImprove toughnessGood anti-fatigueQuenching agentsChemical compositionBoron containing

The invention provides a boron-containing die steel and a heat treatment method thereof. The boron-containing die steel comprises the following chemical compositions in percentage by mass: 0.35 to 0.45 percent of C, 1.2 to 1.6 percent of B, 0.6 to 0.8 percent of Al, 1.8 to 2.5 percent of Cr, 0.4 to 0.6 percent of Mo, 0.3 to 0.5 percent of Ni, 0.05 to 0.30 percent of Ti, 0.02 to 0.15 percent of Ta, 0.05 to 0.20 percent of Nb, 0.5 to 1.0 percent of Mn, 0.3 to 0.5 percent of Si, 0.03 to 0.06 percent of Y, 0.008 to 0.020 percent of Ca and the balance of Fe, wherein Ti+Ta+Nb is greater than 0.30 and less than 0.55; S is less than 0.03; and P is less than 0.03. The heat treatment method of the boron-containing die steel of the invention comprises the following steps: heating the die steel in a heating furnace to the temperature of between 880 DEG C and 920 DEG C and then carrying out heat preservation for 4 to 8 hours; then continuously heating the die steel at the temperature of between 1,050 DEG C and 1,080 DEG C, carrying out heat preservation for 2 to 4 hours, carrying out furnace cooling to the temperature of between 950 DEG C and 980 DEG C and carrying out heat preservation for 1 to 3 hours; next, cooling the die steel in quenching oil; and finally, heating the processed die steel in the heating furnace to the temperature of between 220 DEG C and 250 DEG C, carrying out heat preservation for 8 to 15 hours, carrying out furnace cooling to the temperature of 150 DEG C, discharging the processed die steel and carrying out air cooling on the processed die steel. The die steel of the invention has the advantages of low cost and better toughness. The heat treatment method has simple process.

Owner:XI AN JIAOTONG UNIV

Electrophotographic photosensitive member and electrophotographic apparatus

InactiveUS20110117484A1Good exfoliationIncrease resistanceElectrographic process apparatusCorona dischargeChemistry

An electrophotographic photosensitive member includes a photoconductive layer, an intermediate layer, and a surface layer. When Si+C atom density in the surface layer is represented by DS×1022 atoms / cm3, the DS is 6.60 or more, and when the maximal value of H / (Si+H) in a distribution of hydrogen quantity in the photoconductive layer in a layer thickness direction is represented by HPmax, the average value of the H / (Si+H) in the second photoconductive region is represented by HP2, the DS and the HP2 satisfy the following expression (1) and the DS and the HPmax satisfy the following expression (2).HP2≧0.07×DS−0.38 Expression (1)HPmax≦0.04×DS+0.60 Expression (2)

Owner:CANON KK

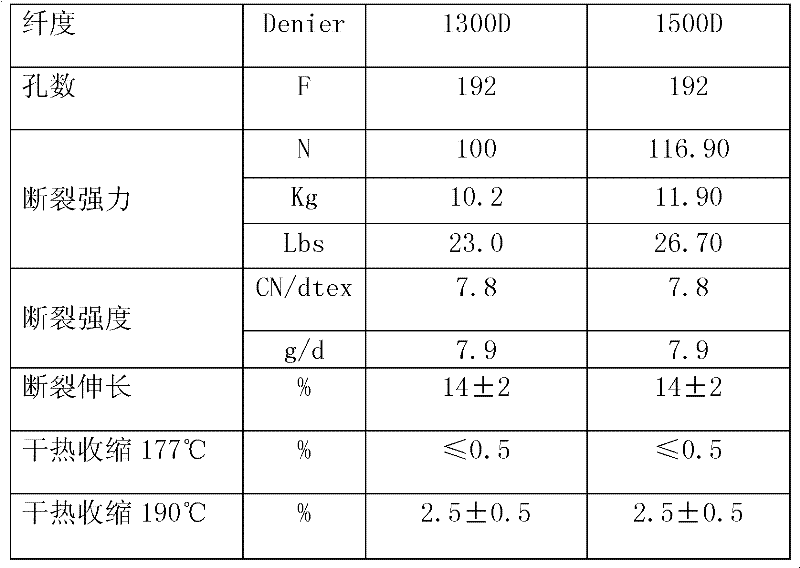

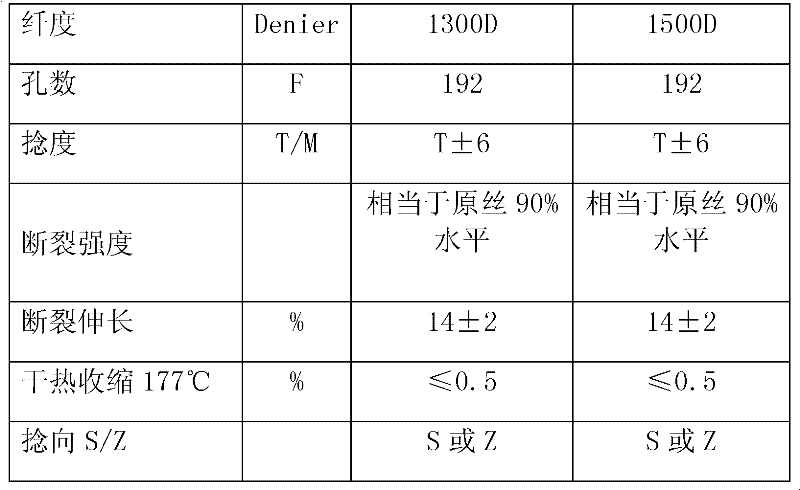

Manufacturing method of mine blow dryer

InactiveCN102392671AGood abrasion and tear resistanceReduce weightTunnel/mines ventillationTextiles and paperEngineeringTear resistance

The invention relates to a manufacturing method of a mine blow dryer, and the method comprises the following steps: manufacturing a foundation, namely weaving and expanding 1300D or 1500D ultralow contraction twisted polyster fiber filaments serving as warps and wefts by use of a braiding machine to form the gridded foundation; manufacturing a PVC (polyvinyl chloride) rolling film; and laminatinga film on the PVC rolling film and foundation, which are subjected to high temperature plasticizing, by a film laminator to obtain the mine blow dryer. The mine blow dryer manufactured by adopting the method provided by the invention has the advantages of good abrasive resistance and tear resistance, light weight, good water-proof, anti-fouling, mildew-proof, anti-flaming and anti-static effects and long service life, is ageing-resistant and can be formed singly.

Owner:浙江天地塑业有限公司

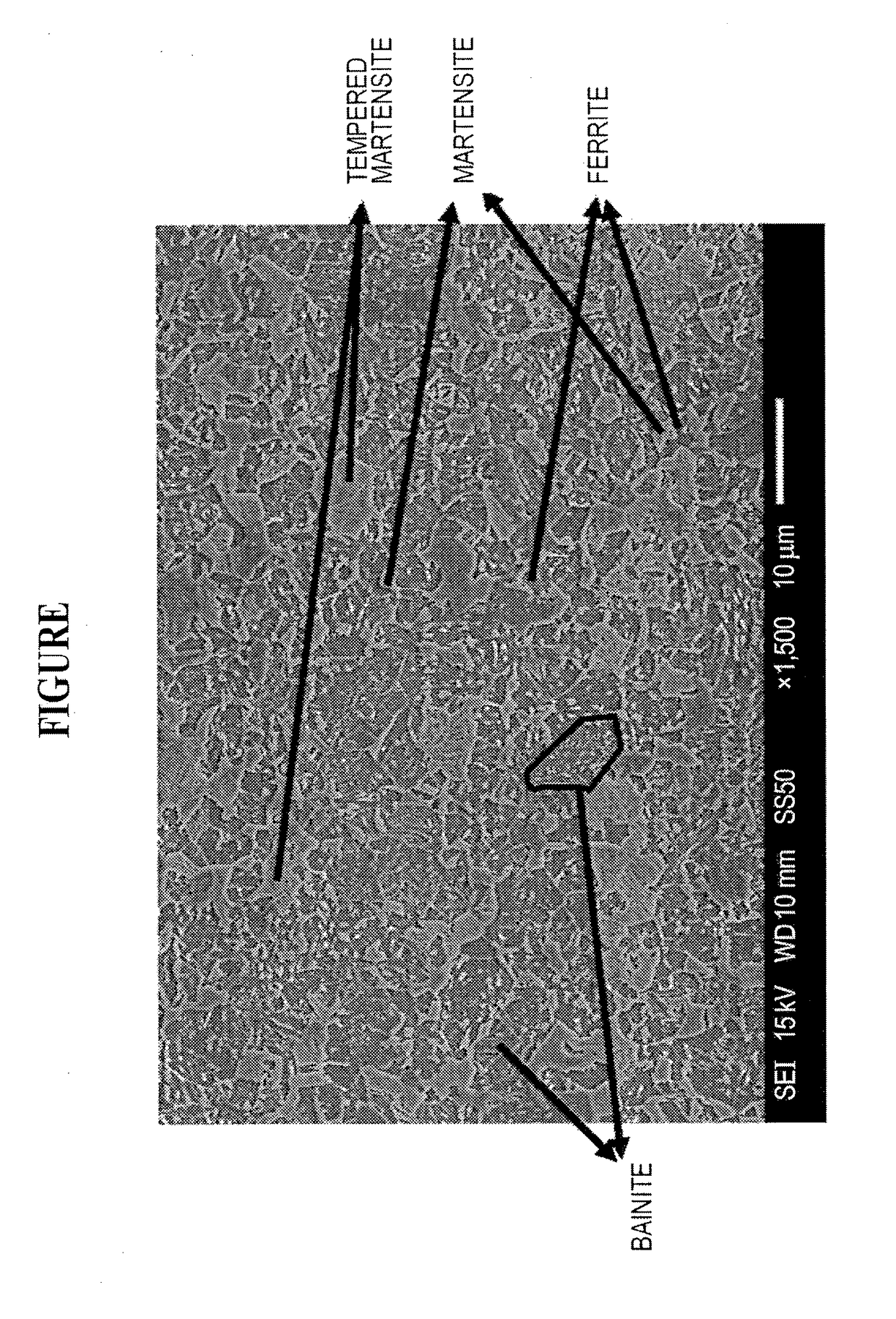

High-yield-ratio high-strength galvanized steel sheet and method for manufacturing the same

ActiveUS20190032187A1Nice appearanceImprove coatabilityHot-dipping/immersion processesFurnace typesSheet steelChemical composition

Provided are a high-yield-ratio high-strength galvanized steel sheet and a method for manufacturing thereof. The high-yield-ratio high-strength galvanized steel sheet has a steel sheet having a specified chemical composition and a metallographic structure including, in terms of area ratio, in terms of area ratio, 15% or less of ferrite, 20% or more and 50% or less of martensite, and bainite and tempered martensite in a total amount of 30% or more, and a galvanized layer formed on the steel sheet having a coating weight of 20 g / m2 to 120 g / m2 per side, in which a yield strength ratio is 65% or more, a tensile strength is 950 MPa or more, and Mn oxides are contained in the galvanized layer in an amount of 0.015 g / m2 to 0.050 g / m2.

Owner:JFE STEEL CORP

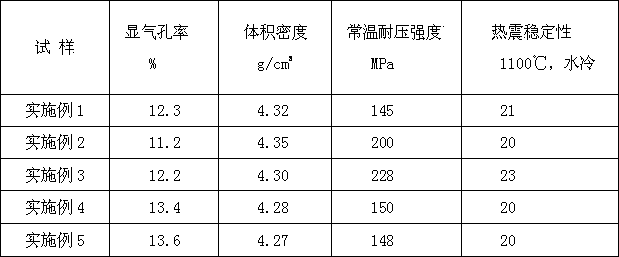

Production method of metal compounded chromium oxide bricks

The invention discloses a production method of metal compounded chromium oxide bricks. The content of Cr2O3 in chromium oxide bricks is not less than 80%, and a coal water slurry vaporizing furnace liner material having better performances than original chromium oxide bricks is formed through adding one or more of silicon, chromium, aluminum and iron to a formula of present chromium oxide bricks and through compounding. The metal compounded chromium oxide bricks produced in the invention have the characteristics of strong thermal shock resistance, low porosity and strong coal slag corrosion resistance, can meet strict conditions of large scale formation, high pressure, high productivity and high requirements of present coal water slurry vaporizing furnaces, and prolong the service life of the whole vaporizing furnace liner.

Owner:REFRACTORY MATERIAL OF SINOSTEEL CORP

Active nanocomposite materials and production method thereof

ActiveUS8834907B2Easy to oxidizeImprove efficiencyPigmenting treatmentMaterial nanotechnologyMaterials scienceIndustry sector

The present invention refers to new active nanocomposite materials, comprising a matrix and additives. The present invention also describes a process for obtaining these nanocomposite materials and their use in various industry sectors.

Owner:LAB ARGENOL

Cleaning and massaging shower gel and preparation method thereof

PendingCN113116785AGood massageExfoliates wellCosmetic preparationsToilet preparationsBiotechnologyShower gel

The invention relates to the field of wash supplies, and discloses cleaning and massaging shower gel and a preparation method thereof. The shower gel comprises the following ingredients in parts by weight: 3-4 parts of flos matricariae chamomillae extracts, 0.5-2.5 parts of citron fruit peel extract, 1-2 parts of chlorella extract, 2-3 parts of tea saponin, 4.5-5.5 parts of alkyl glycoside, 3-4 parts of cleaning and massaging particles, 0.1-0.3 part of ethylenediaminetetraacetic acid disodium salt, 0.05-0.1 part of sodium benzoate and 60-70 parts of water. Each cleaning and massaging particle comprises an activated carbon core layer and a porous zein / polylactic acid composite coating layer coating the activated carbon core layer. In the cleaning and massaging particles used by the invention, activated carbon is coated with porous zein / polylactic acid, so that the activated carbon can be prevented from damaging skin, the cleaning and massaging particles have better massaging and exfoliating effects, and cannot generate an adverse effect on the deoiling effect of the activated carbon.

Owner:何平蓉

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com