Patents

Literature

47results about How to "High low temperature strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

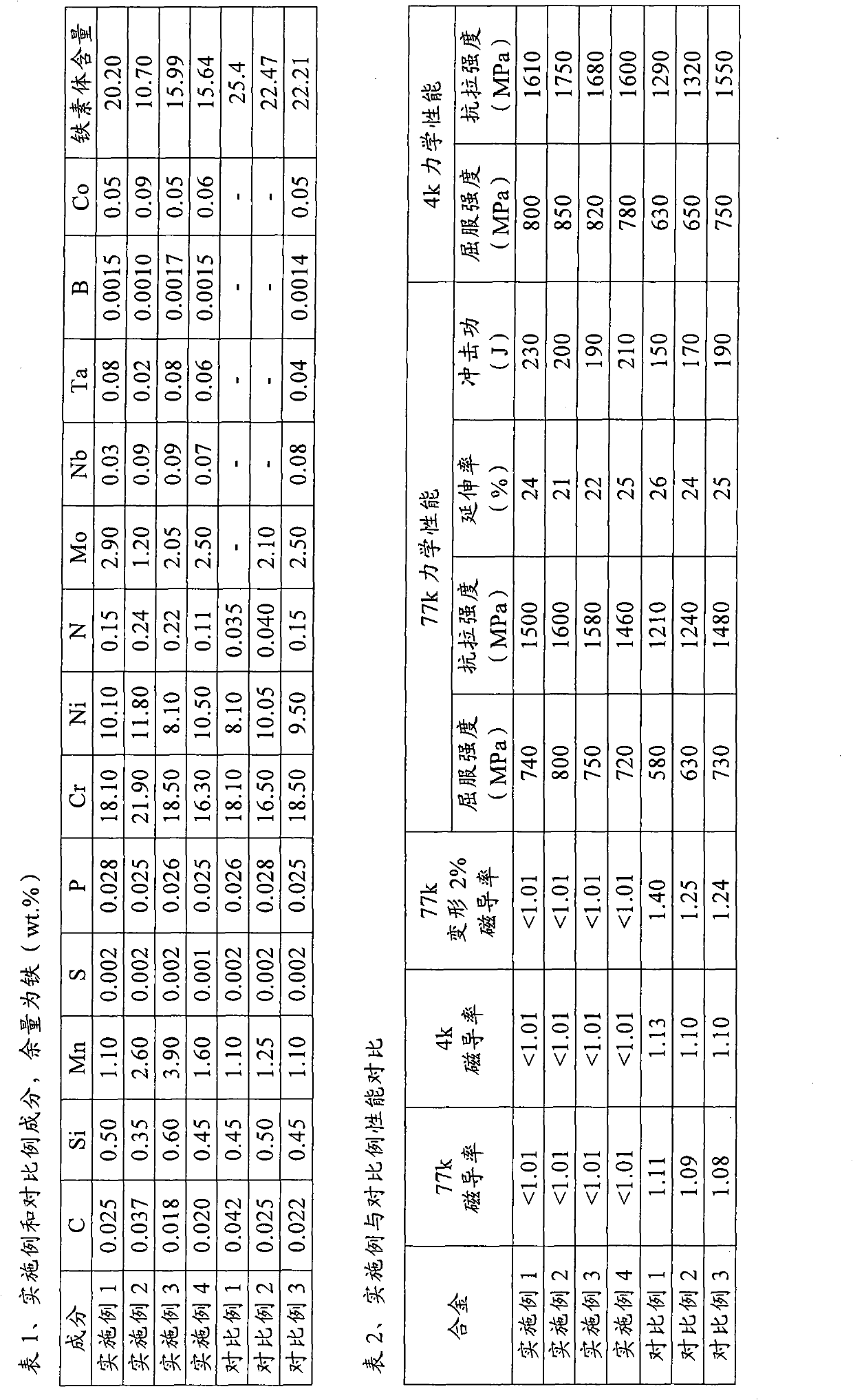

Austenitic stainless steel

ActiveCN102041457AHigh low temperature strengthHigh strengthTemperature control deviceProcess efficiency improvementNuclear fusionMetallurgy

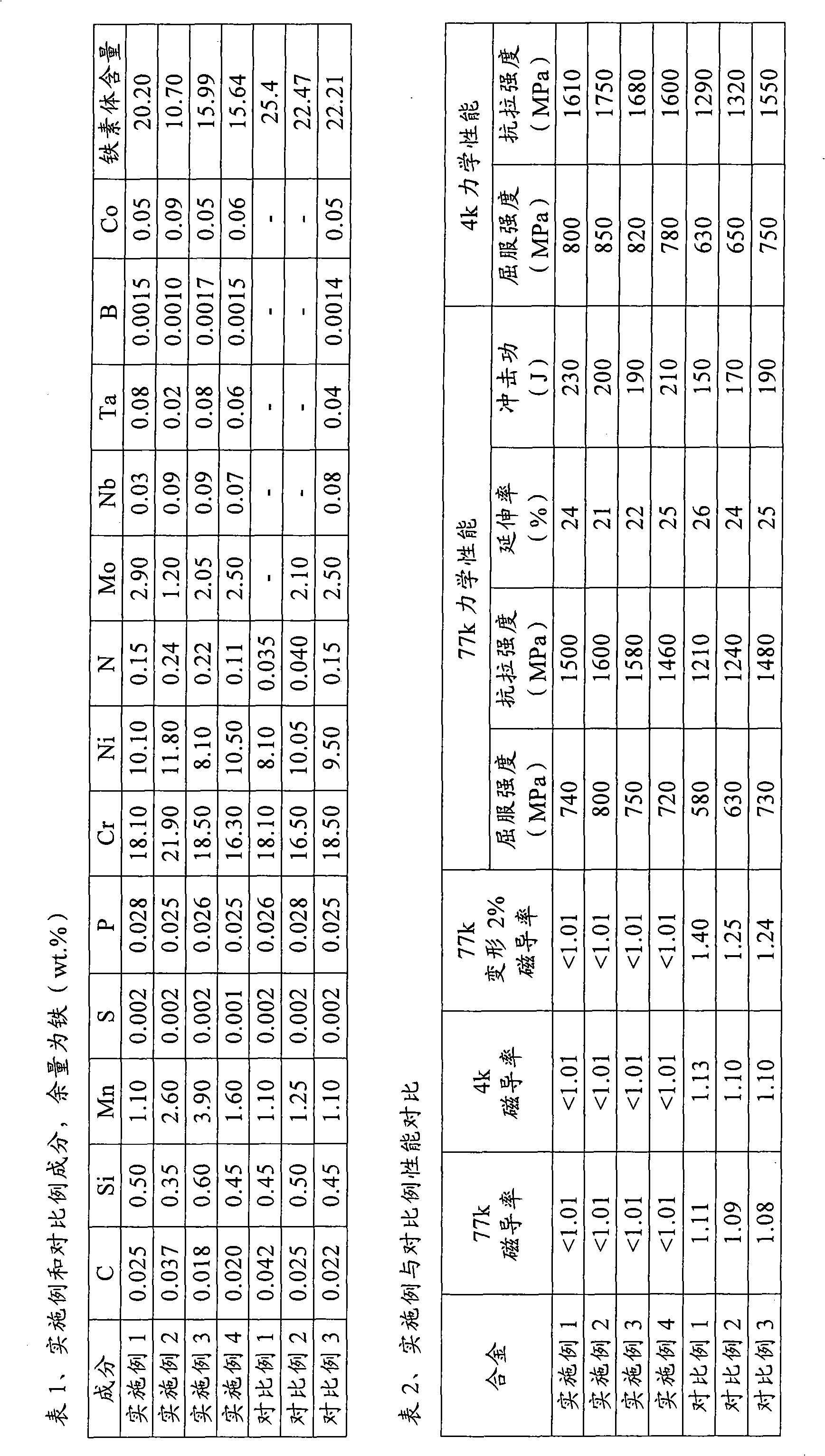

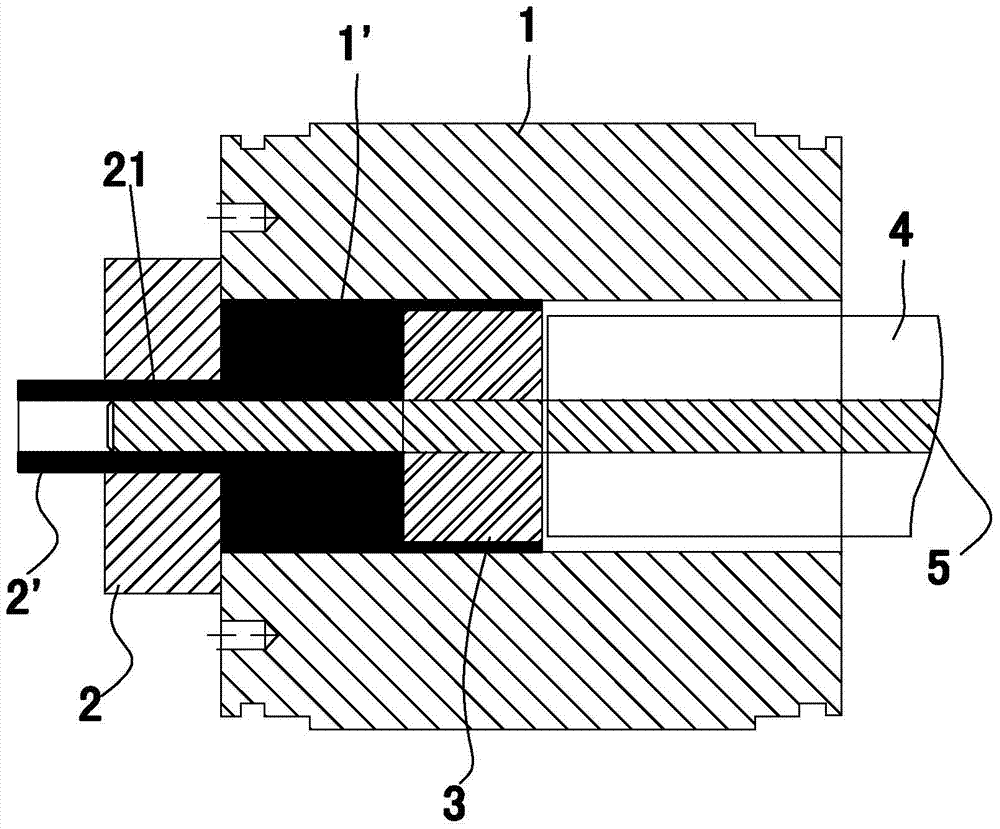

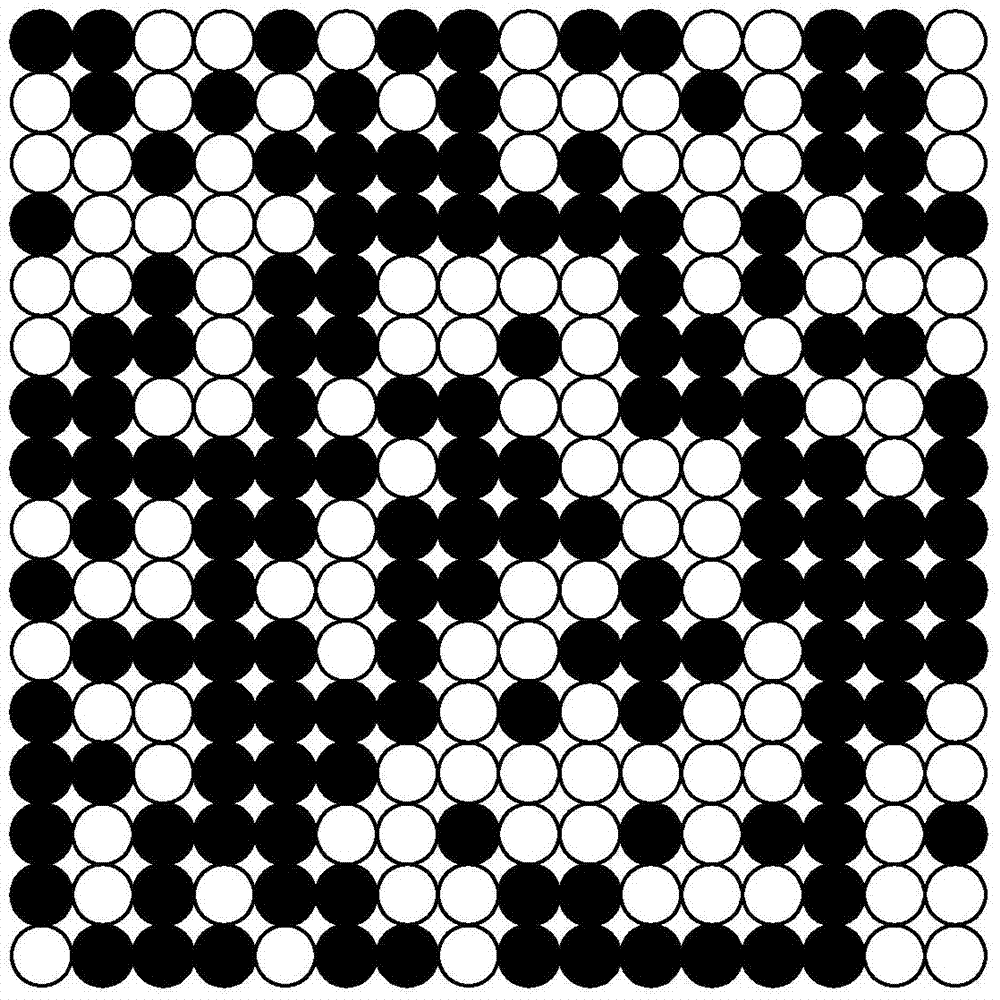

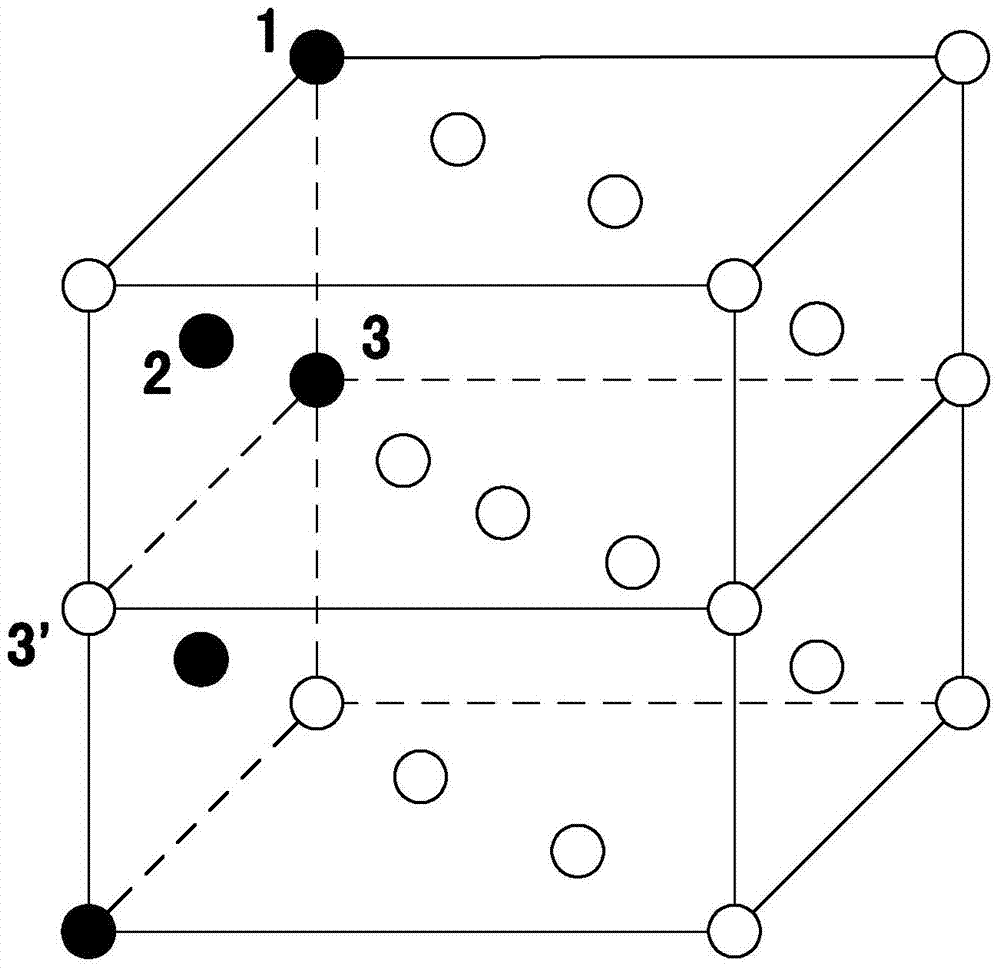

The invention relates to austenitic stainless steel which is high in low temperature strength, low temperature toughness and low temperature non-magnetism as well as better in neutron irradiation resistance, can be used in a magnet support structure of a nuclear fusion reactor, and comprises the components by mass percent: 16.00-22.0% of Cr, 8.00-12.00% of Ni, 1.00-3.00% of Mo, 0.06-0.25% of N, 0.010-0.040% of C, 1.00-4.00% of Mn, less than or equal to 1.00% of Si, 0.01-0.10% of Nb, 0.01-0.10% of Ta, 0.030-0.10% of Co, less than or equal to 0.03% of P, less than or equal to 0.005% of S, 0.0005-0.0018% of B, and the balance of Fe and unavoidable impurities; and furthermore, the value of Val (Cr-Ni) is less than 20.5, and Val (Cr-Ni)= 3* (Cr+Mo)+4.5*Si-2.8*Ni-1.4*Mn-84*(C+N).

Owner:BAOSTEEL DESHENG STAINLESS STEEL

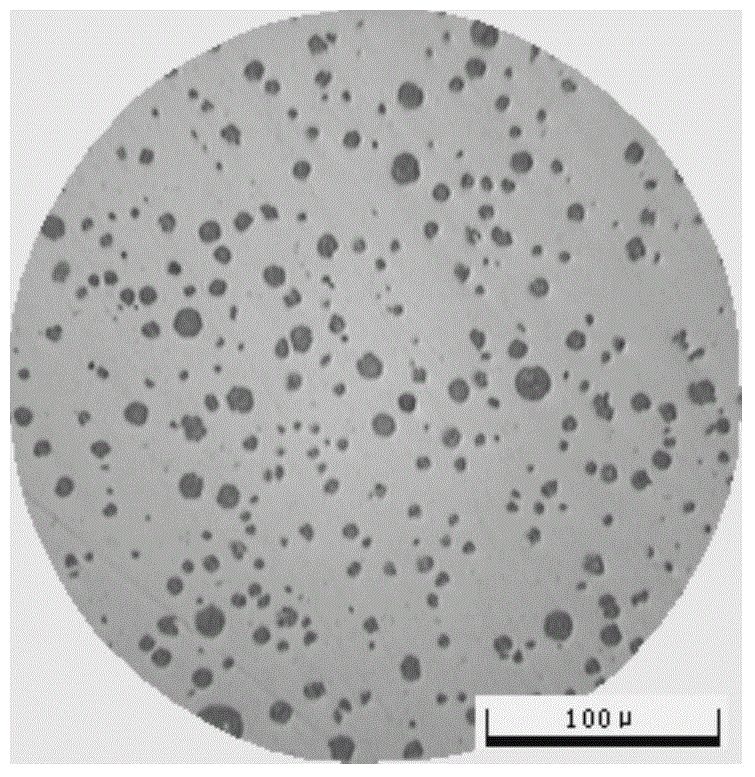

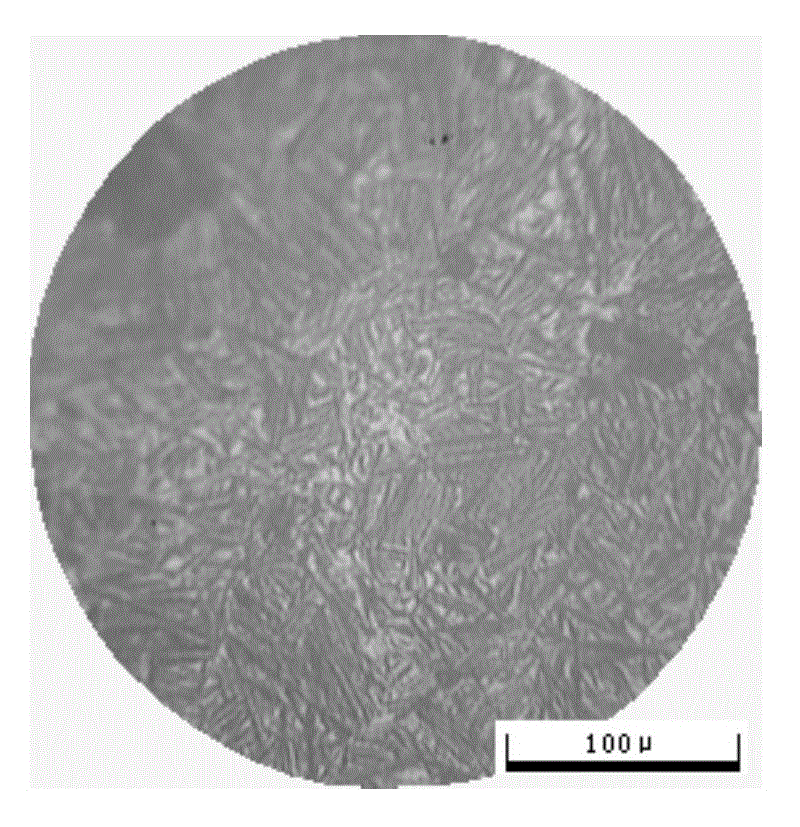

Preparation method of artificial core in petroleum geology research and application of artificial core

InactiveCN105547778AHigh similarityClose to the structurePreparing sample for investigationEpoxyPolyethylene glycol

The invention discloses a preparation method of an artificial core in a petroleum geology research. The preparation method comprises the following steps: during the process of cementing quartz sand and epoxy resin through a cementing agent, introducing a nano porous material and a metal thin sheet, performing curing under pressure, soaking a core in acid or alkali or leaching the core to form slits, finally flushing the artificial core with distilled water, and drying. By the adding of polyethylene glycol and citric acid, the artificial core has high surface wettability, and the surface property is closer to natural core. According to the preparation method, the slits, micron-level pores and nano-level pores of the artificial core can be quantitatively controlled, so that the prepared artificial core is extremely high in similarity with the natural core and can meet simulation and test on such physical properties as sound wave, transfusion and conductivity of the core in the petroleum geology research, thus providing an experimental support for oil-gas exploration development.

Owner:河北地质大学 +1

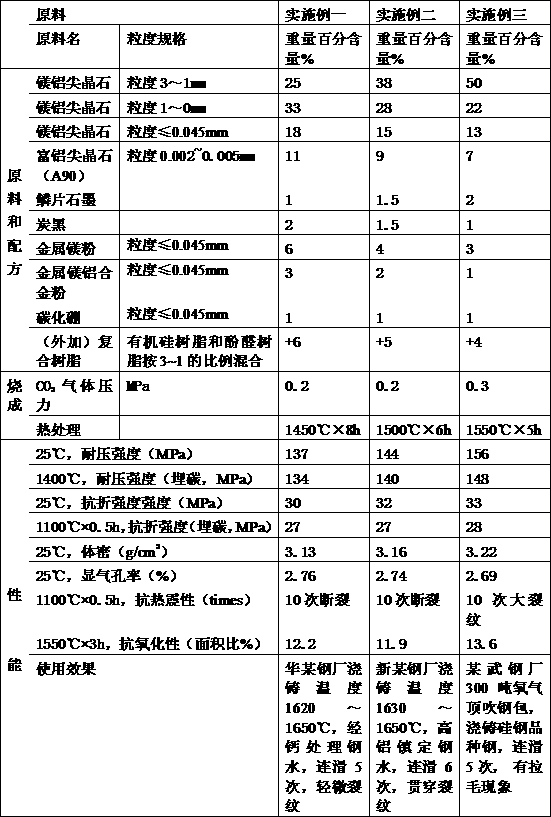

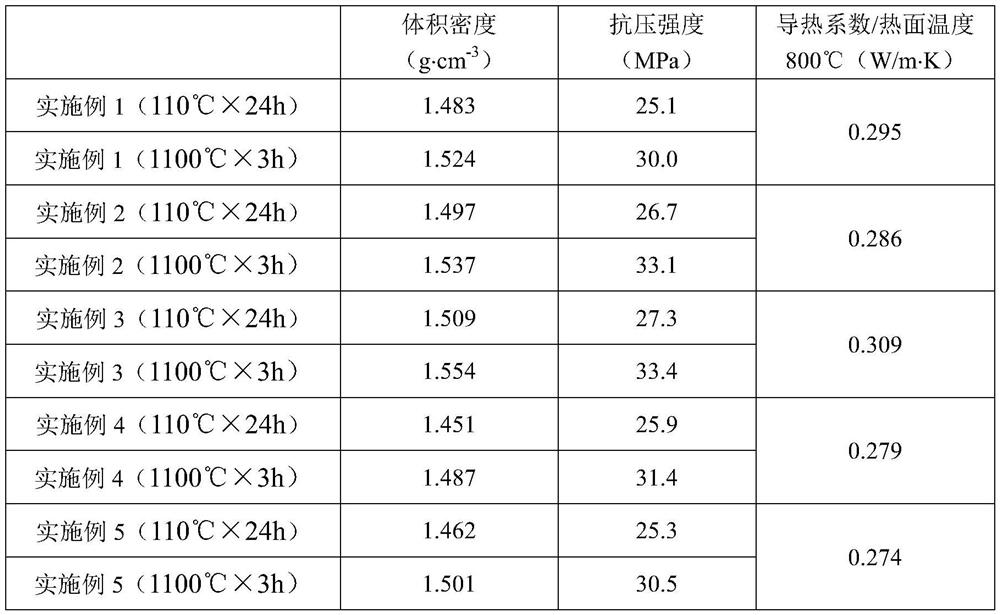

Process of preparing mineral bonding material and its composite material with phosphate and aluminium-silicon material

InactiveCN1673169AHigh low temperature strengthGood high temperature characteristicsClaywaresFiberAlkaline earth metal

The present invention relates to method of preparing mineral bonding material and its composite materials with phosphate and aluminum-silicon material at relatively low temperature. Under relatively low temperature, aluminum-silicon material with reaction activity is made to produce bonding reaction with phosphate to obtain one kind of amorphous solid Al-Si-P mineral bonding material. The Al-Si-P mineral bonding material may be used as basic material to prepare various composite materials with different performance via adding bauxite, silicon powder, flyash, mineral slag, fiber, etc. The said composite materials may be formed through casting or pressing, and the materials have excellent endurance, high mechanical strength and good high temperature performance.

Owner:SOUTH CHINA UNIV OF TECH

Formula of anti-dezincification extrusion drawing brass pipe and production method thereof

The invention provides a formula of an anti-dezincification extrusion drawing brass pipe and a production method thereof. The method comprises the following production steps: with 46-50% of electrolytic copper, 18-20% of arsenic brass foundry return, 0.2-0.3% of arsenic copper alloy, 0.1-0.3% of boron copper alloy and 30-32% of zinc ingot as raw materials, sequentially performing casting of a solid copper ingot, extrusion of the solid copper ingot into a copper pipe, stretching, annealing, inspection of a finished product of the copper pipe and storage of the finished product of the copper pipe. The brass pipe produced by use of the formula and method provided by the invention has the advantages of relatively good anti-dezincification and anti-corrosion properties and surface quality, light weight, good heat conductivity, high low-temperature strength, firmness and good anti-dezincification and anti-corrosion properties.

Owner:龙岩市鸿航金属科技有限公司

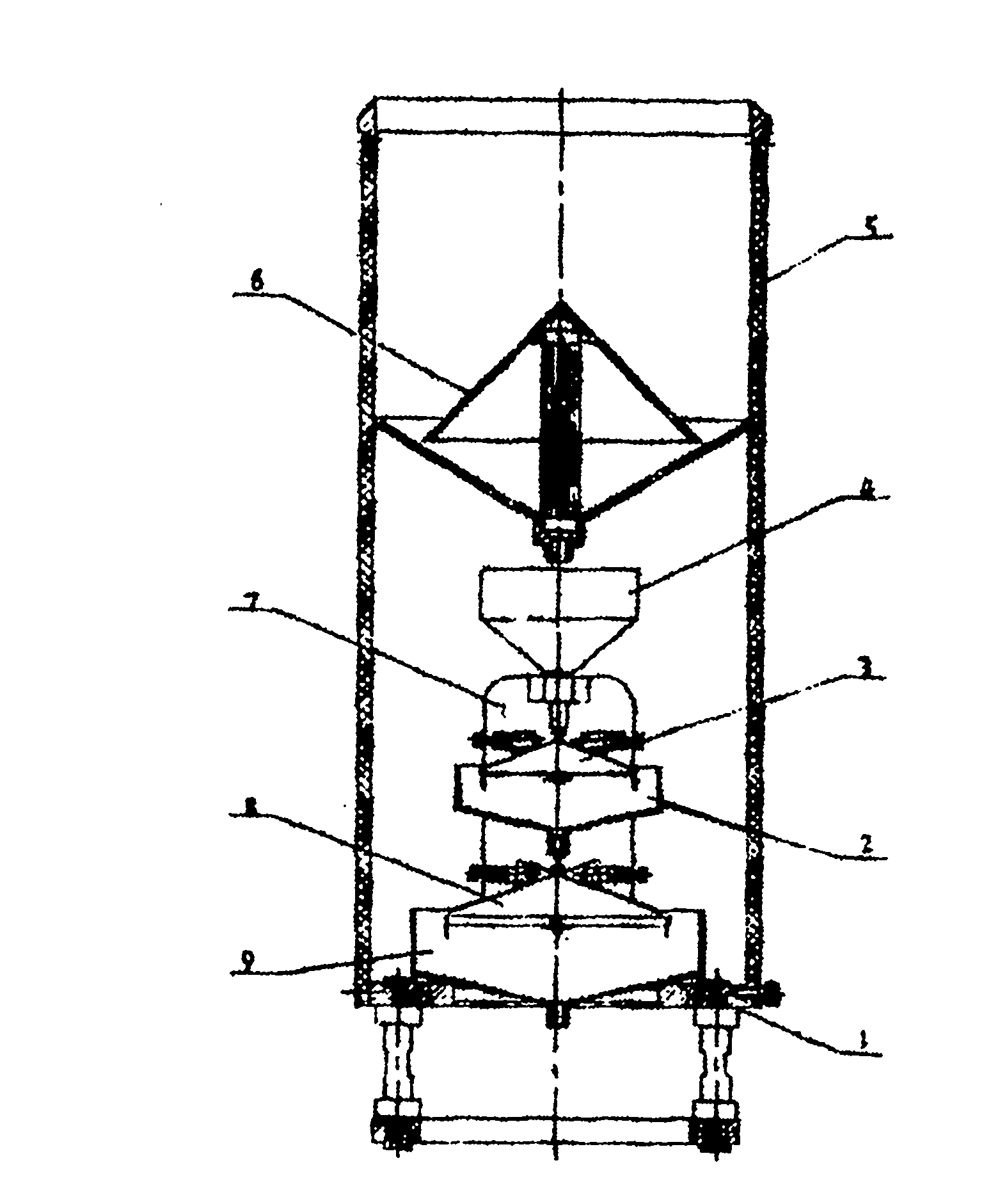

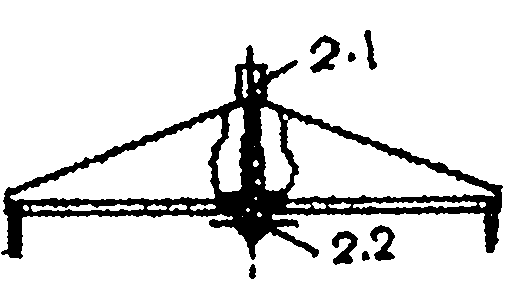

0.5mm sensitivity double-skip-bucket type rainfall sensor

InactiveCN102116878AImprove wash resistanceHigh surface hardnessRainfall/precipitation gaugesICT adaptationHardnessEngineering

The invention discloses a 0.5mm sensitivity double-skip-bucket type rainfall sensor. The bottom of a cylindrical rain container is provided with a base; the base of the rain container is provided with a lower water collector, a large skip bucket, an upper water collector, a small skip bucket and a funnel from bottom to top in turn; each water collector is arranged on a vertical plate; and an anti-blocking device is arranged above the funnel. The upper small skip bucket is designed to be a symmetric slope container, the lower large skip bucket is designed to be a labyrinthic container, the centers of gravity of a left bucket chamber and a right bucket chamber of each skip bucket are symmetric, and the skip bucket swings in a balanced way, so that stable performance is guaranteed during impact of heavy rains, and the sensor has high measuring accuracy. A hydrophobic layer has high flushing resistance and high surface hardness, and is environment-friendly and safe. Error is not influenced by raininess, and instant rainfall can be measured. Stable work and accurate measuring data of the rainfall sensor are guaranteed. Failed components can be easily approached during maintenance, and the failed components are easy to disassemble and replace, so that the manufacturing cost and the field maintenance cost are reduced.

Owner:天津华云天仪特种气象探测技术有限公司

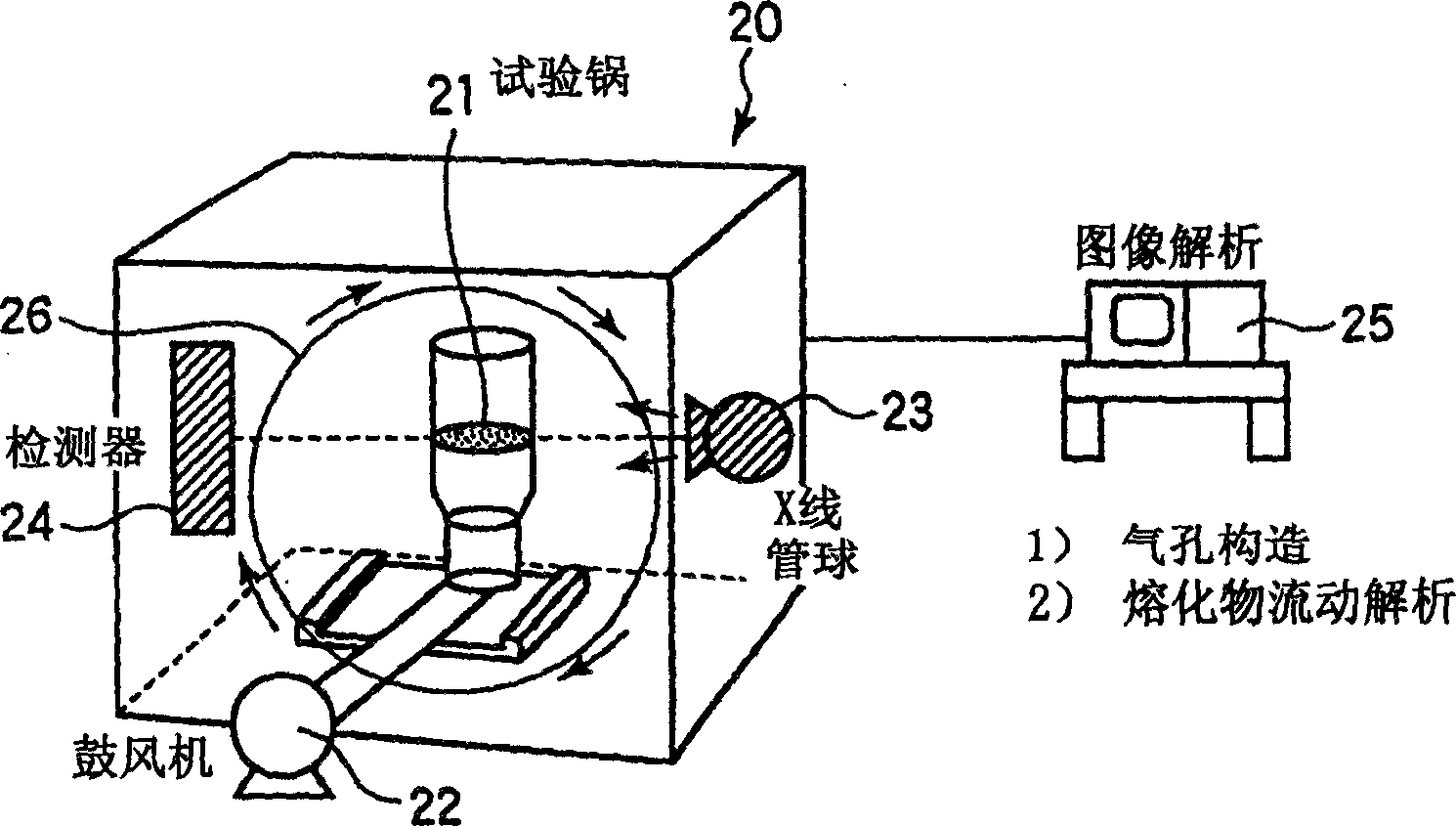

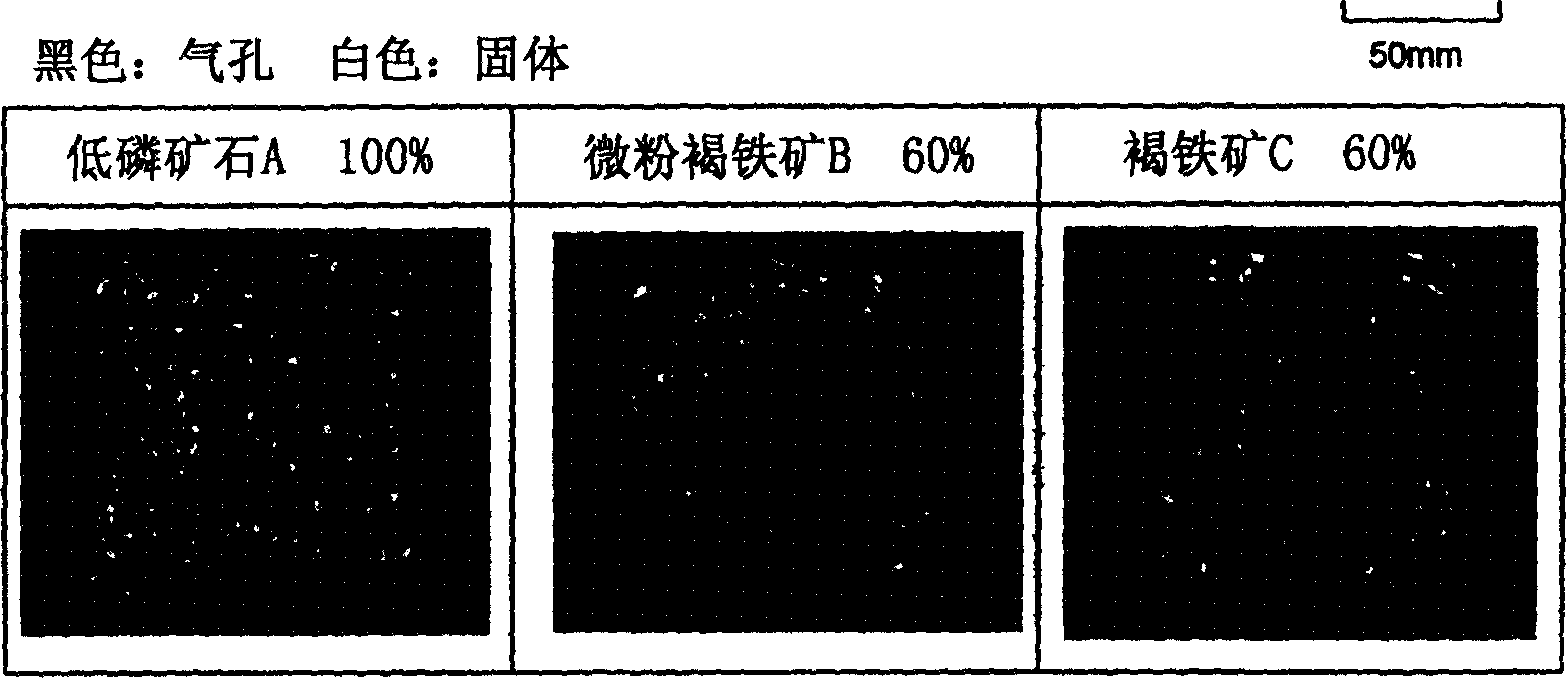

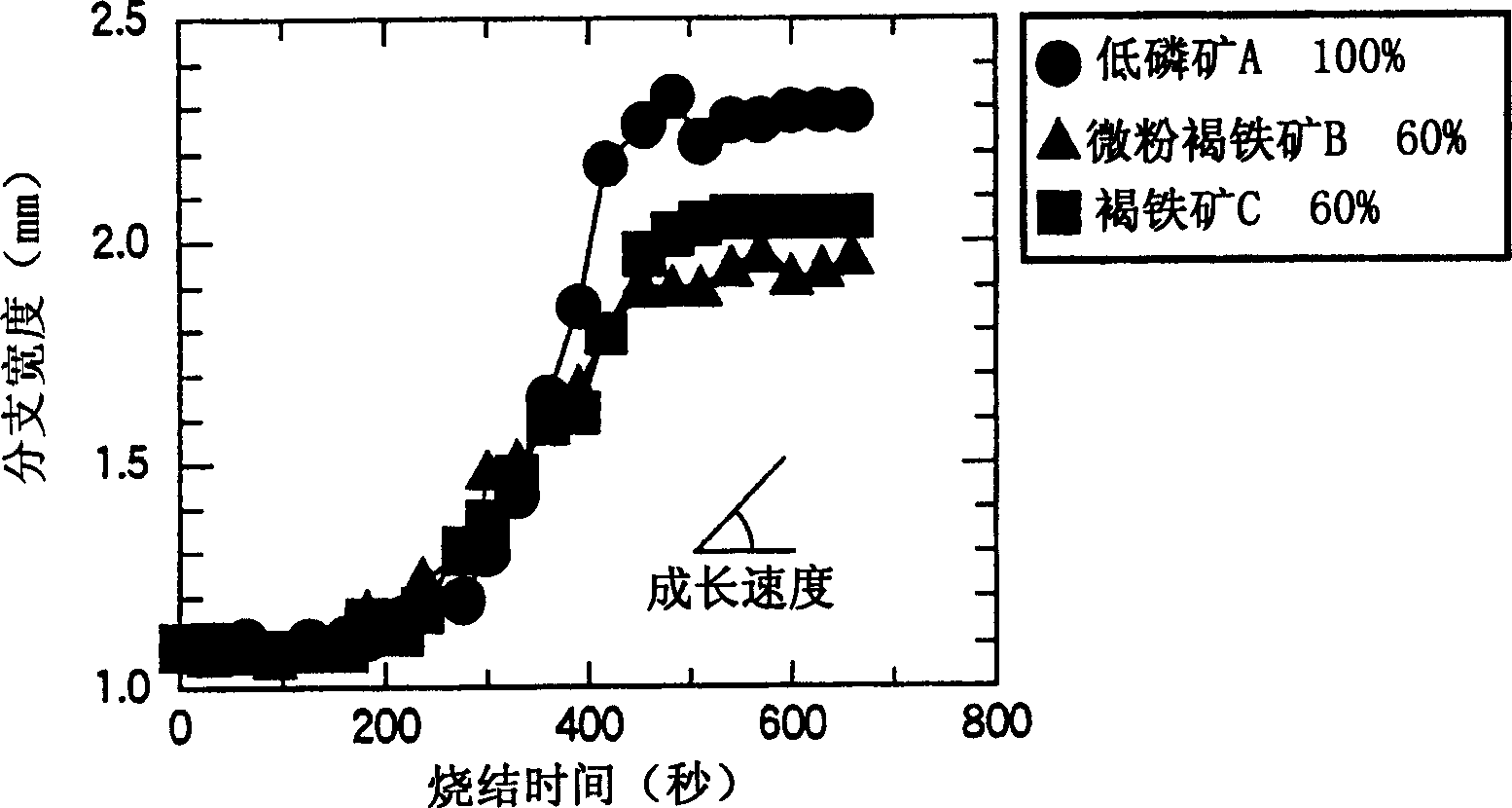

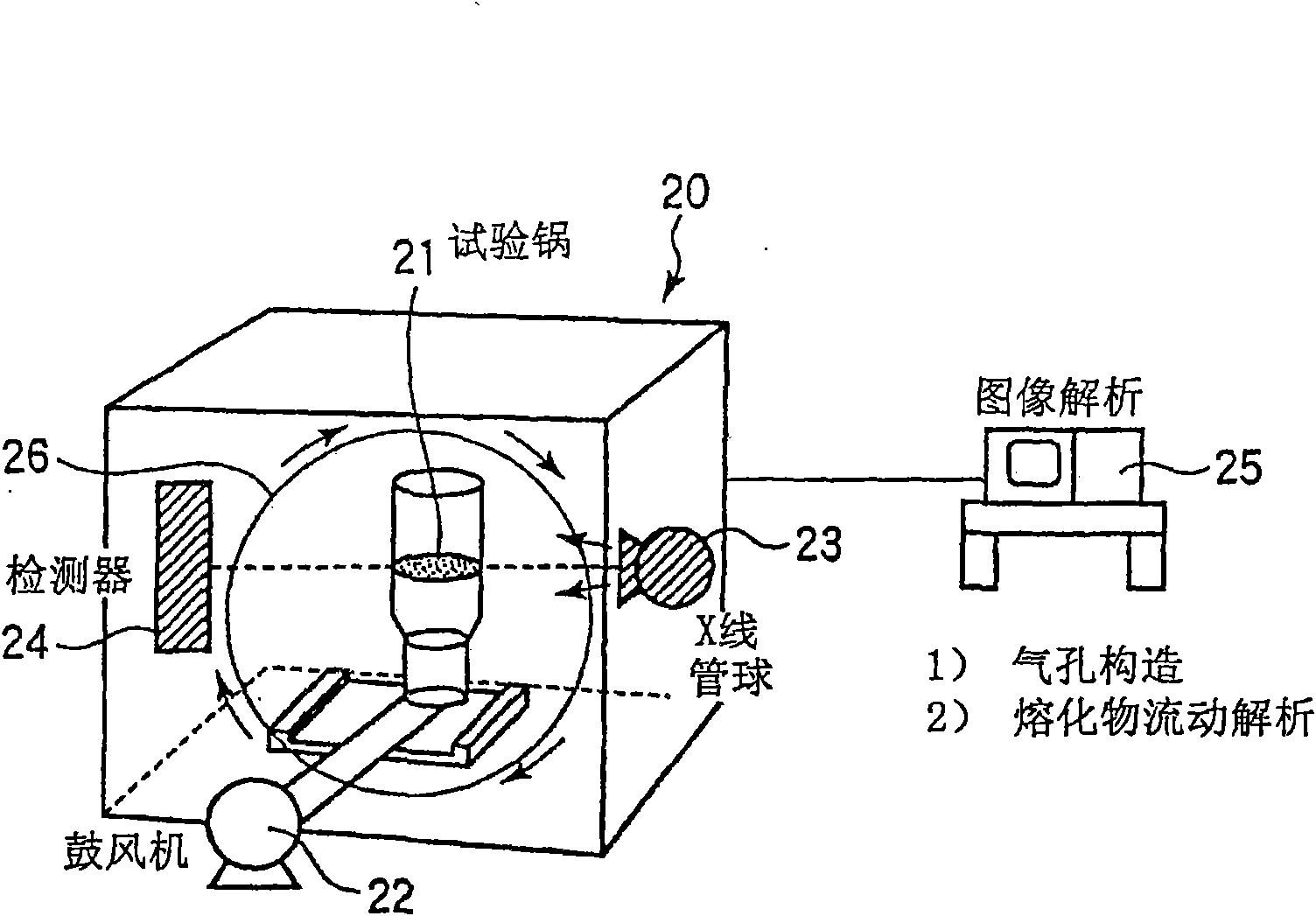

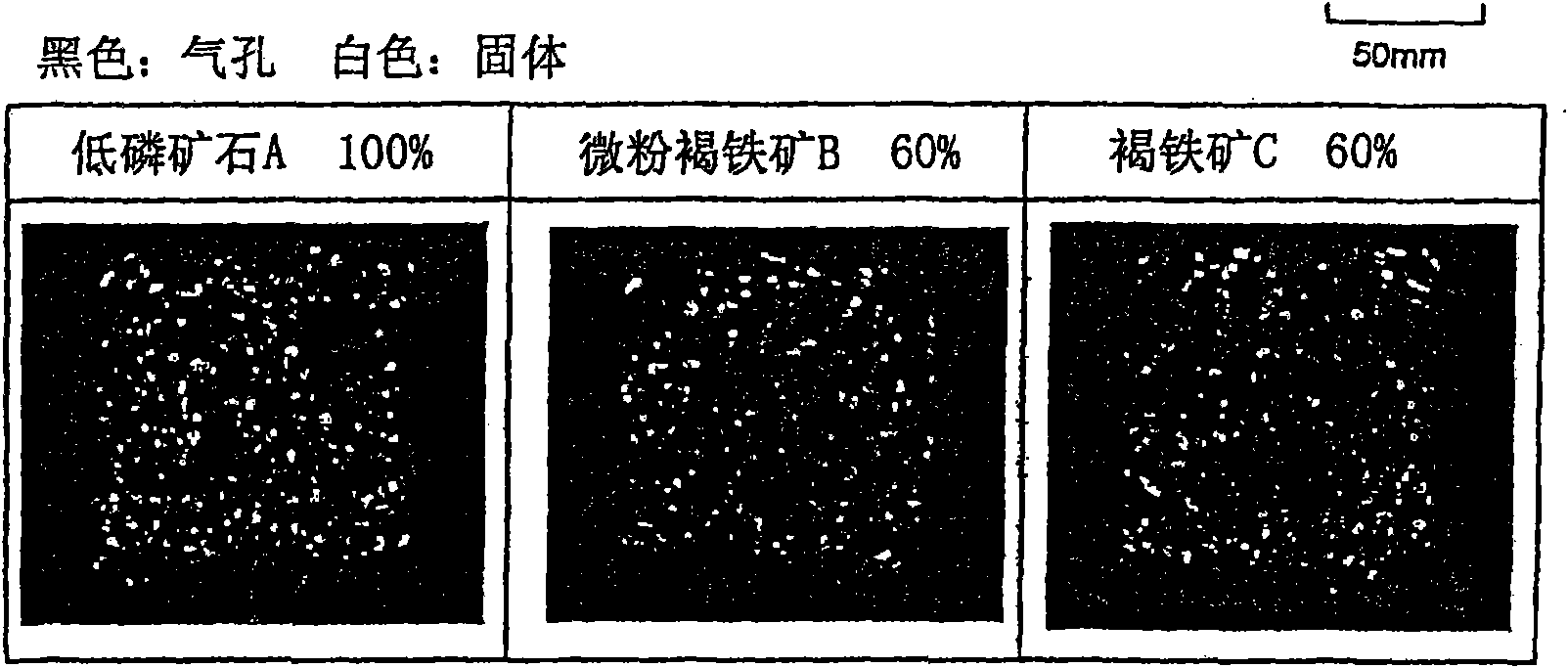

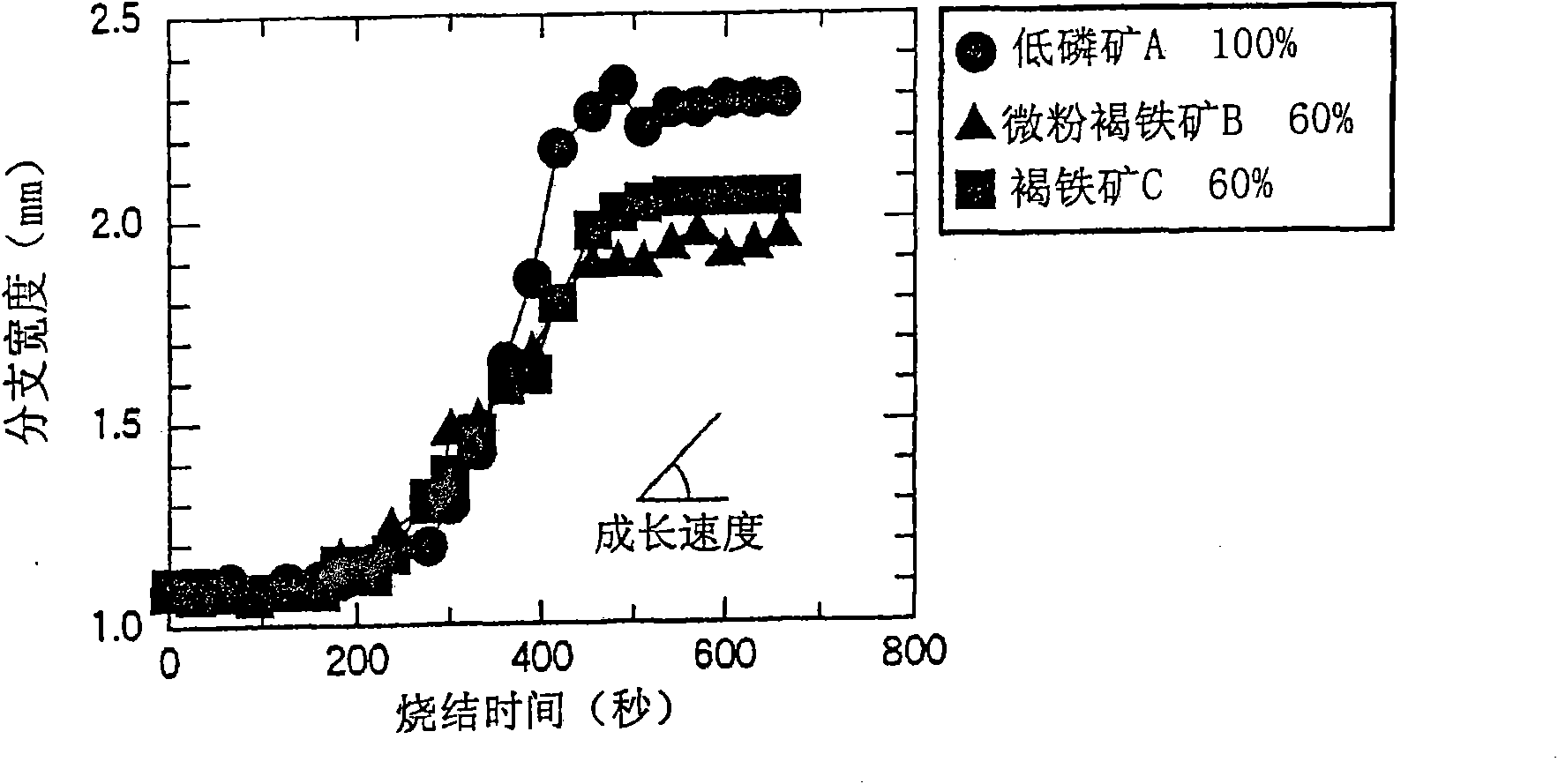

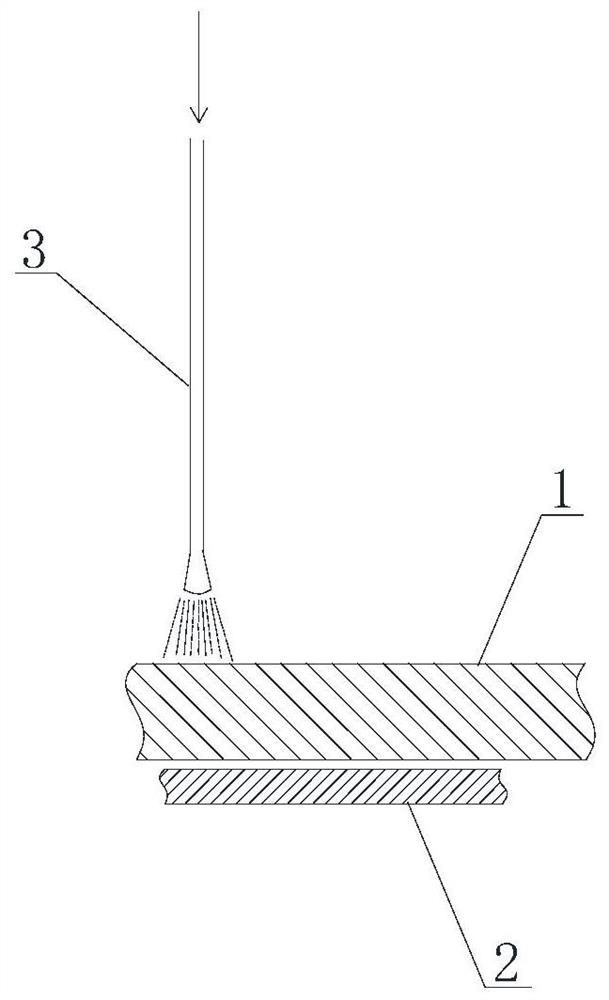

Method for producing sintered ore, method for producing raw material for sintering, granulated pellet, and sintered ore

A method for producing a sintered ore (50a) which comprises forming, on the surface of a nucleus particle (51) containing an iron ore, a first coating layer (52) using an iron-containing substance and optionally an SiO2-containing material, and subsequently a second coating layer (53) using limestone and a solid fuel based material, to prepare a granulated particle (50), and then sintering the granulated particle (50), wherein the iron-containing substance used for forming the first coating layer (52) has a porosity of 20 % or less or has a porosity of 20 % or less and a content of Al2O3 of 2.1 mass % or less, and wherein the iron ore for the nucleus particle has a porosity higher than that of the iron-containing substance used for the first coating layer (52) or has a porosity and / or a content of Al2O3 higher than that or those of the iron-containing substance.

Owner:JFE STEEL CORP

Coating for centrifugal casting high alloy furnace tube metal mould and method thereof

InactiveCN1520951AHigh low temperature strengthImprove plasticityFoundry mouldsFoundry coresCelluloseSodium Bentonite

The present invention is metal type paint for centrifugal casting high-alloy furnace tube and its production process. The material includes zirconite powder, silica sol, fluotrite powder, cellulose, PVA and bentonite; and the mixing production process includes dry mixing zirconite powder, fluotrite powder and bentonite inside a crushing roller mill for 15 min, dissolving cellulose and PVA in water and mixing and milling for 3 hr, and adding silica sol and mixing and milling for 30 min. The paint can form coating with increased low temperature strength, increased low temperature plasticity, raised flush resistance and vibration resistance.

Owner:BC P INC CHINA NAT PETROLEUM CORP

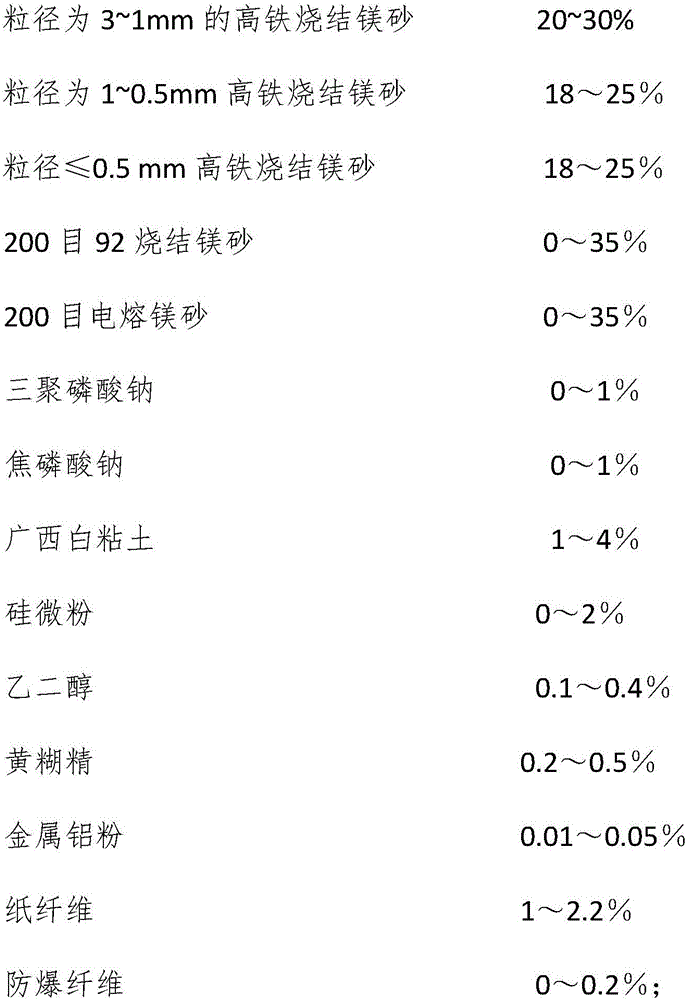

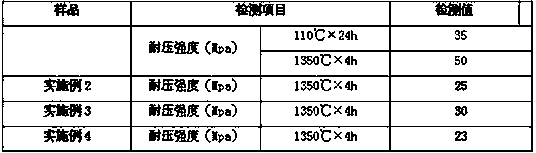

Anti-collapse tundish smearing material and preparation method thereof

The invention relates to an anti-collapse tundish smearing material and a preparation method thereof, and belongs to the technical field of unshaped refractory material; the anti-collapse tundish smearing material is characterized by being prepared from the following raw materials by the weight percentage: 20-30% of high-iron sintered magnesia with the particle size of 3-1 mm, 18-25% of high-iron sintered magnesia with the particle size of 1-0.5 mm, 18-25% of high-iron sintered magnesia with the particle size of less than or equal to 0.5 mm, 0-35% of 200-mesh 92 sintered magnesia, 0-35% of 200-mesh fused magnesite, 0-1% of sodium tripolyphosphate, 0-1% of sodium pyrophosphate, 1-4% of Guangxi white clay, 0-2% of a silica micro-powder, 0.1-0.4% of ethylene glycol, 0.2-0.5% of canary dextrin, 0.01-0.05% of a metal aluminum powder, 1-2.2% of paper fibers, and 0-0.2% of explosion-proof fibers, wherein the total percentage of the raw materials is 100%. The smearing material has the advantages of excellent construction performance, good water retention, no cracks during curing, high low-temperature strength, no collapse and no cracking during quick baking, and good use performance.

Owner:山东国茂冶金材料有限公司

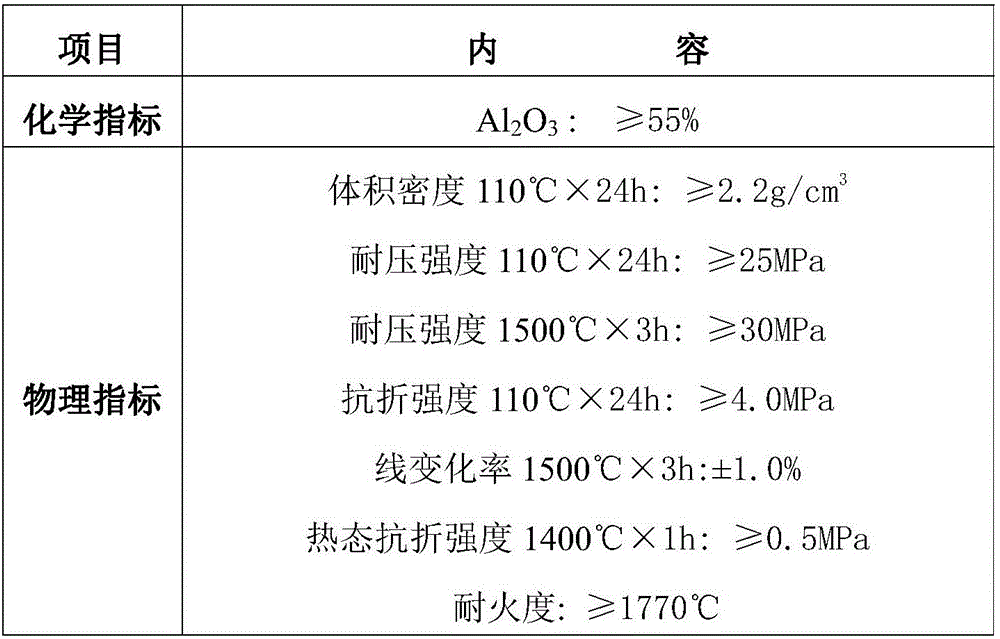

Low-cost high-strength high-temperature-resistant coating material and preparation method thereof

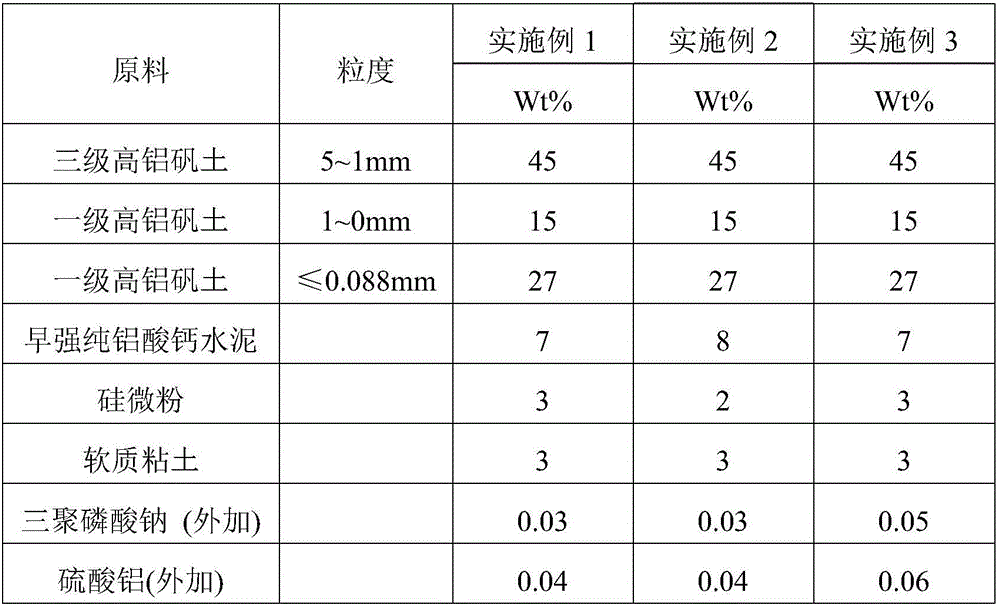

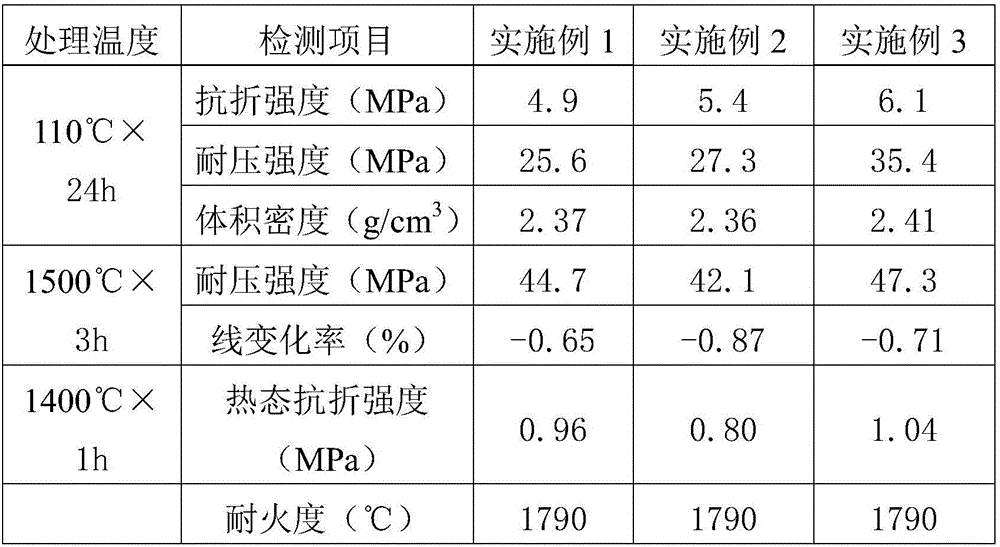

The invention relates to a low-cost high-strength high-temperature-resistant fireproof coating material and a preparation method thereof. The coating material is characterized by comprising, by mass, 45 to 50% of grade-III high-alumina bauxite with a particle size of 5 to 1 mm, 10 to 15% of grade-I high-alumina bauxite with a particle size of 1 to 0 mm, 23 to 28% of grade-I high-alumina bauxite with a particle size of less than 180 meshes, 7 to 8% of pure calcium aluminate cement, 2 to 3% of silica micropowder, 2 to 3% of soft clay, 0.02 to 0.05% of an extra water reducer and 0.03 to 0.06% of an extra flocculating agent. According to the invention, through addition of the water reducer, water addition in construction of the coating material is greatly reduced, so the strength of the coating material is improved; through addition of the flocculating agent, water addition in construction of the coating material is not increased and the coating material with the water reducer is deprived of fluidity, so good coating properties are obtained; and through usage of early-strength cement with high content of a CA phase, the strength of the coating material is further improved.

Owner:上海彭浦特种耐火材料厂有限公司 +1

Method for preparing mineral bonding materials and composite materials thereof from phosphoric acid and aluminium-silicon materials

InactiveCN1721356AHigh low temperature strengthGood high temperature characteristicsClaywaresSilica fumeIon

The present invention relates to one kind of mineral bonding material prepared with phosphoric acid and alumina and silica material at relatively low temperature and its composite material. At relatively low temperature, alumina and silica material with reaction activity and phosphoric acid produce bonding reaction to form one kind of amorphous solid mineral bonding Al-Si-P material. The mineral bonding Al-Si-P material may be used as base material and added with bauxite, silica powder, flyash, mineral slag, fiber, etc to prepare various kinds of composite material with different performances. The composite materials may be cast or pressed to form optionally without needing of introducing alkali earth ions, and the prepared material has high durability, high mechanical strength and good high temperature performance.

Owner:SOUTH CHINA UNIV OF TECH

Thermal-state repair spray coating and preparation method thereof

The invention belongs to the technical field of spray coating, and particularly relates to thermal-state repair spray coating for quickly repairing a working lining in a thermal state and a preparation method of the thermal-state repair spray coating. The thermal-state repair spray coating is prepared from the following components in percentage by weight: 70-76% of brown aluminium oxide, 4.5-5.5%of Guangxi white mud, 4.5-5.5% of pure calcium aluminate 70 cement, 1.5-2.5% of boric acid, 4.5-5.5% of silicon metal, 1.5-2.5% of aluminum metal and 7-9% of silicon carbide. According to the thermal-state repair spray coating, in the thermal state, the conditions of severe local erosion, peeling or local damage occurring in the use process of the working lining are quickly repaired, a prepared finished product is good in bonding, high in strength and long in service life.

Owner:河南恒耐尔耐火材料有限公司

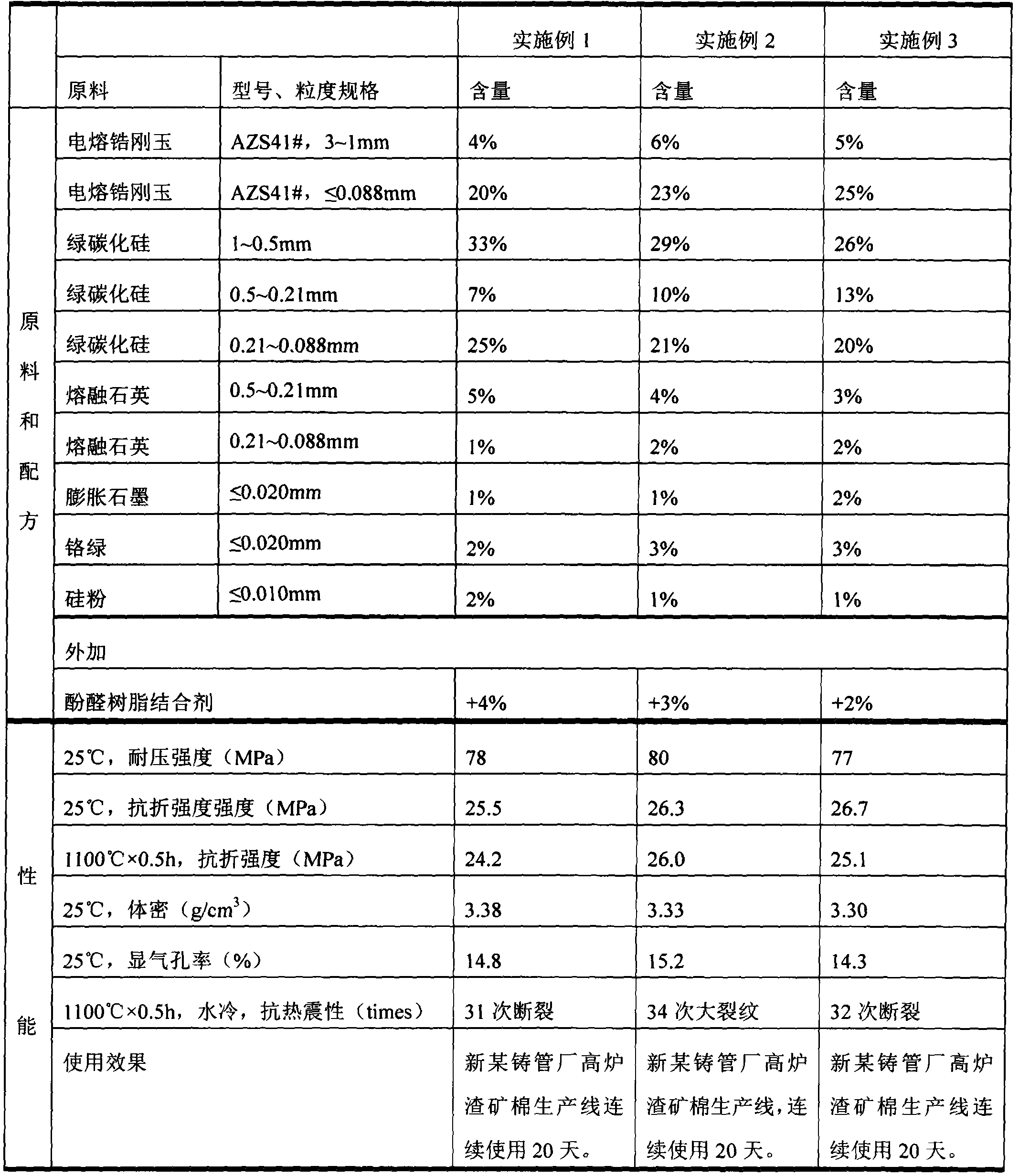

Flow controlling water gap for production of mineral wool from blast furnace slag and production process thereof

The invention relates to a flow controlling water gap for production of mineral wool from blast furnace slag and a production process thereof, and belongs to the field of refractory materials. The flow controlling water gap is prepared from the following components: 3-6% of electrically-fused zirconia corundum with the granularity of 3-1mm, 20-25% of electrically-fused zirconia corundum with the granularity smaller than or equal to 0.088mm, 25-35% of green silicon carbide with the granularity of 1-0.5mm, 5-15% of green silicon carbide with the granularity of 0.5-0.21mm, 20-25% of green silicon carbide with the granularity of 0.21-0.088mm, 3-5% of fused quartz with the granularity of 0.5-0.21mm, 1-2% of fused quartz with the granularity of 0.21-0.088mm, 1-2% of expanded graphite with the granularity of smaller than or equal to 0.020mm, 2-3% of chrome green with the granularity of smaller than or equal to 0.020mm, 1-2% of silicon powder with the granularity of smaller than or equal to 0.010mm and 2-4% of plaenolic resin binder. The production process comprises the following steps: mixing, ageing a mixture, performing isostatic pressing forming, drying, sintering, performing flaw detection, performing glaze spraying and the like. The flow controlling water gap has excellent erosion resistance, heat shock resistance and oxidation resistance, and has the service life of more than 20 days, which is far longer than the service life of graphite water gap (about 4 days).

Owner:RUITAI MATERIALS TECHNOLOGY CO LTD +1

Sintered ore

A method for producing a sintered ore (50a) which comprises forming, on the surface of a nucleus particle (51) containing an iron ore, a first coating layer (52) using an iron-containing substance andoptionally an SiO2-containing material, and subsequently a second coating layer (53) using limestone and a solid fuel based material, to prepare a granulated particle (50), and then sintering the granulated particle (50), wherein the iron-containing substance used for forming the first coating layer (52) has a porosity of 20 % or less or has a porosity of 20 % or less and a content of Al2O3 of 2.1 mass % or less, and wherein the iron ore for the nucleus particle has a porosity higher than that of the iron-containing substance used for the first coating layer (52) or has a porosity and / or a content of Al2O3 higher than that or those of the iron-containing substance.

Owner:JFE STEEL CORP

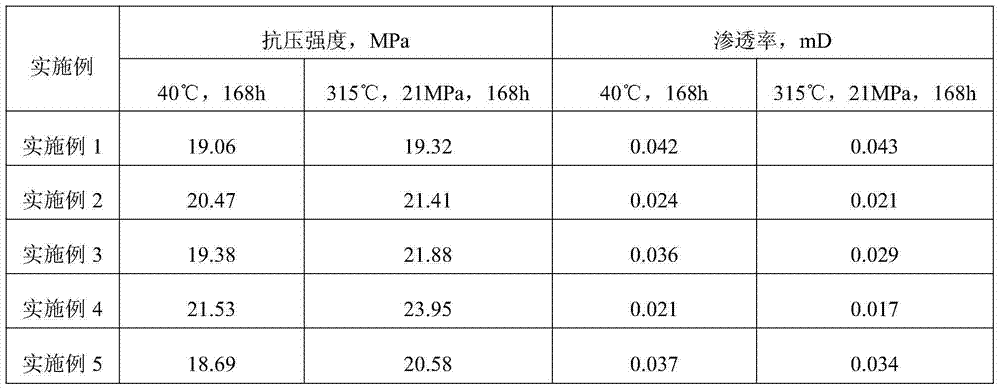

High-temperature-resisting thermal recovery cement and preparation method thereof

The invention discloses high-temperature-resisting thermal recovery cement and a preparation method thereof. The thermal recovery cement comprises the following components in parts by weight of 55-65 parts of aluminate cement grog, 10-30 parts of phosphorite dregs, 10-30 parts of slags, 1-3 parts of ceramic fibers and 1-3 parts of rubber powder. The preparation method comprises the following steps of weighing the aluminate cement grog, the phosphorite dregs and the slags, mixing so as to obtain a mixing powder body, pouring the mixing powder body into a ball mill for grinding until the specific surface area of 250-300m<2> / kg is achieved, adding the ceramic fibers and the rubber powder, and stirring for ten minutes in a mixing manner to obtain the high-temperature-resisting thermal recovery cement. The high-temperature-resisting thermal recovery cement and the preparation method thereof provided by the invention have the advantages that an engineering property of the thermal recovery cement is easy to regulate, and the intensity is high under the low temperature; for a cement stone made of the thermal recovery cement, an excellent high temperature resistance property is realized, the intensity is not decayed when the formed hardened cement is subjected to the high temperature, the permeability is not increased, the thermal recovery cement has the certain tenacity, the well-cementing requirement of a thick oil thermal production well is met, a principle of the preparation method is reliable, the operation is simple and convenient, and the production cost is low.

Owner:SOUTHWEST PETROLEUM UNIV

Investment casting core production process for turbosuperchager volute and pump parts

ActiveCN109894575AHigh low temperature strengthAvoid deformationFoundry mouldsFoundry coresWaxTurbocharger

The invention relates to an investment casting core production process for turbosuperchager volute and pump parts. The investment casting core production process for the turbosuperchager volute and pump parts adopts an investment casting process for producing a core, and comprises the following steps of (1) carrying out a wax mould pressing process; (2) carrying out a shell making process; (3) carrying out a dewaxing process; and (4) finishing. According to the investment casting core production process for the turbosuperchager volute and pump parts provided by the invention, the core is highin low-temperature strength and not easy to deform; the core is high in dimensional precision; the core is long in preservation period; the core is high in high-temperature strength and not easy to leak molten steel; the core is convenient to clean without the need for using a chemical method for clearing shells; the core is compact in structure; and the casting surface smoothness is high and canreach to Ra3.2 which is the same as general investment casting. According to the investment casting core production process for the turbosuperchager volute and pump parts provided by the invention, after a core rough blank is prepared, the core rough blank can be checked and repaired, so that the casting rejection caused by the core surface quality problem can be greatly reduced. According to theinvestment casting core production process for the turbosuperchager volute and pump parts provided by the invention, after the core is used, an inner cavity has no need to be dried, so that the shellmaking period can be greatly shortened, the shell turnover rate is improved, and the economic benefit is improved.

Owner:SHANGHAI LIANGJI BOFANG AUTOMOBILE ENGINE PARTS MFG CO LTD

High temperature resistant composite cement and preparation method thereof

InactiveCN106477924AStable physical and chemical propertiesSimple physical and chemical propertiesCement productionActivated sludgeFiber

The invention provides high temperature resistant composite cement. The high temperature resistant composite cement is prepared from 48-72 parts of a portland cement clinker, 5-9 parts of gypsum, 11-17 parts of activated sludge, 12-33 parts of fly ash, 3-6 parts of limestone, 12-33 parts of electric furnace slag, 11-32 parts of granulated blast furnace slag, 2-4 parts of ceramic fibers and 2-5 parts of rubber powder. The high temperature resistant composite cement has the advantages of stable thermally recovered cement physical and chemical properties and easy engineering performance distribution. A preparation method of the high temperature resistant composite cement is simple, is convenient to operate and realizes a low cost, strong production controllability and good consistency of the product. The thermally recovered cement has high low temperature strength, prevents strength declining after high temperature treatment and has good high temperature resistance. Through use of phosphor slag and other slag, compressive strength reduction of aluminate cement in a hydration later period is solved and set cement compressive strength after treatment at a temperature more than 300 DEG C is guaranteed. Through use of ceramic fibers and rubber powder, the toughness of brittle aluminate cement is improved and downhole condition demands are satisfied.

Owner:GUANGXI UNIV

Method for preparing ADI nodular cast iron capable of resisting impact of low temperature of 40 DEG C below zero

InactiveCN104805350AImprove mechanical propertiesEvenly distributedProcess efficiency improvementManganeseDuctile iron

A method for preparing an ADI nodular cast iron capable of resisting the impact of a low temperature of 40 DEG C below zero relates to a method for preparing a low-temperature-resistant ADI ductile iron, and solves the technical problem that the impact energy of a conventional ADI ductile iron 900 / 650 / 09 in a high-cold environment is relatively low. The method comprises the following steps: firstly, melting ductile cast iron Q10, low-manganese steel scrap and returns and a proper amount of nickel plates and then adding nickel plates and sheet copper for smelting so as to obtain an iron liquid; secondly, performing spheroidization and inoculation treatment; thirdly, adding a desulfurization agent; fourthly, casting to obtain a sample; fifthly, preserving heat of the sample twice, then placing the sample into a nitrate medium, and discharging to obtain the ADI nodular cast iron. The ADI nodular cast iron has the yield strength of 660-690 MPa, the tensile strength of 910-950 MPa and the elongation of 9-11%, and the unnotched impact value of the ADI nodular cast iron prepared at the temperature of 40 DEG C below zero is 105-120 J. The method is applied to the field of nodular cast iron preparation.

Owner:齐齐哈尔市精铸良铸造有限责任公司

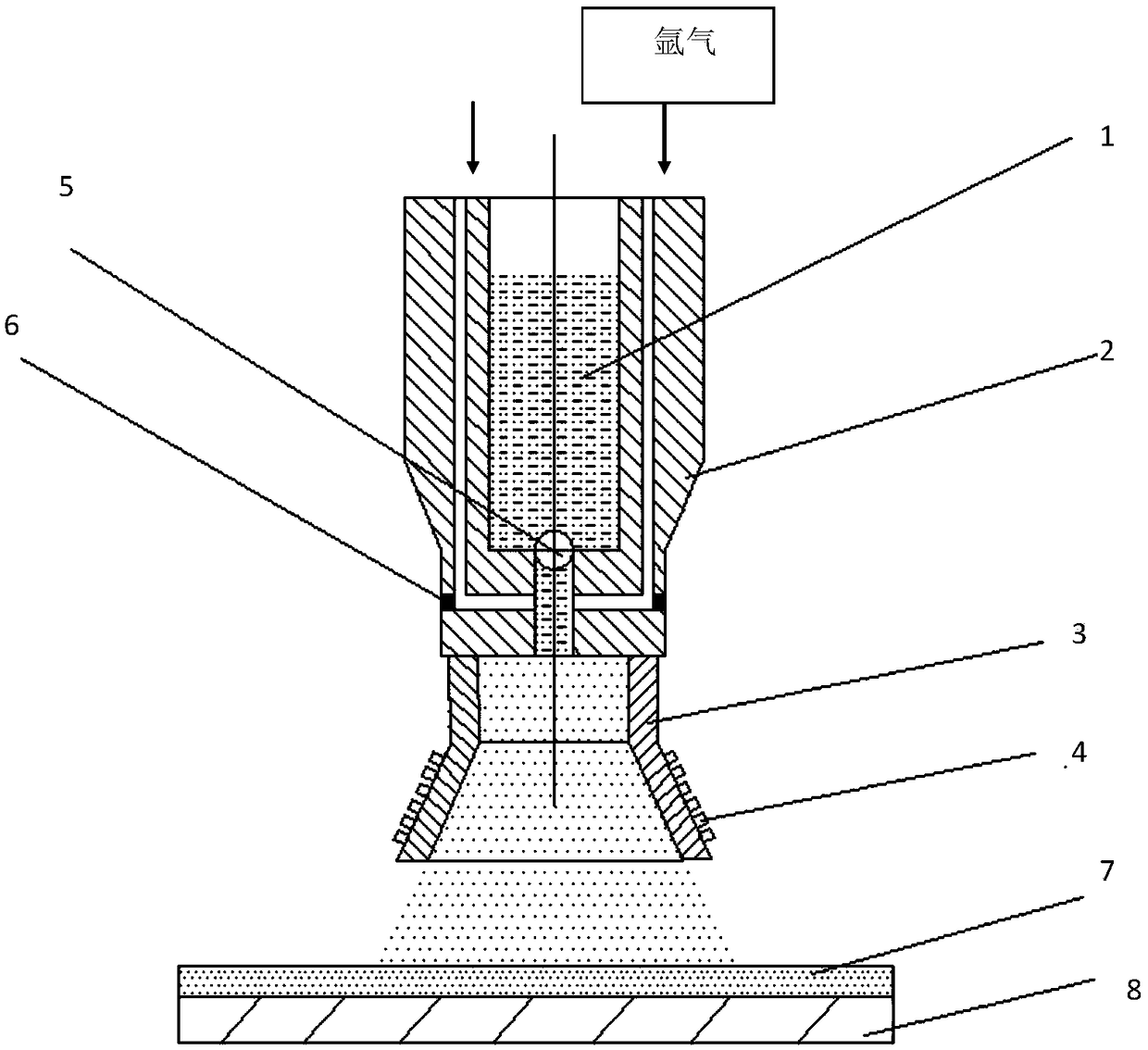

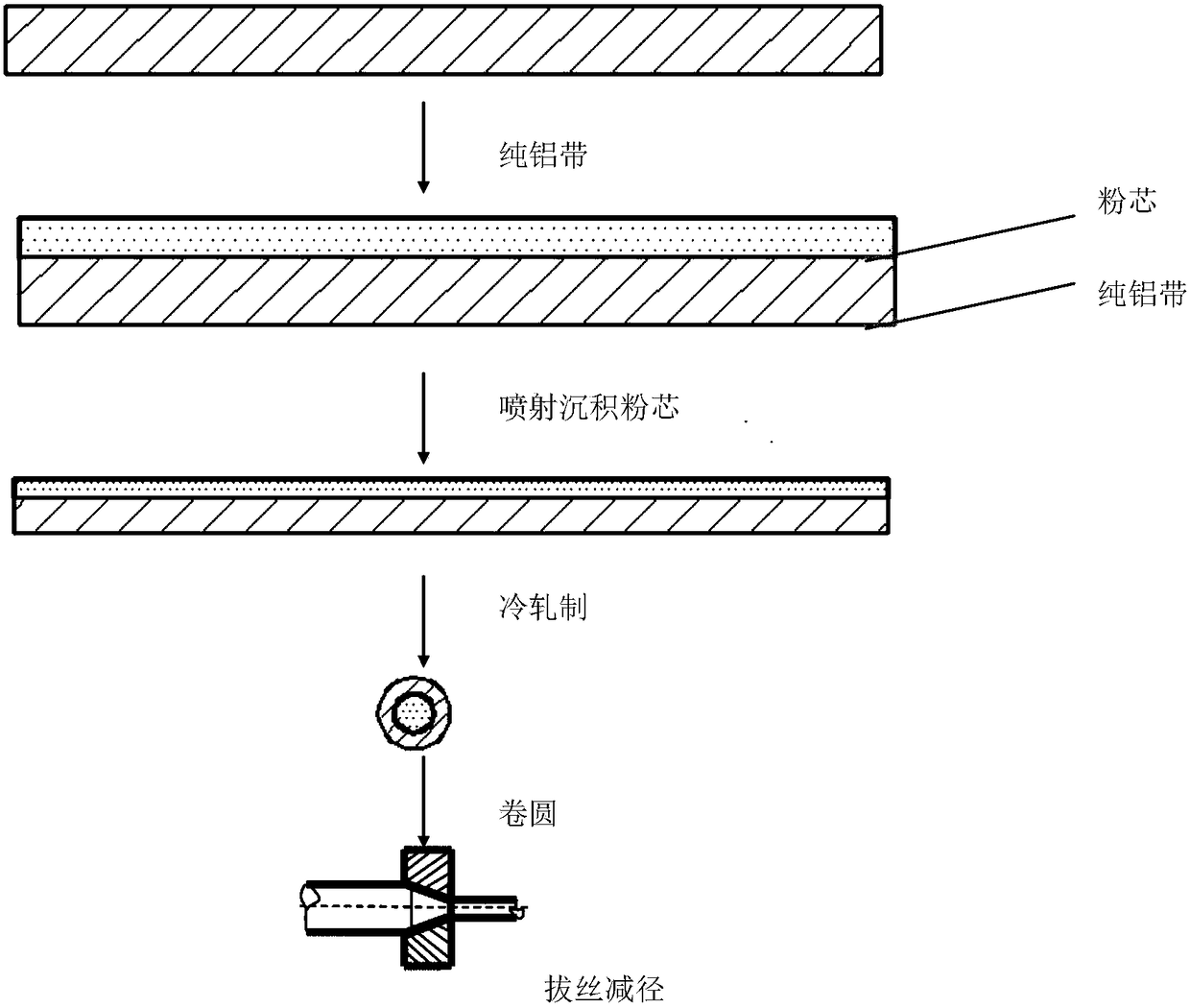

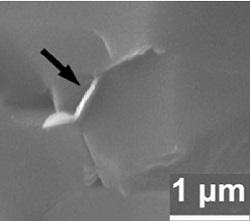

Powder core wire and low-temperature-resistant high-entropy alloy prepared by electric-arc deposition of powder core wire

ActiveCN108950352AHigh low temperature strengthHigh and low temperature hardnessMolten spray coatingHigh entropy alloysDuctility

The invention provides a powder core wire and a low-temperature-resistant high-entropy alloy prepared by electric-arc deposition of the powder core. The powder core wire comprises an aluminum belt anda powder core, wherein each of the aluminum belt and the powder core consists of Co, Cr, Fe, Ni and Cu in an equal atomic ratio being 1 to 1 to 1 to 1 to 1 to 1; and the thickness of the aluminum belt is 0.5 mm. The preparation method for the wire comprises the following steps of: (1) preparing the powder core; (2) spraying a deposited powder core; (3) performing cold-rolling; and (4) performingtube coiling and wire drawing. A prepared high-entropy alloy coating has high low-temperature-resistant strength, high low-temperature hardness and high low-temperature ductility.

Owner:JIANGSU UNIV OF TECH

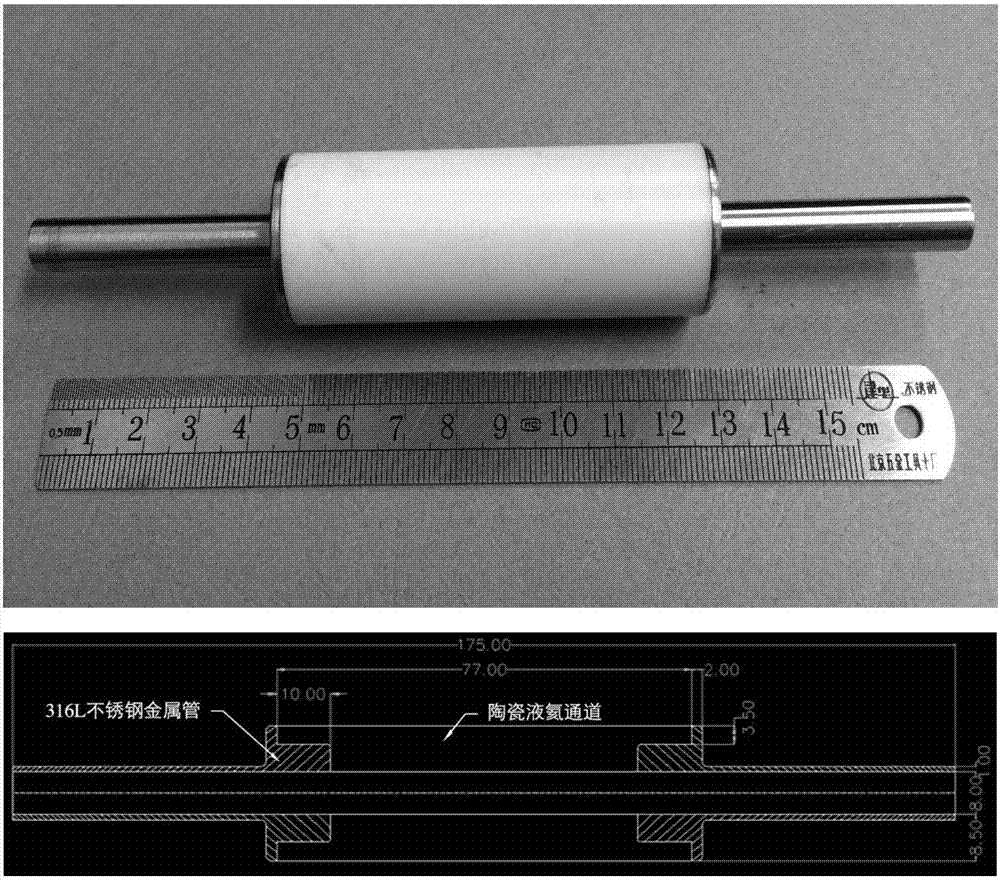

Ceramic channel used in cryogenic liquid helium environment and preparation method thereof

InactiveCN108002830AHigh densityFine grainDomestic cooling apparatusLighting and heating apparatusEpoxyFiber

The invention discloses a ceramic channel used in a cryogenic liquid helium environment and a preparation method thereof. The method includes the following steps of mixing ceramic powder with an organic solvent to obtain a mixture, conducting cold isostatic pressing and high-temperature sintering on the mixture to obtain the ceramic channel, and connecting the ceramic channel and a metal connectorin a sealing mode. The ceramic powder is yttria-stabilized zirconia powder in which the molar percentage of yttria is 2 to 3%. According to the method, a zirconia ceramic material is used to replacecommon fiber and epoxy resin materials to make the liquid helium channel, so that the strength, toughness, corrosion resistance and radiation resistance of the channel are all significantly improved,and the service life is greatly prolonged. The shortcomings that the fiber and the epoxy resin materials are prone to ageing and lead to deterioration of airtightness are overcome, and the requirements of a full superconducting tokamak device for the liquid helium channel can be met.

Owner:TSINGHUA UNIV

Evanescent mode water-based paint for large alloy steel casting

InactiveCN108788001AGood water swelling performanceEvenly distributedFoundry mouldsFoundry coresFiberWater based

The invention discloses an evanescent mode water-based paint for a large alloy steel casting. The evanescent mode water-based paint comprises the following components in parts by weight: 30 45 parts of quartz powder, 7 17 parts of zircon powder, 5 10 parts of talcum powder, 10 15 parts of bauxite, 15 parts of synthetic mullite, 2 4 parts of perlite particles, 4 6 parts of sodium bentonite, 2 4 parts of sodium carboxymethyl starch, 1 3 parts of cassava starch, 0.5-1.5 parts of refractory fiber, and 1 3 parts of mica powder. The evanescent mode water-based paint for the large alloy steel castingovercomes the casting defect that there air holes in the surface due to poor air permeability of the paint and improves the low-temperature strength, high-temperature strength and high-temperature air permeability of a coating, thereby enabling the large alloy steel casting to meet the requirements for mass production.

Owner:河北冀凯铸业有限公司

Method for preparing mineral bonding materials and composite materials thereof from phosphoric acid and aluminium-silicon materials

InactiveCN100424027CHigh low temperature strengthImprove high temperature resistanceClaywaresFiberAlkaline earth metal

The present invention relates to one kind of mineral bonding material prepared with phosphoric acid and alumina and silica material at relatively low temperature and its composite material. At relatively low temperature, alumina and silica material with reaction activity and phosphoric acid produce bonding reaction to form one kind of amorphous solid mineral bonding Al-Si-P material. The mineral bonding Al-Si-P material may be used as base material and added with bauxite, silica powder, flyash, mineral slag, fiber, etc to prepare various kinds of composite material with different performances. The composite materials may be cast or pressed to form optionally without needing of introducing alkali earth ions, and the prepared material has high durability, high mechanical strength and good high temperature performance.

Owner:SOUTH CHINA UNIV OF TECH

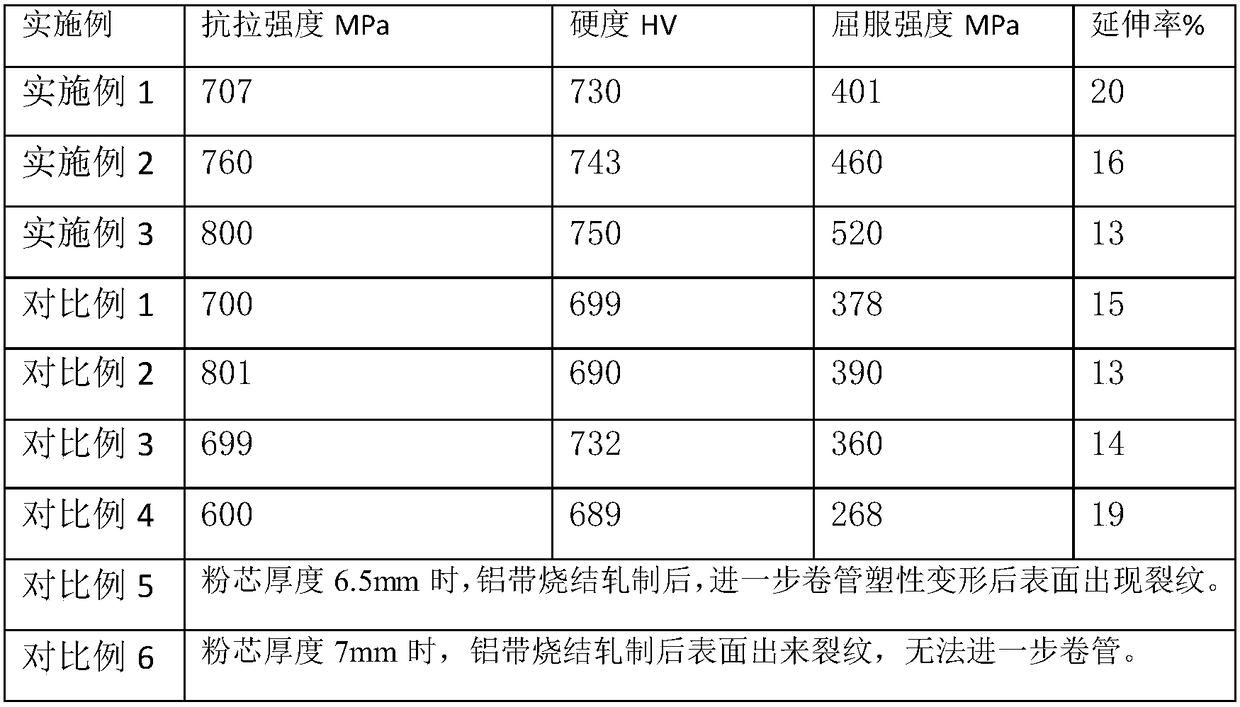

Alkaline sliding plate for continuous casting of special steel and preparation process thereof

The invention relates to an alkaline sliding plate for continuous casting of special steel and a preparation process thereof. The advantages of various carbon sources are compounded, magnesium metal powder is added into the sliding plate taking magnesium aluminate spinel as a main raw material, CO2 is adopted as a sintering atmosphere, and the CO2 reacts with the Mg powder at a high temperature togenerate MgO and graphene; the generated MgO has high reaction activity and reacts with Al2O3 in situ to form spinel to promote sintering; and the graphene and spinel generated in situ fill fine holes, so that the material is more compact, and the erosion resistance and oxidation resistance of the sliding plate are enhanced.

Owner:YIXING REFRACTORY MATERIAL +1

Lightweight high-strength refractory castable

ActiveCN113800894AImprove high temperature performanceImprove insulation performanceCeramicwareFiberInsulation layer

The invention discloses a lightweight high-strength refractory castable which comprises the following raw materials in percentage by weight: 25-35% of lightweight high-strength microporous alumina aggregate, 25-35% of alumina hollow spheres, 3-5% of floating beads, 5-8% of kyanite powder, 5-8% of calcined bauxite fine powder, 5-8% of silica powder, 6-9% of alpha-Al2O3 micro powder, 5-10% of alumina cement, 3-5% of refractory fibers, 0.1-0.3% of a composite water reducing agent and 0.02-0.05% of a water-based silicon polyether defoaming agent. The refractory castable can effectively reduce the water-cooling heat loss of a high-temperature water-cooling furnace roller of a thin slab continuous casting and rolling tunnel type heating furnace, improve the heat efficiency of the heating furnace and prolong the service life of a heat insulation layer of the furnace roller, and has the characteristics of stable performance, light volume weight, good mechanical property and excellent heat insulation performance and thermal shock resistance stability.

Owner:武汉钢铁有限公司

Austenitic stainless steel

ActiveCN102041457BHigh low temperature strengthHigh strengthTemperature control deviceProcess efficiency improvementNeutron irradiationNuclear fusion

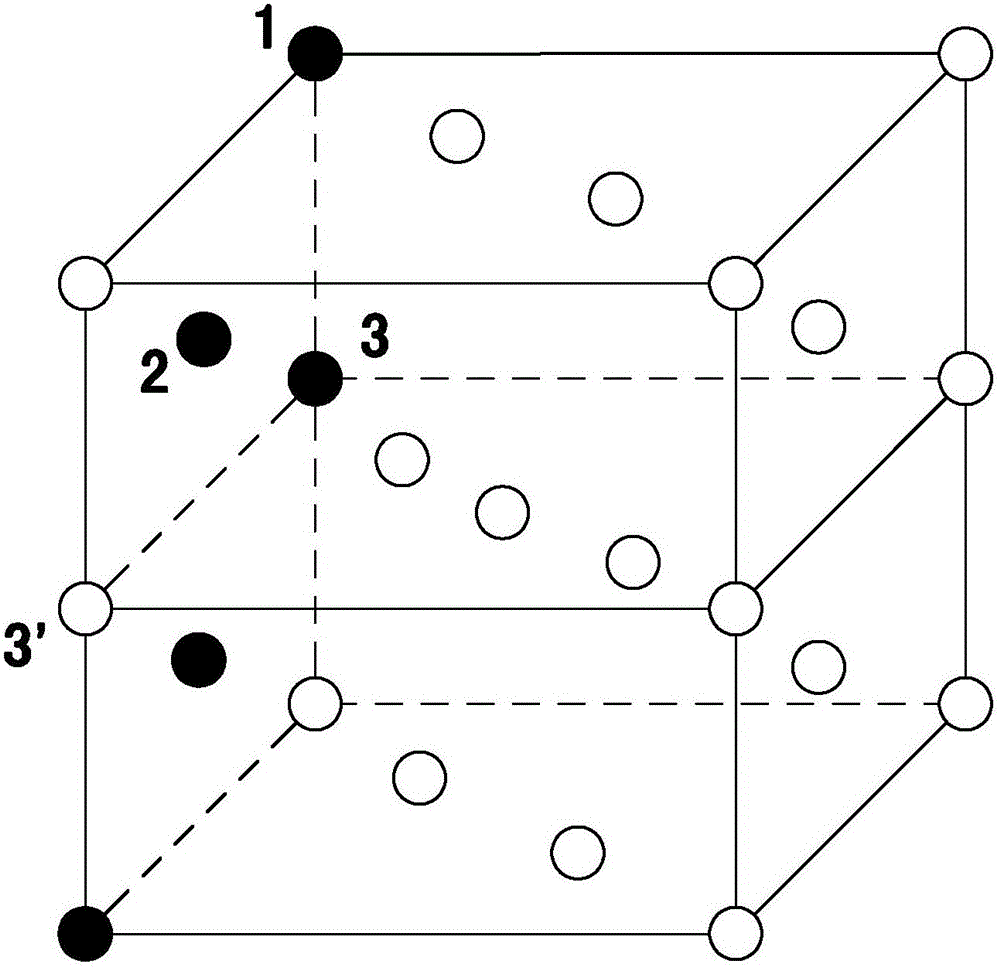

The invention relates to austenitic stainless steel which is high in low temperature strength, low temperature toughness and low temperature non-magnetism as well as better in neutron irradiation resistance, can be used in a magnet support structure of a nuclear fusion reactor, and comprises the components by mass percent: 16.00-22.0% of Cr, 8.00-12.00% of Ni, 1.00-3.00% of Mo, 0.06-0.25% of N, 0.010-0.040% of C, 1.00-4.00% of Mn, less than or equal to 1.00% of Si, 0.01-0.10% of Nb, 0.01-0.10% of Ta, 0.030-0.10% of Co, less than or equal to 0.03% of P, less than or equal to 0.005% of S, 0.0005-0.0018% of B, and the balance of Fe and unavoidable impurities; and furthermore, the value of Val (Cr-Ni) is less than 20.5, and Val (Cr-Ni)= 3* (Cr+Mo)+4.5*Si-2.8*Ni-1.4*Mn-84*(C+N).

Owner:BAOSTEEL DESHENG STAINLESS STEEL

No-water stemming material for blast furnace taphole and its prepn

InactiveCN100453509CShorten the blasting timeExtend the tapping timeBlast furnace componentsBlast furnace detailsCarbide siliconSlag

The present invention relates to amorphous refractory material, and is especially one kind of no-water stemming material for blast furnace taphole and its preparation process. The no-water stemming material is prepared with coke powder 15-25 wt%, clay 10-20 wt%, bauxite corundum 20-36 wt%, silicon carbide 10-20 wt%, asphalt 8-16 wt%, sericite 5-9 wt%, additive 1-5 wt% and binding agent 12-22 wt%, and through crushing, sieving, pre-mixing, rolling, kneading and extruding. The no-water stemming material has excellent plasticity and sintering performance, high strength at high and middle temperature and high slag and molten iron flush resistance, and can meet the requirement of high strength smelting in blast furnace.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

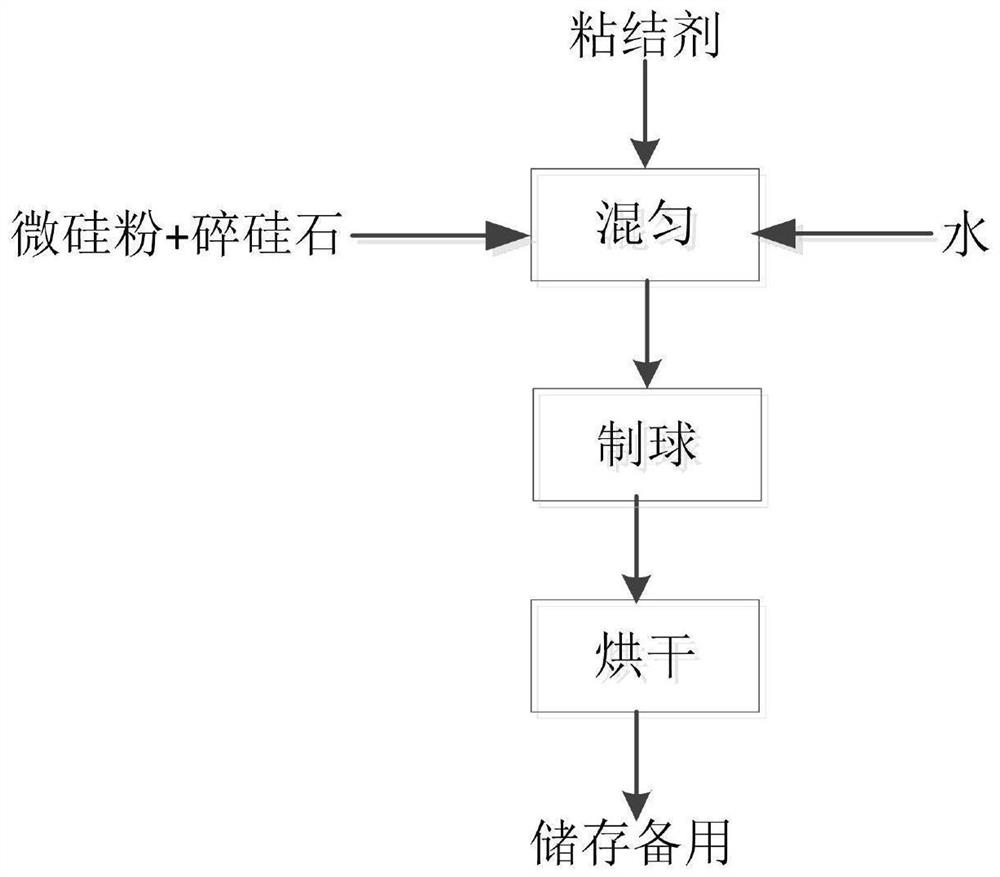

Silica fume pellet binder formula

The invention relates to a formula of a micro-silicon powder pellet adhesive. A novel high-temperature adhesive is obtained by adding starch, lignin, polyacrylamide, a silane coupling agent, sodium silicate and sodium hydroxide according to a certain proportion. The novel high-temperature binder, broken silica and water are added into micro-silicon powder according to a certain proportion, uniformly mixed, pressed and formed in ball pressing equipment, dried and then measured in low-temperature and high-temperature strength. According to the binder disclosed by the invention, the low-temperature strength and the high-temperature strength of the micro-silicon powder pellets are improved, and the micro-silicon powder pellets are used as industrial silicon raw materials, so that the silicon recovery rate can be improved, and the production cost is reduced.

Owner:GUIZHOU INST OF TECH

Environment-friendly low-temperature-resistant composite steel

InactiveCN106987781AHigh low temperature strengthImprove toughnessMetal layered productsEnvironmental resistanceCobalt

The invention discloses environment-friendly low-temperature-resistant composite steel which comprise a first steel layer on the surface layer and a second steel layer on the inner layer. The first steel layer is prepared from, by weight, 77-88 parts of iron, 5-12 parts of cobalt, 3-9 parts of phosphorus, 7-14 parts of titanium and 2-7 parts of tungsten. The second steel layer is prepared from, by weight, 84-91 parts of iron, 8-16 parts of cobalt, 4-10 parts of vanadium, 3-8 parts of chromium and 1-5 parts of nickel. The environment-friendly low-temperature-resistant composite steel is of a composite structure and has the advantages of being high in low-temperature strength, good in toughness, good in wear resistance, nontoxic and free of pollution.

Owner:SUZHOU DOUBLE GOLD IND

Asphalt mixture modifier and application method thereof

The invention relates to an asphalt mixture modifier and an application method thereof; the modifier comprises the following components by mass percentage: more than or equal to 50 percent and less than 100 percent of plastics or recycled waste plastics, and more than o and less than 50 percent of SBS, recycled rubber tire powder, fiber, asphalt or waste oil. The method comprises the following steps: the modifier and mineral aggregate are added into a mixing pot of a mixing plant to be mixed, the temperature of the mineral aggregate is no lower than 170DEG C, and the mixing time is shorter than 10s; and then the asphalt is sprayed in to be mixed when the temperature is no lower than 140DEG C, the mixing time is continued for 35 to 60s, and modified asphalt mixture is prepared. The plastics or the recycled waste plastics in the modifier can be compatible and mixed with the asphalt, and improve various application performance of the asphalt mixture and the overall road performance of a road surface. The method continuously mixes the modifier and the mineral aggregate and the asphalt so that the construction is convenient and the cost is low, simultaneously reduces the aging of the asphalt, saves energy, utilizes the recycled material, and meets the environment protection requirements in a plurality of aspects.

Owner:翁晓娜

Method for local remelting reinforcement of aluminum alloy part

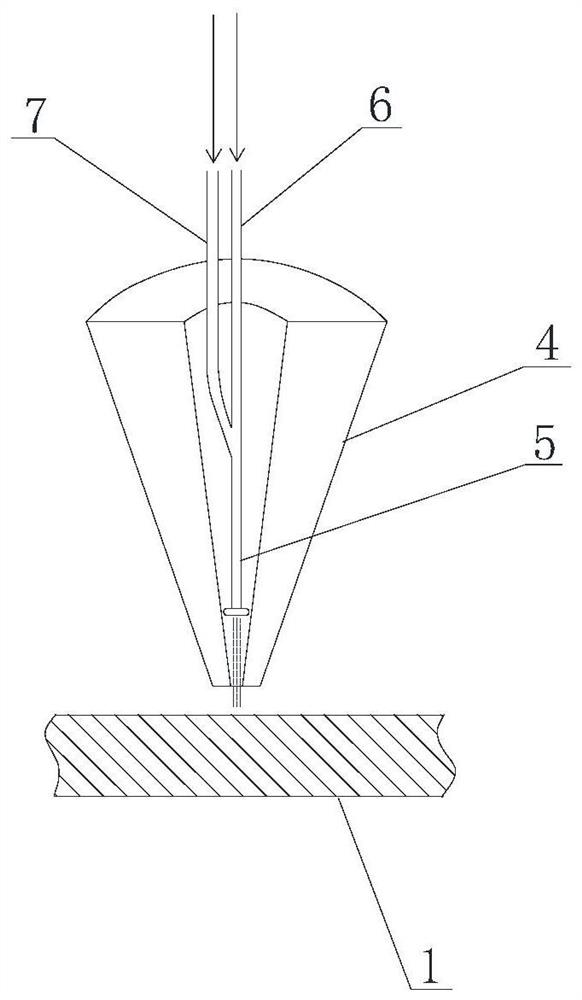

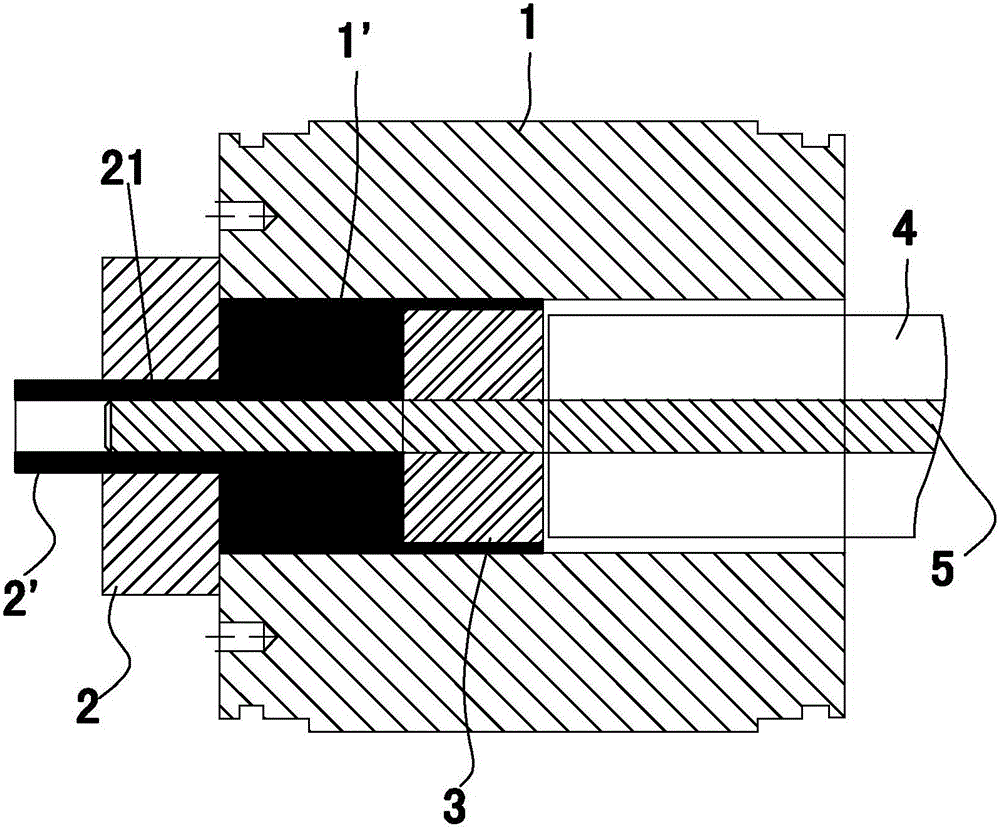

PendingCN113355668AHigh strengthImprove high temperature strengthMetallic material coating processesIncreasing energy efficiencyAlloy elementLaser light

The invention discloses a method for local remelting reinforcement of an aluminum alloy part. The method comprises the following steps that a, two kinds of powder, namely pre-feeding powder and alloy powder added with alloy elements is prepared; and b, the aluminum alloy part is subjected to laser remelting, specifically, b1, the pre-feeding powder is conveyed to the position, needing to be remelted, of the aluminum alloy part, and a covering layer is formed; and b2, an annular laser beam is adopted for laser heating, an alloy powder pipe is arranged in the center of the annular laser beam, the annular laser beam is focused in the remelting area for heating, after a molten pool is formed, in-light powder feeding is carried out through the alloy powder pipe, alloy powder is fed into the molten pool, alloy elements in the alloy powder are rapidly fused into molten liquid of the molten pool, and a remelting part is obtained. According to the method for local remelting reinforcement of the aluminum alloy part, powder is fed in laser light, and reinforcing elements such as iron, chromium, copper and nickel in the alloy powder are molten into a remelting area, so that the strength, especially the high-temperature strength, of the remelting part is greatly improved.

Owner:BINZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com