Formula of anti-dezincification extrusion drawing brass pipe and production method thereof

A production method and brass tube technology, applied in the field of plumbing and sanitary parts, can solve the problems of poor anti-dezincification and corrosion resistance, and achieve good anti-dezincification and corrosion resistance, good physical properties and good anti-dezincification and corrosion resistance , light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

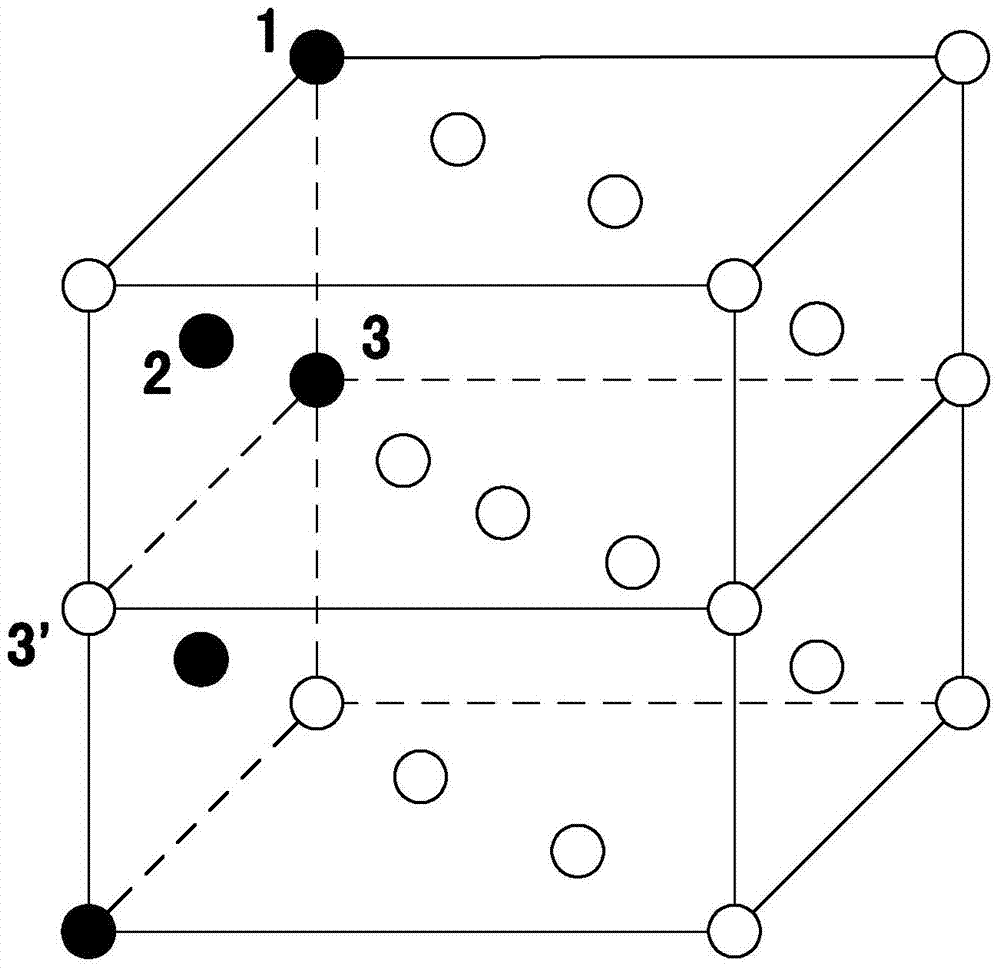

[0030] Embodiment 1 of the present invention discloses a formula for anti-dezincification extrusion-drawn brass tube, which includes the following raw material composition in weight percentage: electrolytic copper 46%, arsenic brass return charge 18%, arsenic-copper alloy 0.2%, boron Copper alloy 0.1%, zinc ingot 30%. Each of the above-mentioned raw materials is a dry raw material.

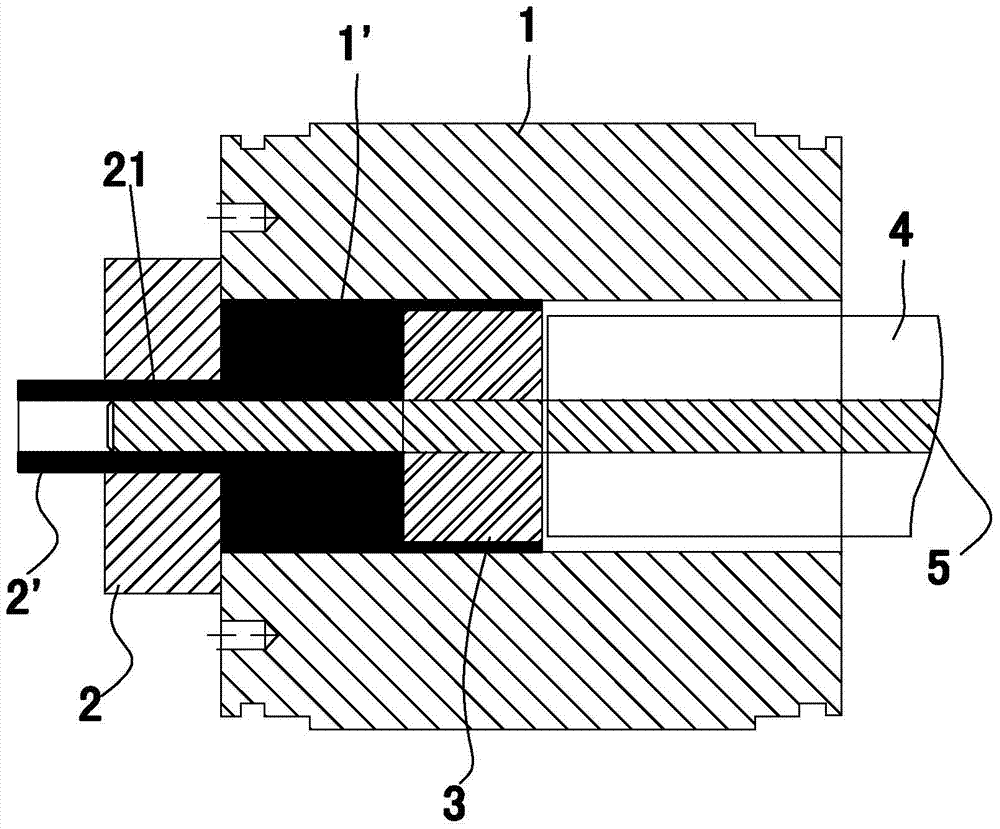

[0031] The production method for producing dezincification-resistant extruded and drawn brass tubes using the above-mentioned brass tube raw materials includes: melting and casting solid copper ingots → extruding solid copper ingots into copper tubes → stretching → annealing → finished copper tube inspection → finished copper tubes Tube storage; where:

[0032] The step of described casting solid copper ingot comprises:

[0033] 1) The industrial voltage and high voltage are 380V. The electrolytic copper raw materials accounting for 46% of the brass tube raw materials are put into the power freq...

Embodiment 2

[0052] Embodiment 1 of the present invention discloses a formula for anti-dezincification extrusion-drawn brass tube, which includes the following raw material composition in weight percentage: electrolytic copper 48%, arsenic brass return charge 19%, arsenic-copper alloy 0.3%, boron Copper alloy 0.2%, zinc ingot 31%. Each of the above-mentioned raw materials is a dry raw material.

[0053] The production method for producing dezincification-resistant extruded and drawn brass tubes using the above-mentioned brass tube raw materials includes: melting and casting solid copper ingots → extruding solid copper ingots into copper tubes → stretching → annealing → finished copper tube inspection → finished copper tubes Tube storage; where:

[0054] The step of described casting solid copper ingot comprises:

[0055] 1), the industrial voltage is 380V, and the electrolytic copper raw material accounting for 48% of the brass tube raw material is put into the power frequency copper mel...

Embodiment 3

[0070] Embodiment 3 of the present invention discloses a formula for anti-dezincification extrusion-drawn brass tube, which includes the following raw material composition in weight percentage: 50% electrolytic copper, 20% arsenic brass return charge, 0.3% arsenic-copper alloy, boron Copper alloy 0.3%, zinc ingot 32%. Each of the above-mentioned raw materials is a dry raw material.

[0071] The production method for producing dezincification-resistant extruded and drawn brass tubes using the above-mentioned brass tube raw materials includes: melting and casting solid copper ingots → extruding solid copper ingots into copper tubes → stretching → annealing → finished copper tube inspection → finished copper tubes Tube storage; where:

[0072] The step of described casting solid copper ingot comprises:

[0073] 1), the industrial voltage is 380V, and the electrolytic copper raw material accounting for 50% of the raw material of the brass tube is put into the power frequency cop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com